Page 1

INSTRUCTIONS

Ti-Lite Carbo AirBlock

351 (29mm), 2651 (40mm), 2607 (57mm)

1251 E. Wisconsin Avenue • Pewaukee, WI 53072 USA

Tel: 262-691-3320, Fax: 262-691-3008

Web: www.harken.com, Email: harken@harken.com

Strictly follow all instructions to avoid an accident,

damage to your vessel, personal injury or death. See

www.harken.com for additional safety information.

Chart A—Block Specifications

Part

No.

351*

26 51*

2607*

*Includes 4' (1.2m) line

Chart B—Line Replacement

Part

No.

351

2651

2607

Maximum Working Load (MWL) Breaking Load (BL)

Size

(mm)

29 330 150 1000 454

40 485 220 1200 544

57 792 360 2380 1080

lb kg lb kg

Reorder

Part No.

HCP1438 1/ 16 2 Maxibraid

HCP1419 3/32 2.5 Maxibraid

HCP392 1/8 3 Maxibraid

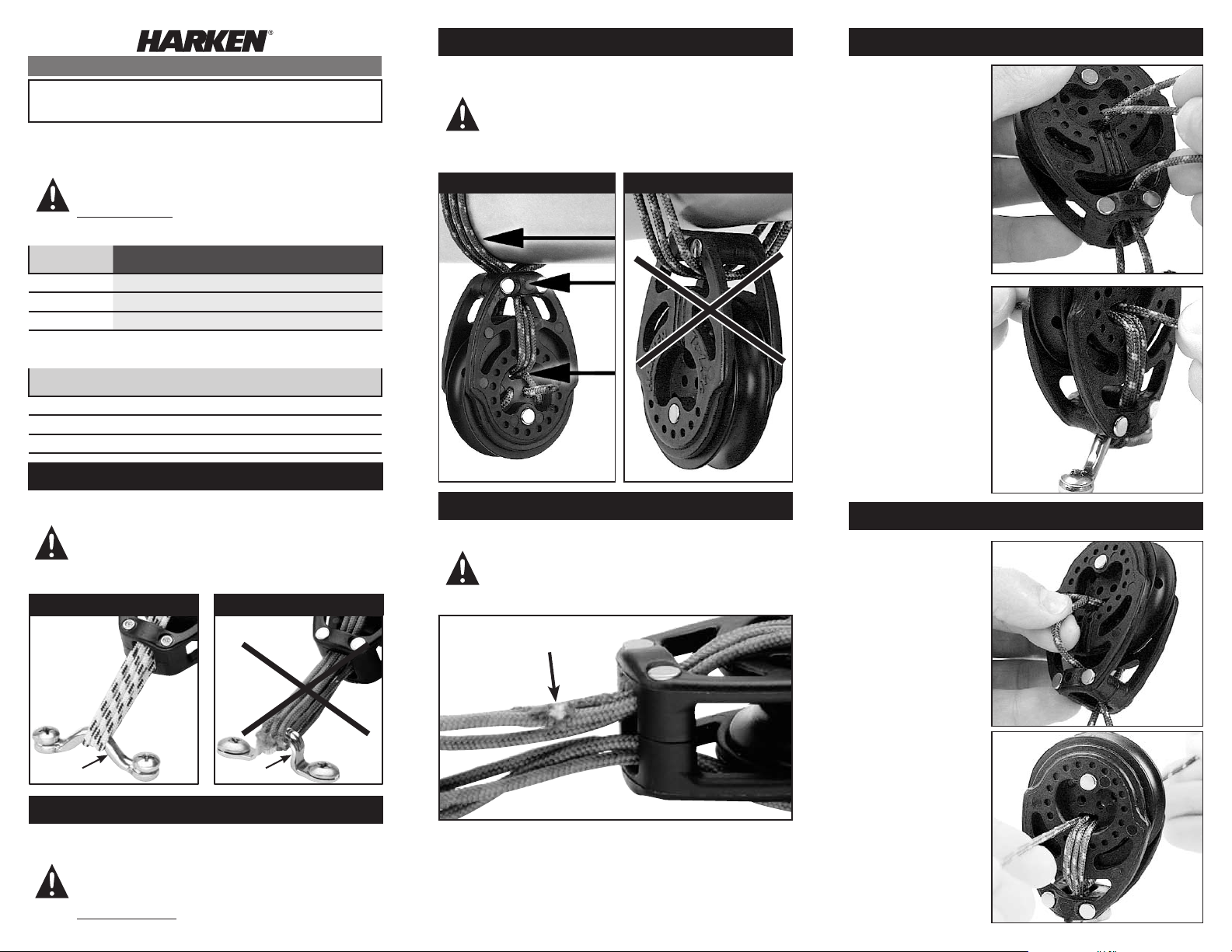

Tie Only to Objects with Rounded Edges

Line Ø

in mm

®

Line Type

Use Three (3) Loops of Supplied Line

WARNING!: Use three loops of the line supplied.

Using fewer loops will weaken the block causing

it to break suddenly causing an accident, damage

to your vessel, personal injury or death. See

www.harken.com for additional safety information.

CORRECT INCORRECT

3 LOOPS

HEAD

MOUTH

A Tie to Bail/Eyestrap—Parallel

A1 Pass line through

mouth, through head,

around bail, through

head and through

mouth in opposite

direction.

A2 Repeat A1 two times.

See: E Finish—

Dead-End Line.

A1

A2

WARNING!: Attach only to objects with rounded edges.

Do not tie block to stamped eyestrap. This will cause

line to chafe and break suddenly causing an accident,

damage to your vessel, personal injury or death. See

www.harken.com for additional safety information.

CORRECT

Rounded Sharp

INCORRECT

Tie to Mouth of Block

WARNING!: Tie only to the mouth of the block as

shown. Do not tie to head of block. This will cause

the block to break suddenly causing an accident,

damage to your vessel, personal injury or death. See

www.harken.com for additional safety information.

Inspect Line Every Time You Sail

WARNING!: Failure to inspect and replace UVdamaged, worn or frayed line can cause the line

to break suddenly causing an accident, damage

to your vessel, personal injury or death. See

www.harken.com for additional safety information.

Inspect line for chafe or UV-damage every time you sail. Replace

damaged line immediately. Replace line with no visible damage after

no more than two-years use. Consult Chart B (left) for replacement

line or use block breaking strength, Chart A (left) to select the

correct line.

B Tie to Bail/Eyestrap—Perpendicular

B1 Pass line through

mouth, through head,

around bail so line

crosses. Go through

head and through

mouth in opposite

direction.

B2 Repeat B1 two

times, crossing line

each time.

See: C Tie to Boom.

for complete

instructions.

See: E Finish—

Dead-End Line.

B1

B2

Page 2

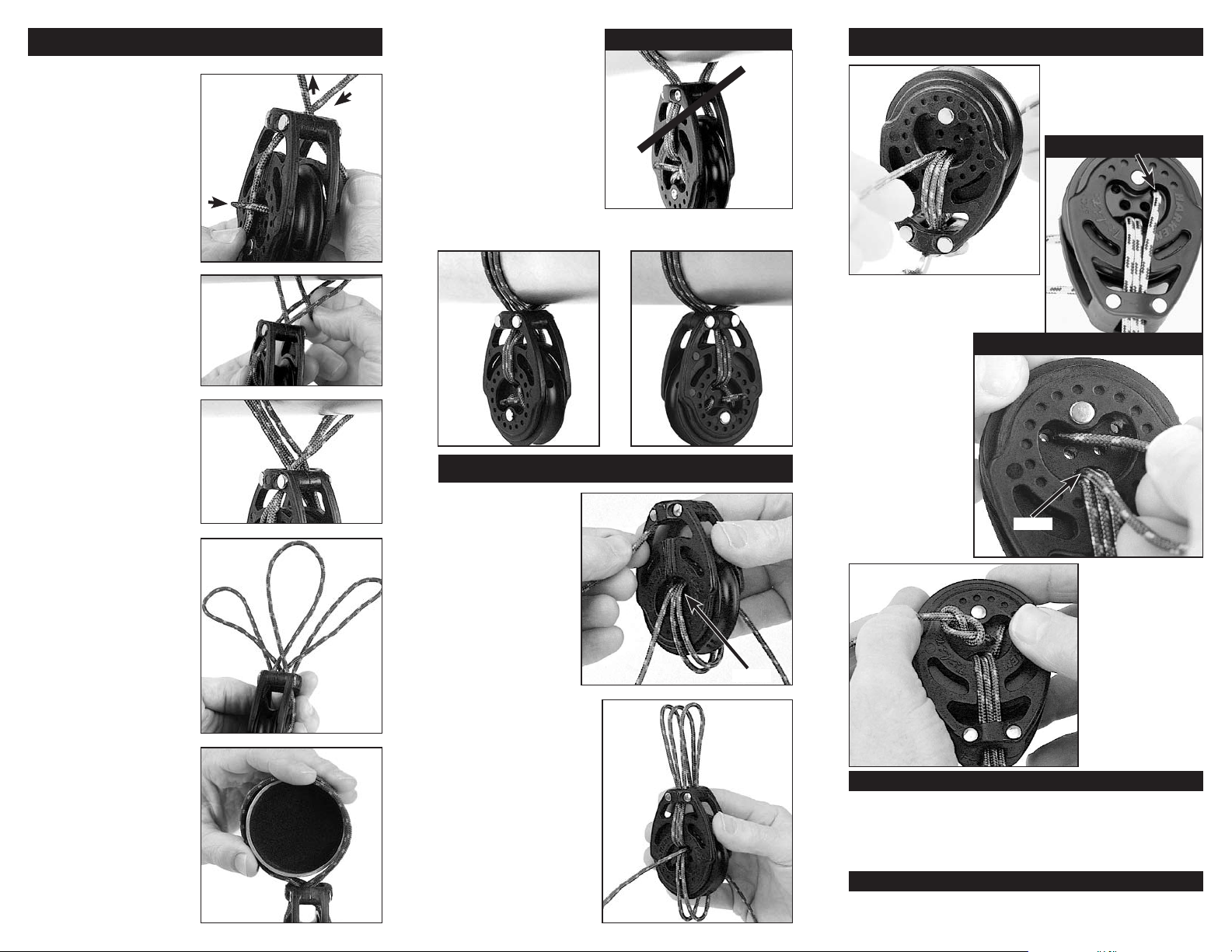

C Tie to Boom—Large Diameter Object

C1 Pass line through

mouth, through head

and around boom so

line crosses as shown.

C2 Repeat C1.

Cross lines.

C3 Repeat C1.

Cross lines.

See: E Finish—

Dead-End Line.

C4 If you have access

to end of boom, make

three loops as shown.

Cross each loop

separately as shown.

C5 Slide crossed lines

onto end of boom.

See: E Finish—

Dead-End Line.

C1

C2

C3

C4

C5

C6 IMPORTANT!

INCORRECT

You must use crossed

lines when tying to

a large diameter so

head of block is

not damaged.

C7 Once tied, block can be rotated to either

a parallel or perpendicular position (C8).

C7 C8

D Add Becket

D1 Pass line through

mouth to make two

becket loops.

D2 Follow instructions

A, B, C or D to attach

to bail, post or boom.

See: E Finish—

Dead-End Line.

MOUTH

C6

D1

D2

E Finish—Dead-End Line

E1 Cinch block to

E1

desired tension.

INCORRECT

CORRECT

E2 Start with line

coming out of mouth,

pass it through small

dead-end hole. On

2607 (57mm) pass

line from mouth

through outer hole

at side of rivet then

through inner hole.

MOUTH

E3 Tie a loose figure

E3

eight knot. Move knot

so it is tight against

block. Leave at least

25mm (1") of line

beyond knot. Repeat

for other line end.

Trim excess line.

Maintenance

Harken® equipment is designed for minimal maintenance, but some

maintenance is required for optimum and safest possible operation

and to comply with the Harken limited warranty.

In general, the most important aspect of maintenance is to keep your

equipment clean by frequently flushing with fresh water.

Warranty

For additional safety, maintenance and warranty information see

www.harken.com or the Harken® catalog.

Printed in USA 4927/03-10

E2

Loading...

Loading...