Page 1

USA – Tel: (+1) 262-691-3320 • Web: www.harken.com • Email: harken@harken.com

Italy – Tel: (+39) 031.3523511 • Web: www.harken.it • Email: techservice@harken.it

ONLINE INSTRUCTIONS

Bolt Down Fairleads

3274, 3275, 3276 3277, 3278, 3279

Strictly follow all instructions to avoid an accident, damage to your vessel, personal injury

or death. See www.harken.com/manuals for additional safety information.

IMPORTANT! See Inspection and Maintenance at end of manual.

Features

A

vailable in three configurations: single, double, triple

Weight saving: built of 60-61T6 Hard Lube-anodized aluminum

Easy, one person mounting: using hexagonal head fasteners

Dimensions

W

L

Part

No. Description

3274 Single, 12 mm 1

3275 Double, 12 mm 2

3276 Triple, 12 mm 3

3277 Single, 16 mm 2

3278 Double, 16 mm 3

3279 Triple, 16 mm 4

L

Length

in mm in mm in mm in mm lb kg lb kg

7

/84811/1618 11/828.23/810 2000 908 4000 1816

7

/87411/1618 11/828.23/810 2000 908 4000 1816

7

/89911/1618 11/828.23/810 2000 908 4000 1816

3

/8607/822 11/431.89/1614 4000 1816 8000 3632

9

/16917/822 11/431.89/1614 4000 1816 8000 3632

3

/41217/822 11/431.89/1614 4000 1816 8000 3632

W

Width

H

Height

Max line ØMaximum

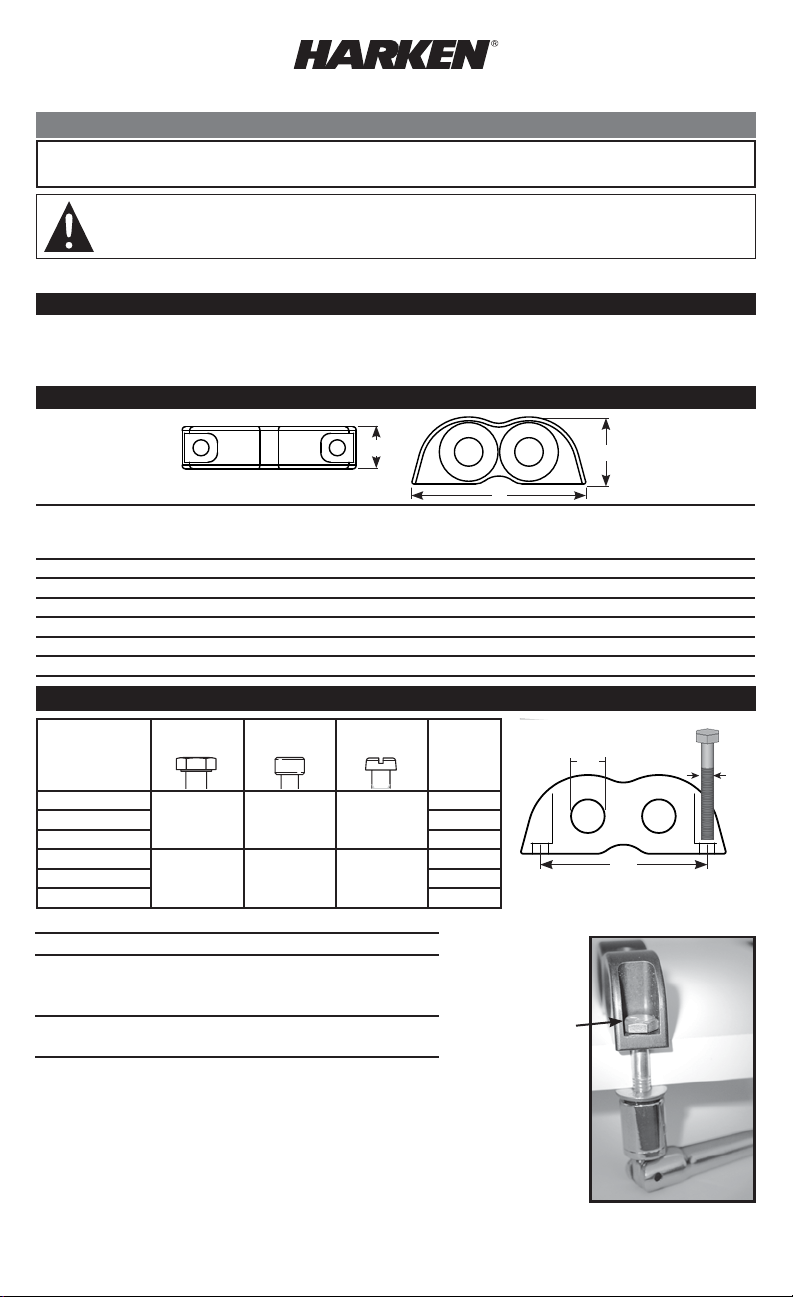

Fasteners (Not Included)

Hex Head

Part

No.

3274 .47 12

3275 .47 12

3276 .47 12

3277 .63 16

3278

3279

A

in mm in mm

.63 16

.63 16

B

6 mm

5

/16"

8 mm

Socket Head

Cap Screw

B

1

/4"

6 mm

5

/16"

8 mm

Cheese Head

(Phillister Head)

B

6 mm

5

/16"

8 mm

C

1.26 32

2.24 57.4

3.27 82.8

1.46 37

2.68 67.5

3.86 98.0

Method Fasteners

Through-deck mounting.

Access from below.

Mounting to tapped holes.

No access from below.

Hex Head*

Socket Head Cap Screw

Cheese Head (Phillister Head)

Socket Head Cap Screw

Cheese Head (Phillister Head)

Hex head is held

by sides of inset.

Hex head* bolts are ideal for one-person though-deck fastening.

The hexagonal head is held by the sides of the inset when being tightened.

Note: In the 12 mm version, only 6 mm hex head bolts will fit.

Choose fasteners that are made from A4 (316) or A2 (18-8) stainless steel. Make

sure to use large washers or backing plates and lock washers or locknuts under

deck. It is installer's responsibility to choose correct screws, nuts, washers, or

threaded plates, taking account materials and loads they will have to bear. Harken

assumes no responsibility for incorrect installation of fairleads or for an incorrect

choice of mounting fasteners.

H

working load Breaking load

A

C

®

B

Page 2

Deck Strength

Fairleads must be installed on a flat area of deck, reinforced if necessary to bear a load equal to the

breaking load of fairlead to be used. Marine epoxy suppliers are a good source of deck reinforcement

techniques. Also contact suppliers of G10 reinforcement. It is installer's responsibility to carry out all

structural tests needed to ensure that deck can bear load. Consult the yard that built the boat in case of

doubt over the suitability of mounting location and deck strength. Harken

®

assumes no responsibility

for incorrect installation of fairlead or for an incorrect choice of mounting screws.

WARNING! Failure to ensure the correct deck strength type can result in the fairleads pulling off the

deck suddenly and unexpectedly during high loads.

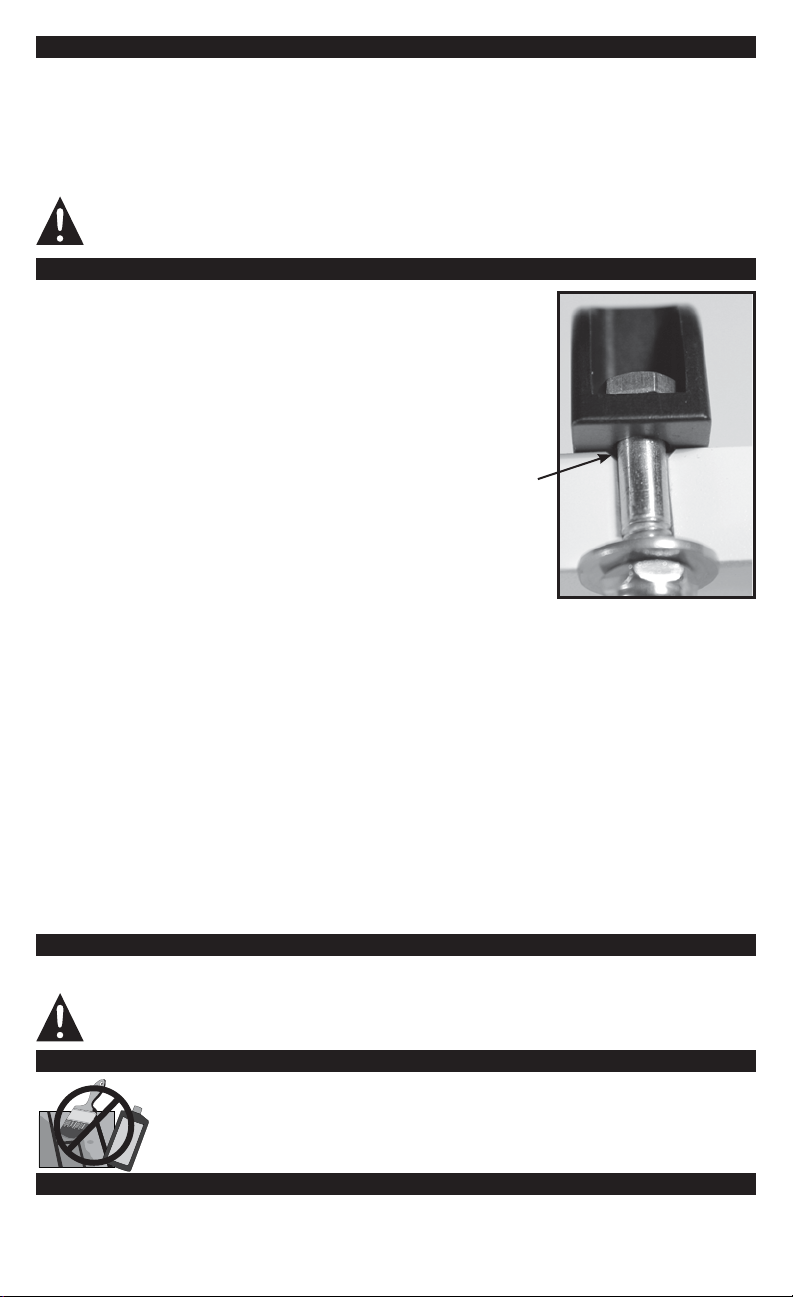

Mounting Fairleads

Carefully drill holes. Slightly bevel the top of the hole to allow sealant to

form a small ring at deck level. Use marine sealant, making sure sealant

fills hole and beveled area. Secure fairlead using all fastener holes. Secure

under the deck using large washers or backing plate and washers and

locknuts.

Slight bevel allows

sealant to form a

ring at deck level.

Inspect

Carefully inspect fairleads and mounting hardware for any signs of loosening, cracks or damage.

WARNING! Failure to inspect fairleads and mounting hardware can result in fairleads pulling

off deck suddenly and unexpectedly during high load.

Maintenance

Clean by frequently flushing with fresh water.

IMPORTANT! Exposure to some teak cleaners and other caustic solutions can

result in discoloration of part and is not covered under the Harken warranty.

Warranty

For additional safety, maintenance and warranty information see www.harken.com/manuals or the

®

Harken

catalog.

Printed in USA 5053.W 04/14

Loading...

Loading...