Page 1

INSTRUCTIONS

Loop Block

3195, 3196, 3199, 3201

Telephone: (262) 691-3320 • Fax: (262) 691-3008 Web: http://www.harken.com • E-mail: harken@harken.com

1251 East Wisconsin Avenue • Pewaukee, WI 53072 U.S.A.

WARNING! Strictly follow all instructions to avoid an accident, damage to your vessel,

personal injury or death. See www.harken.com/manuals for additional safety information.

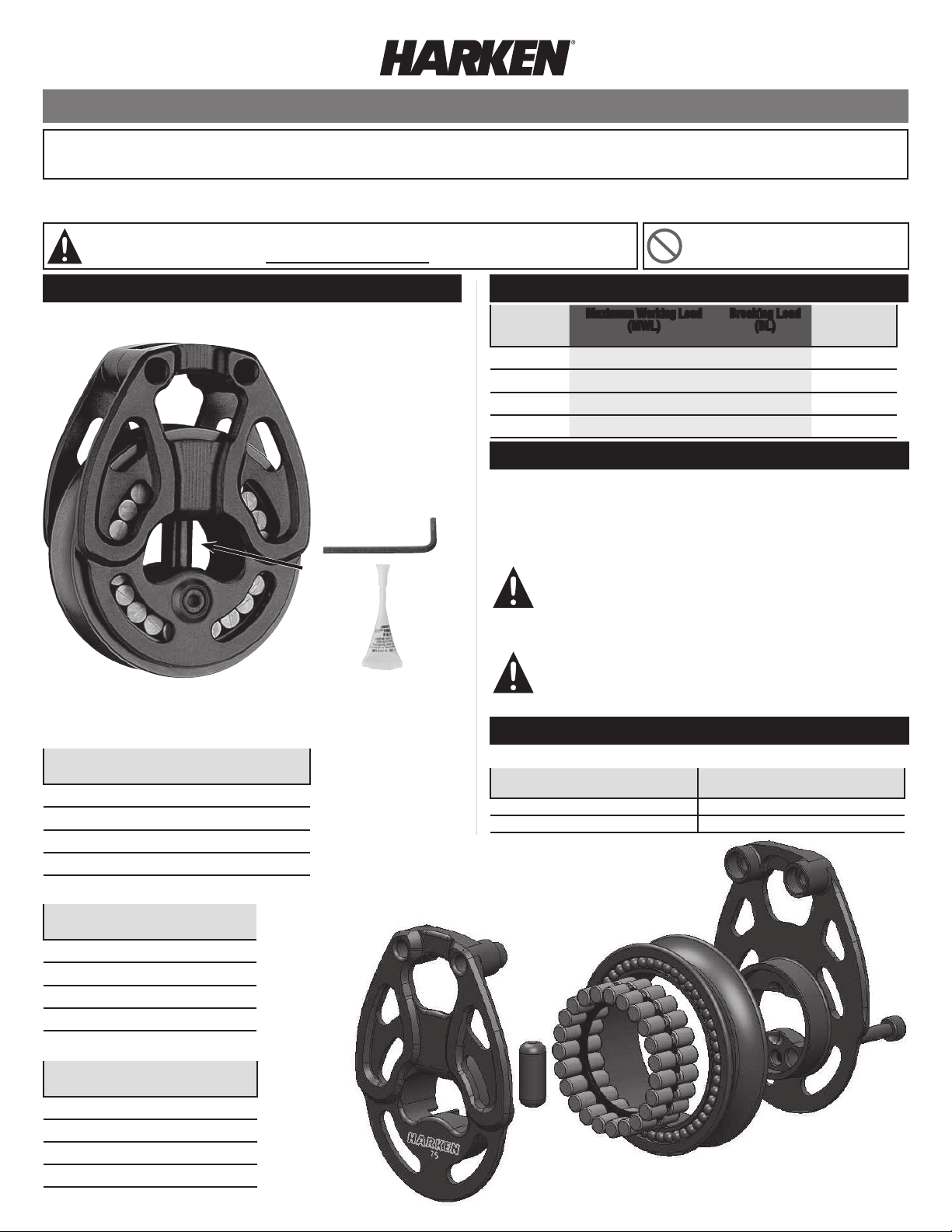

Parts

Part

Sheave

No.

Ø

1

3

4

6

6

2

1) Head

2) Sideplates

3) Sheave

4) Dead-End Post

5) Block Mouth

6) Screw

7) Allen Wrench

8) Blue Loctite

5

3195

57mm 2500 1134 5,000 2268 5mm

3196

75mm 5,000 2,268 10,000 4536 8mm

3199

100mm 7,500 3,402 15,000 6804 11mm

3201

125mm 11,000 4,990 22,000 9977 14mm

®

Loop and/or High Strength Lashing Line

Refer to chart above and choose loop and/or high strength lashing that

matches or exceeds break strength (BS) of block. Note: See chart for

7

maximum line diameter that will fit through mouth.

WARNING! Webbing or smaller lashings can be damaged by being

pinched between post and sideplate. Damaged webbing or lashings

can part suddenly under load. Use only loops when terminating at

dead-end post.

WARNING! Knots weaken line considerably. Consult qualified rigger

or line manufacturer for advice on securing line. Use high strength

8

loops or consult rigger for recommendations on lashing. Using the

wrong line or securing the line improperly can cause an accident.

= Incorrect. Avoid to prevent accidents.

Specifications

Maximum Working Load

(MWL)

lb kg lb kg

Breaking Load

(BL)

You Must Supply

Max line Ø

that fits

through mouth

Loop Block Replacement Part Numbers

Part

No.

3195

3196

3199

3201

Part

No.

3195

3196

3199

3201

Part

No.

3195

3196

3199

3201

Sheave ØSideplate ASideplate

57mm H-43623 H-43624

75mm H-43456 H-43457

100mm H-43757 H-43758

125mm H-43814 H-43815

Sheave

w/Side Balls

H-21635B HBB85

H-21550B HBB86

H-22123B HBB87

H-23750C HBB88

Screw

HFS796 H-43625

HFS806 H-43461

HFS816 H-43759

HFS814 H-43816

Roller Cage

Assembly

Dead-End

Post

Small Control Line Included

4' (1.2 m) line included for lashing to head.

B

Sideplate A

Block

Part No.

3195

3196

Dead-End

Post

Replacement

Part No.

HCP1438 2 mm

HCP1419 2.5 mm

Roller Cage

Assembly

Sheave

Line

Length

Sideplate B

Block

Part No.

3199

3201

Replacement

Part No.

HCP1419 2.5 mm

HCP392 3 mm

Length

Line

Screw

Page 2

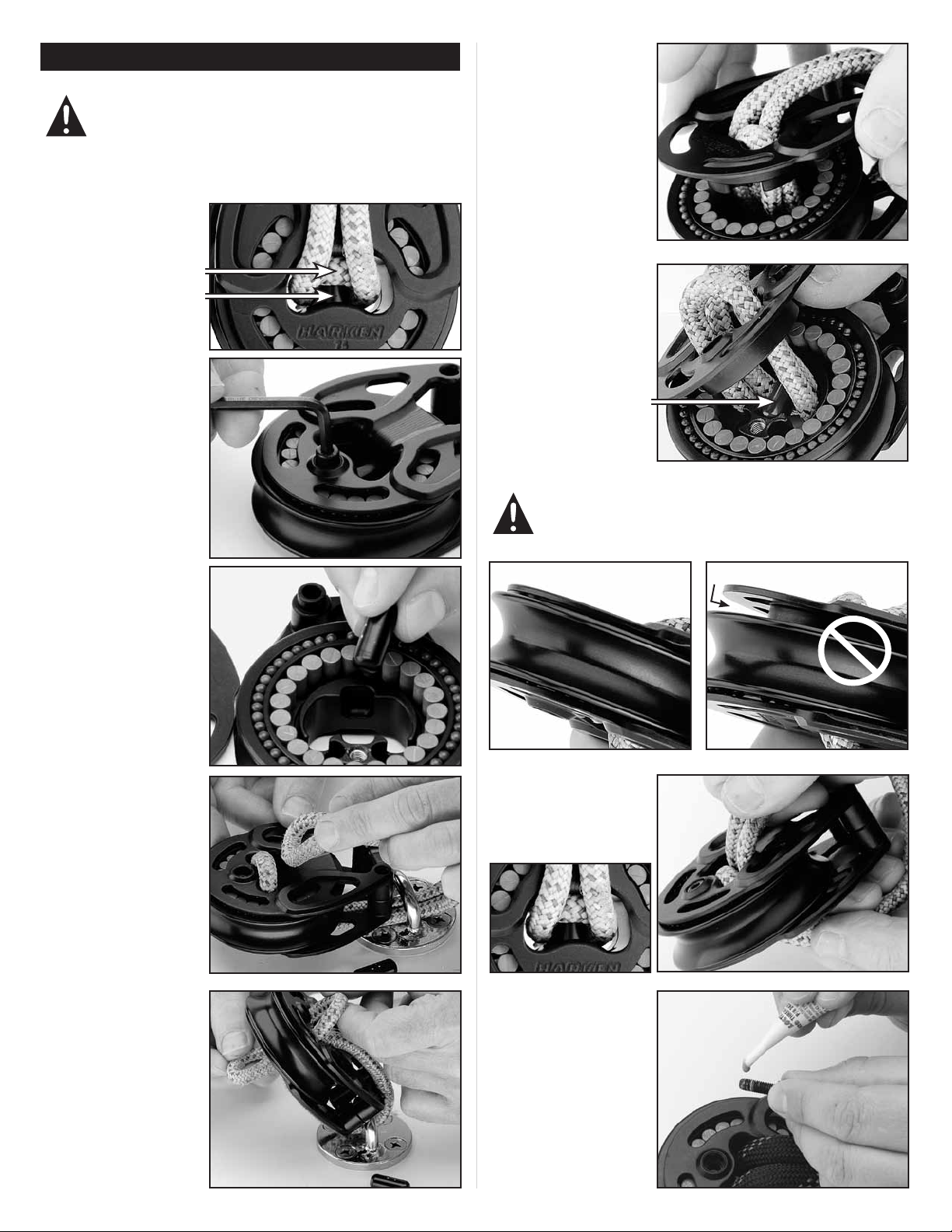

Terminating to Dead-End Post

WARNING! Webbing or smaller lashings can be damaged by

being pinched between post and sideplate. Damaged webbing

or lashings can part suddenly under load. Use only loops when

terminating at dead-end post.

Terminating to dead-end post lets you attach block to a closed bail such

as a padeye.

5. Open sideplates without

pulling line through block.

Dead-end post

1. Remove screw..

2. Remove dead-end post.

Loop

6 Part legs of loop and insert

dead-end post. Make sure

dead-end post is seated

straight in sideplate. Put

sideplates together.

Dead-end post

WARNING! If sideplates are angled to one another, dead-end post

is not seated correctly. This will cconsiderably weaken the block so

it can easily break under load. Block sideplates must be parallel to

one another when assembled.

Sideplates are not parallel

3. Insert loop into block

mouth as shown.

4. Pass loop ends through

mouth so loops extend

beyond block's sideplates

as shown.

7. Pull loops to seat ends

on dead-end post.

8. Reassemble block using

blue Loctite® on screw.

Page 3

9. Lash loop to head of

block with small control

line using a Carrick bend or

a square knot and run tail

up behind wrap, then down,

and under itself on each side

of knot. Pull tight to secure.

For knot tying resources see

www.harken.com/knots.

10. Further secure stop knot

by carefully melting line

ends with a hot knife.

WARNING! If lashing comes loose, block can flip and cause line

to jam, resulting in loss of control. Inspect lashing often and

redo if necessary.

If lashing comes loose block

can flip so that sheet rides

off sheave.

WARNING! Attaching line to block head will considerably weaken

block so it can easily break under load. Attach loop/lashing only

through mouth of sheave.

3. Re-assemble block. Use

blue Loctite

®

on screw.

Do not attach

to head

Terminating Loop Outside Block or Using Lashing

If terminating line outside block or lashing using multiple strands

of smaller-diameter line you must remove the dead-end post.

1. Use allen wrench

to remove screw.

2. Remove dead-end post.

Dead-end post

4. Lash loop to head of

block with small control

line using square knot. Run

line ends up and behind

lashing, then down and

under itself on each side

of knot. Pull tight to secure.

5. Secure stop knot by

carefully melting line

ends with a hot knife.

Page 4

WARNING! Using a loop in a choker style weakens the loop

connection. Do not use choker style connection.

ALL INSTALLATIONS

Anchor Point Chafing or Cutting

WARNING! Loops or lashings running over a sharp edge can cause

part to break under load. Attach to fitting with a rounded edge.

3. Inspect loops and lashings. Replace if there are signs of wear or if the

colored tracer fades from UV damage.Pull loop out of mouth and inspect

loop/lashing carefully for any signs of wear, UV-damage, fatigue or strand

separation. Replace loop if it shows signs of UV-damage or wear.

WARNING! Failure to replace damaged or weakened parts can

cause part to break under load. Replace all loops and lashings

every year or if there is any sign of wear, UV damage, fatigue

or strand separation. If in doubt replace. Consult chart to match

strength of loop/lashing to block and load.

4. Inspect lashing at head

of block to make sure knot

is holding tightly.

Loops must be attached to round bails such as those found on padeyes

or pins. Sharp edges on many perforated toerails will cut loop, severely

weakening it. When loop is attached to a plate, it must be at least 1/4"

thick and have rounded edges to keep loop from being damaged.

Round edges to prevent

damage to loop

Sharp edges will

damage loop

Inspect Parts Every Time you Sail

WARNING! Failure to inspect and correct block and loop or

lashing may result in block breaking under load. Inspect parts

each time you sail. If parts are under load during long passages

it is important to inspect them carefully while in use.

1. Inspect block to make

sure that screw is secure.

If screw is loose, remove

it, use blue Loctite

it in place and retighten.

2. Inspect sideplates to

make sure they are parallel

to each other. If they are

angled dead-end post may

not be seated. Take block

apart, install bail correctly

and secure with screw and

blue Loctite

®

to hold

®

.

Maintenance

Harken equipment is designed for minimal maintenance, but some maintenance

is required to give the best service and to comply with the Harken limited warranty.

Cleaning: Flush blocks and loops/high strength lashing lines thoroughly with fresh

water. Periodically, disassemble the blocks and clean with detergent and fresh water.

When assembling block, make sure screws and holes are dry. Use blue Loctite® to

secure screw before assembling.

Important: Exposure to some teak cleaners and other caustic solutions can result

in discoloration of part and is not covered under the Harken warranty.

Warranty

For additional safety, maintenance and warranty information see www.harken.com/

manuals or the Harken® catalog.

Printed in USA. 4641 04-12

Loading...

Loading...