Page 1

INSTRUCTIONS

LOUPS

®

3139, 3140, 3141, 3142, 3143, 3144, 3145, 3146, 3147, 3148, 3149, 3150, 3202, 3203, 3151 (Dogbone)

Tel: 262-691-3320, Fax: 262-701-5780 • Web: www.harken.com, Email: harken@harken.com

WARNING! Strictly follow all instructions to avoid an accident, damage to your vessel,

personal injury or death. See www.harken.com/manuals for additional safety information.

Loups® offer a variety of ready-made soft attachment rigging solutions for racing and cruising yachts. When fitting hardware, choose the Loup® that exactly

matches the attachment method and strength shown in the chart below. Custom length Loups are also available. If you have questions, please contact Harken.

Loup strength will vary depending on: Configuration – One configuration may be more than twice as strong as another. Carefully match strength requirements to the

configuration and corresponding SWL shown in the chart below. Attachment Points – Determine weakest link in the attachment chain. Is it the block? The Loup? The

padeye? Consult chart below for padeye loading at various angles. Condition of Attachment – Loup must attach to round bails or radiused corners. Sharp, rough edges

or corners will cut into Loups, reducing their strength over time. Age of Loup – Strength of Loup is based on their being in like new condition. See chart below.

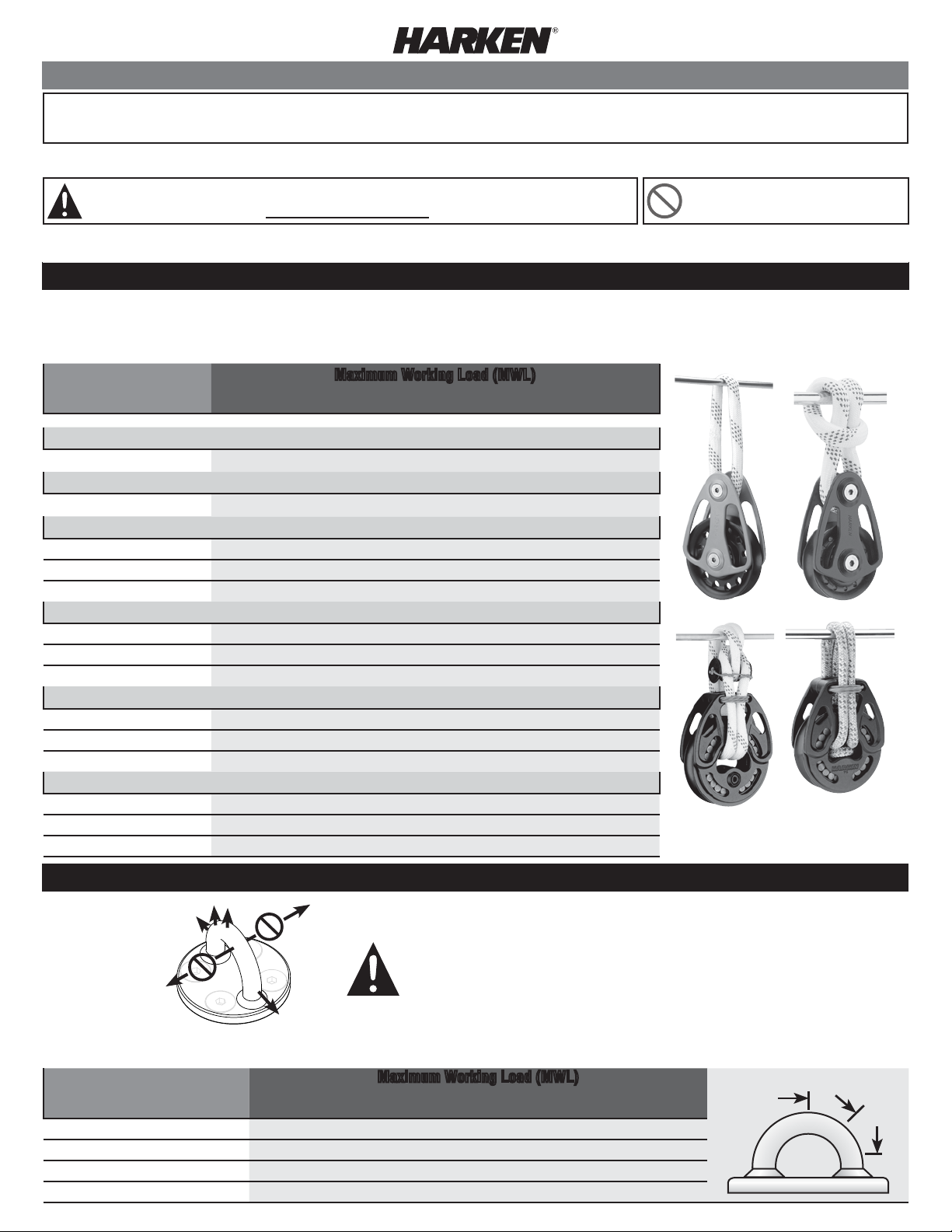

Loup®

Part

No.

5mm — ONE YELLOW, TWO ROWS OF DARK-COLORED TRACERS

3202

7mm — ONE YELLOW, FOUR ROWS OF DARK-COLORED TRACERS

3203

9mm — TWO (2) ROWS OF COLORED TRACERS

3139

3140

3140

10mm — THREE (3) ROWS OF COLORED TRACERS

3142

3143

3144

11mm — FOUR (4) ROWS OF COLORED TRACERS

3145

3146

3147

12mm — FIVE (5) ROWS OF COLORED TRACERS

3148

3149

3150

Length Vertical Choker With Dogbone Basket

in mm lb kg lb kg lb kg lb kg

8 203 1275 578 1000 453

10 254 2550 1155 2040 920

4 100 2800 1270 2240 1015 — — 5600 2540

8 200 2800 1270 2240 1015 — — 5600 2540

11 280 2800 1270 2240 1015 — — 5600 2540

5 125 4200 1900 3360 1520 — — 8400 3810

9 230 4200 1900 3360 1520 — — 8400 3810

15 380 4200 1900 3360 1520 5645 2560 8400 3810

5 125 5700 2585 4560 2065 — — 11400 5170

9 230 5700 2585 4560 2065 — — 11400 5170

16 400 5700 2585 4560 2065 — — 11400 5170

6 150 7150 3240 5680 2575 — — 14200 6440

11 280 7150 3240 5680 2575 — — 14200 6440

17 430 7150 3240 5680 2575 — — 14200 6440

N15W24983 Bluemound Rd., Pewaukee, WI 53072-4974 USA

Loup® Strength

Maximum Working Load (MWL)

— —

— —

2550 1156

5100 2310

= Incorrect. Avoid to prevent accidents.

Vertical

With Dogbone

Choker

Basket

Harken® Padeye Strength

MWL

WARNING! Load applied sideways to the bail greatly

reduces the strength. Always align padeye bail to load

for maximum strength to prevent breakage below

Maximum Working Load.

MWL: Maximum Working Load

Even when bail is aligned with load, padeye strength will vary depending on load angle—see below.

Part

No.

627

629

648

689

Description

Small round 5000 2270 4500 2040 4300 1950

Large round 20000 9070 12000 5440 14000 6350

High-load medium 11800 5358 10375 4705 8500 3855

Large diamond 8500 3855 8000 3628 7800 3540

MWL

1 2 3

lb kg lb kg lb kg

Maximum Working Load (MWL)

Load

Angle

1

2

3

Page 2

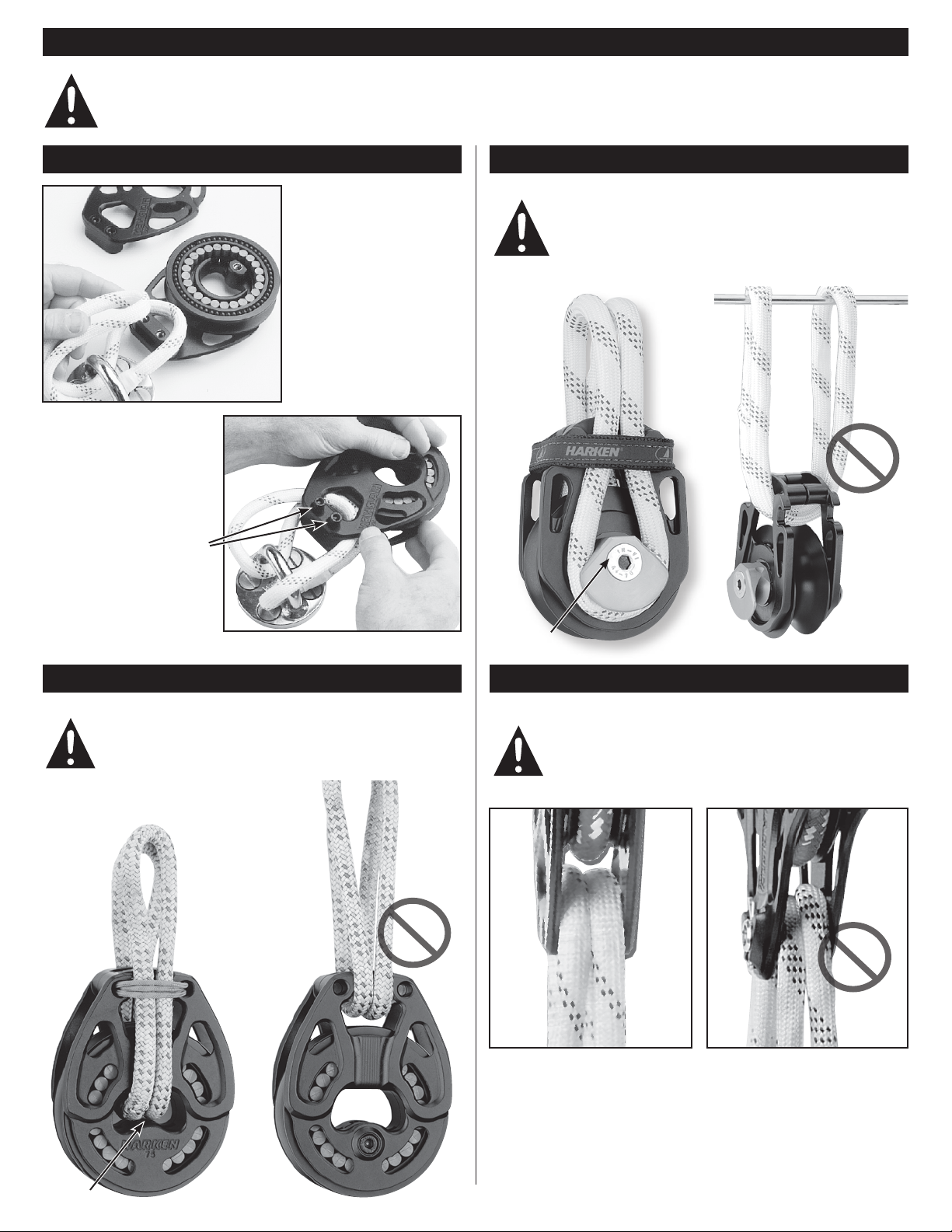

Attaching Loups® to Blocks

WARNING! Block may break suddenly if attached incorrectly. Before attaching Loup you must understand block manufacturer's directed method of attachment. Some blocks are designed to secure Loup to head and others to attach Loup through

center of sheave or to protrusions coming out from center of sheave. Attaching Loups improperly may cause an accident.

Harken® Straphead Block

Attach Loup to head only

if you are sure that it is a

Harken Straphead block.

Harken Straphead blocks

have two screws in head

(see photo at right).

Screws

Harken Grand Prix High-Load Snatch Block

WARNING! Attaching Loup to block head will

considerably weaken block so it can easily break

under load. Attach Loups only to thimble at

sheave center.

Do not attach

to head

Harken Black Magic® Loop Block

WARNING! Attaching line to block head will considerably weaken block so it can easily break under load.

Attach loop/lashing only through mouth of sheave.

Do not attach

to head

Thimble

Attaching to Blocks or Hardware

WARNING! If Loups are stacked they will push outward

on block sideplates when load is applied, causing block

to break especially if crosspin is held using a cotter pin.

This can cause an accident. Make sure Loup can lie

side-by-side.

Make sure Loup will lie, sideby-side between Loup and

sheave. Loups will settle and

flatten when load is applied.

If Loup is stacked (one strand

on top of the other) even a

small amount, line can push

outward and break sideplate.

Mouth

Page 3

Attaching Dogbone to Loup

Put a figure 8 stop knot in

one end of the lashing line

and pass it into the hole

in the bone.

Pass one end of the Loup

into the other. Slip the

Dogbone into end so it

is captured as shown.

®

Anchor Point Chafing or Cutting

WARNING: Loups or lashings running over a sharp edge can

cause part to break under load. Secure to items with rounded

edges only.

Attach Loups only to round bails such as those found on padeyes

or pins. Sharp edges such as those found in many perforated

toerails will cut into Loups severely weakening them. If a Loup is

attached to a plate, the edges must be rounded so that they are not

damaged. The thickness of the plate must be at least 1/4" to avoid

damaging the Loup.

Tie a single overhand knot

around each outer Loup.

Don’t draw the legs of the

Loups together; let them

assume their loaded

position.

Pass the end of the line

back through the hole

in the bone and tie a

figure 8 stop knot. Use

a hot knife to trim ends.

Round edges to prevent

damage to loop

Sharp edges will

damage loop

Hardware and attaching Loups can gradually lose strength from wear

and UV rays. Inspect parts often and and during long passages.

Inspect

WARNING! Hardware and attaching Loups can gradually

lose strength from wear and UV rays. Inspect parts often

and during long passages.

You must periodically inspect Loups and head lashings for signs

of UV damage or wear. Be sure to pull Loup out of block mouth

and inspect carefully for any sign of wear, UV damage, fatigue or

strand separation. The Loup's outer jacket protects the inner core,

but can become damaged from prolonged UV exposure. Loups

have colored tracers that are designed to fade after prolonged UV

exposure. If tracers appear faded, rub them with your fingernail. If

flecks become fuzzy the Loup should be replaced. Inspect Loups

often for signs of chafing, especially where they rub on edges.

WARNING! Loups may degrade without showing obvious signs

and break under load. Replace all Loups and lashings every

year or if there is any sign of wear, UV-damage, fatigue or

strand separation. If in doubt replace. Consult chart to match

strength of Loup/lashing to block and load.

Harken equipment is designed for minimal maintenance, but some maintenance

is required to give the best service and to comply with the Harken limited warranty.

Cleaning: Flush blocks and loops/high strength lashing lines thoroughly with fresh

water. Periodically, disassemble the blocks and clean with detergent and fresh water.

When assembling block, make sure screws and holes are dry. Use blue Loctite® to

secure screw before assembling.

IMPORTANT! Exposure to some teak cleaners and other caustic solutions can

result in discoloration of part and is not covered under the Harken warranty.

For additional safety, maintenance and warranty information see www.harken.com/

manuals or the Harken® catalog.

®

Loctite

is a registered trademark of Henkel AG & Company KGaA Loup®/Loups

Maintenance

Warranty

®

are registered trademarks of Yale Cordage

Page 4

Corporate Headquarters

N15W24983 Bluemound Rd, Pewaukee, WI 53072 USA

Telephone: (262) 691-3320 • Fax: (262) 701-5780

Web: www.harken.com • Online Catalog: www.harkenstore.com

1B Green Street, Brookvale, N.S.W. 2100, Australia

Telephone: (61) 2-8978-8666 • Fax: (61) 2-8978-8667

Web: harken.com.au • Email: info@harken.com.au

ZA Port des Minimes, BP 3064, 17032 La Rochelle Cedex 1, France

Telephone: (33) 05.46.44.51.20 • Fax: (33) 05.46.44.25.70

Via Marco Biagi, 14, 22070 Limido Comasco (CO) Italy

Telephone: (39) 031.3523511 • Fax: (39) 031.3520031

30-36 Fanshawe Street, P.O. Box 1951, Auckland 1001, New Zealand

Telephone: (64) 9-303-3744 • Fax: (64) 9-307-7987

Web: harken.co.nz • Email: harken@harken.co.nz

ul. Rydygiera 8, budynek 3A, lokal 101, I pi

Tel: +48 22 561 93 93 • Fax: +48 22 839 22 75

Main Office and Harken Brandstore: Västmannagatan 81B

Telephone: (46) 0303 61875 • Fax: (46) 0303 61876

Mailing address: Harken Sweden AB, Box 64, SE -440 30 Marstrand

Bearing House, Ampress Lane, Lymington, Hampshire S041 8LW, England

Telephone: (44) 01590-689122 • Fax: (44) 01590-610274

Web: harken.co.uk • Email: enquiries@harken.co.uk

Email: harken@harken.com

Harken Australia Pty, Ltd.

Harken France

Web: harken.fr • Email: info@harken.fr

Harken Italy S.p.A.

Web: harken.it • Email: info@harken.it

Harken New Zealand, Ltd.

Harken Polska SP ZOO

ętro, 01-793 Warszawa, Poland

Web: harken.pl • Email: polska@harken.pl

Harken Sweden AB

SE-113 26 Stockholm Sweden

Web: harken.se • Email: harken@harken.se

Harken UK, Ltd.

Please visit: http://www.harken.com/locator.aspx

to locate Harken dealers and distributors

Printed in USA 4967 04/14

Loading...

Loading...