Page 1

ONLINE INSTRUCTIONS

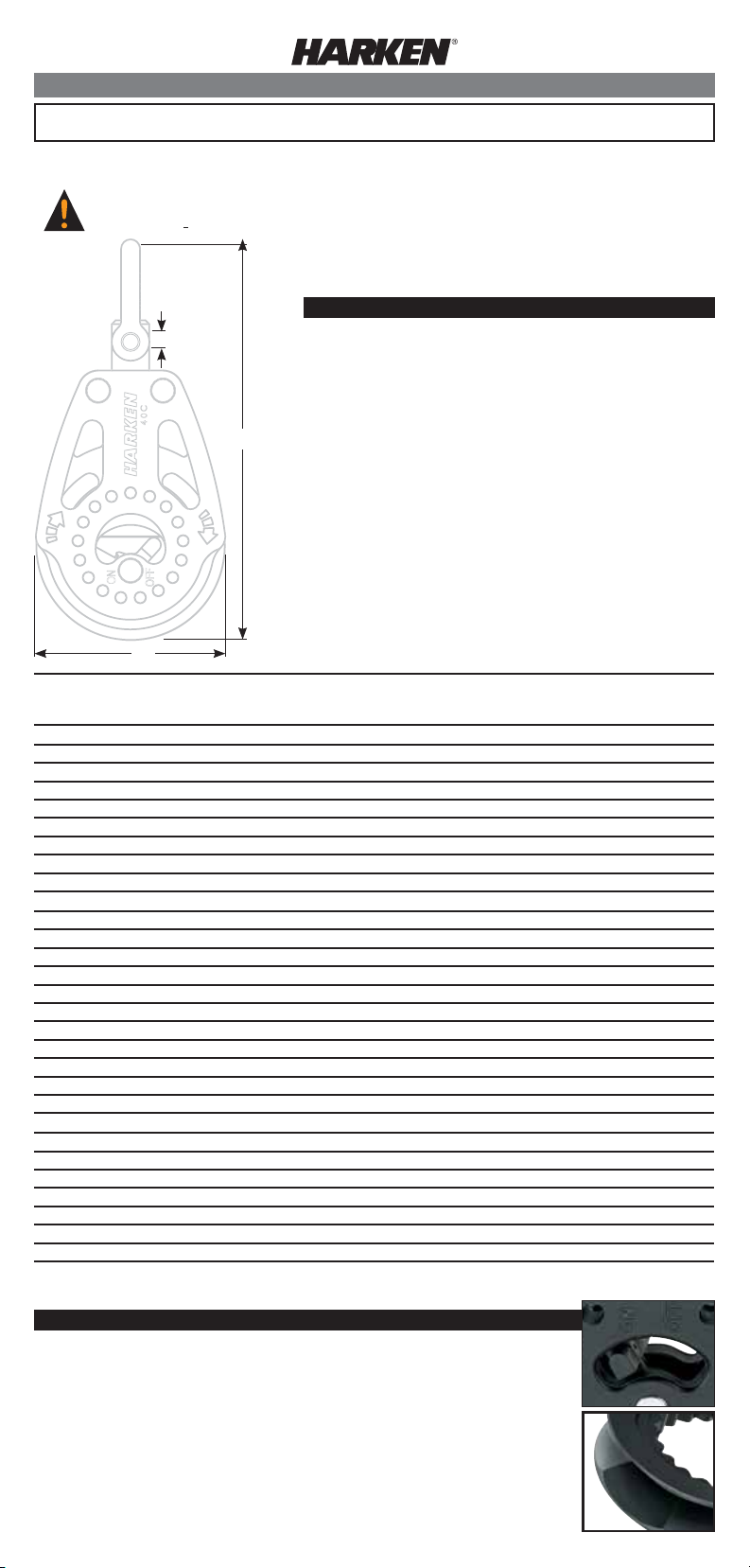

40 mm, 57 mm, 75 mm Carbo Ratchets

USA – Tel: (+01) 262-691-3320 • Web: www.harken.com • Email: harken@harken.com

Italy – Tel: (+39) 031.3523511 • Web: www.harken.it • Email: techservice@harken.it

Strictly follow all instructions to avoid an accident, damage to your vessel, personal injury

or death. See www.harken.com for additional safety information.

IMPORTANT: See Inspection and Maintenance

at end of manual.

C

Features

Glass-filled nylon sideplates: load-carrying curved bearing

races.

Machined Hardkote-anodized aluminum sheaves: strength

and corrosion resistance.

B

Eight-facet sheave: holds line securely.

Ratchet on/off switch: 40 mm–2608/2609/2614;

57/75 mm–all blocks.

Ratchet always on: 2610/2611.

Cam arm locking plates: Allows cam arms to be locked in more

than five positions for fair leads.

Cheek: Line-shedding, small mounting footprint and drain holes.

Common uses: Main/jib/spinnaker sheets/traveler controls/

genoa sheets/foreguys

A

Part

No.

Description in mm in mm in mm in mm lb kg lb kg

A B C

Max line ØMaximum

working load*

40 mm

2608 Single/swivel 19/1640 33/8 865/3243/810 300 136 1000 454

2609 Single/swivel/becket 1

2610 Single/swivel/471 Carbo-Cam

2611 Single/swivel/471 Carbo-Cam

2612 Triple/swivel/471 Carbo-Cam

2613 Triple/swivel/471 Carbo-Cam

2614 Cheek 1

2619 Triple/471 Carbo-Cam

®

* 19/1640 33/8865/3241/46 150 68 300 136

®

/becket* 19/1640 4 1025/3241/46 300 136 600 272

®

** 19/1640 311/16943/1651/46 750 340 1500 680

®

/becket 19/1640 45/161103/1651/46 900 408 1800 816

®

/29 mm/becket 19/1640 43/41213/1651/46 900 408 1800 816

9

/1640 4 1025/3243/810 300 136 1000 454

9

/1640 23/470 — —3/810 300 136 1000 454

57 mm

2135 Single/swivel 21/457 41/161033/1653/810 500 227 2000 907

2136 Single/swivel/becket 2

2137 Cheek 2

2138 Single/swivel/150 Cam-Matic

2139 Single/swivel/150 Cam-Matic

2140 Triple/swivel/150 Cam-Matic

2141 Triple/swivel/150 Cam-Matic

57 mm fiddle/ratchet 21/457 45/81183/8103/165 793 360 2380 1080

2673

2674 57 mm/fiddle/ratchet/becket 2

2675 57 mm/fiddle/ratchet/150 Cam-Matic

2676 57 mm/fiddle/ratchet/150 Cam/becket 2

®

* 21/457 41/161033/1653/810 300 136 750 340

®

/becket* 21/457 415/161253/1653/810 600 272 1500 680

+

®

*

®

/becket 21/457 415/161253/8101/46 1800 816 4500 2041

1

/457 415/161253/1653/810 500 227 2000 907

1

/457 31/483 — —3/810 500 227 2000 907

21/457 41/161033/8101/46 1500 680 3750 1700

1

/457 55/81433/8103/165 793 360 2380 1080

®

21/457 45/81183/8103/165 793 360 2380 1080

1

/457 55/81433/8103/165 793 360 2380 1080

75 mm

2670 Single/swivel 215/1675 53/81371/467/

2671 Single/swivel/becket 2

2672 Cheek 2

2694 75 mm/fiddle/ratchet 2

2695 75 mm/fiddle/ratchet/becket 2

2696 75 mm/fiddle/ratchet/150 Cam-Matic

2697 75 mm/fiddle/ratchet/150 Cam/becket 2

*Maximum working loads and breaking loads for blocks based on cam strengths **Can be used as becket block – add 281

eyestrap

becket – add 137 eyestrap

+

Can be used as becket block – add 137 eyestrap and (2) HFS929 panhead screws (M5X45)

15

/1675 61/21651/467/

15

/1675 41/16103 — —7/1612 750 341 3000 1361

15

/1675 63/161571/2121/46 1212 550 3637 1650

15

/1675 77/161891/2121/46 1212 550 3637 1650

++

®

*

215/1675 63/161571/2121/46 900 408 3350 1020

15

/1675 77/161891/2121/46 1212 550 3637 1650

16

12 750 341 3000 1361

16

12 750 341 3000 1361

++

Breaking

load*

Can be used as

Ratchet Blocks

Ratchet blocks are hand and crew savers. The eight-sided sheave grips loaded

sheets with up to 15: 1 holding power yet allows a line to be eased instantly with

control. They allow the crew to hand hold main, jib and spinnaker sheets with

only a fraction of the effort that a regular block requires. An on/off switch allows

the ratchet to be turned off in light air to trim and ease lines more easily.

The 2608, 2609 and 2614 have on/off switches; other 40 mm ratchet blocks are

always in ratchet mode.

57 mm (10:1 Holding Power), 75 mm (15:1 Holding Power)

All 57 and 75 mm ratchet blocks have on/off switches.

40 mm

Page 2

Ratchet Direction

Arrow on side of block shows direction that sheave

will spin when ratchet is switched on. Refer to arrow

when reeving block or mounting cheek block.

2614 / 2137 / 2672 Cheek Block

Position block so ratchet turns in desired direction. Flip block to change direction. Use chart below or use

block as a template. Mark holes using centerpunch. Check marks with block before drilling. Remove block

and drill holes using drill size from chart below. Bevel top of deck holes using a small knife to allow sealant to mass. Place gasket under block. Through-bolt block using recommended stainless steel fasteners,

washers and locknuts.

Ratchet cheek blocks include metric panhead screws, washers and nuts. See chart below:

Block

Part No. Size

2614 40 mm 3.25

2137 57 mm 4.25

2672 75 mm 5.25

*Fastener length: Add deck thickness and overhang for nut and washer.

Block

Part

Size

40 mm 2614

57 mm 2137

75mm 2672

E

Drill Size Block Thickness (G)

1

/

8

11

/

64

13

/

64

7

22

/

8

25 1 M4 x 60 mm

31 11/

4

A B C D E F

in mm in mm in mm in mm in mm in mm

No.

5

/

64

4 11/238 — —9/

7

/

32

6 11/238

9

/

32

7 2 51

F

B A

2614

D

2137, 2614, 2672

Supplied

Fastener x Lengthmm in mm in

M3 x 40 mm

M5 x 60 mm

32

3

/89.421/648.3 21/457 31/1678

1

/212.731/6412.4 215/1675 41/16103

E

C

6.9 19/1640 21/457

F

B

A

2137, 2672

D

G

3-Way Cam-Lock – 2135 / 2136 / 2138 / 2139 / 2170 / 2171, 2673,

2674, 2675, 2676, 2694, 2695, 2696, 2697

1

3-Way U-Lock – 2140 / 2141 / 2612 / 2613 / 2619

The 3-Way U-Lock on doubles and triples allows a change

of headpost direction from front to side or allows the

block to swivel. To change headpost direction, remove

shackle, turn post, install shackle. Remove U-Lock to

allow block to swivel.

1. Cam lever up.

Block locks in

front or side

position.

2. Cam lever down.

Block turns

freely.

2

Page 3

6:1 Right-Angle Reeving

Dead-end on cam

6:1 Right-Angle Reeving

Dead-end on becket

2

3

4

5

6

6

1

Adjust Cam Angle (Single/40 mm) Reverse Cam Cleat (Single Only)

5:1 Right-Angle Reeving

Dead-end on Becket

6:1 Right-Angle Reeving

Dead-end on becket

1. Loosen cam arm locking plate screw and pull outward

to disengage.

2. Rotate cam arm to desired position.

3. Press locking plate in and tighten screw. Avoid

binding sheave, do not over-tighten screw.

1. Remove screws from cam.

2. Assemble as shown. Note: use plastic plate on cam

bottom.

3. Tighten screws. Do not overtighten screws.

Cam pawls should snap shut smartly.

Adjusting Cam Angle 57 mm (Single/Triple/Fiddle), 75 mm (Fiddle)

1. Remove three cam arm screws on each side.

2. Carefully note position of three screw holes in

block (see diagram).

2. Rotate cam arm to desired position and line

up cam arm holes with screw holes on block.

3. Insert screws into screw holes and tighten.

Do not overtighten screws or sheave will bind.

Part No.

HFS889

1

2

Reeving Multi-Purchase Systems

Right-angle reeving dead-end on becket

6

4

5:1 8:1

5

3

1

2

5

6:1

6

1

2

5

4

3

For larger, printable diagrams, please see: www.harken.com.

Parts — 40 mm Carbo Ratchets

A

C

1

B

2608/2609 40 mm Single Ratchet

No. Description Qty Part No.

1 Shackle Assembly Micro

5

/32" 246

A Shackle Strap 1 HSB104

B Shackle Clevis Pin

5

/32 X .488 1 HSB105

C Split Ring 1 HSB24

Right-angle reeving

dead-end on cam

4

8

6

7

3

2

5

1

6:1

6

2

4

5

1

6

3

2610/2611 40 mm Single Ratchet

w/471 Carbo Cam

1 Screw M3X30 Slotted Panhead 1 HFS888

2 Washer Cam Arm Left 1 H-26265B

3 Washer Cam Arm Right 1 H-27031B

4 Nut M3 1 HFS939

5 Cam Arm Left 1 H-46865

6 Cam Arm Right 1 H-46866

7 Nut M4 2 HFS890

8 Cam Cleat Micro Carbo 1 471

9 Micro Flairlead Black 1 424B

Cam Screws M4X30 Slotted

10

Panhead

11 Cam Plate for Reversing Cam 1 H-27034B

12 Shackle Assembly Micro 5/32” 246

A Shackle Strap 1 HSB104

B Shackle Clevis Pin

C Split Ring 1 HSB24

5

/32 X .488 1 HSB105

2 HFS889

2

1

7

4

6

5

B

12

A

C

11

8

9

10

Page 4

Parts — 40 mm Carbo Ratchets

3

4

2

1

5

10

11

2619 40 mm Triple Ratchet/29 mm/Carbo Cam

1 Nut M3 1 HFS939

2 Washer Left 1 H-26265B

3 Washer Right 1 H-27031B

4 29mm 90 Degree Fixed Block 1 352

5 Spring 1 097

6 Eyestrap, Micro 1 281

Cam Arm Fastener M4X70

7

Custom

8 Cam Arm 1 H-27052C

9 Cam Nut M4 2 HFS890

10 Cam Cleat, Micro Carbo 1 471

11 Micro Flairlead Black 1 424B

Cam Screw M4 X 30 Slotted

12

Panhead

13 U-Lock 1 H-27808A

Shackle 5mm Hybrid Shallow

14

Bow

7

8

1 HFS895

2 HFS889

1 HCP1568

2612/2613 40 mm Triple Ratchet w/Carbo Cam

6

9

1 Nut M3 1 HFS939

2 Washer Left 1 H-26265B

3 Washer Right 1 H-27031B

4 Cam Arm Fastener M4X70

Custom

5 Cam Arm 1 H-27052C

6 Cam Nut M4 2 HFS890

7 Cam Cleat, Micro Carbo 1 471

8 Micro Flairlead Black 1 424B

Cam Screw M4 X 30 Slotted

9

Panhead

10 U-Lock 1 H-27808A

Shackle 5mm Hybrid Shallow

11

Bow

4

5

2

1

7

13

14

6

3

9

11

1 HFS895

2 HFS889

1 HCP1568

8

10

12

2614 40 mm Cheek Block

1

2

3

4

3

4

1 M3-.5X40mm Slotted

Panhead Screw

2 Gasket 1 H-34924A

3 M3 Flatwasher 3 HFS1008

4 M3 Full Nut 3 HFS939

3 HFS1014

Inspect Block and Shackle Before You Sail

WARNING! Failure to inspect and replace damaged metal parts and/or worn or frayed line

can cause block or system to break suddenly causing an accident, damage to your vessel,

personal injury or death. See www.harken.com for additional safety information.

Frequently inspect shackles and shackle posts for signs of corrosion, cracks, or elongation. When

replacing shackles, use the correct Harken parts to maintain the proper strength. Replace line as

necessary, taking into consideration the maximum size recommendation.

Maintenance

Harken equipment is designed for minimal maintenance. However, some upkeep is required to give

the best service and comply with the Harken limited warranty.

Keep your equipment clean and free-running by frequently flushing with fresh water. Periodically

clean with mild detergent and water solution. Spin sheaves to distribute soap solution evenly.

Flush with fresh water.

Important: Exposure to some teak cleaners and other caustic solutions can result in discoloration

of part and is not covered under the Harken warranty.

Warranty

For additional safety, maintenance, and warranty information see www.harken.com or the Harken

catalog.

M1005/04-26-11

Loading...

Loading...