Page 1

INSTRUCTIONS

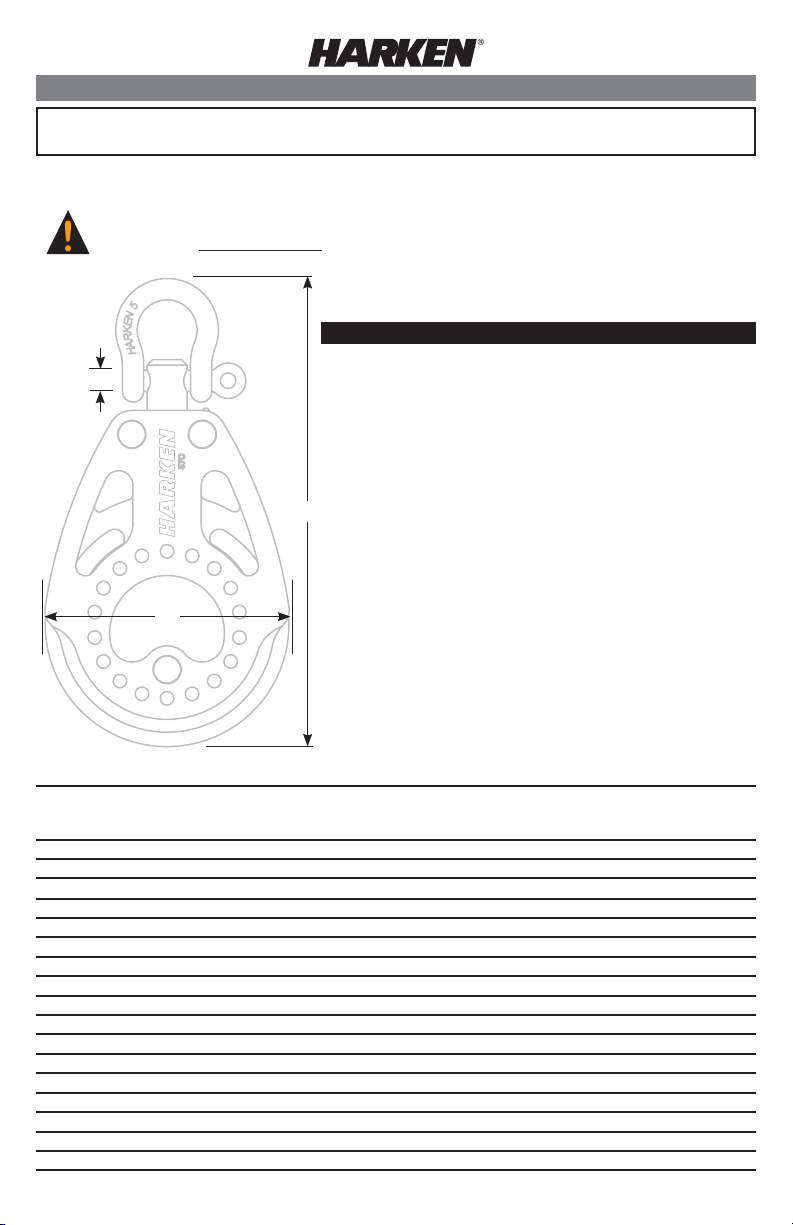

57 mm Carbo AirBlock

All blocks except 2607 Ti-Lite

USA – Tel: (+1) 262-691-3320 • Web: www.harken.com • Email: harken@harken.com

Italy – Tel: (+39) 031.3523511 • Web: www.harken.it • Email: techservice@harken.it

Strictly follow all instructions to avoid an accident, damage to your vessel, personal injury

or death. See www.harken.com for additional safety information.

®

IMPORTANT: See Inspection and Maintenance

at end of manual.

C

Features

Glass-filled nylon sideplates: load-carrying curved bearing

races.

Single fixed: Integral becket allows 2:1 or 3:1 purchase.

Doubles/triples: U-Locks holds the swivel in front/side position,

or lets block spin freely.

Triple w/cam: Compact cam arm supports high-load purchases of

5:1 or 6:1.

B

Cam arm locking plates: Allows cam arms to be locked in more

than five positions for fair leads.

Cheek: Line-shedding, small mounting footprint and drain holes.

Common uses: Main/jib sheets, mainsheet fine-tune, outhauls,

A

cunninghams, vangs, control lines

Max Line Size: 7/16" (10 mm)

Do not apply a load greater than the Maximum working load (MWL) of the Carbo AirBlock listed below.

Part

No. Description

2600 Single/swivel 2

2601 Single/swivel/becket 2

2606 Cheek 2

2607 Ti-Lite* Important: Consult instruction sheet at: http://www.harken.com/pdf/4927.pdf

2615 Single/swivel/150 Cam-Matic

2616 Single/swivel/150 Cam-Matic

®

** 21/457 45/161103/

®

/becket** 21/457 53/161323/

2621 Fiddle 2

2622 Fiddle/becket 2

2623 Fiddle/150 Cam-Matic

2624 Fiddle/150 Cam-Matic

®

®

/becket 21/457 67/81753/

2602 Double/swivel 2

2603 Double/swivel/becket 2

2604 Triple/swivel 2

2605 Triple/swivel/becket 2

2617 Triple/swivel/150 Cam-Matic

2618 Triple/swivel/150 Cam-Matic

®

** 21/457 43/4121 — 6 1500 680 3750 1700

®

/becket** 21/457 55/8142 — 6 1800 816 4500 2040

2631 Quadruple/swivel 2

A B C

in mm in mm in mm lb kg lb kg

1

/457 45/161103/

1

/457 53/161323/

1

/457 35/892 — — 792 359 2380 1079

1

/457 6 1533/

1

/457 67/81753/

21/457 6 1533/

1

/457 43/4121 — 6 1584 720 3300 1500

1

/457 55/8142 — 6 1584 720 3300 1500

1

/457 43/4121 — 6 2380 1080 5000 2270

1

/457 55/8142 — 6 2380 1080 5000 2270

1

/457 43/4121 — 6 2380 1080 5000 2270

16

16

16

16

16

16

16

16

working load

5 792 359 2380 1079

5 792 359 2380 1079

5 300 136 750 340

5 600 272 1500 680

5 792 359 2380 1079

5 792 359 2380 1079

5 792 359 2380 1079

5 792 359 2380 1079

*Can be used as becket block **Maximum working loads and breaking loads for blocks based on cam strengths

Maximum

Breaking

load

Page 2

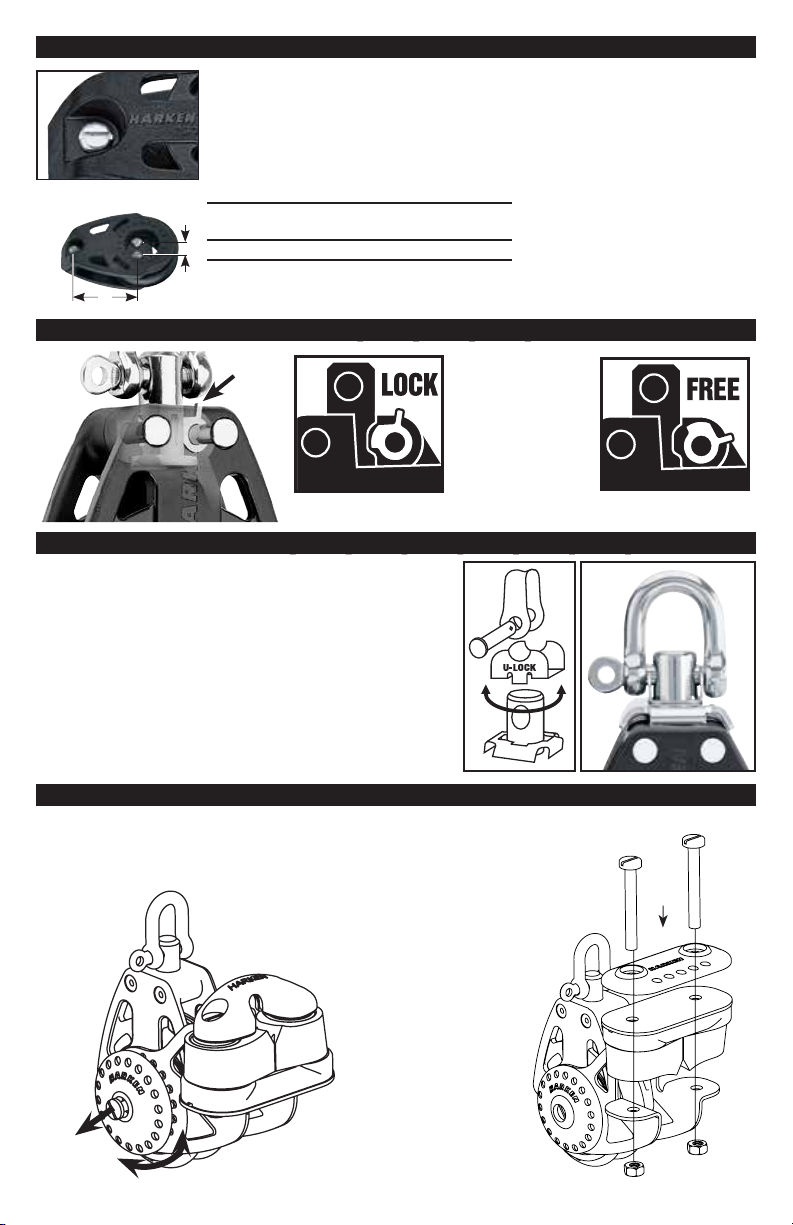

2606 Cheek Block

Using block as template, mark holes using a centerpunch. Remove block and

drill holes using a

knife to allow sealant to mass. Through-bolt block using recommended

stainless steel fasteners, washers and locknuts.

13

/64" (5.2 mm) drill. Bevel top of deck holes using a small

Part

No. Fasteners

B

2606 M5 or #10 PH/RH* 1

*Fastener length: Add deck thickness and overhang for nut

A

and washer.

A B

in mm in mm

7

/8471/212

3-Way Cam-Lock—2600 / 2601 / 2615 / 2616 / 2621 - 2624

1

3-Way U-Lock—2602 / 2603 / 2604 / 2605 / 2617 / 2618 / 2629 / 2631

The 3-Way U-Lock on doubles and triples allows a change

of headpost direction from front to side or allows the

block to swivel. To change headpost direction, remove

shackle, turn post, install shackle. Remove U-Lock to

allow block to swivel.

1. Cam lever up.

Block locks in

front or side

position.

2. Cam lever down.

Block turns

freely.

2

Adjust Cam Angle (Single/Triple) Reverse Cam Cleat (Single Only)

1. Loosen cam arm locking plate screw and

pull outward to disengage.

2. Rotate cam arm to desired position.

3. Press locking plate in and tighten screw.

Avoid binding

sheave, do

not over tighten

screw.

1

2

1. Remove screws from cam.

2. Assemble as shown. Note: use

plastic plate on cam bottom.

3. Tighten screws. Do not

overtighten screws. Cam

pawls should snap shut smartly.

Part No.

HFS889

Page 3

Reeving Multi-Purchase Systems

5:1 Right-Angle Reeving

Dead-end on Becket

4:1 Right-Angle Reeving

Dead-end on Becket

6:1 Right-Angle Reeving

Dead-end on becket

Right-angle reeving dead-end on becket

4:1 5:1 8:1 8:1

2

4

3

1

4

5

4

5

3

1

2

6

For larger, printable diagrams, please see: www.harken.com.

6

1

2

5

4

3

4

8

6

7

3

2

5

1

Inspect Block and Shackle Before You Sail

WARNING! Failure to inspect and replace damaged metal parts and/or worn or frayed line

can cause block or system to break suddenly causing an accident, damage to your vessel,

Frequently inspect shackles and shackle posts for signs of corrosion, cracks, or elongation. When

personal injury or death. See www.harken.com for additional safety information.

replacing shackles, use the correct Harken parts to maintain the proper strength. Replace line as

necessary, taking into consideration the maximum size recommendation.

Maintenance

Harken equipment is designed for minimal maintenance. However, some upkeep is required to give

the best service and comply with the Harken limited warranty.

Keep your equipment clean and free-running by frequently flushing with fresh water. Periodically

clean with mild detergent and water solution. Spin sheaves to distribute soap solution evenly.

Flush with fresh water.

Important: Exposure to some teak cleaners and other caustic solutions can result in discoloration

of part and is not covered under the Harken warranty.

Warranty

For additional safety, maintenance and warranty information see www.harken.com or the Harken

catalog.

M1002/1-17-11

Loading...

Loading...