Page 1

BOSUN'S CHAIR 2234

Adult Size Standard – Not for Use by Children

User Instruction Manual

4790/03-11-13

WARNING! Falling Hazard. Follow these general warnings to avoid a fall possibly resulting

in serious injury or death.

• Children do not t this chair and can easily slip out.

• Do not use this product for fall-arrest purposes. It is a working platform. Using bosun's chair for fall

arrest could fail to sufciently restrain a falling person.

• Alterations or misuse of this equipment or failure to follow these instructions could lead to a fall.

WARNING! Strictly follow all instructions to avoid potential hazards that may kill or hurt

you and others. See www.harken.com/manuals, for general warnings and instructions.

IMPORTANT

If you have questions on the use, care, or suitability of this equipment for your application, contact Harken Inc.

Please read these instructions carefully before using the equipment.

This manual may be modified without notice. See: www.harken.com/manuals for updated versions.

PLEASE SAVE THESE INSTRUCTIONS

Page 2

GENERAL Table of Contents

Parts 2

Applications 3

Training 3

Inspection 3-4, 7

Chair Fit 4

Attaching Halyards/Lifting Ropes 5, 8-9

Use 6, 8, 10

Sailboat Use 7-9

Industrial Use 10

Maintenance 11

Inspection Records 11

Warranty 12

Parts

1

2

3

4

7

6

1. Stainless steel triangle attachment points

2. High strength “seat belt” webbing

3. Ballistic nylon fabric throughout

4. Adjustable back support

5. D-rings and webbing loops for the

attachment of tools or parts

6. Extra-wide padded seat

7. Wide-mouth pockets on each side

8. Downhaul attachment on bottom of chair

5

8

2 Bosun's Chair — General 03/11/13

Page 3

GENERAL Applications

This chair is designed to be used as a work positioning platform to ensure comfortable seating while suspended. It

must be used in conjunction with a separate full-body, fall-arrest harness. The bosun's chair and harness must each

have its own separate suspension system led and secured as instructed below. This chair is only to be used for

work purposes. Do not use this chair for sport.

WARNING: Do not use this product for fall-arrest purposes. Use of bosun's chair for fall-arrest could

fail to sufficiently restrain a falling person, possibly resulting in serious injury or death.

Limitations

Capacity: This system is designed for use by one person with a combined weight (clothing, tools, etc.) of no

more than 100 kg (220 lbs).

No Free Fall: A separate full-body, fall-arrest harness restraint system must be rigged so that no vertical

free fall is possible.

Training: This equipment must be used by persons trained and competent in its correct application and safe use.

If you are in doubt about the correct use of the bosun’s chair, have a rigging professional do the aloft work.

Training

It is the responsibility of the purchaser and user of this bosun's chair to assure that they are familiar with

the instructions; are trained in the correct care and use of the equipment; and are aware of the operating

characteristics, application limits, and consequences of its improper use.

Inspection

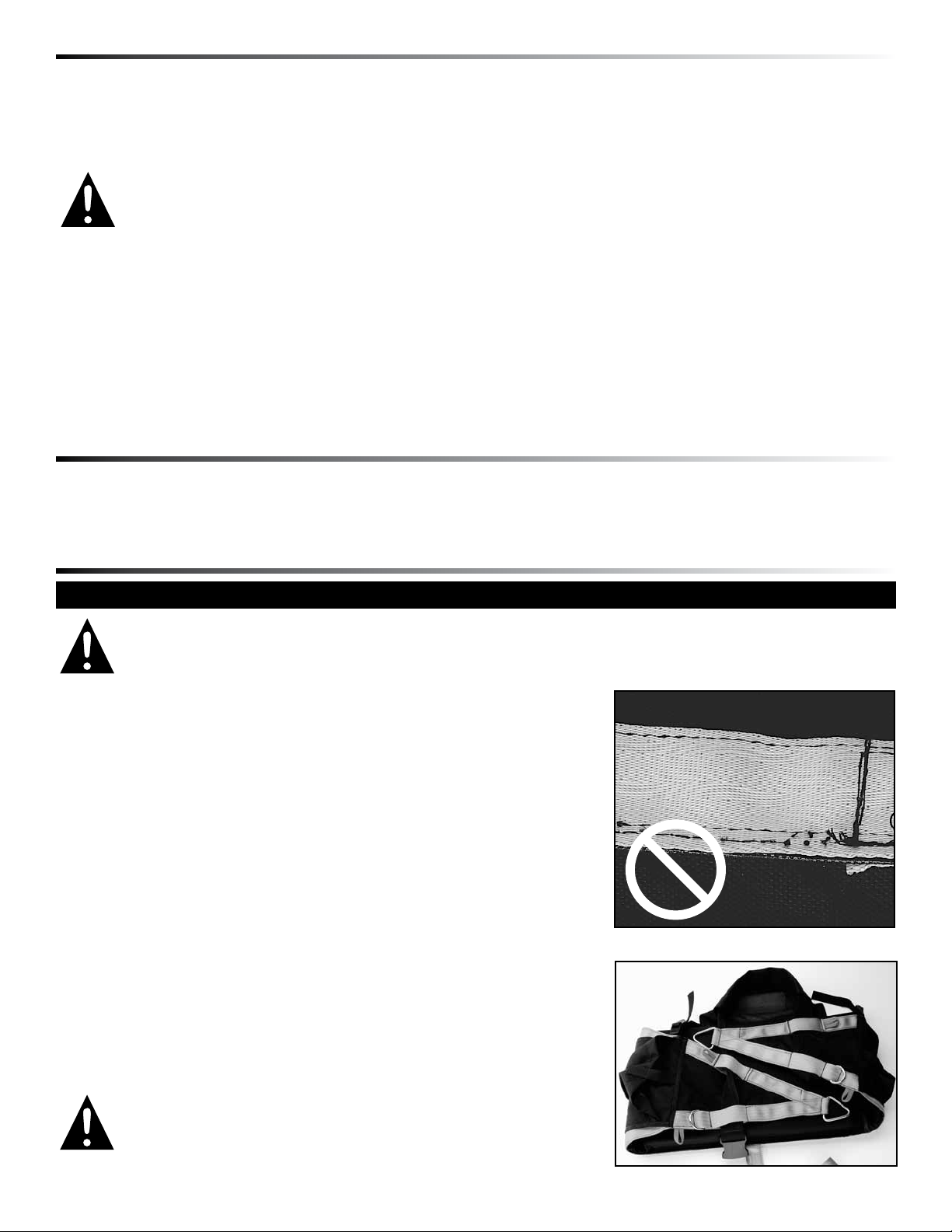

INSPECT BEFORE EACH USE

WARNING! Failure to perform inspection steps each time chair and hoisting equipment are used could

lead to a fall, possibly resulting in serious injury or death. Go through inspection check list below each

time chair is used.

Inspection should be recorded in inspection and maintenance log.

Inspection Check List

r Inspect the chair carefully for wear or abrasion to webbing and cut or

worn threads. See photo at right and Service section on Page 4.

r Inspect triangle attachment points carefully for signs of wear, fatigue,

or corrosion. Expose welded area to make sure it is secure.

r Inspect belt and buckle to ensure locking device is secure and unworn

and strap is correctly fastened.

See Service section on Page 4.

r Before going aloft, inspect all other equipment that will be used for

damage or wear. Inspect all halyards and standing rigging. Do not rely

on any equipment that is suspected of being worn, damaged, corroded,

needs replacement, or is out of date. If there is any doubt about the

condition of standing rigging at masthead, do not go aloft. Be especially

wary of going aloft on a boat with a furler that has had a halyard wrap

around top of stay.

Do not use chair if there are cut or worn threads.

WARNING! If wear or damage is detected, do not go aloft.

03/11/13 Bosun's Chair — General 3

Page 4

GENERAL Inspection

Service

A competent person must inspect equipment frequently, at least every

12 months, and ALWAYS BEFORE USE.

Ensure product markings are still legible.

If wear or damage is detected, return to manufacturer for repair or replacement.

Any attempt to modify or repair equipment by user will void the warranty.

WARNING! Modifying, changing, or temporarily securing the

equipment to “get the job done” could lead to a fall.

If chair has been subjected to a severe shock load, it must be removed

from service and replaced.

WARNING! A chair that has been subjected to a shock load

can be severely weakened and subject to further deterioration

through normal use. Do not use the chair after a shock load.

Inspect Weld

Failure to replace such a chair may result in the chair breaking,

leading to a fall.

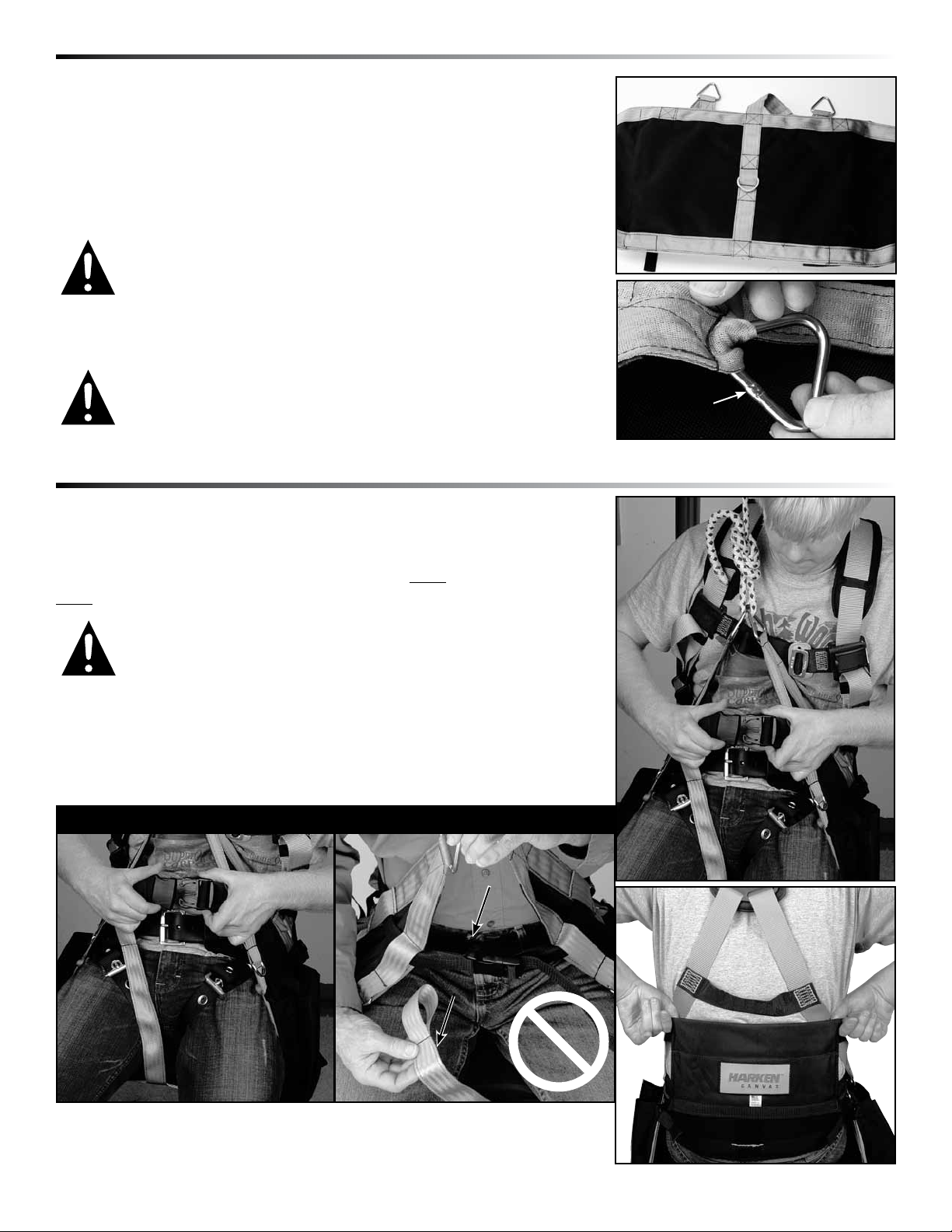

Chair Fit

Before using for first time, perform a comfort and adjustability test in a safe

place to ensure chair is correct size, has sufficient adjustment, and

has acceptable comfort level for intended use.

Weight should be centered on seat. Crotch strap must be used. Legs

must be on either side of crotch strap.

WARNING! Failure to use crotch strap can result in user slipping

out of chair and falling. Always use the crotch strap.

Adjust webbing buckles on back support and waist strap to ensure a snug,

comfortable fit.

Ensure locking tabs on waist buckle are fully snapped into place.

Ensure steel triangle attachment points are clear of clothing, and to front of body.

CORRECT

INCORRECT

Waist Strap

Crotch Strap

Waist strap inserted through crotch strap. Waist strap must be inserted through crotch

strap before it is fastened.

4 Bosun's Chair — General 03/11/13

Page 5

GENERAL Attaching Halyards/Lifting Ropes

Always use two lifting ropes when going aloft, one attached to bosun's

chair and one attached to separate full-body harness.

WARNING! Both equipment and people can fail to secure a

suspended person—using only a single lifting rope greatly

increases risk of falling. Always use a separate lifting rope

attached to a separate full-body harness.

Do not depend on snap shackles; tie each lifting rope or use approved

carabiner, hook, or D-ring for industrial applications. Use both stainless

triangles using a secure locking knot. Secure unused snap shackle out of

the way so it does not catch.

WARNING! Snap shackles can open suddenly. Any shackle,

even stainless steel “D” shackle versions, are subject to stress

corrosion. Tie each lifting rope or use approved carabiner,

hook, or D-ring for industrial applications.

Shackles may have been stressed in other load

applications while sailing. Overloading is not

always apparent, especially when using highload stainless steel such as type 17-4. Stress

CORRECT

INCORRECT

corrosion in this material is only detectable

using dyes or X-ray imaging.

Do not depend on snap shackles; tie each

lifting rope using knot shown on pages 8-9 or

use approved carabiner, hook, or D-ring for

industrial applications.

Snap shackles can open suddenly.

Also any shackle is subject to stress

corrosion and may fail suddenly.

Always secure halyard or other attachment system to BOTH triangles.

Make sure steel triangles are seated flat in webbing

INCORRECT INCORRECTCORRECT

03/11/13 Bosun's Chair — General 5

Page 6

GENERAL Attaching Halyards/Lifting Ropes

Do not tie halyard to D-rings or small webbing loops on side of chair.

INCORRECT

These are for suspending tools only.

DANGER! Supporting person on D-rings or webbing loops on side

of chair will cause rings or straps to fail, leading to a fall. Do not

use side straps for support!

Ensure halyards or lines are not tangled and do not trail or loop over any sharp

edges. If tangle or jam occurs at winch, use secondary halyard to hold person.

Additionally, suspended person must secure to mast or other suitable surface.

WARNING! If tangled line frees, halyard can suddenly let go,

leading to a fall. Suspended person must secure to mast while

freeing jam so there are two lifting ropes.

Use

Do not stand in chair when aloft.

WARNING! Standing or in any way getting out of chair position while hoisted, described on Page 4 under

Chair Fit, can lead to a fall. Always stay seated.

Make sure no one is below person working aloft.

Secure tools carefully to prevent dropping them and causing damage or injury.

WARNING! Tools and equipment are easily dropped, possibly

causing serious injury or death to those below hoisted person.

Keep people clear of area below chair.

If in doubt about correct use of bosun’s chair, contact rigging professional before going aloft. A rigging professional

can demonstrate correct use of equipment and help you avoid accidents.

6 Bosun's Chair — General 03/11/13

Page 7

SAILING System Requirements

SAILING

Two suspension systems are required. When used for aloft rigging

separate full-body harness must be used along with bosun's chair.

Harness and bosun's chair must each have its own halyard led to

separate internal halyard sheaves as instructed below. Each halyard

must go to separate stopper and winch.

WARNING! Both equipment and people can fail to secure

a suspended person—using only a single halyard greatly

increases risk of serious injury or death. Use two halyards,

one to full-body harness.

Use only halyards with internal mast sheaves. Critical parts of externally

attached masthead blocks can wear, corrode, or crack. Because they

cannot be inspected easily, failure can happen suddenly and unexpectedly

CORRECT INCORRECT

Internal Halyard

WARNING! Do not use externally attached masthead blocks.

Always use internal halyards to avoid a fall.

Inspect

Inspect condition of all halyards to make sure all parts are in new condition. If necessary use trace lines to run

halyards out of mast to inspect. Inspect halyards for wear, fraying, or degradation from sun's UV rays. Replace

halyards showing any of these signs before going aloft. Use only halyards that are in new condition. If there is

any doubt about condition of halyard, do not use.

External Halyard

WARNING! Halyards that are frayed, worn, or degraded from UV damage can part suddenly, leading

to a fall. Use only halyards in new condition.

Inspect all stays and standing rigging for any signs of wear, fatigue, or damage. If boat is equipped with furler, know

history of stay inside furler. If there has been a halyard wrap, do not rely on stay to hold mast. It may be weakened

and not visible under foil.

WARNING! If working on mast with furler do not go aloft if there has been a halyard wrap that was

forced by trying to furl. Weight of being aloft can cause stay or connecting fittings to break, causing

mast to collapse, leading to a fall.

03/11/13 Bosun's Chair — Sailboat 7

Page 8

SAILING Tying to Bosun's Chair/Use

SAILING

Tying

Always use two halyards when going aloft; one attached to bosun's chair, and one attached to separate full-body

harness. Tie each halyard using method shown below.

Use Figure 8 Follow-Through Knot commonly used by climbers. See www.harken.com/knots for further knot-tying resources.

WARNING! If you have any questions about how to tie halyards to chair/full-body harness using following

instructions do not go aloft. Knot failure can lead to a fall, possibly resulting in serious injury or death.

CORRECT

A

A

INCORRECT

Loop rope underneath and over top of itself. Do not run line over “A”.Come up from underneath “A” to make a

figure 8.

A

Make sure you have a figure 8 exactly as

shown above. Have a long tail as shown

8 Bosun's Chair — Sailboat 03/11/13

Go through both triangles and trace line

following figure 8.

Page 9

SAILING Tying to Bosun's Chair

SAILING

Continue tracing figure 8.

Hoisting

When using halyards to hoist person aloft, ensure they are securely held and locked off. Always keep halyards wrapped

securely on winches. Halyards must be wrapped three or more times around winch and line secured in self-tailing

jaws. Stoppers must be closed when hoisting person aloft and when they hold someone in place for working.

WARNING! Do not rely solely on stoppers for holding person aloft.

Stoppers or clutches may slip suddenly, leading to a fall. Always keep

halyard wrapped on winch when using stopper.

Working Aloft

Do not drill through mast while suspended on halyard. Drill entering mast can

make contact with halyard and weaken it. Also see general use instructions.

WARNING! Drilling through mast can weaken internal halyards

causing them to break. Avoid drilling where halyards are led.

Lowering

When lowering a person, keep at least three halyard wraps on a primary and backup winch. Two people must

work together, one in charge of lowering using one winch, the other with line securely wrapped on backup winch.

To prevent line jams and

overrides, carefully align wraps on winch so that one does not overlap another. If jam

occurs, close stoppers. Use backup winch halyard to take up tension and free override or line jam. Have aloft

worker temporarily secure themself to mast. If lowering to new hoisted working position, carefully close

stoppers and keep halyards wrapped on winches and secured in self-tailing jaws.

Tightly cinch all four strands of rope exiting

the knot.

WARNING! Attempting to free jams on winch drum without stopper or second halyard can result in jam

suddenly freeing, leading to a fall. Suspended person must secure to mast while freeing jam so there

03/11/13 Bosun's Chair — Sailboat 9

are two lifting ropes.

Page 10

INDUSTRIAL System Requirements

When bosun's chair is used in conjunction with fall-arrest system it must be

certified by the country where the product will be used.

Bosun's chair is only a working platform. It must be attached to a secondary

support system which meets the industrial safety standards of the country where

the product will be used.

Fall-arrest system must consist of a full-body harness worn as the main bodyholding device. It must be connected to a shock-absorbing lanyard and approved

anchor device.

Connectors (hooks, carabiners, and D-rings) must be capable of supporting loads

specified by the industrial standards of the country where the product will be used.

Standards

This equipment has been tested to European standard — EN813:2008.

Use

If using other anchor devices or anchor points, ensure they are certified to EN795

standards, and are positioned as closely as possible to directly overhead. Noncertified anchor points may look secure however they may be cracked, rotten,

or corroded, or their fastening method may not be secure, especially if device

Inspect

was designed for other purposes.

WARNING! Noncertified anchor points may give way suddenly

leading to a fall, possibly resulting in serious injury or death.

Use only certified anchor points.

Inspect all connections and fasteners to make sure they are secure. Especially

pay attention to screw-pin fasteners.

WARNING! If screw-pin fastener loosens, connection can let go,

leading to a fall. Always inspect and secure all connecting fasteners.

Rescue

When using this equipment, employer must be trained and have a rescue plan and means to implement it.

The plan must communicated to users, authorized persons, and rescuers.

Suspension Trauma

Make sure plan includes training to treat victim suffering from suspension trauma and reflow syndrome.

WARNING! Rescued worker may appear fine after being lowered. However, failure to properly treat

victim after an arrest from even a relatively short fall can lead to reflow syndrome and death. Research

and follow first aid practices for suspension trauma.

Shock Load

If bosun's chair has been subjected to a shock load, chair must be removed from service immediately and

destroyed by user or an authorized person.

WARNING! A chair that has been subject to a shock load can be severely weakened and subject to

further deterioration through normal use. Do not use the chair after a shock load. Failure to replace

such a chair may result in chair breaking, leading to a fall.

10 Bosun's Chair — Industrial 03/11/13

Page 11

GENERAL Maintenance

Wash with fresh cold water to remove any dirt and salt water.

Allow to dry naturally, away from direct heat.

Store in a dry, ventilated place, away from direct sunlight to avoid corrosion, mold/mildew damage, and UV degradation.

Inspection Records

A record must be kept for each component, subsystem, and system, with following details (see example record log below).

It is the responsibility of the user organization to provide the record and to enter onto the record the details required.

EQUIPMENT RECORD

Product:

Model/Type

Description

Serial Number

2234

Manufacturer

HARKEN

Purchase Date Date First Put Into Use

Other important information (i.e. document number):

Date

Reason for Entry

(Periodic exam or repair)

Bosun's Chair

Address

N15W24983 Bluemound Rd., Pewaukee, WI

USA 53072

EXAMINATION/REPAIR HISTORY

Defect notes, repairs carried out, and

other important information

Name and signature of

competent person

Tel/Fax/Email/Website

(262) 691-3320 / (262) 701-5780

harken@harken.com / www.harken.com

Date of next periodic

examination

03/11/13 Bosun's Chair — General 11

Page 12

04

97653 23436

Worldwide Limited Warranty

COVERAGE. HARKEN® warrants that each HARKEN product,

when properly used and maintained, will be free from defects in

material and workmanship from the date of receipt of the product

by the final customer.

THE LIMITED WARRANTY. This limited warranty applies to all

Harken products purchased. The sole and exclusive remedy

under this LIMITED WARRANTY for original defects in materials or workmanship of a HARKEN product shall be the repair or

replacement, at HARKEN’s sole discretion, of the defective part or

component, in accordance with the terms of this warranty.

WARRANTOR. For products originally sold in the Unites States,

the limited warranty for the products is supplied by HARKEN,

INC.. For products originally sold in the European Union, the

limited warranty for the products is supplied by the dealer who

sold the product through the Harken Distributors in that country.

For products originally sold in the rest of the world, the limited

warranty for the products is supplied directly by the Harken

Distributors in that country. When "HARKEN” is mentioned

throughout this Limited Warranty, it refers to the entity as defined

in this paragraph.

OWNER – NON-TRANSFERABLE WARRANTY. This warranty is

made by HARKEN with the original purchaser of the product and

does not extend to any third parties. The rights of the original

purchaser under this warranty may not be assigned or otherwise

transferred to any third party.

WARRANTY TERM. The LIMITED WARRANTY covers any

original defects in material or workmanship manifested within

12 months of the date of receipt of the product by the final customer.

NOT COVERED. The LIMITED WARRANTY does not apply to, nor

shall HARKEN have any liability or responsibility for, damages or

expenses relating to defects caused by misuse, abuse, failure to

install, use, maintain, or store the HARKEN product as specified

in the warranty booklet, service booklet, manuals, catalogue, or

other literature available from HARKEN.

The LIMITED WARRANTY does not apply to, and neither shall

HARKEN have any liability or responsibility in respect to, damages, or expenses relating to:

• defects in material or workmanship that did not exist when the

product was first delivered;

• defects in material or workmanship that are manifested outside

the warranty period;

• defects which are not reported to HARKEN within sixty (60)

days of discovery;

• a product that has been altered or modified from factory

specifications;

• damage or deterioration of cosmetic surface finishes, including

cracking, crazing, discoloration, or fading;

• accidents, misuse, abuse, abnormal use, improper use, lack of

reasonable or proper maintenance or storage;

• installation, service, or repairs improperly performed, or replace

ment parts or accessories not conforming to HARKEN’s

specifications;

• use exceeding the recommended and permitted limits or

loads of the product and/or the product on which the product

is installed;

• normal wear or deterioration occasioned by the use of the

product or its exposure to the elements;

• ropes, lines, buckles, and webbing;

• loss of time, loss of use, inconvenience, travel expense, costs

related to procuring any substitute product, transportation costs,

any incidental or consequential damages arising out of the non use of the product, or compensation for inconvenience or loss

of use while the product is being repaired or otherwise not

available, or other matters not specifically covered hereunder;

• the costs to remove, disassemble or reinstall the product;

• removal, storage, and replacing of the product on which the

product has been installed, even where this is necessary to carry

out the warranty service.

The LIMITED WARRANTY does not cover, nor shall HARKEN

have any liability or responsibility in respect to, damages or

expenses relating to the following products and/or components:

• washers and spacers;

• ball bearings, roller bearings, thrust bearings.

Online warranty registration. Registering this product online at www.harken.com is critical to receive product updates or any recall

information. Harken will not sell this information or use it for solicitation.

Please visit: http//www.harken.com/dealers/dealers.php

for an up-to-date list of Harken dealers and distributors

Printed in USA 4790 03-11-13

Loading...

Loading...