Page 1

INSTRUCTIONS

®

T2™ Ratchamatic

USA – Tel: (+01) 262-691-3320 • Web: www.harken.com • Email: harken@harken.com

Italy – Tel: (+39) 031.3523511 • Web: www.harken.it • Email: techservice@harken.it

Blocks

WARNING! Strictly follow all instructions to avoid an accident, damage to your vessel,

personal injury or death. See www.harken.com/manuals for additional safety information.

2159, 2160

Features

Versatile attachment: block can be lashed or spliced.

Ratchet engages automatically as load increases.

10:1 Holding power with 180° wrap.

Shifts crisply from ratchet to free run (light air) mode.

Sheave runs free with light load.

Sideplates are lightweight, UV-resistant, glass fiber-reinforced

plastic. Eight-sided, Hardcoat-anodized aluminum sheave.

®

Delrin

ball bearings for low friction.

Delrin is a registered trademark of E. I. du Pont de Nemours and Company or its affiliates.

Specifications

Part

No. Description Sheave Ø

2159

40 mm 40 mm

2160

57 mm 57 mm

Max line Ø Maximum working load Breaking load

in mm lb kg lb kg

3

/8 10 300 136 1000 454

3

/8 10 500 227 2000 907

Replacement Line

Replacement line

Part

No. Description

2159

40 mm 40 mm HCP1419

2160

57 mm 57 mm HCP392

Sheave ØReplacement

Loops /Lines

Ø

3

/32 2.5 4 1.22 Maxibraid

1

/

8

3 4 1.22 Maxibraid

Sideplate

Laps

Bail

Line length

before making loop

Terms

Mouth

Trigger

Sheave

Head

Lashing

Strands

Line

Typein mm ft m

Important information on choosing line, knots and splices.

Go to www.harken.com/knots

Contents

Planning Installation Including Warnings

Using T2 Ratchamatic

Inspect Line Every Time You Sail

Lashing to Boom

Lashing to Bail Using Harken Supplied Line

Using Alternate Line Knots and Splices

Maintenance

Warranty

1

Page No.

2

3

3

4

4

5

5

5

Page 2

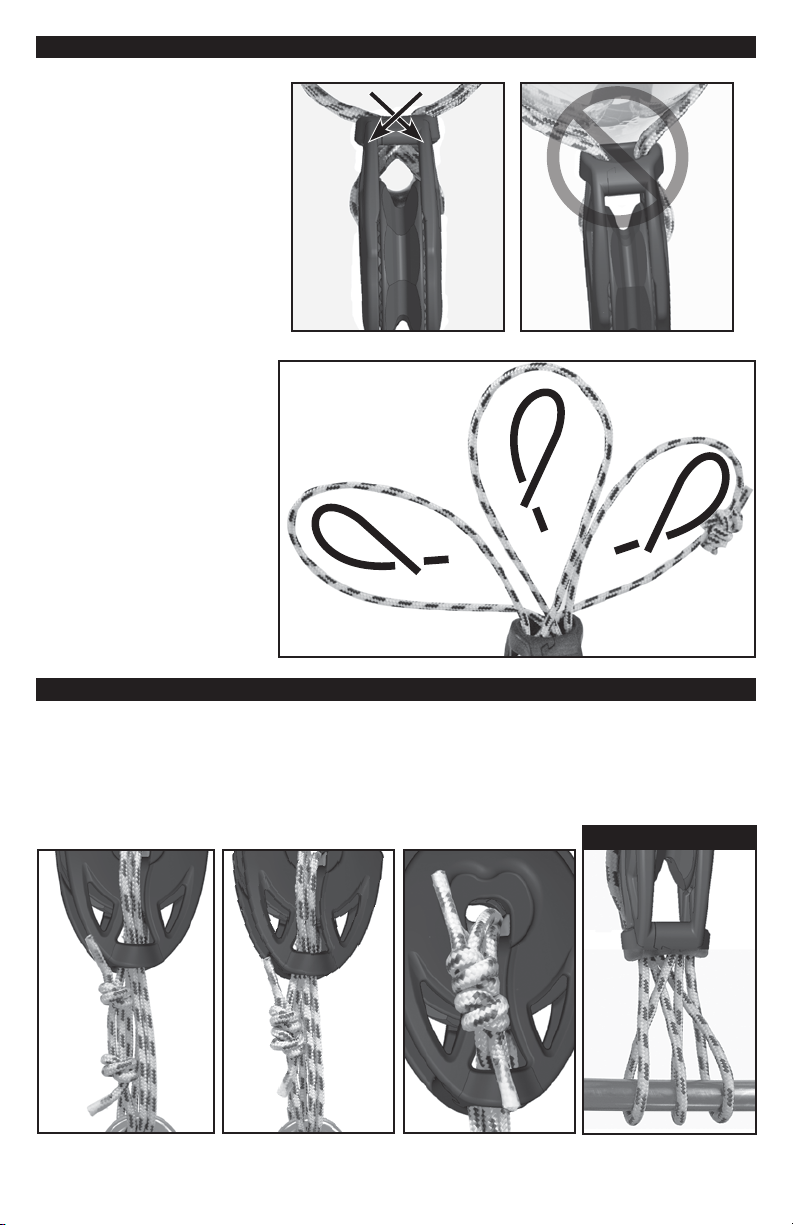

Planning Installation

WARNING! Lashing to objects with sharp edges can cause line to chafe and break suddenly

when load is applied.

1. Lash only to objects with rounded edges.

Avoid sharp corners.

Rounded

Sharp

WARNING! Lashing to objects with sharp edges can cause line to chafe and break suddenly

when load is applied.

2. Always lash to mouth of the block. Ratchet mechanism will only work with lashing line on trigger.

Head is not strong enough to secure line.

Mouth

Head

Head

Do not lash through block head.

Do not lash through block head.

Head

WARNING! Lashing to head of block seriously weakens the block. This will cause

the block to break suddenly when load is applied. Always lash to mouth.

3. Use three laps of line to create six strands to match the maximum working load of the block.

WARNING! Using fewer laps will weaken block causing it to break suddenly when

load is applied. Use three laps of line.

4. IMPORTANT! Do not use

mouth as an adjustable

block. Carbo

®

surface will

wear or wear the line if

used as a 2:1 adjustable

block under load.

2

Laps

Three laps, six strands are

required for proper strength.

This block only has two laps,

four strands of supplied line.

2

Page 3

Using T2 Ratchamatic Block

Ratchet blocks are hand and crew savers. The eight-sided sheave grips loaded sheets with up to 10:1

holding power. Ratchamatic blocks spin freely in both directions under low load. At higher load, ratchet

engages, providing holding power. As the load decreases, the ratchet shifts back into light air mode

and free spins. Unloaded main and jib sheets run out freely during mark roundings and asymmetrical

spinnakers run free during jibes.

Ratchet Direction Arrow on side of block shows direction that sheave will spin in ratchet mode.

Refer to arrow when reeving block.

Inspect Line Every Time You Sail

Inspect lashing line for chafe or UV-damage every time you

sail. Replace damaged line immediately. Replace line with

no visible damage every two-years. Use Harken replacement

line, but if using own line, see “Using Alternate Line, Knots and

Splices” and chart on back page for important information to

help you select the correct line.

WARNING! Failure to inspect and replace UV-damaged, worn or frayed line can cause

the line to break suddenly when load is applied.

Check knots or splices before

sailing. Use a double fisherman's

knot or other secure knot.

See www.harken.com/knots

WARNING! Failure to inspect and correct knots can cause the line to slip suddenly when

load is applied.

Replacement Line

Part

No. Description

2159

40 mm 40 mm HCP1419

2160

57 mm 57 mm HCP392

Sheave ØReplacement

Loops /Lines

Replacement line

Ø

3

/32 2.5 4 1.22 Maxibraid

1

/

8

3 4 1.22 Maxibraid

Line length

before making loop

3

Line

Typein mm ft m

Page 4

When lashing to a large object

such as a boom, cross each line to

prevent pushing out on sides

of head. See next page.

If you have access to end of

boom, twist each lap. Secure

using double fishermans knot or

other secure knot. See "Lashing

to Bail Using Harken-Supplied

Line" below.

Lashing to Boom

Over

Under

Lines can pull block head apart.

Over

Under

Under

Over

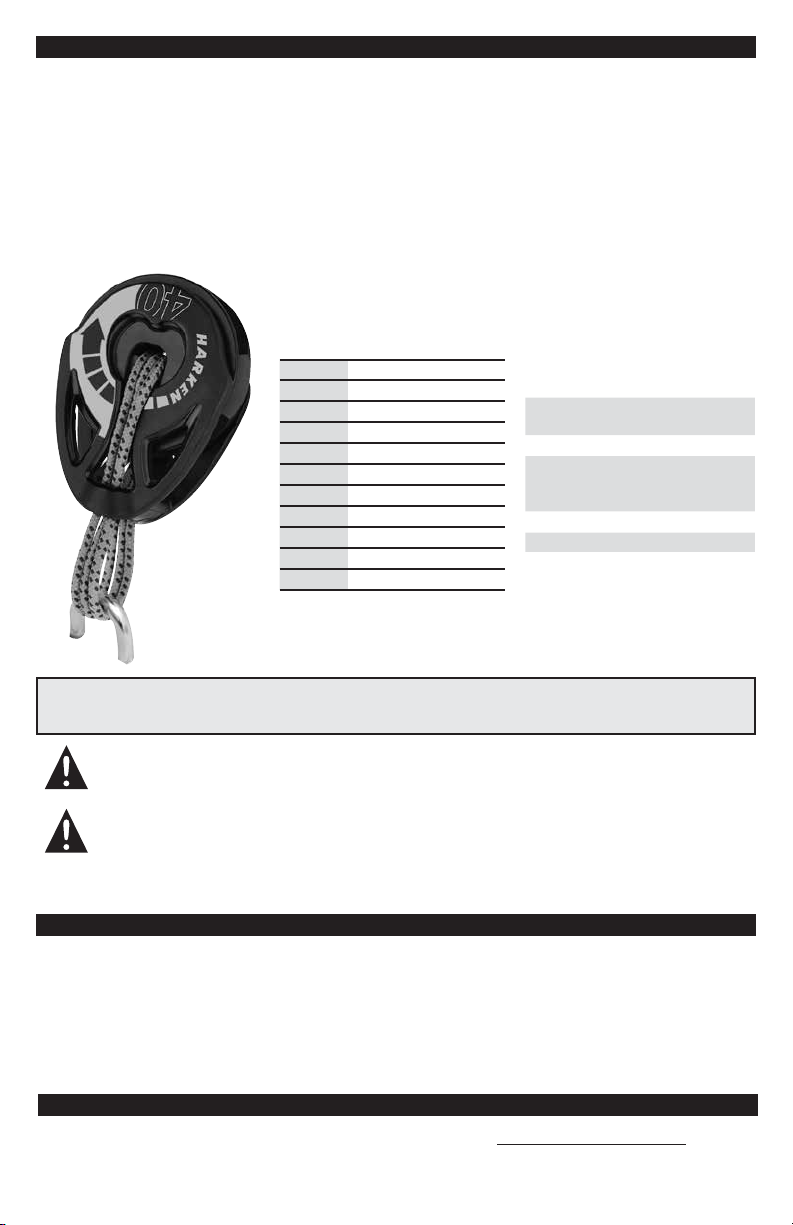

Lashing to Bail Using Harken-Supplied Line

Note sheave direction of rotation when block is under load in ratchet mode. Make sure the block is

facing the correct way before lashing. Use three laps to create six strands. Tie ends using double fisherman's knot or other secure knot. Knot can also be located on side of block. Photos are not intended to

teach this knot. See www.harken.com/knots or consult a knot tying book. IMPORTANT! If you are not

comfortable tying this or another secure knot, get help from a professional rigger.

Lashing 90°

To lash block at 90° cross lines

each pass similar to lashing

to boom.

4

Page 5

Using Alternate Line, Knots and Splices

Harken is not liable or responsible for use of line used to secure blocks. Go to Harken Limited Warranty at www.harken.com

for complete details. It is your responsibility to choose the correct line for the block. When choosing line, use a breaking

load that exceeds the block's breaking load to account for strength loss from:

1. Knots slipping or breaking much lower than line breaking load. Spectra

specialized knots.

2. Splices slipping or failing due to the incorrect type or execution.

3. UV damage increasing with each passing year.

4. Chafing seriously reducing strength.

If you are not comfortable choosing line, work with a qualified rigger. Go to www.harken.com/knots for additional information.

IMPORTANT! Fewer lashing strands require line with higher breaking load.

Lashing Line Minimum Breaking Load

Strands lbs kg

Six (6)

Strands

1

2

3

4

5

6

7

8

9

10

2000 907

1000 454

667 302

500 227

400 181

333 151

286 130

250 113

222 101

200 91

®

or Dyneema®-type lines require

A breaking load of 2000 lb (900 kg)

Fewer strands of higher-strength line

More strands of lower-strength line

Check fit of lashing line in block mouth

Notes

can be achieved by using:

OR

Read important information on choosing line, knots and splices at: www.harken.com/knots.

WARNING! Failure to account for loss of strength due to chafe or UV damage when choosing

line can result in line breaking suddenly when load is applied.

WARNING! Improper knots or splices can weaken the block installation causing it to break

suddenly when load is applied.

Dyneema is a registered trademark of DSM Dyneema.

Spectra is a registered trademark of Honeywell International, Inc.

Maintenance

Harken equipment is designed for minimal maintenance. However, some upkeep is required to give the

best service and comply with the Harken limited warranty.

Keep your equipment clean and free-running by frequently flushing with fresh water. Periodically clean with

mild detergent and water solution. Spin sheaves to distribute soap solution evenly.

Flush with fresh water.

IMPORTANT! Exposure to some teak cleaners and other caustic solutions can result in discoloration

of part and is not covered under the Harken warranty.

Warranty

For additional safety, maintenance and warranty information see www.harken.com/manuals or the

Harken catalog.

5029.W 06-14

5

Loading...

Loading...