Page 1

INSTALLATION SHEET

Small Boat Furling

207/208/436

N15W24983 Bluemound Rd. • Pewaukee, WI 53072 U.S.A.

Telephone: (262) 691-3320 • Fax: (262) 701-5780

Web: harken.com • E-mail: harken@harken.com

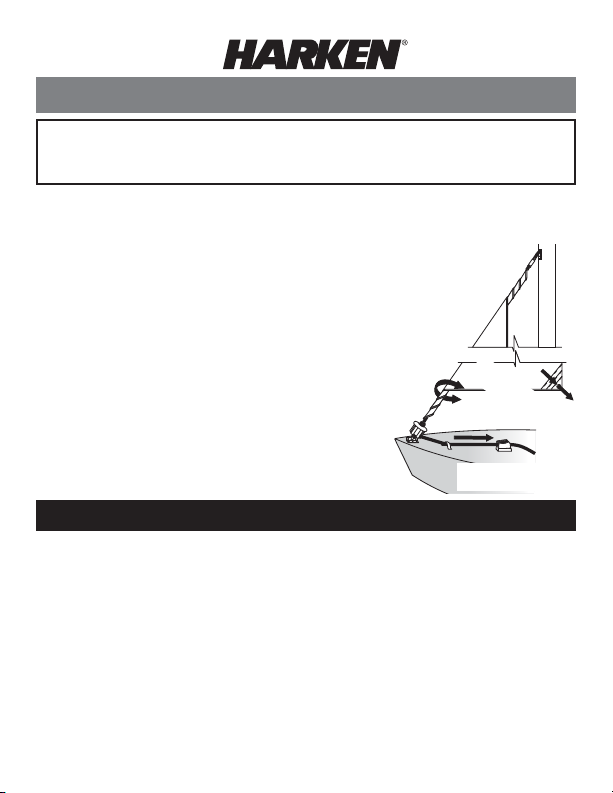

How It Works: To furl the jib, pull the furling

line and the sail rolls up around its own luff.

To un-furl, uncleat the furling line and pull the

jib sheet.

Sail with Luff Wire Required: Your sail must

have a 1 x 19 counterlaid stainless steel wire

sewn into the luff with thimbles that are sewn

firmly to the tack and head so they will not

turn. Many small boat sails already have this.

If your sail has a luff rope and hanks, they

must be replaced by a qualified sailmaker.

INSTALLATION

The system consists of the furling drum and the upper swivel.

Drum: Attach the drum to the stem fitting behind the forestay. On

many boats the forestay is removed and the jib luff wire replaces it.

In this case, the jib remains on the boat in its furled position when

the boat is not in use and a cover protects the sail from UV exposure.

Furling Line: Use 3/16" (5 mm) or 1/4" (6 mm) Dacron line. To figure the

length, add 15' (4.5 m) to the distance from the furler to the cleat.

Feed the line through the little hole in the top of the drum from the

bottom side and tie a tight overhand or figure “8” knot in the end.

Spin the drum and wind up about 141/2' (4.4 m) of line.

Pull on Jib Sheet

Unfurling

Furling

Pull on Furling Line

Page 2

Upper Swivel: Attach the upper swivel to the jib halyard. Fasten the

head of the jib to the upper swivel and attach the tack to the top of

the drum. Hoist the sail with the halyard, snug it up and cleat.

Furling Line Lead and Cleat: Lead the furling line through the aft

slot on the starboard side of the drum so it does not rub and lead it

to a point on the starboard side of the foredeck where the line lead

is exactly perpendicular to the luff wire or forestay. Mount a plastic

bullseye fairlead at this point or use a 348 bullet block on an eyestrap.

Lead the line aft and mount a 356 cam cleat with fairlead. Tie a figure

“8” knot in the end and you’re ready to furl.

Maintenance

Harken equipment is designed for minimal maintenance, but some maintenance is

required to give the best service and to comply with the Harken limited warranty.

In general, the most important aspect of maintenance is to keep your equipment

clean by frequently flushing with freshwater.

In corrosive atmospheres, stainless parts may show discoloration around holes,

rivets and screws. This is not serious and may be removed with a fine abrasive.

With the exception of winches, do not use grease unless specifically recommended in the instruction sheets.

Many Harken products are provided with specific instruction sheets that detail

maintenance procedures. Instruction sheets are available at no charge by contacting Harken or a Harken distributor.

Furling System: Keep furling units clean by flushing frequently with fresh water.

Periodically clean the lower unit and the halyard swivel with detergent and fresh

water to remove deposits of salt and dirt. Lubrication is not required.

Important! Exposure to some teak cleaners and other caustic solutions can result

in discoloration of part and is not covered under the Harken warranty.

Warranty

For additional safety, maintenance and warranty information see www.harken.com/

manuals or the Harken® catalog.

Printed in USA. 4404 12/13

Loading...

Loading...