Page 1

INSTRUCTIONS

Mastbase Blocks 1988, 1990, 3123, C8508

Over-the-Top Blocks 3002, 3003, 3004, C8322, C8624

N15W24983 Bluemound Rd. • Pewaukee, WI 53072 U.S.A.

Telephone: (262) 691-3320 • Fax: (262) 701-5780

Web: www.harken.com • E-mail: harken@harken.com

Strictly follow all instructions to avoid an accident, damage

to your vessel, personal injury, or death. See www.harken.com/

manuals for additional safety information.

Fasteners (FH)

A4 (316) or A2 (18-8)

stainless steel

Size Type Qty

5

/8"

16 mm

5

/8"

16 mm

5

/8"

16 mm

5

/8"

16 mm

5

/8"

16 mm

5

/8"

16 mm

5

/8"

16 mm

5

/8"

16 mm

5

/8"

16 mm

Part

No. Block

1988 Mastbase

1990 Mastbase

3123 Mastbase

C8508 Mastbase

3002 Over the top

single

3003 Over the top

double

3004 Over the top

triple

C8322 Over the top

single

C8624 Over the top

single

Max

Line Ø

3

/8"

10 mm

1

/2"

12 mm

11

/16"

18 mm

3

/4"

19 mm

3

/8"

10 mm

3

/8"

10 mm

3

/8"

10 mm

1

/2"

12 mm

9

/16"

14 mm

Maximum

Working Load

(MWL)

2500 lbs

1136 kg

5000 lbs

2273 kg

11000

4990 kg

15000

6804 kg

2500 lbs

1136 kg

2500 lbs

1136 kg

2500 lbs

1136 kg

2500 lbs

1136 kg

5000 lbs

2272 kg

Breaking Load

(BL)

5000 lbs

2272 kg

10000 lbs

4536 kg

22000 lbs

9980 kg

30000 lbs

13608 kg

5000 lbs

2272 kg

5000 lbs

2272 kg

5000 lbs

2272 kg

5000 lbs

2272 kg

10000 lbs

4536 kg

Purchase

Flathead 3

Flathead 4

Hexhead

Bolt

Hexhead

Bolt

Flathead 2

Flathead 4

Flathead 6

Flathead 2

Flathead 2

2

3

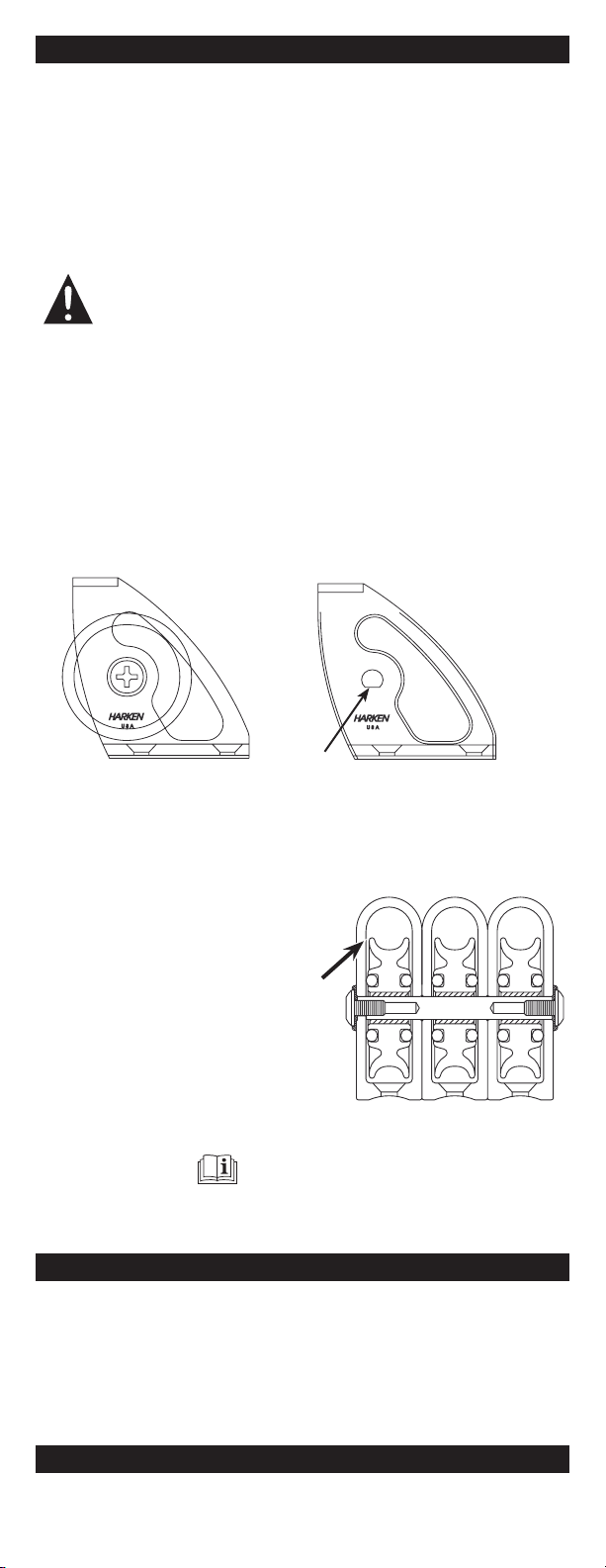

Install 1988,1990, 3123 Mastbase Blocks

Note: Install blocks so sheave is leaning away from mast. “Harken”

will be towards mast. See drawing below.

1. Remove sheave. Remove screw from port side of assembly. Pull

out centerpost from starboard side.

Tip: Don’t worry about losing balls in sheave, they are captive. If

post is stuck, leave screw halfway in and push on screw head to

push post out port side.

2. Mark position of holes. Keep “Harken” towards mast.

WARNING! You must mount to solid deck construction using specified fasteners in all mounting holes and nuts, washers or backing

plates to achieve correct maximum working load.

Tip: To make sure block is aligned with load, drill forward hole, insert

screw and sheave, run line to deck block and let block center itself.

Remove and drill other hole(s).

3. Mount carrier. Drill holes and screw to deck using sealant, backing

plates, and locknuts. 1988, 1990 – Do not overtighten screws; sheave

will bind. Tip: Slightly bevel top of hole in deck to allow sealant to mass

near top of hole.

4. Installing sheave: Slip post in from starboard side and seat end of shaft

in flat. Use blue Loctite

Mast

®

provided on screw and secure.

Flat in hole

retains post

Port Side: “Harken” must be towards mast.

Page 2

Install 3002, 3003, 3004 Over-the-Top Blocks

1. Remove sheave(s). Remove phillips screw from left side of assembly

(see diagram below) and pull out center post.

Tip: Don’t worry about losing balls in sheave(s), they are captive. If

post is stuck, leave screw halfway in and push on screw head to push

post out right side.

2. Mark position of holes.

Tip: Insert shaft without sheaves to hold carriers together while marking

holes.

WARNING! You must mount to solid deck construction using

specified fasteners in all mounting holes and nuts, washers

or backing plates to achieve correct maximum working load.

3. Mount carrier(s). Drill holes and screw to deck using sealant and backing

plates.

Tip: Slightly bevel top of hole in deck to allow sealant to mass near top

of hole.

Note: On multiple sheave models, make sure carrier with flat in hole is

placed on left side.

4. Install sheave. Slip post in from right side and seat end of shaft in flat.

Use blue Loctite

®

provided on phillips screw and secure.

Left side (sheave towards left)

Additional information:

www.harken.com/manuals

Loctite® is a registered trademark of Henkel AG & Company KGaA

®

is a registered trademark of Ultra Safety Systems, Inc.

Tef-Gel

Flat in hole to retain post.

Note: C8624 – 3" (75 mm) sheave

version has flat on opposite side so it

is visible with sheave towards right.

Use Blue

Loctite® here

Maintenance

Keep your equipment clean and free-running by frequently flushing with fresh water.

Periodically clean with mild detergent and water solution. Spin sheaves to distribute

soap solution evenly. Occasionally disassemble and clean rollers and balls with

detergent and water solution. Assemble using blue Loctite® on screws.

Stainless fasteners which pass through aluminum blocks should be coated with an

antiseize compound such as Tef-Gel®.

IMPORTANT! Exposure to some teak cleaners and other caustic solutions can result in

discoloration of part and is not covered under the Harken warranty.

Warranty

For additional safety, maintenance and warranty information see www.harken.com/

manuals or the Harken

®

catalog.

Printed in USA. 4542 01/14

Loading...

Loading...