Page 1

Carbon

Jib Reefing & Furling

Installation Manual

Unit 2/2.5

Page 2

TABLE OF CONTENTS

Parts 3

Pictures and list of all parts

Specifications 4

Rod sizes

Clevis pin sizes

Luff tape sizes

Rigging, attachment to lower unit

Retrofits, fitting rod

Tools required

Supplies for gluing foils

Alignment splints

Headstay length

Preparation for Assembly 5-6

Foil cut length

Top foil cut length

If you have a short top foil

Cutting top foil

Assembly 7-11

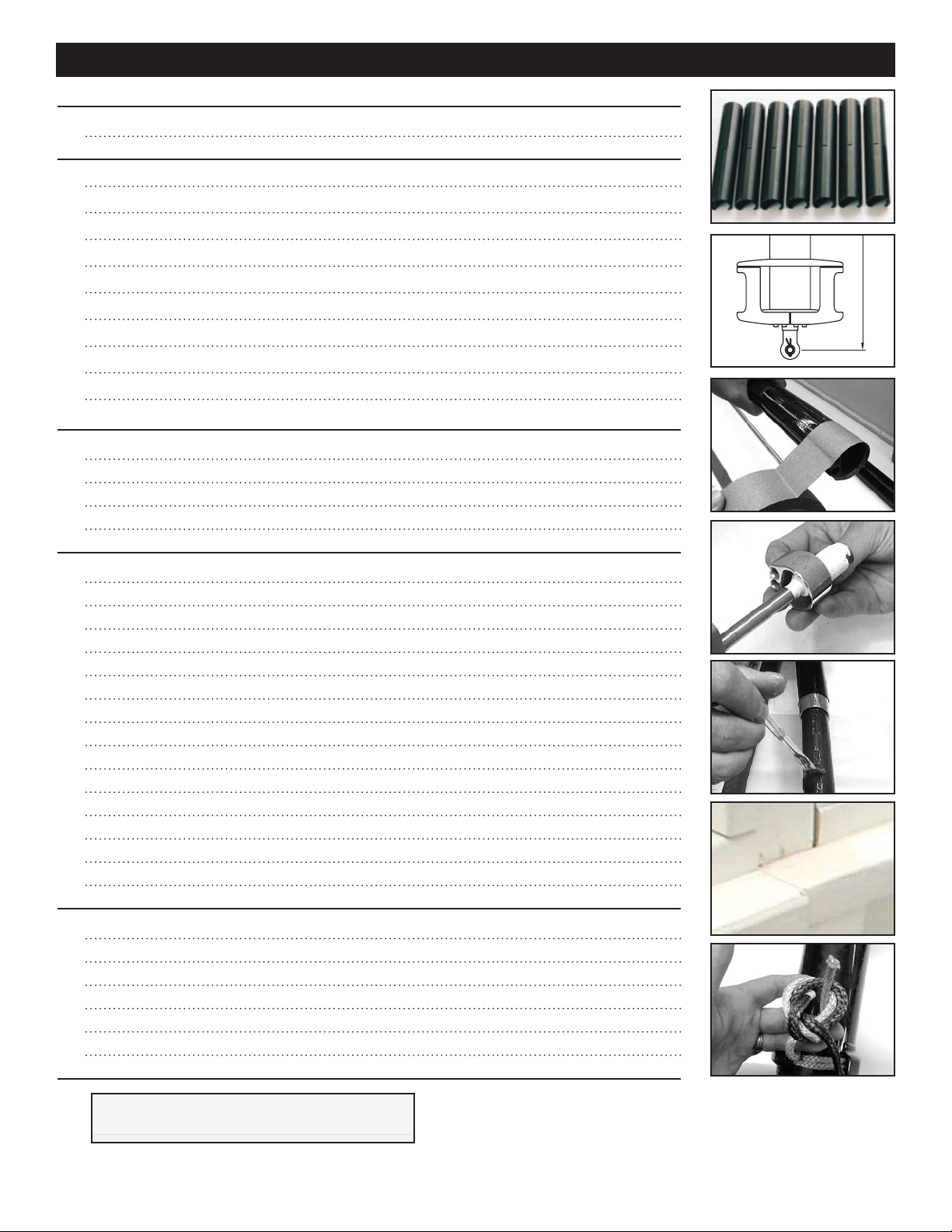

Sliding foils onto rod

Attaching feeder

Joining foils using connectors

Preparing foil for gluing

Gluing foils using Hysol® adhesive

Gluing feeder

Aligning joined foils

Sliding halyard swivel onto foils

Capping foils with trim cap

Removing splint

Installing Navtec® eye

Installing carbon furling unit

Assembling turnbuckle

Foil height

Commissioning 12-16

Tying soft attachment lines

Halyard wraps

Prevent halyard wraps

Pendants

Halyard restrainer

Halyard tension

Warranty

Warranty of Harken Carbon parts is

one year from the time of purchase.

2 2/2.5 Carbon Furler December 2001

Page 3

PARTS

1

Toggle

*Cross pin includes (2) H2912A bushings.

(36) Connector bushings

Prefeeder

Cross pin*

Cotter pin

3 4

Smalley Ring

Clevis pin

Trim Cap

Bottom

(Feeder)

Connector

Halyard

Swivel

Regular Connectors

Torque Tube Connector

5

2

Top Bushing

Feeder

1

Prefeeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 947

Toggle . . . . . . . . . . . . . . . . . . . . . .5/8" (15.9mm) . . . . H-29364C

Toggle . . . . . . . . . . . . . . . . . . . . . .3/4" (19mm). . . . . . H-27385C

Cross Pin . . . . . . . . . . . . . . . . . . . .5/8" (15.9mm) . . . . H-29388A

Cross Pin . . . . . . . . . . . . . . . . . . . .3/4" (19mm). . . . . . H-27407A

Cotter Pin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . HFG344

Smalley Rings . . . . . . . . . . . . . . . .5/8" (15.9mm) . . . . HCP1352

Smalley Rings . . . . . . . . . . . . . . . .3/4" (19mm). . . . . . HCP1062

Clevis Pin . . . . . . . . . . . . . . . . . . .5/8" (15.9mm) . . . . H-29385A

Clevis Pin . . . . . . . . . . . . . . . . . . .3/4" (19mm). . . . . . H-29386A

2

Bottom (Feeder) Connector. . . . . . . . . . . . . . . . . . . . . H-27448BF

Regular Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . 1096F

Top Bushing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-27508BF

Torque Tube Bushing. . . . . . . . . . . . . . . . . . . . . . . . . . H-27902BF

3

Connector Bushings (36) . . . . . . . . . . . . . . . . . . . . . . H-27495A

Trim Cap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-27904B

Feeder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-29238B

4

Halyard Swivel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H-29662C

5

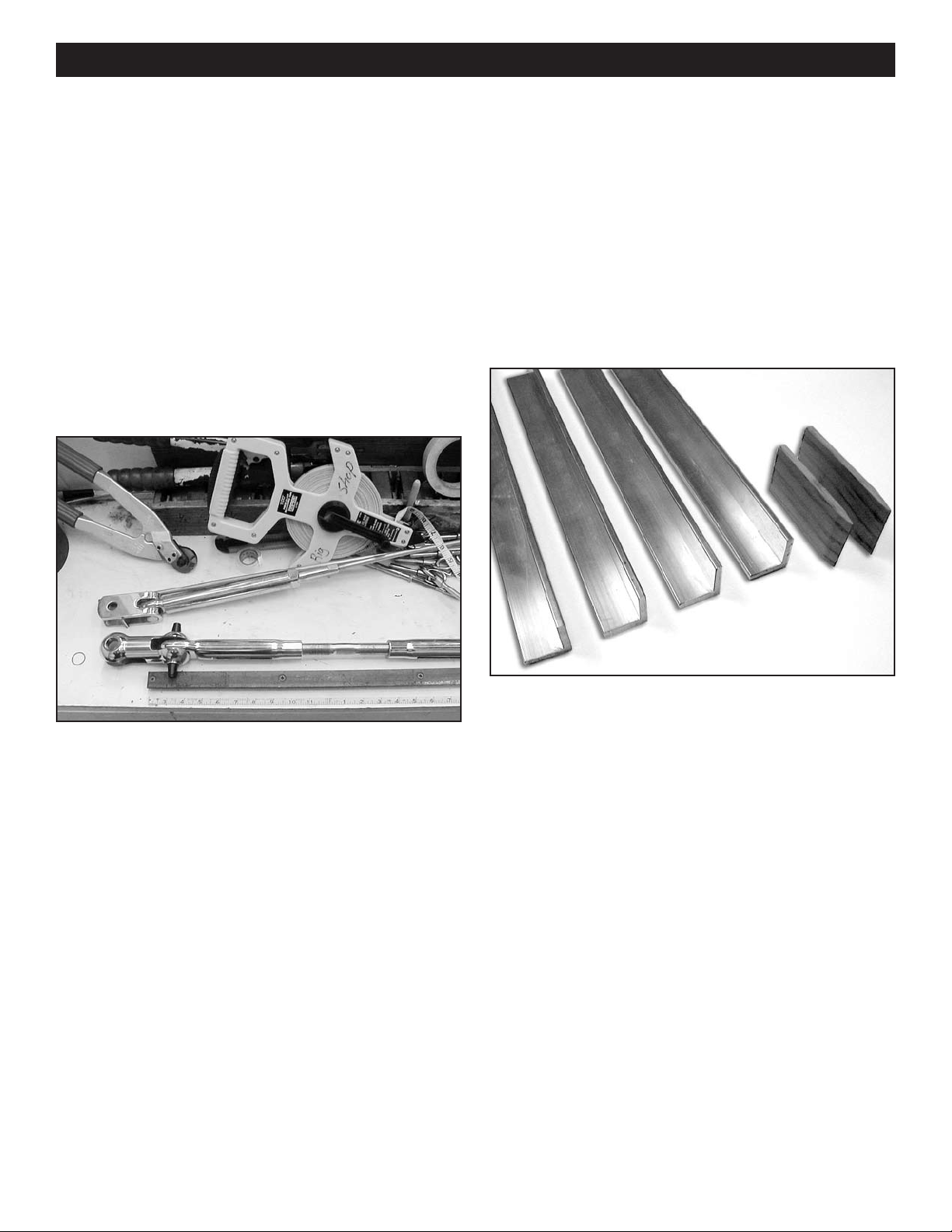

Lower Unit Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . H-27374EF

Lacing Lines (3) 1/4" (6mm) Spectra®. . . . . . . . . . . . . HFG6907

Lower Unit

Assembly

May 2002 2/2.5 Carbon Furler 3

Page 4

SPECIFICATIONS

■ ROD SIZES

-12, -17, -22 (7.14mm, 8.38mm, 9.53mm)

■ CLEVIS PIN SIZES

5

/8", 3/4" (15.9 mm, 19.1 mm)

■ LUFF TAPE SIZE

6

/32", (5mm)

#6,

■ RIGGING, ATTACHMENT TO LOWER UNIT

If no turnbuckle is required, attach the rod marine eye directly

to the integral toggle on the 2.5.

If a turnbuckle is required, it must terminate in a marine eye

that will fit directly to the integral toggle. Use a Navtec C560

5

turnbuckle or similar for rod with either a

3

/4" (19mm) pin diameter.

or

/8" (15.9mm) pin

■ TOOLS REQUIRED

Sharp Hacksaw, Sandpaper, Small Triangular File, Heat Gun,

Razor Knives, Sandpaper.

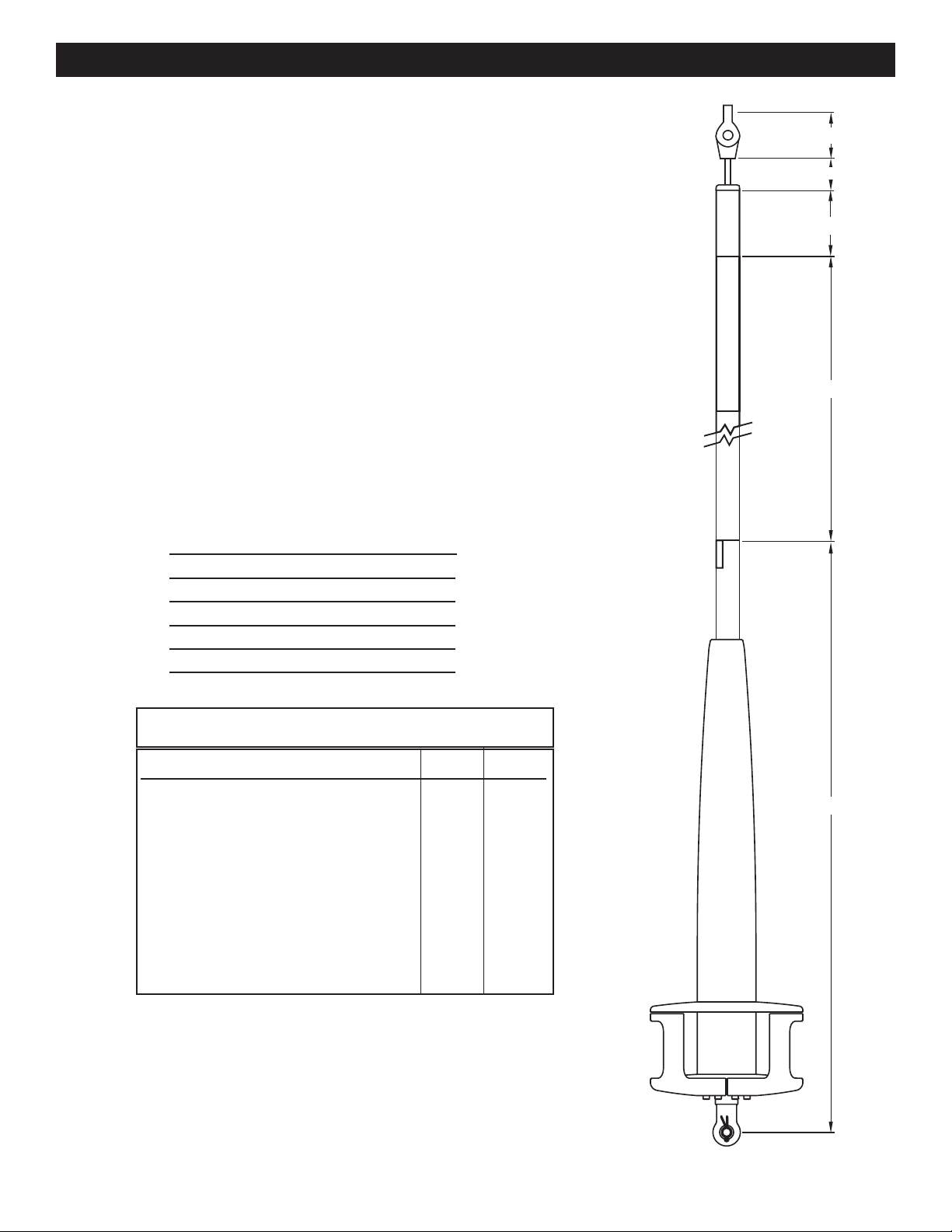

■ SUPPLIES REQUIRED FOR GLUING FOILS

Rigging tape, blue masking tape, 9430 Hysol Epoxy

(supplied), Scissors, mixing cup, mixing stick, glue brushes,

acetone, paper towels cut into quarters, plastic to cover

splint area, clear packaging tape, wood alignment stick

and placemat-sized table covering.

Alignment Splints - Use 90° angle extrusion to make splints.

3

Sides to be about

/4" (19mm). Cut extrusion into 8" (203mm)

lengths and remove burrs from cutting.

■ RETROFITS, FITTING ROD

If you plan to reuse the existing rod and turnbuckle:

Lower End—If you are using a standard Navtec turnbuckle

with integral toggle, the lower body must be replaced with a

standard Navtec marine eye body. Check to make sure that

this eye will mate with the Harken integral toggle. Two cross

pin sizes are available. They are the same size as the clevis

pin. See above.

Upper End—You must take apart the marine eye so that you

are left with a threaded nosepiece. Check to see if this is pos

sible. If necessary, contact Navtec or Riggarna for correct pro

cedure. You will slip carbon foils over this threaded nosepiece.

If you cannot remove this fitting you will need to cut the rod.

■ HEADSTAY LENGTH

Note: When cutting rod to length or making up new rod, make

sure that you can take apart the rod terminal (usually the top

eye) so that you are left with a threaded nosepiece.

Make up the rod headstay or adjust the turnbuckle so the

Harken toggle fits below the rod terminal eye. The pin-to-pin

1

distance of the Harken toggle is 3

/4" (83mm).

Note: The 2.5 Carbon furler has an integral toggle. No

additional toggle is required below the furler.

-

4 2/2.5 Carbon Furler May 2002

Page 5

PREPARATION FOR ASSEMBLY Foil Cut Length • Top Foil Cut Length • Short Top Foil? • Cutting Top Foil

■ FOIL CUT LENGTH

The Carbon 2.5 furler has an integral toggle. No additional toggle is required below the unit.

To check the foil length, lay foils alongside the stay before cutting top foil. Make sure

that turnbuckle is set to desired length.

A

■ TOP FOIL CUT LENGTH

Instructions for worksheet below:

1 Fill in total pin-to-pin headstay length.

2 Fill in A length.

3 Adjust B length if necessary.

Note: There must be enough space between top of carbon foils and bottom of rod

terminal to allow for turnbuckle adjustment. As turnbuckle is adjusted, terminal is

pulled down towards top of rod. If no turnbuckle is used, there only needs to be

1

minimal space—

/2" (12mm)–between the carbon foil and rod terminal.

We have put 4" (100mm) as a starting point. This may need to be adjusted based

upon how turnbuckle was set when headstay was measured. If there is less than

4" (100mm) “take-up”, less space can be left and vice versa. The space between foil

trim cap and bottom of turnbuckle must be more than “take-up” on turnbuckle.

4 Add A, B, E and subtract from total pin-to-pin headstay length. SUM = _________

5 Choose the number from foil multiplier below closest to, but not greater than,

sum from step 4. Fill in D length.

6 X 72" = 432 6 X 1828.8mm = 10972.8

7 x 72" = 504 7 x 1828.8mm = 12801.6

8 x 72" = 576 8 x 1828.8mm = 14630.4

9 x 72" = 648 9 x 1828.8mm = 16459.2

10 x 72" = 720 10 x 1828.8mm = 18288.0

11 x 72" = 792 11 x 1828.8mm = 20116.8

C

D

5 Add A, B, D, E. Subtract from pin-to-pin length for C (top foil length).

WORKSHEET: DETERMINE TOP FOIL LENGTH

Dimensions Inches mm

A Center of PIN to bottom of terminal _______ _______

E

B Bottom of terminal to top of foil 4 102

C Top foil _______ _______

Foils below 8" (203mm) see next page

D _____ x 72" (1828.8mm) foils _______ _______

E Top of feeder to center of clevis pin 523/4 1340

Total pin-to-pin headstay length

_______ _______

IF YOU HAVE SHORT TOP FOIL

If top foil is less than 8" (203mm) do not use a recessed top connector. The top foil must

be at least 4" (101mm). If it is less, shorten the upper 72" (1.83m) foil to make the upper

foil 4" (101mm).

CUTTING TOP FOIL

Once you have checked the top foil length by laying foils alongside the rod, use a sharp

hacksaw to cut top foil. Tape foil and cut along tape. Sand bottom end of the foil so it

is square and to remove any carbon burrs. Lightly sand inside of foil where it will be

bonded with 220 grit to remove any grease or mold release agent.

June 2002 2/2.5 Carbon Furler 5

Page 6

PREPARATION FOR ASSEMBLY

Tape outside ends of all foils using blue masking tape. To

make sure tape edge lines up with end of foil, extend the

tape over foil end. Use a sharp razor knife to trim tape even

with foil.

Coat rod with mold release agent or wax to keep epoxy

from adhering.

Heat rod terminal and remove threaded screw and threaded

nosepiece. If rod terminal has been upset (peened), follow

Navtec or Riggarna procedures for removing peening.

Tape threads of nosepiece and tape nosepiece so it will not

slip down foil when pushing it back out.

6 2/2.5 Carbon Furler December 2001

Page 7

ASSEMBLY

Assuming that installation is done from the top, slide

bottom foil onto rod so end with holes is at bottom

end of foil.

Slide feeder over so, so rounded sail groove corners will be at

the bottom end of foil.

Slide full-length 72" (1.83m) foils onto the rod.

Assemble connectors onto rod in preparation for glueing.

Place one bushing half in socket on either side of connector,

grooved side up. Bring connector up on rod and place other

bushing half on rod and rotate bushing so seam is at top

and bushing assembly stays in place.

Place foil on bench with grooves facing up and supported on

wood blocks.

June 2002 2/2.5 Carbon Furler 7

Page 8

ASSEMBLY

You must follow four-step

mixing instructions shown

below exactly or the foil

connector bond will fail.

Adhesive Alert

Cool Weather

Temperature should be higher than 60°F (15°C).

If you glue at a lower temperature:

50°F (10°C) minimum

gently warm joints with a hair dryer to no more than:

100°F (38°C), a temperature at which you can still

hold the foil comfortably in your hand.

If glued in temperature less than 60°F (15°C, allow glued

foils to cure undisturbed for 48-hours before moving.

Warm Weather

Surfaces must be dry.

Remove plastic clip from Hysol® adhesive pack.

1) Mix for five minutes in bag.

2) Pour entire contents into cup.

3) Squeegee remaining epoxy into cup.

4) Continue to thoroughly stir epoxy in cup.

Adhesive Working Times:

75°F (24°C) - 1 hour

85°F (29°C) - 45 minutes

Allow glued foils to cure undisturbed for 24-hours

Use glue brush to coat the inside of the foil for one or two

inches. Coat 1/2 of the outside of the connector with epoxy

and slowly insert the connector into the foil. Work the con

nector in and out as you insert it to adhere the epoxy without

dry spots on the inside of the foil. As excess epoxy comes off

the connector, clean it up using the acid brush. Use excess

to coat feeder area of connector. Clean up the end of the foil

using paper towel wetted with acetone taking care that no

epoxy is in the sail grooves.

8 2/2.5 Carbon Furler May 2002

-

Page 9

ASSEMBLY

Lightly coat feeder area of connector and slip feeder into

place.

Use glue brush to coat inside of foil for one or two inches.

Coat half the outside of connector with epoxy and slowly

insert connector into foil. Work connector in and out

as you insert to adhere epoxy without dry spots on inside

of foil. As excess epoxy comes off connector, clean up

using acid brush.

Clean up end of foil using paper towel wetted with acetone,

taking care that no epoxy is in sail grooves.

Coat the remaining half of connector with epoxy and insert

into foil as described above, cleaning up excess epoxy. Take

special care to clean epoxy from sail grooves.

May 2002 2/2.5 Carbon Furler 9

Page 10

ASSEMBLY

Lay plastic against foil and place splint against foil. Tightly

wrap clear packaging tape around splint near both ends.

Insert wood alignment stick between foil and feeder and

inspect to make sure that foil/feeder are aligned.

Coat bottom foil reinforcement (torque tube connector) with

epoxy and insert into foil as directed above.

Insert plastic bushings in top connector as directed above.

Coat outside of connector with epoxy as directed above and

insert into top foil. Clean up excess epoxy.

Slide halyard swivel onto foils. Make sure swivel side is

towards top of stay!

Slide trim cap over threaded nosepiece. Heat cap in hot

water to help it slide over nosepiece. Attach trim cap using

®

Superglue

.

Make sure foils are straight and grooves are facing up.

Inspect lower unit to make sure that feeder and bottom foil

are aligned correctly. Allow to cure undisturbed overnight.

After curing overnight, remove splint. Use a small triangular

file to clean excess epoxy while tape remains in place.

Remove tape and use a razor knife to carefully remove any

excess epoxy. Make sure halyard swivel passes all points.

Install top rod eye using red Loctite® on locking screw or

with upset as per manufacturer's instructions.

Remove eight socket-head cap-screws located on underside

of lower unit and remove lower cap. Remove three set

screws located at top of torque tube.

10 2/2.5 Carbon Furler December 2001

Page 11

ASSEMBLY

Slide lower unit onto bottom foil.

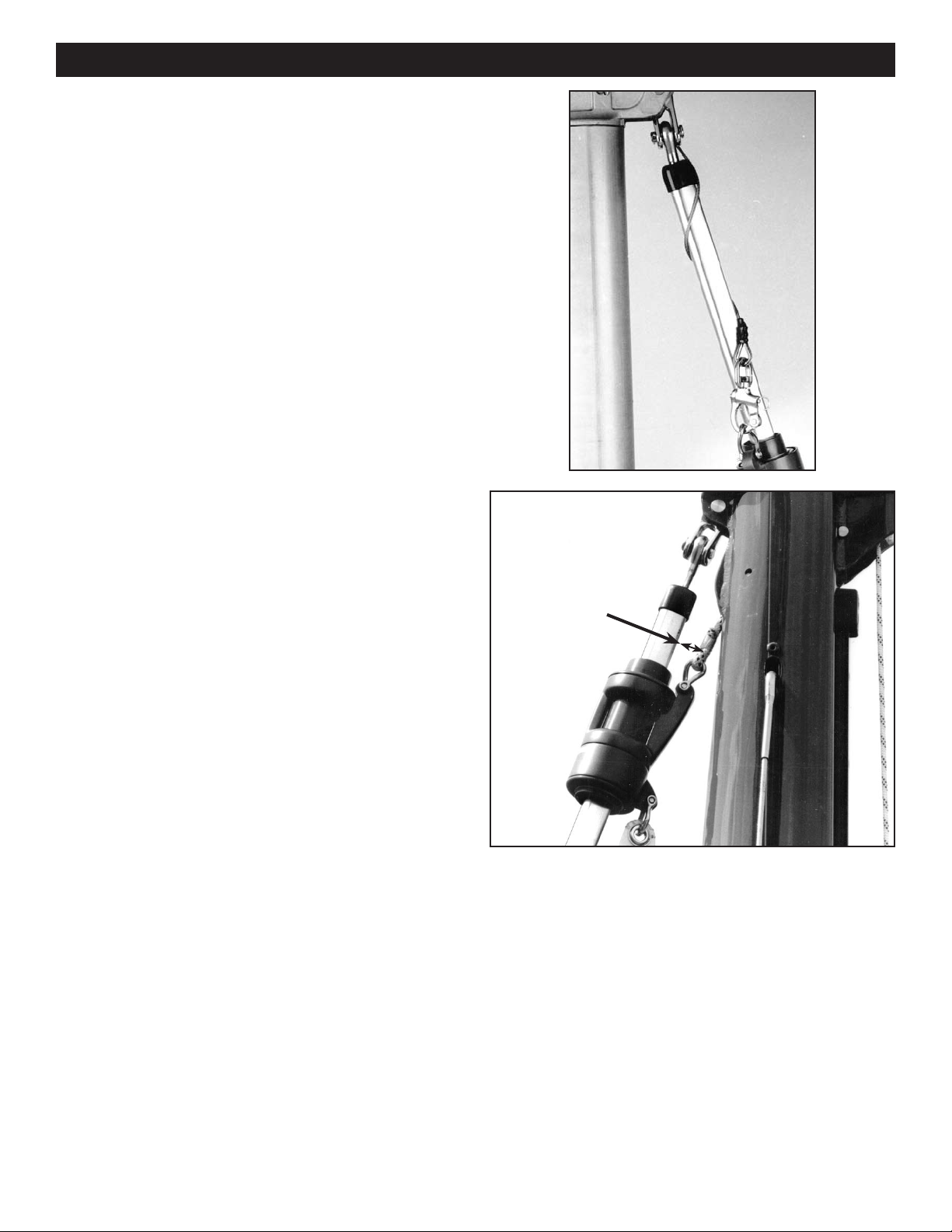

Assemble turnbuckle. Attach turnbuckle eye to toggle using

cross pin with tapered ends. Secure Cross Pin using Circlip

(Smalley Rings) supplied. Note: Make sure the end of the

toggle with the long slot is towards the bottom.

Bring the lower unit down so that Cross Pin seats in the

®

housing. Install cap using Blue Threadlocker

on the

eight screws.

■ FOIL HEIGHT

Check the clearance between the top of the foil and top

terminal.

TIP: Check clearance when the unit is on the ground,

before raising the headstay into position.

WARNING: It is critical to have clearance between the top

foil and the top rigging fitting when the stay adjuster is in

the fully closed position. If the fittings touch, the unit will

jam or in the case of a Sta-Lok fitting, the terminal may

become unscrewed. This could cause catastrophic

failure to the spar and a life threatening situation

It is the responsibility of the rigger to check clearance.

Long Slot

December 2001 2/2.5 Carbon Furler 11

Page 12

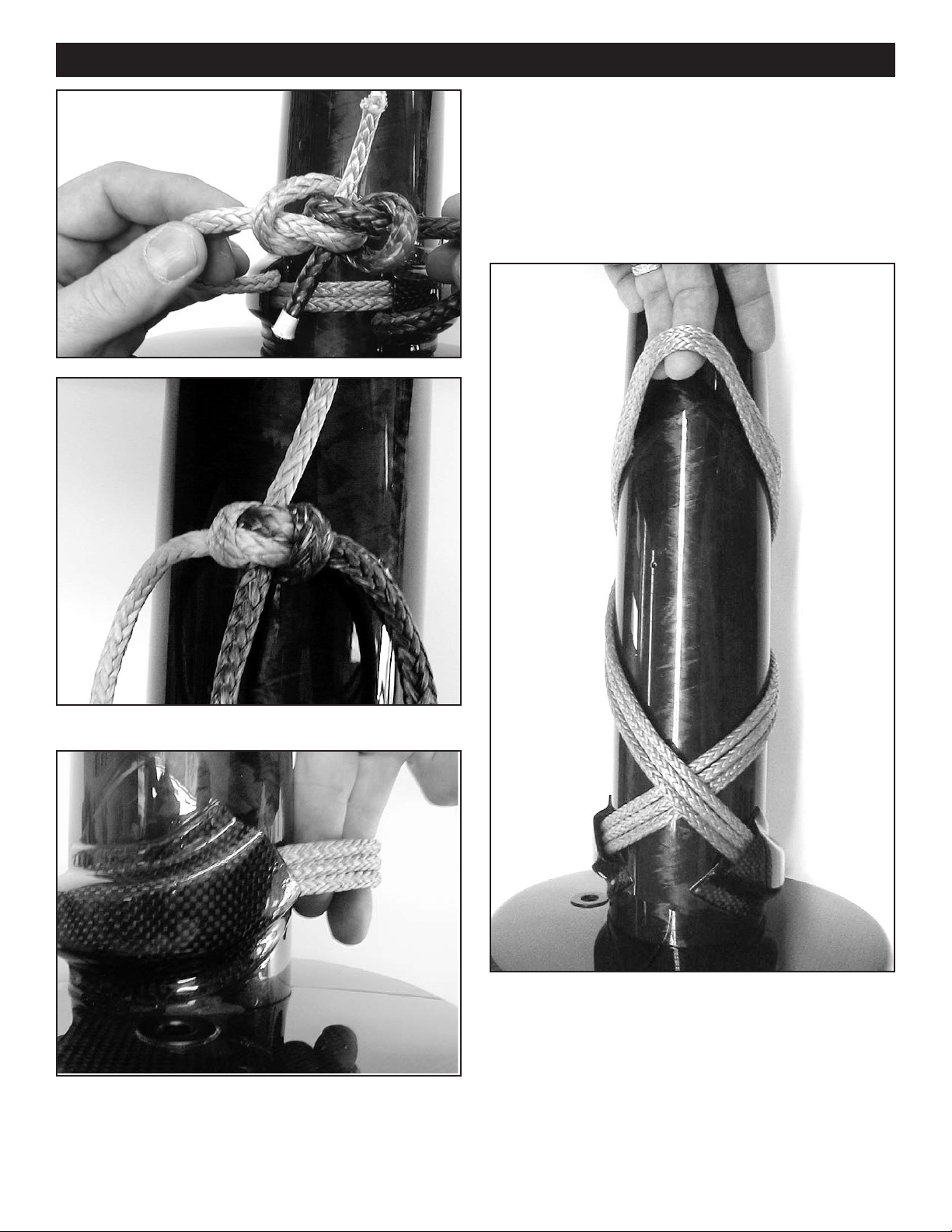

COMMISSIONING Tying Soft Attachment Lines

You must lace line around the furler/halyard swivel three times

when attaching the sail or halyard.

Harken recommends us of a Hunter's Bend. This knot can

be highly tensioned without slipping and like a bowline can

be untied afterwards. There are other bends and knots that

will also work.

Lace line three times around the torque tube/halyard swivel

to capture sail or halyard. After lacing line, tie ends on side

opposite sail.

1 Form a loop in line that comes from left tunnel. Below this,

form a second loop with line from the right tunnel.

2 Twist loop clockwise and arrange ends of line so they are

below standing loops as shown.

12 2/2.5 Carbon Furler December 2001

Page 13

COMMISSIONING Tying Soft Attachment Lines

3 Take end that is now

running down to right.

Tuck it down under

crossing lines

and up through

loop, towards

you.

4 Pass other end up and over crossing lines and then down

into loop, away from you.

5 At this point knot will not look anything like the finished

bend. Set knot by gently pulling on bitter ends and then

standing parts until it looks like Drawing 6.

December 2001 2/2.5 Carbon Furler 13

Page 14

COMMISSIONING Tying Soft Attachment Lines

6

7 Finished bend drawn up and set. If your bend does not

look like this untie and repeat the process.

9 If furler is installed under deck, lace tack pendant as

pictured. Rigging a pendant directly from carbon tunnels

will damage unit.

8 It is important to keep tack/luff as close to torque tube and

as low as possible. A tack line that is too long will angle up

too far and damage the carbon tunnels. When sail is bent on,

check to make sure tack line is not pulling up against the

carbon tunnels.

14 2/2.5 Carbon Furler December 2001

Page 15

COMMISSIONING Halyard Wraps • Prevent Halyard Wraps

■ HALYARD WRAPS

The most serious problem with furling systems occurs when

the jib halyard wraps around the headstay foil. Halyard wraps

will prevent furling or unfurling and may cause serious dam

age to the unit and the halyard. In severe cases, halyard wraps

may cause loss of the headstay.

To prevent wraps, the halyard must exert a slight pull to

the rear. This allows the foils to turn while the halyard

remains stationary.

■ PREVENT HALYARD WRAPS

WARNING: The sail must be fitted to foils before operation.

1 Halyard swivel should be within top 4" (100mm) of foil.

2 Halyard must pull slightly to rear (8 - 10°).

3 Halyard must be snug, but not too tight.

If a halyard wraps, do not force unit to turn. Attempt to open

8 - 10°

sail by alternately furling and unfurling sail slightly.

If the sail can be unfurled, lower sail by releasing jib halyard.

Severe halyard wraps can only be cleared by going aloft and

freeing halyard.

If the sail will not furl or unfurl, it may be possible to remove

jib sheets and manually wrap/unwrap the sail around/from

the headstay.

Important: Testing at the dock does not indicate halyard angle

is correct. In wave action, halyard may wrap if lead angle is

not correct. The diverging 8-10° angle mentioned above is

critical.

December 2001 2/2.5 Carbon Furler 15

Page 16

COMMISSIONING Pendants • Halyard Restrainer

■ PENDANTS

If your sail is not long enough to position halyard swivel

properly, you must add a pendant to sail. Pendants should

be plastic-coated wire permanently attached to the head of

sail so height will be correct. Adjustable length pendants

are not acceptable as they might not be adjusted correctly

during a sail change.

■ INSTALL A PENDANT

1 Raise sail, but do not attach tack shackle.

2 Position halyard swivel correctly near top of headstay

and secure halyard.

3 Secure a piece of rope to sail tack. Lead line through

tack shackle on furling drum and tension sail.

4 Measure distance from tack shackle to sail tack and

have a pendant of this length permanently attached to

head of sail.

5 Repeat this procedure for every jib.

TIP: Pendants are used at head of sail. Short pendants

may be added at tack to improve visibility under genoa, but

remember that visibility is already improved by shackling

to tack swivel. Tack pendants increase heeling moment

by raising sailplan. You may install pendants at both

head and tack of sail.

■ HALYARD RESTRAINER

To prevent wraps, the jib halyard must pull slightly to the

rear. On some boats the halyard sheaves are located too

close to the headstay and a halyard restrainer must be used.

Use halyard restrainers only when required by the masthead

geometry. Restrainers tend to limit sail luff length and may

cause problems if not properly installed.

Mount the restrainer as high as possible on the face of the

mast. Position the restrainer so the foils will not hit it when

under load.

The restrainer should deflect the halyard 8 - 10°. If the

angle is more than 10°, you may experience difficulty in

tensioning the sail luff, friction in furling and possible damage

to the foils. To decrease deflection angles, shorten the luff of

the sail.

TIP: Boats used in charter service should consider using a

halyard restrainer, regardless of masthead geometry.

8 - 10°

16 2/2.5 Carbon Furler December 2001

Page 17

COMMISSIONING Halyard Tension

■ HALYARD TENSION

The jib halyard should be firm, but not too tight.

TIP: The luff foil system supports the sail along its entire

length so halyard tension is required only to shape sails,

not to support them. Use only enough halyard tension to

remove some wrinkles along the luff. Do not tension the

halyard enough to cause vertical wrinkles in the luff. Use

halyard tension to adjust draft position of the sail to suit

sailing conditions. Your halyard should be firm but not

tight. If in doubt, release halyard tension. To protect

the sail, ease the halyard when the boat is not in use.

December 2001 2/2.5 Carbon Furler 17

Page 18

Corporate Headquarters

1251 East Wisconsin Avenue, Pewaukee, Wisconsin 53072 USA

Telephone: (262) 691-3320

Web: www.harken.com

• Fax: (262) 691-3008 • Cable: Harken Pewaukee

• Online Catalog: www.harkenstore.com

Email: harken@harken.com

Harken France

ZA. Port des Minimes, BP 3064, 17032 - La Rochelle Cedex 1, France

Telephone: (33) 05.46.44.51.20

Web: www.harken.fr

• Fax: (33) 05.46.44.25.70

Email: harken@harken.fr

Harken Italy S.P.A.

Via Marco Biagi, 14, 22070 Limido Comasco, (CO), Italy

Telephone: (39) 031.3523511

Web: www.harken.it

• Fax: (39) 031.3520031

Email: info@harken.it

Harken UK Ltd.

Bearing House, Ampress Lane

Lymington, Hampshire S041 8LW, England

Telephone: (44) 01590-689122

• Fax: (44) 01590-610274

Web: www.harken.co.uk

Email: enquiries@harken.co.uk

Harken Poland

ul. Lisa Kuli 4 Lok.1, 01-512 Warszawa, Polska

Telephone: +48 607 979 747

Web:

www.harken.com

Email:

polska@harken.com

Harken Sweden

Mjölkekilsgatan 6, Box 64

S-440 30 Marstrand, Sweden

Telephone: (46) 303-618 75

Web: www.harken.se

• Fax: (46) 303-618 76

Email: harken@harken.se

Harken Adriatik d.o.o.

Obala 107

6320 Portoroz, Slovenia

Telephone

Web: www.harken.si

/Fax: 5-6774122

Email: info@harken.si

Harken Australia, Pty, Ltd.

1B Green Street

Brookvale, N.S.W. 2100, Australia

Telephone: (61) 2-8978-8666

Web: www.harken.com.au

• Fax: (61) 2-8978-8667

Email: info.harken.com.au

Harken New Zealand, Ltd.

30-36 Fanshawe Street

Auckland 1001, New Zealand

Telephone: (64) 9-303-3744

Web: www.harken.co.nz

• Fax: (64) 9-307-7987

Email: harken@harken.co.nz

Please visit: http://www.harken.com/dealers/dealers.php

for an up-to-date list of Harken dealers and distributors

4362/9-08

Loading...

Loading...