Page 1

Hydraulic

Jib Reefing & Furling

Installation Manual

Unit 3/3.25

WARNING!: Strictly follow all instructions to avoid an

accident, damage to your vessel, personal injury or death.

See www.harken.com for additional safety information.

Page 2

Table of Contents Dimensions

■ TABLE OF CONTENTS

General Specifications

Dimensions .......................................................................2

Stainless Surface, Port Side Up, Hoses and Fittings .......

Drain System, Valves, Pressure, Oil .................................

3

4

Parts ...............................................................................5 - 6

Preparation

Headstay Cut Length, Connectors ....................................

Foil Cut Length, Top Foil Cut Length ................................

Short Top Foil, Connector and Foil Quantity ....................

Cutting Top Foil .................................................................

7

8

9

9

Assembly

Foil Assembly ...............................................................10 - 11

Attach Stay – Rod Unit 3 .................................................

Stay to Lower Unit Connection - Rod Unit 3.25 .............

Attach Stay – Wire ...........................................................

Lower Toggle and Cowling ..............................................

Install Torque Tube, Raise Foils .......................................

Foil Length Check ...........................................................

Raise Unit; Gear Box Pressure ........................................

Install Hoses, Oil Level, Headstay Tension

......................19

Halyard Wraps .................................................................

12

13

14

15

16

17

18

20

Pendants ..........................................................................21

Halyard Restrainer ...........................................................

Halyard Tension ...............................................................

Backstay Tension .............................................................

Before Operation, Manual Operation ...............................

21

22

22

23

DIMENSIONS *Unit with 7/8" (22.2 mm) clevis

A B C D E

1

/2"

34

876 mm

F G H I J

12"

305 mm

*Subtract 3/8" (10 mm) for 3/4" (19 mm) clevis. Add 1/2" (13 mm) for

1" clevis (A to F only).

1

/8"

24

613 mm

1

/4"

7

184 mm

5

/8"

20

524 mm

3

/8"

7

200 mm

1

/2"

9

241 mm

3

/4"

7

197 mm

3

/4"

10

273 mm

12"

305 mm

Warranty — Online at www.harken.com or call, write,

email or fax Harken, Inc., Pewaukee, WI USA

2 Hydraulic 3/3.25 7/17/08

Page 3

General Specifications Stainless Surface/Port Side Up/Hoses/Fittings

■ STAINLESS STEEL SURFACE

Be careful not to scratch the stainless steel surfaces of the

lower unit. Lay the unit on terry cloth or other soft material

while assembling.

The hydraulic unit is polished stainless and does not have

chrome plating. This surface can be polished using standard

stainless steel polishes to maintain its appearance.

■ PORT SIDE UP

Keep the port side of the unit facing up when sitting on its

side.

If unit will sit for a long period of time, or is stored or

shipped, keep the port side of the lower unit facing up. This

will prevent gear oil from leaking out of a pressure relief

valve.

TIP: When the port side is up, the sideplate with the winch

handle socket will be facing down.

If a small amount of gear oil does leak out of the valve during

shipping or installation, it will drip out of the bottom of the

unit when up in sailing position. Use a rag to catch this

leakage.

■ HOSES

Hoses are not supplied with furler.

Use SAE 100 R1 or R2 hoses.

Sizes depend on the distance that the hoses will run and the

power source. For shorter runs use:

3

Two Drive Hoses: -6 (

One Drain Hose: -4 (

/8" ID)

1

/4" ID)

Contact Harken for further hose size recommendations.

■ HOSE END FITTINGS

Hose fittings are not supplied with furler.

All fittings must be stainless steel. Standard attachment

method uses female hose end fittings.

Furling unit end fittings have JIC 37° flair fittings.

Note: Do not use locking solution or tape on connections.

Hose end fittings sizes:

Drive fittings - JIC 9/16-18 female swivel

Drain fittings - JIC 7/16-20 female swivel

■ ALTERNATE FITTING METHOD

Remove furling unit end fittings. Use SAE straight thread

O-ring male hose end fittings:

Drive fitting - 9/16-18

Drain fitting - 7/16-20

April 2000 Hydraulic 3/3.25 3

Page 4

General Specifications Drain System/Valves/Pressure/Oil

■ DRAIN SYSTEM

Besides the main hoses for forward and reverse, a fitting for

a drain hose is included. The drain hose must be lead to the

main reservoir in the power unit.

Power Requirements

Rotation at No LoadRecommended Flow RateSize

50 RPM5 GPM (16 l/min.)3/3.25

The unit will work with any Harken hydraulic power pack.

Best performance will be with the hydraulic 6 or 8 system.

See performance charts.

■ VALVES ON POWER UNIT

Furler can be used with open or closed center, 4-way,

3-position control valves.

■ MAXIMUM OPERATION PRESSURE

Set relief valve on power plant at 140 Bar or 2000 PSI.

Harken power packs ship with valves set at 140 Bar.

■ OIL SPECIFICATIONS

Gear box oil - AGMA8, 90 weight gear oil

18 ounce (510 g) capacity

Note: The gear box is filled with oil at the factory.

Under normal conditions there is no need to change

the gear box oil.

Hydraulic fluid is a petroleum based oil, ISO viscosity

grade 46, anti-corrosion, anti-foam, anti-oxidant,

anti-rust, anti-wear additives.

Fluid examples: Exxon Nuto, Shell Tellus, BP Energol HLP

CAUTION!: The only parts of furler to be

disassembled by installer are the Torque Tube and

Lower Cowling. All other work should be performed

by factory-authorized personnel. Work performed

by unauthorized personnel may void the Harken

limited warranty.

Note: Some fluid may drip from the unit during shipping.

This is normal and should stop once the unit is in its sailing

position. All units are tested before leaving the factory.

Units are shipped port side facing up.

Make sure unit is shipped or stored port side up. If it is

not, gear oil will leak out of the pressure relief valve.

4 Hydraulic 3/3.25 10/7/08

Page 5

Parts

■ MAIN COMPONENTS

Halyard Swivel Torque Tube

Cowling Toggle

■ MAIN HOUSING

April 2000 Hydraulic 3/3.25 5

Page 6

Parts

■ MISCELLANEOUS PARTS

Red Loctite® Foil Screws Foil Wedges

6 mm, 8 mm

Allen Wrench

Blue Loctite® Torque Tube Screws Super Bonder

Cross Pin Clevis Pin Cotter Pin

Circlip Tack Shackle Feeder

■ RIGGER PARTS

Trim Cap Connectors Long Bottom

Connector

■ TERMINAL-WIRE

Nosepiece Wedge

Main Body Former

Drive Pin

■ TERMINAL-ROD UNIT 3

Unit 3

Nosepiece Cotter Pins

■ TERMINAL-ROD UNIT 3.25

Nosepiece Drive Pin Collar

Unit 3.25

■ FOILS

Bottom Foil Foils

6 Hydraulic 3/3.25 April 2000

Page 7

Preparation Headstay Cut Length/Connectors

■ HEADSTAY CUT LENGTH

The following cut lengths will result in the headstay adjuster

1

/2 open. At this cut length, 21/2" (64 mm) of adjustment

being

will remain in the stay adjuster in either direction.

Subtract the following from the headstay length and cut the

stay at that point.

HEADSTAY CUT LENGTH CHART

CLEVIS PIN SIZE

3

/4" (19.1 mm)7/8" (22.2 mm) 1" (25.4 mm)

7

/16" wire 241/2" (622 mm) ---

1

/2" wire

9

/16" wire 251/4" (641 mm) 253/4" (654 mm)

11 mm wire

12 mm wire

14 mm wire

-22 rod (9.53 mm)

-30 rod (11.1 mm)

-40 rod (12.7 mm)

1

/2" (622 mm)

24

3

23

/4" (603 mm) 241/8" (613 mm) ---

7

/8" (632 mm)

24

7

24

/8" (632 mm) ---

1

25

/4" (641 mm) 253/4" (654 mm)

1

24

/8" (613 mm)

1

24

/8" (613 mm) 253/4" (654 mm)

---

Note: The Harken hydraulic furler has an integral toggle. No

additional toggle is required below the furler.

■ STRINGING CONNECTORS ON STAY

Make sure the trim cap is at the top and the correct number

of connectors are used. The long bottom connector must be

slid on the wire or rod last.

■ -40 (12.7mm) ROD COLDHEAD HEIGHT

Make sure the length of coldhead does not interfere with the

1

drive pin. There is

/4" (6.5 mm) between the collet bottom

and the rollpin.

April 2000 Hydraulic 3/3.25 7

Page 8

Preparation Foil Cut Length/Top Foil Cut Length

■ FOIL CUT LENGTH - UNIT 3 / 3.25

Foil cut length is based on pin-to-pin length as measured

from center of upper pin (attaches the stay to the mast) to

center of lower pin (attaches the furling unit to the boat).

Measurement includes the masthead toggle. The hydraulic

furler has a lower integral toggle. No additional toggle is

required below the unit.

1

There must be more than 2

above the trim cap when the adjuster is set to the half way

point. The total adjuster stroke is 5" (127 mm). (See inset 1)

To check foil length, lay foils alongside stay before cutting

top foil. Set stay adjuster to the half way point.

■ TOP FOIL CUT LENGTH

Instructions For Worksheet Below:

1 Fill in total pin-to-pin length.

2 Fill in A length. Fill in G from numbers below.

3/4" (19.1 mm) Clevis Pin = 31" (787 mm)

7

/8" (22.2 mm) Clevis Pin = 311/4" (794 mm)

1" (25.4 mm) Clevis Pin = 31

3 Add A, B, E, F, G and subtract from total pin-to-pin length.

SUM = _________

4 Choose the number from foil multiplier below closest to,

but not greater than, sum from step 3. Fill in D length.

*7 x 84 = 588 **7 x 2133.6 = 14935.2

8 x 84 = 672 8 x 2133.6 = 17068.8

9 x 84 = 756 9 x 2133.6 = 19202.4

10 x 84 = 840 10 x 2133.6 = 21336.0

11 x 84 = 924 11 x 2133.6 = 23469.6

12 x 84 = 1008 12 x 2133.6 = 25603.2

5 Add A, B, D, E, F, G.

Subtract from pin-to-pin length for C (top foil length).

/2" (63.5 mm) of adjustment

3

/4" (806 mm)

WORKSHEET: DETERMINE TOP FOIL LENGTH

DIMENSIONS INCHES MM

A Center of PIN to Bottom of Terminal _____ _____

B †Bottom of Terminal to Top of Foil 3.5 89

C Top Foil _____ _____

Foils below 19" (483 mm) see next page

D __?__ 84" (2133.6 mm) Foils *_____ **_____

(Quantity)

E Feeder Gap 3 76

F Bottom Foil 24 610

G Clevis Pin to Foil _____ _____

Total Pin-to-Pin Length _____ _____

†With Swage Eye: Bottom of the Terminal is the point where foils jam

on the eye. The top foil will ride on shoulder when in use.

BEFORE CUTTING SEE NEXT PAGE.

8 Hydraulic 3/3.25 April 2000

Page 9

Preparation Short Top Foil/Connector and Foil Quantity/Cutting Top Foil

■ IF YOU HAVE A SHORT TOP FOIL

If top foil is:

Less than 15" (381 mm) with Norseman, Sta-Lok or rod eye;

Less than 19" (483 mm) with a swage marine eye.

Refer to Charts below.

TIP: With longer top foils, a 10" (254 mm) recessed top

connector is used as a bushing for the halyard swivel.

This is a problem with shorter top foils. Do not use this

10" (254 mm) top bushing with short top foil lengths.

Swage Eye: Recess the top connector 3 - 6" (76 - 150 mm)

to allow the top of the foil to ride on the shoulder of the

marine eye.

TOP FOIL - OPTION 1

LINE C (pg. 8) LINE C (pg. 8) TOP FOIL

Norseman, Sta-lok Swage Eye CUT LENGTH

or Rod Eye

1" (25 mm) 1" (25 mm) 8.5" (220 mm)

2" (51 mm) 2" (51 mm) 9.5" (241 mm)

3" (76 mm) 3" (76 mm) 10.5" (267 mm)

4" (102 mm) 4" (102 mm) 11.5" (292 mm)

5" (127 mm) 12.5" (318 mm)

6" (152 mm) 13.5" (343 mm)

7" (178 mm) 14.5" (368 mm)

TOP FOIL - OPTION 2

LINE C (pg. 8) LINE C (pg. 8) TOP FOIL

Norseman, Sta-lok Swage Eye CUT LENGTH

or Rod Eye

5" (127 mm) 5" (127 mm)

6" (152 mm) 6" (152 mm)

7" (178 mm) 7" (178 mm)

8" (203 mm) 8" (203 mm)

9" (229 mm) 9" (229 mm)

10" (254 mm) 10" (254 mm)

11" (279 mm) 11" (279 mm)

TOP FOIL - OPTION 3

LINE C (pg. 8) LINE C (pg. 8) TOP FOIL

Norseman, Sta-lok Swage Eye CUT LENGTH

or Rod Eye

8" (203 mm) 15.5" (394 mm)

9" (229 mm) 16.5" (419 mm)

10" (254 mm) 17.5" (445 mm)

11" (279 mm) 18.5" (470 mm)

12" (305 mm) 12" (305 mm) 19.5" (495 mm)

13" (330 mm) 13" (330 mm) 20.5" (521 mm)

14" (356 mm) 14" (356 mm) 21.5" (546 mm)

15" (381 mm) 22.5" (572 mm)

16" (406 mm) 23.5" (597 mm)

17" (432 mm) 24.5" (622 mm)

18" (457 mm) 25.5" (648 mm)

■ CONNECTOR & FOIL QUANTITY

Refer to the Top Foil Length Worksheet.

Unit 3/3.25 requires the same number of regular connectors

as the number of foils. (Exception: OPTION A/B = Use one

fewer regular connector than foils.) In addition, a trim cap

and long bottom connector are required.

■ CUTTING TOP FOIL

Once you have checked the top foil length, cut the top foil.

Deburr and clean all shavings from the foil.

Important: Failure to deburr or clean the inside of the foil

may cause it to seize to a connector when installing on rod.

Rough up the top 1" (25 mm) of the foil using a file or

sandpaper.

April 2000 Hydraulic 3/3.25 9

Page 10

Assembly Foils

■ ASSEMBLE FOIL

Slide trim cap and one connector to top of headstay.

TIP: When working with rod, tape connectors in place or

use a pusher wire longer than foil to hold connectors.

Note: Slide only trim cap to top of stay if:

1 Top foil is less than 19" (483 mm) for swage

eye installation.

2 Top foil is less than 15" (381 mm) for Norseman,

Sta-Lok or rod eye installation.

Slide top foil to top of stay, screw holes toward the bottom.

®

Coat the connector with red Loctite

.

Place a wedge in the indentation with the circular mold

mark towards the connector.

If working with a swage eye, push the connector into the

top foil until it is recessed about 5 or 6" (127 or 152 mm).

If working with a Norseman, Sta-Lok or rod eye, push

the connector into the top foil until it is recessed about

1

/2" (13 mm).

Use super bonder to glue the trim cap to the roughened

foil top.

Slide the next connector to the top of the stay.

Coat half of the connector and the indentation with

®

red Loctite

.

Place a plastic connector wedge in the indentation

closest to the top foil.

10 Hydraulic 3/3.25 April 2000

Page 11

Assembly Foils

®

Coat three foil screws with red Loctite

Screw them into connector until tight.

Continue assembly.

Slide halyard swivel onto foil, tall end up.

.

®

Install feeder screws toward bottom, using blue Loctite

on screws.

Sta-Lok®: For easier installation, push the bottom foil completely

over the bottom connector to expose as much wire as possible.

Slide torque tube onto foils.

April 2000 Hydraulic 3/3.25 11

Page 12

Assembly Attach Stay—Rod Unit 3

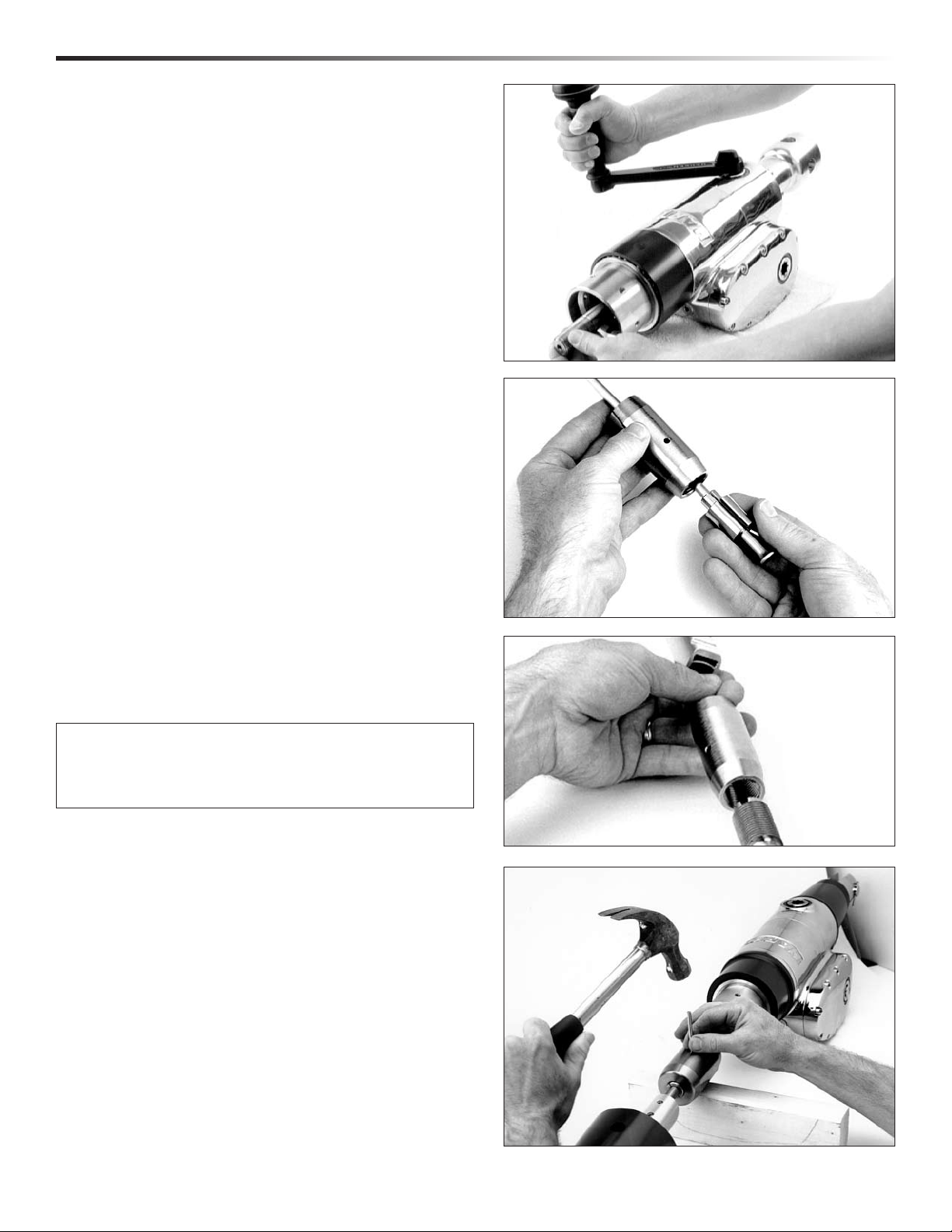

■ ATTACHING STAY TO LOWER UNIT—ROD UNIT 3

Use a winch handle to crank the terminal completely out

of lower unit.

Make sure halyard swivel and torque tube have been slipped

®

on foils. Then apply a few drops of red Loctite

to threads of

nosepiece.

Screw nosepiece onto terminal until flats align with two

cotter pin holes in terminal body.

TIP: The flats will align with the holes when the threads of

the nosepiece are flush with the top of the terminal body.

Slowly turn the nosepiece while easing a cotter pin into

the hole. The cotter pin will slip through the terminal when

the holes align with the flats. Insert the two cotter pins and

spread.

Clean excess Loctite

®

from terminal body using special care

to insure that no red Loctite

®

is present on threaded stud.

12 Hydraulic 3/3.25 April 2000

Page 13

Assembly Attach Stay—Rod Unit 3.25

■ ATTACHING STAY TO LOWER UNIT - ROD UNIT 3.25

Use a winch handle to crank the terminal completely out of

the lower unit.

Make sure halyard swivel and torque tube have been slipped

on the foils.

Slip the rod adapter main body onto the rod.

Sandwich the nosepiece over the rod and insert into the main

body, narrow end first. Jiggle the main body or use a small

screwdriver to push the nosepiece completely into main

body.

Put several drops of the blue Loctite

of the stud. Thread the stud into the main body until the

®

on the large threads

slot aligns neatly with the hole in the main body.

TIP: Sight through the pin hole to find the optimum thread

engagement. Make sure the stud is threaded far enough so

the pin is securely seated in the slot, yet not threaded too

far to block the pin.

Hammer the pin into the main body.

®

Clean excess Loctite

care to insure that no Loctite

from the terminal body using special

®

is present on the lower threaded

stud.

April 2000 Hydraulic 3/3.25 13

Page 14

Assembly Attach Stay—Wire

■ ATTACHING STAY TO LOWER UNIT — WIRE

Assemble wire terminal per Sta-lok instructions.

Note: To prevent seizing nosepiece threads when forming

wires, put red Loctite

Open terminal up for inspection. Put sealant inside terminal.

®

on the threads to lubricate them.

Use a winch handle to crank the terminal completely out of

the lower unit.

®

Apply red Loctite

to the stud or the socket of wire terminal.

Thread the hydraulic unit onto the Sta-Lok terminal and wire.

Protect stainless steel housing and sideplates from scratching

when rotating unit. Use saw horses that are padded and have

terry cloth covering.

TIP: Lift the lower unit by the tack swivel shackle and lower

end of unit. Spin lower unit into Sta-Lok terminal.

Put red Loctite

®

on the pin and drive it into place.

Clean excess Loctite® from the terminal body using

special care to insure that no Loctite® is present on

the lower threaded stud.

14 Hydraulic 3/3.25 April 2000

Page 15

Assembly Lower Toggle and Cowling

■ INSTALL LOWER TOGGLE AND COWLING

The integral toggle can be installed so the clevis pin runs

either fore/aft or athwartships.

Choose the correct hole in the base and use the cross pin to

secure the lower toggle so clevis pin runs the correct direction.

Slip the cowling in place.

Secure using the circlip provided.

April 2000 Hydraulic 3/3.25 15

Page 16

Assembly Install Torque Tube

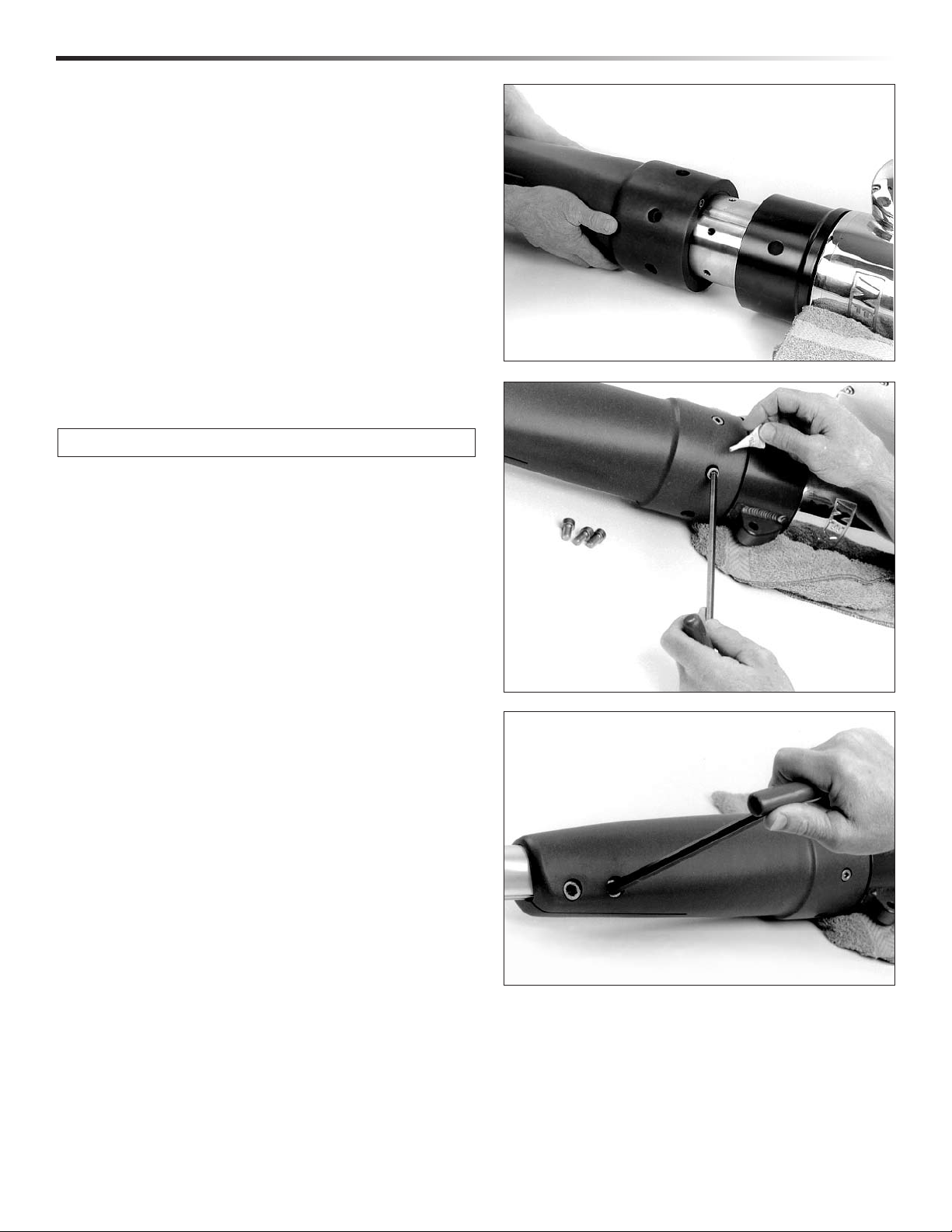

■ INSTALL THE TORQUE TUBE

Secure the torque tube to the lower unit using the six

®

cap screws provided. Use blue Loctite

on the screws.

TIP: Insert all six screws BEFORE tightening.

■ RAISE FOILS

Push the foils to the correct height.

Use an allen wrench to secure the torque tube to the foils

using the two screws provided.

®

Use blue Loctite

on the screws.

16 Hydraulic 3/3.25 April 2000

Page 17

Assembly Foil Length Check

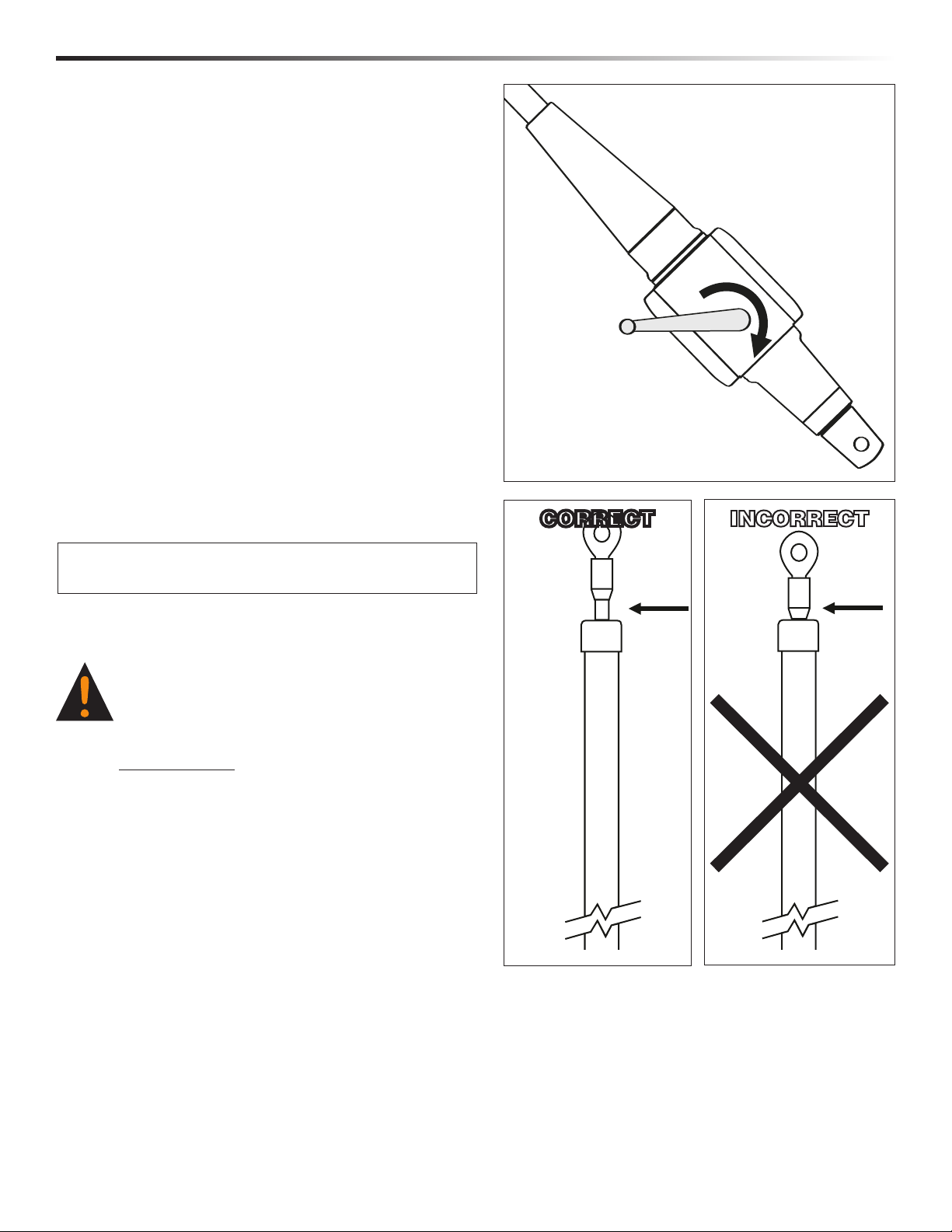

■ CHECK FOIL LENGTH

Once the foils and lower unit are assembled, use a winch

handle to close the stay adjuster. Turn the handle in a

clockwise direction.

Check the clearance between the top of the foil and top

terminal.

TIP: Check clearance when the unit is on the ground,

before raising the headstay into position.

WARNING!: It is critical to have clearance

between top foil and top rigging fitting when stay

adjuster is in fully closed position. If fittings touch,

unit will jam or in the case of a Sta-Lok fitting,

terminal may unscrew. This could cause a catastrophic spar failure which may cause an accident,

damage to your vessel, personal injury or death. See

www.harken.com for additional safety information.

NOTE: A swage eye terminal will be recessed into the top foil.

Check to make sure the top of the foil is not jammed on the

“eye” of the marine eye.

It is the responsibility of the rigger to check clearance.

CORRECT INCORRECT

7/17/08 Hydraulic 3/3.25 17

Page 18

Assembly Raise Furling Unit/Gearbox Pressure

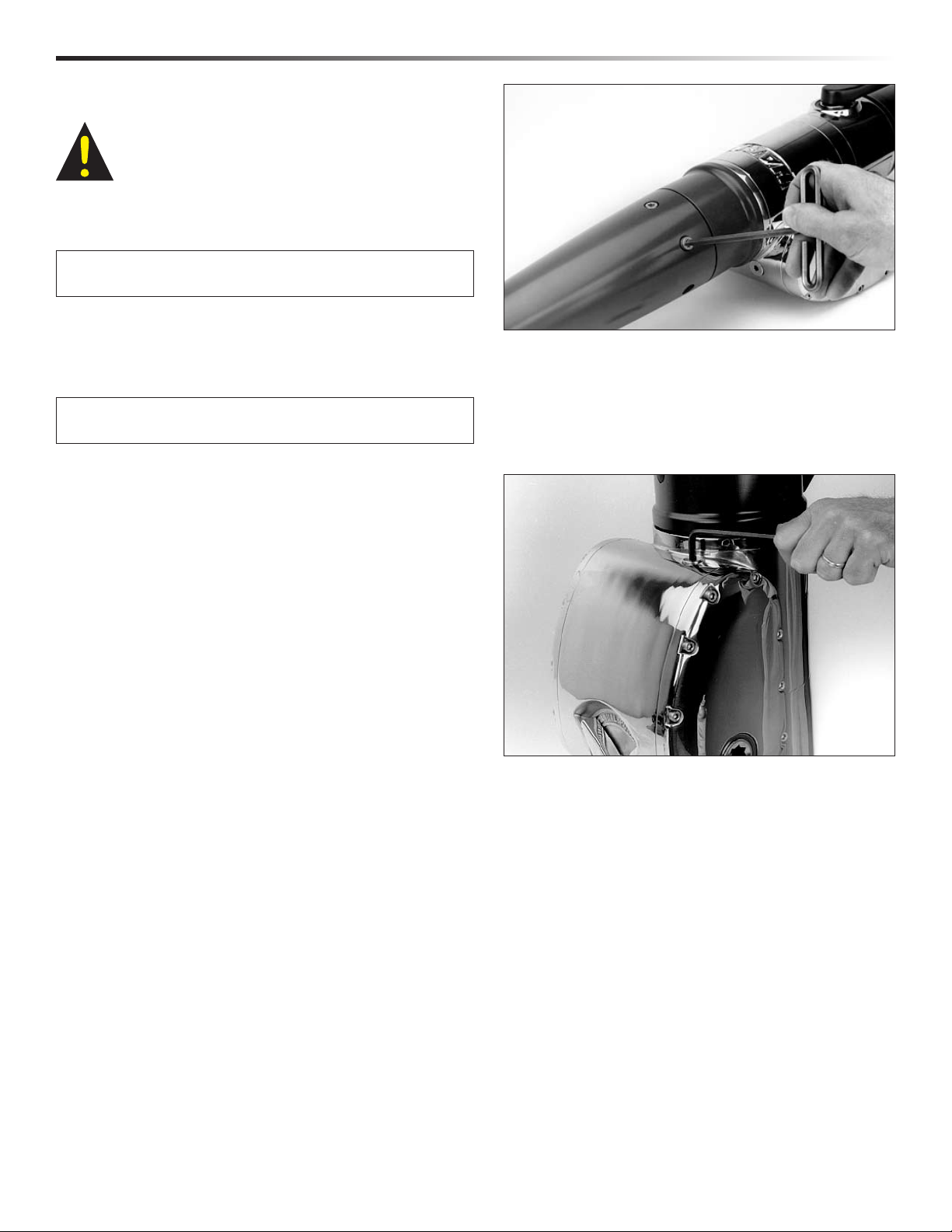

■ RAISE FURLING UNIT ON MAST

CAUTION!: To prevent damage to the stay adjuster,

make sure the torque tube is secured to foils and

lower unit before moving unit.

If the unit will sit for a long time, make sure the port side of

the lower unit is facing up.

TIP: The sideplate with the winch handle socket will be

facing down.

Once you have closed the stay adjuster to confirm there

is clearance above the foils, open the adjuster all the way.

Turn the stay adjuster counter-clockwise to open the adjuster

completely. This makes it easier to connect the stay to the boat.

TIP: Cover unit with terry cloth & padding to protect

stainless finish.

■ GEARBOX PRESSURE

It is possible that pressure has built up in the gear box

during shipping.

Once the unit is in sailing position, relieve pressure by

using a 6mm allen wrench to open the filler valve on

top of the lower unit.

Install the cap so it is wrist tight (20 foot pounds).

18 Hydraulic 3/3.25 7/17/08

Page 19

Assembly Install Hoses/Gear Oil Level/Headstay Tension

■ INSTALL HOSES

Use hose end fittings which are:

Drive: JIC 9/16-18 female swivel

Drain: JIC 7/16-20 female swivel

Do not use locking solution or tape on connections.

Alternate Method: Remove furling unit end fittings and

use SAE straight thread O-ring male hose end fittings.

■ CHECK GEAR OIL LEVEL

CAUTION!: Do not overfill gear oil as this will

cause leaking from the breather valve which

may cause damage to your vessel.

Oil can be checked from top of case. Insert a small metal

stick into filler hole at top of gear housing.

Oil should be at bottom of gears. When unit is in angled

sailing position, oil level will be 2" (51 mm) from top

of housing.

■ ADJUST HEADSTAY TENSION

There is no need to unlock turnbuckle. If sail is up, make

sure halyard is loose.

Do not adjust under sail.

Insert winch handle and rotate counter clockwise to loosen

or clockwise to tighten stay. Total adjustment is 5" (127mm).

CAUTION!: When tightening the stay, if handle

becomes suddenly hard to turn, stop immediately.

Forcing handle when adjuster is completely closed

will damage gears.

All final rig tensioning or spar bending should be done

using a conventional backstay adjuster.

7/17/08 Hydraulic 3/3.25 19

Page 20

Adjustments Halyard Wraps/Prevent Halyard Wraps

■ HALYARD WRAPS

The most serious problem with furling systems occurs when the jib

halyard wraps around the headstay foil. Halyard wraps will prevent

furling or unfurling and may cause serious damage to the unit and the

halyard. In severe cases, halyard wraps may cause headstay loss.

To prevent wraps, the halyard must exert a slight pull to the rear.

This allows the foils to turn while the halyard remains stationary.

WARNING!: In severe cases, a halyard wrap can cause loss of

control of boat and/or headstay can break suddenly which can

cause an accident, damage to your vessel, personal injury or

death. See www.harken.com for additional safety information.

■ PREVENT WRAPS

WARNING!: Sail must be fitted to foil length before using to

prevent a halyard wrap which could lead to headstay breakage

causing an accident, damage to your vessel, personal injury or

death. See www.harken.com for additional safety information.

1 Halyard swivel should be within the top 4" (100 mm)

of the foil.

8 - 10°

2 Halyard must pull slightly to the rear (8 - 10°).

3 Halyard must be snug, but not too tight.

TIP: With the sail raised, walk away from the boat and look at the

masthead with binoculars. Use the halyard swivel as a measurement

reference. 4" (100 mm) is /3 the length of the swivel. There should be

less foil exposed above the swivel than 1/3 of the swivel.

If a halyard wraps, do not force the unit to turn. Attempt to open the

sail by alternately furling in and out slightly.

If the sail can be unfurled, lower the sail by releasing the jib halyard.

Severe halyard wraps can only be cleared by going aloft and freeing

the halyard.

If the sail will not furl or unfurl, it may be possible to remove the jib sheets

and manually wrap the sail around the headstay.

Remember: Testing at the dock does not indicate the halyard angle is

correct. In wave action, the halyard may wrap if the lead angle is not

correct. The 8-10° diverging angle mentioned above is critical.

20 Hydraulic 3/3.25 7/17/08

Page 21

Adjustments Pendant/Halyard Restrainer

■ PENDANTS

If your sail is not long enough to position the halyard swivel

properly, you must add a pendant to the sail. Pendants

should be plastic coated wire permanently attached to the

sail so the height will be correct. Adjustable length pendants

are not acceptable as they might not be adjusted correctly

during a sail change.

■ INSTALL A PENDANT

1 Raise the sail, but do not attach tack shackle.

2 Position the halyard swivel correctly near the top of

the headstay and secure the halyard.

3 Secure a piece of rope to the sail tack. Lead the line

through the tack shackle on the furling drum and

tension the sail.

4 Measure the distance from the tack shackle to the

sail tack and have a pendant of this length permanently

attached to the head of the sail.

5 Repeat this procedure for every jib.

TIP: Pendants are used at the head of the sail. Short

pendants may be added at the tack to improve visibility

under the genoa, but remember that visibility is already

improved by shackling to the tack swivel. Tack pendants

increase heeling moment by raising the sailplan. You may

install pendants at both the head and tack of the sail.

■ HALYARD RESTRAINER

To prevent wraps, jib halyard must pull slightly to rear. On

some boats halyard sheaves are located too close to headstay

and a halyard restrainer must be used.

Use halyard restrainers only when required by masthead

geometry. Restrainers tend to limit sail luff length and may

cause problems if not properly installed.

Mount restrainer as high as possible on face of mast.

Position restrainer so foils will not hit it when under load.

The restrainer should deflect halyard 8 - 10°.

CAUTION!: If halyard angle is more than 10°, you

may experience difficulty in tensioning sail luff,

friction in furling and possible damage to foils.

To decrease deflection angles, shorten sail luff.

8 - 10°

10/07/08 Hydraulic 3/3.25 21

Page 22

Adjustments Halyard Tension/Backstay Tension

■ HALYARD TENSION

The jib halyard should be firm, but not too tight.

TIP: The luff foil system supports the sail along its entire

length so halyard tension is required only to shape sails,

not to support them. Use only enough halyard tension to

remove some wrinkles along the luff. Do not tension the

halyard enough to cause vertical wrinkles in the luff. Use

halyard tension to adjust draft position of the sail to suit

sailing conditions. Your halyard should be firm but not

tight. If in doubt, release halyard tension. To protect the

sail, ease the halyard when the boat is not in use.

■ BACKSTAY TENSION

Good stay tension helps furlers turn more easily. Make sure

to ease jib halyard before tightening backstay to prevent

damage to furler.

CAUTION!: Tensioning backstay without easing

halyard will cause halyard to tighten excessively

causting damage to halyard swivel and tack swivel.

22 Hydraulic 3/3.25 10/15/08

Page 23

Adjustments Before Operation/Manual Operation

■ BEFORE OPERATION

WARNING!: Before operating, consult pages on

halyard lead angle. If sails are changed, make

sure halyard lead angle is correct. A halyard wrap

cannot be tolerated on a hydraulic furler In severe

cases, a halyard wrap can cause loss of control of

boat and/or headstay can break suddenly which can

cause an accident, damage to your vessel, personal

injury or death. See www.harken.com for additional

safety information.

Make sure to ease sheets before operating the system.

CAUTION!: Do not use hydraulic furler to sheet sail.

The direction of furling is up to the individual. Make sure

suncover is rolled correctly.

TIP: Label buttons “in” and “out” and be consistent in their

use when rolling and unrolling sail. This way, it will be

possible to furl in tdesired direction at night when sail

is hard to see.

■ MANUAL OPERATION

To furl or unfurl the unit manually, push the lever to manual

and insert a winch handle in the starboard socket. Rotate to

move the sail in or out.

TIP: Use a short 8" (200 mm) handle to increase furling

speed furling.

7/17/08 Hydraulic 3/3.25 23

Page 24

Corporate Headquarters

1251 East Wisconsin Avenue, Pewaukee, Wisconsin 53072 USA

Telephone: (262) 691-3320

Web: www.harken.com

• Fax: (262) 691-3008 • Cable: Harken Pewaukee

• Online Catalog: www.harkenstore.com

Email: harken@harken.com

Harken France

ZA. Port des Minimes, BP 3064, 17032 - La Rochelle Cedex 1, France

Telephone: (33) 05.46.44.51.20

Web: www.harken.fr

• Fax: (33) 05.46.44.25.70

Email: harken@harken.fr

Harken Italy S.P.A.

Via Marco Biagi, 14, 22070 Limido Comasco, (CO), Italy

Telephone: (39) 031.3523511

Web: www.harken.it

• Fax: (39) 031.3520031

Email: info@harken.it

Harken UK Ltd.

Bearing House, Ampress Lane

Lymington, Hampshire S041 8LW, England

Telephone: (44) 01590-689122

• Fax: (44) 01590-610274

Web: www.harken.co.uk

Email: enquiries@harken.co.uk

Harken Poland

ul. Lisa Kuli 4 lok.1, 01-512 Warszawa, Polska

Telephone: 022 561 93 93

Web:

www.harken.com

Email:

polska@harken.com

• Fax: 022 839 22 75

Harken Sweden

Mjölkekilsgatan 6, Box 64

S-440 30 Marstrand, Sweden

Telephone: (46) 303-618 75

Web: www.harken.se

• Fax: (46) 303-618 76

Email: harken@harken.se

Harken Adriatik d.o.o.

Obala 107

6320 Portoroz, Slovenia

Telephone

Web: www.harken.si

/Fax: 5-6774122

Email: info@harken.si

Harken Australia, Pty, Ltd.

1B Green Street

Brookvale, N.S.W. 2100, Australia

Telephone: (61) 2-8978-8666

Web: www.harken.com.au

• Fax: (61) 2-8978-8667

Email: info.harken.com.au

Harken New Zealand, Ltd.

30-36 Fanshawe Street

Auckland 1001, New Zealand

Telephone: (64) 9-303-3744

Web: www.harken.co.nz

• Fax: (64) 9-307-7987

Email: harken@harken.co.nz

Please visit: http://www.harken.com/dealers/dealers.php

for an up-to-date list of Harken dealers and distributors

Printed in USA 4902/10-08

Loading...

Loading...