Page 1

Herror!

HI 6200 Single Channel Weight Processor

User Guide

FastFind Links

Product Description

Installation

Initial Setup

Ways to Set Scale Parameters

Setting Scale Parameters

Troubleshooting

Hardy Installation and Commissioning

Page 2

Hardy Process Solutions

9440 Carroll Park Drive San Diego

San Diego, CA 92121

Copyright © 2019 Hardy Process Solutions

All Rights Reserved

Notice of Rights

No part of this manual may be reproduced or copied, translated or transmitted, in any form or by any

means, without the prior written permission of Hardy Process Solutions.

Notice of Liability

Information provided in this manual is intended to be accurate and reliable. However, Hardy Process

Solutions, Inc. assumes no responsibility for its use, nor for any infringement of rights of third parties

which may result from its use. THIS DOCUMENT IS PROVIDED “AS IS” AND ANY EXPRESS OR

IMPLIED WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN NO

EVENT SHALL HARDY PROCESS SOLUTIONS, INC. BE LIABLE FOR ANY DIRECT, INDIRECT,

INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT

LIMITED TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA,

OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND ON ANY THEORY OF

LIABILITY, WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING NEGLIGENCE

OR OTHERWISE) ARISING IN ANY WAY OUT OF THE USE OF THIS DOCUMENT, EVEN IF

ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

Trademarks

All trademarks and registered trademarks are the property of their respective owners.

Hardy Process Solutions HI 6200 Weigh Processor User Guide Part Number 0596-0358-01, Rev A

Page 3

CONTENTS

How to Use This Guide ............................................................................................ 6

Introduction ............................................................................................................ 6

Audience ................................................................................................................ 6

Changes in This Revision ...................................................................................... 6

Related Documents ............................................................................................... 6

User Feedback ...................................................................................................... 6

Organization of the Guide ...................................................................................... 7

Document Conventions ......................................................................................... 8

1 Product Description ............................................................................................. 9

1.1 Overview ............................................................................................................. 10

1.2 Models ................................................................................................................. 11

1.3 Key Features ....................................................................................................... 12

1.3.1 WAVERSAVER

1.3.2 C2

1.3.3 INTEGRATED TECHNICIAN™ Operator Diagnostics ............................... 12

®

Electronic Calibration .......................................................................... 12

®

........................................................................................ 12

2 Installation ........................................................................................................... 13

2.1 Hardy Field Service ............................................................................................. 14

2.2 Pre-installation Planning ...................................................................................... 14

2.3 Unpacking ........................................................................................................... 16

2.4 Climatization ........................................................................................................ 17

2.5 Handling Precautions .......................................................................................... 17

2.5.1 Sources of Electrical Interference ............................................................... 1 8

2.6 Mounting the HI 6200 .......................................................................................... 19

2.7 Wiring the HI 6200 ............................................................................................... 21

2.8 Powering on the HI 6200 ..................................................................................... 22

3 Initial Setup ......................................................................................................... 23

3.1 Initial Setup .......................................................................................................... 24

4 Setting Scale Parameters ................................................................................... 26

4.1 Using the Touch Screen ...................................................................................... 27

4.2 Using the Embedded Webserver ........................................................................ 29

Hardy Process Solutions HI 6200 Weigh Processor User Guide 3

Page 4

4.2.1 Saving “Known Good” Parameters ............................................................. 32

4.2.2 Restoring from “KnownGood” Parameters ................................................. 34

4.3 Using a PLC ........................................................................................................ 36

4.3.1 EIP .............................................................................................................. 36

4.3.2 Setting Up Communications ....................................................................... 36

4.3.3 Configuration Parameters ........................................................................... 38

4.3.4 Configuration with AOP .............................................................................. 39

4.3.5 PLC Commands ......................................................................................... 39

READ PARAM CMD ............................................................................................ 40

ZERO CMD ......................................................................................................... 40

TARE CMD .......................................................................................................... 41

CAL LOW CMD ................................................................................................... 41

CAL HIGH CMD .................................................................................................. 41

C2 CAL CMD ....................................................................................................... 42

IT Test ................................................................................................................. 42

Stability Test ........................................................................................................ 42

IT Test Reduced .................................................................................................. 43

C2 Search ............................................................................................................ 43

WRITE CMD ........................................................................................................ 43

Set Default Parameters ....................................................................................... 44

Set Default Network Parameters ......................................................................... 44

Write to NVM (non-volatile memory) ................................................................... 44

Save Last Good Configuration ............................................................................ 44

4.3.6 Modbus ....................................................................................................... 45

5 Setting Scale Parameters ................................................................................... 54

5.1 Pre-Calibration Procedures ................................................................................. 55

5.2 Calibration Setup Procedures ............................................................................. 56

5.2.1 Unit of Measure .......................................................................................... 56

5.2.2 Motion Tolerance ........................................................................................ 56

5.2.3 Zero Tolerance ........................................................................................... 56

5.2.4 Auto Zero Tracking ..................................................................................... 56

5.2.5 Auto Zero Tolerance ................................................................................... 57

5.2.6 Number of Averages ................................................................................... 57

5.2.7 Span Weight ............................................................................................... 57

5.2.8 Ref Weight .................................................................................................. 57

5.2.9 Gravity Correction ....................................................................................... 57

5.2.10 Tare Weight .............................................................................................. 58

5.2.11 WAVESAVER® ........................................................................................ 59

5.3 Calibrating the Scale ........................................................................................... 60

5.3.1 Pre-calibration Procedures ......................................................................... 60

5.3.2 C2

®

Calibration ........................................................................................... 61

Hardy Process Solutions HI 6200 Weigh Processor User Guide 4

Page 5

5.3.3 Hard Calibration .......................................................................................... 61

6 Troubleshooting ................................................................................................. 62

6.1 Troubleshooting Table ......................................................................................... 63

6.2 Weighing System Test ........................................................................................ 64

6.3 Electrical Check Procedures ............................................................................... 64

6.3.1 Load Sensor/Point Input/Output Measurements ........................................ 64

6.3.2 Load Check ................................................................................................ 65

7 Hardy Installation and Commissioning ............................................................ 67

7.1 Emergency Service and Support ......................................................................... 67

Index ....................................................................................................................... 77

Hardy Process Solutions HI 6200 Weigh Processor User Guide 5

Page 6

HOW TO USE THIS GUIDE

Introduction

The Hardy Process Solutions HI 6200 Weigh Processor is a state-of-the-art product. It uses

advanced microprocessor technology and front-end signal processing of stain-gauge type

load sensors to provide super-accurate weighing coupled with operator-friendly interfaces

and reliability. These features make the instrument ideally suited for all types of industrial

manufacturing weighing applications.

To benefit from Hardy’s entire feature set of WAVESAVER®, C2® Calibration, and

INTEGRATED TECHNICIAN™ diagnostics, complete your scale system using all Hardy

components.

Do not operate or work on this equipment unless you have read and understand the

instructions and warnings in this manual. Failing to follow the instructions or heed the

warnings can result in injury or death.

Audience

This manual describes how to install, configure, operate, maintain, and troubleshoot the

HI 6200 Weigh Processor. It is intended for individuals responsible for installing, configuring,

operating, and servicing the HI 6200.

Changes in This Revision

N/A - this is first version of this document.

Related Documents

Hardy Process Solutions provides manuals in PDF format that can be downloaded from our

website free of charge. Go to http://www.hardysolutions.com/, click the Support Center link,

and then hover over Doc & Program Downloads for each product.

User Feedback

Hardy Process Solutions appreciates your business, and welcomes all corrections or

suggestions for improving this manual. Please send your comments to

hardysupport@hardysolutions.com. Include the document title, and refer to specific sections

and paragraphs whenever possible. All comments become the property of Hardy Process

Solutions. Thank you!

Hardy Process Solutions HI 6200 Weigh Processor User Guide 6

Page 7

How to Use This Guide

Organization of the Guide

Chapter 1 ‒ Product Description

This chapter provides an overview of the HI 6200, along with a description of the

available models and key features.

Chapter 2 ‒ Installation

This chapter describes how to install the HI 6200.

Chapter 3 ‒ Initial Setup

Describes the initial setup steps to perform before using the HI 6200 for the first time.

Chapter 4 ‒ WAYS TO SET Scale Parameters

This chapter describes the different ways to set HI 6200 scale parameters.

Chapter 5 ‒ Setting Scale Parameters

This chapter describes how to calibrate the HI 6200.

Chapter 6 ‒ Troubleshooting

This chapter provides information for identifying and resolving HI 6200 problems.

Chapter 7 ‒ Hardy Installation and Commissioning

This chapter describes Hardy product installation and commissioning.

APPENDIX A - Specifications

This appendix lists the HI 6200 specifications.

APPENDIX B - List of Parameter IDs

This appendix lists the parameter IDs for the HI 6200.

APPENDIX C - Frequently Asked Questions

This appendix provides answers to frequently asked questions.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 7

Page 8

How to Use This Guide

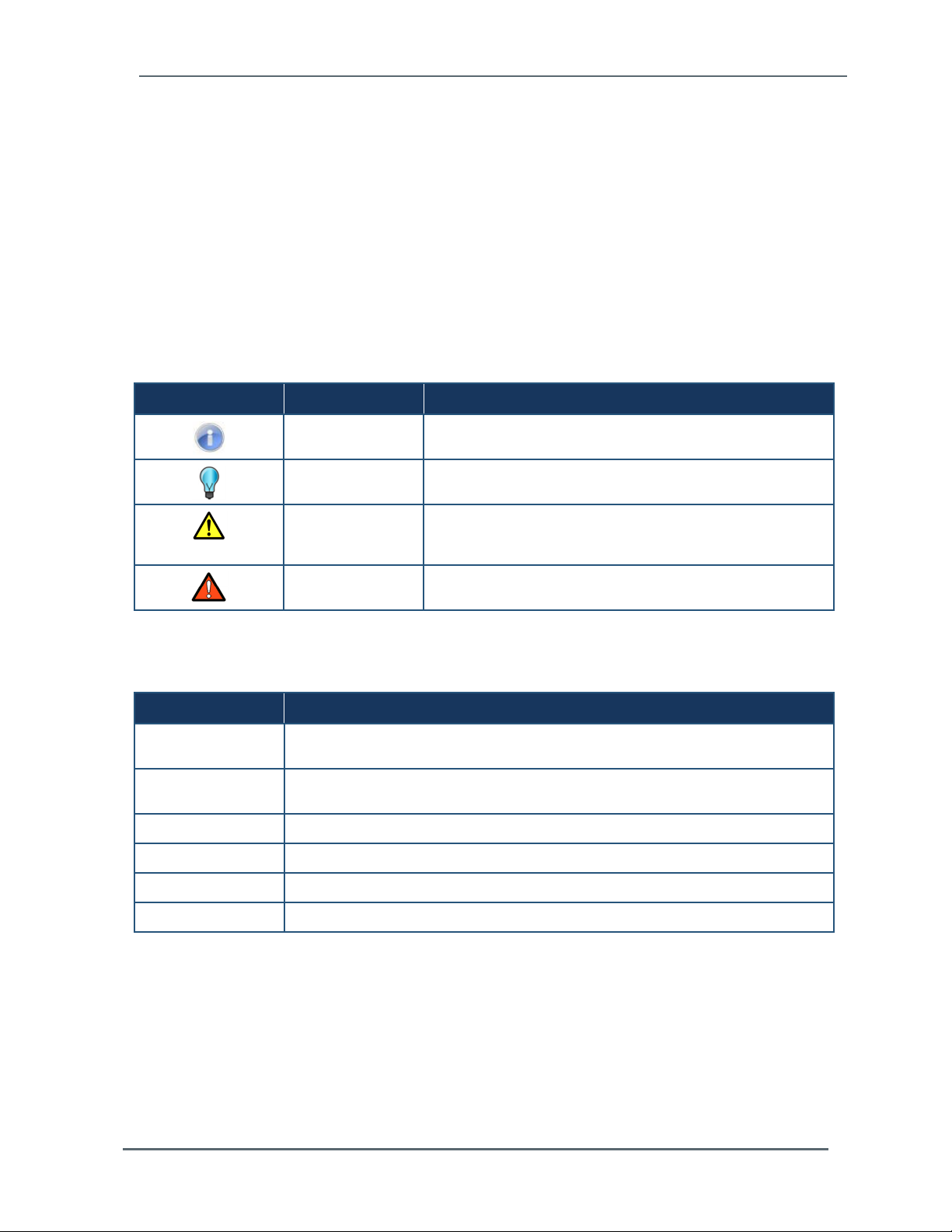

Document Conventions

This document uses the following conventions to draw attention to certain information.

Terminology

In this guide, the terms “HI 6200,” “instrument,” and “system” are used interchangeably to

describe the Hardy Process Solutions HI 6200.

Safety and Warnings

Symbol Meaning Description

Note Notes emphasize or supplement important points of the main

Tip Tips provide helpful information, guidelines, or suggestions for

Caution Indicates a potential hazard or unsafe practice, which, if not

Warning Warnings indicate that failure to take a specified action could

text.

performing tasks more effectively.

avoided, could result in minor injury, harm to the patient or

operator, or damage to property or the device.

result in data loss or other serious consequences.

Typographic Conventions

Convention Description

Bold Indicates text on a window, other than the window title, including menus, menu

Italic or < > Indicates a variable, which is a placeholder for actual text provided by the user or

page/code

[ ] square brackets Indicates optional values.

options, buttons, fields, and labels.

system.

Indicates text that is displayed on page or entered by the user.

{ } braces Indicates required or expected values.

| vertical bar Indicates a choice between two or more options or arguments.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 8

Page 9

1 PRODUCT DESCRIPTION

Topics:

Overview (page 10)

Models (page 11)

Key Features (page 12)

This chapter provides an overview of the HI 6200

Single Channel Weight Processor. This chapter also

lists the available models and describes the

instrument’s key features.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 9

Page 10

Chapter 1 – Product Description

1.1 Overview

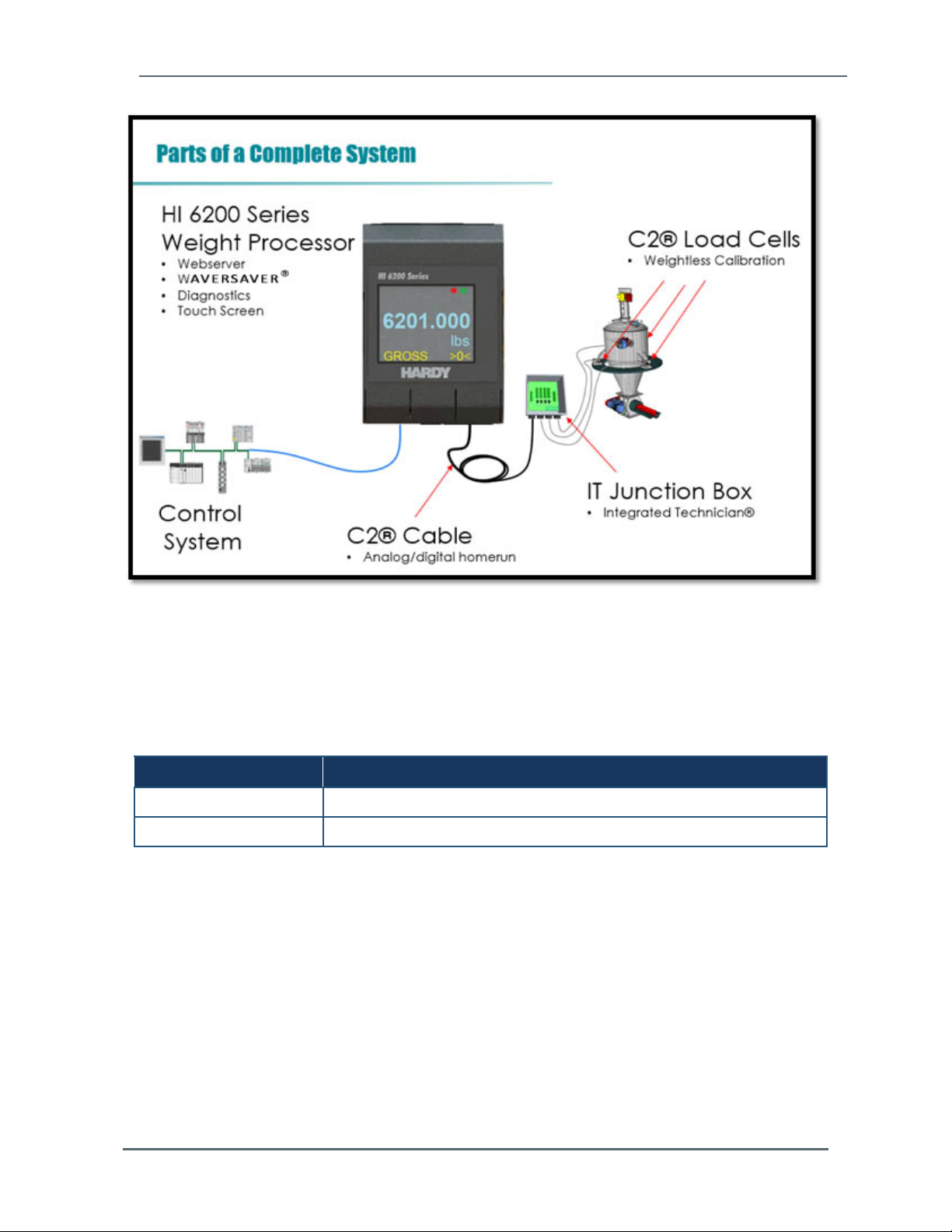

The HI 6200 series are high-performance, single-channel Weight Processors featuring

industrial Ethernet-based communication, Industrial Internet of Things (IIoT) compatibility,

remote diagnostics, and a user-friendly touch-screen interface. The HI 6200 is ideally suited

for OEMs and system integrators who build machinery where fast, stable weight data along

with low-cost of ownership are critical components to their successful design.

Ultra-compact at just 2 inches wide and 3 inches high, the HI 6200 series saves cabinet

space. This form factor allows for high-density panel design over traditional weighing

instrumentation, reducing machine cost and control cabinet footprint.

The HI 6200 is designed for a wide variety of process weighing applications such as:

Batching Blending

Filling and dispensing Check weighing

Force measurement Level by weight and weight rate monitoring

The 24-bit analog-to-digital converter is capable of sampling sensor (s) output up to 4,800

times per second and provides fast stable weight measurements to a control system at 100

times per second. These capabilities provide accurate weight measurement and control and

tolerate large “dead” loads or over sizing of load sensors.

The HI 6200 also features Hardy’s entire Process Toolbox™. The Hardy Process Toolbox is

a set of productivity tools that support industrial weighing functions. Each tool saves time,

increases accuracy, improves efficiency or reduces risk in process weighing applications,

including WAVERSAVER

®

to eliminate vibration, C2® electronic calibration and Integrated

Technician™ diagnostics.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 10

Page 11

Chapter 1 – Product Description

1.2 Models

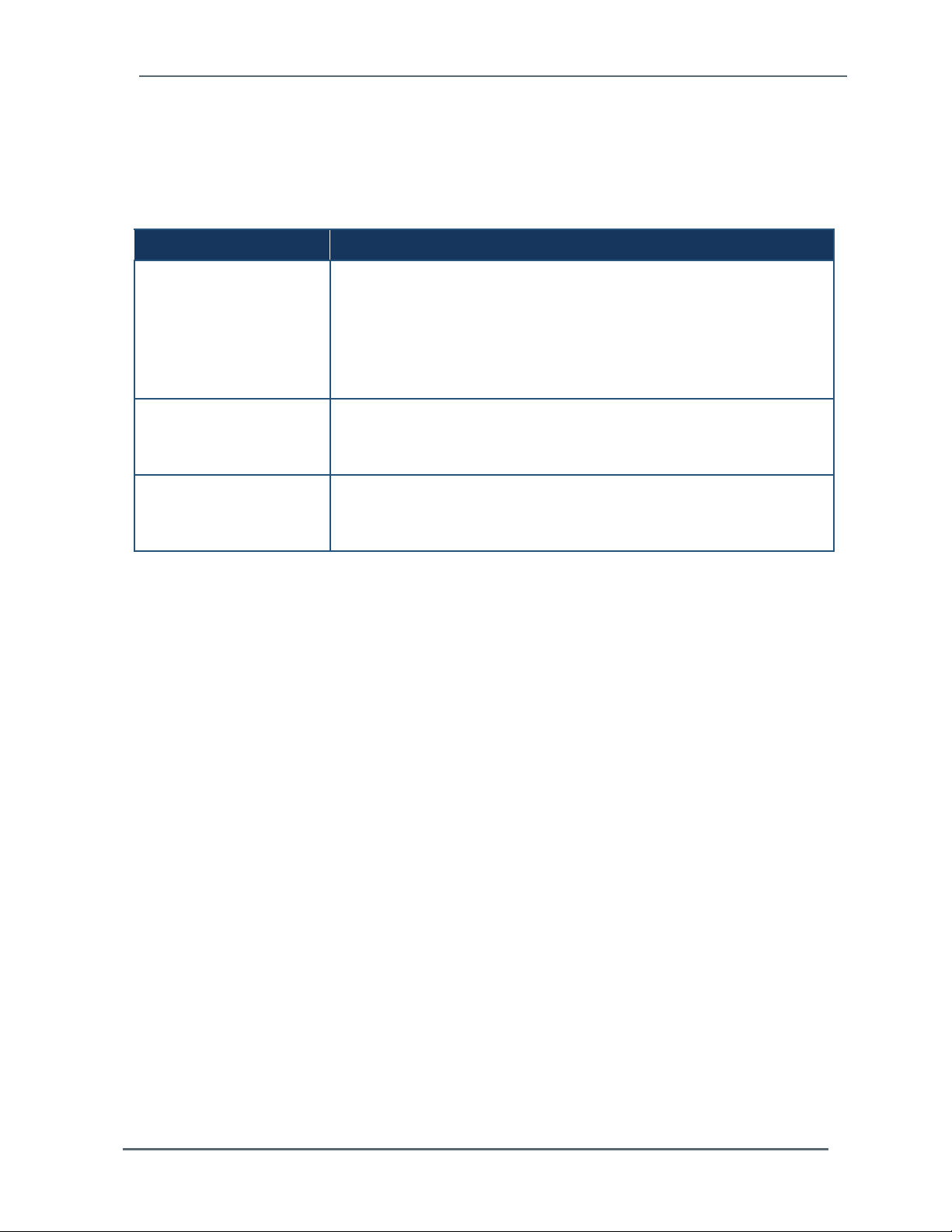

The HI 6200 is available in the following models.

Figure 1-1. HI 6200 Models

Model Description

HI6200-WP-10-EIP-000 Single Channel Weight Processor, Ethernet Comms with Display

HI6200-WT-10-ANA-000 Single Channel Weight Transmitter, Analog Out with Display

Hardy Process Solutions HI 6200 Weigh Processor User Guide 11

Page 12

Chapter 1 – Product Description

1.3 Key Features

1.3.1 WAVERSAVER®

Hardy's WAVERSAVER® core technology eliminates the effects that surrounding vibration

has on the scale weight signal, providing only true data for fast, accurate weight reading.

1.3.2 C2® Electronic Calibration

The Hardy C2® core feature provides quick and easy electronic calibration of a weighing

system without requiring heavy test weights.

1.3.3 INTEGRATED TECHNICIAN™ Operator Diagnostics

Hardy's INTEGRATED TECHNICIAN (IT) core feature helps you troubleshoot your weighing

system and diagnose problems from the HI 6200 webserver. These tests display system

weights, voltages, and pass/fail information that allow you to isolate a problem to the

instrument, cabling, or sensors, reducing troubleshooting times and maintenance costs.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 12

Page 13

2 INSTALLATION

Topics:

Hardy Field Service (page

14)

Pre-installation Planning

(page 14)

Unpacking (page 16)

Climatization (page 17)

Handling Precautions

(page 17)

Mounting the HI 6200

(page 19)

Wiring the HI 6200 (page

21)

Powering on the HI 6200

(page 22)

This chapter describes how to install the HI 6200

Weight Processor.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 13

Page 14

Chapter 2 – Installation

2.1 Hardy Field Service

Hardy Process Solutions provides local field service for all scales and weighing equipment.

Hardy’s factory trained technicians can perform service on all Hardy equipment as well as

most other manufacturers’ systems. Enabled by the Hardy Process Toolbox, our technicians

spend less time onsite, saving you money and reducing your downtime.

Services include the following (click a service below for more information):

Installation & Commissioning

Calibration and Preventative Maintenance

Onsite Emergency Support

Service Agreements with Defined Turnaround Times

Product, Service, and PLC Integration Training

Pre-Installation Site Audit

Scale Installed-Base Evaluation

PLC Integration Support

Engineering Design Support and Specification Development

Quality Documentation Creation

To request any of these services, or to discuss your needs with a trained Hardy Service

Agent, call 800-821-5831 option 4 between 6:30 AM and 5:30 PM PST. For emergency

downtime service after hours, leave a message in our emergency mailbox and your call will

be returned promptly, or email us at hardysupport@hardysolutions.com for a response the

next business day.

2.2 Pre-installation Planning

Successful installation of the HI 6200 requires careful pre-installation planning. Proper

planning will help provide for a more efficient installation and greater reliability, availability,

and serviceability.

All pre-installation activities should be scheduled and completed before equipment delivery.

The pre-installation process includes:

Working with Hardy Field Service to ensure that all hardware and cables in the specified

configuration and all cables of the appropriate length are on-site and ready to install

Selecting key personnel who will handle the installation.

Preparing a preliminary layout of the installation.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 14

Page 15

Chapter 2 – Installation

Reviewing the power and the heating, ventilation, and air-conditioning (HVAC)

requirements, and then ordering any additional support equipment.

Making a final layout of the installation and reviewing the layout with Hardy Field Service.

Verifying that the electrical service wiring has been installed at the predetermined location

before installing the HI 6200.

To aid with your pre-installation planning, verify the availability of each item in the following

site preparation checklist. The following tasks might require several weeks to complete:

Acquiring required power outlets.

Arranging for an electrician.

Adding or modifying air conditioning systems.

Making room alterations to accommodate the HI 6200.

Ordering third-party equipment to support the HI 6200.

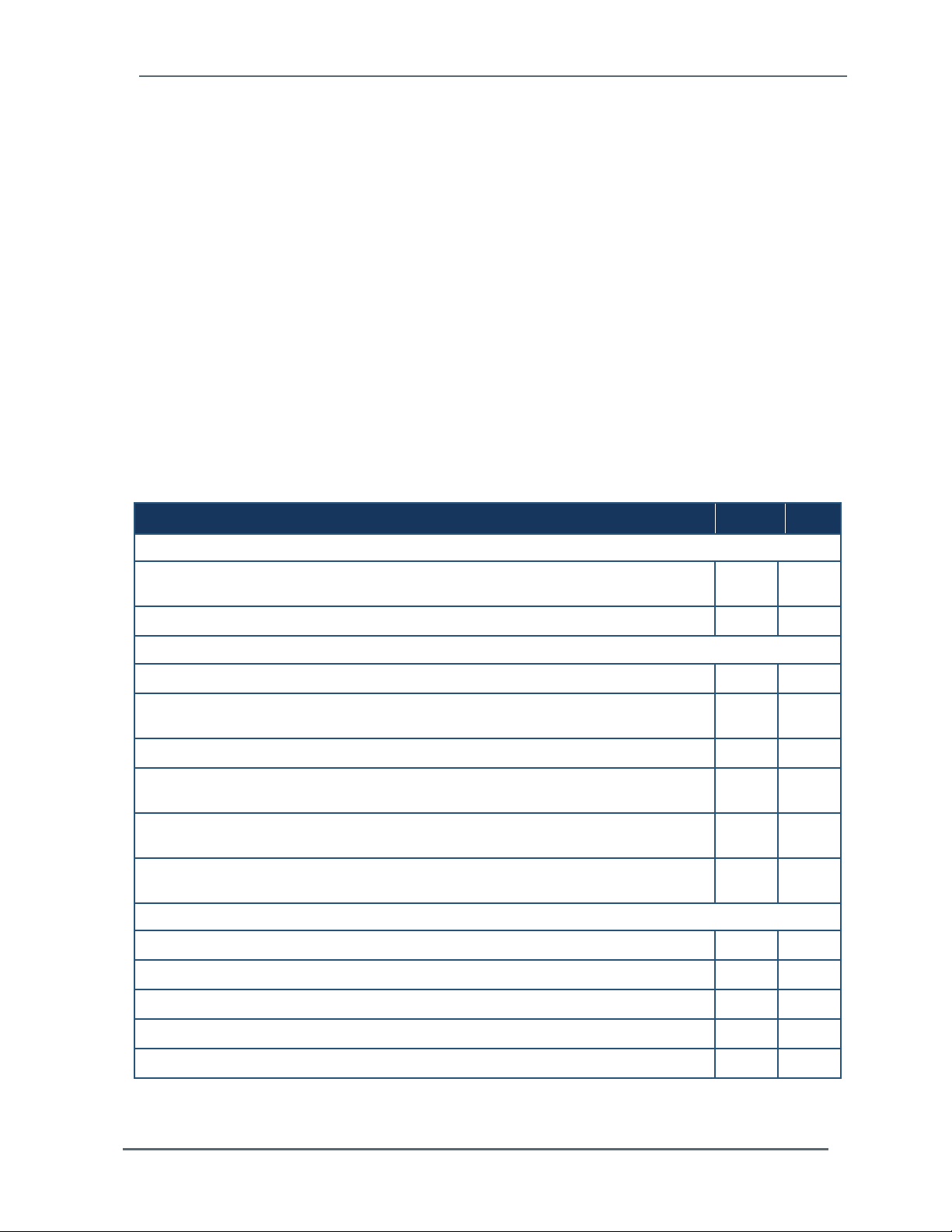

Checklist Question Yes No

Safety

Is the installation location room free of any equipment servicing hazards, such as electrical

or data cables that obstruct access?

Does the installation location have a fire-protection system?

Space Planning

Are there cutouts or channels to route cables?

Can the temperature be maintained between -20°C to 55°C (-4°F to 131°F) during

operations?

Can the humidity level be maintained between 0% and 90% non-condensing?

Is the installation location protected against dust, pollution, and metallic particulate

contamination?

Does the installation location take into account environmental considerations, such as

vibration and acoustics?

Is all equipment not supplied by Hardy Process Solutions (for example, power supply) on

site and ready for use?

Electrical Requirements

Is there a sufficient number of AC outlets for the equipment?

Are the AC outlets on different lines?

Are the input circuit breakers adequate for equipment loads?

Are uninterruptible power supplies (UPS) in place?

Have all sources of electrical interferences been addressed?

Hardy Process Solutions HI 6200 Weigh Processor User Guide 15

Page 16

Chapter 2 – Installation

2.3 Unpacking

The HI 6200 is shipped directly from Hardy Process Solutions.

1. Before signing the packing slip, inspect the packaging for damage, and report damage of

any kind to the carrier company.

2. Check that everything in the package matches the bill of lading.

3. If items are missing or you have any questions, contact Customer Service by phone, fax,

or email.

4. Record the model number and serial number of the HI 6200 series instrument. Store this

information in a convenient, secure location for reference when contacting Customer

Service, buying parts, or upgrading firmware.

A Return Material Authorization (RMA) number is required before returning any damaged

product. Use the website to request an RMA at https://www.hardysolutions.com/support-

center/repairs-form/view Have the following items ready:

Your Name, Company name, shipping address, email address and telephone number

Model Number & Serial number of the unit

Brief description of the problem

In case of damage due to shipping, notify the delivering carrier immediately for an

inspection.

WARNING: ELECTROSTATIC DISCHARGE MAY DAMAGE SEMICONDUCTOR

COMPONENTS IN THE INSTRUMENT. DO NOT TOUCH THE CONNECTOR

PINS.

AVERTISSEMENT: UNE DÉCHARGE ÉLECTROSTATIQUE PEUT

ENDOMMAGER DES COMPOSANTS SEMI-CONDUCTEURS DANS LE

INSTRUMENT. NE PAS TOUCHEZ LE CONNECTEUR.

WARNING: POWER DOWN THE SYSTEM BEFORE SERVICING THE

INSTRUMENT. DO NOT UNPLUG UNDER POWER.

AVERTISSEMENT: SYSTÈME D'ALIMENTATION AVANT D'ENTREVOIR LE

INSTRUMENT. NE PAS DÉBRANCHER SOUS LE POUVOIR.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 16

Page 17

Chapter 2 – Installation

2.4 Climatization

An HI 6200 shipped or stored at extreme temperatures requires time to adjust to operating

temperatures before startup.

If the HI 6200 arrives in very hot or very cold weather, do not unpack it until it has been

allowed to reach room temperature (one to two hours).

Immediately exposing the HI 6200 to warm temperatures can cause condensation to occur,

which could damage the electronics.

If you notice any condensation, allow the HI 6200 to stand unattended for one to two hours,

and then unpack it.

2.5 Handling Precautions

Observe the following precautions when handling the HI 6200:

Wear an approved wrist-strap grounding device when handling the instrument.

Touch a grounded object or surface to rid yourself of any electrostatic discharged prior to

handling the instrument.

Handle the instrument from the bezel in front away from the connector. Never touch the

connector pins.

Do not install the instrument right next to an AC or high voltage DC module.

Route all the load voltage cables away from high voltage cables.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 17

Page 18

Chapter 2 – Installation

2.5.1 Sources of Electrical Interference

Ensure that the HI 6200 is protected from sources of electrical interference. The following

table provides examples of electrical interference.

Potential Source Description

Wall outlets Power outlets for building maintenance and janitorial equipment, such as

vacuum cleaners and floor buffers, must be wired from circuit breakers on a

power panel separate from the computer system panel. The ground wires from

these outlets must connect to the normal building distribution panel and not to

the system ground. If a separate power source and separate ground are not

provided, maintenance and janitorial equipment can induce electrical noise

that can affect operation of the HI 6200. Your electrician can verify whether

maintenance outlets are on separate panels.

Lightning In geographical areas subject to lightning storms, you may want install

lightning protection for your HI 6200. The principles of lightning protection and

personnel safety are described in the National Fire Protection Association

(NFPA) Handbook.

Electromagnetic interference Electromagnetic interference can cause various problems. The HI 6200 is

designed to reduce its susceptibility to radiated and conducted interference. A

Hardy Process Solutions representative can advise you about common

causes of electromagnetic interference.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 18

Page 19

Chapter 2 – Installation

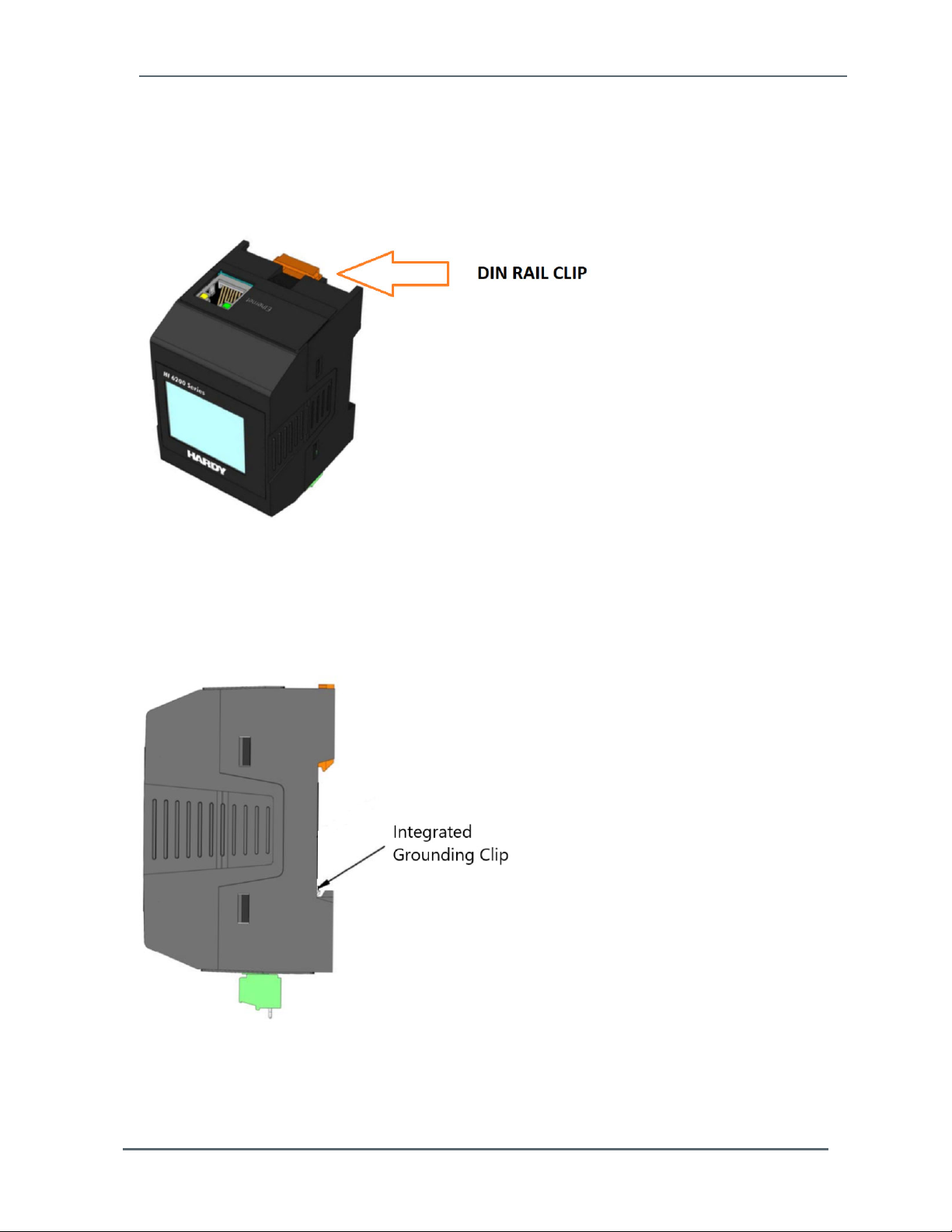

2.6 Mounting the HI 6200

The HI 6200 is designed for mounting on a 35mm DIN rail using the spring-loaded DIN clip

integrated into the body of the instrument.

Figure 2-1. DIN Rail Clips

To mount the HI 6200:

1. Engage the bottom of the DIN rail.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 19

Page 20

Chapter 2 – Installation

2. Snap the top of the HI 6200 onto a DIN rail.

Figure 2-2. Mounts on the DIN Rail (Horizontal Mounting)

Figure 2-3. Mounts on the DIN Rail (Vertical Mounting)

To remove the HI 6200:

1. Locate the slot on the top of DIN rail clip.

2. Gently pry up until the instrument releases.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 20

Page 21

Chapter 2 – Installation

2.7 Wiring the HI 6200

The HI 6200 has screw-down terminal blocks for power and load cell connections, and an

RJ-45 jack on the top for Ethernet communications. For detailed information about wiring

terminations, refer to the installation and interconnection diagram in document #0584-0107

on the Hardy website.

When tightening wiring onto the screw-down terminal blocks, remove the terminal blocks

from the instrument to prevent undue stress on the instrument.

Figure 2-4. HI 6200 Wire Terminations to Hardy Sensors and Junction Boxes

Caution: Do not over-tighten the screw-down terminal blocks. Otherwise, you

might shear sensor wires and cause intermittent or complete failure of the

weighing system.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 21

Page 22

Chapter 2 – Installation

Observe the following wiring best practices:

If conduit is used, do not run load cell cable parallel to, or in the same conduit with, power

wiring, relay cable, or other high-energy cables.

If you connect four wire load sensors with C2 and four wire load sensors without C2

directly to the termination base assembly, install wire jumpers in the termination base

assembly where indicated.

Required load cell cable for C2 electronic calibration system and INTEGRATED

TECHNICIAN is Hardy Process Solutions part number C2Cable (6020-0001-0).

2.8 Powering on the HI 6200

After wiring the HI 6200, power on the instrument and check that Status and Scale LEDs on

the front panel indicate normal operation. Press Status Light for additional detail on

condition.

Figure 2-5. Status and Scale LEDs

Table 2-1. LEDs

LED Color and Status Description

Steady Green Instrument is operating normally.

Flashing green Error, no calibration. Press the on-screen Status button for more information.

Steady red Read failure or EEPROM write error. Press the on-screen Status button for

Flashing red Read convert error. Press the on-screen Status button for more information.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 22

more information.

Page 23

3 INITIAL SETUP

Topics:

Initial Setup (page 24)

This chapter describes how to set up the

HI 6200 prior to initial use.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 23

Page 24

Chapter 3 – Initial Setup

3.1 Initial Setup

The following steps describe the minimum configuration procedures to perform when setting

up the HI 6200 for the first time. Perform these procedures in the order shown.

For detailed descriptions of scale parameters and how to use them when setting up a scale

system, see Chapter 5.

1. Choose a calibration method: C2 OR Hard Cal (not both).

Recommended Method: Perform C2 – Electronic Calibration:

a. Remove all live weight from the scale. Leave all dead load weight, like vessels,

mixers, etc. on the scale.

b. Press Do C2 Cal.

c. Place a verification weight on the scale to ensure the weight reading matches and that

calibration is successful.

Alternate Method: Perform Hard Cal- Traditional

a. Traditional Calibration requires a zero point and the physical placement of test weights

on the scale. To set the Zero Value, if all “live load” weight is removed from the Scale,

the Zero Value should be 0.00. If any weight is on the scale when setting this value,

the weight must be equal to the amount of load on the scale.

b. Wait 12 seconds or more.

c. Click in the Ref Weight text field and enter the reference weight you want. In our

example, we entered 0 lbs. If you want the reference weight to be 5.0 lbs., enter 5.0.

d. Click the Do Cal Low button to do the Trad Cal Zero. A “Cal Completed OK” message

appears briefly if the calibration was successful. An Error number appears if the

calibration was not successful. See the Error list in Chapter 8 for help in correcting the

error.

e. To set the Span Weight, place a certified test weight on the scale.

f. In the Span Weight text field, enter the amount of live load weight placed on the scale.

g. Click the Do Cal High button. A “Cal Completed OK” message appears briefly if the

calibration was successful.

h. An Error message appears if the calibration was not successful. See the error list in

Chapter 8, for help in correcting errors.

i. Step 9. The scale is now calibrated

Hardy Process Solutions HI 6200 Weigh Processor User Guide 24

Page 25

Chapter 3 – Initial Setup

Multi-Point Calibration

Multi‐PointCalibration,(alsocalledmidpointcorrection)issimplyacalibrationwith3‐5points.

Standardtwo‐pointcalibrationassumeslinearity(astraightline).However,calibrationtojust2end

pointsmaynotaccommodatefornon‐linearity(acurvedline)thatmayhappeninthemiddleofthe

loadcurve.

Multi‐Pointcalibrationletsuserscalibrateatthree,fourorfivevaluesonthecurve.Amulti‐point

calibrationmeans,incomparisontoatwo‐pointcalibration,thatyoucancalibratenon‐linearity

significantlymoreaccurately

Toachievethebestpossibleaccuracy,themulti‐pointcalibrationshouldcovertheentirerangeof

thedesiredmeasurementvalues(fromzerotothehighestpossiblevalue).

ToaccessMulti‐PointCalibrationfromthewebbrowser,clickontheMulti‐PointCalibrationlinkat

thebottomoftheCalibrationpage.

a. First, select the number of Cal Points necessary to accommodate for non-linearity

that can’t be mechanically corrected in the system. Users that have previously

performed a Calibration or set the span weight value using traditional calibration, will

see that value populated as the highest number of Cal Points selected (for example,

point 3-5 depending on your instrument.).

b. Perform each calibration step by step from Cal Point 1 to the next point Weight (e.g.

Cal Point 2 then Cal Point 3) until you reach your last selected point

c. The system will be calibrated with multiple points, providing the most accurate

method for a non-linear calibration.

Note: Multi-Point Calibration is only available through the Webserver, not the panel display.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 25

Page 26

4 WAYS TO SET SCALE

PARAMETERS

Topics:

Using the Touch Screen (page 27)

Using the Embedded Webserver

(page 29)

Using a PLC (page 36)

For convenience, the HI 6200 Weight

Processor provides the following ways to set

scale parameters:

Front panel touch screen provides access

to all instru

Embedded Webserver provides access to

ment settings and parameters.

the touch screen settings along with

advanced diagnostics, parameter cloning,

and firmware upgrade parameters.

PLC provides PLC communications (EIP

or Modbus).

Hardy Process Solutions HI 6200 Weigh Processor User Guide 26

Page 27

Chapter 4 – Ways to Set Scale Parameters

4.1 Using the Touch Screen

To set up the HI 6200 using its front panel touch screen:

1.

At the lower right side of the screen, press the Setup button to access the Setup me

2.

From the Set-up area, press the left or right arrow key to scroll through the main me

Press the top selection or the OK button to access the secondary menus.

3.

nus.

nus.

Press the left or right arrow key to scroll through the secondary menus.

4.

5.

To make a selection, press a secondary menu item or the OK

To return to the previous menu, press the Back

6.

To return to the home screen, press the Home button.

7.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 27

button.

button.

Page 28

Chapter 4 – Ways to Set Scale Parameters

Table 4-1 shows the organization of the touch screen menus.

Table 4-1. Touch Screen Menus

Home Zero Command

Tare Comman d

Mode Net

Set‐U p Calib ration C2 Gravity UserInputvariable

Gross

RefWeight UserInputvariable

DoC2 Comma nd

NumDevices DeviceInfo

HardCal CalLo wWeight UserInputvariable

DoCalLo w Comman d

SpanWeight UserInputvariable

DoCalHigh Comma nd

CalDate UserInputvariable

Communication EtherNetTCP/IP Ena bleDHCP On

Off

FixedIP UserInputvariable

DynamicIP U serI nputvariable

MaskAddress UserInputvariable

GatewayAddress UserInputvariable

DNSServer Use rInputvariable

EtherNetUDP HardyPort UserInputvariable

ModbusTCP Status DeviceInfo

EtherNet/IP Status DeviceInfo

ProfiNet reserve

Filter Filter Fast

Balanced

Stable

Custom

Off

Operations AutoZero Auto Zero Enable

Disable

Tolerance UserInputvariable

TareOps TareWeight UserInputvariable

ZeroOps ZeroTolerance UserInputvariable

Zero

Setting s DecimalPt. UserInputvariable

Capacity UserInputvariable

Grads 1

2

5

10

100

InstrumentID UserInputvariable

Motio nTo lera nce U serI nputvariable

OperatorID UserInputvariable

Units oz

lb

ton

g

kg

mt

Security None checkmark

Medium checkmark

High checkmark

Password UserI nputvariable

Info FWVersion informationonly

Produc tSN informationonly

HWrev. informationonly

Hardy Process Solutions HI 6200 Weigh Processor User Guide 28

Page 29

Chapter 4 – Ways to Set Scale Parameters

4.2 Using the Embedded Webserver

The embedded Webserver is a graphical point-and-click interface that can be accessed

using a computer that has an Internet connection. Using the embedded Webserver, you can

access the same instrument settings and parameters available from the front panel touch

screen plus the following additional features:

Advanced diagnostics

Parameter cloning

Firmware upgrade

To set up th

If the HI 6200 is powered on, power it off.

1.

2.

Connect either end of a straight-through or crossover Ethernet cable to t

connector o

e HI 6200 using its

n the top of the HI 6200. Connect the other end of the cable to

embedded Webserver:

he RJ-45

a Network

Switch or Router.

3.

Power up the HI 6200. The instrument automatically negotiates setting

variety of op

Wait approximately 15 seconds, and then check whether the green light o

4.

port is blin

can skip

erating systems and network config

king. If it is blinking, the computer can communica

to step 5. Otherwise, perform the following steps:

urations.

te with the HI 6200 and you

s suitable for a

f the Ethernet

a. The HI 6200’s default static IP address is 192.168.0.100. To communicate with the

instrument, configure th

octets in the

octet) is a n

IP address) are the same as the HI 6200 and the node ident

umber from 0 to 255 other than 100. For example: 192.168.0.

e computer’s IP address so the network

identifier (first three

ifier (last

101.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 29

Page 30

Chapter 4 – Ways to Set Scale Parameters

b. On your computer, right-click the Local Area Connection icon of the network adapter,

and then cli

ck Properties

.

In the Networking tab, check Internet Protocol Version 4 (TCP/IPv4), and then cli

c.

Properties.

Check Internet Protocol

Version 4 (TCP/IPv4).

Click Properties.

ck

d.

In the General tab, select Use the following IP address, and then enter the followin

values:

IP address = 192.168.0.101

Subnet mask = 255.255.255.000

Complete the IP address

and Subnet mask fields.

Click OK.

g

Hardy Process Solutions HI 6200 Weigh Processor User Guide 30

Page 31

Chapter 4 – Ways to Set Scale Parameters

e. Click OK in the TCP/IP Properties dialog box.

f. To return the computer to the original network settings, return to the Inter

(TCP/IP) dialog, sele

Open a web browser on the computer, enter the static IP address of the

5.

instrument (192.168.000

ct check Obtain an IP address automatically, and click OK

.100), and press the Enter key. The Home page appears (see

Figure 4-1).

net Properties

.

HI 6200

Figure 4-1. Embedded W

ebserver Home Page

Hardy Process Solutions HI 6200 Weigh Processor User Guide 31

Page 32

Chapter 4 – Ways to Set Scale Parameters

4.2.1 Saving “Known Good” Parameters

You can save the HI 6200 configuration to a different location in memory in order to restore

the configuration if it becomes compromised.

1.

Open a web browser on the computer, enter the static IP address of the

instrument that you set in a previous step (for example: the factory default is

192.168.000

page 31).

2.

Click Configuration, and then click Diagnostics.

3. Click Parameters

.100), and press the Enter key. The Home page appears (see Figure 4-1

.

HI 6200

on

Hardy Process Solutions HI 6200 Weigh Processor User Guide 32

Page 33

Chapter 4 – Ways to Set Scale Parameters

4. Make sure all the parameter values are set to your requirements.

5.

Click the Save As KnownGood bu

tton.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 33

Page 34

Chapter 4 – Ways to Set Scale Parameters

4.2.2 Restoring from “KnownGood” Parameters

After you use the procedure in section 4.2.1 to save a last-known good configuration, you

can restore the HI 6200 to that configuration if necessary.

1.

Open a web browser on the computer, enter the static IP address of the

instrument (192.168.000

Figure 4-1 on

2.

Click Configuration, and then click Diagnostics

3.

Click Parameters

page 31).

.

.100), and press the Enter key. The Home page appears (see

.

HI 6200

4.

Click Known Good Cfg

Hardy Process Solutions HI 6200 Weigh Processor User Guide 34

.

Page 35

Chapter 4 – Ways to Set Scale Parameters

5. Click the Restore KnownGood button.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 35

Page 36

Chapter 4 – Ways to Set Scale Parameters

4.3 Using a PLC

4.3.1 EIP

Many of the set-up procedures in this section require an EIP system. In this section, the

Allen Bradley system is used.

Note: The HI 6200 is not

Make sure the HI 6200 is installed with the HI 6020IT, HI 6020JB, HI 6010IT or HI

6010JB Junction Boxes. It is compatible with the HI 215JB without the IT functions.

compatible with the obsolete HI 215IT Junction Boxes.

4.3.2 Setting Up Communications

The following procedure describes how to set up communications between the ControlLogix

PLC and the HI 6200. This procedure requires a new or open RS Logix® 5000 project. For

instructions, see your RS LOGIX 5000 manual.

For this setup example/instructions, use the

download from the Hardy website. For information about how to install EDS files, see the

Rockwell instructions.

1.

In the program Controller Organizer, find the I/O Configuration section.

2.

Right-click the Ethernet Module under which you will be installing the HI6200-WS module.

Select New Module to display a list

3.

From the catalog list, select the Hi6200 Series EDS_AOP modu

4.

EDS_AOP file. This file is available as a free

of modules.

le.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 36

Page 37

Chapter 4 – Ways to Set Scale Parameters

5. Configure the module by entering a unique name and entering the instrument’s IP

address.

Enter a

unique

name.

Enter the

instrument’s

IP address.

In the Connection tab, make sure the Requested Packet Interval (RPI) is set to 10ms

6.

.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 37

Page 38

Chapter 4 – Ways to Set Scale Parameters

7. Click OK. The module appears in the controller organizer in the I/O configuration under

the Ethernet section.

8.

Repeat this procedure fo

r any additional modules.

4.3.3 Configuration Parameters

Table 4-2 lists the parameters used when configuring the IO. (See an explanation of

Parameters in Chapter 5.)

Table 4-2. IO Parameters

Configuration Parameters Data Type

Enable/Disable Configuration INT

Decimal Point SINT

Grads SINT

Unit SINT

WAVERSAVER SINT

Num Averages INT

Loadcell Sensitivity INT

AutoZero INT

AutoZero Tolerance FLOAT

Gravity Correction FLOAT

Motion Tolerance FLOAT

Zero Tolerance FLOAT

Tare Weight FLOAT

Reference Weight FLOAT

Span Weight FLOAT

Scale Capacity FLOAT

Hardy Process Solutions HI 6200 Weigh Processor User Guide 38

Page 39

Chapter 4 – Ways to Set Scale Parameters

4.3.4 Configuration with AOP

Using the EDS_AOP file makes configuring the HI 6200 instrument fast and easy.

Note: If the configuratio

n is “enabled” in the AOP or configuration table, the

configuration table downloads into the instrument every time the connection is

established.

Open the

1.

To use the configuration parameters, set the parameter Enabl

2.

Table to Enable. Otherwise any changes done

Properties of the Module and go to the Configuration section.

e/Disable Configuration

through the configuration tab will not

applied to the instrument.

Make any required chan

3.

Click Apply. The configuration table is downloaded to the instrument. The

4.

then uses th

e information in the table to set parameters automa

ges.

tically.

be

instrument

4.3.5 PLC Commands

The PLC can control the HI 6200 using the commands in Table 4-3. The sections following

the table provide detailed descriptions about the commands.

Table 4-3. Hardy Commands

Command Number Command

(0x00)0 Read Parameter

(0x01)1 Zero Cmd

(0x02)2 Tare Cmd

(0x64) 100 dec Cal Low Cmd

(0x65) 101 dec Cal High Cmd

(0x66) 102 dec C2 Cal Cmd

(0x80) 128 dec IT Test

Hardy Process Solutions HI 6200 Weigh Processor User Guide 39

Page 40

Chapter 4 – Ways to Set Scale Parameters

Command Number Command

(0x81) 129 dec Stability Test

(0x82) 130 dec IT Test (Reduced Voltage)

(0x83) 131 dec C2 Search

(0x92) 146 dec Write INT Value Command (e.g., number of averages to 50)

(0x93) 147 dec Write FLOAT Value Command (e.g., motion tolerance to 1.5)

(0x94) 148 dec Set Default Parameters (all parameters except IP addresses)

(0x95) 149 dec Set Default Network Parameters (IP addresses only)

(0x97) 151 dec Save Last Good Configuration to Non-volatile Memory

(0x98) 152 dec Restore Last Good Configuration from Non-volatile Memory

READ PARAM CMD

Hex value: 0x00

Decimal value: 0

To read a parameter, write the hexadecimal value 0x00 to the CMD register (register #0),

and write the parameter number in the

parameter value may then be read from the

ParameterID register of the output table. The

ParameterValue register in the input table.

This value can be in integer or floating-point format, depending on the parameter. The

Command status register in the reply contains the lower 16 bits of the system Command

status word.

Status word bit 0: A/D error

Status word bit 7 (0x80): Not Found - the requested parameter number does not exist

Status word bit 6 (0x40): Motion status

ZERO CMD

Hex value: 0x01

Decimal value: 1

Write the hexadecimal value 0x01 to the command register to zero the gross weight. If this

command succeeds, the status register reads 0.

Status Error code 1 Fail

Status Error code 2 ADC Failure

Status Error code 3 Out of tolerance

Status Error code 4 Motion

Status code FF cmd in progress

Hardy Process Solutions HI 6200 Weigh Processor User Guide 40

Page 41

Chapter 4 – Ways to Set Scale Parameters

TARE CMD

Hex value: 0x02

Decimal value: 2

Performing a tare command changes the net weight to “0” and moves the tared value into

the “tare weight” parameter. Write the hexadecimal value 0x02 to the command register to

zero the net weight. If this command succeeds, the Cmd Status (lower 8 bits of

CmdStatusNCount) reads 0.

Status Error code 1 Fail

Status Error code 2 ADC Failure

Status Error code 4 Motion

Status code FF cmd in progress

CAL LOW CMD

Hex value: 0x64

Decimal value: 100

Write the hexadecimal value 0x64 to the command register to perform the low step of a

traditional calibration. If this command succeeds, the status register reads 0.

Status Error code 1 Fail

Status Error code 2 ADC Failure

Status Error code 4 Motion

Status code FF cmd in progress

CAL HIGH CMD

Hex value: 0x65

Decimal value: 101

Write the hexadecimal value 0x65 to the command register to perform the high step of a

traditional calibration.

Status Error code 1 Fail

Status Error code 2 ADC Failure

Status Error code 4 Motion

Hardy Process Solutions HI 6200 Weigh Processor User Guide 41

Page 42

Chapter 4 – Ways to Set Scale Parameters

HardcalFailCounts 8 Insufficient number of counts between hard cal hi and hard cal lo

Status code FF cmd in progress

C2 CAL CMD

Hex value: 0x66

Decimal value: 102

Write the hexadecimal value 0x66 to the command register to perform a C2 calibration.

Status Error code 1 Fail

Status Error code 2 ADC Failure

Status Error code 4 Motion

Status Error code 5 no C2 cells

Status Error code 6 C2 capacities not equal

Status Error code 7 Non-Hardy C2 load sensor

Status code FF cmd in progress

IT Test

Hex value: 0x80

Decimal value: 128

Write the hexadecimal value 0x80 to the command register to perform an Integrated

Technician test. This test requires an IT summing card.

Status Error code 1 Fail or no IT Summing Card Found

Status code FF cmd in progress

Stability Test

Hex value: 0x81

Decimal value: 129

Write the hexadecimal value 0x81 to the command register to perform the stability test.

Status Error code 1 Fail

Status code FF cmd in progress

Hardy Process Solutions HI 6200 Weigh Processor User Guide 42

Page 43

Chapter 4 – Ways to Set Scale Parameters

IT Test Reduced

Hex value: 0x82

Decimal value: 130

Write the hexadecimal value 0x82 to the command register to perform an Integrated

Technician test with reduced voltage. This test requires an IT summing card.

Status Error code 1 Fail or No IT Summing Card Found

Status code FF cmd in progress

C2 Search

Hex value: 0x83

Decimal value: 131

Write the hexadecimal value 0x83 to the command register to force the module to search for

and read/update C2 data.

Status Error code 1 Fail

Status code FF cmd in progress

WRITE CMD

Hex value: 0x92

Decimal value: 146

Set the value of a parameter. Write the hexadecimal value 0x92 in the command register 0,

the parameter ID number in the

ParameterValue register of the output table.

Status Error code 1 Fail

Status Error code 0x0B Value out of range too high

Status Error code 0x0C Value out of range too low

Status Error code 0x0D Not allowed

Status Error code 0x80 Invalid parameter ID

ParameterID register, and the desired value in the

Hardy Process Solutions HI 6200 Weigh Processor User Guide 43

Page 44

Chapter 4 – Ways to Set Scale Parameters

Set Default Parameters

Hex value: 0x94

Decimal value: 148

Write the hexadecimal value 0x94 to the command register to set all parameters and

calibration back to default settings.

Status Error code 1 Fail

Set Default Network Parameters

Hex value: 0x95

Write to NVM (non-volatile memory)

Hex value: 0x96

Save Last Good Configuration

Hex value: 0x97

Table 4-4. Instrument Status Word Bits

Bit Description

0 A/D converter error - bad input from the load sensor.

1 A/D converter failure - no output from the converter to the processor.

2 Motion - indicates weight is in motion (changing).

3 Center of Zero

6 Calibration in Progress

7 Error parameter ID Not Found

Table 4-5. Command Status Return Value

Return Value Description

0 Success

1 Fail

2 Fail - ADC error and ADC failure

3 Fail - out of tolerance

4 Fail - motion

5 Fail - no C2 load cells found

Hardy Process Solutions HI 6200 Weigh Processor User Guide 44

Page 45

Chapter 4 – Ways to Set Scale Parameters

Return Value Description

6 Fail - C2 capacities not equal

7 Fail - non-Hardy C2 load sensor

8 Fail - not enough counts between Cal low and Cal high weights

11 Fail – param value too high

12 Fail – param value too low

13 Fail – not allowed

128 Fail – Parameter ID not found

4.3.6 Modbus

Modbus is an application-layer messaging protocol that supports client/server

communications between devices connected on different types of buses or networks. All

HI 6200 series units have Modbus TCP built-in. To have the instrument communicate

through Modbus-TCP, use the touch screen or web browser to configure the HI 6200 for

Modbus TCP.

If you do not have a Modbus PLC available to test the Modbus communications, download

the Hardy Modbus-Link client software from the Hardy website to test communications with

the HI 6200 instrument. The package communicates with the HI 6200 only and is not a full

communications package. If you encounter problems with this test, contact Hardy Customer

Service.

Modbus services are specified by function codes that are elements of MODBUS

request/reply PDUs. MODBUS is implemented for the HI 6200 using TCP/IP over Ethernet.

In this client/server configuration, the client is the module requesting data and the server is

the module providing the data.

Note: MODBUS is locat

ed at level 7 of the OSI model and accessed at a reserved

system port 502 on the TCP/IP stack. It supports communication with up to 10

different hosts (sockets).

4.3.6.1 Configuring MODBUS

1. Download the Hardy Modbus-Link client software:

Hardy Process Solutions HI 6200 Weigh Processor User Guide 45

Page 46

Chapter 4 – Ways to Set Scale Parameters

a. Open a web browser on your computer.

b. Go to the Hardy website: http://www.hardysolutions.com

c. Click the Support Center link, hover over Doc & Program Downloads, and click

HI 4000 Series Support Page. Then download the client

sof

tware from the HI 4050

Weight Controller page.

After downloading the client software, double-click the

2.

install th

Link icon ap

3.

Double-click the Hardy Modbus-Link icon to open the Hardy Modbus-Lin

e software on your computer. When the installation completes, a Hardy Modbus-

pears on your Desktop.

Hardy Modbus-Link .exe

Figure 4-2).

file to

k display (see

Figure 4-2.

From the Connection menu, click Connect. The TCP/IP Connection dialog box appears.

4.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 46

Hardy Modbus-Link Display

Page 47

Chapter 4 – Ways to Set Scale Parameters

5. If TCP/IP is not selected in the top-right field, select it from the pull-down list.

6.

In the IP Address field at the bottom right, type the address of the HI 6200 inst

with which you want to communicate

7.

Click OK. The red No Connection message disappears and the values at the top of

page chang

e. Your computer is now connected to

.

Select TCP/IP.

Type the address of the HI 6200 instrument.

the HI 6200.

rument

the

Hardy Process Solutions HI 6200 Weigh Processor User Guide 47

Page 48

Chapter 4 – Ways to Set Scale Parameters

8. From the Setup menu, click Poll Definition. In the Poll definition dialog box, select the

following set

Function = 04 INPUT REGISTER

–

tings, and then click OK

:

Address =

–

0

– Length = 10

9.

On the Hardy Modbus-Link page, from the Display menu, click Float. The

appears in r

aware of random numbe

egister 6 (net) or register 8 (gross). Other registers are not floa

rs in other registers.

Weight value

t values, so be

Hardy Process Solutions HI 6200 Weigh Processor User Guide 48

Page 49

Chapter 4 – Ways to Set Scale Parameters

10. From the Display menu, click Long. This allows you to write an integer value into the

non-float registers.

11.

From the Functions menu, select Read/Write Registers

OR

Click button 23 to open the Write multiple registers dialog box

:

12. Double-click the top register. When the Enter Value box appears, enter the new value

you want to

the Tare co

write to this register. The following figure shows writing a value of 2

mmand nu

mber.

, which is

Hardy Process Solutions HI 6200 Weigh Processor User Guide 49

Page 50

Chapter 4 – Ways to Set Scale Parameters

13. Click OK to accept the value, and then click the Send button to send the values to the HI

6200.

14. When the Response OK message appears, click OK

Change the display back to Float and confirm that the Tare command cha

15.

.

nged the Net

weight to zero.

4.3.6.2 I/O Tables for Communications to PLC

Table 4-6 and Table 4-7 on page 51 are common for the EtherNet/IP and Modbus – TCP

communication protocols.

Table 4-6. Output Table

Output Table Type

Command INT

Aux Command Information INT

Parameter Value DINT

Parameter ID INT

Reserved 1 INT

Reserved 2 INT

Reserved 3 INT

Reserved 4 INT

Reserved 5 INT

Total 10

Command, Aux Command Information, Parameter ID, and Parameter Value are used

to send commands to the instrument, write new parameter values, read existing parameter

Hardy Process Solutions HI 6200 Weigh Processor User Guide 50

Page 51

Chapter 4 – Ways to Set Scale Parameters

values, and read data values. The command is a 16-bit value used for the command string,

as shown above in the command section.

The 16-bit

Aux Command Information is used for specific information required for special

commands. The parameter ID register is used to select the parameter to read/write. The

Parameter Value is used to set the new value for a write. This register is ignored if doing a

read.

The following values are reserved to provide padding, so the user-selectable read-only

parameters are aligned between the output and input tables:

Reserved 1 Reserved 4

Reserved 2 Reserved 5

Reserved 3

Table 4-7. Input Table

Input Table Type

Command Echo INT

Command Status and Sample Counts INT

Parameter Value DINT

Parameter ID INT

Instrument Status INT

Net Weight REAL

Gross Weight REAL

Total 10

The first fou

r variables in the input table in Table 4-7

Command Echo, Command Status,

Parameter ID, and Parameter Value match closely the first four variables in the

output table in Table 4-6.

Command Echo echoes the command from the output table. This allows the user to ensure

that the correct command has been executed and that the command status value is valid.

Command Status and Sample Counts returns the command status of the command being

run and the Counts from 0 – 255 repeat. The value returned in the lower byte of the register

is the status code for the command. This code is one of the following values:

Hardy Process Solutions HI 6200 Weigh Processor User Guide 51

Page 52

Chapter 4 – Ways to Set Scale Parameters

A zero indicating the command passed.

A value of 0xFF indicating the command is in process.

An error code indicating the reason the command failed (see Table 4-5).

The upper 8 bits of the r

egister are a cyclic “measurement update count,” which increment

by 1 (one) each time a new measurement value is taken, following a 0 to 255 then repeat

cycle. If this value remains the same in two consecutive reads from the instrument, the

communication or the measurement function has failed and appropriate action must be

taken.

Parameter ID is an echo of the value sent in the output table. Parameter Value is the

current value for the specified Parameter ID. This parameter value may ether be an integer

or in floating point format depending on which Parameter ID is specified.

Instrument Status is a 16-bit value that provides the current state of all the major

functions within the instrument. They reflect the status of all the major functions and should

be used with the “measurement update count” to determine the health of the instrument.

Net Weight and Gross Weight values are always provided.

The

4.3.6.3 Default Parameter Values

Table 4-8 shows the default parameters values.

Table 4-8. Default Parameters Values

Configuration Table Data Type Default Range Values

Gravity Correction FLOAT 1.0 0.9-1.1

Decimal Point BYTE 2 0-5

Grad Size

BYTE

Motion Tolerance FLOAT 10.0 .00001-999999.99

Zero Tolerance FLOAT 10.0 .00001-999999.99

Tare Weight FLOAT 0.0

Reference Weight FLOAT 0.0 .00001-999999.99

Scale Cap FLOAT 999999.0 .00001-999999.99

Span Weight FLOAT 1000.0 .00001-999999.99

0 0-9 0 = 1

1 = 2

2 = 5

3 = 10

4 = 20

5 = 50

6 = 100

7 = 200

8 = 500

9 = 1000

Hardy Process Solutions HI 6200 Weigh Processor User Guide 52

Page 53

Chapter 4 – Ways to Set Scale Parameters

Configuration Table Data Type Default Range Values

AutoZero Tolerance FLOAT 10.0 0 -999999.99

Enable AutoZero Tracking

Unit

Load Cell Sensitivity

Waversaver

BYTE

BYTE

BYTE

BYTE

0 0-1 0 = off

1 = on

1 0-5 0 = oz

1 = lb

2 = ton

3 = g

4 = kg

5 = t

4 0-8 0 = 1.0 mV/V

1 = 1.5 mV/V

2 = 2.0 mV/V

3 = 2.5 mV/V

4 = 3.0 mV/V

5 = 3.5 mV/V

6 = 4.0 mV/V

7 = 4.5 mV/V

8 = 5.0 mV/V

3 0-5 0 = Off

1 = 7Hz

2 = 3.5 Hz

3 = 1Hz

4 = 0.5Hz

5 = 0.25Hz

Num Averages INT 10 1-255

Hardy Process Solutions HI 6200 Weigh Processor User Guide 53

Page 54

5 SETTING SCALE PARAMETERS

Topics:

Pre-Calibration Procedures

(page 55)

Calibration Setup Procedures

(page 56)

Calibrating the Scale (page

60)

This chapter provides the recommended calibration

procedure for the HI 6200 Weight Processor. For

the instrument to work properly, it must be

calibrated prior to operation, and then verified

periodically or when not in use for extended periods

of time. We recommend a scale verification rather

than a calibration. Be sure to follow all the

procedures completely to ensure that the weights

read by the instrument are accurate.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 54

Page 55

Chapter 5 – Setting Scale Parameters

5.1 Pre-Calibration Procedures

1. Determine whether the load sensors are installed properly. See your load sensor’s

installation manual for proper installation instructions.

2. A down arrow on some sensors and cells shows the correct direction of the applied load.

If the arrow points in the wrong direction, reposition the load sensor so the arrows face

down.

3. Check for binding on the load sensor, mount, or other parts of the weighing system.

WARNING: BINDING ON A SCALE/VESSEL OR LOAD CELL DOES NOT

ALLOW THE LOAD SENSOR FREE VERTICAL MOVEMENT AND MAY

PREVENT THE INSTRUMENT FROM RETURNING TO THE ORIGINAL ZERO

REFERENCE.

AVERTISSEMENT: LIER SUR UNE ÉCHELLE / RÉCIPIENT OU CELLULE DE

CHARGE NE PERMET PAS LA CELLULE DE CHARGE LIBRE CIRCULATION

VERTICALE ET PEUT EMPÊCHER L'APPAREIL DE REVENIR AU POINT DE

RÉFÉRENCE ZÉRO D'ORIGINE.

4. Load sensors must be mounted so that 100% of the load (Vessel w/Contents) passes

vertically through all the sensors comprising the system. Verify that nothing is binding the

load sensors. This means that nothing is draped across the scale/vessel or the load

sensor, such as a hose, electrical cord, tubes, or other objects.

5. Verify that nothing is in contact with the scale/vessel other than service wires and piping

that have been properly mounted with flexible connections. Flexible pipes are not to be

used in any other than the horizontal plane and are not to be used to correct pipe

alignment problems. Vertical or at angles other than horizontal will have a negative effect

on the scale’s ability to repeat and provide accurate weight readings.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 55

Page 56

Chapter 5 – Setting Scale Parameters

5.2 Calibration Setup Procedures

5.2.1 Unit of Measure

The unit of measure can be set to ounces, pounds, tons, grams, kilograms, or metric tons.

Any weight value input to the module (for example, REFERENCE WEIGHT, SPANWEIGHT)

is in the currently selected units. The unit of measure can be set at any time, not just at

calibration. Setting the unit of measure before calibrating reminds you what unit of measure

is being displayed.

Note: The weigh scale module does not need to be calibrated again after

changing the unit of measure.

5.2.2 Motion Tolerance

Motion Tolerance defines the amount the weight reading needs to change in a 1 second

period of time to make the scale go into MOTION status. If the change over the last 1

second is less than the Motion Tolerance, the scale will not indicate in motion. “Motion

Indicate” means the weight on the scale is currently changing. The scale cannot be

calibrated, tared, or zeroed while in motion.

5.2.3 Zero Tolerance

Zero Tolerance sets the range of weights so that the Zero Command works as an offset of

the calibrated Zero. The amount of weight zeroed off is cumulative. The zero command fails

if the current gross weight plus any previously zeroed amount exceeds the Zero Tolerance.

5.2.4 Auto Zero Tracking

Auto Zero Tracking adjusts for zero weight automatically. This capability allows the module

to ignore material build-up in the weighing system within a preset auto zero tolerance. For

auto zero to work, the current gross weight must be within the auto zero tolerance. The

current gross, plus any previously zeroed weight must be within the Zero Tolerance level

value and the scale must not be in motion. Zero This is not used in all applications and

should be reviewed before use.

Track Enable either enables the Auto Zero tracking if on or disables the Auto Zero if off.

Note: The amount of weight zeroed off is cumulative. The Auto Zero command will

not run if the current gross weight plus any previously zeroed amount exceeds the

zero tolerance value.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 56

Page 57

Chapter 5 – Setting Scale Parameters

5.2.5 Auto Zero Tolerance

When Auto Zero Tolerance is entered and Auto Zero Tracking is enabled, any weight within

the entered tolerance of zero and not in motion causes the display to read zero

automatically.

The amount of weight zeroed off is cumulative. The auto zero command does not run if the

current gross weight plus any previously zeroed amount exceeds the zero tolerance or if the

scale is in motion.

5.2.6 Number of Averages

Number of Averages sets the number of weight readings used to compute the displayed

weight. The average is a sliding average so that a new average reading is available for

display at every reading. Setting a very high Number of Averages AND a high

WAVERSAVER setting may slow system performance.

5.2.7 Span Weight

Span Weight is a calibration high reference point derived from an actual measured weight.

Do not confuse Span Weight with the Scale Capacity. If you place a 100 pound weight on

the scale, the Span Weight would be 100 pounds.

5.2.8 Ref Weight

Ref Weight is a calibration low or C2 Cal reference point derived from an actual measured

weight, normally zero.

5.2.9 Gravity Correction

Objects weigh about 0.5% less at the equator than they weigh at each pole because the

force of gravity is less at the equator than at the poles. An object weighing 100 pounds at the

North Pole on a spring scale, for example, weighs 99.65 pounds at the equator. Depending

on the latitude of your location, your scales measure in between.

Table 5-1 shows the gravitation correction factor for a few cities around the world.

Note: Make sure the scale system is clean and ready to receive product. This step

establishes the gross zero reference. You must perform a C2 calibration after

setting the Gravity Correction; otherwise, the correction factor will not work.

In general, if your location is between the 45th parallel and the equator, gravity correction is

greater than 1.0. For example, you add 1.0006 for an error that is .06% because gravity is

Hardy Process Solutions HI 6200 Weigh Processor User Guide 57

Page 58

Chapter 5 – Setting Scale Parameters

less at these latitudes. For locations between the 45th parallel and the North or South Pole,

your correction factor is less than 1.0 (for example, .9994 for an error that is -.06%).

Gravity Correction compensates for an object weighing less at the equator than at the North

or South Pole. This allows you to enter the correction factory for your location and apply it to

your C2 calibration. This is not used for the hard calibration.

Table 5-1. Gravitation Correction Factor for Selected Cities

City

Amsterdam 0.999369 Istanbul 1.000406 Paris 0.999048

Athens 1.000684 Havana 1.001872 Rio de Janeiro 1.001884

Auckland, NZ 1.000782 Helsinki 1.001405 Rome 1.000326

Bangkok 1.002392 Kuwait 1.001405 San Francisco 1.000702

Brussels 0.999503 Lisbon 1.000615 Singapore 1.00269

Buenos Aires 1.001004 London 0.999445 Stockholm 0.99877

Calcutta 1.00191 Los Angeles 1.001028 Sydney 1.00104

Cape Town 1.00104 Madrid 1.000461 Taipei 1.001741

Chicago 0.99922 Manilla 1.000461 Tokyo 1.000886

Copenhagen 0.999075 Mexico City 1.002102 Vancouver, BC 0.999653

Nicosia 1.00093 New York 1.000433 Washington, DC 1.000601

Jakarta 1.002631 Oslo 0.998726 Wellington, NZ 0.999399

Frankfurt 0.999579 Ottawa 1.000007 Zurich 0.999821

Gravity

Acceleration

City

Gravity

Acceleration

City

Gravity

Acceleration

5.2.10 Tare Weight

Tare weight is the amount of weight tared off with the last tare command or the amount you

entered. The tare weight equals the difference between the net and gross weight readings.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 58

Page 59

Chapter 5 – Setting Scale Parameters

5.2.11 WAVESAVER®

There are six selectable levels. 0 provides no vibration immunity with the fastest response

time, while 5 provides the most vibration immunity with the slowest response time. Default

setting is 3.

Table 5-2. WAVESAVER® Levels

Immunity Setting

Off 0

7.5 Hz 1

3.5 Hz 2

1.0 Hz 3 (default)

0.50 Hz 4

0.25 Hz 5

WARNING: BINDING ON A SCALE/VESSEL OR LOAD CELL CAN DENY THE

LOAD CELL FREE VERTICAL MOVEMENT AND PREVENT THE INSTRUMENT

FROM RETURNING TO THE ORIGINAL ZERO REFERENCE POINT.

ATTENTION: LIEU SUR UNE ÉCHELLE / UN BATEAU OU UNE CELLULE DE

CHARGE PEUT ENDOMMAGER LE MOUVEMENT VERTICAL LIBRE DE LA

CHARGE DE CHARGE ET ÉVITER L'INSTRUMENT DE RETOURNER AU

POINT DE RÉFÉRENCE ZERO ORIGINAL.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 59

Page 60

Chapter 5 – Setting Scale Parameters

5.3 Calibrating the Scale

5.3.1 Pre-calibration Procedures

1. Determine whether the load sensors are installed properly. See your load sensor’s

installation manual for proper installation instructions.

2. A down arrow on some sensors and cells shows the correct direction of the applied load.

If the arrow points in the wrong direction, reposition the load sensor so the arrows face

down.

3. Check for binding on the load sensor, mount, or other parts of the weighing system.

WARNING: BINDING ON A SCALE/VESSEL OR LOAD CELL DOES NOT

ALLOW THE LOAD SENSOR FREE VERTICAL MOVEMENT AND MAY

PREVENT THE INSTRUMENT FROM RETURNING TO THE ORIGINAL ZERO

REFERENCE.

AVERTISSEMENT: LIER SUR UNE ÉCHELLE / RÉCIPIENT OU CELLULE DE

CHARGE NE PERMET PAS LA CELLULE DE CHARGE LIBRE CIRCULATION

VERTICALE ET PEUT EMPÊCHER L'APPAREIL DE REVENIR AU POINT DE

RÉFÉRENCE ZÉRO D'ORIGINE.

4. Load sensors must be mounted so that 100% of the load (Vessel w/Contents) passes

vertically through all the sensors comprising the system. Verify that nothing is binding the

load sensors. This means that nothing is draped across the scale/vessel or the load

sensor, such as a hose, electrical cord, tubes, or other objects.

Verify that nothing is in contact with the scale/vessel other than service wires and piping that

have been properly mounted with flexible connections. Flexible pipes are not to be used in

any other than the horizontal plane and are not to be used to correct pipe alignment

problems. Vertical or at angles other than horizontal will have a negative effect on the

scale’s ability to repeat and provide accurate weight readings.

Hardy Process Solutions HI 6200 Weigh Processor User Guide 60

Page 61

Chapter 5 – Setting Scale Parameters

5.3.2 C2® Calibration

1. Navigate to the C2 menu.

2. Make sure the number of load cells in the Num Devices menu corresponds to the actual

number of C2 devices installed. If the number varies, check that each load cell/point