Page 1

WEIGH SCALE

J

HI 1746WS System troubleshooting Quick Reference Guide

Series B

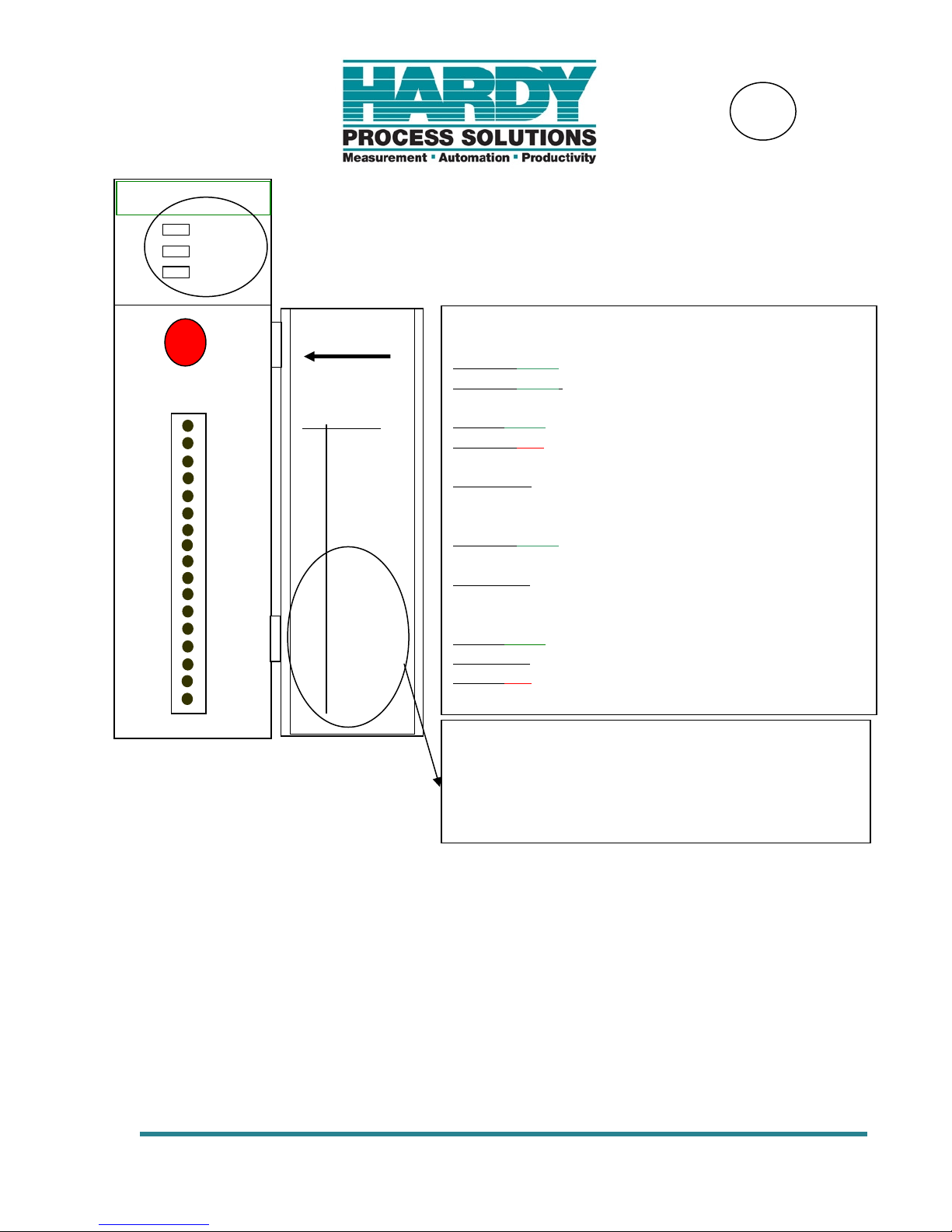

HI 1746-WS

The Button

J2

Pin | Signal

16 Aux In

15 N.C

14 GND

13 +V

12 Relay 2

11 +V

10 Relay 1

9 C28 C2+

7 -Exc

6 -Sen

5 -Sig

4 +Sig

3 +Sen

2 +Exc

1 Shield

LEDS

Run/Fault LED

Flashing Green Self-Test is running.

Flashing Green, (5Hz Flash Speed) - Self-Test Failed, or

calibration has not been completed correctly.

Steady Green Self-Test Passed

Flashing Red Weigh Scale Module has a fault.

(The load cell Millivolt signal level is out of range.)

Steady Red Module has a major problem. Contact Hardy

Instruments Customer Support for assistance.

Comm. LED

Flashing Green, Block transfer is being performed.

(Normal Operation)

LED is Off, No Communication, check I/O configuration.

C2 LED

Steady Green, C2 load cell(s) has been found.

LED is Off, No C2 load cells have been found.

Steady Red, Unable to read load cell data or the Load cell

data is in error.

C2+ = gray, C2- = Violet, voltage 4.9vdc

Excitation = 5vdc

Signal range is –0.1mvdc to 15.3mvdc

What do I check first?

• Are the COMM and FAULT led green?

Sense lines installed to the junction box or jumpers.

Shields landed to make this the single ground point

o See led section above:

o IF NO see reverse page

o C2 led is dependent on, if the load cells are C2 enabled. (See led section above.)

• Does the weight change increase as weight is applied?

o Monitor the PLC screen to verify:

Simply apply weight to the scale

• Does it return to the original weight reading or drift about and then

return to zero?

• Is the weight correct?

• Is the weight stable to 1:10,000?

Is the weight correct at multiple weighing stages?

Verify the load cell signal output

Hardy Instruments • 9440 Carroll Park Dr. • Suite 150 • San Diego, CA 92121-5201

Tel 858.278.2900 • Fax 858.278.6700 • www.hardyinstruments.com • hardyinfo@hardyinst.com

Page 2

The performance of the module is greatly affected by the module’s setup. If the module

system configuration is in question, contact your System Engineer or Hardy Instruments

Technical Support for additional assistance. 1-800-644-8550 ext 1757

A flashing red FAULT led on the front of the HI1746-WS module means there is a load

cell or signal input problem.

Typically, the following possibilities apply.

1. Is the wiring correct?

a. Load cell

b. Intermediate connection in the summing junction box.

c. Cable runs routed away from high voltage.

d. Shields terminated all the way back to a single ground drain.

i. Load cell shields do not contact the body of the load cell.

ii. Verify, with an ohmmeter, the shield is continuous to a single ground

point.

2. Is the load cell installed correctly?

a. Upside down

b. Is the load cell mounting level?

c. Is the weight force applied only in the vertical plane?

3. Is the load cell is damaged?

a. Impact, Welding, Lightning,

b. Miss-handling the load cell or cable.

4. Monitor load cell for valid signal voltages.

a. Measure excitation for 5 volts DC

b. Measure the signal input for a positive 0-15 millivolts.

c. Insure the sense lines are attached or the sense jumpers are installed. Sense

lines maintain the Millivolt reference level.

i. Sense lines are attached to the sense connections on the module

terminal strip to the Excitation terminal of the summing junction box.

ii. Sense jumpers are factory installed on the module terminal strip from

excitation plus to sense plus and excitation minus to sense minus.

iii. The sense jumpers should only be removed if sense wire is installed.

5. Are the piping and flexures correctly installed?

a. Mechanical will show as slow weight response, incorrect weight, unstable

weight, or no weight response.

i. Verify all pipes and conduit attached to the scale are flexible and not

applying or dividing any force.

ii. If you can shake the pipe and conduit, it is flexible.

iii. Relocating pipe supports away from the scale will allow a greater

range of movement.

iv. Verify any overload, lift-off, or check rod assemblies are not

interfering with the scale operation.

Hardy Instruments • 9440 Carroll Park Dr. • Suite 150 • San Diego, CA 92121-5201

Tel 858.278.2900 • Fax 858.278.6700 • www.hardyinstruments.com • hardyinfo@hardyinst.com

Page 3

v. Insure no objects are lodged under the scale system, limiting the

scale’s movement. A typical scale only deflects .020”.

vi. Apply a test weight to a load point and verify you are seeing the

correct weight. Move the test weight to the next load point and verify

the correct weight. Differences of more than 2.5% indicate a problem.

If there are problems with the end user understanding the programming aspect, there are

sample programs with explanations at www.hardyinst.com under support and tech-notes

or sample programming.

Hardy Instruments • 9440 Carroll Park Dr. • Suite 150 • San Diego, CA 92121-5201

Tel 858.278.2900 • Fax 858.278.6700 • www.hardyinstruments.com • hardyinfo@hardyinst.com

Loading...

Loading...