Hardy Process Solutions 400, 300, HIBS300, HIBS200, HIBS400 Operation And Installation Manual

...Page 1

HARDY BENCH SCALES

OPERATION AND INSTALLATION

MANUAL

Hardy Process Solutions

Corporate Headquarters

9440 Carroll Park Drive

San Diego, CA 92121

Phone: (858) 278-2900

FAX: (858) 278-6700

Web-Site: www.hardysolutions.com

Hardy Process Solutions

Copyright 2014-2019 Hardy Process Solutions. All Rights Reserved. Printed in the U.S.A.

, #0596-0339-01 Rev A2

Page 2

CAUTION:

UNPACK WITH CARE

WHEN UNPACKING, DO NOT DISCARD THE PACKING CASE OR ANY

PACKING MATERIAL, UNTIL THE CONTENTS OF THE PACKING CASE

ARE INSPECTED AND CAREFULLY COMPARED WITH THE SHIPPING

DOCUMENTS.

IF ANYTHING IS UNSATISFACTORY, PLEASE NOTIFY HARDY

PROCESS SOLUTIONS IMMEDIATELY BY CALLING, FAXING OR EMAILING TO:

Hardy Service Center

Hardy Process Solutions

9440 Carroll Park Drive

San Diego, California 92121

Phone: (800) 821-5831 or (858) 278-2900

F AX:(858) 278-6700

E-mail: hardysupport@hardysolutions.com

Web Address: www.hardysolutions.com

TO RETURN DEFECTIVE OR DAMAGED PRODUCT(S) CALL HARDY

TECHNICAL SUPPORT FOR A HARDY SERVICE TICKET NUMBER

(HST#). YOUR COMPANY NAME, ADDRESS, TELEPHONE NUMBER,

SERIAL NUMBER OF THE UNIT AND A BRIEF DESCRIPTION OF THE

PROBLEM SHOULD BE READY WHEN CALLING. FOR ALL

NON-WARRANTY REPAIRS A PURCHASE ORDER OR CREDIT CARD IS

ALSO REQUIRED.

IN CASE OF DAMAGE DUE TO SHIPPING, NOTIFY THE DELIVERING

CARRIER IMMEDIATELY FOR AN INSPECTION.

Page 3

Table of Contents

Chapter 1 - Overview 1-1

Introduction 1-1

Description 1-1

The Stainless Steel Top Cover 1-1

Lower Frame Assembly 1-1

Scale Interface 1-1

Hardy Bench Scale Models 1-2

400 Series – HIBS400-xxxx 1-2

300 Series – HIBS300-xxxx 1-2

200 Series – HIBS200-xxxx 1-2

Chapter 2 - Specifications 2-1

Hardy Bench Scale Specifications 2-1

Standard Sizes & Capacities 2-2

Chapter 3 - Installation 3-1

Precautions 3-1

Unpacking 3-1

Adjusting the Mechanical Overload Stops 3-1

Leveling the Scale 3-3

Scale Connections 3-4

Table of Contents

Chapter 4 - Calibration 4-1

About Calibration of the Hardy Bench Scale 4-1

C2 Second Generation Calibration 4-1

Test Weight Calibration (Hard Cal) 4-1

Material Substitution 41

Chapter 5- Troubleshooting 5-1

SCOPE 5-1

Problem: 5-1

Scale Does Not Respond When Weight is Applied 5-1

Scale Indication is not linear 51

Scale Reads Backwards 5-1

Scale Reading drifts or is Erratic 5-1

Service and Repair (All Models) 5-2

i

Page 4

Chapter 1 - Overview

CHAPTER 1 - OVERVIEW

Introduction Congratulations on your purchase of a Hardy

Bench Scale. Behind your purchase is over 90

years of quality, reliability and technical innova

tion.

The Hardy Bench Scales are designed for table

top or floor applications requiring high accuracy

and reliability. The covers are all stainless steel

for durability. The bases have no bearings, spirit

levels, or moving parts that can be damaged or

wear out. The active element of the scale is a

precise and accurate strain gauge load sensor.

Description All Hardy Bench Scales come standard in

12”x12”, 18”x18”, and 24”x24” size s, an d ran ge

in capacity from 5lbs – 1,000lbs (2.27kg to 454

kg). Custom sizes and capacities are available

from Hardy upon request.

The basic Hardy Bench Scale consists of three

major components:

-

1. Stainless Steel Top Cover.

2. Lower Frame Assembly with a load sensor

3. Four Leveling feet.

The Stainless S teel Top Cover

Lower Frame Assembly

Scale Interface Directly attach the scale’s 10 foot (3 meter) cable

The top cover is a single piece constructed of

heavy gauge 304 Stainless Steel. The cover pro

vides a washdown weighing surface and offers

protection to the load sensor and electronics.

The lower frame comes equipped with four leveling feet, a load sensor, a shock load and corner

overload protection. Depending on the model,

the frame is made of stainless steel or painted

carbon steel.

to any weighing instrument or controller. If inter

facing with a Hardy Controller, you can take full

®

advantage of WAVERSAVER

and C2® Elec-

-

1-1

-

Page 5

Hardy Bench Scales

tronic Calibration (C2 is only available with HI

BS400 series).

NOTE: WAVERSAVER® and C2® are registered trade-

marks of Hardy Process Solutions.

Hardy Bench Scale Models

400 Series – HIBS400-xxxx

300 Series – HIBS300-xxxx

The HI BS400 Series is Hardy’s top of the line

industrial bench scale. With all stainless steel

construction and a hermetically sealed, IP68/

IP69K, FM Hazardous approved, stainless steel

Advantage® load cell, the HI BS400 is built for

the heaviest wash down applications and corro

sive environments. Hardy has built its C2 weightfree calibration technology into every scale,

delivering the lowest total cost of ownership on

the market. C2 calibration saves time during

commissioning and replacement, rem ov es per

sonnel from processing areas, and keeps your

process cleaner by eliminating the need for

potentially contaminated test weights.

The Hardy HI BS300 Series is a Hardy’s lowest

cost stainless steel industrial scale, built to han

dle light wash down and humid environments.

Each bench scale is equipped with an FM

approved IP67 aluminum load cell, and comes

with NTEP (pending) certifications standard. The

HI BS300 does not come with C2.

-

-

-

200 Series – HIBS200-xxxx

1-2

The HI BS200 Series is Hardy’s lowest cost

industrial scale, featuring a painted carbon steel

base and IP67 aluminum load cell made for use

in dry and dusty environments. Each aluminum

load cell is FM approved, and the HI BS200

comes with NTEP (pending) certifications stan

dard. The HI BS200 does not come with C2.

-

Page 6

CHAPTER 2 - SPECIFICATIONS

Hardy Bench Scale Specifications

Platter Construction

• 304 Stainless Steel (all models)

• Size: 12" x 12", 18" x 18" and 24" x 24

(custom sizes are available)

Deck Height

• 12" x 12": 5, 25, 50, 150 lbs: 3.75" to 4.5"

(9.5 to 11.4 cm) adjustable

• 18" x 18": 50, 25, 50, 150 lb

(

9.5 to 11.4 cm) adjustable

• 18 x 18": 300, 500 lbs: 5.5" x 6.5" (14 to 16.5

cm) adjustable

• 24" x 24": all capacities 5.5" x 6.5" (14 to

16.5 cm) adjustable

Capacity Range

5 lbs to 1000 lbs (2.27 to 454 kg)

Rated Output

Overload: 300% R.O.

End loading: 100% R.O.

Corner loading: 100% R.O.

Chapter 2 - Specifications

s: 3.75" to 4.5"

Cable Length

Platform to Instrument - 9 to 10 feet nominal (3

meters)

Base Construction

HIBS400 & HIBS300: Stainless Steel

HIBS200: Painted Carbon Steel

Load Sensors

HIBS400:

•C2® stainless steel, hermetically sealed

• Load Sensor Sensitivity: 2.0mV/V +/- 5%

(for longer cable lengths, contact the Factory)

IP68/IP69K

2-1

Page 7

Hardy Bench Scales

HIBS300 & HIBS200:

• Aluminum, environmentally potted,

• Load Sensor sensitivity: 2.0 +/- 0.2 mV/V

Resolution

5000 divisions of scale capacity

ccuracy

A

Combined Error: 0.02%

Temperature

Operating: -10 to +40 degrees celsius

Storage: -20 to +65 degrees celsius

Warranty

Two year limited warranty

Approvals

NTEP (HIBS300 and HIBS200 Only) Pending

FM IS Hazardous Class I, Div 1 Load Cell

Shipping Weight

12" x 12": 38 lbs (17.2 kg)

18" x 18": 59 lbs (26.8 kg)

24" x 24": 104 lbs (47.2 kg)

IP67

Standard Sizes & Capacities

2-2

Page 8

Chapter 3 - Installation

CHAPTER 3 - INSTALLATION

Precautions Do not store or operate the scale out of its spec-

ified temperature range. (See Temperature

Ranges in Chapter 2)

Do not store other equipment on the scale when

it is not in use or in storage.

Do not allow a build-up of debris on, around or

under the scale.

Do not set the scale in water or allow water to

settle around the scale. Provide Proper drainage.

Do not allow static or other electrical discharges

through the scale.

Do not try to repair the scale. Contact Hardy

Process Solutions T echnical Su pport Department

for any and all repairs.

Unpacking Hardy Bench scales are shipped fully assembled

and only require adjustment of the overload

stops and adjustment of the leveling feet. If there

is any damage to the shipping container or to the

scale, save all the packaging material and file a

report with the shipper.

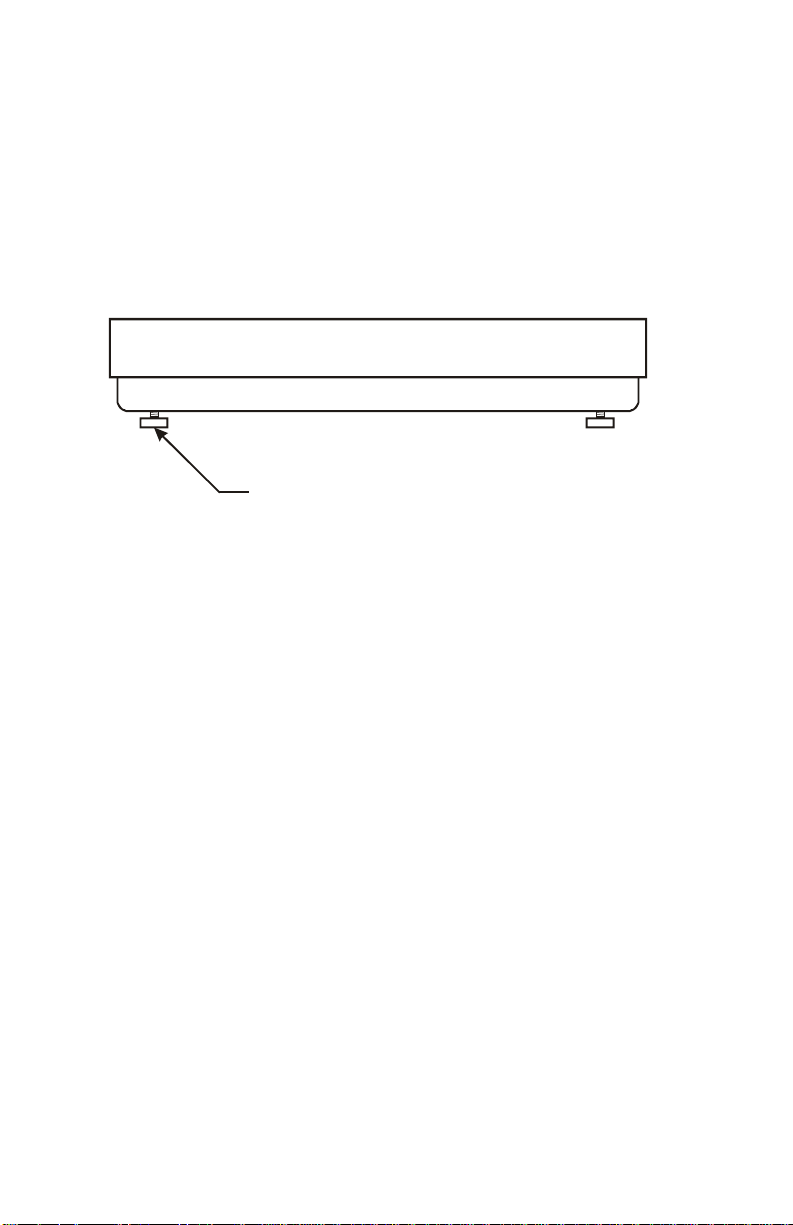

Adjusting the Mechanical Overload Stops

There is a bolt in each corner of the frame that is

fully engaged for shipping protection. Each

should be adjusted to allow the load cell to

deflect to its maximum deflection distance, but

no further.

3-1

Page 9

Hardy Bench Scales

Maximum Deflection at Capacity: HI BS400

HISPB1 Load Sensor (24” x 24”)

Capacity Deflection (mm)

50 kg 0.22

100 kg 0.20

250 kg 0.10

500 kg 0.25

HISP6 Load Sensor (12” x 12” and 18” x 18”)

Capacity Deflection (mm)

10 kg 0.17

20 kg 0.22

50 kg 0.22

3-2

100 kg 0.22

200 kg 0.25

Maximum Deflection at Capacity: HI BS300 &

HI BS200

1250 Load Sensor (24” x 24”)

Capacity Deflection (mm)

50 kg <0.40

100 kg <0.40

250 kg <0.40

500 kg <0.40

Page 10

Chapter 3 - Installation

1042 Load Sensor (12” x 12” and 18” x 18”)

Capacity Deflection (mm)

10 kg <0.40

20 kg <0.40

50 kg <0.40

100 kg <0.40

200 kg <0.40

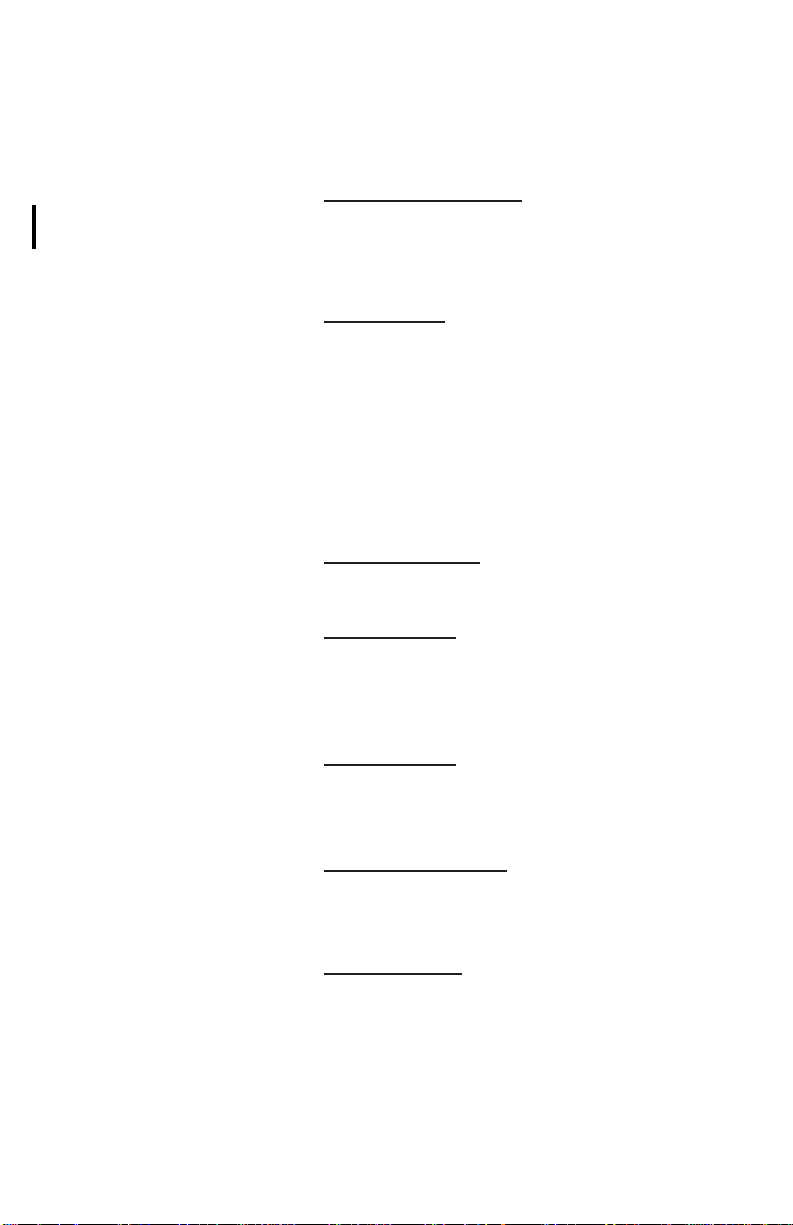

Leveling the Scale Step 1. The Hardy Bench Scales come with an

integrated leveling indicator at the front

of the base. (See Fig. 3-1). Remove

the top cover and locate the indicator

at the center of the front of the scale

base.

FIG. 3-1 LEVELING INDICATOR

3-3

Page 11

Hardy Bench Scales

Leveling

Foot

Step 2. To level the platform, turn the leveling

feet clockwise to lower the scale cor

ner, or co unter clockwise to raise it

until you show a level reading by cen

tering the bubble in the center of the

indicator.

4 Places

FIG. 3-2 LEVELING FEET

-

-

Scale Connections To connect the scale, you must first remove the

cover, unr oll the ca ble and run th e cab le thr oug h

the hole in the back of the unit. Replace the

cover.

3-4

Page 12

Chapter 3 - Installation

FIG. 3-3 RUNNING CABLE THROUGH HOLE IN BACK

(12”X12” OR 18” X18” INCH SCALE)

FIG. 3-4 HOLE FOR THE CABLE IS AT THE BACK

OF THE INSIDE OF A 24” X 24” SCALE

3-5

Page 13

Hardy Bench Scales

Make sure the cable is not pinched and is clear

of the feet. The Bench Scale requires a recom

mended DC or AC excitation voltage of 5 volts

with a maximum of 15 volts. Wire the Scale cable

to an instrument or indicator following the color

code label found on the cable.

For HI BS200 and HI BS300 Scale Models:

+ Excitation Green

- Excitation Black

+ Sense Blue

- Sense Brown

+ Signal Red

- Signal White

Shield Bare

For HI BS400 Scale Models with C2 Electronic

Calibration:

+ Excitation Red

- Excitation Black

+ Signal Green

- Signal White

+ C2 Gray

- C2 Violet

Shield Yellow or Bare

-

WARNING USE CAUTION WHEN WIRING. MAKE SURE

TO DISCONNECT ALL POWER TO THE

SCALE. FAILURE TO REMOVE POWER CAN

RESULT IN SCALE OR INSTRUMENT DAM

AGE, DEGRADATION OF PERFORMANCE OR

PERSONAL INJURY

NOTE: Hardy Process Solutions provides drawings you

may download on the Hardy Bench Scales page

under the Docs & Programs tab. Drawings are

provided for each of the Hardy Bench Scale

models in .dxf, dwg, .pdf, and 3D formats. These

drawings include the wiring configurations.

3-6

-

Page 14

Chapter 3 - Installation

FIG. 3-5 EXPLODED VIEW OF 12” X 12” OR

18” X 18” SCALE SHOWING SELECTED PARTS

3-7

Page 15

Hardy Bench Scales

3-8

FIG. 3-6 EXPLODED VIEW OF 24” X 24” SCALE

SHOWING SELECTED PARTS

Page 16

CHAPTER 4 - CALIBRATION

Chapter 4 - Calibration

About Calibration of the Hardy Bench Scale

C2 Second Generation Calibration

NOTE: Hardy C2 calibration is only available in the

Test Weight Calibration (Hard Cal)

The Hardy Bench Scales come calibrated from

the factory . Make sure the scale is correctly wired

to the weighing instrument or indicator. Refer to

the weighing instrument or indicator manual for

calibration instructions.

C2 electronically calibrates a scale system without the need for test weights. If you are using a

Hardy Process Solutions Weight Controller,

Weight Processor , Indicator or W eigh Module, all

that’s required is to enter a reference point. Re fer

to the instrument or module manual for calibra

tion instructions using C2/

HI BS400 model as a standard feature.

This is the traditional means of calibration requiring certified class F test weights equal to a minimum of 80% of the rated scale capacity.

Three weights between 10% and 100% of the

scale capacity should be available to check the

mid-range. Several low capacity weights equiva

lent to one or two instrument divisions are necessary to check the system sensitivity.

-

-

NOTE: Traditional Calibration is required for the HI

BS200 and HI BS300 models because they do

not come with C2 load cells.

Material Substitution When certified test weights are not available you

can use an accurately weighed material to cali

brate the system. In this method, a material is

weighed on a secondary, calibrated scale and

delivered to the site of the scale to be calibrated.

The secondary calibrated scale should be of the

same accuracy or greater and have a capacity

approximately equal to the scale being cali

brated.

-

-

4-1

Page 17

Chapter 5- Troubleshooting

CHAPTER 5- TROUBLESHOOTING

SCOPE All the information in Chapter 5 pertains to the

troubleshooting and resolution of operating prob

lems that may occur. All maintenance personnel

and users should be familiar with both Chapters

3 and 4 before attempting to troubleshoot prob

lems with the Scale.

Problem:

-

-

Scale Does Not Respond When Weight is Applied

Scale Indication is not linear

Scale Reads Backwards

Step 1. Make sure the scale is wired correctly

to the instrument or network and there

are no breaks in the wiring.

Step 2. Check to see if there is packing mate-

rial or debris wedged under or against

the scale.

Step 3. Make sure the corner mechanical

overload stops are not engaged with

the platform. Lower as necessary.

Step 1. Check the instrument for proper cali-

bration.

Step 2. Check to see if there is packing mate-

rial or debris wedged under or on the

side of the scale.

Step 3. Make sure the corner mechanical

overload stops are not engaged with

the platform. Lower as necessary.

Step 4. Make sure all electrical connections

are tight with no corrosion and that

there has not been an ingress of mois

ture to the system.

Step 1. Check for correct wiring to the instru-

ment. The +- signal or excitation wires

may be reversed.

-

Scale Reading drifts or is Erratic

Step 1. Make sure all electrical connections

are tight with no corrosion and that

there has not been an ingress of mois

ture to the system.

-

5-1

Page 18

Hardy Bench Scales

Step 2. Make sure the corner mechanical

overload stops are not engaged with

the platform. Lower as necessary.

Step 3. Verify that the instrument or network is

operating properly.

Step 4. Make sure there are no high voltage

wires close to the scale.

Step 5. Check that the scale and instrument

are properly grounded.

Step 6. If high static electricity is present a

ground strap should be added from the

top cover to the chassis and to earth

ground.

Service and Repair (All Models)

For Service and Repairs, contact your local

Hardy Representative.

Before returning any product to Hardy Process

Solutions, please contact the Hardy Service Cen

ter for a return authorization number. Please

have the scale model number and a serial num

ber and a brief description of the problem ready

when you call.

Technical Support

Hardy Process Solutions

9440 Carroll Park Drive

San Diego, California 92121

US Customers Only: 800-821-5831

Outside the US: 858-278-2900

-

-

5-2

Loading...

Loading...