Page 1

HI WS100 CONFIGURATION SOFTWARE

OPERATION AND INSTALLATION

MANUAL

Corporate Headquarters

3860 Calle Fortunada

San Diego, CA 92123-1825

Phone: (858) 278-2900

FAX: (858) 278-6700

Web-Site: http://www.hardyinst.com

Hardy Instruments Document Number: 0596-0241-01 REV A-1

Copyright November 1999 H ard y Inst ruments, Inc. All Rights Reserved . Printed in the U.S.A. (941028)

Page 2

1-2

Page 3

Table of Contents

Table of Contents

TABLE OF CONTENTS - - - - - - - - - - - - - - - - - - - - - -I

TABLE OF ILLUSTRATIONS - - - - - - - - - - - - - - - - - - -I

CHAPTER 1 - OVERVIEW - - - - - - - - - - - - - - - - - - - - -1-1

A Brief Description of Chapter 1 - - - - - - - - - - - - - - - - - -1-1

About Hardy Manuals - - - - - - - - - - - - - - - - - - - - - - -1-2

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-2

C2® Calibration - - - - - - - - - - - - - - - - - - - - - - - - - -1-3

IT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-3

Weighing System Tests - Optional - - - - - - - - - - - - - - -1-4

CHAPTER 2 - REQUIREMENTS - - - - - - - - - - - - - - - - - -2-1

General Introduction to Chapter 2 - - - - - - - - - - - - - - - - -2-1

Operating System Requirements - - - - - - - - - - - - - - - - - -2-1

Minimum Hardware Requirements - - - - - - - - - - - - - - - - -2-1

Software Requirements - - - - - - - - - - - - - - - - - - - - - -2-1

RSLogix OR EQUAL (FOR REMOTE MODE OPERATION ONLY) -2-1

CHAPTER 3 - INSTALLATION - - - - - - - - - - - - - - - - - - -3-1

Installing the Hardy Instruments Configuration Software - - - - - - -3-1

Installation of RSLOGIX - - - - - - - - - - - - - - - - - - - - - -3-1

Installation of RSLINX or RSLINX Lite - - - - - - - - - - - - - - -3-1

Wiring Diagram for the HI 215IT Junction Box - - - - - - - - -3-2

CHAPTER 4 - SETUP - - - - - - - - - - - - - - - - - - - - - - -4-1

A Brief Description of Chapter 4 - - - - - - - - - - - - - - - - - -4-1

Presetup Procedures - - - - - - - - - - - - - - - - - - - - - - - -4-1

Setup Procedures - - - - - - - - - - - - - - - - - - - - - - - - -4-3

Comm Setup for SLC Models (Except SLC 5/02) - - - - - - - -4-3

Comm Setup for the SLC 5/02 - - - - - - - - - - - - - - - - -4-5

Comm Setup for the HI 1746WS Remote Rack - - - - - - - - -4-7

i

Page 4

HI WS100 CONFIGURATION SOFTWARE

CHAPTER 5 - OPERATING PROCEDURES - - - - - - - - - - - -5-1

A Brief Description of Chapter 5 - - - - - - - - - - - - - - - - - -5-1

Reading Live Weight, - - - - - - - - - - - - - - - - - - - - - - -5-1

Taring the HI 1746-WS - - - - - - - - - - - - - - - - - - - - -5-1

Zeroing HI 1746-WS - - - - - - - - - - - - - - - - - - - - - -5-2

Relay 1 and Relay Status - - - - - - - - - - - - - - - - - - -5-2

Setting the ROC Units - - - - - - - - - - - - - - - - - - - - -5-2

Errors - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-2

Calibration Procedures - - - - - - - - - - - - - - - - - - - - - - -5-2

C2 Calibration - - - - - - - - - - - - - - - - - - - - - - - - -5-2

Hard Calibration Procedures - - - - - - - - - - - - - - - - - -5-3

Soft Calibration - - - - - - - - - - - - - - - - - - - - - - - -5-4

Setting Parameters - - - - - - - - - - - - - - - - - - - - - - - - -5-5

Set Point Setup Procedures - - - - - - - - - - - - - - - - - - - -5-8

About Set Points - - - - - - - - - - - - - - - - - - - - - - - -5-8

Three General Rules for Set Points - - - - - - - - - - - - - - -5-8

Reading C2 Load Cell Serial Numbers - - - - - - - - - - - - - - -5-9

Remote Screen - - - - - - - - - - - - - - - - - - - - - - - - - -5-10

CHAPTER 6 - TROUBLESHOOTING - - - - - - - - - - - - - - -6-1

A Brief Description of Chapter 6 - - - - - - - - - - - - - - - - - -6-1

IT Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - -6-1

ii

Page 5

Table of Illustrations

Table of Illustrations

CHAPTER 3 - INSTALLATION - - - - - - - - - - - - - - - - - - -3-1

FIG. 3-1 C2 LOAD CELL CONNECTION/HI 215IT

JUNCTION BOX - - - - - - - - - - - - - - - - - - - - -3-2

FIG. 3-2 NON C2 LOAD CELL CONNECTION/HI 215IT

JUNCTION BOX - - - - - - - - - - - - - - - - - - - - -3-3

CHAPTER 4 - SETUP - - - - - - - - - - - - - - - - - - - - - - -4-1

FIG. 4-1 INTRO PAGE - - - - - - - - - - - - - - - - - - - - - -4-3

FIG. 4-2 COMM SETUP - - - - - - - - - - - - - - - - - - - - - -4-4

FIG. 4-3 REMOTE SELECTED/ENTER FILE#, STARTING WORD -4-5

FIG. 4-4 SAMPLE OF REQUIRED LADDER LOGIC

FOR INTEGER TYPE FILES SLC 5/02 - - - - - - - - - -4-6

FIG. 4-5 CHECKING “USE INTEGER FILE. . . “/SLC 5/02 - - - - -4-7

FIG. 4-6 HI 1746WS REMOTE RACK LADDER LOGIC - - - - - -4-11

CHAPTER 5 - OPERATING PROCEDURES - - - - - - - - - - - -5-1

FIG. 5-1 LIVE WEIGHT PAGE - - - - - - - - - - - - - - - - - - -5-1

FIG. 5-2 C2 CALIBRATION - - - - - - - - - - - - - - - - - - - -5-3

FIG. 5-3 HARD CALIBRATION - - - - - - - - - - - - - - - - - -5-4

FIG. 5-4 SOFT CALIBRATION - - - - - - - - - - - - - - - - - - -5-5

FIG. 5-5 PARAMETERS SETTINGS - - - - - - - - - - - - - - - -5-6

FIG. 5-6 SETPOINT SCREEN - - - - - - - - - - - - - - - - - - -5-8

FIG. 5-7 C2 SERIAL NUMBER SCREEN - - - - - - - - - - - - -5-10

FIG. 5-8 REMOTE DISPLAY - - - - - - - - - - - - - - - - - - - -5-11

CHAPTER 6 - TROUBLESHOOTING - - - - - - - - - - - - - - -6-1

FIG. 6-1 INTEGRATED TECHNICIAN TEST - - - - - - - - - - - -6-1

I

Page 6

CHAPTER 1 - OVERVIEW

Chapter 1 - Overview

A Brief Description of Chapter 1

This manual provides the user and service personnel

with a description of the specifications, installation,

setup, operation, communication procedures for the

Hardy Instrument’s HI 100WS Configuration Software to configure the HI 1746-WS Weigh Scale Mod-

ule, designed for use in Allen-Bradley’s SLC 5/02

©

,

5/03, 5/04, 5/05 programmable controllers. Chapter 1

provides a general intro duction to the HI WS 100 Co n-

figuration Software. The HI 100WS Software is C2

and I

NTEGRATED TECHNICIAN

(IT)® enabled. The HI

100WS Software i s desi gned t o run on th e W i ndows

®

®

95/98/NT/2000 platforms in conjunction with Allen-

©

Bradley’s RS Linx

gramming Software for Windows

or RS Linx Lite© Industrial Pro-

®

95/98/NT/2000.

To get the maximum service from this product, users

should operate this software in accordance with recommended practices either implied or expressed in

this manual. Before using the HI WS100 Software, all

users and maintenance personnel should read and

understand all cautions, warnings, and safety procedures, referenced or explicitly stated in this manual.

Hardy Instruments appreciates your business. Should

you not understand any information in this manual or

experience any problems with the product, please

contact our Customer Support Department at:

Phone: (858) 278-2900

FAX: (858) 278-6700

e-mail: support@hardyinst.com

Web Address: hardyinst.com

NOTE: C2

marks of Hardy Instruments Inc. Windows

®

, I

NTEGRATED TECHNICIAN

®

are registered trade-

®

is a regis-

tered trademark of the Microsoft Corporation.

©

RSLinx

and RSLinx Lite© SLC 500©are registered

trademarks of the Rockwell Corporation.

NOTE: Hardy Instru m ent s bas es all procedures on the

assumption that th e us er has an adequate underst an d-

1-1

Page 7

HI WS100 CONFIGURATION SOFTWARE

ing of all Allen-Bradley SLC 500 products. In addition the user should understand process control and

be able to interpret ladder logic instructions necessary to generate the electronic signals that control

your application(s).

About Hardy Manuals Every Hardy Installation and Operation manual is

organized into easily referenced chapters, that are

almost always the same:

• Chapter 1 - Provides an introduction to the

instrument and an Overview of the equipment and its capabilities.

• Chapter 2 - Provides a complete list of

Specifications.

• Chapter 3 - Contains information needed to

install the HI 1746-WS (both standard and

optional equipment) and the HI 215IT series

Junction Box.

• Chapter 4 - Provides complete hardware

Configuration instructions for setting dip

switches and jumpers.

• Chapter 5 - Pertains to the firmware/soft-

ware Setup and preparation procedures to

calibrate and operate the instrument.

• Chapter 6 - Provides all Calibration

instructions.

• Chapter 7 - Pertains to the Operating Pro-

cedures of the HI 1746-WS.

• Chapter 8 - Pertains to the Troubleshoot-

ing procedures for repair of the instrument.

Hardy Instruments hopes that this manual meets your

needs for information and operation. All corrections

or suggestions for improvements of this manual are

welcome and can be sent to the Technical Publications Department or Cust omer Supp ort De partment at

Hardy Instruments Inc.

Description The HI WS100 Configuration Software is a program

that enables the user to configure a remote HI 1746WS Weigh Scale Module. The HI 1746-WS Weigh

Scale Module is a self contained microprocessor

based I/O module with control inputs and outputs, that

is designed to be eas ily plu gged int o the back plan e of

1-2

Page 8

Chapter 1 - Overview

an Allen-Bra dley SLC 5/02, 5/03, 5/04 or 5/05 programmable controller and/or Remote Rack. The HI

100WS is IT enabled which means you can perform

the I

NTEGRATED TECHNICIAN

®

C2

Calibration C2 Second Generation Calibration enables a scale

(IT) Tests.

system to be calibrated electronically without using

certified test weights which equal the systems load

capacity. A C2 weighing system consists of up to

eight (8) C2 load sensors, a junction box, interconnect

cable and an instrument with C2 capabilities such as

the HI 1746-WS Weight Scale Module. All Hardy

Instruments C2 certified load sensors contain digital

information detailing its unique performance characteristics. If the system is fitted with C2 type load cells

the HI WS100 software displays the serial numbers

programmed into each load cell. From the serial numbers the operator can look up the parameters of each

loadcell by going to the Hardy Instruments Internet

Site. http://www.hardyinst.com

IT I

®

NTEGRATED TECHNICIAN

is a system diagnostics

utility which continuously monitors the weighing system (with up to 4 load sensors) for possible malfunctions. For full functionality the HI 215IT junction box

(J Box) should be used. Full IT functionality allows

the operator to rapidly troubleshoot a weighing system from the HI 100WS Configuration Software,

Parameters Edit Display. The test are:

• Loadcell Impedance - The user can see the

impedance determined at calibration (Base

R), the impedance found during the test

(Read R), and the test result (Good or Bad).

also shown are the volts at the loadcells at

calibration (Sense V), and the current going

to the load cells at the time of the reading.

• RTZ - (Return to Zero) This test gives a

pass/fail on whether there is a zero load. If

you have a “J Box”, indi vidual load cell s can

be tested. If you do not have a :”J Box” the

test is done on the combined loadcells.

1-3

Page 9

HI WS100 CONFIGURATION SOFTWARE

• DVM - (Digital Volt Meter) If you have a “J

Box”, the voltage outputs from the individual loadcells can be read. If you do not have

a “J Box” the voltage is a combined voltage

output from all loadcells in the system.

• System Test - If you have a “J Box” you

can read the weight being read on individual

load cells and the internal reference.

Weighing System Tests - Optional

Requires the HI 215IT Junction Box. This te st i s u sed

to diagnose drifting or unstable weight reading problems. The Weighing System Test does the following:

1. Disconnects the controller and engages an internal reference signal to see if the problem is within

the instrument.

1. Disconnects the load sensors and engages an

internal (in the junction box) reference signal to

see if the cable between the instrument and the

Junction Box is causing the problem.

2. Reads the weight of each load sensor to s ee if the

load sensor might be causing the problem.

The ability to read the weight seen by each individual

load sensor allows use of this test to make cornering,

leveling and load sharing adjustment s to the weighing

system.

1-4

Page 10

CHAPTER 2 - REQUIREMENTS

Chapter 2 - Requirements

General Introduction to Chapter 2

Operating System Requirements

Minimum Hardware Requirements

All the information in Chapter 2 pertains to the hardware and software requirements for HI WS100 Configuration Software. These requirements are the

minimum requirements for loading and operating HI

WS100 Configuration Software. Check to see if the

personal computer on which you want to install HI

WS100 Configuration Software, meets these requirements. It is very important that the user be familiar

with this section before installing or operating this

software.

HI WS100 Configuration Software runs on the following operating systems:

• Windows NT 4.0/2000

• Windows 95/98

HI WS100 Configuration Software requires

the following hardware:

• CPU - Pentium® 133 MHz or better

• 3 MB free space on your hard drive

•RAM - 16 MB

• Monitors - SVGA, configured for 640 x 480

resolution or better

• Floppy Drive - 3.5”, 1.44 MB drive or better

NOTE: The HI WS100 must run in conjunction with Allen

Bradley’s RS LINX or RS LINX LITE therefore the HI

WS100 hardware requirements are in addition to

hardware requirements for RS LINX or RS LINX

LITE.

Software Requirements

RSLogix OR EQUAL (FOR REMOTE MODE OPERATION ONLY)

NOTE: RSLOGIX

Allen Bradley’s RS LINX

ware.

Allen Bradley’s RSLOGIX

Corporation.

®

is a registered trademark of the Rockwell

®

or RS LINX® LITE soft-

®

software or equivalent.

2-1

Page 11

HI WS100 CONFIGURATION SOFTWARE

2-2

Page 12

CHAPTER 3 - INSTALLATION

Chapter 3 - Installation

Installing the Hardy Instruments Configuration Software

Contact your local Hardy Representative or Hardy

Instruments Sales Department for information about

how to purchase the Hard y WS 100 Configuration

Software for Windows.

Step 1. The SETUP program copies the required

files to your hard disk.

Step 2. Run Windows NT/95/98/2000 and insert

the Configuration Installation System Disk

into the 3.5” floppy drive.

Step 3. Click on START.

Step 4. Click on Run.

Step 5. In the Run field type the command:

a:setup. If your floppy drive is drive b

enter: b:setup.

Step 6. Press the Enter key.

Step 7. You can also use the Add/Remove Func-

tion in the Control Panel dialogue box.

1 Click on Start

1 Move the cursor to Settings.

1 Select Control Panel.

Installation of RSLOGIX

Installation of RSLINX or RSLINX Lite

1 Double click on the Add/Remove Programs

icon.

1 Click on the Install button.

Step 8. The SETUP program will lead you

through the installation pro cess .

Please refer to your Allen Bradley Installation and

Operation manual for instructions.

Please refer to your Allen Bradley Installation and

Operation manual for instructions.

3-1

Page 13

HI WS100 CONFIGURATION SOFTWARE

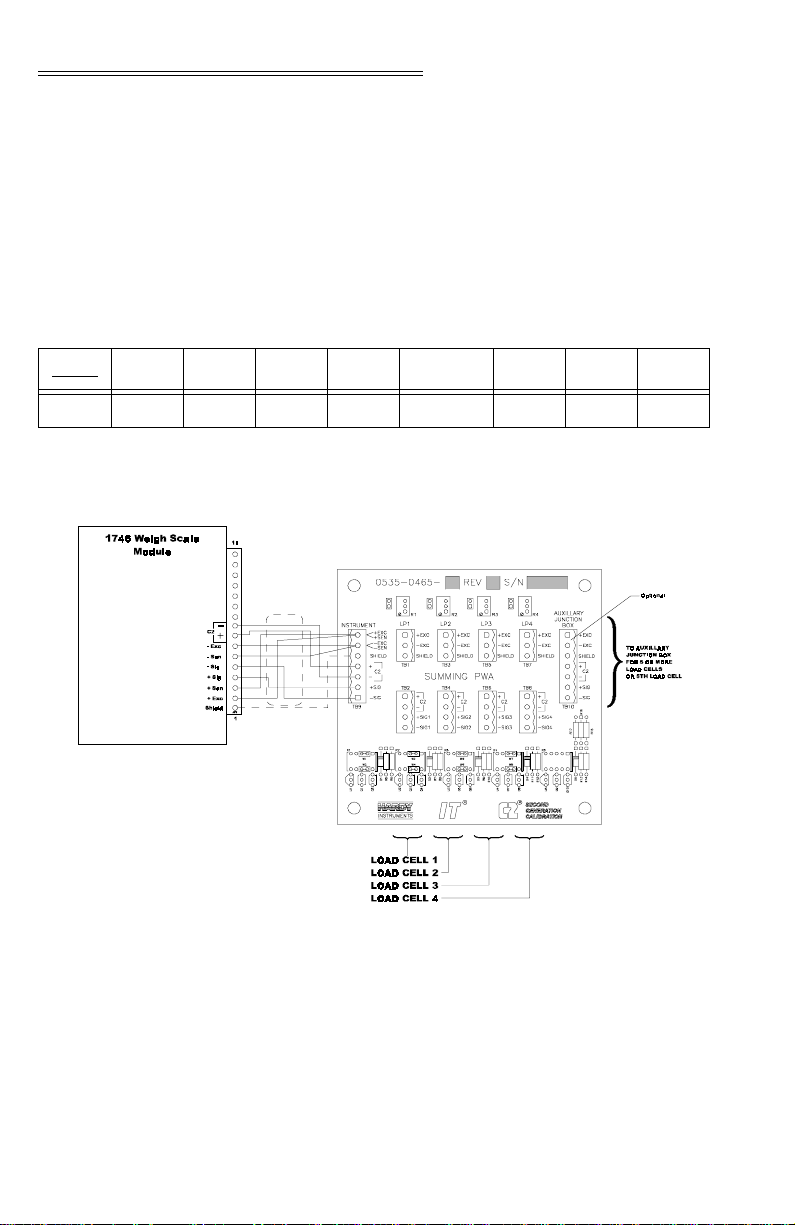

Wiring Diagram for the HI 215IT Junction Box

C2 Loadcell

Cable

Connection

When connecting the HI 215IT Junction box using C2

loadcell/point cable (6020-0001) use the following

color code:

(J1)

Model EXC + SEN + SIG + SIG - SEN - EXC - C2 + C2 -

J-BOX RED B LUE GRN WHT BRWN BLK GREY VIO

Table 1: C2 CABLE COLOR CODE/HI 215IT J-BOX

FIG. 3-1 C2 LOAD CELL CONNECTION/HI 215IT JUNCTION BOX

1 Recommended load cell cable, Hardy Instru-

ments (Prt. #6020-0001)

2 Attach the load shield to the terminal block

mounted next to the J1 connector on the HI

200DNWM Module.

3-2

Page 14

Chapter 3 - Installation

3 Do not run load cell cable in parallel with or

in the same conduit with power w iring, relay

cables or any other high energy cables.

4 Remove the factory installed jumpers for C2

wire load cell connection.

5 IT summing Card (Prt. #0535-0465)

Non-C2 Loadcell Cable Connection (J1)

1 Attach the load cell cable to the terminal

block mounted next to the J1 connector on

the HI 200DNWM Module.

2 Factory installed jumpers to remain in place

for 4 wire load cell connection.

3 Do not run load cell cable in parallel with or

in the same conduit with power w iring, relay

cables or any other high energy cables.

4 Eight (8) conductor load cell cable required

when:

• Cable runs are greater than 50 feet.

• With Soft Calibration

FIG. 3-2 NON C2 LOAD CELL CONNECTION/HI 215IT JUNCTION BOX

3-3

Page 15

HI WS100 CONFIGURATION SOFTWARE

3-4

Page 16

CHAPTER 4 - SETUP

Chapter 4 - Setup

A Brief Description of Chapter 4

Presetup Procedures Step 1. Make sure that the HI 1746-WS is

All information contained in Chapter 4 pertains to

firmware and software settings to prepare the HI

1746WS Weight Module controller for calibration

and operation. Alternatives to these procedures

explicit or implied, contained in this section are not

recommended. It is very important that the user and

service personnel be familiar with the pro cedures co ntained in this chapter, before going through the setup

procedures. The Setup procedures require either

Allen-Bradley DOS PLC 5 00 AI Se ries Ladder Logic

Editor*, or Allen-Bradley RSLogix 500* and AllenBradley RSLinx™ or RSLinx™ Lite.

installed in the rack correctly.

Step 2. Make sure that the HI 1746-WS has been

setup correctly and that all data necessary

to run the HI 1746-WS module has been

entered into RSLogix 500 configuration

software.

Step 3. Check the module ID code to verify that

the jumper has been set for the proper

mode of operation (Local ID Code =

13635, Remote ID Code = 3235). If you

have put the HI 1746-WS module in a

local rack and get the 3235 ID number the

jumper is set incorrectly.

Step 4. If you have set the jumper for the HI 1746-

WS module for local mode of operation

and placed the module in a rem ote rack the

1747 ASB will display an invalid module

error.

Step 5. If these errors occur, remove the HI 1746-

WS and reset the jumper to the proper

mode of operation. (See the HI 1746-WS

Weigh Module Installation and Operation

Manual (Prt. #0596-0234-01), Chapter 3,

Page 3-2 for instructions)

Step 6. Reinstall the module.

Step 7. Repeat Steps 3 & 4.

4-1

Page 17

HI WS100 CONFIGURATION SOFTWARE

NOTE: If you are using RSLogix 500, the HI 1746-WS (in

local mode) is configured as an “Other” card with an

I/O module ID code of 13 635, M0 and M1 le ngth s are

128.

NOTE: If you are using RSLogix 500, the HI 1746-WS (in

remote mode) is configured as an “Other” card with

an I/O module ID code of 3235, with two input words

and two output words. In remote mode the HI 1746WS has no M files. Instead, it has files inside that correspond to the 32 word I and O files of the local mode

HI 1746-WS, and to its M files. These files are called

“logical” files, meaning that they perform the function of the I,O, and M files in the local mode but are

not directly accessible through the SLC backplane.

Step 8. Double click on the HI WS100 Icon on

your Windows Desktop. The HI WS100

will automatically launch RSLinx.

NOTE: If you are st arting HI WS10 0 for the first time you will

get a “Communi cation Failure” message. Don’t

worry about this message at this time. The Comm

Setup has not been configured yet. Once the HI

WS100 has been configured correctly the “Communication Failure” message goes away.

4-2

Step 9. The Intro Sheet displays with the setup

instructions in a text field. (See Fig. 4-1)

Scroll through the Text field and read the

instructions for setting up the HI 100WS

Configuration Softwar e before star ting th e

setup procedures.

Page 18

Setup Procedures

Chapter 4 - Setup

FIG. 4-1 INTRO PAGE

Comm Setup for SLC Models (Except SLC 5/02)

Step 1. Click on the Comm Setup Tab. The Comm

Setup Page appears. (See Fig 4-2)

4-3

Page 19

HI WS100 CONFIGURATION SOFTWARE

FIG. 4-2 COMM SETUP

Step 2. Enter the SLC slot number of the installed

HI 1746-WS Weigh Module in the Slot

textfield.

Step 3. Enter the Station number of your SLC in

the Station textfield. This number must be

an Octal number for the Station number.

Step 4. Select a driver (supplied by RSLinx) by

clicking on the down arrow on the

“Driver” pull down menu. Click on the

driver you want to use to communicate

with the HI 1746-WS.

CAUTION:

4-4

DO NOT CLICK IN THE CHECK BOX NEXT TO

THE “USE DTSA.TXT FILE”.

Step 5. If the HI 1746-WS module is installed in a

remote rack, click in the check box next to

the word “Remote?”. (See Fig. 4-3)

Page 20

Chapter 4 - Setup

FIG. 4-3 REMOTE SELECTED/ENTER FILE#, STARTING WORD

Step 6. Enter the integer number used in the Lad-

der Logic for remote operation of the HI

1746-WS Weigh Module in the textfield

next to “File#”. In our example we entered

the number 7.

Step 7. Enter the starting number us in the Ladder

Logic for remote operation of the HI 1746-

WS Weigh Module in the textfield next to

“starting word”.

Step 8. Click on the Save button to save the set-

tings.

Comm Setup for the SLC 5/02

Normally the HI WS100 talks to the HI 1746-WS via

the “M Files”. The SLC 5/ 02 does not su pport communication commands for direct reading and writing

of M Files. The SLC 5/02 suppor ts comm ands to read

and write “integer” type files.

Step 1. Write the ladder logic provided (See Fig.

4-4) to copy the integer file to the HI

12746-WAS’s M files. The ladder logic

4-5

Page 21

HI WS100 CONFIGURATION SOFTWARE

enables the HI 1746-WS to read the information in the integer file.

FIG. 4-4 SAMPLE OF REQUIRED LADDER LOGIC FOR INTEGER TYPE

FILES SLC 5/02

NOTE: Our example has the HI 1746-WS weigh module

located in slot #3 of the SLC and the integer file #9

(N9) is chosen with the starting word = 0.

Step 2. Click in the check box next to the “Use

integer file (required by 5/02, needs ladder

logic support)”. (See Fig. 4-5) The program will write to the specified integer file

number (7,8,9, etc. for N7, N8, N9,. . .)

starting at the specified offset (starting

word) within that file. The program

4-6

Page 22

Chapter 4 - Setup

requires a total of 43 integer words: 21 for

the M0 file, 21 for the M1 file, and 1 as a

flag.

FIG. 4-5 CHECKING “USE INTEGER FILE. . . “/SLC 5/02

Comm Setup for the HI 1746WS Remote Rack

Legend

The ladder logic example below must be running so

that the WS100 Configuration Software will work

with the 1746 module installed in a Remote Rack. The

addresses shown in the ladder logic example are arbitrary locations. If the file is added to an existing program, these address locations can be changed for the

system to insure there are no conflicts. The color coding of the locations is as follows:

Green: Slot # for scanner module in local

rack and portion of the M file to be

used.

Yellow: Integer files used for data defining

the M file, (read/write, length,

address). Also status/error bits pertaining to the transfers of data.

4-7

Page 23

HI WS100 CONFIGURATION SOFTWARE

Pink: Integer file specified in the WS 100

program COMM SETUP screen

that it will use to read/write data.

The WS 100 Configuration Program also specifies the starting

word in this file. The WS 100 will

17 words starting at the specified

word of th e file. The first word is

used as a trigger to start the write

process. Words 2-9 are the write

data, and words 10-17 are the read

data.

No Color: Status bits used for pro-

gram control.

4-8

Page 24

Chapter 4 - Setup

4-9

Page 25

HI WS100 CONFIGURATION SOFTWARE

4-10

Page 26

Chapter 4 - Setup

FIG. 4-6 HI 1746WS REMOTE RACK LADDER LOGIC

4-11

Page 27

HI WS100 CONFIGURATION SOFTWARE

4-12

Page 28

Chapter 5 - Operating Procedures

CHAPTER 5 - OPERATING PROCEDURES

A Brief Description of Chapter 5

NOTE: The HI WS100 will not read non-C2 load cell serial

Reading Live Weight, Step 1. Click on the Live Weight Tab. The Live

All information contained in Chapter 5 pertains to the

operation of the HI WS100 Configurat ion Software.

The Operating Procedures include, Reading Live

Weight, Calibration, Creating or modifying Setpoint(s) Parameters, reading C2 load cell serial numbers and quickly monitoring Gross Wei ght (remot e

modules only) for the HI 1746-WS Weigh Module.

numbers.

Weight page appears. (See Fig. 5-1) The

Gross, Net and Tare weights are displayed.

In addition the Rate of Change (ROC) and

the ROC Units are displayed. Relay 1 and

Relay 2 status are displayed.

FIG. 5-1 LIVE WEIGHT PAGE

Taring the HI 1746-WS Step 2. To Tare the HI 1746-WS click on the Tare

button.

5-1

Page 29

HI WS100 CONFIGURATION SOFTWARE

Zeroing HI 1746WS

Relay 1 and Relay Status

Setting the ROC Units

Errors Step 6. The lights next to Motion, Excite Error, A/

Calibration Procedures

Step 3. To Zero the HI 17 46-WS click o n the Zero

button.

Step 4. The Relay 1 and Relay 2 status fields dis-

play only two values:

• Low = O voltage output

• High =5 volts output.

Step 5. Click on the radio button next to the unit

you want to use for the Rate of Change.

(Default is Minute)

D Conversion Error and A/D Convertor

Failure should all be green. A red light

indicates an error in the weight readings.

Step 1. Click on the Calibrate Tab. The Calibra-

tion page appears. (See Fig. 5-2)

Step 2. HI WS100 gives you three choices for

Calibration:

• C2 Calibration

• Hard Cali bration

• Soft Calibration

C2 Calibration Step 3. Click in the radio button next to C2. The

C2 Cal parameters appear. (See Fig. 5-2)

Step 4. Follow the instructions in the Text Area

Field for C2 Calibration. For additional

information consult your HI 1746-WS

manual (Prt. #0596-0234-01) Chapter 5 Calibration.

5-2

Page 30

Chapter 5 - Operating Procedures

FIG. 5-2 C2 CALIBRATION

Hard Calibration Procedures

Step 1. Click on the radio button n ext to Hard Cal-

ibration. The Hard Calibration parameters

appear. (See Fig. 5-3)

Step 2. Follow the instructions in the Text Area

Field for Hard Calibration. For additional

information consult your HI 1746-WS

manual (Prt. #0596-0234-01) Chapter 5 -

Calibration.

5-3

Page 31

HI WS100 CONFIGURATION SOFTWARE

FIG. 5-3 HARD CALIBRATION

Soft Calibration Step 1. Click on the radio button next to Soft Cali-

bration. The Soft Calibration parameters

appear. (See Fig. 5-4)

Step 2. Follow the instructions in the Text Area

Field for Soft Calibration. For additional

information consult your HI 1746-WS

manual (Prt. #0596-0234-01) Chapter 5 Calibration.

5-4

Page 32

Chapter 5 - Operating Procedures

FIG. 5-4 SOFT CALIBRATION

Setting Parameters Step 1. Click on the Parameter Tab. The Parame-

ter page appears. (See Fig. 5-5)

Step 2. Set the Tare weight - Double click in the

Tare Weight field and enter the Tare

Weight Value. The Tare Value is an artifi-

cial zeroing of the weight hopper so that a

new weight can be displayed. Also, the

action of ad j usting out the known weight

of the container from the total indicated

weight, so that the indicator reads net

weight directly. You must click in the

check box next to Tare Enabled to enable

the Tare Function.

Step 3. Set the Weight Unit of measure - The

Weight Unit of Measure can be set to

either kilograms or pounds. Any weight

value input to the module (e.g. CAL-LO,

CAL-HI setpoints) are in the currently

selected units. The unit of measure can be

set at any time, not just at calibration. Set-

ting the unit of measure before calibrating

reminds the user what unit of measure is

5-5

Page 33

HI WS100 CONFIGURATION SOFTWARE

being displayed. It is important to note that

the weigh scale module does not need to

be calibrated again after changing the unit

of measure.

Step 4. Set the WAVERSAVER level - There are

5 selectable levels. 0 provides the least

vibration immunity with the fastest

response time. 4 provides the most vibration immunity with the slowest response

time. The Default setting is 2. Click on the

pull down menu next to WAVERSAVER

and click on your selection.

5-6

FIG. 5-5 PARAMETERS SETTINGS

Step 5. Set the Number of Averages (NumAver-

ages) - Click on the up or down arrow to

reach the value you want or double click in

the field and enter the value. The range is

1-255. The Number of Averages sets the

number of weight readings which will be

used to compute the displayed weight. Th e

average is a sliding average so that a new

average reading is available for display at

every reading.

Page 34

Chapter 5 - Operating Procedures

Step 6. Set the ROCTimeBase - Click on the up

or down arrow to reach the value you want

or double click in the field and enter the

value. The Rate of Change Time Base is

the time period you want for weight sam-

pling to determine the Rate of Change,

either loss in weight or gain in weight. The

range is 1 - 1800 seconds.

Step 7. Set the Zero Tolerance - Double click in

the Zero T olerance field. The default value

is 10 units of measure. Ent er th e new Zer o

Tolerance value. The range is 1 to 32766.

Zero Tolerance sets the range of weights

so that the Zero Command works, as an

offset of the calibrate d Zero. Zero Toler-

ance is the number of graduations from

zero that will be accepted as zero by the

module. To enable Zero Tolerance click in

the check box next to “Zero Enabled” so

that a check mark is visible. The operator

can reset this value at any time.

Step 8. Set the Auto Zero Tolerance - The

default value is 10 units of measure. The

range is 1 to 32766.

• Double click in the Auto Zero Tolerance field.

• Enter a positive value that does not

exceed the maximum zero tolerance

value or is not a negative value.

• Click in the check box next to ”Zero

Track Enabled” to activate Auto

Zero Tolerance tracking.

• The Auto Zero Tolerance setting

automatically sets the Zero Tolerance so that the Zero Command

works, as an offset of the calibrated

Zero.

Step 9. Set the Motion Tolerance Value - Click

in the Motion T olerance field and enter the

motion value. The motion tolerance is the

tolerance value used to determine if the

scale is in motion. If the motion is outside

5-7

Page 35

HI WS100 CONFIGURATION SOFTWARE

the motion value entered, the light next to

Motion Tolerance will turn to red. When

the scale motion is within the tolerance the

light turns green.

Step 10. Click on the Save button to save the new

parameters.

Set Point Setup Procedures

About Set Points The set point value is the target we ight or level. It may

be set in net, gross or Rate of Change (ROC). When

the set point is reached a relay is energized or de-energized depending what you want the relays to do. The

HI 1746-WS has two output relays which can be s etup

in HI WS100 Configuration Software.

Step 1. Click on the Setpoint Tab. The Setpoint

page appears. (See Fig. 5-6)

Three General Rules for Set Points

5-8

FIG. 5-6 SETPOINT SCREEN

1. Set points activate at the set point plus the preact.

2. Set points deactivate at the set point plus the

deadband.

Page 36

Chapter 5 - Operating Procedures

3. The deadband should be numerically larger than

the preact to prevent relay chatter.

Step 2. Double click in the Value field.

Step 3. Enter the desir ed set point value.

Step 4. Double click in the Preact field.

Step 5. Enter the desired Preact value. Preact is

the number of units above or below the set

point value of which the relay will trip.

Use as an “in flight” compensation value.

Step 6. Double click in the Deadband field.

Step 7. Enter the desired Deadband value. Dead-

band is a value used to prevent relay chat-

ter once the setpoint is reached. You can

use positive or negative values. The nega-

tive value can be used as a low trip limit,

the positive value can be used as a high

trip limit.

Step 8. Click in the radio button next to the Set-

point Mode you want.

Step 9. Click in the radio button next to the Value

units you want to read the weight. Gross,

Net, or ROC.

Step 10. Click on the Save button to save the set-

tings.

Reading C2 Load Cell Serial Numbers

Step 1. Click on the C2 Tab. The C2 page

appears. (See Fig. 5-7)

Step 2. Go to the Hardy Internet Site (http://

www.hardyinst.com) where you can look

up the parameters of your load cell(s).

5-9

Page 37

HI WS100 CONFIGURATION SOFTWARE

FIG. 5-7 C2 SERIAL NUMBER SCREEN

Remote Screen Step 1. Click on the Remote Tab. The Remote

page appears. (See Fig. 5-8)

NOTE: The Remote Display will only appear if the HI 1746-

WS module is installed in a remote chassis, with the

jumper set to the remote mode of operation.

Step 2. The Remote screen is a quick way to mon-

itor gross weight of an HI 1746-WS module, installed in a remote chassis and

operating in the remote mode. This screen

gives the user a faster Gross Weight reading than the Live Weight display.

Step 3. The indicator lights for Motion, and A/D

Conversion and A/D Converter should all

be green in normal operation. A motion

red light means the scale exceeds the

Motion To lerance setting. A/D Conversion

and A/D Converter red lights means a malfunction.

5-10

Page 38

Chapter 5 - Operating Procedures

FIG. 5-8 REMOTE DISPLAY

5-11

Page 39

HI WS100 CONFIGURATION SOFTWARE

5-12

Page 40

CHAPTER 6 - TROUBLESHOOTING

Chapter 6 - Troubleshooting

A Brief Description of Chapter 6

Chapter 6 provides instructions on how to use Hardy

Instruments I

NTEGRATED TECHNICIAN

™ to perform

various tests for fault isolation troubleshooting of the

load cells in your weighing system. I

T

ECHNICIAN

used in conjunction with the HI 2215IT

NTEGRATED

Junction Box can tell you which load cell is not functioning properly, thereby eliminating the necessity of

having to physically go to the load cell for testing.

You can see from your PC desktop which cell is not

working properly.

IT Troubleshooting Step 1. Click on the Integrated Technician tab. the

Integrated Technician page appears. (See

Fig. 6-1)

FIG. 6-1 INTEGRATED TECHNICIAN TEST

Step 2. In the “Number of Sensors (JBox only)”

field you will see an up and down arrow. A

few things need to be said about this field.

• If you have all C2 load cells and an HI

215IT Junction Box, w hen y ou cal ibrate

6-1

Page 41

HI WS100 CONFIGURATION SOFTWARE

the instrument, HI WS100 automatically

loads the number of C2 load cells that

are incorporated in your weight system.

The number will automatically display

in the Number of Sensors field. Having

the HI 215IT Junction Box enables the

configuration software to list the test

results for each individual load cell in

your weighing system.

• If you have non-C2 load cells and an Hi

215JT Junction Box, then you need to

add the number of load cells in your system by clicking on the up or down

arrows or double clicking in the field

and typing the number, to enter the

number of load cells in your weight system. Having the HI 215IT Junction Box

enables the configuration software to list

the test results for each individual load

cell in your weighing system.

• If you do not have the HI 215IT Junction Box, the configuration software will

give you a combined test result of all the

load cells in your weighing system. (See

Fig. 6-1)

Step 3. Click on the Test b utton. After a seco nd or

two the results of the test will appear in the

fields. The tests are:

1. Loadcell Impedance

• Base R is the impedance at the

time of the last Calibration.

• Read R is the impedance reported

during the test.

• Test R indicates whether the cell

is good or bad.

NOTE: Keep in mind that if you have the HI 215IT Junction

Box the Tes t R result will appear for each load cell.

Therefore you will know exactly which load cell

failed. If you do not have an HI 215I T Jun c ti on i t wi ll

6-2

Page 42

Chapter 6 - Troubleshooting

give a combined fail result but not for the specific

load cell that failed. You will still have to determine

which Load Cell failed.

2. Return to Zero Test (RTZ) - This test

returns a pass/fail result on whether

there is a zero load.

• If you have an HI 215IT Junct ion

Box, individual load cells can be

tested.

• If you do not have an HI 215IT

Junction box the result will be for

the combined load cells in your

weighing syst em.

3. Digital Volt Meter (DVM) - This test

returns the voltage outputs from the

load cells.

• If you have an HI 215IT Junct ion

Box, the voltage output for each

individual load cell is read.

• If you do not have an HI 215IT

Junction box the voltage output

read will be for the combined

load cells in your weighing system.

4. System Test - Reads the weight for

the load cells in your system.

• If you have an HI 215IT Junct ion

Box, the weight for each individual load cell can be read as well

as the internal reference.

• If you do not have an HI 215IT

Junction box the weight read will

be combined weight for all the

load cells in your weighing system.

6-3

Loading...

Loading...