Page 1

3. Cable the communication ports located on the bottom of the

instrument according to the communications protocol used and by

referring to the I-I diagram available on the Hardy website.

4. Cable the DC power located on the bottom of the instrument by

first removing the terminal connector and securely capturing wire

leads by following notes for Power Input terminations found in the

I-I Diagram and the User Guide. The pre-installed jumper found on

the terminal connects the Earth ground and the internal ground

making them common, and should remain in place.

5. Power up system.

Initial Instrument Set-Up:

Refer to the HI 6300 or HI 6500 Users Guide for Initial Instrument SetUp.

Hardy Process Solutions sincerely appreciates your business. We encourage

input about the performance and operation of our products from our

customers. Should you not understand any information in this guide or

experience any problems with this product, please contact our Technical

Support Dept. at:

Phone: (858) 278-2900

Toll Free: 1-800-821-5831

FAX: (858) 278-6700

E-Mail: hardysupport@hardysolutions.com

Or visit our web site at:

http://www.hardysolutions.com

Proudly made in the U.S.A

PN: 0596-0336-01 Rev. A 07/14

HI 6300 and HI 6500 series PMWS Quick Start Guide

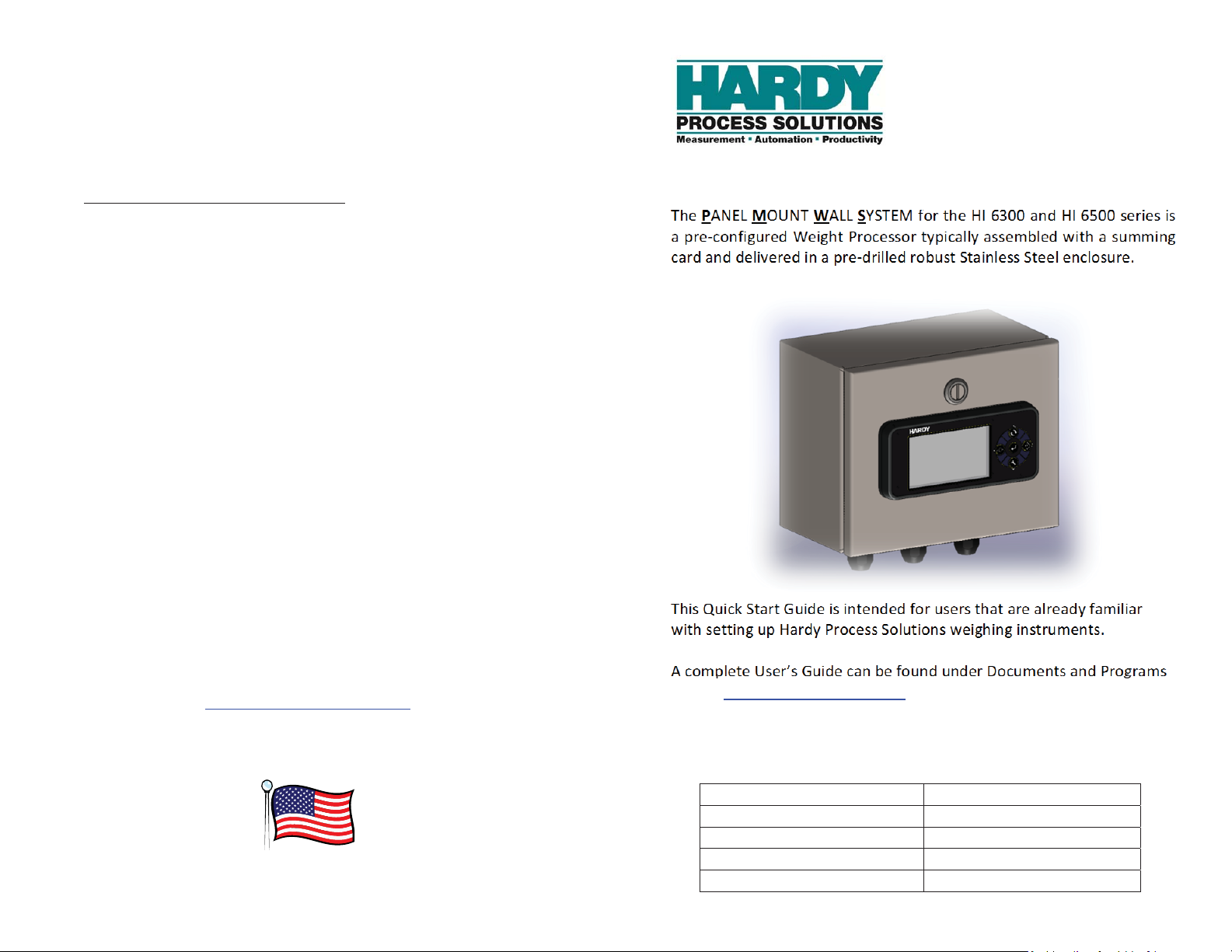

The PANEL MOUNT WALL SYSTEM for the HI 6300 and HI 6500 series is

a pre-configured Weight Processor typically assembled with a summing

card and delivered in a pre-drilled robust Stainless Steel enclosure.

This Quick Start Guide is intended for users that are already familiar

with setting up Hardy Process Solutions weighing instruments.

A complete User’s Guide can be found under Documents and Programs

online: www.hardysolutions.com Navigate to the Product menu>

Weighing Instruments > Weight Processors > HI 6500 (or HI 6300).

The User’s Guide and I-I diagrams are located in the Docs & Programs tab.

Hardy Product I/I Diagram Part Number

HI 6300 Weight Processor 0584-0076

HI 6310 Weight Processor 0584-0077

HI 6500 Weight Processor 0584-0082

HI 6510 Weight Processor 0584-0083

Page 2

Enclosure Installation:

1. Locate and remove the Enclosure Bracket Hardware Bag inside the

enclosure along with enclosure manufacturer instructions.

2. Determine an enclosure mounting scheme that best fits your

installation requirements. Brackets can be placed vertically or

horizontally in relation to the enclosure (vertical shown below).

3. Install enclosure brackets.

4. Install glands for wiring. (Do not remove integrated gland plug from

glands that will not be used for wiring).

Note: If using an AC/DC power converter, install the converter

to the right of the summing card and wire the DC out to

the instrument before mounting. Pre-drilled holes for

DIN rail installation can be found on the enclosure back

mounting plate.

Caution: You must use a power-limited 12-24 VDC power supply

(Class 2) on the DC input wiring. DC power should be

supplied by a clean primary line, directly from the DC

power source.

5. Place enclosure at its installation location, mark for wall or structure

mounting and drill holes.

6. Install enclosure.

Wiring:

1. Once the PMWS is installed, re-open for easy access to sensor,

communications and power connections.

Caution: Make sure the power is shut off before connecting any

wires into the Panel Mount Wall System.

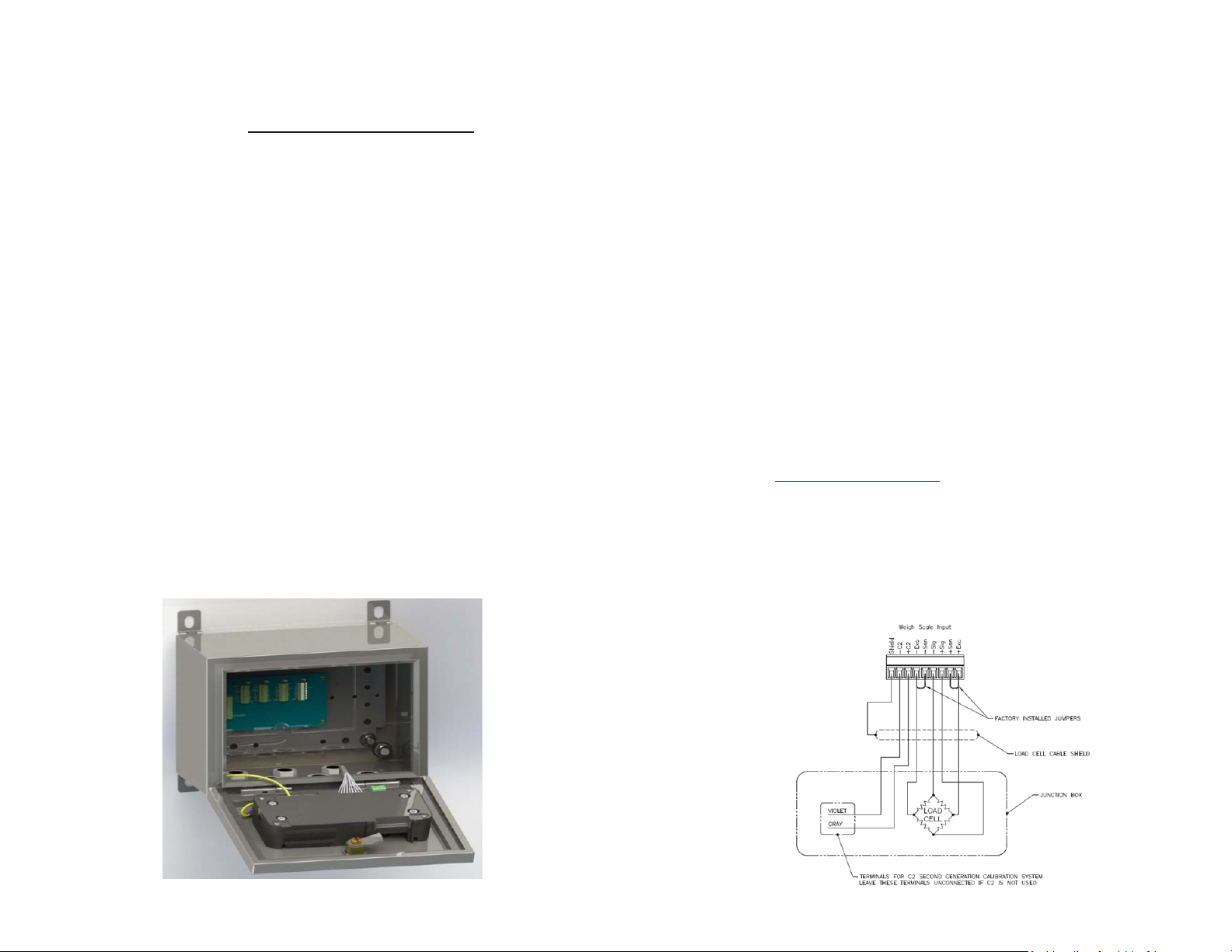

2. Wire load sensors to their respective locations on the summing

card. If only a single sensor is being used, remove and wire to the

quick-disconnect located on the bottom of the instrument.

a. If conduit is used, do not run load cell cable parallel to, or in the same

conduit with, power wiring, relay cable or other high energy cables.

b. Factory installed jumpers are to remain in place only for four wire, non

C2 load cell connections. Excitation and sense wires are to be

connected together to the summing card.

c. C2 cable is required for weightless calibration and INTEGRATED

TECHNICIAN® (IT) (Hardy Process Solutions P/N 6020-0001).

d. See Users Guide for additional information on load cell connections. A

complete User’s Guide can be found under Documents and Programs

online: www.hardysolutions.com Navigate to the Product menu>

Weighing Instruments > Weight Processors > HI 6500 (or HI 6300).

The User Guide is on the Docs & Programs tab.

e. Terminal block wire size range: 22 AWG minimum / 16 AWG

maximum. Wire temperature rating to be 90° C. Wire tightening

torque is to be 2 lbs-in minimum / 4 lbs-in maximum.

f. For clarity, only one load sensor connection is shown.

Loading...

Loading...