Page 1

HI HLPS SERIES

LOAD POINT ASSEMBLIES

OPERATION AND INSTALLATION

MANUAL

Corporate Headquarters

9440 Carroll Park Drive, Suite 150

San Diego, CA 92121

Phone: (858) 278-2900

FAX: (858) 278-6700

Web-Site: http://www.hardysolutions.com

Hardy Process Solutions Document Number: 0596-0237-01 Rev G

Copyright 1999-2013 Hardy Process Solutions All Rights Reserved. Printed in the U.S.A. (941028)

Page 2

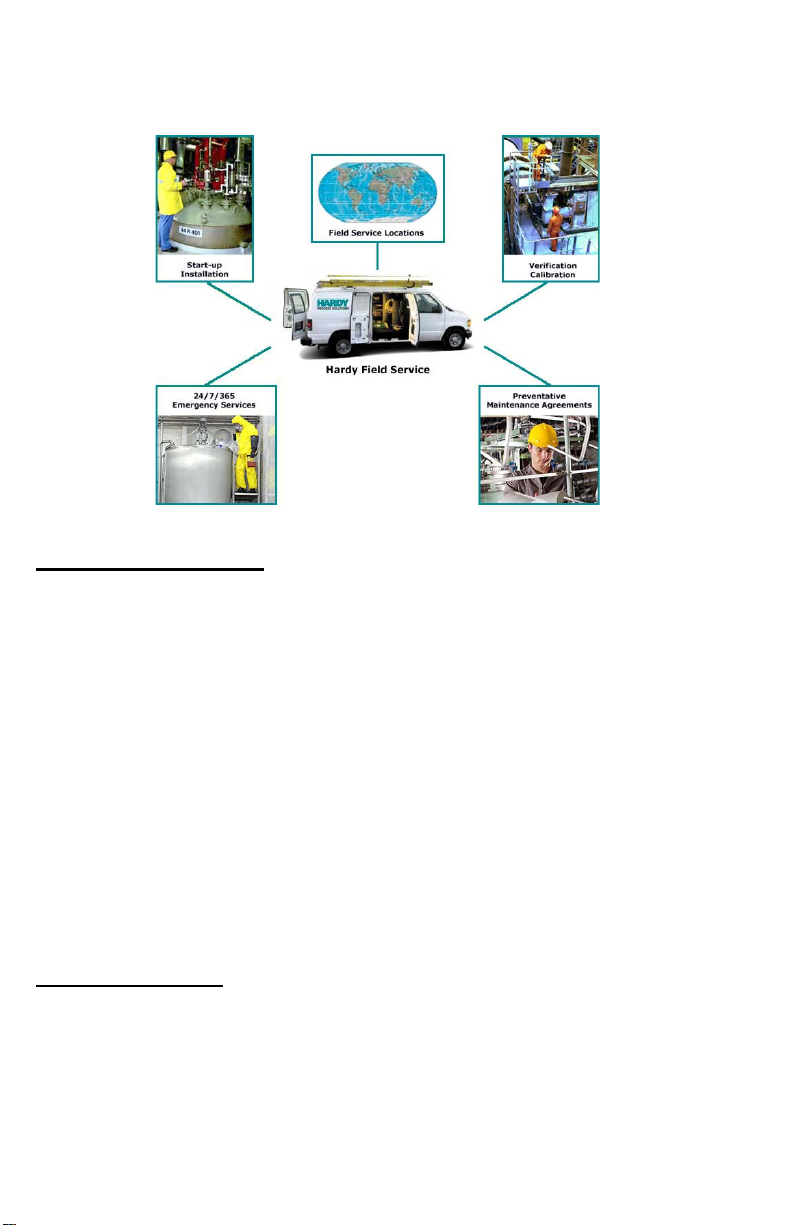

Local Field Service

Hardy has over 200 field technicians in the U.S., and more positioned throughout the

world to assist you in your support needs. We also have factory engineers who will

travel to your facility anywhere in the world to help you solve challenging applica

tions. We're ready to support you with:

• Installation and start-up

• Routine maintenance and certification

• Plant audits and performance measurement

• Emergency troubleshooting and repair

To request Emergency Service and Troubleshooting, Start-up, Installation, Calibration, Verification or to discuss a Maintenance Agreement please call 800-821-5831

Option 4 or Emergency Service after hours (Standard Hours 6:00 AM to 5:30 PM

Pacific Standard Time) and weekends 800-821-5831 Option 4.

-

Outside the U.S

Hardy Process Solutions has built a network of support throughout the globe. For specific field service options available in your area please contact your local sales agent

or our U.S. factory at +1 858-292-2710, Option 4.

Page 3

CAUTION: UNPACK WITH CARE

WHEN UNPACKING, DO NOT DISCARD THE PACKING CASE OR ANY PACKING MATERIAL, UNTIL THE

CONTENTS OF THE PACKING CASE ARE

INSPECTED AND CAREFULLY COMPARED WITH

THE SHIPPING DOCUMENTS.

IF ANYTHING IS UNSATISFACTORY, PLEASE

NOTIFY HARDY INSTRUMENTS IMMEDIATELY BY

CALLING, FAXING OR E-MAILING TO:

Customer Support Department

HARDYPROCESS SOLUTIONS

9440 Carroll Park Drive, Suite 150

San Diego, California 92121

Phone: (800) 821-5831

(858) 278-2900

FAX: (858) 278-6700

E-mail: hardysupport@hardysolutions.com

Web Address: www.hardysolutions.com

A RETURN AUTHORIZATION NUMBER IS REQUIRED

BEFORE RETURNING ANY DAMAGED PRODUCT.

CALL THE CUSTOMER SUPPORT DEPARTMENT TO

GET THE NUMBER. YOUR COMPANY NAME,

ADDRESS, TELEPHONE NUMBER, SERIAL NUMBER

OF THE UNIT AND A BRIEF DESCRIPTION OF THE

PROBLEM SHOULD BE READY WHEN CALLING.

IN CASE OF DAMAGE DUE TO SHIPPING, NOTIFY

THE DELIVERING CARRIER IMMEDIATELY FOR AN

INSPECTION.

Page 4

Page 5

Table of Contents

Table of Contents

General Information - - - - - - - - - - - - - - - - - - - - - - - - 1

Three Load Point Types - - - - - - - - - - - - - - - - - - - - - - 2

Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

Installation of the Ground Strap - - - - - - - - - - - - - - - - - - - 3

Site Preparation - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Basic Engineering Principles for Positioning Load Point Assemblies - 5

Principle #1 - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Principle #2 - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Principle #3 - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Principle #4 - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Typical Mounting Arrangements - - - - - - - - - - - - - - - - - - 6

Round Vessel with 3 Load Point Assemblies 7

Round Vessel with 3 Load Point Assemblies - Angle Config. #1 - 7

Round Vessel with 3 Load Point Assemblies - Angle Config. #2 - 8

Square Hopper with 3 Load Point Assemblies - Even

Load Distribution - - - - - - - - - - - - - - - - - - - - - - - 8

Square Hopper with 3 Load Point Assemblies - Uneven

Load Distribution - - - - - - - - - - - - - - - - - - - - - - - 9

Round Vessel with 4 Load Point Assemblies - - - - - - - - - - 9

Typical 4 - Load Point Assembly Installation - - - - - - - - - - 10

Typical 6 - Load Point Assembly Installation - - - - - - - - - - 11

Level Requirements - - - - - - - - - - - - - - - - - - - - - - - - 11

Stiffness - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Installation Procedures - - - - - - - - - - - - - - - - - - - - - - - 12

Pre-Installation Procedures - - - - - - - - - - - - - - - - - - - 12

Installing Load Point Assemblies with Anchor Bolts - - - - - - - 13

Installing the Base Plate - - - - - - - - - - - - - - - - 13

Installing the Top Plate to the Load Surface - - - - - - 18

Adjusting the Anti-Lift Off Device - - - - - - - - - - - - - - - - - 21

Replacing the Load Sensor - - - - - - - - - - - - - - - - - - - - - 21

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - 25

Physical Checks - - - - - - - - - - - - - - - - - - - - - - - - 25

Electrical Tests for Load Point Assembly Problems - - - - - - - 25

Zero Balance Test - - - - - - - - - - - - - - - - - - - 25

Bridge Resistance Test - - - - - - - - - - - - - - - - 26

Resistance to Ground Test - - - - - - - - - - - - - - - 26

Electrical Termination Cable Color Codes - - - - - - - - - - - - - - 27

Model Numbers - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Three Leg Systems - - - - - - - - - - - - - - - - - - - - - - 28

Four Leg Systems - - - - - - - - - - - - - - - - - - - - - - - 29

Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

i

Page 6

HI HLPS SERIES LOAD POINT ASSEMBLY

ii

Page 7

OPERATION AND INSTALLATION MANUAL

Congratulations, on your purchase of the Hardy Process Solutions

Load Point Assembly. This product, is engineered to set a new standard in load point assemblies. Hardy combined new innovations with

previously extra cost features and just plain common sense features

and provided you with optimum performance unequaled anywhere.

General Information The Hardy HI HLPS Hermetic Load Point System

provides accurate output in the most demanding

applications. The load sensor performance exceeds

IP68 and NEMA 6 Standards for Wash Down Resis

tance.

Use the HI HLPS Free Sliding Load Point System for

medium capacity vessels. The pre-assembled Free

Sliding Load Point System consists of three low pro

file mount types (See Figs. 1,2,3) that are designed to

eliminate the effects of unwanted forces and resulting

in exceptional load measuring accuracy.

Each load point consists of a stainless steel load sensor which is hermetically sealed (gauge area and cable

entry), Enhanced C2

tion, matched mV/V and mV/V/Ohm and a 1/4 inch

conduit adapter. The load points are pre-assembled at

our factory, eliminating any assembly in th e field.

Each load point is fitted with a grounding strap and

anti-lift-off protection. The load points mounting

hardware is available in either stainless or galvanized

steel.

®

Second Generation Calibra-

-

-

Page 1

Page 8

HI HLPS SERIES LOAD POINT ASSEMBLY

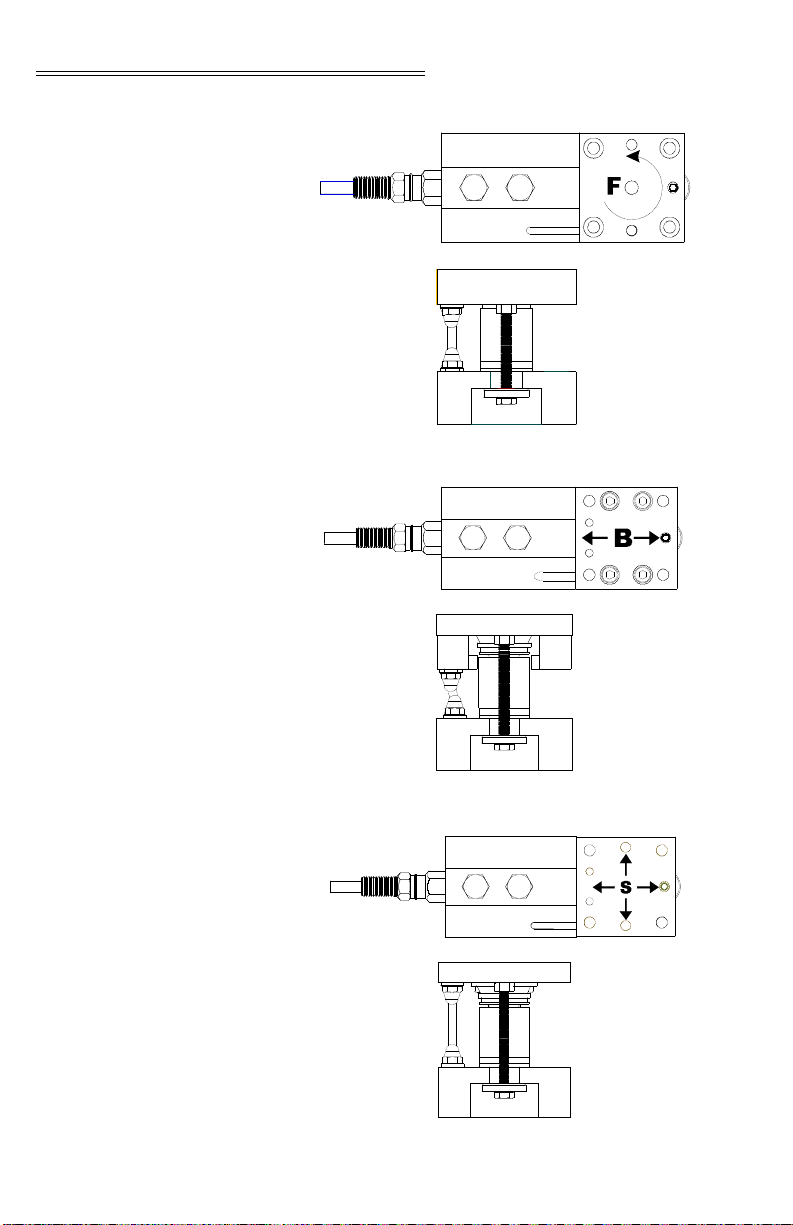

Three Load Point Types

FIG. 1: FIXED PIN LOAD POINT

Page 2

FIG. 2: BUMPER PIN LOAD POINT

FIG. 3: FREE SLIDING PIN LOAD POINT

Page 9

OPERATION AND INSTALLATION MANUAL

Unpacking • Do not remove the load point assembly from it’s

packaging until just before installation. Although

the load sensor is designed for harsh environ

ments, it is a precision instrument and should be

treated as such.

• Inspect the box, packing and the load point

assembly for any signs of damage that might

occur during shipment. Since almost all of the

load point assemblies are shipped F.O.B. our fac

tory, such damage is normally the responsibility

of the carrier and should be reported to them.

• LOAD SENSOR CERTIFICATION SHEETS

ARE AVAILABLE 24 HOURS A DA Y IN

THE SUPPORT SECTION OF OUR WEB

SITE: http://www.hardysolutions.com

• Write down the serial number(s) on the inside of

the back cover for reference when talking to

Hardy Customer Service. Store this information

in a secure dry location for future reference.

-

-

-

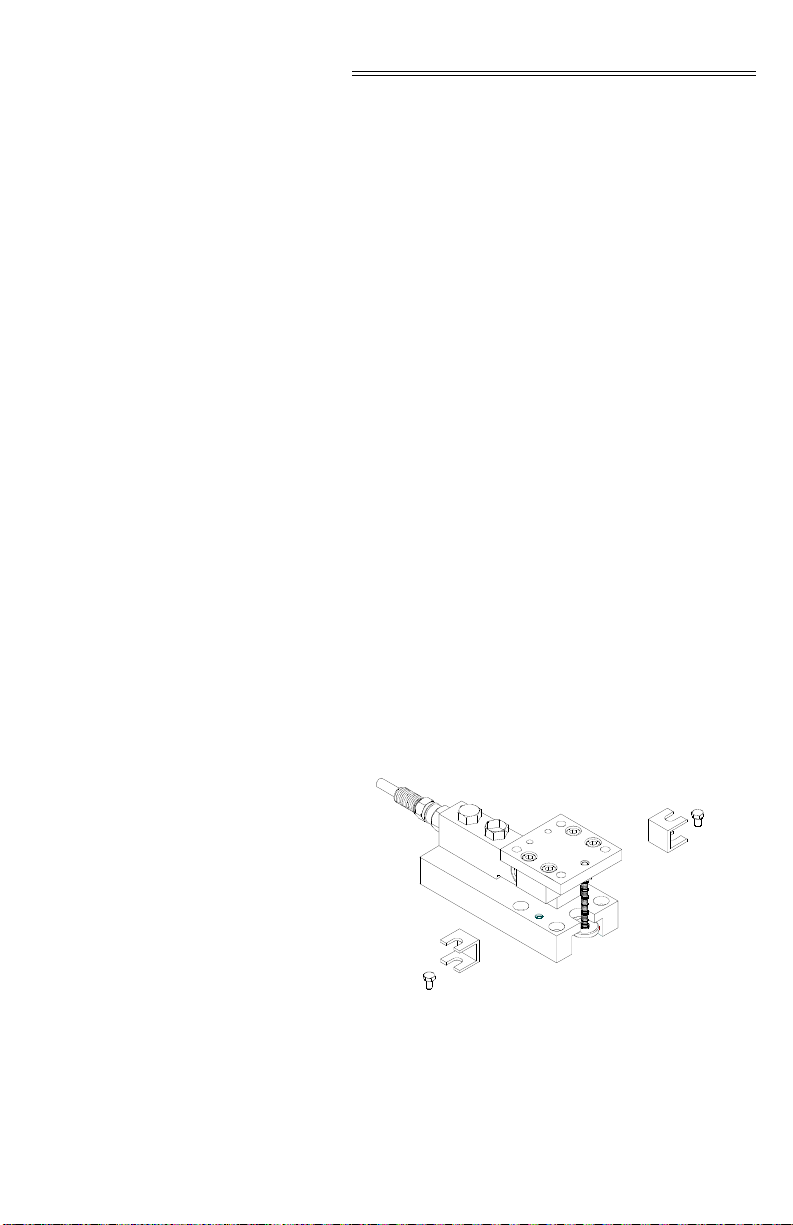

Installation of the Ground Strap

Step 1. Cut the plastic strap that fastens the

ground strap to the Load Point Assembly.

Step 2. Use a box-end wrench to remove the two

shipping brackets from the load point. (See

Fig. 4)

FIG. 4: REMOVING SHIPPING BRACKETS

Step 3. Remove the shipping brackets, which are

intended only for use during shipment

from the factory. They offer no protection

Page 3

Page 10

HI HLPS SERIES LOAD POINT ASSEMBLY

if you are shipping the vessel fully

assembled on the load points.

Step 4. Save the two shortest machine screws (the

hex bolts that fasten the shipping brackets

to the base plate). You will use them to

install the ground strap. (See Fig. 1-4)

Step 5. Place one of the ground strap connectors

over the threaded hole in the base plate.

These are the ones that fastened the ship

ping bracket to the base. (See Fig. 5)

-

FIG. 5: GROUND STRAP INSTALLED

Step 6. Install a hex bolt. Tighten with a box-end

wrench.

Step 7. Place the other ground strap connector

over the threaded hole in the top plate.

Step 8. Install the other hex bolt. Tighten with a

box-end wrench.

Step 9. Fig. 5 shows the ground strap installed on

the left side when facing the front of the

load point assembly. However, you can

install the strap on either side if necessary.

NOTE: Do not connect the ground strap to the base plate on

the right side and to the top plate on the left side or

vice versa. Crossing over will interfere with the load

cell performance.

Page 4

Page 11

OPERATION AND INSTALLATION MANUAL

Site Preparation • All mounting surfaces for the base and loading

plate must be level. The distance between the

mounting surface of the loading plate and base

must be within 1/32” of the nominal height, “H”.

The Load Point Assemblies in a system must be

level to within +/- 0.5

• When mounting the base plate on concrete, use

grout to level the plate.

• Do any welding before installing the load points.

• Provide proper drainage to prevent the load point

assembly from standing in water.

Precautions • Always treat the Load Sensor as a precision

instrument. Leave the load point assembly in its

packaging until it is time for installation.

• NEVER CARRY OR SWING THE LOAD SENSORS BY THEIR CABLES.

• Never allow moisture to get into any int erconnections.

• HARDY SOLUTIONS RECOMMENDS THAT

YOU DO NOT CUT YOUR ADVANTAGE

OR ADVANTAGE LITE® LOAD SEN

o

.

®

SOR CABLE. BECAUSE YOUR C2®

ACCURACY WILL BE AFFECTED AND

THE WARRANTY VOIDED.

Basic Engineering Principles for Positioning Load Point Assemblies

Principle #1 • Position the Load Points Assemblies so that the

load (weight) is distributed as evenly as possible

between each load point assembly in the scale.

• When the installation does not allow even distribution of the load, select higher capacity load

point assemblies.

NOTE: All load point assemblies must have the same capacity

when used in one scale.

Page 5

Page 12

HI HLPS SERIES LOAD POINT ASSEMBLY

Principle #2 • All scales should include one fixed pin-load

mount (F), one bumper pin-load mount (B). All

other load point assemblies in a scale must be the

free-sliding mount (S).

Principle #3 • Place the fixed pin-load mount and the bumper

pin load mount as far as possible from each other .

• The fixed pin load mount and the bumper pin

load mount must be mounted in the same longitu

dinal axis.

• In applications that use three load points it is

sometimes difficult to mount the fixed-pin and

bumper load mounts in-line. Therefore the fixed

pin and bumper load mounts can be positioned at

o

a 45

angle from each other and 45o from the

free-pin load mount. See the mounting diagrams

below for more information.

Principle #4 • If possible, the fixed-pin load mount should be

installed so that the load mount is oriented in the

direction of travel (e.g. when under a conveyor,

the load mount must be in the same longitudinal

axis with the direction of the travel of the con

veyor). The load mount must be oriented in the

direction of any prevalent side force.

-

-

Typical Mounting Arrangements

NOTE: You can orient the load point assemblies to meet your

system installation requirements. All load point

o

assemblies can be rotated 360

in 90o increments. The

examples above are recommendations only. The only

requir ed orientation is that the bumper load cell must

point either towards or directly away from the fixed

load point.

Use the load cell cable for the pointer to ensure that

the vessel cannot rotate and allow the cells to slide off

their mounts.

Page 6

Page 13

Round Vessel with 3

F

S

B

<45

o

Load Point

Assemblies

Round Vessel with 3 Load Point Assemblies - Angle Config. #1

OPERATION AND INSTALLATION MANUAL

FIG. 6: THREE LOAD CELLS IN ROUND

CONFIGURATION

FIG. 7: ANGLE FOR FIXED AND BUMPER LOAD

CELLS IN ROUND CONFIGURATION

Page 7

Page 14

HI HLPS SERIES LOAD POINT ASSEMBLY

F

S

B

O

Round Vessel with 3 Load Point Assemblies - Angle Config. #2

FIG. 8: ANGLE FOR ALL LOAD CELLS IN ROUND

CONFIGURATION

NOTE: Load Cells can be oriented with cables pointed either

in or out. For three load point systems, the mounting

locations should be spaced120 degrees apart. For

four load point systems the mounting locations should

be spaced 90 degrees apart.

Square Hopper with 3 Load Point Assemblies - Even Load Distribution

Page 8

FIG. 9: ANGLE FOR FIXED AND BUMPER LOAD

CELLS IN SQUARE CONFIGURATION

Page 15

OPERATION AND INSTALLATION MANUAL

F

S

B

Square Hopper with 3 Load Point Assemblies - Uneven Load Distribution

FIG. 10: ANGLE FOR THREE LOAD CELLS IN

SQUARE CONFIGURATION

NOTE: This configuration is an exception to the even load

distribution principle. Use this configuration in cir

cumstances where you arrange several hopperin close

proximity to each other.

-

Round Vessel with 4 Load Point Assemblies

FIG. 11: FOUR LOAD CELLS IN ROUND

CONFIGURATION

Page 9

Page 16

HI HLPS SERIES LOAD POINT ASSEMBLY

FIG. 12: FOUR LOAD CELLS FACING

INWARD IN ROUND CONFIGURATION

Typical 4 - Load Point Assembly Installation

Page 10

FIG. 13: FOUR LOAD CELLS POSITIONED IN

A RECTANGULAR CONFIGURATION

Page 17

OPERATION AND INSTALLATION MANUAL

Typical 6 - Load Point Assembly Installation

FIG. 14: SIX LOAD CELLS POSITIONED IN A

RECTANGULAR CONFIGURATION

NOTE: In case there is doubt concerning load point assembly

installation, contact your local Hardy Process Solu

tions dealer , Application Engineering Department, or

Customer Support Department for assistance.

You can orient the load point assemblies to meet your

system installation requirements. All load point

assemblies can be rotated 360

o

in 90o increments. The

examples above are recommendations only.

Level Requirements For scales that must meet NIST Class 3 (OIML Class

3) specifications:

1. The base plate support surfaces must be

within 0.2 degrees (0.4mm/100mm)

2. The top plate support surfaces in the load

carrier must be within 0.5 degrees (0.9mm/

100mm)

For scales with accuracy requirements => 0.1%

1. The base plate support surfaces must be

within 0.4 degrees (0.08mm/100 mm)

2. T op plate support surfaces in the load carrier

must be within 1 degree (1.8mm/100mm)

Stiffness Load variations and external forces can cause support

surface level variations.

Page 11

Page 18

HI HLPS SERIES LOAD POINT ASSEMBLY

For scales that must meet NIST Class 3 (OIML Class

3) specifications:

1. Maximum base plate angle variation: 0.2

degrees.

2. Maximum top plate angle variation 0.5

degrees.

For scales that must meet accuracy specifications =>

0.1%

1. Maximum base plate angle variation 0.2

degrees

2. Maximum top plate angle variation 1 degree.

Installation Procedures

Pre-Installation Procedures

Step 1. Position the base plates with load cells on

the support surfaces and line them up in

accordance with the basic principles for

positioning. (See Principle #2, pg. 6)

Step 2. We recommend scribing or marking a cen-

terline on the top plate. (See Fig. 15)

FIG. 15: MARKING TOP PLATE FOR

INSTALLATION

Page 12

Page 19

OPERATION AND INSTALLATION MANUAL

Installing Load Point Assemblies with Anchor Bolts

Installing the Base Plate

The outline drawing located on the

www.hardysolutions.com Web Site provide the Base

Plate and Top Plate dimensions for the Load Point

Assembly. They include the thru hole diameters and

center distances.

Step 1. Make sure that the concrete foundation is

level.

Step 2. To assist in the installation of the anchor

bolts we recommend creating a template

using the thru hole diameters of the top

plate mounting dimensions. For drilling

dimensions, see the drawings accessed

from the Products page on the Hardy

Process Solutions web site. Note that the

holes for top and bottom are in direct

alignment, but the thickness of the top and

bottom plates differ.

Fig. 16 and Table 1 provide side dimensions and hole

diameters only.

Page 13

Page 20

HI HLPS SERIES LOAD POINT ASSEMBLY

Page 14

FIG. 16: BASE AND TOP PLATE DRAWINGS

TABLE 1: BASE & TOP PLATE DIMENSIONS

Page 21

OPERATION AND INSTALLATION MANUAL

FIG. 17: ANCHOR BOLTS TEMPLATE

Step 3. Use wood or metal to create the templates.

The size of the template depends on the

size of the anchor bolts.

Step 4. Mark a point on on each template. Then,

using the I/I diagram, make another mark

on the template measuring from the thru

hole center points on the base plate.

Step 5. Drill the thru holes the same size as the

base plate thru holes at each of the marks

you made on the templates.

Step 6. On the vessel or structural support that

will rest on the load point assemblies,

measure from the point where you want to

position the center of the fixed-pin load

point assembly’s top plate to where you

want the centers of the top plates of the

other load point assemblies used in the

weighing system. As you mark each cen

ter point location, check the typical mounting arrangements for load point systems

above.

Step 7. Place the center of the Anchor Bolt pattern

at the exact centers as measured in Step 6.

You can use the templates to assist in

locating these center points.

Page 15

-

Page 22

HI HLPS SERIES LOAD POINT ASSEMBLY

Step 8. When you place the anchor bolts into the

concrete foundation, slip the templates

over the anchor bolts so that the bolt center

distances will be the same as the base plate

thru holes of the load cell. You can leave

the templates there until after the concrete

drys or remove them when you think the

concrete has set to the point where the

anchor bolts won’t move.

Step 9. Allow room to install the jacking nuts and

washers. Yo u are going to make the level

adjustments with the jacking nuts. (See

Fig. 18)

Page 16

FIG. 18: INSTALLING THE FOUR ANCHOR

BOLTS FOR THE BASE PLATE

Step 10. Install the jacking nuts onto the anchor

bolts so there is about 1/2 inch between the

concrete foundation and the jacking nuts.

Don’t worry about level at this point, you

will level everything after the Load Point

Assembly/base plate is installed.

Step 11. Install four flat washers on each anchor

bolt above the jacking nuts. (See Fig. 17)

Step 12. Slide the load point assembly/base plate

onto the anchor bolts. You can install the

load point assemblies in one of four orien

tations. (See Fig. 19)

-

Page 23

OPERATION AND INSTALLATION MANUAL

FIG. 19: LOAD POINT ASSEMBLIES ORIEN-

TATION

This illustration uses the fixed load point

assembly, but you can do the same with

any of the load point assembly types.

Step 13. Use a bubble level to level the load point

assembly from side to side and corner to

corner. Use a box end wrench to adjust

each of the jacking nuts until each load

point assembly in the system is level.

Step 14. Install the base plate nuts finger tight. You

may need to adjust the jacking nuts later as

you install the rest of the load point assem

blies for the weighing system.

Step 15. If you replaced a loading pin or load cell,

make sure you grease the sliding and

fixed pins and the fixed pin housings in the

top plate and the load cell. Clean the stain

less plate on the under side of the top plate

and verify that the stainless plate is free of

scratches or other damage. Replace the

Stainless plate if scratched or damaged.

Step 16. Install the rest of the load point assemblies

according to the Positioning Principles.

(See Principles, pgs. 6 & 7)

-

-

NOTE: Load variations and external forces can cause sup-

port surface level variations.

Page 17

Page 24

HI HLPS SERIES LOAD POINT ASSEMBLY

Step 17. Level all the installed load point assem-

blies and adjust them according to the following base plate level requirements:

Installing the

Top Plate to

the Load

Surface

WARNING UNDER NO CIRCUMSTANCES MUST WELD-

Step 1. Disconnect the power to the controller to

which the load cells are connected.

Step 2. Disconnect all wires to the Summing Junc-

tion Box.

Step 3. You should have scribed or marked a cen-

terline on the top surface of the top plate to

locate the center. (See Fig. 6)

Step 4. Mark the point you want the center of the

top plate to be located on the support

bracket. Place the top plate center over the

support bracket mark and:

ING CURRENT BE ALLOWED TO PASS

THROUGH THE LOAD SENSOR. TO DO SO

WILL DESTROY THE LOAD SENSOR AND

COULD POSSIBLY CAUSE PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

• Be sure to shield the entire load cell and

cable from any slag that might drop.

• Tack weld the top plate to the support

bracket.

• If you want to fasten the top plate to the

support bracket, use a marker or scribe

and trace the thru hole pattern of the top

plate on the support bracket. Drill four

thru holes or drill and tap four holes for

the fasteners. Install the top plate to the

support bracket using the four fasteners.

Page 18

Step 5. With the top plates installed, put the vessel

support bracket with the top plate onto the

pins of the load cells. The sliding load cell

pins must be riding on the stainless plate.

Make sure that the fixed pin is centered in

the top plate housing. The horizontal posi

tion is not critical, but the vertical position

-

Page 25

OPERATION AND INSTALLATION MANUAL

is. Use the C dimensions to determine the

proper height between the support surface

and the top of the top plate. (See Fig. 20)

Step 6. Level all the installed load point assem-

blies and make adjustments according to

the following top plate level requirements:

FIG. 20: HEIGHT DIMENSION C

MODEL # HEIGHT C

HI HLPS 1125, 2.25K,4.5K 3.54

HI HLPS 11.25K 4.72

HI HLPS 22.5K 6.69

(90)

(120)

(170)

TABLE 2: HEIGHT DIMENSION C

Step 7. To adjust the level of the top plate, use

shim stock between the top plate and the

support bracket. (See Fig. 21)

Page 19

Page 26

HI HLPS SERIES LOAD POINT ASSEMBLY

FIG . 21: ADJUSTING FOR LEVEL WITH SHIM

Step 8. If you tack welded the top plate to the sup-

port bracket, lift the vessel off the load cell

pins if you can) and finish welding the top

plate to the support bracket. If you cannot,

be sure to shield the entire load cell and

cable from any slag that might drop.

Lower the vessel back onto the sliding

loading pins.

STOCK

WARNING UNDER NO CIRCUMSTANCES MUST WELD-

ING CURRENT BE ALLOWED TO PASS

THROUGH THE LOAD SENSOR. TO DO SO

WILL DESTROY THE LOAD SENSOR AND

COULD POSSIBLY CAUSE PERSONAL

INJURY AND/OR PROPERTY DAMAGE.

Step 9. Pour grout up to the bottom surface of the

base plate and let dry.

CAUTION: DO NOT ALLOW GROUT TO COME IN CON-

TACT WITH THE ANTI-LIFT OFF DEVICE.

(SEE FIG. 13)

Page 20

Page 27

OPERATION AND INSTALLATION MANUAL

Adjusting the Anti-Lift Off Device

Replacing the Load Sensor

Step 1. Use a box end wrench to loosen the adjust-

ment hex nut that fastens the anti-lift-off

device to the top plate. (See Fig. 22)

FIG. 22: ANTI-LIFT OFF DEVICE

ADJUSTMENT

Step 2. Use a box-end wrench or your fingers to

adjust the hex screw until the gap between

the base plate and the washer are

between.0785” (2mm) and.1570” (4mm).

Step 3. Use a box-end wrench and tighten the

adjustment hex nut.

Step 1. Use a box-end wrench to loosen the nut

that fastens the anti-lift-off device to the

top plate. Remove the anti-lift-off device.

(See Fig. 14)

Step 2. Use a box-end wrench to remove the two

hex bolts that fasten the ground strap.

Remove the ground strap from the top

plate and the base plate.

Step 3. Jack up the vessel support leg and lift off

the top plate.

Step 4. Use a box-end or crescent wrench to

remove the two load sensor bolts that fas

ten the Load Sensor to the base plate. (See

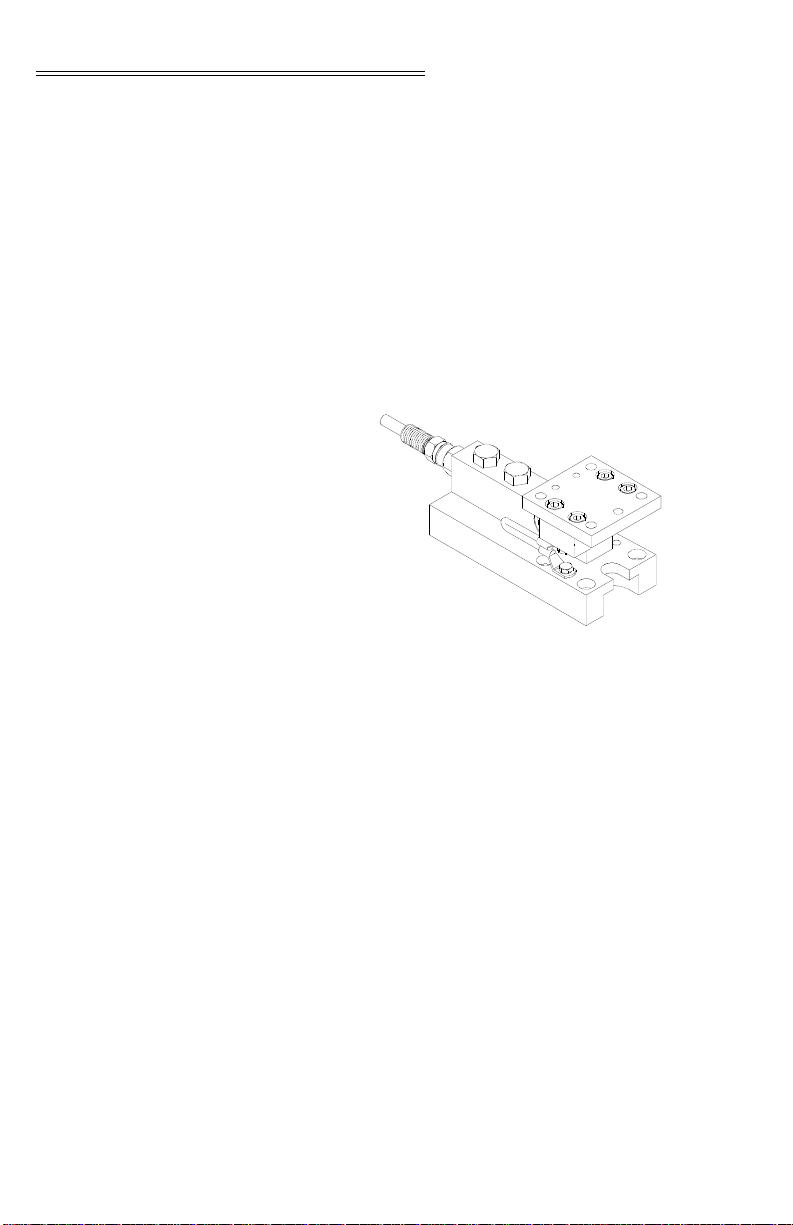

Figs. 23 and 24)

Page 21

-

Page 28

HI HLPS SERIES LOAD POINT ASSEMBLY

FIG. 23: EXPLODED ISO VIEW OF FREE

SLIDING LOAD POINT ASSEMBLY

Page 22

FIG. 24: EXPLODED ISO VIEW OF BUMPER

LOAD POINT ASSEMBLY

Step 5. Remove the old load sensor.

Step 6. Align the load cell bolt thru holes with the

threaded base plate bolt holes.

Page 29

OPERATION AND INSTALLATION MANUAL

Step 7. Screw the two load cell bolts into the base

plate until they are finger tight only.

Step 8. The height (B) dimension is the minimum

required service area above the load cell

baseplate to remove the load cell bolts.

(See Fig. 24 & Table 3)

FIG. 25: B DIMENSION

MODEL # HEIGHT B

HI HLPS 1125, 2.25K,4.5K 2.91

(74.0)

HI HLPS 11.25K 4.02

(102)

HI HLPS 22.5K 5.83

(148)

TABLE 3: B DIMENSIONS

Step 9. Use a torque wrench and tighten the bolt

farthest from the cable end first. Then

tighten the bolt nearest the cable end.

Step 10. Again refer to the B dimensions. Use the

following torque values:

Page 23

Page 30

HI HLPS SERIES LOAD POINT ASSEMBLY

MODEL #

HI HLPS1125-43B

HI HLPS1125-43F

HI HLPS1125-43S

HI HLPS2.25K-43B

HI HLPS2.25K-43F

HI HLPS2.25K-43S

HI HLPS4.5K-43B

HI HLPS4.5K-43F

HI HLPS4.5K-43S

HI HLPS11.25K-43B

HI HLPS11.25K-43F

HI HLPS11.25K-43S

HI HLPS22.5K-43B

HI HLPS22.2K-43F

HI HLPS22.5K-43S

TABLE 4: LOAD CELL BOLT TORQUE

Foot pounds

(NewtonMeters

or Joules)

65 (88.5)

295 (400)

515 (700)

VALUES

Page 24

Step 11. Inspect the Stainless Plate for scratches or

damage. If there are scratches or damage:

• Use a box-end wrench to remove the

two hex machine screws that fasten the

stainless plate to the top plate. (See Fig.

24)

• Discard the old stainless plate.

• Place the new stainless plate so that the

thru holes are aligned with the threaded

holes in the top plate.

• Replace the two hex machine screws.

• Lower the vessel down onto the load

points.

• Reinstall the ground strap and anti-liftoff device. (See Figs. 23 & 24)

Page 31

OPERATION AND INSTALLATION MANUAL

Troubleshooting

Physical Checks Before doing any electrical tests do the following:

Step 1. Visually inspect each load point assembly

for physical damage. Look for distortions

or cracks in all metal parts.

Step 2. Check all welds to be sure they are not

cracked of have deep pot marks.

Step 3. Check all cables for cracks, cuts or crimp-

ing. Check for any abrasions on the cables.

Step 4. Look for structural changes in the scale or

supporting structures.

Step 5. Look for binding of any kind on the load

point assembly.

Step 6. Chapter 8, Page 8-2 of the Hardy Control-

ler Manual explains how to troubleshoot

using Integrated Technician. See: http://

www.hardysolutions.com for the support

page or contact your local Hardy Repre

sentative for information as to where to get

manuals for Hardy products.

-

Electrical Tests for Load Point Assembly Problems

Zero Balance Test

Step 7. Get the Load Sensor certification sheets

for referencing while troubleshooting. The

certifications are available to you 24 hours

a day on the support section of our Web

Site: http://www.hardysolutions.com.

If you find any of the problems stated above, replace

the part that is damaged.

Problem: Changes in the Zero Balance.

Cause: Load Cell has been overloaded.

Remedy:

Step 1. Use a millivolt meter or Integrated Techni-

cian feature (See Physical Checks, Step 6)

Page 25

Page 32

HI HLPS SERIES LOAD POINT ASSEMBLY

and measure the LPS output under “no

load” conditions. The reading should be

less than 1% of the full scale output.

NOTE: Sensors can shift up to about 10% of their full scale

and still function correctly.

Step 2. If the output has shifted more than 1%,

replace the sensor.

Assumption: A 5VDC excitation on a sensor with a

3mV/V output sensitivity, a 1% shift in zero balance

will yield a 0.1 mV/V change from the specification.

Bridge Resistance Test

Resistance to Ground Test

Problem: Changes in Bridge Resistance

Cause: Failure of a compensating element, or by a

broken or burned bridge wire. Often cause by an elec

trical transient such as lightning.

Remedy:

Step 1. Use an Ohmmeter and measure the resis-

tance between the EXC + and EXC- leads.

The value for the EXC leads should be

1106 ohms + - 5 ohms.

Step 2. Use an Ohmmeter and measure the resis-

tance between the SIG + and SIG - leads

The value for the SIG leads should be

1,000 ohms + - 1 ohm.

Step 3. Readings that exceed the ranges indicated

suggest damage and the load cell should

be throroughly inspected or replaced.

Problem: Electrical leakage is creating an unstable

output from the instrument.

Cause: W ater contamination in the load sensors or

cables.

Remedy:

-

Step 1. Tie together the load sensor excitation (2),

signal (2) and ground (1) wires.

NOTE: Be careful NOT to include the two C2 wires.

Page 26

Page 33

OPERATION AND INSTALLATION MANUAL

Step 2. Use a megohmmeter and measure the

resistance between all five wires tied

together and the load cell metal body.

• The measured value should be 5,000

megohms or more.

WARNING WHEN USING A MEGGER DO NOT EXCEED

50 VOLT RANGE.

• If the sensor fails this test remove the

ground wire and test with only the four

live leads.

• If the sensor passes the test an insulation

problem in the cable is most likely.

Step 3. Replace the load cell if the cell fails both

tests.

Electrical Termination Cable Color Codes

The cable is 6 conductor, shielded (floating) and 20

feet in length.

EXC+ Red

EXC - Black

SHIELD Yellow

C2+ Gray

C2- Violet

SIG + Green

SIG - White

Model Numbers

NOTE: The -43F/B/S indicates a stainless steel load sensor

with stainless steel mounting hardware. For galva

-

nized mounting hardware use -45 F/B/S

Capacity Model # Model # Model #

LBS Kn Fixed Assembly Bumper Assembly Slider Assembly

1,125 5 HI HLPS1125-43F HI HLPS1125-43B HI HLPS1125-43S

2.25K 10 HI HLPS2.25K-43B HI HLPS2.25K-43B HI HLPS2.25K-43S

TABLE 5: MODEL NUMBERS & CAPACITIES

Page 27

Page 34

HI HLPS SERIES LOAD POINT ASSEMBLY

Capacity Model # Model # Model #

LBS Kn Fixed Assembly Bumper Assembly Slider Assembly

4.5K 20 HI HL PS4.5K-43F HI HLPS4. 5K-43B HI HLPS4.5K-43S

11.25K 50 HI HLPS11.25K-43F HI HLPS11.25K-43B HI HLPS11.25K-43S

22.5K 100 HI HLPS22.5K-43F HI HLPS22.5K-43B HI HLPS22.5K-43S

TABLE 5: MODEL NUMBERS & CAPACITIES

Model #

Spare Load Sensor

HI SBH04-1125

HI SBH04-2.25K

HI SBH04-4.5K

HI SBH04-11.25K

HI SBH04-22.5K

Three Leg Systems

Page 28

TABLE 6: SPARE LOAD SENSORS

To tal Capacity

Model # Pounds Kn.

HI 3S3375-43 3.375k 15

HI 3S6.75K-43 6.75k 30

HI 3S13.5K-43 13.5k 60

HI 3S37.5K-43 33.75k 150

HI 3S67.5K-43 67.5k 300

TABLE 7: THREE LEG SYSTEMS

Page 35

OPERATION AND INSTALLATION MANUAL

Four Leg Systems

To tal Capacity

Model # Pounds Kn.

HI 4S4.5K-43 4.5k 20

HI 4S9K-43 9k 40

HI 4S18K-43 18k 80

HI 4S45K-43 45k 200

HI 4S90K-43 90k 400

TABLE 8: FOUR LEG SYSTEMS

Specifications

Operating Specifications

Rated Output (F.S.) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2+-0.002mV

Non-Linearity- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - +-0.018% R.O.

Hysteresis - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - <-0.025% R.O.

Zero Balance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - <+-1.0% R.O.

Creep @ 5 Min. - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - <+-0.02% R.O.

Temp Effect Output- - - - - - - - - - - - - - - - - - - - - - - - - - - - - <+-0.0012% R.O./C

Temp Effect Sensitivity - - - - - - - - - - - - - - - - - - - - - - - - - - <+-0.0010% R.O./C

Input Resistance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1050 to 1200 ohms

Output Resistance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1000 +- 1 ohm

Insulation Resistance- - - - - - - - - - - - - - - - - - - - - - - - - - - - >5000 meg ohms

Excitation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5-15VDC

Safe Load Limit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 200% Emax

Ultimate Load - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 300% Emax

Safe Side Load - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 100% Emax

Environmental Specifications

Operating Temperature - - - - - - - - - Minus 40o F to Plus176o F (-40o C to +80o C)

Compensated Temperature - - - - - - - 14o F to 104o F (Minus 10o C to Plus 40o C)

Load Sensor Material - - - - - - - - - - 17-4PH Martensitic (Magnetic) Stainless Steel

Load Sensor Fittings - - - - - - - - - - - Coated Tool Steel

Top Plate & Base Plate Material - - - 316 Stainless Steel or Galvanized Steel

Conduit Adapter - - - - - - - - - - - - - - .250-18 NPT

Page 29

Page 36

HI HLPS SERIES LOAD POINT ASSEMBLY

Hermetic Sealing

Gauging Area - - - - - - - - - - - Welded Cylindrical Sleeve

Cable Entry- - - - - - - - - - - - - Glass to Metal Header

Page 30

Page 37

OPERATION AND INSTALLATION MANUAL

Print the unit serial number and model number for reference when ordering

parts for the HI HLPS Load Point Assembly

The serial number can be found on the side of the load sensor, or by entering the

SelfTest Mode.

Scale Name/Location:

Model Number:

Serial Number 1:

Serial Number 2:

Serial Number 3:

Serial Number 4:

Serial Number 5:

Serial Number 6:

Serial Number 7:

Serial Number 8:

Page 31

Page 38

HI HLPS SERIES LOAD POINT ASSEMBLY

Page 32

Loading...

Loading...