Page 1

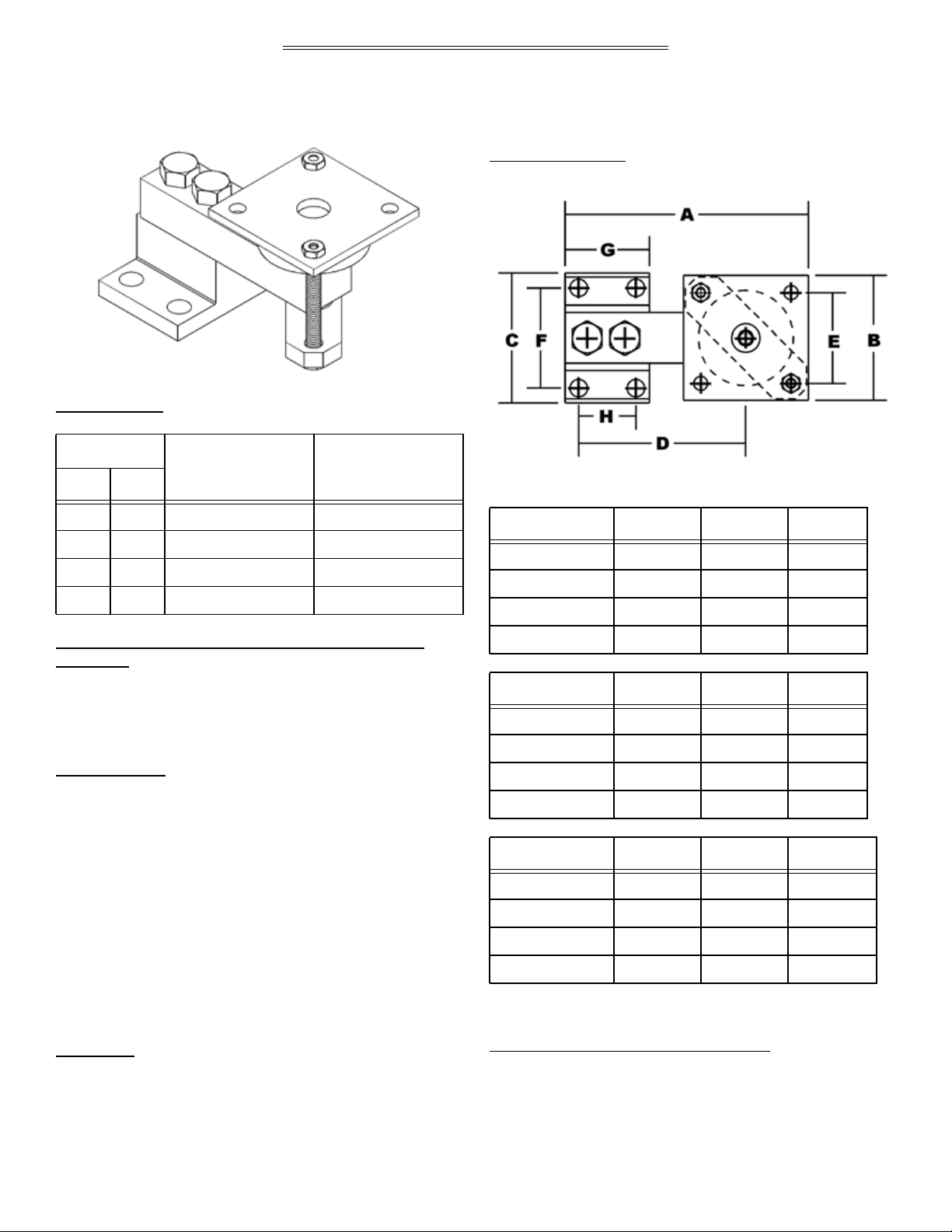

ADVANTAGE LITE SERIES: HI LPRE

INSTALLATION AND ASSEMBLY INSTRUCTIONS

Model Numbers

CAPACITY

LB KG

440 200 HI LPRE440-33C HI SB02-440

1100 500 HI LPRE1.1K-33C HI SB02-1.1K

2200 1000 HI LPRE2.2K-33C HI SB02-2.2K

4400 2000 HI LPRE4.4K-33C HI SB02-4.4K

Load Point

Model Number

Load Sensor

Model Number

• Never allow moisture to get into any interconnections.

• Keep the Load Point Assembly free of debris.

Physical Dimensions

MODEL # A B C

HI LPRE440-33C 6.13 (155.8) 3.15 (80.0) 3.27 (83.0)

HI LPRE1.1K-33C 6.13 (155.8) 3.15 (80.0) 3.27 (83.0)

HI LPRE2.2K-33C 6.13 (155.8) 3.15 (80.0) 3.27 (83.0)

Basic Engineering Principle for Positioning Load Point Assemblies

• Load Point Assemblies should be positioned such that the

load (weight) is distributed as evenly as possible between

each load point assembly in the scale.

Site Preparation

• All foundations for the HI LPRE load point assemblies

require a metal base plate adequate to prevent any deformation of the plate when welding the base or spacer of the load

point assembly to the foundation.

• All mounting surfaces for the base and loading plate must be

level. The Load Point Assemblies in a system must be level

to within ± 0.5

o

.

• Welding should be done prior to the installation of the load

sensor. Otherwise disconnect load sensor wiring from the

instrument and bypass each load sensor with heavy ground

strap from live weight side of each load point to earth

ground.

Precautions

• Always treat the Load Sensor as a precision instrument.

Leave the assembly in its packaging until it is time for installation.

• NEVER CARRY OR SWING THE LOAD SENSORS

BY THEIR CABLE.

HI LPRE4.4K-33C 6.13 (155.8) 3.15 (80.0) 3.27 (83.0)

MODEL # D E F

HI LPRE440-33C 4.22 (107.1) 2.28 (58.0) 2.52 (64.0)

HI LPRE1.1K-33C 4.22 (107.1) 2.28 (58.0) 2.52 (64.0)

HI LPRE2.2K-33C 4.22 (107.1) 2.28 (58.0) 2.52 (64.0)

HI LPRE4.4K-33C 4.22 (107.1) 2.28 (58.0) 2.52 (64.0)

MODEL # G H Height*

HI LPRE440-33C 2.12 (53.9) 1.44 (36.5) 3.37 (54.7)

HI LPRE1.1K-33C 2.12 (53.9) 1.44 (36.5) 3.37 (54.7)

HI LPRE2.2K-33C 2.12 (53.9) 1.44 (36.5) 3.63 (92.1)

HI LPRE4.4K-33C 2.12 (53.9) 1.44 (36.5) 4.59 (116.6)

* Measured from the bottom of the base to the top plate bolts.

Electrical Termination Cable Color Codes

WARNING: Load cell cable length has been calculated

into C2 calibration data. Hardy Process Solutions recommends that you do not cut your Advantage or

Advantage Lite load sensor cable, as your C2 accuracy

will be affected and the warranty will be voided.

Page 2

The cable is 6 conductor, shielded (floating) and 20 feet in length.

EXC+ Red EXC - Black

SHIELD Yellow C2+ Gray

C2- Violet SIG + Green

SIG - White

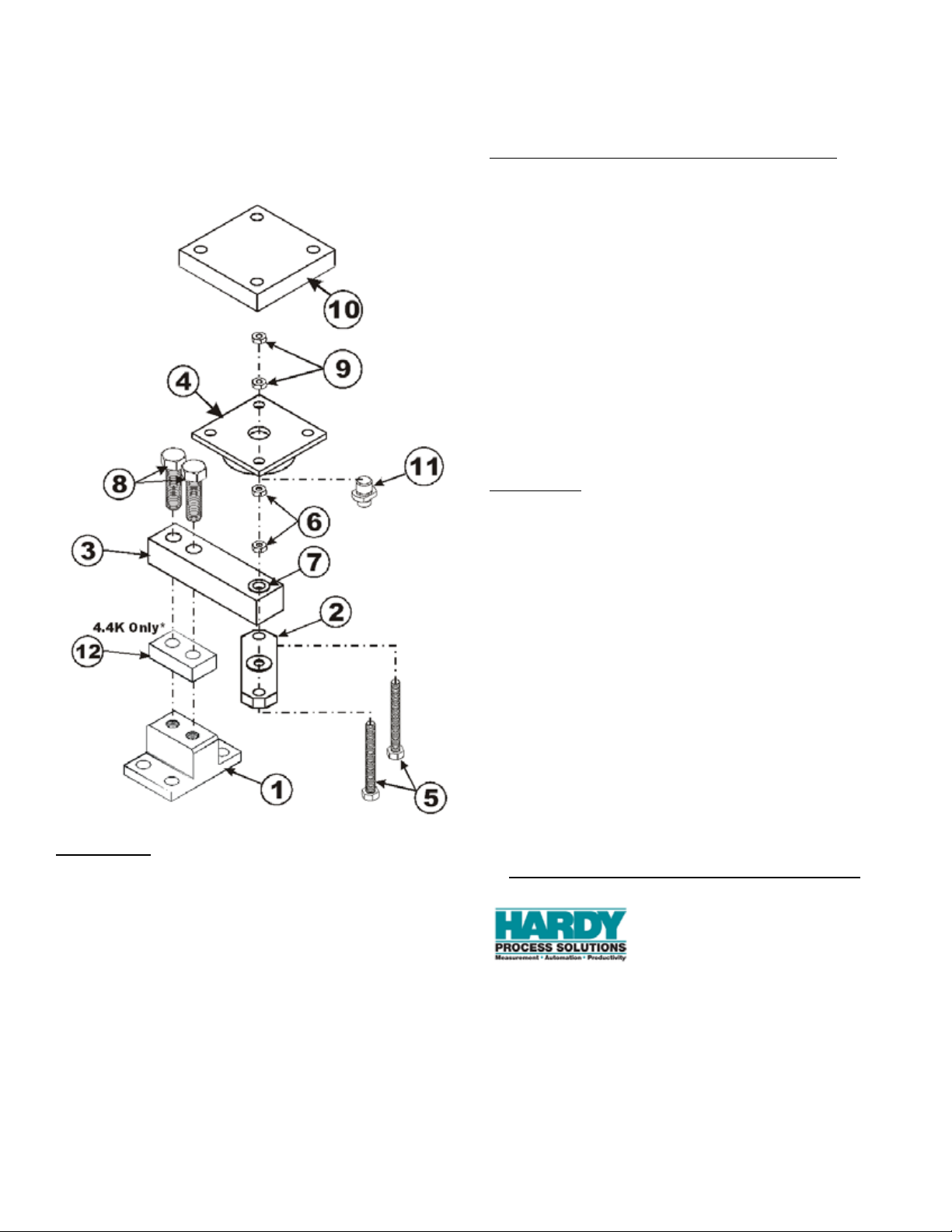

ISO Exploded View

Part Numbers

9. Upper Hex Nuts - 5/16” - 18 - A4 - 80 (For Shipping Only)

10. Optional Top Plate for Bolting or Welding

11. Load Pin - Prt. # 5504-0016-01

12. *Spacer (4.4 K Only)

Recommended Fasteners and Torque Specifications Use when attaching the load point assembly with fasteners to a vessel or support base plate.

• Fasteners - 3/8” - 16 with washer or 7/16” - 14 without

washer, or M10 with washer. 3/8 bolts allow for more

adjustments.

• Torque - HI LPRE440

Minimum - 15 ft-lb (20 Nm)

Maximum - 35 ft-lb (45 Nm)

• Torque - HI LPRE1.1K

Minimum - 15 ft-lb (20 Nm)

Maximum - 35 ft-lb (45 Nm)

• Torque - HI LPRE2.2K

Minimum - 25 ft-lb (35 Nm)

Maximum - 35 ft-lb (45 Nm)

• Torque - HI LPRE4.4K - 90 ft-lb (125 Nm)

Specifications

• Load Cell Material - 17-4 PH Stainless Steel

• Sealing - Potted

• Mount Material - Stainless Steel

• Capacities - 440,1.1k, 2.2k, 4.4k

• C2 Second Generation Calibration

• Matched mV/V/ohm - Yes

• Rate Output mV/V - 2 ± 0.002

• Hysteresis - < ± 0.025%

• Non-Linearity - < ± 0.025%

• Temp. Effect on Output% of Output /C - <= ± 0.002

• Temp. Effect on Zero Balance% of R.O/C - <= ± 0.002

• Zero Balance - <= ± 1.0%

• Comp Temp C -10 to +40

• Operating Temp -40 to +80

• Safe Load -% of Rated Load - 150

• Ultimate Load -% of Rated Load - 150

• Input Resistance - 1050 to 1200 Ohms ± 50

• Output Resistance - 1001 ± 1.0%

• Washdown - IP67

1. Base, Load Point - Prt. # 5504-0001-01

2. Lift Off Plate - 440 & 1.1K (Prt. # 5504-0018-01) 2.2K

(5504-0018-02) 4.4K (Prt. # 5504-0018-03)

3. Load Sensor (See Front Page)

4. Rubber Element - 5504-0015-01

5. Lift Off Hex Bolts:

• 5/16” - 18 x 3.5” - A4 - 80 (Stainless) 4.4 K

• 5/16” - 18 x 3.0 - A4 - 80 (Stainless) 2.2 K

• 5/16” - 18 x 2.75 - A4 - 80 (Stainless) 440 & 1100

6. Lift Off Hex Nuts - 5/16” - 18 - A4 - 80 (Stainless)

7. Load Cup - 440 & 1.1K (Prt. # 5504-0017-01) 2.2K (Prt. #

5504-0017-02) 4.4K (Prt. # 5504-0017-03)

8. Load Sensor Hex Bolts:

• 440lb. (1.1K) K - M12 x 35mmL - A4 - 80 (Stainless)

• 2.2 K - M12 x 45mmL - A4 - 80 (Stainless)

• 4.4 K - M12 x 60mmL - A4 - 80 (Stainless)

Hardy Process Solutions

9440 Carroll Park Drive, Suite 150

San Diego, CA 92121

(858) 278-2900

(800) 821-5831

FAX: (858) 278-6700

e-mail: hardysupport@hardysolutions.com

Web Address: http://www.hardysolutions.com

Hardy Process Solutions Document Number: 0596-0284-01 Rev E

Copyright March 2012 Hardy Process Solutions. All Rights Reserved. Printed in the USA

Loading...

Loading...