Page 1

HI 6600 Series Modular Sensor System User Guide

HI 6600 Series Modular Sensor System

User’s Guide

Page | 1

Hardy Process Solutions Document Number: 0596-0333-01 REV A

Page 2

Local Field Service

HI 6600 Series Modular Sensor System User Guide

Hardy has over 200 field technicians in the U.S., and more positioned throughout the world to assist you

in your support needs. We also have factory engineers who will travel to your facility

world to help you solve challenging applications. We're ready to support you with:

Installation and start-up

Routine maintenance and certification

Plant audits and performance measureme nt

Emergency troubleshooting and repair

anywhere in the

To request Emergency Service and Troubleshooting, Start-up, Installation, Calibration, Verification or to

discuss a Maintenance Agreement please call 800-821-5831 or Emergency Service after hours (Standard

Hours 6:30 AM to 5:30 PM Pacific Standard Time) and weekends.

Outside the U.S

Hardy Process Solutions has built a network of support throughout the globe. For specific field service options

available in your area please contact your local sales agent or our U.S. fact ory at

+1 858-292-2710.

Page 3

HI 6600 Series Modular Sensor System User Guide

Contents

• • • • • •

Conte nts .......................................................................................................................................... 3

Chapter 1 ......................................................................................................................................... 8

HI 6600 Series Overview ................................................................................................................ 8

Introduction to the HI 6600 Modular Sensor System.............................................................. 8

Typical Applications

HI 6600 Series Model Numbers

Chapter 2

Specifications and Features

Chapter 3

HI 6600 Hardwa re Installation

Chapter 4 ....................................................................................................................................... 25

Instrument Configuration

......................................................................................................................................... 11

Basic Specifications

HI 6610 Weight Processing Module (WPM) ................................................................. 11

Hardy Gateway Module (HI 6600) ....................................................................................... 12

Network Connectivity

Optional HI 6110 Front Panel Display

Environmental Requirements

Approvals ....................................................................................................................... 13

Network Certifications

Features and Capabilities

Hardy Process Toolbox

C2® and eCal ™ Calibration

INTEGRATED TECHN I CI A N® ........................................................................................ 14

WAVERSAVER® ........................................................................................................... 14

......................................................................................................................................... 15

Safety

..................................................................................................................................... 15

General Precautions

Unpacking ............................................................................................................................. 15

Tool List ......................................................................................................................... 16

Installing the HI 6610 Modules ............................................................................................ 16

Overview of the HI 6600 Hardware ...................................................................................... 17

Installation ...................................................................................................................... 17

Cabling the Units Together

DC Power Input .................................................................................................................... 19

Connecting Sensors ........................................................................................................ 20

Installing the Optional Display

Blind Unit (No display)

Optional Remote Display Mount

Mounting the Optional Front Panel Display .................................................................... 22

Making Longer Display Interface Cables

Using the Webserver ............................................................................................................. 26

............................................................................................................ 9

.......................................................................................... 10

................................................................................................................ 11

................................................................................................................. 11

...................................................................................................... 12

.................................................................................. 13

.............................................................................................. 13

....................................................................................................... 13

........................................................................................................... 13

....................................................................................................... 13

............................................................................................... 13

............................................................................................................ 15

........................................................................................................... 15

.................................................................................................. 19

.................................................................................................. 21

...................................................................................................... 21

......................................................................................... 21

............................................................................. 24

.................................................................................................................. 25

Page | 3

Page 4

HI 6600 Series Modular Sensor System User Guide

Using the HI 6110 Front Panel Display

Mode Button

Chann e l Identific ation

System Discovery

Naming the Weight Processing Modules

Ordering the Weight Proces s ing Modules

Deleting or Replacing Channels

Savi n g a n d R e s t o r ing Config u r a t i o n D a t a U s i n g t h e USB p o r t ........................................ 30

Suggested Minimum Steps When Setting Up the Instrument For the First Time........... 31

Capacity Parameter

Decimal Point Parameter ................................................................................................ 32

Graduation Size Parameter ............................................................................................. 32

Instrument ID ................................................................................................................. 33

Motion Tolerance Parameter .......................................................................................... 33

Operator ID Parameter

Unit (of Measure) Parameter .......................................................................................... 33

Filter Parameter Menu

NumAverages Parameter

WAVERSAVER® Parameter

Calibration

Pre-Calibration Procedures

Electrical Check Procedures .................................................................................................. 36

Load Cell/Point Input/Output Measurements ................................................................. 36

Load Check

C2 & eCAL Electronic Calibratio n

C2 and eCAL Calibration

Sensitivity Parameter

Ref Weight Parameter

Cal Tolerance Parameter

Gravitation Correction .................................................................................................... 38

C2 and eCAL Calibration Process

Hard Calibration .................................................................................................................... 41

Hard Cal Commands and Parameters ............................................................................. 41

Cal Lo Weight Parameter

Cal Tolerance Parameter

Do Cal Lo Command

Do Cal Hi Command

Span Weight Parameter

Chapter 5

Instrument Operation

........................................................................................................................................ 43

Operations ............................................................................................................................. 43

Tare Parameters and Commands

Tare Amount

Tare Offset

Tare Command

Zero Parameters and Comm ands

Zero Tolerance

Zero Amount

Zero Command

Auto Mode

..................................................................................................................... 28

............................................................................................................... 29

.............................................................................................................. 29

.......................................................................................................... 32

..................................................................................................... 33

........................................................................................................ 34

.................................................................................................. 34

.............................................................................................................................. 35

................................................................................................. 35

....................................................................................................................... 37

Commands and Parameters ....................................................... 37

........................................................................................................ 37

....................................................................................................... 37

................................................................................................... 38

................................................................................................. 41

................................................................................................... 41

....................................................................................................... 41

........................................................................................................ 41

.................................................................................................... 42

........................................................................................................................ 43

................................................................................................ 43

.................................................................................................................... 43

....................................................................................................................... 44

................................................................................................................. 44

................................................................................................ 44

................................................................................................................. 44

.................................................................................................................... 45

................................................................................................................ 45

........................................................................................................................ 45

.................................................................................... 27

............................................................................... 30

.............................................................................. 30

.......................................................................................... 30

........................................................................................... 34

............................................................................................. 37

...................................................................................... 40

Page | 4

Page 5

HI 6600 Series Modular Sensor System User Guide

Count Operations

Determining Piece Count:

Chapter 6 ....................................................................................................................................... 47

Network Communications

Maximum Number of Channels Supported for PLC Communication Formats ............. 48

LAN Connection ............................................................................................................ 48

IP address. ...................................................................................................................... 49

Enable DHCP

Mask Address Parameter ................................................................................................ 49

Gateway Address Parameter

DNS Server Parameter

Fixed IP Configuration ................................................................................................... 50

Direct Connect Hardware ............................................................................................... 50

Windows PC Configuration: Windows 2000 ................................................................ 51

Windows XP

Windows 7

Direct Connect Configuration - HI 6600 HGM

EtherNet/IP®

EtherNet/IP Commands and Parameters

The EtherNet/IP Diagnostics Screen ................................................................................ 53

Ethernet UDP Parameters

Hardy Port ...................................................................................................................... 55

Modbus TCP

Modbus TCP Commands and Parameters ...................................................................... 55

Installing the Hardy Modbus-Link Te st Package .............................................................. 57

Configuring MODBUS TCP

Modbus-RTU (over RS-485) ..................................................................................................... 62

Modbus-RTU Commands and Parameters

Slave Address Parameter

Baud Rate Parameter ....................................................................................................... 62

Parity Parameter .............................................................................................................. 63

Modbus Setup

Modbus Functions

Profibus-DP .......................................................................................................................... 65

Profibus Configuration

Initialization Process

Profibus-DP .GSD File .................................................................................................... 68

Pre-Initialization Procedures

USB Memory Stic k

Restore Command

Chapter 7 ....................................................................................................................................... 74

Security ......................................................................................................................................... 74

Optional HI 6110 Display Security Options

The Display Lock

The Keypad Lock

The Configuration Lock

The Read Only, Security & Calibration Locks ............................................................... 81

Modifying the Calibration Param e te r s

Modifying the Read Only Paramete r s

Chapter 8 ....................................................................................................................................... 84

..................................................................................................................... 46

................................................................................................. 46

................................................................................................................. 47

.................................................................................................................. 49

............................................................................................. 49

..................................................................................................... 50

.................................................................................................................... 51

....................................................................................................................... 51

...................................................................... 52

........................................................................................................................... 52

.................................................................................. 53

......................................................................................................... 55

........................................................................................................................... 55

............................................................................................. 57

............................................................................ 62

.................................................................................................. 62

.................................................................................................................. 64

............................................................................................................ 64

....................................................................................................... 66

........................................................................................................ 67

............................................................................................. 68

.................................................................................................................. 73

............................................................................................................ 73

................................................................................ 74

.............................................................................................................. 75

.............................................................................................................. 78

..................................................................................................... 79

.................................................................................. 83

................................................................................... 83

Page | 5

Page 6

HI 6600 Series Modular Sensor System User Guide

Troubleshooting ............................................................................................................................ 84

Assembly Notes, War ni ngs & Cautions

Updating Instrument Firmware

Information Page

Indicator Lights Summary .............................................................................................. 86

Common Error Messages

Diagnostics ............................................................................................................................ 87

Trouble Shooting Using Integrated Technician (IT®)

Stability Test ALL

PASS/FAIL and Stability Test

WAVERSAVER TEST

Weight and Voltage ALL ............................................................................................... 88

RTZ (Return to Zero) Test

IT Test

.............................................................................................................................. 89

General Trou b l e sh o o t i n g Flow Chart Index

A - Electrical and Mechanical Review

A1. Checking for Unstable Components in a Weighing System

B. Guidelines for Electrical, Mechanical or Configuration Issues

B1 - Guidelines to Verify Electrical Installation

B2 - Guidelines to V erify Mechanical Installation

B3 - Verify Configuration/Filter Settings to Improve Stability

C - Integrated Technician and Stability Test Overview

E Non-Return to Zero (System with IT Summing Card.)

F. Verify Individual Load Sensor Millivolt Output readings

G- Calibration Error s During Calibration

H. Mechanical Installation

J- Electrical Inspection

K - Installation Check Points

M. Weight Processor’s Optional Front Display Blank or Locked

Tests and Diagnostics

Diagnostic testing from the Optional Front Panel

Parameters ........................................................................................................................... 107

System and Load Cell Tests

Overview of Typical Load Cell System

INTEGRATED TECHNICIAN

Stability Test

Running the Stability Test from the Web Interface ........................................................... 110

Running the Stability Te st from the Optional Front Panel ................................................. 110

Weight and Voltage Tests ................................................................................................ 111

Weig ht and Vo ltage Test from the W eb interface .............................................................. 111

Running the IT test from the Optional Front Pa nel .......................................................... 111

Appendix A ................................................................................................................................. 113

Communications I/O Table ......................................................................................................... 113

I/O Tables for Communications to PLCs

OUTPUT Table Description

Portion of the OUTPUT table used for the Hardy Gateway Module (HGM) ............... 114

Portion of the OUTPUT table used for Weigh Processing Modules (WPM s) ............. 114

INPUT Table Description

Portion of the INPUT table used for the Hardy Gateway Module (HGM) ................... 114

............................................................................................................... 85

.......................................................................................................... 87

............................................................................................................. 88

.................................................................................................... 88

.................................................................................................... 89

...................................................................................................... 102

........................................................................................................... 103

.................................................................................................... 104

.............................................................................................................. 106

...................................................................................................... 108

.................................................................................................................. 109

.................................................................................................... 114

........................................................................................................ 114

....................................................................................... 84

........................................................................................... 85

............................................................. 87

............................................................................................. 88

.................................................................................. 91

.......................................................................................... 92

......................................................... 93

................................................... 94

............................................................................. 95

.......................................................................... 96

......................................................... 97

.................................................................... 98

................................................................. 99

......................................................... 100

.................................................................................. 101

.................................................... 105

................................................................ 106

............................................................................... 108

................................................................................................ 109

..................................................................................... 113

Page | 6

Page 7

HI 6600 Series Modular Sensor System User Guide

Portion of the INPUT table used for Weigh Processing Modules (WPMs) ................. 115

Hardy Command Numbers

Appendix B ................................................................................................................................. 118

Default Parameter IDs and Values

Default Parameters and Values Table

Appendix C ................................................................................................................................. 120

Drawings & Templates

II Diagrams ......................................................................................................................... 120

Image of HI 6600 Hardy Gateway Module II Diagram ...................................................... 121

Image of HI 6610 Weight Processing Module II Diagram

Optional HI 6110 Display Panel Mounting Template

Appendix D ................................................................................................................................. 124

Spare Parts .................................................................................................................................. 124

Spare Parts

Appendix E ................................................................................................................................. 125

Wiring Junction Boxes or Summing Cards

Connecting to Hardy Junction Boxes or Summing Cards

HI 6010 Summ ing Box Diagram ........................................................................................... 126

.................................................................................................................... 120

............................................................................................................................ 124

...................................................................................................... 116

..................................................................................................... 118

........................................................................................ 118

........................................................... 122

................................................................... 123

......................................................................................... 125

.............................................................. 125

Page | 7

Page 8

HI 6600 Series Modular Sensor System User Guide

Chapter 1

HI 6600 Series Overview

• • • • • •

This Manual describes installation, setup and operating procedures for the HI 6600 Series Modular Sensor

System. Be sure to read and understand all cautions, warnings, and safety procedures in this manual to ensure

safe installation and operation of the instrument.

Hardy Process Solutions sincerely appreciates your business. We encourage input about the performance and

operation of our products from our customers. Should you not understand any information in this manual or

experience any problems with this product, please contact our Technical Support Department at:

Phone:

(858) 278-2900

Toll Free:

FAX:

E-Mail:

Website:

Please visit our website for the latest revision of the HI 6600 Series User Guide and sign up for the Hardy

Newsletter to get the latest information on all Hardy products and services. For answers to technical issues

and service problems, please visit the Hardy WebTech section of our website or contact a technician by

phone during our normal operating hours (6:30 AM to 5:30 PM Pacific Time).

1-800-821-5831

(858) 278-6700

hardysupport@hardysolutions.com or hardyinfo@hardysolutions.com

www.hardysolutions.com

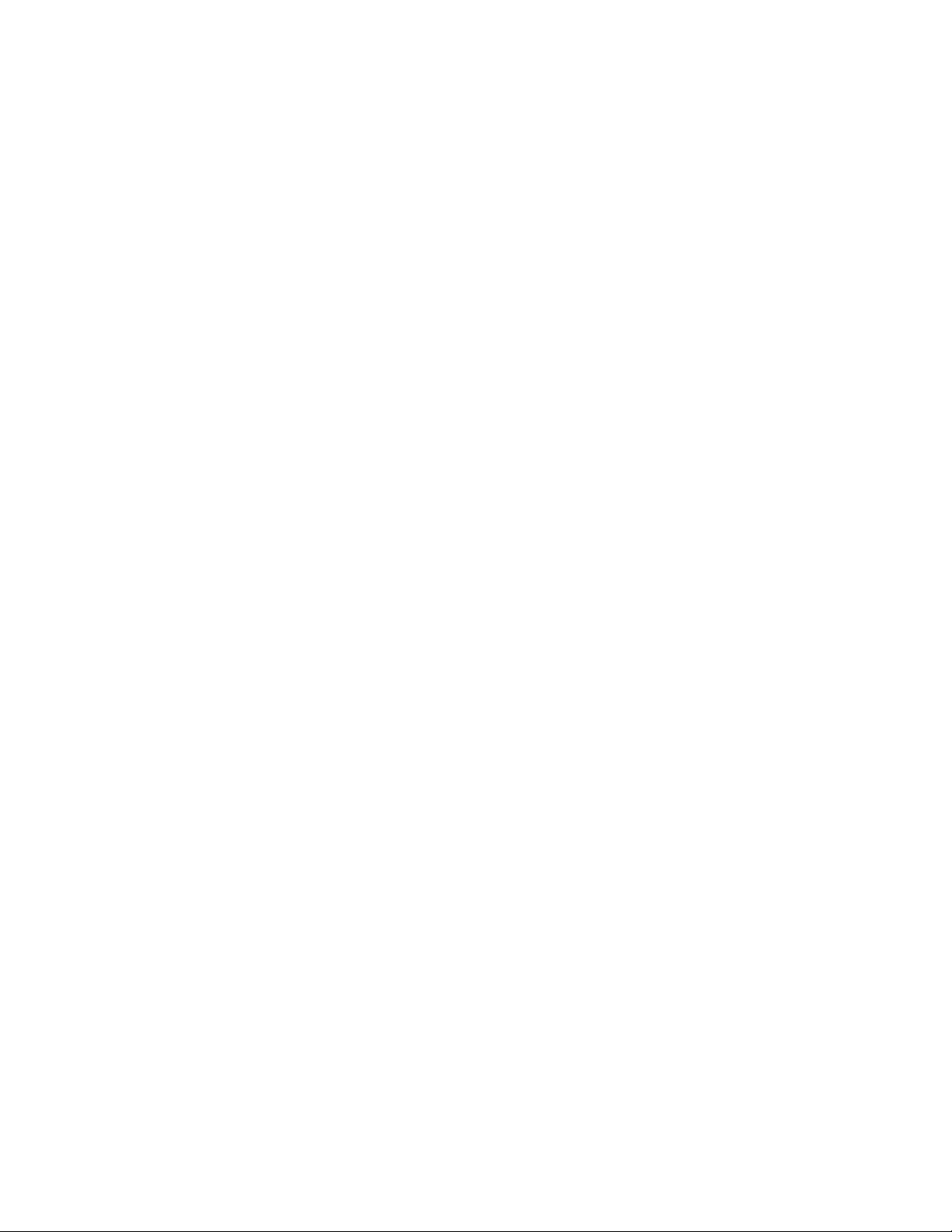

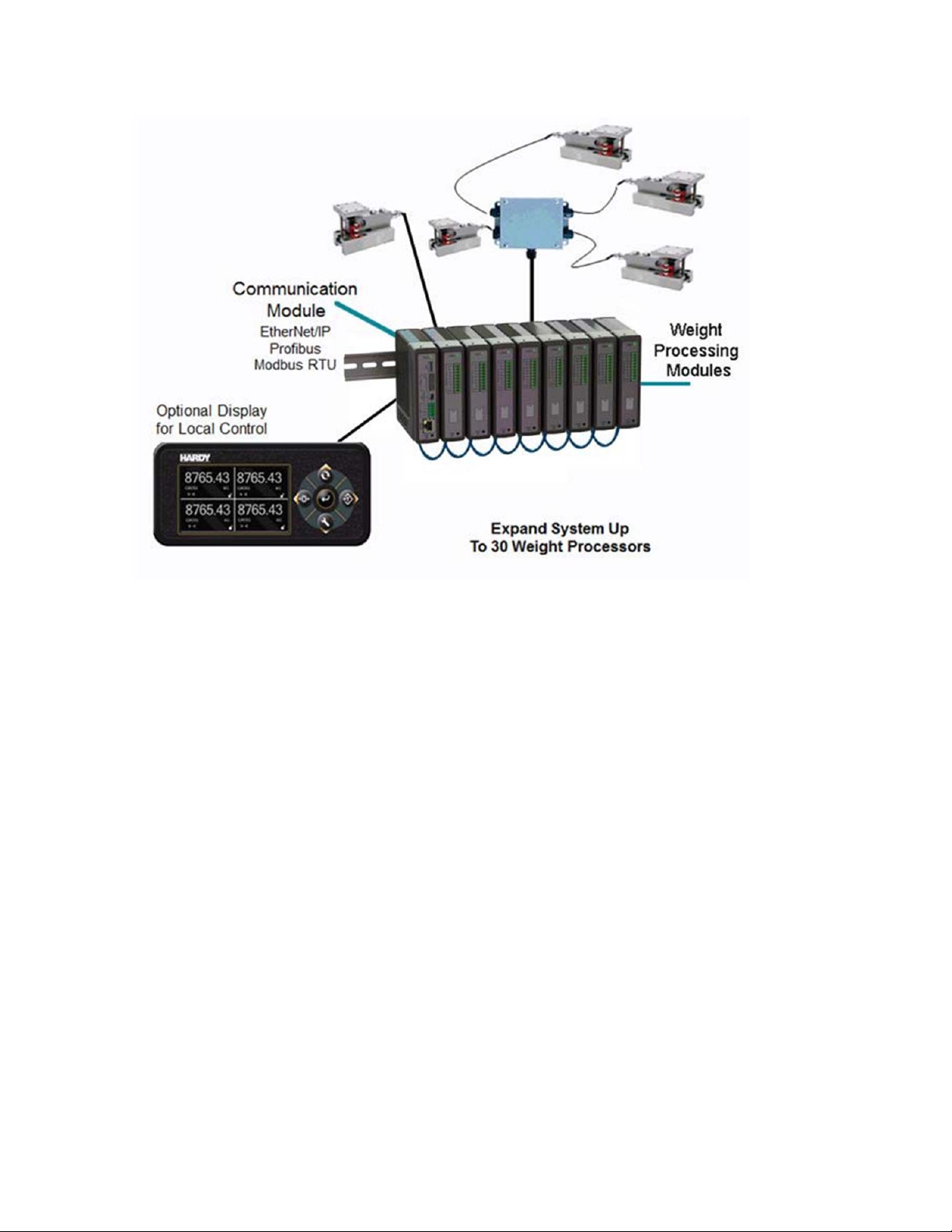

Introduction to the HI 6600 Modular Sensor System

The HI 6600 Modular Sensor System consists of at least one HI 6600 Hardy Gateway Module (HGM) and up

to 30 HI 6610 Weight Processor Modules (WPM).

The system communicates with PLCs, PACs and DSCs over EtherNet/IP, Profibus-DP, Modbus-RTU and

other popular communication pr ot ocols via a single communication link.

Page | 8

Page 9

HI 6600 Series Modular Sensor System User Guide

The system is used for front end signal processing o f strai n - g age typ e s ensors a n d load c e l ls for all types of

industrial and machine weighing applications.

Sensor System conditions, converts and

load sensors or scales to a variety of control and monitoring systems.

The HardyNet Gateway Module (HGM or HI 6600) offers users many communication choices including

Ethernet TCP/IP, Modbus RTU, Modbus TCP and either EtherNet/IP or Profibus-DP.

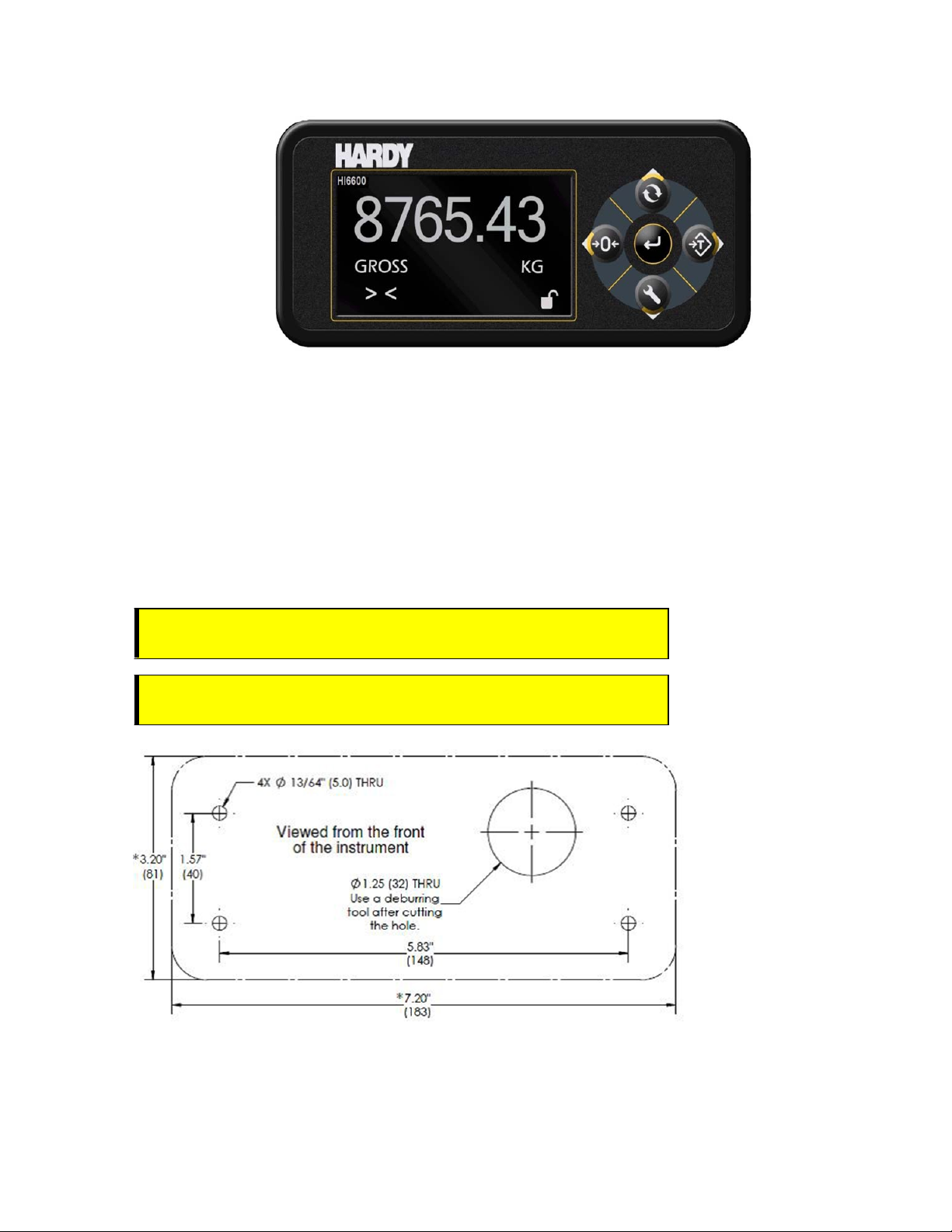

The HI 6600 series can be used with or without an optional Hardy HI 6110 display. The display is a bright

4.3” high-contrast LCD capable of high-resolution graphics and help text discrete messaging. The HI 6110

display can be panel mounted near the Gateway Module or remotely up to 100 feet away to provide a user

interface for operating, calibrating or setting-up the system.

The modular array, small enclosures and low power consumption enable high density cabinet design for

systems that require up to 30 channels of processed weight .

Operating blind or with an optional display, the Modular

communicates stable processed weight readings from connected

Typical Applications

Ideally suited for applications that require multiple channels of weight, the HI 6600 series serves a variety of

industrial weighing needs found in batching, blending, filling, dispen sing, inventory management, level by

weight and check by weight verification.

Page | 9

Page 10

HI 6600 Series Model Numbers

HI 6600 Series Modular Sensor System User Guide

Model Number

HI 6600-EIP Hardy Gateway Module - EtherNet/IP

HI 6600-PB Hardy Gateway Module - Profibus-DP

HI 6610-WP Weight Processing Module, no display

HI 6110

Description

Optional Multi-Channel Display

Page | 10

Page 11

HI 6600 Series Modular Sensor System User Guide

Chapter 2

Specifications and Featur es

• • • • • •

Chapter 2 provides specifications for HI 6600 series instruments. The specifications listed are designed to assist in the

installation, operation and troubleshooting of your instrument. All service personnel should be familiar with this section

before installing or repairing the instrument.

Basic Specifications

HI 6610 Weight Processing Module (WPM)

Number of Channels

Each Weight Processing Module is a single channel of weight. HI 6600 Modular Sensor System can support up to 30

channels. The actual number of channels that can be transmitted by a single I/O table request depends on the PLC

interface format.

EtherNet/IP: Up to 30 Channels per request

Modbus-TCP: Up to 14 Channels per request

Modbus-RTU: Up to 14 Channels per request

Profibus-DP: Up to 10 Channels per request

Update Rate per Weight Processing Module (WPM)

110 times per second per channel (processed weight, display, communications)

Weight Pr oce ssi ng Module (WPM) Resolution

Displayed - 1:10,000

Internal - 1:8,388,608

WAVERSAVER

User Selectable

OFF, 7.50 Hz, 3.50 Hz, 1.00 Hz (default ) , 0.50 Hz, 0.25 Hz

®

Averages

Load Sensor Input per WPM

Page | 11

1 to 250

User-selectable in Single Increments

Up to four 350-ohm full Wheatstone bridge, strain gauge load sensor/cells (5 volt excitation) can be connected

to the weigh scale input on each WPM.

Page 12

HI 6600 Series Modular Sensor System User Guide

Note: Connecting 2 or more load cells requires a summing card or Junction Box.

Non-linearity

0.0015% of full scale

Common Mode Rejection

110 dB at or below 60 Hz

Common Mode Voltage Range

2.5 VDC maximum (with respect to earth ground)

Load Cell Excitation

5 VDC +/- 1.15 VDC maximum

Isolation from digital section 100 0 VDC minimum

C2 Calibration Input

Isolation from digital section 1000 VDC minimum

Load Sensor Cable Lengths per Weight Processing Module

250 feet maximum of C2 authorized cable (Maximum of4 load sensors) with a

Junction box

DC Input Volt age Weight Process ing Module (with 4x 350ohm load cells)

1.72 Watts, 12-27 VDC, 71-118 mA

Maximum System Span Distance

500 feet (150 meters) span from the first Weight Processor Module to the Hardy Gateway Module

Summing Card or IT

Hardy Gateway Module (HI 6600)

Network Connectivity

Ethernet TCP/IP

Ethernet UDP

Modbus-RTU over RS485

Modbus TCP

EtherNet/IP (EIP models only)

Profibus-DP (PB models only)

USB Port: For Parameter Saving and Backup to PC

Display Port: For optional Front Panel Display

Scoreboard: Uses RS485 port to stream weight readings to a large display or data logger

DC Input Volta ge Hardy Gateway Module (HGM)

3.90 Wat ts, 12-24 VDC, 162-290 mA

Page | 12

Page 13

HI 6600 Series Modular Sensor System User Guide

Optional HI 6110 Front Panel Display

Monochrome 480 x 272 LCD di splay with back light

Five tactile keys for menu item selection

Displays in either white on black or black on white

IP66 rated when mounted on a smooth, rigid surface (minimum 16-gage) using the supplied gasket

2 watts maximum

Environmental Requirements

Operating Temperature Range

-10ºC to 60º C (14º to 140º F)

Temperature Coefficient

Less than 0.005% of full scale per degree C for Cal-LO and Cal-HI reference point s

Storage Temperature Range

-40 to 85º C (-40º to 185º F)

Humidity Range

0-90% (non-condensing)

Environmental

Intended for Building-in, indoor use only at ambient temperatures between 10ºC to 60º C (14º to 140º F) wi t h a

pollution degree of 2.

Approvals

UL, CUL and CE

Hazardous Area Class I, Division 2, Groups A,B,C,D, T4A (pending)

Hazardous Area Class III, Division 2, Groups E, F, G, T4A (pending)

Network Certifications

EtherNet/IP ODVA Conformance Tested, Level 3)

Profibus-DP by Profibus.org (pending)

Features and Capabilities

Hardy Process Toolbox

The Hardy Process Toolbox is a set of productivity tools that support process weighing functions. Each tool in the Hardy

Process Toolbox saves time, increases accuracy, improves efficiency or reduces risk in process weighing applications.

The HI 6600 includes the Toolbox functions discussed below.

C2® and eCal™ Calibration

Traditional calibration uses certified test weights. C2® (or eCAL™ as it is called in China) Electronic Calibration allows

a scale to be calibrated without the need for test weights. A C2 or eCAL weighing system consists of up to four load cell

sensors per WPM, a junction box, interconnect cable, and an instrument with C2 capabilities (e.g., the HI 6600 series

instrument).

Page | 13

Page 14

HI 6600 Series Modular Sensor System User Guide

Each Hardy Process Solutions C2-certified load sensor outputs digital information used for calculating the calibration.

When the HI 6600 series instrument reads the signals from the load sensors, it calibrates the scale based on the load

sensor’s output plus a user-supplied reference point value (from 0 to any known weight on the scale).

INTEGRATED TECHNICIAN

In conjunction with an IT junction box, the HI 6600 seri es fe at ures I NTE G R ATED TECHNICIAN® (IT), a system

diagnostics program that makes it possible to diagnose weighing system problems from Hardy’s Web Server or a

connected optional display panel. IT reads individual load sensor voltages and weights and isolates individual system

components for quick and easy troubleshooting

NOTE:

on the system.

WAVERSAVER

When measuring small weight changes, the effects of mechanical vibration and noise from feeders and other plant

environmental conditions can introduce substantial interference. WAVERSAVER factors out vibration, noise, and other

interference-related signals from the load cell so the weight processor can better decipher the actual weight data.

While WAVERSAVER can factor out noise with frequencies as low as 0.25 Hz, five cut-off frequencies can be selected,

with higher frequencies providing a faster response time. The default factory setting is 1.00 Hz vibration frequency

immunity.

If you do not have a Hardy IT Junction Box connected to the HI 6600, the weight reading is the total for all load cells

®

®

C2, INTEGRATE D TECHNICIAN and WAVERSAVER are regi stered trademarks of Hardy Process Solutions.

Page | 14

Page 15

HI 6600 Series Modular Sensor System User Guide

Chapter 3

HI 6600 Hardware Installation

• • • • • •

Chapter 3 covers physical installation of HI 6600 Modular Sensor System. User and service personnel should read this

chapter before installing or operating the HI 6600 Modular Sensor System.

Safety

Before you begin installing your HI 6600 series equipment, please review the important safety precautions

below.

Do not operate or work on this equipment unless you have read and understand the instructions and warnings in this

Manual. Failure to follow the instructions or heed the warnings could result in injury or death. Hardy Process Solutions

provides manuals in PDF format that are easily downloaded from our website, free of charge. Look under the Docs &

Programs tab on the web page for each product.

General Precautions

Always disconnect the power cord before disassembling.

Always replace broken or damaged module s or hardw a re i m mediately.

Always check to be sure that no loose parts are sitting on printed circuit boards or electrical connectors or wires

when disassembling or reassembling.

Always protect printed circuit boards from electrostatic discharge (ESD). Always use approved ESD wrist straps

and anti-static pads.

Unpacking

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY

IMPAIR SUITABILITY FOR DIVISION 2.

A VERTISSEMENT – Risque d’explosion – La substitution de composants peut

diminuer la conformité pour la Division 2

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT

UNLESS POWER HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE

NON-HAZARDOUS

A V ER TISSEME NT – Risque d’explosion – Ne p as débrancher l’équipement à

moins que l’alimen tation soit cou pée ou que la zone ne présente p as de risques

1) Before signing the packing slip, inspect the packaging for damage, and report damage of any kind to the carrier

company.

Page | 15

Page 16

HI 6600 Series Modular Sensor System User Guide

2) Check to see that everything in the package matches the bill of lading.

3) If items are missing or you have any questions, contact Customer Service at:

Hardy Process Solutions

9440 Carroll Park Drive San Diego, CA 92121

Phone: (800) 821-5831

International: (858) 292-2710

FAX

:

(858) 278-6700

Web Site:

E-Mail:

Record the model number and serial number of the HI 6600 series instrument. Store them in a convenient, secure location

for reference when contacting Hardy Customer Service Department or to buy parts or firmware upgrades.

http//www.hardysolutions.com

hardysupport@hardysolutions.com

Tool List

To install the HI 6600 series the following tools will be required.

Jewelers screw driver (to make and modify cable assemblies)

10-50 mm Unibit (for optional display installation)

Drill with 5mm drill bit (for optional display installation)

8 mm nut wrench or socket (for Optional Display)

Installing the HI 6610 Modules

Before getting started, take the following precautions:

WARNING - Electrostatic discharge may damage semiconductor components in

the module. DO NOT TOUCH THE CONNECTOR PINS.

AVERTISSEMENT – Les décharges électrostatiques peuvent endommager les

composants semi-conducteurs dans le module. NE TOUCHEZ PAS les broches du

connecteur.

Wear an approved wrist-strap grounding device when handling the instrument.

Touch a grounded object or surface to rid yourself of any electrostatic discharged prior to handling the

instrument.

Handle the instrument from the bezel in front away from the connector. Do not touch the connector pins.

Do not install the instrument right next to an AC power source or high voltage DC equipment

Route all the low voltage cables away from high voltage cables

Page | 16

Page 17

HI 6600 Series Modular Sensor System User Guide

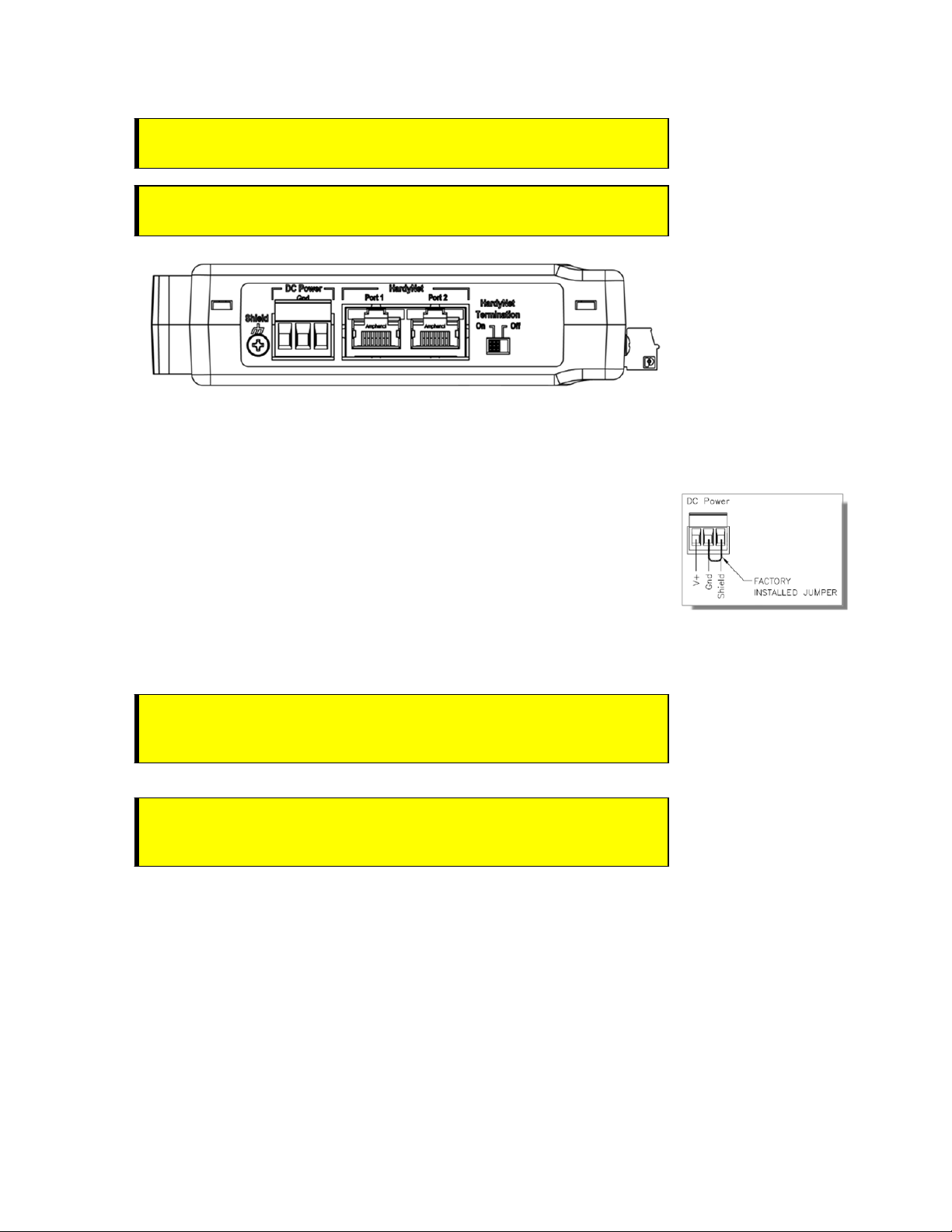

Overview of the HI 6600 Hardware

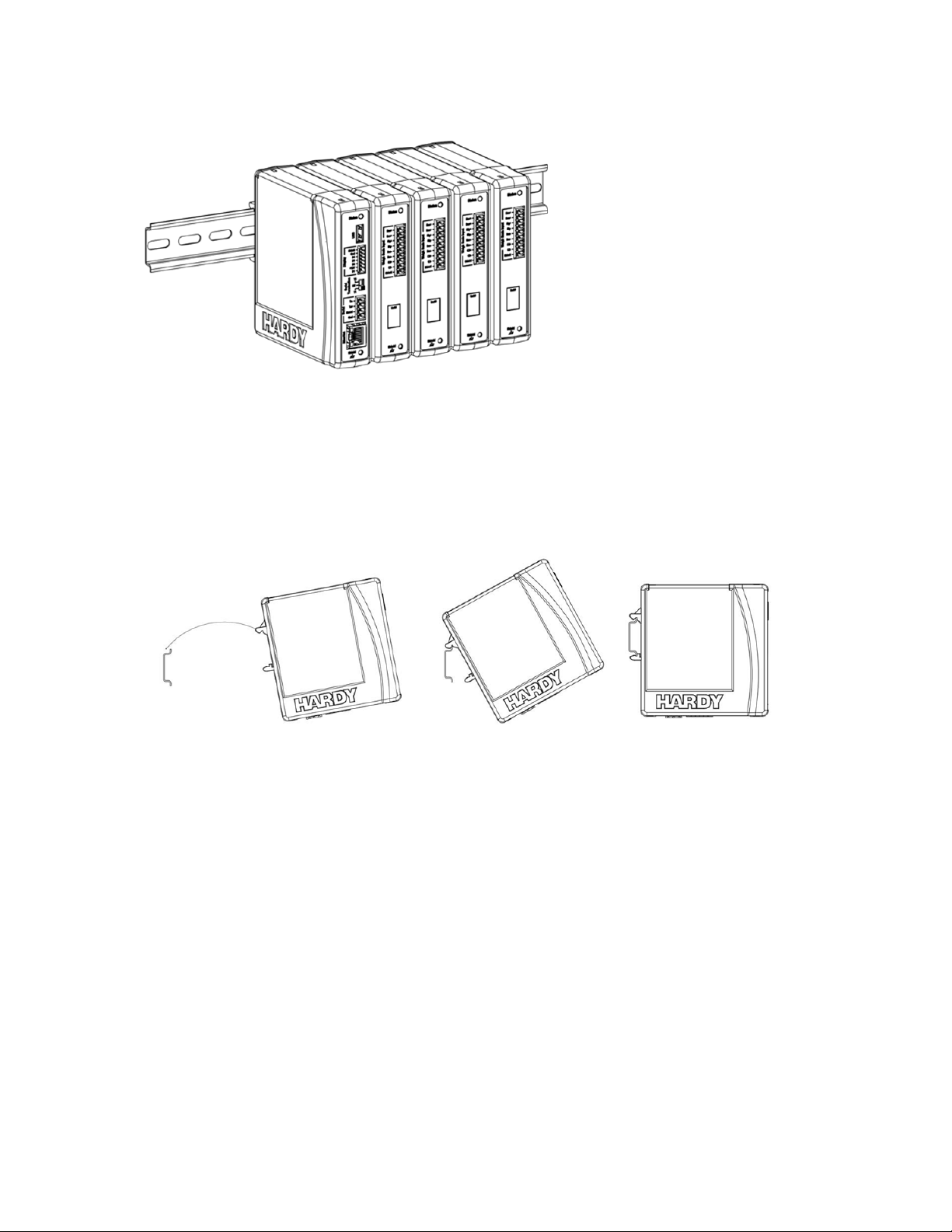

Before installing the HI 6600 Series, familiarize yourself with the basic configuration as shown below.

DC Power, Shield, Ports for HardyNet and a Termination switch can be found on the bottom of both the Hardy Gateway

Module and the Weight Processing Modules.

The RJ45 ports located on the bottom are used to connect the system using Cat5e cabling. Communications between

modules (HardyNet) as well as power distributed from the Gateway Module to the Weight Processing Modules is carried

on the Cat5e cabling.

Weight Processing Module Hardy Gateway Module

The Weigh Scale Input is located on the front of the HI 6610 Weight Processing Module.

Located on the front of the HI 6600 Gateway module is a USB port (used to store system settings), a Display

port (for connecting to an optional HI 6110 display), Serial Termination switch, Serial Port and an Ethernet Port.

Installation

The HI 6600 Series WPMs and HGMs are designed to be installed on a DIN rail as shown below.

Page | 17

Page 18

HI 6600 Series Modular Sensor System User Guide

The MAXIMUM span between the first and last module that comprise a system is 500 feet (150 meters).

Note: Use Heavy Gage DIN rail conforming to EN 60715 and EN 50022.

Use of thin or light gage DIN rail is not recommended.

Begin by installing the WPMs or HGMs onto the DIN rail as shown below.

1) Hook DIN rail bracket onto the DIN rail using the groove at the top of the bracket

2) Push the module down on the top of the DIN rail and then rotate the bottom of the module onto the bottom

bracket of the DIN rail until it clicks into place.

3) While holding the HI 6600 series i nstrument, gently pull the bottom of the HI 6600

verify that it is mounted correctly.

away from the DIN rail to

To remove, pull up on the bottom of the front corner of the module to disengage the bottom DIN rail catch first, and then lift

up on the module to remove the top DIN rail catch.

Note: Between 8 – 12 pounds of upward force is required to remove a Hardy HI Series Instrument from most DIN rail.

Page | 18

Page 19

HI 6600 Series Modular Sensor System User Guide

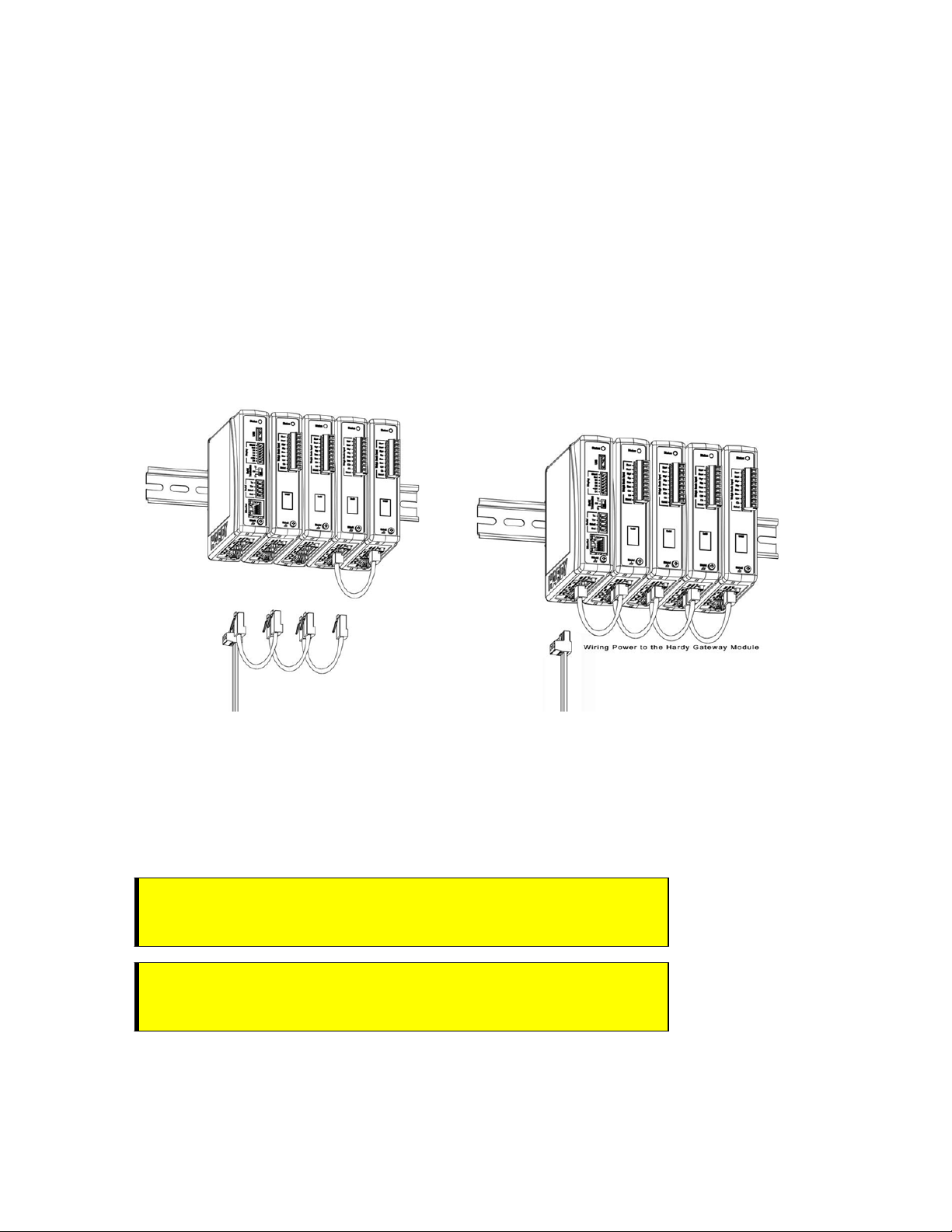

Cabling the Units Together

Once the units are all placed on a DIN rail, connect them together in a series using the RJ45 ports on the bottom of the

units and Cat5e cable.

The Cat5e cabling carries communications between the modules and distributes power from the Hardy Gateway Module

to the Weigh Processing Modules.

Redundant DC power may also be supplied individually to each Weight Processing Module via the DC power input

terminal located on the bottom of the module. DC power supplied to individual Weight Processing Modules is isolated

and not distributed to other modules on the system.

At minimum, DC power must be supplied to the Gateway Module.

The maximum distance between the first and last module on a system is 500 feet (150 meters).

DC Power Input

Page | 19

WARNING - Do not operate with incorrect line voltage. To do so will result in

property damage and/or personal injury. Make sure that the power source does

not exceed 24 VDC.

A VER TISSE MENT – Assurez-vous que la source d’alimentation ne dépass e pas

240 V. L’utilisation d’un mauvaise voltage peut résulter en dégâts matériels

et/ou des risques de blessures.

Page 20

HI 6600 Series Modular Sensor System User Guide

WARNING - Be careful not to reverse the ground and hot wires, which can

result in damage to the equipment.

A V ERTI SSEMENT – Attention à ne pas inverser le sol et fils chauds, ce qui peut

entraîner des dommages à l'équipement.

A power-limited 12-24 VDC power supply (Class 2) must be used on the DC input wiring.

DC power should be supplied by a clean primary line, directly from the DC power source.

1) Make sure the VDC power is shut off before installing the wires to the

connector.

2) Connect the 24 VDC voltage wire, ground wire and shield wire to the

connector that

jumper connects the Earth

them common, and should remain in place.

plugs into the DC voltage header at the rear panel. The

ground and the internal ground making

3) Plug the connector into the bottom panel.

4) Apply VDC power to the unit .

WARNING - If the HI 6600 series equipment is used in a manner that is not

specified by the manufacturer, th e pro t ecti on provided by the equip men t may

be impaired.

A V ERTI SSEMENT – Si l'équipement de série HI 6600 est utilisé d'une façon qui

n'est pas spécifiée par le fabricant, la protection fournie par l'équipement peut

être altérée.

Connecting Sensors

The diagrams below show Hardy Load Sensors with C2 and non-Hardy Load Cells (4 wire and 6 wire are similar except

6 wire adds sense wiring) that do not have C2. Wire the terminal connector that plugs into the front of the Weight

Processor Modules by carefully following the Weigh Scale Input termination label.

Page | 20

Page 21

HI 6600 Series Modular Sensor System User Guide

Non-C2 load cell wiring Hardy load sensor with C2

Note: when connecting the HI 6600 series instrument to a

connected between the +Sen and –Sen

Diagram for further detail. You can find the I/I Diagram in the Hardy website under Products>

WARNING - Instrument power should be routed away from all ot her signal

cables to avoid electrical interference.

AVERT ISSEM ENT – Tens ion de l'appareil doivent être acheminés à l'écart de

tous les autres câbles de signau x pour éviter toute interfé rence électrique.

connections for the junction box and the instrument. See the I/I

junction box, the sense lines woul d be

Installing the Optional Display

The following section provides details on how to mount the Optional Front Panel Display and connect to the HI 6600

HGM.

Blind Unit (No display)

The front display is not necessary for the HI 6600 series instrument to operate as a weight processor. Blind units can be

fully configured using the Web browser communication.

Optional Remote Display Mount

The HI 6600 Modular Sensor System is compatible with HI 6110 displays.

Page | 21

Page 22

HI 6600 Series Modular Sensor System User Guide

The optional display for the HI 6600 series instrument can be mounted in a remote location up to 250 feet (75 meters)

from the Hardy Gateway Module by modifying the supplied cable.

Mounting the Optional Front Panel Display

(1) Make sure that all Electrostatic Discharge (ESD) precautions are taken before and during installation.

(2) A thin plastic template comes with the product. Make the hole pa ttern in the panel door or cover using the

dimensions provided on the diagram s below.

WARNING - We recommend installing the HI 6600 series modules in a

NEMA 4, 4X or IP 55 rated enclosure or better.

AVERTISSEMENT – Nous vous recommandons d'installer le HI 6600 dans

un boîtier NEMA 4, 4X ou IP 55 ou mieux.

Panel Hole Dimensions (not displayed to scale)

Page | 22

Page 23

HI 6600 Series Modular Sensor System User Guide

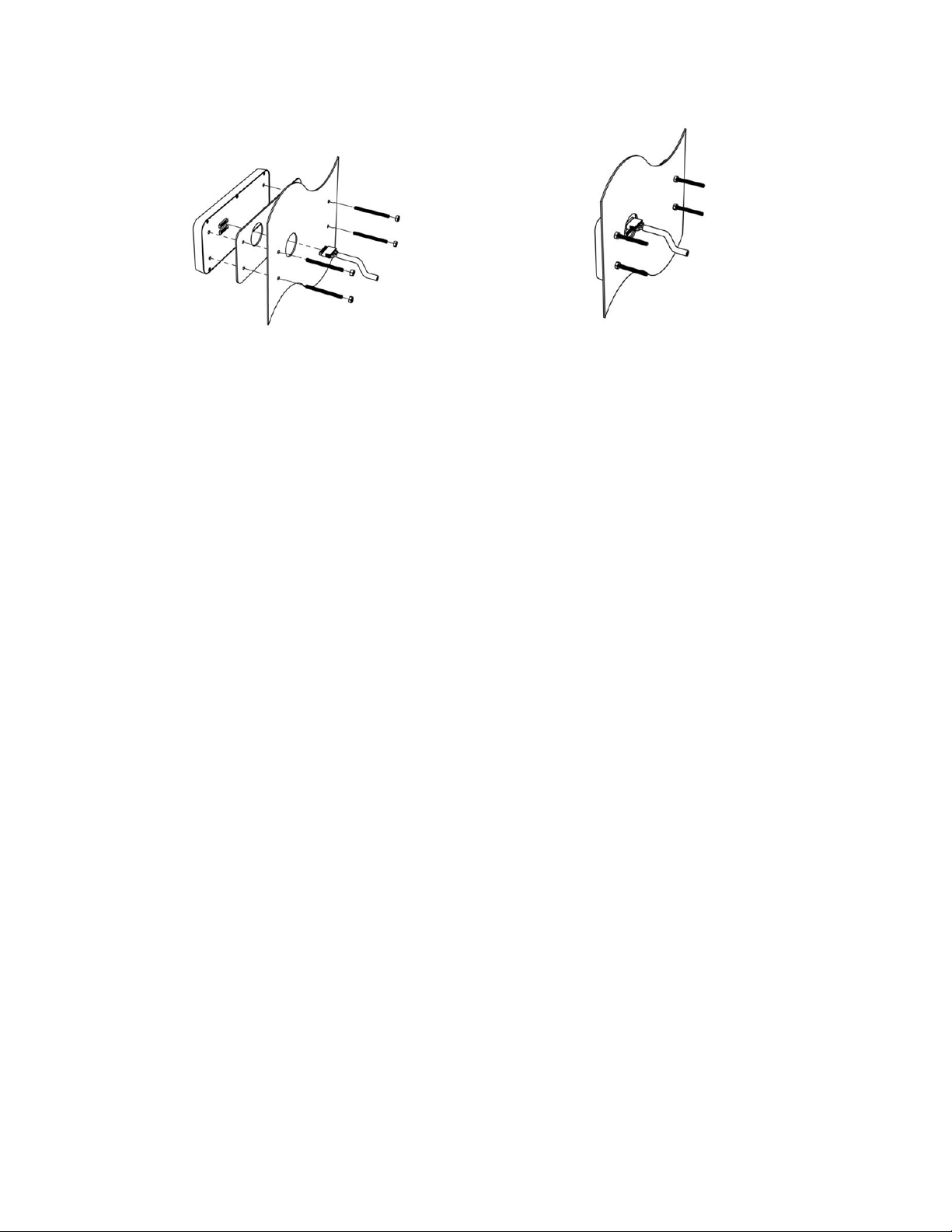

i) Connect and hand-tighten the four screw rods into the Optional Front Panel display.

ii) Place the gasket over the screw rods then slide the screw rods through the panel until flush with the surface.

iii) Place washer and nut onto the screw rods sticking through the panel. Tighten nuts so that the gasket is fully

compressed and that the metal bezel of the display is in contact with the panel. Nuts should be torqued to 20 inch-lbs

to ensure the seal required for an IP-66 rating.

iv) Remove the terminal connectors from the cable assembly provided and replace the original cable with the desired

cable length. See instructions above for Making Longer Display Interface Cables below.

v) Connect the display cable to the back of the display and to the Display Port located on the front of the Hardy

Gateway Module

Page | 23

Page 24

HI 6600 Series Modular Sensor System User Guide

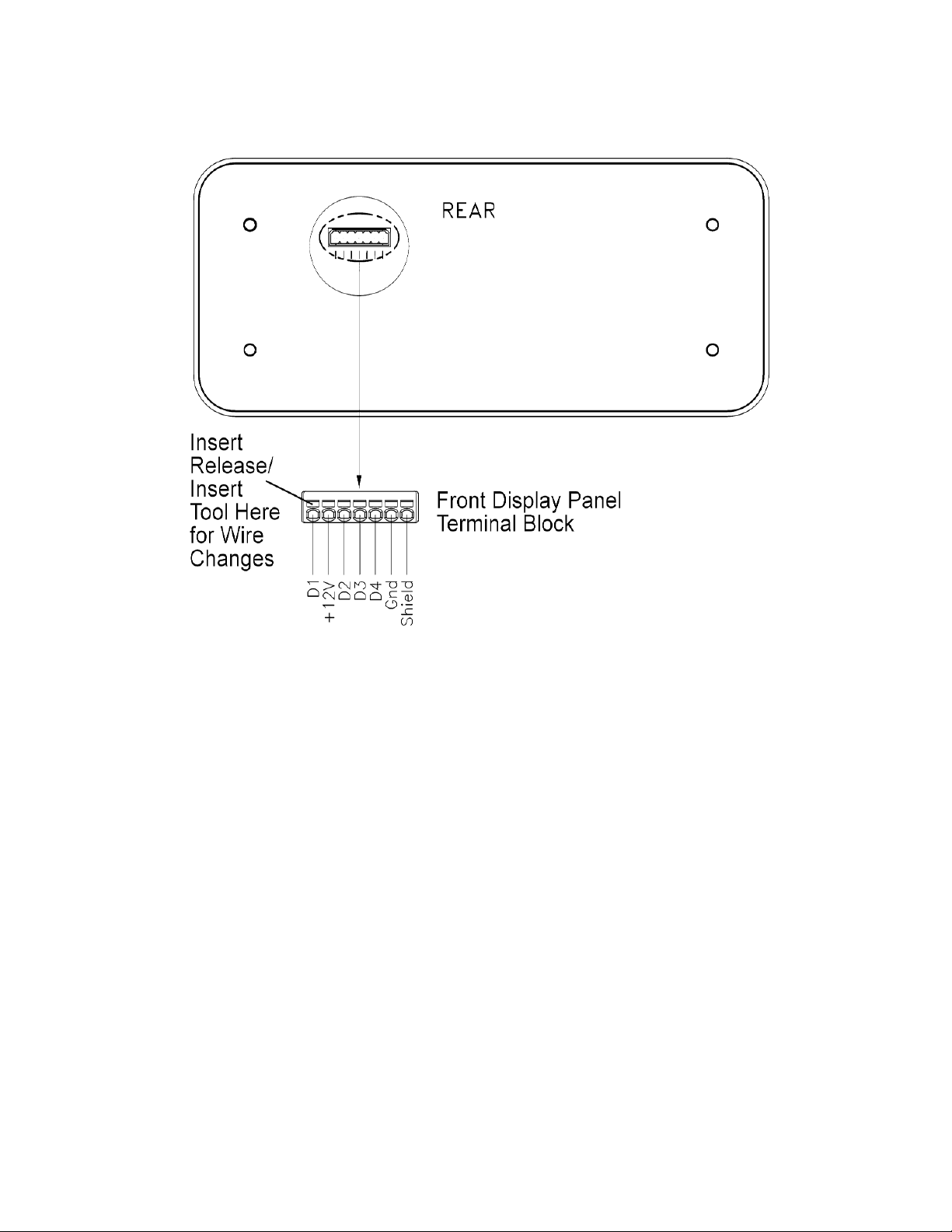

Making Longer Display Interface Cables

The terminal block uses a spring cage type contact. There is a slot provided to use an insert/release tool. The

tool is a 2.0 mm x 0.4 mm wide flat blade screw driver. Inserting the end of the small screwdriver tool opens

the cage contact and allows one wire to be inserted. Removing the insertion tool with bare conductor wire

inserted will lock the connection.

Wiring Specifications

Page | 24

Wire size: 20 AVG maximu m / 26 AVG minimum

Maximum cable length: 100 ft. (30.48 meters)

Use three twisted pairs with a drain wires

Pair wires +12 and GND, D1 and D2, D3, and D4

Page 25

Chapter 4

HI 6600 Series Modular Sensor System User Guide

Instrument Configuration

• • • • • •

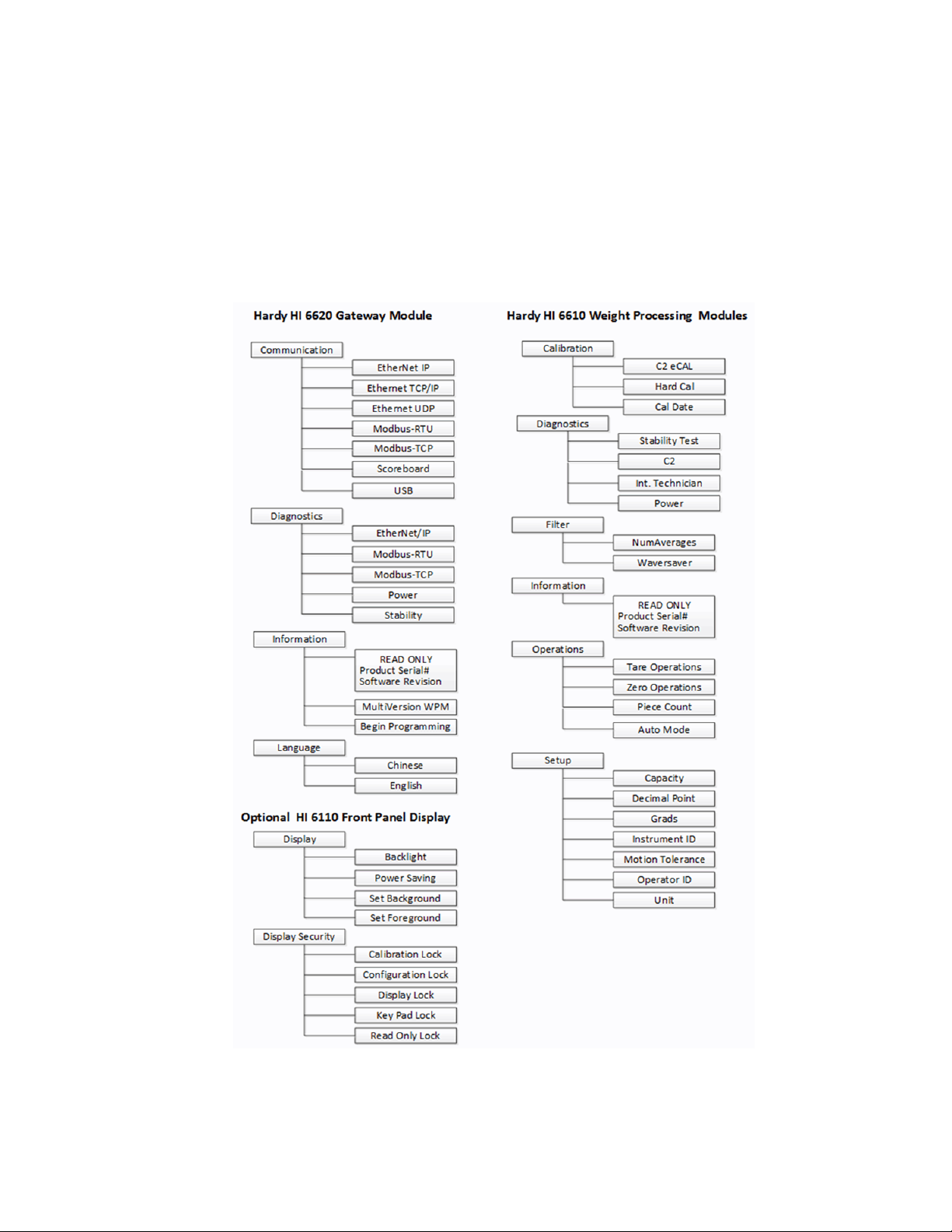

Menu Structure

The menu tree below shows the location of commands and parameters used to configure and use the system.

Page | 25

Page 26

HI 6600 Series Modular Sensor System User Guide

The system can be set-up, calibrated and operated either through the built-in Webserver or through an optional

front panel display. The menu structure above may be followed using either interface.

Using the Webserver

To use the Webserver, a connection must first be established between the Hardy Gateway Module and a connect

PC. The following steps will assist in establishing a connection:

1) Connect an Ethernet cable between the RJ45 port located on the front of the HI 6600 Gateway Module’s

RJ45 and a PC then power up the instrument. A cross-over cable is not required, but can be used.

2) The instrument will auto-negotiate settings suitable for a variety of operating systems and network

configurations. Wait approximately 15 seconds and check to see if the green light of the Ethernet port is

on and blinking – if so, skip to step 8 – you are connected.

3) If the green light on the Ethernet port does not light up, use the Optional Display to check that the unit’s

Enable DHCP is turned off and follow steps 4 through 8 If an optional display is not available, please call

Hardy Tech Support for further assistance.

4) Using the unit’s Fixed IP address (the default is 192.168.000.100), the PC must now be assigned a unique

IP address (for example, 192.168.000.101)

There are two simple rules for the IP Address:

•

It must have the same network identifier as the computer.

•

It must have a different node identifier than the computer.

5) On a PC running windows, open Internet Properties (TCP/IP).

Click in the ‘Use the Following IP Address’ checkbox; then enter the following into the TCP/IP Properties

dialog.

•

IP Address = 192.168.0.101

•

Subnet Mask = 255.255.255.000

6) Select OK on the TCP/IP Properties dialog box. The computer is now configured.

7) Enter the HI 6600 HGM’s IP address into the Windows PC Web browser to access the embedded web

browser. For example: http://192.168.000.100

NOTE

Additional information for setting up communications between the Gateway Module and the

PLC, DCS, or PC is under Network Communications (Chapter 6).

Page | 26

Page 27

HI 6600 Series Modular Sensor System User Guide

Once connected, browse the webpages by following the menu tree presented in the beginning of this chapter.

Changes are made by clicking the item and either selecting an option or inputting a value using your PCs keyboard.

NOTE: Selections and inputs are ONLY saved to memory by clicking SAVE PARAMETERS in the webpage.

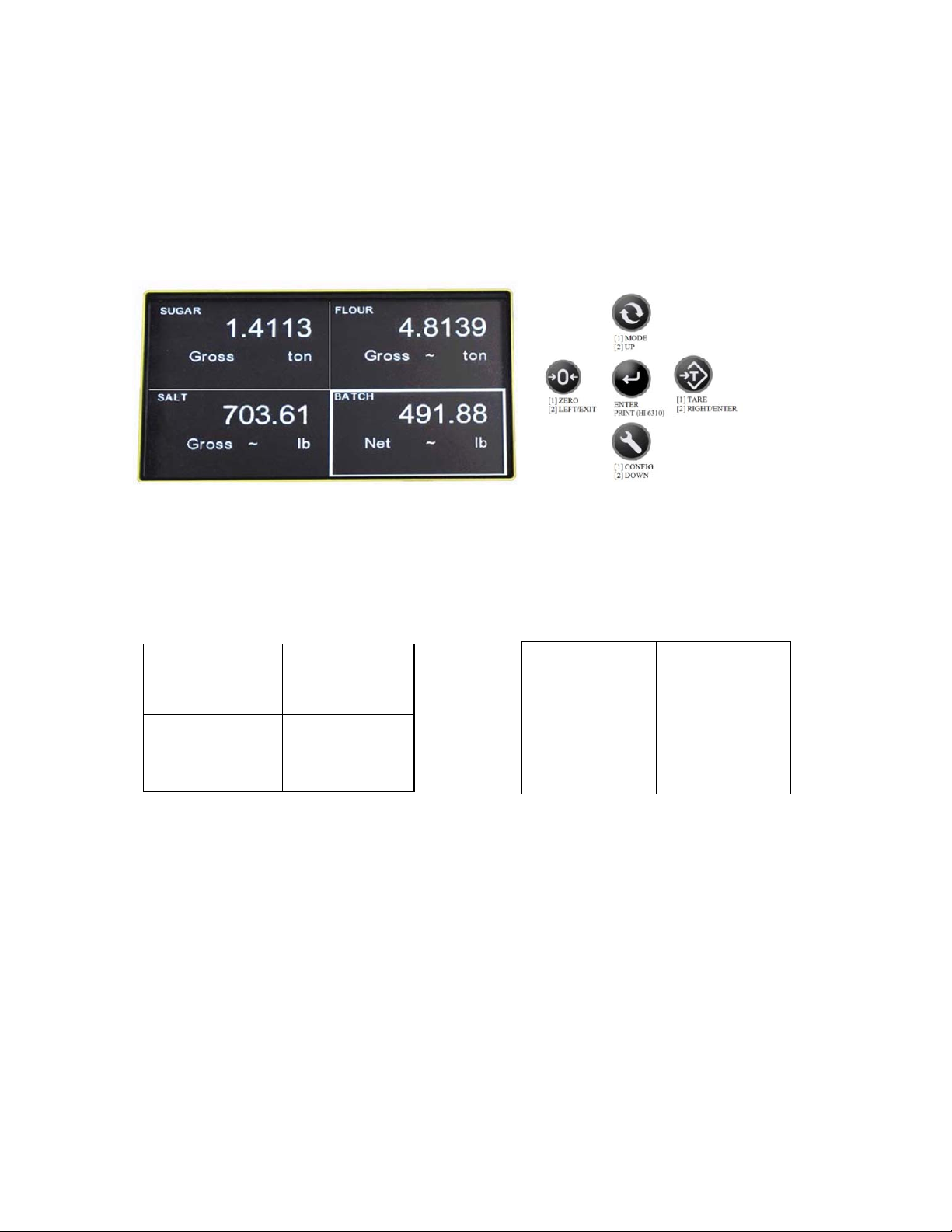

Usin g the HI 6110 Front Panel Display

1) Toggle between showing multiple channels and a single-channel by pressing the ENTER button

2) Move the quadrant outline to th e desired channel by using th e arrows keys. Press ENTER to select

the channel, once a channel is selected it will show in fu ll-display mode and change functio n of the

buttons from navigation (up, down, left, right) to instrument function (mode, config, zero, tare).

Instrument 1 Instrument 2

Instrument 3 Instrument 4

Instrument 3 Instrument 4

Scroll through available instruments by pressing the UP and DOWN arrows.

1) Enter Set-Up for the selected channel by pressing the CONFIG button.

Pressing the CONFIG button minimizes the displayed weight value and shows a list of submenus to

the left that follow the menu tree presented in the beginning of this chapter.

Page | 27

Instrument 5 Instrument 6

Page 28

HI 6600 Series Modular Sensor System User Guide

2) Navigate UP and DOWN the submenus using the arrow keys, then select a menu by pressing the

ENTER button.

3) Fixed options within a submenu are selected by using the UP & DOWN buttons to navigate to the

choice, then by pressing ENTER key to select. Once an option is selected, back out of the submenu by

pressing the LEFT arrow key.

4) Entering Numeric and Alphanumeric values are done pressing the UP & DOWN buttons to change a

value and RIGHT & LEFT buttons to move the position of the cursor. Once a value is keyed in, press

the ENTER key to save then the LEFT arrow key to return to main menus.

5) Values are saved to memory only by backing out to the top level.

Mode Button

Press the Mode Button to switch between differe nt weighing modes of:

Page | 28

•

GROSS: Displays the GROSS weight of the system.

NET: Displays the NET weight of the system. The NET weight displayed is the

the TARE value.

COUNT: Counts the number of objects once the weight for one object is set.

GROSS weight minus

Page 29

HI 6600 Series Modular Sensor System User Guide

The displayed mode on the instrument can also be changed by selecting DISPLAY MODE on the Operations

webpage and choosing Gross, Net or Count from the drop-down menu or by sending the DISPLAY MODE

command over communications.

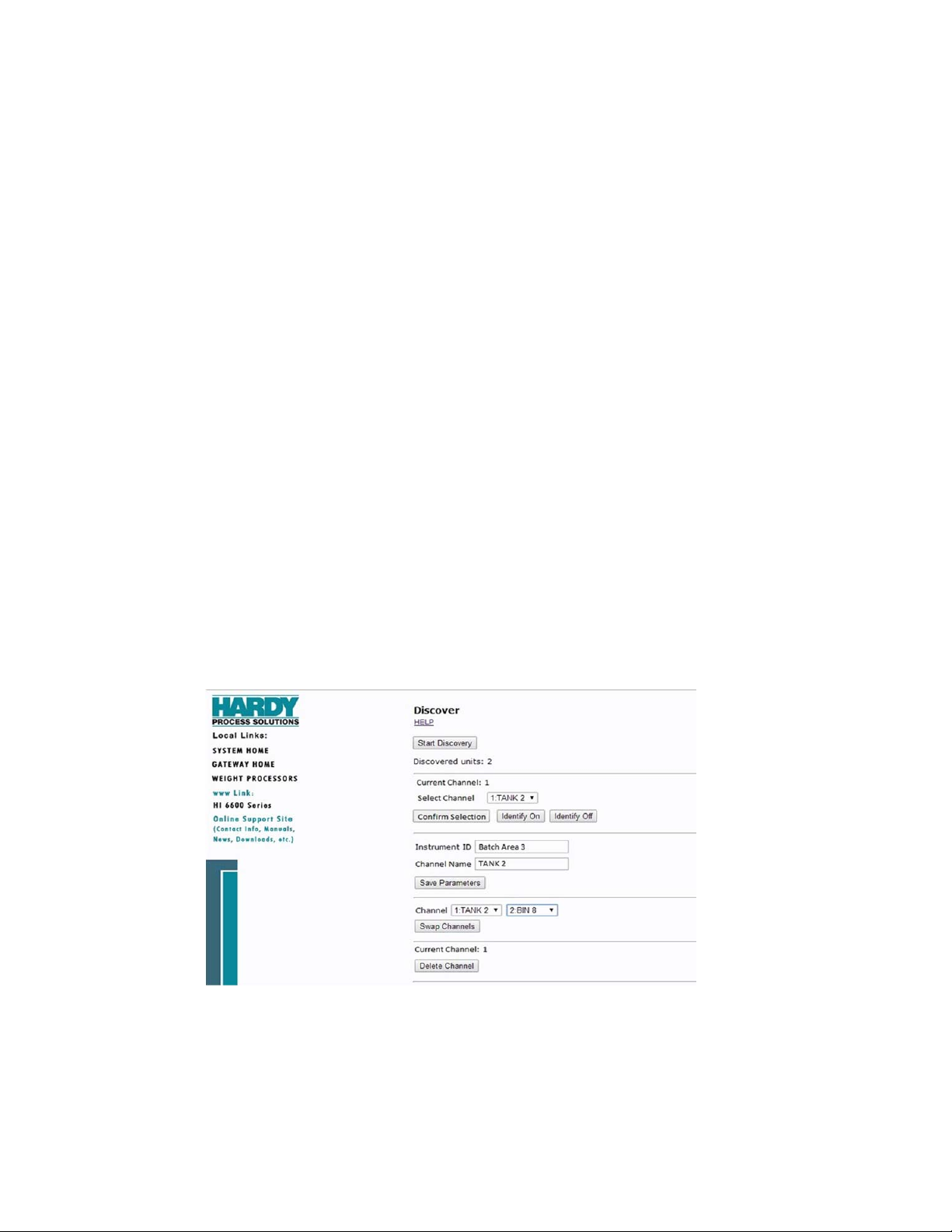

Channel Identification

System Discovery

Once the HI 6600 Series Modular Sensor System is installed, connected and powered, a discovery process is

required to allow the Hardy Gateway Module to identify all Weight Processing Modules present on the HardyNet.

This discovery process can be initiated in a number of ways and should be used each time the HardyNet syste m is

changed. Examples of changes are removing a module from the system or adding a new module to the system.

The system initiates a discovery process that enables the Gateway Module to identify and track changes to the

Weight Processor Modules connected on the HardyNet. The discovery process can also be initiated manually by

selecting Start Discovery under the HardyNet sub-menu of the HI 6600 Gateway Module.

Discovered Weight Processing Modules are added to a list that is saved in non-volatile memory of the Gatew a y

Module. The discovery process is designed to only add units that are not alread y saved in memory. If a Weight

Processing Module has been physically removed or disconnected from the system, it must be manually deleted

from the list of available modules by selecting Delete Channel. A module that is accidentally deleted can be

discovered again by power cycling the Gateway Module or again by manually selecting Start Discovery

The number of Weight Processor Modules discovered (ie: channels of weight) connected to the system will be

displayed as Discovered units: XX on the Web Browser as shown below or listed in the Discovery section of the

optional front panel display once the process is complete.

Using the Webserver (shown below) is recommend for initial system set-up and changes to a system with a large

number of channels.

Page | 29

Page 30

HI 6600 Series Modular Sensor System User Guide

Namin g t h e Weight Processing Modules

To ease identification of a particular Weight Processor Module, a meaningful name (ie: Ingredient C or BIN

8) may be assigned to the module by using Select Channel, Confirm Selection, then identifying the physical

location of the module by pressing Identify On/Identify Off which will cause the LED on the selected module

to blink. Once the particular module is identified, rename the module and press Save Parameters in the Web

Server or ENTER on the front panel display to save the module name into memory.

Each Weight Processor Module is as sign ed a channel num ber during t he discovery

Processor Modules are listed in the order they are discovered,

process. Weight

not by physical position or location

on the HardyNet.

Ordering the Weight Processing Modules

The order in which the channels appear in the drop down menus or on t he opt ional display may be changed

by using Swap Channel in the web serve r or by selecting the

display, pressing enter to ‘capture’ the

enter again to

NOTE:

on the list.

‘release’ the channel to its new position.

The channel will retain its Channel Name but be reassigned a new channel number and position

Deleting or Replacing Channels

Deleting an unwanted channel from the system is completed by selecting Delete Channel (for example when

a spare channel is connected to the system).

Parameters associated with channels remain in non-volatile memory of the Gateway

therefore be transferred to a replacement Weight Processing Module by following these steps:

channel, moving it by usi ng the UP/DOWN arr ows , then pre ssi ng

channel using the front panel of the optional

Module and can

1) Delete Channel of the Wei ght Processor Module to be removed.

2) Remove the deleted We ight Processor Module. by disconnecting the RJ45 connectors

lifting gently up the unit to lift it off the DIN rail

3) Place the new Wei ght Processor Module on the DIN Rail and connect the RJ45

the new module to Hardy Net

4) Start Discovery to find the new module. Parameters from the removed module will

the new module.

NOTE:

The new module will appear at the end of the channel list. If need be, reassign the

channel number and change its order in the list by using the Swap Channel process

described above.

on the bottom and

connectors to reconnect

now be applied to

Saving and Restoring Configuration Data Using the USB port

The HI6600 Gateway Module provides a USB port to save parameters to a memory stick. Parameters

can be saved, restored, copied and modified from one instrument or channel to anot her inst rument or

channel using this feature. Details of use can be found in the USB Memory Stick section of the Network

Communications section of this manual.

Page | 30

Page 31

HI 6600 Series Modular Sensor System User Guide

Suggested Minimum Steps When Setting Up the Instrument For the First Time

Choose a specific Weight Processor Module to set up by selecting a channel either from the front panel display

or on the webserver.

Channel

1) Choose channel to set-up

SET UP (minimum)

1) Select Unit of Measure

2) Input Total Scale Capacity

3) Select Graduation Size

4) Select Decimal Point Position

5) Input Motion Tolerance

Filter

1) Num Averages

2) Waversaver

Calibration

1) Cal Date

2) Cal Method

a. C2 eCal

b. Hard Cal

3) Complete Cal Procedure

Page | 31

Page 32

HI 6600 Series Modular Sensor System User Guide

Setup Parameter Menus

The Setup Menus consists of the following parameters:

Capacity

Decimal Point

Grads

Instrument ID

Motion Tolerance

Operator ID

Unit

Capacity Parameter

Scale Capacity is the scale's nominal operating capacity (the total weight capacity of the scale system). If this value is

exceeded by six graduations, dashes appear on the front display. Communications to and from optional devices are not

affected.

If a Capacity value is entered which conflicts with either the decimal point value or the graduation value, the decimal

point and/or graduation values are automatically modified to match the programmed capacity. It is therefore

recommended that the Capacity parameter is entered first before setting the Decimal Point and Grad parameters.

RANGE: .000001 - 999999 (Default 999999).

On the Web page Or Using the Front Panel Display: enter the capacity in the text box provided or enter the capacity

using the arrow keys.

Decimal Point Parameter

Use the Decimal Point Parameter to set the resolution you want for the WPM.Here you set the location of the decimal point for

the weight resolution. The higher the number, the

scale. Note

RANGE: 0-5 (default 2) Not to exceed 1 part in 100,000

On the Web page Or Using the Front Panel Display: from the Decimal Point pull-down list, select the decimal position for

this instrument or select from the list of decimal point values supported using the arrow keys.

that setting more decimal points does affect the overall accuracy of the instrument.

Graduation Size Parameter

The Graduation Size is the Minimum increment displayed by the instrument. The Base Graduation Number can be

calculated by dividing the Total Load Cell Capacity by 10,000.

For example, with two decimal points selected, a graduation size of 10 will display increments of .10 units and the

graduation size .50 will display increments of.50 units. For a scale with 10,000 capacity, graduation size = 1

RANGE:1, 2, 5,10, 20, 50, 10, 200, 500, 1000 (default 1)

On the Web page Or Using the Front Panel Display: from the Decimal Point pull-down list, select the decimal position

for this instrument

or

select from the list of graduati on values supported using the arrow keys.

farther to the left the decimal point moves and the higher the resolution of the

Page | 32

Page 33

HI 6600 Series Modular Sensor System User Guide

Instrument ID

Use this parameter to assign a meaningful name to the system to make it easier to identify on a network. The assignment

applies to the Gateway Module only, channels connected to the Gateway may also be assigned a name by fo llowing the

Naming the Weight Processing Modules section located in the beginning of this chapter.

Motion Tolerance Parameter

The value you enter for Motion Tolerance sets the amount of deviation to allow for your process. This value must be

greater than or equal to the Graduation Sizes. We recommend 3 times the graduation size.

The base motion number can be calculated by using the following formula:

Base Motion Number = (Total Load Cell Capacity x 0.0003)

RANGE: .000001 - 999999 (default 10)

On the Web page or Using the Front Panel Display: enter the value in the text box provided or input the desired motion

tolerance value using the arrow keys.

Operator ID Parameter

The Operator ID is the ID of the user who is going to operate the Weight Processor or service the instrument. Select three

letters or numbers or any combination of letters and numbers that adequately identifies the user.

On the Web page or Using the Front Panel Display: enter the value in the text box pro vided or input a value using the

arrow keys, then pressing the enter button to save.

Unit (of Measure) Parameter

The Unit (of measure) parameter sets the scale to either English or Metric units. The Selections are:

Ounces

Pounds

Ton

Gram

Kilogram

Metric Ton

On the Web page or Using the Front Panel Display: select the desired weight units from the pull-down list then click

Change Unit to save or select from the list of values supported using the arrow keys.

Page | 33

Page 34

HI 6600 Series Modular Sensor System User Guide

Filter Parameter Menu

There are two parameters in the Filter menu

NumAverages (Number of Averages)

WAVERSAVER

NumAverages Parameter

The value you enter for NumAverages (the Number of Averages) sets the number of weight readings used to compute a

sliding average of displayed weight. This helps reduce the effects of material impact and/or vibration if material does not

enter or exit the scale evenly. This setting helps the instrument ignore the effects of material impact and/or vibration.

Applications requiring very qui c k wei g ht readings should reduce this setting to its minimum. If the weight is unstable,

increase the averages. The HI 6600 series instrument does 110 updates per second, which translates to an update

approximately every 9 milliseconds. If you average enough weight readings, the weight loss or gain remains smooth. If

you average the weight too much you can cause over filling. Also see

unstable weight readings.

RANGE:1-250 (default 10)

On the We b p a ge Or Using the Front Panel Display: enter the value for the number of readings to factor into the

average.

WAVERSAVER® Parameter

Typically, mechanical noise (from other machinery in a plant environment) is present in forces larger than the weight

variations you want to detect. WAVERSAVER® reduces the effects of the vibratory forces that exist in all industrial

weight control and measurement applications so the device can better calculate the actual weight. WAVERSAVER

enables the Weight Processor to distinguish between actual weight data and mechanical noise, both of which are typically

conveyed in the load cell signal. WAVERSAVER can be configured to ignore noise with frequencies as low as 0.25 Hz.

One of three higher additional cut off frequencies may be selected to provide a faster instrument response time. The

function is user selectable and can be turned off.

RANGE: 0.25 Hz, 0.5 Hz, 1.0 Hz, 3.50 Hz, 7.50 Hz, OFF (default 1.0 Hz)

Chapter 1 describes the benefits of using the WA VER SAV ER feature.

On the Web page Or Using the Front Panel Display: from the pull-down list, select the FILTER menu and

then select the value for WAVERSAVER.; Or select from the list of values supported using the arrow keys.

WAVERSAVER for information on filtering

Page | 34

Page 35

HI 6600 Series Modular Sensor System User Guide

Calibration

The parameters in the System Calibration menu are shown be low.

C2 or eCAL

Sensitivity

Gravity

Ref Wt (Refer ence Wei gh t)

Do C2 Calibration

Cal Tol (Calibration Tolerance)

Num Dev (# of C2 Sensors)

Hard Cal

Cal Tol (Calibration Tolerance)

Sensitivity

Cal Lo Wt (Zero Reference Point)

Do Cal Lo

Span Wt (Span Weight)

Do Cal Hi

This section describes C2 or eCAL and traditional calibration procedures. For the Weight

readings, they must be routinely calibrated both during

important that users

6600 WPM modules.

and service personnel be familiar with the procedures in this chapter before installing or operating the HI

operation or when it has not used for an extended period of time. It is

Processor Modules to give precise

All calibration is done in the Gross m ode. Be sure to follow all the procedures completely

weights read by the unit are accurate.

In some incidents it is better to verify a calibration than just re-do the calibration. If during

is found to be out of calibration, check for damage and a

recalibrate. Perform a calibration and

functioning

Always verify your scale after any calibrati on and maintenance routine.

or installed correctly.

perform a scale verification. No calibration process ensures the load cells are

mechanical problem. When all checks OK, then

to insure that the

the scale verification, it

NOTE: Do not perform a calibration while an application is in operation.

Pre-Calibration Procedures

Veri fy that the load cells have been properly installed.

Refer to your load cell operations and installation manual for proper installation instructions.

On some sensors and cells an arrow indicates the direction of the applied load. If the arrow is pointing in

the wrong direction, change the position of the load cell so that it is mounted in the direction of the

applied load.

Check for binding on the Load Cell or other parts of the weighing system.

Page | 35

Page 36

HI 6600 Series Modular Sensor System User Guide

WARNING - Binding on a scale/vessel or load cell does not allow the load cell free

vertical movement and may prevent the instrument from returning to the original zero

reference point.

AVERTISSEMENT –

Lier sur une échelle / récipient ou cellule de charge ne

permet pas la cellule de charge libre circulation verticale et peut e mpêcher

l'appareil de revenir au point de référence zéro d'origine.

A load cell must be mounted so that

w/Contents)

Veri fy that nothing is binding the load

nothing is draped

hose, electrical cord, tubes, or

in

contact with the scale/vessel other than service wires and

piping that have been

connections. Flexible pipes are not to be used in any other than the

horizontal

problems. Vert ical or at

effect on the scales ability to repeat and

readings.

passes vertically through the load cell.

across the scale/vessel or the load cell, such as a

properly mounted with flexible

plane and are not to be used to correct pipe alignment

angles other than horizontal will have an

100% of the load (Vessel

cell. This means that

other objects. Veri fy that nothing is

provide accurate weight

Electrical Check Procedures

Load Cell/Point Input/Output Measurements

The HI 6610 WPM instrument is designed to supply

5 VDC excitation to as many as four 350-Ohm load

cells/points per channel. The expected output from

each load cell/point will depend on the mV/V rating

of the load cell/point and the weight.

For example, a 2mV/V load cell/point will respond

with a max imum of 10 mVDC at the load sensor’s

full weight capacity, which includes the weight of

the vessel and the weight of the product as

measured by the load cell/point. Thus, if the load

cell/point weight capacity is rated at 1000 pounds,

the load cell/point will be 10 mVDC at 1000

pounds, 7.5 mVDC at 750 pounds, 5 mVDC at 500

pounds and so on.

A zero reference point will vary from system to

system depending on the “Dead Load” of the vessel.

“Dead Load” is the weight of the vessel and appurtenances only, with no product loaded. In our example we will assume

the dead load to be 500 pounds.

Page | 36

Page 37

HI 6600 Series Modular Sensor System User Guide

NOTE: The operating range for the scale in this example is 5-10 mVDC with a 500 pound weight

zeroing the instrument, the 0 reading refers to the zero reference point

weight.

NOTE:

Load cell/point measurements are checked with a digital v oltmeter at the load cell connector

on the front of the module or by using INTEGRATED TECHNICIAN with a

Box. The scale calibration must be completed to enable IT to

and not absolute 0 mVDC or absolute 0

Hardy IT Junction

function correctly.

range. A fter

Load Check

Place a load (weight) on the scale or vessel, and check to see if the weight reading on the input table changes in the proper

direction.

For example, if the display reads 100 pounds and a 20-pound weight is placed on the vessel or scale, the display should

read 120 or some value over 100. With the display reading 100 pounds, if a 20-pound load is placed on the vessel or scale

and the reading is 80 pounds, the reading is going in the wrong direction and indicates some problem with the system.

If the display reads improperly or shows no change, something is wrong with the setup. If the display changes weight in

the proper direction, remove the weight and proceed to calibrate the instrument. Refer to Chapter 9 on troubleshooting for

additional help to determine the cause of the poor weight reading.

C2 & eCAL Electronic Calibration

C2 (also known as eCAL) Electronic Calibration, calibrates a scale system electronically without using certified test

weights. Digital information within a Hardy C2 or eCAL- certified load sensor details its unique performance

characteristics. The HI 6600 series instrument reads the performance characteristics of each load sensor and detects the

number of load sensors in the system.

Before running C2or eCAL calibration, run all of the pre-calibration procedures. Make sure you have configured the HI

6600 series instrument. This includes setting the units, decimal point, NumAverages etc. For instructions on setting up

your instrument, please see the Chapter on Instrument Configuration.

NOTE:

command.

C2 and eCAL Calibration

Sensitivity Parameter

The load cell sensitivity, defined in mV/V, sets the expected change in analog signal over the full scale range of an analo g