Page 1

Weight Processor

HI 6300 Series

User’s Guide

Hardy Process Solutions Document Number: 0596-0328-01 REV B

Page 2

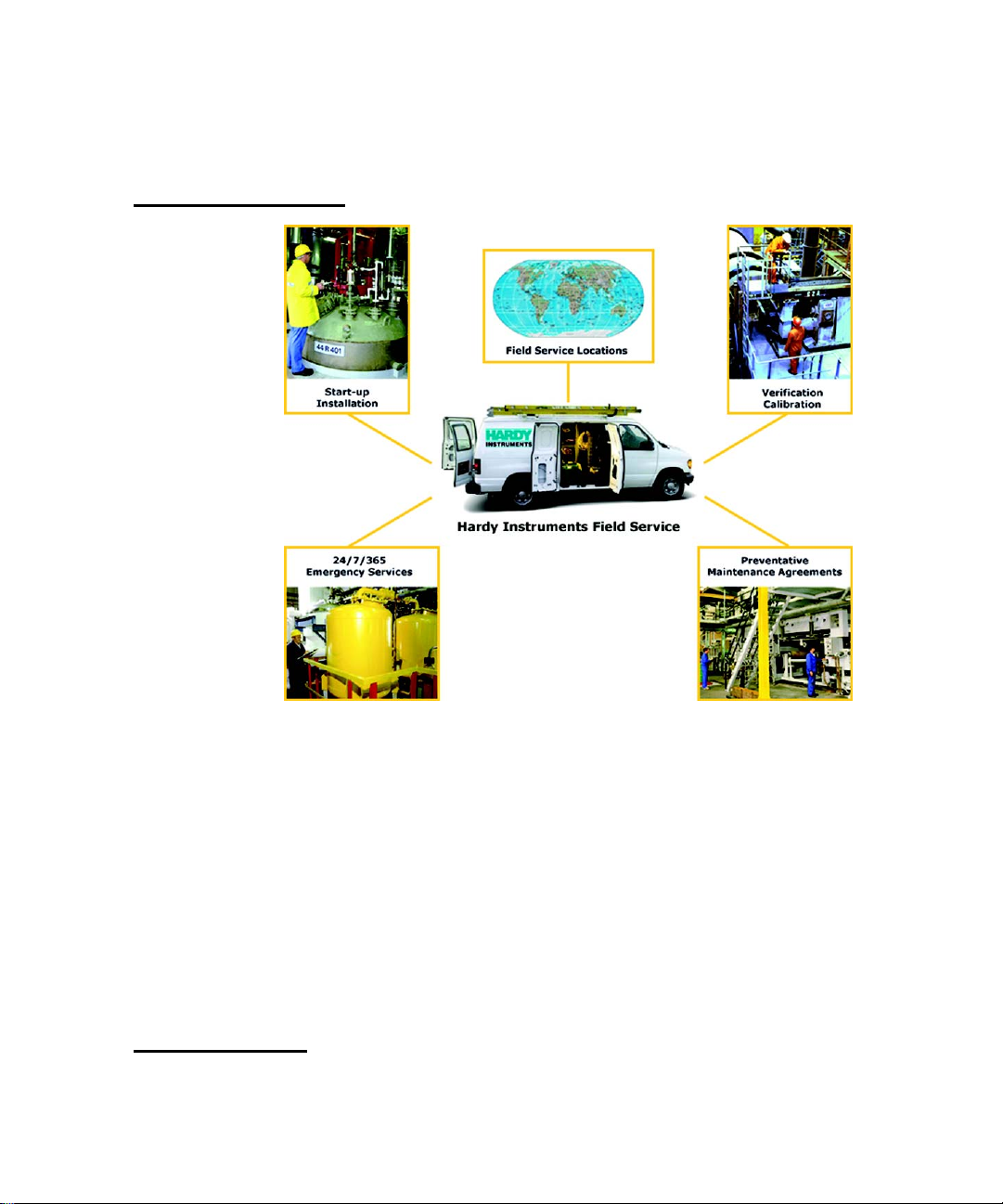

Local Field Service

Hardy has over 200 field technicians in the U.S., and more positioned throughout the world to

assist you in your support needs. We also have factory engineers who will travel to your facility

anywhere in the world to help you solve challenging applications. We're ready to support you with:

• Installation and start-up

• Routine maintenance and certification

• Plant audits and performance measurement

• Emergency troubleshooting and repair

To request Emergency Service and Troubleshooting, Start-up, Installation, Calibration, Verification

or to discuss a Maintenance Agreement please call 800-821-5831 or Emergency Service after hours

(Standard Hours 6:30 AM to 5:30 PM Pacific Standard Time) and weekends.

Outside the U.S

Hardy Process Solutions has built a network of support throughout the globe. For specific field service options available in your area please contact your local sales agent or our U.S. factory at

+1 858-292-2710.

Page 3

• • • • • •

Contents

Chapter 1 Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

General Introduction to the HI 6300 Series Weight Processor - - - - - - - - - - 1

HI 6300 Series Weight Processor Description- - - - - - - - - - - - - - - - - - 1

Typical Applications - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

Features and Capabilities - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

Hardy Process Toolbox- - - - - - - - - - - - - - - - - - - - - - - - - - 2

C2® and eCal™ Calibration - - - - - - - - - - - - - - - - - - - - - - - 2

WAVERSAVER®- - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

INTEGRATED TECHNICIAN® - - - - - - - - - - - - - - - - - - - - - 3

Weighing System Tests- - - - - - - - - - - - - - - - - - - - - - - - - - 3

Chapter 2 Specifications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Basic Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

General - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Number of Channels - - - - - - - - - - - - - - - - - - - - - - - 5

Update Rate - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Resolution - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

WAVERSAVER - - - - - - - - - - - - - - - - - - - - - - - - - 5

Averages - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Non-linearity - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Common Mode Rejection - - - - - - - - - - - - - - - - - - - - 5

Common Mode Voltage Range - - - - - - - - - - - - - - - - - - 5

Front Panel (optional) - - - - - - - - - - - - - - - - - - - - - - 6

Load Cell Excitation - - - - - - - - - - - - - - - - - - - - - - - 6

C2 Calibration Input - - - - - - - - - - - - - - - - - - - - - - - 6

Cable Lengths - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Network Connectivity - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Environmental Requirements - - - - - - - - - - - - - - - - - - - - - - - 6

Operating Temperature Range - - - - - - - - - - - - - - - - - - 6

Temperature Coefficient - - - - - - - - - - - - - - - - - - - - - 6

Storage Temperature Range - - - - - - - - - - - - - - - - - - - 6

-40 to 85º C (-40º to 185º F) - - - - - - - - - - - - - - - - - - - 6

Humidity Range - - - - - - - - - - - - - - - - - - - - - - - - - 6

Maximum Altitude for Installation - - - - - - - - - - - - - - - - 6

Pending Approvals - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Contents

i

•

•

•

•

•

•

Page 4

Chapter 3 HI 6300 Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

Spare Parts List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Tool List - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8

Installing the HI 6300 Series Instrument - - - - - - - - - - - - - - - - - - - - 8

Installation options for the HI 6300 series instrument - - - - - - - - - - - 9

Mounting the Front Panel Display- - - - - - - - - - - - - - - - - 9

Panel Mount Option 1 - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Panel Mount Option 2 - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Making Longer Display Interface Cables - - - - - - - - - - - - - - - - - 13

DIN Rail Mount - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

Wall Mount - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 16

Remote Display Mount - - - - - - - - - - - - - - - - - - - - - - - - - - 18

Blind Unit (No display) - - - - - - - - - - - - - - - - - - - - - - - - - 19

Disassembly and Reassembly Notes and Cautions - - - - - - - - - - - - - 21

Load Cell Wiring Diagrams - - - - - - - - - - - - - - - - - - - - - - - - - - 22

Connecting to the Hardy HI 215IT or HI 6010/6020IT Summing Box - - - - 23

Chapter 4 Network Configuration- - - - - - - - - - - - - - - - - - - - - - - - - - - 25

Ethernet TCP/IP Network Configuration - - - - - - - - - - - - - - - - - - - - 25

LAN Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 26

DHCP Configuration Using the Front Panel - - - - - - - - - - - - 26

Direct Connect Hardware - - - - - - - - - - - - - - - - - - - - - 28

Windows PC Configuration- - - - - - - - - - - - - - - - - - - - 28

Windows 2000 - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Windows XP- - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Windows 7 - - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Direct Connect Configuration - HI 6300 Series Instrument - - - - - - - - - 30

Ethernet-UDP - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 30

Modbus-RTU (over RS-485) - - - - - - - - - - - - - - - - - - - - - - - 31

Wiring Pinout - - - - - - - - - - - - - - - - - - - - - - - - - - 31

Modbus Setup - - - - - - - - - - - - - - - - - - - - - - - - - - 31

Modbus Functions - - - - - - - - - - - - - - - - - - - - - - - - 32

Modbus Registers - - - - - - - - - - - - - - - - - - - - - - - - 32

Network Command Interface - - - - - - - - - - - - - - - - - - - 32

Communications Parameters for the HI 6310 Only - - - - - - - - - - - - - - - 35

Printer (over RS-232) - - - - - - - - - - - - - - - - - - - - - - - - - - 35

USB Memory Stick - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

Analog 4-20mA - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 36

•

•

•

ii

Contents

•

•

•

Chapter 5 Instrument Configuration - - - - - - - - - - - - - - - - - - - - - - - - - 39

Using the Home Page to set Parameters - - - - - - - - - - - - - - - - - - - - 39

Page 5

Using the Front Panel Display Menus to Set Parameters - - - - - - - - - - - - - 40

Front Panel Display - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

The Five Button Command Cluster - - - - - - - - - - - - - - - - - - - - 40

Using the Mode, Zero, and Tare buttons - - - - - - - - - - - - - - - - - - 41

Entering Numeric and Alphanumeric Values - - - - - - - - - - - 42

Commands and Parameters - - - - - - - - - - - - - - - - - - - - - - - - 44

Calibration Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - 45

C2 (eCal) Commands and Parameters - - - - - - - - - - - - - - - 45

Ref Weight Parameter - - - - - - - - - - - - - - - - - - - - - - 47

Sensitivity Parameter - - - - - - - - - - - - - - - - - - - - - - - 47

Hard Cal Commands and Parameters - - - - - - - - - - - - - - - - - - - 48

Cal Lo Weight Parameter - - - - - - - - - - - - - - - - - - - - 48

Cal Tolerance Parameter - - - - - - - - - - - - - - - - - - - - - 49

Span Weight Parameter- - - - - - - - - - - - - - - - - - - - - - 50

Cal Date Parameter- - - - - - - - - - - - - - - - - - - - - - - - 51

Communication Menu - - - - - - - - - - - - - - - - - - - - - - - - - - 51

HI 6310 Only - - - - - - - - - - - - - - - - - - - - - - - - - - 52

Ethernet TCP/IP Commands and Parameters- - - - - - - - - - - - 52

Enable DHCP Parameter - - - - - - - - - - - - - - - - - - - - - 52

Fixed IP Parameter - - - - - - - - - - - - - - - - - - - - - - - - 53

Mask Address Parameter - - - - - - - - - - - - - - - - - - - - - 54

Gateway Address Parameter - - - - - - - - - - - - - - - - - - - 54

DNS Server Parameter - - - - - - - - - - - - - - - - - - - - - - 54

Ethernet UDP Parameters- - - - - - - - - - - - - - - - - - - - - 54

Hardy Port Parameter - - - - - - - - - - - - - - - - - - - - - - 54

Modbus-RTU Commands and Parameters - - - - - - - - - - - - - - - - - 55

Slave Address Parameter - - - - - - - - - - - - - - - - - - - - - 55

Printer Command Parameters - - - - - - - - - - - - - - - - - - - - - - - 57

USB Memory Stick Parameters - - - - - - - - - - - - - - - - - - - - - - 58

4-20 mA Communications Commands and Parameters - - - - - - - - - - - 60

Weight Source Parameter - - - - - - - - - - - - - - - - - - - - - 60

Diagnostics Parameter Menu - - - - - - - - - - - - - - - - - - - - - - - - - 61

See the Chapter 9 for further information on Diagnostics. - - - - - - - - - 62

Display Parameter Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - 62

Backlight Parameter - - - - - - - - - - - - - - - - - - - - - - - 62

Power Saving Parameters - - - - - - - - - - - - - - - - - - - - - 62

Auto Enable Parameter - - - - - - - - - - - - - - - - - - - - - - 62

Wait Time Parameter- - - - - - - - - - - - - - - - - - - - - - - 63

Set Background Parameter - - - - - - - - - - - - - - - - - - - - 63

Set Foreground Parameter - - - - - - - - - - - - - - - - - - - - 63

Split Screen Parameters and Commands- - - - - - - - - - - - - - - - - - 64

Filter Parameter Menu - - - - - - - - - - - - - - - - - - - - - - - - - - 66

NumAverages Parameter - - - - - - - - - - - - - - - - - - - - - 66

WAVERSAVER® Parameter- - - - - - - - - - - - - - - - - - - 67

Contents

•

•

•

iii

•

•

•

Page 6

Information Page- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 68

Language Parameter Menu - - - - - - - - - - - - - - - - - - - - - - - - 68

Operations Parameter Menu - - - - - - - - - - - - - - - - - - - - - - - - - - 69

Tare Operations Commands and Parameters - - - - - - - - - - - - - - - - 69

Tare Amount Parameter - - - - - - - - - - - - - - - - - - - - - 69

Tare Offset Parameter - - - - - - - - - - - - - - - - - - - - - - 70

Tare Command - - - - - - - - - - - - - - - - - - - - - - - - - 71

Zero Operations Commands and Parameters- - - - - - - - - - - - - - - - 71

Zero Tolerance Parameter - - - - - - - - - - - - - - - - - - - - 71

Zero Amount Parameter - - - - - - - - - - - - - - - - - - - - - 71

Zero Command - - - - - - - - - - - - - - - - - - - - - - - - - 72

Auto Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 72

Count Operations Parameters and Commands - - - - - - - - - - - - - - - 72

Security Parameter Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - 74

The Calibration Lock Parameters - - - - - - - - - - - - - - - - - - - - - 75

Calibration Lock Parameter - - - - - - - - - - - - - - - - - - - - 75

Calibration Password Parameter - - - - - - - - - - - - - - - - - 75

The Configuration Lock Parameters- - - - - - - - - - - - - - - - - - - - 76

Configuration Lock Parameter - - - - - - - - - - - - - - - - - - 76

Configuration Password Parameter - - - - - - - - - - - - - - - - 76

The Display Lock Parameters- - - - - - - - - - - - - - - - - - - - - - - 76

Display Lock Parameter - - - - - - - - - - - - - - - - - - - - - 76

Display Password Parameter - - - - - - - - - - - - - - - - - - - 77

The Keypad Lock Parameters- - - - - - - - - - - - - - - - - - - - - - - 77

Keypad Lock Parameter - - - - - - - - - - - - - - - - - - - - - 77

Keypad Password Parameter - - - - - - - - - - - - - - - - - - - 78

The Read Only Lock Parameters - - - - - - - - - - - - - - - - - - - - - 78

Read Only Lock Parameter - - - - - - - - - - - - - - - - - - - - 78

Read Only Password Parameter - - - - - - - - - - - - - - - - - - 78

Setup Parameter Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - 79

Capacity Parameter- - - - - - - - - - - - - - - - - - - - - - - - 79

Decimal Point Parameter - - - - - - - - - - - - - - - - - - - - - 79

Graduation Size Parameter - - - - - - - - - - - - - - - - - - - - 80

Instrument ID Parameter - - - - - - - - - - - - - - - - - - - - - 81

Motion Tolerance Parameter - - - - - - - - - - - - - - - - - - - 81

Operator ID Parameter - - - - - - - - - - - - - - - - - - - - - - 82

Unit (of Measure) Parameter - - - - - - - - - - - - - - - - - - - 82

•

•

•

iv

Contents

•

•

•

Chapter 6 Calibration- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 85

Pre-Calibration Procedures - - - - - - - - - - - - - - - - - - - - - - - - - - 85

Electrical Check Procedures - - - - - - - - - - - - - - - - - - - - - - - - - - 86

Load Cell/Point Input/Output Measurements - - - - - - - - - - - - - - - 86

Load Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 87

Page 7

C2 & eCAL Electronic Calibration- - - - - - - - - - - - - - - - - - - - - - - 87

Gravitation Correction - - - - - - - - - - - - - - - - - - - - - - - - - - 87

C2 and eCAL Calibration from the Web Page - - - - - - - - - - - - - - - 89

C2 Calibration from the Front Panel- - - - - - - - - - - - - - - - - - - - 90

Hard Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 91

Hard Calibration from the Web page - - - - - - - - - - - - - - - - - - - 91

Hard Calibration from the Front Panel- - - - - - - - - - - - - - - - - - - 92

Chapter 7 Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 95

Getting Started - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 95

Mode Button- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 95

Zero Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 95

Tare Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 97

Auto Mode Tracking – Disabled (Default) - - - - - - - - - - - - - - - - 98

Auto Mode Tracking – Enabled - - - - - - - - - - - - - - - - - - - - - 98

Split Screen Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - 101

Making Longer Display Interface Cables - - - - - - - - - - - - - - - - - 101

Chapter 8 Security - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 105

Display Security Options - - - - - - - - - - - - - - - - - - - - - - - - - - - 105

The Display Lock - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 106

The Keypad Lock - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 108

The Configuration Lock - - - - - - - - - - - - - - - - - - - - - - - - - - - - 110

The Read Only, Security & Calibration Locks - - - - - - - - - - - - - - - - - 111

Modifying the Security Parameters- - - - - - - - - - - - - - - - - - - - - - - 112

Modifying the Calibration Parameters - - - - - - - - - - - - - - - - - - - - - 112

Modifying the Read Only Parameters - - - - - - - - - - - - - - - - - - - - - 113

Chapter 9 Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 115

Error Messages - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 116

Trouble Shooting Using Integrated Technician (IT®) - - - - - - - - - - - - - - 117

Stability Test ALL - - - - - - - - - - - - - - - - - - - - - - - - - - - - 117

PASS/FAIL and Stability Test - - - - - - - - - - - - - - - - - - - - - - 118

WAVERSAVER TEST - - - - - - - - - - - - - - - - - - - - - 118

Weight and Voltage ALL - - - - - - - - - - - - - - - - - - - - - - - - - - - 118

Weight - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 118

RTZ (Return to Zero) Test - - - - - - - - - - - - - - - - - - - - - - - - 119

IT Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 119

Sensor Number - - - - - - - - - - - - - - - - - - - - - - - - - 119

General Troubleshooting Flow Chart Index- - - - - - - - - - - - - - - - - - - 121

Contents

v

•

•

•

•

•

•

Page 8

A - Guideline Instability: Electrical and Mechanical review.- - - - - - - - - - - 122

A1. Checking for Unstable Components in a Weighing System - - - - - - - - - 123

B. Guidelines for Electrical, Mechanical or Configuration Issues - - - - - - - - 124

B1 - Guidelines to Verify Electrical Installation- - - - - - - - - - - - - - - - - 125

B2 - Guidelines to Verify Mechanical Installation - - - - - - - - - - - - - - - 126

B3 - Guidelines to Verify Configuration/Filter Settings to Improve Stability - - - 127

C - Integrated Technician and Stability Test Overview - - - - - - - - - - - - - 128

E Testing for Non-Return to Zero (System with IT Summing Card.) - - - - - - - 129

F. Verify Individual Load Sensor Millivolt Output readings - - - - - - - - - - - 130

G- Calibration Errors When Performing the Calibration - - - - - - - - - - - - - 131

H. Mechanical Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - 132

J- Electrical Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - 133

K - Installation Check Points - - - - - - - - - - - - - - - - - - - - - - - - - 134

M. Weight Processor’s Front Display is Blank or Locked - - - - - - - - - - - - 135

N. Analog Out (HI 6310 Only)- - - - - - - - - - - - - - - - - - - - - - - - - 136

Tests and Diagnostics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 137

Parameters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 138

System and Load Cell Tests - - - - - - - - - - - - - - - - - - - - - - - - - - 139

Overview of Typical Load Cell System - - - - - - - - - - - - - - - - - - 139

INTEGRATED TECHNICIAN - - - - - - - - - - - - - - - - - - - - - - 140

Stability Test- - - - - - - - - - - - - - - - - - - - - - - - - - - 140

Weight and Voltage Tests - - - - - - - - - - - - - - - - - - - - 142

•

•

•

vi

Contents

•

•

•

Page 9

Chapter 1

• • • • • •

Overview

General Introduction to the HI 6300 Series Weight Processor

This Manual describes installation, setup and troubleshooting procedures for the HI 6300

Series Weight Processor. Be sure to read and understand all cautions, warnings, and safety

procedures in this manual to ensure safe operation and repair of this instrument.

Hardy Process Solutions sincerely appreciates your business. We encourage input about the

performance and operation of our products from our customers. Should you not understand

any information in this manual or experience any problems with this product, please contact

our Technical Support Department at:

Phone:

(858) 278-2900

Toll Free:

F AX:

1-800-821-5831

(858) 278-6700

E-Mail:

Or visit our web site at:

http://www.hardysolutions.com

Our web site provides information about our products and process weighing applications.

You can also update the HI 6300 User Guide. The latest revised manuals are available

FREE in the product selection pull down menu on our Web Site. Other pages on the site

provide answers to questions about weighing instruments, PLC plug in modules, load

points, summing boxes, process weighing or other Hardy Process Solutions products. Be

sure to sign up for the Hardy Newsletter to get the latest information on all Hardy products

and services. For answers to technical issues and service problems, check the Hardy

WebTech on our Hardy Web Site. Most problems can be resolved by the Hardy WebTech,

365 days a year, 24 hours a day 7 days a week. You can still contact a technician by phone

during our normal operating hours (6:30 AM to 5:30 PM Pacific Time) if necessary.

hardysupport@hardysolutions.com or hardyinfo@hardysolutions.com

HI 6300 Series Weight Processor Description

The HI 6300 series of single-channel weight processing instruments is suitable for

PLC-based or stand-alone weighing applications. The primary function of the

HI 6300 series is to provide stable gross or net weight in a variety of units such as oz,

lb, ton, gm, kg and mt.

Overview

•

•

1

•

•

•

•

Page 10

The HI 6300 series can be used with or without a display. The display is a bright 4.3”

high-contrast LCD capable of high-resolution graphics and discrete messaging. The

unit can be panel mounted, DIN mounted, and remote display mounted. The thin

enclosure and ultra-low power consumption allows for high density control cabinet

design.

Typical Applications

The HI 6300 series serves a variety of industrial weighing applications found in batching,

blending, filling, dispensing, inventory management, level by weight and check by weight

verification.

Features and Capabilities

Hardy Process Toolbox

The Hardy Process Toolbox is a set of productivity tools that support process weighing

functions. Each tool in the Hardy Process Toobox saves time, increases accuracy, improves

efficiency or reduces risk in process weighing applications. The HI 6300 includes the

following Toolbox functions.

C2® and eCal™ Calibration

Traditional calibration uses certified test weights. C2® (or eCAL

Electronic Calibration allows a scale to be calibrated without the need for test weights. A

C2 or eCAL weighing system consists of up to four load cell sensors per channel, a junction

box, interconnect cable, and an instrument with C2 capabilities (e.g., the HI 6300 series

instrument). Each Hardy Process Solutions C2-certified load sensor outputs digital

information used for calculating the calibration. When the HI 6300 series instrument reads

the signals from the load sensors, it calibrates the scale based on the load sensor’s output

plus a user-supplied reference point value (from 0 to any known weight on the scale).

™ as it is called in China)

•

•

•

2

Chapter 1

•

•

•

WAVERSAVER

When measuring small weight changes, the effects of mechanical vibration and noise from

feeders and other plant environmental conditions can introduce substantial interference.

WAVERSAVER factors out vibration, noise, and other interference-related signals from the

load cell so the rate controller can better decipher the actual weight data.

While WAVERSAVER can factor out noise with frequencies as low as 1.00 Hz, three cutoff frequencies can be selected, with higher frequencies providing a faster response time.

The default factory setting is 1.00 Hz vibration frequency immunity.

®

Page 11

NOTE

INTEGRATED TECHNICIAN

In conjunction with an IT junction box, the HI 6300 features INTEGRATED

TECHNICIAN

®

(IT), a system diagnostics program that makes it possible to diagnose

®

weighing system problems from the instrument’s front panel or over the available

networks. IT reads individual load sensor voltages and weights and isolates individual

system components for quick and easy troubleshooting

If you do not have a Hardy IT Junction Box connected to the HI 6300, the weight reading

is the total for all load cells on the system.

Weighing System Tests

These tests are used to diagnose drifting or unstable weight reading problems. It requires a

Hardy IT Junction Box for full utilization, for example the HI 215IT or the HI 6010IT. The

ability to read the weight seen by the individual load sensors allows you to use this test for

making cornering, leveling and load sharing adjustments to the weighing system.

INTEGRATED TECHNICIAN provides the following problem detection support:

1.

Integrated Technician Weight and Voltage Test

sensor in the system to see if the load sensor might be causing the problem.

2.

Integrated Technician Stability Test

: Disconnects the load sensors and engages

an internal (in the junction box) reference signal to see if the Junction box, the cable

between the instrument and the Junction Box, or the instrument is causing the

problem.

3.

Integrated Technician Return to Zero Test

each Hardy load cell during a C2 calibration when zero is used as the reference.

Later when the test is run it measures and compares the voltage with zero weight out

from each load cell to the stored value and indicates either a pass or fail. This test

insures the integrity of the weighing system.

: Reads the weight of each load

: Measures and stores the mV out of

NOTE

W AVER SAVER, C 2, and INTEGRATED TECHNICIAN ar e r egistered trademarks of Har dy

Process Solutions.

Overview

3

•

•

•

•

•

•

Page 12

•

•

•

4

Chapter 1

•

•

•

Page 13

Chapter 2

• • • • • •

Specifications

Chapter 2 provides specifications for HI 6300 series instruments. The specifications

listed are designed to assist in the installation, operation and troubleshooting of your

instrument. All service personnel should be familiar with this section before installing

or repairing the instrument.

Basic Specifications

General

Number of Channels

•

1 Channel

Update Rate

•

55 Updates per Second

Resolution

•

Internal 1:262,144

WAVERSAVER

•

User Selectable

OFF

7.50 Hz

3.50 Hz

1.00 Hz (default)

Averages

•

1 to 250 User-selectable in Single Increments

Power

•

12-27 VDC

Input

•

Up to four 350-ohm full Wheatstone bridge, strain gauge load sensor/cells (5 volt

excitation) can be connected to the weigh scale input

Non-linearity

•

0.0015% of full scale

Common Mode Rejection

•

110dB at or below 60 Hz

Common Mode Voltage Range

•

2.5 VDC maximum (with respect to earth ground)

Specifications

•

•

•

5

•

•

•

Page 14

Fr ont Panel (optional)

•

Monochrome 480 x 272 LCD display with backlight

•

Five tactile keys for menu item selection

Load Cell Excitation

•

5 VDC +/- 1.15 VDC maximum

•

Isolation from digital section 1000 VDC minimum

C2 Calibration Input

•

Isolation from digital section 1000 VDC minimum

Cable Lengths

•

250 feet maximum of C2 authorized cable (Maximum of 4 load sensors) with IT

Junction box

Network Connectivity

Ethernet TCP/IP

Ethernet UDP

Modbus-RTU over RS485

HI 6310 Only

Analog 4-20 mA

Printer port

USB port

Environmental Requirements

Operating Temperature Range

•

0 to 60º C (32º to 140º F)

Temperature Coefficient

•

Less than 0.005% of full scale per degree C for Cal-LO and Cal-HI reference points

•

•

•

6

Chapter 2

•

•

•

Storage Temperature Range

-40 to 85º C (-40º to 185º F)

Humidity Range

•

0-90% (non-condensing)

Maximum Altitude for Installation

•

2000 Meters (6,562 Feet)

Pending Approvals

•

UL, CUL and CE

•

Hazardous Class I, Division 2, Groups A,B,C,D, T4A and Class I, II, III, Division 2,

Groups F, G, T4A

Page 15

Chapter 3

• • • • • •

HI 6300 Installation

Chapter 3 covers unpacking, cabling, interconnecting, configuring, and installing the HI

6300 series of instruments. User and service personnel should read this chapter before

installing or operating the weighing functions of the instrument.

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY

IMPAIR SUITABILITY FOR DIVISION 2.

AVERTISSEMENT – Risque d’explosion – La substitution de composants peut

diminuer la conformité pour la Division 2

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT

UNLESS POWER HAS BEEN SWITCHED OFF OR THE AREA IS KNOWN TO BE

NON-HAZARDOUS

Unpacking

AVERTISSEMENT –

moins que l’alimentation soit coupée ou que la zone ne présente pas de risques

Step 1. Before signing the packing slip, inspect the packing for damage, and report

damage of any kind to the carrier company.

Step 2. Check to see that everything in the package matches the bill of lading.

Step 3. If items are missing or you have any questions, contact Customer Service at:

Step 4. Record the model number and serial number of the HI 6300 series instrument.

Store them in a convenient, secure location for reference when contacting Hardy

Customer Service Department or to buy parts or firmware upgrades

Risque d’explosion – Ne pas débrancher l’équipement à

Hardy Process Solutions

9440 Carroll Park Drive

San Diego, CA 92121

Phone: (800) 821-5831

International:

FAX

: (858) 278-6700

Web Site:

E-Mail:

(858) 292-2710

http//www.hardysolutions.com

hardysupport@hardysolutions.com

Installation

•

•

•

7

•

•

•

Page 16

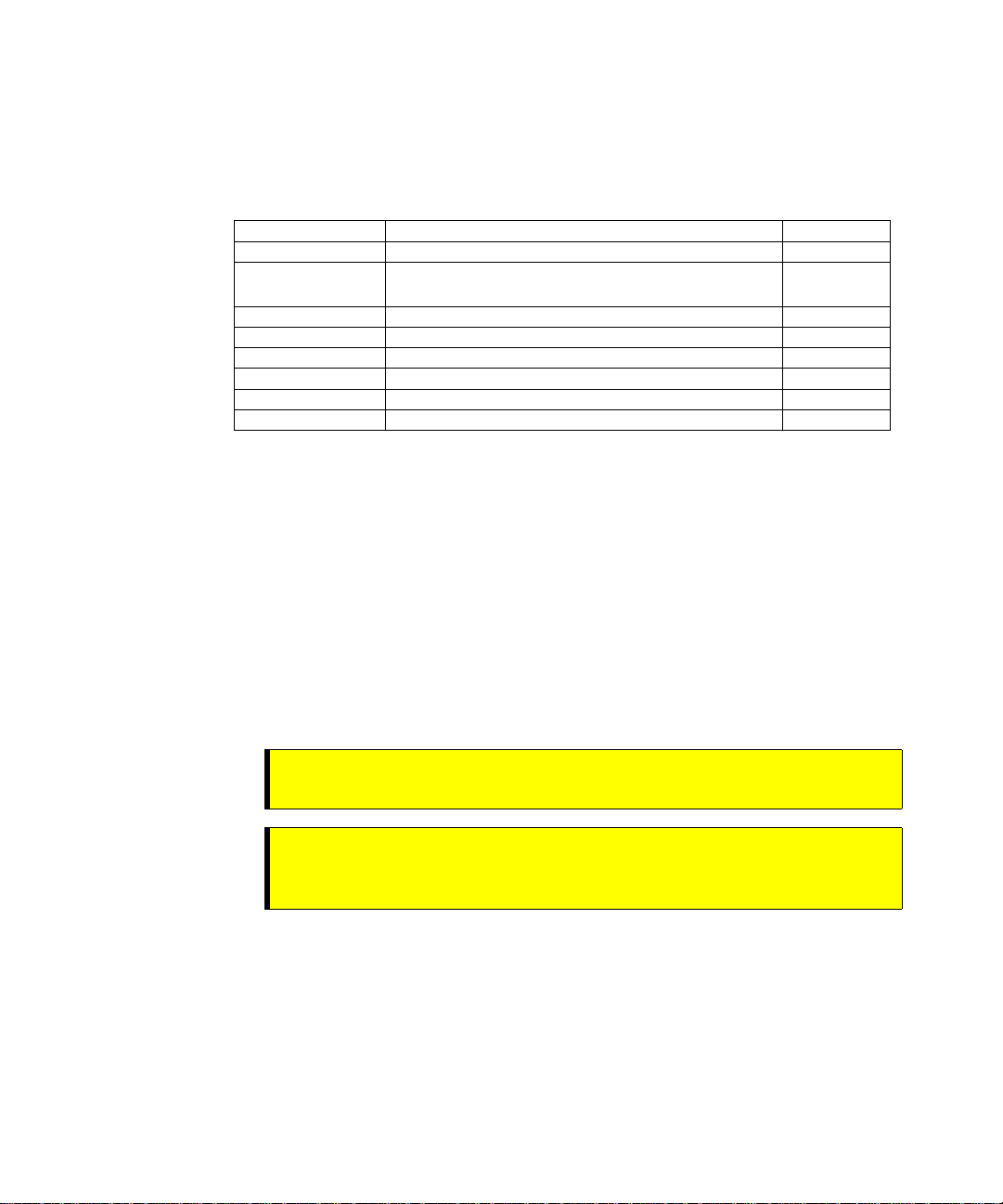

Spare Parts List

Part Reference Description Quantity

HI 6110 HI 6300 Series Instrument Display (Optional) 1

0551-0653-01-0 HI 6300 Series Alt. Panel and Wall Mount Kit

0578-0072-01 Paper Mounting Template 1

0524-0034-01-0 Mounting Gasket 1

2140-0092-0 J1, 3-pin Power Connector 1

2140-0139-09-0 J2, 9-pin Load Cell Connector 1

2140-0139-06-0 J3, 6-pin Serial Port Connector 1

2140-0139-03-0 J4, 3-pin 4-20mA Connector 1

Tool List

Step 5. Be sure to complete the warranty registration on the Hardy Process Solutions web

site.

1

(optional)

To install the HI 6300 series the following tools will be required.

•

Drill with 5mm drill bit

•

Jewelers screw driver (if cable assemble needs to be modified)

•

4mm nut driver with a maximum outside dimension of 8mm

•

10-50 mm Unibit (for optional display installation)

•

•

•

8

Chapter 3

•

•

•

Installing the HI 6300 Series Instrument

Before getting started, take the following precautions:

WARNING -

the module. DO NOT TOUCH THE CONNECTOR PINS.

WARNING AVERTISSEMENT –

endommager les composants semi-conducteurs dans le module. NE TOUCHEZ

PAS les broches du connecteur.

•

Wear an approved wrist-strap grounding device when handling the module.

•

Touch a grounded object or surface to rid yourself of any electrostatic discharged prior

to handling the module.

•

Handle the module from the bezel in front away from the connector. Do not touch the

connector pins.

•

Do not install the module right next to an AC or high voltage DC module.

•

Route all the low voltage cables away from high voltage cables.

Electrostatic discharge may damage semiconductor components in

Les décharges électrostatiques peuvent

Page 17

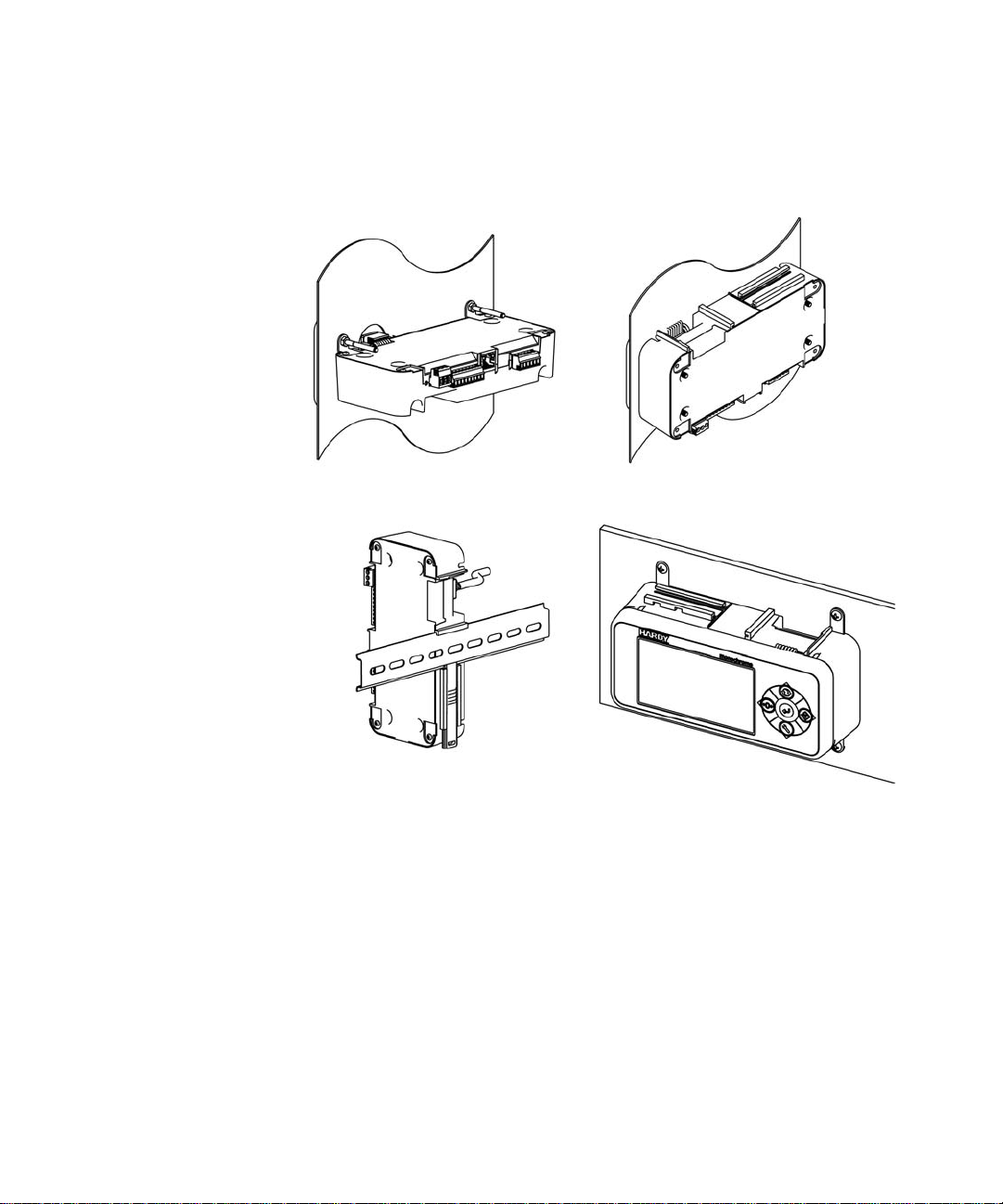

Installation options for the HI 6300 series instrument

The HI 6300 series instrument can be mounted in four different configurations. There are

two panel mount options, one DIN rail mount option, and a wall mount option.

Panel Mount Option 1 with mounting kit Panel Mount Option 2

DIN Rail Mount Wall Mount with mounting kit

Panel Mount Option 1 and Wall Mounts require additional hardware, which is

available in the Panel Mount Option 1 and Wa ll Mount kit sold separately (Part#

0551-0653-01-0).

The following sections provide details on how to mount the front panel display on a

panel door or cover and how to install and connect the front panel to the HI 6300 series

instrument for each of these four configurations.

Mounting the Front Panel Display

Step 1. Make sure that all Electrostatic Discharge (ESD) precautions are taken before and

during installation.

Installation

•

•

•

9

•

•

•

Page 18

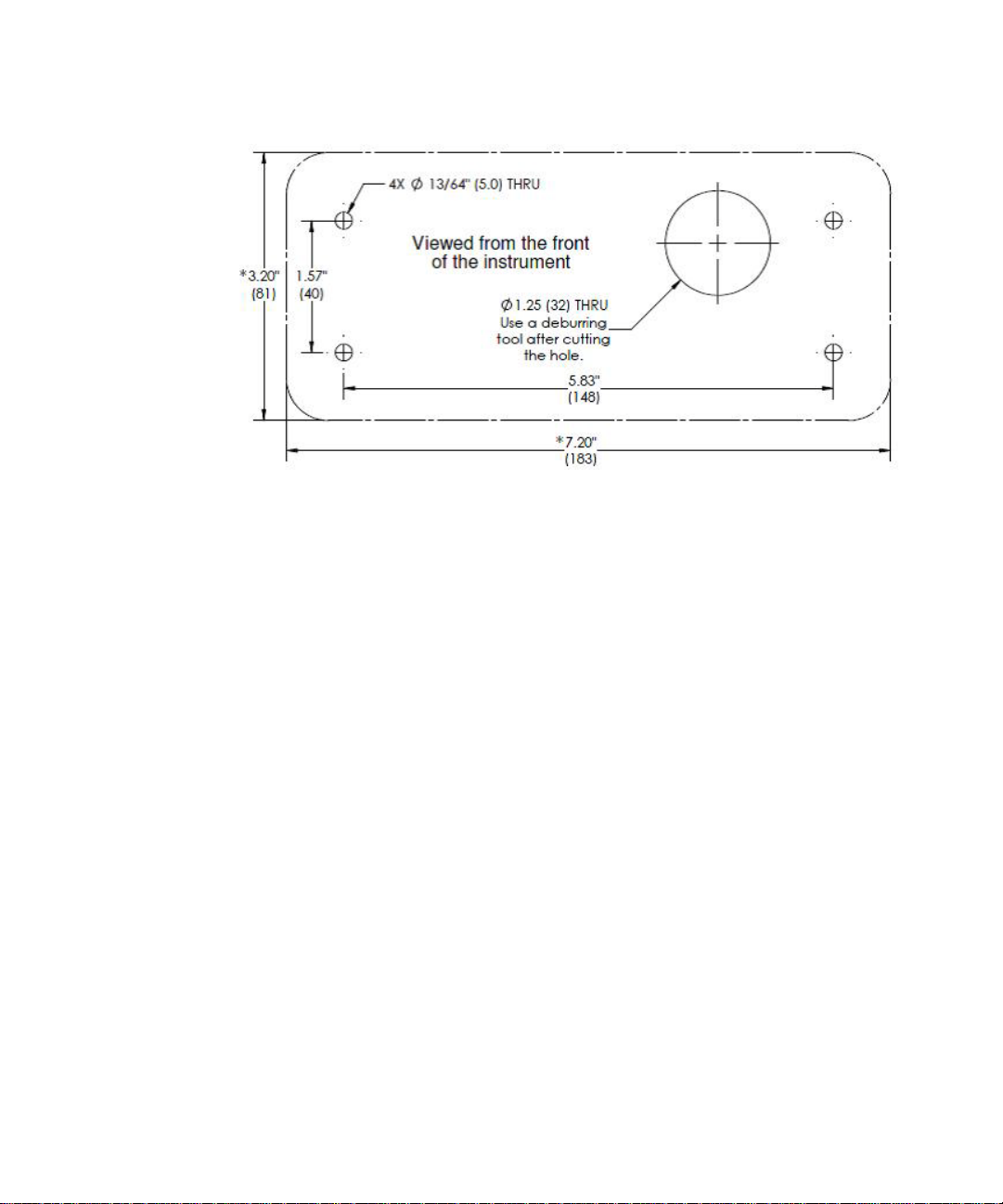

Step 2. A thin plastic template comes with the product. Make the hole pattern in the panel

door or cover using the dimensions provided on the diagrams below.

Panel Hole Dimensions (not displayed to scale)

A printable template is available on the Hardy website. Printers and copy machines can

distort or reduce the template measurements shown above. If you are not using the plastic

template included with the product, verify the dimensional accuracy of any paper template

before use.

CAUTION: We recommend installing the HI 6300 in a NEMA 4, 4X or IP 55 rated enclosure or better.

•

•

•

10

Chapter 3

•

•

•

ATTENTION

Nous vous recommandons d'installer le HI 6300 dans un boîtier NEMA 4, 4X ou IP 55

ou mieux.

Page 19

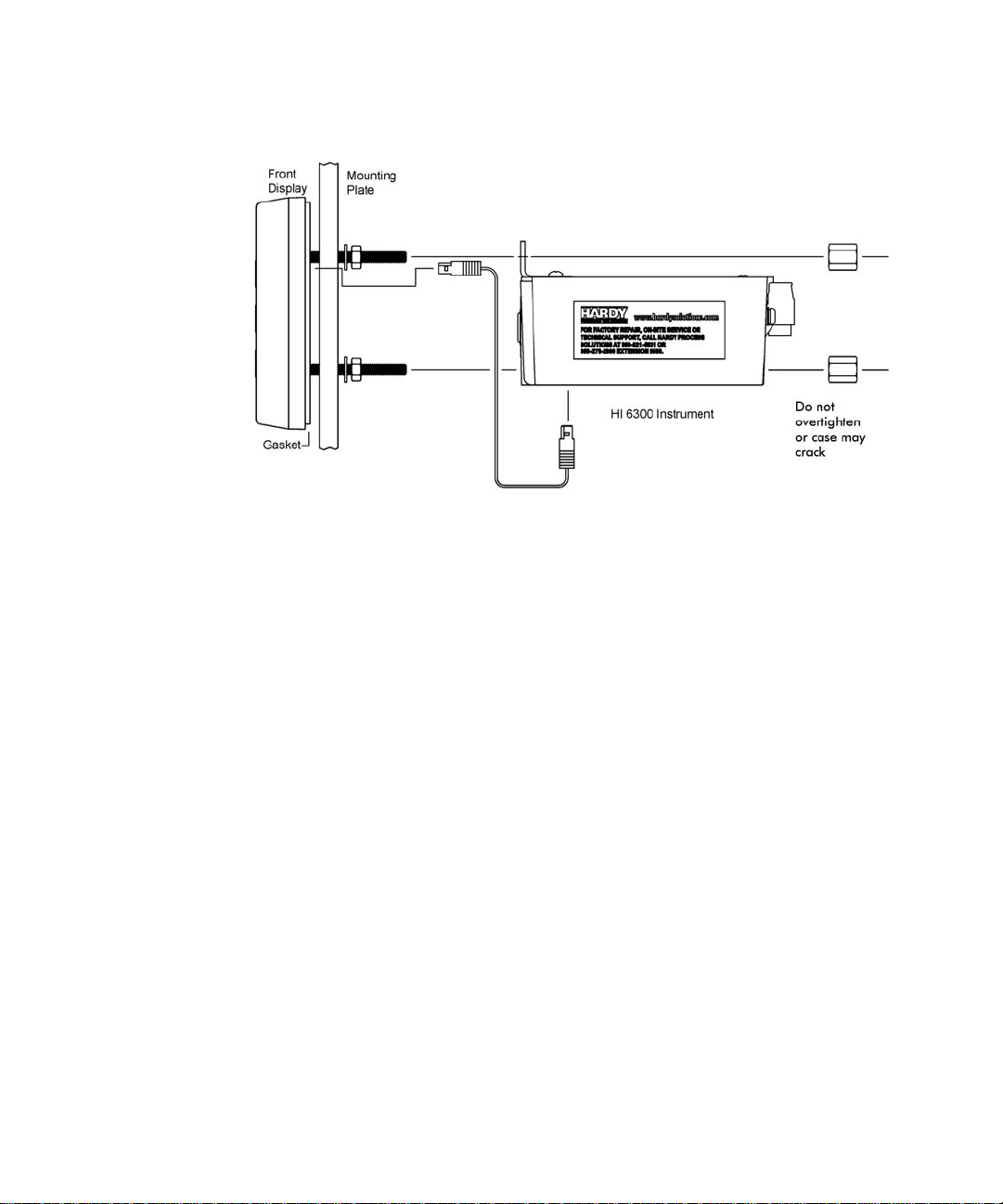

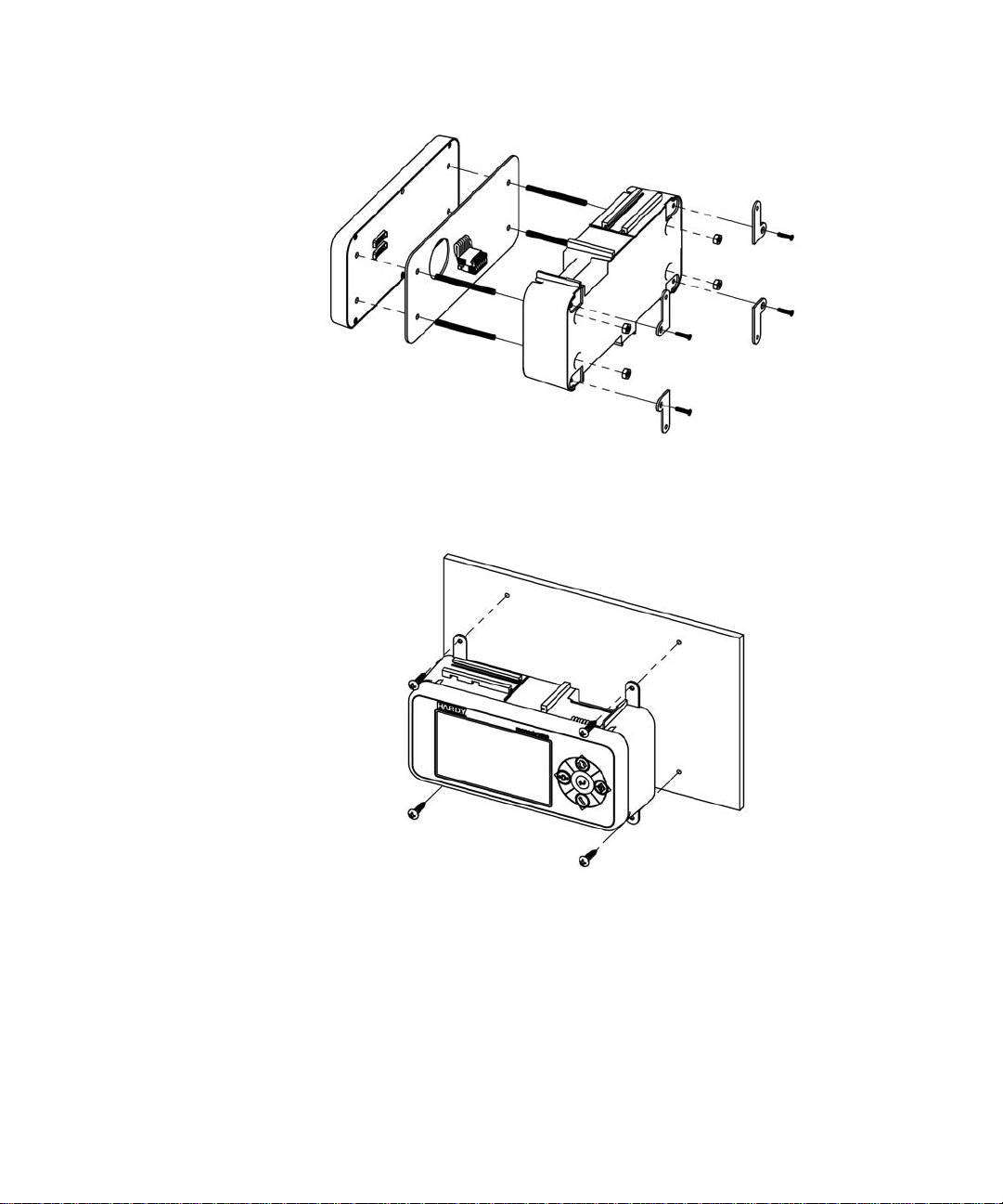

Panel Mount Option 1

FIG. 1 Exploded View of the Panel Mount Assembly – Option 1 with optional

mounting kit

Step 1. Screw the Panel Mounting Brackets to the top of the enclosure

Step 2. Connect and hand tighten the four screw rods into the front panel display

Step 3. Push the screw rods and cable assembly though the holes in the panel.

Step 4. Connect the front panel display cable assembly

Step 5. Tighten the four 4mm nuts enough to completely compress the gasket for IP65

Step 6. Position the enclosure with the connectors at the back

Step 7. Align the screw rods with the holes in the brackets and the enclosure

Step 8. Connect the cable assembly

Step 9. Slide the enclosure onto the screw rods until flush with the panel

Step 10. Install and tighten keeper nuts.

CAUTION: Do not over tighten the bracket screws or the mounting nuts as this may damage the

enclosure.

ATTENTION

Ne pas trop serrer les écrous de montage car cela pourrait endommager l'enceinte.

Installation

•

•

•

11

•

•

•

Page 20

NOTE

Finished Panel Mount Assembly – Option 1

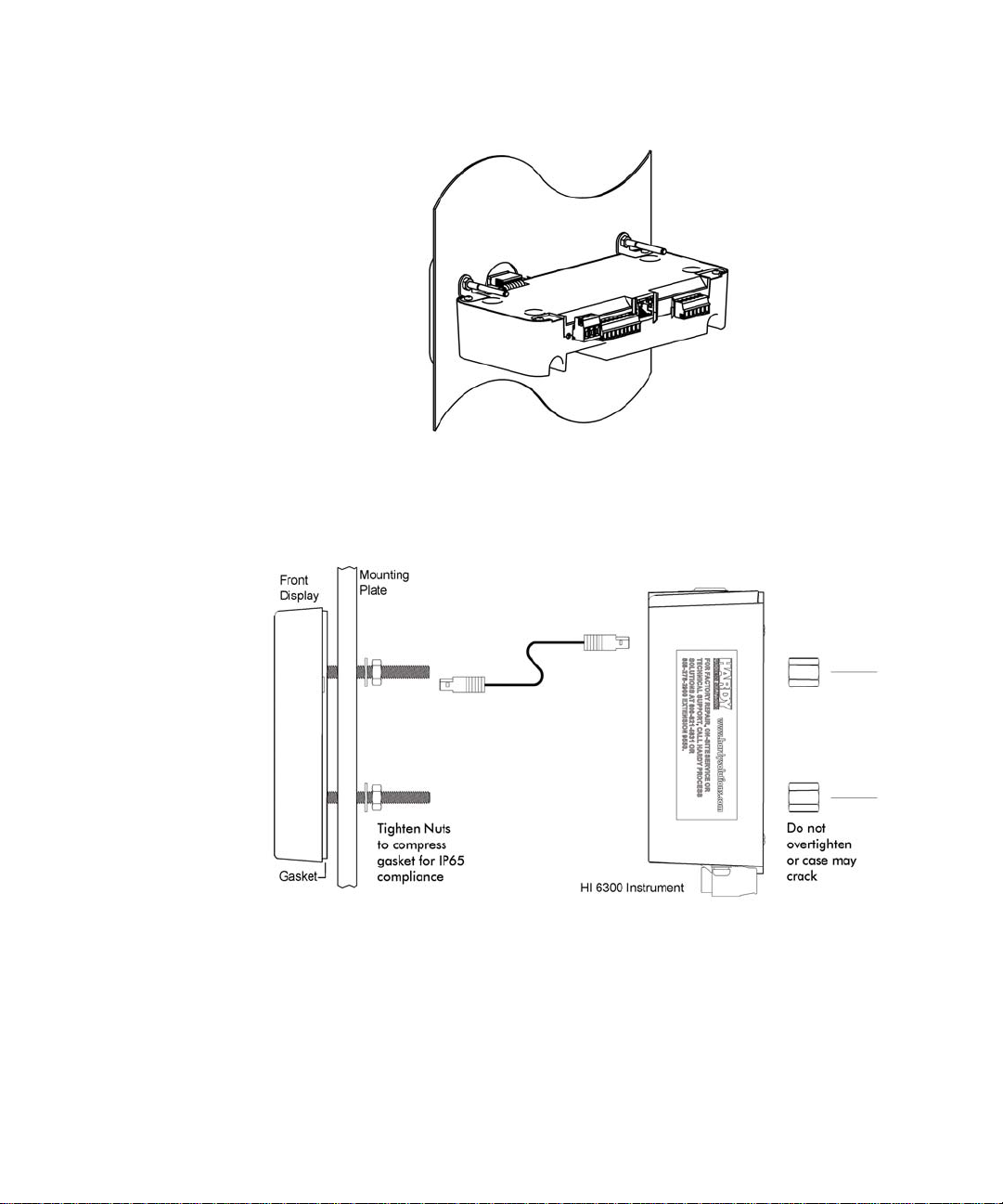

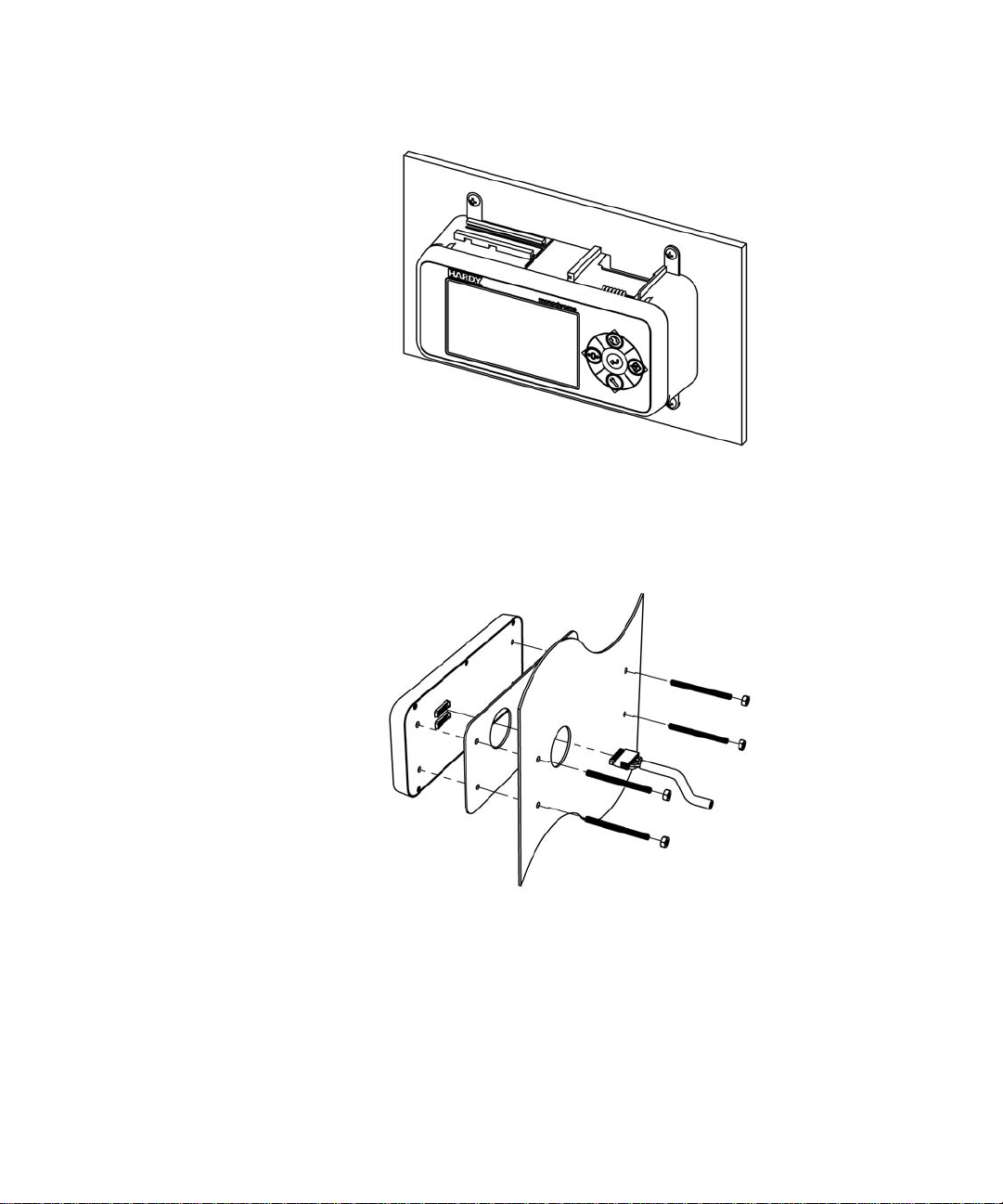

Panel Mount Option 2

Exploded View of the Panel Mount Assembly – Option 2

No brackets are needed for this installation.

•

•

•

12

Chapter 3

•

•

•

Step 1.

Connect and hand tighten the four screw rods into the front panel display

Step 2. Connect the front panel display cable assembly

Step 3. Push the screw rods and cable assembly though the holes in the panel.

Page 21

Step 4. Secure display to panel using four 4mm nuts and washers on the screw rods.

Step 5. Tighten the four 4mm nuts enough to completely compress the gasket for IP65

compliance.

Step 6. Position the enclosure with the connectors pointing downwards

Step 7. Align the screw rods with the holes in the enclosure

Step 8. Connect the cable assembly

Step 9. Slide the enclosure onto the screw rods until flush with the panel

Step 10.

Using the 4 mm x 12 mm keeper nuts supplied, secure the enclosure screw rods

CAUTION: Do not over tighten the bracket screws or the mounting nuts as this may damage the

enclosure.

ATTENTION

Ne pas trop serrer les écrous de montage car cela pourrait endommager l'enceinte.

Finished Panel Mount Assembly – Option 2

Making Longer Display Interface Cables

If you need to install the front panel further away from the HI 6300 series than is possible

with the supplied cable then, you will need to make a display cable between the panel and

the instrument.

Wiring Specifications

•

Wire size: 20 AVG maximum / 26 AWG minimum

•

Maximum cable length: 100 ft. (30.48 meters)

•

Use three twisted pairs with a drain wires

•

Pair wires +12 and GND, D1 and D2, D3, and D4

Installation

•

•

•

13

•

•

•

Page 22

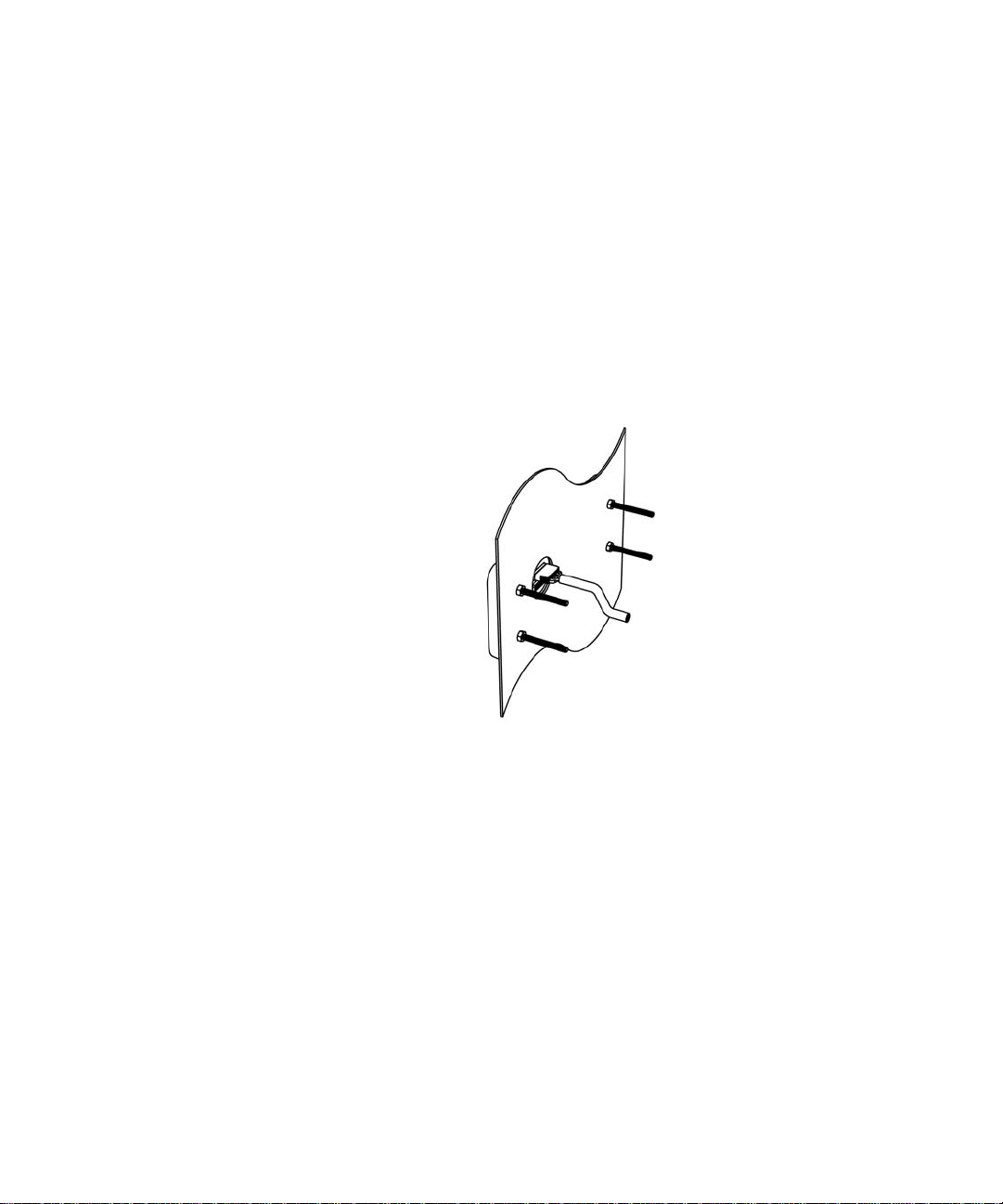

View from the rear of the front display panel

The terminal type is a spring cage type contact. There is a slot provided to use an

insert/release tool. The tool is a 2.0 mm x 0.4 mm wide flat blade screw driver. Inserting

the tool opens the cage contact and allows one or two bare wires to be inserted. Removing

the insertion tool with bare conductor inserted will lock the connection.

•

•

•

14

Chapter 3

•

•

•

View from the front of the instrument showing the display connector.

Page 23

NOTE

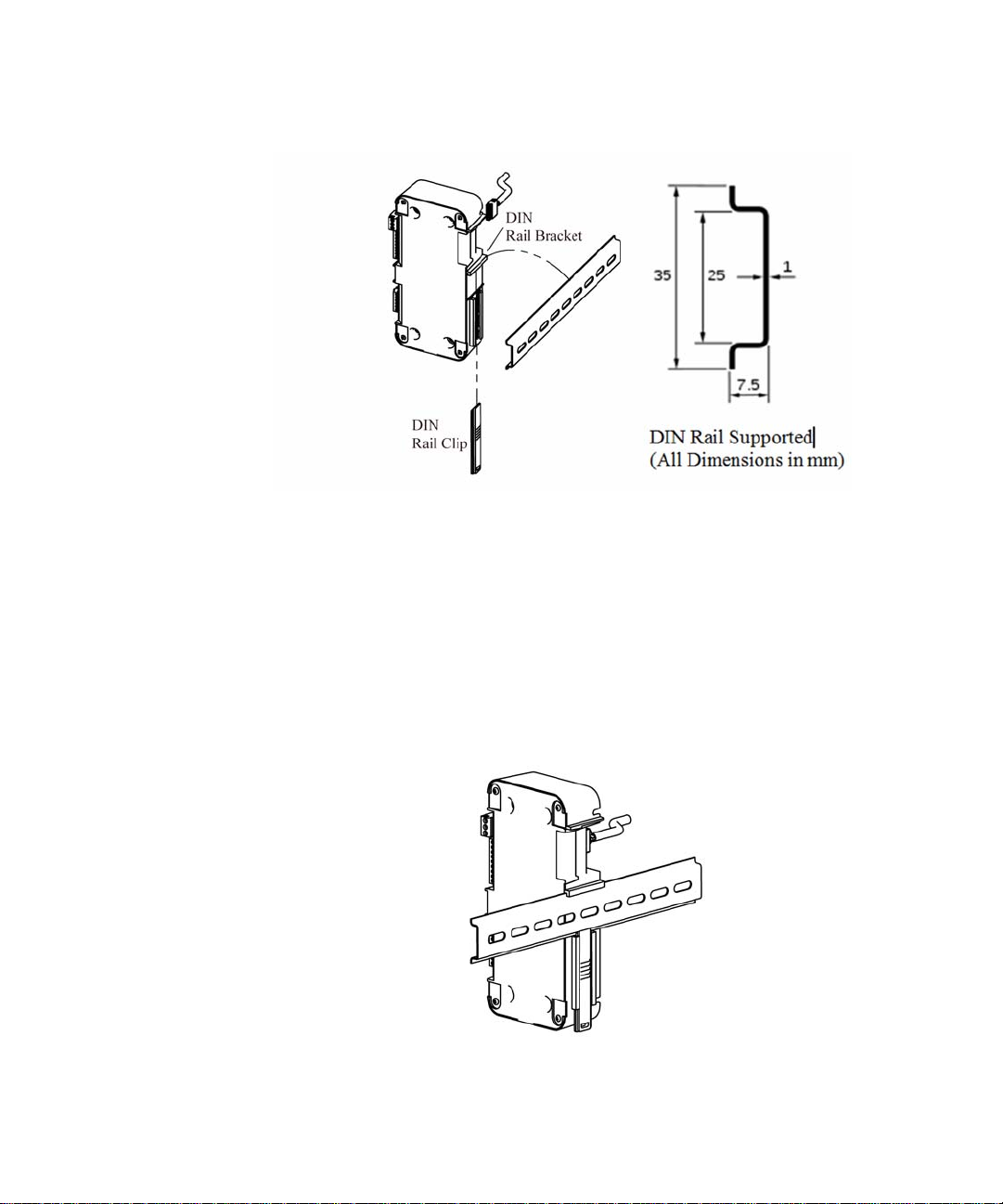

DIN Rail Mount

Exploded View of the DIN Rail Mount Assembly

The DIN Rail mount can be used with a remote display or operated as a Blind unit

Step 1. Pull down the DIN rail clip to expose the DIN Rail bracket. Do not fully remove the

clip from the housing.

Step 2. Hook DIN rail bracket onto the DIN rail using the groove at the top of the bracket

Step 3. Push the DIN rail clip up until it locks in place.

Step 4. While holding the HI 6300 series instrument, gently pull the bottom of the HI 6300

away from the DIN rail to verify that it is mounted correctly.

Completed DIN Rail Mount Assembly

Installation

•

•

•

15

•

•

•

Page 24

Wall Mount

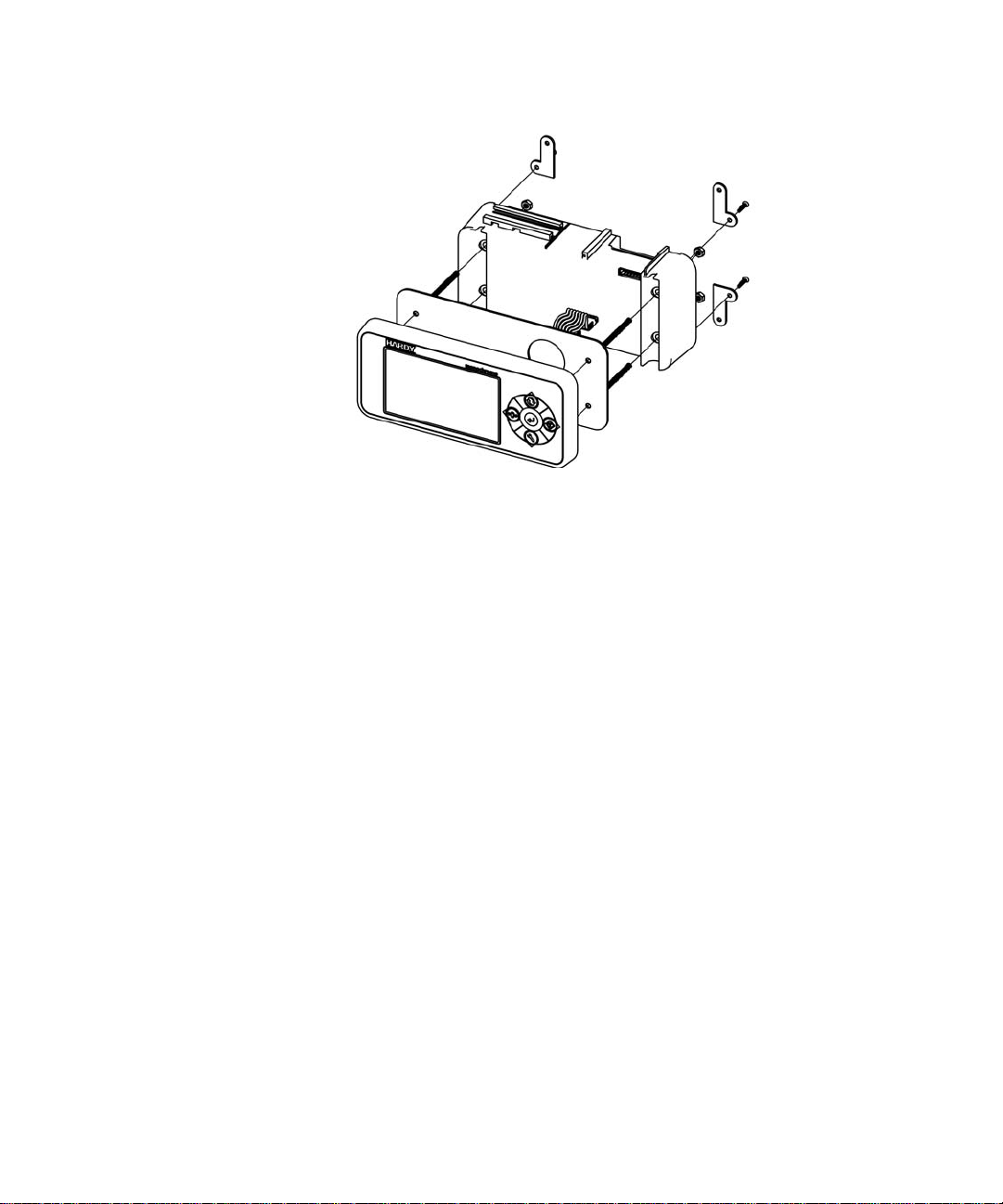

Wall Mount Assembly exploded from the front with optional mounting kit

To wall mount the HI 6300 series instrument, the display and weight processor need to be

assembled; then the assembled instrument can be mounted onto the wall.

Step 1. Connect and hand tighten the four screw rods into the front panel display

Step 2. Connect the front panel display cable assembly

Step 3. Push the screw rods and cable assembly though the holes in the gasket.

Step 4. Position the enclosure with the connectors pointing downwards

•

•

•

16

Chapter 3

•

•

•

Step 5. Align the screw rods with the holes in the enclosure

Step 6. Connect the cable assembly

Step 7. Slide the enclosure onto the screw rods until flush with the gasket

Step 8. Using the washers and nuts supplied, tightened the nuts onto the screw rods

Page 25

Step 1. Attach the mounting brackets using the supplied brackets and screws

Exploded View of the Wall Mount Assembly – Rear View

Step 2. Place the assembled wall mounted unit against the wall

Step 3. Mark the centers of the wall mounting brackets

Step 4. Drill and insert the required wall plugs if attaching to brick, concrete, or plaster board.

If attaching to wood use a pilot drill to ensure alignment.

Step 5. Position the assembled wall unit over the holes and using the appropriate screw fasten

to the wall.

Installation

•

•

•

17

•

•

•

Page 26

Completed Wall Mount Assembly

Remote Display Mount

Exploded View of the Remote Display Mount Assembly

The display for the HI 6300 series instrument can be mounted in a remote location and

the supplied cable can be modified to support the desired length of cable (not supplied).

Step 1. Connect and hand tighten the four screw rods into the front panel display

•

•

•

18

Chapter 3

•

•

•

Page 27

Step 2. Disable the cable assembly provided, and replace the original cable with the desired

cable length (not provided--up to 100 ft (30.48 meters)). Build the cable assembly

using the instructions above for

13

.

Making Longer Display Interface Cables

on page

Step 3. Connect the front panel to the newly assembled display cable

Step 4. Push the screw rods and cable assembly though the holes in the gasket.

Step 5. Slide the screw rods through the panel until flush with the surface

Step 6. Using the washers and nuts supplied, tightened the nuts onto the screw rods. Tighten

the nuts enough to completely compress the gasket for IP65 compliance

Step 7. Connect the cable assembly to the HI 6300 series instrument

Finished Remote Display Mount Assembly

Blind Unit (No display)

The front display is not necessary for the HI 6300 series instrument to operate as a scale

controller. Blind units can be fully configured using the Web browser communication.

Installation

•

•

•

19

•

•

•

Page 28

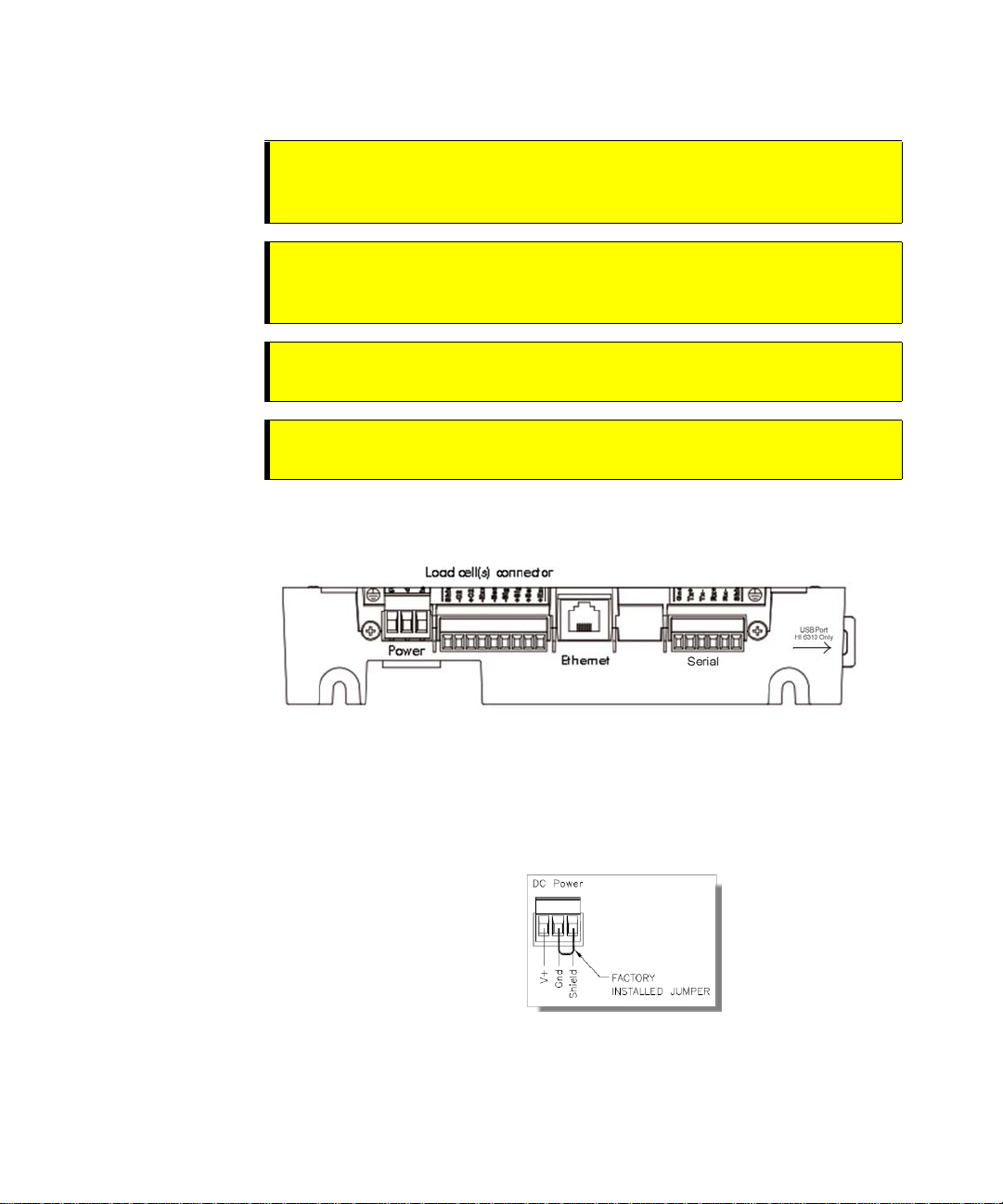

DC Power Input

WARNING - Do not operate with incorrect line voltage. To do so will result in

property damage and/or personal injury. Make sure that the power source does

not exceed 24 VDC.

AVERTISSEMENT –

Assurez-vous que la source d’alimentation ne dépasse pas

240 V. L’utilisation d’un mauvaise voltage peut résulter en dégâts matériels

et/ou des risques de blessures.

WARNING - Be careful not to reverse the ground and hot wires, which can

result in damage to the equipment.

AVERTISSEMENT –

Attention à ne pas inverser le sol et fils chauds, ce qui peut

entraîner des dommages à l'équipement.

The illustration below shows the connections on the HI 6300 unit.

You must use a power-limited DC power supply (Class 2) on the DC input wiring. DC

power should be supplied by a clean primary line, directly from the DC power source.

Step 1. Make sure the VDC power is shut off before installing the wires to the connector.

Step 2. Connect the 24 VDC voltage wire, ground wire and shield wire to the connector that

plugs into the DC voltage header at the rear panel.

•

•

•

20

Chapter 3

•

•

•

Step 3. Plug the connector into the header at the rear panel.

Step 4. Apply VDC power to the unit.

Page 29

Disassembly and Reassembly Notes and Cautions

•

Installation of this equipment must comply with International, National and Local

Electrical and Mechanical codes.

•

Make sure that any disassembly is done in a clean, well ventilated, properly controlled

static-free environment.

•

Always make sure that the assemblies and sub-assemblies are well supported and

insulated when working on the instrument.

•

Place small fasteners, connectors and electrical parts in closed containers so as not to

lose parts during reassembly.

•

Read the disassembly instructions before disassembly. If you find the instructions for

disassembly unclear, contact the Hardy Process Solutions Technical Support

Department for additional information and assistance.

•

Do not disconnect any electrical plug, connector or terminal unless an identification tag

is present or one is attached. Always note where the connector or plug was attached to

the electrical component or wiring harness.

•

Install complete hardware groups (screws, washers, lock washers, spacers, etc.) back to

the original point of removal.

•

Replace broken or damaged hardware immediately!

•

Verify that no loose parts are sitting on printed circuit boards or electrical connectors or

wires when disassembling or reassembling.

•

Always protect printed circuit boards from electrostatic discharge (ESD). Always use

approved ESD wrist straps and anti-static pads.

Installation

•

•

•

21

•

•

•

Page 30

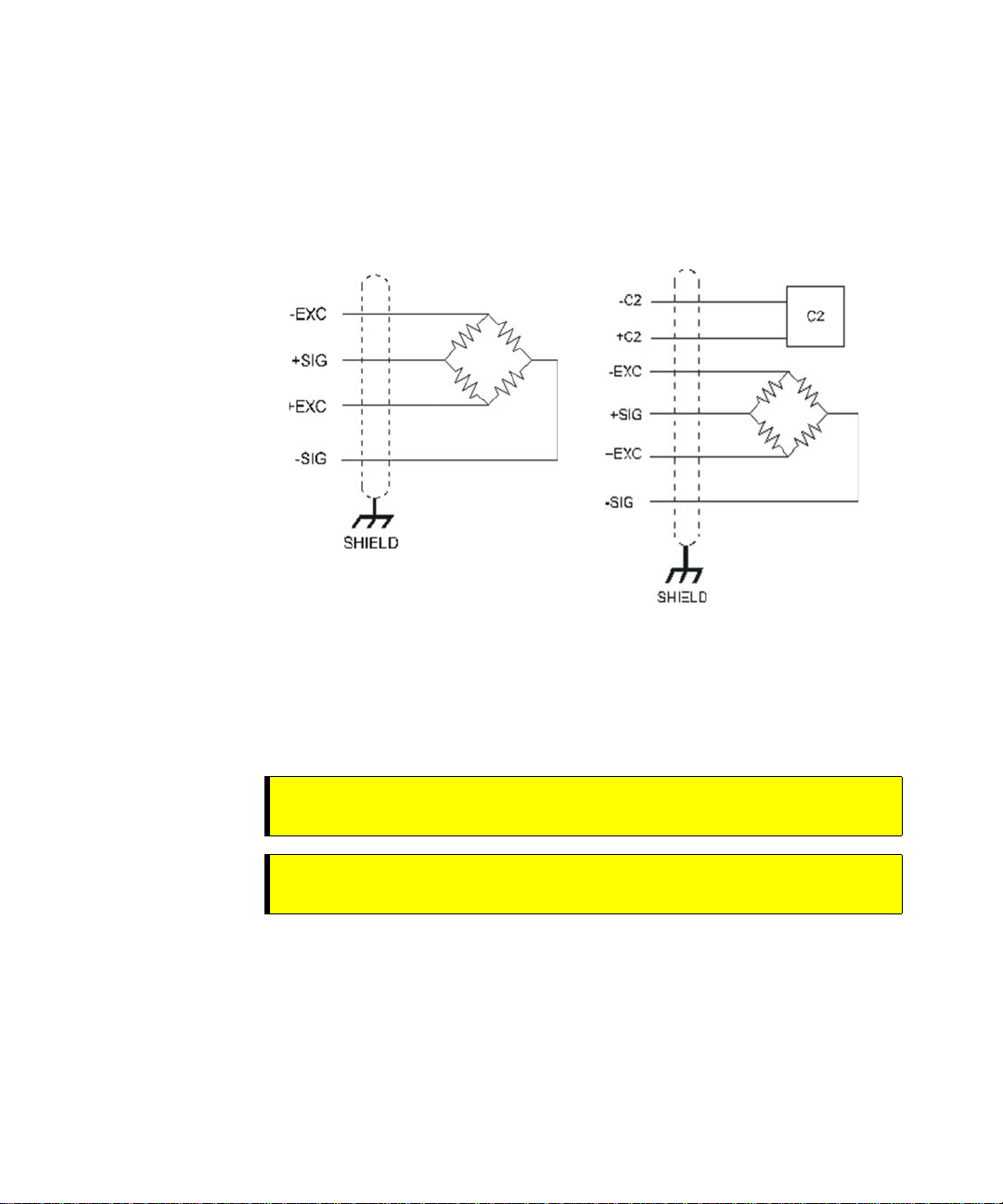

Load Cell Wiring Diagrams

The diagrams below show how Hardy Load Sensor with C2 wiring differs from

standard Load Cell wiring. C2 wiring is required when using a Integrated Technician

summing junction box. The C2 wires are used for communicating IT and C2

commands.

Industry standard load cells wiring Hardy load sensor C2 wiring

•

•

•

22

Chapter 3

•

•

•

The simple wiring diagram above shows how to connect a single load cell to the HI

6300 series instrument. Note: when connecting the HI 6300 series instrument to a

junction box, the sense lines would be connected between the +Sen and –Sen

Connections for the junction box and the instrument.

WARNING - Instrument power should be routed away from all other signal

cables to avoid electrical interference.

AVERTISSEMENT –

Tension de l'appareil doivent être acheminés à l'écart de

tous les autres câbles de signaux pour éviter toute interférence électrique.

Page 31

Connecting to the Hardy HI 215IT or HI 6010/6020IT Summing Box

HI 215 Junction Box Wiring Diagram

Installation

•

•

•

23

•

•

•

Page 32

NOTE

HI 6010 Summing Box Diagram

When connecting a Hardy Summing Box to the HI 6300, you must remove the two

factory installed jumpers on pins 1 & 2 and on pins 5 & 6 on the module and install

C2 and sense wires. C2 wires carry the commands for Integrated Technician and the

C2 calibration information.

•

•

•

24

Chapter 3

•

•

•

Page 33

Chapter 4

• • • • • •

Network Configuration

Chapter Four contains step-by-step instructions for configuring Hardy HI 6300 series

instruments and related communication networks. We recommend reading these

procedures because having a correct configuration is necessary to ensure trouble-free

operation.

This chapter explains how to either configure the HI 6300 series instrument from its

own front panel or with a PC-based Web interface connected to the HI 6300 series

instrument over a standard Ethernet network. The features of the HI 6300 series

instrument operate the same way in either case. You must use the Web interface to

configure units that do not have a display.

Before operating the HI 6300Weight Processor, make sure that:

•

Power and load point cables are properly installed and in working order.

•

Communication cables are properly installed and in working order.

Ethernet TCP/IP

NOTE

Do not confuse the on-board Ethernet TCP/IP communication with EtherNet/IP®.

Ethernet/IP is an industrial protocol that does not transmit Web traffic.

An embedded Web server in the HI 6300 series instrument allows you to easily configure

every parameter of the instrument via a standard Web browser. A standard Ethernet

network is required to provide the connectivity between the HI 6300 series instrument and

your desktop / laptop computer.

The HI 6300 series instrument is designed with a standard 10/100 BASE-T Ethernet

connection for linking to any Windows PC. Once connected, you can monitor, download

Hardy software from the Internet, or configure the HI 6300 series instrument from that PC.

A Help function can assist you in setup or trouble-shooting. The browser also links to the

Hardy Web Site where the user can find additional services and support.

There are two primary ways to connect the HI 6300 series instrument to your computer:

LAN Connection: Connect the HI 6300 series instrument to an existing Ethernet-

Network Configuration

based Local Area Network (LAN) that has connectivity to your

desktop or laptop computer. See the LAN Connection section

below.

Network Configuration

•

•

•

25

•

•

•

Page 34

Direct Connection:

LAN Connection

To connect the HI 6300 series instrument to a LAN, you simply connect a standard Ethernet

cable between the instrument and the common network hub. You will then need to

determine which scheme is used on the network to assign IP addresses. Every node on the

network must have a unique IP address or conflicts will result.

Contact your Network Administrator for the IP address to use for the instrument.

The IP address can be set manually (Fixed IP), or it can be set automatically by a network

service called DHCP.

A direct point-to-point connection between the HI-6300 and your

desktop or laptop computer using any standard Ethernet cable. See

the

Direct Connection

section below.

NOTE

NOTE

If the DHCP service fails, the instrument will default to the Fixed IP address after a power cycle. If the DHCP service is repaired, the instrument will revert back to using the DHCP IP address.

If you are required to use Fixed IP addresses, refer to the section

Using the Front Panel

Fixed IP Configuration

below. For automatic IP assignment (DHCP), use the following

steps:

DHCP Configuration Using the Front Panel

DHCP works only if a DHCP server is installed on your network.

Step 1. From the Configuration menu, Use the UP or DOWN button to select the

communication menu, then select the Ethernet TCP/IP menu item.

Step 2. Select the DHCP menu item and use the ENTER key to enable/disable this

feature.

Step 3. Select the DHCP IP address menu item and verify that a correct IP address has

been assigned to the instrument by the network server. If an incorrect IP address

has been assigned contact your system administrator; or use a Fixed IP address.

Step 4. This is the IP address to use in your web browser to access the Web Interface.

From here you can jump to the section

You cannot change the values of the DHCP IP address. The LEFT button returns the

operator to the Ethernet TCP/IP Menu.

•

•

•

26

Chapter 4

•

•

•

Page 35

Fixed IP Configuration Using the Front Panel

The HI 6300 series instrument can be configured to use any Fixed IP address. The

Fixed IP addresses must be carefully selected to avoid accidentally configuring two

devices to the same address with unpredictable results. Since ‘guessing’ a value could

lead to personal or property damage and/or interrupted network services, your network

administrator should provide this address.

Read-only screens can display a limited number of characters per line. To see the complete

IP address in DHCP, you need to do the following:

Step 1. Press the CONFIG button to enter the Configuration menu; and use the UP or

DOWN buttons to select the Communication menu, then use the UP or DOWN

buttons to select the Ethernet TCP/IP menu item and press the RIGHT or ENTER

button to access the Ethernet TCP/IP menu.

Step 2. Select the Fixed IP menu item.

Step 3. Starting at the right-most digit, enter the IP number using the standard format. Use

the

UP or DOWN buttons to select each number, and press the LEFT or

RIGHT button to move between numbers.

Step 4.

Press the ENTER button to save the entry.

Step 5. Use the LEFT button to exit the menu structure.

Step 6. The IP address is now saved and the instrument’s embedded Web browser is now

availa

ble at the entered IP address. From here you can jump to the Network

Options Configuration section.

Step 7. Cycle power to establish the fixed IP address as the current operating address.

This method of interconnect between an HI 6300 series instrument and a standard Windows

PC allows you to configure the instrument using the embedded web browser, even if an

Ethernet network is not part of the normal installation. A desktop or laptop may be used on

location as necessary.

Step 1.

Both sides of the link require configuration of their IP addresses to establish

a working connection. The following steps will walk you through the process

of connecting the hardware and configuring the HI 6300 series instrument and

PC with compatible IP addresses.

From the Summary display, press Enter to

activate the Configuration menu. Use the down arrow to select Communications

and press Enter.

Step 2. Use the down arrow again to select Ethernet, and select IP to display the IP screen.

Network Configuration

•

•

•

27

•

•

•

Page 36

Step 3. Starting at the right-most digit, enter

the IP number using the standard

format. Use the up/down arrows to

select each character, and press the

left arrow to move to the next digit.

Step 4. Press Enter to save the entry.

Step 5. Press the Exit key four times to exit the IP, Ethernet,

configuration

menus.

communications and

The IP address is now saved and the instrument’s embedded Web browser is now available

at the entered IP address. From here you can jump to the

Network Options Configuration

section.

Both sides of the link require configuration of their IP addresses to establish a working

connection. The following steps will walk you through the process of connecting the

hardware and configuring the HI-6300 and PC with compatible IP addresses.

Direct Connect Hardware

Any standard Ethernet cable with RJ-45 connectors at each end can be used to connect

the HI 6300 series instrument to your PC. A ‘crossover’ cable is not required. Simply

plug the cable into each instrument.

Windows PC Configuration

Windows 2000

Step 1. After starting your computer, click the Start button.

Step 2. Click on Settings > Control Panel to display the Windows Control Panel.

Step 3. Click the Network icon to display the Network dialog.

Step 4. Click on TCP/IP; then click the Properties button to open the TCP/IP Properties

dialog. Click the IP Address tab.

Step 5. If the ‘Use the Following IP Address’ box is already checked, write down the

displayed IP Address and jump to the

Direct Connect Configuration – HI 6300

section below.

Step 6. Click the ‘Specify an IP Address’ check box; then enter the following into the

TCP/IP Properties dialog.

IP Address =

192.168.0.100

Subnet Mask = 255.255.255.000

Step 7. Select OK on the TCP/IP Properties dialog. The computer is now fully

configured.

Step 8. To return the PC to the original network settings, return to the ‘Internet Properties

(TCP/IP) dialog, select ‘Obtain an IP address automatically,’ and click OK.

•

•

•

28

Chapter 4

•

•

•

Page 37

Windows XP

Step 1. After starting your computer, click Start.and then Control Panel.

Step 2. Click on Settings > Network Connections.

Step 3. Right click on ‘Local Area Connection’ and select Properties.

Step 4. Click on Internet Protocol (TCP/IP) and click on the Properties button to open the

Internet Properties (TCP/IP) Properties dialog.

Step 5. If the ‘Use the Following IP Address’ box is already checked, write down the

displayed IP Address and jump to the

Direct Connect Configuration – HI 6300

section below.

Step 6. Click the ‘Use the Following IP Address’ check box; then enter the following into

the TCP/IP Properties dialog.

IP Address = 192.168.0.100

Subnet Mask = 255.255.255.000

Step 7. Select OK on the TCP/IP Properties dialog box. The computer is now fully

configured.

Step 8. To return the computer to the original network settings, return to the ‘Internet

Properties (TCP/IP) dialog, select ‘Obtain an IP address automatically,’ and click

OK.

Windows 7

Step 1. After starting your computer, click the Start button.

Step 2. Click on Control Panel to display the Windows Control Panel.

Step 3. Click on Network; then click Internet

Step 4. Click on Network Sharing Center.

Step 5. Click on Change Adapter Settings in the left-hand column.

Step 6. Right click on Local Area Connection and select Properties.

Step 7. Click on Internet Protocol Version 4 (TCP/IPV4)

Step 8. Click the Properties button to open the Internet Properties (TCP/IP) Properties

dialog.

Step 9. If the ‘Use the Following IP Address’ box is already checked, then write down the

displayed IP Address and jump to the

Direct Connect Configuration – HI 6300

section below.

Step 10. Click in the ‘Use the Following IP Address’ checkbox; then enter the following

into the TCP/IP Properties dialog.

IP Address = 192.168.0.100

Subnet Mask = 255.255.255.000

Network Configuration

•

•

•

29

•

•

•

Page 38

Step 11. Select OK in the TCP/IP Properties dialog box. The computer is now fully

configured.

Step 12. To return the computer to the original network settings, return to the Internet

Properties (TCP/IP) dialog , select ‘Obtain an IP address automatically,’ and click

OK.

Direct Connect Configuration - HI 6300 Series Instrument

The HI 6300 must now be assigned a unique IP address that will connect to the Windows

PC. There are two simple rules for the IP Address:

•

It must have the same network identifier

as the computer

•

It must have a different node identifier

than the computer.

If your Windows PC already had an IP address assigned, simply increment by one the Node

Identifier field of the IP Address you wrote down in the Windows PC configuration steps

above. If your Windows PC was originally set to automatically obtain an IP address

(DHCP), use 192.168.100.50 for the HI 6300 IP address.

Ethernet-UDP

HardyPort

UDP or TCP/IP. You send commands to the instrument to read or set parameters. The

commands are text strings of the form

is the Ethernet port number that one can use to connect to this instrument via

PARAMETERNUMBER

or

•

•

•

30

Chapter 4

•

•

•

PARAMETERNUMBER=PARAMETERVALUE

For example, send the command 00000090 to read the gross weight value. The response

will be something like:

Gross = 10.3

To set a parameter, send a command like 0000000D = 0.5 - this command sets the Motion

Tolerance parameter to 0.5

See the Operation/Diagnostics/Parameters web page for a list of parameter numbers.

The HI 6300 series instrument has only 1 TCP/IP socket available for this command

interface, so only 1 master can connect, say using HYPERTERMINAL Telnet. There

is no such limit with UDP – any number of masters can send UDP commands.

Page 39

Modbus-RTU (over RS-485

Step 1. Setup a slave address assigned to the HI 6300 series instrument from the

communications menu and the Modbus-RTU submenu.. Use a unique address

between 1 and 247

Step 2. Set the Baud Rate to the same as the master device, typically 9600 or 19,200

Step 3. Set the Parity Bit parameter to match that of the Modbus-RTU master (EVEN,

ODD, or OFF)

Wiring Pinout

)

The RS 485 serial port pinout is:

Pin 1 Pin 2 Pin 3 Pin 4 Pin 5 Pin 6

Ground TX+ TX- RX+ RX- Shield

Modbus Setup

•

Slave Address

•

Set

Baud Rate

•

Set

Parity

may be set to any number in the range of 1-247.

parameter to match the settings of the Modbus master

to match the settings of the Modbus master

Network Configuration

•

•

•

31

•

•

•

Page 40

Modbus Functions

The Modbus functions allowed in the HI 6300 are:

Function 3: Modbus Read Holding Registers

Function 4: Modbus Read Input Registers

Function 6: Modbus Write Single Register

Function 16 (0x10): Modbus Write Multiple Registers.

Modbus Registers

This instrument has 64 16-bit MODBUS input registers and 64 16-bit output registers. The

data in these registers is in "big endian" format, meaning that the most significant byte

comes first.

•

The first 6 registers (0 – 5) are used for the “command interface” in the unit.

•

Registers 6 & 7 will contain the Net weight in 32 bit floating point format.

•

Registers 8 & 9 will contain the Gross weight in 32 bit floating point format.

•

Registers 10 and 11 will contain the statusword

•

Registers 12 and 13 (HI 6310 only) are for the count function.

Network Command Interface

The "network command interface" uses 6 registers (0 – 5) in and 6 registers out.

•

Register 0: command (shown below)

•

Register 1: status

•

Registers 2, 3: Parameter number. See the diagnostics/parameters web page for a list of

parameter numbers.

•

Registers 4, 5: parameter value

The Modbus master sends a 'command' by writing a value to register 0.

return value is an error.

Any non-zero

•

•

•

32

Chapter 4

•

•

•

Here is a list of Hardy command numbers:

•

0: READ PARAM CMD

(register #0), and write the parameter number in the parameter ID number in registers 2

and 3, most significant word first. The parameter value may then be read from registers

4 and 5, again most significant word first. This value may be in integer or floating point

format, depending on the parameter. The status register in the reply will contain the

lower 16 bits of the system status word.

•

Status word bit 0: A/D error.

•

Status word bit 6 (0x40): Motion status.

•

Status word bit 15 (0x8000): Not Found - the requested parameter number does

not exist

•

1: ZERO CMD

status register will read 0 if this command succeeds.

•

•

. Write a #1 to the command register to ZERO the gross weight. The

Status Error code 1 (motion)

Status Error code 2 (A/D error)

. To read a parameter, write a #0 to the command register

Page 41

•

Status Error code 3 (out of tolerance)

•

2: T ARE CMD

register will read 0 if this command succeeds:

•

•

•

4: WRITE NONVOL CMD

non-volatile memory.

•

•

0x64 (100 decimal): CAL LOW CMD

perform the low step of a traditional calibration. The status register will read 0 if this

command succeeds:

•

•

•

•

0x65 (101decimal): CAL HIGH CMD

perform the high step of a traditional calibration.

•

•

•

•

. Write a #2 to the command register to ZERO the net weight. The status

Status Error code 1 (motion)

Status Error code 2 (A/D error)

. Write a #4 to the command register to save parameters in

No Error Codes

Calibration_Fail 1

Calibration_Fail_Motion 3

Calibration_Fail_Adc_Error 4

Calibration_Fail 1

Calibration_Fail_Motion 3

Calibration_Fail_Adc_Error 4

HardcalFailCounts 8: not enough counts between hard cal hi and hard cal lo

. Write a 0x64 hex to the command register to

. Write a 0x65 hex to the command register to

•

0x66 (102 decimal): C2 CAL CMD

perform a C2 calibration.

•

Calibration_Fail 1

•

Calibration_Fail_Motion 3

•

Calibration_Fail_Adc_Error 4

•

Calibration_Fail_Noc2 5

•

Calibration_Fail_C2capeq 6

•

Calibration_Fail_C2clones 7

•

0x1000 (4096 decimal): WRITE INTEGER CMD

parameter. Write 0x1000 in the command register 0, the parameter ID number in

registers 2, 3 and the desired value in registers 4, 5.

•

No Error Codes

•

0x1001 (4097 decimal): WRITE FLOAT CMD

parameter. Write 0x1001 in the command register 0, the parameter ID number in

registers 2, 3 and the desired float value in registers 4, 5.

•

Failure 1

. Write a 0x66 hex to the command register to

. Set the value of an integer

. Set the value of a floating point

Network Configuration

•

•

•

33

•

•

•

Page 42

•

TooHigh -1 : value is above legal limit

•

TooLow -2 : value is below legal limit

•

ErrorNotFound 0x8000 : parameter id not found

All communications will be controlled by the Modbus functions. The Modbus

protocol will determine the function, address, size, and offset register for the

message. The command interface data will be within the data portion of the

message and will define the command to our unit.

Example 1: If you wish to read the span weight value you would:

1. Enter the Span parameter ID into registers 2 & 3. The Span ID is 0x0000 0201.

a. Place 0x0000 into data register #2.

b. Place 0x0201 into data register #3.

2. Enter the command #0 into data register #0.

3. Run the Modbus Function code #16 (write multiple registers).

4. Run the Modbus Function code #4 (read multiple registers).

5. Read the value for the span parameter in data registers #4 & 5. This value will be

in floating point format.

•

•

•

34

Chapter 4

•

•

•

Example 2: If you wish to write a new span value of 100.55:

1. Enter the Span parameter ID into data registers 2 & 3. The Span ID is

0x0000 0201.

a. Place 0x0000 into data register #2.

b. Place 0x0201 into data register #3.

2. Enter the new value into data registers 4 & 5. The float value 100.55 in hex is

0x42C9 1999.

a. Place 0x42C9 into data register #4.

b. Place 0x1999 into data register #5.

3. Enter the write float command into data register #0. The write float command is

0x1001.

a. Place 0x1001 into data register #0.

Page 43

4. Run the Modbus Function code #16 (write multiple registers).

5. Run the Modbus Function code #4 (read multiple registers). This will allow the

user to read the status of the command in data register #1.

If you wish to then read back the value you have written:

6. Enter the command #0 into data register #0.

7. Run the Modbus Function code #16 (write multiple registers), or Function code

#6 (write single register) insuring the correct data location is being set.

8. Run the Modbus Function code #4 (read multiple registers).

Read the value for the span parameter in data registers #4 & 5. This value will be in

floating point format.

Communications Parameters for the HI 6310 Only

Printer (over RS-232)

Available on the HI 6310 only.

The HI 6310 can transmit Gross, Net, Count, Tare values to a serial printer over RS-232.

The printer Baud rate is user selectable at 600, 1200, 2400, 4800, 9600, or 19200 (default

is 9600).

A sample wiring connection from the HI 6310 to the printer port is shown above. The

printer parameters can be configured through the web interface or the display panel.

Step 1. Set the baud rate for the RS232 printer, default is 9600.

Step 2. Set the parity bit, default is EVEN

Step 3. Select what values to transmit over the serial interface to the printer using the

printer mode, default is disabled.

Network Configuration

•

•

•

35

•

•

•

Page 44

a. Gross Weight

b. Net Weight

c. Tare Weight

d. Unit Count

e. All – Gross, Net, Tare, and Count (if Count enabled) values

f. OFF, Printer disabled.

USB Memory Stick

Available on the HI 6310 only.

The HI 6310 provides an interface to an external USB memory stick that allows HI 6310

parameters to be saved, restored. or copied to another instrument.

The USB memory stick commands can be activated through the web interface or the

display panel.

To access the USB Menu, from the front keypad, select Configuration > Enter,

Communications > Enter, USB >Enter, UP or DOWN arrow to Save or Restore > Enter.

On the

Web page

: Configuration; communications; USB; save/restore.

•

•

•

36

Chapter 4

•

•

•

Step 1. Insert the USB stick into the HI6310

Step 2. Using the web interface or display panel, save or restore system parameters.

Analog 4-20mA

Available on the HI6310 only

The analog 4-20mA output is directly proportional to the programmed gross, net, or count

range; by setting the low value equal to 4mA and the high value equal to 20mA. These

values can be set from either the front panel or the web interface.

Page 45

The 4-20mA parameters can be configured through the web interface or the display panel.

From the front display: select the configuration menu then UP or DOWN to

communications, enter; UP or DOWN to 4-20mA, enter; UP or DOWN to setting you

want for Source; enter the value for 4mA; enter the value for 20mA or mA output (read

only). Press enter to select and UP or DOWN arrows to enter value.From the Website,

select the Communications Menu and then

Step 1. Select the source for the 4 to 20mA output, default is gross

a. Gross.

b. Net

c. Count

d. Manual

Step 2. Set the 4mA value

Step 3. Set he 20mA value

Step 4. Save Parameters

NOTE

Setting the weigh source to manual allows the mA output setting to be set to a fixed

output. This is used to test the circuit level to the host.

Network Configuration

•

•

•

37

•

•

•

Page 46

•

•

•

38

Chapter 4

•

•

•

Page 47

Chapter 5

• • • • • •

Instrument Configuration

Using the Home Page to set Parameters

Enter your HI 6300 series home page by typing the IP Address you used to set up the

instrument (see Chapter 4 for information on setting the IP Address) accessing the

instrument via a direct connection on a PC.

From the Home Page, click Configuration to open the Configuration page. Select

Instrument Setup to open the Instrument Setup page.

The HI 6300 series instrument Configuration process sets up the instrument to operate

as a scale. This includes configuring, units of measure, WAVERSAVER®, motion

tolerance and other instrument parameters required for your process.

Instrument Configuration

•

•

•

39

•

•

•

Page 48

Using the Front Panel Display Menus to Set Parameters

Front Panel Display

The Front Panel Display is a 480 x 272 LCD graphical display. The Summary screen

displays the current weight in the selected mode (Gross, Net or Count (HI 6310 only))

and the selected engineering units (oz, lb, t (ton), g, kg, mt (Metric Ton)).

The Five Button Command Cluster

•

•

•

40

Chapter 5

•

•

•

TARE Command Button

When the TARE button is pressed the NET weight value is set to zero.

Page 49

ZERO Command Button

When the ZERO button is pressed the GROSS weight value is set to zero.

MODE Command Button

The MODE button toggles the weight displayed between GROSS and NET.

•

HI6310 only. Count is included if this mode is enabled

CONFIG (Configuration) Command Button

The CONFIG button minimizes the displayed weight value and provides a submenu

structure on the screen which is navigated by the button cluster.

Press

ENTER

button to display the Menus and Sub-Menus or to enter the configured

values or selected items form a pick list into non-volatile memory.

•

HI6310 only. The ENTER button acts as a PRINT key, when the print mode is enabled.

The second level menu functions are selected when the CONFIG button is pressed. While

the unit is in the second level menu the function for each button is changed to UP, DOWN,

LEFT, or RIGHT to allow the user to navigate, select, and/or enter values for different

parameters to configure the instrument.

To move UP or DOWN a list of submenu items the UP or DOWN buttons are used. To

select the submenu item either the ENTER or RIGHT button can be used. When the

ENTER or RIGHT button is pressed the menu structure transitions to a lower level in

the menu hierarchy. This lower level may have an additional submenu list to select

from or it may require the user to enter a value.

Using the Mode, Zero, and Tare buttons

The HI6300 series instrument Weight Controller display shows the weight in Gross or

Net mode. Use the MODE button to change from displaying Gross weights to

displaying Net weights.

To Tare the Scale, press the

“Tare OK.” If the Tare is unsuccessful, you will get a message “Tare Failed.” Check the

Motion Tolerance parameter. Chapter 4 provides configuration instructions for the Motion

Tolerance Parameter.

To Zero the Scale, press the ZERO button. If the Zero is successful you will get a message:

“Zero OK.” If the Zero is unsuccessful, you will get a “Zero Failed” message. Check the

Zero Tolerance parameter. Instructions for setting the Zero Tolerance parameter value is

provided in Chapter 4.

TARE

button. If the Tare is successful, you will get a message:

Instrument Configuration

•

•

•

41

•

•

•

Page 50

The CONFIG Menu Structure

To configure and setup the HI 6300 series instrument press the CONFIG button. To enable

the user to continue to monitor the process the display the weight, mode, and zero symbol

are reduced and placed in the top right hand corner.

A submenu list is provided on the left hand side, with the item that would be selected

by highlighted and identified by the ♦ symbol.

•

•

•

42

Chapter 5

•

•

•

The numeric or alphanumeric value for the selected item is display in the area shown as

--- Value -----

in the above illustration, along with help text for the item selected.

--

If more than five item are in the submenu list, use the UP/DOWN button to scroll through

the submenu list. To select the item from the submenu list press the RIGHT or ENTER key.

Entering Numeric and Alphanumeric Values

At the lowest level of the menu hierarchy the user may need to enter a numeric or which

could represent a tolerance or an Ethernet IP address or an alphanumeric value for entering

a user ID or security password.

When a parameter value is selected, either the current value is displayed or a 0. In either

case a flashing underscore is generated under the least significant digital or character.

The LEFT and RIGHT buttons move the cursor left and right within the numeric value

or character set. In the following three number examples the cursor starts under the 300

value, the LEFT button moves the cursor under the 2000 value in example 2, and in

example 3 the RIGHT button moves the cursor under the 40 value.

Example 1: 12345.01

Example 2: 12

Example 3: 1234

345.01

5.01

Page 51

The UP and DOWN arrows are used to change the displayed digit.

0→1→2→3→4→5→6→7→8→9→.→ →0

The UP button increments from 0 through 9, then the decimal point, space, and back to 0,

while the DOWN button decrements from 9 through 0, then the space, decimal point and

back to 9.

Example 4: 12345.01

Example 5: 0

Example 6:

2345.01

2345.01

In example 4, the LEFT button is used to select the 10000 value, in example 5 the DOWN

button is used to decrement the value to 0, and in example 6 the value is removed to change

the original value from 12345.10 to the new value of 2345.01

Once the correct value has been entered, the ENTER button is pressed to accept the value

and the left button will return the user to the next higher level in the menu hierarchy.

When a menu item, such as user ID or password enables the use of alphanumeric characters,

the process is similar to entering a numeric value with additional characters available when

you use the UP/DOWN buttons as shown below.

0→1→…….→9→a→b→…….→z→0

In this example a 4 character security code is entered, and in place of the value being

display, four entry boxes are displayed as in example 7.

Example 7: □ □ □ □