Page 1

QUICK INSTALLATION GUIDE

4.05

3.200

3.000

2.590

1.274

.41

.205

.44

.475

.755

5.250

7.08

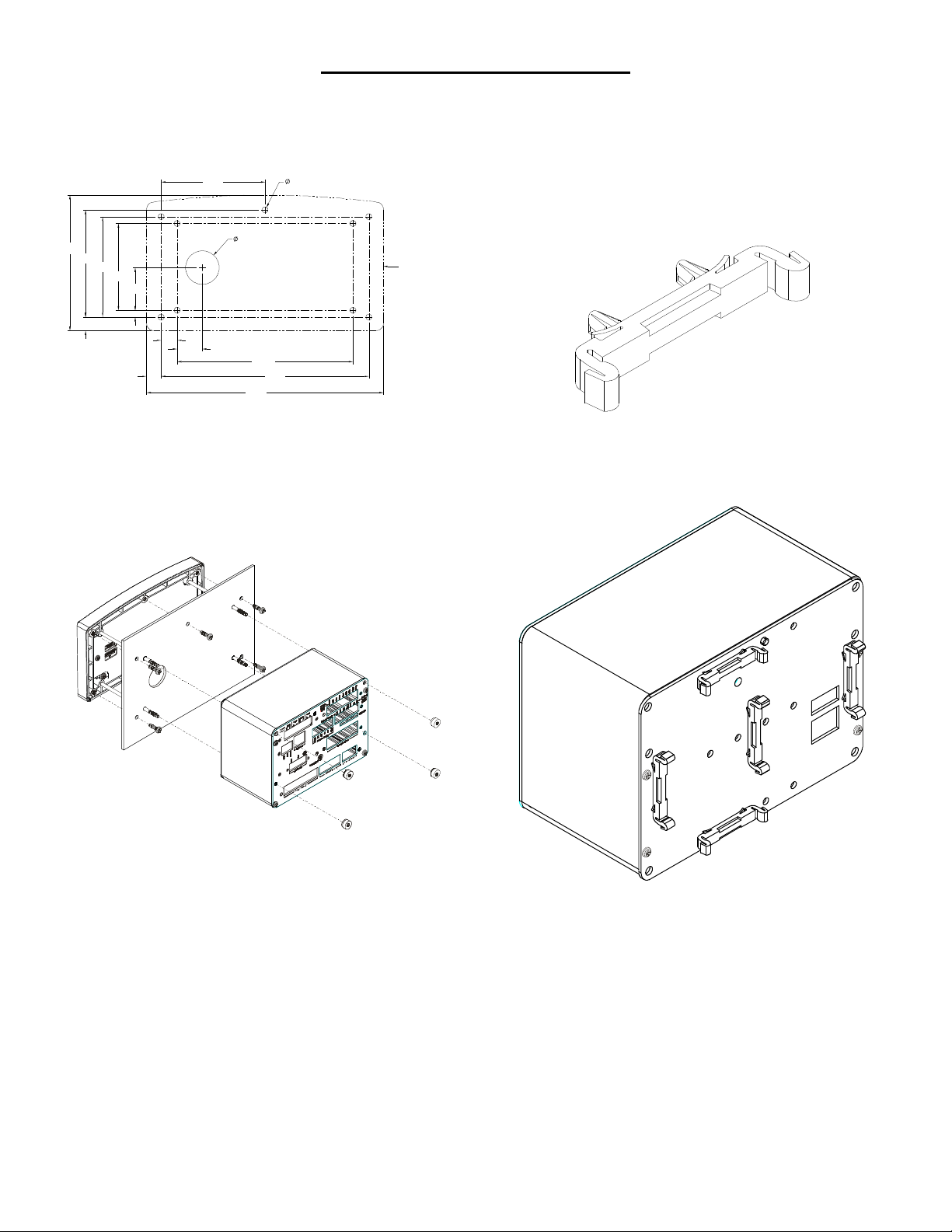

MECHANICAL INSTALLATION

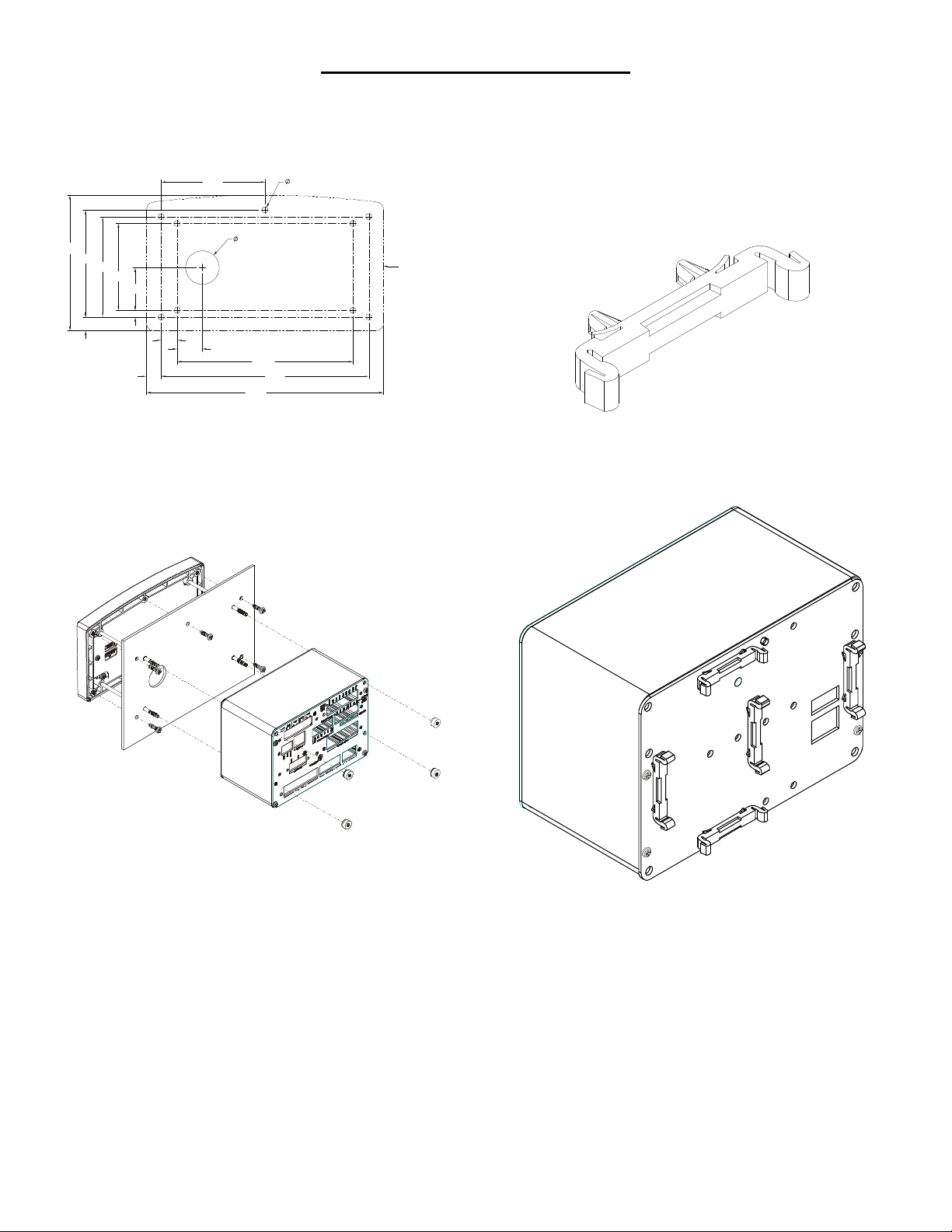

Installing the HI 4060 Rate Controller in a Panel

6.200

.172 THRU, 9 PL

INSTRUMENT

BEZEL OUTLINE

3.100

1.25 THRU

FIG. 1 PANEL HOLE DIMENSIONS

Step 1. Make sure that all Electrostatic Discharge (ESD) precautions

are taken before and during installatio n.

Step 2. Use the attached template to make the hole pattern in the panel

door or cover. (See Attached)

Step 8. Thread the four (4) 6-32 thumb screws onto the threaded rods

until tight. Do not use pliers on the thumb screws.

DIN Rail Installation HI 4060 Rate Controller

Step 1. Snap the DIN rail mounting feet into any of the two holes on

the front panel of the electronic en closure. (See Figs. 5 & 6)

FIG. 3 DIN RAIL MOUNTING FOOT

FIG. 2 PANEL MOUNT INSTALLATION

Step 3. Use a phillips head screwdriver and install the five (5) 6-32 x

1/2 inch screws that fasten the bezel to the pane l. (See Fig . 3)

Use a torque screw driver and torque each screw to 10 inch/

pounds. DO NOT OVERTIGHTEN!

Step 4. Thread the four (4) threaded rods through the approp ria te

holes in the panel and into the bezel. For t he retr ofit y ou don’t

have to place the rods through the holes. (See Fig. 4)

Step 5. Hand tighten each rod un til you ca n no lon ger turn th e rod. Do

not force the rods or use pliers of any kind.

Step 6. Put the Display cable and connector th rou gh th e 1 in c h hole in

the panel door or c ove r and plug the d isp lay c onn ecto r into the

Step 7. Gently slide the electronic enclosu r e onto the threaded rods

display header in the beze l. (See Fig. 3)

while making sure the display cable glides easily into the

enclosure and does not kink. Move the electronic enclosure

toward the panel until it stops. (See Fig. 3)

FIG. 4 VERTICAL AND HORIZONTAL ORIENTATION

Step 2. When installing firm ly pu sh the mou nting feet u ntil y ou hear a

snapping sound. The snap mean s they are mounted correctly.

Step 3. After installation give each mounting foot a little tug to make

sure they are seated correctly.

NOTE: There are several horizontal and vertical mounting

options. It is highly recommended that at least two

mounting feet be used per enclosur e.

Step 4. To mount the en closure onto a DIN rail. Place the moun ting

feet on the DIN Rail and firmly press down un til the mo unting

feet snap onto the rail.

Page 2

Step 5. To remove the mo unting feet use a finger on the clip and gen-

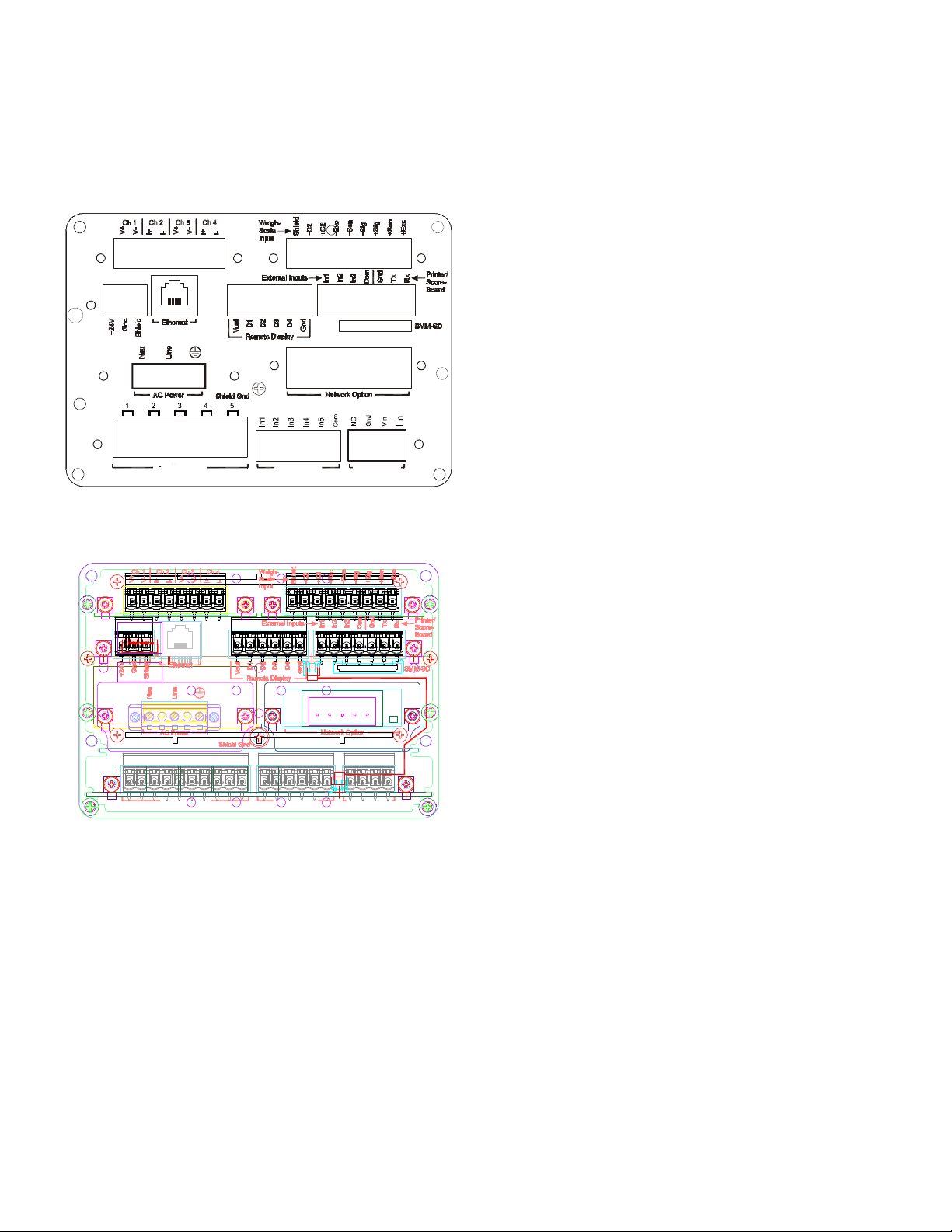

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

tly pull up on the tab.

NOTE: For Remote Display installation please see Chapter 3,

Installation, of the HI 4060 User’s Guide.

LOAD POINT INSTALLATION

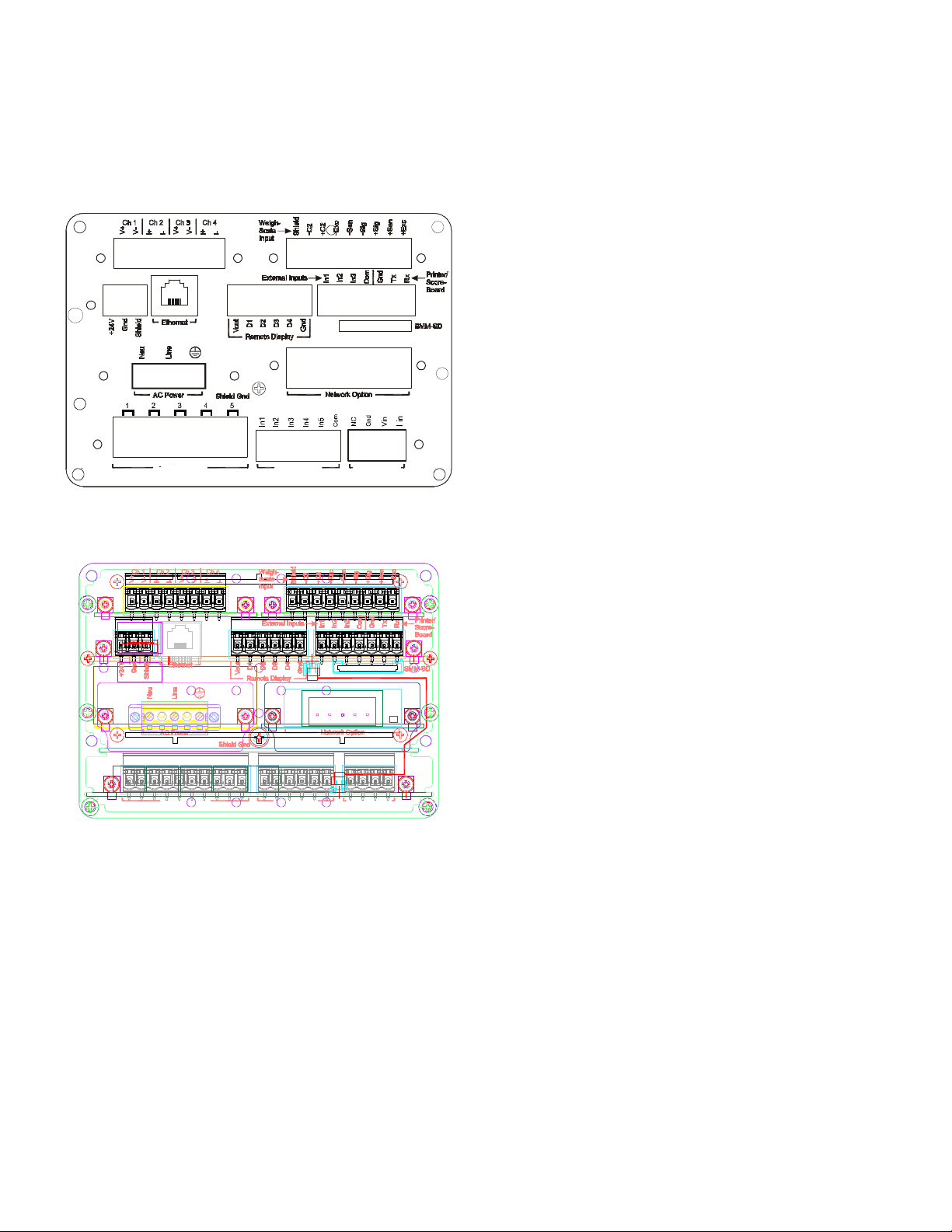

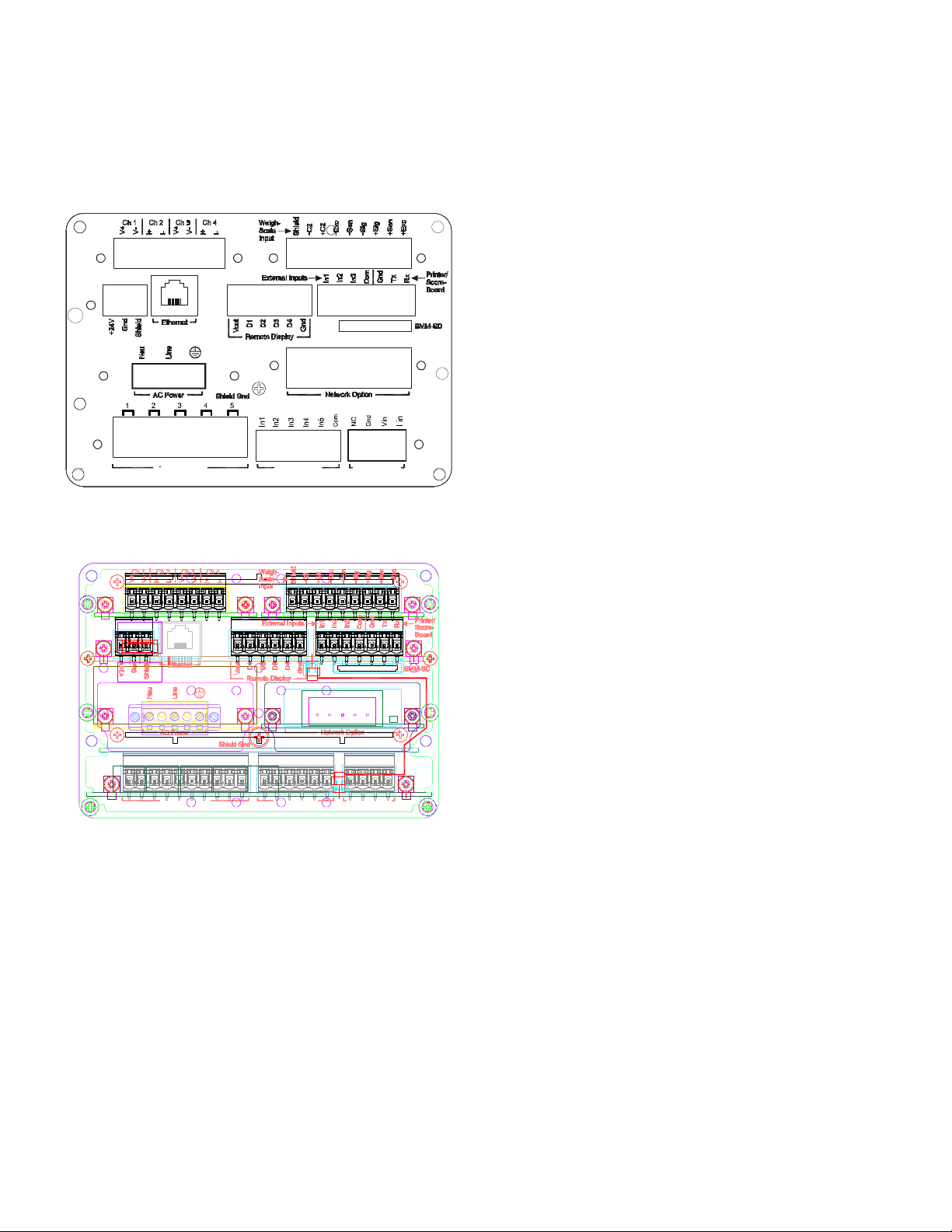

FIG. 5 REAR PANEL

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Pr t. # 6020-0001) wires to the Channel terminal

block according to the cabl e color chart.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

Step 4. For more information concerning C2 Lo ad Point connection,

consult the HI 4060 User Gui de.

Non-C2 Load Point Connection

NOTE: Cable Color Codes vary between vendors, check with your

supplier for the Color Code f or your Non -C2 load point . Do

not connect wires to the -C2 and +C2.

Step 1. Remove the factory installed jumper from the terminal block if

you have 6 wire load cell cable that i ncl udes sense wires from

the load cell or junction box.

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Prt. # 6020-0001) wires to the Channel 1 terminal

block according to the Non-C2 cable color chart, or pe r manu

facturers specification.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

INPUT POWER WIRING

WARNING: DO NOT PLUG THE POWER CONNECTOR INTO THE

HEADER WITH LIVE POWER. T O DO SO WILL RESULT IN PROP-

ERTY DAMAGE AND/OR PERSONAL INJURY.

-

FIG. 6

C2® Load Point Connection

Cable color Code for C2 Lo ad Points (left to right facing the rea r pa nel):

Step 1. Remove the factory installed jumpers from the terminal block

• Shield Ground W i re

•C2- Violet

•C2+ Grey

• EXC- Black

•SEN- Brown

• SIG- White

• SIG+ Green

•SEN+ Blue

•EXC+ Red

if you are connecting an 8 wire cable from the junction box.

(See Fig. 8)

WARNING:

INCORRECT TYPE IT MAY CAUSE AN EXPLOSION WHICH WILL

CAUSE PROPERTY DAMAGE OR PERSONAL INJURY.

IF A LITHIUM BATTERY IS REPLACED WITH AN

AC Input Power Wiring (-AC)

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 240 VAC.

WARNING: I

ON THE AC INPUT WIRES, THE DISCONNECT MUST ACT ON

BOTH THE LINE AND NEUTRAL WIRES IN A DOUBLE POLE, DOU-

BLE THROW ARRANGEMENT I.E. DPDT RELAY. USING OTHER

AUTOMATIC DISCONNECT ARRANGEMENTS MAY CAUSE PER-

SONAL INJURY AND/OR PROPERTY DAMAGE.

Step 1. The HI 4060 is configur ed with a univ ersal power suppl y rated

Step 2. Make sure the VAC power is shut off before installing the

Step 3. Install a 3-wire, minimum 14 AWG power line to the 3 -pin ter-

F AN AUTOMATIC DISCONNECT DEVICE IS USED

• The AC power should be supplied by a “clean” primary line, directly from the power panel. This line

should not supply any other equipment, including

the feeding unit, and shou ld be sup pli ed with a min i

mum 10 amp breaker.

• AC Power Input (See Fig. 7)

Neu (Low)

Line (HI)

Earth Ground

from 11 0 to 24 0 VA C .

wires to the connector.

minal block connector.

-

Page 3

DC Power Input (-DC)

Rat e

Rat e

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 24 VDC.

• Use the HI 4060 Rate Controller User Guide for

Configuration, Operation and Troublesh ooting

instructions.

CAUTION: Y

SUPPLY (CLASS 2) ON THE DC INPUT WIRING.

OU MUST USE A POWER LIMITED DC POWER

• The DC power sh ould be s upplied by a “clean” pri mary li ne,

directly from the DC power source.

Step 1. Make sure the VDC power is shut off before installing the

wires to the connector.

Step 2. Connect the 24 VDC Voltage wire, Ground wire and Shield

wire to the connector that plugs into the DC voltage header at

the rear panel. Make sure that the shiel d is connected to the

local Earth Ground connectio n.

Step 3. Plug the connector into the header at the rear panel. (See Fig.

7)

Step 4. Apply VDC power to the unit.

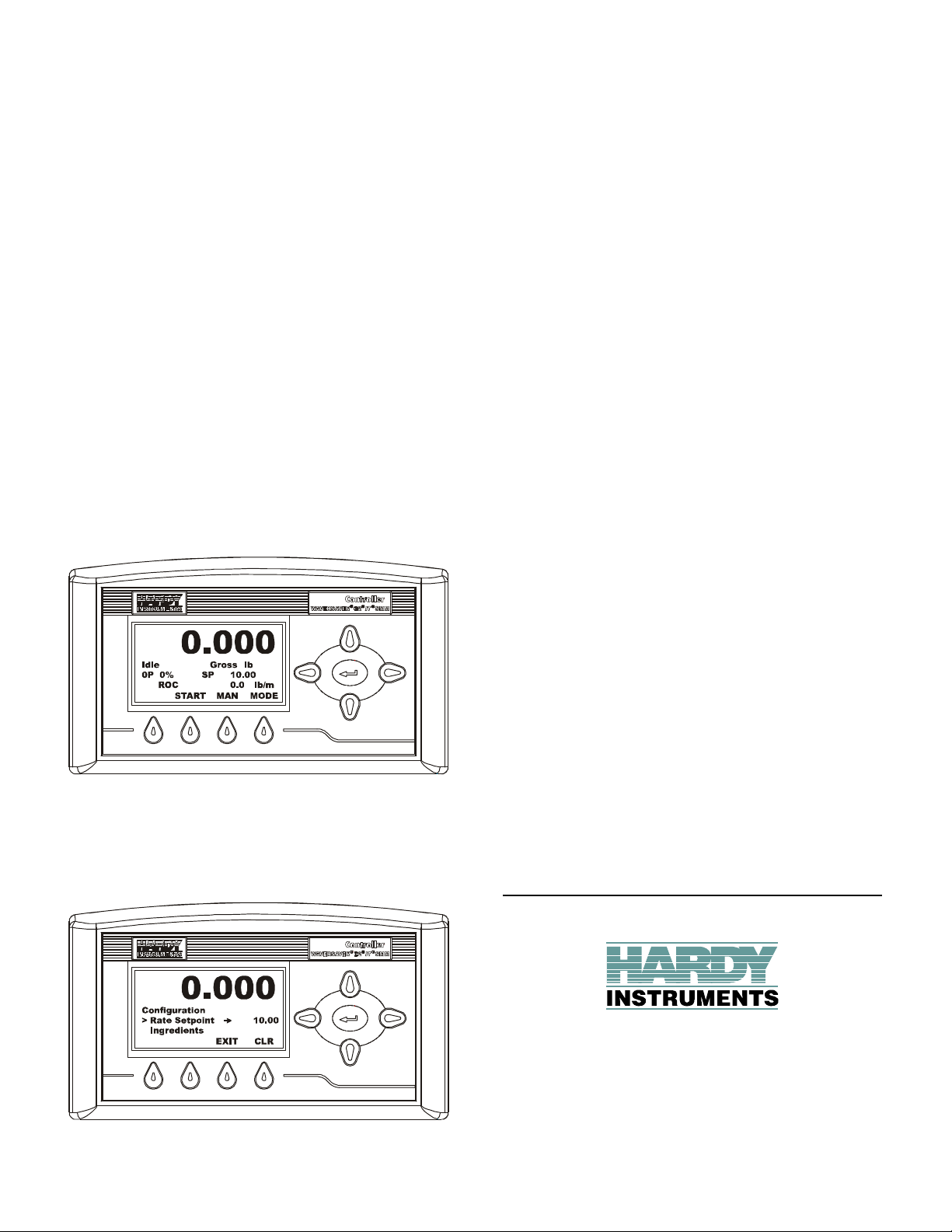

STARTING THE HI 4060

Step 1. Connect the power connector (AC or DC) to the HI 4060.

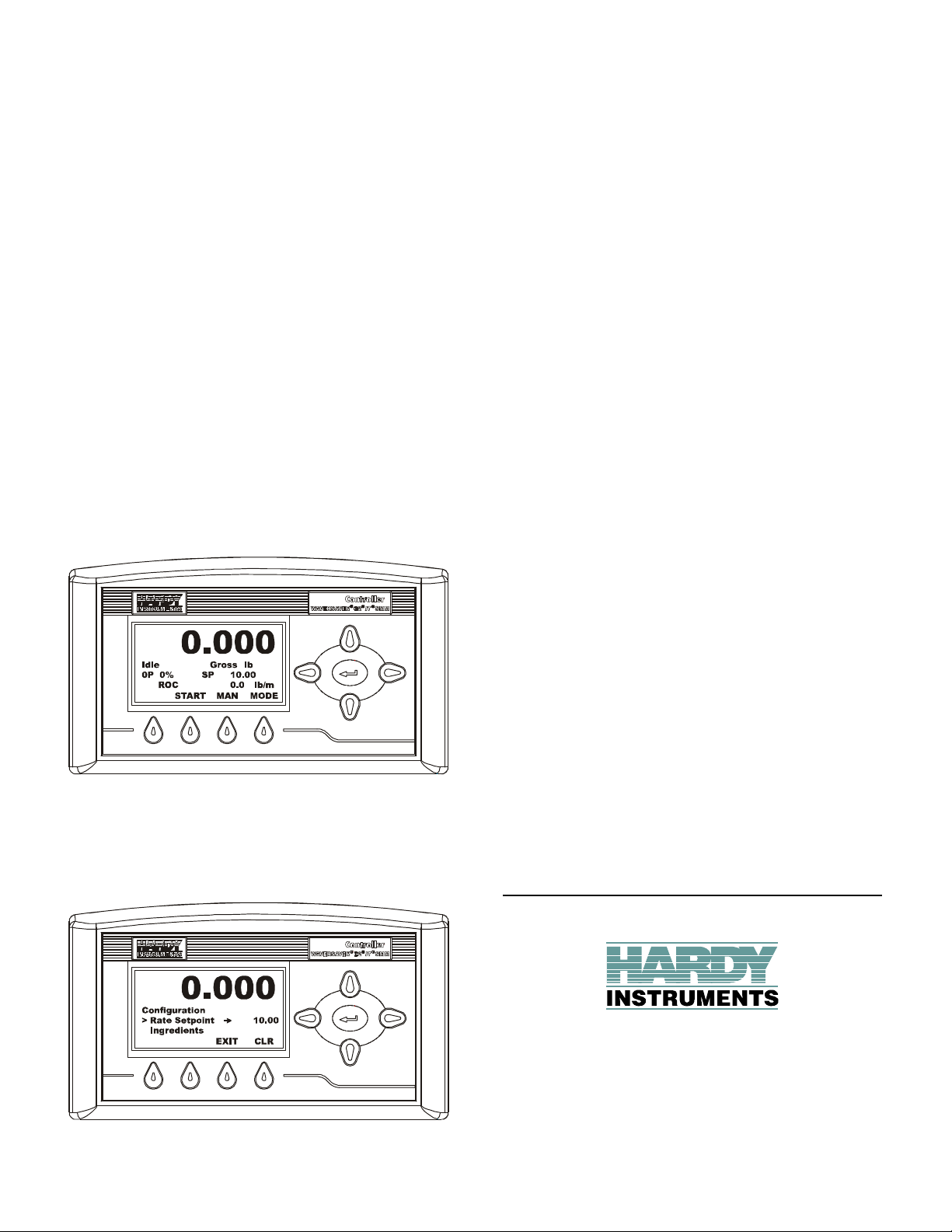

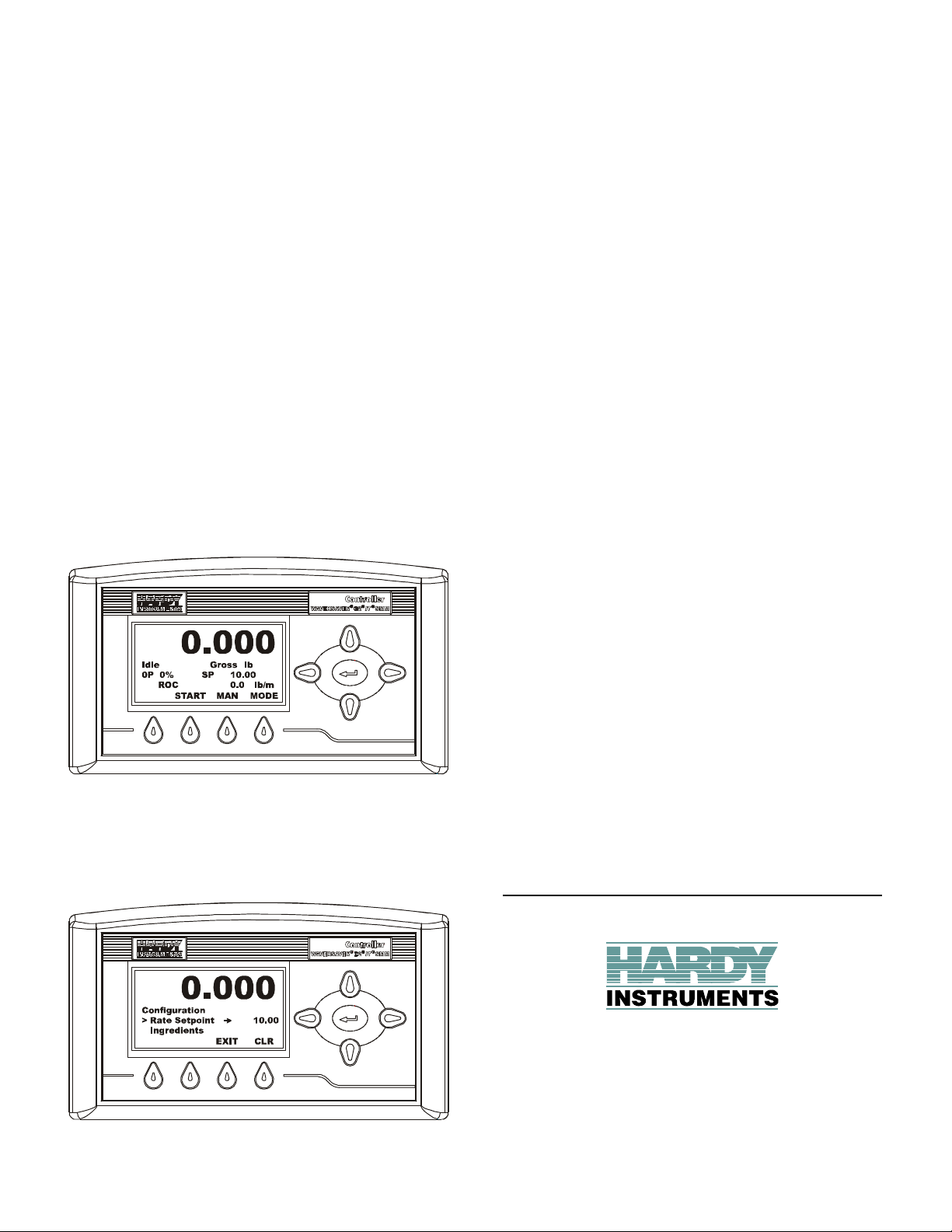

Step 2. The Instrument boots up to the Summary Display. (See Fig. 9)

FIG. 7 SUMMARY DISPLAY

Step 3. Press the Enter but ton to go to t he Config uration menus. (See

Fig. 8)

FIG. 8 CONFIGURATION DISPLAY

9440 Carroll Park Drive Suite 150, San Diego, CA 92121

Telepho ne: 1-800-821-5831 FAX: (858) 278-6700

Web Address: http://www.hardyinstruments.com

Hardy Instruments D ocument Number: 0596 - 0308-01 Rev. B

Copyright June 2008, Dynamic Instruments, All Rights Reserved. Printed in

the U.S.A.

Page 4

QUICK INSTALLATION GUIDE

4.05

3.200

3.000

2.590

1.274

.41

.205

.44

.475

.755

5.250

7.08

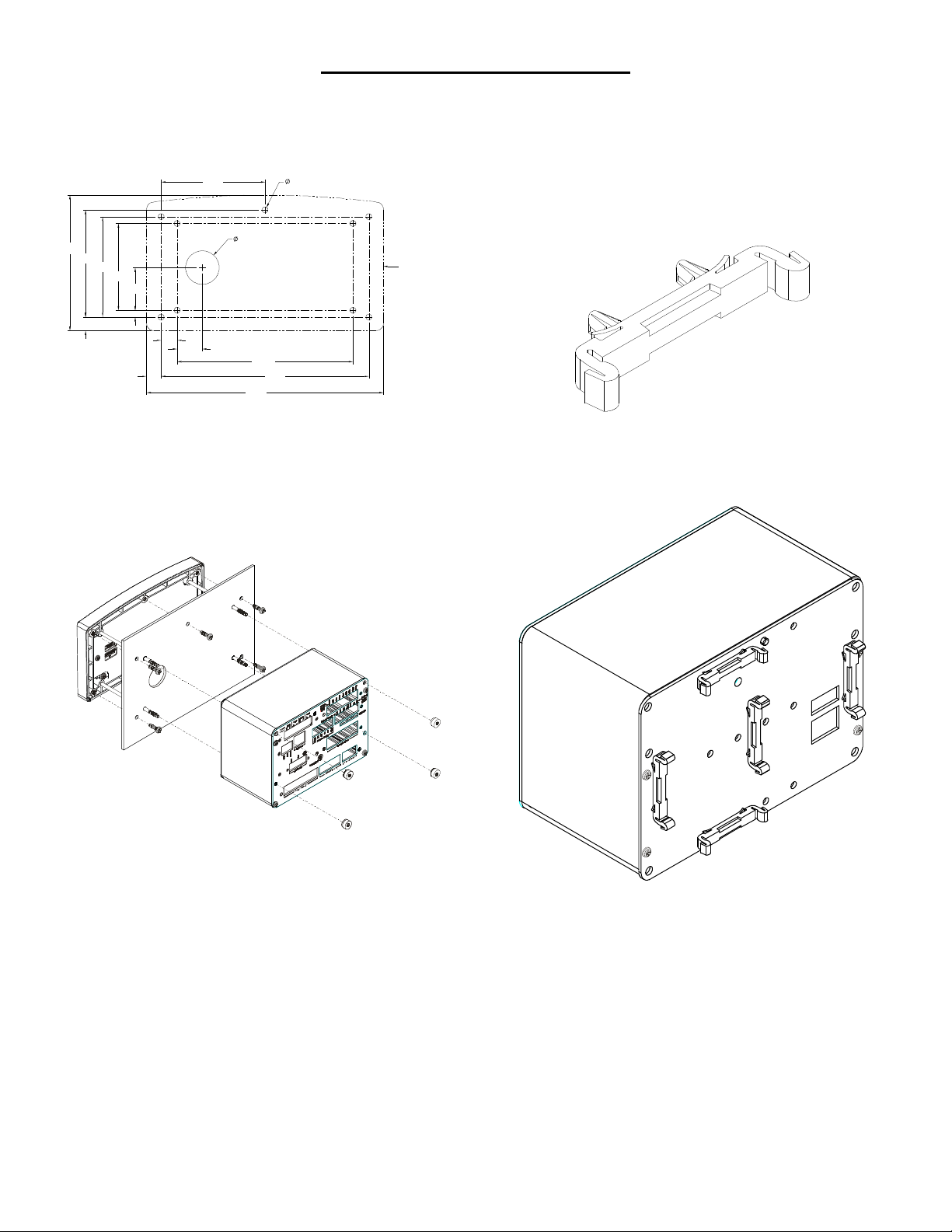

MECHANICAL INSTALLATION

Installing the HI 4060 Rate Controller in a Panel

6.200

.172 THRU, 9 PL

INSTRUMENT

BEZEL OUTLINE

3.100

1.25 THRU

FIG. 1 PANEL HOLE DIMENSIONS

Step 1. Make sure that all Electrostatic Discharge (ESD) precautions

are taken before and during installatio n.

Step 2. Use the attached template to make the hole pattern in the panel

door or cover. (See Attached)

Step 8. Thread the four (4) 6-32 thumb screws onto the threaded rods

until tight. Do not use pliers on the thumb screws.

DIN Rail Installation HI 4060 Rate Controller

Step 1. Snap the DIN rail mounting feet into any of the two holes on

the front panel of the electronic en closure. (See Figs. 5 & 6)

FIG. 3 DIN RAIL MOUNTING FOOT

FIG. 2 PANEL MOUNT INSTALLATION

Step 3. Use a phillips head screwdriver and install the five (5) 6-32 x

1/2 inch screws that fasten the bezel to the pane l. (See Fig . 3)

Use a torque screw driver and torque each screw to 10 inch/

pounds. DO NOT OVERTIGHTEN!

Step 4. Thread the four (4) threaded rods through the approp ria te

holes in the panel and into the bezel. For t he retr ofit y ou don’t

have to place the rods through the holes. (See Fig. 4)

Step 5. Hand tighten each rod un til you ca n no lon ger turn th e rod. Do

not force the rods or use pliers of any kind.

Step 6. Put the Display cable and connector th rou gh th e 1 in c h hole in

the panel door or c ove r and plug the d isp lay c onn ecto r into the

Step 7. Gently slide the electronic enclosu r e onto the threaded rods

display header in the beze l. (See Fig. 3)

while making sure the display cable glides easily into the

enclosure and does not kink. Move the electronic enclosure

toward the panel until it stops. (See Fig. 3)

FIG. 4 VERTICAL AND HORIZONTAL ORIENTATION

Step 2. When installing firm ly pu sh the mou nting feet u ntil y ou hear a

snapping sound. The snap mean s they are mounted correctly.

Step 3. After installation give each mounting foot a little tug to make

sure they are seated correctly.

NOTE: There are several horizontal and vertical mounting

options. It is highly recommended that at least two

mounting feet be used per enclosur e.

Step 4. To mount the en closure onto a DIN rail. Place the moun ting

feet on the DIN Rail and firmly press down un til the mo unting

feet snap onto the rail.

Page 5

Step 5. To remove the mo unting feet use a finger on the clip and gen-

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

tly pull up on the tab.

NOTE: For Remote Display installation please see Chapter 3,

Installation, of the HI 4060 User’s Guide.

LOAD POINT INSTALLATION

FIG. 5 REAR PANEL

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Pr t. # 6020-0001) wires to the Channel terminal

block according to the cabl e color chart.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

Step 4. For more information concerning C2 Lo ad Point connection,

consult the HI 4060 User Gui de.

Non-C2 Load Point Connection

NOTE: Cable Color Codes vary between vendors, check with your

supplier for the Color Code f or your Non -C2 load point . Do

not connect wires to the -C2 and +C2.

Step 1. Remove the factory installed jumper from the terminal block if

you have 6 wire load cell cable that i ncl udes sense wires from

the load cell or junction box.

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Prt. # 6020-0001) wires to the Channel 1 terminal

block according to the Non-C2 cable color chart, or pe r manu

facturers specification.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

INPUT POWER WIRING

WARNING: DO NOT PLUG THE POWER CONNECTOR INTO THE

HEADER WITH LIVE POWER. T O DO SO WILL RESULT IN PROP-

ERTY DAMAGE AND/OR PERSONAL INJURY.

-

FIG. 6

C2® Load Point Connection

Cable color Code for C2 Lo ad Points (left to right facing the rea r pa nel):

Step 1. Remove the factory installed jumpers from the terminal block

• Shield Ground W i re

•C2- Violet

•C2+ Grey

• EXC- Black

•SEN- Brown

• SIG- White

• SIG+ Green

•SEN+ Blue

•EXC+ Red

if you are connecting an 8 wire cable from the junction box.

(See Fig. 8)

WARNING:

INCORRECT TYPE IT MAY CAUSE AN EXPLOSION WHICH WILL

CAUSE PROPERTY DAMAGE OR PERSONAL INJURY.

IF A LITHIUM BATTERY IS REPLACED WITH AN

AC Input Power Wiring (-AC)

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 240 VAC.

WARNING: I

ON THE AC INPUT WIRES, THE DISCONNECT MUST ACT ON

BOTH THE LINE AND NEUTRAL WIRES IN A DOUBLE POLE, DOU-

BLE THROW ARRANGEMENT I.E. DPDT RELAY. USING OTHER

AUTOMATIC DISCONNECT ARRANGEMENTS MAY CAUSE PER-

SONAL INJURY AND/OR PROPERTY DAMAGE.

Step 1. The HI 4060 is configur ed with a univ ersal power suppl y rated

Step 2. Make sure the VAC power is shut off before installing the

Step 3. Install a 3-wire, minimum 14 AWG power line to the 3 -pin ter-

F AN AUTOMATIC DISCONNECT DEVICE IS USED

• The AC power should be supplied by a “clean” primary line, directly from the power panel. This line

should not supply any other equipment, including

the feeding unit, and shou ld be sup pli ed with a min i

mum 10 amp breaker.

• AC Power Input (See Fig. 7)

Neu (Low)

Line (HI)

Earth Ground

from 11 0 to 24 0 VA C .

wires to the connector.

minal block connector.

-

Page 6

DC Power Input (-DC)

Rat e

Rat e

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 24 VDC.

• Use the HI 4060 Rate Controller User Guide for

Configuration, Operation and Troublesh ooting

instructions.

CAUTION: Y

SUPPLY (CLASS 2) ON THE DC INPUT WIRING.

OU MUST USE A POWER LIMITED DC POWER

• The DC power sh ould be s upplied by a “clean” pri mary li ne,

directly from the DC power source.

Step 1. Make sure the VDC power is shut off before installing the

wires to the connector.

Step 2. Connect the 24 VDC Voltage wire, Ground wire and Shield

wire to the connector that plugs into the DC voltage header at

the rear panel. Make sure that the shiel d is connected to the

local Earth Ground connectio n.

Step 3. Plug the connector into the header at the rear panel. (See Fig.

7)

Step 4. Apply VDC power to the unit.

STARTING THE HI 4060

Step 1. Connect the power connector (AC or DC) to the HI 4060.

Step 2. The Instrument boots up to the Summary Display. (See Fig. 9)

FIG. 7 SUMMARY DISPLAY

Step 3. Press the Enter but ton to go to t he Config uration menus. (See

Fig. 8)

FIG. 8 CONFIGURATION DISPLAY

9440 Carroll Park Drive Suite 150, San Diego, CA 92121

Telepho ne: 1-800-821-5831 FAX: (858) 278-6700

Web Address: http://www.hardyinstruments.com

Hardy Instruments D ocument Number: 0596 - 0308-01 Rev. B

Copyright June 2008, Dynamic Instruments, All Rights Reserved. Printed in

the U.S.A.

Page 7

QUICK INSTALLATION GUIDE

4.05

3.200

3.000

2.590

1.274

.41

.205

.44

.475

.755

5.250

7.08

MECHANICAL INSTALLATION

Installing the HI 4060 Rate Controller in a Panel

6.200

.172 THRU, 9 PL

INSTRUMENT

BEZEL OUTLINE

3.100

1.25 THRU

FIG. 1 PANEL HOLE DIMENSIONS

Step 1. Make sure that all Electrostatic Discharge (ESD) precautions

are taken before and during installatio n.

Step 2. Use the attached template to make the hole pattern in the panel

door or cover. (See Attached)

Step 8. Thread the four (4) 6-32 thumb screws onto the threaded rods

until tight. Do not use pliers on the thumb screws.

DIN Rail Installation HI 4060 Rate Controller

Step 1. Snap the DIN rail mounting feet into any of the two holes on

the front panel of the electronic en closure. (See Figs. 5 & 6)

FIG. 3 DIN RAIL MOUNTING FOOT

FIG. 2 PANEL MOUNT INSTALLATION

Step 3. Use a phillips head screwdriver and install the five (5) 6-32 x

1/2 inch screws that fasten the bezel to the pane l. (See Fig . 3)

Use a torque screw driver and torque each screw to 10 inch/

pounds. DO NOT OVERTIGHTEN!

Step 4. Thread the four (4) threaded rods through the approp ria te

holes in the panel and into the bezel. For t he retr ofit y ou don’t

have to place the rods through the holes. (See Fig. 4)

Step 5. Hand tighten each rod un til you ca n no lon ger turn th e rod. Do

not force the rods or use pliers of any kind.

Step 6. Put the Display cable and connector th rou gh th e 1 in c h hole in

the panel door or c ove r and plug the d isp lay c onn ecto r into the

Step 7. Gently slide the electronic enclosu r e onto the threaded rods

display header in the beze l. (See Fig. 3)

while making sure the display cable glides easily into the

enclosure and does not kink. Move the electronic enclosure

toward the panel until it stops. (See Fig. 3)

FIG. 4 VERTICAL AND HORIZONTAL ORIENTATION

Step 2. When installing firm ly pu sh the mou nting feet u ntil y ou hear a

snapping sound. The snap mean s they are mounted correctly.

Step 3. After installation give each mounting foot a little tug to make

sure they are seated correctly.

NOTE: There are several horizontal and vertical mounting

options. It is highly recommended that at least two

mounting feet be used per enclosur e.

Step 4. To mount the en closure onto a DIN rail. Place the moun ting

feet on the DIN Rail and firmly press down un til the mo unting

feet snap onto the rail.

Page 8

Step 5. To remove the mo unting feet use a finger on the clip and gen-

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

tly pull up on the tab.

NOTE: For Remote Display installation please see Chapter 3,

Installation, of the HI 4060 User’s Guide.

LOAD POINT INSTALLATION

FIG. 5 REAR PANEL

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Pr t. # 6020-0001) wires to the Channel terminal

block according to the cabl e color chart.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

Step 4. For more information concerning C2 Lo ad Point connection,

consult the HI 4060 User Gui de.

Non-C2 Load Point Connection

NOTE: Cable Color Codes vary between vendors, check with your

supplier for the Color Code f or your Non -C2 load point . Do

not connect wires to the -C2 and +C2.

Step 1. Remove the factory installed jumper from the terminal block if

you have 6 wire load cell cable that i ncl udes sense wires from

the load cell or junction box.

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Prt. # 6020-0001) wires to the Channel 1 terminal

block according to the Non-C2 cable color chart, or pe r manu

facturers specification.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

INPUT POWER WIRING

WARNING: DO NOT PLUG THE POWER CONNECTOR INTO THE

HEADER WITH LIVE POWER. T O DO SO WILL RESULT IN PROP-

ERTY DAMAGE AND/OR PERSONAL INJURY.

-

FIG. 6

C2® Load Point Connection

Cable color Code for C2 Lo ad Points (left to right facing the rea r pa nel):

Step 1. Remove the factory installed jumpers from the terminal block

• Shield Ground W i re

•C2- Violet

•C2+ Grey

• EXC- Black

•SEN- Brown

• SIG- White

• SIG+ Green

•SEN+ Blue

•EXC+ Red

if you are connecting an 8 wire cable from the junction box.

(See Fig. 8)

WARNING:

INCORRECT TYPE IT MAY CAUSE AN EXPLOSION WHICH WILL

CAUSE PROPERTY DAMAGE OR PERSONAL INJURY.

IF A LITHIUM BATTERY IS REPLACED WITH AN

AC Input Power Wiring (-AC)

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 240 VAC.

WARNING: I

ON THE AC INPUT WIRES, THE DISCONNECT MUST ACT ON

BOTH THE LINE AND NEUTRAL WIRES IN A DOUBLE POLE, DOU-

BLE THROW ARRANGEMENT I.E. DPDT RELAY. USING OTHER

AUTOMATIC DISCONNECT ARRANGEMENTS MAY CAUSE PER-

SONAL INJURY AND/OR PROPERTY DAMAGE.

Step 1. The HI 4060 is configur ed with a univ ersal power suppl y rated

Step 2. Make sure the VAC power is shut off before installing the

Step 3. Install a 3-wire, minimum 14 AWG power line to the 3 -pin ter-

F AN AUTOMATIC DISCONNECT DEVICE IS USED

• The AC power should be supplied by a “clean” primary line, directly from the power panel. This line

should not supply any other equipment, including

the feeding unit, and shou ld be sup pli ed with a min i

mum 10 amp breaker.

• AC Power Input (See Fig. 7)

Neu (Low)

Line (HI)

Earth Ground

from 11 0 to 24 0 VA C .

wires to the connector.

minal block connector.

-

Page 9

DC Power Input (-DC)

Rat e

Rat e

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 24 VDC.

• Use the HI 4060 Rate Controller User Guide for

Configuration, Operation and Troublesh ooting

instructions.

CAUTION: Y

SUPPLY (CLASS 2) ON THE DC INPUT WIRING.

OU MUST USE A POWER LIMITED DC POWER

• The DC power sh ould be s upplied by a “clean” pri mary li ne,

directly from the DC power source.

Step 1. Make sure the VDC power is shut off before installing the

wires to the connector.

Step 2. Connect the 24 VDC Voltage wire, Ground wire and Shield

wire to the connector that plugs into the DC voltage header at

the rear panel. Make sure that the shiel d is connected to the

local Earth Ground connectio n.

Step 3. Plug the connector into the header at the rear panel. (See Fig.

7)

Step 4. Apply VDC power to the unit.

STARTING THE HI 4060

Step 1. Connect the power connector (AC or DC) to the HI 4060.

Step 2. The Instrument boots up to the Summary Display. (See Fig. 9)

FIG. 7 SUMMARY DISPLAY

Step 3. Press the Enter but ton to go to t he Config uration menus. (See

Fig. 8)

FIG. 8 CONFIGURATION DISPLAY

9440 Carroll Park Drive Suite 150, San Diego, CA 92121

Telepho ne: 1-800-821-5831 FAX: (858) 278-6700

Web Address: http://www.hardyinstruments.com

Hardy Instruments D ocument Number: 0596 - 0308-01 Rev. B

Copyright June 2008, Dynamic Instruments, All Rights Reserved. Printed in

the U.S.A.

Page 10

QUICK INSTALLATION GUIDE

4.05

3.200

3.000

2.590

1.274

.41

.205

.44

.475

.755

5.250

7.08

MECHANICAL INSTALLATION

Installing the HI 4060 Rate Controller in a Panel

6.200

.172 THRU, 9 PL

INSTRUMENT

BEZEL OUTLINE

3.100

1.25 THRU

FIG. 1 PANEL HOLE DIMENSIONS

Step 1. Make sure that all Electrostatic Discharge (ESD) precautions

are taken before and during installatio n.

Step 2. Use the attached template to make the hole pattern in the panel

door or cover. (See Attached)

Step 8. Thread the four (4) 6-32 thumb screws onto the threaded rods

until tight. Do not use pliers on the thumb screws.

DIN Rail Installation HI 4060 Rate Controller

Step 1. Snap the DIN rail mounting feet into any of the two holes on

the front panel of the electronic en closure. (See Figs. 5 & 6)

FIG. 3 DIN RAIL MOUNTING FOOT

FIG. 2 PANEL MOUNT INSTALLATION

Step 3. Use a phillips head screwdriver and install the five (5) 6-32 x

1/2 inch screws that fasten the bezel to the pane l. (See Fig . 3)

Use a torque screw driver and torque each screw to 10 inch/

pounds. DO NOT OVERTIGHTEN!

Step 4. Thread the four (4) threaded rods through the approp ria te

holes in the panel and into the bezel. For t he retr ofit y ou don’t

have to place the rods through the holes. (See Fig. 4)

Step 5. Hand tighten each rod un til you ca n no lon ger turn th e rod. Do

not force the rods or use pliers of any kind.

Step 6. Put the Display cable and connector th rou gh th e 1 in c h hole in

the panel door or c ove r and plug the d isp lay c onn ecto r into the

Step 7. Gently slide the electronic enclosu r e onto the threaded rods

display header in the beze l. (See Fig. 3)

while making sure the display cable glides easily into the

enclosure and does not kink. Move the electronic enclosure

toward the panel until it stops. (See Fig. 3)

FIG. 4 VERTICAL AND HORIZONTAL ORIENTATION

Step 2. When installing firm ly pu sh the mou nting feet u ntil y ou hear a

snapping sound. The snap mean s they are mounted correctly.

Step 3. After installation give each mounting foot a little tug to make

sure they are seated correctly.

NOTE: There are several horizontal and vertical mounting

options. It is highly recommended that at least two

mounting feet be used per enclosur e.

Step 4. To mount the en closure onto a DIN rail. Place the moun ting

feet on the DIN Rail and firmly press down un til the mo unting

feet snap onto the rail.

Page 11

Step 5. To remove the mo unting feet use a finger on the clip and gen-

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

tly pull up on the tab.

NOTE: For Remote Display installation please see Chapter 3,

Installation, of the HI 4060 User’s Guide.

LOAD POINT INSTALLATION

FIG. 5 REAR PANEL

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Pr t. # 6020-0001) wires to the Channel terminal

block according to the cabl e color chart.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

Step 4. For more information concerning C2 Lo ad Point connection,

consult the HI 4060 User Gui de.

Non-C2 Load Point Connection

NOTE: Cable Color Codes vary between vendors, check with your

supplier for the Color Code f or your Non -C2 load point . Do

not connect wires to the -C2 and +C2.

Step 1. Remove the factory installed jumper from the terminal block if

you have 6 wire load cell cable that i ncl udes sense wires from

the load cell or junction box.

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Prt. # 6020-0001) wires to the Channel 1 terminal

block according to the Non-C2 cable color chart, or pe r manu

facturers specification.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

INPUT POWER WIRING

WARNING: DO NOT PLUG THE POWER CONNECTOR INTO THE

HEADER WITH LIVE POWER. T O DO SO WILL RESULT IN PROP-

ERTY DAMAGE AND/OR PERSONAL INJURY.

-

FIG. 6

C2® Load Point Connection

Cable color Code for C2 Lo ad Points (left to right facing the rea r pa nel):

Step 1. Remove the factory installed jumpers from the terminal block

• Shield Ground W i re

•C2- Violet

•C2+ Grey

• EXC- Black

•SEN- Brown

• SIG- White

• SIG+ Green

•SEN+ Blue

•EXC+ Red

if you are connecting an 8 wire cable from the junction box.

(See Fig. 8)

WARNING:

INCORRECT TYPE IT MAY CAUSE AN EXPLOSION WHICH WILL

CAUSE PROPERTY DAMAGE OR PERSONAL INJURY.

IF A LITHIUM BATTERY IS REPLACED WITH AN

AC Input Power Wiring (-AC)

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 240 VAC.

WARNING: I

ON THE AC INPUT WIRES, THE DISCONNECT MUST ACT ON

BOTH THE LINE AND NEUTRAL WIRES IN A DOUBLE POLE, DOU-

BLE THROW ARRANGEMENT I.E. DPDT RELAY. USING OTHER

AUTOMATIC DISCONNECT ARRANGEMENTS MAY CAUSE PER-

SONAL INJURY AND/OR PROPERTY DAMAGE.

Step 1. The HI 4060 is configur ed with a univ ersal power suppl y rated

Step 2. Make sure the VAC power is shut off before installing the

Step 3. Install a 3-wire, minimum 14 AWG power line to the 3 -pin ter-

F AN AUTOMATIC DISCONNECT DEVICE IS USED

• The AC power should be supplied by a “clean” primary line, directly from the power panel. This line

should not supply any other equipment, including

the feeding unit, and shou ld be sup pli ed with a min i

mum 10 amp breaker.

• AC Power Input (See Fig. 7)

Neu (Low)

Line (HI)

Earth Ground

from 11 0 to 24 0 VA C .

wires to the connector.

minal block connector.

-

Page 12

DC Power Input (-DC)

Rat e

Rat e

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 24 VDC.

• Use the HI 4060 Rate Controller User Guide for

Configuration, Operation and Troublesh ooting

instructions.

CAUTION: Y

SUPPLY (CLASS 2) ON THE DC INPUT WIRING.

OU MUST USE A POWER LIMITED DC POWER

• The DC power sh ould be s upplied by a “clean” pri mary li ne,

directly from the DC power source.

Step 1. Make sure the VDC power is shut off before installing the

wires to the connector.

Step 2. Connect the 24 VDC Voltage wire, Ground wire and Shield

wire to the connector that plugs into the DC voltage header at

the rear panel. Make sure that the shiel d is connected to the

local Earth Ground connectio n.

Step 3. Plug the connector into the header at the rear panel. (See Fig.

7)

Step 4. Apply VDC power to the unit.

STARTING THE HI 4060

Step 1. Connect the power connector (AC or DC) to the HI 4060.

Step 2. The Instrument boots up to the Summary Display. (See Fig. 9)

FIG. 7 SUMMARY DISPLAY

Step 3. Press the Enter but ton to go to t he Config uration menus. (See

Fig. 8)

FIG. 8 CONFIGURATION DISPLAY

9440 Carroll Park Drive Suite 150, San Diego, CA 92121

Telepho ne: 1-800-821-5831 FAX: (858) 278-6700

Web Address: http://www.hardyinstruments.com

Hardy Instruments D ocument Number: 0596 - 0308-01 Rev. B

Copyright June 2008, Dynamic Instruments, All Rights Reserved. Printed in

the U.S.A.

Page 13

QUICK INSTALLATION GUIDE

4.05

3.200

3.000

2.590

1.274

.41

.205

.44

.475

.755

5.250

7.08

MECHANICAL INSTALLATION

Installing the HI 4060 Rate Controller in a Panel

6.200

.172 THRU, 9 PL

INSTRUMENT

BEZEL OUTLINE

3.100

1.25 THRU

FIG. 1 PANEL HOLE DIMENSIONS

Step 1. Make sure that all Electrostatic Discharge (ESD) precautions

are taken before and during installatio n.

Step 2. Use the attached template to make the hole pattern in the panel

door or cover. (See Attached)

Step 8. Thread the four (4) 6-32 thumb screws onto the threaded rods

until tight. Do not use pliers on the thumb screws.

DIN Rail Installation HI 4060 Rate Controller

Step 1. Snap the DIN rail mounting feet into any of the two holes on

the front panel of the electronic en closure. (See Figs. 5 & 6)

FIG. 3 DIN RAIL MOUNTING FOOT

FIG. 2 PANEL MOUNT INSTALLATION

Step 3. Use a phillips head screwdriver and install the five (5) 6-32 x

1/2 inch screws that fasten the bezel to the pane l. (See Fig . 3)

Use a torque screw driver and torque each screw to 10 inch/

pounds. DO NOT OVERTIGHTEN!

Step 4. Thread the four (4) threaded rods through the approp ria te

holes in the panel and into the bezel. For t he retr ofit y ou don’t

have to place the rods through the holes. (See Fig. 4)

Step 5. Hand tighten each rod un til you ca n no lon ger turn th e rod. Do

not force the rods or use pliers of any kind.

Step 6. Put the Display cable and connector th rou gh th e 1 in c h hole in

the panel door or c ove r and plug the d isp lay c onn ecto r into the

Step 7. Gently slide the electronic enclosu r e onto the threaded rods

display header in the beze l. (See Fig. 3)

while making sure the display cable glides easily into the

enclosure and does not kink. Move the electronic enclosure

toward the panel until it stops. (See Fig. 3)

FIG. 4 VERTICAL AND HORIZONTAL ORIENTATION

Step 2. When installing firm ly pu sh the mou nting feet u ntil y ou hear a

snapping sound. The snap mean s they are mounted correctly.

Step 3. After installation give each mounting foot a little tug to make

sure they are seated correctly.

NOTE: There are several horizontal and vertical mounting

options. It is highly recommended that at least two

mounting feet be used per enclosur e.

Step 4. To mount the en closure onto a DIN rail. Place the moun ting

feet on the DIN Rail and firmly press down un til the mo unting

feet snap onto the rail.

Page 14

Step 5. To remove the mo unting feet use a finger on the clip and gen-

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

tly pull up on the tab.

NOTE: For Remote Display installation please see Chapter 3,

Installation, of the HI 4060 User’s Guide.

LOAD POINT INSTALLATION

FIG. 5 REAR PANEL

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Pr t. # 6020-0001) wires to the Channel terminal

block according to the cabl e color chart.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

Step 4. For more information concerning C2 Lo ad Point connection,

consult the HI 4060 User Gui de.

Non-C2 Load Point Connection

NOTE: Cable Color Codes vary between vendors, check with your

supplier for the Color Code f or your Non -C2 load point . Do

not connect wires to the -C2 and +C2.

Step 1. Remove the factory installed jumper from the terminal block if

you have 6 wire load cell cable that i ncl udes sense wires from

the load cell or junction box.

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Prt. # 6020-0001) wires to the Channel 1 terminal

block according to the Non-C2 cable color chart, or pe r manu

facturers specification.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

INPUT POWER WIRING

WARNING: DO NOT PLUG THE POWER CONNECTOR INTO THE

HEADER WITH LIVE POWER. T O DO SO WILL RESULT IN PROP-

ERTY DAMAGE AND/OR PERSONAL INJURY.

-

FIG. 6

C2® Load Point Connection

Cable color Code for C2 Lo ad Points (left to right facing the rea r pa nel):

Step 1. Remove the factory installed jumpers from the terminal block

• Shield Ground W i re

•C2- Violet

•C2+ Grey

• EXC- Black

•SEN- Brown

• SIG- White

• SIG+ Green

•SEN+ Blue

•EXC+ Red

if you are connecting an 8 wire cable from the junction box.

(See Fig. 8)

WARNING:

INCORRECT TYPE IT MAY CAUSE AN EXPLOSION WHICH WILL

CAUSE PROPERTY DAMAGE OR PERSONAL INJURY.

IF A LITHIUM BATTERY IS REPLACED WITH AN

AC Input Power Wiring (-AC)

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 240 VAC.

WARNING: I

ON THE AC INPUT WIRES, THE DISCONNECT MUST ACT ON

BOTH THE LINE AND NEUTRAL WIRES IN A DOUBLE POLE, DOU-

BLE THROW ARRANGEMENT I.E. DPDT RELAY. USING OTHER

AUTOMATIC DISCONNECT ARRANGEMENTS MAY CAUSE PER-

SONAL INJURY AND/OR PROPERTY DAMAGE.

Step 1. The HI 4060 is configur ed with a univ ersal power suppl y rated

Step 2. Make sure the VAC power is shut off before installing the

Step 3. Install a 3-wire, minimum 14 AWG power line to the 3 -pin ter-

F AN AUTOMATIC DISCONNECT DEVICE IS USED

• The AC power should be supplied by a “clean” primary line, directly from the power panel. This line

should not supply any other equipment, including

the feeding unit, and shou ld be sup pli ed with a min i

mum 10 amp breaker.

• AC Power Input (See Fig. 7)

Neu (Low)

Line (HI)

Earth Ground

from 11 0 to 24 0 VA C .

wires to the connector.

minal block connector.

-

Page 15

DC Power Input (-DC)

Rat e

Rat e

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 24 VDC.

• Use the HI 4060 Rate Controller User Guide for

Configuration, Operation and Troublesh ooting

instructions.

CAUTION: Y

SUPPLY (CLASS 2) ON THE DC INPUT WIRING.

OU MUST USE A POWER LIMITED DC POWER

• The DC power sh ould be s upplied by a “clean” pri mary li ne,

directly from the DC power source.

Step 1. Make sure the VDC power is shut off before installing the

wires to the connector.

Step 2. Connect the 24 VDC Voltage wire, Ground wire and Shield

wire to the connector that plugs into the DC voltage header at

the rear panel. Make sure that the shiel d is connected to the

local Earth Ground connectio n.

Step 3. Plug the connector into the header at the rear panel. (See Fig.

7)

Step 4. Apply VDC power to the unit.

STARTING THE HI 4060

Step 1. Connect the power connector (AC or DC) to the HI 4060.

Step 2. The Instrument boots up to the Summary Display. (See Fig. 9)

FIG. 7 SUMMARY DISPLAY

Step 3. Press the Enter but ton to go to t he Config uration menus. (See

Fig. 8)

FIG. 8 CONFIGURATION DISPLAY

9440 Carroll Park Drive Suite 150, San Diego, CA 92121

Telepho ne: 1-800-821-5831 FAX: (858) 278-6700

Web Address: http://www.hardyinstruments.com

Hardy Instruments D ocument Number: 0596 - 0308-01 Rev. B

Copyright June 2008, Dynamic Instruments, All Rights Reserved. Printed in

the U.S.A.

Page 16

QUICK INSTALLATION GUIDE

4.05

3.200

3.000

2.590

1.274

.41

.205

.44

.475

.755

5.250

7.08

MECHANICAL INSTALLATION

Installing the HI 4060 Rate Controller in a Panel

6.200

.172 THRU, 9 PL

INSTRUMENT

BEZEL OUTLINE

3.100

1.25 THRU

FIG. 1 PANEL HOLE DIMENSIONS

Step 1. Make sure that all Electrostatic Discharge (ESD) precautions

are taken before and during installatio n.

Step 2. Use the attached template to make the hole pattern in the panel

door or cover. (See Attached)

Step 8. Thread the four (4) 6-32 thumb screws onto the threaded rods

until tight. Do not use pliers on the thumb screws.

DIN Rail Installation HI 4060 Rate Controller

Step 1. Snap the DIN rail mounting feet into any of the two holes on

the front panel of the electronic en closure. (See Figs. 5 & 6)

FIG. 3 DIN RAIL MOUNTING FOOT

FIG. 2 PANEL MOUNT INSTALLATION

Step 3. Use a phillips head screwdriver and install the five (5) 6-32 x

1/2 inch screws that fasten the bezel to the pane l. (See Fig . 3)

Use a torque screw driver and torque each screw to 10 inch/

pounds. DO NOT OVERTIGHTEN!

Step 4. Thread the four (4) threaded rods through the approp ria te

holes in the panel and into the bezel. For t he retr ofit y ou don’t

have to place the rods through the holes. (See Fig. 4)

Step 5. Hand tighten each rod un til you ca n no lon ger turn th e rod. Do

not force the rods or use pliers of any kind.

Step 6. Put the Display cable and connector th rou gh th e 1 in c h hole in

the panel door or c ove r and plug the d isp lay c onn ecto r into the

Step 7. Gently slide the electronic enclosu r e onto the threaded rods

display header in the beze l. (See Fig. 3)

while making sure the display cable glides easily into the

enclosure and does not kink. Move the electronic enclosure

toward the panel until it stops. (See Fig. 3)

FIG. 4 VERTICAL AND HORIZONTAL ORIENTATION

Step 2. When installing firm ly pu sh the mou nting feet u ntil y ou hear a

snapping sound. The snap mean s they are mounted correctly.

Step 3. After installation give each mounting foot a little tug to make

sure they are seated correctly.

NOTE: There are several horizontal and vertical mounting

options. It is highly recommended that at least two

mounting feet be used per enclosur e.

Step 4. To mount the en closure onto a DIN rail. Place the moun ting

feet on the DIN Rail and firmly press down un til the mo unting

feet snap onto the rail.

Page 17

Step 5. To remove the mo unting feet use a finger on the clip and gen-

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

tly pull up on the tab.

NOTE: For Remote Display installation please see Chapter 3,

Installation, of the HI 4060 User’s Guide.

LOAD POINT INSTALLATION

FIG. 5 REAR PANEL

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Pr t. # 6020-0001) wires to the Channel terminal

block according to the cabl e color chart.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

Step 4. For more information concerning C2 Lo ad Point connection,

consult the HI 4060 User Gui de.

Non-C2 Load Point Connection

NOTE: Cable Color Codes vary between vendors, check with your

supplier for the Color Code f or your Non -C2 load point . Do

not connect wires to the -C2 and +C2.

Step 1. Remove the factory installed jumper from the terminal block if

you have 6 wire load cell cable that i ncl udes sense wires from

the load cell or junction box.

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Prt. # 6020-0001) wires to the Channel 1 terminal

block according to the Non-C2 cable color chart, or pe r manu

facturers specification.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

INPUT POWER WIRING

WARNING: DO NOT PLUG THE POWER CONNECTOR INTO THE

HEADER WITH LIVE POWER. T O DO SO WILL RESULT IN PROP-

ERTY DAMAGE AND/OR PERSONAL INJURY.

-

FIG. 6

C2® Load Point Connection

Cable color Code for C2 Lo ad Points (left to right facing the rea r pa nel):

Step 1. Remove the factory installed jumpers from the terminal block

• Shield Ground W i re

•C2- Violet

•C2+ Grey

• EXC- Black

•SEN- Brown

• SIG- White

• SIG+ Green

•SEN+ Blue

•EXC+ Red

if you are connecting an 8 wire cable from the junction box.

(See Fig. 8)

WARNING:

INCORRECT TYPE IT MAY CAUSE AN EXPLOSION WHICH WILL

CAUSE PROPERTY DAMAGE OR PERSONAL INJURY.

IF A LITHIUM BATTERY IS REPLACED WITH AN

AC Input Power Wiring (-AC)

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 240 VAC.

WARNING: I

ON THE AC INPUT WIRES, THE DISCONNECT MUST ACT ON

BOTH THE LINE AND NEUTRAL WIRES IN A DOUBLE POLE, DOU-

BLE THROW ARRANGEMENT I.E. DPDT RELAY. USING OTHER

AUTOMATIC DISCONNECT ARRANGEMENTS MAY CAUSE PER-

SONAL INJURY AND/OR PROPERTY DAMAGE.

Step 1. The HI 4060 is configur ed with a univ ersal power suppl y rated

Step 2. Make sure the VAC power is shut off before installing the

Step 3. Install a 3-wire, minimum 14 AWG power line to the 3 -pin ter-

F AN AUTOMATIC DISCONNECT DEVICE IS USED

• The AC power should be supplied by a “clean” primary line, directly from the power panel. This line

should not supply any other equipment, including

the feeding unit, and shou ld be sup pli ed with a min i

mum 10 amp breaker.

• AC Power Input (See Fig. 7)

Neu (Low)

Line (HI)

Earth Ground

from 11 0 to 24 0 VA C .

wires to the connector.

minal block connector.

-

Page 18

DC Power Input (-DC)

Rat e

Rat e

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 24 VDC.

• Use the HI 4060 Rate Controller User Guide for

Configuration, Operation and Troublesh ooting

instructions.

CAUTION: Y

SUPPLY (CLASS 2) ON THE DC INPUT WIRING.

OU MUST USE A POWER LIMITED DC POWER

• The DC power sh ould be s upplied by a “clean” pri mary li ne,

directly from the DC power source.

Step 1. Make sure the VDC power is shut off before installing the

wires to the connector.

Step 2. Connect the 24 VDC Voltage wire, Ground wire and Shield

wire to the connector that plugs into the DC voltage header at

the rear panel. Make sure that the shiel d is connected to the

local Earth Ground connectio n.

Step 3. Plug the connector into the header at the rear panel. (See Fig.

7)

Step 4. Apply VDC power to the unit.

STARTING THE HI 4060

Step 1. Connect the power connector (AC or DC) to the HI 4060.

Step 2. The Instrument boots up to the Summary Display. (See Fig. 9)

FIG. 7 SUMMARY DISPLAY

Step 3. Press the Enter but ton to go to t he Config uration menus. (See

Fig. 8)

FIG. 8 CONFIGURATION DISPLAY

9440 Carroll Park Drive Suite 150, San Diego, CA 92121

Telepho ne: 1-800-821-5831 FAX: (858) 278-6700

Web Address: http://www.hardyinstruments.com

Hardy Instruments D ocument Number: 0596 - 0308-01 Rev. B

Copyright June 2008, Dynamic Instruments, All Rights Reserved. Printed in

the U.S.A.

Page 19

QUICK INSTALLATION GUIDE

4.05

3.200

3.000

2.590

1.274

.41

.205

.44

.475

.755

5.250

7.08

MECHANICAL INSTALLATION

Installing the HI 4060 Rate Controller in a Panel

6.200

.172 THRU, 9 PL

INSTRUMENT

BEZEL OUTLINE

3.100

1.25 THRU

FIG. 1 PANEL HOLE DIMENSIONS

Step 1. Make sure that all Electrostatic Discharge (ESD) precautions

are taken before and during installatio n.

Step 2. Use the attached template to make the hole pattern in the panel

door or cover. (See Attached)

Step 8. Thread the four (4) 6-32 thumb screws onto the threaded rods

until tight. Do not use pliers on the thumb screws.

DIN Rail Installation HI 4060 Rate Controller

Step 1. Snap the DIN rail mounting feet into any of the two holes on

the front panel of the electronic en closure. (See Figs. 5 & 6)

FIG. 3 DIN RAIL MOUNTING FOOT

FIG. 2 PANEL MOUNT INSTALLATION

Step 3. Use a phillips head screwdriver and install the five (5) 6-32 x

1/2 inch screws that fasten the bezel to the pane l. (See Fig . 3)

Use a torque screw driver and torque each screw to 10 inch/

pounds. DO NOT OVERTIGHTEN!

Step 4. Thread the four (4) threaded rods through the approp ria te

holes in the panel and into the bezel. For t he retr ofit y ou don’t

have to place the rods through the holes. (See Fig. 4)

Step 5. Hand tighten each rod un til you ca n no lon ger turn th e rod. Do

not force the rods or use pliers of any kind.

Step 6. Put the Display cable and connector th rou gh th e 1 in c h hole in

the panel door or c ove r and plug the d isp lay c onn ecto r into the

Step 7. Gently slide the electronic enclosu r e onto the threaded rods

display header in the beze l. (See Fig. 3)

while making sure the display cable glides easily into the

enclosure and does not kink. Move the electronic enclosure

toward the panel until it stops. (See Fig. 3)

FIG. 4 VERTICAL AND HORIZONTAL ORIENTATION

Step 2. When installing firm ly pu sh the mou nting feet u ntil y ou hear a

snapping sound. The snap mean s they are mounted correctly.

Step 3. After installation give each mounting foot a little tug to make

sure they are seated correctly.

NOTE: There are several horizontal and vertical mounting

options. It is highly recommended that at least two

mounting feet be used per enclosur e.

Step 4. To mount the en closure onto a DIN rail. Place the moun ting

feet on the DIN Rail and firmly press down un til the mo unting

feet snap onto the rail.

Page 20

Step 5. To remove the mo unting feet use a finger on the clip and gen-

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

tly pull up on the tab.

NOTE: For Remote Display installation please see Chapter 3,

Installation, of the HI 4060 User’s Guide.

LOAD POINT INSTALLATION

FIG. 5 REAR PANEL

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Pr t. # 6020-0001) wires to the Channel terminal

block according to the cabl e color chart.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

Step 4. For more information concerning C2 Lo ad Point connection,

consult the HI 4060 User Gui de.

Non-C2 Load Point Connection

NOTE: Cable Color Codes vary between vendors, check with your

supplier for the Color Code f or your Non -C2 load point . Do

not connect wires to the -C2 and +C2.

Step 1. Remove the factory installed jumper from the terminal block if

you have 6 wire load cell cable that i ncl udes sense wires from

the load cell or junction box.

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Prt. # 6020-0001) wires to the Channel 1 terminal

block according to the Non-C2 cable color chart, or pe r manu

facturers specification.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

INPUT POWER WIRING

WARNING: DO NOT PLUG THE POWER CONNECTOR INTO THE

HEADER WITH LIVE POWER. T O DO SO WILL RESULT IN PROP-

ERTY DAMAGE AND/OR PERSONAL INJURY.

-

FIG. 6

C2® Load Point Connection

Cable color Code for C2 Lo ad Points (left to right facing the rea r pa nel):

Step 1. Remove the factory installed jumpers from the terminal block

• Shield Ground W i re

•C2- Violet

•C2+ Grey

• EXC- Black

•SEN- Brown

• SIG- White

• SIG+ Green

•SEN+ Blue

•EXC+ Red

if you are connecting an 8 wire cable from the junction box.

(See Fig. 8)

WARNING:

INCORRECT TYPE IT MAY CAUSE AN EXPLOSION WHICH WILL

CAUSE PROPERTY DAMAGE OR PERSONAL INJURY.

IF A LITHIUM BATTERY IS REPLACED WITH AN

AC Input Power Wiring (-AC)

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 240 VAC.

WARNING: I

ON THE AC INPUT WIRES, THE DISCONNECT MUST ACT ON

BOTH THE LINE AND NEUTRAL WIRES IN A DOUBLE POLE, DOU-

BLE THROW ARRANGEMENT I.E. DPDT RELAY. USING OTHER

AUTOMATIC DISCONNECT ARRANGEMENTS MAY CAUSE PER-

SONAL INJURY AND/OR PROPERTY DAMAGE.

Step 1. The HI 4060 is configur ed with a univ ersal power suppl y rated

Step 2. Make sure the VAC power is shut off before installing the

Step 3. Install a 3-wire, minimum 14 AWG power line to the 3 -pin ter-

F AN AUTOMATIC DISCONNECT DEVICE IS USED

• The AC power should be supplied by a “clean” primary line, directly from the power panel. This line

should not supply any other equipment, including

the feeding unit, and shou ld be sup pli ed with a min i

mum 10 amp breaker.

• AC Power Input (See Fig. 7)

Neu (Low)

Line (HI)

Earth Ground

from 11 0 to 24 0 VA C .

wires to the connector.

minal block connector.

-

Page 21

DC Power Input (-DC)

Rat e

Rat e

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 24 VDC.

• Use the HI 4060 Rate Controller User Guide for

Configuration, Operation and Troublesh ooting

instructions.

CAUTION: Y

SUPPLY (CLASS 2) ON THE DC INPUT WIRING.

OU MUST USE A POWER LIMITED DC POWER

• The DC power sh ould be s upplied by a “clean” pri mary li ne,

directly from the DC power source.

Step 1. Make sure the VDC power is shut off before installing the

wires to the connector.

Step 2. Connect the 24 VDC Voltage wire, Ground wire and Shield

wire to the connector that plugs into the DC voltage header at

the rear panel. Make sure that the shiel d is connected to the

local Earth Ground connectio n.

Step 3. Plug the connector into the header at the rear panel. (See Fig.

7)

Step 4. Apply VDC power to the unit.

STARTING THE HI 4060

Step 1. Connect the power connector (AC or DC) to the HI 4060.

Step 2. The Instrument boots up to the Summary Display. (See Fig. 9)

FIG. 7 SUMMARY DISPLAY

Step 3. Press the Enter but ton to go to t he Config uration menus. (See

Fig. 8)

FIG. 8 CONFIGURATION DISPLAY

9440 Carroll Park Drive Suite 150, San Diego, CA 92121

Telepho ne: 1-800-821-5831 FAX: (858) 278-6700

Web Address: http://www.hardyinstruments.com

Hardy Instruments D ocument Number: 0596 - 0308-01 Rev. B

Copyright June 2008, Dynamic Instruments, All Rights Reserved. Printed in

the U.S.A.

Page 22

QUICK INSTALLATION GUIDE

4.05

3.200

3.000

2.590

1.274

.41

.205

.44

.475

.755

5.250

7.08

MECHANICAL INSTALLATION

Installing the HI 4060 Rate Controller in a Panel

6.200

.172 THRU, 9 PL

INSTRUMENT

BEZEL OUTLINE

3.100

1.25 THRU

FIG. 1 PANEL HOLE DIMENSIONS

Step 1. Make sure that all Electrostatic Discharge (ESD) precautions

are taken before and during installatio n.

Step 2. Use the attached template to make the hole pattern in the panel

door or cover. (See Attached)

Step 8. Thread the four (4) 6-32 thumb screws onto the threaded rods

until tight. Do not use pliers on the thumb screws.

DIN Rail Installation HI 4060 Rate Controller

Step 1. Snap the DIN rail mounting feet into any of the two holes on

the front panel of the electronic en closure. (See Figs. 5 & 6)

FIG. 3 DIN RAIL MOUNTING FOOT

FIG. 2 PANEL MOUNT INSTALLATION

Step 3. Use a phillips head screwdriver and install the five (5) 6-32 x

1/2 inch screws that fasten the bezel to the pane l. (See Fig . 3)

Use a torque screw driver and torque each screw to 10 inch/

pounds. DO NOT OVERTIGHTEN!

Step 4. Thread the four (4) threaded rods through the approp ria te

holes in the panel and into the bezel. For t he retr ofit y ou don’t

have to place the rods through the holes. (See Fig. 4)

Step 5. Hand tighten each rod un til you ca n no lon ger turn th e rod. Do

not force the rods or use pliers of any kind.

Step 6. Put the Display cable and connector th rou gh th e 1 in c h hole in

the panel door or c ove r and plug the d isp lay c onn ecto r into the

Step 7. Gently slide the electronic enclosu r e onto the threaded rods

display header in the beze l. (See Fig. 3)

while making sure the display cable glides easily into the

enclosure and does not kink. Move the electronic enclosure

toward the panel until it stops. (See Fig. 3)

FIG. 4 VERTICAL AND HORIZONTAL ORIENTATION

Step 2. When installing firm ly pu sh the mou nting feet u ntil y ou hear a

snapping sound. The snap mean s they are mounted correctly.

Step 3. After installation give each mounting foot a little tug to make

sure they are seated correctly.

NOTE: There are several horizontal and vertical mounting

options. It is highly recommended that at least two

mounting feet be used per enclosur e.

Step 4. To mount the en closure onto a DIN rail. Place the moun ting

feet on the DIN Rail and firmly press down un til the mo unting

feet snap onto the rail.

Page 23

Step 5. To remove the mo unting feet use a finger on the clip and gen-

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

tly pull up on the tab.

NOTE: For Remote Display installation please see Chapter 3,

Installation, of the HI 4060 User’s Guide.

LOAD POINT INSTALLATION

FIG. 5 REAR PANEL

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Pr t. # 6020-0001) wires to the Channel terminal

block according to the cabl e color chart.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

Step 4. For more information concerning C2 Lo ad Point connection,

consult the HI 4060 User Gui de.

Non-C2 Load Point Connection

NOTE: Cable Color Codes vary between vendors, check with your

supplier for the Color Code f or your Non -C2 load point . Do

not connect wires to the -C2 and +C2.

Step 1. Remove the factory installed jumper from the terminal block if

you have 6 wire load cell cable that i ncl udes sense wires from

the load cell or junction box.

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Prt. # 6020-0001) wires to the Channel 1 terminal

block according to the Non-C2 cable color chart, or pe r manu

facturers specification.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

INPUT POWER WIRING

WARNING: DO NOT PLUG THE POWER CONNECTOR INTO THE

HEADER WITH LIVE POWER. T O DO SO WILL RESULT IN PROP-

ERTY DAMAGE AND/OR PERSONAL INJURY.

-

FIG. 6

C2® Load Point Connection

Cable color Code for C2 Lo ad Points (left to right facing the rea r pa nel):

Step 1. Remove the factory installed jumpers from the terminal block

• Shield Ground W i re

•C2- Violet

•C2+ Grey

• EXC- Black

•SEN- Brown

• SIG- White

• SIG+ Green

•SEN+ Blue

•EXC+ Red

if you are connecting an 8 wire cable from the junction box.

(See Fig. 8)

WARNING:

INCORRECT TYPE IT MAY CAUSE AN EXPLOSION WHICH WILL

CAUSE PROPERTY DAMAGE OR PERSONAL INJURY.

IF A LITHIUM BATTERY IS REPLACED WITH AN

AC Input Power Wiring (-AC)

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 240 VAC.

WARNING: I

ON THE AC INPUT WIRES, THE DISCONNECT MUST ACT ON

BOTH THE LINE AND NEUTRAL WIRES IN A DOUBLE POLE, DOU-

BLE THROW ARRANGEMENT I.E. DPDT RELAY. USING OTHER

AUTOMATIC DISCONNECT ARRANGEMENTS MAY CAUSE PER-

SONAL INJURY AND/OR PROPERTY DAMAGE.

Step 1. The HI 4060 is configur ed with a univ ersal power suppl y rated

Step 2. Make sure the VAC power is shut off before installing the

Step 3. Install a 3-wire, minimum 14 AWG power line to the 3 -pin ter-

F AN AUTOMATIC DISCONNECT DEVICE IS USED

• The AC power should be supplied by a “clean” primary line, directly from the power panel. This line

should not supply any other equipment, including

the feeding unit, and shou ld be sup pli ed with a min i

mum 10 amp breaker.

• AC Power Input (See Fig. 7)

Neu (Low)

Line (HI)

Earth Ground

from 11 0 to 24 0 VA C .

wires to the connector.

minal block connector.

-

Page 24

DC Power Input (-DC)

Rat e

Rat e

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 24 VDC.

• Use the HI 4060 Rate Controller User Guide for

Configuration, Operation and Troublesh ooting

instructions.

CAUTION: Y

SUPPLY (CLASS 2) ON THE DC INPUT WIRING.

OU MUST USE A POWER LIMITED DC POWER

• The DC power sh ould be s upplied by a “clean” pri mary li ne,

directly from the DC power source.

Step 1. Make sure the VDC power is shut off before installing the

wires to the connector.

Step 2. Connect the 24 VDC Voltage wire, Ground wire and Shield

wire to the connector that plugs into the DC voltage header at

the rear panel. Make sure that the shiel d is connected to the

local Earth Ground connectio n.

Step 3. Plug the connector into the header at the rear panel. (See Fig.

7)

Step 4. Apply VDC power to the unit.

STARTING THE HI 4060

Step 1. Connect the power connector (AC or DC) to the HI 4060.

Step 2. The Instrument boots up to the Summary Display. (See Fig. 9)

FIG. 7 SUMMARY DISPLAY

Step 3. Press the Enter but ton to go to t he Config uration menus. (See

Fig. 8)

FIG. 8 CONFIGURATION DISPLAY

9440 Carroll Park Drive Suite 150, San Diego, CA 92121

Telepho ne: 1-800-821-5831 FAX: (858) 278-6700

Web Address: http://www.hardyinstruments.com

Hardy Instruments D ocument Number: 0596 - 0308-01 Rev. B

Copyright June 2008, Dynamic Instruments, All Rights Reserved. Printed in

the U.S.A.

Page 25

QUICK INSTALLATION GUIDE

4.05

3.200

3.000

2.590

1.274

.41

.205

.44

.475

.755

5.250

7.08

MECHANICAL INSTALLATION

Installing the HI 4060 Rate Controller in a Panel

6.200

.172 THRU, 9 PL

INSTRUMENT

BEZEL OUTLINE

3.100

1.25 THRU

FIG. 1 PANEL HOLE DIMENSIONS

Step 1. Make sure that all Electrostatic Discharge (ESD) precautions

are taken before and during installatio n.

Step 2. Use the attached template to make the hole pattern in the panel

door or cover. (See Attached)

Step 8. Thread the four (4) 6-32 thumb screws onto the threaded rods

until tight. Do not use pliers on the thumb screws.

DIN Rail Installation HI 4060 Rate Controller

Step 1. Snap the DIN rail mounting feet into any of the two holes on

the front panel of the electronic en closure. (See Figs. 5 & 6)

FIG. 3 DIN RAIL MOUNTING FOOT

FIG. 2 PANEL MOUNT INSTALLATION

Step 3. Use a phillips head screwdriver and install the five (5) 6-32 x

1/2 inch screws that fasten the bezel to the pane l. (See Fig . 3)

Use a torque screw driver and torque each screw to 10 inch/

pounds. DO NOT OVERTIGHTEN!

Step 4. Thread the four (4) threaded rods through the approp ria te

holes in the panel and into the bezel. For t he retr ofit y ou don’t

have to place the rods through the holes. (See Fig. 4)

Step 5. Hand tighten each rod un til you ca n no lon ger turn th e rod. Do

not force the rods or use pliers of any kind.

Step 6. Put the Display cable and connector th rou gh th e 1 in c h hole in

the panel door or c ove r and plug the d isp lay c onn ecto r into the

Step 7. Gently slide the electronic enclosu r e onto the threaded rods

display header in the beze l. (See Fig. 3)

while making sure the display cable glides easily into the

enclosure and does not kink. Move the electronic enclosure

toward the panel until it stops. (See Fig. 3)

FIG. 4 VERTICAL AND HORIZONTAL ORIENTATION

Step 2. When installing firm ly pu sh the mou nting feet u ntil y ou hear a

snapping sound. The snap mean s they are mounted correctly.

Step 3. After installation give each mounting foot a little tug to make

sure they are seated correctly.

NOTE: There are several horizontal and vertical mounting

options. It is highly recommended that at least two

mounting feet be used per enclosur e.

Step 4. To mount the en closure onto a DIN rail. Place the moun ting

feet on the DIN Rail and firmly press down un til the mo unting

feet snap onto the rail.

Page 26

Step 5. To remove the mo unting feet use a finger on the clip and gen-

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

Relay Outputs

Analog Inputs

Digital Inputs

Control

Output

tly pull up on the tab.

NOTE: For Remote Display installation please see Chapter 3,

Installation, of the HI 4060 User’s Guide.

LOAD POINT INSTALLATION

FIG. 5 REAR PANEL

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Pr t. # 6020-0001) wires to the Channel terminal

block according to the cabl e color chart.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

Step 4. For more information concerning C2 Lo ad Point connection,

consult the HI 4060 User Gui de.

Non-C2 Load Point Connection

NOTE: Cable Color Codes vary between vendors, check with your

supplier for the Color Code f or your Non -C2 load point . Do

not connect wires to the -C2 and +C2.

Step 1. Remove the factory installed jumper from the terminal block if

you have 6 wire load cell cable that i ncl udes sense wires from

the load cell or junction box.

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Prt. # 6020-0001) wires to the Channel 1 terminal

block according to the Non-C2 cable color chart, or pe r manu

facturers specification.

Step 3. Plug the terminal block into the Channel connector on the rear

panel.

INPUT POWER WIRING

WARNING: DO NOT PLUG THE POWER CONNECTOR INTO THE

HEADER WITH LIVE POWER. T O DO SO WILL RESULT IN PROP-

ERTY DAMAGE AND/OR PERSONAL INJURY.

-

FIG. 6

C2® Load Point Connection

Cable color Code for C2 Lo ad Points (left to right facing the rea r pa nel):

Step 1. Remove the factory installed jumpers from the terminal block

• Shield Ground W i re

•C2- Violet

•C2+ Grey

• EXC- Black

•SEN- Brown

• SIG- White

• SIG+ Green

•SEN+ Blue

•EXC+ Red

if you are connecting an 8 wire cable from the junction box.

(See Fig. 8)

WARNING:

INCORRECT TYPE IT MAY CAUSE AN EXPLOSION WHICH WILL

CAUSE PROPERTY DAMAGE OR PERSONAL INJURY.

IF A LITHIUM BATTERY IS REPLACED WITH AN

AC Input Power Wiring (-AC)

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 240 VAC.

WARNING: I

ON THE AC INPUT WIRES, THE DISCONNECT MUST ACT ON

BOTH THE LINE AND NEUTRAL WIRES IN A DOUBLE POLE, DOU-

BLE THROW ARRANGEMENT I.E. DPDT RELAY. USING OTHER

AUTOMATIC DISCONNECT ARRANGEMENTS MAY CAUSE PER-

SONAL INJURY AND/OR PROPERTY DAMAGE.

Step 1. The HI 4060 is configur ed with a univ ersal power suppl y rated

Step 2. Make sure the VAC power is shut off before installing the

Step 3. Install a 3-wire, minimum 14 AWG power line to the 3 -pin ter-

F AN AUTOMATIC DISCONNECT DEVICE IS USED

• The AC power should be supplied by a “clean” primary line, directly from the power panel. This line

should not supply any other equipment, including

the feeding unit, and shou ld be sup pli ed with a min i

mum 10 amp breaker.

• AC Power Input (See Fig. 7)

Neu (Low)

Line (HI)

Earth Ground

from 11 0 to 24 0 VA C .

wires to the connector.

minal block connector.

-

Page 27

DC Power Input (-DC)

Rat e

Rat e

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 24 VDC.

• Use the HI 4060 Rate Controller User Guide for

Configuration, Operation and Troublesh ooting

instructions.

CAUTION: Y

SUPPLY (CLASS 2) ON THE DC INPUT WIRING.

OU MUST USE A POWER LIMITED DC POWER

• The DC power sh ould be s upplied by a “clean” pri mary li ne,

directly from the DC power source.

Step 1. Make sure the VDC power is shut off before installing the

wires to the connector.

Step 2. Connect the 24 VDC Voltage wire, Ground wire and Shield

wire to the connector that plugs into the DC voltage header at

the rear panel. Make sure that the shiel d is connected to the

local Earth Ground connectio n.

Step 3. Plug the connector into the header at the rear panel. (See Fig.

7)

Step 4. Apply VDC power to the unit.

STARTING THE HI 4060

Step 1. Connect the power connector (AC or DC) to the HI 4060.

Step 2. The Instrument boots up to the Summary Display. (See Fig. 9)

FIG. 7 SUMMARY DISPLAY

Step 3. Press the Enter but ton to go to t he Config uration menus. (See

Fig. 8)

FIG. 8 CONFIGURATION DISPLAY

9440 Carroll Park Drive Suite 150, San Diego, CA 92121

Telepho ne: 1-800-821-5831 FAX: (858) 278-6700

Web Address: http://www.hardyinstruments.com

Hardy Instruments D ocument Number: 0596 - 0308-01 Rev. B

Copyright June 2008, Dynamic Instruments, All Rights Reserved. Printed in

the U.S.A.

Loading...

Loading...