Page 1

QUICK INSTALLATION GUIDE

Mechanical Installation

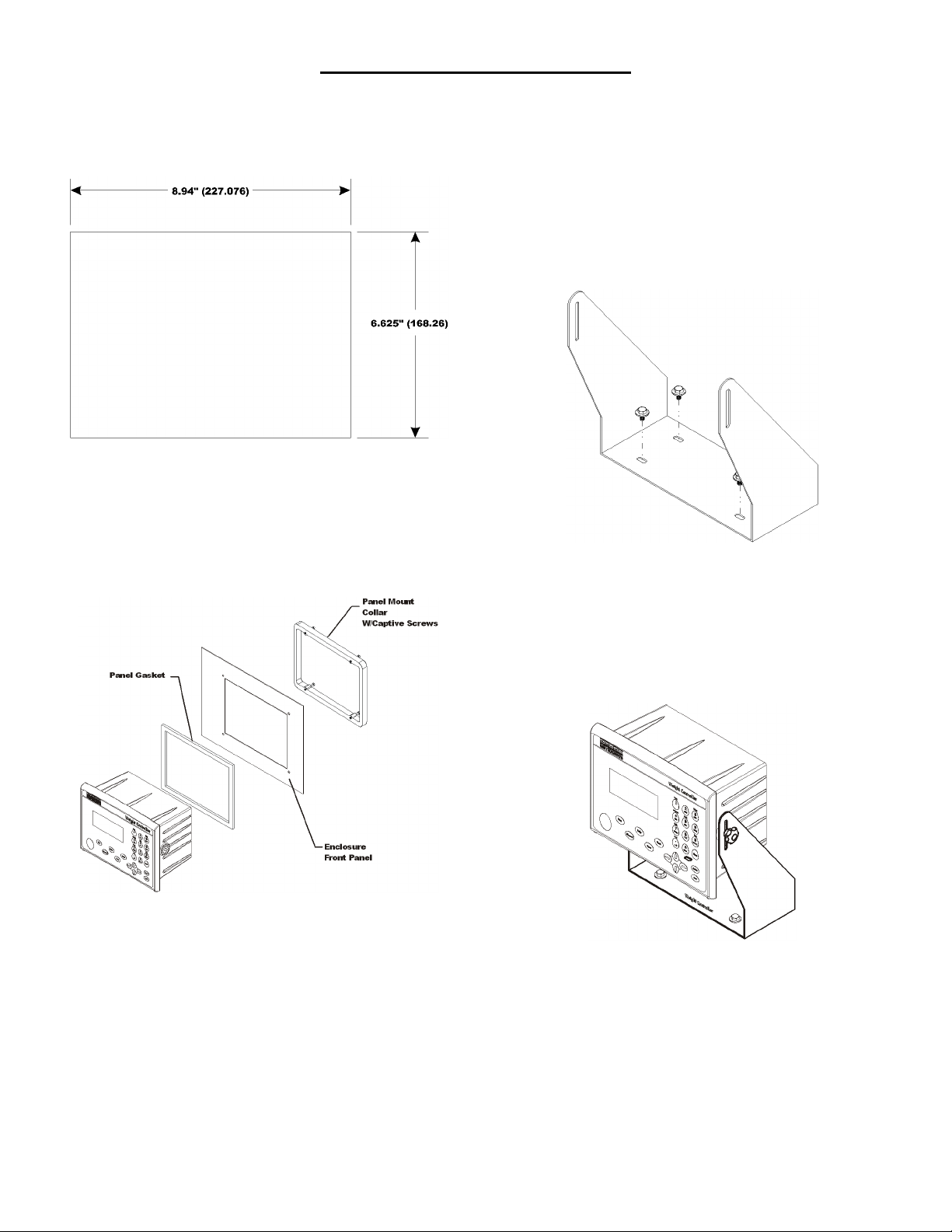

Installing the HI 3030 Weight Controller in a Panel

FIG. 1 PANEL CUTOUT DIMENSIONS

Step 1. Make sure that all Electrostatic Discharge (ESD) precautions

are taken before and during installation.

Step 2. Slide the gasket over the rear of the instrument until the gasket

is flush with the back side of the front panel. (See Fig.2)

Installing the HI 3030 Weight Controller in a Swivel/Wall

Mount

NOTE: When mounted on a wall the unit should support a

weight of 14 lbs for one minute without coming loose

or damaging the equipment or fasteners.

Step 1. Use four (4) 1/4 x 20 fasteners to fasten the swivel mount to a

horizontal surface. (See Fig. 3)

FIG. 3 INSTALLING THE SWIVEL MOUNT TO A HORIZON-

TAL SURFACE

FIG. 2 PANEL MOUNT INSTALLATION

Step 3. Gently slide the Weight Controller with the gasket into the cut-

out in the enclosure front panel or door until the gasket is flush

with the enclosure front panel. (See Fig. 3-4) Be sure to secure

the instrument with both hands when installing.

Step 4. Gently slide the Panel Mount Collar over the rear of the instru-

ment. (See Fig. 2)

Step 5. Push the captive screws through the holes in the Enclosure

Front Panel and install the screws into the tapped holes on the

instrument until the screws are finger tight.

Step 6. Use a slotted head screwdriver and tighten each screw until the

instrument is snug against the panel. Use a torque screw driver

and torque each screw to 10 inch/pounds. DO NOT OVERTIGHTEN!

Step 2. Place the Weight Controller between the Swivel Mount brack-

ets so that the threaded holes in the instrument are aligned with

the slots in the Swivel bracket. (See Fig.4)

FIG. 4 WEIGHT CONTROLLER INSTALLING IN A SWIVEL

MOUNT

Step 3. Screw the two fastener knobs into the threaded holes on each

side of the Weight Controller until the brackets are snug

against the instrument. (See Fig. 5)

Page 2

Load Point Installation

FIG. 5 REAR PANEL/4 LOAD POINT CONNECTIONS

• The AC power should be supplied by a “clean” primary line, directly from the power panel. This line

should not supply any other equipment, including

the feeding unit, and should be supplied with a minimum 10 amp breaker. (See Fig. 7)

C2® Load Point Connection

WARNING: LOAD CELL CABLE LENGTH HAS BEEN CALCU-

LATED INTO C2 CALIBRATION DATA. HARDY RECOMMENDS

THAT YOU DO NOT CUT YOUR ADVANTAGE OR ADVANTAGE

LITE LOAD SENSOR CABLE, AS YOUR C2 ACCURACY WILL BE

AFFECTED AND THE WARRANTY WILL BE VOIDED.

Cable color Code for C2 Load Points (left to right facing the rear panel):

• Shield Ground Wire

• C2- Violet

• C2+ Grey

• EXC- Black

• SEN- Brown

• SIG- White

• SIG+ Green

• SEN+ BLUE

• EXC+ RED

Step 1. Remove the factory installed jumper from the terminal block if

you are connecting an 8 wire cable from the junction box.

Step 2. Connect the cable (Recommended load cell cable: Hardy

Instruments Prt. # 6020-0001) wires to the Channel terminal

block according to the cable color chart.

Step 3. Plug the terminal block into the Channel connector on the rear panel.

Step 4. For more information concerning C2 Load Point connection,

consult the HI 3000 Series Installation and Service Manual.

FIG. 6 POWER WIRING DIAGRAM

• Power Input J1

J1-1 Net (Low)

J1-2 Line (HI)

J1-3 Ground

Step 1. The HI 3000 Series instruments are configured with a univer-

sal power supply rated from 120 to 240 VAC.

Step 2. Install a 3-wire, minimum 14 AWG power line to the 3-pin ter-

minal block connector.

Step 3. The Instrument boots up to the Summary Screen which will

display 1, 2 or 4 Channels. (See Figs. 7 & 8)

FIG. 7 SUMMARY DISPLAY/2 CHANNELS

Non-C2 Load Point Connection

NOTE: Cable Color Codes vary between vendors, check with you

supplier for the Color Code for your Non-C2 load point.

Step 1. Remove the factory installed jumper from the terminal block if

you have 6 wire load cell cable that includes sense wires from

the load cell or junction box.

Step 2.

Connect the cable (Recommended load cell cable: Hardy Prt. #

6020-0001) wires to the Channel 1 terminal block according to

the Non-C2 cable color chart, or per manufacturers specification

.

Step 3. Plug the terminal block into the Channel connector on the rear panel.

AC Input Power Wiring

WARNING: DO NOT OPERATE WITH INCORRECT LINE VOLT-

AGE. TO DO SO WILL RESULT IN PROPERTY DAMAGE AND/OR

PERSONAL INJURY. MAKE SURE THAT THE POWER SOURCE

DOES NOT EXCEED 240 VAC.

NOTE: For DC Input Power Wiring See the HI 3030 Weight Con-

troller Installation and Service Manual.

FIG. 8 SUMMARY DISPLAY/4 CHANNELS

• Go to the HI 3030 Weight Controller User Guide for

operating instructions.

• Go to the HI 3030 Weight Controller Installation and

Service Manual for further Installation and Configuration Instructions.

9440 Carroll Park Drive, San Diego, CA 92121

Telephone: 1-800-821-5831 FAX: (858) 278-6700

Web Address: http://www.hardysolutions.com

Hardy Document Number: 0596-0264-01 REV E

Copyright 2011, Hardy Process Solutions. Printed in the U.S.A.

Loading...

Loading...