Page 1

HI 3000 Series

Operation and Installation Manual

Hardy Process Solutions Document Number: 0596-0258-01 Rev P

Page 2

Local Field Service

Hardy has over 200 field technicians in the U.S., and more positioned throughout the world to assist you in your support needs. We also have factory engineers who will travel to your facility anywhere in the world to help you solve

challenging applications. We're ready to support you with:

• Installation and start-up

• Routine maintenance and certification

• Plant audits and performance measurement

• Emergency troubleshooting and repair

To request Emergency Service and Troubleshooting, Start-up, Installation, Calibration, Verification or to discuss a

Maintenance Agreement please call 800-821-5831 Ext. 1757 or Emergency Service after hours (Standard Hours 6:00

AM to 6:00 PM Pacific Standard Time) and weekends

Ext. 1111.

Outside the U.S

Hardy Process Solutions has built a network of support throughout the globe. For specific field service options available in your area please contact your local sales agent or our U.S. factory at +1 858-292-2710, Ext. 1757.

Page 3

i Table of Contents

Table of Contents

Table of Contents - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - i

Table of Illustrations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - I

Communications Installation & Operation - - - - - - - - - - - - - - - - - - - - - - - - - - 1

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

DeviceNet™ - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

Hardy Control-Link TCP/IP (Ethernet) - - - - - - - - - - - - - - - - - - 1

PRS-232 Simplex Serial Port - - - - - - - - - - - - - - - - - - - - - - 1

Communication Option Cards - - - - - - - - - - - - - - - - - - - - - - - - 1

Remote I/O - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

ControlNet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

Profibus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

MOD-Bus/TPC/IP - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

OPC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

EtherNet/IP™ - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3

Allen-Bradley Remote I/O - - - - - - - - - - - - - - - - - - - - - - - - 3

Allen-Bradley License - - - - - - - - - - - - - - - - - - - - - - - - 3

Common Applications - - - - - - - - - - - - - - - - - - - - - - - - 3

Monitoring Weighing Parameters - - - - - - - - - - - - - - - - - - 4

Short Glossary of Terms - - - - - - - - - - - - - - - - - - - - - - - 4

Tare Value - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Remote I/O Board Cable Termination Dip Switch Configuration - - - - - - 4

About Cable Termination - - - - - - - - - - - - - - - - - - - - - - 4

Dip Switch Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Installing the RIO Option Board - - - - - - - - - - - - - - - - - - - - - 4

Connector Pin Out - - - - - - - - - - - - - - - - - - - - - - - - - - 5

LED Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

Removing the Remote I/O Option Card - - - - - - - - - - - - - - - - - - - - 5

Remote I/O Configuration Procedures from the Front Panel - - - - - - - 5

Remote I/O Configuration Procedures from the Web Page - - - - - - - - 7

Discrete Remote I/O Mapping - - - - - - - - - - - - - - - - - - - - - - 9

About Discrete Remote I/O Mapping - - - - - - - - - - - - - - - - - 9

General Information - - - - - - - - - - - - - - - - - - - - - - - - - 9

For Reads: - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

Mapping - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 10

Cabling Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

General Introduction to Cabling - - - - - - - - - - - - - - - - - - - - - - - 11

Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Input Power Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Digital Input Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

Output Relay Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

Load Point Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

-JB Option Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 13

Ethernet Cable Connection and Setup - - - - - - - - - - - - - - - - - - - - 13

DeviceNet Connection and Setup From the Front Panel - - - - - - - - - - - 16

®

C2

Load Point Connection - - - - - - - - - - - - - - - - - - - - - - - 12

Non-C2 Load Cell Connection - - - - - - - - - - - - - - - - - - - - - - 12

RS 232 Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - 12

RS 232 Connection Pinout - - - - - - - - - - - - - - - - - - - - - - 13

Setting the IP Address for the Blind Remote - - - - - - - - - - - - - - - 15

Setting or Changing the IP Address using the Ethernet - - - - - - - - 15

For HI 3010 Only - - - - - - - - - - - - - - - - - - - - - - - - - - 16

For HI 3030, HI 3600, HI 3300 - - - - - - - - - - - - - - - - - - - - 17

Page 4

HI 3000 Series ii

User Guide

ControlNet Option Card Installation - - - - - - - - - - - - - - - - - - - - - - 18

Removing the ControlNet Option Card - - - - - - - - - - - - - - - - - - - - 19

ControlNet Connection and Setup - - - - - - - - - - - - - - - - - - - - - - 19

Hardware Requirements: - - - - - - - - - - - - - - - - - - - - - - - - 19

Software Requirements: - - - - - - - - - - - - - - - - - - - - - - - - - 19

Setting the ControlNet Node Address from the Front Panel - - - - - - - - 20

Activating ControlNet and Setting the ControlNet Node Address

from the Web Page - - - - - - - - - - - - - - - - - - - - - - - - - - - 20

LED Status Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - 22

EtherNet/IP™ Option Card Installation - - - - - - - - - - - - - - - - - - - - 22

Removing the EtherNet/IP Option Card - - - - - - - - - - - - - - - - - - - - 23

Setting Up the EtherNet I/P Address from the Front Panel - - - - - - - - 23

Setting Up the EtherNet I/P Address from the Web Page - - - - - - - - - 24

LED Status Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - 25

LED 1 - Link (Activity) - - - - - - - - - - - - - - - - - - - - - - - - 25

LED 2 - Module Status - - - - - - - - - - - - - - - - - - - - - - - - 25

LED 3 - Network Status - - - - - - - - - - - - - - - - - - - - - - - 26

LED 4 - Activity - - - - - - - - - - - - - - - - - - - - - - - - - - - 26

Profibus Option Card Installation - - - - - - - - - - - - - - - - - - - - - - - 26

Profibus Connection and Setup - - - - - - - - - - - - - - - - - - - - - - - 26

Hardware Requirements: - - - - - - - - - - - - - - - - - - - - - - - - 26

Software Requirements: - - - - - - - - - - - - - - - - - - - - - - - - - 26

Cabling Guidelines - - - - - - - - - - - - - - - - - - - - - - - - - 26

Cable Specification - - - - - - - - - - - - - - - - - - - - - - - - - 27

LED Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 28

Removing the Profibus Option Card - - - - - - - - - - - - - - - - - - - - - 28

Analog Output Option Card Installation - - - - - - - - - - - - - - - - - - - - 28

Electrical Connection - - - - - - - - - - - - - - - - - - - - - - - - - - 29

Removing the Analog Option Card - - - - - - - - - - - - - - - - - - - - - - 29

Rear Cover Installation (HI 3000-RC) - - - - - - - - - - - - - - - - - - - - - 29

Removing the NEMA 4 Plug - - - - - - - - - - - - - - - - - - - - - - - 30

Installing the NEMA 4 Plug - - - - - - - - - - - - - - - - - - - - - - - - 30

Installing the Cord Grip Assemblies - - - - - - - - - - - - - - - - - - - 30

Removing the Cord Grip Assembly - - - - - - - - - - - - - - - - - - - - 32

Installing the HI 3000-RC Rear Cover - - - - - - - - - - - - - - - - - - - - 32

Network Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

About Networks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

Simple Ethernet Network - - - - - - - - - - - - - - - - - - - - - - - - - - 35

Materials Required - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

Hardy Control-Link Ethernet Network - - - - - - - - - - - - - - - - - - - - - 37

Materials Required - - - - - - - - - - - - - - - - - - - - - - - - - 37

Setting Node Addresses for HI 3000 Series Instruments from the Browser 38

Using the Ping Tool - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

DeviceNet Network Setup - - - - - - - - - - - - - - - - - - - - - - - - - - 41

RSNetWorx Setup for HI 3000 Series Instruments - - - - - - - - - - - - 41

Slave Mode Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 43

Building a Scanlist in RSNetWorx - - - - - - - - - - - - - - - - - - - - - - 45

ControlNet Network Setup - - - - - - - - - - - - - - - - - - - - - - - - - - 46

RSNetWorx Setup for HI 3000 Series Instruments with ControlNet

Option Card - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 46

Schedule the Network Using RSNetWorx for ControlNet - - - - - - - - - 47

Verify the Network Properties - - - - - - - - - - - - - - - - - - - - 47

Survey the Network for Connected Devices - - - - - - - - - - - - - 47

Schedule the Network and Save the Configuration - - - - - - - - - - 47

Selecting the ControlNet Node Address from the Front Panel - - - - - - - 47

Selecting the ControlNet Node Address from the Web Page - - - - - - - 48

Page 5

iii Table of Contents

PROFIBUS-DP Network Setup - - - - - - - - - - - - - - - - - - - - - - - - 49

Initialization Process - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 49

Profibus-DP .GSD File - - - - - - - - - - - - - - - - - - - - - - - - - - 49

Pre-Initialization Procedures - - - - - - - - - - - - - - - - - - - - - - - 49

Initialization Procedures - - - - - - - - - - - - - - - - - - - - - - - - - 50

Selecting the Profibus Node Address from the Front Panel - - - - - - - - 52

Selecting the Profibus Node Address from the Web Page - - - - - - - - 53

MODBUS - TCP/IP Over Ethernet - - - - - - - - - - - - - - - - - - - - - - 54

About MODBUS/TCP/IP Over Ethernet - - - - - - - - - - - - - - - - - 54

Installing MODBUS - - - - - - - - - - - - - - - - - - - - - - - - - - - 55

Enabling MODBUS in the HI 3000 Module - - - - - - - - - - - - - - 55

Installing Hardy Modbus-Link - - - - - - - - - - - - - - - - - - - - 56

Using MODBUS with Excel

®

- - - - - - - - - - - - - - - - - - - - - - - 60

OPC Network Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 60

OPC SERVER - - - - - - - - - - - - - - - - - - - - - - - - - - - 61

Configuring Omniserver to Communicate with an HI 3000 Module - - 61

Setting Up OPC Communication with a Client - - - - - - - - - - - - - - 72

About OPC Clients - - - - - - - - - - - - - - - - - - - - - - - - - 72

Setting up the Output to the OPC Server and the Client from the

HI 3000 Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 77

Adding the HI 3000 Module to the Hardy Control-Link (TCP/IP) Network - 77

Mapping Parameters to the HardyFloat Output Table - - - - - - - - - - - 79

Configuring EtherNet/IP Using RSLogix5000

®

- - - - - - - - - - - - - - - - 83

Mapping - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 85

E-Mail Configuration and Operation - - - - - - - - - - - - - - - - - - - - - - - - 87

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 87

Understanding IP Addresses - - - - - - - - - - - - - - - - - - - - - - - - - 87

Glossary of E-Mail Terms - - - - - - - - - - - - - - - - - - - - - - - - - - 87

Gateway - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 87

SMTP - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 88

DNS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 88

POP - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 88

Configuring the E-Mail Server - - - - - - - - - - - - - - - - - - - - - - - - 88

Entering the Mail Server Name from the Front Panel - - - - - - - - - 89

Continuing E-Mail Configuration from the Web Page - - - - - - - - - 90

Configuring Standard E-Mail - - - - - - - - - - - - - - - - - - - - - - - 90

Configuring Custom E-Mail - - - - - - - - - - - - - - - - - - - - - - - 91

About Custom E-Mail - - - - - - - - - - - - - - - - - - - - - - - - 91

About Tokens - - - - - - - - - - - - - - - - - - - - - - - - - - - - 91

Testing E-Mail - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 94

Setting up Filters in E-mail Applications - - - - - - - - - - - - - - - - - - - 95

Security Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 97

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 97

Security Levels - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 97

Setting up Passwords from the Front Panel - - - - - - - - - - - - - - - - - 97

Setting up Passwords from the Browser - - - - - - - - - - - - - - - - - - - 98

Log On Procedures - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 99

Logging on from the Front Panel - - - - - - - - - - - - - - - - - - - - - 99

Log On from the Browser - - - - - - - - - - - - - - - - - - - - - - - - 100

Log Off Procedures from the Front Panel - - - - - - - - - - - - - - - - - 100

HI 3001 Master Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 103

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 103

Getting Started - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 103

Help - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 103

Page 6

Glossary of terms

Index

HI 3000 Series iv

User Guide

About Help - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 103

Front Panel Display - - - - - - - - - - - - - - - - - - - - - - - - - - - 103

Button Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - 103

Start Button - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 103

Stop Button - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 103

Help Button - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 103

Station Button - - - - - - - - - - - - - - - - - - - - - - - - - - - - 103

Buttons Button - - - - - - - - - - - - - - - - - - - - - - - - - - - - 104

Setup/3/DEF Button - - - - - - - - - - - - - - - - - - - - - - - - - 104

Test/9/WXYZ Button - - - - - - - - - - - - - - - - - - - - - - - - - 104

Setting the IP Address - - - - - - - - - - - - - - - - - - - - - - - - - - - - 104

Installing the HI 3001 - - - - - - - - - - - - - - - - - - - - - - - - - - - - 104

Selecting an Instrument on the Network - - - - - - - - - - - - - - - - - - - 104

Software Downloads for HI 3000 Series - - - - - - - - - - - - - - - - - - - 104

Page 7

I Table of Illustrations

Table of Illustrations

Communications Installation & Operation - - - - - - - - - - - - - - - - - - - - - - - - - - 1

FIG. 1 CONTROLNET ARCHITECTURE - - - - - - - - - - - - - - - - - 2

FIG. 2 ETHERNET/IP™ NETWORK - - - - - - - - - - - - - - - - - - - - 3

FIG. 3 TERMINATING SWITCH FOR TERMINATING LAST MODULE - - - 4

FIG. 4 REMOTE I/O OPTION CARD - - - - - - - - - - - - - - - - - - - 4

FIG. 5 REMOTE I/O/SLIDE INTO OPTION SLOT #0 - - - - - - - - - - - - 5

FIG. 6 REMOTE I/O OPTION CARD INSTALLED - - - - - - - - - - - - - 5

FIG. 7 CONFIGURATION MENU/SELECTING SETUP - - - - - - - - - - 5

FIG. 8 CONFIGURATION MENU/SELECTING OPTIONS - - - - - - - - - 6

FIG. 9 OPTIONS/SELECTING REMOTE I/O - - - - - - - - - - - - - - - - 6

FIG. 10 REMOTE I/O MENU/SETTING PARAMETERS - - - - - - - - - - - 6

FIG. 11 REMOTE I/O/SETTING RACK SIZE - - - - - - - - - - - - - - - - 6

FIG. 12 REMOTE I/O SELECTING STARTING QUARTER - - - - - - - - - 6

FIG. 13 INSTRUMENT HOME PAGE/SELECTING CONFIGURATION - - - 7

FIG. 14 CONFIGURATION - OPTIONS PAGE/SELECTING VIEW

REMOTE I/O CONFIGURATION - - - - - - - - - - - - - - - - - - - - - - - 7

FIG. 15 REMOTE I/O CONFIGURATION PAGE - - - - - - - - - - - - - - 7

FIG. 16 REMOTE I/O CONFIGURATION/SELECTING BAUD RATE - - - - 7

FIG. 17 REMOTE I/O CONFIGURATION/SELECTING RACK SIZE - - - - - 8

FIG. 18 REMOTE I/0 CONFIGURATION/SELECTING QUARTER - - - - - - 8

FIG. 19 REMOTE I/O CONFIGURATION/SELECTING LAST QUARTER - - 8

Cabling Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 11

FIG. 20 POWER WIRING DIAGRAM - - - - - - - - - - - - - - - - - - - - 11

FIG. 21 POWER SUPPLY BOARD REAR PANEL - - - - - - - - - - - - - 11

FIG. 22 DRY CONTACT WIRING DIAGRAM - - - - - - - - - - - - - - - - 12

FIG. 23 REAR PANEL/LOAD POINT CONNECTIONS - - - - - - - - - - - 12

FIG. 24 SERIAL PORT CONNECTION - - - - - - - - - - - - - - - - - - - 13

FIG. 25 -JB OPTION CONNECTIONS - - - - - - - - - - - - - - - - - - - 13

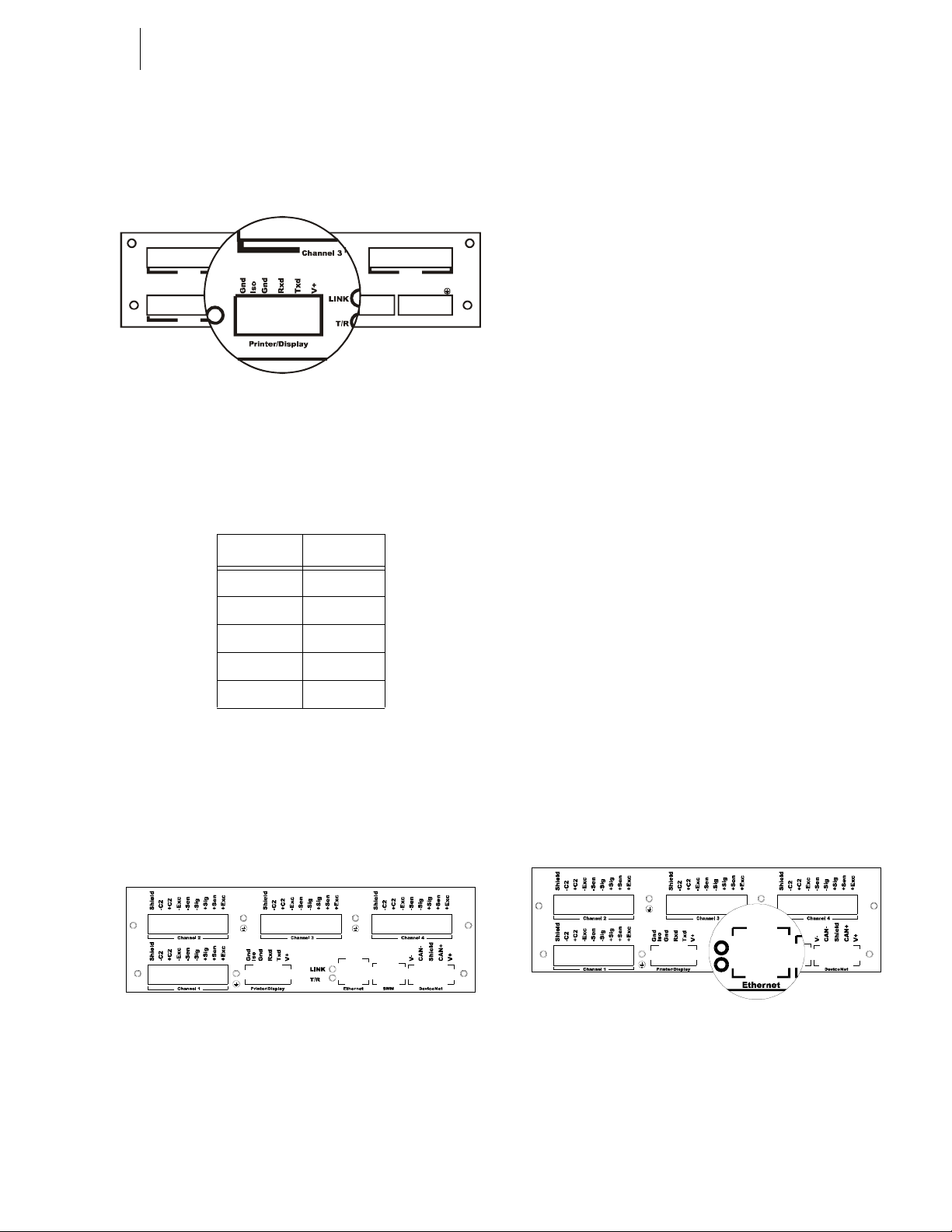

FIG. 26 REAR PANEL/ETHERNET RJ 45 CONNECTION - - - - - - - - - - 13

FIG. 27 CONFIGURATION MENU/SELECTION SETUP - - - - - - - - - - 14

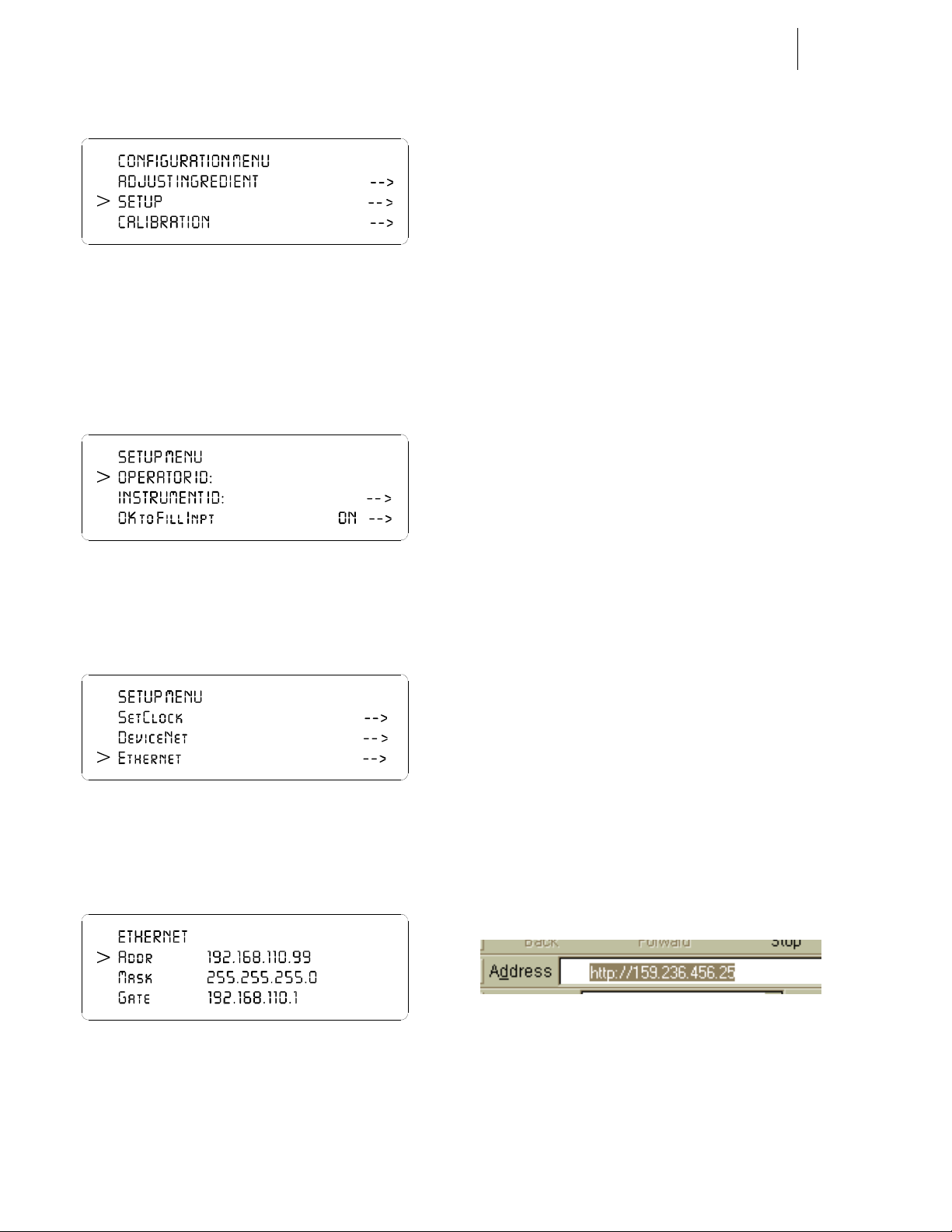

FIG. 28 SETUP MENU - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

FIG. 29 SETUP MENU/ETHERNET SUB-MENU - - - - - - - - - - - - - - 14

FIG. 30 ETHERNET MENU/DEFAULT IP ADDRESS - - - - - - - - - - - - 14

FIG. 31 ENTER IP ADDRESS IN BROWSER ADDRESS FIELD - - - - - - 14

FIG. 32 WEB PAGE - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

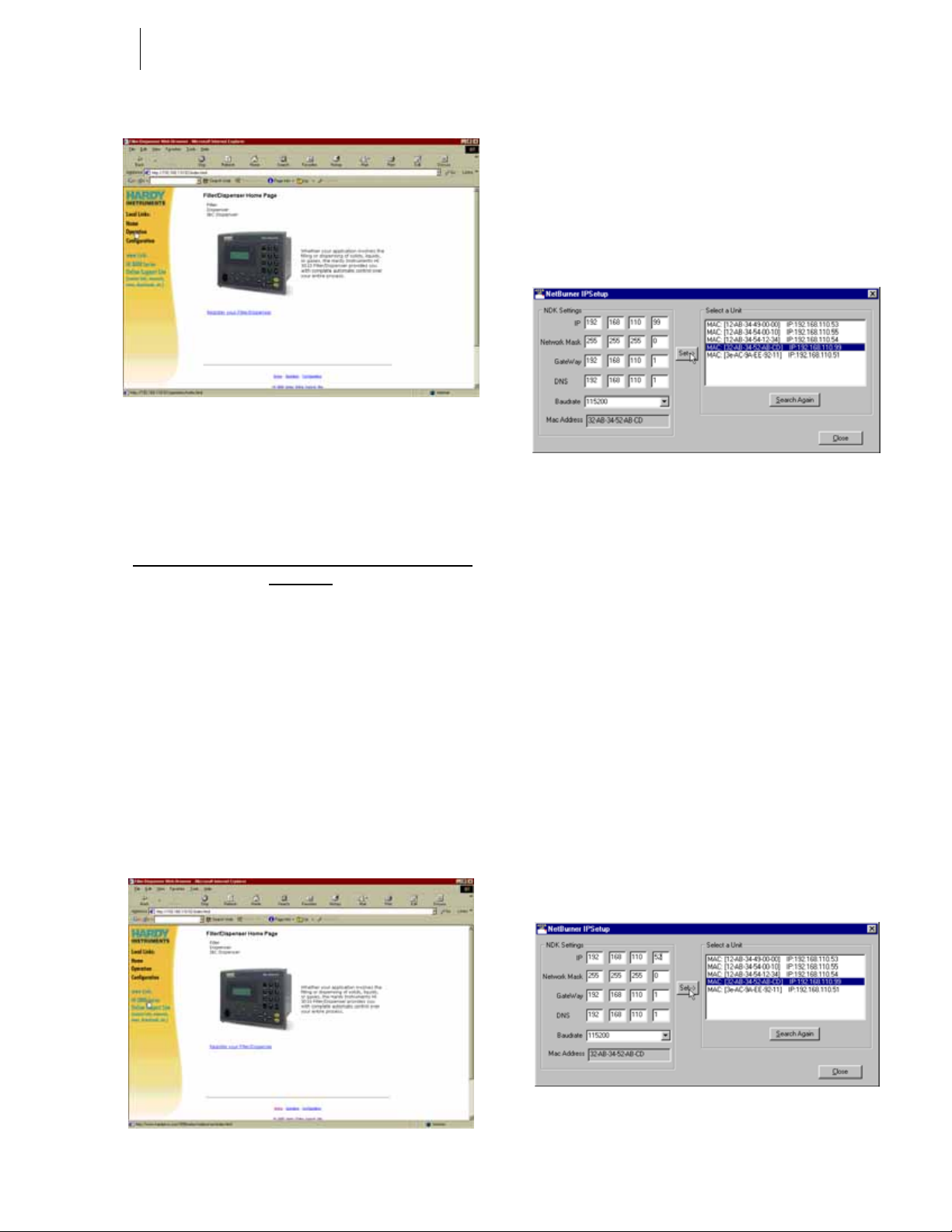

FIG. 33 INSTRUMENT WEB PAGE - - - - - - - - - - - - - - - - - - - - - 15

FIG. 34 IP SETUP MENU - - - - - - - - - - - - - - - - - - - - - - - - - 15

FIG. 35 IP SETUP/SETTING NEW ADDRESS - - - - - - - - - - - - - - - 15

FIG. 36 NEW IP ADDRESS IS RESET - - - - - - - - - - - - - - - - - - - 16

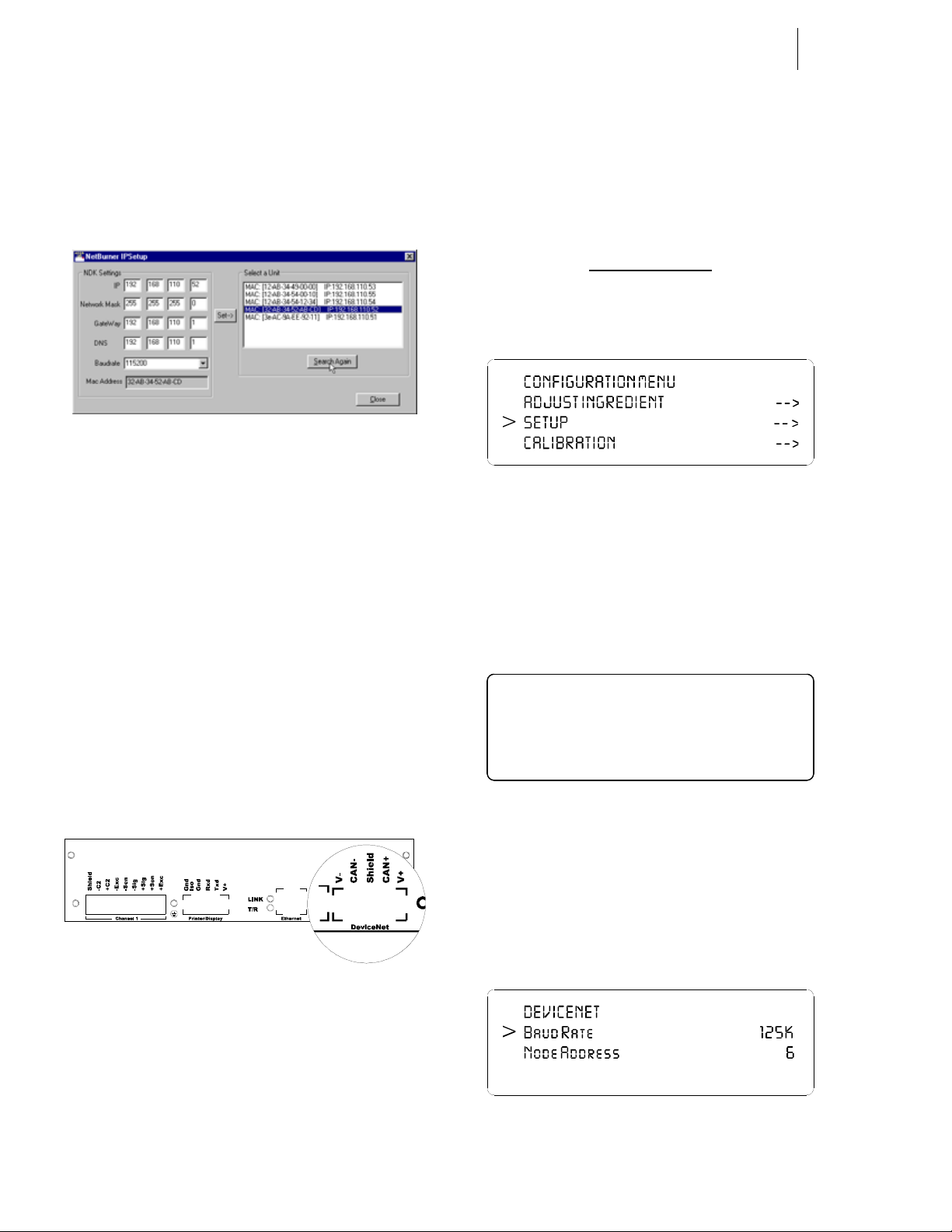

FIG. 37 REAR PANEL/DEVICENET CONNECTION - - - - - - - - - - - - 16

FIG. 38 CONFIGURATION MENU/SELECTING SETUP - - - - - - - - - - 16

FIG. 39 SETUP MENU/SELECTING DEVICENET - - - - - - - - - - - - - 16

FIG. 40 DEVICENET SUB-MENU/SETTING THE BAUD RATE - - - - - - - 16

FIG. 41 DEVICENET/SELECTING NODE ADDRESS - - - - - - - - - - - - 17

FIG. 42 CONFIGURATION MENU/SELECTING SETUP - - - - - - - - - - 17

FIG. 43 CONFIGURATION MENU - - - - - - - - - - - - - - - - - - - - - 17

FIG. 44 OPTIONS MENU/SELECTING DEVICENET I/O - - - - - - - - - - 17

FIG. 45 DEVICENET SUB-MENU/SETTING THE BAUD RATE - - - - - - - 17

FIG. 46 DEVICENET/SELECTING NODE ADDRESS - - - - - - - - - - - - 18

FIG. 47 CONTROLNET/OPTION CARD - - - - - - - - - - - - - - - - - - 18

FIG. 48 CONTROLNET/SLIDE INTO OPTION SLOT #0 - - - - - - - - - - 18

FIG. 49 CONTROLNET OPTION CARD INSTALLED - - - - - - - - - - - - 19

FIG. 50 CONTROLNET CABLE ASSEMBLIES - - - - - - - - - - - - - - - 19

FIG. 51 ROTARY SWITCHES/SETTING NODE ADDRESS TO 0, 0 - - - - - 19

Page 8

HI 3000 Series II

Operation and Installation

FIG. 52 REAR PANEL CONTROLNET CONNECTORS AND LEDS - - - - - 19

FIG. 53 CONFIGURATION MENU/SELECTING SETUP - - - - - - - - - - 20

FIG. 54 CONFIGURATION MENU/SELECTING OPTIONS - - - - - - - - - 20

FIG. 55 OPTIONS/SELECTING CONTROLNET I/O - - - - - - - - - - - - - 20

FIG. 56 CONTROLNET I/O MENU/SETTING NODE ADDRESS - - - - - - - 20

FIG. 57 HOME PAGE/SELECTING CONFIGURATION - - - - - - - - - - - 20

FIG. 58 CONFIGURATION PAGE/SELECTING OPTIONS - - - - - - - - - 21

FIG. 59 OPTIONS PAGE/SELECTING VIEW CONTROLNET

CONFIGURATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

FIG. 60 CONTROLNET PAGE/ACTIVATING CONTROLNET - - - - - - - - 21

FIG. 61 CONTROLNET CONFIGURATION PAGE/ENTERING

NODE ADDRESS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

FIG. 62 CONTROLNET CONFIGURATION/ENTERING NODE

ADDRESS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

FIG. 63 ETHERNET I/P/OPTION CARD - - - - - - - - - - - - - - - - - - 23

FIG. 64 ETHERNET/I/P/SLIDE INTO OPTION SLOT #0 - - - - - - - - - - - 23

FIG. 65 ETHERNET/IP OPTION CARD INSTALLED - - - - - - - - - - - - 23

FIG. 66 CONFIGURATION MENU/SELECTING OPTIONS - - - - - - - - - 24

FIG. 67 OPTIONS/SELECTING ETHERNET/IP I/O - - - - - - - - - - - - - 24

FIG. 68 ETHERNET/IP MENU/SETTING IP ADDRESS - - - - - - - - - - - 24

FIG. 69 HI 3000 HOME PAGE/SELECTING CONFIGURATION - - - - - - - 24

FIG. 70 CONFIGURATION PAGE/SELECTING OPTIONS - - - - - - - - - 25

FIG. 71 OPTIONS PAGE/SELECTING VIEW ETHERNET/IP

CONFIGURATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

FIG. 72 ETHERNET/IP PAGE/SETTING IP ADDRESS - - - - - - - - - - - 25

FIG. 73 CONNECTOR/DIP SWITCHES/LEDS - - - - - - - - - - - - - - - 25

FIG. 74 PROFIBUS DB9 SERIAL CONNECTOR WITH SLIDE

SWITCH/MALE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 26

FIG. 75 DB9 CONNECTOR ON THE HARDY PROFIBUS OPTION CARD - - 27

FIG. 76 ROTARY SWITCHES/SETTING NODE ADDRESS TO 0, 0 - - - - - 27

FIG. 77 LED INDICATORS - - - - - - - - - - - - - - - - - - - - - - - - - 28

FIG. 78 ANALOG OUTPUT OPTION 2AN - - - - - - - - - - - - - - - - - - 29

FIG. 79 INSTALLING THE ANALOG OPTION CARD IN A 3000 CHASSIS - 29

FIG. 80 ANALOG ELECTRICAL CONNECTIONS - - - - - - - - - - - - - - 29

FIG. 81 NEMA 4X REAR COVER - - - - - - - - - - - - - - - - - - - - - - 30

FIG. 82 INSTALLING NEMA 4 PLUG - - - - - - - - - - - - - - - - - - - - 30

FIG. 83 INSTALLING THE HEX NUT ONTO THE CORD GRIP ASSEMBLY - 30

FIG. 84 CORD GRIP INSTALLED - - - - - - - - - - - - - - - - - - - - - 31

FIG. 85 INSTALLING THE HEX NUT ONTO THE CORD GRIP ASSEMBLY - 31

FIG. 86 CORD GRIP INSTALLED - - - - - - - - - - - - - - - - - - - - - 31

FIG. 87 INSTALLING CABLES IN THE CORD GRIP ASSEMBLY - - - - - - 32

FIG. 88 ALIGNING THE REAR COVER TO THE CHASSIS - - - - - - - - - 32

FIG. 89 REAR COVER, NEMA 4 PLUGS, AND CORD GRIPS INSTALLED - 33

Network Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 35

FIG. 90 SIMPLE HARDY CONTROL-LINK NETWORK - - - - - - - - - - - 35

FIG. 91 IP ADDRESS CONFIGURATION - - - - - - - - - - - - - - - - - - 35

FIG. 92 CONTROL PANEL - - - - - - - - - - - - - - - - - - - - - - - - - 36

FIG. 93 NETWORK DIALOG BOX/SELECT TCP/IP - - - - - - - - - - - - - 36

FIG. 94 NETWORK DIALOG BOX/SELECT PROPERTIES - - - - - - - - - 37

FIG. 95 TCI/IP PROPERTIES/IP ADDRESS - - - - - - - - - - - - - - - - 37

FIG. 96 INTERNET PROPERTIES DIALOG BOX - - - - - - - - - - - - - - 37

FIG. 97 HARDY CONTROL-LINK ETHERNET NETWORK - - - - - - - - - 37

FIG. 98 FILLER/DISPENSER HOME PAGE/SELECTING

CONFIGURATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 38

FIG. 99 CONFIGURATION PAGE/SELECTING HARDY CONTROL-LINK - - 38

FIG. 100 CONFIGURATION - HARDY CONTROL-LINK PAGE - - - - - - - - 38

Page 9

III Table of Illustrations

FIG. 101 CONFIGURATION - HARDY CONTROL-LINK/INSTRUMENT

SELECTION PULL DOWN LIST - - - - - - - - - - - - - - - - - - - - - - - 39

FIG. 102 CONFIGURATION PAGE WITH INSTRUMENTS NOT

ASSIGNED A NODE ADDRESS - - - - - - - - - - - - - - - - - - - - - - - 39

FIG. 103 SELECTED INSTRUMENT WITH IP ADDRESS IN

IP ADDRESS FIELD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

FIG. 104 HI-3010 (IP ADDRESS 192.168.110.68) ASSIGNED TO NODE 0 - - 39

FIG. 105 SELECTED INSTRUMENT WITH IP ADDRESS IN IP ADDRESS

FIELD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 39

FIG. 106 HI-3010 (IP ADDRESS 192.168.110.24) ASSIGNED TO NODE 1 - - 40

FIG. 107 INSTRUMENTS ASSIGNED TO NODE 0 THROUGH NODE 7 - - - 40

FIG. 108 SAVING THE CONFIGURATION - - - - - - - - - - - - - - - - - - 40

FIG. 109 TRANSFERRING THE NODE CONFIGURATION FROM

NODE 0 TO NODE 1 - - - - - - - - - - - - - - - - - - - - - - - - - - - - 40

FIG. 110 SELECTING EDS WIZARD - - - - - - - - - - - - - - - - - - - - 41

FIG. 111 EDS WIZARD DIALOG BOX - - - - - - - - - - - - - - - - - - - - 41

FIG. 112 SELECTING “REGISTER AN EDS FILE” - - - - - - - - - - - - - - 41

FIG. 113 SELECTING THE HARDY EDS FILE - - - - - - - - - - - - - - - - 41

FIG. 114 SELECTING THE HARDY EDS FILE - - - - - - - - - - - - - - - - 42

FIG. 115 EDS FILE INSTALLATION TEST RESULTS DIALOG BOX - - - - - 42

FIG. 116 CHANGE GRAPHIC IMAGE DIALOG BOX - - - - - - - - - - - - - 42

FIG. 117 FINAL TASK SUMMARY DIALOG BOX - - - - - - - - - - - - - - 42

FIG. 118 HARDWARE/VENDOR/HARDY INSTRUMENTS INC. INSTALLED - 43

FIG. 119 GRAPH/HARDY FILLER ICON - - - - - - - - - - - - - - - - - - - 43

FIG. 120 MODULE TAB/SELECTING SLAVE MODE - - - - - - - - - - - - - 43

FIG. 121 SLAVE MODE DIALOG BOX - - - - - - - - - - - - - - - - - - - - 43

FIG. 122 INPUT PAGE/SELECTING AUTOMAP - - - - - - - - - - - - - - - 44

FIG. 123 INPUT PAGE/INPUTS MAPPED - - - - - - - - - - - - - - - - - - 44

FIG. 124 OUTPUT PAGE/SELECTING AUTOMAP - - - - - - - - - - - - - - 44

FIG. 125 OUTPUT PAGE/OUTPUTS MAPPED - - - - - - - - - - - - - - - 44

FIG. 126 GRAPH OF NETWORKED MODULES - - - - - - - - - - - - - - - 45

FIG. 127 HARDY FILLER PROPERTIES LIST - - - - - - - - - - - - - - - - 45

FIG. 128 SCANLIST PAGE/AVAILABLE DEVICES - - - - - - - - - - - - - - 45

FIG. 129 SCANLIST PAGE/SCANLIST - - - - - - - - - - - - - - - - - - - 46

FIG. 130 INPUT PAGE/CHANGE PARAMETERS - - - - - - - - - - - - - - 46

FIG. 131 CONFIGURATION MENU/SELECTING SETUP - - - - - - - - - - 47

FIG. 132 CONFIGURATION MENU/SELECTING OPTIONS - - - - - - - - - 48

FIG. 133 OPTIONS/SELECTING REMOTE I/O - - - - - - - - - - - - - - - - 48

FIG. 134 CONTROLNET I/0 MENU/SELECTING THE NODE ADDRESS - - - 48

FIG. 135 ELECTING CONFIGURATION FROM THE HOME

PAGE OF THE HI 3000 INSTRUMENT - - - - - - - - - - - - - - - - - - - 48

FIG. 136 CONFIGURATION PAGE/SELECTING OPTIONS - - - - - - - - - 48

FIG. 137 CONFIGURATION - OPTIONS/SELECTING VIEW

CONTROLNET CONFIGURATION OPTION - - - - - - - - - - - - - - - - - 49

FIG. 138 CONTROLNET CONFIGURATION PAGE/SELECTING

THE NODE ADDRESS - - - - - - - - - - - - - - - - - - - - - - - - - - - 49

FIG. 139 PROFIBUS LOGO - - - - - - - - - - - - - - - - - - - - - - - - - 49

FIG. 140 SIMPLE PROFIBUS NETWORK WITH TRUNK AND DROP LINES - 49

FIG. 141 HARDWARE CATALOG/SELECTING ANYBUS-S PDP FOLDER - - 50

FIG. 142 ANYBUS-S PDP PARAMETERS DIALOG BOX - - - - - - - - - - - 50

FIG. 143 SELECTING THE INPUT AND OUTPUT SIZE - - - - - - - - - - - 51

FIG. 144 ANYBUS-S PDP APPEARS IN THE NETWORK - - - - - - - - - - 51

FIG. 145 DOWNLOADING HI 3000 SERIES CONFIGURATION - - - - - - - 51

FIG. 146 SELECT DESTINATION MODULE DIALOG BOX - - - - - - - - - - 52

FIG. 147 SELECT STATION ADDRESS DIALOG BOX 52

FIG. 148 DOWNLOADING CONFIGURATION PROMPT - - - - - - - - - - - 52

FIG. 149 INITIALIZATION COMPLETE - - - - - - - - - - - - - - - - - - - 52

Page 10

HI 3000 Series IV

Operation and Installation

FIG. 150 CONFIGURATION MENU/SELECTING SETUP - - - - - - - - - - 52

FIG. 151 CONFIGURATION MENU/SELECTING OPTIONS - - - - - - - - - 53

FIG. 152 OPTIONS/SELECTING PROFIBUS I/0 - - - - - - - - - - - - - - - 53

FIG. 153 PROFIBUS I/0 MENU/SELECTING THE NODE ADDRESS - - - - - 53

FIG. 154 SELECTING CONFIGURATION FROM THE HOME

PAGE OF THE HI 3000 INSTRUMENT - - - - - - - - - - - - - - - - - - - 53

FIG. 155 CONFIGURATION PAGE/SELECTING OPTIONS - - - - - - - - - 53

FIG. 156 CONFIGURATION - OPTIONS/SELECTING VIEW

PROFIBUS CONFIGURATION OPTION - - - - - - - - - - - - - - - - - - - 54

FIG. 157 PROFIBUS CONFIGURATION PAGE/SELECTING THE

NODE ADDRESS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 54

FIG. 158 MODBUS COMMUNICATION DIAGRAM - - - - - - - - - - - - - - 55

FIG. 159 MACHINE MONITOR/SELECTING CONFIGURATION - - - - - - - 55

FIG. 160 CONFIGURATION/SELECTING OPTIONS - - - - - - - - - - - - - 55

FIG. 161 CONFIGURATION - OPTIONS/SELECTING MODBUS - - - - - - - 55

FIG. 162 MODBUS - OPTIONS PAGE - - - - - - - - - - - - - - - - - - - - 55

FIG. 163 MODBUS - OPTIONS/ENABLED] - - - - - - - - - - - - - - - - - 56

FIG. 164 HARDY MODBUS-LINK DISPLAY - - - - - - - - - - - - - - - - - 56

FIG. 165 HARDY MODBUS-LINK/SELECTING CONNECT - - - - - - - - - - 56

FIG. 166 TCP/IP CONNECTION DISPLAY - - - - - - - - - - - - - - - - - - 57

FIG. 167 TCP/IP CONNECTION DISPLAY/SELECTING TCP/IP - - - - - - - 57

FIG. 168 TCP/IP CONNECTION DISPLAY/ENTERING THE IP ADDRESS - - 57

FIG. 169 MAPPING DISPLAY/CLICKING ON DESTINATION SCRATCHPAD: HFO4 (HARDY FLOAT OUT - WORD 4) - - - - - - - - - - 57

FIG. 170 MAPPING DISPLAY/SELECTING DESTINATION SCRATCHPAD: HFO4 - - - - - - - - - - - - - - - - - - - - - - - - - - - - 57

FIG. 171 MAPPING DISPLAY/SELECTING SOURCE MFI0 (MODBUS FLOAT IN - WORD 0) - - - - - - - - - - - - - - - - - - - - 58

FIG. 172 MAPPING DISPLAY/MAPPING THE SOURCE TO THE

DESTINATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

FIG. 173 MAPPING DISPLAY/HFO - FLOAT VARIABLES/ENTERING

A VALUE FOR WORD 0 - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

FIG. 174 HARDY MODBUS-LINK DISPLAY/SELECTING DISPLAY/FLOAT

INVERSE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 58

FIG. 175 HARDY MODBUS-LINK DISPLAY/555.0000 APPEARS - - - - - - - 59

FIG. 176 HARDY MODBUS-LINK DISPLAY/SELECTING BUTTON 23 READ/WRITE MULTIPLE REGISTERS - - - - - - - - - - - - - - - - - - - 59

FIG. 177 HARDY MODBUS-LI NK DISPLAY/WRITER MULTIPLE

REGISTERS DISPLAY - - - - - - - - - - - - - - - - - - - - - - - - - - - 59

FIG. 178 HARDY MODBUS-LINK/ENTER VALUE DISPLAY - - - - - - - - - 59

FIG. 179 HARDY MODBUS-LINK/ENTER VALUE DISPLAY/ENTERING 999 - 59

FIG. 180 HARDY MODBUS-LINK/WRITE MULTIPLE

REGISTERS/SENDING NEW VALUE - - - - - - - - - - - - - - - - - - - - 60

FIG. 181 RESPONSE OK POP UP - - - - - - - - - - - - - - - - - - - - - - 60

FIG. 182 MAPPING DISPLAY WITH VALUE “999.0000” RECEIVED

FROM THE HARDY MODBUS-LINK CLIENT - - - - - - - - - - - - - - - - 60

FIG. 183 OPC HETEROGENEOUS COMPUTING ENVIRONMENT - - - - - 61

FIG. 184 OPC CLIENT/SERVER/ITEMS - - - - - - - - - - - - - - - - - - - 61

FIG. 185 OMNISERVER CONFIGURATION DIALOG BOX - - - - - - - - - - 61

FIG. 186 OMNISERVER CONFIGURATION DIALOG BOX - - - - - - - - - - 62

FIG. 187 WINSOCK DEVICE CONFIGURATION/DEFAULT PARAMETERS - 62

FIG. 188 WINSOCK CONFIGURATION/ENTERING HI 3000 SETUP

PARAMETERS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 62

FIG. 189 PINGING HI 3000 MODULE/CONNECTION INDICATED - - - - - - 62

FIG. 190 HI 3000 DEVICE ICON WITH IP ADDRESS - - - - - - - - - - - - 63

FIG. 191 PROTOCOLS DIALOG BOX - - - - - - - - - - - - - - - - - - - - 63

FIG. 192 PROTOCOL DEFINITION/DOUBLE OR RIGHT CLICK ON

Page 11

V Table of Illustrations

PROTOCOL SETTINGS - - - - - - - - - - - - - - - - - - - - - - - - - - - 63

FIG. 193 PROTOCOLS DEFINITION DIALOG BOX/CREATING

PROTOCOL NAME AND DESCRIPTION - - - - - - - - - - - - - - - - - - 63

FIG. 194 PROTOCOL DEFINITION/BINARY FORMATS PAGE - - - - - - - 64

FIG. 195 PROTOCOLS DEFINITION - - - - - - - - - - - - - - - - - - - - 64

FIG. 196 PROTOCOL SETTINGS WITH NEW PROTOCOL DEFINITIONS - - 64

FIG. 197 SELECTING TOPICS ICON - - - - - - - - - - - - - - - - - - - - 64

FIG. 198 TOPICS PAGE/SELECTING A NEW TOPIC - - - - - - - - - - - - 64

FIG. 199 TOPIC DEFINITION DIALOG BOX/CREATING TOPIC DEFINITION 65

FIG. 200 TOPIC DEFINITION/VARIABLES PAGE - - - - - - - - - - - - - - 65

FIG. 201 TOPIC DEFINITION/HARDYFLOAT ICON - - - - - - - - - - - - - 65

FIG. 202 PROTOCOL PAGE/HIGHLIGHTING HARDYOPC_FLOAT - - - - - 66

FIG. 203 PROTOCOL PAGE/SELECTING NEW ITEM - - - - - - - - - - - - 66

FIG. 204 ITEM DEFINITION DIALOG BOX - - - - - - - - - - - - - - - - - - 66

FIG. 205 ITEM DEFINITION - - - - - - - - - - - - - - - - - - - - - - - - - 66

FIG. 206 ITEM DEFINITION/ENTERING FO00 - - - - - - - - - - - - - - - - 66

FIG. 207 ITEM DEFINITION - - - - - - - - - - - - - - - - - - - - - - - - - 67

FIG. 208 PROTOCOL PAGE/ITEM LIST ENTERED - - - - - - - - - - - - - 67

FIG. 209 ITEM DEFINITION/SEND DATA TRIGGER - - - - - - - - - - - - - 67

FIG. 210 ITEM DEFINITION/SEQUENCE NUMBER IN - - - - - - - - - - - - 67

FIG. 211 ITEM DEFINITION/SEQUENCE NUMBER OUT - - - - - - - - - - 68

FIG. 212 PROTOCOL PAGE/SELECTING HOST MESSAGE - - - - - - - - 68

FIG. 213 HOST MESSAGE DEFINITION - - - - - - - - - - - - - - - - - - - 68

FIG. 214 REQUEST PAGE WITH NO REQUEST MESSAGE - - - - - - - - - 69

FIG. 215 SELECTING WWW LINK - - - - - - - - - - - - - - - - - - - - - - 69

FIG. 216 HI 3000 SUPPORT SITE - - - - - - - - - - - - - - - - - - - - - - 69

FIG. 217 EPS FILES/SELECTING OPC FLOAT DPD FILE - - - - - - - - - - 69

FIG. 218 FILE DOWNLOAD DIALOG BOX - - - - - - - - - - - - - - - - - - 69

FIG. 219 SAVE AS DIALOG BOX/SELECTING PROGRAM FILES - - - - - - 70

FIG. 220 PROGRAM FILES/SELECTING DESCARTES OMNISERVER - - - 70

FIG. 221 OMNISERVER FOLDER SAVING DPD FILE - - - - - - - - - - - - 70

FIG. 222 HOST MESSAGE - - - - - - - - - - - - - - - - - - - - - - - - - 70

FIG. 223 CHAINS AND TRIGGERS PAGE - - - - - - - - - - - - - - - - - - 71

FIG. 224 PROTOCOL DEFINITION/SELECTING UNSOLICITED

MESSAGES - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 71

FIG. 225 UNSOLICITED MESSAGE DEFINITION PAGE - - - - - - - - - - - 71

FIG. 226 UNSOLICITED MESSAGE DEFINITION/NAME AND

DESCRIPTION ENTERED - - - - - - - - - - - - - - - - - - - - - - - - - - 71

FIG. 227 UNSOLICITED MESSAGE DEFINITION/RECEIVED PAGE - - - - - 72

FIG. 228 UNSOLICITED MESSAGE DEFINITION/RECEIVED MESSAGE - - 72

FIG. 229 WONDERWARE/SELECTING WWCLIENT - - - - - - - - - - - - - 73

FIG. 230 WONDERWARE/CLOSE THE LOG VIEWER - - - - - - - - - - - - 73

FIG. 231 WWCLIENT/SELECTING CREATE CONNECTION - - - - - - - - - 73

FIG. 232 CREATE CONNECTION DIALOG BOX - - - - - - - - - - - - - - - 73

FIG. 233 CREATE CONNECTION DIALOG BOX - - - - - - - - - - - - - - - 73

FIG. 234 IOT CONNECTION - - - - - - - - - - - - - - - - - - - - - - - - 73

FIG. 235 ITEM DIALOG BOX - - - - - - - - - - - - - - - - - - - - - - - - 74

FIG. 236 WWCLIENT/LIST OF IOT CONNECTIONS - - - - - - - - - - - - - 74

FIG. 237 WWCLIENT/LIST OF ITEMS (FI00) - - - - - - - - - - - - - - - - 74

FIG. 238 WONDERWARE/OPENING WINDOWMAKER - - - - - - - - - - - 74

FIG. 239 WINDOWMAKER DIALOG BOX - - - - - - - - - - - - - - - - - - 74

FIG. 240 WINDOWMAKER/OPENING A NEW WINDOW - - - - - - - - - - - 74

FIG. 241 WINDOW MAKER/CREATING A NEW WINDOW - - - - - - - - - - 75

FIG. 242 MACHINE MONITOR WINDOW ENTERING ###.#### - - - - - - - 75

FIG. 243 WINDOWMAKER/SELECTING ANIMATION LINKS - - - - - - - - 75

FIG. 244 WINDOWMAKER/OBJECT TYPE DIALOG BOX - - - - - - - - - - 75

FIG. 245 WINDOWMAKER/ACCESS NAME DIALOG BOX - - - - - - - - - - 75

Page 12

HI 3000 Series VI

Operation and Installation

FIG. 246 WINDOWMAKER/ADD ACCESS NAME DIALOG BOX - - - - - - - 76

FIG. 247 WINDOWMAKER/SELECTING TAGNAME DICTIONARY - - - - - - 76

FIG. 248 WINDOWMAKER/CREATING A TAG NAME - - - - - - - - - - - - 76

FIG. 249 WINDOWMAKER/SELECT TAG DIALOG BOX/SELECTING IPS - - 76

FIG. 250 NEWLY CREATED WINDOW - - - - - - - - - - - - - - - - - - - 77

FIG. 251 WINDOWMAKER/SELECTING RUNTIME - - - - - - - - - - - - - 77

FIG. 252 WINDOWMAKER/RUNTIME VALUE - - - - - - - - - - - - - - - - 77

FIG. 253 HI 3030 MAIN WEB PAGE/SELECTING CONFIGURATION - - - - 77

FIG. 254 CONFIGURATION PAGE/SELECTING HARDY CONTROL LINK - - 77

FIG. 255 HARDY CONTROL-LINK PAGE/SELECTING LISTED

HI 3000 MODULE IP ADDRESS - - - - - - - - - - - - - - - - - - - - - - - 78

FIG. 256 HARDY CONTROL-LINK PAGE SELECTING NODE 5 - - - - - - - 78

FIG. 257 SELECTED INSTRUMENT’S IP ADDRESS APPEARS

IN THE NODE 5 TEXT FIELD - - - - - - - - - - - - - - - - - - - - - - - - 78

FIG. 258 SAVING THE NODE ADDRESS ASSIGNMENT - - - - - - - - - - 78

FIG. 259 OK MESSAGE BOX - - - - - - - - - - - - - - - - - - - - - - - - 78

FIG. 260 NODE IP ADDRESS CONFIGURED - - - - - - - - - - - - - - - - 78

FIG. 261 CONFIGURATION PAGE/SELECTING MAPPING SETUP - - - - - 79

FIG. 262 MAPPING SETUP PAGE 1 - - - - - - - - - - - - - - - - - - - - - 79

FIG. 263 MAPPING SETUP PAGE 1/SELECTING HARDY

CONTROL-LINK FLOAT OUT - - - - - - - - - - - - - - - - - - - - - - - - 79

FIG. 264 HARDY CONTROL-LINK FLOAT OUT SELECTED/WORD 0 - - - - 79

FIG. 265 HARDY CONTROL-LINK FLOAT OUT/WORD 0 (EFO0) SET

AS MAPPING DESTINATION - - - - - - - - - - - - - - - - - - - - - - - - 80

FIG. 266 MAPPING SETUP 2/SOURCE SELECTION PAGE - - - - - - - - - 80

FIG. 267 MAPPING SETUP 2/SELECTING PROCESS

DATA/GROSS WEIGHT - - - - - - - - - - - - - - - - - - - - - - - - - - - 80

FIG. 268 PROCESS DATA/GROSS WEIGHT CHANNEL 1 (HF14) - - - - - - 80

FIG. 269 GROSS WEIGHT-CHANNEL 1 ASSIGNED TO HARDY

CONTROL-LINK FLOAT OUT - - - - - - - - - - - - - - - - - - - - - - - - 80

FIG. 270 GROSS WEIGHT ASSIGNED TO HARDY CONTROL-LINK

FLOAT OUT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 80

FIG. 271 HARDY CONTROL-LINK FLOAT OUT/WORD 2 - - - - - - - - - - 80

FIG. 272 HARDY CONTROL-LINK FLOAT OUT/WORD 2 SELECTED

AS DESTINATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 81

FIG. 273 MAPPING PAGE 2 SELECTING NET WEIGHT - - - - - - - - - - - 81

FIG. 274 PROCESS DATA/SELECTING NET WEIGHT/CHANNEL 1 - - - - - 81

FIG. 275 CURRENT MAPPINGS/NET WEIGHT/CHANNEL 1 (HFI8)

ASSIGNED TO HARDY CONTROL-LINK FLOAT OUT (EFO2) - - - - - - - - 81

FIG. 276 NET WEIGHT ASSIGNED TO HARDY CONTROL-LINK

FLOAT OUT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 81

FIG. 277 HARDY CONTROL-LINK FLOAT OUT/WORD 4 - - - - - - - - - - 81

FIG. 278 HARDY CONTROL-LINK FLOAT OUT/WORD 4 SELECTED

AS DESTINATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 81

FIG. 279 MAPPING PAGE 2 SELECTING GROSS WEIGHT - - - - - - - - - 82

FIG. 280 PROCESS DATA/SELECTING GROSS WEIGHT/CHANNEL 2 - - - 82

FIG. 281 CURRENT MAPPINGS/GROSS WEIGHT/CHANNEL 2 (HFI8)

ASSIGNED TO HARDY CONTROL-LINK FLOAT

OUT/WORD 4 (EFO4) - - - - - - - - - - - - - - - - - - - - - - - - - - - - 82

FIG. 282 GROSS WEIGHT ASSIGNED TO HARDY CONTROL-LINK

FLOAT OUT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 82

FIG. 283 HARDY CONTROL-LINK FLOAT OUT/WORD 6 - - - - - - - - - - 82

FIG. 284 HARDY CONTROL-LINK FLOAT OUT/WORD 4

SELECTED AS DESTINATION - - - - - - - - - - - - - - - - - - - - - - - 82

FIG. 285 MAPPING PAGE 2 SELECTING NET WEIGHT - - - - - - - - - - - 82

FIG. 286 PROCESS DATA/SELECTING NET WEIGHT/CHANNEL 2 - - - - - 82

FIG. 287 CURRENT MAPPINGS/GROSS WEIGHT/CHANNEL 2 (HFI9)

Page 13

VII Table of Illustrations

ASSIGNED TO HARDY CONTROL-LINK FLOAT

OUT/WORD 4 (EFO4) - - - - - - - - - - - - - - - - - - - - - - - - - - - - 83

FIG. 288 GROSS WEIGHT ASSIGNED TO HARDY CONTROL-LINK

FLOAT OUT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 83

FIG. 289 SELECTING AN EXPANDED MAP - - - - - - - - - - - - - - - - - 83

FIG. 290 EXPANDED MAP DIALOG BOX - - - - - - - - - - - - - - - - - - 83

FIG. 291 I/O CONFIGURATION/ADDING A NEW MODULE - - - - - - - - - 84

FIG. 292 SELECT MODULE TYPE - - - - - - - - - - - - - - - - - - - - - 84

FIG. 293 MODULE PROPERTIES DIALOG BOX - - - - - - - - - - - - - - - 84

FIG. 294 REQUESTED PACKED INTERVAL/SELECTING 50.0

MILLISECONDS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 85

FIG. 295 ETHERNET-MODULE HARDY ADDED TO I/O

CONFIGURATION LIST - - - - - - - - - - - - - - - - - - - - - - - - - - - 85

E-Mail Configuration and Operation - - - - - - - - - - - - - - - - - - - - - - - - 87

FIG. 296 INSTRUMENT HOME PAGE/SELECTING CONFIGURATION - - - 88

FIG. 297 CONFIGURATION WEB PAGE/SELECTING E-MAIL - - - - - - - - 88

FIG. 298 E-MAIL CONFIGURATION WEB PAGE - - - - - - - - - - - - - - 89

FIG. 299 CONFIGURATION MENU/SELECTING SETUP - - - - - - - - - - 89

FIG. 300 SETUP MENU/SELECTING ETHERNET - - - - - - - - - - - - - - 89

FIG. 301 ETHERNET SUB-MENU - - - - - - - - - - - - - - - - - - - - - - 89

FIG. 302 ETHERNET MENU/ENTERING INSTRUMENT IP ADDRESS - - - - 90

FIG. 303 ETHERNET MENU/ENTERING DNS IP ADDRESS - - - - - - - - - 90

FIG. 304 SETTING THE STANDARD 3-MAIL/MAIL SERVER, USER ID,

RETURN MAIL ADDRESS - - - - - - - - - - - - - - - - - - - - - - - - - - 90

FIG. 305 SETTING THE STANDARD E-MAIL “MAIL TO” ADDRESSES

AND SELECTING SETPOINTS - - - - - - - - - - - - - - - - - - - - - - - 90

FIG. 306 CUSTOM E-MAIL WEB PAGE - - - - - - - - - - - - - - - - - - - 91

FIG. 307 E-MAIL TEMPLATE FOR E-MAIL #0 - - - - - - - - - - - - - - - - 91

FIG. 308 PARTS OF AN E-MAIL ADDRESS - - - - - - - - - - - - - - - - - 91

FIG. 309 LIST OF PARAMETER DESCRIPTIONS AND

HEXADECIMAL NUMBERS - - - - - - - - - - - - - - - - - - - - - - - - - 92

FIG. 310 MAP DICTIONARY - - - - - - - - - - - - - - - - - - - - - - - - - 92

FIG. 311 EXPANDED VIEW OF ENTERED TOKENS - - - - - - - - - - - - 92

FIG. 312 CONFIGURATION WEB PAGE/SELECTING MAPPING SETUP - - 93

FIG. 313 MAPPING SETUP1/SENDING CUSTOM E-MAIL - - - - - - - - - - 93

FIG. 314 MAPPING SETUP 1/SELECTING SEND EMAIL - - - - - - - - - - 93

FIG. 315 ENTERING EMAIL NUMBER - - - - - - - - - - - - - - - - - - - - 93

FIG. 316 SEND EMAIL #0 ENTERED IN THE EQUATION - - - - - - - - - - 93

FIG. 317 MAPPING SETUP 2 PAGE - - - - - - - - - - - - - - - - - - - - - 94

FIG. 318 SELECTING LOCAL INPUTS - - - - - - - - - - - - - - - - - - - 94

FIG. 319 SELECTING LOCAL INPUT #1 - - - - - - - - - - - - - - - - - - - 94

FIG. 320 EQUATION ENTERED (HO3.0=HI0.0) - - - - - - - - - - - - - - - 94

FIG. 321 E-MAIL MAPPING COMPLETE - - - - - - - - - - - - - - - - - - 94

FIG. 322 TESTING E-MAIL - - - - - - - - - - - - - - - - - - - - - - - - - 94

Security Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 97

FIG. 323 CONFIGURATION MENU/SELECTING SECURITY - - - - - - - - 97

FIG. 324 SECURITY MENU/SETTING SECURITY MENU - - - - - - - - - - 97

FIG. 325 SET SECURITY MENU - - - - - - - - - - - - - - - - - - - - - - 97

FIG. 326 SECURITY LEVELS ASSIGNED FOR EACH MENU - - - - - - - - 98

FIG. 327 HOME PAGE/SELECTING CONFIGURATION - - - - - - - - - - - 98

FIG. 328 CONFIGURATION PAGE/SELECTING SECURITY - - - - - - - - - 98

FIG. 329 ENTER NETWORK PASSWORD DIALOG BOX - - - - - - - - - - 98

FIG. 330 PASSWORD AUTHENTICATION FAILED - - - - - - - - - - - - - 99

FIG. 331 CONFIGURATION/SECURITY PAGE - - - - - - - - - - - - - - - 99

FIG. 332 CONFIGURATION - SECURITY PAGE TYPING PASSWORDS - - - 99

Page 14

HI 3000 Series VIII

Operation and Installation

FIG. 333 CONFIGURATION - SECURITY/SELECTING SECURITY

LEVEL FOR A MENU - - - - - - - - - - - - - - - - - - - - - - - - - - - - 99

FIG. 334 CONFIGURATION - SECURITY/PARAMETERS SET FOR

SECURITY LEVELS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 99

FIG. 335 LOGGING ON/ENTERING USER NAME - - - - - - - - - - - - - - 100

FIG. 336 LOGGING ON/ENTERING PASSWORD - - - - - - - - - - - - - - 100

FIG. 337 LOGGING ON/STATUS DISPLAY - SECURITY LEVEL HI - - - - - 100

FIG. 338 LOG ON/ENTER NETWORK USER ID AND PASSWORD - - - - - 100

FIG. 339 REMOVING USER NAME - - - - - - - - - - - - - - - - - - - - - 100

FIG. 340 ENTER A “0” - - - - - - - - - - - - - - - - - - - - - - - - - - - - 101

HI 3001 Master Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 103

FIG. 341 MASTER DISPLAY/FRONT PANEL - - - - - - - - - - - - - - - - 103

FIG. 342 HI 3030 BUTTON CONFIGURATION - - - - - - - - - - - - - - - - 104

FIG. 343 HI 3010 BUTTON CONFIGURATION - - - - - - - - - - - - - - - - 104

FIG. 344 MASTER CONFIGURATION DISPLAY/HARDY 3030

WEIGHT CONTROLLER AT IP ADDRESS 192.168.110.24 - - - - - - - - - 104

FIG. 345 SUMMARY DISPLAY/HI 3030 WEIGHT CONTROLLER - - - - - - 104

FIG. 346 3000 SERIES DOWNLOAD PAGE - - - - - - - - - - - - - - - - - 104

Page 15

1 Communications

Installation & Operation

COMMUNICATIONS: INSTALLATION & OPERATION

Overview

The HI 3000 Series of instruments provide the user total

monitoring and instrument control via HI 3000 instruments’

built-in and optional connectivity which includes:

• DeviceNet (For Cable Installation See

Cabling Section - For Network Configuration See Network Section)

• Hardy Link Ethernet (TCP/IP) (For Cable

Installation See Cabling Section - For Network Configuration See Network Section)

• IR Port (Wireless)

• RS-232 Simplex Serial Port

• Remote I/O (For Cable Installation See

Cabling Section)

• ControlNet (For Cable Installation See

Cabling Section - For Network Configuration See Network Section)

• Profibus I/O (For Cable Installation See

Cabling Section - For Network Configuration See Network Section)

• Ethernet/IP (For Cable Installation See

Cabling Section - For Network Configuration See Network Section)

Hardy Control-Link TCP/IP (Ethernet)

All HI Series 3000 instruments are designed with a selectable 10/100 base T Ethernet connection which links your PC

to an embedded web server in the instrument. You can connect to an HI Series 3000 instrument via the Internet,

Intranet, Extranet, or VPN (Virtual Private Network). Your

computer must have an ethernet card and cable with an RJ45

connector to connect to the HI 3000 Series instrument. Once

connected you can transfer data, configure, and control any

of the instruments from your web browser from any location

in your plant or enterprise. Help wizards are also available to

assist when performing setup or troubleshooting of an instrument. In addition the browser connects you to the Hardy web

site which connects the user to a full range of customer services and support. File downloads from your control room

are a snap. No more hauling devices to download files to the

instrument. Should you want to download a file or monitor

the instrument from your laptop at the site, simply connect a

short cable from the laptop to the Ethernet connection at the

rear panel of the instrument to transfer files, monitor or configure the instrument. No matter where you are, if you are

connected to our instrument you can operate, configure and

troubleshoot any HI 3000 Series Instrument.

Now the user can connect to any of the HI Series 3000 products from anywhere in the world, 365 days a year, 24 hours a

day, 7 days a week. Hardy’s connectivity puts you in touch

with your weigh process or vibration monitor at your convenience no matter where you are or where the instrument is

located.

DeviceNet™

DeviceNet is a low-level network designed to connect the

Hardy HI 3000 Series Instruments to higher-level controllers

such as PCs, PLCs, or embedded controllers. The DeviceNet

Network is an open, global industry-standard communication network designed to provide an interface through a single cable from a programmable controller or PC directly to

all HI 3000 Series instruments as well as smart devices such

as sensors, push buttons, motor starters, simple operator

interfaces, drives and other weigh modules. With DeviceNet

the user can monitor or control multiple applications from

one display and allows 3rd party I/O to be easily added to

any system. You no longer have to hard-wire each device to

an I/O module or I/O block. The network also provides

access to the intelligence present in the instruments for superior diagnostics and troubleshooting to help increase system

up time. The DeviceNet network lets you monitor your

plant-floor devices from a central location and reconfigure

them as your needs change or service them as required. The

DeviceNet network's capabilities help reduce integration,

and reduce installation and wiring costs.

NOTE: RSNetWorx™ is a trademark of Rockwell Auto-

mation. DeviceNet™ is a trademark of the Open

DeviceNet Vendor Association, Inc. ControlLink™ is a trademark of Hardy Instruments Inc.

PRS-232 Simplex Serial Port

NOTE: The RS-232 is a Serial Port for a Printer or

Scoreboard.

The HI 3000 Series instruments allow the user to control the

instrument using Hardy’s DeviceNet™ ControlLink™ Software or RSNetWorx™ which can be purchased from Rockwell Automation.

Communication Option Cards

Remote I/O

Under license from The Allen-Bradley Corporation, Hardy

Process Solutions has developed a Remote I/O Interface for

the HI 3000 Series products.

Hardy Instruments worked with substantial customer input

and Allen-Bradley to identify and design the remote I/O

communications network which best matched the needs of

system integrators and end users for industrial and process

applications. The interface is fast, field proven, requires minimal wiring, requires no special software drivers, and is stan-

Page 16

HI-3000 Series 2

Operation and Installation

dard on many Allen-Bradley programmable controllers.

Setting each address and baud rate in the instrument, connecting three wires, and writing some ladder logic is all that

is needed to begin communicating weighing parameters to

and from an HI 3000 Series controller.

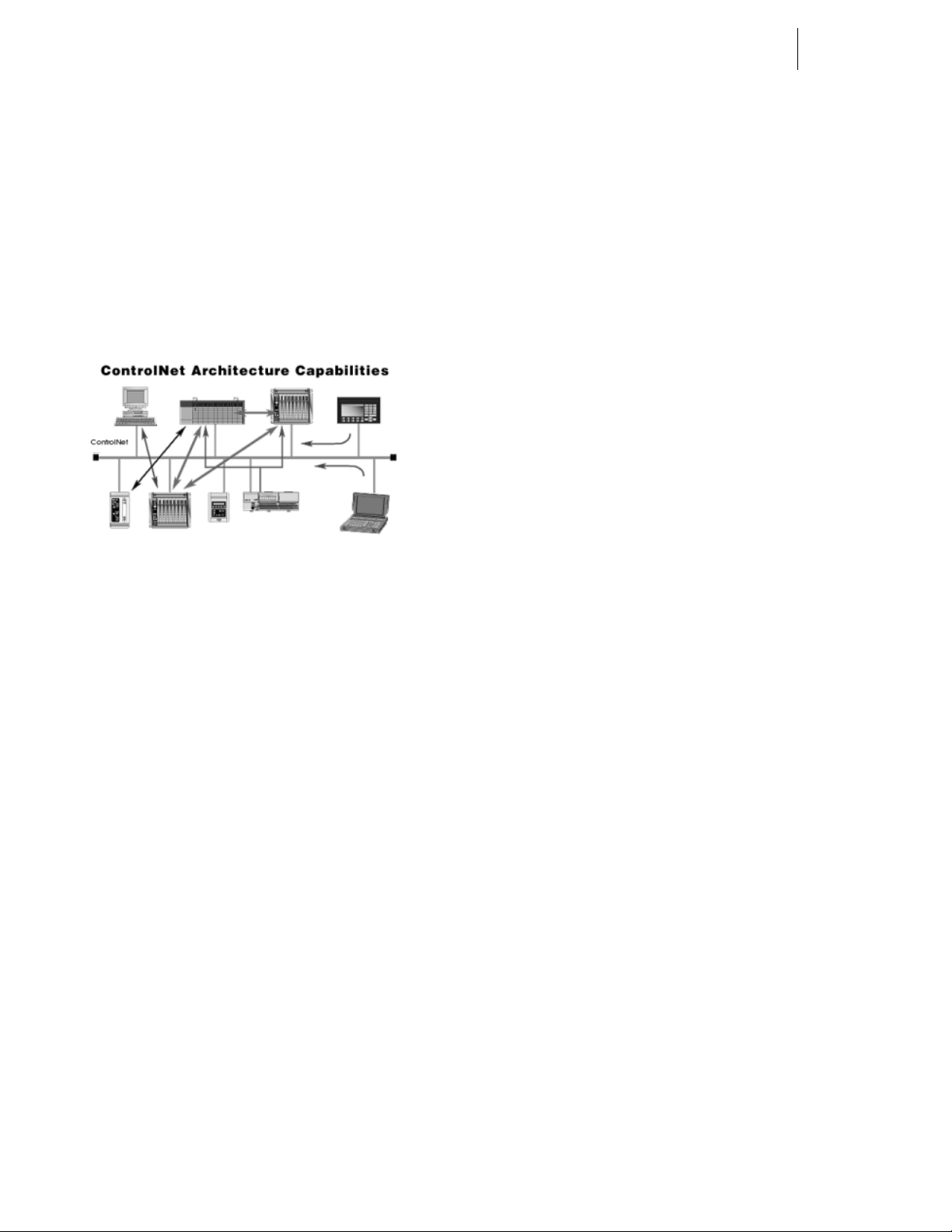

ControlNet

ControlNet enables multiple controllers to control I/O on the

same wire and permits multicast of both inputs and peer-topeer data, reducing traffic on the wire and increasing system

performance. (See Fig. 1)

FIG. 1: CONTROLNET ARCHITECTURE

ControlNet is highly deterministic and repeatable. These are

important requirements to ensure dependable, synchronized

and coordinated real-time performance. Determinism is the

ability to reliably predict when data will be delivered, and

repeatability ensures that transmit times are constant and

unaffected by devices connecting to, or leaving, the network.

These capabilities are further enhanced with user selectable

I/O and controller interlocking update times to match application requirements.

ControlNet meets the requirements of real-time, high speed

applications at the Automation and Control Layer and integrates complex control systems such as batch control systems, weigh process control systems and systems with

multiple controllers and human-machine interfaces.

*.GSD file and setting the Node Address and Input and Output Sizes is all you need to begin communicating weighing

parameters to and from an HI 3000 Series controller to a

PLC, PC or DCS system controller.

MOD-Bus/TPC/IP

TCP/IP is the common transport protocol of the Internet and

is actually a set of layered protocols, providing a reliable

data transport mechanism between machines. Ethernet has

become the de facto standard of corporate enterprise systems

and it has also become the de facto standard for factory networking. Ethernet has matured to the point that the cost of

implementing this network solution has been dropping to

where its cost is commensurate with those of today's fieldbuses. Using Ethernet TCP/IP in the factory allows true integration with the corporate Intranet and MES systems that

support your factory.

Combining a versatile, scaleable, and ubiquitous physical

network (Ethernet) with a universal networking standard

(TCP/IP) and a vendor-neutral data representation (MOD-

®

BUS

) gives a truly open, accessible network for exchange

of process data. It is also extremely simple to implement for

any device that supports TCP/IP sockets.

Simplicity: MODBUS

®

instruction set and wraps TCP/IP around it. If you

BUS

already have a MODBUS

®

TCP/IP simply takes the MOD-

®

driver and if you understand

Ethernet and TCP/IP sockets, you can in short period of

time, have a driver up and running and talking to a PC.

There are no exotic chipsets required to be purchase d from

vendors, and you can use standard PC Ethernet cards to talk

to your implemented device. As the cost of Ethernet falls,

you benefit from the price reduction of the hardware, and as

the performance improves from 10 to 100 Mbit and soon to 1

Gbit, your technology moves with it protecting your investment.

NOTE: Mod-BUS

®

is a registered trademark of Sch-

neider Automated Inc.

Profibus

The Profibus-DP Communication Profile is designed for

efficient data exchange at the field level. The central automation devices, such as PLC/PC or process control systems,

communicate through a fast serial connection with distributed field devices such as I/O, drives and valves, as well as

measuring transducers. Data exchange with the distributed

devices is mainly cyclic. The communication functions

required for this are defined by the basic DP functions in

accordance with the EN 50 170 standard. In addition to these

basic functions, DP also offers extended acyclic communication services for the parameterization, operation, monitoring

and alarm handling of intelligent field devices. Loading the

OPC

OLE for Process Control (OPC) enables an HI 3000 module

to communicate with any device that supports OLE/COM.

The architecture is designed to utilize the Microsoft distributed OLE technology (DCOM) to facilitate clients interfacing to remote servers.

Page 17

3 Communications

Installation & Operation

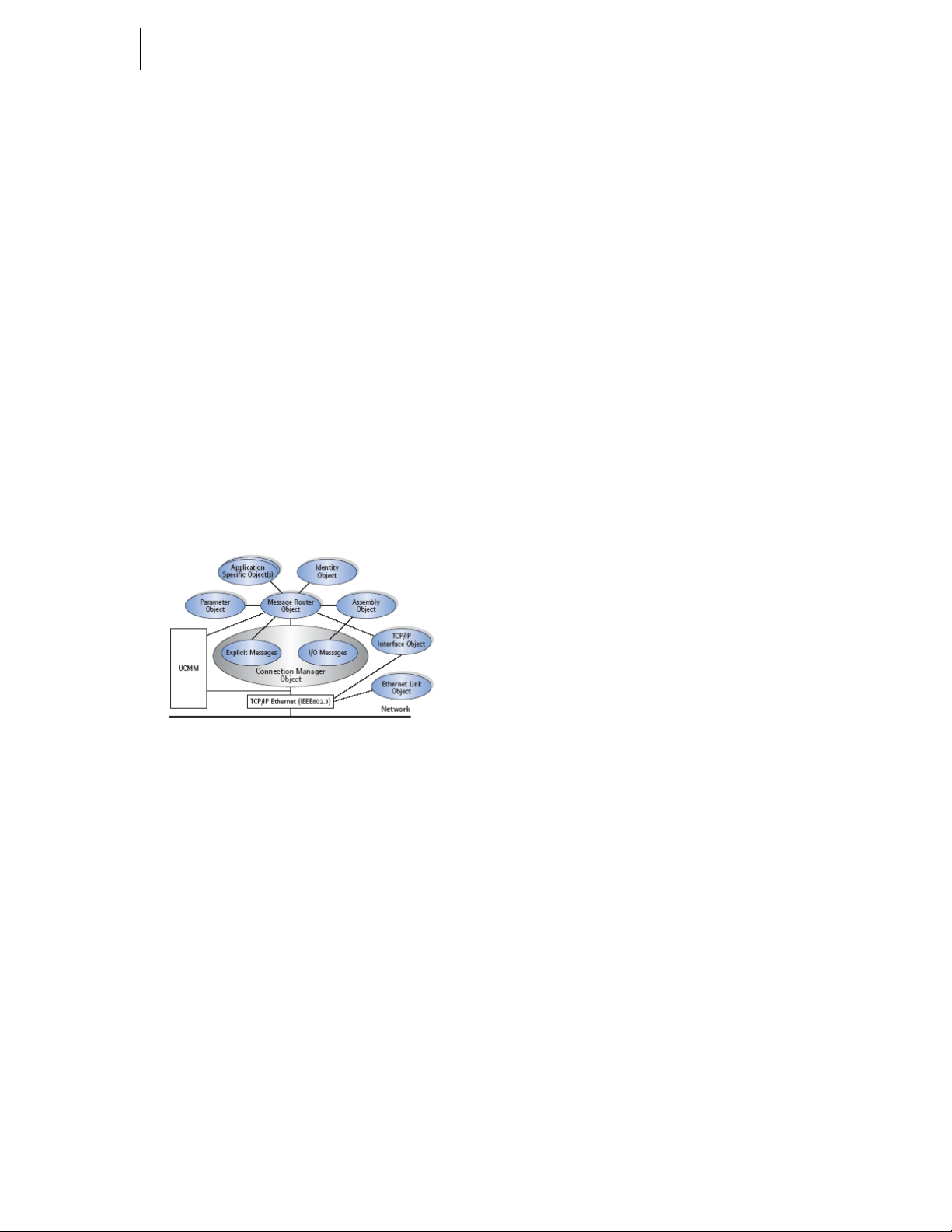

EtherNet/IP™

EtherNet/IP, short for Ethernet Industrial Protocol, is an

open industrial networking standard that takes advantage of

commercial, off-the-shelf Ethernet communication chips and

media. Ethernet technology, enables the user to access

device-level data from the Internet.The Ethernet/IP networking standard supports both implicit messaging (real-time I/O

messaging) and explicit messaging (message exchange).

EtherNet/IP is an open network that takes advantage of commercial technology that already exists.

TCP/IP is the transport and network layer protocol of the

Internet and is commonly linked with all Ethernet installations and the business world. TCP/IP provides a set of services that any two devices can use to share data. Because

Ethernet technology and standard protocol suites such as

TCP/IP have been published for public use, standardized

software tools and physical media have been mass-produced

and are readily available, offering you the benefits of known

technology and accessibility. The UDP/IP (User Datagram

Protocol) is also used in conjunction with the Ethernet network. UDP/IP provides fast, efficient data transport required

for real-time data exchange.

is needed to begin communicating weighing parameters to

and from an HI 3000 Series controller.

Each Hardy HI 3000 Series represents a quarter (1/4) rack of

discrete I/O (32 bits in the PLC Output and Input image

files) to the scanning PLC and supports both discrete and

block transfers. The PLC continually exchanges 32 bits of its

PLC Input Image Table and 32 bits of its Output Image T able

with each 1/4 rack device. In a 1771 I/O Rack, these bits

would normally be transferred from and to discrete input and

output modules. For the weight controller, the Output Image

bits are used to send commands to the weight controller and

the Input Image bits return weight data and scale status bits.

These actions are referred to as “discrete writes and “discrete

reads”. The user is also able to exchange blocks of data with

a 1/4, 1/2, 3/4, Full rack device via Block Transfer instructions in the PLC ladder logic program. These commands are

referred to as “block writes” and “block reads”.

The host programmable controller can access all configuration and weighing parameters in an HI 3000 Series Instrument, including performing scale calibration. The HI 3000

Series module can be used as a local display and keyboard

for weighing parameters, or function as a blind controller

properly digitizing the load cell signal and providing responsive setpoint control.

FIG. 2: ETHERNET/IP™ NETWORK

NOTE: EtherNet/IP™ is a trademark of Rockwell Auto-

mation Inc.

Allen-Bradley Remote I/O

Allen-Bradley License

Under license from The Allen-Bradley Corporation, Hardy

has developed a Remote I/O Interface for the HI 3000 Series

products.

Hardy Process Solutions worked with substantial customer

input and Allen-Bradley to identify and design the remote I/

O communications network which best matched the needs of

system integrators and end users for industrial and process

applications. The interface is fast, field proven, requires minimal wiring, requires no special software drivers, and is standard on many Allen-Bradley programmable controllers.

Setting each address and baud rate in the instrument, connecting three wires, and writing some ladder logic is all that

Using the Remote I/O interface shortens development time

and provides the most functional weighing interface available for your Allen-Bradley programmable controller.

Before starting system design, you should also read the

Installation and Operation manual of the HI 3000 Series.

Information contained in this manual is subject to change.

Always check the latest version of this manual at our web

site (http://www.hardysolutions.com) before beginning system design. This product incorporates technology which is

licensed by Allen-Bradley Company Inc. Allen-Bradley

does not technically approve, warrant or support this product. All warranty and support for this product is provided by

Hardy. PLC

®

, PLC-2®, PLC-3®, PLC-5®, SLC500® Series

are registered trademarks of the Allen-Bradley Company,

Inc.

Common Applications

The HI 3000 Remote I/O can be used in conjunction with

Allen-Bradley programmable controllers to tackle a variety

of process control needs. The most basic use of the interface

is to simply allow the programmable controller to read

weight data from one or more HI 3000 Series weight controllers. In addition to reading weight some other applications

are:

• Filling

• Dispensing

• Batch Weighing Control

• Monitoring Rate of Flow

Page 18

HI-3000 Series 4

Operation and Installation

• Evaluating Totalized Weight

• Check Weighing

• Weight Level Alarming

• Condition Monitoring

NOTE: The 3000 Series have 4 mappable outputs in the

HI 3010 FillerDispenser and HI 3030 Multiscale controller and up to seven (7) on some of

the other 3000 Series products.

Monitoring Weighing Parameters

The HI 3000 series weight controllers are capable of calculating five types of weight data, including the standard Gross

and Net weights. In addition to the standard Gross and Net

weights there are three options such as Peak Force, Totalized

Weight (block transfer only), and Rate-of-Change or mass

flow rate entering or leaving a vessel.

Short Glossary of Terms

1. Gross Weight - is used to describe the total weight

of the container and the contents.

2. Net Weight - is the weight of the contents of the

container only.

3. Tare Value - The action of adjusting out the known

weight of the container from the total indicated

weight, so that the indicator reads weight directly.

4. Dead Load - The weight of the vessel and other

equipment which will be ignored during zero calibration.

are connected one to another in a series. The first and last

Remote I/O module must be terminated.

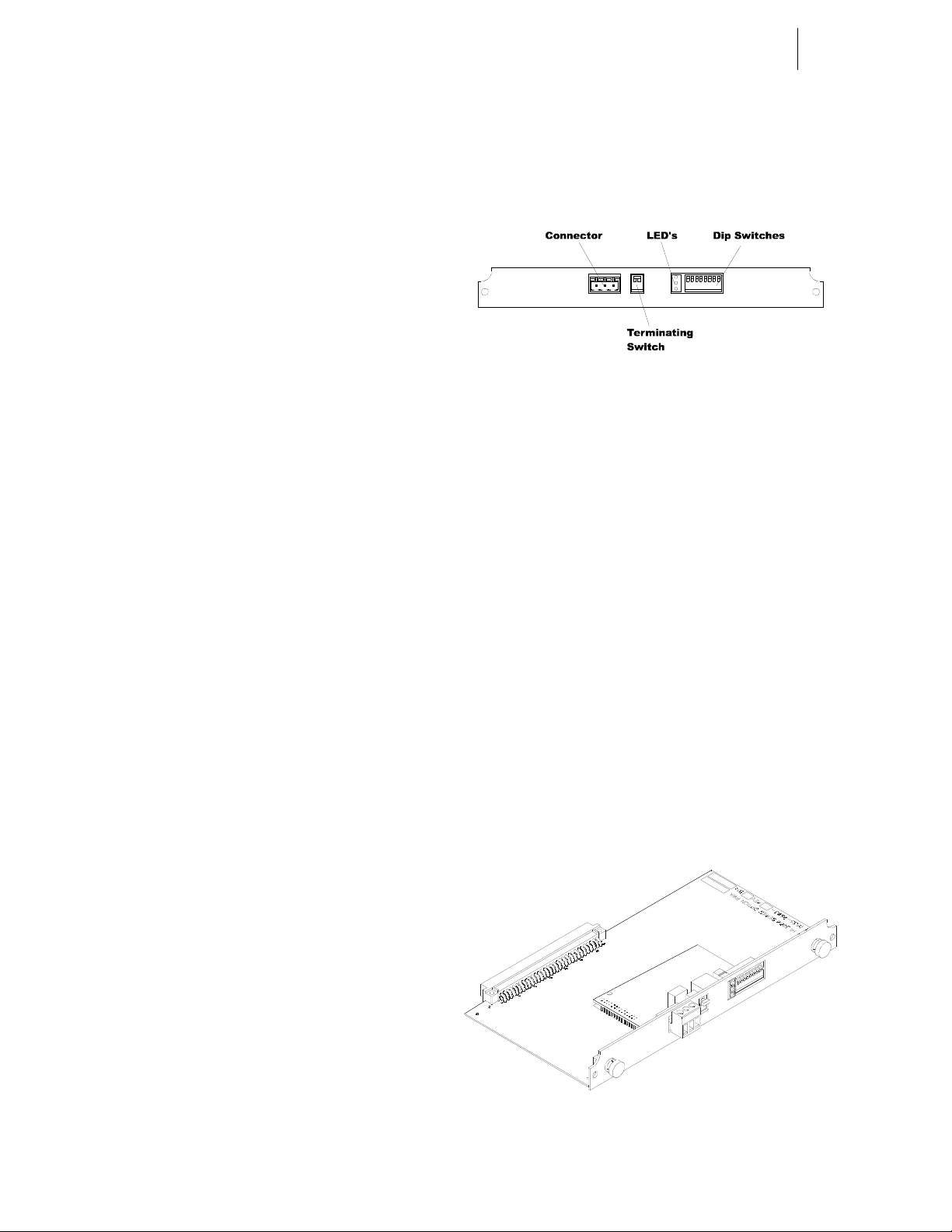

Step 1. The Terminating Switch is accessible from the rear

of the HI 3000 Series Module. (See Fig. 3)

FIG. 3: TERMINATING SWITCH FOR

TERMINATING LAST MODULE

Step 2. On the first module and the last module turn the ter-

minating switch to ON.

Step 3. For all other devices on the daisy chain the termi-

nating must be set to OFF.

Dip Switch Settings

Set all the Dip Switch Settings to ON. (See Fig. 3)

Installing the RIO Option Board

CAUTION: M

STRAP WHEN INSTALLING THE REMOTE I/O OPTION

C

ARD.

AKE SURE THAT YOU USE AN ANTI-STATIC

Tare Value

Current Gross Weights become the Tare value by pushing

the Tare Push Button on the front panel of the HI 3000

instrument, remote functions contact closure, discrete write

or block transfer command by the PLC, or can be entered as

a numeric value via the keypad on the front panel of the HI

3000 Series instruments This new tare value is the reference

point for Net Weight.

TV = G - N

TV = Tare Value (weight)

G = Gross Weight

N = Net Weight

Remote I/O Board Cable Termination Dip Switch Configuration

About Cable Termination

HI 3000 Series Remote I/O Modules are connected to a cable

in daisy-chain fashion and are referred to as “nodes”. A

Daisy Chain is a hardware configuration in which devices

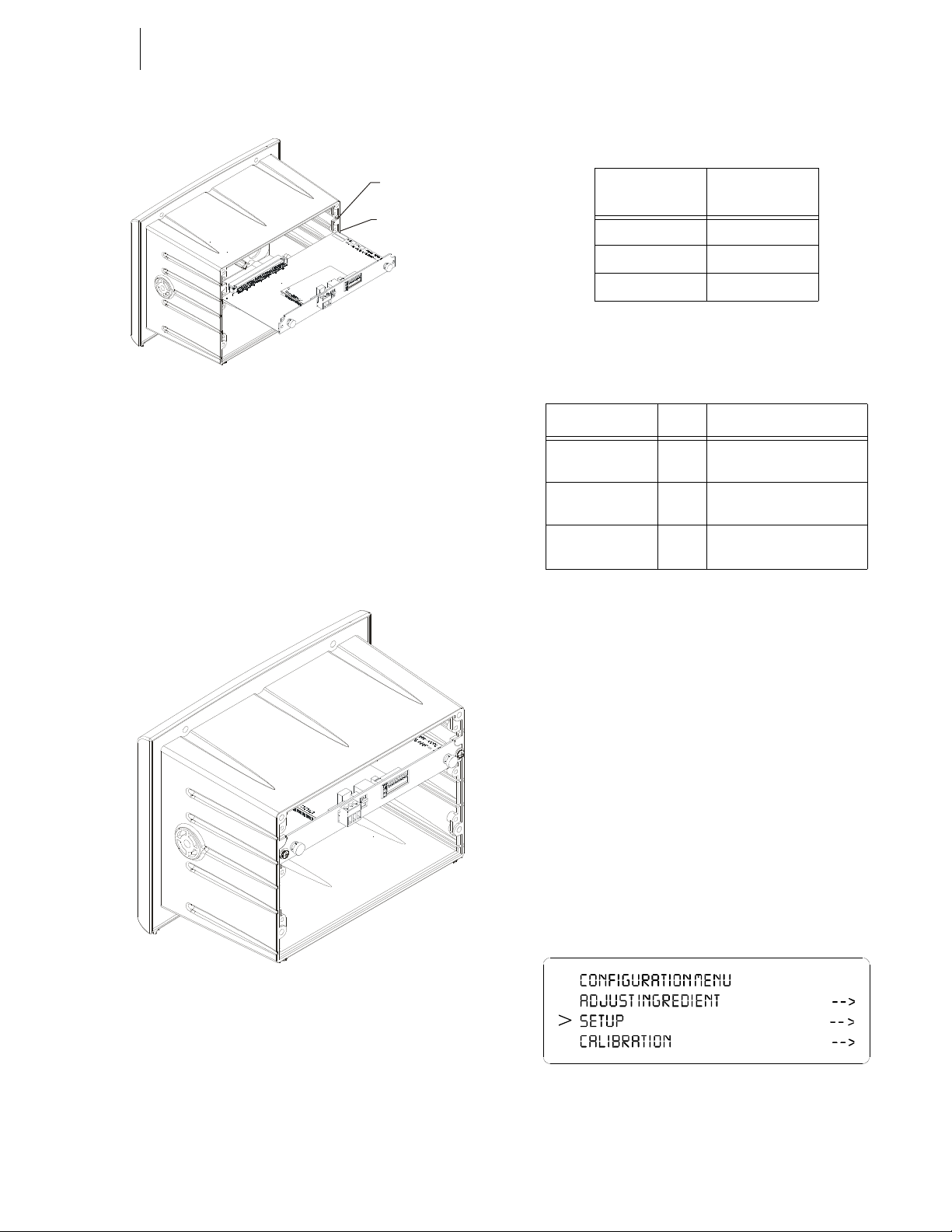

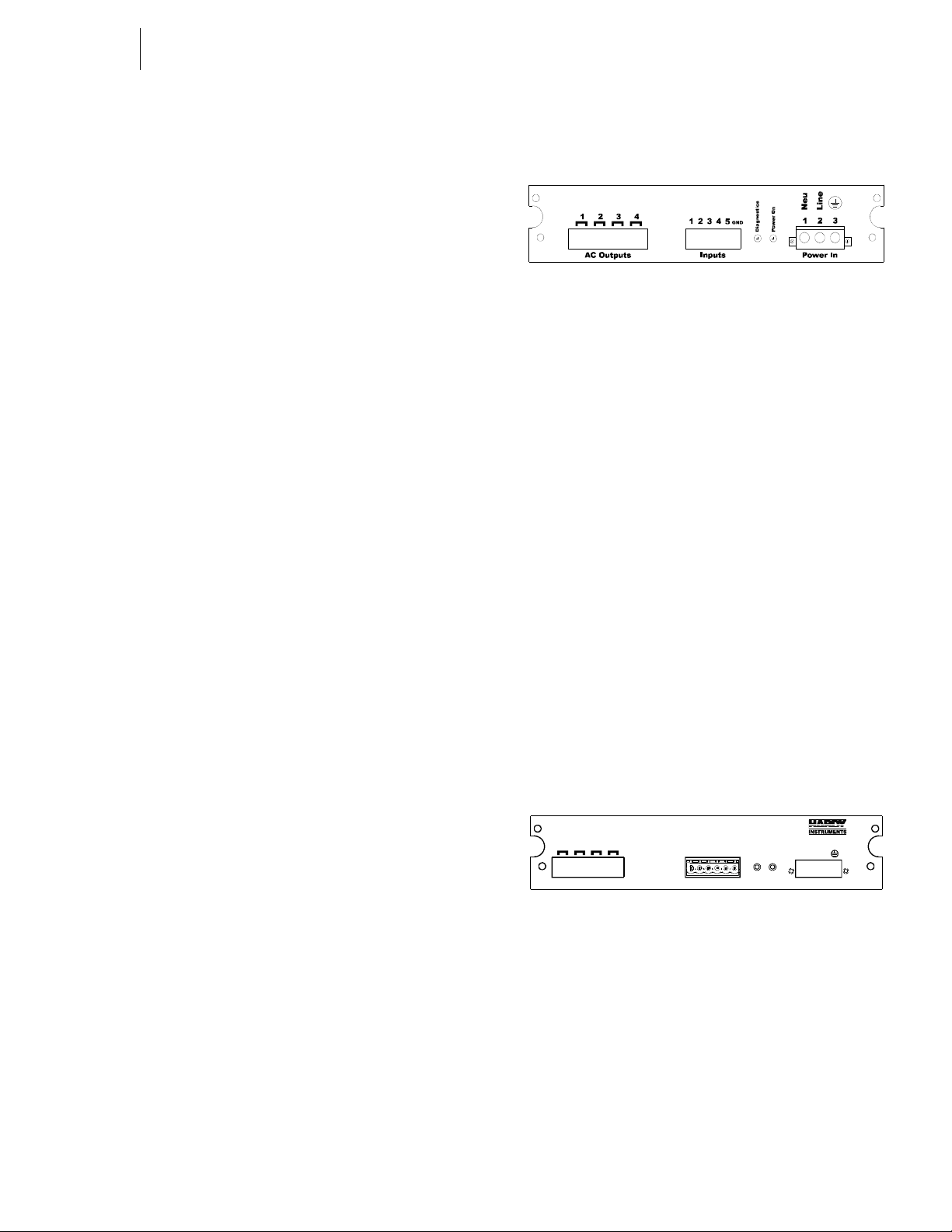

Step 1. Position the RIO Option Card with the back plane

connector facing Option Slot #0. (See Fig. 4)

NOTE: You can only use Option Slot #0 when installing

the RIO Option Card.

FIG. 4: REMOTE I/O OPTION CARD

Step 2. Slide the RIO Option Card into Slot #0. (See Fig. 5)

Page 19

5 Communications

Installation & Operation

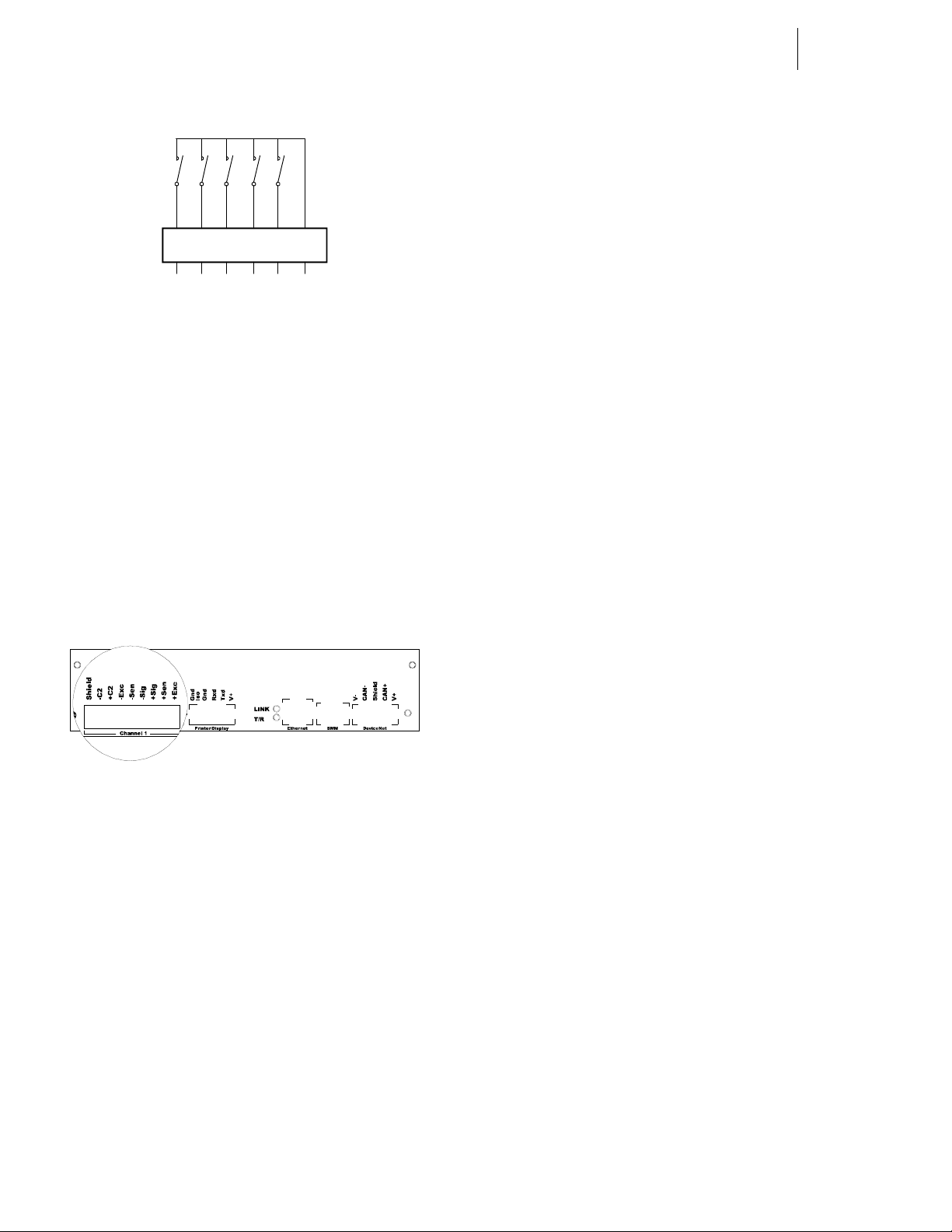

Connector Pin Out

Option Slot 1

Option Slot 0

FIG. 5: REMOTE I/O/SLIDE INTO OPTION SLOT #0

Step 3. Push the Remote I/O card up against the back plane

and gently press until the card connector seats in the

back plane connector.

Step 4. Use a phillips head screw driver and install the two

(2) screws that fasten the RIO card panel to the HI

3000 Instrument Chassis. (See Fig. 6)

Step 5. Tighten the screws until the RIO panel is snug. Do

not overtighten.

Screw Terminal

(3-pin)

1Blue

2Shield

3 Clear

Description

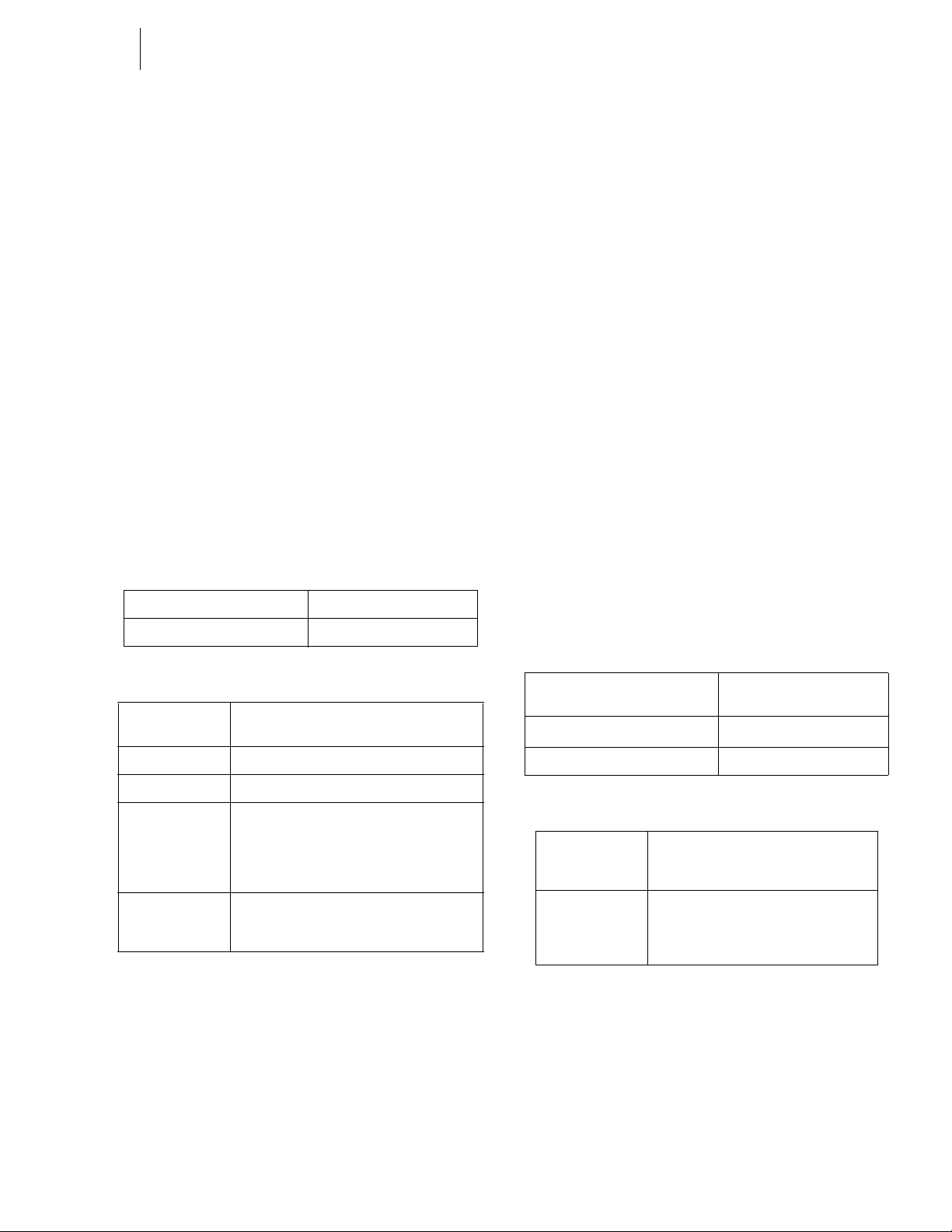

TABLE 1: SCREW TERMINAL (3-PIN) PIN OUT

LED Indicators

LED Color Function

Error

(Top LED)

Power

(Bottom LED)

Active

(Middle LED)

Red Off: Normal Operation

On: Bus off/error

Green Off: Power is Off

On: Power is On

Green Off: No Communication

On: Communication Active

TABLE 2: LED INDICATORS

Removing the Remote I/O Option Card

FIG. 6: REMOTE I/O OPTION CARD INSTALLED

Step 6. Connect the Remote I/O cable to the 3 pin connec-

tor on the RIO board.

Step 7. Connect the other end of the Remote I/O cable to

the PLC, SLC or PC Remote I/O Interface card.

Step 1. Disconnect the cables.

Step 2. Use a phillips head screw driver and remove the

two (2) screws that fasten the RIO Option Card

panel to the HI 3000 Chassis.

Step 3. Using the thumb and index finger on both hands,

grasp the two (2) knobs on the RIO Card panel and

pull away from the instrument.

Step 4. When the RIO Option Card clears the chassis, store

in a static free, safe location.

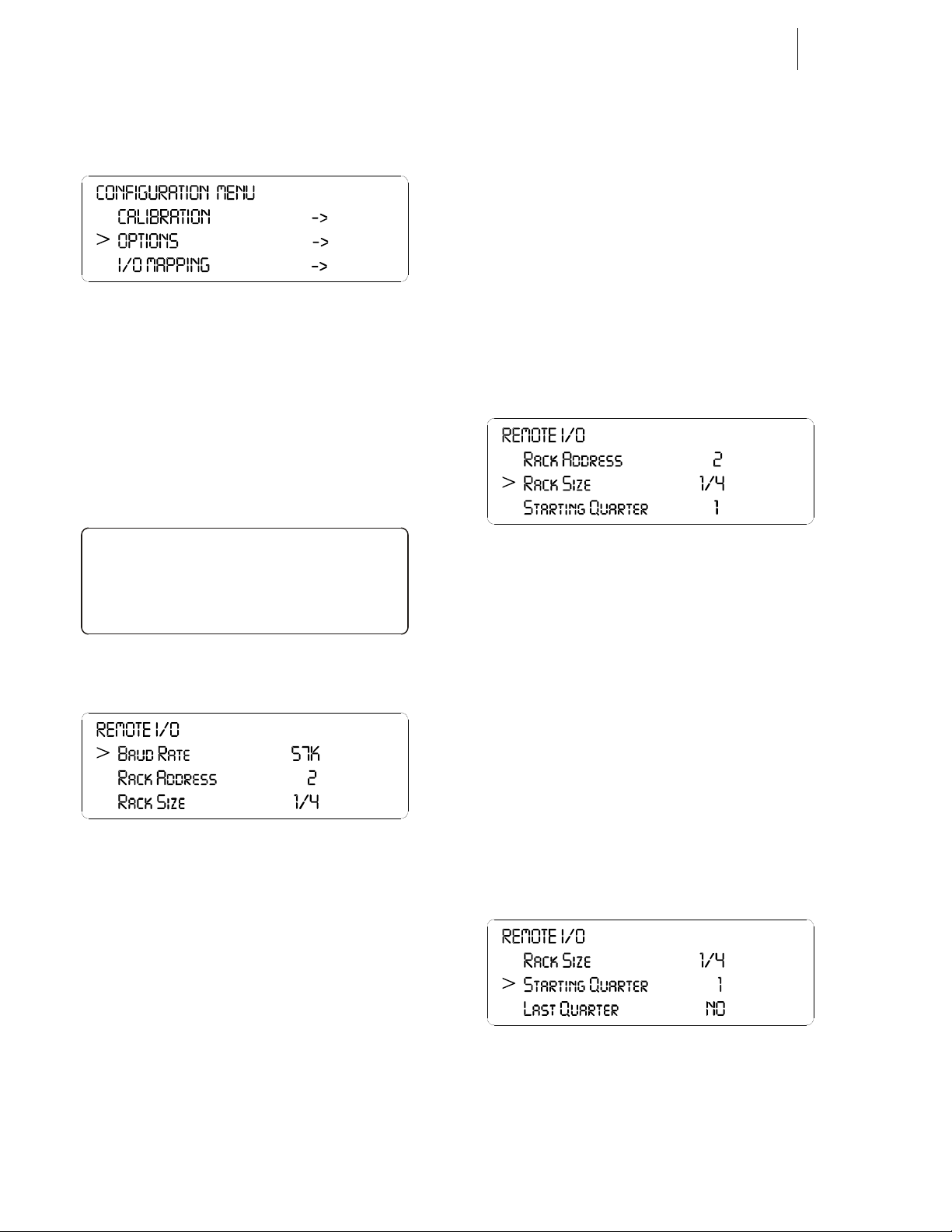

Remote I/O Configuration Procedures from the Front Panel

Step 1. At the front panel click on the Setup/3 button. The

Configuration Menu appears. (See Fig. 7)

FIG. 7: CONFIGURATION MENU/SELECTING

SETUP

Page 20

HI-3000 Series 6

>

Re mot e I/ O ON ->

Cont r ol N et I/ O OFF

Operation and Installation

Step 2. Push the up or down arrows until the cursor is next

to “OPTIONS”. (See Fig. 8)

FIG. 8: CONFIGURATION MENU/SELECTING

OPTIONS

Step 3. Press the Enter button. The Options submenu

appears with Remote I/O selected. (See Fig. 9)

Step 4. If the cursor is not in front of Remote I/O, push the

up arrow until the cursor is aligned with Remote I/

O.

Step 5. Press the Enter button. The Remote I/O Menu

appears. (See Fig. 10)

OPTIONS

• You can set the rack address in one of two

ways.

1. Press on the clear button to clear the

existing value then use the alphanumeric keys to enter the address for this

module.

2. Press on the right or left arrow buttons

to select the address.

• Address Range - 0-59

Step 9. Press the Enter button to save the setting.

Step 10. Press the down arrow button until the cursor is in

front of Rack Size. (See Fig. 11)

FIG. 11: REMOTE I/O/SETTING RACK SIZE

FIG. 9: OPTIONS/SELECTING REMOTE I/O

FIG. 10: REMOTE I/O MENU/SETTING

PARAMETERS

Step 6. Press the right or left arrow buttons to select the

Baud Rate. Left arrow decreases the rate and the

right arrow increases the rate. Baud Rate Selections

are:

• 57 kbaud

• 115 kbaud

• 230 kbaud.

Step 7. Press the Enter button to save the setting.

Step 8. Press the down arrow button until the cursor is in

front of Rack Address.

Step 11. Press the right arrow button to select the rack size

of this module. The choices are:

• 1/4 quarter (Can start at 1,2,3,4)*

• 1/2 half (Can start at 1,2,3)*

• 3/4 three quarter (Can start at 1,2)*

• FULL (Can start at 1)*

NOTE: *The starting points are important when making

the starting quarter selection. For example you

can have a 1/4 rack start at quarter 1 and a 1/2

rack start at quarter 2.

Step 12. Press the Enter button to save the setting.

Step 13. Press the down arrow button until the cursor is in

front of Starting Quarter. (See Fig. 12)

FIG. 12: REMOTE I/O SELECTING STARTING

QUARTER

Step 14. Press the right or left arrow buttons to select the

starting quarter for this module. Keep in mind the

starting quarter requirements due to rack size.

Page 21

7 Communications

Installation & Operation

Step 15. Press the Enter button to save the setting.

Step 16. Press the down arrow button until the cursor is in

front of Last Quarter.

Step 17. Press the right or left arrow buttons to toggle

between NO and YES. If the module is in the last

quarter select YES. If the module is not in the last

quarter select NO. Make sure you make the correct

selection each time.

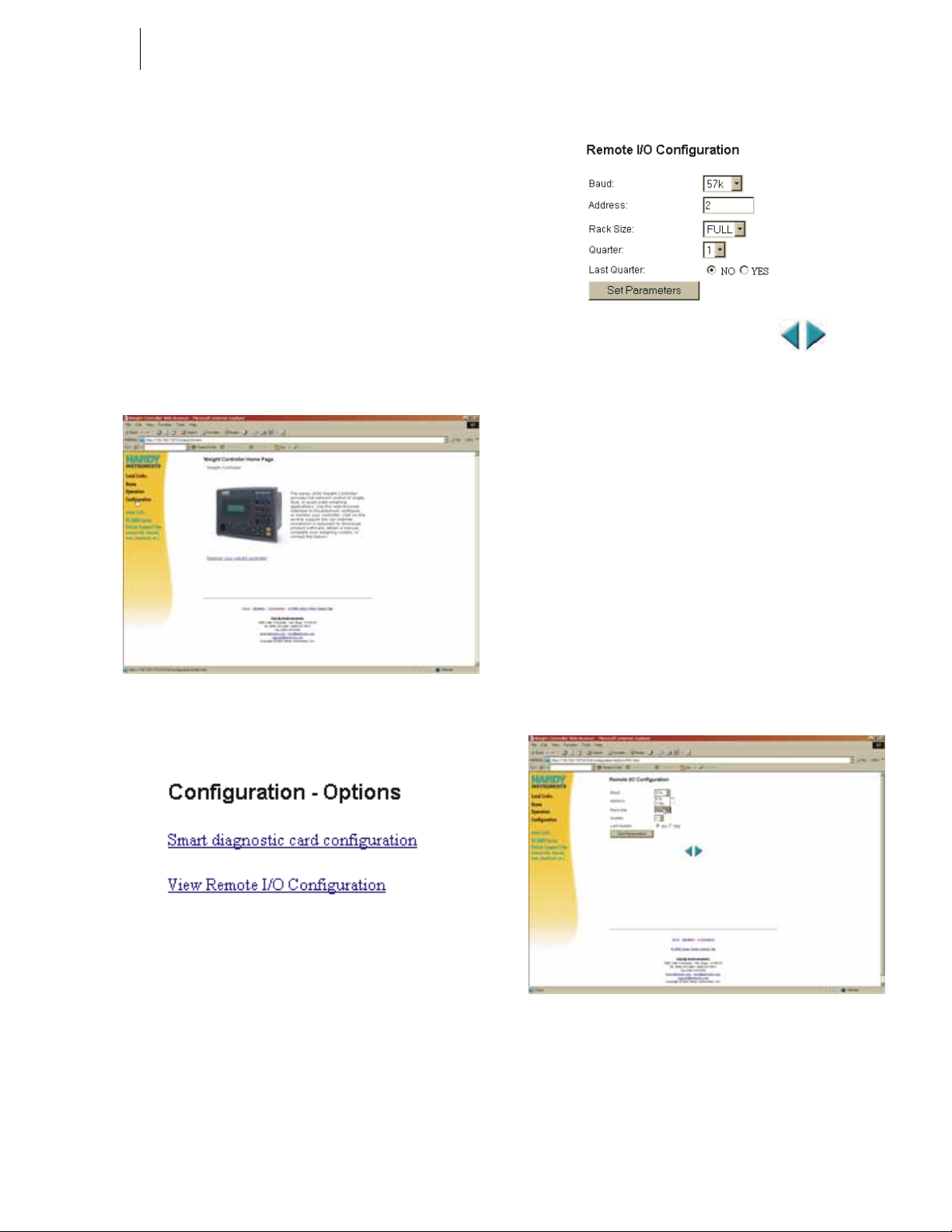

Remote I/O Configuration Procedures from the Web Page

Step 1. From the Home Page of the Instrument Click on

Configuration. (See Fig. 13) The Configuration

Options page appears. (See Fig. 14)

FIG. 15: REMOTE I/O CONFIGURATION PAGE

Step 3. To select the Baud rate click on the Baud: pull

down menu. (See Fig. 16)

Step 4. Click on the Baud Rate you want to select. Baud

Rate Selections are:

FIG. 13: INSTRUMENT HOME PAGE/SELECTING

CONFIGURATION

FIG. 14: CONFIGURATION - OPTIONS PAGE/

SELECTING VIEW REMOTE I/O CONFIGURATION

• 57 kbaud

• 115 kbaud

• 230 kbaud.

NOTE: If you only select one parameter (e.g. Address)

you need to click on set configuration to set the

entry. You do not need to select every category

before setting the configuration.

Step 2. Click on View Remote I/O Configuration. (See Fig.

14) The Remote I/O Configuration page appears.

(See Fig. 15)

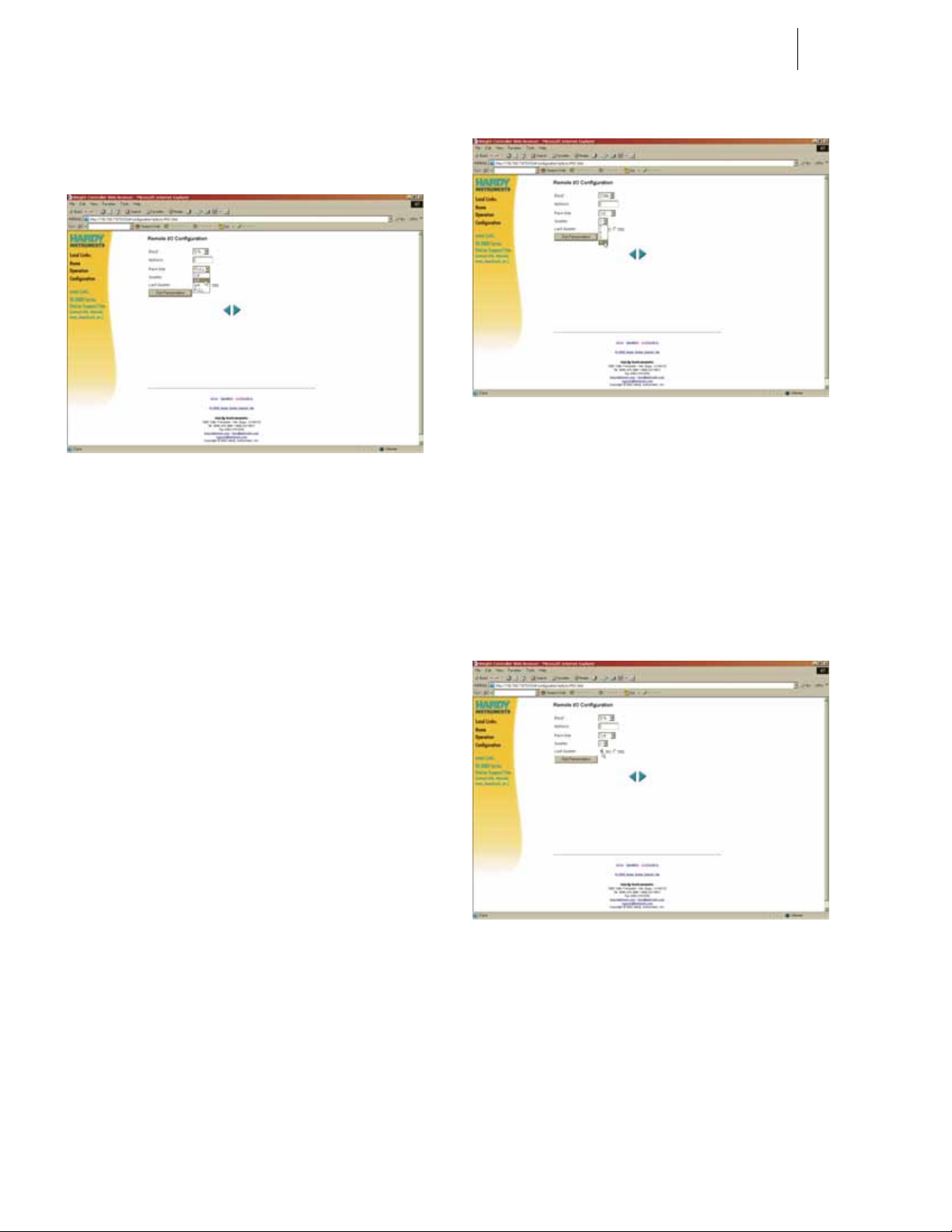

FIG. 16: REMOTE I/O CONFIGURATION/

SELECTING BAUD RATE

Step 5. To set the Node Address double Click in the

Address Field. Type in the Node Address of this

module.

• Address Range - 0-59

Page 22

Step 6. To Select the Rack Size, click on the Rack Size pull

down menu. (See Fig. 17)

HI-3000 Series 8

Operation and Installation

FIG. 18: REMOTE I/0 CONFIGURATION/

SELECTING QUARTER

FIG. 17: REMOTE I/O CONFIGURATION/

SELECTING RACK SIZE

Step 7. Click on the Rack Size of this module.

The choices are:

• 1/4 quarter (Can start at 1,2,3,4)*

• 1/2 half (Can start at 1,2,3)*

• 3/4 three quarter (Can start at 1,2)*

• FULL (Can start at 1)*

NOTE: *The starting points are important when making

the starting quarter selection. For example you

can have a 1/4 rack start at quarter 1 and a 1/2

rack start at quarter 2.

Step 8. To select the Quarter Location, click on the Quarter

pull down menu. (See Fig. 18)

Step 9. Click on the Quarter location number of this instru-

ment.

Step 10. You need to determine if this instrument is in the

last quarter. If this instrument is not the Last Quarter click in the radio button next to NO (NO is the

default selection). If this instrument is the Last

Quarter click in the radio button next to YES. (See

Fig. 19)

FIG. 19: REMOTE I/O CONFIGURATION/

SELECTING LAST QUARTER

Step 11. Click on the Set Parameters button to set the config-

uration.

Page 23

9 Communications

Installation & Operation

Discrete Remote I/O Mapping

NOTE: The input and output tables on the HI 3010

device always start with word 0, regardless of

where the words end up in the PLC tables. In the

HI 3030 Byte 0 of Word 0 is reserved and cannot

be used.

About Discrete Remote I/O Mapping

Discrete Remote I/O Mapping is used when you want to

communicate from a 1/4 or 1/2 rack, due to the constraints

when getting information in and out of these units.

General Information

• bit: FEDCBA98 76543210

• W0: SWYYYYYY 00000000

S - command-type: 0 = normal 1 = short

W - R/W action: 0 = read 1 = write

Y - depends on W

For Reads:

W0: 10AX XNNN 0000 0000 command word (LSB unused)

W1: - - - - - - - - QQQR RRRR data word (MSB unused)

1. RSO45=HFI3 (This maps the Net Weight in lbs

into a short int at word 13, RO)

2. CMD0=RSI0 (This indicates there is a command in

the RIO in-table word 0.)

PLC puts into the Output file (assuming HI3000 is at 1

st

¼

rack 2):

SWA

0:020: 10000001 00000000

QQQRRRRR

0:021: 000000 00101101

S = 1 A short command

W = 0 A read

A = 0 No ACK

NNN = 1 Read one word

RRRRR = 13 Word Offset 13+32, (i.e. RO45)

QQQ = 1 Copy to RO1 . . .

This copies one word from word 45 of the RIO out-table to

word 1 of the RIO out-table. The data becomes available for

RIO discrete PLC reads. Anything that can be mapped can

be selected by the command, including remote data. Largerrack users can specify up to 7 words to read into the discrete

I/O area.

For Writes:

A If A=1, unit acknowledges by copying data

byte to bits RO0.8~RO0.15

XX Reserved. Set to zero.

NNN Number of words to copy out (0 thru 7)

RRRRR Index in output scratchpad table of first source

word to copy. Scratchpad starts at word 32 of

Output Table. Data will be copied, without

conversion, to word QQQ and subsequent

words

QQQ Destination word in Output table of first copied

word (note that RO1 is first usable full RIO

word)

NOTE: If command comes from RI, output will be in RO.

If input is DI, output will be in DO.

Read Example: For HI 3010

Read Net Weight into word RSO1 as 16 bit integer in 1/4

rack at address 2, first quarter:

In Mapping write the following:

W0: 11MNNNNN 00000000 Command Word (LSB

unused)

JJJJJJJJ JJJJJJJJ

W1:

J J J J J J J J J J J J J J J J J J) Second (optional) data word

(W2:

M Data Length

0 = 1 word

1 = 2 words (not usable for 1/4 rack)

NNNNN Index in input scratchpad table of word to

change. One or two data words will be

copied without conversion. Scratchpad

table begins at word 32 of Input Table.

First Data Word

NOTE: There is no command echo for writes.

Write Example 1: For HI 3030

Write 1042 to ingredient 1 Number of Fills:

In Mapping:

Page 24

HI-3000 Series 10

Operation and Installation

User sets: HSO5=RS141 Meaning - Number of Fills

= RIO Short Input word 41.

User Writes:CMD0=RSI0 Meaning - There is a com-

mand at RIO in-table word 0.

PLC puts into its Output file (assuming HI3000 is at 1

rack 2):

SWMNNNNN

O:020: 11001001 00000000

J J J J J J J J J J J J J J J J J J

0:021: 00000100 00010010

S = 1 A short command

W = 1 A Write

M = 0 Write 1 word

NNNNN=1001)

Word Offset = 9 (32+9=41)

2

JJJJJJJJ JJJJJJJJ Value to write 2

Write Example 2: For HI 3010

Write 597.1 to ingredient 1 target weight:

In Mapping:

User sets: HFO9=RFI45 Meaning - ingr1 target wt =

RIO Float Input word 45.

User Writes:CMD0=RSI0 Meaning - There is a com-

mand at RSIO in-table word 0.

PLC puts into its Output file (assuming HI3000 is at 1

rack 2) and 1/2 rack sizes:

SWMNNNNN

0:020: 11101101 00000000

J J J J J J J J J J J J J J J J J J

0:021: 01000100 00010101

J J J J J J J J J J J J J J J J J J

0:022: 01000110 01100110

S = 1 A short command

W = 1 A Write

M = 1 Write 2 word

NNNNN=(1101)

Word Offset - 13(32+13=45)

2

Mapping

Mapping is used to:

1. Configure local inputs and outputs of the 3000 Con-

st

¼

NOTE: The 3000 Controllers are Masters on DeviceNet,

Any number of Sources can be mapped to one Destination

using the Boolean Statements in the Advanced Mapping

Screen.

Step 1. Select One Destination from the pull down lists in

Step 2. Select one Source in the same manner as in step a.

st

¼

Step 3. If more than one source is desired, select one of the

Step 4. To initiate the displayed mapping equation, select

Step 5. To Unmap - or remove a mapping equation - only

Step 6. For more information about Mapping go to the

troller using Boolean or non-Boolean statements.

2. Map parameters between Controllers using an

Ethernet Network.

3. Map parameters, setpoints, or commands between

the local controller and any of the supported communication networks, including ControlNet, AllenBradley Remote I/O and DeviceNet.

meaning any parameter can be assigned

(mapped) to 3rd party I/O on the DeviceNet Network. The Rockwell Automation software package "RSNetworx" is used to assign the I/O on the

plant network. HI 3000 Controllers can also be

Slave Devices.

the Local, Network, or Control fields. Once

selected, the Destination will automatically fill in

on the left-hand side of the equation in the mapping

field.

The source can reside in the local controller as a

parameter, as a point on one of the network tables,

or as a parameter on another 3000 Controller on the

Ethernet network. Once selected, the source will

automatically fill in on the right-side of the equation in the mapping field.

Boolean Operators (And, Or, Not), and then repeat

step b to select the next source.

the 'Map' key.

the destination needs to be selected and the Unmap

key pressed.

Mapping Chapter for each individual HI 3000

Series product.

J . . = 01000100 00010101

Value to write 0x4415 = MSW of IEEE float

597.1

j . . = 01000110 01100110

Value to write 0x4666 = LSW of IEEE float

597.1

Page 25

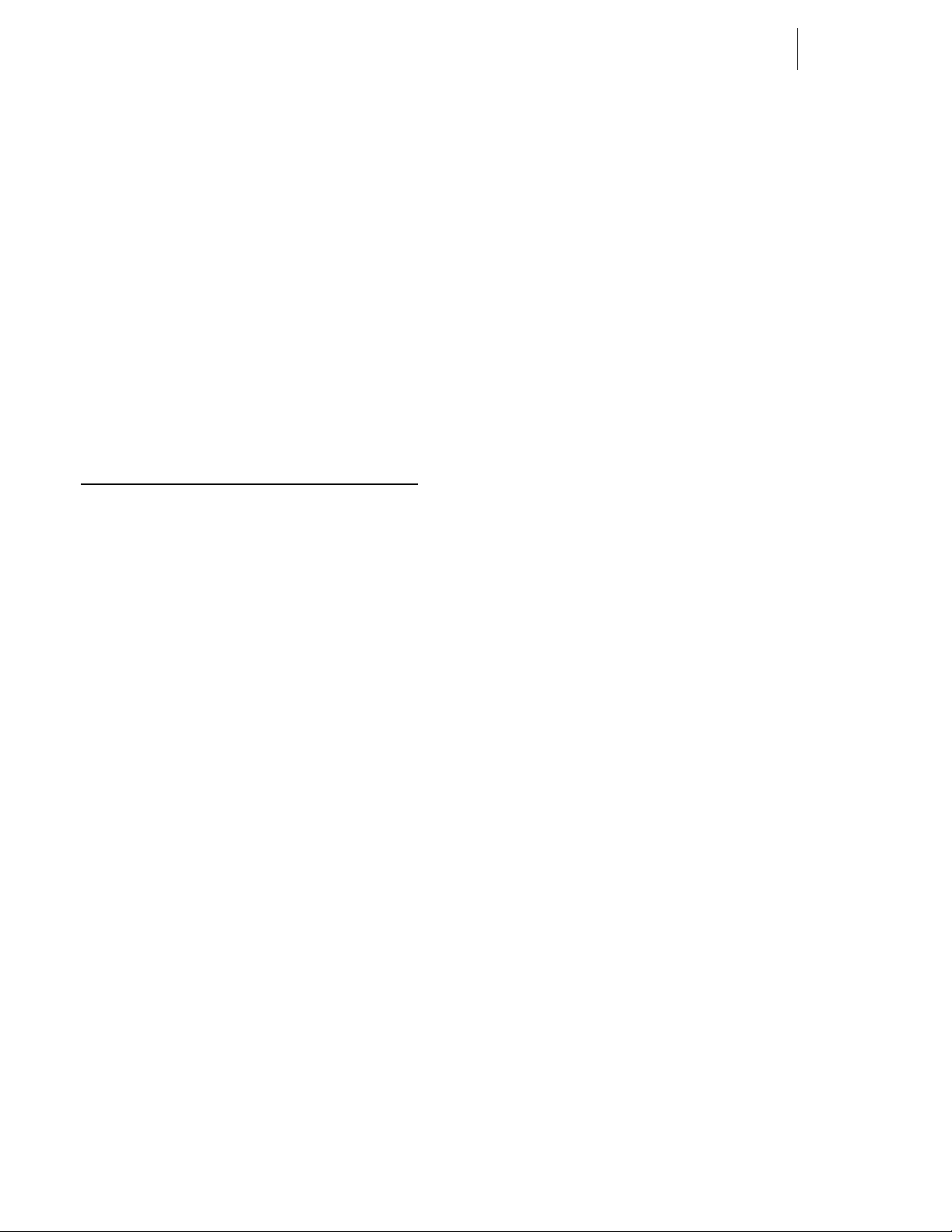

11 Cabling

Power In

Power On

Diagnostics

Inputs

Gnd

1234

5

Neu

Line

www.hardyinst.com/3000

2341

Outputs

Installation

CABLING: INSTALLATION

General Introduction to Cabling

This section pertains to unpacking the instrument and installation of the Power, Load Cells, DeviceNet and Ethernet

Cables. For more detailed installation information please