Page 1

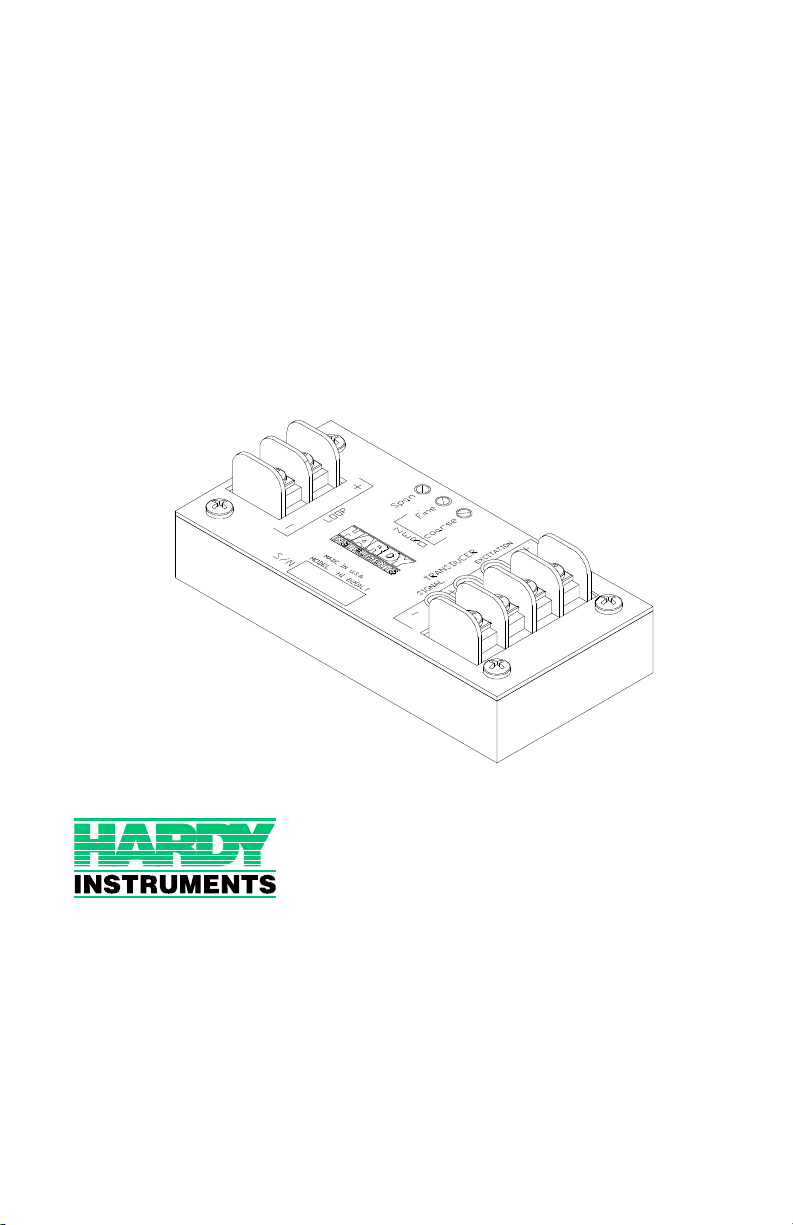

HI 2201LT Loop Powered Level Weight Transmitter For

Hazardous Areas

HI 2204LT Loop Powered Level Weight Transmitter

OPERATION AND INSTALLATION

MANUAL

Corporate Headquarters

9440 Carroll Park Drive, Suite 150

San Diego, CA 92121

Phone: (858) 278-2900

FAX: (858) 278-6700

Web-Site: http://www.hardyinst.com

Hardy Instruments Document Number: 0596-0138-01 Rev E

Copyright November 1999 H ard y Inst rum ents, Inc. All Rights Reserved. Printed i n the U .S.A . (941 028)

Page 2

1-2

Page 3

Table of Contents

Table of Contents

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1

Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2

Physical Dimensions - - - - - - - - - - - - - - - - - - - - - - - -2

Power Requirement - - - - - - - - - - - - - - - - - - - - - - - -2

Load Cell Excitation - - - - - - - - - - - - - - - - - - - - - - - -2

Zero Offset Range - - - - - - - - - - - - - - - - - - - - - - - - -2

Sensitivity - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2

Linearity - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2

Operating Temperature Range - - - - - - - - - - - - - - - - - - -2

Temperature Coefficient - - - - - - - - - - - - - - - - - - - - - -3

Signal Current Ripple - - - - - - - - - - - - - - - - - - - - - - -3

Power Supply Rejection - - - - - - - - - - - - - - - - - - - - - -3

Approvals (HI 2201LT Only) - - - - - - - - - - - - - - - - - - - -3

Approvals HI 2201LT & HI 2204LT - - - - - - - - - - - - - - - - -3

Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3

Junction Box with Strain Gage Summing Board

(HI 2201LT-A3 or HI 2201LT-A5) - - - - - - - - - - - - - - -3

Input - Strain Gage Transducer - - - - - - - - - - - - - - - - - - -4

Output/Power Loop - - - - - - - - - - - - - - - - - - - - - - - -4

Earth Ground and Signal Return - - - - - - - - - - - - - - - - - -6

Precautions on Grounding - - - - - - - - - - - - - - - - - - - - -7

Isolation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7

Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7

Calibration Controls - - - - - - - - - - - - - - - - - - - - - - - -8

Coarse (Zero) - - - - - - - - - - - - - - - - - - - - - - - - -8

Fine (Zero) - - - - - - - - - - - - - - - - - - - - - - - - - - -8

Span - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8

Calibration Procedures - - - - - - - - - - - - - - - - - - - - - - -8

Example - - - - - - - - - - - - - - - - - - - - - - - - - - - -9

Trouble Shooting Procedures - - - - - - - - - - - - - - - - - - - -10

Malfunction: No Output - - - - - - - - - - - - - - - - - - - - - - -10

Malfunction: No Change in Input - - - - - - - - - - - - - - - - - -10

Malfunction: Output Drifts - - - - - - - - - - - - - - - - - - - - -10

Factory Mutual (FM) Approval (HI 2201LT Only) - - - - - - - - - - -11

i

Page 4

HI 2201 LT

ii

Page 5

HI 2201LT/HI 2204LT

Overview The model HI 2204LT Loop Powered Level Weight

Transmitter and model HI 2201LT Loop Powered

Level Weight Transmitter for Hazardous Areas furnish power to strain gage transducers, measure the

return voltage, and adjust the 4-20 milli amp loop current to be proportional to the transducer signal.

The HI 2201LT is Factory Mutual approved and safe

to use in hazardous operating environments. The HI

2204LT IS NOT Factory Mutual approved and

should not be used in a hazardous environment.

The HI 2201LT/HI 2204LT can be used to transmit

any strain gage signal with a bridg e resistance of more

than 88 ohms. This allows transmission of pressure,

load, weight, force and torque signals including up to

four 350 ohm, full bridge, load cells.

The HI 2201LT/HI 2204LT powers itself and the

attached strain gage transducers from the 4-20 ma

loop power. This allows sensitive strain gage signals

to be transmitted over long distances without the

expense of installing additional power to remote locations. A common, low-cost power supply can be

placed anywhere in the 4-20 ma loop.

As the power supply provides loop power, the HI

2201LT/HI 2204LT controls the current flow (4-20

ma) representing the strain gage signal and receiving

devices can be placed anywhere along the loop to

monitor current flow. Typical receiving devices

include:

• Chart Records

• Panel Meters

• Bar Graphs

• Programmable Controllers

•Computers

• Relay Set Point Modules

Most receiving devices may be characterized as a load

resistor allowing the 4-20 ma signal t o cause a proportional voltage drop across it. Multiple receivers may

be placed on the loop provided the loop p ower su pply

can drive the combined loads. this can be calculated

by adding the voltage requirements of the HI 2201LT/

1

Page 6

HI 2201LT/HI 2204LT

Specifications

HI 2204LT (14 VDC) to that of each receiving device

(loop resistance x 20 ma).

The Level Indicator applies power to each transducer

in pulses a few milliseconds long at a rate of 90 pulses

per second. The Level Indicator measures the voltage

across the output terminals of the transducer with

each power pulse, and it converts the average into a

smooth current that varies with the transducer signal.

This method of powering the transducer allows the

Level Indicator to power up to four load cells . Though

each load cell requires more than 4 ma excitation, the

Level Indicator itself draws no more than 4 ma average current at zero weight load, and no more than 20

ma average current at full scale.

The Level Indicator is potted and sealed to withstand

typical industrial environments. It is small enough to

be mounted on a load cell summing board inside of a

standard 5” x 7” x 3.5” NEMA 4 enclosure.

Physical

Dimensions

Power

Requirement

Load Cell

Excitation

Zero Offset Range Coarse: 2 mV/V

Sensitivity 3 mV/V (Continuously Adjustable from 2 mV/V to 3

Linearity 0.11% of full scale*

2

Length: 4.50 Inches (114.3 mm)

Width: 2.15 Inches (54.6 mm)

Height: 1.30 Inches 33.02 mm)

Weight: 8 oz. (.227 Kgs)

Minimum: 15 VDC

Maximum: 50 VDC

Zero Scale: 4 ma

Full Scale: 20 ma

5 V (pulsed) , 90 hz

fine: 0.04 mV/V

mV/V)

* Some barrier protectio n is required where the 2201

is located in a hazardous area.

Page 7

HI 2201LT/HI 2204LT

Operating

Temperature

Range

Temperature

Coefficient

Signal Current

Ripple

Power Supply

Rejection

Approvals (HI

2201LT Only)

Approvals HI

2201LT & HI

2204LT

Installation The Loop Powered Level Weight Transmitter is usu-

0o C to +60o C (+32o F to +140o F)

0.025% per degree Celsius

20 mV p-p at 20 ma into 500 ohms

0.015% (max) 20 to 30 V

0.10% (max) 15 to 50 V

FM approved

CE

ally installed close to the strain gage(s) to minimize

the expense of special wiring, such as load cell cable.

Wiring positions are indicated on the top surface next

to each terminal strip.

Junction Box with

Strain Gage

Summing Board

(HI 2201LT-A3 or

HI 2201LT-A5)

The transmitter is available in a NEMA 4 junction

box.(See Fig. 1)

3

Page 8

HI 2201LT/HI 2204LT

FIG. 1 HI 2201LT/HI 2204 (-A3 OR -A5) IN

NEMA 4 JUNCTION BOX/TOP VIEW

The HI 2201/2204LT-A3 and HI 2201/2204LT-A5

Loop Powered Level Weight Transmitter comes

mounted on a load cell summing board within a

NEMA 4 junction box. The load cell summing board

is designed to allow balancing pots to be instal led if

required. (See Fig. 2)

FIG. 2 TRANSMITTER INSTALLED ON LOAD

CELL SUMMING BOARD (-A3 OR -A5

OPTION)

Input - Strain Gage

Transducer

Output/Power

Loop

4

Strain Gage signals are typically very low in voltage

causing them to be susceptible to noise. It is a good

practice to isolate strain gage signals from high voltage (110 VAC) lines. It is highly recommended that

the transducer signal wire be routed in its own conduit. The transducer cable should have a shield which

can be earth grounded near the transmitter.

The loop power connection provides power to the HI

2201LT/HI 2204LT and provides the 4-20 mA signal.

The transmitter must have from 15 VDC to 50 VDC

across its LOOP terminals at up to 20 mA (full scale

output). since all devices in the output/power loop are

in series minimum pow er supply voltage, at 2 0 mA,

must equal the total voltage drop across all of the

other devices in the loop, plus 15 VDC for the HI

2201LT.

Page 9

HI 2201LT/HI 2204LT

Loop Powered Level

Weight Transmitter

+-

Power

Supply

Receiver

#3

-

+

Receiver

#1

Receiver

#2

4mA-20mA

The transmitter output loop can be wired with any two

conductor shielded cable. The two inner conductors

are connected to the output of the transmitter at the

two terminals marked LOOP. (See Fig. 3 & 4)

Note which wire is connected to each terminal to

maintain correct polarity within the loop.

FIG. 3 OUTPUT LOOP TERMINAL S

5

Page 10

HI 2201LT/HI 2204LT

DC

Power

Supply

+

Loop Powered Level

Weight Transmitter

+

Isolator

+

+

Relays

Set

Point

RCVR

+

RCVR+110

VAC

110

VAC

110

VAC

110

VAC

FIG. 4 OUTPUT/POWER LOOP WIRING

NOTE: Be sure to shield the tie point for CE compliance.

Earth Ground and

Signal Return

“Earth Ground” is used here to indicate a point actually connected to a path into the Earth’s ground. The

term “signal return” is used to indicate a return path

for signals to the negative side of th e power supply, or

in the case of the output/loop, signal return means the

more negative side of the voltage being measured.

(See Figs. 4 & 5)

FIG. 5 TYPICAL SYST EM WIRING WITH ISOLATION

NOTE: Be sure to shield the tie point for CE compliance.

Receivers may be inserted into the minus or the plus

power supply/transmitter path, or both. It is not necessary that one of the transmitter output leads be connected directly to ground.

6

Appropriate grounding and shielding helps to protect

the signals from noise. However, it may be necessary

to try various ground/shiel d configur atio ns to find the

best one for a particular installation. Figures 4 & 5 are

examples only.

The transducer cable shield should be connected to

either the earth ground or the signal return, on the

input side of the transmitter to protect against noise,

but not to both. The recommended configuration consists of the transducer cable shield connected to the

output/power cable shield and to the signal return.

Page 11

HI 2201LT/HI 2204LT

Precautions on

Grounding

NOTE: Only the one point where the loop is alr eady gr ounded

Isolation The AC power sources for this instrument must be

1. Do not connect the signal return to the earth

ground at more than one point in the output/

power loop.

2. Any receiver or electronic device inserted in the

output/power loop must be designed so that the

connections to the loop are isolated from gro und .

can accept a grounded lead.

3. Do not connect the earth ground to the signal

return in the transmitter input circuit.

4. Do not connect any of the transducer signal wires

to the earth ground.

separate and isolated from the power supplied to any

switches, relays, solenoids, or motors which can introduce excessive noise into the instrument’s circuits.

Load cells and load cell signal wires are not typically

grounded, and they are not typically connected to

their shields or to the load cell case. If the recommendations given in the grounding and shielding section

are followed, there will be no need for isolation in the

transmitter/load-cell circuit. In fact, in the load cell

circuit, isolation adds to the cost and inaccuracy and is

not recommended.

It is generally not necessary to provide isolation in the

output loop. However, when ground-loop problems

do occur, a Loop isol ator d e sign ed t o hand le the 4 ma

to 20 ma Loop Powered Level Weight Transmitter

signal may be installed. (See Fig. 5)

Calibration The HI 2201LT Loop Powered Level Weight Trans-

mitter is calibrated at the factory for 4 ma current output with zero millivolts input and 20 ma output for 15

mV input (based on a 3mV/V input source and 5 V

excitation). In most cases, the transmitter will require

a very simple recalibration to the system in which it is

installed. The calibration procedure provided is

designed to be used either in new installations or for

recalibration of existing systems, and will work with 3

mV/V or 2 mV/V load cells. Be sure to read all cali-

7

Page 12

HI 2201LT/HI 2204LT

Calibration

Controls

Coarse (Zero) The Coarse Control is used to remove large deadloads

Fine (Zero) This control is a fine offset adjustment. Its range is

Span The Span Control adjust the gain of the transmitter. It

brations instructions before attempting to calibrate the

instrument.

or offsets such as the weight of the scale’s platform,

container or any other constant weight on the load

cells which is part of the weighing equipment itself.

This control can subtract as much as 65% of full scale

from the transmitter’s output.

sufficient to fine tune the COARSE adjustment.

determines how many millivolts (of transducer signal)

per volt (of transducer excitation) will be represented

by the 4 ma to 20 ma output range.

The gain can be adjusted from 3 mV input per volt of

excitation to as high as 0.8 mV input per volt of excitation. This broad range of sensitivity allows for the

wide variation in transducer range that remains after

deadload compensation is subtracted by the COARSE

Zero adjustment.

Calibration

Procedures

8

The measuring instruments used in the following procedure must be designed so that test leads are isolated

from ground. These are either “floating” and/or “isolated” and/or “differential” types.

Insertion of any measuring device, or voltage dropping resistor for a measuring devic e in the output/

powers loop requires that t he power sup ply voltage be

high enough to supply the extra voltage (See InputStrain Gage T ransducer). The following is an example

using load cells in a weighing application.

Step 1. Remove any weight from the scale. Allow

deadload to remain. If deadload is counter balanced, also allow counterbalancing to

remain.

Page 13

HI 2201LT/HI 2204LT

Step 2. Install a milli ammeter, in series, into the

output/power loop of the transmitter. If a

voltmeter is to be used for measurements,

and a resistor for calibration is not already

installed in the system, install a 100 ohm,

+- 0.1%, 1/4 W resistor, in series, into the

output/power loop of the transmitter. Voltmeter readings are show in parentheses.

Step 3. If a voltmeter is used, attach the voltmeter

across the 100 ohm resistor.

Step 4. Adjust the transmitter FINE control for a 4

ma (1/4 V) reading on the meter. If necessary, center the FINE control, and adjust

COARSE control first.

Step 5. Place a know weight on the scale. If possi-

ble, use a full scale weight for best results.

Step 6. Adjust the SPAN for 20 ma (2V) for full-

scale.

• Divide: Calibration Weight/FullScale

Weight = (F)raction of full scale.

• Multiply: (F) (16 ma) = 1, the current caused by the calibration

weight.

• Add: 1 + 4 ma = Calibration Current, 1c

• Adjust the SPAN to produce the

Calibration Current, 1c, in the output/power loop.

Example Calibration Weight = 750 pounds

Full Scale Capacity = 1000 pounds

Adjust SPAN for:

(750/1000) (16 ma) + 4 ma = 1c

(0.75) (16 ma) + 4 ma = 1c

12 ma + 4 ma = 1c

16 ma = 1c

9

Page 14

HI 2201LT/HI 2204LT

Step 7. Remove the calibration weight and

recheck that the zero reading is still 4 ma

(0.4 V). Adjust the FINE control if necessary.

Step 8. Place the calibration weight back on the

scale and recheck that the calibration reading is still correct. Adjust the SPAN control if necessary.

Step 9. Repeat steps 7 & 8 until no further adjust-

ment is necessary to keep both measurements within the system tolerances.

Step 10. Calibration is complete.

Trouble Shooting

Procedures

Malfunction: No

Output

Malfunction: No

Change in Input

This section is intended to provide assistance in solving minor system problems.

Checks to be made:

1. Check voltage at + & - loop connections. You

should get a reading of 15 VDC to 50 VDC.

2. Verify load cell connections.

3. Using an Oscilloscope, verify that you have a

pulsed 5 VDC between terminals labeled - & +

excitation.

Checks to be made:

1. Load Cell signal output below original setting. If

the signal level returned by the Load Cells is

below the previous deadload setting, measure

approximately 2.3 ma between the loop + & - terminals.

2. Load Cell signal output above original setting. If

the signal level returned by the load cell is above

the previous Span setting, measure approximately 23 ma between the loop + & - terminals.

Malfunction:

Output Drifts

10

Checks to be made:

1. Verify load cell connections.

2. V erify Power Supply output and confirm that it is

outputting a constant voltage.

Page 15

HI 2201LT/HI 2204LT

Factory Mutual (FM)

Approval (HI 2201LT

Only)

The HI 2201L T is FM approved and inst rinsically safe

for Class I, II, III, Division I, Division II, Groups

A,B,C,D,E,F and G hazardous locations in accordance with entity requirements and Hardy drawing

No. 0582-0563.

The HI 2201LT is approved with the MTL 705 Barrier

(See Fig. 6) or with any other FM-approved barrier

provided that the maximum entity parameters are met.

(See Fig. 7)

FIG. 6 MTL705 BARRIER

FIG. 7 FM APPROVED BARRIER

11

Page 16

HI 2201LT/HI 2204LT

12

Loading...

Loading...