Page 1

Operator’s Manual

PROFIBUS Interface Option

for the HI 2151 Series

Weight Controller

OPERATION AND

INSTALLATION

MANUAL

Document Part Number 0596-0231-01 Revision E

9440 Carroll Park Dr. • San Diego, CA 92121

Tel 858.278.2900 • Fax 858.278.6700 • www.hardysolutions.com

Page 2

HI 2151 Series Weight Controller

Profibus Interface Option

Page 3

Table of Contents

Table of Contents

SECTION 1 OVERVIEW ....................................................................................................................... 1

1.1. Scope .......................................................................................................................... 1

1.2. Description ......................................................................................................................... 1

1.3. Function .......................................................................................................................... 1

1.4. Specifications ..................................................................................................................... 1

1.5. PROFIBUS-DP Capabilities ............................................................................................... 2

1.5.3 Data Exchange ................................................................................................. 2

1.5.4 Diagnostics ....................................................................................................... 2

1.5.5 Baud Rate Auto-Detect ..................................................................................... 3

1.5.6 Multiple Nodes .................................................................................................. 3

1.5.7 GSD File ........................................................................................................... 3

1.5.8 Type File ........................................................................................................... 3

1.6 Performance Characteristics .............................................................................................. 3

SECTION 2 INSTALLATION ................................................................................................................ 5

2.1. Scope .......................................................................................................................... 5

2.2 Unpacking .......................................................................................................................... 5

2.3 Installing the Profibus Interface Option Card ..................................................................... 5

2.4. Connecting the Network Cable to the Card ....................................................................... 8

2.5. Cable and Connector Requirements .................................................................................. 9

2.6 Cable Pin Definitions .......................................................................................................... 9

2.7 Communication Rate/Cable Lengths/Connectors ............................................................ 10

SECTION 3 SETUP ............................................................................................................................ 11

3.1 Scope ........................................................................................................................ 11

3.2 Panel, Wall and Remote Setup Procedure ...................................................................... 11

3.3 Blind Unit Setup Procedure .............................................................................................. 13

3.3.1 Setting the Address for Blind Units .................................................................................. 14

SECTION 4 BLOCK READS .............................................................................................................. 15

4.1. Scope ........................................................................................................................ 15

4.2. Transfer Commands ........................................................................................................ 15

4.2.1 Overview of Transfer Commands ................................................................... 15

4.2.2 Overview of Block Transfer Commands ......................................................... 15

4.3 Detailed Command Set For Block Reads ........................................................................ 16

4.4 Response/Error Code Setup ............................................................................................ 16

4.5 Block Read Command Setup ........................................................................................... 17

4.6 Block Read Example ........................................................................................................ 17

4.7 Set Point Status/Description Bytes .................................................................................. 18

Page 4

HI 2151 Series Weight Controller

Profibus Interface Option

4.7.1 Set point Status............................................................................................... 18

4.7.2 Set point Description ....................................................................................... 18

4.8 Block Read Data Numbers ............................................................................................... 19

SECTION 5 BLOCK WRITES ............................................................................................................ 27

5.1 Scope 27

5.2 Overview of Transfer Commands .................................................................................... 27

5.3 Overview of Block Transfer Commands .......................................................................... 27

5.4 Detailed Command Set for Block Transfer (Writes) ......................................................... 28

5.5 Block Write Example ........................................................................................................ 28

5.6 Block Write Command Numbers ...................................................................................... 29

SECTION 6 SELECTABLE READS................................................................................................... 36

6.1 Scope 36

6.2 Overview of Transfer Commands .................................................................................... 36

6.3 Overview of Selectable Transfer Commands .................................................................. 36

6.4 Detailed Data Set for Selectable Read(S) ....................................................................... 37

6.5 Selectable Read Command Setup Procedures ............................................................... 37

6.6 Selectable Read Command Example .............................................................................. 38

6.7 Selectable Read Data ...................................................................................................... 39

6.7.1 Full Status and Weight Data .......................................................................... 39

6.7.2 Floating Point Weight Data ............................................................................ 40

6.7.3 Set point Relay Status 1-8 ............................................................................. 40

6.7.4 Read Tare Value ............................................................................................ 41

6.7.5 Calibration Parameters .................................................................................. 41

6.7.6 Sticker Value (Not valid for the HI 2151/30WC) ............................................ 42

6.7.7 Configuration of Rate-of-Change ................................................................... 42

6.7.8 Configuration of Analog Output ..................................................................... 42

6.7.9 Configuration of Standard RS232 Port .......................................................... 42

6.7.10 Instrument ID ................................................................................................. 43

6.7.11 Instrument identification ................................................................................. 43

6.7.12 Response/Error Code ..................................................................................... 43

6.7.13 Integrated Technician (Not Valid for HI 2151/20WC) ..................................... 44

SECTION 7 SELECTABLE WRITES ................................................................................................. 45

7.1 Scope ........................................................................................................................ 45

7.2 Overview of Transfer Commands .................................................................................... 45

7.3 Overview of Selectable Transfer Commands .................................................................. 45

7.4 Detailed Command Set for Selectable Writes .................................................................. 46

7.5 Selectable Write Command Setup Procedures ............................................................... 46

7.6 Operator Selectable Write Example ................................................................................. 47

7.7 Selectable Write Commands ............................................................................................ 48

7.7.1 Set Point Relay Functions ............................................................................. 48

7.7.2 Send Tare Value ............................................................................................ 49

7.7.3 Scale Calibration Parameters ........................................................................ 49

Page 5

Table of Contents

7.7.4 Sticker Value (This data is not valid for the HI 2151/30WC) ......................... 49

7.7.5 Configuration of Rate-of-Change ................................................................... 49

7.7.6 Configuration of Analog Output ..................................................................... 50

7.7.7 Configuration of Standard RS232 Port .......................................................... 50

7.7.8 WAVERSAVER & Excitation Monitor (HI 2151/30WC Only) ......................... 50

SECTION 8 TROUBLESHOOTING PROCEDURES ......................................................................... 51

8.1. Scope ........................................................................................................................ 51

8.2 Disassembly and Reassembly Notes and Cautions ........................................................ 51

8.3 TroubleShooting Guide .................................................................................................... 52

8.3.1 LED Does Not Come ON (See Fig. 8-1) ........................................................ 52

8.3.2 Self Test Fails ................................................................................................ 52

8.4 Error Codes ...................................................................................................................... 53

8.4 Clearing Profibus Diagnostic Code Associated Bit(S) ..................................................... 55

8.5 PROFIBUS Status Indicators ........................................................................................... 56

8.5.1 PROFIBUS Interface Card LED ..................................................................... 56

8.5.2 HI 2151 Series Indicator Light ....................................................................... 56

APPENDIX A - IEEE FOR NORMAL FLOAT TYPE ............................................................................ 57

APPENDIX B - DECIMAL, HEX, OCTAL, AND BINARY CONVERSION CHART .............................. 58

Page 6

Page 7

Section 1 OVERVIEW

Batching/Blending

Check Weighing

Filling/Dispensing

Force Measurement

Level by Weight

Rate Monitoring

1.1. SCOPE

This manual describes the operating procedures, specifications, installation, and setup for

the Hardy Process Solutions, PROFIBUS Interface Option -B12, which is used with the

Hardy HI 2151 Series Weight Controllers.

To ensure the maximum service life and safe operation of the PROFIBUS Interface Card,

use the card only as described in this manual and observe the cautions, warnings, and

safety procedures.

Hardy Process Solutions appreciates your business. Should you have any problems, please

contact our Customer Service Department at:

Phone: (858) 278-2900 FAX: (858) 278-6700

1.2. DESCRIPTION

Section 1: Overview

Using the Siemens SPC3 chip set, the PROFIBUS Option B12 interface card serves as a

high speed, intelligent client to a scanning PROFIBUS-compatible server that is setup on a

PC or PLC (Programmable Logic Controller). This arrangement supports PROFIBUS-DP

(Decentralized Periphery) and allows users to access data exchanged between the server

and the HI 2151 Weight Controller for use in PLC ladder logic, chart, or other programs.

You can configure the HI 2151 Series-B12 to function as either a local display for

weighing parameters or a blind controller that digitizes load cell signals and provides

responsive set point control.

1.3. FUNCTION

The PROFIBUS Interface Option allows the PROFIBUS server to use all of the Hardy HI

2151/20WC configuration, weighing, and scale-calibration functions. The interface

provides bi-directional communications between a server and client and allows the server

to access all configuration and weighing parameters of the HI 2151 Series Weight

Controllers.

Two data transfer options let you select commands and summaries: Selectable Transfers or

Block Transfers (a set of pre-defined data blocks). The Write commands (outputs) are sent

from the server to the weight controller. The Read Data Summaries (inputs) return weight

and scale status data to the server.

Passing the data in integer format eliminates conversion steps and reduces the time needed

to incorporate the PROFIBUS Interface Option into the server’s ladder logic or chart code.

The Interface uses transmission medium (2 or 4 wire cable) characteristic of serial field bus

applications.

1.4. SPECIFICATIONS

The PROFIBUS Interface Option is used for the following applications:

1

Page 8

HI 2151 Series Weight Controller

Profibus Interface Option

1.5. PROFIBUS-DP CAPABILITIES

1.5.1 Watch Dog

Watch Dog communication control detects failures in the bus or the assigned DPM1 (DPMaster - Class 1, which is the central controller in PROFIBUS-DP). If the interface card

detects no successful data transfers within a set interval, it switches its outputs to the failsafe state until successful communication is resumed.

1.5.2 Configuration

Configuration data contains the range of input and output areas and the information about

the data consistency (byte or word length).

The default configuration for Hardy PROFIBUS Interface is 16 words or 32 bytes.

For the 32 byte I/O the identifier bytes have the following format:

Number of Configuration bytes: 2

• Config byte 1 77 (hexadecimal)

• Config byte 2 77 (hexadecimal)

The maximum number of bytes of I/O can be achieved by setting:

Number of Configuration bytes: 4

• Config byte 1 7D (Hex)

• Config byte 2 7D (Hex)

• Config byte 3 7D (Hex)

• Config byte 4 7D (Hex)

For 112 bytes of input and 112 bytes of output.

NOTE: See DIN Standard 19245, Part 3, Paragraph 8.3.5, page 55, for a description of the config

data.

1.5.3 DATA EXCHANGE

The PROFIBUS Interface Option can exchange the Input (Read) and Output (Write) data

between devices. The PROFIBUS inputs and outputs are either selectable or block reads.

The PROFIBUS Interface Option supports the standard 16-word or 32-byte format for

transfers, but you can set it to any buffer size that is less than or equal to 112 bytes.

PRE-DEFINED BLOCKS ARE UP TO 32 BYTES IN LENGTH. IF LESS THAN 32

BYTES ARE DESIRED FOR BUS TRAFFIC CONSIDERATIONS, THEN

SELECTABLE TRANSFERS SHOULD BE USED.

NOTE: Two bytes equal one word.

1.5.4 DIAGNOSTICS

The PROFIBUS Interface Option has built-in diagnostics. Write command errors set

diagnostic bits, e.g. the NACK (not acknowledge) bit.

2

Page 9

1.5.5 BAUD RATE AUTO-DETECT

The PROFIBUS network can support up to 12 Mbaud transfer rates. The server’s Auto Detect function finds the system baud rate (the rate of the slowest component), which

eliminates the need for board settings.

1.5.6 MULTIPLE NODES

Depending on the PLC, the PROFIBUS network is configurable to include several nodes

(The HI 2151 weight controller is one node) up to a maximum of 126.

1.5.7 GSD FILE

Some PLC’s require the GSD file (HRDY2151.GSD) to assist in setting up the HI

2151/20WC Weight Controller on the PROFIBUS network. See your PLC O&M manual

or the Hardy web site. To get the GSD file file from the Hardy Website:

1. Select Support

2. Highlight Online Support

3. Click on Sample Programs.

Section 1: Overview

4. Select it from the GSD pull-down list.

1.5.8 TYPE FILE

Six Type files, referred to as the Device Data Base (DDB) Files, may be needed to

configure some of the Siemens PLCs. They are included on the Hardy disk (See DIN

Standard 19245, Part 3, Paragraph 13, Page 197) Refer to the specific Siemens PLC

manual for instructions. If type files are needed for older model PLCs, contact Hardy Tech

Support.

Description for the use of the type files:

Window COM: Copy the attached type file HI2151ax.200 in the directory

s:\COMWINx0\TYPEDAT5x. After starting WIN COM you can select your

device in the family “Others”.

DOS Com V4.x: Copy the attached files depending on your selected language

with the DOS Com under the directory of the Com.

HI2151TE.200 - English Version

HI2151TD.200 - German Version

HI2151TF.200 - French Version

HI2151TI.200 - Italian Version

HI2151TS.200 - Spanish Version

1.6 PERFORMANCE CHARACTERISTICS

Environmental Requirements

1. Temperature:

Operating - 10º to 50º º F)

Storage - 20º to 85º C (- º F)

3

Page 10

HI 2151 Series Weight Controller

Siemens TI 505 or others using (Motorola) Protocol (Bytes)

One Word (Expressed in Bytes)

Least Significant Byte (LSB)

Most Significant Byte (MSB)

7 6 5 4 3 2 1 0 7 6 5 4 3 2 1

0

Siemens S5 and S7 & Allen-Bradley PLC5 PLC series or others using (Intel) Protocol (Bytes)

One Word (Expressed in Words)

Most Significant Byte (MSB)

Least Significant Byte (LSB)

7 6 5 4 3 2 1 0 7 6 5 4 3 2 1

0

Profibus Interface Option

2. Humidity:

0 to 80% Relative Humidity (Non-condensing)

Baud Rate

9,600 kbaud to 12 Mbaud - (Auto-Selectable)

Process Control Standards Reference

Process Fieldbus (PROFIBUS) - DIN 19 245

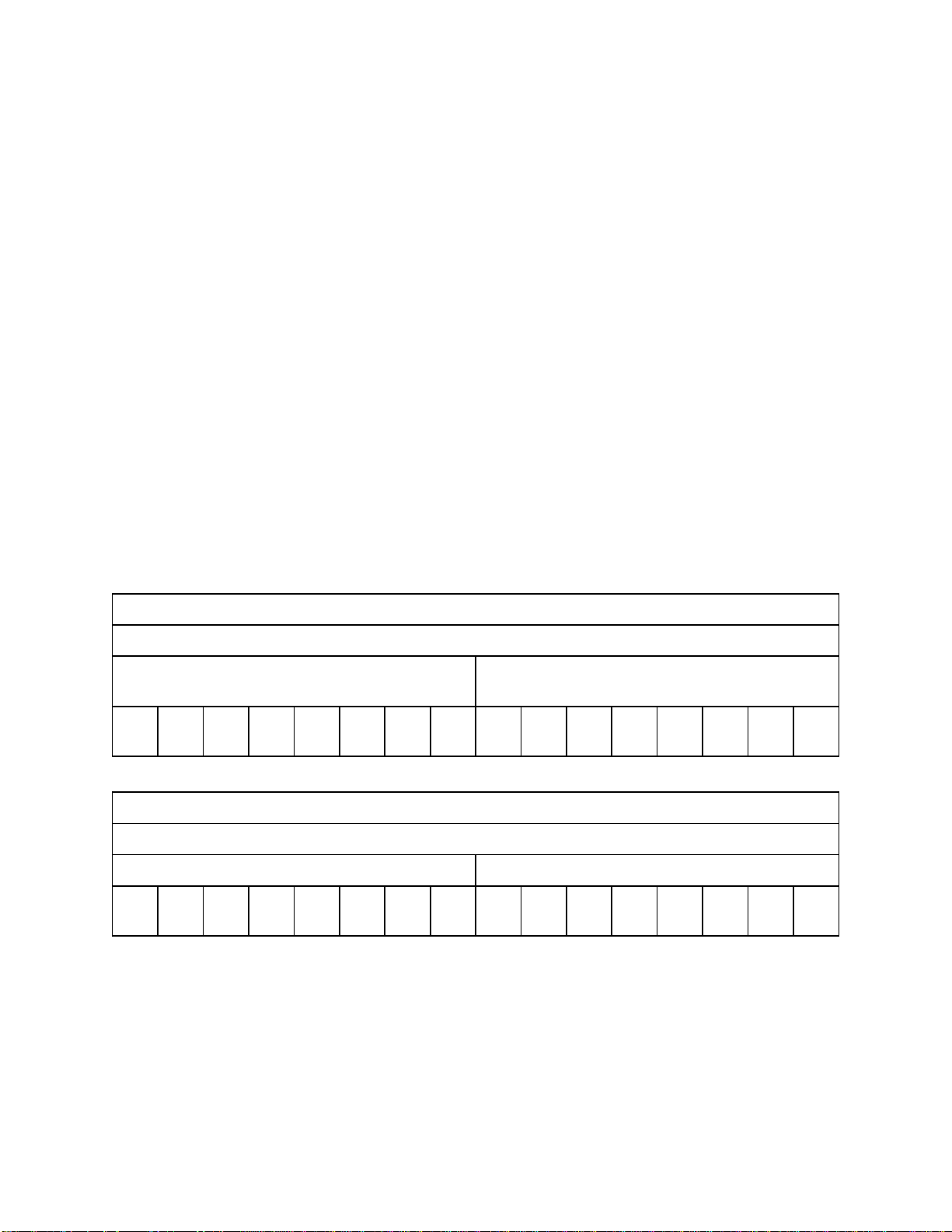

Reference Data Protocols

Master manuals will reference data either in bytes or words using the different protocols

that are particular to a server or series of servers. For example:

1. The Siemens TI 505 Series of PLCs use the Motorola protocol and expresses reference

data in bytes.

2. The Siemens S5 and S7 PLC series and the Allen-Bradley PLC5 PLC series use an

Intel protocol and express reference data in words.

3. The PROFIBUS manual references both bytes and words.

This means that the Least Significant Byte (LSB) and the Most Significant Byte (MSB)

locations vary. Note that two bytes equals one word. (See the charts below)

TABLE 1-1 REFERENCE DATA PROTOCOLS

4

Page 11

SECTION 2 INSTALLATION

NEVER INSTALL OR REMOVE THE PROFIBUS INTERFACE CARD

WITH THE POWER CORD CONNECTED.

2.1. SCOPE

Chapter 2 explains unpacking, cabling and interconnection, and installation of the -B12

PROFIBUS Interface Card. Operators and maintenance personnel should read the

procedures in this chapter before installing or operating the PROFIBUS interface card.

2.2 UNPACKING

1. Inspect the packing for damage of any kind, before signing for or opening the package.

2. Report any damage to the carrier company immediately.

3. Check to see that everything in the package matches the bill of lading. You should

normally have:

Purchased with a new Weight controller

1 - HI 2151-B12 Series Weight Controller + PROFIBUS Interface Option.

Section 2: Installation

1 - HI 2151 Series Operation &Installation Manual

1 - PROFIBUS Operation & Installation Manual

1 - CD with the GSD File and Type Files.

Purchased separately to retrofit an HI 2151 Series WC:

1 - HI-2151 Series-B12 PROFIBUS Interface (PCB)

NOTE: The PROFIBUS Interface PCB is completely interchangeable between HI-2151 Series

Weight Controllers.

4 - #4 Phillips pan head, SEM Machine Screws.

1 - PROFIBUS Operation & Installation Manual

1 - CD with the GSD File and Type Files.

Configuration Instructions - Prt. #0597-0428-01

4. Record the model number and serial number of the weight controller or interface card

and EPROM version. Store this information in a convenient, secure location for

reference when buying parts or firmware upgrades.

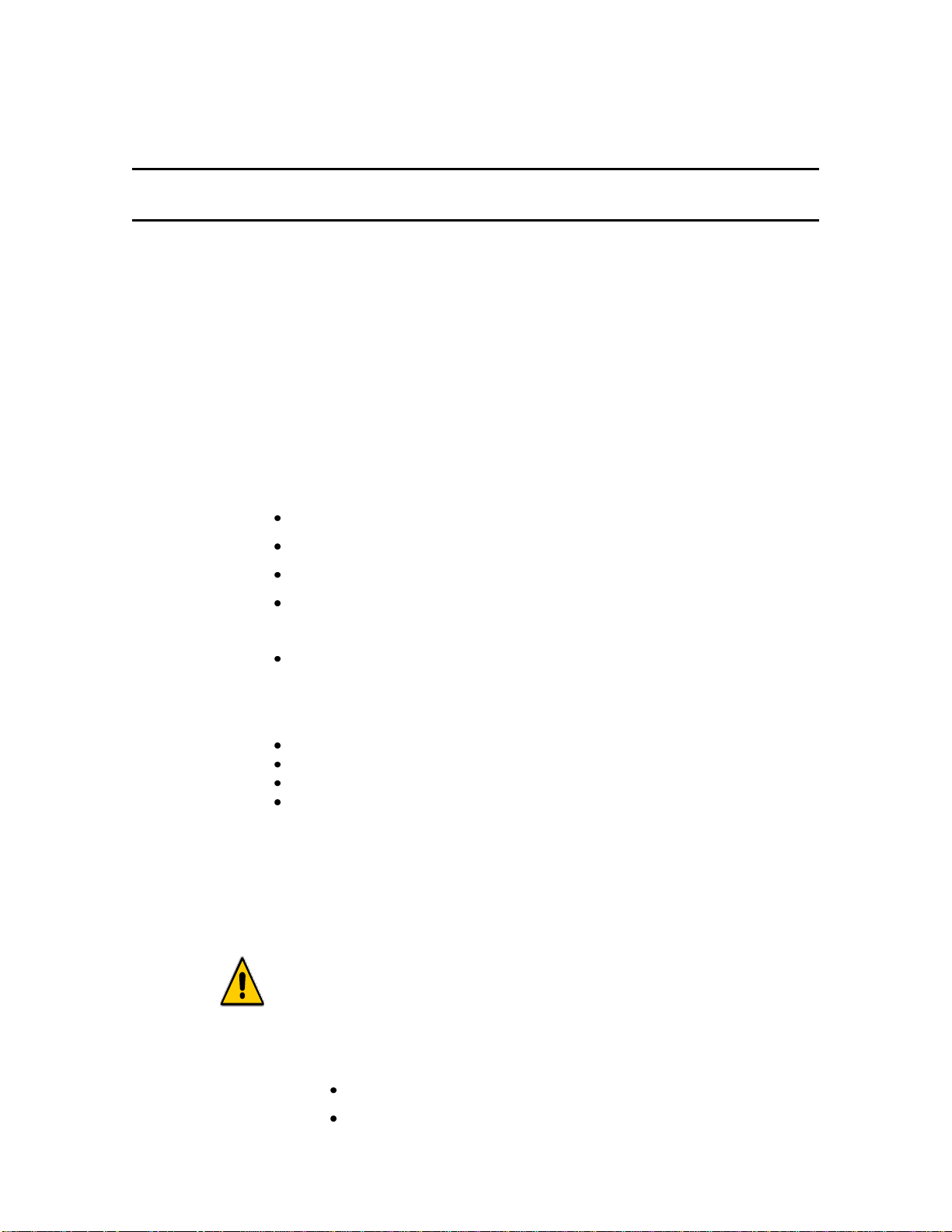

2.3 INSTALLING THE PROFIBUS INTERFACE OPTION CARD

1. Disconnect all power cords from the HI 2151 Series Weight Controller.

2. Accessing the printed circuit boards

A. Wall Mount Installation (NEMA 4x Enclosure)

Open the front panel of the NEMA enclosure.

A/D converter PCB and Power/Relay PCB are fastened to the rear panel.

5

Page 12

HI 2151 Series Weight Controller

Profibus Interface Option

B. Panel Mount, Remote, and Blind Installations.

Remove the four Phillips head machine screws that fasten the chassis to

the HI 2151 Series WC cover.

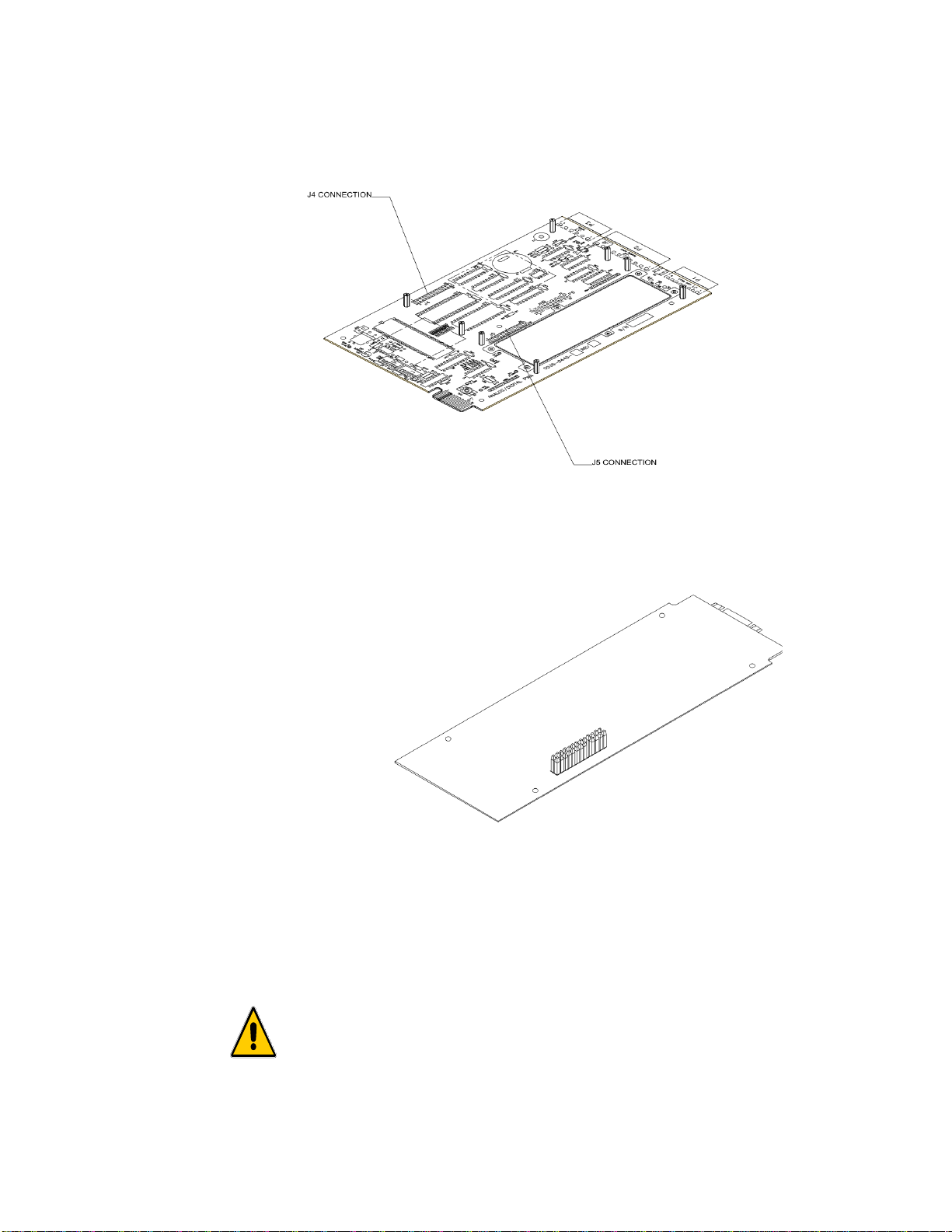

Figure 2-2

3. Pull the chassis completely out of the cover.

4. Place the chassis on an anti-static pad.

5. Put on an anti-static wristlet and connect it to the anti-static pad.

6. Analog to Digital PCB is clearly visible and there are eight standoffs mounted on the

board. (See Fig. 2-2)

7. Remove the PROFIBUS Interface Card from the anti-static bag.

6

Page 13

Section 2: Installation

MAKE SURE THAT ALL THE PINS ARE PLUGGED INTO THE J4 OR

J5 CONNECTOR. FAILURE TO PROPERLY INSTALL THE PROFIBUS

INTERFACE CARD WILL RESULT IN PERSONAL INJURY OR

PROPERTY DAMAGE.

Figure 2-3

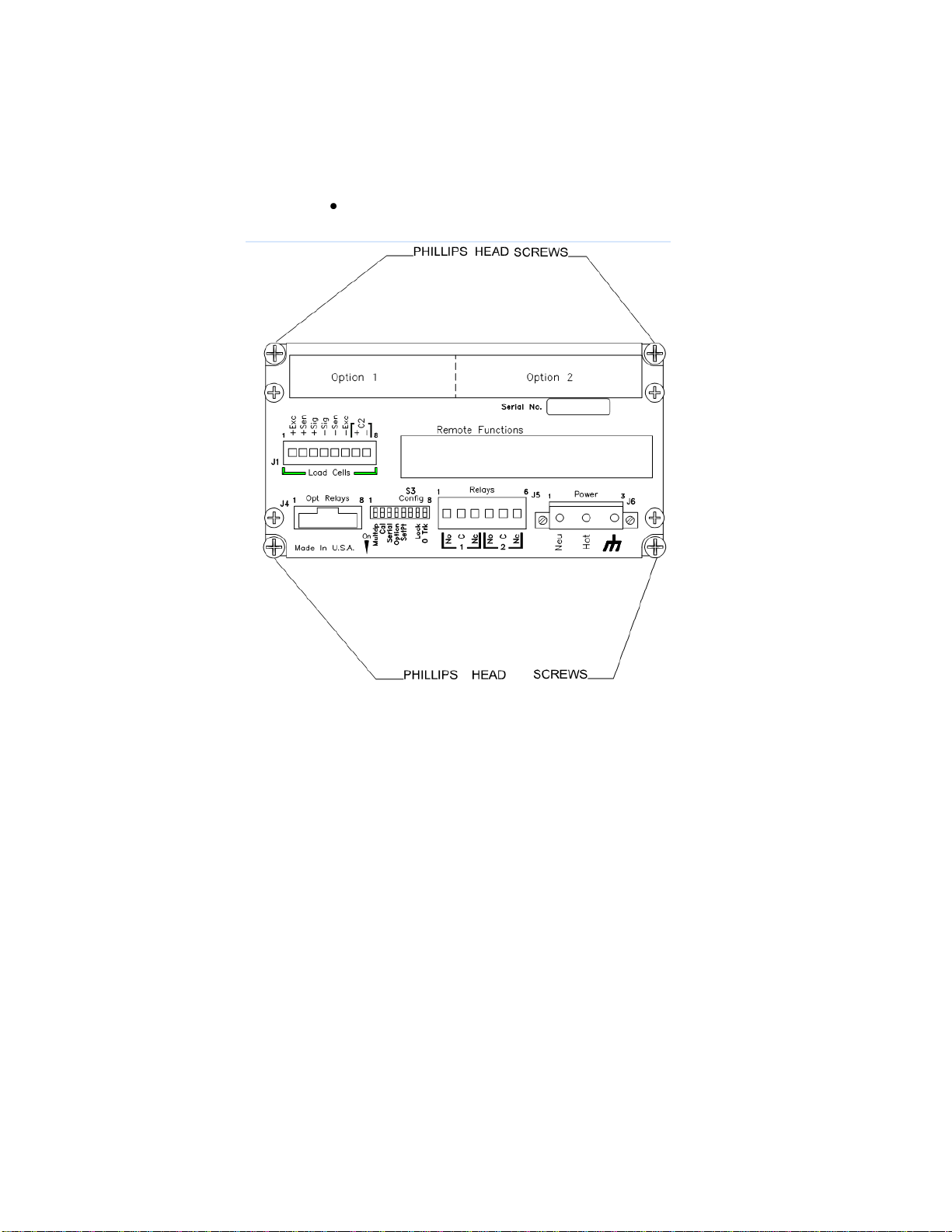

8. On the solder side of the PROFIBUS Interface Card, the side opposite the components,

there is a pin connector. (See Fig. 2-3)

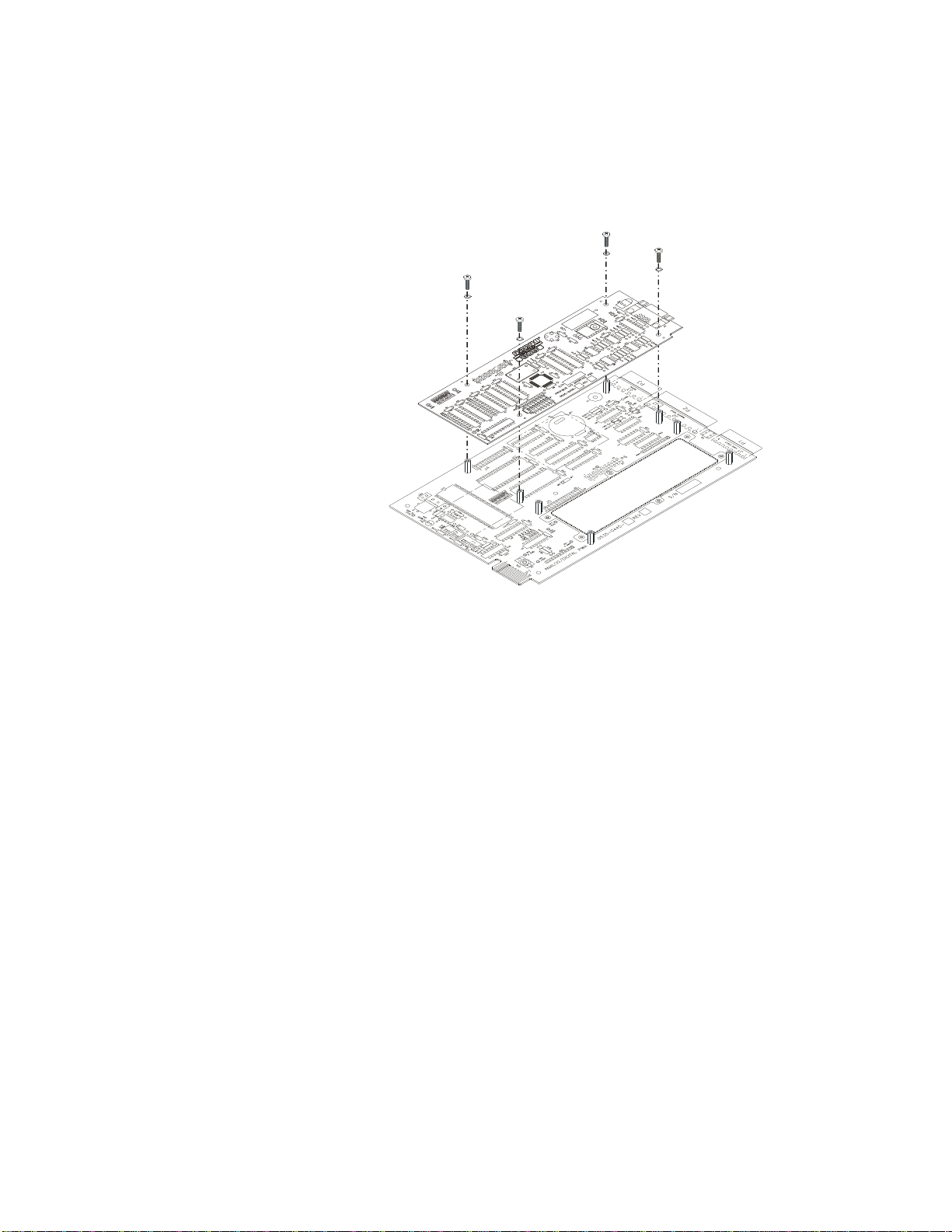

Figure 2-4

9. With the pin connector side down, carefully plug the PROFIBUS Interface Card into

either connector J4 or J5 (See Fig. 2-2) whichever is available. These connectors also

refer to option 1 or option 2 on the rear panel. Option 1 uses connector J5. Option 2

uses connector J4. (See Fig. 2-4)

7

Page 14

HI 2151 Series Weight Controller

Profibus Interface Option

10. The through holes on the PROFIBUS Interface Card should line up with the threaded

holes in the standoffs. A little adjustment is sometimes necessary to line them up.

(See Fig. 2-5)

Figure 2-5

11. Place the washers over the holes on the component side of the PROFIBUS Interface

Card and install the four Phillips pan head SEM screws (See Fig. 2-5).

NOTE: For blind installations the dip switches will need to be set before reinstalling the chassis.

(See Chapter 3, paragraph 3.2 for instructions)

12. Slide the chassis back into the HI 2151 Series WC cover.

13. Replace the four Phillips pan head SEM screws that fasten the chassis to the HI 2151

Series WC cover.

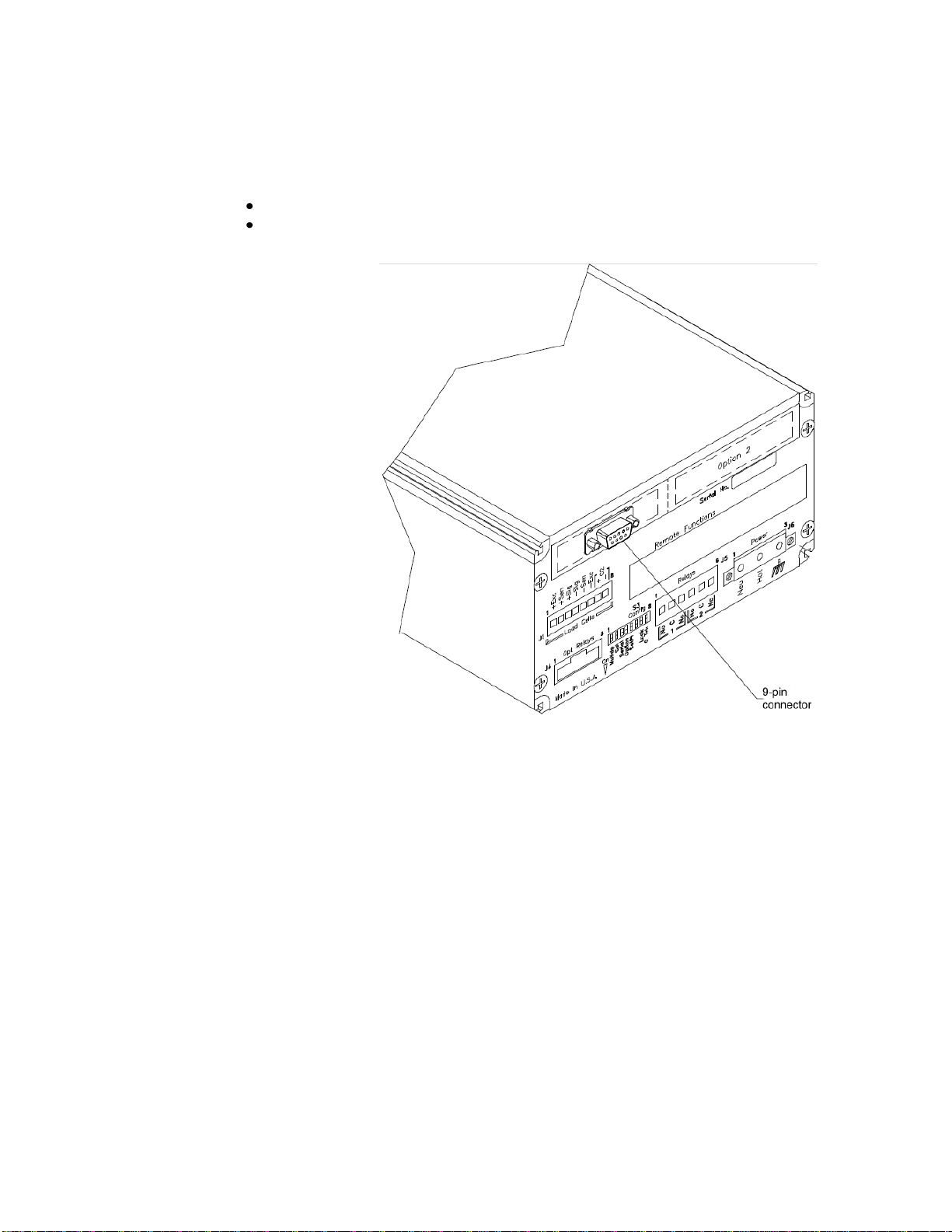

2.4. CONNECTING THE NETWORK CABLE TO THE CARD

1. The 9-pin female connector is located on the rear panel of the chassis. If the

PROFIBUS Interface Card is plugged into slot J5 the 9-pin connector will be in Option

Slot 1. If the PROFIBUS interface card is plugged into slot J4 the 9-pin connector will

be in Option Slot 2.

2. Plug the Siemens cable assembly and bus connector into the 9-pin female connector on

the rear panel of the chassis. (See Fig. 2-6)

NOTE: If the weight controller is the last node on the bus, the terminating resistor must be ON.

NOTE: It is highly recommended that the Siemens cable and bus connector listed be used. Check

with your closest Siemens Electronics dealer for pricing and availability.

8

Page 15

2.5. CABLE AND CONNECTOR REQUIREMENTS

Siemens Bus Connector - (SINEC L2) Prt. # 6ES7-972-0BA20-OXAO

Siemens Cable LWF, CMX 75C (shielded) - (SINEC L2) Prt. #6XV1-830-OAH10

Section 2: Installation

2.6 CABLE PIN DEFINITIONS

Pin 1 - Ground (outer braided shield)

Pin 3 - Signal “B” (Red)

Pin 8 - Signal “A” (Green)

Figure 2-6

9

Page 16

HI 2151 Series Weight Controller

Transmission

Speed

Without

Repeater

32 Nodes

With 1

Repeater

64 Nodes

With 2

Repeaters

92 Nodes

With 3

Repeaters

122 Nodes

9.6 k

1200 m

2400 m

3600 m

4800 m

19.2 k

1200 m

2400 m

3600 m

4800 m

93.75 k

1200 m

2400 m

3600 m

4800 m

1875 k

600 m

1200 m

1800 m

2400 m

500 k

400 m

800 m

1200 m

1600 m

1.5 M

200 m

400 m

600 m

800 m

3,6,12 M

100 m

200 m

300 m

400 m

Profibus Interface Option

2.7 COMMUNICATION RATE/CABLE LENGTHS/CONNECTORS

Shielded twisted pair two wire cable is required for the PROFIBUS Interface Connection.

The characteristic impedance of the cable should be in the range between 135 and 165

Ohms (3 to 20 MHZ), the cable capacity (conductor-conductor) should be <30 pF/M and

the conductor area should be 0,34 mm2. The 9 pin din connector on the option board is

used for all PROFIBUS connections.

10

Page 17

SECTION 3 SETUP

3.1 SCOPE

Chapter 3 consists of all the procedures to setup the PROFIBUS Interface Option. To

make sure that the interface option works properly, programmers and maintenance

personnel should be familiar with this chapter before setting up or operating the system.

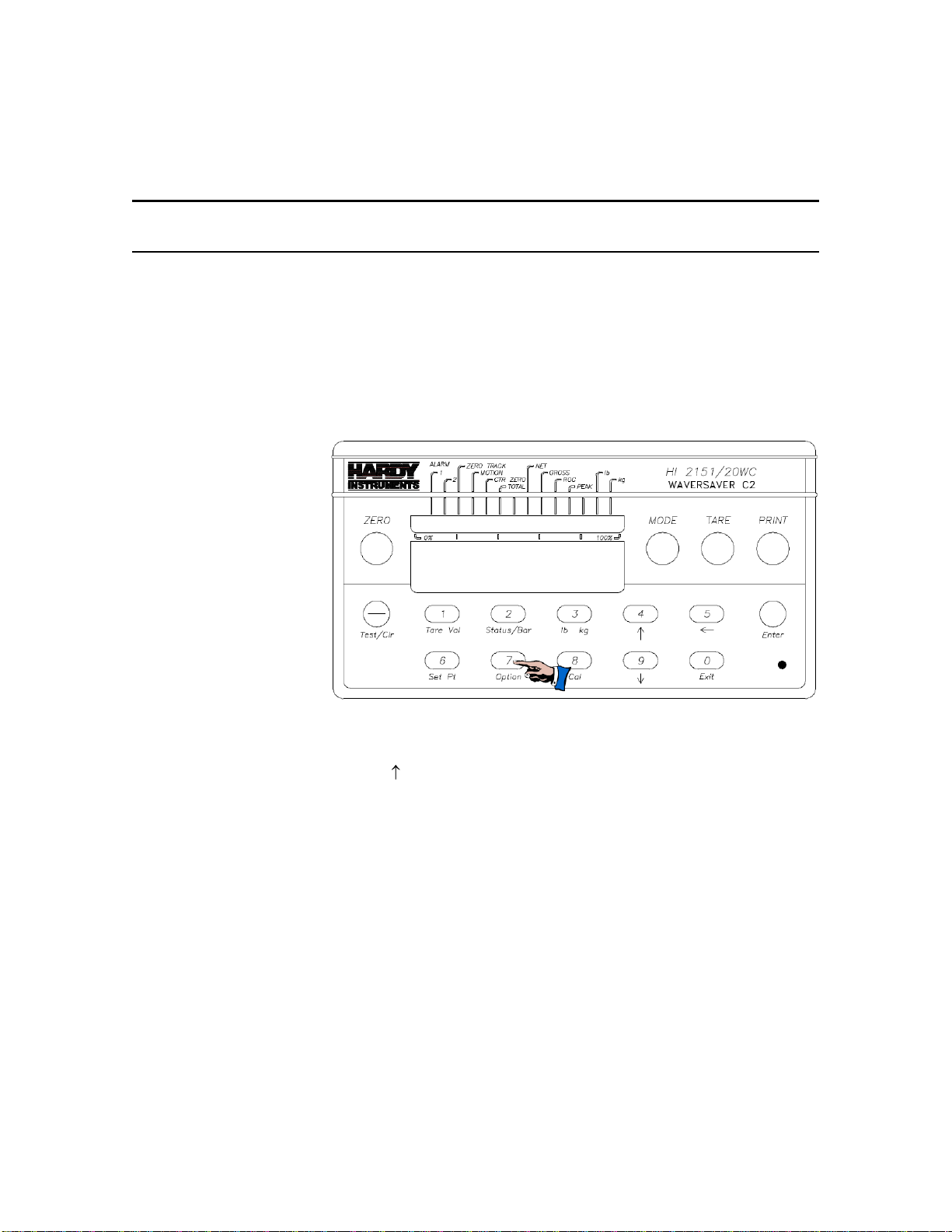

3.2 PANEL, WALL AND REMOTE SETUP PROCEDURE

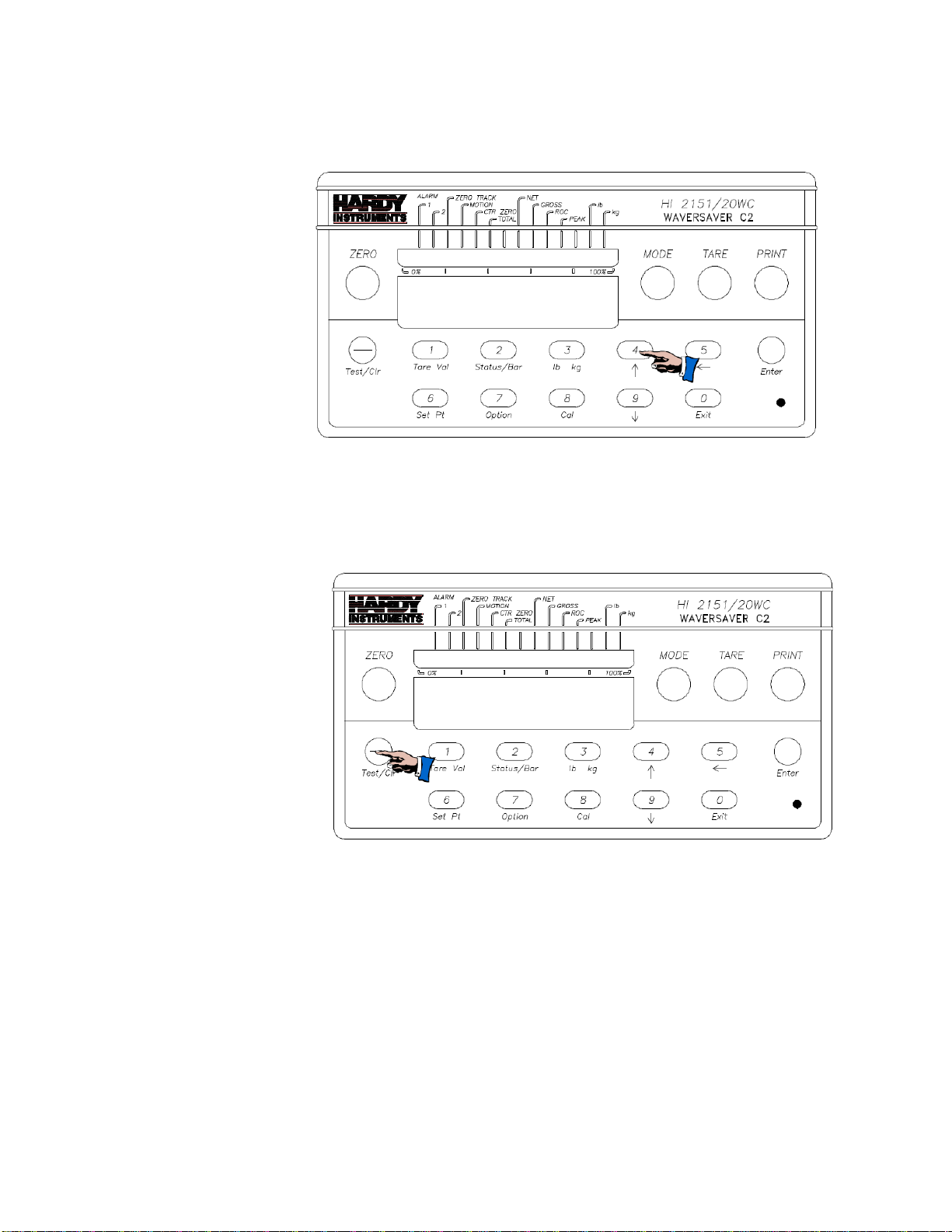

1. Press the 7/Option button. (See Fig. 3-1) The first option appears.

Section 3: Setup

Figure 3-1

2. Press the “4/Up” ( ) arrow button until ProFi appears on the display. (See Fig. 3-2)

3. Press the “Enter” button. The current node station address appears.

4. Use the keypad to enter a node station address (the valid address range is 1-125). The

station address must be a unique number for each node on the bus.

5. Press the “Enter” button to set the node station address.

NOTE: The PROFIBUS node address number is displayed in decimal on the weight controller.

11

Page 18

HI 2151 Series Weight Controller

Profibus Interface Option

6. Press the Test/Clr button. The display should now show four “0's”. (See Fig. 3-3)

Figure 3-2

NOTE: On an uncleared display, numbers are added to the right of the existing number.

Figure 3-3

7. Use the keypad to enter the new number.

8. Press the “Enter” button to set the address.

9. Exit the Options Menu by pressing the “Exit” button.

NOTES:

1. It may be necessary to configure the PLC (using manual or auto configuration) in

addition to powering down and powering up the instrument to activate the new menu

selections. See your PLC manual to determine if this is necessary

2. The PROFIBUS Station Address cannot be changed through the PROFIBUS Network.

3. The PROFIBUS node address number is displayed in decimal on the weight controller.

12

Page 19

3.3 BLIND UNIT SETUP PROCEDURE

A blind HI 2151 Series Weight Controller is configured without a front panel and keypad.

To set the PROFIBUS station address, a dip switch on the PROFIBUS Interface Card and

the Power & Relay PCB, must be set.

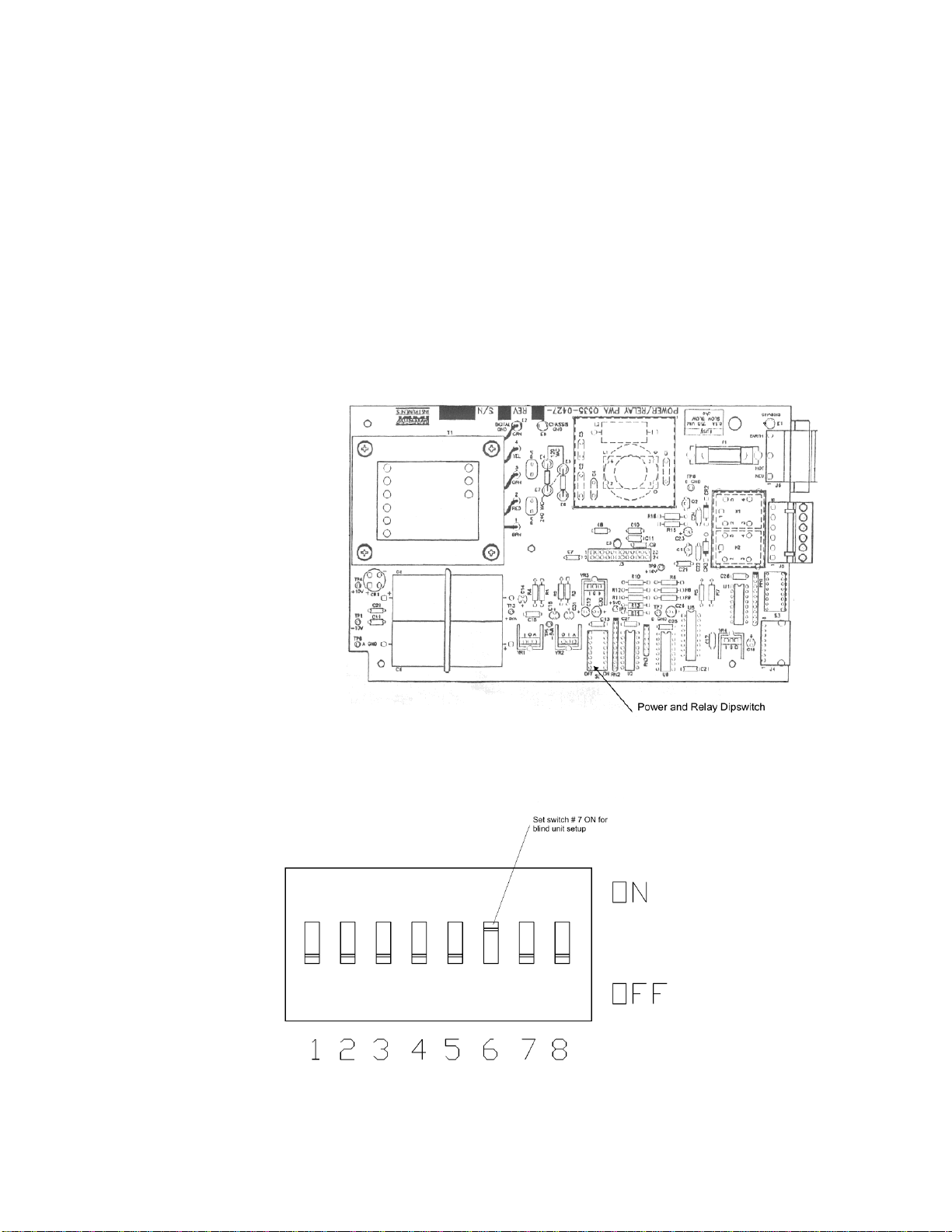

To set the power and relay (Prt # 0535-0427) dipswitches for the PROFIBUS Interface

Card:

1. Disconnect the power cord.

2. Open the panel door.

3. On the Power & Relay Printed Circuit Board (Prt # 0535-0427) there is a dipswitch

S2. (See Fig. 3-4)

Section 3: Setup

Figure 3-4

4. Set the #6 Dipswitch to “on” and the other switches to “off” (See Fig. 3-5)

Figure3-5

13

Page 20

HI 2151 Series Weight Controller

PROFIBUS PCB DIPSWITCH

SETTING ADDRESS

To set the address to 17, set

switches 1 and 5

and all other switches .

dipswitch

ON OFF

Profibus Interface Option

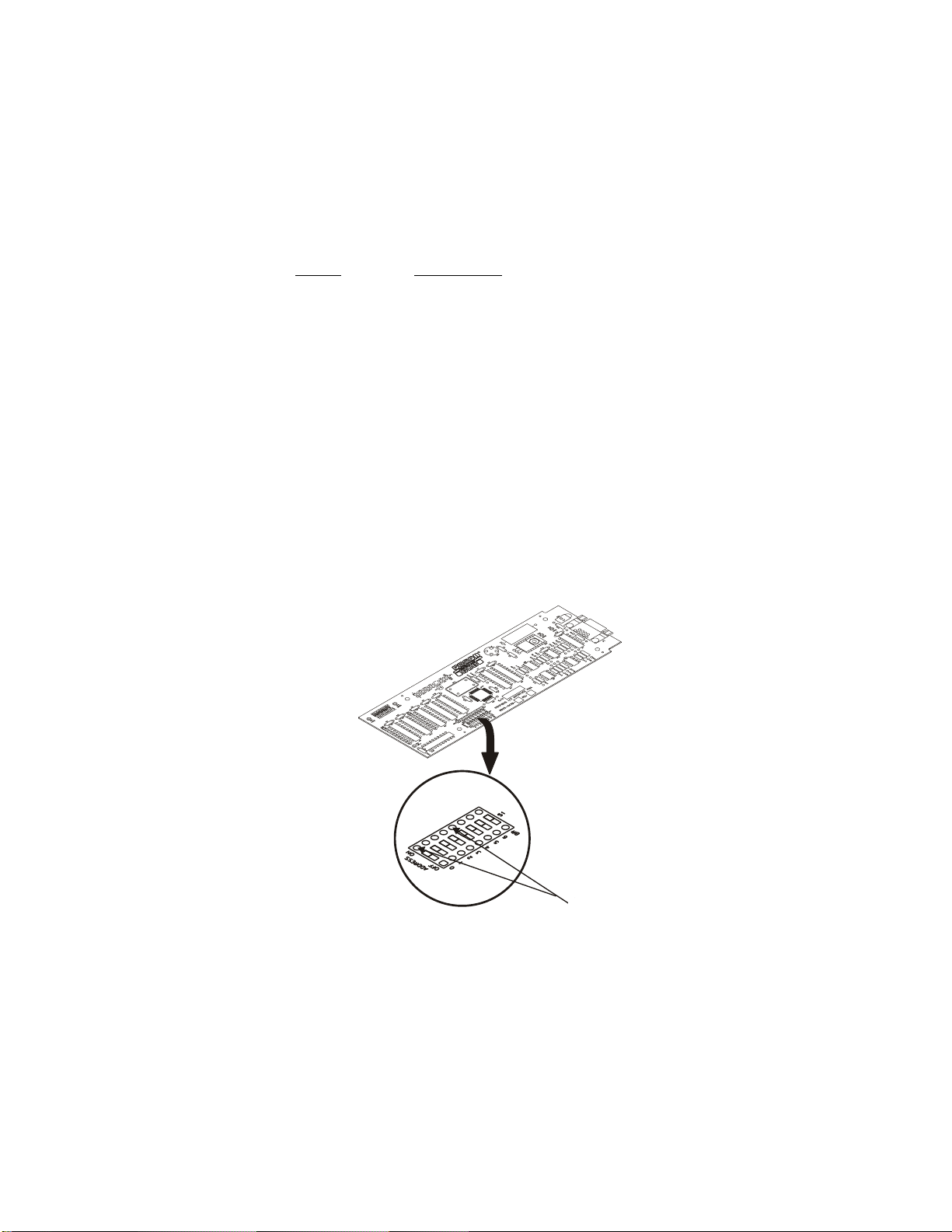

3.3.1 SETTING THE ADDRESS FOR BLIND UNITS

1. The Dipswitches on the PROFIBUS Interface Card represent a binary value as

follows:

Switch Binary Value

1 1

2 2

3 4

4 8

5 16

6 32

7 64

8 Not used

2. A PROFIBUS address can have a binary value from 1 to 125.

3. To set the address move the dipswitches that total the address binary number to the

“on” position. For example: Address 17 requires dip switches 5 (16) and 1 (1) to be

turned “on”, and all the other switches must be turned “off”. (See Fig. 3-6)

4. After setting the address, the PLC can communicate with the Blind Weight Controller.

NOTE: The PROFIBUS Station Address cannot be changed through the PROFIBUS network.

Figure 3-6

NOTE: For PROFIBUS Card Serial Numbers 1001 - 1050, the dipswitch numbers do not match

the silk screened numbers on the circuit board. To set an address of 17 on the dipswitch

14

turn on 1 & 5, which correspond to the silk screened numbers 0 & 4.

Page 21

SECTION 4 BLOCK READS

1. The PLC server determines the amount of bytes that can be

transferred; not the PROFIBUS interface option.

2. When using the HI 2151 Series PROFIBUS interface, the user can

select the Block Read Data Summaries and Block Write Commands as

required. However, the amount of bytes that can be transferred is

dependent on the data transfer capability of the server being used.

3. The ladder logic program provides the server with the ability to read

and write weight data by referencing the PROFIBUS address, the byte

numbers and number of bytes.

PLC

LADDER LOGIC

PROGRAM

WRITE/READ

#5400 (hex) +

BLOCK READ

DATA NUMBER

RESPONSE

# BETWEEN

14-20 or #23 (hex) +

DATA REQUESTED

DATA EXCHANGE

BLOCK TRANSFER

4.1. SCOPE

Chapter 4 covers block read commands for the PROFIBUS Interface Option. Programmers

and users should be familiar with this chapter before operating the PROFIBUS Interface

Option.

4.2. TRANSFER COMMANDS

4.2.1 OVERVIEW OF TRANSFER COMMANDS

1. PROFIBUS Interface Card maximum buffer size: 112 byte

2. Siemens PLC

TI 505 Series PLCs

Requires the Field Interface Module (FIM) to communicate over PROFIBUS.

Can continually exchange up to 32 words or 64 bytes for both PLC input and

output with each client device.

Section 4: Block Reads

S5 Series PLCs

Requires IM 308C Module to communicate over PROFIBUS.

Can continually exchange up to 244 bytes for PLC input and output with each

client device.

S7 Series PLC

PROFIBUS ready, does not require additional modules.

Can continually exchange up to 244 bytes for PLC input and output with each

client device.

3. Allen-Bradley PLC5 Series

Requires PROFIBUS DP module to communicate over PROFIBUS.

Can continually exchange up to 244 bytes for both PLC Input and Output with

each client device.

4.2.2 OVERVIEW OF BLOCK TRANSFER COMMANDS

15

Page 22

HI 2151 Series Weight Controller

Profibus Interface Option

NOTE: The decimal point is not included in values transferred. The decimal position is a separate

parameter.

4.3 DETAILED COMMAND SET FOR BLOCK READS

NOTE: We recommend that front panel functions be controlled through the PROFIBUS network

and that the front panel control be disabled or locked out. (See the HI 2151 Series

Weight Controller Operation and Installation Manual for lockout instructions)

1. The Block Read data to be input to the server is always initiated by a Block Write

Command designating the block number that the HI 2151/20WC Weight Controller

will send to the server.

NOTE: If your server Device does not have built in PROFIBUS diagnostic capability set up the

Response/Error “90" diagnostics first, (See section 4.4) before proceeding. The write “90"

must be set before entering a block write command so that the verification process can

determine if the first block write command sent is valid or not.

2. The weight controller receives the block number command from the server, verifies

that the block number is correct, processes the weight data and prepares a response

byte (an error code response number) to the server ’s command.

NOTES: Changes to Block Writes/Charts should be made in program mode.

To prevent errors and erroneous data from being sent to the HI 2151 Series Weight

Controller, in run mode, follow the procedures below:

1. Set the Write Block Number to “0".

2. Write the new parameter to the output buffer.

3. Change the Block Number from “0" to the new number.

4.4 RESPONSE/ERROR CODE SETUP

1. The server ’s PROFIBUS diagnostics capability determines if the error code

information is automatically displayed on the server screen. The error code number

indicates if the parameter number write command is valid. (See Chapter 8, paragraphs

8.2.3 and 8.2.4)

If the PROFIBUS diagnostics are built into the server, an error code response number

is automatically displayed.

NOTES: The first 6 bytes of the diagnostic information is reserved as defined in the Profibus

Standard. Bytes 7-12 are used by the HI 2151 Series PROFIBUS interface option to

provide automatic response/error codes.

If the PROFIBUS diagnostics are not built in to the server - a write number “90" must be

performed to get the error code response.

All write commands require a 50 millisecond response delay.

The write “90" command is used for Block Transfers only, for Selectable Transfers a write

“0" command is used.

16

2. Use write “90" procedures to retrieve an error code response number. For the Error

Code List, See Chapter 8.

Page 23

Section 4: Block Reads

Block Write Command Number 84: Select Block Read Data

Byte definitions:

Block Write Number 84 (Hex 54)

Select Read Type

Block Read Value 0

Enter Block Number

a. Enter the following information to output to the weight controller:

K1: Contains Hex 5400 (Selects Block Write #84: Selects Read Summary Data)

K2: Contains Hex 5A00 (Selects Block “90" error code:)

b. MOVW1: Downloads the information in K1 & K2 into WY17-WY18 (Weight

Controller)

c. Data is read to: WX1-WX2:

WX1: Contains Hex 5A00 (Block Read Summary Data #90)

WX2: Contains Error Code (Error code number from the Error Code Table,

See Below)

4.5 BLOCK READ COMMAND SETUP

1. Use the Block Write Command 84 (54 hex) to select the Block Read Number(s).

2. On initial start up if no Block number is selected, the PROFIBUS Interface Option

will return a Default Block Number, which is Block Read Data number 20 (14 hex):

Instrument Identification.

4.6 BLOCK READ EXAMPLE

1. The following example is a setup to read the Full Status and Weight Data from the HI

2151 Series Weight Controller.

Move Word 1 (MOVW1) selects the Block to Read, in this case 20 (14 hex) - Full

Status and Weight Data. Block 20 (14 hex) has 15 words, therefore the data is

transferred to WX1 through WX15.

K1: Contains hex 5400 (Block 84: Select Read Summary Data)

K2: Contains hex 1400 (Block 20: Full Status and Weight Data - The block

number to read)

C1: When C1 is ON, Block Read 20 information is read to WX1-WX15

MOVW1: Downloads the information in K1 and K2 into WY17 and WY18 (weight

controller)

Data is read to WX1 - WX15

17

Page 24

HI 2151 Series Weight Controller

Relay 8

Relay 7

Relay 6

Relay 5

Relay 4

Relay 3

Relay 2

Relay 1

Bit 0

Bit 1

Bit 2

Bit 3

Bit 4

Bit 5

Bit 6

Bit 7

.

Relays

LSB/MSB

Relay 1 = Gross

Relay 2 = Net

0102

Relay 3 = ROC

(Rate-of-Change)

Relay 4 = Peak

0300

Relay 5 = Total

Relay 6 = Gross

0401

Relay 7 = Gross

Relay 8 = Gross

0101

Profibus Interface Option

4.7 SET POINT STATUS/DESCRIPTION BYTES

4.7.1 SET POINT STATUS

NOTE: Relays 1 and 2 are swapped on bits 6 and 7 for set point status.

4.7.2 SET POINT DESCRIPTION

1. The set point value is the target weight or level. The set points can be set to track

peak, gross, net, rate-of-change (ROC) or total. Here is a description of the set point

mode selection:

Peak 0

Gross 1

Net 2

ROC 3

Total 4

Example:

The proper set point description bytes for the desired Relay types are as follows:

18

Page 25

4.8 BLOCK READ DATA NUMBERS

Block Read Data Number 20: Full Status and Weight Data

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Number 20 (Hex 14)

Indicator Status 1

Rate of Change currently displayed

Set point Relay 2 Active

Set point Relay 1 Active

Peak Force (weight) currently displayed

Totalized weight currently displayed

Reserved for future use

Reserved for future use

Reserved for future use

Indicator Status 2

Weight currently displayed in pounds units

Zero Track feature enabled

Reserved for future use

Current Gross weight = 0

Weight in motion, i.e. changing

Gross Weight currently displayed

Net Weight currently displayed

Weight currently displayed in kilogram units

Dipswitch Settings (Exterior)

Re-calibrate toggle

Option menu keypad lockout

Set point menu keypad lockout

Lb/Kg, Net/Gr, Tare, Zero keypad lockout

Zero tracking enable

Reserved for future use

RS 232 command lockout

Multi-drop enable (RS 422 only)

Dipswitch Settings (Interior)

Reserved for future use

Enable Gross Weight output on RS232 port

once per second

Calibration lockout for NTEP (Legal for Trade)

mode

Ignore incoming serial checksums (RS232 port)

Peak force is a result of averaged gross weight

NTEP (Legal for Trade) mode enable

Eliminate “>” on print out (RS232 port)

Reserved for blind unit toggle

Remote Functions Status

Force display to Rate-of-Change

Add current net weight to total

Hold value on display

Hold option card updates

Force display to Net weight mode

Toggle Lbs/Kg

LSB

MSB

bit 0

bit 1

bit 2

bit 3

bit 4

bit 5

bit 6

bit 7

LSB

bit 0

bit 1

bit 2

bit 3

bit 4

bit 5

bit 6

bit 7

MSB

bit 0

bit 1

bit 2

bit 3

bit 4

bit 5

bit 6

bit 7

LSB

bit 0

bit 1

bit 2

bit 3

bit 4

bit 5

bit 6

bit 7

MSB

bit 0

bit 1

bit 2

bit 3

bit 4

bit 5

1

1

1

0

1

2

1

1

1

1

1

1

0

1

2

3

4

5

Section 4: Block Reads

19

Page 26

HI 2151 Series Weight Controller

Acquire Tare

Print request (RS232 port)

Fixed Pont Weight Data

Rate-of-Change Value

Peak Force or Weight

Total Weight in Accumulator

Gross Weight

Net Weight

Tare Value

Total Words/Bytes

bit 6

bit 7

2

2

2

2

2

2

15

3

5

7

9

11

13

4

4

4

4

4

4

30

6

10

14

18

22

26

Block Read Data Number 21: Floating Point Weight Data (For IEEE Information See Appendix A)

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Number 21 (Hex 15)

Reserved for future use

Displayed Parameter in floating point, one of the

following parameters*

Rate-of-Change Value

Peak Force or Weight

Total Weight in Accumulator

Gross Weight

Net Weight

Reserved for future use

Currently displayed value type

O = Gross

1 = Net

2 = Rate-of-Change

3 = Peak Hold

4 = Total Weight

* Only the currently displayed value is output as

floating point, configured via mode button on

the front panel.

Total Words/Bytes

LSB

MSB

LSB

MSB

1

2

1

4

0

1

3

1

1

4

1

1

8

0

1

2

6

7

Profibus Interface Option

NOTE: For Set Point Status and Description Byte information please see Paragraph 4.7.

20

Page 27

Section 4: Block Reads

Block Read Data Number 22: Set Point Relay Status 1-2

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Number 22 (Hex 16)

Set point Status on/off (See Paragraph 4.7.1)

Set point Description #1

Set point Description #2

Set point Value #1

Preact Value #1

Dead band Value #1

Set point Value #2

Preact Value #2

Dead band Value #2

Total Words/Bytes

LSB

MSB

LSB

MSB

1

1

2

2

2

2

2

2

14

0

1

2

4

6

8

10

12

1

1

1

1

4

4

4

4

4

4

28

0

1

2

3

4

8

12

16

20

24

Block Read Data Number 23: Set Point Relay Status 3-4

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Number 23 (Hex 17)

Set point Status on/off (See Paragraph 4.7.1)

Set point Description #3

Set point Description #4

Set point Value #3

Preact Value #3

Dead band Value #3

Set point Value #4

Preact Value #4

Dead band Value #4

Total Words/Bytes

LSB

MSB

LSB

MSB

1

1

2

2

2

2

2

2

14

0

1

2

4

6

8

10

12

1

1

1

1

4

4

4

4

4

4

28

0

1

2

3

4

8

12

16

20

24

21

Page 28

HI 2151 Series Weight Controller

Block Read Data Number 24: Set Point Relay Status 5-6

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Number 24 (Hex 18)

Set point Status on/off (See Paragraph 4.7.1)

Set point Description #5

Set point Description #6

Set point Value #5

Preact Value #5

Dead band Value #5

Set point Value #6

Preact Value #6

Dead band Value #6

Total Words/Bytes

LSB

MSB

LSB

MSB

1

1

2

2

2

2

2

2

14

0

1

2

4

6

8

10

12

1

1

1

1

4

4

4

4

4

4

28

0

1

2

3

4

8

12

16

20

24

Block Read Data Number 23: Set Point Relay Status 7-8

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Number 25 (Hex 19)

Set point Status on/off (See Paragraph 4.7.1 )

Set point Description #7

Set point Description #8

Set point Value #7

Preact Value #7

Dead band Value #7

Set point Value #8

Preact Value #8

Dead band Value #8

Total Words/Bytes

LSB

MSB

LSB

MSB

1

1

2

2

2

2

2

2

14

0

1

2

4

6

8

10

12

1

1

1

1

4

4

4

4

4

4

28

0

1

2

3

4

8

12

16

20

24

Profibus Interface Option

22

Page 29

Section 4: Block Reads

Block Read Data Number 26: Read Tare Value

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Number 26 (Hex 1A)

Reserved for future use

Read Tare Value

Total Words/Bytes

LSB

MSB 1

2

3

0

1

1

1

4

6

0

1

2

Block Read Data Number 28: Calibration Parameters

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Number 28 (Hex 1C)

Reserved for future use

Calibration Parameters:

Decimal Point Position

Units of Measure (0 = Pounds 1 = Kilograms)

C2®, Second Generation Calibration Load Cell

Count (One # found on power-up)

Totalizer Decimal Position

Display Graduation Size (“count by”)

Motion Tolerance*

Zero Tolerance

Number of readings averaged*

Span weight value or C2®Reference pont

Scale Capacity

Mid-point Linearity Calibration Value

Auto Zero Tolerance

* NOTE: If this read is performed while scale is in

the calibration mode, the

motion tolerance is “3" and

number of readings averaged

is “200".

Total Words/Bytes

LSB

MSB

LSB

MSB

LSB

MSB

1

1

1

1

1

1

1

2

2

2

1

14

0

1

2

3

4

5

6

7

9

11

13

1

1

1

1

1

1

2

2

2

2

4

4

4

2

28

0

1

2

3

4

5

6

8

10

12

14

18

22

26

NOTE: The data in Block Read #29 is not valid for the HI 2151/30WC.

23

Page 30

HI 2151 Series Weight Controller

Block Read Data Number 29: Sticker Value

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Data Number 29 (Hex 1D)

Reserved for future use

Sticker Value

Total Words/Bytes

LSB

MSB 1

2

3

0

1

1

1

4

6

0

1

2

Block Read Data Number 30: Configuration of Rate-of-Change

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Number 30 (Hex 1E)

Reserved for future use

Displayed Rate-of-Change time

(0 = Sec, 1 = Min, 2 = Hrs)

Rate-of-Change time base evaluation period in seconds

Time base evaluation period:

0 = 1 second 5 = 6 seconds 10 = 60 seconds

1 = 2 seconds 6 = 10 seconds 11 = 120seconds

2 = 3 seconds 7 = 12 seconds 12 = 240seconds

3 = 4 seconds 8 = 15 seconds 13 = 450seconds

4 = 5 seconds 9 = 30 seconds 14 = 900seconds

15 = 1800 secs

Total Words/Bytes

LSB

MSB

LSB

LSB

1

1

1

3

0

1

2

1

1

2

2

6

0

1

2

4

Block Read Data Number 31: Configuration of Analog Output

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Number 31 (Hex 1F)

Weight Parameter (Value)

0 = Gross

1 = Net

2 = Rate-of-Change

3 = Peak Hold

4 = Total Weight

Wt Value is a Zero Scale Analog Output

Weight Value is a Full Scale Analog Output

Total Words/Bytes

LSB

MSB

1

2

2

5

0

1

3

1

1

4

4

10

0

1

2

6

Profibus Interface Option

24

Page 31

NOTE: The data in Block Read #32 is not valid for the HI 2151/30WC.

Block Read Data Number 32: Configuration of Standard RS232 Port

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Number 32 (Hex 20)

Reserved for future use

Reserved for future use

Format of Printout

Print Initiation (0 = Continuous, 1 =Altered

print)

Set point, Dead band and Preact

Rate-of-Change

Tare Weight

Net Weight

Gross Weight

Print Initiation (0 = Continuous, 1 = Altered

print)

Reserved for future use (must be set to 0)

Baud Rate (0 = 600, 1 = 1200, 2 = 2400, 3 = 4800,

4 = 9600, 5 = 19200)

Port Configuration (must be set to 1for printer

output only)

Stop Bits (0 = one stop bit, 1 = two stop bits)

Parity (0 = none, 1 = even, 2 = odd)

Handshake Control (0 = hardware, 1 = software)

Word Length (0 = seven bits, 1 = eight bits)

Device Address (a value from 0-99)

Echo (0 = off, 1 = on)

Total Words/Bytes

LSB

MSB

LSB

MSB

bit 0

bit 1

bit 2

bit 3

bit 4

bit 5

bit 6

bit 7

LSB

MSB

LSB

MSB

LSB

MSB

LSB

MSB

1

1

1

1

1

1

6

0

1

2

3

4

5

1

1

1

1

1

1

1

1

1

1

1

1

12

0

1

2

3

4

5

6

7

8

9

10

11

Block Read Data Number 34: Operator Selectable Read Summary Data

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Number 34 (Hex 22)

User Defined (Refer to Write Block #84)

1

0

Section 4: Block Reads

.

25

Page 32

HI 2151 Series Weight Controller

Block Read Data Number 35: Instrument Identification

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Number 35 (Hex 23)

Firmware revisions level (one character text, i.e.

“A”)

Firmware version (ASCII text number)

Zero Calibration analog to digital converter raw

counts

Span Calibration analog to digital converter raw

counts

Total Words/Bytes

LSB

MSB

1

2

2

2

7

0

1

3

5

1

1

4

4

4

14

0

1

2

6

10

Block Read Data Number 36: Floating Point Data

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Number 36 (Hex 24)

Reserved for Future Use

Gross Weight (Floating Point)

ROC Data (Floating Point)

Total Words/Bytes

LSB

MSB

1

2

2

5

0

1

3

1

1

4

4

10

0

1

2

6

Block Read Data Number 37: Integrated Technician Status

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Read Number 37 (Hex 25)

Excitation Monitor ON/OFF 1 = ON 0 = OFF

Excitation Monitor Error (1 - Error, 0 = OK)

Reserved for Future Use

Total Words/Bytes

LSB

MSB

LSB

MSB

1

1

2

0

1

1

1

1

1

4

0

1

2

3

Profibus Interface Option

26

Page 33

Section 5 Block Writes

PLC

LADDER LOGIC

PROGRAM

WRITE/READ

#5400 (hex) +

BLOCK READ

DATA NUMBER

RESPONSE

# BETWEEN

14-20 or #23 (hex) +

DATA REQUESTED

DATA EXCHANGE

BLOCK TRANSFER

1. It is important to keep in mind that the amount of bytes that can be

transferred is determined by the server not the PROFIBUS

interface option.

2. When using the HI 2151 Series Weight Controller PROFIBUS

interface, the user can select the Block Read Data and Block Write

Commands as required. However, the amount of bytes that can be

transferred is dependent on the data transfer capability of the

server being used.

3. The ladder logic program provides the server with the ability to

read and write weight data by referencing the PROFIBUS address,

the byte numbers and number of bytes.

5.1 SCOPE

Chapter 5 covers block write commands for the PROFIBUS Interface Option.

Programmers and other users be familiar with this chapter before operating the PROFIBUS

Interface Option.

5.2 OVERVIEW OF TRANSFER COMMANDS

1. PROFIBUS Interface Card maximum buffer size 112 byte buffer

2. Siemens PLC

a. TI 505 Series PLC

Requires the Field Interface Module (FIM) to communicate over PROFIBUS.

Can continually exchange up to 32 words or 64 bytes for both server input

and output with each client device.

Section 5: Block Writes

b. S5 Series PLC

Requires IM 308C Module to communicate over PROFIBUS.

Can continually exchange up to 244 bytes for server input and output with

each client device.

c. S7 Series PLC

PROFIBUS ready, does not require additional modules.

Can Continually exchange up to 244 bytes for server input and output with

each client device.

3. Allen-Bradley PLC5 Series

a. Requires PROFIBUS DP module to communicate over PROFIBUS.

b. Can continually exchange up to 244 bytes for both server Input and Output with

each client device.

5.3 OVERVIEW OF BLOCK TRANSFER COMMANDS

27

Page 34

HI 2151 Series Weight Controller

Profibus Interface Option

NOTE: The weight controller will not accept write commands until calibration is sealed. Press

“Enter” at ENDCAL to seal the calibration. (See HI 2151 Series Weight Controller

Operation and Installation Manual, for calibration instructions)

5.4 DETAILED COMMAND SET FOR BLOCK TRANSFER (WRITES)

NOTE: We recommend that front panel functions be controlled through the PROFIBUS network

and that the front panel control be disabled or locked out. (See the HI 2151 Series

Weight Controller Operation and Installation Manual (#0596-0178), for lockout

instructions)

1. All write commands are initiated by the server using a ladder logic program to send a

block number to the HI 2151/20WC.

NOTE: If your server device does not have built in PROFIBUS diagnostic capability set up the

Response/Error “90" diagnostics first, (See section 4.4) before proceeding. The write “90"

must be set before entering a block write command so that the verification process can

determine if the first block write command sent is valid or not.

2. The weight controller receives a block number command, verifies that the block

number is correct, processes the weight data and prepares a response byte (an error

code response number) to the server’s command.

NOTE: Changes to Block Writes/Charts should be made in program mode.

5.5 BLOCK WRITE EXAMPLE

NOTE: When making changes to block writes in run mode, follow the procedures below:

1. Set the Block Number to “0".

2. Write the new parameter to the output buffer.

3. Change the Block Number from “0" to the new number.

The following example is a setup to download set point #1 and #2 values, preacts and dead

bands using Block Write Command 72 (48 hex): Set point Relay Status 1 & 2.

NOTE: Any set point, preact and dead band values can be entered into K memory.

When C1 is activated the Move Word 1 (MOVW1) downloads the information to the

weight controller using WY17 through WY31.

K1: Contains hex 48FF (Selects Block 72 and enables set point relays 1 and 2)

K2: Contains hex 0102 (Sets relay 1 to Gross and relay 2 to Net)

K3: Contains Double 1000 (Sets set point 1 to 1,000)

K5: Contains Double - 5 (Sets Preact 1 to negative -5)

K7: Contains Double - 10 (Sets Dead band 1 to negative -10)

K9: Contains Double - 100 (Sets set point 2 to negative -100)

K11: Contains Double 5 (Sets Preact 2 to 5)

K13: Contains Double 10 (Sets Dead band 2 to 10)

28

Page 35

C1: Starts the program

Block Write Command Number 70: Activate Scale Functions

Byte Definitions

Byte

Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Write Number 70 (Hex 46)

Activate by setting remote functions bit to 1 then

reset to 0

TARE = Current Gross Weight

Initiates print on standard RS232

Add current net weight to Total

Clear Peak Hold

Clear Totalizer Accumulator

Zero the Instrument

Enable Zero Tracking (blind unit only)

Reserved for future use

Total Words/Bytes

LSB

MSB

bit 0

bit 1

bit 2

bit 3

bit 4

bit 5

bit 6

bit 7

1

1

0

1

1

1

0

1

Block Write Command Number 71: Force Relay Status

Byte Definitions

Byte

Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Write Number 71 (Hex 47)

Activate by setting remote functions bit to 1 then

reset to 0

Relay 8

Relay 7

Relay 6

Relay 5

Relay 4

Relay 3

Relay 2

Relay 1

Total Words/Bytes

LSB

MSB

bit 0

bit 1

bit 2

bit 3

bit 4

bit 5

bit 6

bit 7

1

1

0

1

1

2

0

1

MOVW1: Downloads the information in K1-K14 into WY17-WY31 (weight controller)

5.6 BLOCK WRITE COMMAND NUMBERS

Section 5: Block Writes

29

Page 36

HI 2151 Series Weight Controller

Block Write Command Number 72: Set point Relay Status 1-2

Byte Definitions

Byte

Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Write Number 72 (Hex 48)

Set point Enable on/off (See Chapter 4, paragraph

4.7.1)

Set point #1

Set point #2

Set point Description #1

Set point Description #2

Set point Value #1

Preact Value #1

Dead band Value #1

Set point Value #2

Preact Value #2

Dead band Value #2

Total Words/Bytes

LSB

MSB

bit 7

bit 6

LSB

MSB

1

1

2

2

2

2

2

2

14

0

1

2

4

6

8

10

12

1

1

1

1

4

4

4

4

4

4

28

0

1

2

3

4

8

12

16

20

24

Block Write Command Number 73: Set point Relay Status 3-4

Byte Definitions

Byte

Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Write Number 73 (Hex 49)

Set point Enable on/off (See Chapter 4, paragraph

4.7.1)

Set point #3

Set point #4

Set point Description #3

Set point Description #4

Set point Value #3

Preact Value #3

Dead band Value #3

Set point Value #4

Preact Value #4

Dead band Value #4

Total Words/Bytes

LSB

MSB

bit 5

bit 4

LSB

MSB

1

1

2

2

2

2

2

2

14

0

1

2

4

6

8

10

12

1

1

1

1

4

4

4

4

4

4

28

0

1

2

3

4

8

12

16

20

24

Profibus Interface Option

NOTE: For Set point Status and Description Byte information please See Chapter 4, Paragraph 4.6.

30

Page 37

Section 5: Block Writes

Block Write Command Number 74: Set point Relay Status 5-6

Byte Definitions

Byte

Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Write Number 74 (Hex 4A)

Set point Enable on/off (See Chapter 4, paragraph

4.7.1)

Set point #5

Set point #6

Set point Description #5

Set point Description #6

Set point Value #5

Preact Value #5

Dead band Value #5

Set point Value #6

Preact Value #6

Dead band Value #6

Total Words/Bytes

LSB

MSB

bit 3

bit 2

LSB

MSB

1

1

2

2

2

2

2

2

14

0

1

2

4

6

8

10

12

1

1

1

1

4

4

4

4

4

4

28

0

1

2

3

4

8

12

16

20

24

Block Write Command Number 75: Set point Relay Status 7-8

Byte Definitions

Byte

Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Write Number 75 (Hex 4B)

Set point Enable on/off (See Chapter 4, paragraph

4.7.1)

Set point #7

Set point #8

Set point Description #7

Set point Description #8

Set point Value #7

Preact Value #7

Dead band Value #7

Set point Value #8

Preact Value #8

Dead band Value #8

Total Words/Bytes

LSB

MSB

bit 1

bit 0

LSB

MSB

1

1

2

2

2

2

2

2

14

0

1

2

4

6

8

10

12

1

1

1

1

4

4

4

4

4

4

28

0

1

2

3

4

8

12

16

20

24

31

Page 38

HI 2151 Series Weight Controller

Block Write Command Number 76: Send Tare Value

Byte Definitions

Byte

Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Write Number 76 (Hex 4C)

Reserved for future use

Send Tare Value

Total Words/Bytes

LSB

MSB

1

2

3

0

1

1

1

4

6

0

1

2

Block Write Command Number 77: Scale Calibration Action

Byte Definitions

Byte

Pos.

#

Words

Start

Word

# Bytes

Start Byte

Block Write Number 77 (Hex 4D)

Activate by setting and then clearing

Current weight is an empty scale

Current weight is span weight

Store critical data in the Secure Memory

Module

Restore critical data from the Secure Memory

Module

Current weight is Midpoint Linearity value

Reserved for future use

Current weight is the C2® reference point

Reserved for future use

Total Words/Bytes

LSB

MSB

bit 0

bit 1

bit 2

bit 3

bit 4

bit 5

bit 6

bit 7

1

1

0

1

1

2

0

1

Block Write Command Number 78: Scale Calibration Action

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Write Number 78 (Hex 4E)

Reserved for future use

Calibration Parameters:

Decimal Point Position

Units of Measure (0 = Pounds 1 =

Kilograms)

C2®, Second Generation Calibration Load

Cell Count . (One # found on power-up)

Totalizer Decimal Position

Display Graduation Size (“count by”)

Motion Tolerance

LSB

MSB

LSB

MSB

LSB

MSB

1

1

1

1

0

1

2

3

1

1

1

1

1

1

2

0

1

2

3

4

5

6

Profibus Interface Option

32

Page 39

Zero Tolerance

Number of readings averaged.

Span weight value or C2®Reference pont

Scale Capacity

Mid-point Linearity Calibration Value

Auto Zero Tolerance

Total Words/Bytes

1

1

1

2

2

2

1

14

4

5

6

7

9

11

13

2

2

2

4

4

4

2

28

8

10

12

14

18

22

26

Block Write Command Number 79: Sticker Value

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Write Number 79 (Hex 4F)

Reserved for future use

Sticker Value

Total Words/Bytes

LSB

MSB 1

2

3

0

1

1

1

4

6

0

1

2

Block Write Command Number 80: Configuration of Rate-of-Change

Byte Definitions

Byte

Pos.

#

Words

Start

Word

# Bytes

Start Byte

Block Write Number 80 (Hex 50)

Reserved for future use

Displayed Rate-of-Change time (0 = Sec, 1 = Min, 2

= Hrs)

Rate-of-Change time base evaluation period in

seconds

Time base evaluation period:

0 = 1 sec. 5 = 6 sec. 10 = 60 sec.

1 = 2 sec. 6 = 10 sec. 11 = 120 sec.

2 = 3 sec. 7 = 12 sec. 12 = 240 sec.

3 = 4 sec. 8 = 15 sec. 13 = 450 sec.

4 = 5 sec. 9 = 30 sec. 14 = 900 sec.

15 = 1800 sec.

Total Words/Bytes

LSB

MSB

LSB

LSB

1

1

1

3

0

1

2

1

1

2

2

6

0

1

2

4

Block Write Command Number 81: Configuration of Analog Output

Byte Definitions

Byte

Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Write Number 81 (Hex 51)

LSB 1 0 1 0

NOTE: This Block Write (#79) is not valid for HI 2151/30WC

Section 5: Block Writes

33

Page 40

HI 2151 Series Weight Controller

Weight Parameter (Value)

0 = Gross

1 = Net

2 = Rate-of-Change

3 = Peak Hold

4 = Total Weight

Weight Value Represented by a Zero Scale Analog

Output

Weight Value Represented by a Full Scale Analog

Output

Total Words/Bytes

MSB

2

2

5

1

3

1

4

4

10

1

2

6

Block Write Command Number 82: Configuration of Standard RS232 Port

Byte Definitions

Byte

Pos.

#

Words

Start

Word

# Bytes

Start Byte

Block Read Number 82 (Hex 52)

Reserved for future use

Reserved for future use

Format of Printout

Print Initiation (0 = Continuous, 1 =Altered print)

Set point, Dead band and Preact

Rate-of-Change

Tare Weight

Net Weight

Gross Weight

Print Initiation (0 = Continuous, 1 = Altered print)

Reserved for future use (must be set to 0)

Baud Rate (0 = 600, 1 = 1200, 2 = 2400, 3 = 4800, 4 =

9600, 5 = 19200)

Port Configuration (must be set to 1for printer output

only)

Stop Bits (0 = one stop bit, 1 = two stop bits)

Parity (0 = none, 1 = even, 2 = odd)

Handshake Control (0 = hardware, 1 = software)

Word Length (0 = seven bits, 1 = eight bits)

Device Address (a value from 0-99)

Echo (0 = off, 1 = on)

Total Words/Bytes

LSB

MSB

LSB

MSB

bit 0

bit 1

bit 2

bit 3

bit 4

bit 5

bit 6

bit 7

LSB

MSB

LSB

MSB

LSB

MSB

LSB

MSB

1

1

1

1

1

1

6

0

1

2

3

4

5

1

1

1

1

1

1

1

1

1

1

1

1

12

0

1

2

3

4

5

6

7

8

9

10

11

Profibus Interface Option

NOTE: This Block Write (#82) is not valid for HI 2151/30WC

34

Page 41

Section 5: Block Writes

Block Write Command Number 85: Integrated Technician

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Write Number 85 (Hex 55)

WAVERSAVER (1-5)

Excitation Monitor 0 = OFF 1 = ON

Enter Block number (only one) or Selectable

parameter

Reserved for future use

MSB

LSB

MSM

1

1

0

1

2

1

0

1

Block Write Command Number 83: Personalized Selection of Write Commands

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Write Number 83 (Hex 53)

Reserved for future use

Enter Parameter Number

Reserved for future use

Enter Parameter Value

Reserved for future use (if selection is one

byte long)

Repeat for all Write commands desired*

FF (End)

*Note: Be sure not to go over the byte limit of the

server

LSB

MSB

LSB

MSB

LSB

MSB

1

1

1 or 2

0

1

1

1

1

1

1.2 or 4

0 or 1

1

0

1

1

Block Write Command Number 84: Select Read Summary Data

Byte Definitions

Byte Pos.

#

Words

Start Word

# Bytes

Start Byte

Block Write Number 84 (Hex 54)

Select Read Type

Block Read (defaults to block #35

Instrument Identification)

Selectable Read

Enter Block number (only one) or Selectable

parameter

number)* (Repeat for all

selected parameter number)

FF (End)

*Note: Be sure not to go over the byte limit of the

server

Value

0

1

1 0 1

1

0

1

35

Page 42

HI 2151 Series Weight Controller

Profibus Interface Option

Section 6 SELECTABLE READS

6.1 SCOPE

Chapter 6 covers Selectable Read Commands for the PROFIBUS Interface Option.

6.2 OVERVIEW OF TRANSFER COMMANDS

1. PROFIBUS Interface Card maximum buffer size: 112 byte buffer

2. Siemens PLC

a. TI 505 Series PLCs

Requires the Field Interface Module (FIM) to communicate over PROFIBUS.

Can continually exchange up to 32 words or 64 bytes for both PLC input and

output with each client device.

b. S5 Series PLCs

Requires IM 308C Module to communicate over PROFIBUS.

Can continually exchange up to 244 bytes for PLC input and output with

each client device.

c. S7 Series PLC

PROFIBUS ready, does not require additional modules.

Can Continually exchange up to 244 bytes for PLC input and output with

each client device.

3. Allen-Bradley PLC5 Series

a. Requires PROFIBUS DP module to communicate over PROFIBUS.

b. Can continually exchange up to 244 bytes for both PLC Input and Output with

each client device.

6.3 OVERVIEW OF SELECTABLE TRANSFER COMMANDS

1. It is important to keep in mind that the amount of bytes that can be transferred is

determined by the server PLC not the PROFIBUS interface option.

2. When using the HI 2151 Series Weight Controller PROFIBUS interface, the user can

select the Read Data Summaries and Write Commands they require. However, the

amount of bytes that can be transferred is dependent on the data transfer capability of

the server being used.

3. By sending the proper commands to the HI 2151 Series Weight Controller, the server

can specify which weighing parameters and/or status bits should be provided.

4. The ladder logic program provides the server with the ability to read and write weight

data by referencing the PROFIBUS address, the parameter numbers and number of

bytes.

NOTE: The decimal point is not included in values transferred. The decimal position is a separate

parameter.

36

Page 43

Section 6: Selectable Reads

Block Write Command Number 84: Select Read Data

Byte definitions:

Block Write Number 84 (54 Hex)

Select Read Type

Selectable Read Value 1

Enter parameter number (repeat parameter numbers but do not exceed

word/byte limit of the PLC)

FF (end)

Operator Selectable Read Data Number 34

Byte Definitions:

Operator Selectable Read Data Number 34 (22 Hex)

Unused Byte 00

Reads operator selectable commands setup in Block Write Number 84 (Hex)

6.4 DETAILED DATA SET FOR SELECTABLE READ(S)

1. The Selectable Read data to be input to the server is always initiated by a Block Write

Command designating the parameter number that the HI 2151 Series Weight

Controller will send to the server.

NOTE: If your server Device does not have built in PROFIBUS diagnostic capability set up the

Response/Error “0" diagnostics first, (See section 4.4) before proceeding. The write “0"

must be set before entering a block write command so that the verification process can

determine if the first block write command sent is valid or not.

2. The weight controller receives the parameter number command from the server,

verifies that the parameter number is correct, processes the weight data and prepares a

response byte (an error code response number) to the server’s command.

NOTES: Changes to Block Writes/Charts should be made in program mode.

To prevent errors and erroneous data from being sent to the HI 2151 Series Weight

Controller in run mode, follow the procedures below:

1. Set the Block Number to “0".

2. Write the new parameter to the output buffer.

3. Change the Block Number from “0" to the new number.

6.5 SELECTABLE READ COMMAND SETUP PROCEDURES

1. Selectable Read Data use Block Write Number 84 (5401 hex). Block Read number 34

(2200 hex) is returned as an input to the PLC.

2. Block write number 84 allows the user to select the read data summaries desired, and

they are returned in Operator Selectable Read block 34.

37

Page 44

HI 2151 Series Weight Controller

Profibus Interface Option

Full word variables must begin on word boundaries, when transferring operator

selectable commands or data. See example below.

Example Output from the PLC, in this example indicator status 2 is desired. Indicator status

1, is used so that Tare Value starts at a word boundary:

Byte Hex# Description

Byte 0 54 Block Write Number

Byte 1 01 Selectable Read

Byte 2 02 Indicator Status 2

Byte 3 01 Indicator Status 1 (used to maintain word

Byte 4 3C Tare Value

Byte 6 FF END

Example Input to the PLC, indicates the data returned to the PLC from the output above.

Byte Hex# Description

Byte 0 22 Block Read Number

Byte 1 00 Unused

Byte 2 21 Gross Weight (bit 5) in Pounds (bit 0 is

Byte 3 00 Used as place holder (indicator status 1)