Page 1

HI 200DNWM WEIGH MODULE

Series B

OPERATION AND INSTALLATION

MANUAL

Corporate Headquarters

9440 Carroll Park Drive, Suite 150

San Diego, CA 92121

Phone: (858) 278-2900

FAX: (858) 278-6700

Web-Site: http://www.hardyinst.com

Hardy Instruments Document Number: 0596-0227-01 Rev F

Copyright August 1998 Hardy Instruments, Inc. All Rights Reserved. Printed in the U.S.A. (941028)

Page 2

Local Field Service

Hardy has over 200 field technicians in the U.S., and more positioned throughout the

world to assist you in your support needs. We also have factory engineers who will

travel to your facility anywhere in the world to help you solve challenging applications. We're ready to support you with:

• Installation and start-up

• Routine maintenance and certification

• Plant audits and performance measurement

• Emergency troubleshooting and repair

To request Emergency Service and Troubleshooting, Start-up, Installation, Calibration, Verification or to discuss a Maintenance Agreement please call 800-821-5831

Ext. 1757 or Emergency Service after hours (Standard Hours 6:00 AM to 6:00 PM

Pacific Standard Time) and weekends

Ext. 1111.

Outside the U.S

Hardy Instruments has built a network of support throughout the globe. For specific

field service options available in your area please contact your local sales agent or our

U.S. factory at +1 858-292-2710, Ext. 1757.

1-ii

Page 3

Table of Contents

Table of Contents

TABLE OF CONTENTS - - - - - - - - - - - - - - - - - - - -I

TABLE OF ILLUSTRATIONS - - - - - - - - - - - - - - - - -I

CHAPTER 1 - OVERVIEW - - - - - - - - - - - - - - - - - - -1-1

Scope - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-1

About Hardy Manuals - - - - - - - - - - - - - - - - - - - - -1-1

Description - - - - - - - - - - - - - - - - - - - - - - - - - - -1-2

WAVERSAVER

®

C2

Calibration - - - - - - - - - - - - - - - - - - - - - - - -1-4

The Button - - - - - - - - - - - - - - - - - - - - - - - - - - -1-4

What is DeviceNet

Physical Layer (Network Topology) - - - - - - - - - - - - - - -1-5

CHAPTER 2 - SPECIFICATIONS - - - - - - - - - - - - - - -2-1

SCOPE - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Conversion Rate - - - - - - - - - - - - - - - - - - - - - - - -2-1

Resolution - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Excitation Voltage - - - - - - - - - - - - - - - - - - - - - - -2-1

Averages - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Load Sensors - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Non-Linearity - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Isolation - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Temperature Coefficient - - - - - - - - - - - - - - - - - - - -2-2

Temperature Range - - - - - - - - - - - - - - - - - - - - - -2-2

Temperature Storage Range - - - - - - - - - - - - - - - - - -2-2

Physical Dimensions - - - - - - - - - - - - - - - - - - - - - -2-2

Mounting Config - - - - - - - - - - - - - - - - - - - - - - - -2-2

Approvals - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

Display - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

DeviceNet - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

Inputs - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

Outputs - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

Connectors - - - - - - - - - - - - - - - - - - - - - - - - - -2-3

J1 - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-3

J2 - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-3

J3 - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-3

Current Draw at 24VDC - - - - - - - - - - - - - - - - - - - -2-4

®

- - - - - - - - - - - - - - - - - - - - - - - -1-3

®

? - - - - - - - - - - - - - - - - - - - - - -1-4

i

Page 4

HI 200DNWM MANUAL

CHAPTER 3 - INSTALLATION - - - - - - - - - - - - - - - - -3-1

SCOPE - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-1

Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - -3-1

Mechanical Installation - - - - - - - - - - - - - - - - - - - - -3-3

Installing the Bare Weigh Module in an Enclosure - - - - - -3-3

Installing Weigh Module in DIN Rail - - - - - - - - - - - - -3-5

Installing the Pre-stacked Weigh Module - - - - - - - - - -3-9

Electrical Installation - - - - - - - - - - - - - - - - - - - - - -3-10

Wiring Diagram for the J1 Load Sensor 8 Pin Connector - -3-10

Wiring Diagram for the J2 DeviceNet Interface 5 Pin Open -3-11

Wiring Diagram for the J3 Set Point Out 4 Pin - - - - - - - -3-11

Wiring Diagram for the HI 215JB Junction Box - - - - - - -3-11

C2 Loadcell Cable Connection (J1) - - - - - - - - - - -3-11

Non-C2 Loadcell Cable Connection (J1) - - - - - - - -3-13

CHAPTER 4 - CONFIGURATION - - - - - - - - - - - - - - -4-1

SCOPE - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-1

Differences in the Series A and Series B Modules - - - - - - - -4-1

Changing from the Series A to the Series B Module - - - - -4-1

Changing from the Series B to the Series A Module - - - - -4-1

DIP Switch (S1) Configuration - - - - - - - - - - - - - - - - -4-2

DIP Switch Location - - - - - - - - - - - - - - - - - - - -4-2

Configuring the Baud Rate - - - - - - - - - - - - - - - - -4-2

Configuring the DeviceNet Node Address - - - - - - - - - -4-3

CHAPTER 5 - SETUP - - - - - - - - - - - - - - - - - - - - -5-1

SCOPE - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-1

Saving to Non-Volatile Ram - - - - - - - - - - - - - - - - - -5-1

Parameters - - - - - - - - - - - - - - - - - - - - - - - - - -5-2

Command Interface - - - - - - - - - - - - - - - - - - - -5-7

Format of Commands (4 byte input data) - - - - - - - -5-8

Examples Using the Command Interface - - - - - - - -5-9

Setpoints - - - - - - - - - - - - - - - - - - - - - - - - - - -5-10

About SetPoints - - - - - - - - - - - - - - - - - - - - - -5-10

Dead Band Limits - - - - - - - - - - - - - - - - - - - - -5-10

Three General Rules for Set Points - - - - - - - - - - - - -5-11

Preact Limits - - - - - - - - - - - - - - - - - - - - - - - -5-11

Entering Set Points - - - - - - - - - - - - - - - - - - - - -5-11

Setpoint Mode Parameters - - - - - - - - - - - - - - - - -5-12

About Setpoint Mode Parameter - - - - - - - - - - - -5-12

Entering Setpoint Mode Parameters - - - - - - - - - -5-12

ii

Page 5

Table of Contents

CHAPTER 6 - CALIBRATION - - - - - - - - - - - - - - - - -6-1

SCOPE - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-1

Pre-Calibration Procedures - - - - - - - - - - - - - - - - - - -6-1

C2® Calibration (The Button) - - - - - - - - - - - - - - - - - -6-1

C2® Calibration from RS NetWorx

Test Weight Calibration from RS NetWorx

CHAPTER 7 - OPERATION - - - - - - - - - - - - - - - - - -7-1

SCOPE - - - - - - - - - - - - - - - - - - - - - - - - - - - -7-1

Operating Capabilities - - - - - - - - - - - - - - - - - - - - -7-1

Explicit Message Request Parameters - - - - - - - - - - - - -7-1

Monitoring Weight Readings from RS NetWorx - - - - - - - - -7-2

Network Status (DS1) - - - - - - - - - - - - - - - - - - -7-2

Module Status (DS2) - - - - - - - - - - - - - - - - - - - -7-3

CHAPTER 8 - TROUBLESHOOTING - - - - - - - - - - - - -8-1

SCOPE - - - - - - - - - - - - - - - - - - - - - - - - - - - -8-1

Module LED does not Come Back on When Performing

Calibration with The Button - - - - - - - - - - - - - - - - - -8-1

Module LED is Flashing Red - - - - - - - - - - - - - - - - - -8-1

Mechanical Inspection - - - - - - - - - - - - - - - - - - - - -8-1

Load Sharing and Load Sensor Checkout - - - - - - - - - - - -8-3

Guidelines for Instabilities on Formerly Operating Systems - - -8-4

Electrical 8-5

Mechanical Stability and Configuration Settings - - - - - - - - -8-6

®

- - - - - - - - - - - - - -6-2

®

- - - - - - - - - - -6-3

INDEX

iii

Page 6

HI 200DNWM MANUAL

iv

Page 7

CHAPTER 1 - OVERVIEW

CHAPTER 1 - OVERVIEW

Scope This manual provides the user with a

description of the operating procedures,

specifications, installation and setup for

the Hardy Instruments HI 200DNWM

(Hardy Instruments Series 200

DeviceNet™ Weigh Module). To get the

maximum service life from the HI

200DNWM users should use the instrument in accordance with the recommended practices implied or contained in

this manual. The user should read and

understand all cautions, warnings, and

safety procedures referenced or explicitly

stated in the manual, to ensure the safe

operation of this product. Hardy Instruments appreciates your business. Should

you experience any problems, please

contact our Customer Support Department at:

Phone: (858) 278-2900

FAX: (858) 278-6700

Web Site: hardyinst.com

e-mail: support@hardyinst.com

NOTE: DeviceNet is a trademark of the Open DeviceNet

Vendor Association, Inc.

About Hardy Manuals Every Hardy Installation and Operation

manual is organized into easily referenced chapters, that are almost always

the same:

• Chapter One - Provides an introduction and an Overview of the instrument and its capabilities.

1-1

Page 8

HI 200DNWM MANUAL

• Chapter Two - Provides a complete

list of Specifications.

• Chapter Three - Contains information needed to Install the HI

200DNWM weight module.

• Chapter Four - Provides complete

hardware Configuration instructions for setting dip switches and

jumpers.

• Chapter Five - Pertains to the firmware Setup and preparation procedures to calibrate and operate the

module.

• Chapter Six - Provides Calibration

instructions.

• Chapter Seven - Pertains to the

Operation of the HI 200DNWM

weight module.

• Chapter Eight - Pertains to the

Troubleshooting procedures to

repair the module.

Description The Hardy Instruments HI 200DNWM is

a small weigh module that communicates

Net and Gross weights to other devices

connected to a DeviceNet™ Network.

The weigh module supports Hardy’s

®

calibration and has four levels of

C2

WAVERSAVER®. The weigh module

consists of a printed circuit card with

standoffs (for mounting in an enclosure)

or rails for DIN rail mounting. The weigh

module outputs (produces) Gross, Net

and Tare weights and inputs (consumes)

Zero and Tare commands via

DeviceNet™. Configuration includes:

1-2

Page 9

CHAPTER 1 - OVERVIEW

1. Metric Poll

2. Averages (1-255)

3. WAVERSAVER

®

4. Calibration Type (C2® or Hard

Calibration) - Not configurable,

Read Only

5. Span Weight

6. Set Point Values

a. Mode

b. Preact

c. Deadband

NOTE: WAVERSAVER® and C2® are registered trade-

marks of Hardy Instruments, Inc.

Configuration data is stored in an

EEprom. I/O slave messaging is polled.

The weight module supports two TTL

levels out to relays for use as set points.

A bit is supplied when the set point is

reached.

NOTE: Hardy Instruments does not supply the set point

module.

WAVERSAVER® Typically, mechanical noise is present in

forces larger than the weight forces trying to be detected. The HI 200DNWM

weigh module is fitted with WAVER-

®

SAVER

technology which eliminates

the effects of vibratory forces present in

all industrial weight control and measurement applications. By eliminating

the factor of vibratory forces the controller is capable of identifying the actual

weight data. WAVERSAVER

®

enables

1-3

Page 10

HI 200DNWM MANUAL

the weigh module to distinguish between

actual weight data and mechanical noise,

both of which are typically transferred to

the weight controller by the load cell sig-

nal. WAVERSAVER® can be configured from devicenet controller to ignore

noise with frequencies as low as 0.5 Hz.

One of three other additional cut off frequencies may be selected to provide a

faster instrument response time. The

default factory configuration is 1.0 Hz

vibration frequency immunity.

C2® Calibration C2® Second Generation Calibration

enables a scale system to be calibrated

electronically without using certified test

weights which equals the systems load

capacity. All Hardy Instruments C2®

certified load sensors contain digital

information detailing its unique perfor-

mance characteristic s. C2® Calibration is

performed over the network or by simply

pushing “THE BUTTON”and hold until

the module status LED (DS2) goes out.

The Button With one push of “THE BUTTON” the

HI 200DNWM automatically electronically calibrates the weighing system with

®

certified load sensors, making the

C2

system ready for use. This saves system

start up time costs and aggravations.

What is DeviceNet

®

? The DeviceNet network is an open, glo-

bal industry-standard communication

network designed to provide an interface

1-4

Page 11

CHAPTER 1 - OVERVIEW

through a single cable from a programmable controller directly to smart

devices such as sensors, push buttons,

motor starters, simple operator interfaces, drives and weigh modules. You no

longer have to hard-wire each device to

an I/O module or I/O block. Because

you use significantly less wire, you

spend far less time and money on wiring

and installation time. The network also

provides access to the intelligence

present in the devices for superior diagnostics and troubleshooting to help

increase system up time. The DeviceNet

network lets you monitor your plant-

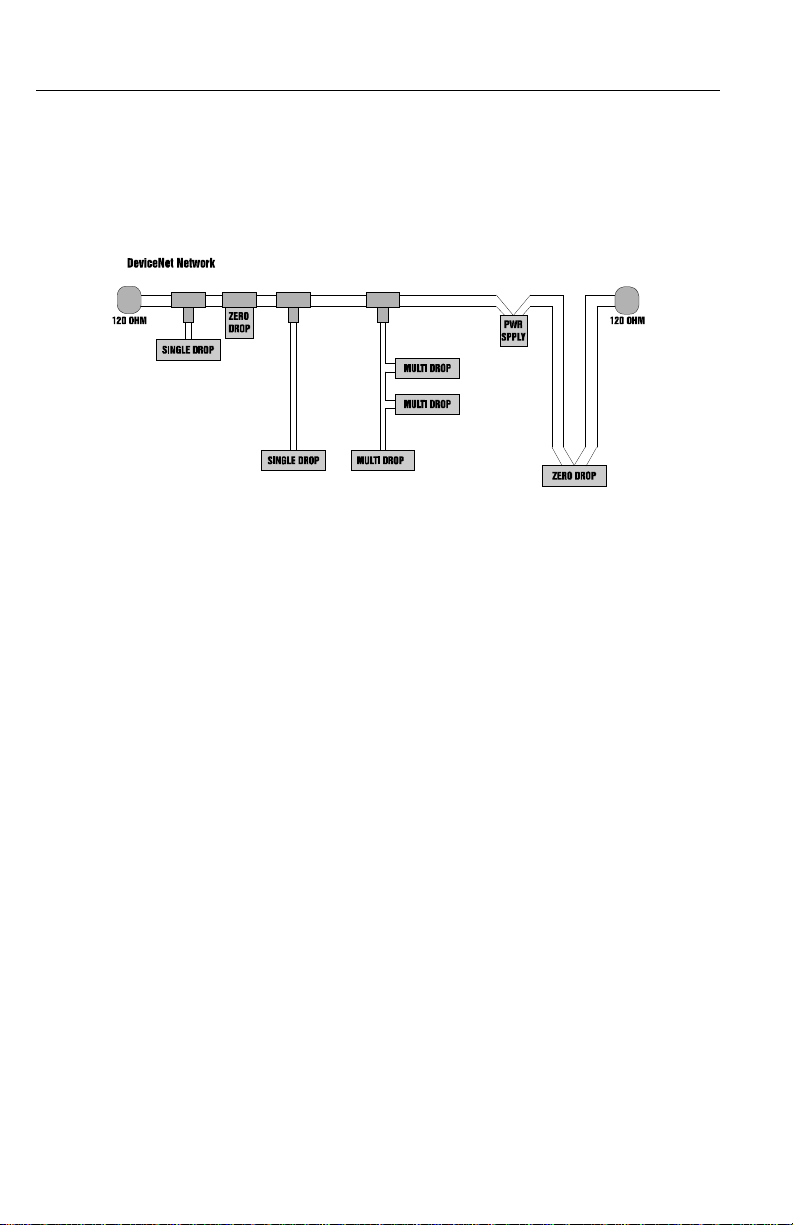

Physical Layer

(Network Topology)

floor devices from a central location and

reconfigure them as your needs change

or service them as required. You can, for

example, configure the weigh module for

different applications. The DeviceNet

network's capabilities help ease integration, and reduce installation and wiring

costs. (See Fig. 1-1)

• Trunk Line (thick or thin cable can

be used)

• 120 ohm terminator at each end.

• Drop lines can extend to a maximum

length of 20’ feet.

• Drops may be daisy chained to multi-

ple nodes.

1-5

Page 12

HI 200DNWM MANUAL

FIG. 1-1 DEVICENET NETWORK

• Zero length drops allow direct connection of nodes to the trunk.

• Multiple power supplies can be used

for load distribution and backup.

1-6

Page 13

CHAPTER 2 - SPECIFICATIONS

CHAPTER 2 - SPECIFICATIONS

SCOPE Chapter 2 lists the specifications of the HI

200DNWM weigh module. Specifications

are listed for the standard module and

optional equipment. The specifications listed

are designed to assist in the installation,

operation and troubleshooting of the module.

All service personnel should be familiar with

this chapter before atte mpti ng an installa tion

or repair of the instrument.

Conversion Rate 10 updates per second (When WAVER-

SAVER is turned OFF or set to 1= 55

updates per second)

Resolution 20 bits

Excita ti on Voltage 0-5 VDC

Averages 1 to 255 User Selectable in Single Incre-

ments.

Load Sensors Up to eight (8) 350 ohm Full Wheatstone

Bridge, Strain Gauge Load Sensors/Cells (5

volt excitation) on one vessel. Using more

than 4 load cells requires an external power

supply.

Non-Linearity 0.0015% of Full Scale

Isolation Non Isolated, uses external solid state relays

for set points.

Voltage Input power - Power from DeviceNet Cable

• 24 VDC +/- 1% Network

• 11-25 VDC Node

2-1

Page 14

HI 200 DNWM MANUAL

Temperature Coefficient

Temperature

Less than 0.0005% per degree C for zero and

span.

-10 degrees C to +50 degrees C

Range

Temperature Stor-

-20 degrees to +85 degrees C

age Range

Physical Dimen-

sions

3.80” W x 8.5” L x 1.0” H (96.52 mm W x

215.9 mm L x 25.4 mm H)

Mounting Config •DIN - Rail

• Enclosure Mounting, pc board mounted

to enclosure backplate.

Approvals ODVA Conformance Tested

Display None

DeviceNet Type: Vendor Specific

I/O Slave Messaging: Polling

Profile: Refer to EDS

Baud Rates: 125K, 250K, 500K

Inputs 4 bytes polled in

Outputs 4 bytes polled out

NOTE: The Metric Poll parameter specifies the default for-

mat of the 4 bytes of output data from the weight

scale. A zero value specifies that the default format is

a 32 byte integer value containing net weight in

pounds, with 3 decimal places. A one value specifies

that the default format is a 32 byte integer value containing net weight in kilograms, with 3 decimal

places.

2-2

Page 15

CHAPTER 2 - SPECIFICATIONS

Connectors Phoenix Combicon type with unsealed screw

terminal mate. PC board side-vertical pins.

All connector numbering is from left to right

when looking down on the board with the

connector side of the board facing toward

you.

J1 Load Sensor 8 Pin

8 + EXC (Plus Excitation) + 5VDC

7 + SEN (Plus Sense)

6 + SIG (Plus Signal)

5 - SIG (Minus Signal)

4 - SEN (Minus Sense)

3 - EXC (Minus Excitation)

2 + C2

1 - C2

J2 DeviceNet Interface 5 pin Open

1V - (Black)

2 CAN- (Blue)

3 SHIELD (Bare)

4 CAN+ (White)

5V+ (Red)

J3 Set Point Out Interface 4 Pin

1 RLY 1 (Set Point Output One)

2 GND (Ground)

3 RLY 2 (Set Point Output Two)

4 +5 VDC

2-3

Page 16

HI 200 DNWM MANUAL

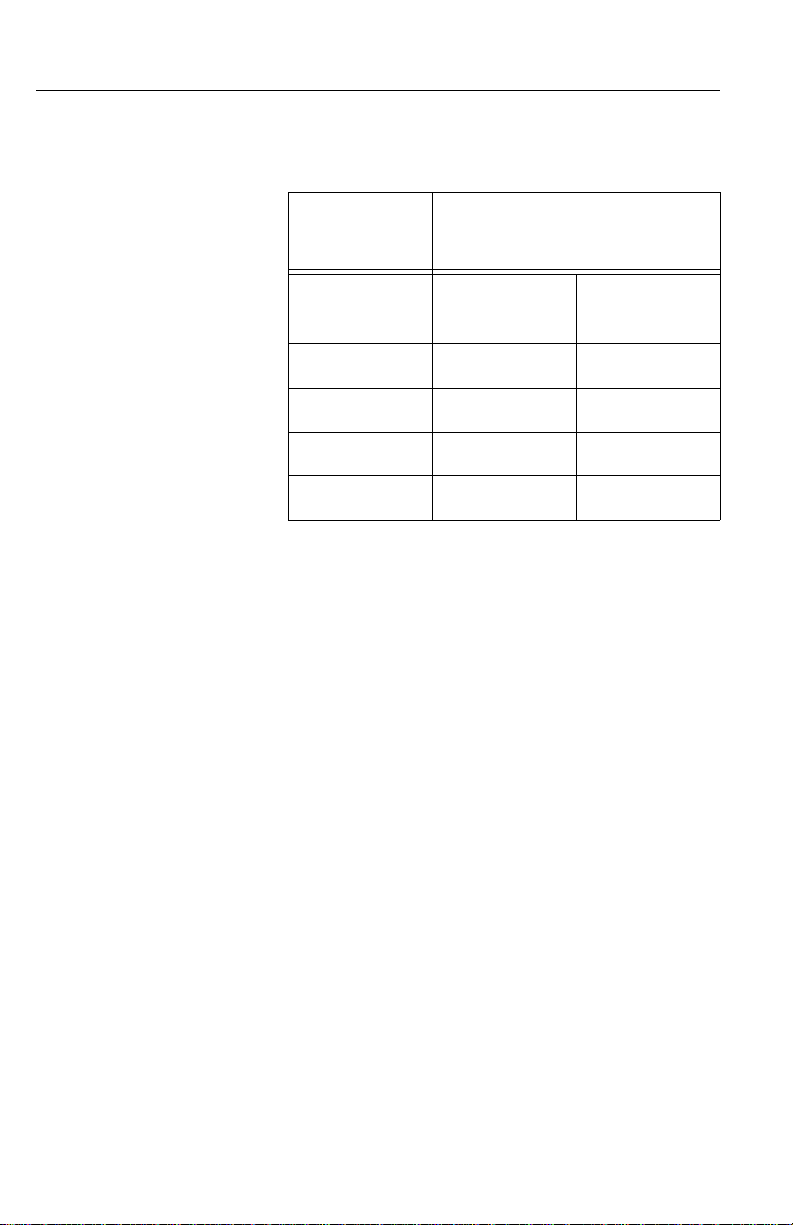

Current Draw at

24VDC

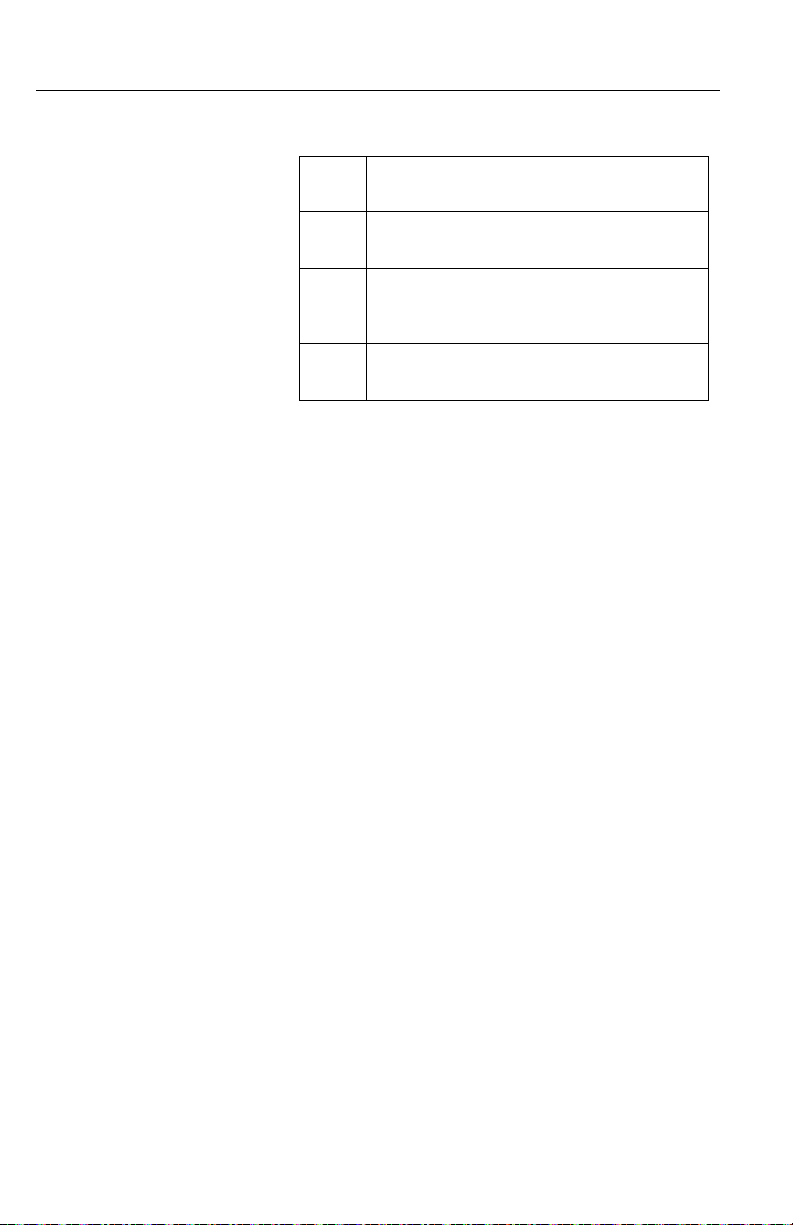

Table 1: Current Draw at 24 VDC

# Load

Cells

Milli-Amp Reading

W/Relay

TTL

W/O Relay

TTL

1 167 ma 166 ma

2 174 ma 171 ma

3 179 ma 175 ma

4 189 ma 179 ma

2-4

Page 17

CHAPTER 3 - INSTALLATION

CHAPTER 3 - INSTALLATION

SCOPE Chapter 3 covers unpacking, cabling, inter-

connecting and installing the HI 200DNWM

weigh module. Users and service personnel

should be familiar with the procedures in this

chapter before installing or operating the

weigh module.

Unpacking 1. Before signing the packing slip, inspect

the packing for damage of any kind.

2. Report any damage to the carrier company immediately.

3. Check to see that everything in the package matches the bill of lading. You

should normally have.

4. HI 200DNWM Module

1 HI 200DNWM module with mating

connectors

1 Installation and Operation Manual

NOTE: Electronic Data Sheet Software is available

on our Website www.hardyinst.com

5. HI 200DNWM-DR Module with DIN

Rail Kit

1 HI 200DNWM module with mating

connectors and a DIN Rail adapter.

1 Installation and Operation Manual

NOTE: Electronic Data Sheet Software is available

on our Website www.hardyinst.com

6. HI 200DNWM-SK1 Modules (2 complete modules pre-stacked)

3-1

Page 18

HI 200DNWM MANUAL

2 HI 200DNWM complete weigh mod-

ules pre-stacked.

1 Installation and Operation Manual

NOTE: Electronic Data Sheet Softwar e available on

our Website www.hardyinst.com

7. HI 200DNWM Module with Stacking

Kit (-SK)

1 HI 200DNWM Module with mating

connectors

4 Standoffs

4 Phillips Pan Head Machine Screws

1 Installation and Operation Manual

NOTE: Electronic Data Sheet Software is available

on our Website www.hardyinst.com

8. HI 200DNWM Module Junction Box (SS - Stainless Steel) or (-PS - Painted

Steel)

1 HI 200DNWM Module with mating

connectors mounted in either a stainless steel or painted steel NEMA 4/

4X enclosure.

1 Summing Card mounted in either a

stainless steel or painted steel NEMA

4/4X enclosure.

1 Installation and Operation Manual

NOTE: Electronic Data Sheet Software is available

on our Website www.hardyinst.com

9. If any items are missing, damaged, or

there are any questions, please contact

Hardy Customer Support at:

3-2

Page 19

CHAPTER 3 - INSTALLATION

Hardy Instruments Inc.

3860 Calle Fortunada

San Diego, CA 92123-1825

Phone: (858) 278-4900

FAX: (858) 278-6700

Web Site: http//www.hardyinst.com

E-Mail:

hardysupport@hardyinst.com

10. Record the model number and serial

number of the Weigh Module. Store this

information in a convenient, secure location for reference when contacting Hardy

Instruments Customer Support Department or to buy parts or firmware

upgrades.

Mechanical

Installation

Installing the

Bare Weigh

Module in an

Enclosure

Step 1. Make sure that the Weigh Module

has at least 2 inches clearance

around the entire weigh module.

(See Fig. 3-1)

Step 2. Drill four thru holes or threaded

holes for four 6-32 pan head

machine screws. (See Fig. 3-2)

Step 3. Mount the four standoffs into the

back panel. (See Fig. 3-3)

Step 4. Fasten the weigh module to the

standoffs by installing the four (4)

pan head screws. (See Fig. 3-3)

3-3

Page 20

HI 200DNWM MANUAL

Step 5. Connect the phoenix connectors to

the headers mounted on the weigh

module.

NOTE: Stand offs and fasteners are not included.

NOTE: Make sure that the connectors are seated properly in

the headers.

3-4

FIG. 3-1 2” CLEARANCE AROUND THE MODULE

FIG. 3-2 HOLE DIAGRAM

Page 21

CHAPTER 3 - INSTALLATION

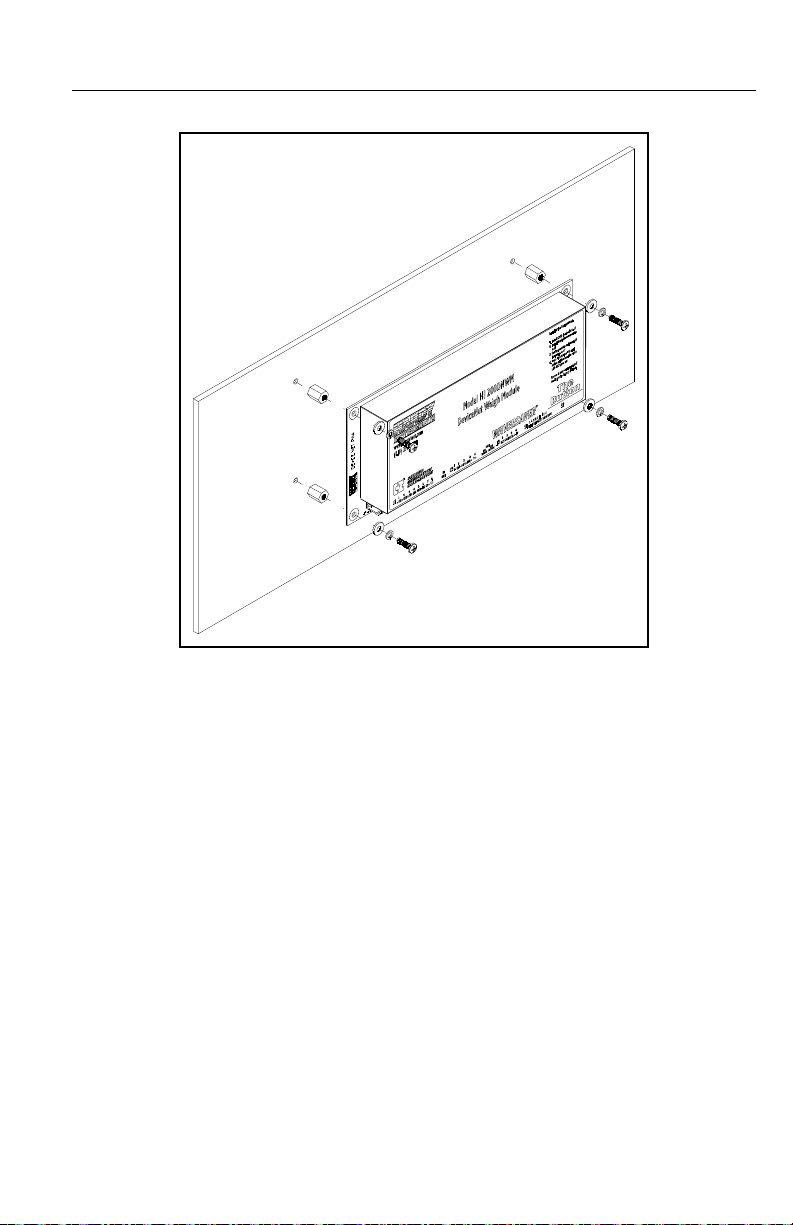

FIG. 3-3 FASTENING MODULE TO BACK PLATE

Installing

Weigh Module

in DIN Rail

Step 1. Take one end piece and one rail

insert. Snap the rail guide insert

into the end piece. Take the other

end piece and install the other rail

guide insert (See Fig. 3-4 & 3-5)

Step 2. Take one of the small rail pieces

and insert the rail pins into the end

piece. (See Fig. 3-6)

Step 3. Take one of the large rail pieces

and insert the rail pins into the

small rail piece. Do this on both

sides. (See Fig. 3-6)

Step 4. Continue installing the rail pieces

until all rail pieces are installed.

(See Fig. 3-7)

3-5

Page 22

HI 200DNWM MANUAL

FIG. 3-4 INSTALLING THE RAIL GUIDE INSERT INTO THE END PIECE

3-6

FIG. 3-5 RAIL GUIDE INSERT IN THE END PIECE

Page 23

CHAPTER 3 - INSTALLATION

FIG. 3-6 INSTALLAT I ON OF THE RAIL PIECES

Step 5. Gently slide the HI 200DNWM

into the assembled DIN Rail until

the board is flush against the other

end piece. (See Fig. 3-7)

Step 6. Take the other assembled end piece

and snap it into the rail pieces. (See

Fig. 3-7)

Step 7. The HI 200DNWM is completely

in the Din Rail assembly ready for

installation. (See Fig. 3-8)

3-7

Page 24

HI 200DNWM MANUAL

FIG. 3-7 INSTALLING THE WEIGH MODULE INTO THE ASSEMBLED

DIN RAIL

FIG. 3-8 WEIGH MODULE INSTALLED IN THE DIN RAIL

NOTE: The Weigh Module can be installed in the DIN Rail

Assembly in either direction.

3-8

Page 25

CHAPTER 3 - INSTALLATION

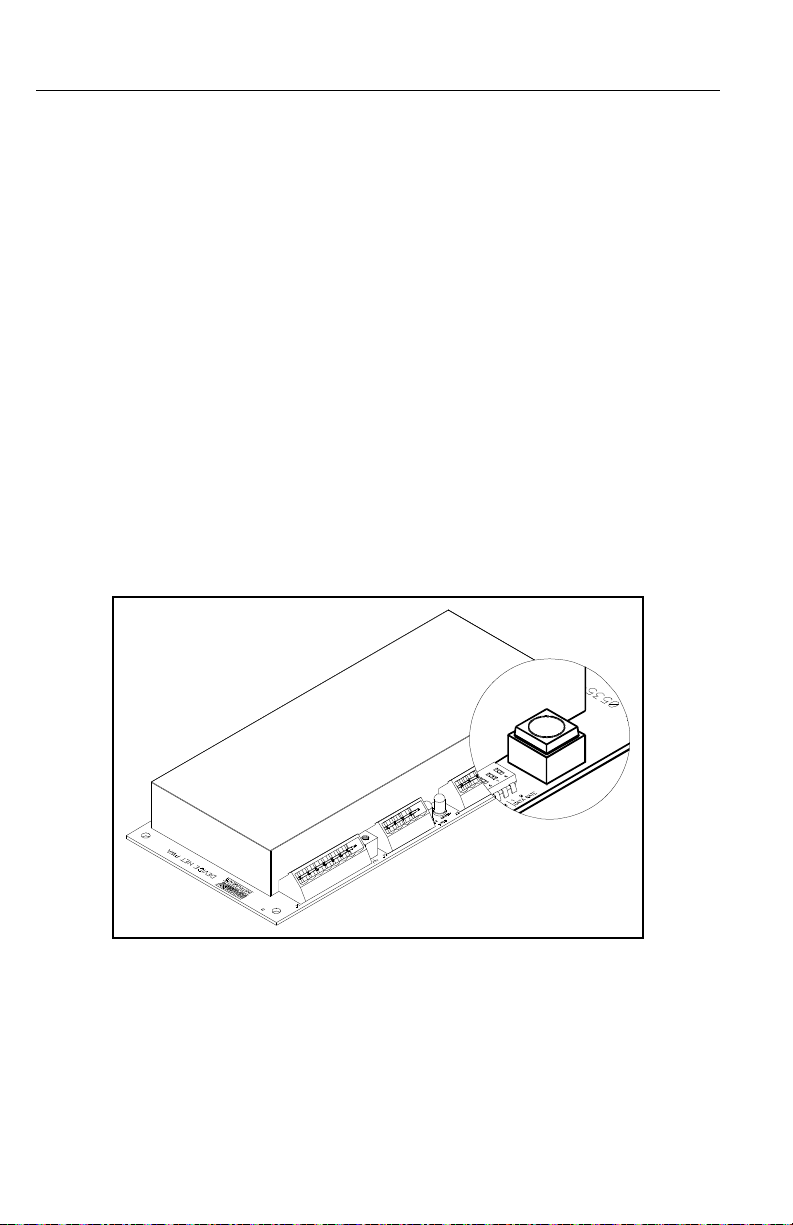

Installing the

Pre-stacked

Weigh Module

Step 1. Drill four (4) thru holes or threaded

holes for four (4) 6-32 threaded

male 1/4” hex standoffs.

Step 2. Screw four (4) 3/8” long x 1/4”

wide male standoffs into the back

panel.

NOTE: The four (4) 3/8” x 1/4” do not come with the stacki ng

kit.

NOTE: Refer to Paragraph 3.1.1 for clearance and hole

diameter specifications.

Step 3. Place the bottom weigh module

onto the 3/8” standoffs.

Step 4. Fasten the 1.25” x 1/4” threaded

female standoffs that come in the

stacking kit to the 3/8” standoffs.

Step 5. Place the second weigh module

over the 1.25” standoffs aligning

the holes with the threaded holes in

the standoffs.

Step 6. Place the four (4) #6 flat washers

over the mounting holes on the second weigh module.

Step 7. Place the four (4) #6 lock washers

over the four (4) flat washers.

Step 8. Screw the four (4) pan-head

machine screws into the previously

mounted standoffs until the upper

weigh module is fastened securely

to standoffs. (See Fig. 3-9)

3-9

Page 26

HI 200DNWM MANUAL

FIG. 3-9 INSTALLING THE STACKING KIT

Electrical

Installation

Wiring Diagram

Pin Description

for the J1 Load

Sensor 8 Pin

Connector

1-C2

2+C2

3 -EXC (Minus Excitation

4 -SEN (Minus Sense)

5 -SIG (Minus Signal)

6 +SIG (Plus Signal)

7 +SEN (Plus Sense)

8 +EXC (Plus Excitation) +5VDC

NOTE: If the sense lines are not used to measure the actual

excitation voltage at the junction box, an error is

introduced. The error is equal to the percentage of

excitation voltage lost between the instrument and the

junction box. If the excitation voltage at the back of

3-10

Page 27

CHAPTER 3 - INSTALLATION

the instrument is 5 volts and the excitation voltage at

the junction box was 4.9 volts, 0.1 volts was lost due

to cable resistan ce. This loss wi ll caus e a lin ear error

of 1% of applied load in all weight readings. This

error is introduced because the programmed millivolt

per volt data of the load point is multiplied by the

voltage between the sense lines to compute the calibrations curve of the load point. (See Chapter 7,

Paragraph 7.3.2, page 7-3)

Wiring Diagram

Pin Description

for the J2

DeviceNet

Interface 5 Pin

Open

1 V- (Black)

2 CAN- (Blue)

3 Shield (Bare)

4 CAN+ (White)

5V+ (Red)

NOTE: All power for the Weigh Module is received through

the DeviceNet cable. A separate power supply is not

required.

Wiring Diagram

Pin Description

for the J3 Set

Point Out 4 Pin

1 RLY1 (Set Point Output One)

2 GND

3 RLY2 (Set Point Output Two)

4 +5 VDC

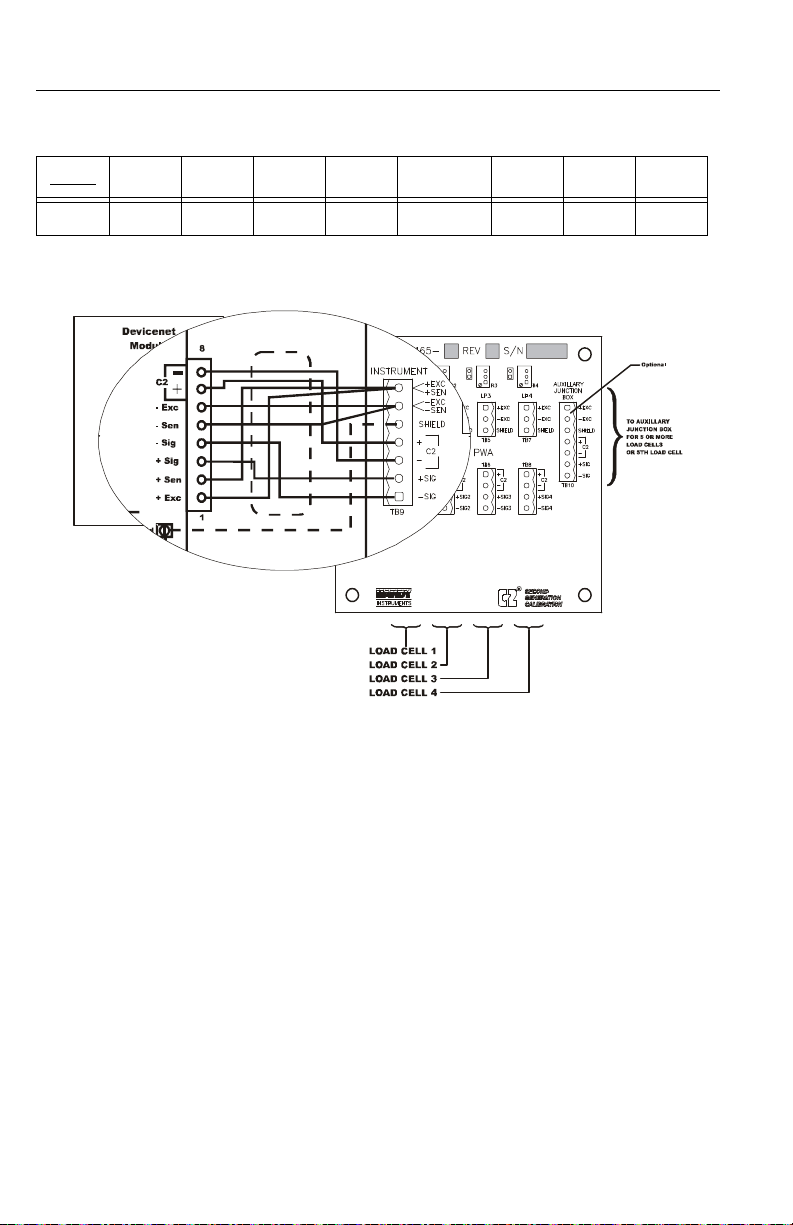

Wiring Diagram

for the HI

215JB Junction

Box

C2 Loadcell

Cable

Connection

(J1)

When connecting the HI 215JB Junction box

using C2 loadcell/point cable (6020-0001)

use the following color code:

3-11

Page 28

HI 200DNWM MANUAL

Model EXC + SEN + SIG + SIG - SEN - EXC - C2 + C2 -

J-BOX RED BLUE GRN WHT BRWN BLK GREY VIO

Table 1: C2 CABLE COLOR CODE/HI 215JB J-BOX

FIG. 3-10 C2 LOAD CELL CONNECTION/HI 215JB JUNCTION BOX

1 Recommended load cell cable, Hardy

Instruments (Prt. #6020-0001)

2 Attach the load shield to the te rminal

block mounted next to the J1 connector on the HI 200DNWM Module.

3 Do not run load cell cable in parallel

with or in the same conduit with

power wiring, relay cables or any

other high energy cables.

4 Remove the factory-installed jumpers

for C2 wire load cell connection.

5 JB summing Card (Part. #0535-0465-

05)

3-12

Page 29

CHAPTER 3 - INSTALLATION

Non-C2

Loadcell

Cable

Connection

(J1)

1 Attach the load cell cable to the ter-

minal block mounted next to the J1

connector on the HI 200DNWM

Module.

2 Factory installed jumpers to remain

in place for 4 wire, non-C2 load cell

connections. (See Fig. 3-11)

3 Do not run load cell cable in parallel

with or in the same conduit with

power wiring, relay cables or any

other high energy cables.

FIG. 3-11 NON C2 LOAD CELL CONNECTION/HI 215JB JUNCTION BOX

3-13

Page 30

HI 200DNWM MANUAL

3-14

Page 31

CHAPTER 4 - CONFIGURATION

CHAPTER 4 - CONFIGURATION

SCOPE Chapter Four consists of all the proce-

dures for configuring the HI 200DNWM

Weigh Module. System configuration

includes only hardware adjustments such

as Jumper and Dip Switch settings. We

recommend that maintenance personnel

be familiar with this chapter before configuring the Weigh Module. Alternative

configuration procedures are not recommended.

Differences in the

Series A and Series B

Modules

Changing from the

Series A to the

Series B Module

Changing from the

Series B to the

Series A Module

The Series B 200 DNWM module uses 4

bytes of input polled data. This requires

each module to use a different .EDS file.

Configuration when using RS NetWorx

for DeviceNet require the new .EDS file.

This adds the 4 bytes of input polled

data. If you want to use the new features

of the module, the 4 bytes of input polled

data need to be mapped into the scanner’s scanlist.

If you do not map the input polled data

into the scanner’s scanlist, the module

will operate as if it were a Series A. No

changes need to be made to any ladder

logic written for the module.

If you change from Series B to the older

module, the configuration when using

RS NetWorx for DeviceNet needs to be

done using the older .EDS file. This will

remove the 4 bytes of input polled data.

These 4 bytes of data must then be

removed from the scanner’s scanlist. All

4-1

Page 32

HI 200DNWM MANUAL

ladder logic written that refers to the 4

bytes of input polled data needs to be

changed and any reference to the output

data also needs to be reviewed and possible modified.

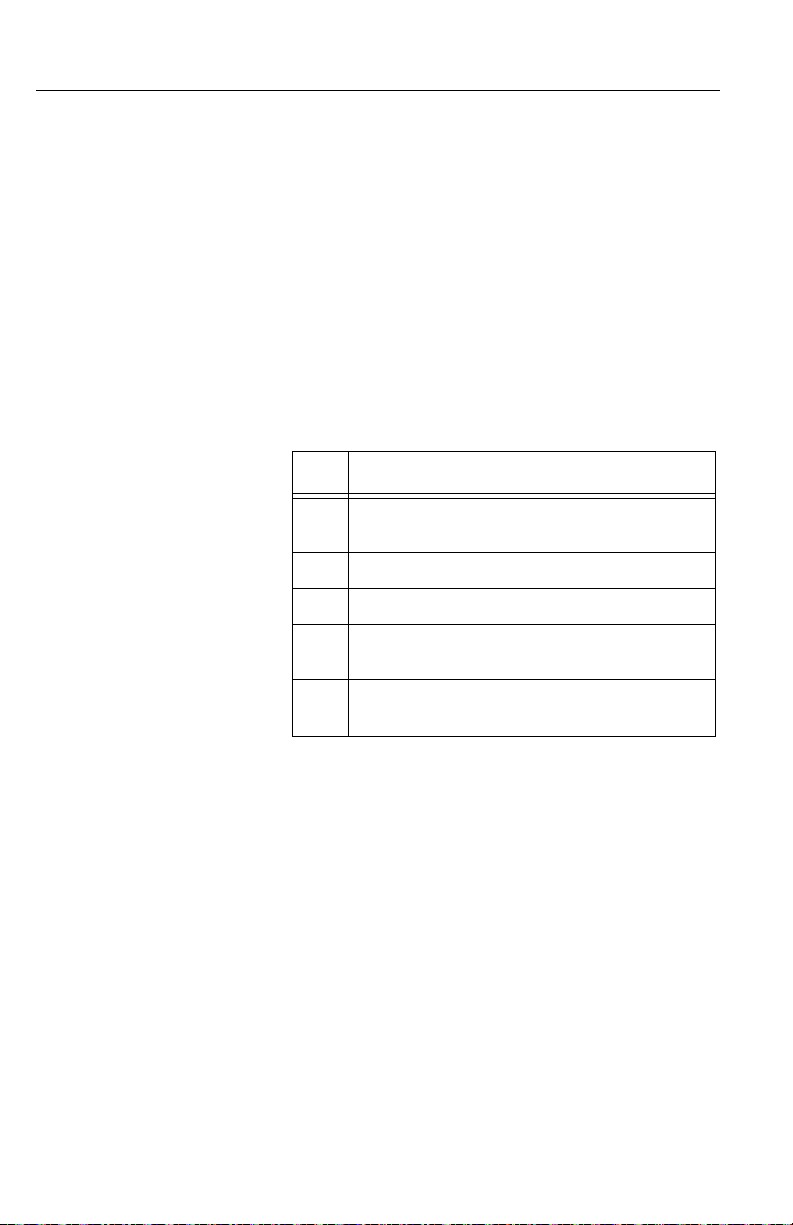

DIP Switch (S1) Configuration

DIP Switch Location

Configuring the

Baud Rate

Configuring the DIP switch sets the following:

1. Baud Rate

2. Node Address

The DIP Switch is located between THE

BUTTON and the J3 Header. (See Fig. 41 & 4-2)

Refer to Table 4-1 to configure the baud

rate. 0 = OFF, 1 = ON (* is the default

setting)

Baud Rate S1-7 S1-8

125 kbps* OFF OFF

250 kbps OFF ON

500 kbps ON OFF

500 kbps ON ON

4-2

Table 4-1: Baud Rate

Page 33

CHAPTER 4 - CONFIGURATION

FIG. 4-1 S1 DIP SWITCH LOCATION

FIG. 4-2 FACTORY DEFAULT DIP SWITCH CONFIGURATION

Configuring the

DeviceNet Node

Refer to Table 4-2 to configure the

DeviceNet Node Address.

Address

4-3

Page 34

HI 200DNWM MANUAL

Address S1-1 S1-2 S1-3 S1-4 S1-5 S1-6

0 OFF OFF OFF OFF OFF OFF

1 OFF OFF OFF OFF OFF ON

2 OFF OFF OFF OFF ON OFF

3OFFOFFOFFOFFONON

“ ““““““

62 ON ON ON ON ON OFF

63 ON ON ON ON ON ON

Table 4-2: DeviceNet Node Addresses

4-4

Page 35

CHAPTER 5 - SETUP

CHAPTER 5 - SETUP

SCOPE All information contained in Chapter 5 per-

tains to software or firmware settings or procedures to prepare the HI 200DNWM weigh

module for calibration and operation. Alternatives to these procedures either explicit or

implied, contained in this section are not recommended. It is very important that the user

and service personnel be familiar with the

procedures contained in this chapter, before

going through the setup procedures.

Saving to Non-Volatile Ram

NOTE: If you have an instrument with version 1.5, please

refer to Devicenet Manual, REV B-6 or earlier for

instructions about Saving to Non-Volatile Ram or

contact Hardy Instruments Customer Service Department.

In version 2.1, the HI 200DNWM does not

automatically save parameters to non-volatile memory. To save parameters to non-volatile RAM, set parameter 38 (Save nonvolatile command) to 1.

This request should be sent after changing

any configuration parameter. It does NOT

need to be sent after altering a command

parameters like TARE or ZERO. It does not

need to be sent after doing a calibration. The

necessary calibration data values are saved

automatically. However, if you change

parameters used during calibration, like

“number of averages”, or “WAVER-

5-1

Page 36

HI 200DNWM MANUAL

SAVER®” for example, the SAVE request

should be sent BEFORE cycling the power.

The non-volatile RAM has a maximum of

5,000,000 writes.

Parameters • Parameter 1 = Metric Poll

True = kgs net False = lbs net

Length in Bytes = 1

NOTE: Default settings are indicated by bold type.

• Parameter 2 = WAVERSAVER® Setting

0 =OFF 1 = 4 Hz, 2 = 2Hz, 3 = 1.0 Hz, 4

= 1/2 Hz

Length in Bytes = 1

NOTE: By selecting OFF (0) or 1 the module increases the

updates per second from 10 to 55.

5-2

• Parameter 3 = Calibration Type

0 = Hard Cal, 1 = C2 Cal, Other = Not

Cal’d (Read Only)

Length in Bytes = 1

• Parameter 4 = Span Weight in Lbs

1 to 2147483647 10000.000

Length in Bytes = 4

• Parameter 5 = Averages

0 to 255 10

Length in Bytes = 1

• Parameter 6 = Set Point One Mode

bit 7 = On/Off bit 1 = Low/High

bit 0 = Net/Gross

Length in Bytes = 1

Page 37

CHAPTER 5 - SETUP

• Parameter 7 = Set Point One Lbs Value

-2147483648 to 2147483647

10000.000

Length in Bytes = 4

• Parameter 8 = Set Point One Deadband

in Lbs

0 to 2147483647 0.100

Length in Bytes = 4

• Parameter 9 = Set Point One Preact in

Lbs

0.00 to 2147483.647

Length in Bytes = 4

• Parameter 10 = Set Point Two Type

bit 7 = On/Off

bit 1 = Low/High

bit 0 = Net/Gross

Length in Bytes = 1

• Parameter 11 = Set Point Two Lbs Value

-2147483648 to 2147483647

100000.000

Length in Bytes = 4

• Parameter 12 = Set Point Two Deadband

in Lbs

0 to 2147483.647 0.100

Length in Bytes = 4

• Parameter 13 = Set Point Two Preact in

Lbs

0 to 2147483647

Length in Bytes = 4

5-3

Page 38

HI 200DNWM MANUAL

• Parameter 14 = Number of C2® Chips

Found

0 to 8 (Read Only)

Length in Bytes = 1

• Parameter 15 = Net Weight in Lbs

Read Only

Length in Bytes = 4

• Parameter 16 = Gross Weight in Lbs

Read Only

Length in Bytes = 4

• Parameter 17 = Tare Weight in Lbs

-999999 - 999999 0.00

Length in Bytes = 4

• Parameter 18 = Tare Command

0 to 1 (Set to True to Complete Command)

Length in Bytes = 1

5-4

• Parameter 19 = Zero Command

0 to 1 (Set to True to Complete Command)

Length in Bytes = 1

• Parameter 20 = Calibrate Low Command

0 to 1 (Set to True to Complete Command)

Length in Bytes = 1

• Parameter 21 = Calibrate High Command

0 to 1 (Set to True to Complete Command)

Length in Bytes = 1

Page 39

CHAPTER 5 - SETUP

• Parameter 22 = Calibrate using C2®

0 to 1 (Set to True to Complete Command)

Length in Bytes = 1

• Parameter 23 = Span Weight in Kgs

0.000 to 2147483.647 0.045

Length in Bytes = 4

• Parameter 24 = Set Point One Kgs Value

Read Only

Length in Bytes = 4

• Parameter 25 = Set Point One Deadband

in Kgs

0.00 to 2147483.647 0.045

Length in Bytes = 4

• Parameter 26 = Set Point One Preact in

Kgs

0 to 2147483.647

Length in Bytes = 4

• Parameter 27 = Set Point Two Kgs Value

-2147483.648 to 2147483.647

4535.923

Length in Bytes = 4

• Parameter 28 = Set Point Two Deadband

in Kgs

0 to 2147483.647 0.045

Length in Bytes = 4

• Parameters 29 = Set Point Two Preact in

Kgs

0 to 2147483.647

Length in Bytes = 4

5-5

Page 40

HI 200DNWM MANUAL

• Parameter 30 = Net Weight in Kgs

Read Only

Length in Bytes = 4

• Parameter 31 = Gross Weight in Kgs

Read Only

Length in Bytes = 4

• Parameter 32 = Tare Weight in Kgs

-999999 - 999999 0.00

Length in Bytes = 4

• Parameter 33 = Relay Outputs

Length in Bytes = 1

• Parameter 34 = A/D Counts

Length in Bytes = 4

• Parameter 35 = Calibration Low Weight

in Lbs.

Length in Bytes = 4

5-6

• Parameter 36 = Calibration Low Weight

in Kgs.

Length in Bytes = 4

The “Calibration Low Weight” parameter specifies the w eight on the scal e when

the low step of a calibration is done in

Traditional Calibration and is the Reference Point for C2 Calibration.

• Parameter 37 = Weight Multiplier

Length in Bytes = 4

This integer parameter can be set to 1,

10, 100, etc. to allow the user to select

Page 41

CHAPTER 5 - SETUP

the number of decimal places in the 32

bit integer weight outputs. The value 0

causes these weight outputs to be in

floating point format.

NOTE: This applies ONLY to the weights as viewed through

the I/O (Command) interface. The explicit message

interface continues to use 3 decimal place 32 bit integer format only.

• Parameter 38 = Write non-volatile com-

mand.

Length in Bytes = 1

Setting this parameter to 1 will cause a

save to non-volatile memory. Calibration data is saved to non-volatile memory

automatically. Other parameters must be

saved using this command.

Command

Interface

• Parameter 39 = Parameter high word.

Length in Bytes = 2

This parameter is used in the command

interface as described below:

The Command Interface allows easy access

to all parameters without using explicit messages.

The HI 200DNWM version 2.1 produces 4

bytes of polled output data and consumes 4

bytes of polled input data. The 4 bytes of

input data can be used to set parameters in

the module and to specify what data should

be placed in the 4 bytes of output data.

5-7

Page 42

HI 200DNWM MANUAL

Format of

Commands (4

byte input

data)

Byte 0 Parameter value, least significant byte. (Used by

the WRITE command only.

Byte 1 Parameter value, second l ea s t sig ni fic ant byte.

(Used by the WRITE command only.)

Byte 2 Parameter number. The parameter number is the

Byte 3 (Command byte): 0=READ command. 1 =

instance of the par ameter object. These are li s ted

in the HI 200DNWM manual .

WRITE command

Most of the HI 200DNWM’s parameters are

only 1 byte long, making it possible to write

them with a single command. There are also

some 4 byte parameters. To write one of

them:

Step 1. First write the 2 most significant

bytes, using a WRITE command as

described above, with 0x27 in the

parameter number field.

Step 2. Write the least significant bytes

using normal parameter numbers.

The module will combine the value

written to parameter 0x27 with the

least significant bytes to produce

the value written to the 4 byte

parameter.

5-8

The 4 bytes written to the output table are as

follows:

• If the Command byte of the input data is

0 (READ), the data is the value of the

specified parameter, least significant byte

first.

Page 43

CHAPTER 5 - SETUP

• If the specified parameter is an invalid

number (0 for example: there is no

parameter number 0), the data is net

weight, with units as determined by the

METRIC POLL parameter.

• If the Command byte of the input data is

non-zero (WRITE), the output data

echoes the input data.

Examples

Using the

Command

Interface

Reading Gross Weight in the polled output

data.

1. First word (2 least significant bytes) of

the input data is not used. Ignore.

2. Lower byte of second word is the param-

eter number. Gross weight in lbs is

parameter #16.

3. Upper byte of second word set is “0”

indicating read.

This causes the unit to output the Gross

weight in lbs to the output polled data area.

Resolution and data type would depend on

the Weight Multiplier setting.

Writing new value to number of averages.

1. First byte of first word on the input data

is the new valued wanted.

2. Upper byte of first word should be 0 and

is not used.

3. Lower byte of second word is the param-

eter number. Averages is parameter #5.

4. Upper byte of second word is set to “1”

to indicate write.

This causes the unit to write the value in the

first byte of the first word to the Averages

5-9

Page 44

HI 200DNWM MANUAL

Setpoints

parameter. During the execution of the command, the output polled data reflects the

input polled data.

About SetPoints

Dead Band

Limits

The set point value is the target weight or

level in either net or gross weight units

The dead band value can be set as a High or

Low value. It is used to deactivate the set

point.

For example:

If a set point value was 1000 pounds and the

dead band was set to 5 pounds, the relay

would close at a 1000 pounds but not open

until the weight dropped to 995 pounds. This

is used if a set point is a high trip limit. A

High dead band would be used for a low trip

limit. Examples are show for Low and High

Trip Limits in Fig. 5-2.

5-10

Page 45

CHAPTER 5 - SETUP

FIG. 5-1 LOW AND HIGH PREACT TRIP LIMITS

Three General

Rules for Set

Points

1. Set Points activate at the set point plus

the preact.

2. Set Points deactivate at the set point plus

the deadband.

3. The deaband should be numerically

larger than the preact.

Preact Limits 1. The preact value is the number of units

below or above the set point at which the

relay will trip.

2. The preact value is used as an “in-flight”

compensation value when filling a vessel. If set to zero, there will be no compensation.

Entering Set

Points

Change the Set Point Parameters in accordance with the DeviceNet Manager you are

5-11

Page 46

HI 200DNWM MANUAL

Setpoint Mode

Parameters

using. Be sure to read the DeviceNet Manager instructions first before setting.

About

Setpoint

Mode

Parameter

Entering

Setpoint

Mode

Parameters

The Setpoint mode parameter is a bit

encoded byte that affects the behavior of the

setpoint.

Bit Description

Bit 7 Setpoint On/Off. Set to 1 to activate the setpoint, set

to 0 to disable it.

Bit 6 Set to 1 to output 0 vol ts (Force Relay Off)

Bit 5 Set to 1 to output 5 vol ts (Force Relay On)

Bit 1 Set to 0 for a gain in weight setpoint, set to 1 for a loss

in weight setpoint.

Bit 0 Set to 1 for a setpoint based on Net weight, or to 0 for

a setpoint based on gross weight.

5-12

Page 47

CHAPTER 6 - CALIBRATION

CHAPTER 6 - CALIBRATION

SCOPE Chapter 6 pertains to the calibration pro-

cedures for the HI 200DNWM weigh

module. Alternatives to any procedures

either implied or explicitly contained in

this chapter are not recommended. In

order for the weigh module to work

properly, it must be calibrated prior to

operation. All calibration should be recalibrated periodically, or when not in

use for extended periods of time. Be sure

to follow all the procedures completely

to insure that the weights read by the

module are accurate. It is very important

that the user and service personnel be

familiar with the procedures contained in

this chapter, before installing or operating the HI 200DNWM weigh module.

Pre-Calibration Procedures

Step 1. Check to see if the load cell/

sensor/points are properly

installed. Refer to your load

cell I&M manual for proper

installation instructions.

Step 2. Check to be sure that the con-

nectors are installed firmly in

the weigh module headers.

NOTE: You need to go thr oug h the p re-calibration pro ce-

dures before each calibration, regardless of the

type of calibration you are performing.

C2® Calibration (The

Button)

Step 1. The Module LED must be

green in color . If it is not do not

try to calibrate the instrument.

Contact Hardy Instruments

6-1

Page 48

HI 200DNWM MANUAL

Customer Support for assistance.

Step 2. Press the RED BUTTON on the

weigh module printed circuit

board and hold the button down

until the Module Status LED

goes off. (See Fig. 6-1)

NOTE: This could take up to 2 seconds.

Step 3. When the Module Status LED

comes back on. Release the

RED BUTTON. The weigh

module system is calibrated.

Step 4. If the LED does not come back

on contact Hardy Customer

Support for assistance.

FIG. 6-1 THE RED BUTTON

C2® Calibration from

RS NetWorx

6-2

®

Step 1. On the PC open RS NetWorx

®

Step 2. Browse the Network.

Step 3. Double click on the Node Icon

of the weigh module you want

to calibrate. For example: Node

Page 49

CHAPTER 6 - CALIBRATION

36. The DeviceNet Weigh

Module Dialog Box appears.

Step 4. Click on the Parameter tab. The

Parameter List appears with the

information for the weigh mod-

ule at address 36.

Step 5. Click on Cal LO.

Step 6. Enter the Cal LO value.

Step 7. Click on the Apply button.

Step 8. Click on Yes.

Step 9. Click on C2 Cal Cmd.

Step 10. Set the C2 Cal Cmd to “1”.

Step 11. Click on the Apply button.

Step 12. Click on Yes.

Step 13. Click on Cmd Save non-vol.

Step 14. Set the Cmd Save non-vol to

“1”.

Step 15. Click on the Apply button.

Step 16. Click on Yes.

Step 17. The calibration is complete.

NOTE: Requires C2® load sensors or load points.

NOTE: RS NetWorx® is a registered trademark of Rock-

well Automation.

Test Weight Calibration from RS Net-

®

Worx

Step 1. On the PC open RS NetWorx

Step 2. Browse the Network.

Step 3. Double click on the Node Icon

®

of the weigh module you want

to calibrate. For example: Node

36. The DeviceNet Weigh

Module Dialog Box appears.

Step 4. Click on the Parameter tab. The

Parameter List appears with the

information for the weigh mod-

ule at address 36.

Step 5. Click on Span Weight.

6-3

Page 50

HI 200DNWM MANUAL

Step 6. Enter the Span Weight Value.

Step 7. Click on Cal LO.

Step 8. Enter the Cal LO weight.

Step 9. Click on Cal LO command.

Step 10. Set the Cal LO to “1”.

Step 11. Click on the Apply button.

Step 12. Click on Yes.

Step 13. Place the test weight on the

scale.

Step 14. Click on Cal HI command.

Step 15. Set the Cal HI command to “1”

Step 16. Click on the Apply button.

Step 17. Click on Yes.

Step 18. Click on Cmd Save non-vol.

Step 19. Set the Cmd Save non-vol to

“1”.

Step 20. Click on the Apply button.

Step 21. Click on Yes.

Step 22. The calibration is complete.

6-4

Page 51

CHAPTER 7 - OPERATION

CHAPTER 7 - OPERATION

SCOPE All information contained in Chapter 7 per-

tains to the operation of the HI 200DNWM

weigh module. We recommend that the processes and procedures contained in this

chapter be followed to insure that the module

give the user maximum quality performance.

It is very important that the user be familiar

with this chapter before operating the weigh

module.

Operating

Capabilities

Explicit Message

Request

Parameters

The HI 200DNWM can do the following or

can be used in the following operations:

1. Monitor Weight Readings

2. Filling

3. Dispensing

4. Check Weighing

5. Batching

The procedures for sending the Explicit

Message Requests are unique to each PLC

and the user needs to refer to their PLC users

guide, PLC DeviceNet Scanner section for

instructions. The HI 200DNWM needs the

following information to respond to an

Explicit Message Request:

•SERVICE:

The HI200DNWM WEIGH

MODULE can process the

“Get_Attribute_Single” (14) and

“Set_Attribute_Single” (16).

• CLASS: The Device Net parameter

Class is 15.

• INSTANCE: The HI 200DNWM

WEIGH MODULE parameter number

7-1

Page 52

HI 200DNWM MANUAL

can be found in the HI 200DNWM

WEIGH MODULE I&O manual.

• ATTRIBUTE: The parameter value

attribute number is 1.

•DATA: (varies)

NOTE: Data length can vary, be sure to enter the correct

length (size) of data or problems will occur.

NOTE: Order of bytes must be least significant first.

Monitoring Weight

Readings from RS

NetWorx

Step 1. On the PC open RS NetWorx.

Step 2. Browse the Network.

Step 3. Double click on the Node Icon of

the weigh module you want to

monitor. For example: Node 36.

The DeviceNet Weigh Module Dia-

log Box appears for Node 36.

Step 4. Click on the Parameters Tab.

Step 5. All the parameters including the

weights are displayed.

Step 6. The NET, GROSS, and TARE

weights are now being monitored.

NOTE: The HI 200DNWM can be used for Batching, Filling,

Dispensing, and Check Weighing applications.

Network Status

(DS1)

STATE LED INDICATION

NOT POWERED/

NOT ON LINE

OFF DEVICE IS NOT ON LINE

1. NO POWER APPLIED

2. Dup_MAC_ID TEST NOT COMPLETE

OPERATIONAL

AND ON-LINE

7-2

GREEN ON LINE NORMAL CONDITION WITH CONNECTIONS

ESTABLISHED.

Table 7-1: NETWORK STATUS (DS1)

Page 53

CHAPTER 7 - OPERATION

STATE LED INDICATION

OPERATION

AND ON LINE

NOT CONNECTED

CRITICAL

FAULT OR LINK

FAILURE

FLASHING

GREEN

RED UNRECOVERABLE FAULT (MAY NEED REPLACING)

ON LINE NORMAL CONDITION NO CONNECTIONS

Dup_MAC_ID PASSED & ON LINE, NO CONNECTIONS

TO OTHER NODES.

FAI LED COMMUIC ATIONS (DUPLICATE Mac ID OR BUS

OFF)

Table 7-1: NETWORK STATUS (DS1)

Module Status

(DS2)

STATE LED INDICATION

NOT POWERED/

NOT ON LINE

OPERATIONAL GREEN NORMAL CONDITION

MINOR FAULT

AND/OR CONNECTION TIMEOUT

CRITICAL

FAULT OR LINK

FAILURE

OFF DEVICE IS NOT ON LINE

FLASHING

RED

RED UNRECOVERABLE FAULT (Board MAY NEED REPLAC-

1. NO POWER APPLIED

RECOVERABLE FAULT A/D ERROR, USUALLY

CAUSED BY BAD CONNECTION TO LOAD CELLS

LOAD CELL OUT OF RANGE. SENSE LINES MUST BE

INSTALLED. (See Chapter 3, Page 3-10 for more information)

ING)

FAILURE IN A-D.

Table 7-2: MODULE STATUS (DS2)

7-3

Page 54

HI 200DNWM MANUAL

7-4

Page 55

CHAPTER 8 - TROUBLESHOOTING

CHAPTER 8 - TROUBLESHOOTING

SCOPE All the information in Chapter 8 pertains to

the troubleshooting and resolution of operating problems that may occur. All maintenance personnel and users should be familiar

with Chapter 8 before attempting to repair

the HI 200DNWM.

Module LED does

not Come Back on

When Performing

Calibration with

The Button

Module LED is

Flashing Red

Mechanical

Inspection

If the Module LED does not come back on

when performing The Button (C2 Calibra-

tion) it indicates a hardware problem. Contact Hardy Customer Support for assistance.

Solution: Check all the connections to be

sure they are securely fastened. Reinstall if

any appear to be loose.

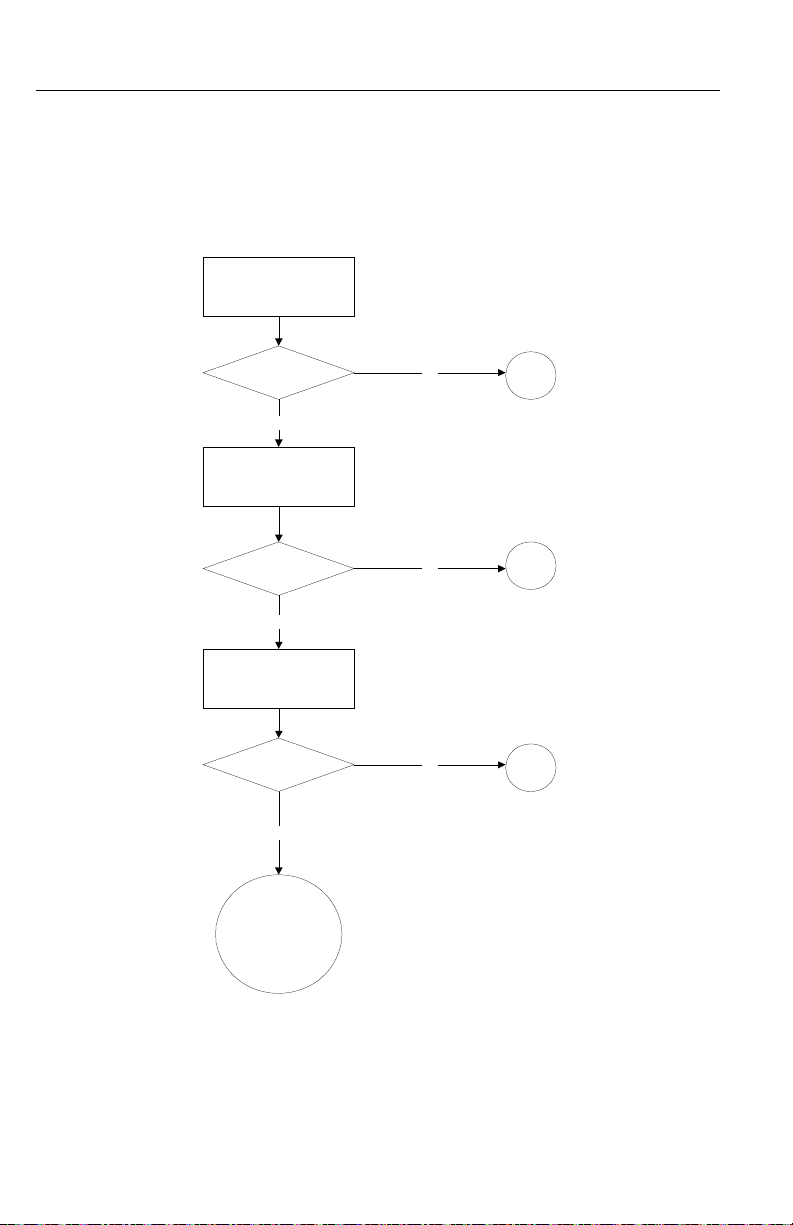

See Fig. 8-1

8-1

Page 56

HI 200DNWM MANUAL

All pipes and conduits

flexible?

Mechanically isolated

from ladders and

connecting structures?

1) Floors or structure does not interact.

2) Local traffic does not interact

3) Protected from forklifts and adjacent processing equipment

Are the load cells properly

mounted?

Are Check rods installed

to dampen vessel

movement?

1) Protects the load cells from overload and impact forces

2) Limits the movement of the vessel

3) Rods must be loose and not interacting with the vessel.

Are cables routed

properly?

1) Product, tools and production aids are off the vessel.

2) No workers are physically on the scale

3) Must protect equipment from environmental damage

4) Insure openings are sealed to keep water and environmental

contaminates from damaging:

(a) Instrument cabinet or enclosure

(b) Summing card

(c) Load Cells

(d) Conduit runs

(e) covers are properly installed

1) Keep flexures on the horizontal

2) Vertical flexures should be avoided

3) Do not use flexures to correct for misaligned piping

4) Do not use hose flexures to make right angle bends

5) Non-flexed piping should have an unsupported

horizontal run using a ratio of 36 times it's diameter.

6) Pipe flexure lengths should be a ratio of 6 times it's diameter

7) Feed and discharge piping flexed

8) Are the flex joints on the correct side of the valve ?

(a) You weigh the output valve, not the input valve

(b) Does the weigh scale see all the product to be

weighed?

(c) If the product applies a force to a valve or pipe, that .

pipe or valve must be included in the weigh vessel.

(d) Proper positioning of the flexures are key.

(e) Your vessel must seem to float.

1) Separate conduit for low and high voltage cables.

2) Do not bundle Low voltage with High voltage cables

3) Maintain at least 3 inches of seperation.

4) Maintain 14"seperation from magnetic fields and 440 vac.

5) Cables are in conduit or tied up and protected from damage.

1) Level, solid mounting base

2) The load cell is mounted right side up.

3) All load cell bolts installed using anti-seize compounds.

4) Mechanically aligned to compensate for expansion and

contraction.

Housekeeping

8-2

FIG. 8-1 MECHANICAL INSPECTION

Page 57

CHAPTER 8 - TROUBLESHOOTING

Load cell wiring is

complete and correct?

1) Does the mV signal i ncrease in a positive direction.

2) If you receive a negative result s, check if load cell is

mounted correctly.

a) The arrow goes with the direction of force.

b) If there isn't an arrow, you must manually verify the

correct direction. A negative reading indicates the

load cell is upside down.

c) Load cells in tension will not reflect a negative

reading if install upside down. If upsi de dow n, only

the force applied by the cable would be included in

the weight readings.

d) If you are still receiving a negative signal, verify

load cell wire color code

Multiple load cells?

MAP the mV reading.

Balance the load

1) Verify a positive reading f rom each l oad cell, using a

volt meter.

2) Record the mV reading and compare each corner for

proper load sharing.

a) Proper load sharing should see only a di fference

of +/- .5 mV.

b) Larger differences due t o m otors and piping,

should not exceed +/- 2 mV.

c) If there isn't any motors, valves, or piping to

explain the mV difference, adjust t he corners and

balance the mV readings.

d) Use shims, or if equipped adjusting bolts on the

load cell mounting hardware.

e) Drawing a load cell map will help determine the

correct leg to adjust and in which direction.

Three load cells balance like a three legged chair.

1) Using a sprit level, verify the vessel is vertically and

horizontally correct.

2) Verify if any height change will effect the attitude of adjacent

vessels or piping.

3) Adjust each legs to dynami cal l y m atch mV outputs

4) Verify the mV readings and physical l evel when complete.

Four load cells or more present a challenge.

1) Use volt meter to determine the sum of the load cell signals

and your target mV setting for each load cell.

2) Read the output of i ndi vi dual load cells.

3) Adjust the load cell with the lowest reading to dynamically

match the target mV readings obtained in step 1.

4) Read the mV readings from each load cell to verify a proper

correction.

5) Repeat step 3 and 4 to achieve a proper load sharing vessel .

6) Verify the mV readings and vessel level when complete.

Load Sharing and

Load Sensor

Checkout

See Figure 8-2

FIG. 8-2 LOAD SHARING AND LOAD SENSOR CHECKOUT

8-3

Page 58

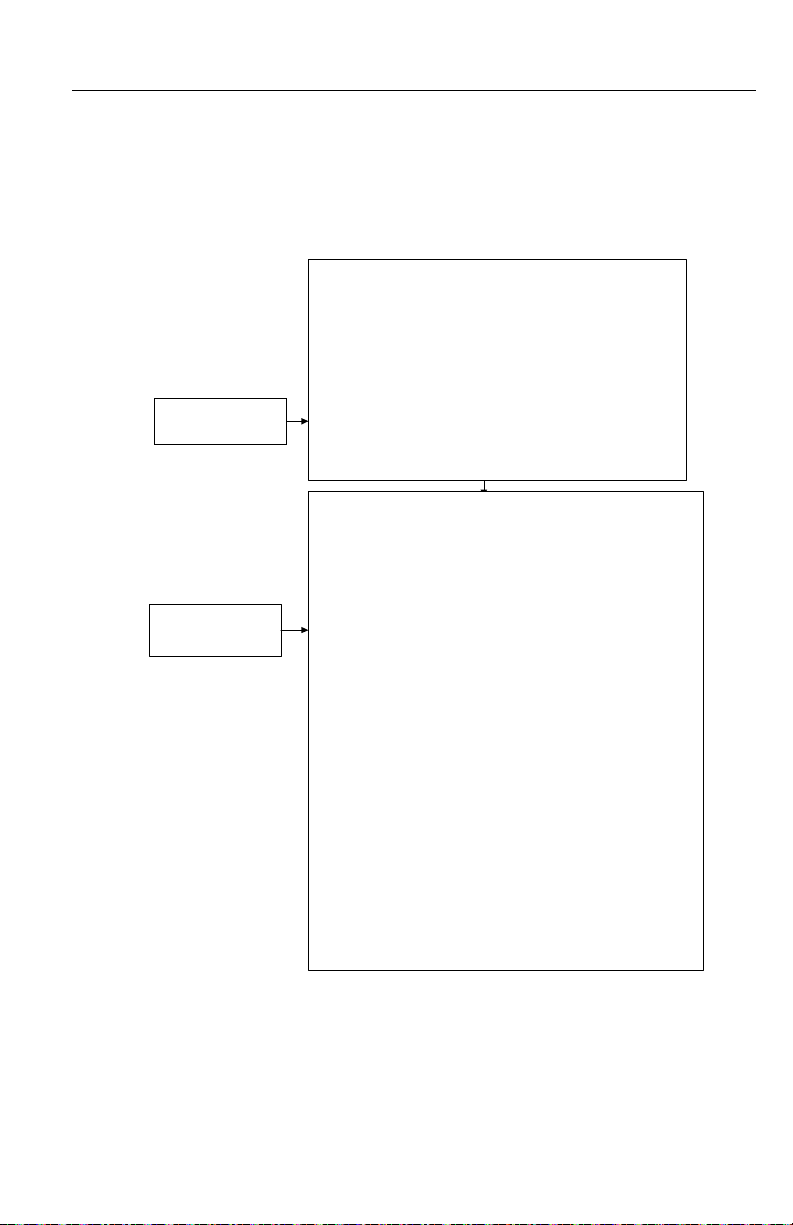

HI 200DNWM MANUAL

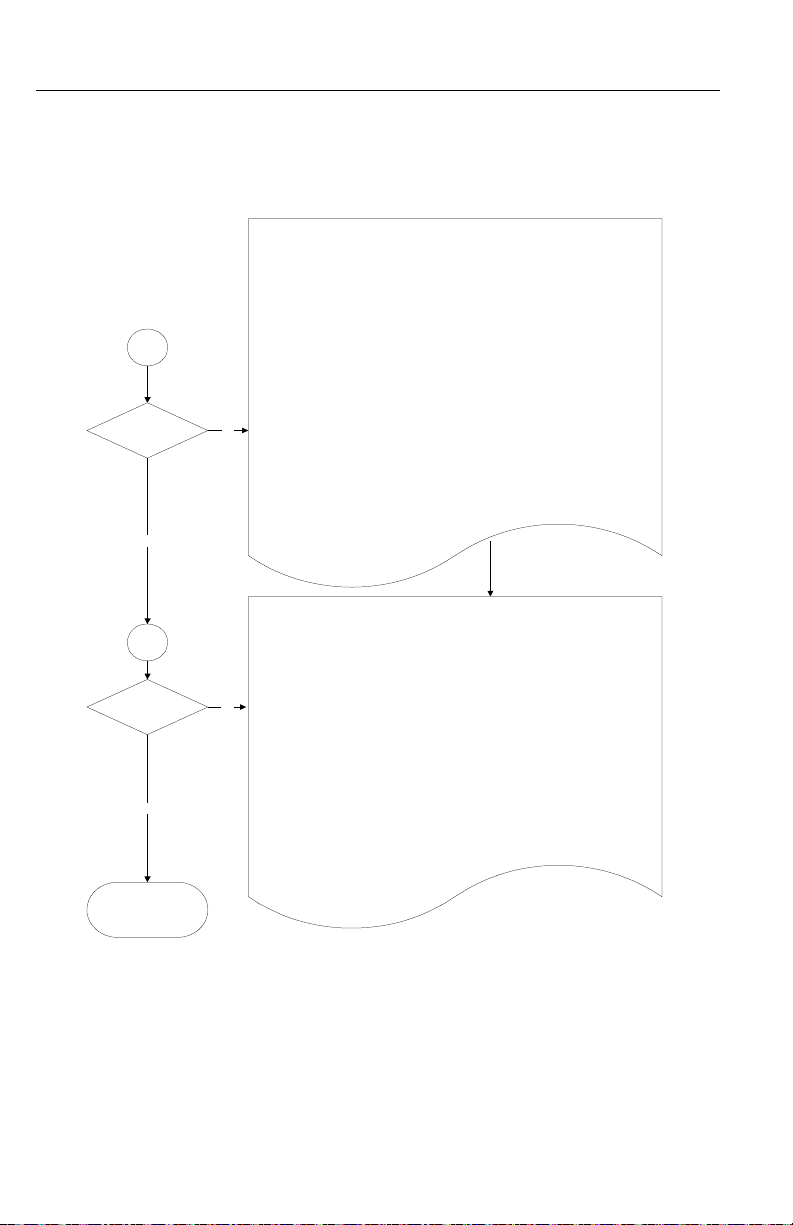

Check for

Electrical Stability

OK ?

Contact Hardy

Instruments

Customer Support

Check for

Mechanical Stability

OK ?

Yes

Check Configuration

settings for

Stability

No

OK ?

Yes

Yes

B1

B2

B3

No

No

Guidelines for

Instabilities on

Formerly Operating Systems

See Figure 8-3

FIG. 8-3 GUIDELINES FOR INSTABILITIES ON FORMERLY OPERAT-

8-4

ING SYSTEMS

Page 59

CHAPTER 8 - TROUBLESHOOTING

ElectricalB1

Physical Grounding

All common equipment share a common ground point.

Keep the ground cable length to earth ground as short as possible.

Install a new ground rod if the cable length is excessive.

Cable -

Cuts or breaks in the loadcell cable insulation allow moisture to wick into the cable

and loadpoints. This can setup stray capacitance charges and allow ground currents

to exist. This could create a highly intermittent situation.

Loadcells

Ground straps must be installed to provide a direct discharge path to ground around

the loadpoints.

Vessel, Fill and discharge piping

Ground all to a common point to eliminate electrical differences in potential, and

static build-up.

Cable Routing

Seperate high voltage sources and cables from low voltage signal cables.

Stay a minimum of 14 inches from Magnetic fields and SCR controls.

Avoid parallel high voltage and signal cable runs.

Cable Shielding -

Ground low voltage cable shields only at the controller end.

Grounding both cable ends will produce ground currents.

Verify, with an ohm meter, the shield is only grounded at the weight controller.

Disconnect the shield at the controller and check for an open circuit between ground

and shield. Reconnect the shield to ground and confirm a proper ground path from

the Junction box to the controller.

Verify the shield is not connect to ground at the Junction Box.

Loadcell cable shields only pass thru the Junction Boxes and are not connected to

ground at that point.

B1.1

B1.3

B1.2

B1.4

B1.5

B1.6

GOTO

B

Electrical See Figure 8-4

FIG. 8-4 GUIDELINES FOR INSTABILITIES ON FORMERLY OPERAT-

ING SYSTEMS - ELECTRICAL

8-5

Page 60

HI 200DNWM MANUAL

Mechanical Stability

Vessel -

When inspecting a vessel keep in mind, the Center of Gravity (COG) should be

low and centered equally over all the load cells.

Insure the load is directly over or under the load point to avoid side-loading.

Insure there isn't any side loading from piping or ext er nal f or c es .

Install flexures on all piping to insure a free float ing v es sel.

Insure the vessel and loadcell mounts are mechanically stable and fixed.

Large changes in individual Loadcells indicate a shift in COG orfaulty Loadcells.

Piping and motors will effect t he indiv idual loadc ell r eadings.

Allow for a higher reading on Loadcells that support motor s and piping.

Insure pneumatic lines are not applying pressure to t he v ess el when ener giz ed.

Use check (stay) rods to minimize vessel movement.

Insure the check rods are loose and not interact ing with the vessel.

Power down all vibration, vacuum and pressurization equipment dur ing the test

process.

B2

Configuration settings

Incorrect Waversaver settings

can cause unstable weight readings

Adjust to the lowest WS setting that gives you a stable reading.

Higher frequencies with low amplitude vibrations; - Use WS settings 2 or 3

Low frequency with high amplitude vibrations; - Use W S se t t ing 0 or 1.

Repeatability -

Divide the total loadcell capacity, including decimal point s , by load cell divisions,

1,000 to 10,000.

(expected stable weight reading).

Resolution -

Divide the total loadcell capacity, including decimal point s , by 30,000.

(The amount you can expect to see, but not nec es s arily s t able)

B3

Stable ?

No

Stable ?

No

Yes

Yes

Contact

Hardy Instruments

Customer Support

Mechanical St a b ility and Configuration Settings

See Figure 8-5

FIG. 8-5 MECHANICAL STABILITY AND CONFIGURATION SETTINGS

8-6

Page 61

Index

Index

A

About Hardy Manuals

About Setpoint Mode Paramete 5-12

About SetPoints 5-10

Approvals 2-2

ATTRIBUTE 7-2

Averages 2-1

B

Batching

Baud Rate 4-2

C

C2 Loadcell Cable Connection

C2® Calibration 1-4

C2® Calibration (The Button) 6-1

C2® Calibration from a Personal

Computer

C2® Second Generation Calibration

7-1

6-2

1-1

3-11

1-4

Calibration Type 1-3

Check Weighing 7-1

CLASS 7-1

Command Interface 5-7

Configuring the Baud Rate 4-2

Configuring the DeviceNet Node Address

4-3

Connectors 2-3

Conversion Rate 2-1

Current Draw at 24VDC 2-4

Customer Support Department 1-1

D

Daisy Chained

DATA 7-2

Deactivate the Set Point 5-10

Dead Band Limits 5-10

DeviceNet 2-2

DeviceNet Cable 2-1

DeviceNet Manager 6-2, 6-3

DeviceNet Node Address 4-3

1-5

DeviceNet™ Network 1-2

DeviceNet™. Configuration 1-2

DIN Rail Adapter 3-1

DIN Rail Kit 3-1

DIP Switch (S1) Configuration 4-2

DIP Switch Location 4-2

Dispensing 7-1

Display 2-2

Drop Lines 1-5

Drops 1-5

E

Electrica

Electrical Installation 3-10

Electronic Data Sheet Software 3-2

Entering Set Points 5-11

Entering Setpoint Mode Parameters

8-5

5-12

Excitation Voltage 2-1

Explicit Message Request Parameters

7-1

F

Filling

7-1

Format of Commands (4 by te input data)

5-8

G

Global Industry-Standard Communication Network

Guidelines for Instabilities on Formerly Operating Systems

H

HI 200DNWM Module Junction Box

1-4

8-4

3-2

HI 200DNWM Module with Stacking

Kit

3-2

HI 200DNWM- SK1 Modules 3-2

High dead band 5-10

high trip limit 5-10

Page 62

HI 200DNWM MANUAL

I

I/O block

I/O module 1-5

Input power 2-1

Inputs 2-2

Installing the Bare Weigh Module in

an Enclosure

Installing the Pre-stacked Weigh Module

Installing Weigh Module in DIN Rail

1-5

3-3

3-9

3-5

INSTANCE 7-1

J

J1

2-3

J2 2-3

J3 2-3

L

load cell I&M manual

Load Sensors 2-1

Load Sharing and Load Sensor Checkout

8-3

Low and High Trip Limits 5-10

low trip limit 5-10

M

Mechanical Installation

Mechanical Stability and Configuration Settings

Metric Poll 2-2

Module LED does not Come Back on

When Performing Calibration with

The Button

Module LED is Flashing Red 8-1

Module Status (DS2) 7-3

Module Status LED 6-2

Monitor Weight Readings 7-1

Monitoring Weight Readings 7-2

Mounting Config 2-2

Multiple power supplies 1-6

8-6

8-1

6-1

3-3

N

Network Sta tus (DS1)

Node Icon 6-2, 6-3

Non-C2 Loadcell Cable Connection

(J1)

3-13

Non-Linearity 2-1

Non-Volatile RAM 5-1

O

Operating Capabilities

Outputs 2-2

P

Parameters

Phoenix Combicon 2-3

Physical Dime nsions 2-2

Physical Layer 1-5

Preact Limits 5-11

Pre-Calibration Procedures 6-1

R

Red Button

Resolution 2-1

S

Saving to Non-Volatile Ram

Scale System 1-4

Set Point Values 1-3

Setpoint Mode Parameters 5-12

Setpoints 5-10

Six (6) Conductor Load Cell Cable 3-

5-2

6-2

7-2

7-1

5-1

13

Span Weight 1-3

Standoffs 1-2

T

Tare Weights

Temperature Coefficient 2-2

Temperature Range 2-2

Temperature Storage Range 2-2

Test Weight Calibration Procedures

1-2

6-3

THE BUTTON 1-4, 4-2

Page 63

The Button 1-4

Three General Rules for Set Points 5-

11

Trunk Line 1-5

U

Unpacking

Unused Wires 3-14

V

Vendor Specific

Voltage 2-1

W

WAVERSAVER

Weigh Module 1-2

What is DeviceNet®? 1-4

Wiring Diagram for the HI 215JB

Junction Box

Wiring Diagram for the J2 DeviceNet

Interface 5 Pin Open

Wiring Dia gram for the J3 Set Point

Out 4 Pin

3-1

2-2

1-3

3-11

3-11

3-11

Index

Z

Zero and Tare commands

Zero Length Drops 1-6

1-2

Loading...

Loading...