Page 1

HI 1769-WS & HI 1769-2WS

WEIGH SCALE MODULE

OPERATION AND INSTALLATION

MANUAL

Corporate Headquarters

9440 Carroll Park Drive

San Diego, CA 92121

Phone: (858) 278-2900

FAX: (858) 278-6700

Web-Site: http://www.hardysolutions.com

Hardy Process Solutions Document Number: 0596-0282-01 Rev T

Copyright 2011-2013 Hardy Process Solutions, All Rights Reserved. Printed in the U.S.A. (941028)

Page 2

Local Field Service

Hardy has over 200 field technicians in the U.S., and more positioned

throughout the world to assist you in your support needs. We also have fac

tory engineers who will travel to your facility anywhere in the world to help you

solve challenging applications. We're ready to support you with:

• Installation and start-up

• Routine maintenance and certification

• Plant audits and performance measurement

• Emergency troubleshooting and repair

To request Emergency Service and Troubleshooting, Start-up, Installation,

Calibration, Verification or to discuss a Maintenance Agreement please call

800-821-5831 Option 4 or Emergency Service after hours (Standard Hours

6:00 AM to 5:30 PM Pacific Standard Time) and weekends.

-

Outside the U.S

Hardy Process Solutions has built a network of support throughout the globe.

For specific field service options available in your area please contact your

local sales agent or our U.S. factory at +1 858-292-2710, Option 4

Page 3

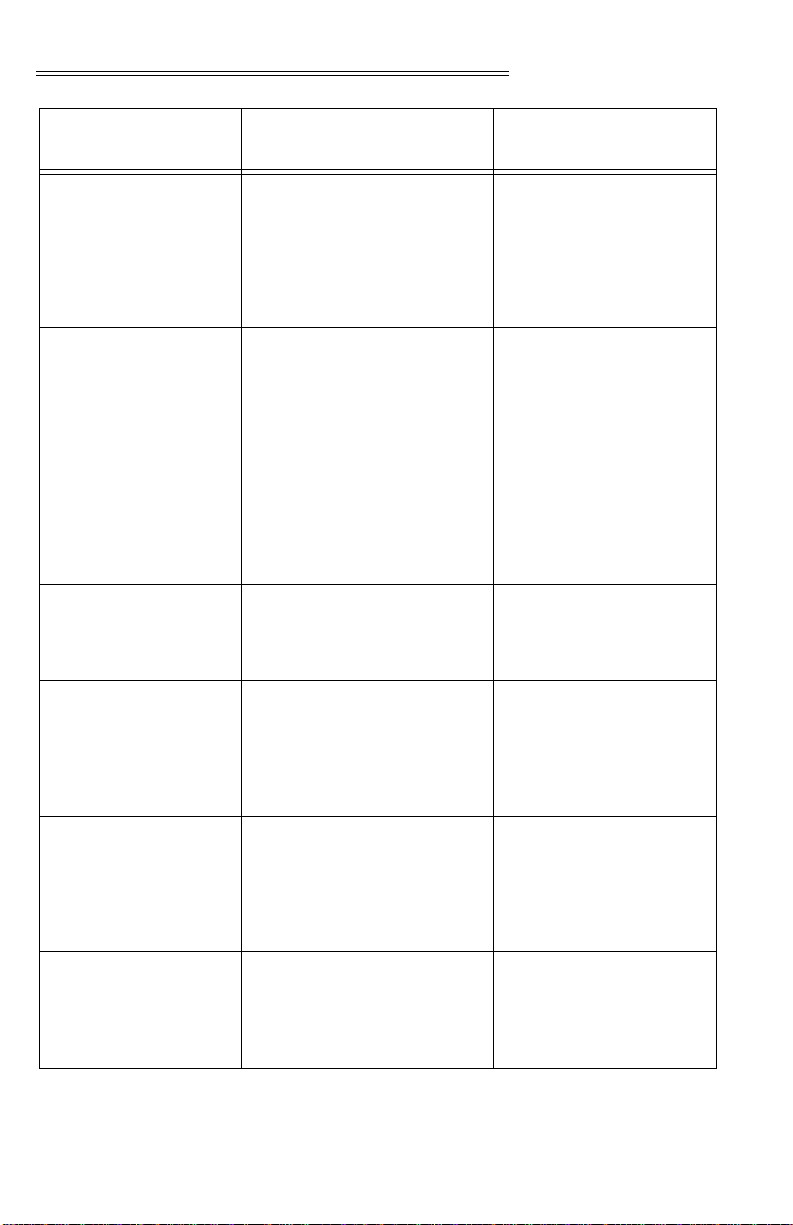

Table of Contents

Table of Contents

HI 1769-WS & HI 1769-2WS - - - - - - - - - - - - - - - - - - - -1-1

WEIGH SCALE MODULE - - - - - - - - - - - - - - - - - - - - -1-1

Local Field Service - - - - - - - - - - - - - - - - - - - - - - - - -1-2

Outside the U.S- - - - - - - - - - - - - - - - - - - - - - - - - - -1-2

TABLE OF CONTENTS - - - - - - - - - - - - - - - - - - - - - -1-I

TABLE OF ILLUSTRATIONS- - - - - - - - - - - - - - - - - - - -1-I

OVERVIEW - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-1

A Brief Description of Chapter 1 - - - - - - - - - - - - - - - - - -1-1

About Hardy Manuals- - - - - - - - - - - - - - - - - - - - - - - -1-2

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-2

WAVERSAVER®- - - - - - - - - - - - - - - - - - - - - - - - - -1-3

C2® Calibration - - - - - - - - - - - - - - - - - - - - - - - - - -1-3

IT ® - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-4

Digital Volt Meter (DVM) - Optional - - - - - - - - - - - - - - -1-4

Rate of Change - - - - - - - - - - - - - - - - - - - - - - - -1-4

Return to Zero Test - Optional - - - - - - - - - - - - - - - - -1-4

Weighing System Tests - Optional - - - - - - - - - - - - - - -1-4

Auto Zero Tracking - - - - - - - - - - - - - - - - - - - - - - - - -1-5

CHAPTER 2 - SPECIFICATIONS- - - - - - - - - - - - - - - - - -2-1

A Brief Description of Chapter 2- - - - - - - - - - - - - - - - - - -2-1

Specifications for a Standard HI 1769-WS Weigh Scale Module - - -2-1

Maximum Installed Modules - - - - - - - - - - - - - - - - - -2-1

Channels- - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Conversion Rate - - - - - - - - - - - - - - - - - - - - - - - -2-1

Averages- - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Resolution - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Non-Linearity- - - - - - - - - - - - - - - - - - - - - - - - - -2-1

WAVERSAVER®- - - - - - - - - - - - - - - - - - - - - - - -2-1

Common-Mode Rejection- - - - - - - - - - - - - - - - - - - -2-1

Common-Mode Voltage Range - - - - - - - - - - - - - - - - -2-2

Bus Input Voltage- - - - - - - - - - - - - - - - - - - - - - - -2-2

Bus Current Load- - - - - - - - - - - - - - - - - - - - - - - -2-2

Bus Power Load - - - - - - - - - - - - - - - - - - - - - - - -2-2

C2 Calibration Input - - - - - - - - - - - - - - - - - - - - - -2-2

Cable lengths- - - - - - - - - - - - - - - - - - - - - - - - - -2-2

i

Page 4

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

Load Cell Excitation- - - - - - - - - - - - - - - - - - - - - - -2-2

C2 Calibration Output- - - - - - - - - - - - - - - - - - - - - -2-2

Environmental Requirements - - - - - - - - - - - - - - - - - - - -2-2

Temperature Coefficient - - - - - - - - - - - - - - - - - - - -2-2

Operating Temperature Range - - - - - - - - - - - - - - - - -2-2

Storage Temperature Range - - - - - - - - - - - - - - - - - -2-2

Humidity Range - - - - - - - - - - - - - - - - - - - - - - - -2-2

Approvals - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

Digital Voltmeter - - - - - - - - - - - - - - - - - - - - - - - -2-2

Optional Equipment- - - - - - - - - - - - - - - - - - - - - - - - -2-3

1756 RTA (Remote Termination Assembly - - - - - - - - - - -2-3

RTA Cable Assemblies - - - - - - - - - - - - - - - - - - - - -2-3

HI 215IT Series Junction Box - - - - - - - - - - - - - - - - - -2-3

Default Parameters - - - - - - - - - - - - - - - - - - - - - - - - -2-3

EMI Suppression Core - - - - - - - - - - - - - - - - - - - - - - -2-4

Cable Diameter- - - - - - - - - - - - - - - - - - - - - - - - -2-4

Supression Frequencies - - - - - - - - - - - - - - - - - - - -2-4

Cable Types - - - - - - - - - - - - - - - - - - - - - - - - - -2-4

Physical Dimensions - - - - - - - - - - - - - - - - - - - - - -2-4

CHAPTER 3 - INSTALLATION - - - - - - - - - - - - - - - - - - -3-1

A Brief Description of Chapter 3- - - - - - - - - - - - - - - - - - -3-1

Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-1

Installing the HI 1769-WS or HI 1769-2WS to an Allen-Bradley

Compact or Micro Logix 1500 Processor - - - - - - - - - - - - - -3-2

Installing the HI 1769-WS or HI 1769-2WS onto the CompactLogix

and MicroLogix 1500 Bank - - - - - - - - - - - - - - - - - - - - -3-2

Installing the Module I/O Connector - - - - - - - - - - - - - - - - -3-4

About the Module I/O Connector - - - - - - - - - - - - - - - -3-4

Installing the HI 1769-WS on a Din Rail - - - - - - - - - - - - - - -3-7

Load Cell Wiring Diagrams - - - - - - - - - - - - - - - - - - - - -3-10

Industry Standard Load Cells - - - - - - - - - - - - - - - - - -3-10

Hardy Load Sensor with C2 - - - - - - - - - - - - - - - - - - -3-11

HI 1769 Remote Terminal Assembly (HI 1769-XX-RT)- - - - - -3-11

RTA Cable Assembly - - - - - - - - - - - - - - - - - - - -3-12

EMI Suppression Core Installation (Prt. #2547-0013) - - - - - -3-14

Hardy HI 215IT Junction Box - - - - - - - - - - - - - - - - - -3-16

CHAPTER 4 - SETUP - - - - - - - - - - - - - - - - - - - - - - -4-1

A Brief Description of Chapter 4- - - - - - - - - - - - - - - - - - -4-1

Power Check - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-1

LEDS- - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-2

Scale Data LEDs - - - - - - - - - - - - - - - - - - - - - -4-2

ii

Page 5

Table of Contents

OK Module Status LED - - - - - - - - - - - - - - - - - - -4-2

Setting Up Communications Between the MicroLogix 1500

Processor and the HI 1769-WS & HI 1769-2WS Weigh Scale

Modules - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-3

Alternative Setup Procedures - - - - - - - - - - - - - - - - - - - -4-5

Configuring the HI 1769-WS in RSLogix 500 for

MicroLogix 1500 - - - - - - - - - - - - - - - - - - - - - - - -4-5

Configuring the HI 1769-WS in RSLogix 5000 for CompactLogix-4-7

Parameters for the HI 1769-WS Module- - - - - - - - - - - - - - -4-10

About Parameters - - - - - - - - - - - - - - - - - - - - - - -4-10

Configuration Parameters for the HI 1769-WS Module - - - - - - - -4-12

Commands- - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-15

About Commands - - - - - - - - - - - - - - - - - - - - - - -4-15

Command Operation - - - - - - - - - - - - - - - - - - - - - -4-16

Possible COMMAND STATUS Values - - - - - - - - - - - - -4-16

Command Table - - - - - - - - - - - - - - - - - - - - - - - -4-17

Calibration Setup Procedures - - - - - - - - - - - - - - - - - - - -4-24

Setting the Metric Parameter - - - - - - - - - - - - - - - - - -4-24

Setting the Motion Tolerance Value - - - - - - - - - - - - - - -4-24

Setting The Zero Tolerance Value- - - - - - - - - - - - - - - -4-25

Setting the Auto Zero Tolerance Value - - - - - - - - - - - - -4-25

Setting the Number of Readings Averages - - - - - - - - - - -4-25

Setting the Span Weight Value - - - - - - - - - - - - - - - - -4-25

Setting the WAVERSAVER Value- - - - - - - - - - - - - - - -4-25

CHAPTER 5 - CALIBRATION5-1

A Brief Description of Chapter 5- - - - - - - - - - - - - - - - - - -5-1

Pre-Calibration Procedures - - - - - - - - - - - - - - - - - - - - -5-1

Electrical Check Procedures - - - - - - - - - - - - - - - - - - - -5-2

Load Cell/Point Input/Output Measurements- - - - - - - - - - -5-2

Load Check - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-4

C2 Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - -5-5

About C2 Calibration - - - - - - - - - - - - - - - - - - - - - -5-5

C2 Calibration Using Ladder Logic - - - - - - - - - - - - - - -5-5

Hard Calibration - - - - - - - - - - - - - - - - - - - - - - - - - -5-6

Hard Calibration Ladder Logic Example - - - - - - - - - - - - -5-6

CHAPTER 6 - TROUBLESHOOTING- - - - - - - - - - - - - - - -6-1

A Brief Description of Chapter 6- - - - - - - - - - - - - - - - - - -6-1

Scale LED is Flashing Red - - - - - - - - - - - - - - - - - - - - -6-1

Mechanical Inspection - - - - - - - - - - - - - - - - - - - - - - -6-1

Load Sharing and Load Sensor Checkout - - - - - - - - - - - - - -6-3

Guidelines for Instabilities on Formerly Operating Systems - - - - -6-5

iii

Page 6

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

Electrical - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -6-6

Mechanical Stability and Configuration Settings - - - - - - - - - - -6-7

INDEX

iv

Page 7

Table of Illustrations

Table of Illustrations

HI 1769-WS & HI 1769-2WS1-1

WEIGH SCALE MODULE1-1

TABLE OF CONTENTS1-I

TABLE OF ILLUSTRATIONS1-I

OVERVIEW1-1

CHAPTER 2 - SPECIFICATIONS2-1

CHAPTER 3 - INSTALLATION3-1

POSITIONING THE MODULE FOR INSTALLATION3-3

CONNECTOR UNLOCK POSITION3-3

CONNECTOR IN LOCKED POSITION3-4

MODULE CONNECTOR INSTALLED3-6

MODULE CONNECTOR REMOVED FOR EASIER CABLING3-7

RAIL FASTENERS IN RETRACTED POSITION3-8

RAIL FASTENERS IN THE CLOSED POSITION3-9

INDUSTRY STANDARD LOAD CELLS WIRING DIAGRAM3-10

HARDY LOAD SENSOR/C2 WIRING DIAGRAM3-11

REMOTE TERMINAL ASSEMBLY3-12

RTA DIN RAIL MOUNT3-12

RTA CABLE ASSEMBLY - HI 1769-WS3-13

RTA CABLE SCHEMATIC - HI 1769-WS3-13

RTA CABLE - HI 1769-2WS3-13

RTA SCHEMATIC HI 1769-2WS3-14

EMI SUPPRESSION CORE3-15

SUPPRESSION CORE OPEN3-15

SUPPRESSION CORE INSTALLED3-16

HARDY HI 215IT JUNCTION BOX WIRING DIAGRAM3-16

CHAPTER 4 - SETUP4-1

MODULE LEDS HI 1769-WS SINGLE CHANNEL4-1

MODULE LEDS HI 1769-2WS DUAL CHANNEL4-2

I/O CONFIGURATION DIALOG BOX4-3

READ I/O CONFIGURATION FROM ONLINE PROCESSOR DIALOG BOX4-

4

CONNECTION/CONFIGURATION - 484-5

EXPANDING CONTROLLER4-6

I

Page 8

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

I/O CONFIGURATION DIALOG BOX4-6

I/O CONFIGURATION DIALOG BOX4-7

SELECTING COMPACTBUS LOCAL4-8

SELECT MODULE TYPE/SELECTING 1769 MODULE/GENERIC4-8

MODULE PROPERTIES DIALOG BOX/CONFIGURATION/SIZE/0 WORDS4-

9

MODULE PROPERTIES DIALOG BOX/CONFIGURATION/SIZE/48

WORD

S4-9

CONTROLLER TAGS/SLOT 14-15

CHAPTER 5 - CALIBRATION5-1

PROPERLY INSTALLED LOAD CELL W/NO BINDING5-2

MILLIVOLTS/WEIGHT SCALE5-4

CHAPTER 6 - TROUBLESHOOTING6-1

MECHANICAL INSPECTION6-2

LOAD SHARING AND LOAD SENSOR CHECKOUT6-4

GUIDELINES FOR INSTABILITIES ON FORMERLY OPERATING SYS-

TEMS6

-5

GUIDELINES FOR INSTABILITIES ON FORMERLY OPERATING SYSTEMS

- ELECTRICAL6-6

MECHANICAL STABILITY AND CONFIGURATION SETTINGS6-7

INDEX1-1

II

Page 9

CHAPTER 1 - OVERVIEW

Chapter 1 - Overview

A BRIEF DESCRIPTION OF CHAPTER 1

This manual provides the user and service personnel

with a description of the specifications, installation,

setup, configuration, operation, communication,

maintenance, and troubleshooting procedures for the

Hardy HI 1769-WS & HI 1769-2WS Compact and

Micro Logix I/O W eigh Scale Modules that mount on

the Allen-Bradley

MicroLogix™

1769-2WS are equipped with WAVERSAVER

Calibration, and I

®

CompactLogix™ and

1500 platform. The HI 1769-WS & HI

®

, C2®

NTEGRATED TECHNICIAN

®

(IT) diag-

nostics. The module is configurable via ladder logic.

The HI 1769-WS & HI 1769-2WS modules mechani

cally lock together by means of a tongue-and-grove

design and have an integrated communication bus that

is connected from module to module by a moveable

bus connector. To get the maximum service life from

this product, users should operate this module in

accordance with recommended practices either

implied or expressed in this manual. Before using the

Weigh Scale Module, all users and maintenance per

sonnel should read and understand all cautions, warnings, and safety procedures, either referenced or

explicitly stated in this manual, to ensure the safe

operation of the module. Hardy Process Solutions

appreciates your business. Should you not understand

any information in this manual or experience any

problems with the product, please contact our Cus

-

tomer Support Department at:

-

Phone: (858) 278-2900

FAX: (858) 278-6700

e-mail: hardysupport@hardysolutions.com

Web Address: www.hardysolutions.com

NOTE: WAVERSAVER®, C2®, IT® are r egistered trademarks

of Hardy Process Solutions Inc. Integrated T echnician

is a trademark of Hardy Process Solutions Inc.

Allen-Bradley®, CompactLogix ™ and Micr oL ogix ™

1500 are trademarks of the Rockwell Corporation.

1-1

Page 10

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

NOTE: Hardy Pr ocess Solutions bases all procedures with the

assumption that the user has an adequate understand

ing of Allen-Bradley ControlLogix®. In addition the

user should understand process control and be able to

interpret ladder logic instructions necessary to gener

ate the electronic signals that control your application(s).

About Hardy Manuals Every Hardy Installation and Operation manual is

organized into easily referenced chapters, that are

almost always the same:

• Chapter 1 - Provides an introduction to the

instrument and an Overview of the equipment

and its capabilities.

• Chapter 2 - Provides a complete list of Specifi-

cations.

• Chapter 3 - Contains complete instructions

needed to install the HI 1769-WS (both standard

and optional equipment) and the Remote Termi

nation Assembly (-RTA)

• Chapter 4 - Provides complete hardware Con-

figuration instructions for setting dip switches

and jumpers.

• Chapter 5 - Provides all Calibration instructions.

• Chapter 6 - Pertains to the Troubleshooting

procedures for repair of the instrument.

-

-

-

Hardy hopes that this manual meets your needs for

information and operation. All corrections or sugges

tions for improvements of this manual are welcome

and can be sent to the Technical Publications Depart

ment or Customer Support Department at Hardy Process Solutions Inc.

Description The HI 1769-WS & HI 1769-2WS Weigh Scale Mod-

ules are self-contained, microprocessor-based ControlLogix I/O modules with control inputs and

outputs, that is designed to be easily plugged into an

Allen-Bradley CompactLogix or MicroLogix 1500

programmable controller The HI 1769-WS Weigh

Scale Module is a single channel module while the

HI 1769-2WS is configured for dual operation which

1-2

-

-

Page 11

Chapter 1 - Overview

can be used for a wide variety of process weighing

applications such as batching, blending, filling/dis

pensing, check weighing, force measurement, level by

weight and weight rate monitoring. The analog to dig

ital converter in the weigh module controller updates

one hundred (100) times per second and is capable of

8,388,608 counts of display resolution. This gives the

instrument the ability to tolerate large “dead” loads,

over sizing of load cells/sensors and still have suffi

cient resolution to provide accurate weight measurement and control. The module calibration is electronic

via C2 electronic calibration. C2 or Hard (Traditional

calibration with weights) is also available for those

not using Hardy C2 certified load sensors.

-

WAVERSAVER

®

Typically, mechanical noise (from machinery in a

plant environment) is present in forces larger than the

weight forces trying to be detected by the module.

The HI 1769-WS & HI 1769-2WS is fitted with

WAVERSAVER

®

technology which eliminates the

effects of vibratory forces present in all industrial

weight control and measurement applications. By

eliminating the factor of vibratory forces the module

is capable of identifying the actual weight data.

WAVERSAVER

®

can be configured to ignore noise

with frequencies as low as 0.25 Hz. One of five higher

additional cut off frequencies may be selected to pro

vide a faster instrument response time. The default

factory configuration is 1.00 Hz vibration frequency

immunity.

C2® Calibration C2 Second Generation Calibration enables a scale

system to be calibrated electronically without using

certified test weights which equals the systems load

capacity. A C2 weighing system consists of up to

eight (8) C2 load sensors, a junction box, interconnect

cable and an instrument with C2 capabilities as long

as power requirements don’t exceed specification. All

Hardy C2 certified load sensors contain digital infor

mation detailing its unique performance characteristics. The modules read the performance

characteristics of each individual load sensor and

-

-

1-3

Page 12

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

detects the quantity of load sensors in the system. All

calibrations can be performed via ladder logic.

®

IT

INTEGRATED TECHNICIAN™ is a system diagnostics

utility. For full functionality the weigh system should

include an HI 215IT series junction box. Full IT func

tionality allows the operator to rapidly troubleshoot a

weighing system.

-

Digital Volt Meter (DVM) - Optional

Requires the HI 215IT Series Junction Box to monitor

both and mV/V readings for the system and per indi

vidual load sensor. Once a problem is detected by the

operator the DVM readings help the operator to iso

late the faulty component. Further, the DVM readings

can be used to level a system and to make corner

adjustments to platform scales. Accuracy is +/- 2% or

better of full scale.

NOTE: If you do not have the HI 215IT Junction Box con-

nected to the module, the mV/V reading as displayed

is the total for all the load cells on the system.

Rate of Change The ROC option measures and displays the rate at

which a material enters or is dispensed from the scale

over a period of time. ROC data uses a 100-entry reg

ister. New weight values are written to the register at

the rate of 1/100th of the time base. The first register

is subtracted from the 101st Register, which is one

time base older than the first register. The ROC is

reported in units per minute. A time base of discrete

values is selectable from 1 to 1800 sec

Return to Zero Test - Optional

Requires the HI 215IT Series Junction Box to monitor

individual load sensors. This test compares the origi

nal voltage reading (saved at calibration) against the

current voltage reading of an empty vessel. The test

checks for damaged load sensors due to electrical zero

shift or abnormal mechanical forces that cause bind

ing on one or all of the load sensors in the system.

-

-

-

-

-

Weighing System Tests - Optional

1-4

Requires the HI 215IT Series Junction Box for full

utilization. This test is used to diagnose drifting or

unstable weight reading problems. The Weighing Sys

tem Test does the following:

-

Page 13

Chapter 1 - Overview

1. Disconnects the controller and engages an inter-

nal reference signal to see if the problem is within

the instrument.

2. Disconnects the load sensors and engages an

internal (in the junction box) reference signal to

see if the cable between the instrument and the

Junction Box is causing the problem.

3. Reads the weight of each load sensor to see if the

load sensor might be causing the problem.

The ability to read the weight seen by each individual

load sensor allows use of this test to make cornering,

leveling and load sharing adjustments to the weighing

system.

AUTO ZERO TRACKING

Auto Zero Tracking indicates zero weight, as long as

any “live weight” on the scale is below the set Auto

Zero Tolerance, this function is turned on and the

scale is not in motion. This capability allows the mod

ule to ignore material build-up in the weighing system

within a pre-set auto zero tolerance.

-

1-5

Page 14

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

1-6

Page 15

CHAPTER 2 - SPECIFICATIONS

Chapter 2 - Specifications

A Brief Description of Chapter 2

Specifications for a Standard HI 1769-WS Weigh Scale Module

Maximum Installed Modules

Channels 1 Channel HI 1769-WS

Conversion Rate 100 updates per second Averages 1-255 User Selectable in single increments Resolution Internal: 1:8,388,608

Chapter 2 lists the specifications for the HI 1769-WS

& HI 1769-2WS Weigh Scale Modules. Specifica

tions are listed for the standard instrument and for

optional equipment. The specifications listed are

designed to assist in the installation, operation and

troubleshooting of the instrument. All service person

nel should be familiar with this section before

attempting an installation or repair of this instrument.

8 modules - per power supply in a single bank (Module(s) must be installed within 4 slots on either side of

the power supply)

2 Channel HI 1769-2WS

-

-

Input Up to four (4) 350 ohm Full Wheatstone Bridge,

Strain Gauge Load Sensors/Cells (5 volt excitation)

on one vessel.

Non-Linearity 0.0015% of Full Scale

WAVERSAVER

Common-Mode Rejection

®

User Selectable

• 4.00 Hz

• 2.00 Hz

• 1.00 Hz (Default)

• 0.50 Hz

• 0.25 Hz

•OFF

120dB from 59 to 61 Hz

2-1

Page 16

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

Common-Mode Vo ltage Range

Bus Input Voltage 5 VDC Bus Current Load <0.5 Amp at 5 VDC Bus Power Load < 5W at 5 VDC C2 Calibration

Input

Cable lengths 500 feet maximum of C2 authorized cable

Load Cell Excitation

C2 Calibration Output

Environmental Requirements

Temperature Coefficient

2.5VDC maximum (with respect to earth ground)

Isolation from digital section 1000 VDC minimum.

250 feet maximum of C2 authorized cable (Maximum

of 4 load sensors) with IT Junction box.

5 VDC

Isolation from digital section 1000 VDC minimum

Less than 0.005% of full scale per degree C for CalLO and Cal-HI reference points

Operating Temperature Range

Storage Temperature Range

Humidity Range 0-95% (non-condensing) Approvals CE, UL/CUL, Class I, Division 2 Groups A, B, C, D

Digital Voltmeter Accuracy 10% of full scale

2-2

0o C to 60o C (32o F to 140o F)

-40o C to 85o C (-40o F to 185o F)

Temperature Code T5

Resolution

• mV/V 4 digits to the right of the decimal

Page 17

Optional Equipment

Chapter 2 - Specifications

1756 RTA (Remote Termination Assembly

RTA Cable Assemblies

HI 215IT Series Junction Box

Default Parameters

Hardy Part # -RTA (HI-1769-XX-RTA if ordered separately) Remote Termination supports two (2) separate HI 1769-WS or HI 1769-2WS weigh scale

modules. Unit includes DIN rail mounting for 35mm

x 15mm DIN rail.

Hardy Part # -C6 (HI 1769-XX-C6)

• Cable Length: 6 ft. (1.525 meters) from

the single channel module to the RTA.

Hardy Part # - D8 (HI 1769-XX-DC6)

• Cable Length: 6 Ft. (1.525 meters) from

2 single or one dual module to the RTA.

NEMA rated waterproof enclosure which sums from

one to four load sensors load sensors.

• -PS1 NEMA 4 Painted Steel

• -SS1 NEMA 4X Stainless Steel

• -FG1 NEMA 4X Fiberglass

Parameter Default Setting

ChanActive On 1

Calib Type none OXFFFF

Tareweight 0.0 lbs 0

Metric lbs 0

WAVERSAVER

SpanWeight 10,000.00 10,000.00

CalLowWeight 0 lbs 0

Num Averages 10 10

ROC Timebase 10 sec 10

®

1 Hz 3

Table 2-1: Default Parameters

2-3

Page 18

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

Parameter Default Setting

ZeroTrackEnable False 0

ZeroTolerance 10.0 lbs 10.0

AutoZeroTolerance 10.0 lbs 10.0

MotionTolerance 5.0 lbs 5.0

Table 2-1: Default Parameters

EMI Suppression Core

Cable Diameter .250 inches Max. (6.4 mm Max) Supression

Up to 500 MHz

Frequencies

Cable Types • Multi-strand

• Single Conductor

Physical Dimensions

Width - .705 inches (17.9 mm)

Height - .724 inches (18.39 mm)

Length - 1.272 inches (32.3 mm)

2-4

Page 19

CHAPTER 3 - INSTALLATION

Chapter 3 - Installation

A Brief Description of Chapter 3

Unpacking Step 1. Before signing the packing slip, inspect

All information contained in Chapter 3 pertains to

unpacking, cabling, interconnecting, configuration

and installing the Weigh Scale Module. Alternatives

to any procedures contained or implied in this chapter

are not recommended. It is very important that the

user and service personnel be familiar with the proce

dures contained in this chapter, before installing or

operating the Weigh Scale module. Hardy Process

Solutions appreciates your business. Should you

experience any problems installing this equipment,

contact Hardy Customer Support for assistance.

the packing for damage of any kind.

Step 2. Report any damage to the carrier company

immediately.

Step 3. Check to see that everything in the pack-

age matches the bill of lading. You should

normally have:

• HI 1769-WS or HI 1769-2WS

Weigh Scale Module

• Operation & Installation Manual

Step 4. Write down the Model and Serial number

of the module. Store this information in a

convenient location for reference when

contacting The Customer Support Depart

ment for parts or service.

-

-

WARNING EXPLOSION HAZARD - DO NOT DISCON-

NECT WHILE CIRCUIT IS ALIVE UNLESS

AREA IS KNOWN TO BE NON-HAZARDOUS.

WARNING EXPLOSION HAZARD - SUBSTITUTION OF

COMPONENTS MAY IMPAIR SUITABILITY

FOR CLASS I, DIVISION 2.

WARNING RISK OF FIRE OR EXPLOSION. DO NOT

OPERATE SWITCH WHILE CIRCUIT IS LIVE.

3-1

Page 20

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

Installing the HI 1769-WS or HI 1769-2WS to an Allen-Bradley CompactLogix or MicroLogix 1500 Processor

WARNING ELECTROSTATIC DISCHARGE MAY DAM-

AGE SEMICONDUCTOR COMPONENTS. DO

NOT TOUCH THE CONNECTOR PINS AND

OBSERVE THE FOLLOWING HANDLING

PRECAUTIONS:

• Wear an approved wrist-strap grounding

device when handling the module.

• Touch a grounded object or surface to rid

yourself of any electrostatic discharged prior

to handling the module.

• Handle the module from the bezel in front

away from the connector. Never, NEVER

touch the connector pins.

• Wiring mus t be in accordance with Class I,

Division 2 wiring methods of the National

Electrical Code, NFPA 70 and acceptable to

the authority having jurisdiction.

• Do not install the module right next to an AC

or high voltage DC module.

• Route all the load voltage cables away from

high voltage cables.

Installing the

HI 1769-WS or

HI 1769-2WS onto

the CompactLogix

and MicroLogix

1500 Bank

3-2

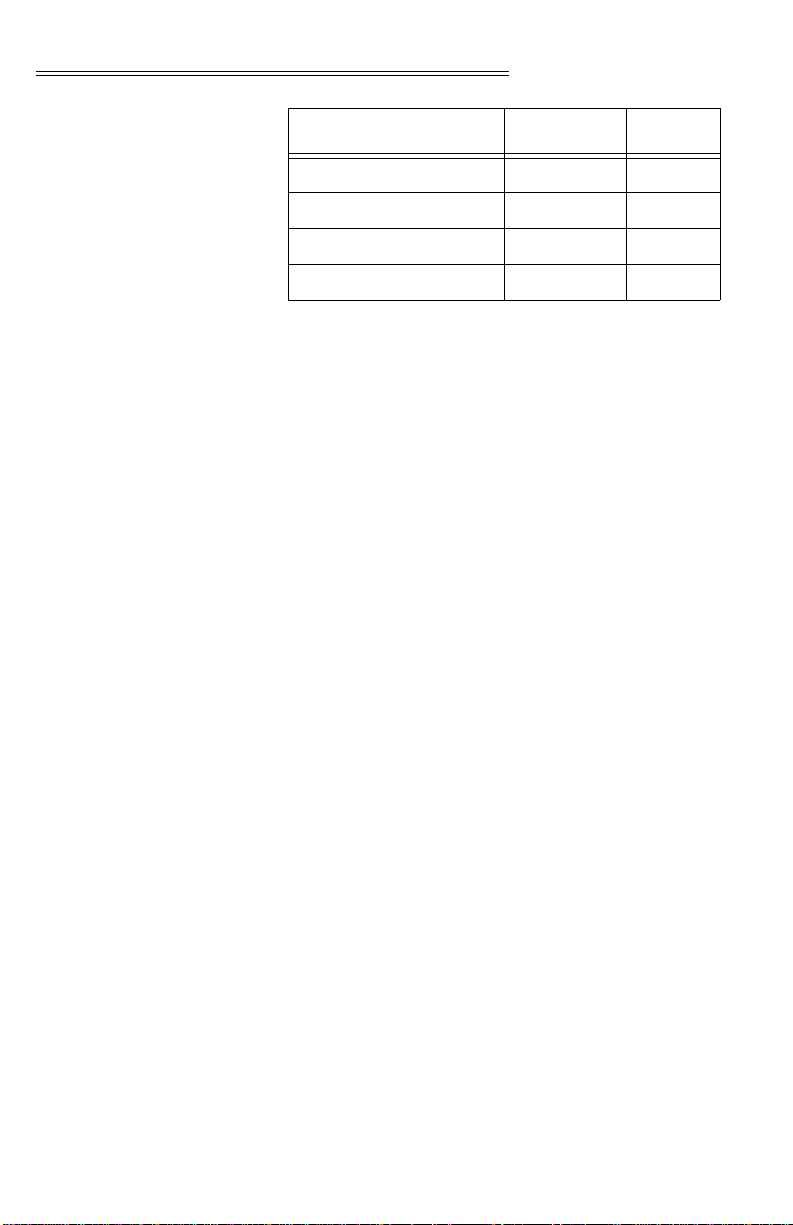

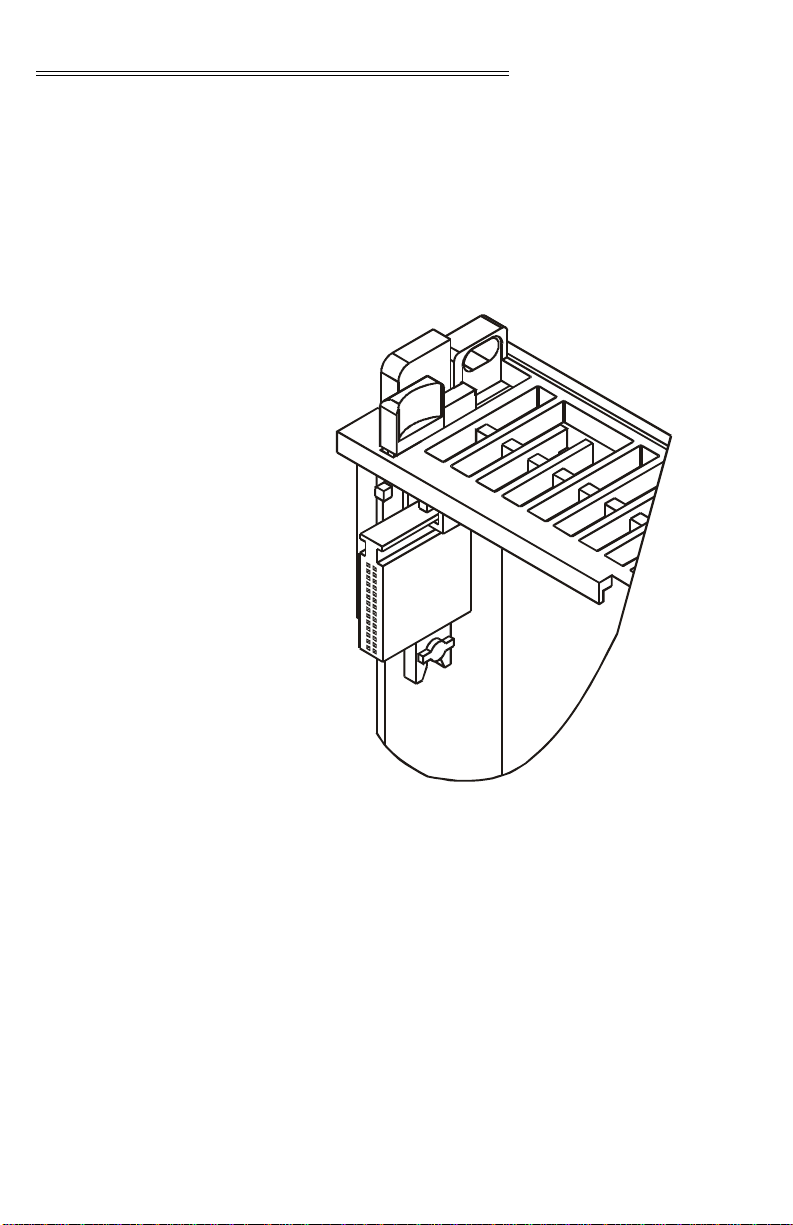

Step 1. Make sure that the module is oriented cor-

rectly for installation. (See Fig. 3-1)

Page 21

Chapter 3 - Installation

Module A

Module B

Lever A

Lever B

FIG. 3-1 POSITIONING THE MODULE FOR

INSTALLATION

Step 2. Pull Lever B back to the unlock position.

FIG. 3-2 CONNECTOR UNLOCK POSITION

3-3

Page 22

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

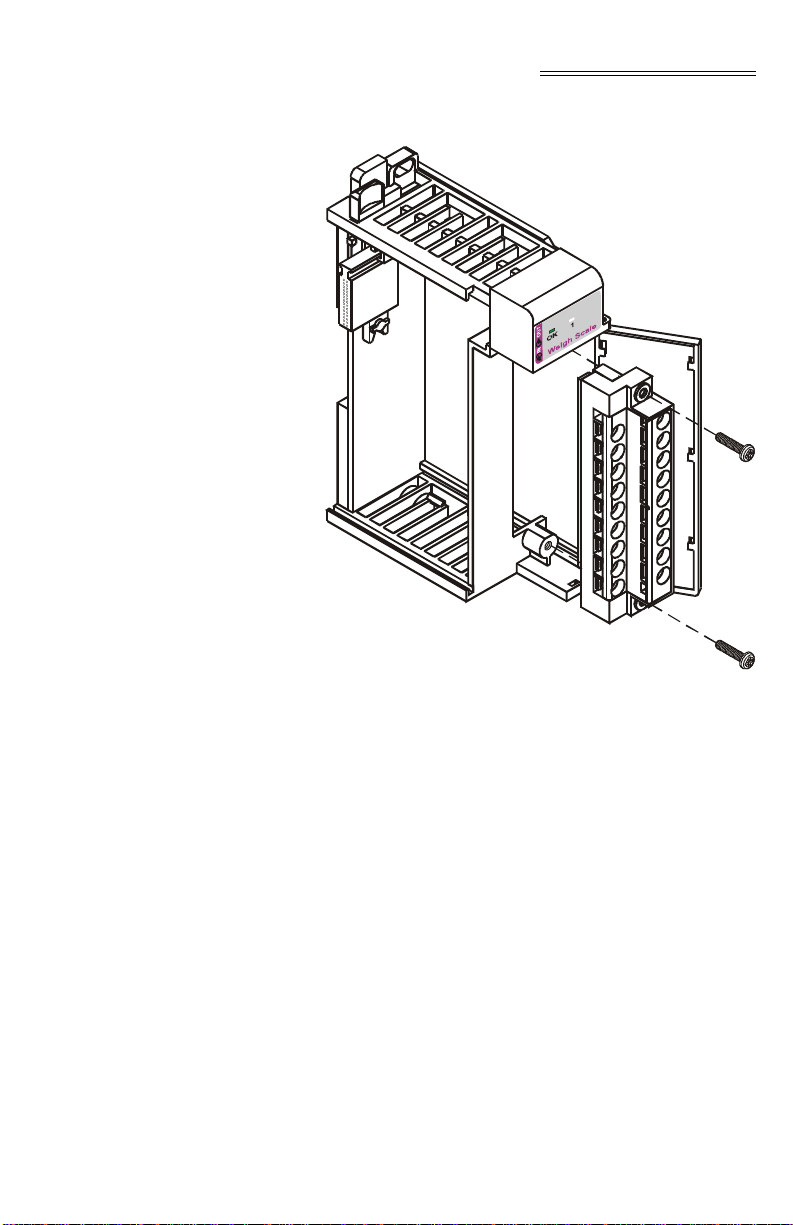

Step 3. Gently slide the HI 1769-WS or HI 1769-

2WS module onto the other module. In our

example we connected two Hardy HI

1769-WS Weigh Modules.

Step 4. When you have the modules aligned, press

Lever B towards Module A to fasten the

connector to Module A. (See Fig. 3-3)

Installing the Module

I/O Connector

About the Module I/O Connector

3-4

FIG. 3-3 CONNECTOR IN LOCKED POSITION

Step 5. The installation is comple.

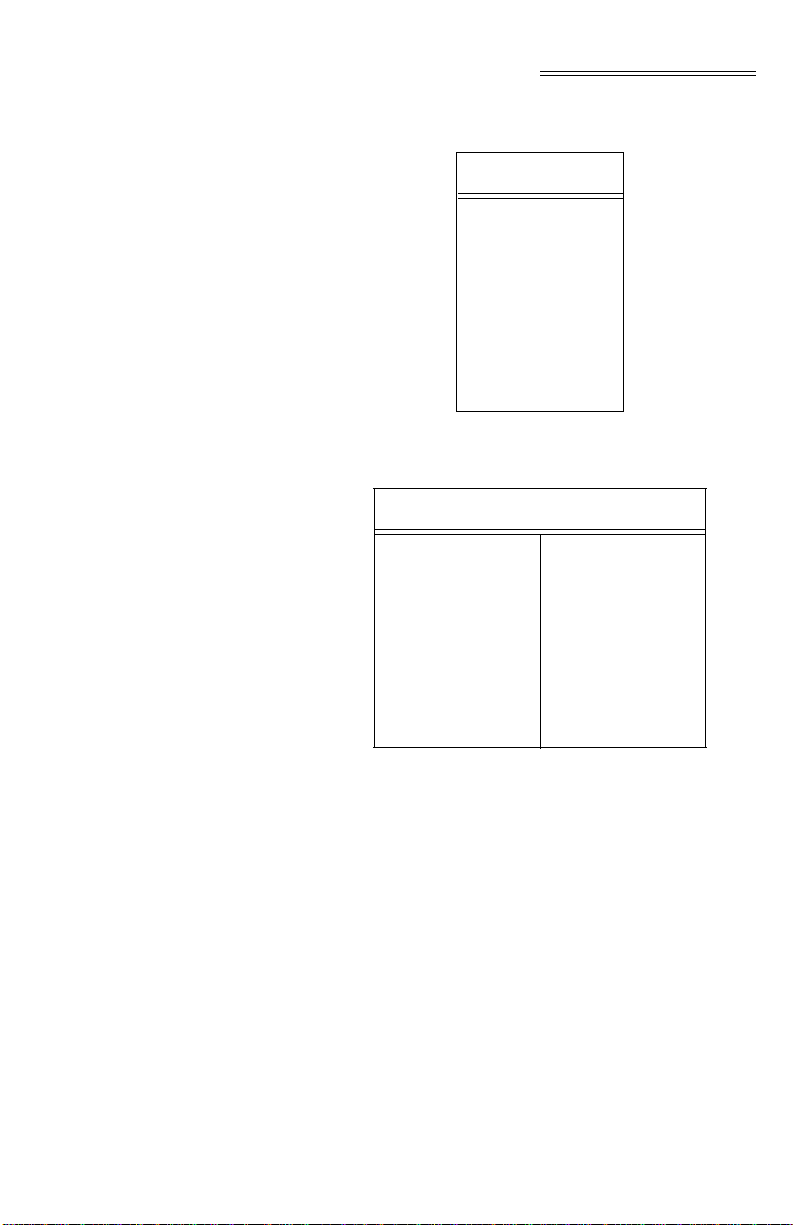

The I/O Connector at the front of the module connects

the module to the Remote Terminal Assembly (RTA), a load sensor, or the HI 215IT Series Junction

Box depending on how many load sensors are

installed in the weighing system. See below for the

pin-out diagram. The pin-out diagram is located on

the inside of the module door. (See Fig. 3-4)

Page 23

Chapter 3 - Installation

Single Channel

Pin 1 Shield1

Pin 3 C2-1

Pin 5 C2+1

Pin 7 Exc-1

Pin 9 Sen-1

Pin 11 Sig-1

Pin 13 Sig+1

Pin 15 Sen+1

Pin 17 Exc+1

Dual Channel

Pin 1 Shield1

Pin 3 C2-1

Pin 5 C2+1

Pin 7 Exc-1

Pin 9 Sen-1

Pin 11 Sig-1

Pin 13 Sig+1

Pin 15 Sen+1

Pin 17 Exc+1

Pin 2 Shield2

Pin 4 C2-2

Pin 6 C2+2

Pin 8 Exc-2

Pin 10 Sen-2

Pin 12 Sig-2

Pin 14 Sig+2

Pin 16 Sen+2

Pin 18 Exc+2

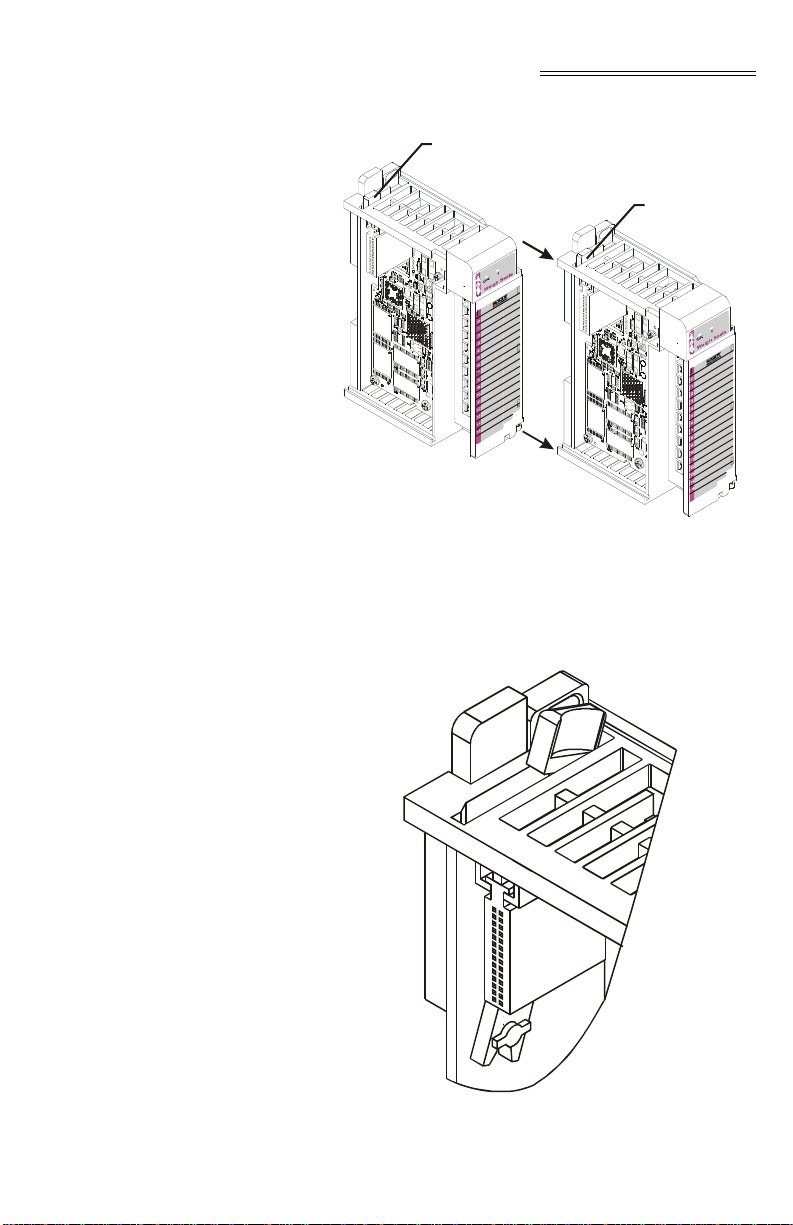

Step 1. Open the Module door to gain access to

the I/O connector. (See Fig. 3-4)

Step 2. To make the cable connections easier you

can remove the connector from the mod

ule. To remove the connector, use a phillips screw driver and remove the two (2)

phillips pan head screws that fasten the

connector to the module. (See Fig. 3-5)

Step 3. Gently pull the connector off of the board

in the module.

3-5

Page 24

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

Step 4. To install the connector reverse steps 2 &

3.

3-6

FIG. 3-4 MODULE CONNECTOR INSTALLED

Page 25

Chapter 3 - Installation

FIG. 3-5 MODULE CONNECTOR REMOVED

FOR EASIER CABLING

Step 5. Install the cable so it allows the module

door to close.

Step 6. Check to be sure that the wires are

securely connected before operating the

module.

NOTE: Most of the problems with modules are due to loose

connections. Be sure to check the I/O connection first

in the event you have a problem r eceiving information

from the load cells.

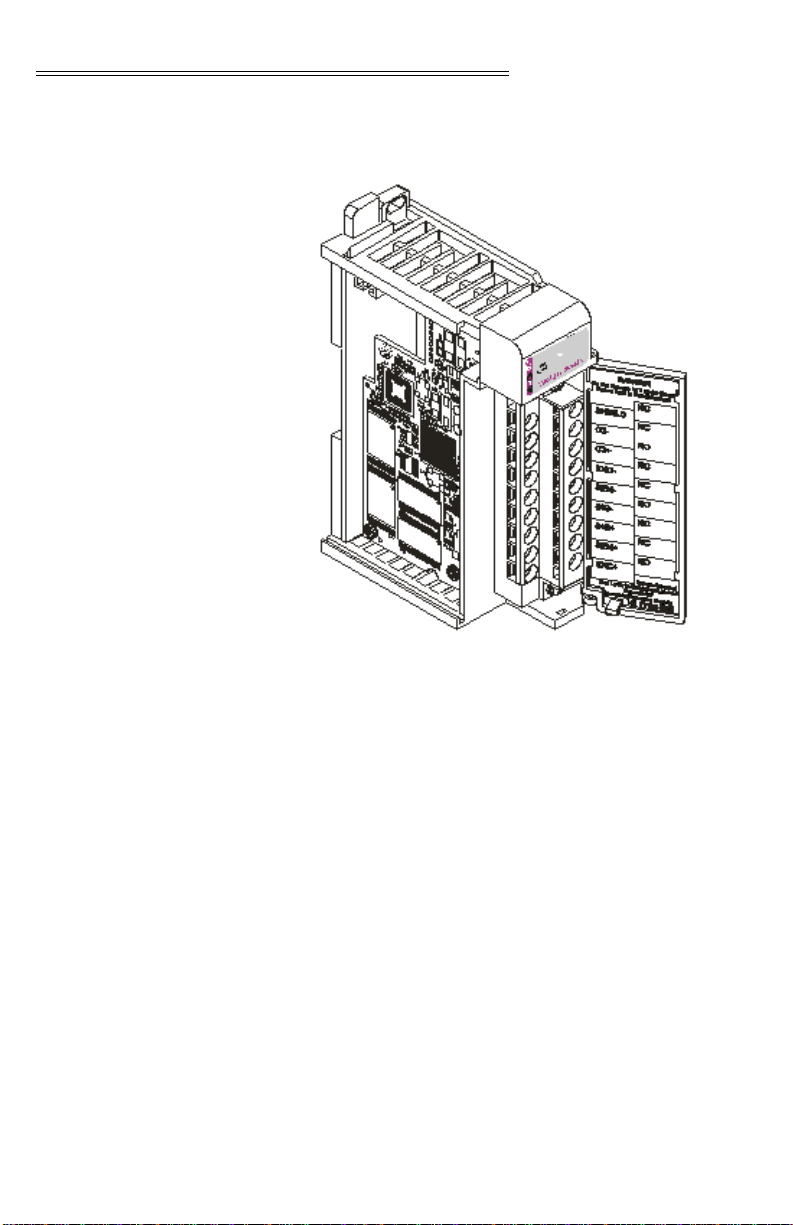

Installing the HI 1769WS on a Din Rail

Step 1. Pull the two DIN rail fasteners out until

they snap into the open position. (See Fig.

3-6)

3-7

Page 26

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

FIG. 3-6 RAIL FASTENERS IN RETRACTED

POSITION

Step 2. Place the module on the DIN rail.

Step 3. While holding the module in place, press

the two rail fasteners towards the center of

the module until they both snap into place.

(See Fig. 3-7)

Step 4. The module is now securely fastened to

the DIN Rail.

Step 5. To remove the module from the DIN rail

reverse steps 2 & 3 above.

Rail

Fasteners

3-8

Page 27

Chapter 3 - Installation

FIG. 3-7 RAIL FASTENERS IN THE CLOSED

POSITION

3-9

Page 28

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

Load Cell Wiring Diagrams

Industry Standard Load Cells

FIG. 3-8 INDUSTRY STANDARD LOAD CELLS

WIRING DIAGRAM

3-10

Page 29

Hardy Load Sensor with C2

Chapter 3 - Installation

FIG. 3-9 HARDY LOAD SENSOR/C2 WIRING

DIAGRAM

WARNING: HARDY PROCESS SOLUTIONS RECOM-

MENDS THAT YOU DO NOT CUT YOUR

ADVANTAGE

® OR ADVANTA GE LITE® LOAD

SENSOR CABLE, BECAUSE YOUR C2®

ACCURACY WILL BE AFFECTED AND

THE WARRANTY VOIDED.

HI 1769 Remote Terminal Assembly (HI 1769-XX-RT)

Provides connection points between the cable assembly from the HI 1769-WS module and the individual

wires from the junction box(es) or load sensor(s). (See

Fig. 3-10) The RTA can be mounted on a DIN Rail.

(See Fig. 3-11)

3-11

Page 30

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

59mm

(2.3")

FIG. 3-10 REMOTE TERMINAL ASSEMBLY

3-12

RTA Cable Assembly

FIG. 3-11 RTA DIN RAIL MOUNT

• Six (6) foot cable and schematic that connects to

the HI 1769-WS module. (See Figs. 3-12& 3-13)

Page 31

Chapter 3 - Installation

FIG. 3-12 RTA CABLE ASSEMBLY - HI 1769-

WS

FIG. 3-13 RTA CABLE SCHEMATIC - HI 1769-

WS

• Six (6) foot cable that connects to the HI 1769-

2WS. (See Figs. 3-14 & 3-15)

FIG. 3-14 RTA CABLE - HI 1769-2WS

3-13

Page 32

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

FIG. 3-15 RTA SCHEMATIC HI 1769-2WS

EMI Suppression Core Installation (Prt. #2547-0013)

NOTE: Install one suppression core for the single channel

For CE requirements you will need to install an EMI

suppression core around the multi-strand portion of

the RTA cable. (See Fig. 3-12 & 3-14)

model and two (2) suppression cores for the dual

channel model.

Step 1. There should be enough of the individual

strands of wire exposed to install the sup

pression core. If there is not enough room,

remove enough of the cable cover until

you can place the suppression core around

all the wire strands.

Step 2. Place the suppression core as close to the

module door as possible and still be able to

close the door.

Step 3. To open the suppression core place a small

slotted screwdriver behind the latch and

pry the latch away from the body of the

core until it clears both catches. (See Fig.

3-16)

-

3-14

Page 33

Chapter 3 - Installation

Latch

FIG. 3-16 EMI SUPPRESSION CORE

Step 4. Open the core until it is wide enough to

enclose all the strands of wire. (See Fig. 3-

17)

FIG. 3-17 SUPPRESSION CORE OPEN

Step 5. Place all the wire strands in the core and

gently close the core until it snaps shut.

(See Fig. 3-18)

3-15

Page 34

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

FIG. 3-18 SUPPRESSION CORE INSTALLED

Hardy HI 215IT Junction Box

FIG. 3-19 HARDY HI 215IT JUNCTION BOX

WIRING DIAGRAM

NOTE: When connecting the Hardy HI 215IT Junction Box

you must remove the two factory installed jumpers

17&15 and 7&9 on the module install sense lines

except when installing four (4) wire non C2 load cells.

3-16

Page 35

CHAPTER 4 - SETUP

Chapter 4 - Setup

A Brief Description of Chapter 4

Power Check Step 1. Check to see that there is power to the

All information contained in Chapter 4 pertains to

firmware and software settings to prepare the module

controller for calibration and operation. Alternatives

to these procedures either explicit or implied, con

tained in this section are not recommended. It is very

important that the user and service personnel be

familiar with the procedures contained in this chapter,

before going through the setup procedures. The Setup

procedures require Allen-Bradley’s RS Logix 5000

(CompactLogix) or RS Logix 500 (MicroLogix 1500)

Allen-Bradley RSLinx™ or RSLinx™ Lite.

PLC and the module.

Step 2. If there is power to the module, the LEDS

should be lit. (See Fig. 4-1 and 4-2)

Step 3. To make any settings the LED’s should be

lit for normal operation:

-

FIG. 4-1 MODULE LEDS HI 1769-WS SINGLE

CHANNEL

4-1

Page 36

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

FIG. 4-2 MODULE LEDS HI 1769-2WS DUAL

CHANNEL

LEDS The module has a Scale LED and an OK LED associ-

ated with it. The LEDs may be green, red or off. They

may be steady, Fast Flashing (5 Hertz) of Slow Flash

ing (1 Hertz)

-

Scale Data LEDs

OK Module Status LED

NOTE: Slow Flashing Red appears briefly when powering up.

NOTE: *Contact Hardy Customer Support for assistance.

4-2

Steady Green Running (Normal)

Slow Flashing Green Error No Calibration

Steady Red Error ERRORADFAILURE -

(hardware induced) status bit is

set.

Flashing Red Read AD Convert Error.

LED is Off Channel is not Enabled

Fast Flashing Green Module communicating with

PLC. (Normal)

Slow Flashing Red Module is not Communicating

with the PLC (Not Normal)

Error, configuration/error in

PLC addressing

Page 37

Chapter 4 - Setup

Setting Up

Communications

Between the

MicroLogix 1500

Processor and the

HI 1769-WS & HI 17692WS Weigh Scale

Modules

NOTE: On the side of the module you will see a label that

reads either Firmware REV A or Firmware REV

B,C,D etc. Both setup procedures are the same except

for the Connection Parameters/Extra Data Length.

For REV A the setting is 0. For all other REVs the set

ting is 48.

To set up communication between the MicroLogix

1500 Processor and the W eigh Scale Module you will

need to do the following in RSLogix 500:

Step 1. We assume you have a project open or

have created a new project. For instruc

tions please see your RS LOGIX 500 manual. The setup instructions begin from this

point.

Step 2. From the I/O Configuration dialog box,

under “#” column heading click on #1 or

the next open slot number available. (See

Fig. 4-3)

-

-

FIG. 4-3 I/O CONFIGURATION DIALOG BOX

4-3

Page 38

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

Step 3. Click on the “Read IO Config” button.

(See Fig. 4-4) The “Read IO Configuration

from Online Processor” dialog box

appears. (See Fig. 4-5)

Step 4. RSLogix 500 automatically reads the I/O

information and enters them into the con

figuration text fields. (See Fig. 4-4)

-

4-4

FIG. 4-4 READ I/O CONFIGURATION FROM

ONLINE PROCESSOR DIALOG BOX

Step 5. The HI 1769-WS I/O is configured and

ready to communicate with the

MicroLogix 1500 Processor.

Step 6. For Firmware REV B you need to double

click on the module which opens the Con

nection Parameters dialog box. Change the

Extra Data Length from a 0 to 48. (See

Fig. 4-5)

-

Page 39

Alternative Setup Procedures

Configuring the

HI 1769-WS in

RSLogix 500 for

MicroLogix 1500

Chapter 4 - Setup

FIG. 4-5 CONNECTION/CONFIGURATION - 48

To set up communication between the MicroLogix

1500 Processor and the W eigh Scale Module you will

need to do the following in RSLogix 500:

Step 1. Under Project, click on the + next to con-

troller. (See Fig. 4-6)

Step 2. Click on I/O Configuration. The I/O Con-

figuration dialog box appears. (See Fig. 4-

7)

4-5

Page 40

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

FIG. 4-6 EXPANDING CONTROLLER

4-6

FIG. 4-7 I/O CONFIGURATION DIALOG BOX

Step 3. From the I/O Configuration dialog box,

under the “#” column heading, click on #1

or the next open slot number available.

(See Fig. 4-8)

Step 4. In the Current Cards Available, double

click on “Other - Requires I/O Type Card

ID” under the Description column head

ing.

Step 5. Enter the following in the appropriate text

fields:

-

Page 41

Chapter 4 - Setup

On some PLC platforms it may be necessary to enter

the Vendor ID, the Product Type, the Product Code,

Input/Output Words and Extra Data Length. See

below:

• HARDY_VENDOR_ID 0x102 (258 decimal)

• HARDY_PRODUCT_TYPE 0x54 (100 decimal)

• HARDY_PRODUCT -CODE 5

• Input Words - 32

• Output Words - 32

• Extra Data Length - 0 for Firmware REV A or 48

for later Firmware REVs.

Step 6. Click on the “Apply.” button.

Step 7. “OTHER” appears under the Part # col-

umn heading. (See Fig. 4-8)

Configuring the

HI 1769-WS in

RSLogix 5000 for

CompactLogix

FIG. 4-8 I/O CONFIGURATION DIALOG BOX

Step 8. The HI 1769-WS I/O is configured and

ready to communicate with the

MicroLogix 1500 Processor.

T o set up communication between the CompactLogix

Processor and the We igh Scale Module you will need

to do the following in RSLogix 5000:

Step 1. Click on the + next to I/O Configuration.

(See Fig. 4-9).

4-7

Page 42

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

FIG. 4-9 SELECTING COMPACTBUS LOCAL

Step 2. Right click on

“CompactBus

Local”. A dia

log box appears.

Step 3. Click on “New

Module”. The

“Select Module

Type” dialog

box appears. (See Fig. 4-10)

-

4-8

FIG. 4-10 SELECT MODULE TYPE/

SELECTING 1769 MODULE/GENERIC

Page 43

Chapter 4 - Setup

Step 4. From the Select Module Type dialog box,

scroll down the list until you find the 1769

Module - Generic Module.

Step 5. Double click on the 1769 Generic Module.

Step 6. Click on the OK button. The Module Prop-

erties dialog box appears. (See Figs. 4-11

& 12)

FIG. 4-11 MODULE PROPERTIES DIALOG

BOX/CONFIGURATION/SIZE/0 WORDS

FIG. 4-12 MODULE PROPERTIES DIALOG

BOX/CONFIGURATION/SIZE/48 WORDS

Step 7. Click in the Name Text box. Enter a

descriptive name for the module. We used

“Hardy_1769WS” for example.

4-9

Page 44

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

Step 8. Click in the Description Text Box. Type in

a description of the module.

Step 9. Click on the down arrow to the right of

Comm Format to open the pull down list.

Step 10. Click on Data-INT to select the Comm

Format.

Step 11. Use the up or down arrows to the right of

Slot, to select the slot number for the

installed HI 1769-WS or HI 1769-2WS.

Step 12. Under Connection Parameters/Input use

the up or down arrows to select 32 words.

Step 13. Under Connection Parameters/Output use

the up or down arrows to select 32 words.

Step 14. Under Connection Parameters/Configura-

tion use the up or down arrows to select:

• For Firmware REV A - 0 words.

• For other Firmware REVs - 48 words.

Step 15. Click on the “Finish” button.

Parameters for the

HI 1769-WS Module

About Parameters The data types that can appear in the I/O files are:

• 16 bit integer

• 32 bit integer

• 32 bit IEEE float.

NOTE: In the 32 bit types, the least significant word comes

first, followed by the most significant word.

Weight values are displayed as either 32 bit integers,

or as 32 bit float depending on the value of the “Met

ric” parameter. (See Parameter Table 4-1 below)

Each channel has a CHANNEL STATUS WORD,

with bits set to indicate the state of that channel. The

bit values are:

4-10

-

Page 45

Chapter 4 - Setup

• #define ERRORADCONVERT 0x0001

• #define ERRORADFAILURE 0x0002

• #define STATUSINMOTION 0x0040

• #define ERRORNOCAL 0x0080

• #define ERROREEPROMWRITE 0x0100

// an error occurred when writing to nonvolatile memory

• #define NVRDEFAULTED 0x0200 // set

if SETDEF AULTPA RAMS command was

given

• #define STATUSCHANENABLED

0x8000 // set if channel is enabled

Name Description Default

ChanActive 16 bit integer, set to 1 if the

channel is active, 0 if not

active

Metric 16 bit integer which

determines the format of

weight values. Metric is the

sum of 3 fields:

1 If bit 7 is set (0x80),

weight is displayed in

Kilograms

2 If bit 6 is set (0x40),

weight is displayed as a

floating point

3. If bit 6 is not set, Weight

is displayed as an

integer, with the 3 least

significant bits giving the

number of decimal

places

WAVERSAVER 16 bit integer

0 No WAVERSAVER

14 Hertz

22 Hertz

31 Hertz

4 0.5 Hertz

5 0.25 Hertz

TABLE 4-1: PARAMETERS

1

0 (weight in pounds, integer

format, 0 decimal places)

3 (1 Hertz)

4-11

Page 46

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

Name Description Default

NumAverages 16 bit integer, 1-255 20

ZeroTrackEnable 16 bit integer

0 turns auto-zero tracking off

1 turns auto-zero tracking on

AutoZeroTolerance 32 bit weight value, format

determined by value of

Metric Parameter

ZeroTolerance 32 bit weight value, format

determined by value of

Metric Parameter

Motion Tolera nce 32 bit weight value, format

determined by value of

Metric Parameter

tareweight 32 bit weight value, format

determined by value of

Metric Parameter.

SpanWeight 32 bit weight value, format

determined by value of

Metric Parameter.

Span Weight is the test weight

used at the high step of a hard

calibration

ROCtimebase 16 bit integer, 1-1800 seconds 10 secs

CalLowWeight 32 bit weight value, format

determined by value of

Metric Parameter

CalLowWeight is the test

weight used at the low step of

a hard calibration and as Ref

Point for C2 Calibration

0

10.0 lbs.

10.0 lbs.

5 lbs

0 lbs.

10,000.0 lbs

0 lbs

Configuration Parameters for the HI 1769-WS Module

4-12

TABLE 4-1: PARAMETERS

The HI 1769-WS & HI 1769-2WS are equipped with

Firmware REV B have 48 words of configuration

data. The HI 1769-WS Firmware REV B has 48

words of configuration data for CompactLogix and

Extended Data on MicroLogix, 24 w ords per channe l.

Page 47

Chapter 4 - Setup

The configuration data is sent from the PLC to the HI

1769-WS module at power-up. The module uses these

parameters provided that:

1. The parameters are in the correct range. Illegal values will be rejected.

2. The “CopyConfig” word (0 for channel 0, 24

for channel 1) is set to 1.

• INT parameters are 2 byte integers

• DINT parameters are 4 byte integers

• REAL parameters are 4 byte IEEE

floating point numbers

NOTE: Parameters labeled “REAL or DINT” will be inter-

preted as floating point or integer according to the

value of the “METRIC” parameter of the channel. If

bit 6 (0x40) of METRIC is set the parameter is float

ing point. If bit 6 is not set, it is a fixed point integer,

with 0-7 decimal places as determined the first 3 bits

of the METRIC parameter.

-

Parameter

Ch0CopyConfig 0 INT

Ch0ChanActive 1 INT

Ch0Metric 2 INT

Ch0Waversaver 3 INT

Ch0NumAverages 4 INT

Ch0ZeroTrackEnable 5 INT

Ch0AutoZeroTolerance 6 REAL or INT

Ch0MotionTolerance 8 REAL or INT

Ch0ZeroTolerance 10 REAL or INT

Ch0SpanWeight 12 REAL or INT

Offset (In

Words)

Data Type

4-13

Page 48

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

Parameter

Ch0CalLowWeight 14 REAL or INT

Ch0ROCtimebase 16 INT

Ch0CopyCal 17 INT

Ch0calzerocount 18 DINT

Ch0CalHighCount 20 DINT

Ch0Spare2 22 INT

Ch0Spare3 23 INT

Ch1CopyConfig 24 INT

Ch1ChanActive 25 INT

Ch1Metric 26 INT

Ch1Waversaver 27 INT

Ch1NumAverages 28 INT

Ch1ZeroTrackEnable 29 INT

Ch1AutoZeroTolerance 30 REAL or INT

Ch1MotionTolerance 32 REAL or INT

Offset (In

Words)

Data Type

4-14

Ch1ZeroTolerance 34 REAL or INT

Ch1SpanWeight 36 REAL or INT

Ch1CalLowWeight 38 REAL or INT

Ch1ROCtimebase 40 INT

Ch1CopyCal 41 INT

Ch1calzerocount 42 DINT

Ch1CalHighCount 44 DINT

Ch1Spare2 46 INT

Ch1Spare3 47 INT

It is important to note in CompactLogix that when

you click on Controller Tags you will not get the

Page 49

Chapter 4 - Setup

parameters in the form above. When you expand the

slot you selected for the these parameters they will

look like the following:

Local:1:C.Data[0]

Local:1:C.Data[1]

Local:1:C.Data[2]

Local:1:C.Data[3]

...and so on

These correspond directly to the parameters in the

table above. (See Fig. 4-13)

FIG. 4-13 CONTROLLER TAGS/SLOT 1

Commands

About Commands The first 16 words are reserved for Channel 0. The

second 16 words are reserved for Channel 1. The first

word in the 16 words of a channel’s output table is

called the COMMAND word.

See the COMMAND table for a list of commands.

The other words in the output data table may need to

be set according to which command is being given.

The commands are executed only once, when the

COMMAND word changes. The first word in the

channel’s input table is an echo of the COMMAND

word. All commands take some time to process; when

you see the echoed value in the input table, the com

mand is complete. The second word in the channel’s

-

4-15

Page 50

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

input table is called the command STATUS. Normally , a 0 value of STATUS means that the command

completed OK and a non-zero status indicates some

kind of error.

Command Operation

Possible COMMAND STATUS Values

Step 1. To start a command, place the command

number into the first word of the output

table.

Step 2. The Input Table contains the response for

that command.

Step 3. If a selected command needs other data

with it, the other words in the output table

should be filled in first, then the command

number. Example:

• WRITEPARAM0, should have

PARAMETER0 Data placed into the

output table before the command

number is written, otherwise the com

mand will fail.

• #define SUCCESS 0

• #define ERRORADCONVERT 0x0001

• #define ERRORADFAILURE 0x0002

• #define STATUSINMOTION 0x0040

• #define OUTOFTOLERANCE -3

• #define INDEXOUTOFRANGE -4

• #define NOSUCHCMD -5

• #define C2FAILNODEVS -6

• #define C2FAILCAPEQ -7 // failure, capacities

not equal

• #define HARDCALFAILCOUNST -8 // failure,

not enough ADC counts between high, low

-

4-16

Page 51

Command Table

Chapter 4 - Setup

Command

NOCMD (no command)

0

Give this command to read

weight from the module.

Weight values will then be

continuously updated

ZEROCMD

1

Zeroes the scale:

May fail if the weight is in

motion, or if there is an A/

D error, or if the weight to

be zeroed out is outside the

Zero Tolerance range.

Required Output Table Values

Written by User (PLC)

O:0 = 0

O:1-0:15 (unused)

O:0 = 1

O:1-O:15 (unused)

Input Table Response

From Weigh Scale

I:0 = 0

I:1 = COMMAND STATUS =

0

I:2 = CHANNEL

ST ATUSWORD

I:3 = Firmware Revision

I:4 = Gross Weight, LSW

I:5 = Gross Weight, MSW

I:6 = Net Weight, LSW

I:7 = Net Weight, MSW

I:8 = Metric Parameter

I:9 = Calibration Type

• Hard Calibration = 0

• C2 Calibration = 1

• No Calibration =

0xFFFF

I:10 = ADC Counts, LSW

I:11 = ADC Counts, MSW

I:12 = ROC (units/min)

I:13 = ROC (units/min)

I:14 = Serial Number

I:15 = ADC Conversion

Counter

I:0 = 1

I:1 = COMMAND STATUS

I:2-I:15 See NOCMD

continuously updating

TARECMD

2

Tares the Scale:

May fail if the weight is in

motion, or if there is an A/

D error.

O:0 = 2

O:1-O:15 (unused)

I:0 = 2

I:1 = COMMAND STATUS

I:2-I:15 See NOCMD

continuously updating

4-17

Page 52

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

Command

WRITEMETRIC

3

Writes the Metric

Parameter. Does NOT save

the value of the metric

parameter to non-volatile

memory.

WRITENONVOLATILE

4

This command is normally

not needed, since the

commands that write

parameters automatically

save values to non-volatile

memory. Exceptions are the

ZEROCMD, TARECMD,

and WRITEMETRIC,

which do not automatically

save.

RELOADNONVOLATILE

0X10

Reread the non-volatile

memory

CALLOWCMD

0x64

Do the low step of a Hard

Calibration.

Results saved to nonvolatile memory.

Required Output Table Values

Written by User (PLC)

O:0 = 3

O:1 - unused

O:2 - unused

O:3 - New METRIC value

O:0 = 4

O:1-O:15 (unused)

O:0 = 0x10

O:1-O:15 (unused)

O:0 = 0x64

O:1-O:15 (unused)

Input Table Response

From Weigh Scale

I:0 = 3

I:1 = COMMAND STATUS

I:2-I:15 See NOCMD,

continuously updating

I:0 = 4

I:1 = 0

I:2-I:15 See NOCMD,

continuously updating

I:0 = 0x10

I:1 = 0

I:2-I:15 See NOCMD

continuously updating

I:0 = 0x64

I:1 = COMMAND STATUS

I:2-I:15 See NOCMD,

continuously updating

CALHIGHCMD

0x65

Do the high setpoint of a

Hard Calibration.

Results saved to nonvolatile memory.

C2CALCMD

0x66

Do a C2 Calibration.

Results saved to nonvolatile memory

4-18

O:0 = 0x65

O:1-O:15 (unused)

O:0 = 0x66

O:1-O:15 (unused)

I:0 = 0x65

I:1 = COMMAND STATUS

I:2-I:15 See NOCMD,

continuously updating

I:0 = 0x66

I:1 = COMMAND STATUS

I:2-I:15 See NOCMD,

continuously updating

Page 53

Chapter 4 - Setup

Command

WRITEPARAM0

0x67

Write a block of

parameters:

To write a single parameter:

Step 1. Do a READPAR-

AM0 command.

Step 2. Copy the parame-

ters read to the

output.

Step 3. Change the param-

eter value

Step 4. Set the command

word.

The Metric Parameter is

processed last, which

means that all parameters

are interpreted according to

the old Metric value.

Results are saved to nonvolatile memory.

If you attempt to set a

parameter value to an

illegal value, the offset of

that parameter will appear

in the COMMAND

STATUS word.

Required Output Table Values

Written by User (PLC)

O:0 = 0x67

O:1 = unused

O:2 = ChanActive

O:3 = Metric

O:4 = WAVERSAVER

O:5 = NumAverages

O:6 = ZeroTrackEnable

O:7 = ROCtimebase (1-1800 sec)

O:8 = AutoZeroTolerance, LSW

O:9 = AutoZeroTolerance, MSW

O:10 = MotionTolerance, LSW

O:11 = Motion Tolerance, MSW

O:12 = ZeroTolerance, LSW

O:13 = ZeroTolerance, MSW

O:14-O:15 = unused

Input Table Response

From Weigh Scale

I:0 = 0x67

I:1 = COMMAND STATUS

I:2-I:15 See READPARAM0

WRITEPARAM1

0X68

If you attempt to set a

parameter value to an

illegal value, the offset of

that parameter will appear

in the COMMAND

STATUS word.

O:0 = 0x68

O:1 = unused

O:2 = TareWeight LSW

O:3 = TareWeight MSW

O:4 = SpanWeight LSW

O:5 = SpanWeight MSW

O:6 = CalLowWeight LSW

O:7 = CalLowWeight MSW

O:8-O:15 = unused

I:0 = 0x68

I:1 = COMMAND STATUS

I:2-I:15 See READPARAM1

4-19

Page 54

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

Command

READPARAM0

0x69

Read a parameter block.

We ight values are

formatted according to the

Metric parameter.

READPARAM1

0x6A

Read a parameter block.

This block contains some

non-user settable

calibration parameters

zerocount = A/D counts at

the last ZEROCMD

calzerocount = A/D counts

at zero weight, as obtained

at the last calibration

CalLowCount: A/D counts

at CalLowWeight

CalHighCount: A/D counts

at Span Weight (Hard

Calibration only)

Required Output Table Values

Written by User (PLC)

O:0 = 0x69

O:1-O:15 = unused

O0 = 0x6A

O:1-O:15 = unused

Input Table Response

From Weigh Scale

I:0 = 0x69

I:1 = 0

I:2 = ChanActive

I:3 = Metric

I:4 = WAVERSAVER

I:5 = NumAverages

I:6 = ZeroTrackEnable

I:7 = ROCtimebase

I:8 = AutoZeroTolerance,

LSW

I:9 = AutoZeroTolerance,

MSW

I:10 = MotionTolerance, LSW

I:11 = MotionTolerance, MSW

I:12 = ZeroTolerance, LSW

I:13 = ZeroTolerance, MSW

I:14-I:15 = unused

I:0 = 0x6A

I:1 = 0

I:2 = tareweight LSW

I:3 = tareweight MSW

I:4 = SpanWeight LSW

I:5 = SpanWeight MSW

I:6 = CalLowWeight, LSW

I:7 = CalLowWeight, MSW

I:8 = zerocount, LSW

I:9 = zerocount, MSW

I:10 = calzerocount, LSW

I:11 = calzerocount, MSW

I:12 = calLowCount, LSW

I:13 = calLowCount, MSW

I:14 = calHighCount, LSW

I:15 = calHighCount, MSW

4-20

Page 55

Chapter 4 - Setup

Command

STABILITYTEST

0x6B

Switch in a specified signal

in place of the normal load

cell signal. With an ITJBOX, 4 individual load

cell signals, or a reference

signal on the JBOX may be

switched in.

Without an IT-JBOX, only

an onboard reference signal

may be switched in.

Giving any other command

after STABILITYTEST

causes the unit to return to

normal operation.

Required Output Table Values

Written by User (PLC)

O:0 = 0x6B

O:1 = signal to switch in

O = onboard reference signal

1-4 = load cell signals on IT-JBOX

5 = reference signal from IT-JBOX

Input Table Response

From Weigh Scale

I:0 = 0x6B

I:1 = COMMAND STATUS

NOTE:

The COMMAND STATUS

INDEXOUTOFRANGE (-4) is

returned if a signal outside the

0-5 range is requested, if you

have an IT-JBOX, or if a signal

other than 0 (onboard refer

ence signal) is requested and

you do not have an IT-JBOX.

I:2-I:15 See NOCMD,

continuously updating

NOTE:

During the Stability Test,

Gross and Net Weights are

results of signal selected for

this test.

-

4-21

Page 56

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

TESTRESULTS

0x6C

Report the results of a previous

INTEGRATED

TECHNICIAN test. No new

test is performed

O:0-0x6C

O:1-15 (unused)

I:0x6C

I:1 = return to zero test result,

bit coded:

• Bits set to 1 indicate nonreturn to zero.

• Bit 0 = combined weight

• Bits 1-4 (JBOX only)

indicate non-return to

zero on a individual

JBOX sensor.

I:2-15 are all INTEGER

values.

• Millivolt/volt readings

have 4 decimal places.

• Load Cell resistance has

zero decimal places.

• Sense V olts has 2 decimal

places.

I:2 = millivolts/volt,

combined, LSW

I:3 = millivolts/volt

combined, MSW

I:4 = millivolts/volt, load

sensor #1, LSW

I:5 = millivolts/volt, load

sensor #1, MSW

I:6 = millivolts/volt, load

sensor #2, LSW

I:7 = millivolts/volt, load

sensor #2, MSW

I:8 = millivolts/volt, load

sensor #3, LSW

I:9 = millivolts/volt, load

sensor #3, MSW

I:10 = millivolts/volt, load

sensor #4, LSW

I:11 = millivolts/volt, load

sensor #4, MSW

I:12 = Sense Volts, LSW

I:13 = Sense Volts, MSW

I:14 = Load cell input

resistance, as determined

from C2 at last calibration,

LSW

I:15 = Load cell input

resistance, MSW

4-22

Page 57

Chapter 4 - Setup

WEIGHSYSTEST

0x6D

Perform an INTEGRATED

TECHNICIAN test.

O:0=0x6D

O:1 = number of sensors

O:2-15 (unused)

I:0 = 0x6D

I:1 = number of sensors

I:2-15 are weight values,

scaled according to the

Metric Parameter value

I:2 = combined gross weight,

LSW

I:3 = combined gross weight,

MSW

I:4 = gross weight on load

sensor #1, LSW

I:5 = gross weight on load

sensor #1, MSW

I:6 = gross weight on load

sensor #2, LSW

I:7 = gross weight on load

sensor #2, MSW

I:8 = gross weight on load

sensor #3, LSW

I:9 = gross weight on load

sensor #3, MSW

I:10 = gross weight on load

sensor #4, LSW

I:11 = gross weight on load

sensor #4, MSW

I:12 = Internal reference

weight, LSW

I:13 = Internal reference

weight, MSW

I:14 = JBOX reference

weight, LSW

I:15 = JBOS reference

weight, MSW

C2SEARCH

0x6E

Search for C2 load sensors.

The COMMAND STATUS is

the number of sensors found.

WEIGHSYSRESULTS

0x6F

Report the results of a previous

INTEGRATED

TECHNICIAN test. No new

test is performed.

O:0=0x6E

O:1-15 (unused)

O:0=0x6F

O:1-15 (unused)

I:0 = 0x6E

I:1 = COMMAND STATUS

I:2-I:15 See NOCMD,

continuously updating

I:0=6F

I:1-15 See WEIGHSYSTEST

4-23

Page 58

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

READC2SERIALNUM

0x70

Read data from a C2 sensor.

The C2SEARCH command

must be performed before this

command is done.

SETDEFAULTPARAMS

0x94

EXTENDED VERSION

0xFF

Read full software version

information

O:0 = 0x70

O:1 = SENSOR NUMBER

(0-7)

O:0 = 0x94

O:1-15 (unused)

O:0 = 0xFF

0:1-15 (unused)

I:0 = 0x70

I:1 = COMMAND STATUS

I:2-9 = Serial Number

I:10 = Sensitivity, LSW

I:11 = Sensitivity , MSW

I:12 = Capacity, LSW

I:13 = Capacity, MSW

NOTE:

Sensitivity is an integer, with

4 decimal places and dimen

sions of millivolts per volt.

Capacity is an integer with 0

decimal places, with units of

pounds.

I:0 = 0x94

I:1 = COMMAND STATUS

I:2-I:15 See NOCMD,

continuously updating

I:0 = 0xFF

I:1 = 0

I:2 = SERIES_REV

I:3 = MAJOR_REV

I:4 = MINOR_REV

I:5 = PATCH_REV

I:6 = BUILD_REV

-

Calibration Setup Procedures

Setting the Metric Parameter

Setting the Motion Tolerance Value

4-24

TABLE 4-2: COMMAND TABLE

The Metric Parameter can be set to either kilograms

or pounds. Any weight value input to the module (e.g.

CALLOWWEIGHT, SPANWEIGHT) are in the cur

rently selected units. The unit of measure can be set at

any time, not just at calibration. Setting the unit of

measure before calibrating reminds the user what unit

of measure is being displayed. It is important to note

that the weight scale module does not need to be cali

brated again after changing the unit of measure.

The motion tolerance is the tolerance value used to

determine if the scale is in motion.

-

-

Page 59

Chapter 4 - Setup

Setting The Zero Tolerance Value

Setting the Auto Zero Tolerance Value

NOTE: There is a short time delay (at least 1 second) before

Setting the Number of Readings Averages

Setting the Span Weight V alue

Setting the WAVERSAVER Value

Sets the range of weights so that the Zero Command

works, as an offset of the calibrated Zero.

When the Auto Zero Tolerance is entered, and Auto

Zero Tracking is enabled, any weight within the

entered tolerance of zero and not in motion, will cause

the display to automatically read zero.

the AutoZero Triggers.

The Number of Averages sets the number of weight

readings which will be used to compute the displayed

weight. The average is a sliding average so that a new

average reading is available for display at every read

ing.

The Span W eight is a reference point derived from an

actual measured weight. This should not be confused

with the scale capacity. If you have a 100 pound

weight and you place it on the scale, the Span Weight

is 100 pounds.

There are 6 selectable levels, 0 means that WAVERSAVER has not been selected. Default setting is #3 1

Hertz.

-

•0 = NO WAVERSAVER

• 1 = 4.0 Hertz

• 2 = 2.0 Hertz

• 3 = 1.0 Hertz - Default

• 4 = 0.5 Hertz

• 5 = 0.25 Hertz

4-25

Page 60

HI 1769-WS/HI 1769-2WS WEIGH SCALE MODULE

4-26

Page 61

CHAPTER 5 - CALIBRATION

Chapter 5 - Calibration

A Brief Description of Chapter 5

NOTE: Do not perform a calibration while the application is

Pre-Calibration Procedures

Chapter 5 pertains to the calibration procedures for

the HI 1769-WS and HI 1769-2WS Weigh Scale

Modules. Alternatives to any procedures either

implied or explicitly contained in this chapter are not

recommended. In order for the Weigh Module to work

properly, it must be calibrated prior to operation. It is

recommended that the module calibration be verified

periodically or when not in use for extended periods

of time. Be sure to follow all the procedures com

pletely to insure that the weights read by the module

are accurate. It is very important that the user and ser

vice personnel be familiar with the procedures contained in this chapter, before installing or operating

the Weigh Module.

in operation.

Step 1. Check to determine if the load cells have

been properly installed.

a. Refer to your load cell I&M manual for

proper installation instructions.

b. On some sensors and cells there is an

arrow that indicates the direction of the

applied load. If the arrow is pointing in

the wrong direction, change the position

of the load cell so that it is mounted in

the direction of the applied load.

-

-

Step 2. Check for Binding on the Load Cell or

other parts of the weighing system.

CAUTION: BINDING ON A SCALE/VESSEL OR LOAD

CELL DOES NOT ALLOW THE LOAD CELL

FREE VERTICAL MOVEMENT AND MAY PRE

VENT THE INSTRUMENT FROM RETURNING

TO THE ORIGINAL ZERO REFERENCE

POINT.

-

5-1

Page 62

HI 1769-WS/HI-1769-2WS WEIGH SCALE MODULE

a. A load cell must be mounted in such a

way that 100% of the load (Vessel w/

Contents) is vertically passed through a

load cell. (See Fig. 5-1)

b. Check to see that nothing is binding the

load cell. This means that nothing is

draped across the scale/vessel or the

load cell, such as a hose, electrical cord,

tubes, or other objects.

c. Check to see that nothing is coming in

contact with the scale/vessel other than

service wires and piping that have been

properly mounted with flexible connec

tors.

-

FIG. 5-1 PROPERLY INSTALLED LOAD CELL W/NO BINDING

Electrical Check Procedures

Load Cell/Point Input/Output Measurements

5-2

Step 3. Typical Load Cell/Point Input/Output

Measurements (EXC & SIG Outputs)

Page 63

Chapter 5 - Calibration

a. The Weigh Module is designed to sup-

ply 5 VDC excitation to as many as four

(4) 350 Ohm load cells/points.

b. The expected output from each load

cell/point depends on the mV/V rating

of the load cell/point and the weight.

c. For example, a 2mV/V load cell/point

will respond with a maximum of 10

mVDC at full weight capacity of the

system which includes the weight of the

vessel and the weight of the product as

measured by the load cell/point.

d. If the load cell/point weight capacity is

rated at 1000 pounds, the load cell/point

will be 10 mVDC at 1000 pounds, 7.5

mVDC at 750 pounds, 5 mVDC at 500

pounds and so on.

e. A zero reference point will vary from

system to system depending on the

“Dead Load” of the vessel. “Dead Load”

is the weight of the vessel and appurte

nances only, with no product loaded. In

our example we will assume the dead

load to be 500 pounds. (See Fig. 5-2)

-

5-3

Page 64

HI 1769-WS/HI-1769-2WS WEIGH SCALE MODULE

FIG. 5-2 MILLIVOLTS/WEIGHT SCALE

f. Based on the example, the operating

range for this scale is 5-10 mVDC with

a 500 pound weight range. Understand

that after zeroing the instrument, the 0

reading refers to the zero reference point

and not absolute 0 mVDC or absolute 0

weight.

NOTE: Load cell/point measurements are checked with a dig-

ital volt meter at the J1 connector on the front of the

module or by using I

NTEGRATED TECHNICIAN with the

HI 215IT Junction Box.

Load Check Step 1. Place a load (weight) on the scale or ves-

sel.

Step 2. Check to see if the weight reading changes

on the ladder logic display in the proper

direction.

• For example: If the ladder logic display reads 100 pounds and a 20 pound

weight is placed on the vessel or

5-4

Page 65

C2 Calibration

Chapter 5 - Calibration

scale, the ladder logic display should

read 120 or some value over 100.

• If the ladder logic display reads 100

pounds and a 20 pound load is placed

on the vessel or scale and the reading

is 80 pounds, the reading is going in

the wrong direction and indicates

some problem with the system.

• If the ladder logic display is reading

improperly or shows no change there

is something wrong with the setup.

Step 3. If the ladder logic display changed weight

in the proper direction, remove the weight

and proceed to calibrate the module.

About C2 Calibration

C2 Calibration Using Ladder Logic

C2 calibration requires C2 load sensors. If you do not

have C2 load sensors you must perform a traditional

calibration with test weights which we call a Hard

Calibration. The Weigh Module reads the perfor

mance characteristics of each individual load cell and

detects the quantity of load cell(s) in the system. C2

Calibration can be performed via Allen Bradley RS

LOGIX 5000/500.

Step 1. Check to be sure that the parameters have

been setup for your weighing process. (See

Chapter 4, Setup)

Step 2. W e have provided a Ladder Logic example

explaining how to perform the C2 Calibra

tion. The Ladder Logic example is available on the Hardy Web Site:

-

http://www.hardysolutions.com

Step 3. Click on “Support”.

Step 4. Click on “Sample Programs”.

Step 5. You will find the sample programs under

the HI 1769-WS Heading.

-

5-5

Page 66

HI 1769-WS/HI-1769-2WS WEIGH SCALE MODULE

Hard Calibration Hard Calibration is the traditional method of calibra-

tion that uses test weights. Hardy recommends that

the test weights total 80 to 100% of the scale capacity.

Hard Calibration Ladder Logic Example

Step 1. Check to be sure that the parameters have

been setup for your weighing process. (See

Chapter 4, Setup)

Step 2. W e have provided a Ladder Logic example

explaining how to set the weigh process

parameters. The Ladder Logic example is

meant to provide a ladder logic model

only. Your application may vary and the

example may or may not meet your

requirements.

Step 3. The Hard Calibration Ladder Logic Exam-

ple is located at the Hardy We b Site. If you

have access to the Internet:

a. Type the following URL:

http://www.hardysolutions.com

b. Click on the Support button.

c. Click on Sample Programs.

d. Click on the pull down menu for the

product you are calibrating.

e. Click on the Ladder Logic Example for

the HI 1769-WS Weigh Module, Hard

Calibration.

5-6

Step 4. If you do not have access to the Internet,

call your local Hardy representative or

Hardy Customer Service Center and we

will forward you a hard copy of the cali

bration ladder logic explanation and ladder

logic example.

-

Page 67

CHAPTER 6 - TROUBLESHOOTING

CHAPTER 6 - Troubleshooting

A Brief Description of Chapter 6

Scale LED is Flashing Red

Mechanical Inspection See Fig. 6-1

All the information in Chapter 6 pertains to the troubleshooting and resolution of operating problems that

may occur. All maintenance personnel and users

should be familiar with Chapter 6 before attempting

to repair the HI 1769-WS.

Solution: Check all the connections to be sure they

are securely fastened. Reinstall if any appear to be

loose.

6-1

Page 68

HI 1769-WS/HI 1769-2WS MANUAL

All pipes and conduits

flexible?

Mechanically isolated

from ladders and

connecting structures?

1) Floors or structure does not interact.

2) Local traffic does not interact

3) Protected from forklifts and adjacent processing equipment

Are the load cells properly

mounted?

Are Check rods installed

to dampen vessel

movement?

1) Protects the load cells from overload and impact forces

2) Limits the movement of the vessel

3) Rods must be loose and not interacting with the vessel.

Are cables routed

properly?

1) Product, tools and production aids are off the vessel.

2) No workers are physically on the scale

3) Must protect equipment from environmental damage

4) Insure openings are sealed to keep water and environmental

contaminates from damaging:

(a) Instrument cabinet or enclosure

(b) Summing card

(c) Load Cells

(d) Conduit runs

(e) covers are properly installed

1) Keep flexures on the horizontal

2) Vertical flexures should be avoided

3) Do not use flexures to correct for misaligned piping

4) Do not use hose flexures to make right angle bends

5) Non-flexed piping should have an unsupported

horizontal run using a ratio of 36 times it's diameter.

6) Pipe flexure lengths should be a ratio of 6 times it's diameter

7) Feed and discharge piping flexed

8) Are the flex joints on the correct side of the valve ?