Page 1

HI 1756 FC

Feeder Control Module

User’s Guide

Hardy Instruments Part Number: 0596-0318-01 Rev A

Page 2

3860 Calle Fortunada, San Diego, CA 92123-1825

Telephone: 1-800-821-5831 FAX: (858) 278-6700

Web Address: http://www.hardyinstruments.com

Hardy Instruments Part Number: 0596-0318-01 REV A

Copyright February 2010, Dynamic Instruments, All Rights Reserved.

Printed in the U.S.A.

Local Field Service

Hardy has over 200 field technicians in the U.S., and more positioned throughout the world to assist you in

your support needs. We also have factory engineers who will travel to your facility anywhere in the world

to help you solve challenging applications. We're ready to support you with:

Installation and start-up

Routine maintenance and certification

Plant audits and performance measurement

Emergency troubleshooting and repair

To request Emergency Service and Troubleshooting, Start-up, Installation, Calibration, Verifica¬tion or to

discuss a Maintenance Agreement please call 800-821-5831 Ext. 1757 or Emergency Service after hours

(Standard Hours 6:00 AM to 6:00 PM Pacific Standard Time) and weekends Ext. 1111.

Outside the U.S

Hardy Instruments has built a network of support throughout the globe. For specific field service options

available in your area please contact your local sales agent or our U.S. factory at +1 858-292-2710, Ext.

1757.

Page 3

Contents

● ● ● ● ●

CHAPTER 1 OVERVIEW..................................................................................... 1

About Hardy Manuals .................................................................................................................................1

HI 1756 FC Overview....................................................................................................................................1

Typical Applications...................................................................................................................................2

Features and Capabilities.............................................................................................................................2

CHAPTER 2 SPECIFICATIONS .......................................................................... 4

Basic Specifications.......................................................................................................................................4

General........................................................................................................................................................4

Power and Utility Requirements .................................................................................................................5

Environmental Requirements......................................................................................................................5

Pending Approvals ......................................................................................................................................6

Parameter Defaults......................................................................................................................................6

CHAPTER 3 INSTALLATION .............................................................................. 7

Unpacking......................................................................................................................................................7

Installing the HI 1756-FC.............................................................................................................................7

Allen-Bradley ControlLogix Pro cesso r o r R emote Rack............................................................................7

A ControlLogix Chassis..............................................................................................................................7

Removing the Module from the Chassis .....................................................................................................8

Installing the Module I/O Connector...........................................................................................................8

Load Cell Wiring Diagrams .........................................................................................................................9

HI 1756 Remote Terminal Assembly (HI 1756-XX-RT)............................................................................9

Hardy HI 215IT Junction Box...................................................................................................................10

CHAPTER 4 CONFIGURATION ........................................................................ 11

Power Check................................................................................................................................................11

LEDS.........................................................................................................................................................11

Setting Up Communications.......................................................................................................................12

Linking the PLC with the HI 1756 FC Feeder Control Module................................................................12

Configuration Output Table Overview.....................................................................................................13

First Word - 0: Command Number...........................................................................................................13

Command Return or Error Codes..............................................................................................................15

●

●

i

Contents

●

●

●

Page 4

Second Word - 1: Format Word ................................................................................................................15

Format Word Decimal Point Parameters...................................................................................................15

Third / Fifth Words - 2, 3, 4: Parameter Number and Value..................................................................16

Parameter 13-18 .........................................................................................................................21 Refills

REC Parameters ........................................................................................................................................

23

Rate Calibration Parameters......................................................................................................................24

Input Table ..................................................................................................................................................25

States (Word 12 of input table).................................................................................................................26

Integrated Technician................................................................................................................................26

CIP Messages............................................................................................................................................27

CHAPTER 5 CALIBRATION.............................................................................. 29

Pre-Calibration Procedures........................................................................................................................29

Electrical Check Procedures ......................................................................................................................29

Load Cell/Point Input/Output Measurements............................................................................................29

Load Check ...............................................................................................................................................30

C2 Calibration.............................................................................................................................................30

C2 Calibration Using Ladder Logic ..........................................................................................................30

Hard Calibration.........................................................................................................................................31

Hard Calibration Ladder Logic Example ..................................................................................................31

CHAPTER 6 TROUBLESHOOTING............................................................... 32

Disassembly and Reassembly Notes, Warnings and Cautions ................................................................32

Weight and Voltage Testing .......................................................................................................................32

IT Test.......................................................................................................................................................33

General Troubleshooting Flow Chart Index.............................................................................................33

A1 - Guidelines for Instabilities on Formerly Operating System..............................................................34

B - Guidelines for Instabilities on Formerly Operating Systems (Cont’d)................................................35

B1 - Guidelines for Instabilities on Formerly Operating Systems (Cont’d)..............................................36

B1 - Guidelines for Instabilities on Formerly Operating Systems (Cont’d)..............................................37

F - Verify Individual Load Cell Millivolt Readings..................................................................................38

Testing an individual load cell signal output requires an IT Summing Junction box or millivolt meter...38

Use the load cell certificate to verify the millivolt per volt (mV/V) rating:..............................................38

G - Calibration Failed................................................................................................................................39

H - Mechanical Inspection ........................................................................................................................40

J - Electrical Inspection.............................................................................................................................41

K - Load Sharing and Load Sensor Checkout...........................................................................................42

Erratic Weight or Rate Control.................................................................................................................43

System and Load Cell Tests........................................................................................................................44

INTEGRATED TECHNICIAN (IT®)......................................................................................................45

Weight and Voltage Test...........................................................................................................................46

●

●

ii

Contents

●

●

●

Page 5

General Policies and Information..............................................................................................................46

Warranty....................................................................................................................................................46

For Further Information Contact ...............................................................................................................47

INDEX ................................................................................................................ 48

iii

●

●

Contents

●

●

●

Page 6

Chapter 1 Overview

● ● ● ● ●

This manual provides users and service personnel wi t h speci fi cat i ons an d p rocedures for

installing, configuring, operating, maintaining, and troub leshooting the Hardy

Instruments HI 1756 FC Rate Controller with WAVERSAVER.®

NOTE WAVERSAVER is a registered trademark of Hardy Instruments, Inc.

To ensure good performance and maximum service life, follow all guidelines described

in this manual. Be sure you understand all cautions, warnings, and safety procedures. If

you find that the information in this manual does not provide the help you need, contact

the HI Customer Service Department at:

Phone: (858) 278-2900

FAX: (858) 278-6700

Web Site: www.hardyinst.com

Support e-mail address: support@hardyinst.com

About Hardy Manuals

An overview of each chapter’s contents is listed below:

Chapter One - Provides an overview of HI 1756 FC capabilities and features

Chapter Two - Provides a overview of HI 1756 FC specific a t i ons

Chapter Three - Describes the steps for installing both the standard and optional HI

1756 FC equipment and the HI 215IT series junction box

Chapter Four - Explains how to configure the HI 1756 FC

Chapter Five - Provides calibration instructions

Chapter Six – Provides troubleshooting procedures for repair of the HI 1756 FC

HI 1756 FC Overview

The HI 1756-FC module is a self-contained, microprocessor-based ControlLogix I/O

module. Its control inputs and outputs will easily plug into the backplane of an AllenBradley ControlLogix programmable controller and/or remote rack. The remote rack

module is connected to the local chassis via a ControlNet link.

The analog-to-digital converter in the weigh module controller updates 100 times per

second and is capable of 8,388,608 counts of resolution. This allows the instrument to

tolerate large “dead” loads, over sizing of load cells/sensors, and still have sufficient

resolution to provide accurate weight measurement and control.

The module supports both C2 electronic calibration and hard calibration (i.e., traditional

calibration with weights).

The HI 1756 FC is a loss-in-weight controller that measures the flow rate from a feeding

device located on a process weighing scale. The user enters the flow parameters, and an

HI 1756 FC algorithm automatically calculates and adjusts the tuning parameters needed

to maintain the desired rate. After comparing the desired flow rate to the actual flow rate

(measured by calculating the loss of weight over short intervals), it computes the

adjustments needed to achieve the desired rate and transmits signals to adjust the speed of

the feeding device.

●

●

1

Chapter 1

●

●

●

Page 7

NOTE

While the system rate calibration can fine tune the flow-rate parameters automatically,

you can also make manual adjustments.

Typical Applications

Closed-loop rate control can be used in a variety of material-flow applications, such as

auger, belt, and vibration-based feeders, converting them from volumetric to gravimetric.

The Feeder Controller controls a single-ingredient, si n gle -feeder. It can be operated in

batch, automatic, or manual mode.

Features and Capabilities

C2® Calibration

Traditional calibration uses certified test weights. C2® Electronic Calibration allows a

scale to be calibrated without the need for test weights. A C2® weighing system consists

of up to eight load cell sensors, a junction box, interconnect cable, and an instrument with

C2® capabilities (e.g., the HI 1756 FC). Each Hardy Instruments C2-certified load sensor

outputs digital information used for calculating the calibration. When the HI 1756 FC

reads the signals from the load sensors, it calibrates the scale based on the load sensor’s

output plus a user-supplied reference point value (from 0 to any known weight on the

scale).

NOTE C2® is registered trademarks of Hardy Instruments Inc.

WAVERSAVER®

n measuring small weight changes, the affects of mechanical vibration and noise

Whe

from the feeders and plant environment can introduce substantial interference.

WAVERSAVER factors out vibration, noise, and other interference-related si gnals fr o m

the load cell so the rate controller can better decipher the actual weight data.

While WAVERSAVER can factor out noise with frequencies as low as 0.25 Hz, five cutoff frequencies can be selected, with higher fre que nci e s pr oviding a faster response time.

The default factory setting is 1 Hz vibration frequency immunity.

Alarms

o HI 1756 FC alarms flag deviations from your specified flow rate.

Tw

The Rate Tolerance Alarm can alert you concerning flow-rate changes. It can be set to

trigger an alarm bit which, if sent to a PLC, can be used to respond (e.g., sound an alarm)

when the flow rate is above or below the tolerance range you select for a time that

exceeds a limit you set.

The Rate Exception Control (REC) Alarm is triggered by an out-of-tolerance flow rate

a guard band tolerance in conjunction with the Rate Tolerance Alarm. The REC sets

using

statusword bits that can flag a low or high rate. These signals can be used to either send

an alarm or shut down the feeder system. During an REC alarm state that has not resulted

in shutdown, the controller will continue to maintain the flow rate while monitoring the

loss in weight until the rate is within tolerance.

Integrated Technician™

e HI 1756 FC Integrated Technician™ (IT®), which requires an HI 215IT series

Th

junction box, provides built-in system diagnostics that makes it possible to diagnose

weighing system problems. IT allows the reading of individual load sensor voltages and

weights and isolates individual system components for quick and easy troubleshooting.

Digital Volt Meter (DVM) - Option

DVM re

quires the HI 215IT Series Junction Box to monitor mV/V readings for each load

sensor and the total system. When the operator detects a problem, the DVM readings help

●

●

2

Chapter 1

●

●

●

Page 8

to isolate the faulty component. Further, the DVM readings can be used to level a system

and to make corner adjustments to platform scales. Accuracy is +/- 2% or better of full

scale.

NOTE If you do not have the HI 215IT Junction Box connected to the module, the mV/V reading

is the total for all load cells on the system.

Weighing System Tests - Optional

is test is used to diagnose drifting or unstable weight reading problems. It requires the

Th

HI 215IT Series Junction Box for full utilization. The ability to read the weight seen by

the individual load sensors allows you to use this test for making cornering, lev eling and

load sharing adjustments to the weighing system.

The Weighing System Test provides the following problem detection support:

1. Disconnects the controller and engages an internal reference signal to see if the

problem is inside of the instrument.

2. Disconnects the load sensors and engages an internal (in the junction box)

reference signal to see if the cable between the instrument and the Junction Box

is causing the problem.

3. Reads the weight of each load sensor to see if the load sensor might be causing

the problem.

Automatic or Manual Co ntrol Modes

omatic mode corrects for variations in desired flow rates automatically.

Aut

Continuous or Batch Modes

ser selectable operating modes provide support for continu ous or batch processing.

U

Automatic or Manual Refill

tomatic refill uses user-selectable refill points to start and stop the refill process

Au

without interrupting the feed process. HI and LO alarms are used to detect a refill failure.

The Manual Refill option only allows for manual refill at any time.

Two and Five-Point Automatic Rate Calibration

e 5-point auto rate calibration creates a high feed accuracy for a wide range of feed

Th

rates. It either provides the user with automatically calculated parameters, or it lets users

manually enter their own derived values.

●

●

3

Chapter 1

●

●

●

Page 9

Chapter 2 Specifications

● ● ● ● ●

Chapter 2 provides specifications for the HI 1756 FC feeder controller and other

equipment that may come with the package. The specifications listed are designed to

assist in the installation, operation and troubleshooting of the in strument. All service

personnel should be familiar with this section before installing or repairing the

instrument.

Basic Specifications

General

Resolution

Internal:1:8,388,608

Input

Up to

eight 350-ohm Full Wheatstone Bridge, Strain Gauge Load Sensor/Cells (5 volt

excitation) on one vessel.

Non-Linearity

0.0015%

of Full Scale

Common-Mode Rejection

11

0dB at or below 60 Hz

Common-Mode Voltage Range

2.

5VDC maximum (with respect to earth ground)

Backplane Input Voltage/ Power Load

5 VDC

Backplane Current Load

<1

0.0125 Amps at 24 VDC (with 4-350 Ohm Load Cells)

Backplane Power Load

< 5W at

< .3W at 24 VDC with 4-350 Ohm Load Cells

C2 Calibration Input

Isol

Cable lengths

1

250 feet maximum of C2 authorized cable (Maximum of 4 load sensors) with IT Junction

box.

and 24 VDC

Amp at 5 VDC

5 VDC

ation from digital section 1000 VDC minimum.

000 feet maximum of C2 authorized cable

C2® Maximum Cable Length

●

●

4

Chapter 2

●

●

●

Page 10

000’ for C2, Non C2, or JB Card

1

250’ for IT

Load Cell Excitation

5 VDC

+/- 1.15 W maximum.

Isolation from digital section 100 0 VDC minimum

C2 Calibration Output

ation from digital section 1000 VDC minimum

Isol

Number of Channels

hannel

1 C

Update Rate

10

0 Updates per Second (10 ms)

Averages

1-255 Use

r-selectable in Single Increments

WAVERSAVER®

User Selectabl

e

OFF

7.50 Hz

3.50 Hz

1.00 Hz (Default)

0.50 Hz

0.25 Hz

Digital Voltmeter (IT)

Accuracy ± 2% of

full scale

Power and Utility Requirements

Voltage

24 VDC (Standard)

100/240 VAC Universal (Optional )

Frequency

63 Hz

47/

Power

10

Watts maximum with options

Environmental Requirements

Digital Voltmeter

Accuracy +/- 2% of full scale

Operating Temperature Range

0

to 60º C (32º F to 140º F)

●

●

5

Chapter 2

●

●

●

Temperature Coefficient

Page 11

Less than 0.005% of full scale per degree C for Cal-LO and Cal-HI reference points

Storage Temperature Range

-4

0 to 85º C (-40 to 185º F)

Humidity Range

0

-90% (non-condensing)

Pending Approvals

UL, CUL, and CE

Parameter Defaults

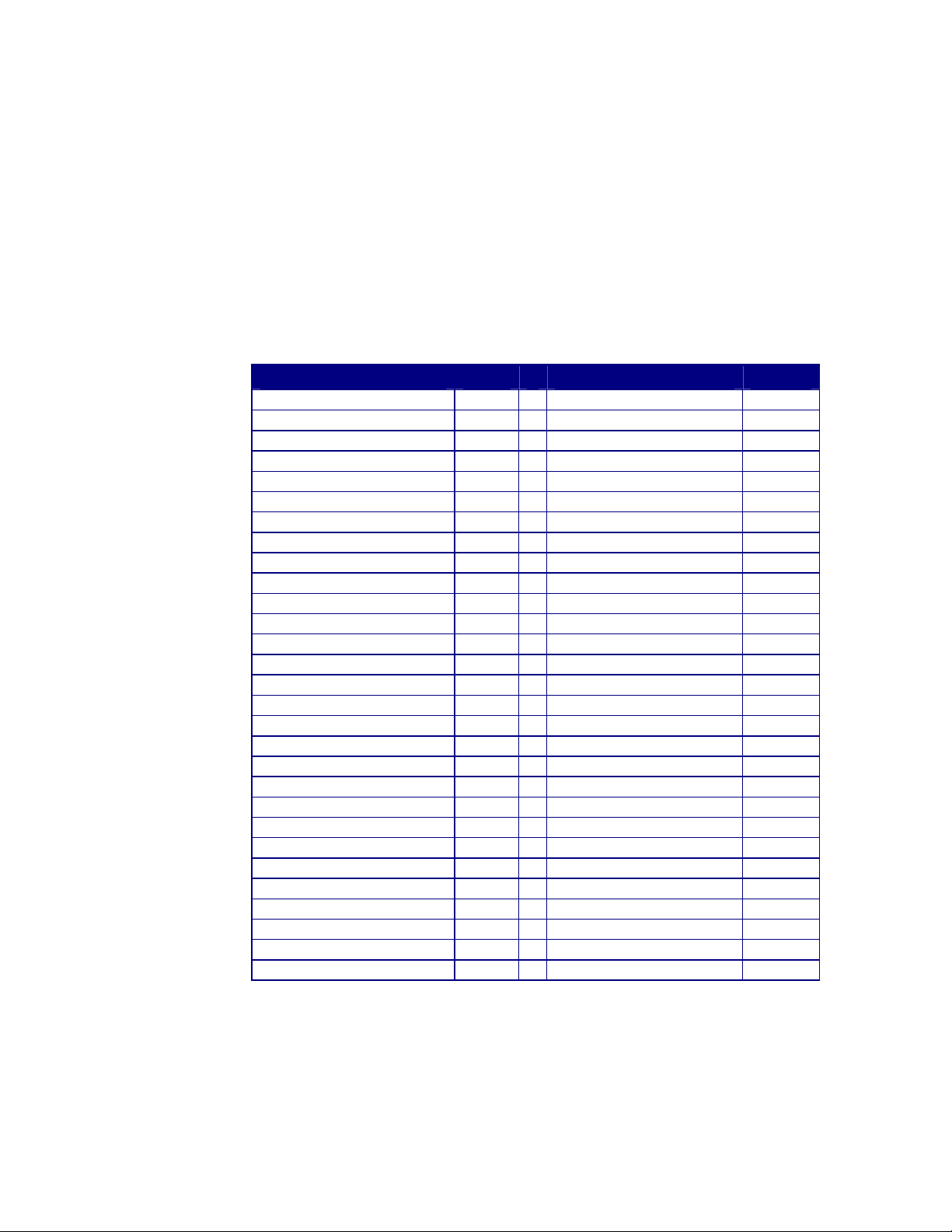

Parameters Default Parameters Default

Chan Active 1 Total

Metric 0 Batch Total 0

span weight 100 Low Alarm Shut Down Rate 0

cal low weight 0 High Alarm Shut Down Rate 100

ROC time base 4 Alarm Delay 100

ROC time units 1 Rate Setpoint 0

Averages 1 REC P Limit 10

WAVERSAVER 3

PID_P 50

PID_I 20

batch amount 10

Preact 0

Mode 0

Prime Time 0

Pause Time 0

Feed time 40

Initial Refill on 0

Auto Refill On 0

Refill Start Weight 10

Refill End Weight 100

Refill Too High Weight 100000

Refill Shut Down Weight 0

Refill Op Adjust 0

Refill Op Adjust Percent 0

Wait Time 0

REC Level 20

REC Time 60

REC Shutdown

Shutoff Low Percent

0.0

0.0

7 Rate Cal Rates

0 percent

1st percent

2nd percent

3rd percent

4th percent

5th percent

100 percent

7 Rate Cal Percentages

0 Percent

1st Percent

2nd Percent

3rd Percent

4th Percent

5th Percent

100 Percent

ADC Average

MANUALOP

FAST_ROC

Zerocount

CalLowCount

0.0

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

None

none

●

●

6

Chapter 2

●

●

●

Page 12

Chapter 3 Installation

● ● ● ● ●

Chapter 3 covers unpacking, cabling, interconnecting, configuring, and installing the

Weigh Scale Module. User and service personnel should r ead this chapter before

installing or operating the Weigh Scale module.

Unpacking

Step 1. Before signing the packing slip, inspect the packing and contents for damage of

any kind. Report any damage to the carrier company immediately.

Step 2. Verify that everything in the package matches the bill of lading.

Step 3. Write down the Model and Serial number of the module. Store this information

in a convenient location for reference when contacting The Custo mer Support

Department for parts or service.

Step 4. Be sure to complete the warranty registration on the Hardy web site.

Installing the HI 1756-FC

Allen-Bradley ControlLogix Processor or Remote Rack

WARNING Electrostatic discharge may damage semiconductor components in the module. DO NOT

TOUCH THE CONNECTOR PINS, and obse rve the foll owing handling precautions:

Wear an approved wrist-strap grounding device when handling the module.

Touch a grounded object or surface to rid yourself of any electrostatic

discharged prior to handling the module.

Handle the module from the bezel in front away from the connector. Do not

touch the connector pins.

Do not install the module right next to an AC or high voltage DC module.

Route all the load voltage cables away from high voltage cables.

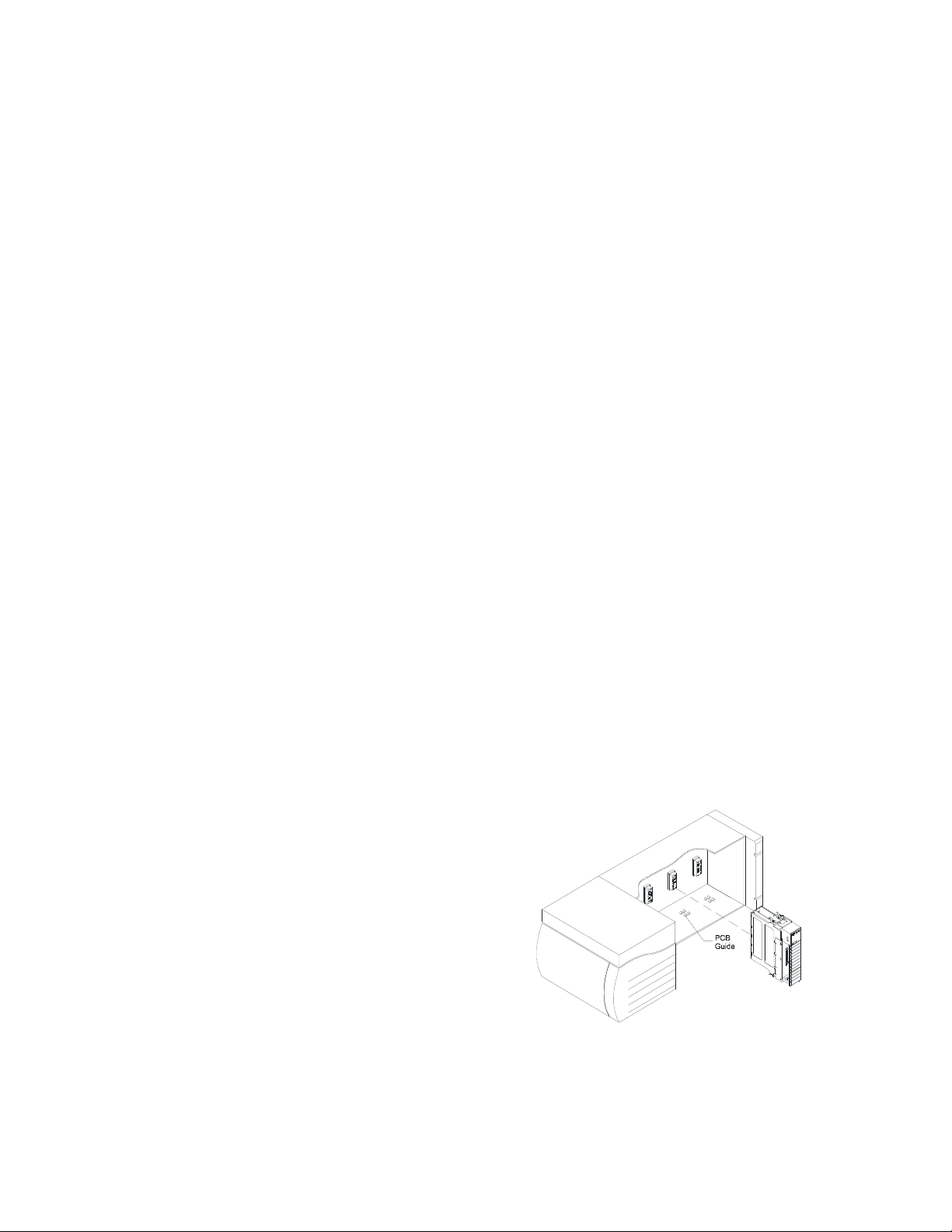

A ControlLogix Chassis

Step 1. Make sure that the module is

oriented correctly for

installation.

Step 2. Gently slide the module into the

Chassis.

Step 3. Slide the digital board between

the PCB Guides on the top plate

and bottom plate of the chassis

to line up the module connector

with the backplane connector

Inserting the module

●

●

7

Chapter 3

●

●

●

Page 13

Step 4. W

hen the module connector is touching the backplane connector, firmly but

carefully push toward the chassis until the pins are plugged in and the top and

bottom module releases are snapped into place.

Module release(s)

Module installed in chassis

Removing the Module from the Chassis

Step 1. Press down on the top and bottom module releases simultaneously until the

module can be pulled away from the chassis. (See Figure above.)

Step 2. Pull the module out of the chassis.

Step 3. Store in a safe, secure location in an anti-static bag or the original enclosure.

Installing the Module I/O Connector

The I/O connector at the front of the module

connects the module to the Remote Terminal

Assembly (-RTA), a load sensor, or the HI

215IT Series Junction Box, depending on

how many load sensors are installed in the

weighing system. (See the pin-out diagram

below.) A pin-out diagram is also located on

the inside of the module door.

Step 1. Open the module door to access to

the I/O connector.

Step 2. Install the cable and connector so it

allows the module door to be shut.

Step 3. With the plug oriented correctly

(See the pin-out diagram below),

plug the I/O male connector into the

I/O connector at the front of the

module.

Note When the door is open, the button you see on the top right has no function.

HI 1756 FC with door open

Check to be sure that the connector is completely

Single Channel

Pin 1 Exc+

●

●

8

Chapter 3

●

●

●

Page 14

plugged in before operating the module.

NOTE Most module-related problems are due to loose

connections. Be sure to check the I/O connection first

in the event you have a problem receiving information

from the load cells or if the relays do not operate

correctly.

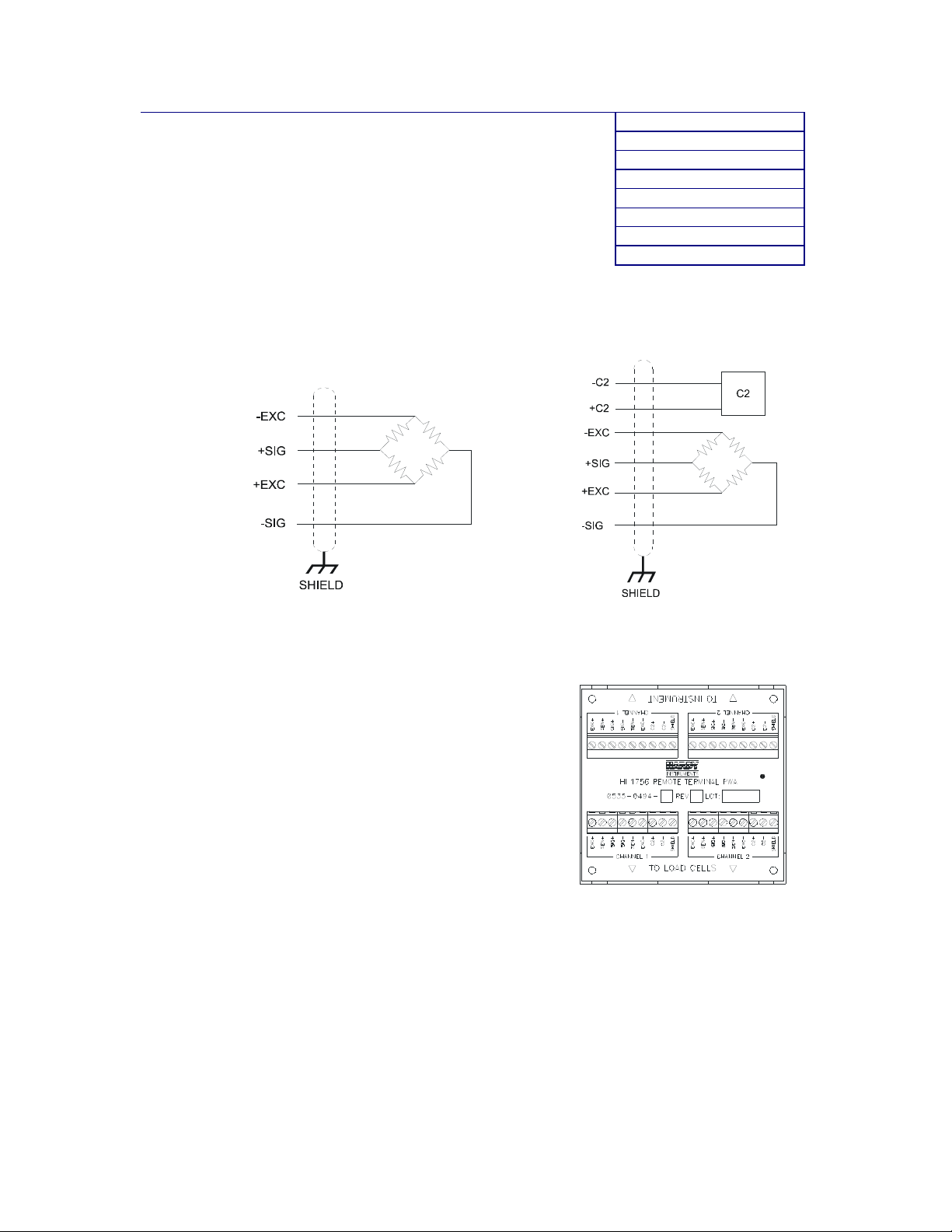

Load Cell Wiring Diagrams

The diagrams below show how Hardy Load Sensor with C2 wiring differs from standard

Load Cell wiring.

n 2 Sense+

Pi

Pin 3 Sig+

Pin 4 SigPin 5 SensePin 6 ExcPin 7 C2+

Pin 8 C2Pin 9 Shield

Industry standard load cells wiring

Hardy load sensor/c2 wiring

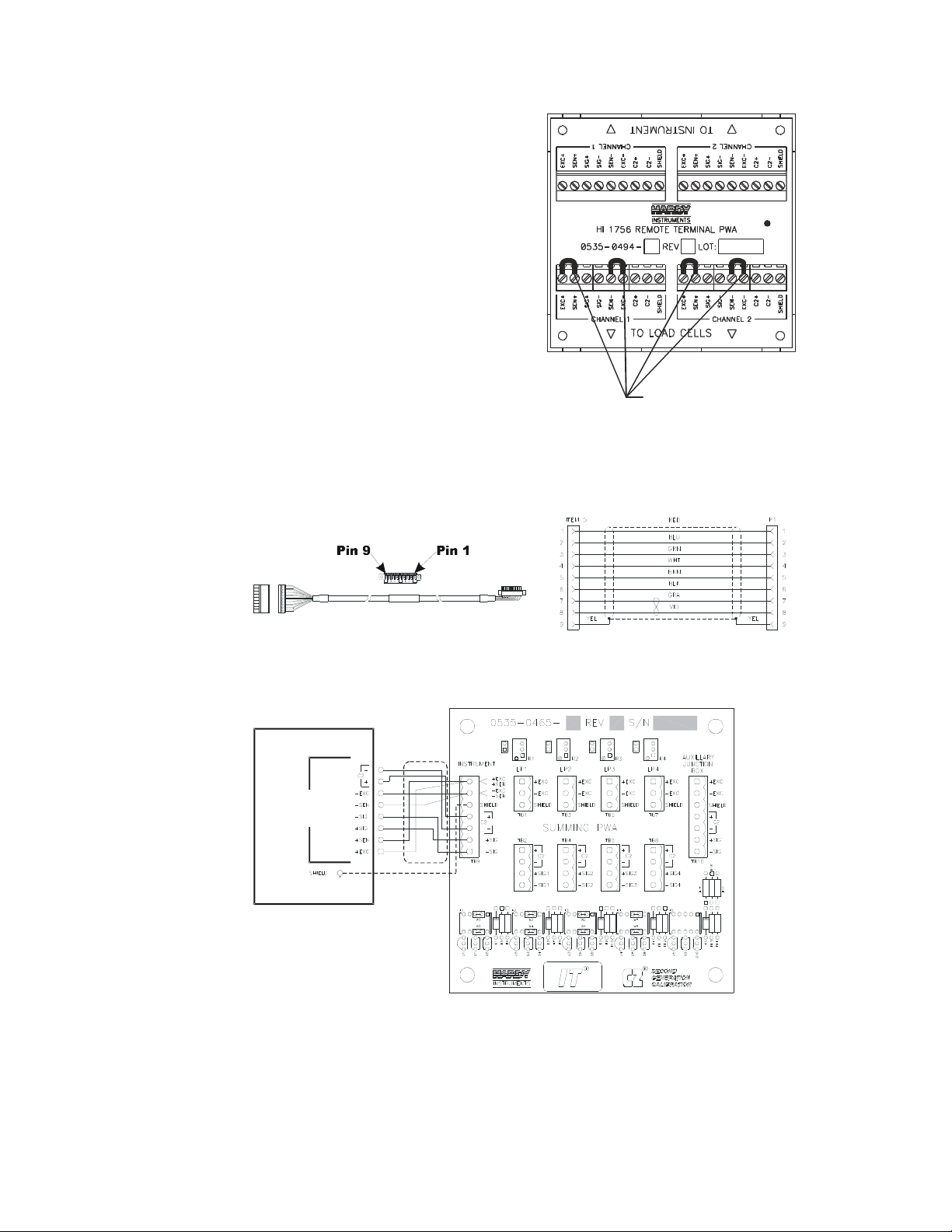

HI 1756 Remote Terminal Assembly (HI 1756-XX-RT)

The Remote Terminal Assembly (RTA)

provides connection points between the cable

assembly from the HI 1756 FC module and

the individual wires from the junction

box(es) or load sensor(s). The RTA comes

with a standard 35 mm Din Rail Mounting

and requires at least a 5” inch long DIN rail

for mounting.

Remote terminal assembly

●

●

9

Chapter 3

●

●

●

Page 15

You must have sense jumpers or sense

lines installed to properly reference the

excitation voltage. To properly reference

a C2 calibration, run sense lines and

remove the sense jumper.

NOTE When using load cells that do not have

sense lines, you will need to jumper the

Sense (-) to the Excitation (-) and the

Sense (+) to the Excitation (+) for one or

both channels.

RTA Cable Assembly and Jumpers

x-foot cable connects to the HI 1756 FC module.

A si

RTA cable assembly - HI 1756WS

Hardy HI 215IT Junction Box

1756 FC

Load

Cell

Connector

J1

Jumpers

RTA with jumpers for load cells without

sense lines

RTA cable schematic

Hardy HI 215IT Junction Box Wiring Diagram

NOTE When connecting the Hardy HI 215IT Junction Box, you must remove the two fa ctory

installed jumpers 1&2 and 5&6 on the module and install sense lines.

●

●

10

Chapter 3

●

●

●

Page 16

Chapter 4 Configuration

● ● ● ● ●

Chapter 4 covers the settings used to prepare the controller for calibration and operation.

The Setup procedures require Allen-Bradl ey’s RS Logix 5000, Allen-Bradley RSLi nx ™

or RSLinx™ Lite.

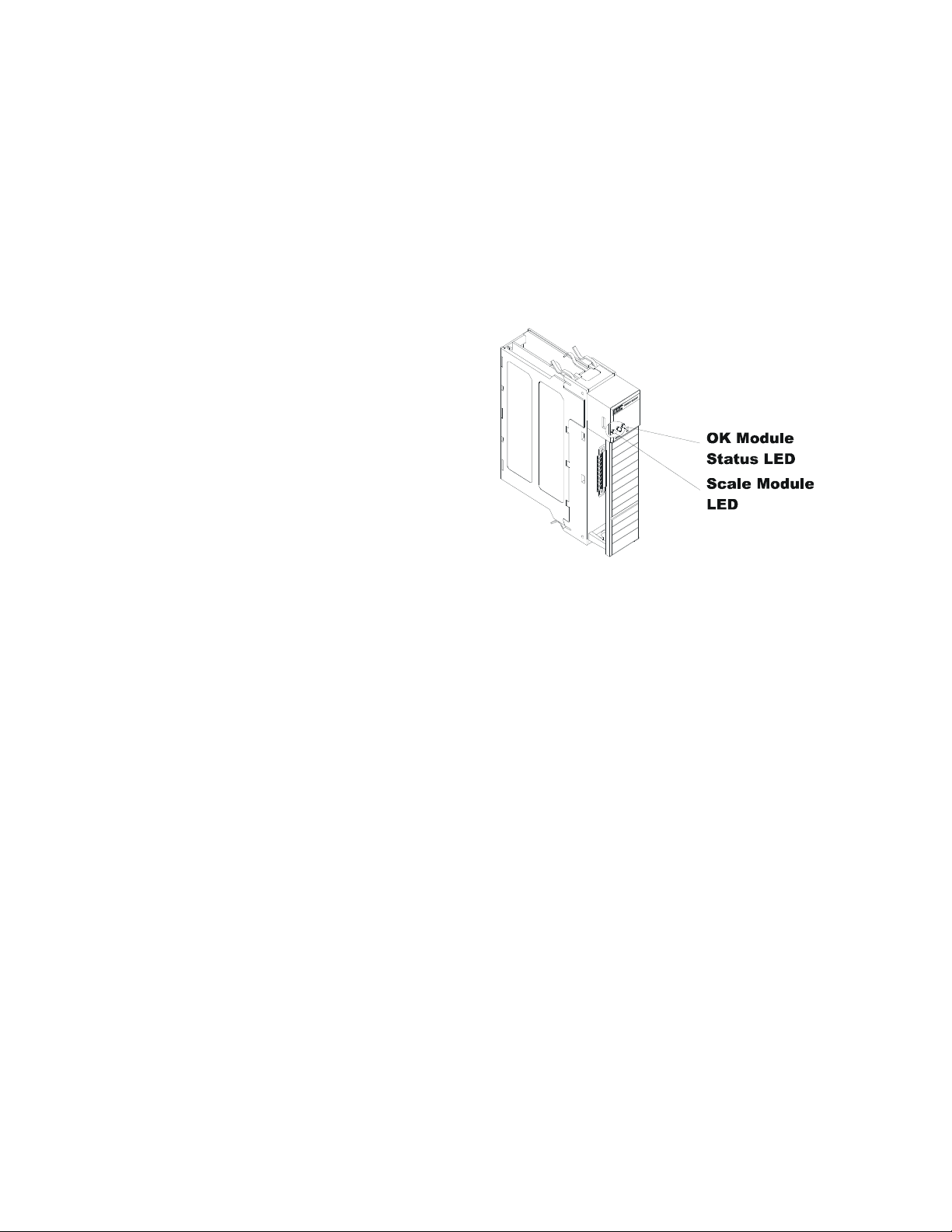

Power Check

To make or change settings, there

must be power to both the PLC and

the module. Verify that the LEDs

are lit for normal operation.

Module LEDs

LEDS

Scale Data LEDs

Flashing Green

Steady Green Running (Normal)

Steady Red Error Read Failure or Error eeprom write. Contact HI

Flashing Red Read Convert Error.

LED is Off Channel is Inactive

OK Module Status LED

Brief Steady During power up the LED lights Red for about one second.

Flashing Green In Program mode. (Normal)

Steady Green In Run Mode. (Normal)

Steady Red Config. Fault The eeprom checksum failed - bad serial

(Backplane Available) data or blank serial eeprom. Contact HI Customer Support.

Steady Red Internal Hardware watchdog timer fault (e.g. bad Hardware

Flashing Red Communication Error.

Feeder is on

Customer Support

eeprom

or Firmware). ASIC is non-operational.

11

●

●

Chapter 4

●

●

●

Page 17

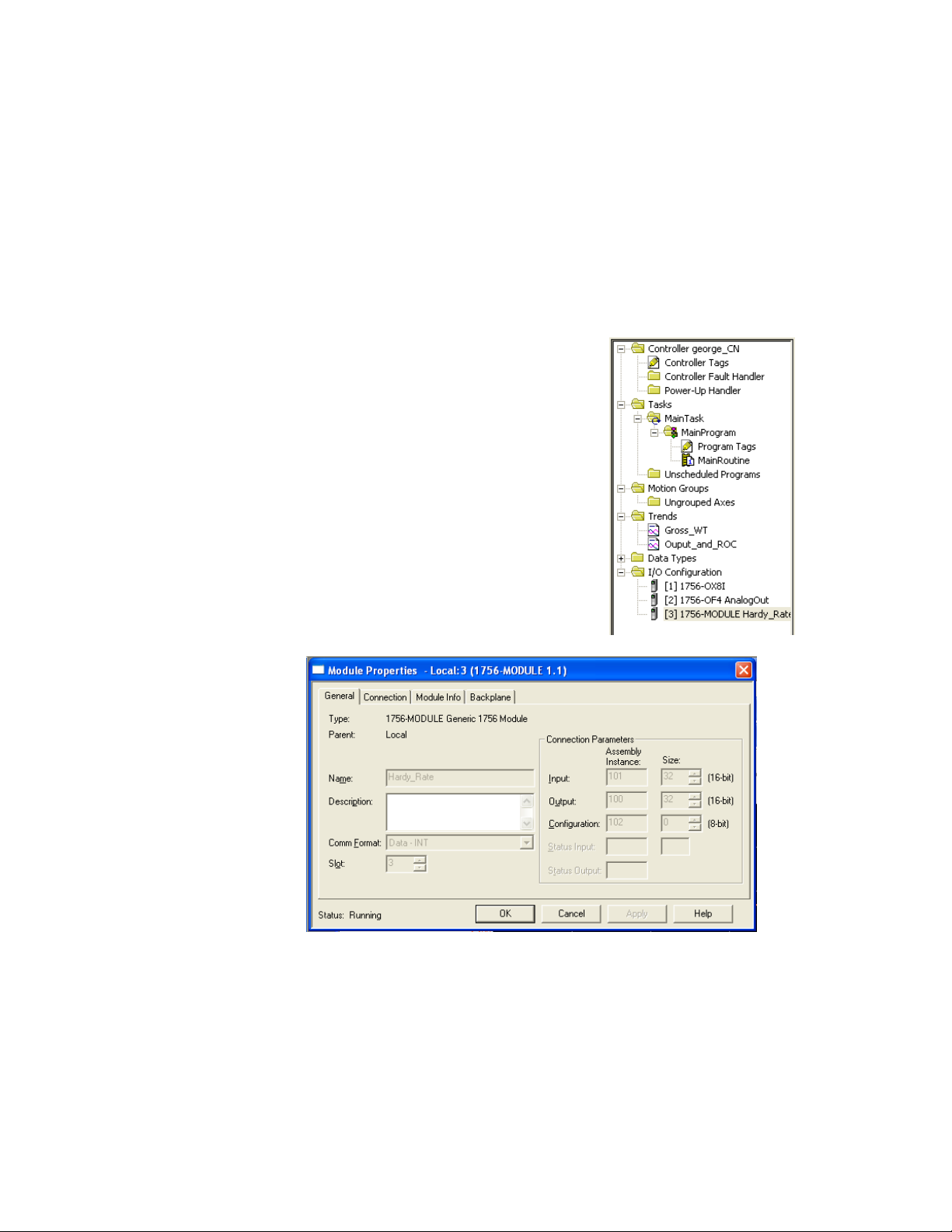

Setting Up Communications

Linking the PLC with the HI 1756 FC Feeder Control Module

To set parameters for the weigh scale module, you must establish communications with a

ControlLogix PLC. Follow the steps below to set up the communication link. You will

need a new or open RS Logix® 5000 project. For instructions, see your RS LOGIX 5000

manual.

Step 1. Look for a list of folders on the left side of the screen. Scroll to and select the

I/O Config folder, which will open a menu.

Step 2. Select New Module to display a list of modules.

Step 3. Select the Generic 1756 module to open the

Module Properties form.

Step 4. Enter the following connection parameters in

the appropriate fields:

Name of Module

Description of Module (Optional)

Slot ID

Input Assembly Instance:101 Size = 32

Output Assembly Instance: 100 Size = 32

Configuration Assembly Instance: 102

Size = 200

Step 5. Select DATA INT from the Comm Format

pull-down list.

Module Properties Dialog Showing General tab

Step 6. Open the Connection Tab.

Step 7. Set the RPI to 20 milliseconds or greater. Do not set this parameter lower than

20 milliseconds.

12

●

●

Chapter 4

●

●

●

Step 8. Click Finish.

Page 18

Configuration Output Table Overview

To configure the module, you send commands via the PLC output table.

The 1756 module uses 32 16-bit INT words in and out. Only 5 words of the output table

are normally used. (Command 0X5E uses ten and 0X5F uses seven)

Word Command structure write

0 Command number

1 Format word (see Format Word below)

2 Value (LSW)

3 Value (MSW)

4 Parameter ID

Param

eters can be read (READPARAM) or written (WRITEPARAM) one at a time:

To read a parameter, put the readparam command number in word 0, the format

word in word 1, and the parameter’s number in word 2 of the output table.

To write a parameter, put the writeparam command number in word 0, the

format word in word 1, and the parameter’s value in words 3 and 4 of the output

table.

First Word - 0: Command Number

The first word in the output table is a command. The possible commands are:

Command # Hex Description

13

●

●

Chapter 4

●

●

●

NOCMD

STARTCMD

STOPCMD

REFILLCMD

WRITENONVOLATILE

MANUALCMD

ABORTCMD

RELOADNONVOLATILE

RATE_CAL_5_POINTS_

DEFINED

RATE_CAL_2_POINTS_

DEFINED

0

1

2

3

4

5

6

0x10

0x5E

0x5F

No command

START

STOP

REFILL

Saves all parameters (including calibration

constants) to the non-volatile memory. Error Return

Values: None

Enters manual mode

Stop, go straight to IDLE mode

Causes the weigh module to re-read the values

stored in its non-volatile memory. Parameters

changed since the last write non-volatile command

are overwritten. Can be used to abort a calibration

or parameter entry session. No error return values.

Runs the 5-point rate calibration at percentage

outputs defined at words 2-6. The percentages have

0 decimal places. They must be > 0, < 100, and in

ascending order, with a minimum of 10 between

them.

Runs the 2-point rate calibration at percentage

outputs defined at words 2-3. The percentages have

0 decimal places, and must be > 0, < 100, and in

ascending order, with a minimum of 10 between

them. This calibration operates at points 2 and 4 of

Page 19

int rate calibration. The other points are filled

a 5-po

with data based on these 2 points.

RATE_CAL_5POINT_CMD

0x60

Runs the 5-point rate calibration at whatever points

have previously been defined.

RATE_CAL_2POINT_CMD

0x61

Runs the 2-point rate calibration at whatever points

have previously been defined.

CALLOWCMD

0x64

Sets the “calLowCount” parameter to the current

A/D average counts when doing a hard calibration.

Calls an Integrated Technician function during low

calibration.

Error Return Values:

STATUSWORD - There was a conversion error or

A/D conversion failure.

HARDCALFAILCOUNTS - There are less than

1000 counts between the zero and the span weights.

CALHIGHCMD

0x65

Sets the Span Weight parameter to the current A/D

average counts when doing Hard CAL.

Error Return Values:

STATUSWORD - There was a conversion error or

A/D conversion failure.

HARDCALFAILCOUNTS - There are less than

1000 counts between the zero and the span weights.

C2CALCMD

0x66

Performs a C2 Calibration. Uses CalLowWeight as

the reference point.

Error Return Values:

STATUSWORD - There was a conversion error or

A/D conversion failure.

C2FAILNODEVS – Detected no C2 load cells.

C2FAILCAPEQ - Detected two load cells with

different capacities.

WRITEPARAM

0x67

Writes the parameters. See Parameter Table

below.

Return Data:

COMMAND STATUS - The status is 0 if the

command succeeded. If a range error was detected

in one of the parameters, a non-zero value is

returned indicating which parameter failed its range.

See Status Table below.

READPARAM

0x69

Reads the parameters. See Parameter Table

below.

Return Data:

COMMAND STATUS See Status Table below.

PARAMETERS

SETDEFAULTPARAMS

0x94

Loads the default settings into RAM, and nonvolatile RAM. Error Return Values: None

14

●

●

Chapter 4

●

●

●

Page 20

Command Return or Error Codes

Commands always return the command word and command status. The command status

word may include the following codes:

Return Codes # Hex Description

SUCCESS 0 Pass

OUTOFTOLERANCE -3 Out of tolerance

INDEXOUTOFRANGE -4 Out of range

NOSUCHCMD -5 Command bad

C2FAILNODEVS -6 No C2 devices

C2FAILCAPEQ -7 Failure, C2 capacities not equal

HARDCALFAILCOUNTS -8 Fails, too few ADC counts between high - low

NOSUCHPARAM -9 Parameter ID incorrect

Second Word - 1: Format Word

Format Word Decimal Point Parameters

Word 1 is the format word. The decimal point parameters, which are set via the format

word, indicate the location of the decimal point within the values to follow (i.e., how

many decimal places the integer values in the input and output tables have). The higher

the number, the farther to the left the decimal point moves and the more precisely the rate

is displayed. However, setting the decimal point far to the left does not ensure that the

measuring device will be accurate enough to distinguish the requested level of precision

from interference factors.

While the decimal point values for total, weight, and rate are separate, each has four bits

in the format word. The maximum decimal place value is 7.

Formatword uses hex format 0000xxxxyyyyzzzz, where 0000 is not used at this time,

xxxx = total DP, yyyy = Weight DP, and zzzz = Rate DP. The DP values position the

decimal point within the number.

0x0123 means TOTAL decimal places is 1, WEIGHT decimal places is 2, RATE decimal

places is 3. For example, writing the value 0x0123 in the format word sets the total

decimal place value, which is used for the TOTAL and BATCH TOTAL values to 1. It

sets the weight decimal place, which is used for the gross weight, to 2, and it sets the rate

decimal place, which is used for the rate of change (ROC) values to 3.

Total Decimal Point (xxxx)

e Total Decimal Point parameter sets the location of the decimal point within the

Th

Totalizer value, which is based on the selected unit of measure.

Range: 0-7 (default 1) In most applications a decimal setting of 0 or 1 is recommended.

Weight Decimal Point (yyyy)

e Weight Decimal Point parameter to indicate the location of the decimal point

Set th

within the weight values, which are based on the selected unit of measure.

Range: 0-7 (default 2)

Rate Decimal Point (zzzz)

e Rate Decimal Point Parameter sets the location of the decimal point within the Flow

Th

Rate value.

15

●

●

Chapter 4

●

●

●

ange: 0-7 (no default)

R

Page 21

Third / Fifth Words - 2, 3, 4: Parameter Number and Value

The third and fourth words in the output table, Parameter Value, are used by the

WRITEPARAM command. The fifth word is the parameter ID, used by the

WRITEPARAM and READPARAM commands. Parameter values are written with the

least significant word first and one 32-bit integer per parameter. For details see the

Parameter Table below. Expanded descriptions are listed below the table by hex number.

All parameters are DINT.

There are 14 spare parameters for possible future use.

Notes When set by a command, all parameters except the rate setpoint are saved to non-volatile

memory. Both rate and scale calibrations are saved automatically when completed

successfully. Totals are not saved automatically when changed, and will be lost if no

WRITENONVOLATILE command is executed before power down.

The section above “Format Word Decimal Point Parameters” explains Weight DP, Rate

DP, and Total DP, which appear in the chart below.

16

●

●

Chapter 4

●

●

●

Parameters

#hex

/sub#

Brief Description (Note: Expanded descriptions are listed

below the chart by hexadecimal number)

Chan Active 1 0-1 flag, determines if a channel is alive.

Metric 2 0-1. Report Weight In. Units of measure listed below

span weight 3 Calibration weight, high. Must be >0. Weight DP.

cal low weight 4 Calibration weight, low. Must be > or = 0. Weight DP.

ROC time base 5 In seconds, 0 decimal places. 1-1800 seconds.

ROC time units 6 0=sec,1=min,2=hr

NumAverages 7 Dint. 1-255. Default = 1

WAVERSAVER 8 0-5 See 8 below

PID_P 9 1 decimal places.

PID_I A 1 decimal places.

Batch amount B Weight DP. Must be > or = zero.

Preact C Weight DP. No limits.

Mode D 15 // 0=continuous or 1=batch.

Prime Time E seconds, 0 decimal places.

Pause Time F seconds, 0 decimal places.

feed time 10 seconds, 0 decimal places.

Initial Refill on 11 0 = no, 1 = yes

Auto Refill On 12 0=off, 1=on

Refill Start

Weight 13 Weight DP. No limits

Refill End

Weight 14 Weight DP. No limits

Refill Too High

Weight 15 Weight DP. No limits.

Refill Shut

Down Weight 16 Weight DP. No limits.

Op Adjust 17 0=off,1= learning, 2= fixed.

Op Adjust % 18 6 decimal places.

Wait Time 19 Seconds, 0 decimal places. Must be > or = 0

Page 22

EC Level 1A 1 decimal place. Must be > or = 0.

R

REC Time 1B Seconds, 0 decimal places. Must be > or = 0

REC Shutdown 1C 0=no, 1=yes

Shutoff Percent 1D 0 decimal places. 0-100

Total 1E Total DP

Batch Total 1 F Total DP. Must be > or = 0

Low Alarm Shut

Down Rate 20 Rate DP. No limits

High Alarm Shut

Down Rate 21 Rate DP. No limits

Alarm Delay 22 Seconds, 0 decimal places. Must be > or = 0.

Rate Setpoint 23 Rate DP. Must be > or = 0, < MAX RATE.

Rate Calibration Parameters See Rate Calibration Parameters section below

REC_P_Limit 1 decimal place. Must be > 0 and < or = 100.0.

7 Rate Cal Rates (xx32) 7 rate calibration rates. All are R DP > or = 0.

0 rate 0032 0x0032 is the minimum rate

1st rate 1032 0x1032 is the next stepped rate

2nd rate 2032 0x2032 is the next stepped rate

3rd rate 3032 0x3032 is the next stepped rate

4th rate 4032 0x4032 is the next stepped rate

5th rate 5032 0x5032 is the next stepped rate

100 rate 6032 0x6032 is the MAX RATE

7 Rate Cal

Percentages

(xx33) // 7 rate calibration percents. Uses 2 decimal places. 0.00-100.00

0 Percent 0033 0x0033 is the minimum %

1st Percent 1033 0x1033 is the next stepped %

2nd Percent 2033 0x2033 is the next stepped %

3rd Percent 3033 0x3033 is the next stepped %

4th Percent 4033 0x4033 is the next stepped %

5th Percent 5033 0x5033 is the next stepped %

100 Percent 6033 0x6033 is the MAX %

End Rate Cal section

ADC Average 34 0x0034 // Read Only

STATE 35 0x0035 // read only – see mode list below

Bit 0 Idle Mode

Bit 1 Auto Mode

Bit 2 Manual Mode

Bit 3 Start Mode

Bit 4 Stop Mode

Bit 5 Shut Off Mode

Bit 6 Pause Mode

Bit 7 Rate Cal Mode

Bit 8 Refill Mode

Bit 9 Full Mode

Bit 10 Manual Hold Mode

Bit 11 Rate Cal Hold Mode

17

●

●

Chapter 4

●

●

●

Page 23

Bit 12 Initial Refill Mode

Two decimal places. This it the output percent when in

MANUALOP 37

FAST_ROC 38

zerocount 0x0A00 AD counts at zero weight

calLowCount 0x0A01

mbers or letters in the titles below correspond to the values in Column 2, Hex#, above

Nu

MANUAL mode.

Lightly averaged rate of change, read only, RATE decimal

places.

Parameter 2 Metric (Unit of Measure)

e Unit parameter sets the scale and related displays to one of the following options:

Th

Pounds (lb) - Default

Ounces (oz)

Ton (ton) short ton

Kilograms (kg)

Grams (g)

Metric Tonnes (t) long ton

Range: LB, OZ, TON, KG, G, T (default LB)

Any weight value input to the module (e.g. CALLOWWEIGHT, SPANWEIGHT) are in

the currently selected unit. The unit of measure can be set at any time, not just at

calibration. Set the metric before calibrating to verify the unit of measure.

Note The weigh scale module does not need to be recalibrated after changing the metric value.

Parameter 3 Span Weight

The

Span Weight is a reference point derived from an actual measured weight. This

should not be confused with the Scale Capacity. If you have a 100 pound weight and you

place it on the scale, the Span Weight would be 100 pounds.

Parameter 4 Cal low weight

s reference weight is the weight of any product on the scale that is not removed during

Thi

calibration (derived from actual measured weight used at cal low or C2 cal). Normally,

you would remove all “live load” weight from the scale to obtain a CalLow Weight of

0.0. The location of the decimal point in this value is based on the Weight decimal point

parameter.

Range: Must be > or = 0.

Parameter 5 ROC time base

e Time Base is the length of time in seconds between two weight readings that are

Th

subtracted to determine the initial flow rate. By increasing the time base, you increase the

time between weight readings. This allows more material to be dispensed during the time

base period. Low flow rates require a longer time base than high flow rates. The

controller measures weight to about 1 part in 10,000. The formula below provides a

minimum. Auto rate calibration uses a minimum of 10 ROC Time p eriods to make the

rate calculation.

TIME BASE > (SCALE CAPACITY/5000)/LOW SETPOINT (units per sec.)

SCALE CAPACITY/5000 = determines minimum weight increment

18

●

●

Chapter 4

●

●

●

Example: (440/5000) = 0.088 lb

e lowest setpoint in units per second @ 3 lb per min is: 3 lb/60 sec = 0.05 lb/sec

Th

Page 24

Thus:

TIM

E BASE = 0.088/0.05

TIME BASE = 1.76 (rounded to 2)

MINIMUM TIME BASE = 2 seconds

Range: In seconds, 0 decimal places. 1-1800 seconds.

Parameter 6 ROC time units

e units of time (seconds, minutes or hours) you want for the Rate of Change. The ROC

Th

display on the summary display will read in these units.

Range: 0=sec, 1=min, 2=hr (default Seconds)

Parameter 7 Averages

s is the number of samples to average when determining a value to reduce the affect

Thi

of material impact and/or vibration as material moves on and off the scale. The Rate

Controller takes 100 readings per second. If you average enough weight readings, the

weight loss or gain remains smooth and the displayed value shows little or no fluctuation,

although it is actually recalculated (by sliding average) with each reading. If a weight

reading fluctuates too much, increase the number of readings in the average, but for

applications that require a very quick weight reading, do not set this value too high.

The averaging parameter is most often set when using any device that outputs an erratic

signal (e.g. a flow meter). Using the averaging function comes at the expense of response

time. A setting of one average takes 10 milliseconds. A setting of 100 averages takes 1

second. The averaging function is a running average, where the input signals are totaled

and the total is divided by the averaging number. The instrument reads one new signal

plus the last number of averages signals and repeats the averaging process again.

19

●

●

Chapter 4

●

●

●

For example: With a setting of 20 averages, the instrument reads the 20 most current

input signals, totals the signals, divides by 20, drops the oldest one, reads one new signal

along with 19 old readings, totals the signals, di vi des by 2 0, d ro ps t he oldest one, etc.

Range: 1-255 (default 1)

See also WAVERSAVER for information on filtering unstable weight readings.

Parameter 8 WAVERSAVER®

apter One provides a detailed description of WAVERSAVER’s function and purpose.

Ch

In short, WAVERSAVER helps to mitigate the effects of vibratory forces, allowing the

HI 1756 FC to distinguish between actual weight data and mechanical noise in the signals

the load cell sends. WAVERSAVER can be configured to ignore noise with frequencies

as low as 0.25 Hz. High values allow faster readings, while the lower values raise the

degree of filtration. 7.5 Hz provides the least vibration immunity with the fastest response

time. 0.25 Hz provides the most vibration immunity with the slowest response time. The

function is user selectable and can be turned off.

Range: OFF, 7.50 Hz, 3.50 Hz, 1.00 Hz (Default), 0.50 Hz, 0.25 Hz

Parameter 9 Rate Calibration Configuration PID P

e P parameter for Rate Calibration. See Chapter 5 for additional instructions on

Th

running Rate Calibration. Rate calibration determines this parameter, so you may not

want to set it. It would be difficult to know what to enter.

P and I

values: Use Rate Calibration to calibrate the system starting flow rate. Rate

calibration establishes the feeder maximum rate, PI settings, and the starting OP% for a

given rate setpoint. From that starting point, the controller adjusts the OP% to maintain

an optimized setpoint. Environment and product conditions require monitoring and

adjustment to meet the requested setpoint target.

Page 25

NOTE

You must calibrate the scale prior to rate calibration.

The PI controller calculates an output percenta ge base d o n the parameters P (proportional)

and I (integral). The rate calibration process can set the values for P and I automatically.

The output percent is determined by the formula:

P*((Setpoint - ActualRate)/MaxRate + I * (integral of the proportional term)).

P and I Must be > or = 0

Parameter A Rate Calibration Configuration PID I

The

I parameter for Rate Calibration. See explanation under Parameter 9 above.

Parameter B Batch amount

batch amount and preact parameters are used when operating in Batch mode. The

The

Batch Amount sets the amount of ingredient in weight units used per batch for the

selected ingredient.

Range: >

0.0 (default 0.0) It is not necessary to enter 0.00 for these parameters) The

decimal point is positioned based on the Weight Decimal parameter for batch amount.

Parameter C Preact

Preact is

used when operating in Batch mode. It is the amount to allow between the batch

amount signal and the time when the feeder actually stops feeding. Where the feeder

slows to a stop, set the preact value so the desired batch amount is dispensed when the

feeder stops completely. The decimal point is positioned based on the Weight Decimal

parameter for preact. No limits.

Range: >0.0 (default 0.0) No limits.

Parameter D Mode

u can operate either in continuous or batch mode depending on the process.

Yo

Range: 0=continuous or 1=bat c h.

Parameter E Prime Time

Th

e time in seconds it takes to get the system up to full flow for the first calibration point.

on the first test OP% run of the rate calibration, the feeder must prime the feeding system

and the feeding system must smoothly feed product at an OP % selected rate.

Range: 1-999 (default 5 sec) Must be > or = 0

Parameter F Pause Time

is is the time you want the feeder to wait between Auto Rate Calibration cycles. If

Th

necessary, more material may be added to the feeder. Note that this parameter should be

set long enough to allow the operator to trigger a "hold" in between feed runs.

We recommend that you make the Pause Time equal to or greater than the Timebase

value you entered for the ROC.

NOTE If a feeder is manually paused before a cycle starts or during a cycle, when the test is

restarted it will run from the beginning.

Parameter 10 Feed Time

Time is the test duration at each rate. Set this to a minimum of 10 X ROC time base.

Feed

Make sure that your feeder hopper holds enough product to complete the high percentage

rate test. You cannot pause or refill during a test phase.

20

●

●

Chapter 4

●

●

●

Must be > 0. Range: 1-999

Page 26

Parameter 13-18 Refills

Automatic Refill uses user-selectable refill points to signal a start or stop of the refill

process without interrupting the feed process. HI and LO alarms can be used to flag a

refill failure.

Manual Refill allows for manual refill at any time. The Manual Refill stops at the Refill

High point.

Initial Refill

itial Refill ensures that the feeder contains enough material to safely begin operation. It

In

can help to decrease the number of refills d uring a run. Review how the Initial Refill

works before you make this selection.

After you select Initial Refill and start the feeder, the instrument checks to see if the

material in the hopper is below the refill end weight. If it is, the instrument goes into refill

mode until the refill end weight is reached.

Parameter 11 Initial Refill on

is value serves as an ON/OFF switch for the initial refill function.

Th

Range: 0 = no, 1 = yes (default NO)

Parameter 12 Auto Refill On

Th

is value serves as an ON/OFF switch for the auto refill function.

Range: 0=off, 1=on

NOTE If Initial Refill is on with Auto Refill off, the unit still goes into refill mode until the unit

high weight is reached. If you wish to prevent this, turn off Initial Refill when you turn off

Auto Refill.

Parameter 13/14 Refill Start Weight and End Weight

Th

e Start Weight, which is set in mass units (actual gross weight), triggers a signal to

begin the refill process. You need to determine when you want the refill to automatically

begin (or an alarm to trigger so an operator can refill the feeder). The Start Weight value

must be higher than the Lo Shutoff value. End Weight signals when the hopper is full.

Range: Start Weight >0.0 (default 10.0) End Weight >0.0 (default 100.0)

Parameter 15/16 Refill Shutdown a

nd Refill Too High Weight

The Refill Shutdown setting stops the process when there is insufficient or no material in

the hopper. This setting can be 0 weight indicating nothing in the hopper or a weight

setting somewhat above the 0 weight and below the Refill Start Weight value. The Refill

Shutdown value must be below the Refill Start Weight value.

The weight you enter for Refill Too High will trigger an alarm should the weight go

above this value while refilling.

Refill Shutdown Range >

0 (default 0) Refill Too High Range >0 (default 100,000)

Parameter 17 OP Adjust

There

are thee options:

OFF: (default) Turns off the function.

21

●

●

Chapter 4

●

●

●

ON-LEARN: (works only with Auto Refill) The HI 1756 FC saves the % output and

change in weight values from previous refills and continuously calculates the optimal

Output % based on these values. This allows the instrument to adjust as conditions and

the material or refill characteristics change over time.

Page 27

XED: With Auto Refill, you can use ON-FIXED to either lock in an effective

ON-FI

learned value or enter a noted value that has worked well on previous applications.

Range: 0, 1 or 2

Parameter 18 OP Adjust %/wgt during refill

Refill OP Adjust %/wgt

This is the OP (Output Percentage) Adjust % per unit of wgt. Rate calibration determines

this parameter, so you may not want to set it. It would be difficult to know what to enter.

The weight of an ingredient in a hopper can affect the rate of feed. For example, a liquid

at the base of a full hopper is under greater pressure than a liquid at the base of a near

empty hopper. If no adjustment is made, the liquid flows out faster when the hopper is

full than when it is low. When the OP Adjust parameter is ON (i.e., not set to OFF), the

OP Adjust %/wgt value will adjust the refill rate to compensate for any change in weight

of the ingredient in the hopper. OP Adjust On Learn is used to calculate this value.

Range: -100 to +100 up to six decimal places (Default 0.0)

Parameter 19 Wait Time

me the controller waits for the material to settle before it calculates the batch total.

Ti

Seconds, 0 decimal places. Must be > or = 0

Parameter 20 Low Alarm

Shut Down Rate

If the actual flow rate is below the setpoint beyond the alarm delay time, the Lo Shutoff

alarm can be configured to signal an alarm condition that can either shut the process

down or lower the output to a set percentage (See Shutoff % Out below). The decimal

point is positioned based on the Rate DP parameter.

NOTE The Lo Shutoff alarm value must be equal to or less than the lowest set point value.

Range: No limits

Parameter 21 High Alarm Shut Down Rate

he actual flow rate is above the setpoint beyond the alarm delay time, the Hi Shutoff

If t

alarm can be configured to signal an alarm condition that can either shut the process

down or lower the output to a set percentage (See Shutoff % Out below). The decimal

point is positioned based on the Rate DP parameter.

Range: No limits

Parameter 22 Alarm Delay

e number of seconds you want the instrument to delay before setting off either a HI

Th

shutoff or LO shutoff alarm after detecting a flow rate that is out of tolerance. This avoids

nuisance alarms and gives the system time to clear a problem.

If a product is easily liquefied, set a very short delay to prevent large spills. If a product

tends to plug or bridge set a longer delay.

Range: 0 decimal places. Must be > or = 0.

Parameter 23 Rate Setpoint

e Rate Setpoint is the ingredient target flow rate (Loss in Weight) you want to

Th

maintain for your process. The decimal point is positioned based on the Rate DP

parameter.

22

●

●

Chapter 4

●

●

●

Range: Must be > or = 0, < the maximum rate set for rate calibration.

Page 28

REC Parameters

Parameter 1A REC Level %

The REC Level % (RECPERCENT or REC LEVEL% parameter) is a percentage of Max

Rate. It is the level of error above or below the Setpoint Rate that you can accept before

the instrument goes into REC mode. For example: If the rate calibration Max Rate is 5.0

lb/min, and the REC level % is 20%, the allowable deviation is 1.0 lb/min from the Rate

Setpoint before a Rate Exception error occurs.

Range: 0-100.0 (default 20%. This allows for a very larg e error. We recommend a setting

between 5% and 10% and allowing a RE+ or RE- indication about every five min.)

Parameter 1B REC Time

e time the unit must remain in the REC mode to get an alarm condition or if the

Th

Shutdown parameter is selected to shutdown the operation.

Range: 0-999 (default 10)

Parameter 1C REC Shutdown

EC Shutdown enables you to shutdown your operation if the system operates in

The R

REC mode beyond the time limit set in REC Time. If you select YES for REC Shutdown

and the RE error goes beyond the REC Time, the HI 1756 FC goes to shutoff mode. If

you select NO, once the deviation goes beyond the REC Time, the system only sends an

alarm bit.

Range: NO/YES (default NO)

Parameter 1D Shutoff Percent

hutdown signal can trigger a fixed OP % response if Shutoff Percent is greater than

A s

0.0%. This allows for processes that should not be halted completely, even if an error

occurs, to continue at a slower rate.

Range: 0 decimal places. 0-100

Parameter 1E Total

ontroller records the total amount dispensed. The Total number displays the amount

The c

of material that has been processed from the start of the process until the process

completes or is interrupted. You would probably not want to reset the Total value each

time you start the module, but for error correction, the Total parameter can be cleared (in

either continuous or batch modes). For example, if a power failure shuts the system down

during a process, before you resume operation you can re-enter the lost total from the

front panel.

CAUTION If you change the Total, stop the system.

Total Range 0 - >99,999.0 wt units (default 0.0)

Parameter 1F Batch Total

atch Total reads the total amount of material for the selected batch that has been

The B

processed from the start of a batch process until the batch process ends (by intent or other

reason). When the Batch is complete, the Batch Total resets to 0.0 for the next batch. The

Batch Total parameter can be changed should there be an error in the batch total amount

while processing.

CAUTION If you change the Batch Total, stop the system.

Batch Total Range 0 - >99,999.0 wt units (default 0.0)

●

●

23

Chapter 4

●

●

●

Page 29

Rate Calibration Parameters

Three types of calibrations determine the flow rate per output percentage:

1. Two-point rate calibration: Used for Auto RateCal. If a two-point Auto Rate

Calibration is selected, two flow rate points (points two and four) are used for

calculating other rate point values. The unit will go to the high rate output percent

for a period of feed time plus prime time (See parameters E and 10 above). When

this period is complete, it saves the actual rate as the high cal rate, then pauses for

a period of pause time (See parameter F) before going to the low rate output

percent for a period of feed time. When this period is complete, it will save the

actual rate as the low cal rate. After doing the auto rate calibration at the low and

high rates, the unit will estimate the zero rate output percent and the Max rate cal

rate and will fill values for the first, third, and fifth five-point calibration rate pairs.

2. Five-point rate calibration: Five-point measurement used with Auto RateCal to

provide tighter flow rate control. The user enters the output percent values, and the

unit then runs at each of these output percents, starting with the highest one, for a

period of feed time or feed time plus prime time on the first run. It saves the actual

rates it observes into the cal rates and estimates the MaxRate and zero output rates.

3. User-set rate calibration: Used when you cannot do an Auto RateCal and you

know the flow rate for all seven output percentage selections. If user-set

calibration is selected, you must manually enter the PI settings and the output %

and rate for all calibration pairs. The entered flow rates can come from experience

with the material, often through trial and error. We recommend that you select

output percentage points where your expected control set point falls between point

two and point four.

Configuring Rate Calibration

OTES Make sure you have enough material to do a Rate Cal at the highest OP%. If, for

N

example, 30 seconds at 90% would empty the hopper, reduce the Rate Cal to a lower

rate.

RateCal Percents

RateCal Percen

ts sets the output percentage for the three cal types.

1. For the 2 pt Cal Type (%Lo & % Hi), make sure that the Hi % is higher than the

Lo % and that there is a separation of at least 10%. You enter Pt2 and Pt4.

2. For the 5 pt Cal Type (Pt1, Pt2, Pt3, Pt4, Pt5), each % should be >

10% different.

3. For the User-set cal Type, you need to know the flow rates for all output

percentage setpoints. You enter the output percentages and the known f low rates

and the correct PI setting.

Range: 0 -100

You can edit other parameters, including adjustable values in the OP% (and/or Cal Rate)

fields.

Example: A calibration pair Output percent of 25% and a cal rate 250 means that a rate of

250 weight units per unit time will be obtained when the output percent is 25 %.

Running Rate Cal

e user enters all OP percentages. The Auto Rate Cal will prime the system then run for

Th

the selected feed time based on the calibration type, pause time, and RateCal Percents

you selected.

24

●

●

Chapter 4

●

●

●

Page 30

Input Table

r the 2 pt Cal Type (Pt2 and Pt4), the two flow rates for the percentages you

1. Fo

selected are the actual flow rates. The instrument calculates the remaining three

flow rates.

2. For the 5 pt Cal Type, you provide the five RateCal percents between the Low and

High output percentages.

3. For the User-set cal Type, you provide known flow rates for output percentage

setpoints (Pt2 and Pt4) and the output percentages. This only establishes the rate

lookup table for startup rates.

25

●

●

Chapter 4

●

●

●

.

The first 5 words of the input table echo the output table, except that the format word is

replaced with a command status that indicates whether a command succeeded or failed.

The next words are the OP% rate of change, the gross weight, rate setpoint, state, version,

and the module status word. There is also a counter which continuously increments.

Command # Offset Description

CMD 0 Command # echo the command from the input

CMD_STATUS 1 Status of command

PARAM_VALUE 2 Parameter value (LSW)

PARAM_VALUE 3 parameter value (MSW)

PARAM_NUMBER 4 Parameter number, in read and write commands

OP 5 Operating %. 2 decimal places 0.00 - 100.00

ROC 6 Uses 'rate decimal places' ROC value (LSW)

ROC 7 ROC value (MSW)

GROSS_WEIGHT 8 Uses 'weight decimal places' Gross wt. (LSW)

GROSS_WEIGHT 9 Gross wt. (MSW)

RATESETPOINT 10 Uses ‘rate decimal places' Total . (LSW)

RATESETPOINT 11 Total . (MSW)

STATE 12 State

Page 31

SION 13 Firmware version

VER

STATUS 14 Statusword (See Statusword below)

COUNTER 15

Statusword

At word

14, the module returns a binary statusword where each bit indicates a state or

condition within the module. To interpret these states, note which bits are ON and use the

chart below to match each bit location to the state it represents.

For Example: If the statusword is 69 with a binary value of 0000 0000 0100 0101, bits 0,

2, and 6 are on. Bit 0 indicates an A/D conversion error, bit 2 indicates status is ON and

bit 6 indicates a shutdown error.

STATUSWORD bit positions refer to these variables:

Word # Definition

ERRORADCONVERT 0x0001/0

Millivolt return from the load cell

system is out of range for the unit.

ERRORADFAILURE 0x0002/1 Unit’s A/D converter not responding.

STATUS_ON 0x0004/2 System on or off

ERRORLOWALARM 0x0008/3 Low alarm

ERRORHIGHALARM 0x0010/4 High alarm

ERRORCONTROL_LOST 0x0020/5 Controller communication failure

ERROR_SHUTDOWN 0x0040/6 Shutdown

ERROR_RANGE 0x0080/7 Out of range value

ERROR_REC 0x0100/8 REC value over high limit

ERROR_RECMINUS 0x0200/9 REC valu e below low limit

ERROR_REFILL_OVER 0x0400/10 Exceed refill limit

STATUS_REFILL 0x0800/11 Refill process active

STATUS_BATCH_COMPLETE 0x1000/12 Batch process completed

ERROREEPROMWRITE 0x4000/14 EEPROM Hardware Error

STATUSCHANENABLED 0x8000/15 Set if channel is enabled

26

●

●

Chapter 4

●

●

●

States (Word 12 of input table)

Mode (state) Table

Mode

Value Mode Value

IDLE_MODE 0 RATE_CAL_MODE 7

AUTO_MODE 1 REFILL_MODE 8

MANUAL_MODE 2 FULL_MODE 9

START_MODE 3 MANUAL_HOLD_MODE 10

STOP_MODE 4 RATECAL_HOLD_MODE 11

SHUT_OFFMODE 5 INITIAL_REFILL_MODE 12

PAUSE_MODE 6

Integrated Technician

If there is NO IT JBOX, the instrument can still measure the sense voltage, the overall

load cell millivolts per volt, and the internal reference weight value. If the user has an IT

Page 32

JBOX, th

attached to the IT JBOX.

To initiate an IT test, do a WRITEPARAM command, with parameter number 0x0036,

and a parameter value equal to the number of sensors, which should be 1-4 if you have an

IT JBOX. If you do not have an IT JBOX, the parameter value does not matter.

To read back the results, do a READPARAM command, with paramet er numbers

0x0036, 0x1036, 0xB036. The return values are listed below.

Integrated Technician Return Values Table

Return Value # Hex Description

PARAMID_ITECH 0x0036

INSTANCE_VSENSE 0036 Sense voltage, 2 decimal places

INSTANCE_DVM_COMBINED 1036 millivolts per volt, 4 decimal places

INSTANCE_IREF_WEIGHT 2036 internal reference weight, weight decimal point

INSTANCE_JBOX_MV/V1 3036 Load cell 1 millivolts per volt, 4 decimal places

INSTANCE_JBOX_MV/V2 4036 Load cell 2 millivolts per volt, 4 decimal places

INSTANCE_JBOX_MV/V3 5036 Load cell 3 millivolts per volt, 4 decimal places

INSTANCE_JBOX_MV/V4 7036 Load cell 4 millivolts per volt, 4 decimal places

INSTANCE_JBOX_REF_WEIGHT 7036 reference weight on IT JBOX, weight decimal pt

INSTANCE_JBOX_WEIGHT1 8036 Sensor 1 on JBOX, weight decimal point

INSTANCE_JBOX_WEIGHT2 9036 Sensor 2 on JBOX, weight decimal point

INSTANCE_JBOX_WEIGHT3 A036 Sensor 3 on JBOX, weight decimal point

INSTANCE_JBOX_WEIGHT4 B036 Sensor 4 on JBOX, weight decimal point

e instrument can also read the weights and voltages of the individual sensors

27

●

●

Chapter 4

●

●

●

CIP Messages

The weight and rate calibration values can be read and written by CIP messages.

Message Type: CIP generic

Service Code: 4C (hex)

Class Name: 4

Instance Name: 254

Object Attribute: none, leave this blank

It is possible and convenient to configure the MSG instruction to use the same tag for

both source and destination.

There are four read and write calibration commands, each consisting of 20 DINT values

(80 bytes) as follows:

Command (see the list of commands below)

Channel (0 or 1)

Rate Decimal points (0-7)

7 pairs of rate calibration values. Each pair has an operating percentage

(OP) with two decimal places, and an associated rate, shown with the

number of decimal places specified by the Rate Decimal points parameter.

CalZeroCounts

CalLowCounts

CalibK

Page 33

1. Command 1: Read calibration values. Use this command to read the rate and

weight calibration values.

2. Command 0x81: Write rate calibration values. Use this command to set the 7

rate calibration pairs.

3. Command 0x82: Write weight calibration. Use this command to set the 3 weight

calibration values: zero counts, low counts, and CalibK (weight per A/D count).

4. Command 0x83: Write both weight and rate calibration values.

The two commands below read and write configuration data. Each returns 52 DINT

values, which are the command, the channel, and the format word, followed by 49

parameter values, which are listed in the order of the parameter IDs.

5. Command 0x0F: Read configuration data.

6. Command 0x8F: Write configurati o n dat a.

The format word is like the one in the configuration data table, but in the least significant

word of the DINT rather than in the most significant word.

Note The values written via these commands are NOT saved automatically to the non-volatile

memory and are lost on power down if no save to non-volatile command is given.

28

●

●

Chapter 4

●

●

●

Page 34

Chapter 5 Calibration

● ● ● ● ●

The Feeder Controller Module should be calibrated before use. We also recommend that

you verify the calibration periodically or wh en not i n use f or exte nded periods of time.

Users and service personnel should be familiar with the procedures in this chapter before

installing or operating the Feeder Controller Module.

NOTE Do not perform a calibration while the application is in operation.

Pre-Calibration Procedures

Verify that the load cells have been properly installed.

Refer to your load cell I&M manual for proper installation instructions.

On some sensors and cells an arrow indicates the direction of the applied load. If

the arrow is pointing in the wrong direction, change the position of the load cell

so that it is mounted in the direction of the applied load.

Check for binding on the Load Cell or other parts of the weighing system.

CAUTION: Binding on a scale/vessel or load cell does not allow the load cell free vertical movement

and may prevent the instrument from returning to the original zero reference point.

A load cell must be mounted so that

100% of the load (Vessel w/Contents)

passes vertically through the load cell.

Verify that nothing is binding the load

cell. This means that nothing is draped

across the scale/vessel or the load cell,

such as a hose, electrical cord, tubes,

or other objects.

Verify that nothing is in contact with

the scale/vessel other than service

wires and piping that have been

properly mounted with flexible

connections.

Electrical Check Procedures

Load Cell/Point Input/Output Measurements

The Feeder Controller Module is designed to supply 5 VDC excitation to as many as four

350-Ohm load cells/points. The expected output from each load cell/point will depend on

the mV/V rating of the load cell/point and the weight.

Properly Installed Load Cell

29

●

●

Chapter 5

●

●

●

Fo

r example, a 2mV/V load cell/point will respond with a maximum of 10 mVDC at the

system’s full weight capacity, which includes the weight of the vessel and the weight of

the product as measured by the load cell/point. Thus, if the load cell/point weight

Page 35

acity is rated at 1000 pounds, the load cell/point will be 10 mVDC at 1000 pounds,

cap

7.5 mVDC at 750 pounds, 5 mVDC at 500 pounds and so on.

A zero reference point will

vary from system to system

depending on the “Dead Load”

of the vessel. “Dead Load” is

the weight of the vessel and

appurtenances only, with no

product loaded. In our

example we will assume the

dead load to be 500 pounds.

The operating range for the

scale in this example is 5-10

mVDC with a 500 pound

weight range. Note that after

zeroing the instrument, the 0

reading refers to the zero

reference point and not

absolute 0 mVDC or absolute

0 weight.

Millivolts/Weight Scale