Page 1

HI 1746-WS

WEIGH SCALE MODULE

OPERATION AND INSTALLATION

MANUAL

Series C

Corporate Headquarters

9440 Carroll Park Drive

San Diego, CA 92121

Phone: (858) 278-2900

FAX: (858) 278-6700

Web-Site: http://www.hardysolutions.com

Hardy Process Solutions Document Number: 0596-0234-01 Rev H

Copyright September 2011 Hardy Process Solutions, Inc. All Rights Reserved. Printed in the U.S.A. (941028)

Page 2

Local Field Service

Hardy has over 200 field technicians in the U.S., and more positioned

throughout the world to assist you in your support needs. We also have factory engineers who will travel to your facility any

solve challenging applications. We're ready to support you with:

where in the world to help you

• Ins

• Rout

• Plant

• Emer

To request Emergency Service and Troub

Calibration, Verification or to discuss a Maintenance Agreement please call

800-821-5831 Ext. 1757 or Emergency Service after hours (Standard Hours

6:00 AM to 6:00 PM Pacific Standard Time) and weekends

tallation and start-up

ine maintenance and certification

audits and performance measurement

gency troubleshooting and repair

leshooting, Start-up, Installation,

Ext. 1111.

Outside the U.S

Hardy Process Solutions has built a network of support throughout the globe.

For specific field service options available in your area please contact your

local sales agent or our U.S. factory at +1 858-292-2710, Ext. 1757.

Page 3

Table of Contents

Table of Contents

TABLE OF CONTENTS - - - - - - - - - - - - - - - - - - - - - -I

TABLE OF ILLUSTRATIONS - - - - - - - - - - - - - - - - - - -I

CHAPTER 1 - OVERVIEW - - - - - - - - - - - - - - - - - - - - -1-1

A Brief Description of Chapter 1 - - - - - - - - - - - - - - - - - -1-1

About Hardy Manuals - - - - - - - - - - - - - - - - - - - - - - -1-2

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-2

WAVERSAVER® - - - - - - - - - - - - - - - - - - - - - - - - - -1-3

C2® Calibration - - - - - - - - - - - - - - - - - - - - - - - - - -1-4

IT® - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1-4

Excitation Monitor - - - - - - - - - - - - - - - - - - - - - - -1-4

Digital Volt Meter (DVM) - Optional - - - - - - - - - - - - - - -1-5

Return to Zero Test - Optional - - - - - - - - - - - - - - - - -1-5

Weighing System Tests - Optional - - - - - - - - - - - - - - -1-5

Auto Zero Tracking - - - - - - - - - - - - - - - - - - - - - - -1-6

Set Point TTL Outputs - - - - - - - - - - - - - - - - - - - - -1-6

CHAPTER 2 - SPECIFICATIONS - - - - - - - - - - - - - - - - -2-1

A Brief Description of Chapter 2 - - - - - - - - - - - - - - - - - -2-1

Specifications for a Standard HI 1746-WS Weigh Scale Module - - -2-1

Modes of Operation - - - - - - - - - - - - - - - - - - - - - -2-1

Conversion Rate - - - - - - - - - - - - - - - - - - - - - - - -2-1

Averages - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Resolution - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Non-Linearity - - - - - - - - - - - - - - - - - - - - - - - - -2-1

Maximum Zero Tolerance - - - - - - - - - - - - - - - - - - -2-1

WAVERSAVER® - - - - - - - - - - - - - - - - - - - - - - - -2-1

Excitation Monitor - - - - - - - - - - - - - - - - - - - - - - -2-1

Common-Mode Rejection - - - - - - - - - - - - - - - - - - -2-2

Common-Mode Voltage Range - - - - - - - - - - - - - - - - -2-2

Backplane Input Voltage - - - - - - - - - - - - - - - - - - - -2-2

Backplane Current Load - - - - - - - - - - - - - - - - - - - -2-2

Power - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2-2

C2 Calibration Input - - - - - - - - - - - - - - - - - - - - - -2-2

Cable lengths - - - - - - - - - - - - - - - - - - - - - - - - -2-2

Load Cell Excitation - - - - - - - - - - - - - - - - - - - - - -2-2

C2 Calibration Output - - - - - - - - - - - - - - - - - - - - -2-2

Set Point (1 & 2) Out - - - - - - - - - - - - - - - - - - - - - -2-2

Environmental Requirements - - - - - - - - - - - - - - - - - - - -2-2

i

Page 4

HI 1746-WS WEIGHT SCALE MODULE

Temperature Coefficient - - - - - - - - - - - - - - - - - - - -2-2

Operating Temperature Range - - - - - - - - - - - - - - - - -2-2

Storage Temperature Range - - - - - - - - - - - - - - - - - -2-2

Humidity Range - - - - - - - - - - - - - - - - - - - - - - - -2-2

Approvals - - - - - - - - - - - - - - - - - - - - - - - - - - -2-3

Digital Voltmeter - - - - - - - - - - - - - - - - - - - - - - - -2-3

Optional Equipment HI 215IT Junction Box - - - - - - - - - - - - -2-3

IT Junction Box HI 215IT-SS or PS Series - - - - - - - - - -2-3

Case Dimensions - - - - - - - - - - - - - - - - - - - - -2-3

Weight - - - - - - - - - - - - - - - - - - - - - - - - - - -2-3

Enclosure Ratings - - - - - - - - - - - - - - - - - - - - -2-3

IT Junction Box HI 215IT-FG Series - - - - - - - - - - - - - -2-3

Case Dimensions - - - - - - - - - - - - - - - - - - - - -2-3

Weight - - - - - - - - - - - - - - - - - - - - - - - - - - -2-3

Enclosure Rating - - - - - - - - - - - - - - - - - - - - - -2-3

Configuration Software for Windows - - - - - - - - - - - - - -2-3

Default Parameters - - - - - - - - - - - - - - - - - - - - - - - -2-4

CHAPTER 3 - INSTALLATION - - - - - - - - - - - - - - - - - - -3-1

A Brief Description of Chapter 3 - - - - - - - - - - - - - - - - - -3-1

Unpacking - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3-1

Installing the HI 1746-WS into an Allen-Bradley SLC 500

Processor or Allen-Bradley Remote Rack - - - - - - - - - - - - -3-1

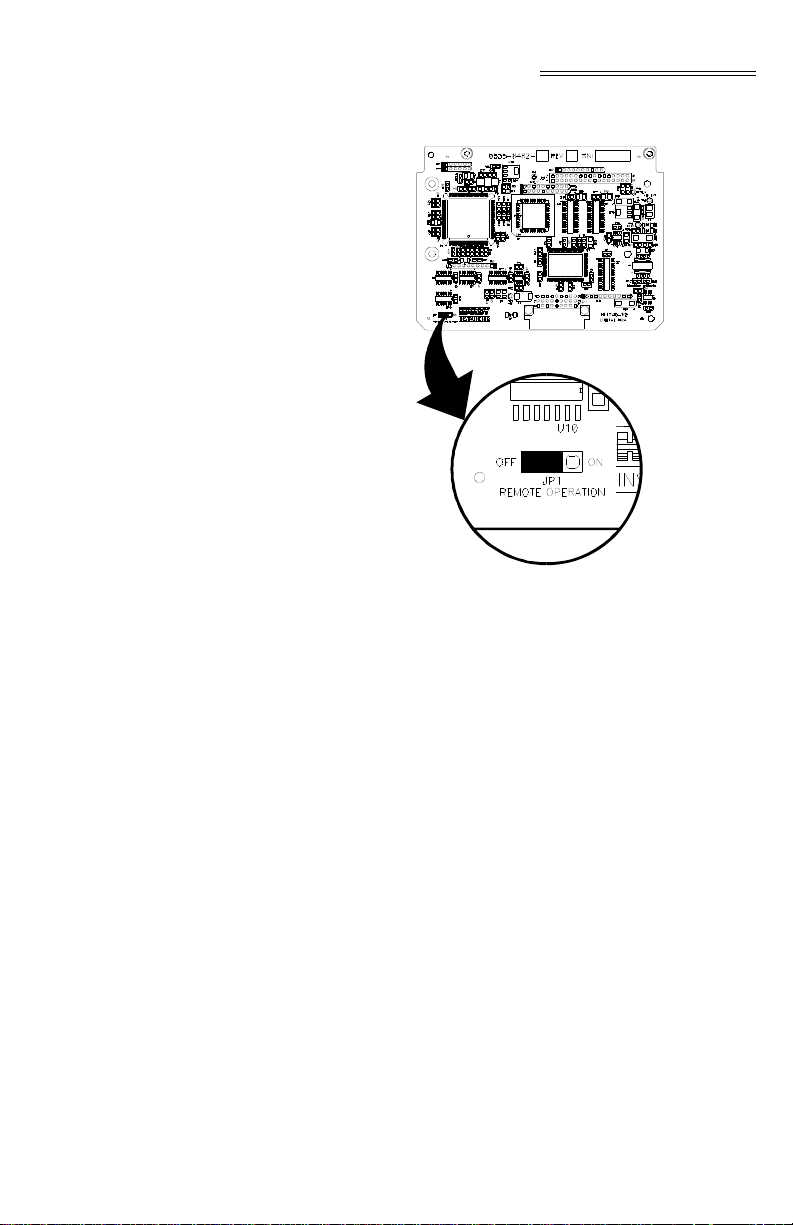

Setting the Jumper for Local or Remote Mode of Operation - - -3-2

Installing the HI 1746-WS into the SLC 500 or Remote

Chassis - - - - - - - - - - - - - - - - - - - - - - - - - - -3-3

Removing the Module from the SLC 500 or Remote Chassis - - - -3-5

Installing the Module I/O Connector - - - - - - - - - - - - - - - - -3-6

About the Module I/O Connector - - - - - - - - - - - - - - - -3-6

Load Cell Wiring Diagrams - - - - - - - - - - - - - - - - - - - - -3-7

Industry Standard Load Cells - - - - - - - - - - - - - - - - - -3-8

Hardy Load Sensor with C2 - - - - - - - - - - - - - - - - - -3-9

Hardy HI 215IT Junction Box - - - - - - - - - - - - - - - - - -3-9

Installing the Hardy Configuration Software (Optional) - - - - - - - -3-10

CHAPTER 4 - SETUP - - - - - - - - - - - - - - - - - - - - - - -4-1

A Brief Description of Chapter 4 - - - - - - - - - - - - - - - - - -4-1

Power Check - - - - - - - - - - - - - - - - - - - - - - - - - - -4-1

LEDS - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4-2

Run/Fault LED - - - - - - - - - - - - - - - - - - - - - - -4-2

Comm. LED - - - - - - - - - - - - - - - - - - - - - - - -4-2

C2 LED - - - - - - - - - - - - - - - - - - - - - - - - - -4-2

Setting Up Communications Between the SLC and the

ii

Page 5

Table of Contents

HI 1746-WS Weigh Scale Module - - - - - - - - - - - - - - - -4-2

Local Mode of Operation - - - - - - - - - - - - - - - - - - - -4-3

Remote Mode of Operation - - - - - - - - - - - - - - - - - - -4-3

About M Files - - - - - - - - - - - - - - - - - - - - - - - - - - -4-3

Direct M File Mapping - - - - - - - - - - - - - - - - - - - - - - -4-3

Local Mode of Operation - - - - - - - - - - - - - - - - - - - -4-3

Remote Mode of Operation - - - - - - - - - - - - - - - - - - -4-5

M File Interface to Set Up for Local Mode of Operation - - - - - - -4-5

M File Data Structure (Words 0 to 5) - - - - - - - - - - - - - -4-5

Logical File Interface to Set Up for Remote Mode of

Operation (8 Word) - - - - - - - - - - - - - - - - - - - - - - -4-6

About Logical Files - - - - - - - - - - - - - - - - - - - - - - -4-6

Command Word Encoding - - - - - - - - - - - - - - - - - - -4-7

Bits 15 & 14 - - - - - - - - - - - - - - - - - - - - - - - -4-7

Bits 8-13 - - - - - - - - - - - - - - - - - - - - - - - - - -4-7

Bits 0-7 - - - - - - - - - - - - - - - - - - - - - - - - - -4-7

Writing to the 32 Word Logical O and logical M0 files - - - - - -4-8

Command Word - - - - - - - - - - - - - - - - - - - - - - - -4-8

Writing to the M0 file - - - - - - - - - - - - - - - - - - - -4-8

For Example - - - - - - - - - - - - - - - - - - - - - - - -4-8

Writing to the O file - - - - - - - - - - - - - - - - - - - - -4-8

For Example - - - - - - - - - - - - - - - - - - - - - - - -4-8

Words 1-7 - - - - - - - - - - - - - - - - - - - - - - - - -4-8

Reading from the 32 Word Logical I and logical M1 files - - - - -4-9

Command Word - - - - - - - - - - - - - - - - - - - - - - - -4-9

Bits 15-14 set to “10” - - - - - - - - - - - - - - - - - - - -4-9

For Example - - - - - - - - - - - - - - - - - - - - - - - -4-9

Bits 15-14 set to “11” - - - - - - - - - - - - - - - - - - - -4-9

For Example - - - - - - - - - - - - - - - - - - - - - - - -4-9

Bits 15-14 set to “01” - - - - - - - - - - - - - - - - - - - -4-9

Bits 15-14 set to “00” - - - - - - - - - - - - - - - - - - - -4-9

Executable Command List - - - - - - - - - - - - - - - - - - - - -4-10

Zero Command (ZEROCMD) - - - - - - - - - - - - - - - - - -4-10

Tare Command (TARECMD) - - - - - - - - - - - - - - - - - -4-10

Write Non-Volatile Command (WRITENONVOLATILE) - - - - -4-11

Reload Non-Volatile (RELOADNONVOLATILE) - - - - - - - - -4-11

Float Integer to Integer Conversion Command (FLOAT2INT) - -4-12

Integer to Float Integer Conversion Command (INT2FLOAT) - -4-12

Cal Low Command (CALLOWCMD) - - - - - - - - - - - - - -4-13

Cal High Command (CALHIGHCMD) - - - - - - - - - - - - - -4-13

C2 Cal Command (C2CALCMD) - - - - - - - - - - - - - - - -4-13

Read C2 Serial Number Command (READC2SERIALNUM) - -4-14

Set Parameters Command (SETPARAM) - - - - - - - - - - - -4-14

iii

Page 6

HI 1746-WS WEIGHT SCALE MODULE

Get Parameters Command (GETPARAM) - - - - - - - - - - -4-15

I/O Setup Ladder Logic for Remote Mode Operation - - - - - -4-16

HI WS100 Configuration Software Interface (Remote Mode

of Operation) - - - - - - - - - - - - - - - - - - - - - - - - - - -4-18

Setting The Process Weighing Parameters - - - - - - - - - - - - -4-20

About the Ladder Logic Example - - - - - - - - - - - - - - - -4-20

Weight Multiplier - - - - - - - - - - - - - - - - - - - - - - - -4-20

SETPARAM - GETPARAM Command and Non Volatile

Memory - - - - - - - - - - - - - - - - - - - - - - - - - - -4-21

Possible Error Returns - - - - - - - - - - - - - - - - - - -4-21

Setting Parameters Ladder Logic Explanation - - - - - - - - - -4-22

SETPARAMS Local Mode of Operation - - - - - - - - - - -4-23

SETPARAMS Remote Mode of Operation - - - - - - - - -4-24

Error Code List - - - - - - - - - - - - - - - - - - - - - - - - -4-28

Calibration Setup Procedures - - - - - - - - - - - - - - - - - - -4-28

Setting the Unit of Measure - - - - - - - - - - - - - - - - - - -4-28

Setting the Motion Tolerance Value - - - - - - - - - - - - - - -4-28

Setting the Zero Tolerance Value - - - - - - - - - - - - - - - -4-29

Setting the Auto Zero Tolerance Value - - - - - - - - - - - - -4-29

Setting the Number of Readings Averages - - - - - - - - - - -4-29

Setting the Span Weight Value - - - - - - - - - - - - - - - - -4-29

Setting the WAVERSAVER Value - - - - - - - - - - - - - - -4-29

CHAPTER 5 - CALIBRATION - - - - - - - - - - - - - - - - - - -5-1

A Brief Description of Chapter 5 - - - - - - - - - - - - - - - - - -5-1

Pre-Calibration Procedures - - - - - - - - - - - - - - - - - - - - -5-1

Electrical Check Procedures - - - - - - - - - - - - - - - - - - - -5-2

Load Cell/Point Input/Output Measurements - - - - - - - - - -5-2

Load Check - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-4

C2 Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - -5-4

About C2 Calibration - - - - - - - - - - - - - - - - - - - - - -5-4

“THE BUTTON” C2 Calibration - - - - - - - - - - - - - - - - -5-5

C2 LED - - - - - - - - - - - - - - - - - - - - - - - - - -5-6

C2 Calibration Using Ladder Logic - - - - - - - - - - - - - - -5-6

Data Locations Used for Ladder Logic Examples (For Local

Mode of Operation Only) - - - - - - - - - - - - - - - - - - - - -5-6

N9:0 - 24 - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-6

N9:50 - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-6

N9:51 - - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-6

N10:0 - 2 - - - - - - - - - - - - - - - - - - - - - - - - - - - -5-6

N10:40 - 46 - - - - - - - - - - - - - - - - - - - - - - - - - -5-7

N10:60 - 72 - - - - - - - - - - - - - - - - - - - - - - - - - -5-7

N10:60 - - - - - - - - - - - - - - - - - - - - - - - - - -5-7

iv

Page 7

Table of Contents

N10:61 - - - - - - - - - - - - - - - - - - - - - - - - - -5-7

N10:62 - - - - - - - - - - - - - - - - - - - - - - - - - -5-7

N10:63-64 - - - - - - - - - - - - - - - - - - - - - - - - -5-7

N10:65-66 - - - - - - - - - - - - - - - - - - - - - - - - -5-7

N10:67-68 - - - - - - - - - - - - - - - - - - - - - - - - -5-7

N10:69-70 - - - - - - - - - - - - - - - - - - - - - - - - -5-7

N10:71-72 - - - - - - - - - - - - - - - - - - - - - - - - -5-7

C2 Calibration Ladder Logic Explanation - - - - - - - - - - - -5-7

C2 Calibration Ladder Logic Example (For Local

Mode of Operation Only) - - - - - - - - - - - - - - - - -5-8

C2 Calibration Ladder Logic Example (For Remote

Mode of Operation Only) - - - - - - - - - - - - - - - - -5-11

Hard Calibration - - - - - - - - - - - - - - - - - - - - - - - - - -5-12

Hard Calibration Ladder Logic Example - - - - - - - - - - - -5-12

CHAPTER 6 - OPERATING PROCEDURES - - - - - - - - - - - -6-1

A Brief Description of Chapter 6 - - - - - - - - - - - - - - - - - -6-1

Block Transfer, Read - - - - - - - - - - - - - - - - - - - - - - - -6-1

Block Transfer, Read Example (For Local Mode Only)

(READWEIGHT) - - - - - - - - - - - - - - - - - - - - - - - - -6-5

Explanation of the READWEIGHT Example - - - - - - - - - -6-5

READWEIGHT Ladder Logic Example - - - - - - - - - - - - -6-6

Block Transfer, Read Ladder Logic Example for Remote

Mode Operation - - - - - - - - - - - - - - - - - - - - - - - - -6-6

Block Transfer, Write - - - - - - - - - - - - - - - - - - - - - - - -6-7

Block Transfer, Write Ladder Logic Example for Remote

Mode Operation - - - - - - - - - - - - - - - - - - - - - - - - -6-9

INDEX

v

Page 8

HI 1746-WS WEIGHT SCALE MODULE

vi

Page 9

Table of Illustrations

Table of Illustrations

CHAPTER 3 - INSTALLATION - - - - - - - - - - - - - - - - - - -3-1

FIG. 3-1 HI 1746-WS WEIGH MODULE IN PROPER

ORIENTATION - - - - - - - - - - - - - - - - - - -3-2

FIG. 3-2 JUMPER LOCATION/JUMPER SET IN THE

DEFAULT OFF (LOCAL MODE) POSITION - - - - -3-3

FIG. 3-3 POSITIONING THE MODULE FOR INSTALLATION - - -3-4

FIG. 3-4 MODULE RELEASE(S) - - - - - - - - - - - - - - - - -3-5

FIG. 3-5 MODULE INSTALLED IN SLC CHASSIS - - - - - - - -3-5

FIG. 3-6 MODULE WITH DOOR OPEN - - - - - - - - - - - - - -3-7

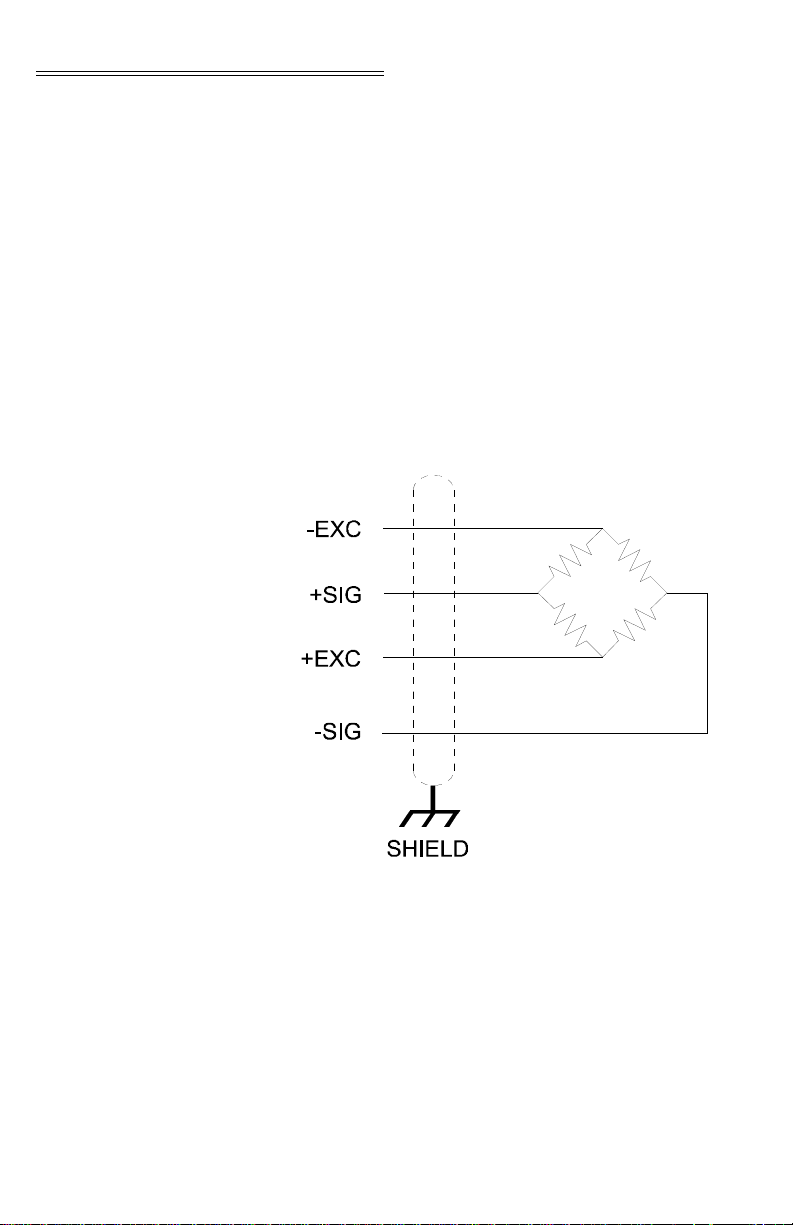

FIG. 3-7 INDUSTRY STANDARD LOAD CELLS WIRING

DIAGRAM - - - - - - - - - - - - - - - - - - - - - -3-8

FIG. 3-8 HARDY LOAD SENSOR/C2 WIRING DIAGRAM - - - - -3-9

FIG. 3-10 HARDY HI 215IT JUNCTION BOX WIRING DIAGRAM -3-9

CHAPTER 4 - SETUP - - - - - - - - - - - - - - - - - - - - - - -4-1

FIG. 4-1 MODULE LEDS - - - - - - - - - - - - - - - - - - - - -4-2

FIG. 4-2 PRIMARY AND REMOTE COMMUNICATION

DIAGRAM - - - - - - - - - - - - - - - - - - - - - -4-7

FIG. 4-3 SETUP I/O FOR REMOTE MODE OF OPERATION - - -4-18

FIG. 4-4 SETPARAMS LADDER LOGIC EXAMPLE/LOCAL

MODE - - - - - - - - - - - - - - - - - - - - - - - -4-23

FIG. 4-5 SETPARAMS LADDER LOGIC EXAMPLE/REMOTE

MODE - - - - - - - - - - - - - - - - - - - - - - - -4-27

CHAPTER 5 - CALIBRATION - - - - - - - - - - - - - - - - - - -5-1

FIG. 5-1 PROPERLY INSTALLED LOAD CELL W/NO BINDING -5-2

FIG. 5-2 MILLIVOLTS/WEIGHT SCALE - - - - - - - - - - - - -5-3

FIG. 5-3 “THE BUTTON” C2 CALIBRATION - - - - - - - - - - -5-5

FIG. 5-4 C2 LED - - - - - - - - - - - - - - - - - - - - - - - - -5-6

FIG. 5-5 C2 LADDER LOGIC EXAMPLE/LOCAL MODE

OF OPERATION - - - - - - - - - - - - - - - - - - -5-10

FIG. 5-6 C2 LADDER LOGIC EXAMPLE/REMOTE MODE

OF OPERATION - - - - - - - - - - - - - - - - - - -5-12

CHAPTER 6 - OPERATING PROCEDURES - - - - - - - - - - - -6-1

FIG. 6-1 READWEIGHT LADDER LOGIC EXAMPLE/LOCAL

MODE OF OPERATION - - - - - - - - - - - - - -6-6

I

Page 10

HI 1746-WS WEIGH SCALE MODULE

II

Page 11

CHAPTER 1 - OVERVIEW

Chapter 1 - Overview

A BRIEF DESCRIPTION OF CHAPTER 1

This manual provides the user and service personnel

with a description of the specifications, installation,

setup, configuration, operation, communication,

maintenance, and troubleshooting procedures for the

Hardy Process Solutions HI 1746-WS Weigh Scale

Module, designed for use in Allen-Bradley’s SLC 5/

02, 5/03, 5/04, 5/05 programmable controllers. The

HI 1746-WS is equipped with W AVERSAVER

Calibration, The Button, and I

CIAN (IT) diagnostics. The module is configurable via

Windows

®

95/98/NT HI WS 100 Configuration Soft-

NTEGRATED TECHNI-

®

, C2®

ware or RS Logix 500© Industrial Programming Software. To get the maximum service life from this

product, users should operate this module in accor

dance with recommended practices either implied or

expressed in this manual. Before using the Weigh

Scale Module, all users and maintenance personnel

should read and understand all cautions, warnings,

and safety procedures, referenced or explicitly stated

in this manual, to ensure the safe operation of the

module. Hardy Process Solutions appreciates your

business. Should you not understand any information

in this manual or experience any problems with the

product, please contact our Customer Support Depart

ment at:

-

Phone: (858) 278-2900

FAX: (858) 278-6700

e-mail: hardysupport@hardysolutions.com

Web Address: http://www.hardysolutions.com

NOTE: WAVERSAVER®, C2®, INTEGRATED TECHNICIAN® are

register ed trademarks of Har dy Pr ocess Solutions Inc.

®

Windows

Corporation. RS Logix 500

is a registered trademark of the Microsoft

©

is a Copyright of Rock-

well Software Inc.

NOTE: Hardy bases all procedures with the assump tio n that

the user has an adequate understanding of all AllenBradley SLC 500 products. In addition the user

1-1

Page 12

HI 1746-WS WEIGH SCALE MODULE

should understand process control and be able to

interpret ladder logic instructions necessary to gener

ate the electronic signals that control your application(s).

About Hardy Manuals Every Hardy Installation and Operation manual is

organized into easily referenced chapters, that are

almost always the same:

• Chapter 1 - Provides an introduction to the

instrument and an Overview of the equipment

and its capabilities.

• Chapter 2 - Provides a complete list of Specifi-

cations.

• Chapter 3 - Contains information needed to

install the HI 1746-WS (both standard and

optional equipment) and the HI 215IT series

Junction Box.

• Chapter 4 - Provides complete hardware Con-

figuration instructions for setting dip switches

and jumpers.

• Chapter 5 - Pertains to the firmware/software

Setup and preparation procedures to calibrate

and operate the instrument.

• Chapter 6 - Provides all Calibration instructions.

• Chapter 7 - Pertains to the Operating Procedures of the HI 1746-WS.

• Chapter 8 - Pertains to the Troubleshooting

procedures for repair of the instrument.

-

Hardy Process Solutions hopes that this manual meets

your needs for information and operation. All correc

tions or suggestions for improvements of this manual

are welcome and can be sent to the Technical Publica

tions Department or Customer Support Department at

Hardy Process Solutions Inc.

Description The HI 1746-WS Weigh Scale Module is a self con-

tained microprocessor based I/O module with control

inputs and outputs, that is designed to be easily

plugged into the back plane of an Allen-Bradley SLC

5/02, 5/03, 5/04 or 5/05 programmable controller and/

or Remote Rack. The HI 1746-WS Weigh Scale Mod

ule can be configured to operate as either a local or

1-2

-

-

-

Page 13

Chapter 1 - Overview

remote module. The HI 1746-WS module can be used

for a wide variety of process weighing applications

such as batching, blending, filling/dispensing, check

weighing, force measurement, level by weight and

weight rate monitoring. The module can control two

(2) relays via two (2) TTL level outputs and transmits

data via the back plane to the SLC. The 20 bit analog

to digital converter in the weigh module controller

updates twenty (20) times per second and is capable

of 985,000 counts of display resolution. This gives the

instrument the ability to tolerate large “dead” loads,

over sizing of load cells/sensors and still have suffi

cient resolution to provide accurate weight measurement and control. The HI 1746-WS module is set up

©

®

95/

by using the SLC 500 AI Series, RS Logix500

Industrial Programming Software for Windows

®

98/NT or the optional Hardy Windows

95/98/NT HI

WS100 Configuration Software. The software config

uration applications must be installed in a PC with

either Ethernet, DH+, DH-485, or RS-232-C that can

initiate communications with the SLC 5/02, 5/03, 5/

04 or 5/05. To calibrate the module you can simply

push “The Button” to effect a C2 calibration. C2,

Hard (Traditional calibration with weights), and Soft

calibration can be implemented from the SLC 500 AI

Series DOS software, RS Logix500

©

Industrial Pro-

gramming Software for Windows® 95/98/NT or from

the optional Hardy WS 100 Configuration Software

for Windows. The HI 1746-WS is IT (Integrated

Technician) enabled which means the module has a

built in IT excitation monitor to detect some load cell

problems and with the addition of the optional HI

215IT Junction Box and the HI WS100 software, the

operator can use the other IT functions for fault isola

tion troubleshooting of the weighing system.

-

-

WAVERSAVER

®

T ypically, mechanical noise (from other machinery in

a plant environment) is present in forces larger than

the weight forces trying to be detected by the module.

The HI 1746-WS is fitted with WAVERSAVER

®

technology which eliminates the effects of vibratory

forces present in all industrial weight control and

1-3

Page 14

HI 1746-WS WEIGH SCALE MODULE

measurement applications. By eliminating the factor

of vibratory forces the module is capable of identify

ing the actual weight data. WAVERSAVER® can be

configured from the Configuration Software to ignore

noise with frequencies as low as 0.25 Hz. One of five

higher additional cut off frequencies may be selected

to provide a faster instrument response time. The

default factory configuration is 1.00 Hz vibration fre

quency immunity.

C2® Calibration C2 Second Generation Calibration enables a scale

system to be calibrated electronically without using

certified test weights which equals the systems load

capacity. A C2 weighing system consists of up to

eight (8) C2 load sensors, a junction box, interconnect

cable and an instrument with C2 capabilities such as

the HI 1746-WS Weight Scale Module. All Hardy C2

certified load sensors contain digital information

detailing its unique performance characteristics. The

HI 1746-WS reads the performance characteristics of

each individual load sensor and detects the quantity of

load sensors in the system. C2 Calibration can be per

formed by pressing “The Button” located in the front

of the module, or via Hardy’s Configuration Software

or Allen-Bradley’s RS Logix 500 software.

-

-

-

IT® INTEGRATED TECHNICIAN™ is a system diagnostics

utility which continuously monitors the weighing sys

tem (with up to 4 load sensors) for possible malfunctions. For full functionality the HI 215IT junction box

and Hardy’s Configuration Software for Windows

should be used. Full IT functionality allows the opera

tor to rapidly troubleshoot a weighing system from

the Configuration Software, I

CIAN Display.

NTEGRATED TECHNI-

Excitation Monitor Continuously monitors a system’s excitation current

to check for open or shorted load sensors or damaged

or broken excitation wire(s), including the wires

between the module and the IT Junction box. If the

measured current deviates more than a +/- 10% toler

ance, an “Excitation Error” bit (Module Status Word

bit 9) is set to 1.

1-4

-

-

-

Page 15

Chapter 1 - Overview

Digital Volt Meter (DVM) - Optional

NOTE: If you do not have the HI 215IT Junction Box con-

Return to Zero Test - Optional

Requires the HI 215IT Junction Box and Hardy Configuration Software to monitor both mV and mV/V

readings per individual load sensor. Once a problem is

detected by the operator the DVM readings help the

operator to isolate the faulty component. Further, the

DVM readings can be used to level a balanced system

and to make corner adjustments to platform scales.

Accuracy is +/- 2% or better of full scale.

nected to the module, the mV/V reading as displayed

in the Configuration Software, T e st display is the total

for all the load cells on the system.

Requires the HI 215IT Junction Box to monitor individual load sensors. The Hardy configuration Software is required when using this option. This test

compares the original voltage reading (saved at cali

bration) against the current voltage reading of an

empty vessel. The test displays a “Passed Return to

Zero T est” or a “Failed Return to Zero T est” s tatement

when running the System Test from the Configuration

Software, Test Display, depending on the outcome of

the test. The test checks for damaged load sensors due

to electrical zero shift or abnormal mechanical forces

that cause binding on one or all of the load sensors in

the system.

-

Weighing System Tests - Optional

Requires the HI 215IT Junction Box. This test is used

to diagnose drifting or unstable weight reading prob

lems. The Weighing System Test does the following:

1. Disconnects the controller and engages an inter-

nal reference signal to see if the problem is within

the instrument.

1. Disconnects the load sensors and engages an

internal (in the junction box) reference signal to

see if the cable between the instrument and the

Junction Box is causing the problem.

2. Reads the weight of each load sensor to see if the

load sensor might be causing the problem.

The ability to read the weight seen by each individual

load sensor allows use of this test to make cornering,

-

1-5

Page 16

HI 1746-WS WEIGH SCALE MODULE

leveling and load sharing adjustments to the weighing

system. The Hardy Configuration Software is highly

recommended for use with this option.

Auto Zero Auto Zero Tracking will indicate zero weight, as long

as any “live weight” on the scale is below the set Auto

Zero T olerance and the scale is not motion. This capa

bility allows the module to ignore material build-up in

the weighing system within a pre-set auto zero toler

ance.

Note The amount of weight zeroed off is cumulative. The

zero command will fail if the current gr oss weight plus

any previously zeroed amount exceeds the zero

tolerance.

-

-

Set Point TTL Outputs

The HI 1746-WS is equipped with two (2) standard

Digital TTL (Transistor - Transistor Logic) Level

Outputs which can be connected to external solid state

relays. Both outputs have individual set point, preact

and deadband parameters. Both outputs are rated at 10

milliamps per line. Each can be programmed to

respond to the standard Net, Gross, Rate of Change

(ROC), Excitation Monitor, Force On or Force Off

mode of operation.

1-6

Page 17

CHAPTER 2 - SPECIFICATIONS

Chapter 2 - Specifications

A Brief Description of Chapter 2

Specifications for a Standard HI 1746-WS Weigh Scale Module

Modes of Operation

Conversion Rate 20 updates per second Averages 1-255 User Selectable in single increments Resolution Displayed: 1:985,000 (@ 3 mV/V)

Input Up to eight (8) 350 ohm Full Wheatstone Bridge,

Chapter 2 lists the specifications for the HI 1746-WS

Weigh Scale Module. Specifications are listed for the

standard instrument and for optional equipment. The

specifications listed are designed to assist in the

installation, operation and troubleshooting of the

instrument. All service personnel should be familiar

with this section before attempting an installation or

repair of this instrument.

Local and Remote

1:656,000 (@ 2 mV/V)

Internal: 1:1,048,576

Strain Gauge Load Sensors/Cells (5 volt excitation)

on one vessel.

Non-Linearity 0.0015% of Full Scale Maximum Zero

Tolerance

WAVERSAVER

Excitation Monitor Current less than +/- 10% expected

®

32766

User Selectable

• 7.50 Hz

• 3.50 Hz

• 1.00 Hz (Default)

• 0.50 Hz

• 0.25 Hz

2-1

Page 18

HI 1746-WS WEIGH SCALE MODULE

Common-Mode Rejection

Common-Mode Vo lta ge Range

Backplane Input Voltage

Backplane Current Load

Power +5 VDC +/- 5% C2 Calibration

Input

Cable lengths 1000 feet maximum of C2 authorized cable

Load Cell Excitation

C2 Calibration Output

110dB at or below 60 Hz

2.5VDC maximum (with respect to earth ground)

5 VDC maximum (with respect to earth ground)

0.250 Amps at 5 VDC

Isolation from digital section 1000 VDC minimum.

250 feet maximum of C2 authorized cable (Maximum

of 4 load sensors) with IT Junction box.

5 VDC +/- 1.15 W maximum.

Isolation from digital section 1000 VDC minimum

Isolation from digital section 1000 VDC minimum

Set Point (1 & 2) Out

Environmental Requirements

Temperature Coefficient

Operating Temperature Range

Storage Temperature Range

Humidity Range 0-90% (non-condensing)

2-2

Discrete outputs (TTL) step function of 0 or +5 VDC

to drive an SSR

Less than 0.005% of full scale per degree C for CalLO and Cal-HI reference points

0o C to 60o C (32o F to 140o F)

-20o C to 85o C (-4o F to 185o F)

Page 19

Approvals UL Certification

cUL Certification

CE Approval

Digital Voltmeter Accuracy +/- 2% of full scale

Resolution

• mV/V 4 digits to the right of the decimal

• mV 1 digit to the right of the decimal

Optional Equipment HI 215IT Junction Box

IT Junction Box HI 215IT-SS or PS Series

Chapter 2 - Specifications

Case Dimensions

6.25”H x 6.25”W x 4.50D (158.75mmH x

158.75mmW x 114.3mmD)

Weight 5 pounds (2.27 Kilograms) Enclosure

-SS Stainless Steel NEMA 4 & 4X

Ratings

-PS Painted Carbon Steel NEMA 4

IT Junction Box HI 215IT-FG Series

Case Dimensions

6.50”H x 8.0”W x 4.46”D (165.1mmH x 203.2mmW

x 113.28mmD)

Weight 5 pounds (2.27 Kilograms) Enclosure

-FG Fiberglass NEMA 4 & $X

Rating

Configuration Software for Windows

Hardy’s Configuration Software for Wind ows allows

the user to configure, monitor, and troubleshoot an HI

1746-WS module and load points from any PC with

an installed Windows

®

95/98 or NT operating system.

2-3

Page 20

HI 1746-WS WEIGH SCALE MODULE

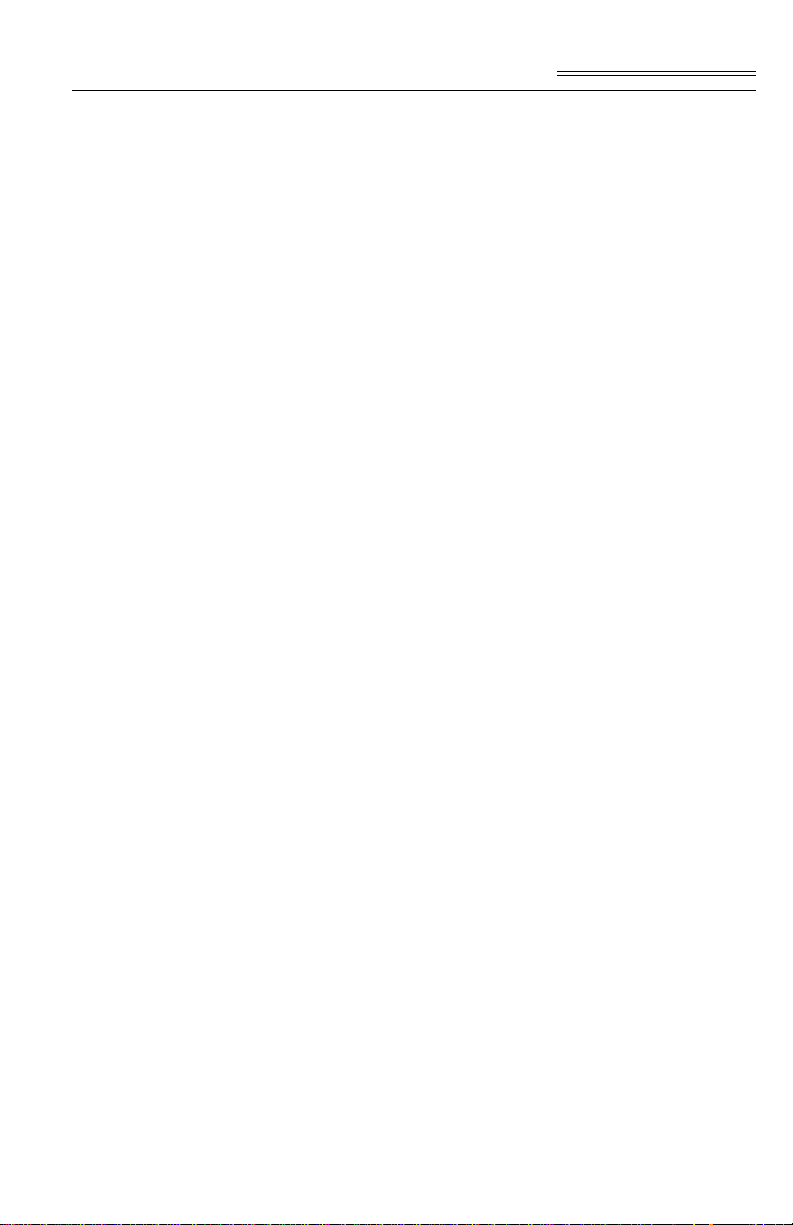

Default Parameters

Parameter Default Setting

Tare Weight 0.0 lbs

WAVERSAVER

Weight Units lbs 0

Span Weight 10,000.0 lbs

Averages 10

Auto Zero Tracking Enabled False 0

Tare Enabled True 1

Zero Enabled True 1

Calibration Type No Calibration -1

®

Table 2-1:

1 Hz 2

Setpoint Mode 1&2 Force Low,

oss

Gr

Setpoint Value 1&2 10000.0 lbs

Setpoint Deadband 1&2 0.1 lbs

Setpoint Preact 1&2 0.0 lbs

Auto-zero Tolerance 10.0 lbs

Motion Tolerance 5.0 lbs

Zero Tolerance 10

Rate of Change Time Base 10

Cal Year 0

Cal Month 0

Cal Day 0

Cal ID 0

0x12

2-4

Page 21

CHAPTER 3 - INSTALLATION

Chapter 3 - Installation

A Brief Description of Chapter 3

Unpacking Step 1. Before signing the packing slip, inspect

All information contained in Chapter 3 pertains to

unpacking, cabling, interconnecting, configuration

and installing the HI 1746-WS Weigh Scale Module.

Alternatives to any procedures contained or implied

in this chapter are not recommended. It is very impor

tant that the user and service personnel be familiar

with the procedures contained in this chapter, before

installing or operating the HI 1746-WS module.

Hardy Process Solutions appreciates your business.

Should you experience any problems installing this

equipment, contact Hardy Customer Support for

assistance.

the packing for damage of any kind.

Step 2. Report any damage to the carrier company

immediately.

Step 3. Check to see that everything in the pack-

age matches the bill of lading. You should

normally have:

• HI 1746-WS Weigh Scale Module

• Operation and Installation Manual

Step 4. Write down the Model and Serial number

of the module. Store this information in a

convenient location for reference when

contacting The Customer Support Depart

ment for parts or service.

-

-

Installing the

HI 1746-WS into an

Allen-Bradley SLC 500

Processor or AllenBradley Remote Rack

WARNING ELECTROSTATIC DISCHARGE MAY DAM-

AGE SEMICONDUCTOR COMPONENTS IN

THE MODULE. DO NOT TOUCH THE CON

NECTOR PINS. PLEASE OBSERVE THE FOLLOWING HANDLING PRECAUTIONS:

-

3-1

Page 22

HI 1746-WS WEIGH SCALE MODULE

• Wear an approved wrist-strap

grounding device when handling

the module.

• Touch a grounded object or surface to rid yourself of any electrostatic discharged prior to

ling the module.

hand

• Handle the module from the

bezel in

nector . Never, NEVER t

connector pins.

• Never install, remove, or wire

any

on. Always disconnect the power

from the SLC when working on

the module.

• Do not install the module right

next

module.

front away from the con-

ouch the

module while the power is

to an AC or high voltage DC

Setting the Jumper

or Local or

f

Remote Mode of

Operation

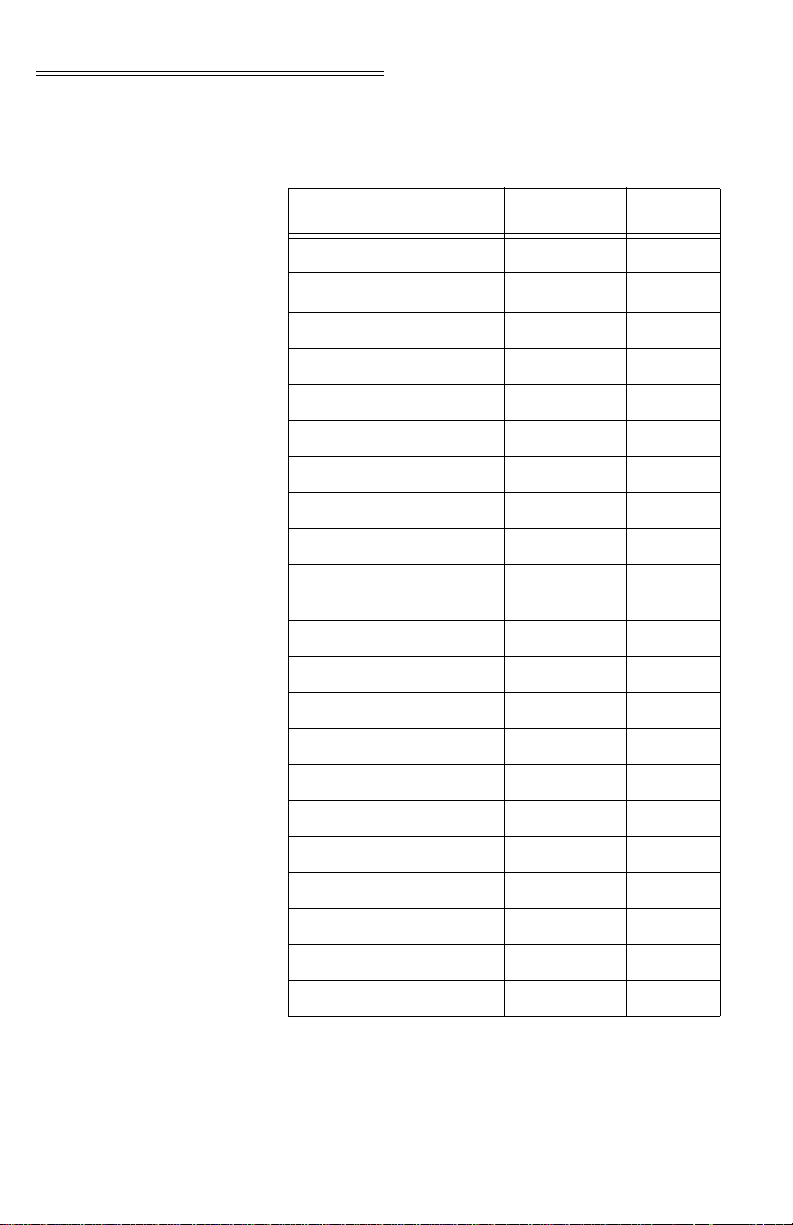

Step 1. Remove the module from its package by

ing the front cover. (See Fig. 3-1)

grasp

FIG. 3-1 HI 1746-WS WEIGH MODULE IN

PROPER ORIENTATION

Step 2. Place the jumper either

for Local or ON for Remote operation.

(See Fig. 3-2)

on OFF (Default)

3-2

Page 23

Chapter 3 - Installation

FIG. 3-2 JUMPER LOCATION/JUMPER SET

IN THE DEFAULT OFF (LOCAL MODE)

POSITION

Installing the HI

746-WS into the

1

SLC 500 or

Remote Chassis

Step 1. Make sure that the module is oriented cor-

rectly for installation. (See Fig. 3-3)

3-3

Page 24

HI 1746-WS WEIGH SCALE MODULE

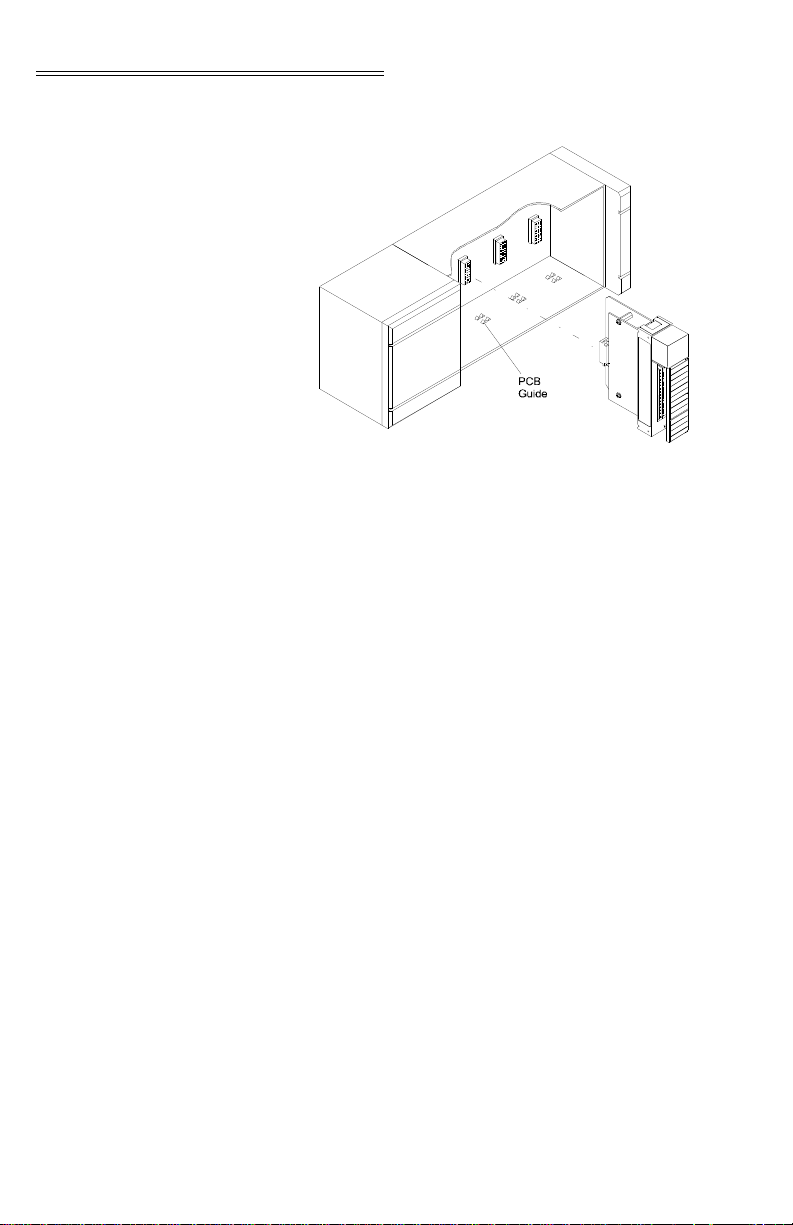

FIG. 3-3 POSITIONING THE MODULE FOR

Step 2. Gently slide the module into the SLC or

Step 3. Slide the digital board between the PCB

Step 4. When the module connector is touching

Step 5. The installation is complete.

INSTALLATION

Remote Chassis.

Guides

of the chassis to line up the module connector with the backplane connector.

the backplane connector

fully push toward the chassis until the pins

are pl

(both top and bottom) are snapped into

place. (See Fig. 3-4 & 3-5)

on the top plate and bottom plate

ugged in and the Processor Releases

, firmly but care-

3-4

Page 25

Chapter 3 - Installation

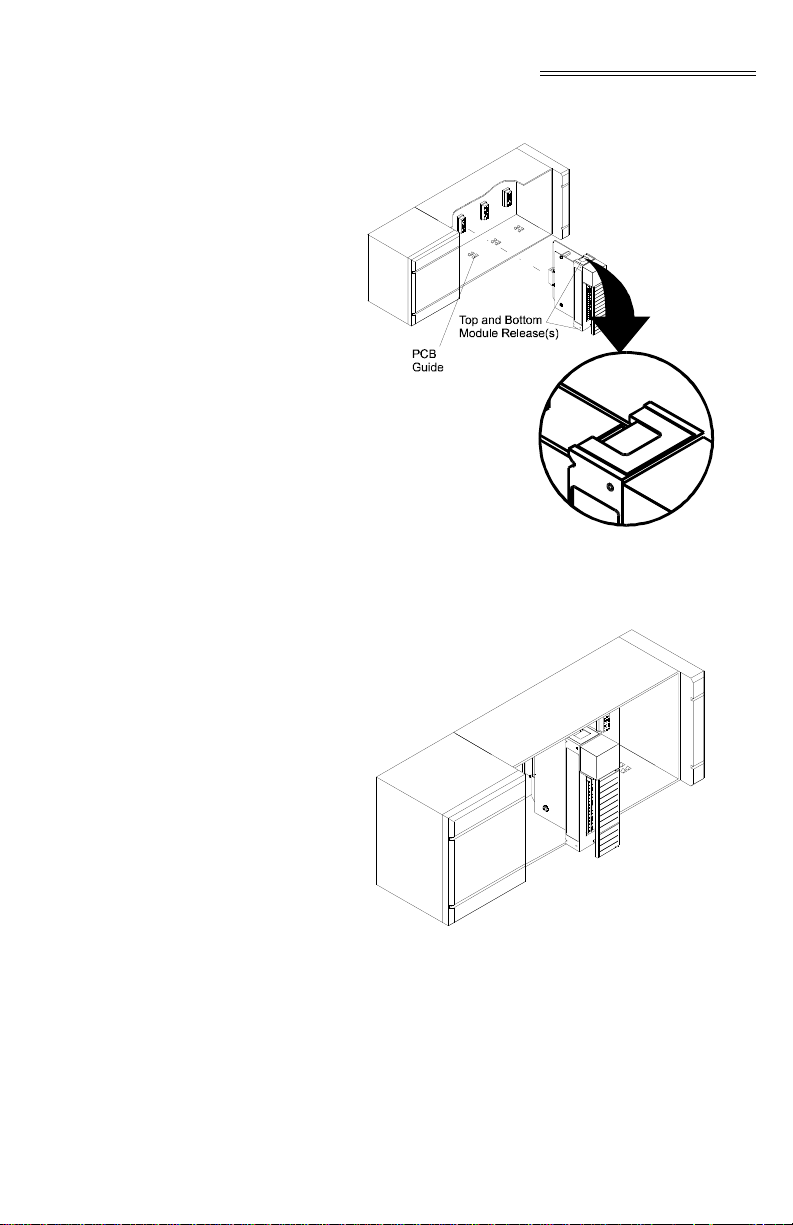

FIG. 3-4 MODULE RELEASE(S)

Removing the Module

rom the SLC 500 or

f

Remote Chassis

FIG. 3-5 MODULE INSTALLED IN SLC

CHASSIS

Step 1. Press down on the top and bottom Proces-

sor Releases simultaneously until the module can be pulled away from the chassis.

(See Fig

. 3-4)

3-5

Page 26

HI 1746-WS WEIGH SCALE MODULE

Step 2. Pull the module out of the Chassis.

Step 3. Store in a safe, secure location in an anti-

Installing the Module I/ O Connector

static bag or the original enclosure.

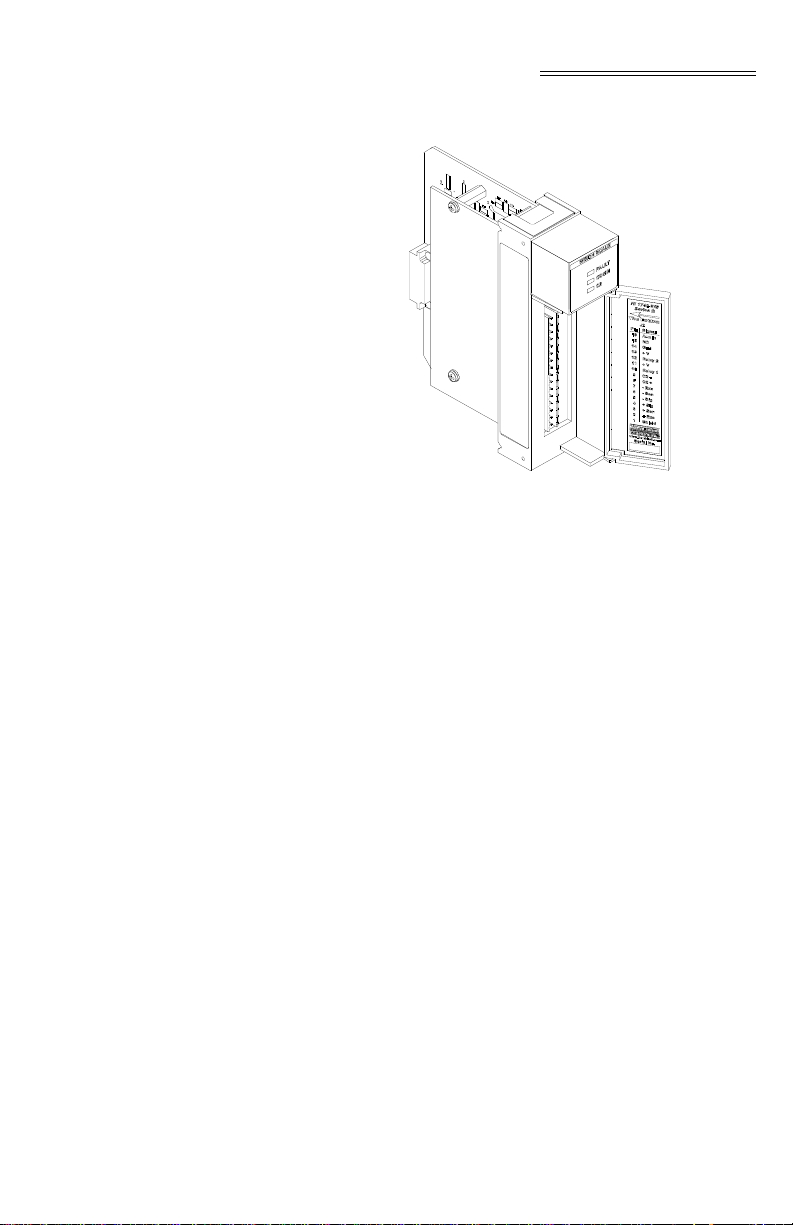

About the Module I/O Connector

The I/O Connector at the front of the module connects

the module to the load sensors and relays, or the HI

215IT Junction Box depending on how many load

sensors are installed in the weighing system. See

below for the pin-out diagram. The pin-out diagram is

located on the inside of the module door. (See Fig. 3-

5)

Pin 16 Aux In

Pin 15 N.C

Pin 14 GND

Pin 13 +V

Pin 12 Relay 2

Pin 11 +V

Pin 10 Relay 1

Pin 9 C2Pin 8 C2+

Pin 7 -Exc

Pin 6 -Sen

Pin 5 -Sig

Pin 4 +Sig

Pin 3 +Sen

Pin 2 +Exc

Pin 1 Shield

3-6

Step 1. Open the Module door to gain access to

the I/O connector. (See Fig. 3-5)

Page 27

Chapter 3 - Installation

FIG. 3-6 MODULE WITH DOOR OPEN

Step 2. Install the cable and

the module door to be shut.

Step 3. There is a bracket (not shown) that allows

to use a tie wrap to secure the cable to

you

the module.

Step 4. With the plug oriented correctly

pin-out diagram above), plug the I/O male

connector into the I/O connector at the

front of the module.

Step 5. Check to be sure that the connector is

pletely plugged in before operating

com

the module.

NOTE: Most of the problems with modules are due to loose

connections. Be sur

in the event you have a problem r eceiving information

from the load cells or if the relays do not operate correctly.

Load Cell Wiring Diagrams

NOTE: The HI 1746 has two factory installed jumpers. If

application is not using C2 load cells do not

your

remove the factory installed jumpers . If your appli-

e to check the I/O connection first

connector so it allows

(See the

3-7

Page 28

HI 1746-WS WEIGH SCALE MODULE

cation requires load cells cables that are less than 50

ft. you must leave the jumpers installed or connect the

sense lines, one or the other. If your application calls

for load cell cables over 50 ft. or you are using C2

load cells, remove the jumpers and connect the sense

lines. The jumpers or sense lines must be installed at

all times.

WARNING: Load cell cable length has been calculated into C2 calibration data. Hardy recommends

t you DO NOT CUT your Advantage or Advantage

tha

Lite load sensor cable, as your C2 accuracy will be

affected and the warranty will be voided.

Industry Standard

Load Cell

s

3-8

FIG. 3-7 INDUSTRY STANDARD LOAD CELLS

WIRING DIAGRAM

Page 29

Hardy Load Sensor with C2

Chapter 3 - Installation

FIG. 3-8 HARDY LOAD SENSOR/C2 WIRING

DIAGRAM

Hardy HI 215IT

unction Box

J

FIG. 3-9 HARDY HI 215IT JUNCTION BOX

WIRING DIAGRAM

NOTE: When connecting the Hardy HI 215IT Junction Box

st remove the two factory installed jumpers

you mu

that are connected to contacts 2&3 and 6&7 on the

module and install sense lines.

3-9

Page 30

HI 1746-WS WEIGH SCALE MODULE

Installing the Hardy Configuration Software (Optional)

Contact your local Hardy Representative or Hardy

Sales Department for information about how to pur

chase the Hardy WS 100 Configuration Software for

Windows.

Step 1. The SETUP program copies the required

files to your hard disk.

Step 2. Run Windows NT/95/98 and insert the

Configuration Installation System Disk

into the 3.5” floppy drive.

Step 3. Click on START.

Step 4. Click on Run.

Step 5. In the Run field type the command:

a:setup. If your floppy drive is drive b

enter: b:setup.

Step 6. Press the Enter key.

Step 7. You can also use the Add/Remove Func-

tion in the Control Panel dialogue box.

a. Click on Start

b. Move the cursor to Settings.

c. Select Control Panel.

d. Double click on the Add/Remove Pro-

grams icon.

e. Click on the In stall button.

-

Step 8. The SETUP program will lead you

through the installation process.

NOTE: HI WS100 Configuration Software is an option. For

Pricing and Information for this product contact your

local Hardy Representative.

3-10

Page 31

CHAPTER 4 - SETUP

Chapter 4 - Setup

A Brief Description of Chapter 4

Power Check Step 1. Check to see that there is power to the

All information contained in Chapter 4 pertains to

firmware and software settings (Local and Remote

modes of operation) to prepare the module controller

for calibration and operation. Alternatives to these

procedures explicit or implied, contained in this sec

tion are not recommended. It is very important that

the user and service personnel be familiar with the

procedures contained in this chapter, before going

through the setup procedures. The Setup procedures

require either Allen-Bradley DOS PLC 500 AI Series

Ladder Logic Editor, Allen-Bradley RS Logix 500,

Allen-Bradley RSLinx™ or RSLinx™ Lite. The

Local Mode of Operation means the Module is

installed in a SLC Chassis and Remote Mode of Oper

ation means the Module is installed in a Remote

Chassis.

SLC and the module.

Step 2. If there is power to the module, the LEDS

should be lit. (See Fig. 4-1)

Step 3. To make any settings the LED’s should be

lit as follows:

a. Run/Fault - Steady Green

b. Communication - Flashing Green

c. C2 - Steady Green if system has C2

load cells or off if there are no C2 load

cells.

-

-

4-1

Page 32

HI 1746-WS WEIGH SCALE MODULE

LEDS

Run/Fault LED Flashing Green Self-Test is running.

Flashing Green (5Hz Flash Speed) - Self-Test

Steady Green Self-Test Passed

Flashing Red Weigh Scale Module has a fault.

Steady Red Module has a major problem.*

FIG. 4-1 MODULE LEDS

iled, or no calibration.

Fa

NOTE: * Contact Hardy Customer Support for assistance.

Comm. LED Steady Green Normal Operation

Flashing Green Block transfer is being performed.

LED is Off No Communication

C2 LED Steady Green A C2 load cell(s) has been found.

LED is Off No C2 load cells have been found.

Steady Red Unable to read loadcell data or the

cell data is in error.

load

Setting Up

Communic

Between the SLC and

the HI 1746-WS Weigh

Scale Module

4-2

ations

To set up communication between the SLC 5XX and

the HI

1746-WS Weigh Scale Module you will need

to select or enter the following information into the I/

O Configuration section of your software:

Page 33

Local Mode of Operation

Chapter 4 - Setup

Type of Device Category: Other

I/O Card ID Code: 13635

M Files

M0 = 128 Words

M1 = 128 Words

There are no G files.

Remote Mode of Operation

About M Files The M File Interface consists of two files, M0 and

Direct M File Mapping

Local Mode of Operation

Type of Device Category: Other

I/O Card ID Code: 3535

Input Words: 8

Output W ords: 8

M1. M0 and M1 files are data files that reside in the

HI 1746-WS W eigh Scale Module. There is no image

for these files in the processor memory. With respect

to the SLC processor (SLC 5/02, 5/03, 5/04, 5/05) the

M0 file is a module output file (a write only file) and

the M1 file is a module input file (a read only file).

With respect to the HI 1746-WS weigh module the

M1 file is for output from the module to the processor

and M0 file is for input from the processor to the

module. The module writes replies in the M1file to

commands that the processor writes into the M0 file.

The M files are used to control and monitor block

transfer operations.

For the 1746 modules used in the local chassis, Hardy

has available direct mapping of the parameters to the

M files. This means that you can write to a specific

location in the M0 file and the1746 will pick up the

change and apply it and reflect the change in the M1

file.

4-3

Page 34

HI 1746-WS WEIGH SCALE MODULE

NOTE: After making the change, you need to save the change

to non-volatile memory.

Changes can be made one word at a time or up to 37

words (all parameters) at a time.

NOTE: If multiple words written to the module at the same

time, data must be in the same order and have the cor

rect length for each parameter.

The mapping is as follows for all the parameters:

Parameter Word

Tare Weight (float) 28

Span Weight (float) 30

CalLO Weight (float) 32

Set Point 1 (float) 34

Dead Band 1 (float) 36

Preact 1 (float) 38

Set Point 2 (float) 40

Dead Band 2 (float) 42

Preact 2 (float) 44

Zero Tolerance (float) 46

Auto Zero Tolerance (float) 48

Motion Tolerance (float) 50

-

4-4

Parameter Word

Metric (int) 52

Waversaver (int) 53

Averages (int) 54

Zero Track Enable (int) 55

Tare Enable (int) 56

Zero Enable (int) 57

ROC Time Base (int) 58

Setpoint 1 Type (int) 59

Setpoint 2 Type (int) 60

Cal Year (int) 61

Cal Month (int) 62

Cal Day (int) 63

Cal ID (int) 64

Page 35

Chapter 4 - Setup

Remote Mode of Operation

NOTE: After making the change you need to save it to non-

M File Interface to Set Up for Local Mode of Operation

CAUTION: THIS SETUP INFORMATION IS FOR THE

For 1746 modules used in the remote chassis, direct

mapping of the parameters to the M files is also avail

able. You can write to a specific location in the M0

file, do a single Executable command, such as com

mand 4 to write non-volatile, and the 1746 will pick

up the change and apply it to the weigh module and

reflect the change in the M1 file.

volatile memory.

The 1746 module is limited to 8 words total for any

read or write at any time, so you are limited to chang

ing a maximum of 7 words at a time. The mapping is

the same as listed above for the local chassis.

LOCAL MODE OF OPERATION ONLY.

BEFORE SETTING UP FOR LOCAL MODE OF

OPERATION CHECK TO BE SURE THE

JUMPER IS SET FOR LOCAL MODE AND

THAT THE MODULE IS INSTALLED IN A

LOCAL SLC CHASSIS. (SEE CHAPTER 3, PG

3-2 FOR MORE INFORMATION)

-

-

-

M File Data Structure (Words 0 to 5)

0 Sequence Number (sequenceNum) is used to

control the flow of commands to the HI 1746-WS

module in order to prevent duplicate or invalid

commands. To write a command to the module,

the processor must copy the current sequence

number from the M1 file to the M0 file. When the

module performs the requested command, it

writes the response into the M1 file, incrementing

the sequence number by 1. To get the sequence

number from the module, a read command

should be used before a write command to

retrieve the next number from the module.

1 Command is used to select the command to be

performed. Enter the command from the Com

mand List.

-

4-5

Page 36

HI 1746-WS WEIGH SCALE MODULE

2 Command Status indicates if the command suc-

ceeded or not. The module writes a value of zero

(0) if the command succeeded. If the command

failed, the module writes an error code value

which indicates the reason for the command fail

ure. (See the Error Code List.) The Error Code

table also lists the commands where the error

code is the sum of possible error bits.

3 Offset specifies which parameter will be read or

written.

4 Length is the number of bytes in a data string

field (32 bytes maximum or 16 words)

5 Datastring field is where the actual data is entered

you want to send to the module, or to receive

from the module. Example: To set the value of

one of the module’s parameters, the value of the

parameter is written in the Datastring field.

Logical File Interface to Set Up for Remote Mode of Operation (8 Word)

-

CAUTION: THIS SETUP INFORMATION IS FOR THE

REMOTE MODE OF OPERATION ONLY.

BEFORE SETTING UP FOR REMOTE MODE

OF OPERATION, CHECK TO BE SURE THE

JUMPER IS SET FOR REMOTE MODE AND

THAT THE MODULE IS INSTALLED IN A

REMOTE CHASSIS. (SEE CHAPTER 3, PG 3-2

FOR MORE INFORMATION)

About Logical Files

4-6

For the remote mode of operation, the HI 1746-WS

has no M files. Instead, the module contains files that

correspond to the 32 word I and O files used when the

module is in the local mode of operation. These files

are referred to as “Logical MFiles”. Logical MFiles

perform the function of the I, O, and M files used in

the local mode of operation but are not directly acces

sible through the SLC backplane. (See Fig. 4-2)

•O = Output

• I = Input referenced to the CPU.

-

Page 37

Chapter 4 - Setup

FIG. 4-2 PRIMARY AND REMOTE

COMMUNICATION DIAGRAM

Command Word

oding

Enc

You may write up to 7 words at a time to either the

Logical O file or the Logical M0 file. Word #0 of the

8 word output file is used to specify where words 1-7

go in either the logical O or M0 file, is called the

“Command Word”. Word #0 of the I file will always

be a copy of the “Command Word”.

Bits 15 & 14 11 = write 0 to 7 words to the logical M0 file,

Read 7

words from the M1 file.

NOTE: You need to run any com mand through M files before

evious writes take effect.

pr

01 = write 0 to 7 words to the logical O file, Read

nfigured) I

(co

10 = configure 0 to 7 words for the I file return, configure 7 words to read from Logical I file.

00 = the configured I file returned.

Bits 8-13 Number of words to write to the logical M0

or logical

O file.

Bits 0-7 Offset (in words) in the logical

M0 or logical O file

where the write begins.

Command Word - 16 bits

Bits 15-14 Bits 13-8 Bits 7-0

4-7

Page 38

HI 1746-WS WEIGH SCALE MODULE

Command Word - 16 bits

Writing to the 32

Word Logical O

Configure the

Read and Write

You must Decide whet her you are going to write to

the M0 or O file.

Binary value indicating number of

words to write

Binary value indicating starting offset for write/read

to begin.

and logical M0

files

Command Word

Writing to the M0 file

• Bits 15-14 set to “11”, will specify a

write to the logical M0 file.

• Bits 13-8 set as a binary value indicating number of words to write (e.g. 2

would be “000010”.

• Bits 7-0 set as a binary value indicating offset word to start writer at (e.g.

28 would be “00011100”.

For Example A command word set to binary value “1100 0010

0001 1100” would indicate a write of 2 words to the

logical M0 file starting at offset word 28.

4-8

Writing to the O file

• Bits 15-14 set to “01”, will specify a

write to the logical O file.

• Bits 13-8 set as a binary value indicating number of words to write (e.g. 2

would be “000010”).

• Bits 7-0 set as a binary value indicating offset word to start write at (e.g. 7

would be “00000111”).

For Example A command word set to binary value “0100 0010

0000 0111” would indicate a write of 2 words to the

logical O file starting at offset word 7.

Words 1-7 Data to be written to the M0 or O files. Number of

words determined by setup of “Command Word

Page 39

Chapter 4 - Setup

Reading from the 32 Word Logical I and logical M1 files

Command Word

Bits 15-14 set to “10”

For Example

Bits 15-14 set to “11”

For Example

Reads are all done in the I file (not to be confused

with the “logical I file”). Word #0 will always be a

copy of the “Command Word”. Words 1-7 of the I file

can be configured to read up to 7 words from either

the Logical M1 or the Logical I file (you cannot read

from both at the same time).

Allows the user to specify what words (up to 7) from

the logical I file to appear in words 1-7 in the I file.

If bits 15-14 are set to 10 in “Command Word” and

words 1-7 of the O file are: 18,19, 20, 21, 16, 15, 24.

The return in the I file words 0-7 would be (in order):

“Command Word”, gross weight (MSW), gross

weight (LSW), net weight (MSW), net weight (LSW),

relay status, module status, and ROC evaluation

period.

When written to the logical M0 file, will cause the I

file to reflect the words at the same starting offset in

the logical M1 file as specified in bits 7-0.

If 2 words are written to the logical M0 file starting at

offset word 28, then offset words 28 and 29 of the log

ical M1 file would appear in words 1 and 2 of the I

file.

-

Bits 15-14 set to “01”

NOTE: The selected words to read are not necessarily the

Bits 15-14 set to “00”

NOTE: After an input byte is configured, the 1746 will

For a write will cause the I file to reflect the words

previously selected to read using the “10” setting.

ones being written to using the “01” setting.

Returns the configuration set up with the “10” command.

remember the configuration as long as it has power.

The Configuration is lost after you power down.

4-9

Page 40

HI 1746-WS WEIGH SCALE MODULE

Executable Command List

CAUTION: ALWAYS PERFORM A READ COMMAND

FIRST BEFORE THE WRITE COMMAND

EVERYTIME, TO GET THE CORRECT

SEQUENCE NUMBER. (SEE THE SETPARAMS EXAMPLE, RUNG 0 FOR THE LADDER LOGIC)

Zero Command

EROCMD)

(Z

SEQ

NUMBER

0

From M1 File 1

COMMAND#

(Hex)

Tare Command (TARECMD)

The Zero Command requests that the current gross

weight be set to zero.

Error Return Values:

• NOTALLOWED - the ZeroEnable parameter is

not

set to TRUE (1),

• OUTOFTOLERANCE - the current weight value

is beyon

d the limits set by the zero tolerance

parameter.

• “ST ATUSWORD” - the command failed because

weight was not stable (in motion), or that

the

there was an A/D error of some kind.

STATUS

1

2

OFFSET

3

LENGTH4DATA

The T are Command requests the current net weight be

set to zero.

5-16

4-10

Page 41

Chapter 4 - Setup

Error Return Values:

• NOTALLOWED - the TareEnable parameter is

not

set to true

• “STATUSWORD” - means the command failed

because the weight was not

stable (in motion) or

there was an A./D error.

SEQ

NUMBER

0

From M1 File 2

COMMAND#

(Hex)

Write Non-Volatile Command (WRITENONVOLA TILE)

SEQ

NUMBER

0

From M1 File 4

COMMAND#

(Hex)

Reload NonVolatile

(RELOADNONVOL

ATILE)

1

STATUS

2

OFFSET

3

LENGTH4DATA

The Write Non-Volatile Command - causes all parameters (including calibration constants) to be saved to

n-volatile memory.

the no

Error Return Values: None

STATUS

1

2

OFFSET

3

LENGTH4DATA

The Reload Non-Volatile Command - causes the

h module to re-read the values stored in its non-

weig

volatile memory. Any parameters changed since the

last write non-volatile command are overwritten. this

command can be used to abort a calibration or parameter entry session.

5-16

5-16

SEQ

NUMBER

0

From M1 File 0x10

COMMAND#

(Hex)

1

Error Return Values: None

STATUS

2

OFFSET

3

LENGTH4DATA

5-16

4-11

Page 42

HI 1746-WS WEIGH SCALE MODULE

Float Integer to Integer Conversion Command (FLOAT2INT)

SEQ

NUMBER

0

From M1 File 0x96

COMMAND#

(Hex)

1

Integer to Float Integer Conversion Command (INT2FLOAT)

The Float Integer Conversion Command - converts a

oating point number into an integer format. (For use

fl

with the SLC 5/02)

Data Input Values: 6 bytes (a four byte float, and a

byte integer)

two

Return Value: 4 byte long intege r, equal to the float

ltiplied by the integer.

mu

STATUS

2

OFFSET

3

LENGTH4DATA

5-16

The Integer to Float Integer Conversion Command -

verts a Float integer to an integer. (For use with

Con

the SLC 5/02)

Data Input Value: A four byte long integer, and a two

e integer.

byt

Return Value: A four byte float, equal to the long

ivided by the two byte integer.

d

Error Return Value:

4-12

SEQ

NUMBER

0

From M1

File

• NOTALLOWED - returned if the two byte integer is zero.

COMMAND#

(Hex)

1

0x97 Integer

STATUS

2

OFFSET

3

DATA6DATA7DATA

Integer

Dividend

LENGTH4DATA

8-16

int2

Divisor

5

Dividend

Page 43

Chapter 4 - Setup

Cal Low Command (CALLOWCMD)

SEQ

NUMBER

0

From M1 File 0x64

COMMAND#

(Hex)

1

Cal High Command (CALHIGHCMD)

The Cal Low Command - sets the “calLowCount”

parameter to the current A/D average counts when

doing a hard calibration.

Error Return Values:

• STATUSWORD - there was a conversion error,

ht in motion or an A/D error or all three.

weig

• HARDCALFAILCOUNTS - there is less than

counts between the zero and the span

100

weights.

STATUS

2

OFFSET

3

LENGTH4DATA

5-16

The Cal High Command - Sets the Span Weight

parameter to the current A/D average counts when

doing Hard CAL.

Error Return Values:

• STATUSWORD - there was a conversion error,

ht in motion or an A/D error or all three.

weig

SEQ

NUMBER

0

From M1 File 0x65

COMMAND#

(Hex)

1

C2 Cal Command (C2CALCMD)

• HARDCALFAILCOUNTS - there is less than

counts between the zero and the span

100

weights.

STATUS

2

OFFSET

3

LENGTH4DATA

5-16

The C2 Cal Command - Performs a C2 Calibration.

4-13

Page 44

HI 1746-WS WEIGH SCALE MODULE

Error Return Values:

• STATUSWORD - there was a conversion error,

weig

ht in motion or an A/D error or all three.

• C2FAILNODEVS - did not detect any C2 load

cells.

• C2FAILCAPEQ - detected two load cells with

ferent capacities.

dif

SEQ

NUMBER

0

From M1 File 0x66

COMMAND#

(Hex)

1

Read C2 Serial Number Command (READC2SERIALN UM)

SEQ

NUMBER

0

From M1 File 0x70

COMMAND#

(Hex)

1

STATUS

2

OFFSET

3

LENGTH4DATA

5-16

The Read C2 Serial Number Command - Reads the 9

serial number from a C2 chip located on every

byte

C2 load cell. Specify the index of the C2 chip to read

in commandData.offset of the Mfile. The index

should be a number of 0 to C2RomX-1 (-1 is a minus

one not a dash one), where C2RomX is the number of

C2 chips. The “serial number” will be 8 bytes of

ASCII text, followed by a 0 terminator.

Error Return Values:

• OUTOFTOLERANCE - specified chip is not

und.

fo

STATUS

2

OFFSET

3

LENGTH4DATA

5-16

Set Parameters Command (SETPARAM)

4-14

Sets a parameter in the module. (See Setting the Process Weighing Parameters below for more detailed

information.)

Page 45

Chapter 4 - Setup

Error Return Values:

• OUTOFTOLERANCE - is returned if an incor-

rect value is entered to a parameter.

• INDEXOUTOFRANGE - is returned if no

parameter co

rresponds to the offset specified.

SEQ

NUMBER

0

From M1 File 0x100 Use Parame-

Get Parameters Command (GETPARAM)

COMMAND#

(Hex)

1

STATUS

2

OFFSET

3

ter Offset

alue from

V

Table 4-1

Reads a parameter, from the module. (See Setting the

Process W eighing Parameters below for more detailed

information.)

Error Return Values:

• OUTOFTOLERANCE - is returned if an incor-

rect value is entered to a parameter.

• INDEXOUTOFRANGE - is returned if no

rresponds to the offset specified.

OFFSET

3

SEQ

NUMBER

0

COMMAND#

(Hex)

1

parameter co

STATUS

2

LENGTH4DATA

5-16

See

eight

W

Multiplier

Section

Below

LENGTH4DATA

5-16

From M1 File 0x101 Use Parame-

ter Offset

V

alue from

Table 4-1

4-15

Page 46

HI 1746-WS WEIGH SCALE MODULE

I/O Setup Ladder Logic for Remote Mode Operation

4-16

Page 47

Chapter 4 - Setup

4-17

Page 48

HI 1746-WS WEIGH SCALE MODULE

FIG. 4-3 SETUP I/O FOR REMOTE MODE OF OPERATION

HI WS100

iguration

Conf

Software Interface

(Remote Mode of

Operation)

4-18

The HI WS100 program communicates w

remote HI 1746-WS module via an integer (N7, N8,

etc.) file, as specified in the “Comm Setup Section of

the HI WS100 Configuration Software Manual Prt.

#0596-0241-01) HI WS100 and requires 17 contiguous words.

ith the

Page 49

Chapter 4 - Setup

A version of the ladder logic is contained in the HI

WS 100 Configuration Software Manual. All

addresses are arbitrary in the ladder logic example

and may need to be changed to match the hardware

configuration of your system and to prevent conflicts

in addressing.

In the Ladder Logic example provided in the HI

WS100 manual note the following:

• N9 is the data file for the data written

to and read from the module and the

trigger bit.

• The ladder logic program needs 17

contiguous words in the data file,

which are:

1. N9:0 is the write trigger

2. N9:1 to N9:8 are write data loca-

tions.

3. N9:9 to N9:17 are read data loca-

tions.

NOTE: These can be from an integer file with 17 contiguous

words available.

4. N10 is the data file for setting up

sections of the M files.

5. N10:0 sets a section of the M file

as read.

6. N10:1 sets the length

7. N10:2 sets the address.

8. N10:5 sets a section of the M file

as write

9. N10:6 sets the length

10. N10:7 sets the address

11. N10:10 to N10:19 are locations

used for checking status

NOTE: Refer to Allen-Bradley 1747 Scanner module manual

for more information on the setup of M files.

4-19

Page 50

HI 1746-WS WEIGH SCALE MODULE

12. M0:x.yy and M1:x.yyy (where x

= slot scanner module is in and

yyy = location within the M file)

are the M files being written to or

read from.

13. M0 is from the processor to the

scanner

14. M1 is from the scanner to the

processor

15. B11:0 is used for program control

bits.

• Insure the following:

1. Data file (i.e. N9) has 17 contiguous words and the file number

and first word are listed in the

appropriate fields in the “COMM

SETUP” screen in WS100 and

the “Remote” box is checked.

2. Proper driver is selected. This

should be the same driver that RS

Logix 500 would use.

3. Station number of the processor

is correct which can be found in

the driver configuration.

4. M file setup data (i.e. N10:0 to

N10:2) is correct for your setup.

5. Slot location is correct in the M

file references.

Setting The Process Weighing Parameters

About the Ladder Logic Example

Weight Multiplier To use one of the commands, place the offset of a

4-20

W e have provided a Ladder Logic example explaining

how to set the weigh process parameters. The Ladder

Logic example is meant to provide a ladder logic

model only. Your application may vary and the exam

ple may or may not meet your requirements.

parameter, from Table 4-1, into the command

Data.offset of the M0file. If you are setting a parame-

-

-

Page 51

Chapter 4 - Setup

ter, place the 4 bytes for a float, or two bytes for an

integer into the dataString.

If you have set the WEIGHTMUL TIPLIER in the output data file to a non-zero value, and you are setting a

parameter of type float, the parameter will be set to

the 4 byte integer value you place in the dataString,

divided by the WEIGHTMULTIPLIER. The parame

ter will be interpreted as pounds or kilograms,

depending on the value of the Metric parameter.

If you are reading a type float parameter, and the

WEIGHTMULTIPLIER is non-zero, the value of the

parameter returned in dataString will be a 4 byte inte

ger, equal to the parameter multiplied by the

WEIGHTMULTIPLIER. The value returned will be

pounds or kilograms, depending on the value of the

Metric Parameter.

If the WEIGHTMULTIPLIER is zero, the dataString

value returned will be a floating point integer.

-

-

NOTE: If using a multiplier, setpoint data to and from the I/O

tables is limited to three (3) decimal places.

SETPARAM GETPARAM

Command and

Non Volatile

Memory

Possible Error Returns

The parameters set using the SETPARAM command

are not automatically saved to non-volatile memory.

A separate command is required (WRITENONVOL

ATILE 4).

Some parameters are not automatically used by the

weigh module, because they are normally used only at

start up. The command to save parameters to non-vol

atile memory does cause a re-initialization, so that the

parameters will then be active.

OUTOFTOLERANCE - is returned if an incorrect

value is entered to a parameter.

INDEXOUTOFRANGE - is returned if no parameter

corresponds to the offset specified.

4-21

-

-

Page 52

HI 1746-WS WEIGH SCALE MODULE

Setting Parameters Ladder Logic Explanation

Rung #0 Does an initial read of the M1 file. This is

necessary to get the sequence number for

future writes.

Rung #1 Loads data into the write location ready to

write. The data required is:

a. Sequence Number

b. Command Number

c. Parameter Offset

d. Parameter Value

Rung #2 Checks to see if the data was loaded from

the previous rung, then writes to the M0

file.

Rung #3 Reads the M1 file for the response.

Rung #4 Checks the results of the read to make sure

that the sequence number was incremented

(write complete) and that the status is zero

(no error). If the check is good, it latches a

bit for the next parameter.

Rung #5 Checks the results of the read and if the

status is not zero (error occurred) restarts

the process of writing this parameter.

4-22

Rungs #6-30 Duplicate the same process as rungs

#1 to #5 for the remaining parameters.

a. Rungs #1-5 - Units

b. Rungs #6-10 - Number of Averages

c. Rungs #11-15 - WAVERSAVER Set-

ting

d. Rungs #16-20 - Zero Tolerance

e. Rungs #21-25 - Auto Zero Tolerance

f. Rungs #26-30 - Mot ion Tolerance

Page 53

SETPARAMS Local Mode of Operation

Chapter 4 - Setup

FIG. 4-4 SETPARAMS LADDER LOGIC EXAMPLE/LOCAL MODE

4-23

Page 54

HI 1746-WS WEIGH SCALE MODULE

SETPARAMS Remote Mode of Operation

4-24

Page 55

Chapter 4 - Setup

4-25

Page 56

HI 1746-WS WEIGH SCALE MODULE

4-26

Page 57

Chapter 4 - Setup

FIG. 4-5 SETPARAMS LADDER LOGIC EXAMPLE/REMOTE MODE

Parameter (type) Offset (Hex)

SpanWeight (float) 0x1C

CalLoW eight (float) 0x20

ZeroT olerance (float) 0x4C

AutoZeroTolerance (float) 0x50

MotionTolerance (float) 0x54

Metric (int) 0=LBS 0x14

WAVERSAVER (int) limits = 0 - 4 0x16

NumAvera ges (int) limits = 1 - 255 0x24

ZeroTrackEnable (int) 0x26

TareEnable (int) 0x28

ZeroEnable (int) 0x2A

RoctimeBase (int) li mits = 1 - 1800 0x2E

Tareweight (float) 0x10

Calyear (int) 0x9C

Calmonth (int) 0x9E

Calday (int) 0xA0

Table 4-1: Parameters and Offsets

4-27

Page 58

HI 1746-WS WEIGH SCALE MODULE

Parameter (type) Offset (Hex)

Calid (int) 0xA2

Table 4-1: Parameters and Offsets

Error Code List SUCCESS 0

NOTALLOWED -1

OUTOFTOLERANCE -3

INDEXOUTOFRANGE -4

NOSUCHCMD -5

C2FAILNODEVS -6

C2FAILCAPEQ -7 (failure, capacities

not equal)

HARCALF AILCOUNTS -8 (failure, not enough

ADC counts between

high, low)

NOTE: For a complete ladder logic example for downloading

all the parameters please go to the Hardy Process

Solutions Inc. We b Si te at: www.hardysolutions.com.

Select Support then click on Sample Programs. If you

do not have access to the Internet contact your local

Hardy Representative or Hardy Customer Support

and we will be glad to fax or mail you a hard copy.

Calibration Setup Procedures

Setting the Unit of Measure

Setting the Motion Tolerance Value

4-28

The Unit of measure (Metric - See Table 4-1) can be

set to either kilograms or pounds. Any weight value

input to the module (e.g. CAL-LO, CAL-HI setpoints)

are in the currently selected units. The unit of measure

can be set at any time, not just at calibration. Setting

the unit of measure before calibrating reminds the

user what unit of measure is being displayed. It is

important to note that the weigh scale module does

not need to be calibrated again after changing the unit

of measure.

The motion tolerance is the tolerance value used to

determine if the scale is in motion.

Page 59

Chapter 4 - Setup

Setting the Zero Tolerance Value

Setting the Auto

olerance

Zero T

Value

Sets the range of weights so that the Zero Command

works, as an offset of the calibrated Zero.

When the Auto Zero Tolerance is entered, and Auto

Zero Tracking is enabled, any weight within the

entered tolerance of zero and within the Auto Zero

Tolerance of the calibrated zero point, with the scale

not in motion, will cause the display to automatically

read zero.

NOTE: There is a short time delay (at least 1 second) before

the Auto

Zero Triggers.

The amount of weight zeroed off is cumulative. The

o command will fail if the current gross weight plus

zer

any previously zeroed amount exceeds the zero

tolerance.

Setting the

Number of

Rea

dings

Averages

Setting the Span

eight Value

W

The Number of Averages sets the number of weight

readings which will be used to compute the displayed

weight. The average is a slid ing average so that a new

average reading is available for display at every reading

The Span W eight is a reference point derived from an

actual measured weight. This should not be confused

with the Scale Capacity. If you have a 100 pound

weight and you place it on the scale, the Span Weight

would be 100 pounds.

.

Setting the

AVERSAVER

W

Value

There are 5 selectable levels. 0 provides the least

vibration immunity with the fastest response time. 4

provides the most vibration immunity with the slowest response time. Default setting is 2.

Immunity Setting

7.5 Hz 0

3.5 Hz 1

1.0 Hz 2

0.5 Hz 3

0.25 Hz 4

4-29

Page 60

HI 1746-WS WEIGH SCALE MODULE

4-30

Page 61

CHAPTER 5 - CALIBRATION

Chapter 5 - Calibration

A Brief Description of Chapter 5

Pre-Calibration Procedures

Chapter 5 pertains to the calibration procedures for

the HI 1746-WS W eigh Scale Module. Alternatives to

any procedures either implied or explicitly contained

in this chapter are not recommended. In order for the

W eigh Module to work properly, it must be calibrated

prior to operation. Calibration procedures require an

understanding of the M File interface. It is recom

mended that the module be re-calibrated periodically

or when not in use for extended periods of time. Be

sure to follow all the procedures completely to insure

that the weights read by the module are accurate. It is

very important that the user and service personnel be

familiar with the procedures contained in this chapter,

before installing or operating the HI 1746-WS Weigh

Module.

Step 1. Check to determine if the load cells have

been properly installed.

a. Refer to your load cell I&M manual for

proper installation instructions.

b. On some single and double ended shear

beam load cells there is an arrow that

indicates the direction of the applied

load. If the arrow is pointing in the

wrong direction, change the position of

the load cell so that it is mounted in the

direction of the applied load.

-

Step 2. Check for Binding on the Load Cell or

other parts of the weighing system.

CAUTION: BINDING ON A SCALE/VESSEL OR LOAD

CELL DOES NOT ALLOW THE LOAD CELL

FREE VERTICAL MOVEMENT AND MAY PRE

VENT THE INSTRUMENT FROM RETURNING

TO THE ORIGINAL ZERO REFERENCE

POINT.

a. A load cell must be mounted in such a

way that 100% of the load (Vessel w/

-

5-1

Page 62

HI 1746-WS WEIGH SCALE MODULE

b. Check to see that nothing is binding the

c. Check to see that nothi

Contents) is vertically passed through a

load cell. (See Fig. 5-1)

load cell. This