Hardinge Talent 6/45, Talent 8/52, Talent 8/66, Talent 10/78 Maintenance Manual

MAINTENANCE MANUAL

TP7086

®

TALENT

6/45

TALENT 8/52

TALENT 8/66

TALENT 10/78

CNC LATHES

Equipped with a Fanuc 0i-T,

Fanuc 0i Mate-T,

or Siemens 810D Control

Revised: March 31, 2006

Manual No. M-448B Litho in U.S.A.

Part No. M B-0009500-0448 January, 2006

- NOTICE -

Damage resulting from misuse, negligence, or accident is not covered by the

Hardinge Machine Warranty.

Information in this manual is subject to change without notice.

This manual covers the maintenance of Hardinge TALENT

equipped with a Fanuc 0i-T, Fanuc 0i Mate-T, or Siemens 810D control.

In no event will Hardinge Inc. be responsible for indirect or consequential

damage resulting from the use or application of the information in this man

ual.

Reproduction of this manual in whole or in part, without written permission

of Hardinge Inc., is prohibited.

CONVENTIONS USED IN THIS MANUAL

- WARNINGS -

Warnings must be followed carefully to avoid the possibility of personal injury or damage to the machine, tooling, or workpiece.

®

CNC lathes

-

- CAUTIONS -

Cautions must be followed carefully to avoid the possibility of damage to the

machine, tooling, or workpiece.

- NOTES -

Notes contain supplemental information.

Hardinge Inc.

One Hardinge Drive

P.O. Box 1507

Elmira, New York 14902-1507 U.S.A.

www.hardinge.com

© 2006, Hardinge Inc. M-448B

READ COMPLETE INSTRUCTIONS CAREFULLY

BEFORE OPERATING MACHINE OR BAR FEED SYSTEM

When this instruction book was printed, the information given was current. However, since we are

constantly improving the design of our machine tools and bar feed systems, it is possible that the

illustrations and descriptions may vary from the machine or bar feed system you received.

- WARNING -

Occupational Safety and Health Administration (OSHA) Hazard Communica

tion Standard 1910.1200, effective May 25, 1986, and various state “employee

right-to-know laws” require that information regarding chemicals used with

this equipment be supplied to you. Refer to the applicable section of the Ma

terial Safety Data Sheets supplied with your machine when handling, storing,

or disposing of chemicals.

Machine should only be used with a bar feed approved by Hardinge Inc.

-

-

HARDINGE SAFETY RECOMMENDATIONS

Your Hardinge machine is designed and built for maximum ease and safety of operation.

However, some previously accepted shop practices may not reflect current safety regulations and

procedures, and should be re-examined to insure compliance with the current safety and health

standards.

Hardinge Inc. recommends that all shop supervisors, maintenance personnel, and machine tool

operators be advised of the importance of safe maintenance, setup, and operation of Hardinge-built

equipment. Our recommendations are described below. READ THESE SAFETY

RECOMMENDATIONS BEFORE PROCEEDING ANY FURTHER.

READ THE APPROPRIATE MANUAL OR INSTRUCTIONS before attempting operation or

maintenance of the machine. Make certain that you understand all instructions.

DON’T ALLOW the operation or repair of equipment by untrained personnel.

CONSULT YOUR SUPERVISOR when in doubt as to the correct way to do a job.

WEAR SAFETY GLASSES AND PROPER FOOT PROTECTION at all times. When neces

sary, wear respirator, helmet, gloves, and ear muffs or plugs.

DON’T OPERATE EQUIPMENT unless proper maintenance has been regularly performed

and the equipment is known to be in good working order.

WARNING or INSTRUCTION TAGS are mounted on the machine for your safety and infor

mation. Do not remove them.

DON’T ALTER THE MACHINE to bypass any interlock, overload, disconnect, or other safety

device.

DON’T OPERATE EQUIPMENT if unusual or excessive heat, noise, smoke, or vibration oc

curs. Report any excessive or unusual vibration, sounds, smoke, or heat as well as any dam

aged parts.

-

-

-

-

REDUCE SPINDLE SPEED if vibration occurs. Bar stock straightness will have an effect on

vibration and balance of the spindle system.

M-448B i

NEVER OPERATE THE MACHINE SPINDLE without a work-holding device if the draw tube is

in the spindle.

TIGHTEN ALL DRAW TUBE SCREWS before beginning spindle operation.

MAKE CERTAIN that the equipment is properly grounded. Consult National Electric Code and

all local codes.

DISCONNECT MAIN ELECTRICAL POWER before attempting repair or maintenance.

ALLOW ONLY AUTHORIZED PERSONNEL to have access to enclosures containing electri

cal equipment.

DON’T REACH into any control or power case area unless electrical power is OFF.

DON’T TOUCH ELECTRICAL EQUIPMENT when hands are wet or when standing on a wet

surface.

REPLACE BLOWN FUSES with fuses of the same size and type as originally furnished.

ASCERTAIN AND CORRECT the cause of a shutdown caused by overload heaters before

restarting the machine.

KEEP THE AREA AROUND THE MACHINE well lighted and dry.

KEEP CHEMICAL AND FLAMMABLE MATERIAL away from electrical or operating equipment.

HAVE THE CORRECT TYPE OF FIRE EXTINGUISHER handy when machining combustible

material and keep chips clear of the work area.

DON’T USE a toxic or flammable substance as a solvent cleaner or coolant.

MAKE CERTAIN THAT PROPER GUARDING is in place and that all doors are closed and

secured.

-

TO REMOVE OR REPLACE the chuck closer it is necessary to remove the guard door at the

left end of the machine. Make certain that the guard door is in place before starting the machine.

DON’T OPEN GUARD DOORS while any machine component is in motion.

MAKE SURE chucks, closers, fixture plates, and all other spindle-mounted work-holding de

vices are properly mounted and secured before starting the machine.

MAKE CERTAIN all tools are securely clamped in position before starting the machine.

REMOVE ANY LOOSE PARTS OR TOOLS left on machine or in the work area before oper

ating the machine. Always check the machine and work area for loose tools and parts espe

cially after work has been completed by maintenance personnel.

REMOVE CHUCK WRENCHES before starting the machine.

BEFORE PRESSING THE CYCLE START PUSH BUTTON, make certain that proper func

tions are programmed and that all controls are set in the desired modes.

KNOW WHERE ALL stop push buttons are located in case of an emergency.

CHECK THE LUBRICATION OIL LEVEL and the status of the indicator lights before operat

ing the machine.

-

-

-

-

-

ii M-448B

MAKE CERTAIN that all guards are in good condition and are functioning properly before op

erating the machine.

-

INSPECT ALL SAFETY DEVICES AND GUARDS to make certain that they are in good con

dition and are functioning properly before the cycle is started.

CHECK THE POSITION of the tool top plate before pressing the Cycle Start push button.

CHECK SETUP, TOOLING, AND SECURITY OF THE WORKPIECE if the machine has been

OFF for any length of time.

DRY CYCLE a new setup to check for programming errors.

MAKE CERTAIN that you are clear of any “pinch point” created by moving slides before start

ing the machine.

DON’T OPERATE any equipment while any part of the body is in the proximity of a potentially

hazardous area.

DON’T REMOVE CHIPS with hands. Use a hook or similar device and make certain that all

machine movements have ceased.

BE CAREFUL of sharp edges when handling a newly machined workpiece.

DON’T REMOVE OR LOAD a workpiece while any part of the machine is in motion.

DON’T OPERATE ANY MACHINE while wearing rings, watches, jewelry, loose clothing, neck-

ties, or long hair not contained by a net or shop cap.

-

-

DON’T ADJUST tooling or coolant hoses while the machine is running.

DON’T LEAVE tools, workpieces or other loose items where they can come in contact with a

moving component of the machine.

DON’T CHECK finishes or dimensions of workpiece near running spindle or moving slides.

DON’T JOG SPINDLE in either direction when checking threads with a thread gage.

DON’T ATTEMPT to brake or slow the machine with hands or any makeshift device.

ANY ATTACHMENT, TOOL, OR MACHINE MODIFICATION not obtained from Hardinge Inc.

must be reviewed by a qualified safety engineer before installation.

USE CAUTION around exposed mechanisms and tooling especially when setting up. Be care

ful of sharp edges on tools.

DON’T USE worn or defective hand tools. Use the proper size and type for the job being per

formed.

USE ONLY a soft-faced hammer on tooling and fixtures.

DON’T USE worn or broken tooling on machine.

MAKE CERTAIN that all tool mounting surfaces are clean before mounting tools.

INSPECT ALL CHUCKING DEVICES daily to make certain that they are in good operating

condition. Replace any defective chuck before operating the machine.

-

-

USE MAXIMUM ALLOWABLE gripping pressure on the chuck. Consider weight, shape, and

balance of the workpiece.

M-448B iii

USE LIGHTER THAN NORMAL feedrates and depth of cut when machining a workpiece di

ameter that is larger than the gripping diameter.

DON’T EXCEED the rated capacity of the machine.

DON’T LEAVE the machine unattended while it is operating.

DON’T CLEAN the machine with an air hose.

KEEP TOTE PANS a safe distance from the machine. Don’t overfill the tote pans.

DON’T LET STOCK project past the back end of the chuck closer or machine spindle without

being adequately covered and properly supported.

FOLLOW each bar feed manufacturer’s guidelines. For performance and safe application,

size and use feed tube bushings, pushers, and spindle liners according to bar feed informa

tion.

MAKE CERTAIN that any bar feed mechanism is properly aligned with the spindle. If the bar

feed is a floor-mounted type, it must be securely bolted to the floor.

-

-

UNLESS OTHERWISE NOTED, all operating and maintenance procedures are to be per

formed by one person. To avoid injury to yourself and others, be sure that all personnel are

clear of the machine when opening or closing the coolant guard door and any access covers.

FOR YOUR PROTECTION - WORK SAFELY

-

iv M-448B

Table of Contents

CHAPTER 1 - POWER-UP, POWER-DOWN, AND LOCK-OUT PROCEDURES

Machine Equipped with a Fanuc Control......................1-1

Power-Up Procedure .............................1-1

Reference Home Procedure ..........................1-2

Power-Down Procedure ............................1-3

Machine Equipped with a Siemens Control ....................1-4

Power-Up Procedure .............................1-4

Power-Down Procedure ............................1-4

Air and Electrical Lock-Out Procedures ......................1-5

Air Lock-Out Procedure ............................1-5

Electrical Lock-Out Procedure .........................1-5

Clearing an Emergency Stop ...........................1-6

Hour Run Meter .................................1-6

CHAPTER 2 - LUBRICATION

Introduction ...................................2-1

Importance of Lubrication ............................2-1

Recommended Grease..............................2-1

Lubrication Alarm ................................2-2

Grease Volume .................................2-2

Axis Lubrication .................................2-3

X and Z Axis Lubrication on TALENT

X and Z Axis Lubrication on TALENT 8/66 and 10/78 Lathes ..........2-4

Tailstock Lubrication on TALENT 6/45 and 8/52 Lathes .............2-5

Tailstock Lubrication on TALENT 8/66 and 10/78 Lathes ............2-6

Live Tool Gear Lubrication ............................2-7

Lubrication Line Replacement ..........................2-8

Replacement Part Numbers ..........................2-8

Replacing a Lubrication Line .........................2-8

®

6/45 and 8/52 Lathes ..........2-3

CHAPTER 3 - AIR SYSTEM

System Description ...............................3-1

Standard Configuration ............................3-1

Optional Configuration ............................3-1

Setting the Air Pressure .............................3-2

Maintenance ..................................3-2

Air Filter/Regulator ..............................3-2

Air Line Lubricator ..............................3-3

Approved Air System Oils ...........................3-3

M-448B v

CHAPTER 4 - COOLANT SYSTEM

Introduction ...................................4-1

System Description ...............................4-2

Water-Based Coolants ..............................4-2

Concentration ................................4-2

pH......................................4-3

Water Quality ................................4-3

Care and Maintenance ............................4-3

Checking the Coolant Level ...........................4-4

Chip Removal ..................................4-5

TALENT

®

6/45 and 8/52 Lathes ........................4-5

TALENT 8/66 and 10/78 Lathes ........................4-5

Cleaning the Coolant Tank ............................4-6

TALENT 6/45 and 8/52 Lathes ........................4-6

TALENT 8/66 and 10/78 Lathes ........................4-7

Replacing the Coolant Pump ...........................4-9

CHAPTER 5 - HYDRAULIC SYSTEM

Introduction ...................................5-1

Hydraulic Tank .................................5-2

Filling the Hydraulic Tank ...........................5-2

Approved Hydraulic System Oils ........................5-2

Draining and Filling the Hydraulic Tank.....................5-3

Adjusting the Hydraulic System Pressure .....................5-4

CHAPTER 6 - MISCELLANEOUS

Battery Maintenance ...............................6-1

Turret Controller Battery Replacement (Non-Live Tooling Machines Only).....6-1

CNC Control Battery Replacement (Fanuc Control Only) ............6-3

Control Configurations ...........................6-3

Fanuc 0i Mate-T Control ..........................6-3

Fanuc 0i-T Control.............................6-5

Turret Zero Reference ..............................6-6

Adjusting the Tailstock Bushing for Center .....................6-8

Cleaning the Power Case Heat Exchanger Air Filter ................6-9

Cleaning the Power Case Plenum Fan Air Filter ..................6-10

APPENDIX ONE - PREVENTIVE MAINTENANCE SCHEDULE

Cleaning the Machine ..............................A1-1

Maintenance Schedule ..............................A1-1

APPENDIX TWO - MACHINE PHOTOGRAPHS

vi M-448B

- NOTES -

M-448B vii

- NOTES -

viii M-448B

CHAPTER 1 - POWER-UP, POWER-DOWN,

AND LOCK-OUT PROCEDURES

- CAUTION -

The recommended operating temperature range is 50° to 95° F [7° to 35° C].

MACHINE EQUIPPED WITH A FANUC CONTROL

- NOTE -

Information relating to machines equipped with a Siemens control begins on page

1-4.

POWER-UP PROCEDURE

- NOTE -

It is important that the power-up procedure is followed as described to ensure safe,

accurate, and repeatable machine operation.

1. Close the main guard door.

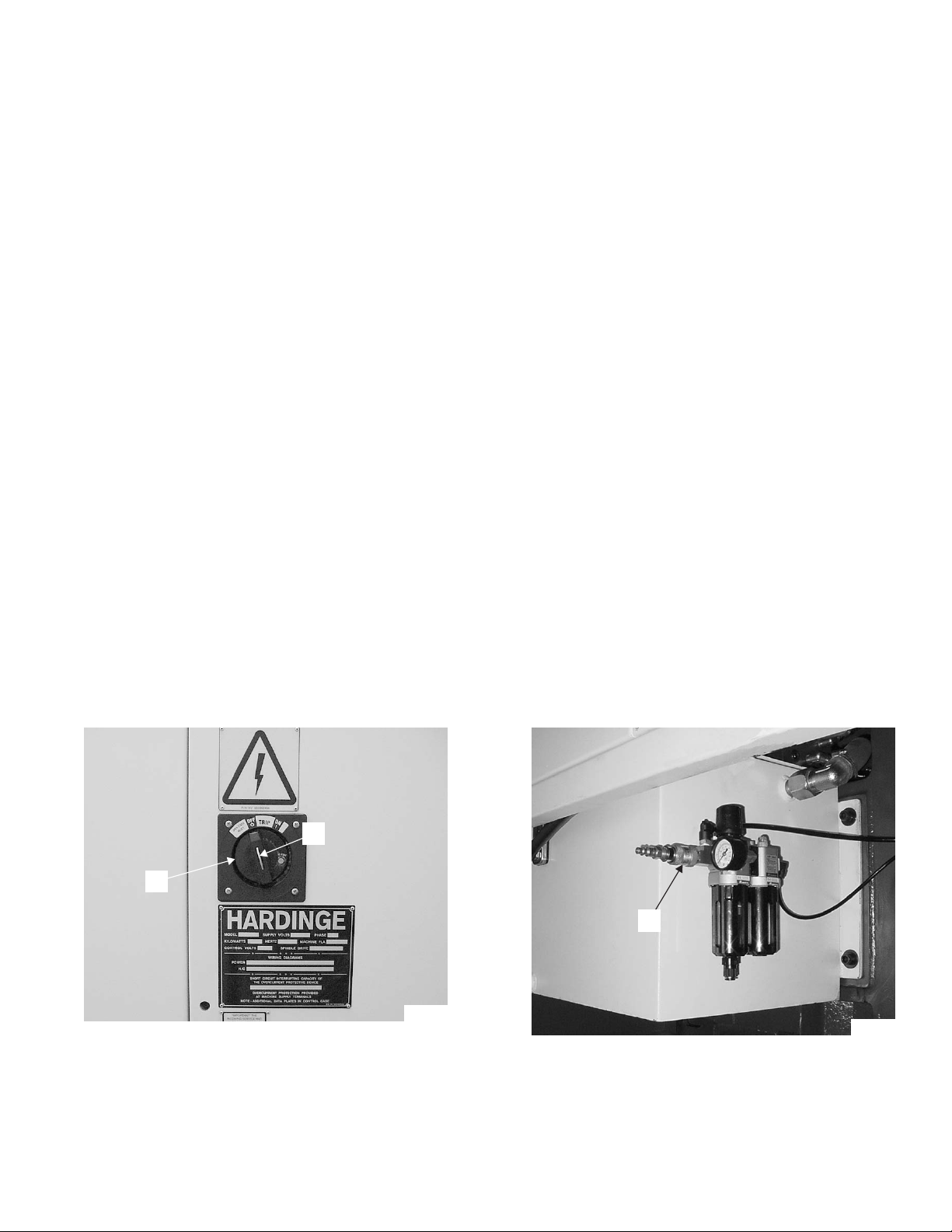

2. Turn main disconnect switch “A”, Figure 1.1, ON.

3. If the machine is equipped with the optional parts catcher, turn main air valve “C”, Figure 1.2,

ON.

4. Check the coolant level. Refill as needed.

5. Check the hydraulic oil level. Refill as needed.

B

A

TP5053

Figure 1.1 - Main Disconnect Switch

C

TP5040

Figure 1.2 - Air Filter Regulator for

Optional Parts Catcher

M-448B 1-1

- CAUTION -

When pressing the Control ON push button, DO NOT press any other push

buttons or keys until the position or alarm screen is displayed. Some push

buttons and keys are used for control maintenance or special operation commands.

- NOTE -

TALENT

®

6/45SV and 8/52SV lathes are not equipped with Control ON/OFF push

buttons. Step 6 will be omitted.

6. Press the Control ON push button and wait until the control display screen is ON.

7. Pull the Emergency Stop push button out and release.

8. Open and close the coolant guard door to perform the guard door switch verification and clear

the verification alarm.

9. Press the Work Light push button.

10. The machine is now ready for the Reference Home procedure.

REFERENCE HOME PROCEDURE

- CAUTION -

When homing the axes, be sure that no interference exists between the

workpiece, spindle tooling, optional tailstock, or turret tooling.

- NOTE -

The X and Z axes must both be jogged approximately 1 inch [25 millimeters] in the

minus direction before a Reference Home can be performed.

The optional tailstock must be at Home position before the X and Z axes can be

homed.

1. Set the Mode Select switch to Jog mode.

2. If the lathe is equipped with the optional tailstock:

Verify the tailstock is at the Home position.

If necessary, turn the Tailstock Jog switch to the right to move the tailstock to the Home

position.

3. Set the Feedrate switch to any setting above 0 (zero).

4. Press and hold the -X push button to jog the turret approximately 1 inch [25 millimeters] in the

minus direction.

5. Press and hold the -Z push button to jog the turret approximately 1 inch [25 millimeters] in the

minus direction.

6. Set the Mode Select switch to Reference mode.

1-2 M-448B

Revised: March 31, 2006

- NOTE -

The X axis must be “homed” before the Z axis is “homed” on machines equipped

with a tailstock.

7. Press the +X push button. The X axis will move to the X Home position and the X Home

indicator light will turn ON.

8. Press the +Z push button. The Z axis will move to the X Home position and the X Home

indicator light will turn ON.

9. If the machine is equipped with the live tooling option, reference the turret as follows:

A) Set the Turret Station selector switch to any station not at the active position.

B) Press the Turret Index push button.

POWER-DOWN PROCEDURE

1. Be sure “Cycle Start” is not active. The Cycle Start push button light will be OFF.

2. Be sure the program has been completed and that the spindle and slides are stationary.

3. Press the Emergency Stop push button.

4. Press the Control OFF push button.

5. Turn main air valve “C”, Figure 1.2, OFF.

6. Turn main disconnect switch “A”, Figure 1.1, OFF.

7. If necessary, lock out the main air valve and main disconnect switch, as outlined on page 1-5.

M-448B 1-3

MACHINE EQUIPPED WITH A SIEMENS CONTROL

- NOTE -

Information relating to machines equipped with a Fanuc control begins on page

1-1.

POWER-UP PROCEDURE

- NOTE -

It is important that the power-up procedure is followed as described to ensure safe,

accurate, and repeatable machine operation.

1. Close the main guard door.

2. Turn main disconnect switch “A”, Figure 1.1, ON.

3. If the machine is equipped with the optional parts catcher, turn main air valve “C”, Figure 1.2,

ON.

4. Check the coolant level. Refill as needed.

5. Check the hydraulic oil level. Refill as needed.

- NOTE -

The machine will power up in the ShopTurn mode.

WAIT until the following alarm message is displayed before proceeding to Step 4:

“3000ê EMERGENCY STOP”

6. Press the Reset push button to clear the Emergency Stop.

7. Open and close the coolant guard door to perform the guard door switch verification and clear

the verification alarm.

8. Press the Axis Home push button. The Axis Home indicator light will start flashing and the X and

Z axes will automatically home.

POWER-DOWN PROCEDURE

1. Be sure “Cycle Start” is not active. The Cycle Start push button light will be OFF.

2. Be sure the program has been completed and that the spindle and slides are stationary.

3. Press the Emergency Stop push button.

4. Turn main air valve “C”, Figure 1.2, OFF.

5. Turn main disconnect switch “A”, Figure 1.1, OFF.

6. If necessary, lock out the main air valve and main disconnect switch, as outlined on page 1-5.

1-4 M-448B

AIR AND ELECTRICAL LOCK-OUT PROCEDURES

- NOTE -

The air lock-out procedure applies only to machines equipped with the optional

parts catcher.

AIR LOCK-OUT PROCEDURE

1. Turn main air valve “C”, Figure 1.2, OFF.

2. Place a lock on the main air valve to prevent the valve from being turned ON.

ELECTRICAL LOCK-OUT PROCEDURE

1. Turn main disconnect switch “A”, Figure 1.1, OFF.

2. Pull lock out tab “B” out.

3. Lock out the main disconnect handle through tab “B”.

M-448B 1-5

CLEARING AN EMERGENCY STOP

The Emergency Stop pish button is located on the operator control panel.

1. Correct the problem that prompted the Emergency Stop condition.

2. Pull the Emergency Stop push button out and release.

HOUR RUN METER

- NOTE -

TALENT

Hour Run meter “D”, Figure 1.3, Is located on the right side of the operator control panel. It records

the amount of time the control has been powered up.

®

6/45SV and 8/52SV lathes are not equipped with an Hour Run meter.

D

Figure 1.3 - Hour Run Meter

(Fanuc Control Shown)

TP5197

1-6 M-448B

- NOTES -

M-448B 1-7

- NOTES -

1-8 M-448B

CHAPTER 2 - LUBRICATION

INTRODUCTION

TALENT®CNC lathe axes are grease lubricated at grease blocks mounted on the right side of the

carriage. The grease system lubricates the ball screws and truck bearings on the linear guideways.

Fresh grease should be added every 600 hours of machine operation or more frequently under

severe operating conditions.

When the grease lubrication system requires maintenance, the machine must be powered down.

Refer to Chapter 1 for the power-up, power-down, and lock-out procedures.

IMPORTANCE OF LUBRICATION

Running conditions of this machine depend heavily upon the lubrication management. Make

certain that the lubrication system is checked frequently under severe operating conditions to keep

the machine in proper working condition.

RECOMMENDED GREASE

The following greases are recommended by Hardinge Inc. for use on the TALENT CNC lathe.

Grease

®

KLÜBER

KLÜBER Isoflex NBU 15 HS 00010994SL

Other greases may not contain certain additive packages needed for proper lubrication and

performance. The additive packages may include rust inhibitors, corrosion inhibitors, and anti-wear

compounds, which have been blended specifically for that application. Although many companies

offer “similar” greases, these may not contain the needed additives to ensure maximum performance

and protection of Hardinge machines.

Isoflex NCA 15 TT 0010994NCA

Hardinge Grease

Cartridge Part Number

M-448B 2-1

LUBRICATION ALARM

The control issues the following lubrication alarms:

• Axis lubrication alarm message after 600 hours of operation.

• Turret lubrication alarm message after 2000 hours of operation. (Live tooling machines

only)

A lubrication alarm does not stop the machine, but will inhibit Cycle Start.

Clear the alarm message as follows:

If the machine is equipped with a Fanuc control, press the Feed Hold and Reset push buttons at the same time to clear the alarm.

If the machine is equipped with a Siemens control, press the Reset key AND HOLD FOR 5

SECONDS to clear the alarm.

GREASE VOLUME

The grease volume presented is dependent upon the grease gun being used. Carefully measure

the amount of grease or count the grease gun strokes necessary to lubricate the guides and ball

screws. Be certain that all air is purged from any grease gun before use.

- NOTE -

The grease gun supplied with the machine delivers 3 cc per full stroke.

The required amount of grease is:

Linear Guides: 3½ cc

Ball Screws: 11 cc

Make certain that all the sliding surfaces are lubricated well by jogging the axes at 50% of the

maximum rapid traverse for a full 30 minutes before resuming automatic operation.

2-2 M-448B

AXIS LUBRICATION

- NOTE -

Grease should be added when the linear guides are still warm from operation.

X AND Z AXIS LUBRICATION ON TALENT

1. Wait for the cycle to end and that the spindles

and slides are stationary.

- NOTE -

Refer to the Operator’s Manual

(M-447) for information on using Rapid

Reference to move axes to the reference position.

2. Move the Z axis to the reference position.

3. Power down and lock out the machine. Refer to

the appropriate power-down procedure in

Chapter 1.

4. Remove cover “A”, Figure 2.1, to gain access

to the fittings on grease manifolds “B” and “C”,

Figure 2.2.

5. Clean the grease fittings.

- NOTE -

Only use a manually operated grease

gun.

Manifold “B” supplies grease to the X

axis. Manifold “C” supplies grease to

the Z axis.

®

6/45 AND 8/52 LATHES

Figure 2.1 - Rear Access Cover

A

TP5196

B

6. Attach the grease gun nozzle to each grease

fitting; slowly and evenly pump in the specified

amount of grease.

7. Wipe the fittings clean of excess grease.

8. Install cover “A”, Figure 2.1.

9. Power up the machine. Refer to the

C

appropriate power-up procedure in Chapter 1.

10. If necessary, clear the lubrication alarm as

outlined in "Lubrication Alarm", page 2-2.

11. Jog the axes at 50% of the maximum rapid

traverse for a full 30 minutes before resuming

automatic machine operation.

M-448B 2-3

Figure 2.2 - Grease Manifolds

TP5038

X AND Z AXIS LUBRICATION ON TALENT®8/66 AND 10/78 LATHES

1. Wait for the cycle to end and that the spindles

and slides are stationary.

- NOTE -

Refer to the Operator’s Manual

(M-447) for information on using Rapid

Reference to move axes to the reference position.

2. Move the Z axis to the reference position.

3. Power down and lock out the machine. Refer to

the appropriate power-down procedure in

Chapter 1.

4. Remove cover "A", Figure 2.1, to gain access

to the X and Z axis grease fittings.

5. Clean Z axis grease fitting "D", Figure 2.3, and

X axis grease fitting "E", Figure 2.4.

- NOTE -

Only use a manually operated grease

gun.

6. Attach the grease gun nozzle to each grease

fitting; slowly and evenly pump in the specified

amount of grease.

7. Wipe the fittings clean of excess grease.

8. Replace cover “A”, Figure 2.1.

9. Power up the machine. Refer to the

appropriate power-up procedure in Chapter 1.

10. If necessary, clear the lubrication alarm as

outlined in "Lubrication Alarm", page 2-2.

11. Jog the axes at 50% of the maximum rapid

traverse for a full 30 minutes before resuming

automatic machine operation.

D

TP6034

Figure 2.3 - Z Axis Grease Fitting

E

TP6035

Figure 2.4 - X Axis Grease Fitting

2-4 M-448B

TAILSTOCK LUBRICATION ON TALENT®6/45 AND 8/52 LATHES

1. Wait for the cycle to end and that the spindles

and slides are stationary.

- NOTE -

Refer to the Operator’s Manual

(M-447) for information on using Jog

mode to move the tailstock.

2. Move the tailstock toward the guard door

opening to gain access to cover “F”, Figure 2.5.

3. Power down and lock out the machine. Refer to

the appropriate power-down procedure in

Chapter 1.

4. Remove cover “F”, Figure 2.5, to gain access

to the fittings on grease manifold “G”, Figure

2.6.

Figure 2.5 - Grease Manifold Access

Cover on Tailstock

5. Clean the grease fittings.

- NOTE -

Only use a manually operated grease

gun.

F

TP5256

6. Attach the grease gun nozzle to each grease

fitting; slowly and evenly pump in the specified

amount of grease.

7. Wipe the fittings clean of excess grease.

8. Replace cover “F”, Figure 2.5.

9. Power up the machine. Refer to the

appropriate power-up procedure in Chapter 1.

10. Move the tailstock to the fixed Home position.

11. If necessary, clear the lubrication alarm as

outlined in "Lubrication Alarm", page 2-2.

G

TP5223

Figure 2.6 - Tailstock Grease Manifold

M-448B 2-5

TAILSTOCK LUBRICATION ON TALENT®8/66 AND 10/78 LATHES

1. Wait for the cycle to end and that the spindles and slides are stationary.

- NOTE -

Refer to the Operator’s Manual (M-447) for information on using Jog mode to move

the tailstock.

2. Move the tailstock toward the guard door opening to gain access to grease fitting “H”, Figure

2.7.

3. Power down and lock out the machine. Refer to the appropriate power-down procedure in

Chapter 1.

4. Clean the grease fitting.

- NOTE -

Only use a manually operated grease gun.

5. Attach the grease gun nozzle to the grease fitting; slowly and evenly pump in the specified

amount of grease.

6. Wipe the fitting clean of excess grease.

7. Power up the machine. Refer to the appropriate power-up procedure in Chapter 1.

8. Move the tailstock to the fixed Home position.

9. If necessary, clear the lubrication alarm as outlined in "Lubrication Alarm", page 2-2.

H

TP6037

Figure 2.7 - Tailstock Grease Fitting

2-6 M-448B

LIVE TOOL GEAR LUBRICATION

- NOTE -

Use Klübersynth UH1 14-1600 grease for live tool gear lubrication.

The live tool gear lubrication should be checked every 2000 hours of machine operation.

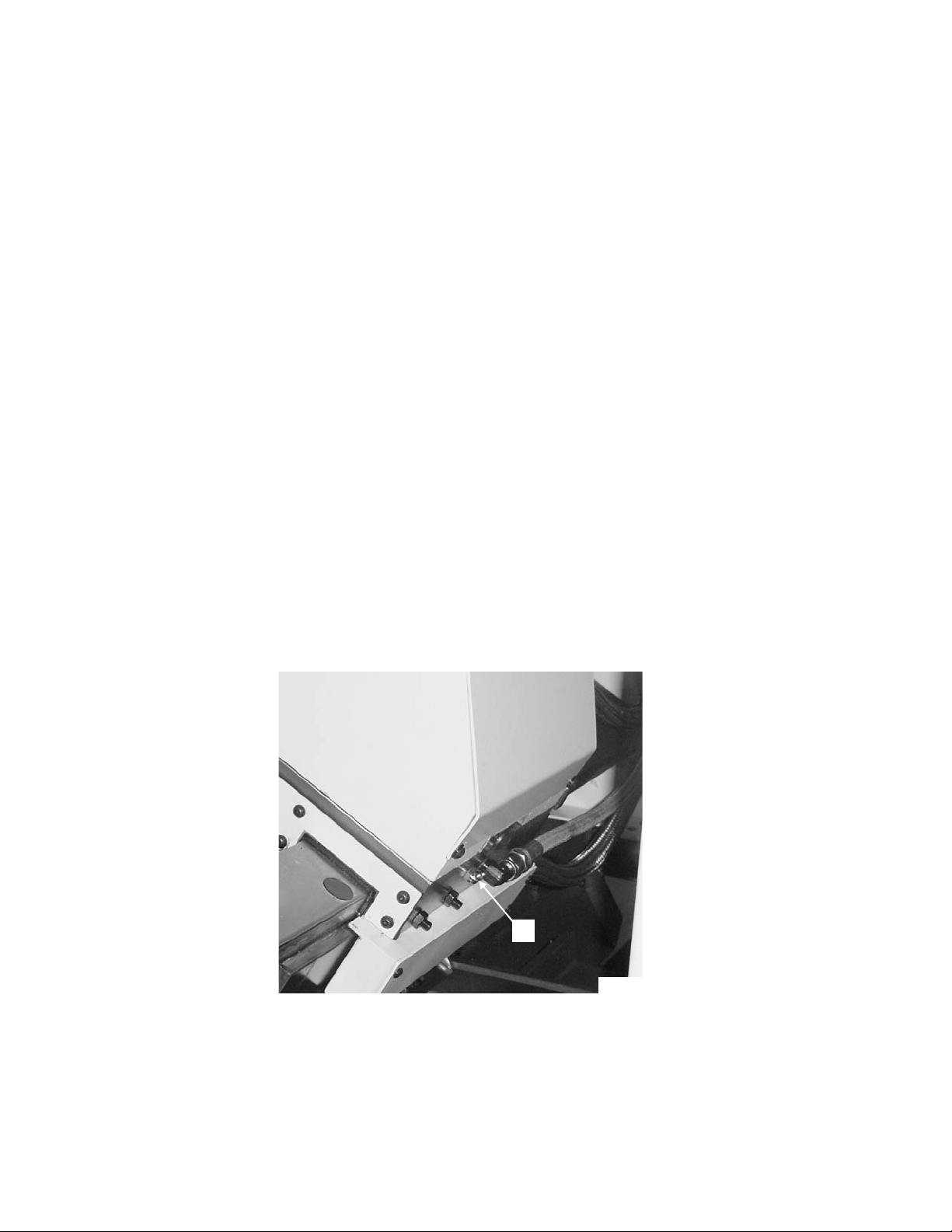

1. Remove plug screw "I", Figure 2.8 or 2.9.

2. Insert a thin tool into the turret, as shown in Figure 2.10, and touch the live tool gear.

- CAUTION -

Contact a Duplomatic Service Center if metallic dust, coolant, or oil is detected in the grease.

3. Check the tool tip for the presence of grease:

If grease is detected, no action is required.

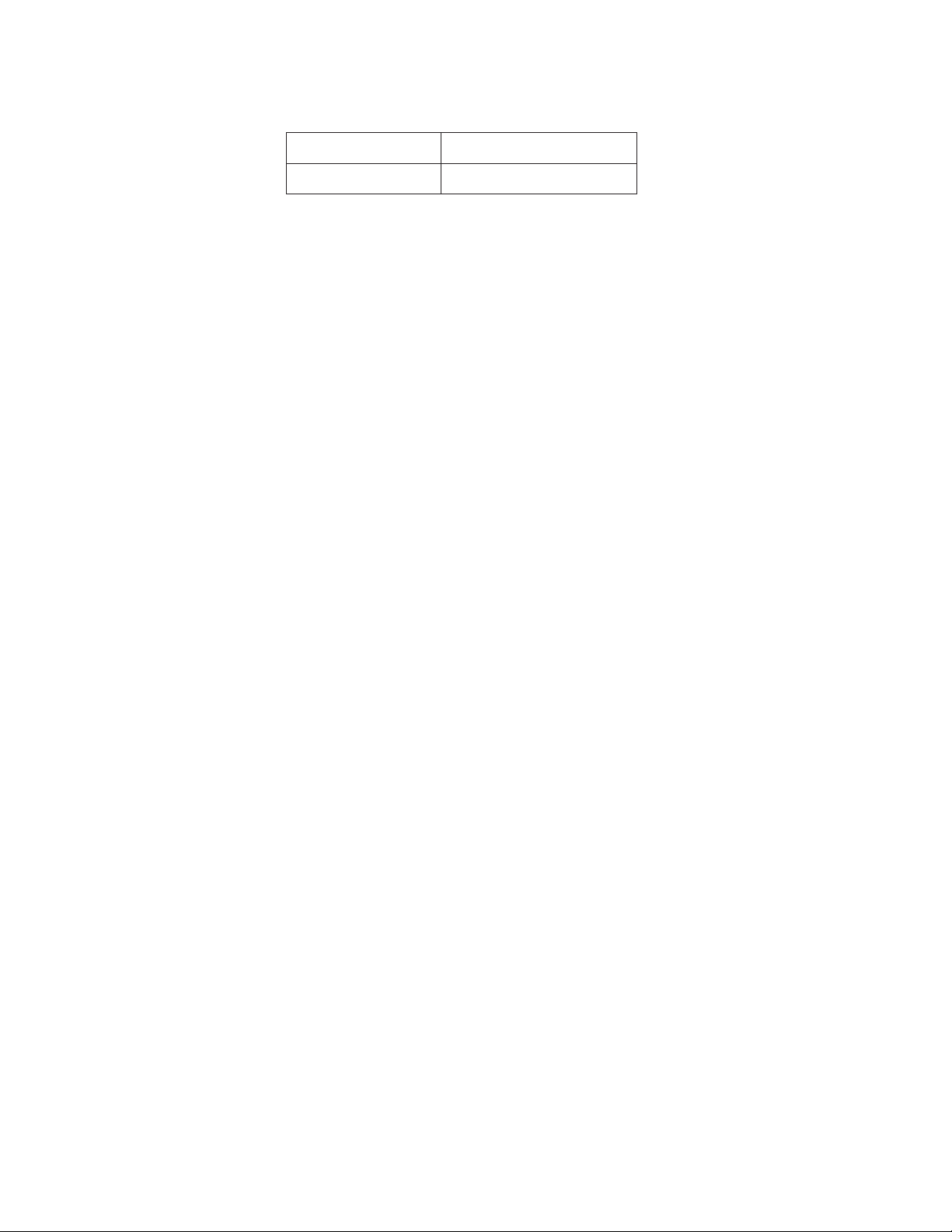

If grease is not detected, add 2 ~ 2.4 in

4. Replace the plug screw.

5. If necessary, clear the lubrication alarm as outlined in "Lubrication Alarm", page 2-2.

3

[30 ~ 40 cm3] of grease as shown in Figure 2.11.

I

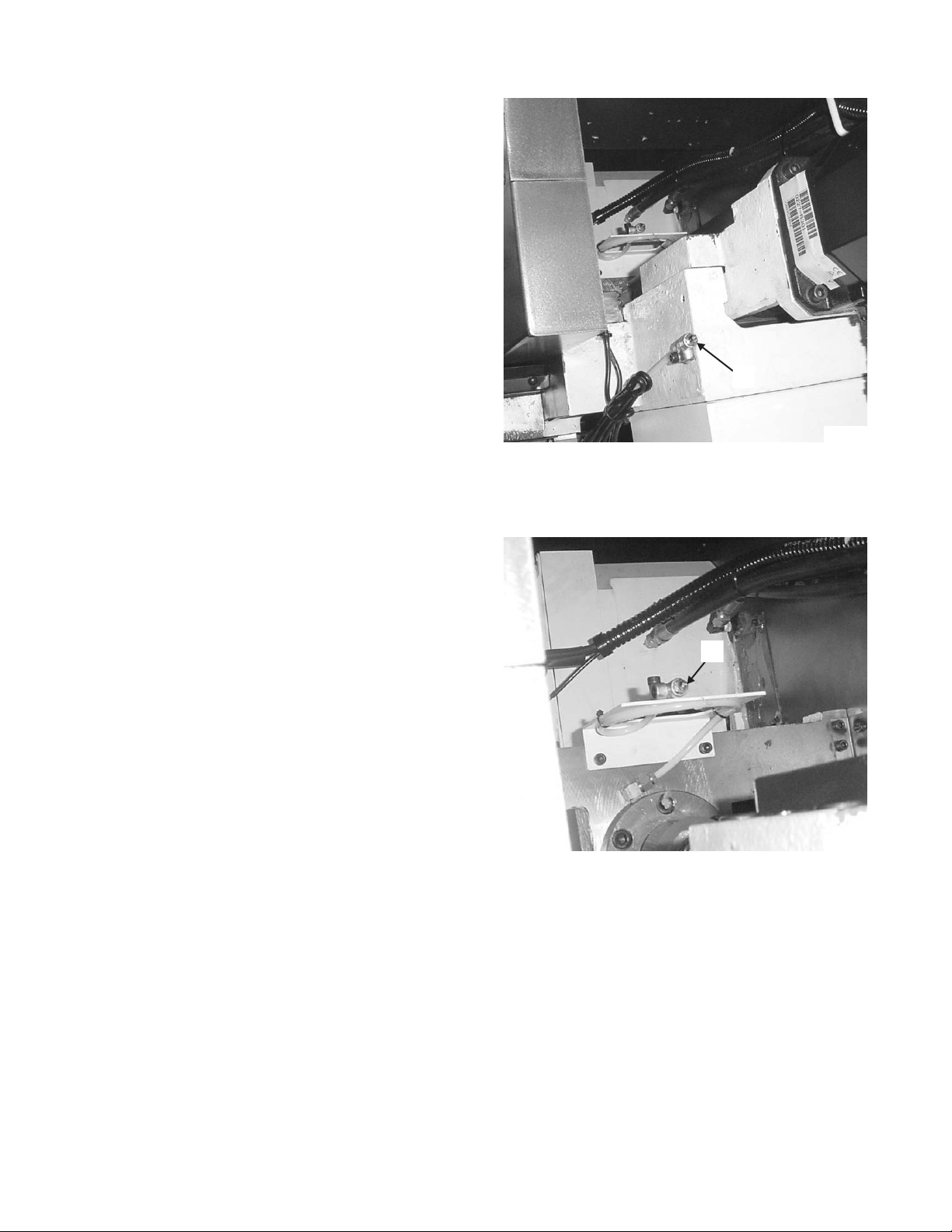

Figure 2.8 - Grease Plug Location

(TALENT

®

6/45 and 8/52 Lathes)

Figure 2.10 - Checking the Grease

TP7097

TP7098

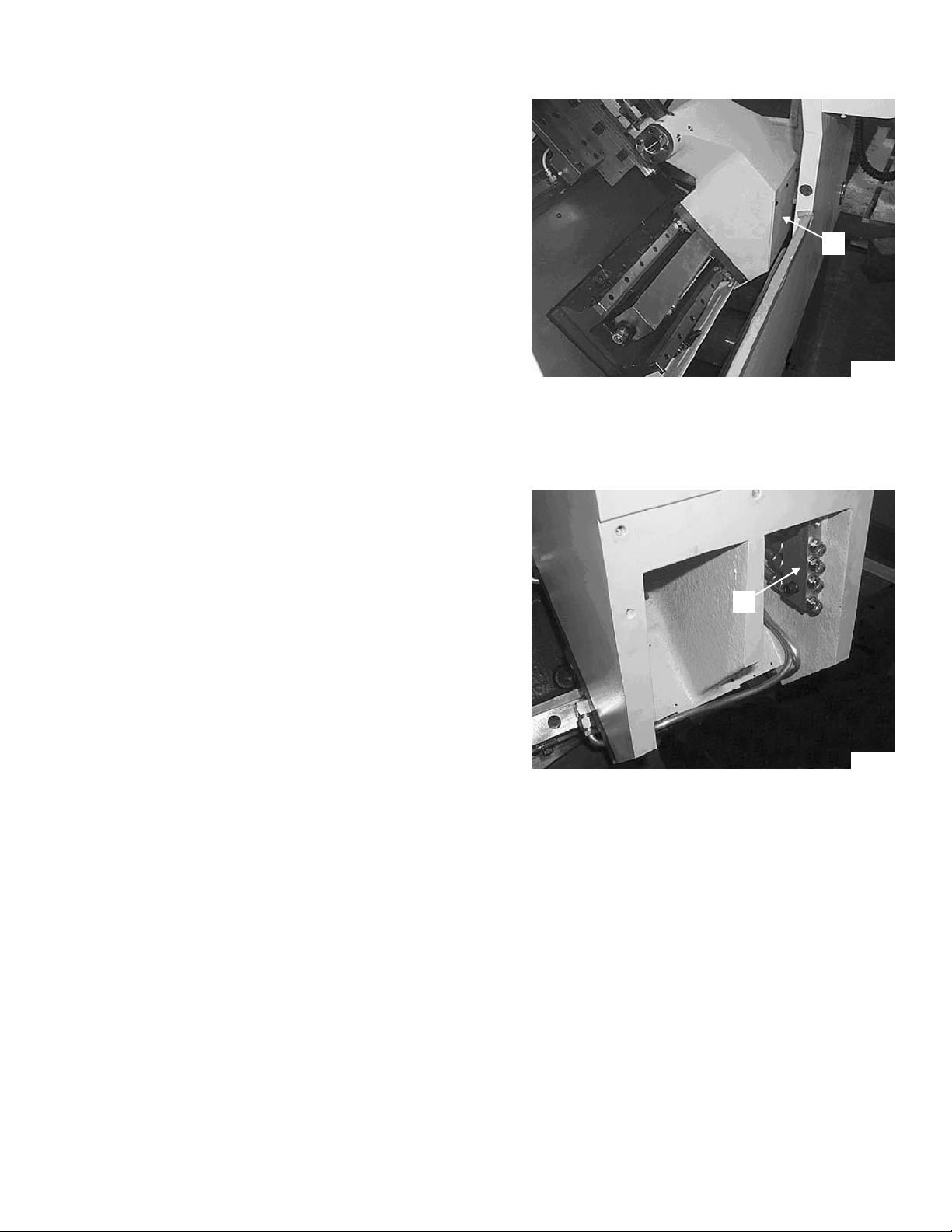

I

TP7100

Figure 2.9 - Grease Plug Location

(TALENT 8/66 and 10/78 Lathes)

TP7099

Figure 2.11 - Adding Grease

M-448B 2-7

LUBRICATION LINE REPLACEMENT

REPLACEMENT PART NUMBERS

Grease Manifold TT 0010234

Tubing TT 0007007

REPLACING A LUBRICATION LINE

1. Wait for the cycle to end and make certain that the spindle is stopped.

2. Remove cover “A”, Figure 2.1, to gain access to the grease manifolds and grease lines.

3. Jog each axis until the grease/lubrication lines are accessible.

4. Power down and lock out the machine. Refer to the appropriate power-down procedure in

Chapter 1.

- NOTE -

Replace the lubrication lines one line at a time.

The ball screw lubrication lines connect to the middle fitting (marked “BS”) on each

grease manifold.

5. Check each lubrication line for damage. Before disconnecting the line being replaced, measure

the length and check the route from the grease manifold to either the linear guide or ball screw.

6. Disconnect the lubrication line and compare the length of the old lubrication line and the

replacement lubrication line.

7. Before installing the replacement line, fill the line with KLÜBER

®

Isoflex NCA 15 or NBU 15

grease.

8. Install the replacement lubrication line:

A) Connect one end of the replacement lubrication line at the grease manifold.

B) Add the specified grease through its fitting until grease appears at the other end of the

lubrication line.

C) Connect that end of the lubrication line.

9. Wipe the fittings clean of excess grease.

10. Install cover “A”, Figure 2.1.

11. Power up the machine. Refer to the appropriate power-up procedure in Chapter 1.

12. Jog the axes at 50% of the maximum rapid traverse for a full 30 minutes before resuming

automatic machine operation.

2-8 M-448B

- NOTES -

M-448B 2-9

- NOTES -

2-10 M-448B

CHAPTER 3 - AIR SYSTEM

SYSTEM DESCRIPTION

The air connection is located at the rear of the machine near the lower left corner. It is mounted on

the side of the hydraulic tank, as shown in Figure 3.1 or 3.2.

The incoming air line should have a minimum inside diameter of 3/8 inch [9.5 mm].

Air is supplied to the following:

The air nozzle located on the front of the machine below the operator control panel

•

The optional parts catcher

•

STANDARD CONFIGURATION

Standard machines are equipped with a quick disconnect fitting, as shown in Figure 3.1.

OPTIONAL CONFIGURATION

- NOTE -

The air filter/regulator is equipped with an automatic drain.

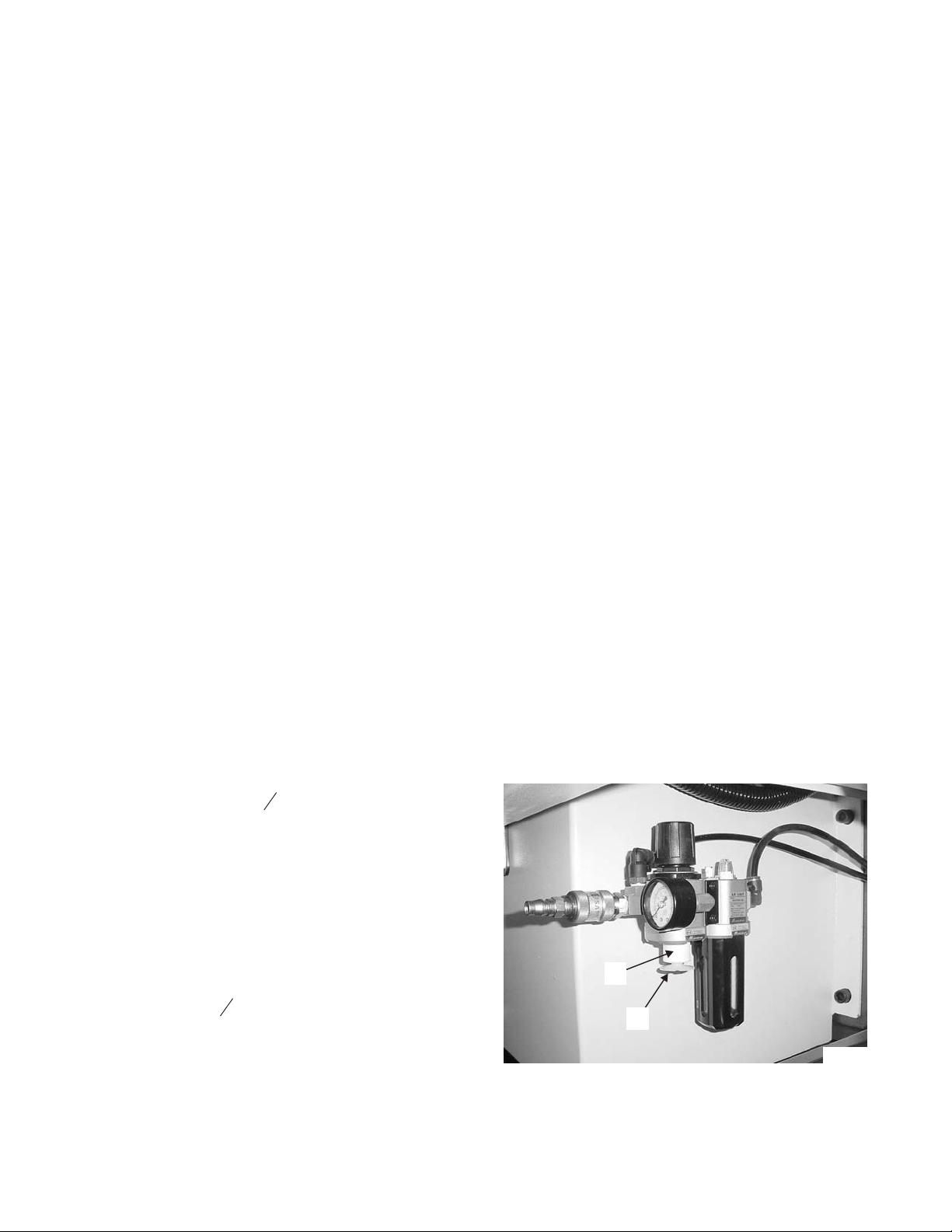

Machines equipped with the optional parts catcher are equipped with a quick-disconnect fitting,

ON-OFF air valve, air filter/regulator, and air line lubricator, as shown in Figure 3.2. An air dryer may

have to be added in the air line if the factory air has excessive moisture.

When a machine equipped with the optional parts catcher is powered up, turn ON the air source

and set regulator knob “A”, Figure 3.2, at a constant pressure from 70 psi to 90 psi [4.9 to 6.2 bars].

A

B

C

TP5219

D

TP5040

Figure 3.1 - Air Connection

(Machine without Optional Part Catcher)

M-448B 3-1

Figure 3.2 - Air Connection

(Machine with Optional Part Catcher)

SETTING THE AIR PRESSURE

- NOTE -

This information applies only to machines equipped with the optional part catcher.

1. Turn main air valve “B”, Figure 3.2, ON.

2. Lift knob “A” up to unlock.

3. Rotate the knob in the appropriate direction to increase or decrease pressure, as needed.

Observe the air pressure on the gauge.

4. Press knob “A” down to secure the pressure setting.

MAINTENANCE

- WARNING -

Turn the air valve OFF and lock out before performing air system maintenance. Refer to page 1-5 for the air system lock-out procedure.

- NOTE -

This information applies only to machines equipped with the optional part catcher.

Air system maintenance consists of the following:

• Cleaning the air system bowls

• Replacing the air filter

• Replacing the air lubrication oil

AIR FILTER/REGULATOR

1. Turn main air valve “B”, Figure 3.2, OFF and lock out.

- NOTE -

Notice the orientation of the locking lugs on the filter bowl when it releases from

the filter/regulator head.

2. Twist filter bowl “C”

1

turn in either direction to

8

release the bowl from the filter/regulator head.

3. Clean the bowl with a lint-free cloth.

4. Unthread filter retainer “F” and remove air filter

“E”, Figure 3.3.

5. Install the replacement air filter and the filter

retainer.

6. Insert the bowl into the filter/regulator head and

twist the bowl

1

turn in either direction to lock

8

the bowl in position.

E

F

TP5246

Figure 3.3 - Air Filter

and Filter Retainer

3-2 M-448B

Loading...

Loading...