Hardinge SERIES I Installation Operation & Maintenance

INSTALLATION, OPERATION,

MAINTENANCE, AND PARTS LIST

SERIES I

MILLING MACHINES

Revised: August 29, 2005

Manual No. M-450 Litho in U.S.A.

Part No. M -0009500-0450 June, 2003

TP5260

CHAPTER 2 - OPERATION

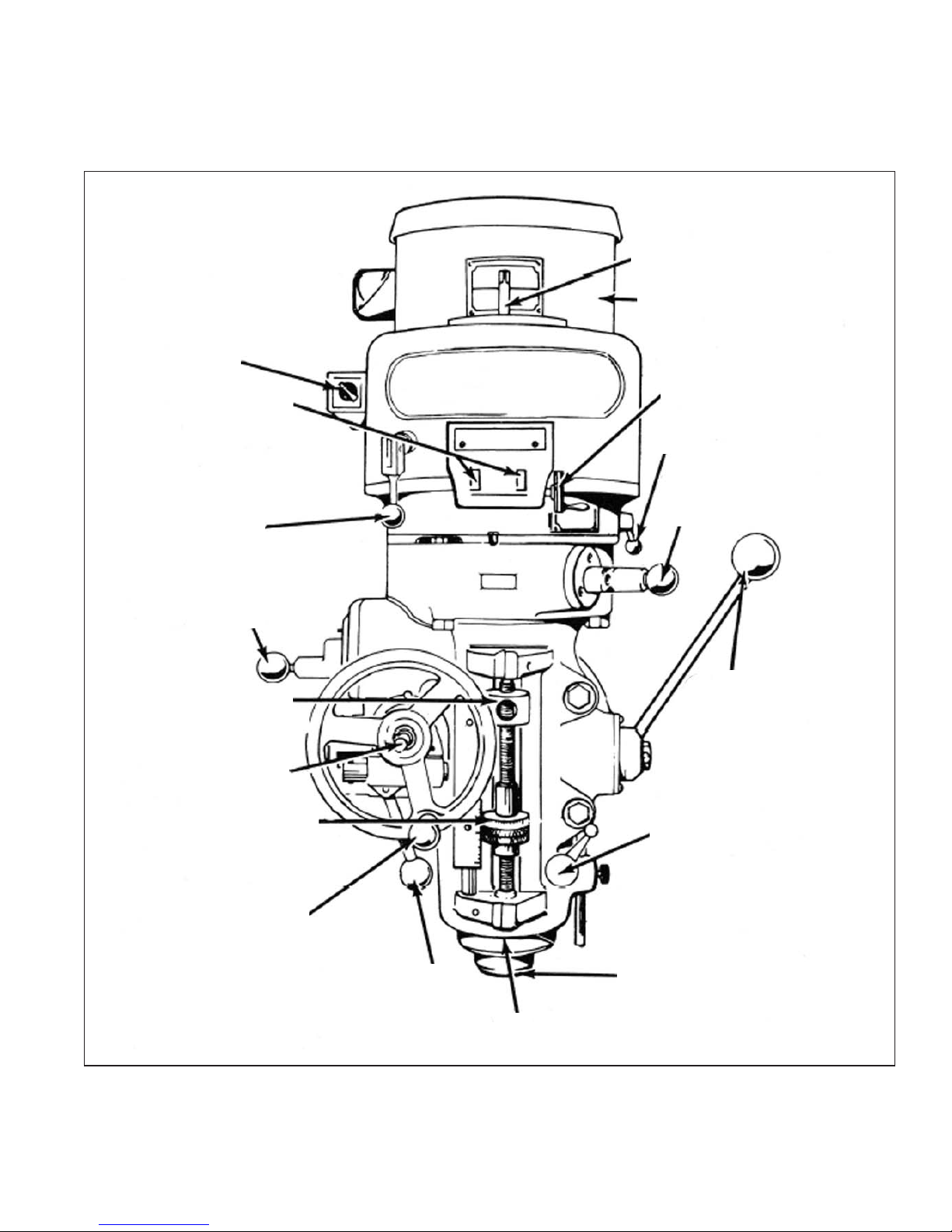

HEAD CONTROLS

R

Q

A

B

C

D

E

G

F

P

O

N

M

L

H

Figure 2.1 - Head Controls Parts Assembly

M-450 2-1

I

J

K

TP5285

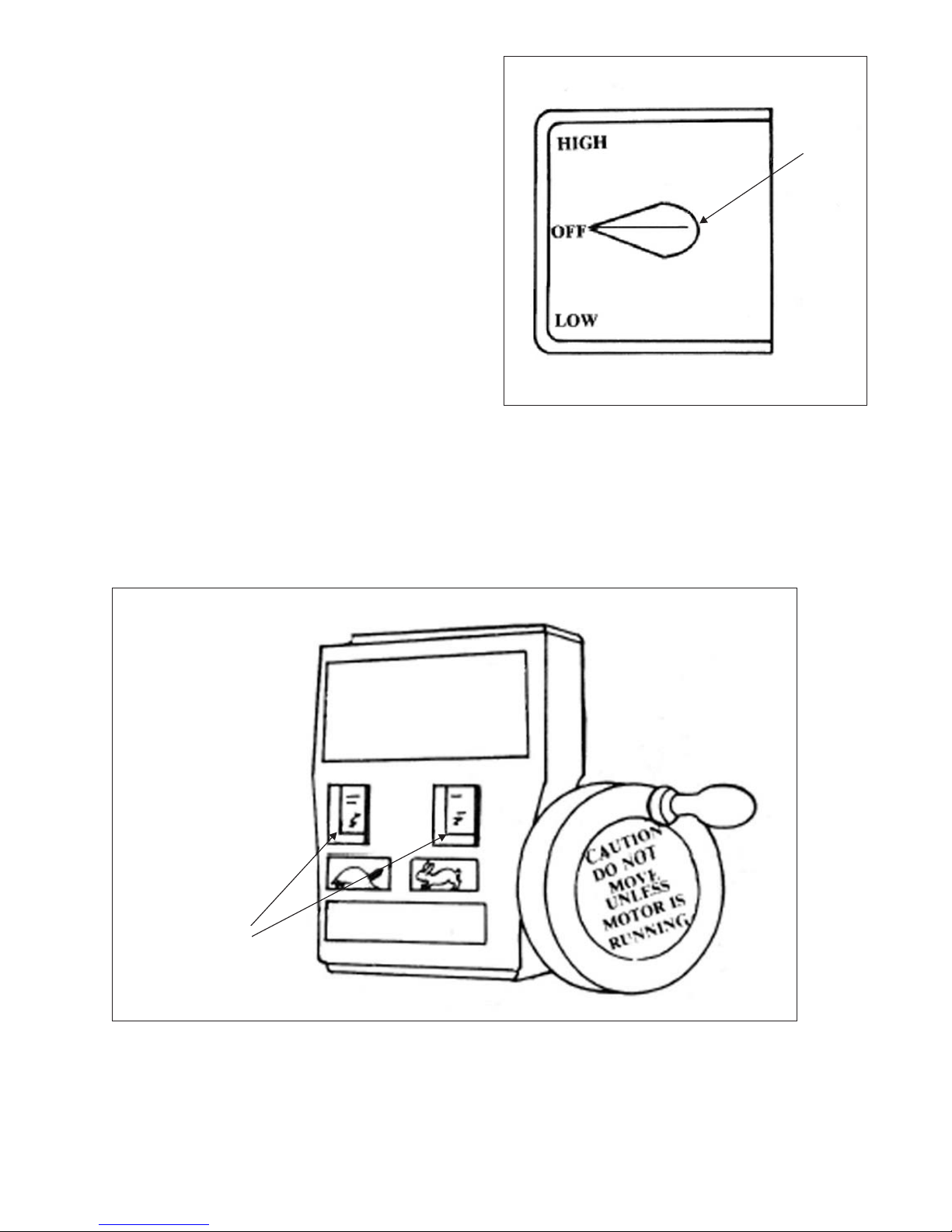

HIGH-LOW RANGE SWITCH

High-Low Range Switch “A”, Figure 2.2, is a

motor reversing switch. When the attachment is in

direct drive (HIGH SPEED), the motor and spindle

A

are turning in a clockwise direction as viewed from

the topof machine. When the attachment is in “Back

Gear”(LOW SPEED), the spindle willrunbackwards

(counter-clockwise) unless the motor direction is

reversed by moving switch to “Low”.

The back gear lever is marked Hi-Lo. This will

indicate the proper switch position. They should be

positioned alike or the spindle will run backwards.

- NOTE -

Spindle should run in clockwise position.

Figure 2.2 - High-Low Range Switch

VARIABLE SPEED DIAL

Variable Speed Dial “B”, Figure 2.3, visibly indicates, in windows, the speed range that the

machine is operating in, 60 to 500 low range, 500 to 4200 high range.

TP5286

B

Figure 2.3 - Variable Speed Dial

2-2 M-450

TP5287

SPINDLE BRAKE

Spindle Brake “C”, Figure 2.4, can be moved in

either direction to stop spindle; however, when

locking spindle, brake lever should be moved either

by pulling towards the operator or pushing away

from the operator, then raised. When brake is worn

out it has to be replaced. There are no adjustments

to be made.

- CAUTION -

BE certain that spindle brake is re

leased before starting the motor.

This is important as the motor can

be damaged if switch is turned on

with brake in locked position.

C

Lock On

Lock Off

TP5288

Figure 2.4 - Spindle Brake

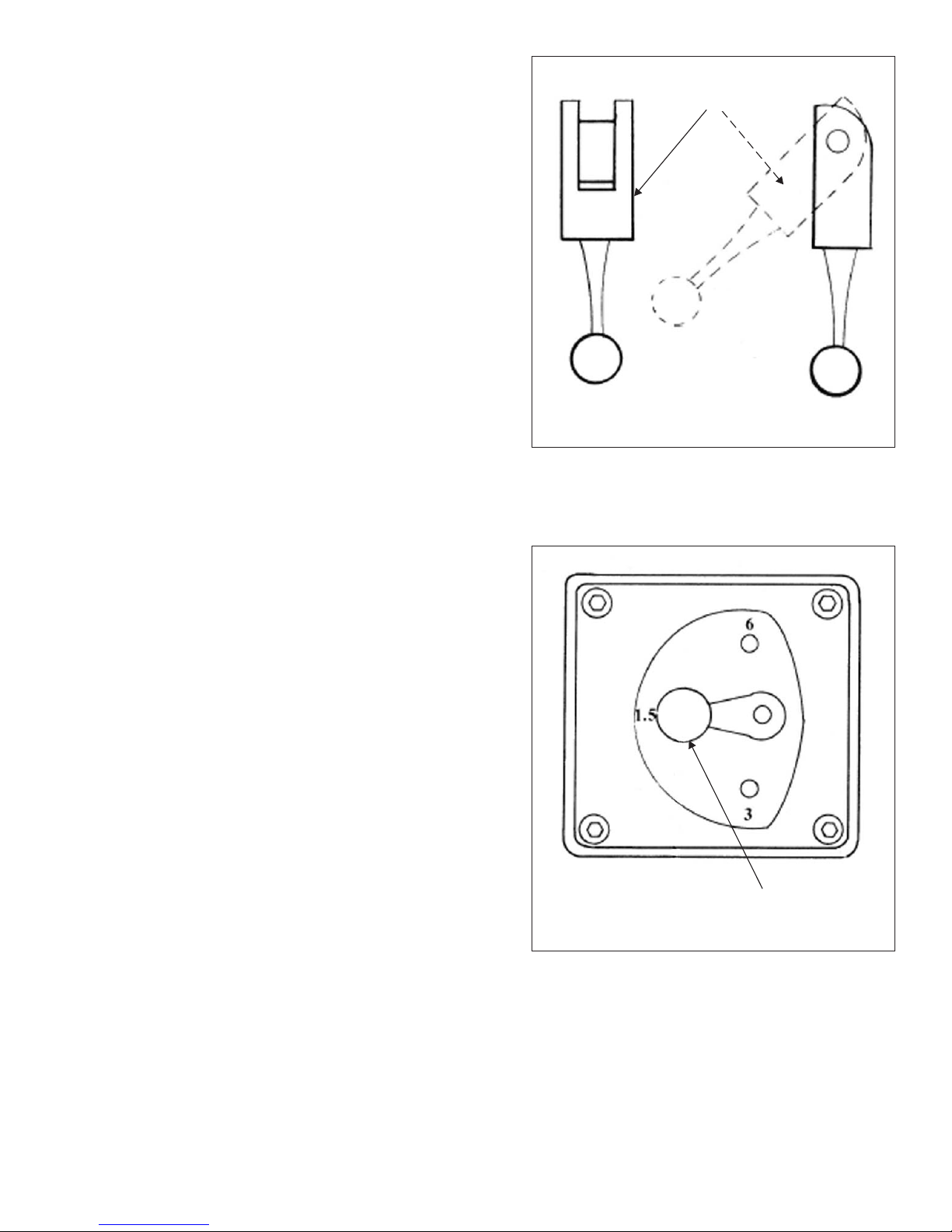

QUILL FEED SELECTOR

The Quill Feed Selector “D”, Figure 2.5, is used

for selecting the three feeds: .0015”, .003” and .006”

per revolution. It is shifted by pulling knob out and

turning from one position to the other. Feeds are

stamped on cover below indentation hole. Feed is

more readily engaged when spindle is running.

D

TP5289

Figure 2.5 - Quill Feed Selector

M-450 2-3

QUILL STOP KNOB

Quill Stop Knob “E”, Figure 2.6, is used to

disengage automatic feed in either direction as well

as the stop point setting working depths.

MICROMETER NUT

Micrometer Nut “F”, Figure 2.6, is used for setting

depths. Each graduation on nut indicates .001” of

depth, it reads directly to scale mounted along the

side of it. Depths may be obtained by setting

micrometer nut in conjunction with quill stop.

E

F

TP5290

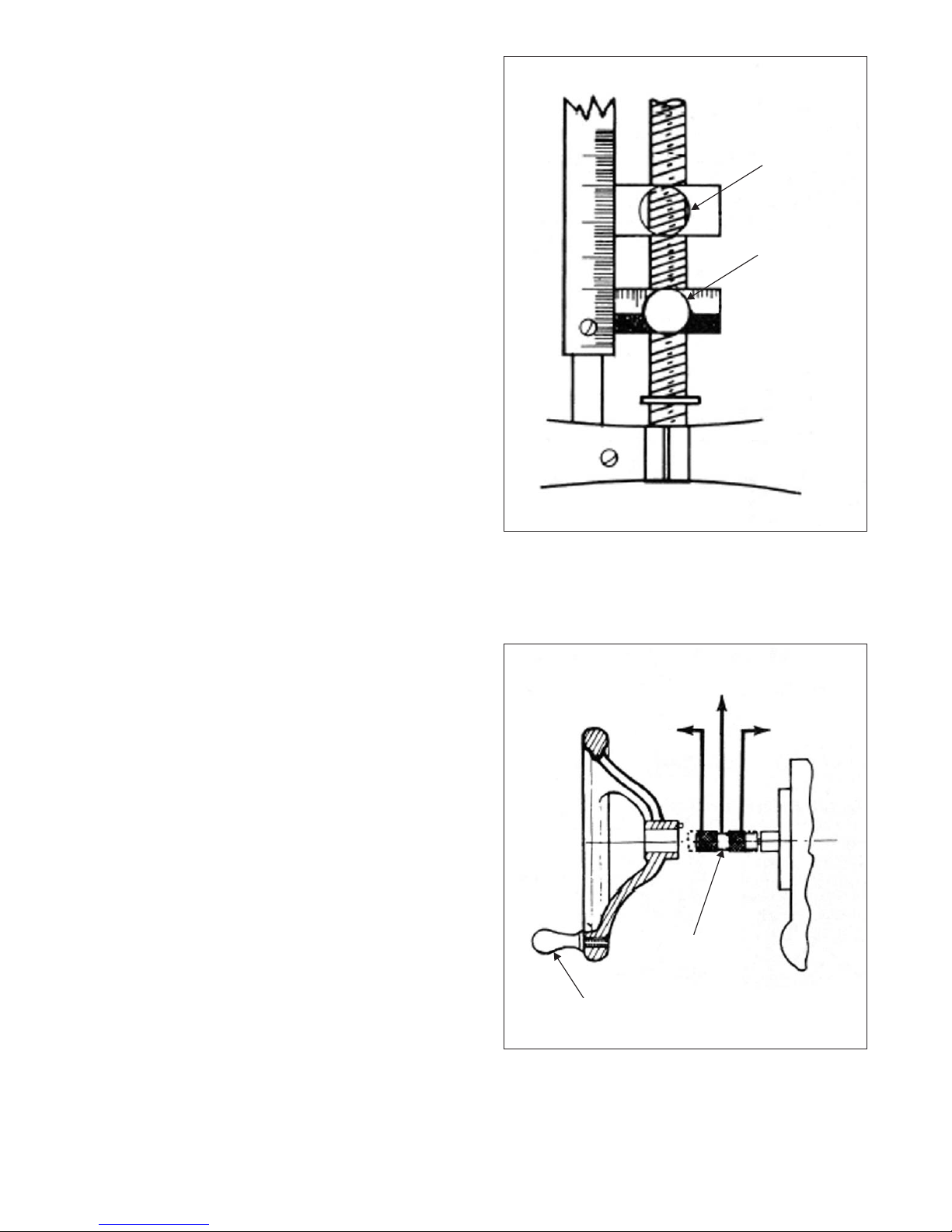

FEED REVERSE KNOB

The position of the Feed Reverse Knob “G”,

Figure 2.7, depends upon direction of spindle

rotation. If boring with right hand cutting tools, pull

feed handle towards operator until clutch becomes

engaged.

Neutral position is between forward and reverse

position. It is recommended that the handle be left in

neutral position when not in use.

MANUAL FEED HANDWHEEL

Feed Reverse Knob “G” should be in neutral

position and Feed Control Lever “I”, Figure 2.8

engaged. Clockwise rotation of Manual Feed

Handwheel “H”, Figure 2.7, moves quill down. The

manual feed handwheel and the quill feed handle

may be disengaged by moving them outward about

.125”.

Figure 2.6 - Quill Stop Knob and

Micrometer Nut

Neutral

Up

G

H

Down

TP5291

2-4 M-450

Figure 2.7 - Feed Reverse Knob and

Manual Feed Handwheel

FEED CONTROL LEVER

Feed Control Lever “I”, Figure 2.8, engages

overload clutch on pinion shaft when positioned left

and will stay engaged until either quill stop comes in

contact with micrometer adjusting nut, forcing feed

control lever to drop out automatically, or release

manually by engaging lever to right.

FEED CONTROL OVERLOAD CLUTCH

The Feed Control Overload Clutch is set at the

factory to hold up to 200 lbs of down pressure on

quill, which will accommodate drills up to .375”

diameter in mild tool steel.

- CAUTION -

This clutch should not be tampered

with in the field.

Engage

I

Disengage

- NOTE -

The feed control lever must be en

gaged in order to use manual feed

controls. the quill feed handle and

manual feed handwheel may be

removed when not in use.

QUILL

Quill “J”, Figure 2.9, contains the spindle

assembly and can be raised or lowered by using the

quill feed handle “M”, Figure 2.10.

SPINDLE

Spindle “K”, Figure 2.9, performs the actual

rotation and also retains the machine tooling.

QUILL LOCK

Quill Lock “L”, Figure 2.9, is a friction lock for use

when quill isin a stationaryposition such as a milling

operation. It is recommended that this lock be used

whenever quill movement is not desired.

TP5292

Figure 2.8 - Feed Control Lever and

Feed Control Overload Clutch

J

K

TP5293

L

M-450 2-5

Figure 2.9 - Quill, Spindle and

Quill Lock

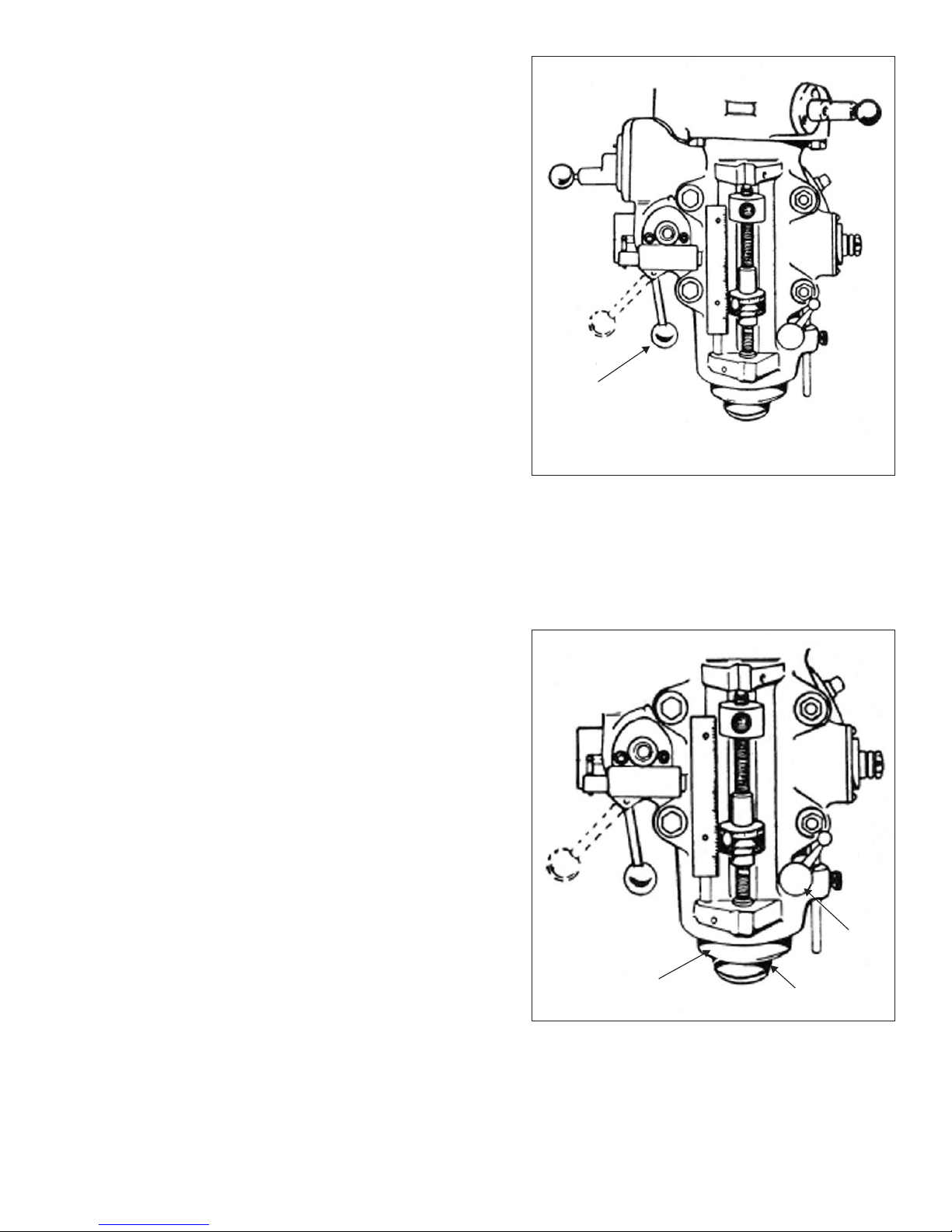

QUILL FEED HANDLE

Quill Feed Handle “M”, Figure 2.10, is used to

raise and lower the quill manually. It is generally

recommended that handle be engaged when using

the power feed. It may be removed by simply pulling

handle off.

POWER FEED TRANSMISSION ENGAGEMENT

CRANK

M

TP5294

Figure 2.10 - Quill Feed Handle

Power Feed Transmission Engagement Crank

“N”, Figure 2.11, engages power feed worm gear.

When lever is in right hand hole, the power feed

worm gear is engaged.

To engage worm gear, pull knob out and crank

handle in clockwise or down direction and move to

opposite position (see Figure 2.12).

- NOTE -

Crank should be rotated counter-clockwise to engage power quill feed. Crank

should be rotated clockwise to disen

-

gage.

- CAUTION -

Power feed worm gear may be en

gaged when spindle is rotating,

however, it should be engaged

gently to avoid damage to worm

gear. The worm gear may be disen

gaged at any time. do not use power

feed at speeds above 3000 RPM.

N

TP5295

Figure 2.11 - Power Feed Transmission

Engagement Crank

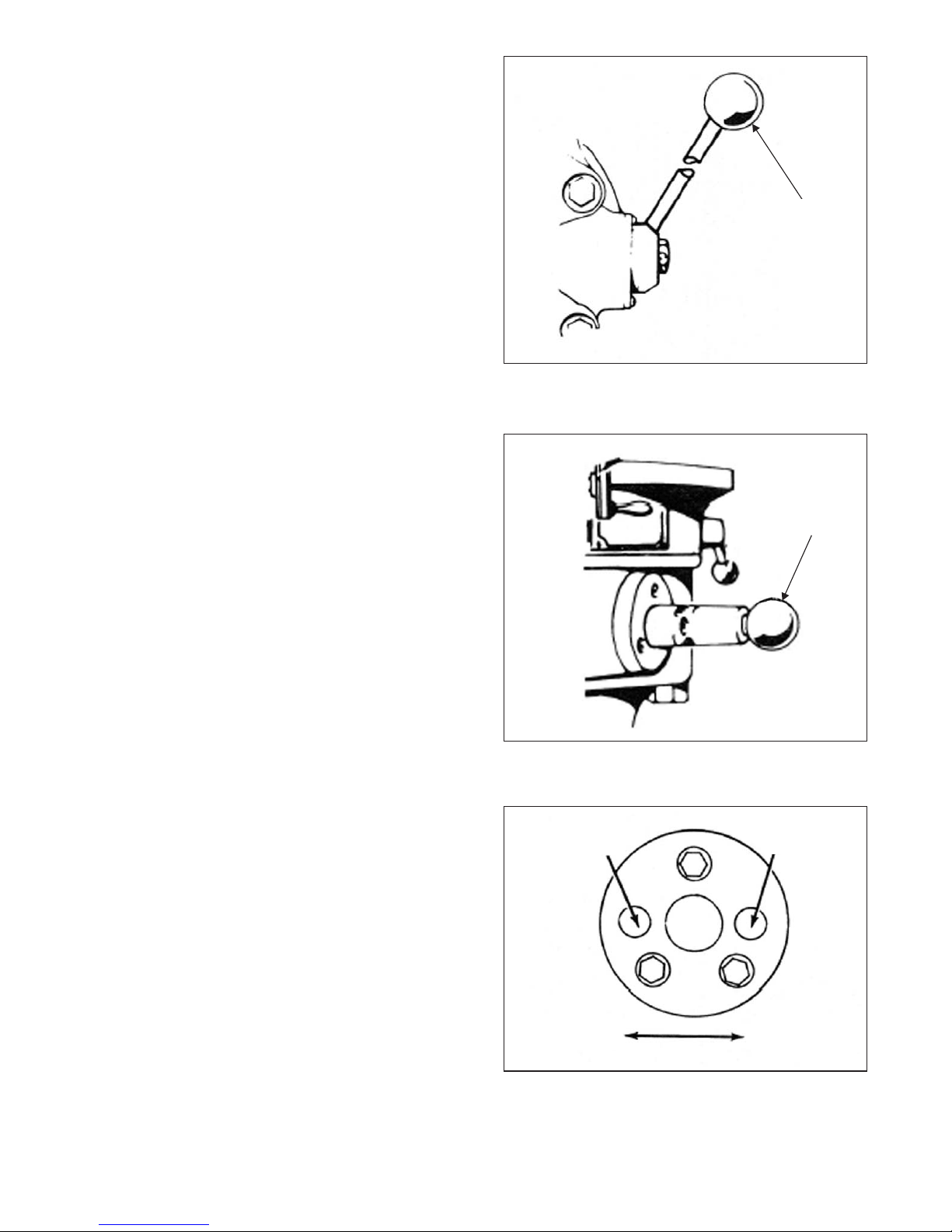

Disengaged Engaged

2-6 M-450

Clockwise

CounterClockwise

TP5296

Figure 2.12 - Worm Gear Disengagement

Loading...

Loading...