Page 1

INSTALLATION, OPERATION,

MAINTENANCE, AND PARTS LIST

SERIES I

MILLING MACHINES

TP8035

Revised: August 3, 2011

Manual No. M-508 Litho in U.S.A.

Part No. M -0009500-0508 June, 2010

Page 2

Information in this manual is subject to change without notice.

This manual covers installation, operation, maintenance, and parts list for

Bridgeport Series I milling machines with serial numbers ending with the let

ter "M". The machine serial number is located on the front of the knee. If the

machine serial number does not end with the letter "M", refer to the latest

version of manual M -0009500-0450.

In no event will Hardinge Inc. be responsible for indirect or consequential

damage resulting from the use or application of the information in this man

ual.

-

-

Reproduction of this manual, in whole or in part, without written permis

-

sion of Hardinge Inc. is prohibited.

ORDERING REPLACEMENT PARTS

Please provide the following information when ordering replacement parts:

1. The complete machine serial number. The machine serial number is located on the front of the

knee.

2. List the following:

A) Manual Number (M-508).

B) Page Number.

C) Item Number.

D) Part Description.

E) Part Number.

F) Quantity of each part required.

3. Specify how and where to ship.

- NOTICE -

Bridgeport is a registered trademark of Hardinge Inc.

© 2010, Hardinge Inc. M-508

Page 3

SAFETY

To prevent serious bodily injury, you should observe the following basic safety precautions when

installing, operating or servicing the milling machine.

1. Follow all instructions in the manual.

2. Wear approved industrial safety glasses and safety shoes.

3. Do not wear gloves, long sleeves, long hair, rings, watches, jewelry or other items that could

become caught in moving parts.

4. Keep all parts of your body away from moving parts (belts, cutters, gears, etc.)

5. Use proper point of operation safeguarding.

These and other safety precautions are discussed in the American National Standard Institute

standard entitled safety requirements for the construction, care, and use of drilling, milling, and

boring machines (ANSI B11-8-1983).

This publication is available from:

American National Standards Institute

25 West 43rd Street, 4th floor

New York, NY 10036

Safeguarding for protection at the point of operation can only be designed and constructed when

the parameters of the particular operation have been determined. As a result, ANSI B11.8-1983,

Section 5.1, states that “it shall be the responsibility of the employer to provide, and ensure use of, a

guard, guarding device, awareness barrier, awareness device, or shield…”

To assist machine users in designing point of operation safeguarding for their specific machine

applications, the Occupational Safety And Health Administration has published a booklet entitled

Concepts and Techniques of Machine Safeguarding (OSHA Publication No. 3067).

This publication is available from:

The Publication Office – OSHA

U.S. Department of Labor

200 Constitution Avenue, NW

Washington, D.C. 20210

The general purpose point of operation shield provided with this machine and shown in certain

illustrations throughout this manual may not be appropriate and cannot be utilized for all possible

applications of the machine. Use additional or alternate safeguarding where this shield is not

appropriate or cannot be utilized. Note that for purposes of display, the shield has been removed in

certain other illustrations in this manual.

M-508 i

Page 4

WARNINGS, CAUTIONS, AND NOTES

- WARNING -

Warning notices are used in this publication to emphasize that hazardous

mechanical conditions, voltages, currents, or temperatures exist in this

equipment which could cause serious personal injury and/or damage to the

equipment.

- CAUTION -

Caution notices are used where equipment might be damaged if care is not

taken.

In situations where inattention could cause either personal injury or damage to the equipment, a

warning notice is used.

- NOTE -

Notes merely call attention to information that is especially significant in under

standing and operating the equipment.

This document is intended for the use of those who install, operate and maintain the milling

machine. Although reasonable care has been exercised in the preparation of this manual to make it

complete and accurate, this manual does not purport to cover all conceivable problems or

applications pertaining to this machine.

-

ii M-508

Page 5

SAFETY RECOMMENDATIONS

DO NOT OPERATE EQUIPMENT until you have read and understood the appropriate opera

tor and safety maintenance manuals.

DO NOT OPERATE EQUIPMENT until you have read and understood all machine and con

trol key signs.

DO NOT OPERATE EQUIPMENT for the first time without a qualified instructor. Consult your

supervisor when in doubt as to the correct way to perform an operation.

DO NOT OPERATE EQUIPMENT unless proper maintenance has been regularly performed

and the equipment is known to be in good working order.

DO NOT ALLOW the operation or repair of equipment by untrained personnel.

WARNING or INSTRUCTION TAGS are mounted on the equipment for your safety and infor

mation. Do not remove them.

DO NOT OPERATE EQUIPMENT if any unusual or excessive heat, noise, smoke, or vibra

tion occurs. Report any excessive or unusual vibration, sounds, smoke, or heat as well as any

damaged parts.

WEAR SAFETY GLASSES with side shields and SAFETY SHOES with steel toes and oil-re

sistant soles at all times. When necessary, wear respirator, helmet, and ear muffs or plugs.

DO NOT OPERATE ANY MACHINE while wearing rings, watches, jewelry, loose clothing,

neckties, or long hair not contained by a net or shop cap.

-

-

-

-

-

DO NOT WEAR GLOVES while operating equipment. Gloves are easily caught in moving

parts.

REMOVE ANY LOOSE PARTS OR TOOLS left on machine or in the work area before operating the machine. Always check the machine and work area for loose tools and parts, especially after work has been completed by maintenance personnel.

REMOVE CHUCK WRENCHES before starting the machine.

NEVER OPERATE A MACHINE after taking strong medication, using non-prescription drugs

or consuming alcoholic beverages.

SAFEGUARD THE CUTTING ZONE (“point of operation”). Use standard, general purpose

safeguards when possible. Use special safeguards when required.

PROTECT YOUR HANDS. Stop the spindle completely before changing tools.

PROTECT YOUR HANDS. Stop the spindle completely before loading or unloading a

workpiece.

DO NOT REMOVE CHIPS with hands. Use a hook or similar device and make certain that all

machine movements have ceased.

DO NOT ADJUST tooling, workpieces or coolant hoses while the machine is running.

PROTECT YOUR HANDS. Stop the spindle completely before taking measurements.

PROTECT YOUR HANDS. Stop the spindle completely before opening safeguards or covers.

NEVER REACH around a safeguard.

M-508 iii

Page 6

PROTECT YOUR HANDS. Stop the machine before changing or adjusting belts, pulleys or

gears.

PROTECT YOUR HANDS. Keep hands and arms clear of spindle start switch when changing

tools.

PROTECT YOUR EYES AND THE MACHINE. Never use a compressed air hose to remove

chips.

KEEP WORK AREA WELL LIGHTED. ask for additional light if needed.

DON’T SLIP. Keep your work area clean and dry. Remove chips, oil and obstacles.

NEVER LEAN ON your machine. Stand away when the machine is running.

MAKE CERTAIN that you are clear of any “pinch points” created by moving slides before

starting the machine.

PREVENT OBJECTS from flying loose. Securely clamp and locate workpiece. Use stop

blocks where necessary. Keep clamps clear of cutter path.

PREVENT CUTTER BREAKAGE. Use correct table feed and spindle speed for the job. Re

duce feed and speed if you notice unusual noise or vibration.

PREVENT CUTTER BREAKAGE. Rotate spindle in clockwise direction for right-hand tools,

counterclockwise for left-hand tools. Use the correct tool for the job.

PREVENT WORKPIECE and cutter damage. Never start the machine when the cutter is in

contact with the workpiece.

DO NOT USE worn or defective tools. Use the proper size and type of tool for the task at

hand.

KEEP ROTATING CRANKS AND HANDWHEELS well lubricated and maintained. Do not re-

move safety springs.

CERTAIN MATERIALS, such as magnesium, are highly flammable in dust and chip form. See

your supervisor before working with these materials.

PREVENT FIRE. Keep flammable liquids and materials away from work area and hot chips.

PREVENT MACHINE from moving unexpectedly. Disengage power feed when not being used

(manual machines only).

PREVENT MACHINE from moving unexpectedly. Always start machine in manual mode.

UNLESS OTHERWISE NOTED, all operating and maintenance procedures are to be per

formed by one person. To avoid injury to yourself and others, be sure that all personnel are

clear of the machine when opening or closing the coolant guard door and any access covers.

-

-

iv M-508

Page 7

INSTALLATION AND USE OF SAFEGUARDS

Both American National Standard B11.8 and OSHA Section 1910.212 assign responsibility for

point of operation safeguarding of milling machines to the employer/user. Therefore, to prevent

serious injury resulting from the rotating cutter, flying chips, or splashing coolant, point of operation

safeguarding should be used on milling machines to the greatest extent practicable.

This booklet provides basic information for the installation and use of the general purpose

safeguard. It also contains the names of several manufacturers of other types of point of operation

safeguarding for vertical milling machines.

Remember, point of operation safeguarding is your responsibility as the employer/user. You are in

the best position to evaluate your safeguarding needs and ensure that the proper safeguards are

installed and used.

- CAUTION -

A safety shield is supplied for protection from chips and coolant with every

machine.

The chip and coolant shields have been designed and are custom manufac

tured with the highest clear impact material commercially available:

polycarbonate (G.E. Lexan). It has an impact strength 5 to 10 times greater

than acrylic (plexiglass) or butyrate (UVEX) materials, thereby offering the

greatest protection for our customers.

Some of the new “easy to dispose of” coolants and/or cutting oils contain

chemicals harmful to polycarbonate. These chemicals are:

Mono-ethanolamine, Di-ethanolamine, Tri-ethanolamine and the combination

thereof. These chemicals may significantly reduce the impact strength of the

shield within days, and could destroy the entire shield in weeks.

Use of use of coolants and/or cutting oils containing these chemicals will

void the warranty on your safety shield, and could cause injury to your workers.

- WARNING -

This safeguard DOES NOT take the place of any other safety practice or

safety equipment.

YOU MUST ALWAYS wear safety glasses and safety shoes.

YOU MUST ALWAYS stop the spindle of the machine completely before

changing or adjusting the workpiece, fixture, or tool.

-

YOU MUST NEVER wear gloves, long sleeves, long hair, rings, watches,

neckties, jewelry or other loose items.

M-508 v

Page 8

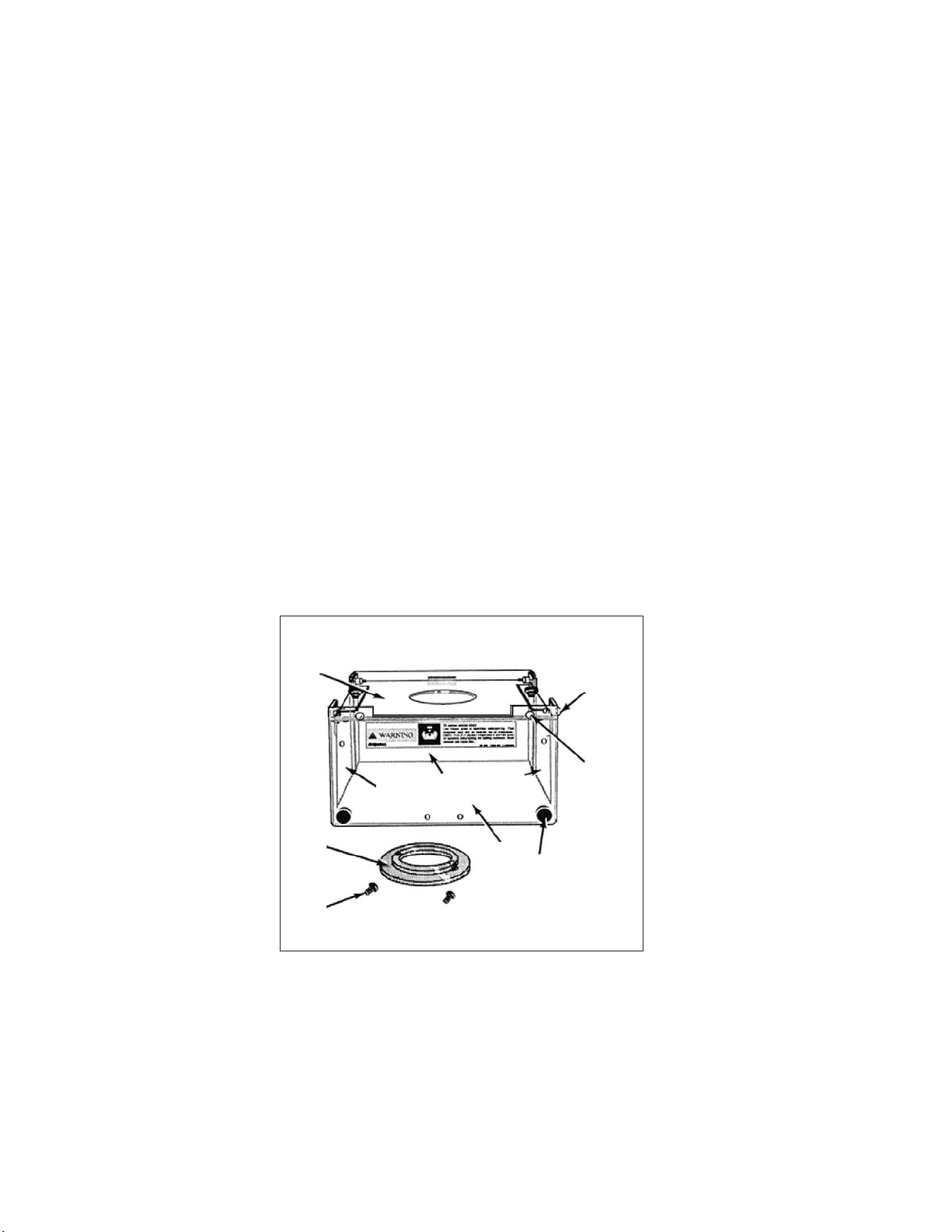

GENERAL PURPOSE SAFEGUARDS

There is no single safeguard which can match the versatility of the Series I machine. As a result,

you will find that the guard assembles shown in Figures I.I and I.II, like all safeguards, will be suitable

for some operations, but not for others. Carefully analyze the operation to be performed before

deciding whether this safeguard is suitable. Adjust the safeguard to suit your special requirements. If

you find that it is not suitable for a particular application, you should use an alternate form of

protection.

Installation for Machines with R-8 Spindle Taper

There are two tapped holes in the nose cap of the spindle to be used for mounting the guard (the

two untapped holes serve to remove the nose cap with a spanner wrench).

1. Place the mounting ring (Item 11) underneath the top of the guard (Item 7).

2. Place two socket head cap screws (Item 12) through the holes in the ring, and hand-start them

into the threaded holes in the nose cap until hand tight.

3. Align guard to be square with table of machine (unless angular mounting is desired).

4. Tighten screws with a hex Allen wrench.

7

6

9

2

11

12

10

1

Figure I.I - Spindle Guard Assembly

(R8 Spindle)

3,4,5

8

TP5262A

vi M-508

Page 9

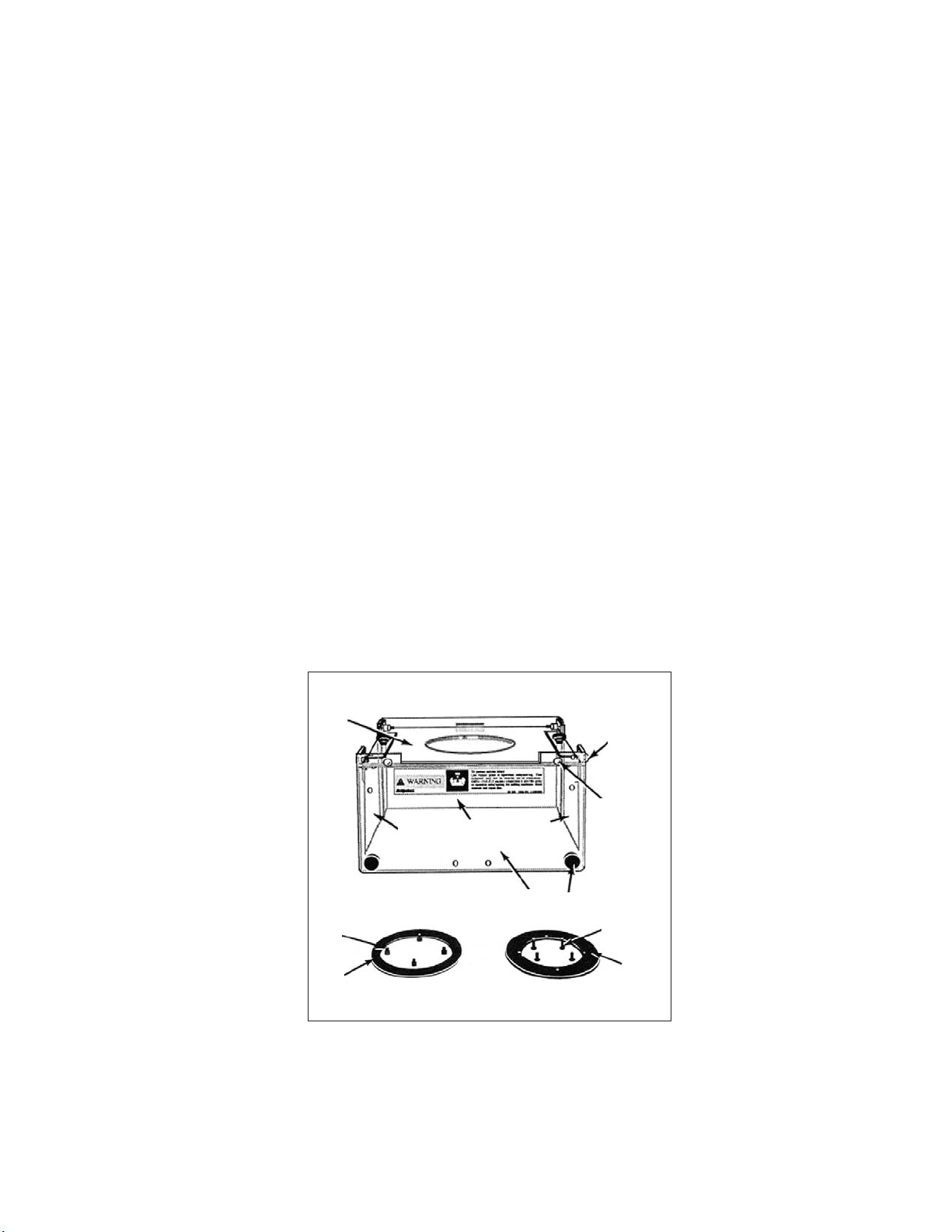

Installation for Machines with Erickson #30 Quick Change Spindles

1. Remove the spindle locknut. This is done by removing the long button head black finish screw,

which is normally left of the cadmium-finished button head screw on the locknut of the spindle.

This will allow you to unscrew the locknut by turning it counter-clockwise.

2. Place the nose cap mounting ring “O” up against the quill nose cap and install the four button

head cap screws “M”.

- NOTE -

The counterbored side of the nose cap mounting ring fits against the nose cap.

Observe the orientation of the mounting holes in the spindle and the mounting ring

to orient the quill guard as desired.

3. Place the mounting ring (Item 11) on the top of the guard (Item 7).

4. Place the locking ring (Item 12) underneath the top of the guard (Item 7).

5. Secure the two rings together with four #8-32 x 5/8 button head cap screws.

6. Lower the quill.

7. Position the guard under the spindle.

8. Use four #8-32 x 1/2 button head cap screws to secure the guard to the spindle.

9. Reinstall the quick change locknut. Refer to assembly instructions.

7

3,4,5

8

6

9

2

13

11

TP5263A

14

12

10

1

Figure I.II - Spindle Guard Assembly

M-508 vii

Page 10

Guard Assembly Component Lists

BP 11060813 – R-8 SHIELD ASSEMBLY

Refer to Figure I.I.

Item Part Number Description Qty

1 BP 11191203 Shield Assembly, Rear 1

2 BP 11010060 Screw, Hand 8-32 x .500 4

3 0300312 Screw, BHC 10-32 x .750 4

4 BP 11010065 Washer, Plastic #10-32 8

5 BP 11010055 Nut, Stop, #10-32 (Elastic) 4

6 BP 11060824 Shield, Right Side 1

7 BP 11060817 Shield Assembly, Top 1

8 BP 11010063 Screw, Drive, "Type U" #12 x .625 2

9 BP 11060820 Shield Assembly, Front 1

10 BP 11060822 Shield, Left Side 1

11 BP 11191201 Ring, Guard Mounting 1

12 0100610 Screw, SHC 1/4-20 x 5/8 2

BP 11060814 – QUICK CHANGE SHIELD ASSEMBLY

Refer to Figure I.II.

Item Part Number Description Qty

1 BP 11191203 Shield Assembly, Rear 1

2 BP 11010060 Screw, Hand 8-32 x .500 4

3 0300312 Screw, BHC 10-32 x .750 4

4 BP 11010065 Washer, Plastic #10-32 8

5 BP 11010055 Nut, Stop, #10-32 (Elastic) 4

6 BP 11060824 Shield, Right Side 1

7 BP 11060816 Shield Assembly, Top 1

8 BP 11010063 Screw, Drive, "Type U" #12 x .625 2

9 BP 11060820 Shield Assembly, Front 1

10 BP 11060822 Shield, Left Side 1

11 BP 12190330 Ring, Guard Mounting 1

12 BP 12190331 Ring, Guard Locking 1

13 0300208 Screw, BHC #8-32 x 1/2 4

14 0300210 Screw, BHC #8-32 x 5/8 4

viii M-508

Page 11

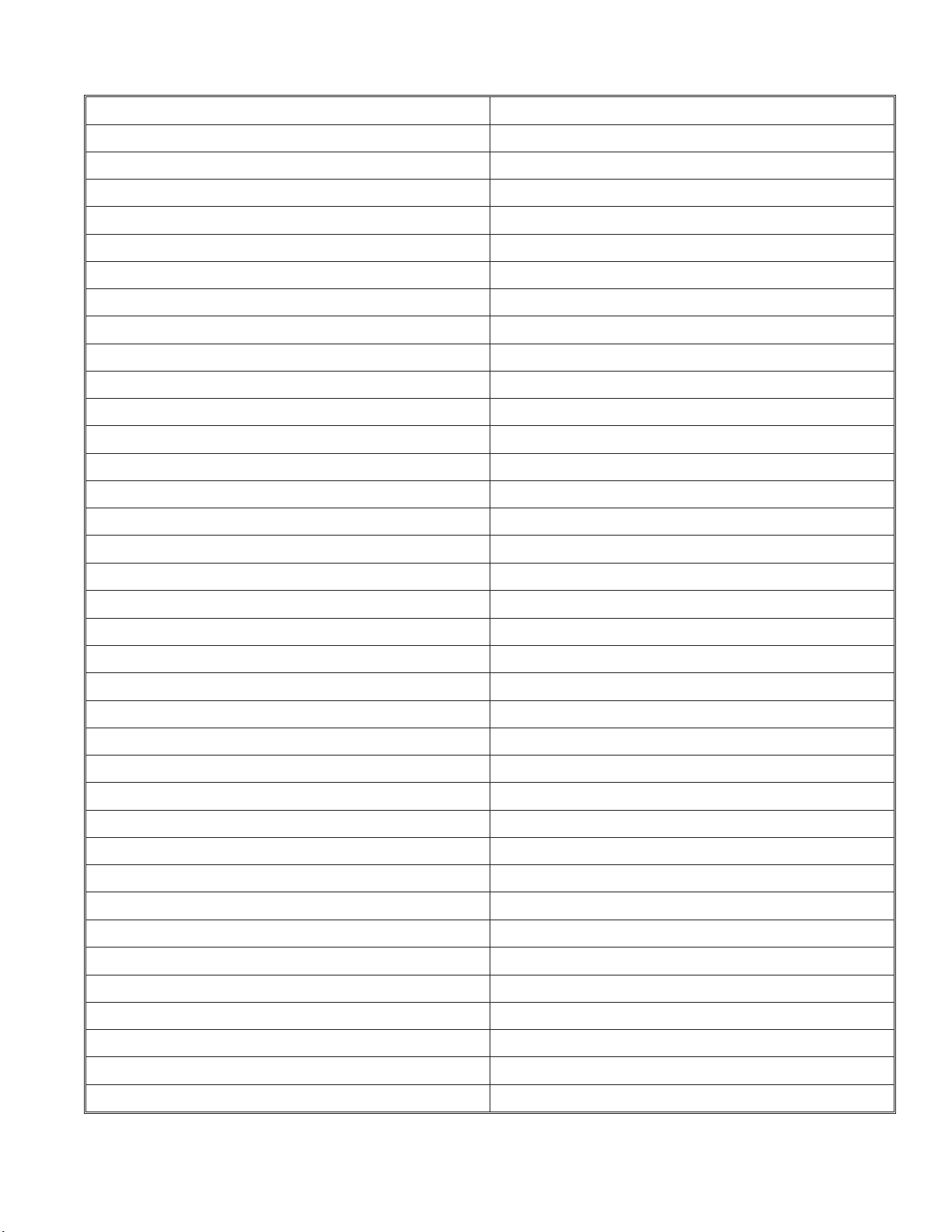

- NOTES -

M-508 ix

Page 12

- NOTES -

x M-508

Page 13

Table of Contents

CHAPTER 1 - INSTALLATION

Uncrating ....................................1-1

Shortages ....................................1-1

Cleaning ....................................1-1

Positioning the Head Upright ...........................1-2

Lifting the Machine................................1-4

Foundation ...................................1-5

Placing on a Solid Foundation .........................1-5

Leveling Bolts and Pads ..........................1-5

Machine Hold-Down Bolts .........................1-5

Leveling the Machine .............................1-6

Machine Power Supply..............................1-7

Connecting the Power Supply .........................1-7

Lubrication ...................................1-8

Alignment of the Head for Fine Work .......................1-9

CHAPTER 2 - OPERATION

Head Controls ..................................2-1

High-Low Range Switch............................2-2

Variable Speed Dial..............................2-2

Spindle Brake ................................2-3

Quill Feed Selector ..............................2-3

Quill Stop Knob ...............................2-4

Micrometer Nut ................................2-4

Feed Reverse Knob .............................2-4

Manual Feed Handwheel ...........................2-4

Feed Control Lever ..............................2-5

Feed Control Overload Clutch .........................2-5

Quill .....................................2-5

Spindle ...................................2-5

Quill Lock ..................................2-5

Quill Feed Handle .............................2-6

Power Feed Transmission Engagement Crank .................2-6

Hi-Neutral-Lo Lever ..............................2-7

Speed Change Handwheel ..........................2-8

Drawbar ...................................2-9

Operational Procedures ............................2-10

Spindle Speed ..............................2-10

Back Gear (Low Speed) ..........................2-10

Direct Drive (High Speed) .........................2-11

Quill Feed ................................2-11

Spindle Brake ...............................2-13

Quill Sensitive Hand Feed .........................2-13

M-508 xi

Page 14

Machine.....................................2-14

Operational Procedures ............................2-14

Swivel the Belt Housing ..........................2-14

Swivel the Turret .............................2-14

Move the Ram Slide ............................2-15

Saddle Clamping .............................2-15

Table Clamping ..............................2-16

Knee Clamping ..............................2-16

CHAPTER 3 - MAINTENANCE

2J-Head.....................................3-1

Motor Removal ................................3-1

Drive Belt Replacement ............................3-2

Timing Belt Replacement ...........................3-2

Brake Shoe Replacement ...........................3-3

Head ......................................3-4

Micro Feed Trip Assembly and Quill Removal .................3-4

Balance Spring Replacement .........................3-5

Feed Trip Adjustment .............................3-5

Collet Aligning Screw Replacement ......................3-6

Gib Adjustment .................................3-7

Adjustment of the Table Gib ..........................3-7

Adjustment of the Saddle Gib .........................3-8

Adjustment of the Knee Gib ..........................3-10

Table Feed Screw Backlash Adjustment......................3-12

Saddle Feed Screw Backlash Adjustment .....................3-13

CHAPTER 4 - PARTS LISTINGS

2J-Head

Top Housing .................................4-1

Back Gear ..................................4-4

2J- and J-Head Lower Housing ..........................4-7

Basic Machine ..................................4-12

Table and Lead Screw Assembly .........................4-15

Flood Coolant ..................................4-17

Lubrication System ...............................4-18

Replacement Motor Assemblies Available .....................4-19

Motor Assembly 2J-Head 2 HP Unified without NFPA, BP 12550150 .......4-19

Motor Assembly 2J-Head 2 HP Unified with NFPA ...............4-19

Motor Assembly 2J-Head 2 HP 575 Volts without NFPA, BP 12550020......4-20

Motor Assembly 2J-Head 2 HP 575 Volts with NFPA ..............4-20

Replacement Motors Available.........................4-20

2J Milling Head (1-1/2 HP) – Spare Parts ...................4-21

2J Milling Head (2 HP) – Spare Parts .....................4-21

Metric Conversion Kits ..............................4-21

BP 2184000 – 2J-Head, Metric Conversion Kit .................4-21

xii M-508

Page 15

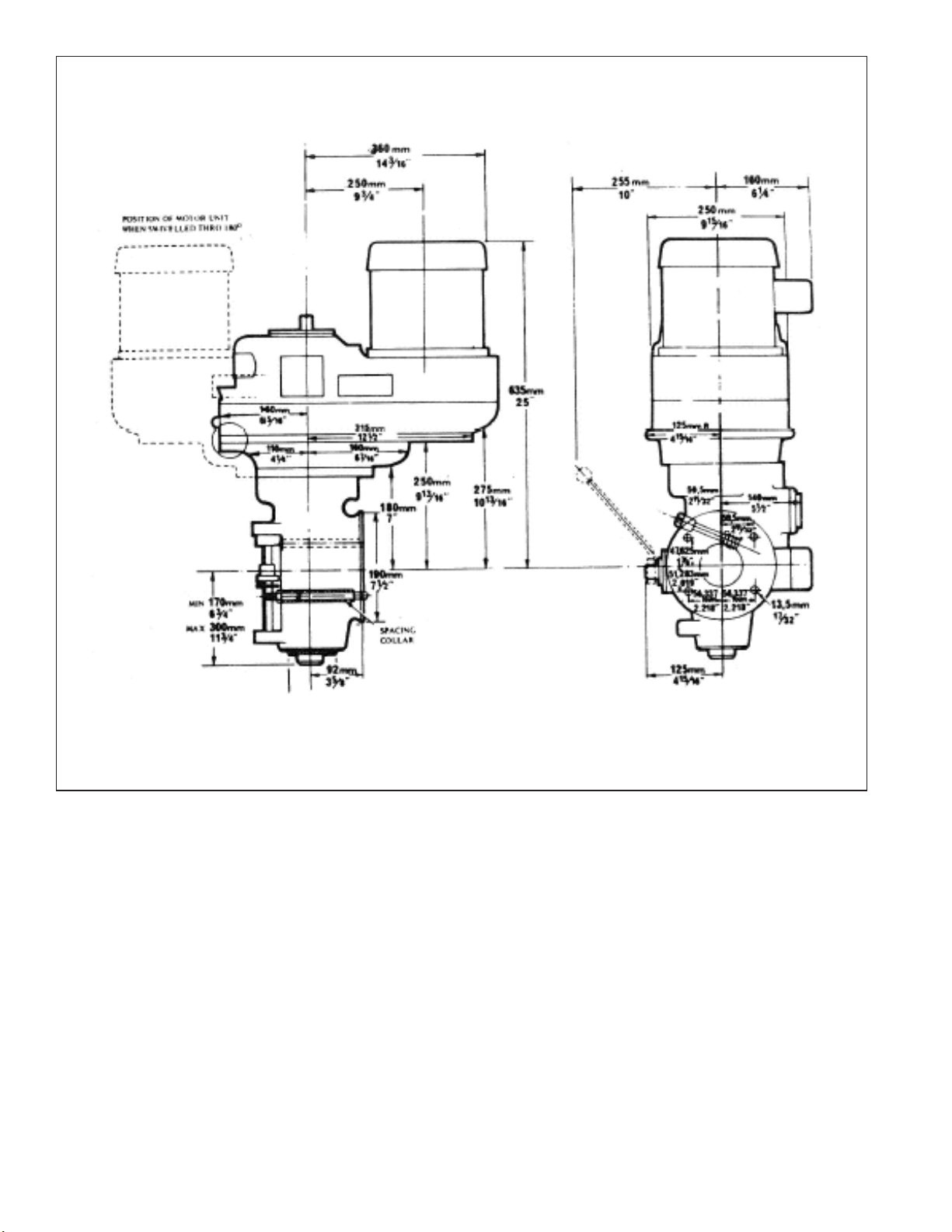

CHAPTER 5 - SPECIFICATIONS

Machine.....................................5-1

Principle Dimensions .............................5-1

Left Side View of Machine .........................5-1

Top View of Machine ...........................5-2

Machine Specifications ............................5-3

2J-Head.....................................5-5

General Speed Recommendations .......................5-5

Table of Cutting Speeds and Feeds ......................5-5

M-508 xiii

Page 16

- NOTES -

xiv M-508

Page 17

CHAPTER 1 - INSTALLATION

UNCRATING

Carefully remove protective crating and skids so that the machine and parts are not marred,

scratched or impaired. In the event of damage having occurred during transit, communicate at once

with our representative and the transportation company making delivery.

SHORTAGES

Check shipment carefully against the itemized packing list which is included in the parts box. In

case of shortages, report them immediately to the representative from whom the machine was

purchased, indicating the parts not received which have been checked on the packing list.

CLEANING

Thoroughly clean protective coating from the machine with a suitable cleaning solution.

- WARNING -

DO NOT use gasoline or any other flammable cleaning agent to clean machine.

- NOTE -

Do not move the table, saddle, knee,

or any moveable part until all ways

have been well cleaned and lubricated.

1. After initial cleaning, move table, saddle and

knee in one direction by hand to limit stop.

2. Clean and lubricate the exposed ways.

3. Move each unit to the opposite limit stop, and

clean and lubricate the exposed ways.

4. Move each unit to the opposite stop once more

and similarly clean and lubricate the exposed

ways.

5. Loosen bolts to unlock the ram, and move it

forward and backward to the full length in order

to clean and lubricate.

TP5277

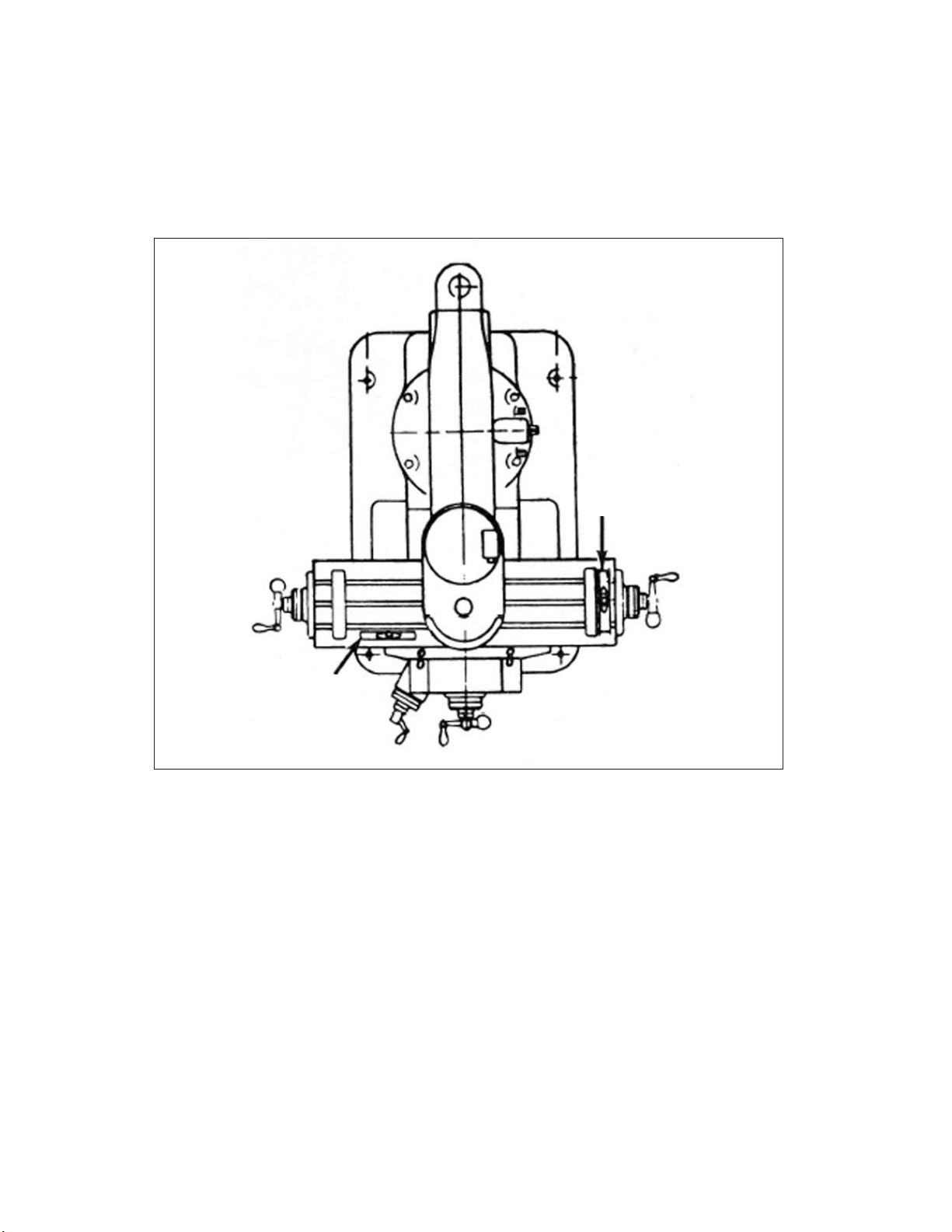

Figure 1.1 - Milling Machine

Left Side View

M-508 1-1

Page 18

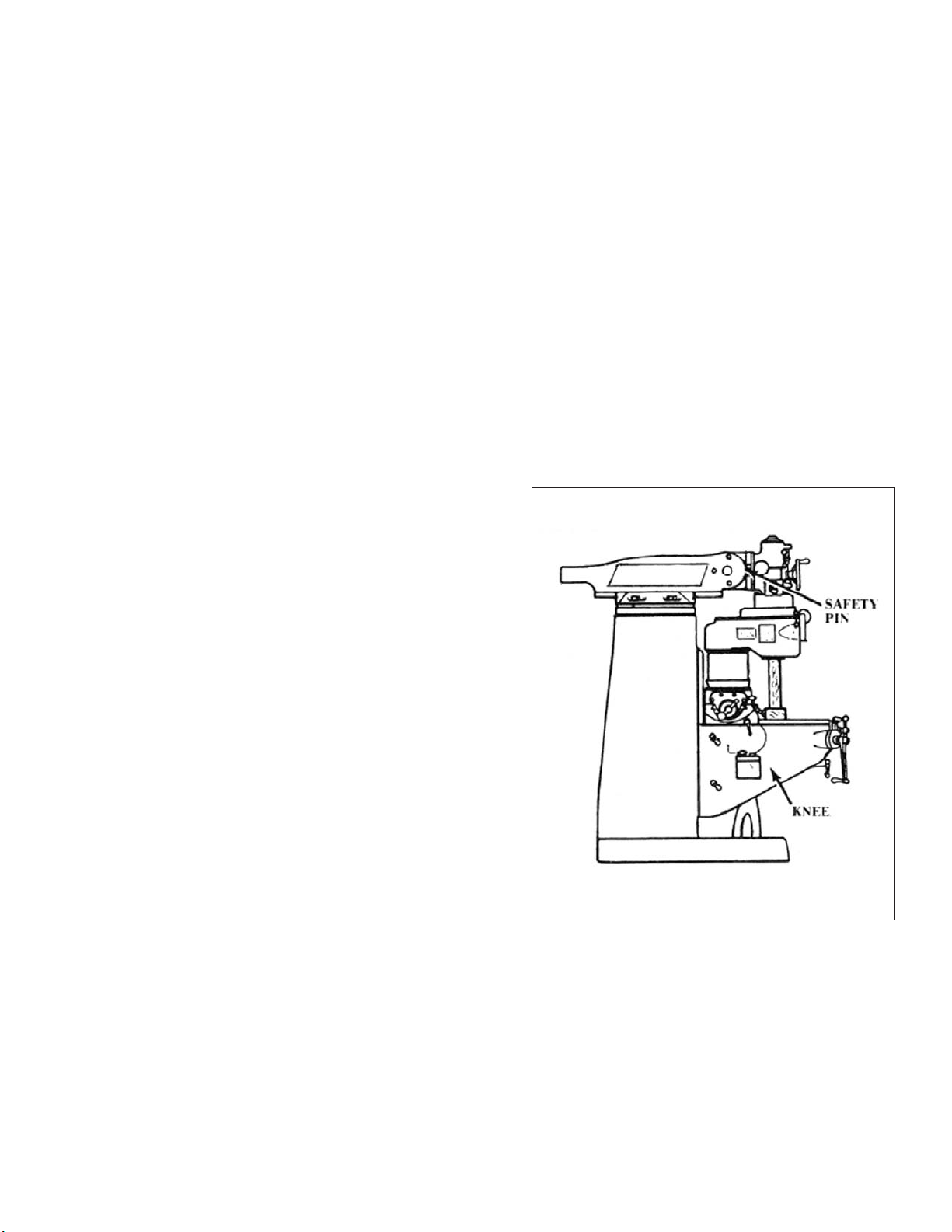

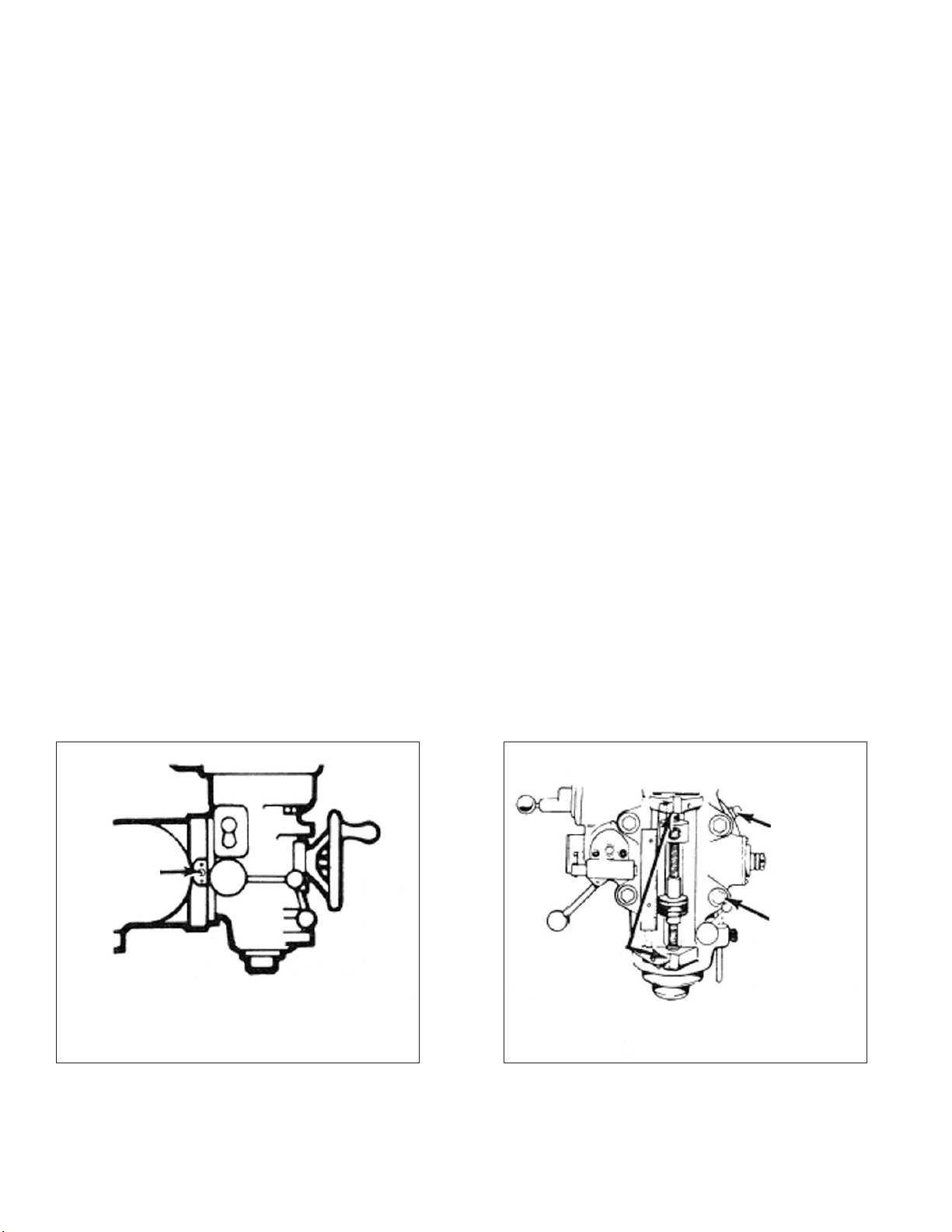

POSITIONING THE HEAD UPRIGHT

If delivery of your machine is made with the milling head in an upside-down position, follow the

instructions below to prepare your machine for operation.

For shipping purposes, the hand cranks are inverted to face the machine. To reverse them,

engage the lock mechanism to the saddle and table. Using a (1-inch) wrench, remove the retaining

lead screw nut and install the hand cranks properly.

Loosen four head mounting bolts “C”, Figure 1.3, and pull stop pin “A”, Figure 1.2, out to detent

and rotate head attachment using the swivel bolt “B”, Figure 1.3, in either direction until it has been

moved within approximately 20% of vertical. It is recommended supporting the head by hand to

relieve the weight on the swivel bolt, as a safety precaution, push the stop pin back in. Continue to

raise the head attachment to vertical position. Align the indicator on the head attachment with the

ZERO line on the ram adapter scale. Tighten all nuts first to 25 lb-ft torque in a diagonal sequence,

then to 50 ft/lbs.

- NOTE -

Care should be taken to avoid excessive pressure since this will cause distortion in

the quill.

1. Lower knee approximately 6” (150mm).

2. Withdraw the safety pin on the left-hand side of ram adapter.

3. Loosen the four unit head mounting bolts.

4. Support unit head manually and use a spanner on swivel bolt to wind into upright position.

5.

Press the safety pin back into the ram adapter after passing the 25° mark.

6. Tighten bolts first to 25 lb-ft torque in a diagonal sequence as noted in Figure 1.4, then to 50

lb-ft. Overtightening could cause bind in the quill movement.

B

A

C

Aligning

Faces

Swiveling Head

To Swivel the Head More Than 25°, the

Safety Pin “A” Must be Pulled Outwards

Figure 1.2 - Positioning Head

TP5278A

Figure 1.3 - Positioning Head

Left View

1-2 M-508

Table

TP5278B

Front View

Page 19

4

1

Figure 1.4 - Tightening Sequence

2

3

TP5280

M-508 1-3

Page 20

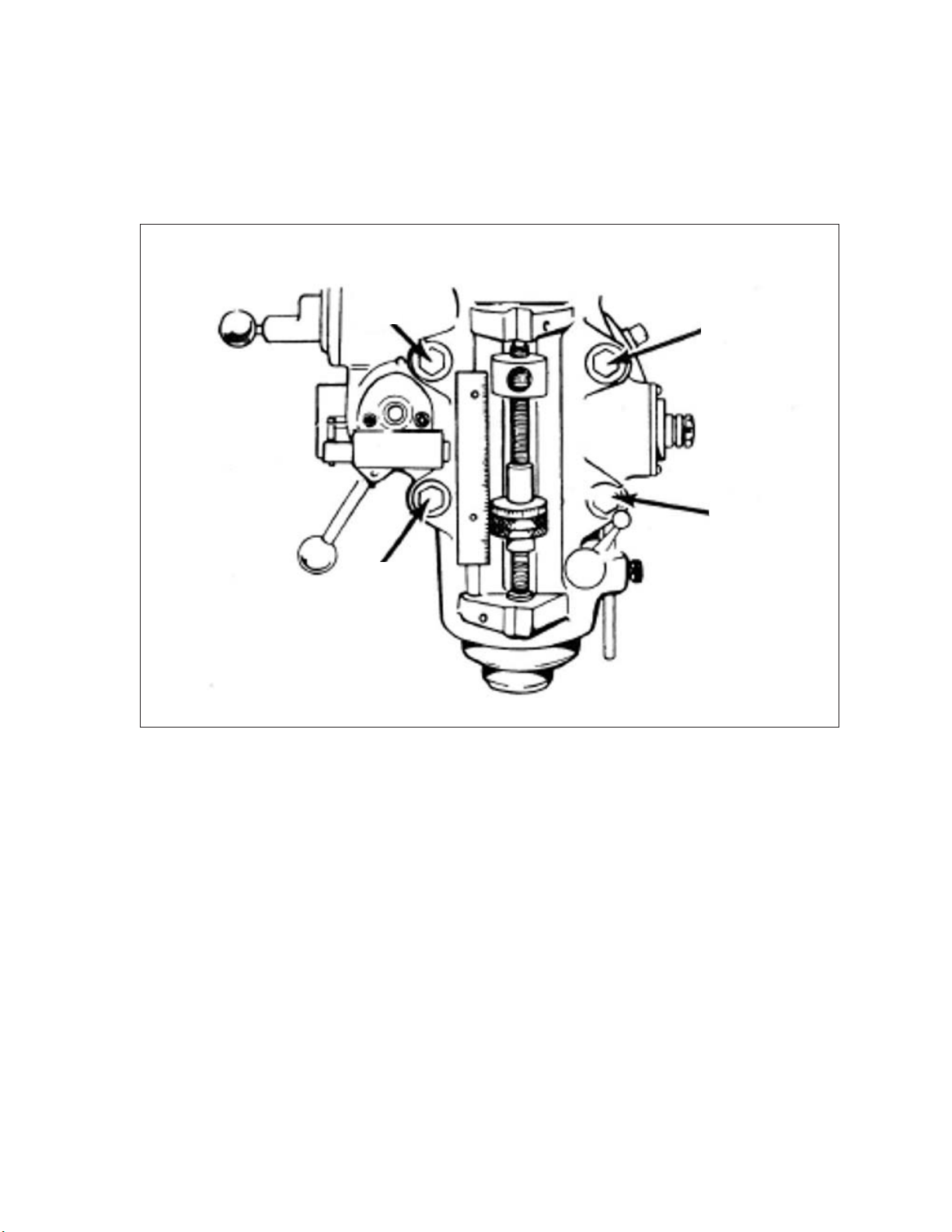

LIFTING THE MACHINE

- WARNING -

BE SURE to use proper sling when lifting. improper lifting could cause seri

ous injury.

Note position of ram and table when lifting with sling. Machine should be lifted by placing a sling

under the ram as illustrated in Figure 1.5.

-

TP5279

Figure 1.5 - Lifting the Machine

1-4 M-508

Page 21

FOUNDATION

PLACING ON A SOLID FOUNDATION

- NOTE -

It is recommended that the machine be secured to the floor to prevent movement

or tipping due to off-center loading. It is the customers responsibility to supply all

necessary hardware if the machine is to be secured to the floor.

When setting machine on a concrete foundation, it is advisable to use grout (thin

mortar) to take care of any unevenness in the concrete as well as to provide a

solid foundation at all points.

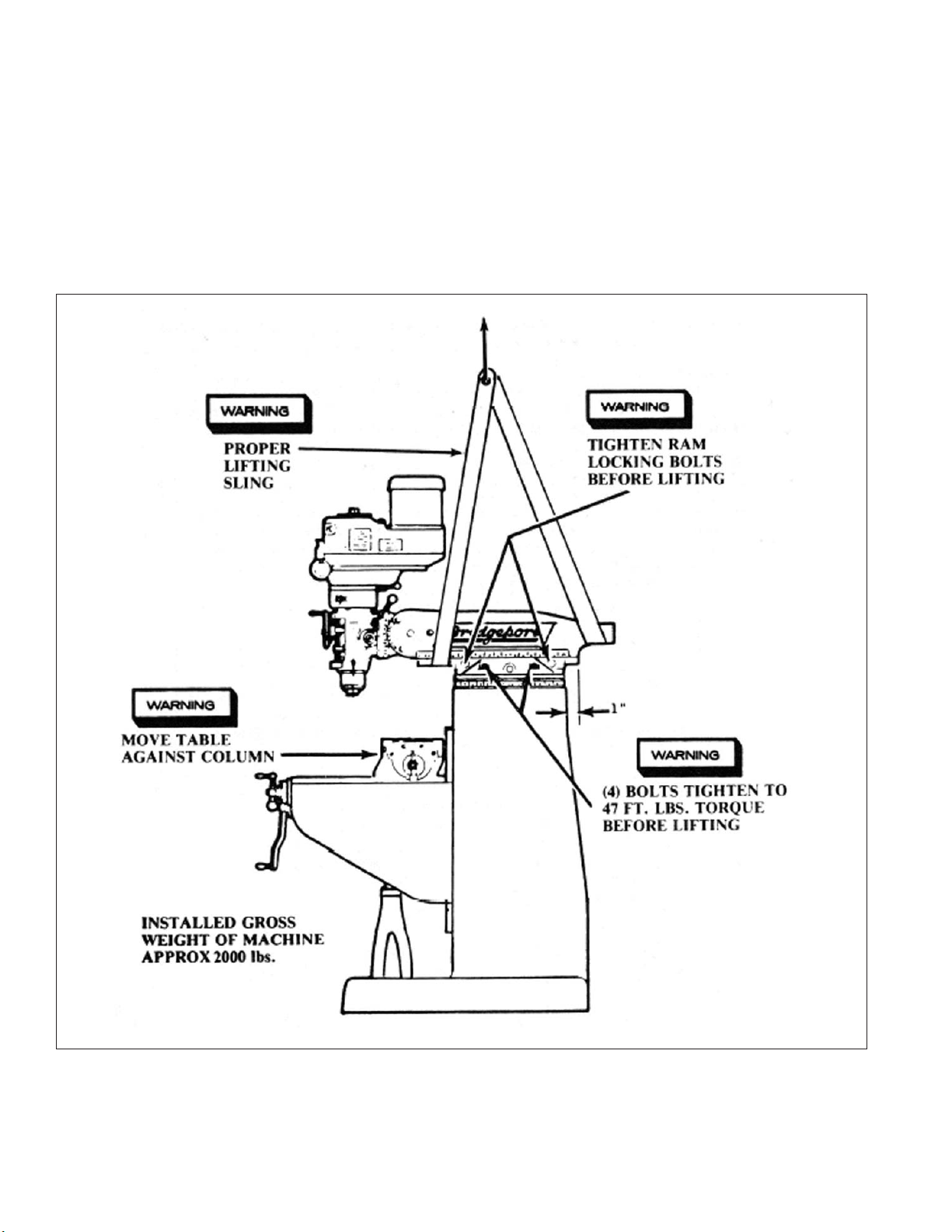

Leveling Bolts and Pads

The machine is supplied with leveling bolts and pads. Thread the bolts through the tapped holes in

the base and position on the machine on the pads. Refer to Figure 1.6. Level the machine as outlined

on the next page.

Machine Hold-Down Bolts

When setting machine on a floor than has any surface irregularities, shims should be used to

correct this condition to the greatest extent possible.

If securing machine to floor with hold-down bolts, make certain that all four corners are making

contact with the floor after machine is leveled. If above condition is not met, it is possible to twist the

column and put a bind into ways.

The machine should be placed on a solid level floor with shims or anti-vibration pads as shown in

Figure 1.7 to insure machine base is positioned evenly.

Leveling

Bolt

Hold-Down

Bolt

Leveling

Pad

Figure 1.6 - Leveling Bolts and Pads

M-508 1-5

TP8006

Figure 1.7 - Hold-Down Bolts

Shims

TP5281

Page 22

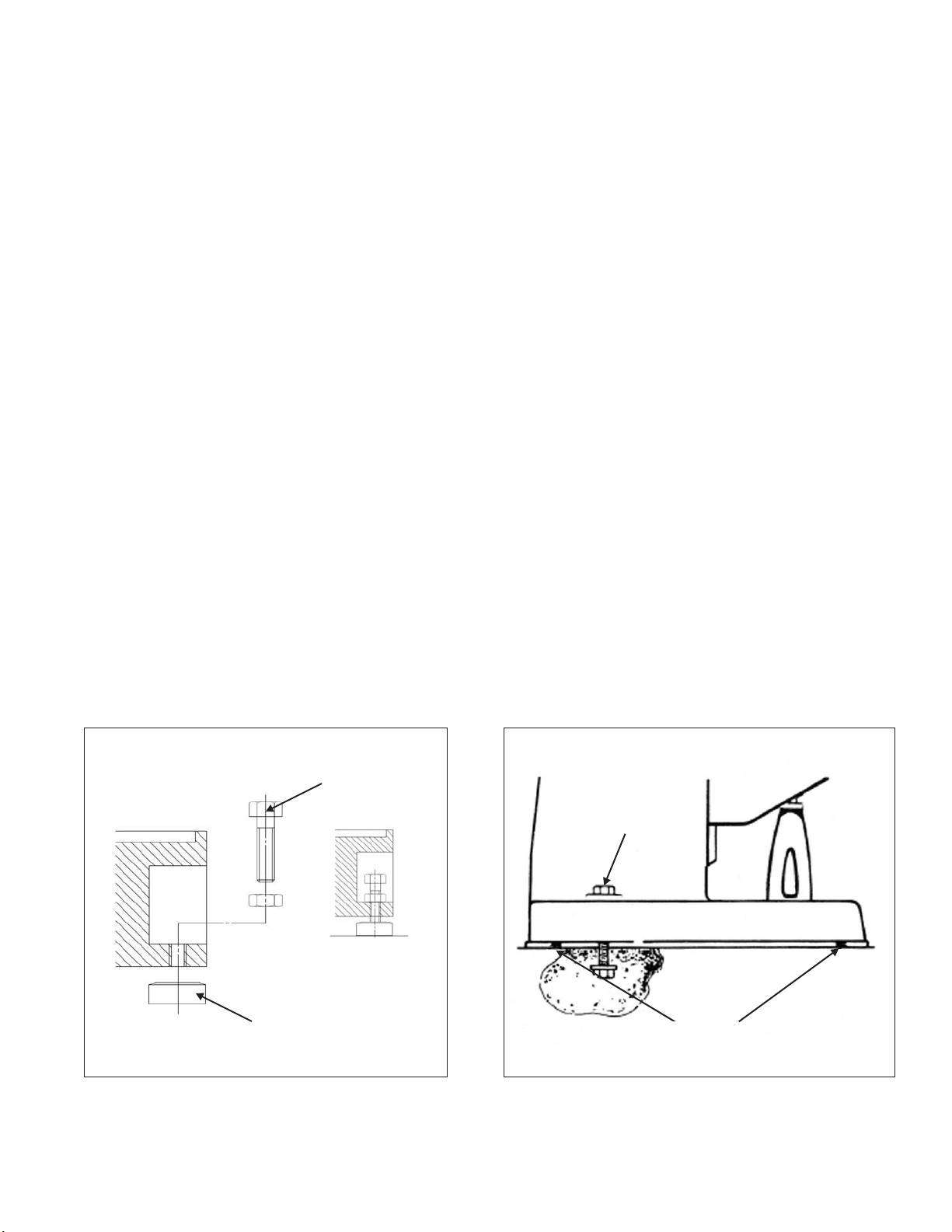

LEVELING THE MACHINE

Set machine by leveling the work table lengthwise and crosswise with a precision instrument as

shown in Figure 1.8.

Level

Level

Figure 1.8 - Leveling the Machine

TP5282

1-6 M-508

Page 23

MACHINE POWER SUPPLY

- WARNING -

Machine must be connected by a qualified electrician.

CONNECTING THE POWER SUPPLY

To connect the machine to the plant supply, have a qualified electrician proceed as follows:

1. Check required voltage against power supply to ensure that they are compatible.

2. Connect machine wiring to power supply making sure connection is in compliance with safety

regulations.

3. Check for correct spindle rotation. In the HIGH SPEED range, the spindle should rotate

clockwise when viewed from the top of the machine.

- NOTE -

Drum switch and Hi-Neutral-Lo lever must be in Hi range when checking spindle

rotation.

M-508 1-7

Page 24

LUBRICATION

1

3

4

Lubrication

Instruction Plate

2

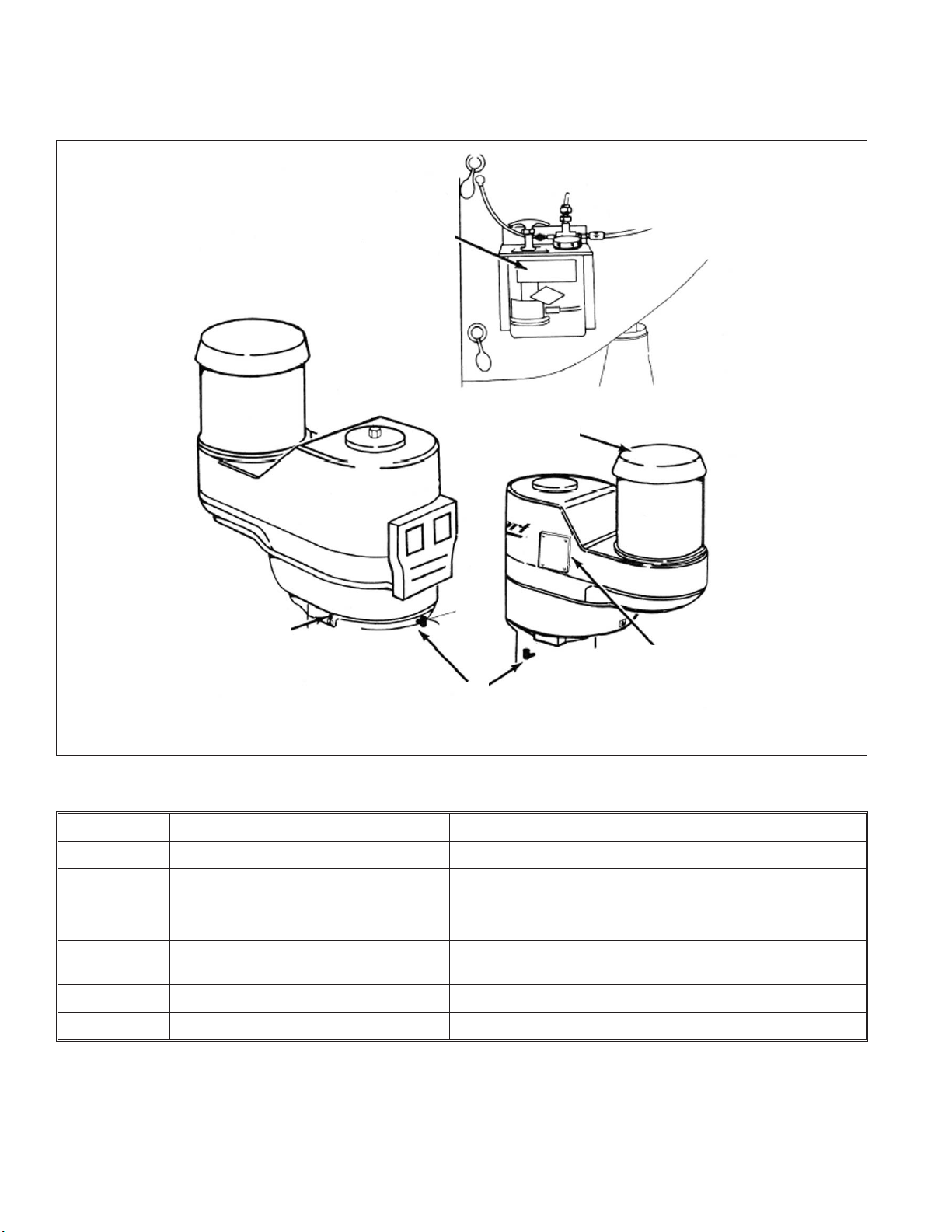

Recommended Lubrication

Few Drops Twice Daily

Figure 1.9 - Lubrication Requirements

Indicator Lubrication Area Type of Lubrication

1 Way Surfaces and Lead Screws Sunoco Waylube #1180 or equivalent

2 Milling Heads (Spindle Bearings)

3 Motor None required. Motor greased for life of bearings

4

Not Shown Power Feed Oil to sight level with Mobilube No. 46 S.A.E. 140

Not Shown Shaping Attachment Mobil 600W Oil or equivalent

S.A.E. 10 or 10W Light Oil

(None on grease-packed heads)

Lubricate with grease every six months as described on

lubrication plate

TP5283

1-8 M-508

Page 25

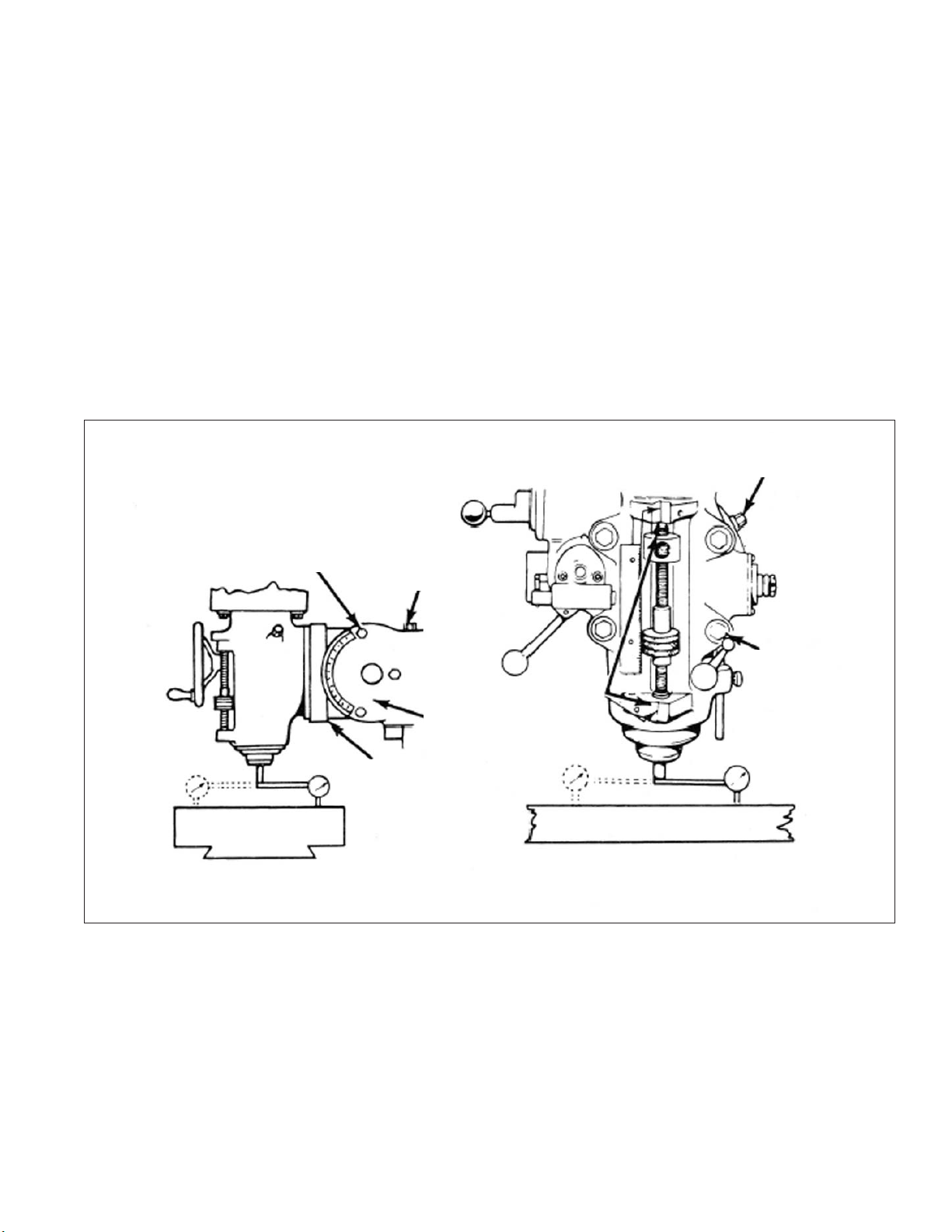

ALIGNMENT OF THE HEAD FOR FINE WORK

For precision boring or work of that nature, where it is necessary to have the head perfectly square

with the table, use method described below. To set head perfectly square with table, adjust ram

adapter through vertical adjusting worm shaft with ram adapter on ram. Loosen four locknuts but

leave drag on same for fine adjustment. To square head to table in the longitudinal axis, mount

indicator as shown in Figure 1.10. For general milling use, graduations provided on the head are

close enough.

Tighten the four head locknuts in a diagonal order as previously described on page 1-2. Tighten

the three ram locking bolts to 50 lb-ft.

- CAUTION -

Do not operate the machine until properly lubricated.

Adjustable

Worm Shaft

3 Ram

Locking Bolts

Zero

Head Alignment Y-Axis

Zero

Figure 1.10 - Head Alignment for Y and X Axis

Vertical Adjustable

Worm Shaft

Ram

Ram Adapter

Aligning

Faces

Zero

Head Alignment X-Axis

Locknuts

Zero

TP5284

M-508 1-9

Page 26

- NOTES -

1-10 M-508

Page 27

CHAPTER 2 - OPERATION

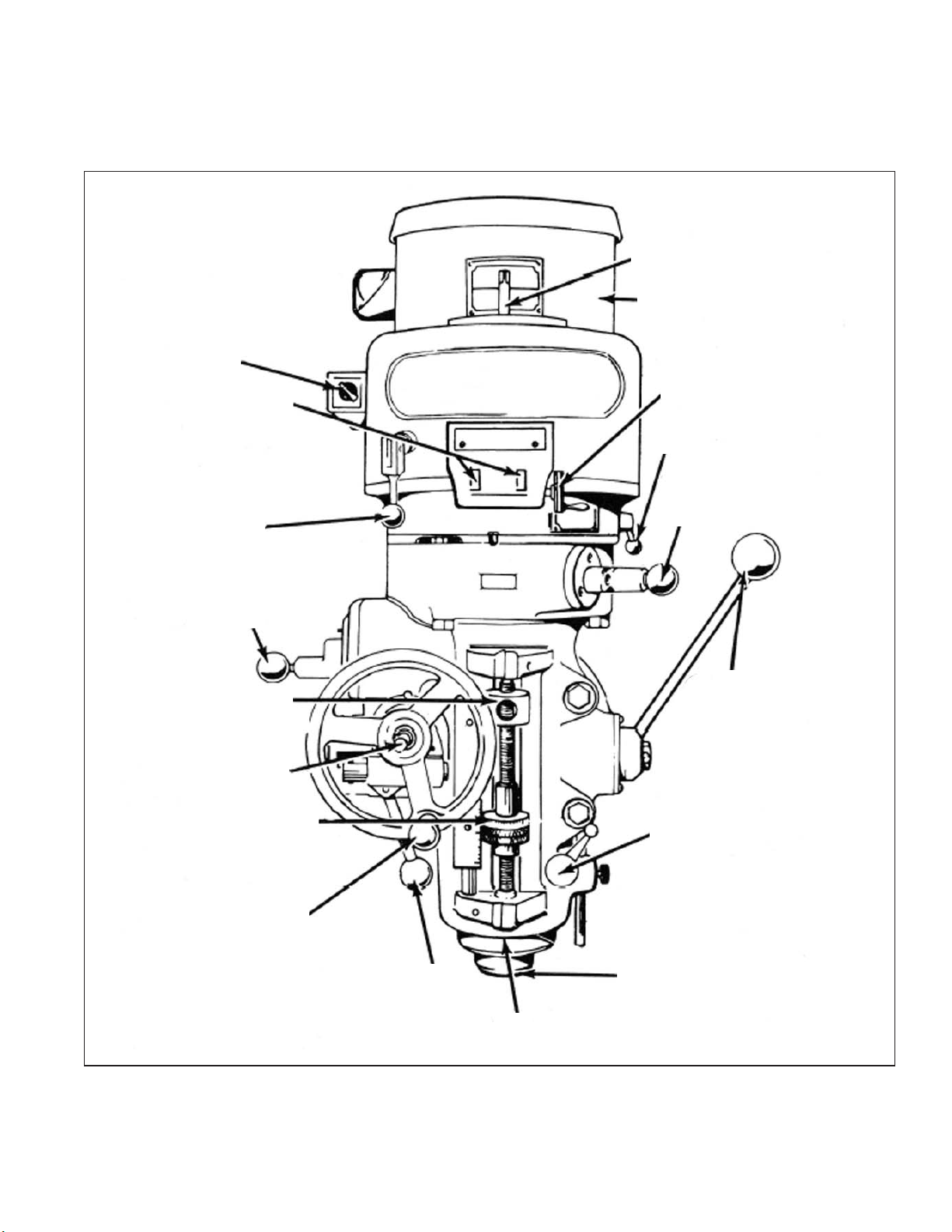

HEAD CONTROLS

R

Q

A

B

C

D

E

G

F

P

O

N

M

L

H

I

J

K

TP5285

Figure 2.1 - Head Controls Parts Assembly

M-508 2-1

Page 28

HIGH-LOW RANGE SWITCH

High-Low Range Switch “A”, Figure 2.2, is a

motor reversing switch. When the attachment is in

direct drive (HIGH SPEED), the motor and spindle

A

are turning in a clockwise direction as viewed from

the top of machine. When the attachment is in “Back

Gear” (LOW SPEED), the spindle will run backwards

(counter-clockwise) unless the motor direction is

reversed by moving switch to “Low”.

The back gear lever is marked Hi-Lo. This will

indicate the proper switch position. They should be

positioned alike or the spindle will run backwards.

- NOTE -

Spindle should run in clockwise position.

Figure 2.2 - High-Low Range Switch

VARIABLE SPEED DIAL

Variable Speed Dial “B”, Figure 2.3, visibly indicates, in windows, the speed range that the

machine is operating in, 60 to 500 low range, 500 to 4200 high range.

TP5286

B

TP5287

Figure 2.3 - Variable Speed Dial

2-2 M-508

Page 29

SPINDLE BRAKE

Spindle Brake “C”, Figure 2.4, can be moved in

either direction to stop spindle; however, when

locking spindle, brake lever should be moved either

by pulling towards the operator or pushing away

from the operator, then raised. When brake is worn

out it has to be replaced. There are no adjustments

to be made.

- CAUTION -

BE certain that spindle brake is re

leased before starting the motor.

This is important as the motor can

be damaged if switch is turned on

with brake in locked position.

C

Lock On

Lock Off

TP5288

Figure 2.4 - Spindle Brake

QUILL FEED SELECTOR

The Quill Feed Selector “D”, Figure 2.5, is used

for selecting the three feeds: .0015”, .003” and .006”

per revolution. It is shifted by pulling knob out and

turning from one position to the other. Feeds are

stamped on cover below indentation hole. Feed is

more readily engaged when spindle is running.

D

TP5289

Figure 2.5 - Quill Feed Selector

M-508 2-3

Page 30

QUILL STOP KNOB

Quill Stop Knob “E”, Figure 2.6, is used to

disengage automatic feed in either direction as well

as the stop point setting working depths.

MICROMETER NUT

Micrometer Nut “F”, Figure 2.6, is used for setting

depths. Each graduation on nut indicates .001” of

depth, it reads directly to scale mounted along the

side of it. Depths may be obtained by setting

micrometer nut in conjunction with quill stop.

E

F

TP5290

FEED REVERSE KNOB

The position of the Feed Reverse Knob “G”,

Figure 2.7, depends upon direction of spindle

rotation. If boring with right hand cutting tools, pull

feed handle towards operator until clutch becomes

engaged.

Neutral position is between forward and reverse

position. It is recommended that the handle be left in

neutral position when not in use.

MANUAL FEED HANDWHEEL

Feed Reverse Knob “G” should be in neutral

position and Feed Control Lever “I”, Figure 2.8

engaged. Clockwise rotation of Manual Feed

Handwheel “H”, Figure 2.7, moves quill down. The

manual feed handwheel and the quill feed handle

may be disengaged by moving them outward about

.125”.

Figure 2.6 - Quill Stop Knob and

Micrometer Nut

Neutral

Up

G

H

Down

TP5291

Figure 2.7 - Feed Reverse Knob and

Manual Feed Handwheel

2-4 M-508

Page 31

FEED CONTROL LEVER

Feed Control Lever “I”, Figure 2.8, engages

overload clutch on pinion shaft when positioned left

and will stay engaged until either quill stop comes in

contact with micrometer adjusting nut, forcing feed

control lever to drop out automatically, or release

manually by engaging lever to right.

FEED CONTROL OVERLOAD CLUTCH

The Feed Control Overload Clutch is set at the

factory to hold up to 200 lbs of down pressure on

quill, which will accommodate drills up to .375”

diameter in mild tool steel.

- CAUTION -

This clutch should not be tampered

with in the field.

Engage

I

Disengage

- NOTE -

The feed control lever must be en

gaged in order to use manual feed

controls. the quill feed handle and

manual feed handwheel may be

removed when not in use.

QUILL

Quill “J”, Figure 2.9, contains the spindle

assembly and can be raised or lowered by using the

quill feed handle “M”, Figure 2.10.

SPINDLE

Spindle “K”, Figure 2.9, performs the actual

rotation and also retains the machine tooling.

QUILL LOCK

Quill Lock “L”, Figure 2.9, is a friction lock for use

when quill is in a stationary position such as a milling

operation. It is recommended that this lock be used

whenever quill movement is not desired.

TP5292

Figure 2.8 - Feed Control Lever and

Feed Control Overload Clutch

J

K

TP5293

L

Figure 2.9 - Quill, Spindle and

Quill Lock

M-508 2-5

Page 32

QUILL FEED HANDLE

Quill Feed Handle “M”, Figure 2.10, is used to

raise and lower the quill manually. It is generally

recommended that handle be dis-engaged when

using the power feed. It may be removed by simply

pulling handle off.

POWER FEED TRANSMISSION ENGAGEMENT CRANK

M

TP5294

Figure 2.10 - Quill Feed Handle

Power Feed Transmission Engagement Crank

“N”, Figure 2.11, engages power feed worm gear.

When lever is in right hand hole, the power feed

worm gear is engaged.

To engage worm gear, pull knob out and crank

handle in clockwise or down direction and move to

opposite position (see Figure 2.12).

- NOTE -

Crank should be rotated counter-clockwise to engage power quill feed. Crank

should be rotated clockwise to disen

-

gage.

- CAUTION -

Power feed worm gear may be en

gaged when spindle is rotating,

however, it should be engaged

gently to avoid damage to worm

gear. The worm gear may be disen

gaged at any time. do not use power

feed at speeds above 3000 RPM.

N

TP5295

Figure 2.11 - Power Feed Transmission

Engagement Crank

Disengaged Engaged

Clockwise

CounterClockwise

TP5296

Figure 2.12 - Worm Gear Disengagement

2-6 M-508

Page 33

HI-NEUTRAL-LO LEVER

The Hi-Neutral-Lo Lever “O”, Figure 2.13, is used to put the attachment into either back gear or

direct drive. Rotate the spindle by hand to facilitate meshing of clutch or gears.

Neutral is provided to permit free spindle rotation for indicating and setup work.

In the high speed position (direct drive) the spindle is driven by tapered clutch teeth. If the clutch is

not meshed tightly, clutch rattle will be heard. This can be corrected by loosening the two securing

screws in lever while in high speed position. The clutch spring will automatically adjust the clutch.

Tighten the two securing crews in lever.

Securing Screws

High

O

Neutral

Low

Figure 2.13 - Hi-Neutral-Lo Lever

- CAUTION -

Do not shift hi-lo lever while motor is running.

TP5297

M-508 2-7

Page 34

SPEED CHANGE HANDWHEEL

- CAUTION -

DO NOT attempt to change spindle RPM unless the motor is running. Dial

speeds will only be approximate. Belt wear will cause a slight variation in

speeds from what is indicated on the dial.

Spindle speeds are adjusted by turning Speed Change Handwheel “P”, Figure 2.14, on the front of

the belt housing. There are two ranges: 60 to 500 and 500 to 4200.

To obtain 60 to 500 (low range):

1. Hold the Hi-Neutral-Lo lever (right rear side

of the attachment) so the gears are clear of

P

one another.

2. Rotate the spindle nose by hand until the

gears line up, then move the Hi-Neutral-Lo

lever to the “Lo” position (back gear).

3. Use the low range on the drum switch to

engage the back gears.

- CAUTION -

- CAUTION -

If the back gears do not mesh, do

Do Not Move

Unless Motor is

Running

not force the lever.

To obtain 500 to 4200 (high range):

1. Hold the Hi-Neutral-Lo lever (right rear side

of the attachment) so the gears are clear of

one another.

2. Rotate the spindle nose by hand until the

gears line up, then move the Hi-Neutral-Lo

lever to the “Hi” position.

3. Set the drum switch to high range.

- CAUTION -

Try to avoid shifting the hi-lo lever when the feed worm is engaged.

Increase

Speed

Decrease

Speed

TP5298

Figure 2.14 - Speed Change Handwheel

2-8 M-508

Page 35

DRAWBAR

When tightening or loosening the Drawbar “R”, Figure 2.15, it is necessary to lock the spindle. To

accomplish this, use the spindle brake which is located on the left side of the belt housing, pulling

towards the operator or pushing away from the operator until it binds, then raise the quill feed handle.

Drawbar has 7/16”-20 right hand thread and should be tightened by hand with normal amount of

pressure using wrench furnished with machine. To loosen collet, back off drawbar and if collet does

not open immediately, give knob on top of drawbar a slight tap. Spindle has non-sticking taper and

collet should release readily.

Q

R

TP5299

Figure 2.15 - Motor and Drawbar

M-508 2-9

Page 36

OPERATIONAL PROCEDURES

Spindle Speed

- CAUTION -

DO NOT change speed when spin

dle is stationary. Change speed only

when spindle is running.

To change speed within range:

1. Start spindle.

2. Turn handwheel “A”, Figure 2.16, to select

required speed.

-

A

TP5300

Figure 2.16 - Spindle Speed Change

Back Gear (Low Speed)

- CAUTION -

DO NOT change range while spindle

is running. Change range only when

spindle is stationary.

To change range from direct to back gear drive:

1. Switch “B”, Figure 2.17, to OFF (Stop spindle

rotation).

2. Move lever “C” through neutral to LOW (This

reverses the spindle rotation).

3. Switch “B” to LOW.

B

C

TP5301

Figure 2.17 - Back Gear Range Change

2-10 M-508

Page 37

Direct Drive (High Speed)

To change range from back gear to direct drive:

1. Switch “B” to OFF (Stop spindle rotation).

2. Move lever “C”, Figure 2.18, through neutral to

HIGH.

3. Rotate spindle by hand until the clutches are

felt to engage.

4. Switch “B” to HIGH.

Quill Feed

FINE HAND FEED

1. Disengage Auto Quill Feed “D”, Figure 2.19.

2. Locate “F” in mid (neutral) position.

3. The quill is now under handwheel control

C

High

Neutral

Figure 2.18 - Direct Drive Lever

Low

TP5302

D

I

H

F

G

Off

E

Engage

On

TP5303

Figure 2.19 - Quill Feed

Fine Hand Feed Control

M-508 2-11

Page 38

AUTOMATIC FEED

- NOTE -

Maximum loading .375” (9.5mm) diameter drill steel.

1. Ensure quill lock “G”, is off.

2. Set micrometer dial “H” to required depth.

3. Engage auto quill feed “D” when motor has stopped

4. Select feed rate “I”.

5. Select feed direction “F”, Figure 2.22.

6. Engage feed trip lever “E”. The feed will automatically trip out at a depth within .010” (.25mm)

7. Hand feed to dead stop for repeating accuracy .001” (.025mm)

- CAUTION -

Do not engage quill feed “D” over 3000 RPM.

Neutral

Up

F

Fine Feed

Handwheel Engage

Figure 2.20 - Quill Feed

Automatic Feed Control

Down

TP5304

2-12 M-508

Page 39

Spindle Brake

Brake lever has capability to rotate in either

direction to brake and lock.

Brake

CAM upwards to lock and prevent movement of

spindle (see Figure 2.21).

Quill Sensitive Hand Feed

Off

Brake

Turn and

Lift to

Lock

TP5306

Figure 2.21 - Spindle Brake

1. Place the handle on the quill feed shaft.

2. Select the most suitable position.

3. Push home until the locating pin engages.

TP5307

Figure 2.22 - Quill Sensitive Hand Feed

M-508 2-13

Page 40

SWIVEL THE BELT HOUSING

- CAUTION -

Incorrect spline alignment can be

caused by unequal tightening of the

locknuts ’J’ causing fluctuation of

the quill feed which can be felt

through the sensitive feed handle. It

is advised to call Hardinge service

department before attempting this

procedure.

1. Loosen three locknuts “J”, Figure 2.23.

MACHINE

- WARNING -

DO NOT remove these locking nuts.

2. Swivel to required angular setting.

3. Tighten three locknuts “J” snugly before final

tightening of locknuts. Run spindle to give

correct spline alignment, then tighten locknuts

securely.

SWIVEL THE TURRET

1. Use wrench supplied with machine to loosen

the four bolts “K”, Figure 2.24.

- WARNING -

DO NOT remove these four bolts.

2. Index to the required setting.

3. Lock the four bolts “K” to 47 lb-ft.

J

Figure 2.23 - Swivel Belt Housing

360°

K

K

K

K

TP5305

TP5308

Figure 2.24 - Swivel Turret

2-14 M-508

Page 41

MOVE THE RAM SLIDE

1. Use wrench provided with machine to loosen

bolts “L” and “M”, Figure 2.25.

2. Use wrench to move the slide to the desired

position using bolt “N”.

3. Tighten bolts “L” and “M”, starting with the rear

bolt.

- NOTE -

It is recommended that on heavy mill

ing work, head should be kept as close

to column as possible, where maxi

mum rigidity is obtained.

SADDLE CLAMPING

When milling with longitudinal table feed only, it is

advisable to clamp the knee to the column (see

Figure 2.28) and the saddle to the knee to add

rigidity to these members and provide for heavier

cuts with a minimum of vibration. The saddle locking

lever is located on the left hand side of the saddle.

L

Figure 2.25 - Ram Slide

Unlock

Rear

M

N

TP5309

Excessive moisture can cause slight table bind.

Use moderate clamping pressure, as this will hold

saddle sufficiently.

Lock

Saddle

Locking Lever

TP5310

Figure 2.26 - Saddle Clamping

M-508 2-15

Page 42

TABLE CLAMPING

The table clamp levers are located on front of

saddle and should always be clamped when

longitudinal movement is not required (see Figure

2.27).

Lock

Table Clamp

Levers

Unlock

Figure 2.27 - Table Clamping

KNEE CLAMPING

The knee clamping levers are at the left side of the knee. Leave clamped at all times unless using

knee in operation (see Figure 2.28).

TP5311

Knee

Clamp

On

Off

TP8033

Figure 2.28 - Knee Clamping

2-16 M-508

Page 43

- NOTES -

M-508 2-17

Page 44

- NOTES -

2-18 M-508

Page 45

CHAPTER 3 - MAINTENANCE

2J-HEAD

MOTOR REMOVAL

1. Run head to adjust to lowest speed.

2. Disconnect power.

3. Remove three screws “A” and cover “B”, Figure

3.1.

4. Using the two screws “A”, compress spring “C”.

5. Rotate the speed changer to the highest

speed.

6. Remove the reversing switch from the belt

housing.

7. Remove the two securing screws “D”.

D

8. Lift the motor and rest the case on stud “E”,

Figure 3.2.

9. Ease the belt over the lower drive disc and

remove the motor.

C

B

A

TP5320

Figure 3.1 - Motor Removal

Front View

E

TP5321

Figure 3.2 - Motor Removal

Side View

M-508 3-1

Page 46

DRIVE BELT REPLACEMENT

1. Remove the motor as described on page

3-1.

2. Remove the three screws “F”, Figure 3.3,

insert into the adjacent tapped holes and

withdraw bearing housing “G”.

3. Remove the two screws and the bushings

“H”.

4. Remove four screws “I” and one screw “J”.

5. Remove four screws securing speed

changer “K”.

6. Remove top housing “L”. Tap to clear the

dowels.

7. Replace the belt.

F

G

I

H

K

L

J

TP5322

TIMING BELT REPLACEMENT

1. Remove the motor.

2. Lower the quill to full extent.

3. Remove the two lower cap screws “M”,

Figure 3.4, from the speed changer

housing.

4. Remove the four cap screws “N”.

5. Remove the top assembly “O”, and tap to

clear dowels

6. Replace the belt.

Figure 3.3 - Drive Belt Replacement

M

O

N

TP5323

Figure 3.4 - Timing Belt Replacement

3-2 M-508

Page 47

BRAKE SHOE REPLACEMENT

1. Remove the top section.

2. Remove the two screws “P”, Figure 3.5.

3. Remove the clutch hub assembly “Q”.

4. Replace the brake shoes “R”.

5. Remove the bearing, drive discs and circlips from the hub assembly “Q”.

6. Replace the bearing and housing “S”.

7. Thread hub “B” through the bearing and reassemble the discs, etc.

S

Q

R

P

Figure 3.5 - Brake Shoe Replacement

TP5324

M-508 3-3

Page 48

HEAD

MICRO FEED TRIP ASSEMBLY AND QUILL REMOVAL

1. Remove screw “A” and ball reverse lever “B”,

Figure 3.6.

2. Remove retaining ring “C”, screw “D” and arm

“E”.

3. Thread shaft “F” through micro nuts and

remove.

4. Remove screw “G” and stop “H”.

B

H

5. Remove quill.

6. Clean all areas, oil liberally and reassemble.

7. Check correct operation of micro feed trip

assembly together with feed trip linkage as

per feed tripping adjustment (see Figure 3.8).

G

A

F

C

E

D

TP5325

Figure 3.6 - Micro Feed Trip Assembly and

Quill Removal

3-4 M-508

Page 49

BALANCE SPRING REPLACEMENT

1. With quill in maximum up position apply quill

lock.

2. Remove screw “I”, hub “J”, and key “K”, Figure

3.7.

3. Remove screws “L”, allowing housing to rotate

slowly releasing spring tension.

4. Lift end of spring from pin on the pinion shaft.

5. Rotate housing “M” counter-clockwise from

head casting.

6. Remove spring from housing and replace.

7. Refit spring to main housing casting. Turn

housing clockwise until spring locates on pin in

pinion shaft.

J

I

1-1/2

Turns

TP5326

M

K

L

Figure 3.7 - Balance Spring Replacement

FEED TRIP ADJUSTMENT

1. Release locknut “N”, Figure 3.8.

2. Engage trip handle lever “P”.

3. Adjust micro nuts against quill stop “O”.

4. Slowly turn adjusting screw “Q” until lever “P”

trips. If set to light will not be able to drill.

5. At this point secure locknut “N”.

6. Check for quick action response.

P

Engage

Q

N

Figure 3.8 - Feed Trip Adjustment

O

TP5327

M-508 3-5

Page 50

COLLET ALIGNING SCREW REPLACEMENT

1. Use felt pen, mark reference line on quill

and nose cap “S”, Figure 3.9.

2. Remove set screw “R”.

3. Unscrew nose cap “S”.

4. Remove lock screw “T” and collet aligning

screw “U”.

5. Replace “U”; insert collet and check that the

dog on the end of the screw does not

interfere with the bottom of the guide slot.

6. Replace lock screw “T”.

7. Replace nose cap “S”; check felt pen

markings for correct alignment.

8. Replace set screw “R”. CAUTION - DO NO

OVERTIGHTEN as this will cause

distortion.

9. Check gap “V” (.003”, .08mm)

R

T

U

S

- CAUTION -

Do not attempt to remove nose

cap before removing set screw

“R”. Doing so will cause serious

damage.

V

T

U

TP5328

Figure 3.9 - Collet Aligning Screw

Replacement

3-6 M-508

Page 51

GIB ADJUSTMENT

ADJUSTMENT OF THE TABLE GIB

The table is equipped with a tapered gib and adjusting screws at the left and right sides of the

table.

To Adjust the Gib:

1. Loosen table clamps "B", Figure 3.10.

2. Clean the slides and apply lubricant.

3. To tighten the gib:

A) Loosen right gib screw "C", Figure 3.11.

B) Tighten left gib screw "A", Figure 3.10, slightly and test the table movement.

C) Repeat step B until a slight drag is felt when moving the table by hand.

D) Tighten the right gib screw.

To loosen the gib:

A) Loosen left gib screw "A", Figure 3.10.

B) Tighten right gib screw "C", Figure 3.11, slightly and test the table movement.

C) Repeat step B until a slight drag is felt when moving the table by hand.

D) Tighten the left gib screw.

A

B

TP8016

Figure 3.10 - Left Table

Gib Adjustment Screw

Figure 3.11 - Right Table

Gib Adjustment Screw

C

TP8017

M-508 3-7

Page 52

ADJUSTMENT OF THE SADDLE GIB

The saddle is equipped with a tapered gib and adjusting screws at the front and rear of the saddle.

To Adjust the Gib:

1. Loosen saddle clamp "D", Figure 3.12.

2. Clean the slides and apply lubricant.

3. Remove wiper retainer "E" and wiper "F", Figure 3.12, to gain access to front gib screw "G",

Figure 3.13.

4. Remove wiper retainer "H" and wiper "I", Figure 3.14, to gain access to rear gib screw "J",

Figure 3.15.

E

D

F

Figure 3.12 - Front Saddle Wiper

and Retainer

H

I

Figure 3.14 - Rear Saddle Wiper

and Retainer

TP8018

TP8021

G

TP8020

Figure 3.13 - Front Saddle

Gib Adjustment Screw

J

TP8023

Figure 3.15 - Rear Saddle

Gib Adjustment Screw

3-8 M-508

Page 53

5. To tighten the gib:

A) Loosen the rear gib screw.

B) Tighten the front gib screw slightly and test the saddle movement.

C) Repeat step B until a slight drag is felt when moving the saddle by hand.

D) Tighten the rear gib screw.

- NOTE -

Press the wipers downward and inward while tightening the mounting screws.

E) Install the wipers and wiper retainers.

To loosen the gib:

A) Loosen the front gib screw.

B) Tighten the rear gib screw slightly and test the saddle movement.

C) Repeat step B until a slight drag is felt when moving the saddle by hand.

D) Tighten the front gib screw.

- NOTE -

Press the wipers downward and inward while tightening the mounting screws.

E) Install the wipers and wiper retainers.

M-508 3-9

Page 54

ADJUSTMENT OF THE KNEE GIB

The knee is equipped with a tapered gib and adjusting screws at the top and bottom of the knee.

To Adjust the Gib:

1. Loosen the two knee clamps located on the left side of the knee.

2. Clean the slides and apply lubricant.

3. Remove wiper "K", Figure 3.16, to gain access to upper gib adjustment screw "L", Figure 3.17.

K

Figure 3.16 - Left Knee Wiper

TP8024

L

TP8025

Figure 3.17 - Upper Knee

Gib Adjustment Screw

3-10 M-508

Page 55

4. To tighten the gib:

A) Loosen lower gib screw "M", Figure 3.18.

B) Tighten the upper gib screw slightly and test the knee movement.

C) Repeat step B until a slight drag is felt when moving the knee by hand.

D) Tighten the lower gib screw.

- NOTE -

Press the wiper downward and inward while tightening the mounting screw.

E) Install the wiper.

To loosen the gib:

A) Loosen the upper gib screw.

B) Tighten lower gib screw "M" Figure 3.18, slightly and test the knee movement.

C) Repeat step B until a slight drag is felt when moving the knee by hand.

D) Tighten the upper gib screw.

- NOTE -

Press the wiper downward and inward while tightening the mounting screw.

E) Install the wiper.

M

TP8026

Figure 3.18 - Lower Knee

Gib Adjustment Screw

M-508 3-11

Page 56

TABLE FEED SCREW BACKLASH ADJUSTMENT

1. Move the table to the center of travel.

2. Insert the larger end of the two-piece backlash adjustment tool, shown in Figure 3.19, into the

left side of the saddle.

3. Loosen lock nut “P”, Figure 3.20, one full turn.

4. Use the smaller end of the backlash adjustment tool to engage lead screw adjusting nut "O".

5. Tighten the lead screw adjusting nut while slowly turning handle “N” until the backlash is .003 to

.005 inches [.08 to .13 millimeters].

6. Use the larger end of the backlash adjustment tool to secure the lock nut.

TP8012

Figure 3.19 - Two-Piece Backlash Adjustment Tool

N

O

P

TP8013

Figure 3.20 - Table Backlash Adjustment

3-12 M-508

Page 57

SADDLE FEED SCREW BACKLASH ADJUSTMENT

1. Move the saddle back (toward the column) 3/4 of the way through the range of travel.

2. Remove four socket head cap screws securing bracket “Q”, Figure 3.21, to knee.

3. Pull the saddle forward to expose lock nut “R” and adjusting nut “S”, Figure 3.22, through the

hole in the front of the knee.

4. Use the larger end of the two-piece backlash

adjustment tool, shown in Figure 3.19, to

loosen lock nut “R”, Figure 3.22.

5. Use the smaller end of the backlash

adjustment tool to engage lead screw adjusting

nut "S".

6. While slowly turning handle “T”, tighten the

adjusting nut until backlash is .003 to .005

inches [.08 to .13 millimeters].

7. Tighten the lock nut.

8. Move the saddle back and replace the four

screws securing bracket “Q”, Figure 3.21, to

the knee.

Q

TP8027

Figure 3.21 Saddle Feed Handle

and Mounting Bracket

R

T

S

TP8011

Figure 3.22 - Saddle Backlash Adjustment

M-508 3-13

Page 58

- NOTES -

3-14 M-508

Page 59

CHAPTER 4 - PARTS LISTINGS

2J-HEAD TOP HOUSING

TP5340

Figure 4.1 - 2J-Head Assembly

M-508 4-1

Page 60

2J-HEAD TOP HOUSING

Item Part Number Description Qty

1 BP 11011033 Screw, Socket Hd Cap, .250”-20 x .750” Lg 3

2 BP 12180094 Cap, Top Bearing 1

3 BP 11181977 Washer, Wave Spring 1

4 BP 11180252 Bearing, Ball, Fafnir #9107 NNP 1

5 BP 11180848 Ring, Snap, #5100-137 1

6 BP 11011069 Screw, Socket Hd Cap, .312”-18 x 6.00” 2

7 BP 11011745 Nut, UNC Hex Jam, .375”-16 1

8 BP 11550001 Motor, 2 HP, Multi Volt, 50/60 1

9 BP 11011148 Screw, Hex Hd Cap, .375”-16 x 1.00” 2

10** BP 12180051 Housing, Upper Belt (see BP 12183923) 1

11 BP 12180066 Stud, Speed Change Chain 1

12 BP 11010535 Pin, Roll, .156”Æ x 1.00” Lg 2

13 BP 11180058 Plate, Speed Change 1

14 BP 12183920 Assembly, Drawbar 1

15 BP 11010606 Pin, Cotter, .093”Æ x .750” 1

16 BP 12180074 Stud, Speed Change Plate Pivot 1

17 BP 11011020 Screw, Socket Hd Cap, #10-32 x .750” 2

18 BP 11180095 Washer 1

19 BP 12180089 Sleeve, Pivot 2

20 BP 12180093 Washer, Drawbar 1

21 BP 11180915 “O”-Ring, Parker # 2-14 1

22 BP 12180056 Housing, Spindle Pulley Bearing Sliding 1

23 BP 11170262 Bearing, #RM9110NPP 1

24 BP 11182124 Insert, Plastic 2

25 BP 12183934 Varidisc, Adjustable Drive A 1

26 BP 11180855 Ring, Retaining, #5102-156 1

27 BP 11182120 Belt, Varispeed 1

28 BP 12180082 Varidisc, Stationary Drive 1

29 BP 12180043 Cap, Brake and Bearing 1

30 BP 11170262 Bearing, #RM9110NPP 1

31 BP 11182081 Spring, Brake 2

32 BP 12180073 Shoes, Brake 2

33 BP 12180078 Spacer, Spindle Pulley 1

34 BP 12180042 Assembly, Spindle Pulley Hub 1

35 BP 11011138 Screw, Hex Hd Cap, .250”-20 x .750” 1

36 BP 12180071 Sleeve, Brake Shoe Pivot Sleeve 1

37 BP 11010513 Pin, Roll, .125” x .437” 1

38 BP 12550007 Key, Drive, Fixed Varidisc 1

39 BP 12550004 Assembly, Key, Drive, Varidisc 1

40 BP 12550006 Varidisc, Stationary Motor 1

41 BP 11011287 Screw, Stainless Steel, .250”-20 x .250” 2

42* BP 11182126 Insert, Plastic Replaceable Type 2

43 BP 12550029 Assembly, Varidisc and Spring 1

44 BP 11182083 Spring, Varidisc Motor Shaft 1

45 BP 11550003 Collar, Adjustable Varidisc Spring 1

46 BP 11011022 Screw, Socket Hd Cap, #10-24 x 1.00” 3

47 BP 11150843 Ring, Snap 1

48 BP 11011052 Screw, Socket Hd Cap, .132”-18 x .750” Lg 1

4-2 M-508

Page 61

Item Part Number Description Qty

49 BP 11182122 Key, Plastic 1

50 BP 11011707 Nut, Hex Jam, .250”-20 1

51 BP 12180084 Key 1

52 BP 12180107 Pin, Taper, #4 x 1.00” 4

53** BP 12180052 Base, Belt Housing (see BP 12183923) 1

54 BP 12180088 Cover, Motor Pulley 1

56 BP 11011552 Screw, Drive, Type U, #0 x .250” 4

58 BP 11182893 Nameplate, Hi-Low Range 1

61 BP 11182894 Nameplate, Quill Feed 1

63 BP 12180053 Housing, Gear 1

64 BP 11011443 Screw, Round Hd Machine, #10-24 x .375” 3

65 BP 11185030 Plate, Gear Housing 1

66 BP 11180818 Ring, Snap, #5100-25 1

67 BP 11182306 Finger, Brake Operating 2

68 BP 12180083 Stud, Brake Finger Pivot 1

69 BP 11192151 Knob, Bakelite, .250”-20 1

70 BP 12190133 Handle, Brake 1

71 BP 12180046 Pin, Brake Lock 1

72 BP 11011260 Screw, Stainless Steel, #10-32 UNF x .250” 1

73 BP 12180104 Sleeve, Brake Lock Shaft 1

74 BP 28025521 Shaft, Brake Lock 1

75 BP 12180069 Cam, Brake Lock 1

78 BP 11011031 Screw, Socket Hd Cap, .250”-20 x .625” 1

80 BP 11011019 Screw, Flat Hd Cap, #10-32 x .500” 1

82 0100204 Screw, Socket Hd Cap, #8-32 x .250” 1

83 BP 12550008 Key 1

* Non-replaceable turcite bushing must be purchased as part of varidisc assembly BP 12550029.

**Items 10 and 53 sold as assembly only.

- NOTE -

IMPORTANT - for 1-1/2 HP, substitute the following parts.

Item Part Number Description Qty

34 BP 12182004 Assembly, Spindle Pulley Hub 1

37 BP 11010513 Pin, Roll, .125” x .437” 1

38 BP 12180102 Key, Pulley 1

39 BP 11182121 Key, Plastic 1

40 BP 12180080 Varidisc, Stationary Motor 1

42* BP 11182123 Insert, Plastic 2

43 BP 12180165 Assembly, Varidisc and Spring 1

45 BP 11182305 Collar, Adjustable Varidisc Spring 1

47 BP 11180860 Ring, Snap 1

* Non-replaceable turcite bushing must be purchased as part of varidisc assembly BP 12180165.

M-508 4-3

Page 62

2J-HEAD BACK GEAR

TP5341

Figure 4.2 - 2J-Head Back Gear Assembly

4-4 M-508

Page 63

2J-HEAD BACK GEAR

Item Part Number Description Qty

1 BP 11011710 Nut, Hex, .312” 1

2 BP 11180133 Dial, Spindle Speed 1

3 BP 11183646 Bushing, Bronze, .502” x .628” x 5.00” 1

4 BP 11011380 Screw, Full Dog Socket Hd Set, .250”-20 x .500” 1

5 BP 12180055 Housing, Speed Changer 1

6 BP 12182003 Block, Plastic Bearing 1

7 BP 11011031 Screw, Socket Hd Cap, .250”-20 x .625” 4

8 BP 11010516 Pin, Roll, .125” x .625” Lg 1

9 BP 11010520 Pin, Roll, .125”Æ x 1.00” Lg 1

10 BP 11183720 Chain, Speed Changer, Morse #35 1

11 BP 12180066 Stud, Speed Change Chain 1

12 BP 12180051 Housing, Belt (see BP 12183923) 1

13 BP 12180094 Cap, Top Bearing 1

14 BP 11011065 Screw, Socket Hd Cap, .312”-18 x 4.00” 1

17 BP 12182001 Hub, Speed Change 1

18 BP 11181233 Screw, Socket Hd Set, .250”-UNC x .375” 2

19 BP 11182178 Handle, Machine, #3302 1

20 BP 11182892 Plate, Caution 1

24 BP 11011287 Screw, Stainless Steel, .250”-20 x .250” 2

25 BP 11011037 Screw, Socket Hd Cap, .250”-20 x 1.250” 4

27 BP 11183645 Bushing, Oilite 1

28 BP 28300619 Pin, Roll, 2.5mm x 12mm Lg 1

29 BP 28025716 Shaft, Speed Changer 1

30 BP 28007307 Gear, Boston Worm 1

31 BP 11180214 Bushing, Oilite Flanged, FB 1

32 BP 11010539 Pin, Roll, .187”Æ x .375” Lg 1

33 BP 12180090 Gear, Speed Changer Spur 1

34 BP 11181923 Washer, Wavy Spring 1

35 BP 12180065 Drum, Speed Change Chain 1

36 BP 11552106 Belt, Timing 1

37* BP 12180042 Hub, Spindle Pulley 1

38* BP 12180064 Sleeve, Timing Pulley Clutch 1

39 BP 12180059 Hub, Splined Gear 1

40** BP 12180062 Gear, Spindle Bull (see BP 12183933) 1

41 BP 11180254 Bearing, Ball, Fafnir #RM9308NPP 2

42 BP 11180803 Ring, Snap, #5000-244 2

43 BP 12180063 Spacer, Bull Gear Bearing 1

44 BP 12180053 Housing, Gear 1

45 BP 11181650 Bolt, Tee 3

46 BP 11181906 Washer, Flat, .469” ID x .938” OD x .063” 3

47 BP 11011750 Nut, HDN Finished Hex Jam, .438”-14 3

48 BP 11181986 Washer, Ball Bearing Gear Sleeve 3

49*** BP 12183924 Bracket, Fixed Clutch 1

50 BP 11011246 Screw, Socket Hd Set, .312”-18 x .312” 2

51 BP 28025615 Guide 2

52 BP 28025671 Screw, Flat Socket Hd Cap, #10-32 x .375” 2

53 BP 11010511 Pin, Roll, .125” x .250” Lg 1

54 BP 11183104 Cup, Oil, Gits #1202 Style L 1

M-508 4-5

Page 64

Item Part Number Description Qty

55 BP 11182071 Spring, Compression, .375” OD x .3.00” Lg 3

56 BP 11181794 Locknut, Bearing, #–08 1

57*** BP 12183924 Sleeve, Bearing 1

58 BP 11181977 Washer, Wave Spring 1

59 BP 12180067 Pinion, Bull Gear Shift 1

60 BP 12180161 Plate, Hi-Low Detent 1

61 BP 11181732 Nut, Hex, .375”-16 3

62 BP 11151913 Lockwasher, .375” 3

63 BP 12180085 Stud 3

66 BP 12180100 Plunger, Hi-Low Detent 1

67 BP 11182072 Spring, .750” x .032 x .563” 1

68 BP 11011017 Screw, Socket Hd Cap, #10-32 x .500” Lg 2

69 BP 11192151 Knob, Bakelite, .250”-20 1

70 BP 12180099 Crank, Hi-Low Shift 1

71 BP 12180096 Block, Hi-Low Pinion 1

72 BP 11010516 Pin, Roll, .125” x .625” Lg 1

73 BP 11011052 Screw, Socket Hd Cap, .132”-18 x .750” Lg 4

74 BP 11181007 Screw, Socket Hd Cap, #8-32 x .625” 2

75 BP 11011022 Screw, Socket Hd Cap, #10-24 x 1.00” 1

76 BP 12180088 Cover, Motor Pulley 1

78 BP 11013079 Key, Woodruff #9 2

79 BP 11180235 Bearing, #203NPP-C8 2

80 BP 12180075 Shaft, Bull Gear Pinion Counter 1

81 BP 12180103 Key, Sq, .312” x .540” 1

82 BP 11181975 Washer, Wave Spring 1

83** BP 28025529 Pinion, Bull Gear (see BP 12183933) 1

84 BP 12180076 Cap, Bull Gear Pinion Bearing 1

85 BP 11011011 Screw, Socket Hd Cap, #10-24 x .625” Lg 2

86 BP 12550016 Pulley, Timing Belt 1

87 BP 11191738 Nut, Hex Jam, .625”-18 1

88 BP 11182912 Nameplate, Speed Change 1

89 BP 11011139 Screw, Flat Hd Machine, #8-32 x .750” 2

90 BP 11182897 Plate, Lubrication 1

93 BP 11598117 Assembly, Reversing Switch 1

*Items 37 and 38 sold as assembly only.

**Items 40 and 83 sold as assembly only.

***Items 49 and 57 sold as assembly only.

- NOTE -

IMPORTANT - For 1-1/2 HP, substitute the following parts.

Item Part Number Description Qty

36 BP 11182106 Belt, Timing 1

37 BP 12182004 Hub, Spindle Pulley 1

86 BP 12180091 Pulley, Timing Belt 1

4-6 M-508

Page 65

2J- AND J-HEAD LOWER HOUSING

TP5343

Figure 4.3 - 2J- and J-Head Lower Housing Assembly

M-508 4-7

Page 66

2J- AND J-HEAD LOWER HOUSING

Item Part Number Description Qty

1 BP 11011445 Screw, Round Hd Machine, #10-24 x .375” Lg 3

2 BP 12190163 Washer, Bevel Pinion 1

3 BP 12190203 Gear, Feed Bevel Pinion 1

4 BP 12190164 Sleeve, Feed Worm Gear Shaft 1

5 BP 11192303 Bushing, Worm Cradle 1

6 BP 11011287 Screw, Stainless Steel, .250”-20 x .250” 2

7 BP 12190165 Spacer, Worm Gear 1

8 BP 12190166 Gear, Feed Drive Worm 1

9 BP 12190167 Shaft, Feed Drive Worm Gear 1

* BP 12193440 Assembly, Gear Drive Shaft 1

10* BP 12190162 Key, Worm Shaft, Sq, .125” x .312” 3

11 BP 11013078 Key, Woodruff #7 3

12 BP 11191796 Locknut, Flexlok, .375”-24 1

13 BP 12190199 Washer, .375” 1

15 BP 11192209 Gear, Feed Reverse Bevel 1

16 BP 12190168 Pin, Feed Engage 1

17 BP 12190059 Cradle, Worm Gear 1

18 BP 12190169 Throw-Out, Worm Gear Cradle 1

19 BP 12190170 Sleeve, Shift 1

20 BP 12190138 Pin, Shift 2

21 BP 11192052 Spring, Compression 2

22 BP 11010517 Pin, Roll, .125” x .750” 2

23 BP 12190064 Crank, Shift (see BP 12193443) 1

24 BP 11192151 Knob, Bakelite, .250”-20 4

25 BP 11011010 Screw, Socket Hd Cap, #10-24 x .500” Lg 7

26 BP 11011258 Screw, Set, #10-24 x .375” 1

27 BP 12190181 Bushing, Cluster Gear Shaft Upper 1

28 BP 28007099 Assembly, Cluster Gear (see BP 12193504) 1

29 BP 12190148 Key, Sq, .125” x 1.750” 1

* BP 12193544 Assembly, Bevel Feed Pinion 1

30* BP 12190175 Assembly, Key, Sq, .125” x .563” 2

31 BP 12193517 Shaft, Cluster Gear 1

32** BP 11190836 Ring, External Retaining, #5100-62 2

33** BP 12190149 Bearing, Bevel Gear 1

34** BP 12190150 Spacer, Bevel Gear Thrust 1

35** BP 12190180 Pinion, Feed Reverse Bevel 1

36* BP 12190146 Gear, Feed Driving 1

37* BP 12190176 Key, Round End, Sq, .125” x .750” 1

38* BP 12190145 Shaft, Cluster Gear Input 1

40* BP 12190144 Gear, Feed Drive 1

41 BP 11190310 Bearing, Needle, Torrington #B-66 1

42 BP 11193637 Bushing 1

43 BP 28007307 Gear, Worm Speed Control 1

44 BP 12190155 Bushing, Feed Worm Shaft 1

45 BP 11011268 Screw, Stainless Steel, Cup 6

46 BP 11011542 Screw, Set, .312”-18 x .938” 5

47 BP 11190152 Washer, Feed Worm Shaft Thrust 1

4-8 M-508

Page 67

Item Part Number Description Qty

* BP 12193435 Assembly, Bevel Feed Gear 1

48* BP 11183646 Bushing, Bronze, .502” x .628” x 5.00” 2

49* BP 12193432 Gear, Feed Reverse Bevel 2

50 BP 12190153 Clutch, Feed Reverse 1

53 BP 11011547 Lock, Screw, Stainless Steel, .312”-18 x .156” 1

54 BP 11011375 Screw, Stainless Steel, .312”-18 x .312” 1

55 BP 12190157 Rod, Reverse Clutch 1

56 BP 11010509 Pin, Roll, .093” x .750” 1

57 BP 12190198 Shaft, Feed Worm 1

58 BP 12190200 Pin, .093” x .312” Lg 1

59 BP 28007308 Pin, .100 x .438” Lg 1

60 BP 12190179 Rod, Feed Shift 1

61 BP 11011260 Screw, Stainless Steel, #10-32 UNF x .250” 1

63 BP 11190061 Fork, Feed Gear Shift 1

64 BP 12193446 Assembly, Cluster Gear Shift Crank 1

66 BP 12190065 Cover, Cluster Gear 1

73 0100424 Screw, Cap, #10-24 x 1.500” 2

74 BP 12190188 Pin, Stop 2

75 BP 12190098 Ring, Clutch 1

76 BP 11011265 Screw, Stainless Steel, .250”-20 x .250” 1

77 BP 12190073 Plug, Brass, .187”Æ x .093” 1

78 BP 12190105 Locknut, Overload Clutch 1

79 BP 11192055 Spring, Safety Clutch 1

80 BP 11192302 Clutch, Overload 1

81 BP 12193549 Sleeve, Overload Clutch 1

82 BP 11191920 Washer, Single Spring 3

83 0350210 Screw, Round Hd Machine, #8-32 x .625” 3

88 BP 11192032 Spring, Compression, .250”Æ x 1.250” 1

89 BP 12190096 Plunger, Overload Clutch Lever Spring 1

90 BP 12190106 Bushing, Quill Pinion Shaft 1

91 BP 12190104 Spacer, Pinion Shaft Worm Gear 1

92 BP 12190103 Gear, Overload Clutch Worm 1

93 BP 12190102 Ring, Overload Clutch 1

94 BP 11190870 Ring, External Retaining 1

95 BP 11010717 Pin, Dowel, .187” x .750” 1

96 BP 12193427 Assembly, Overload Clutch Trip Lever 1

97 BP 12190097 Washer, Overload Clutch 1

98 37 000823102 Ring, External Retaining, #5100-37 1

99 BP 12190068 Cover, Clutch Arm 1

101 BP 11011740 Nut, Hex Jam, .250”-20 1

102 BP 11010717 Pin, Dowel, .187” x .750” 1

103 BP 12190094 Rod, Cam 1

104 BP 12190095 Handle, Trip 1

106 BP 12190067 Bracket, Feed Trip 1

107 BP 11011035 Screw, Socket Hd Cap, .250”-20 x 1.00” 1

111 BP 12193433 Assembly, Reverse Knob 2

113 BP 12190159 Assembly, Handwheel Clutch (see BP 12193519) 1

116 BP 12190154 Assembly, Handwheel Clutch Spring 1

117 BP 11010515 Pin, Roll, .125” x .562” 1

118 BP 12190093 Assembly, Cam Rod Sleeve 1

M-508 4-9

Page 68

Item Part Number Description Qty

119 BP 11010513 Pin, Roll, .125” x .437” 1

120 BP 11192053 Spring, Compression 1

121 BP 12190091 Plunger, Trip 1

122 BP 12190092 Bushing, Feed Trip Plunger 1

123 BP 12190090 Bushing, Trip Plunger 1

125 BP 12190089 Plunger, Feed Trip 1

125 BP 12193519 Assembly, Handwheel 1

127 BP 12190191 Spindle 1

128 BP 11190081 Skirt, Quill 1

129 BP 11191790 Locknut, #06 1

130 BP 11191942 Lockwasher, #W-06 1

131 BP 11190237 Bearing, Spindle 1

132 BP 12190197 Sleeve, Bearing 1

133 BP 12190196 Nosepiece 1

134 BP 12780915 Shield, Spindle Dirt 1

135 BP 11190238 Bearing, Spindle, Set 1

136 BP 12193513 Bearing, Spindle, Set 1

139 BP 11011265 Screw, Stainless Steel, .250”-20 x .250” 1

140 BP 12193540 Screw, Set, R-8 Collet 1

141 BP 11011545 Screw, Locking Set, .250”-32 x .125” 1

142* BP 12190192 Quill (See BP 12194541) 1

143 BP 28300336 Nut, Steel, #6-32 NC 1

144 BP 28300609 Screw, Stainless Steel, #6-32 x .750” 1

145 BP 28007042 Lever, Feed Trip (see BP 12193498) 1

146 BP 12190185 Pin, Trip Lever 1

147 BP 12200103 Rod, Indicator 1

148 BP 12190109 Sleeve, Quill Lock, Tapped 1

149 BP 12200098 Handle, Lock 2

150 BP 11011595 Screw, Washer Hd Machine, #10-32 x .375” 1

151 BP 11192403 Strainer, Felt 1

152 BP 12190111 Bolt, Quill Lock 1

153 BP 12190110 Sleeve, Quill Lock, Untapped 1

154 BP 12200102 Screw, Rod Indicator Thumb 4

155 BP 12191620 Bolt, Tee, .500” 2

156 BP 12190135 Spacer, Lower Clamping Bolt 2

157 BP 12191736 Nut, Hex, .500” x 1.500” 2

158 0350104 Screw, Round Hd Machine, #6-32 x .250” 1

159 BP 11195306 Scale, Quill Micrometer Inch 1

162 BP 12190344 Assembly, Quick Nut 1

163 BP 12190082 Nut, Quill Stop 1

164 BP 12190083 Screw, Quill Stop Micro 1

165 BP 11011121 Screw, Socket Hd Cap, .375”-24 x .625” 1

166 BP 28007063 Shaft, Quill Pinion 1

168 BP 12200111 Pin, Spring 1

170 BP 11010541 Pin, Roll, .187” x .750” Lg 1

171 BP 11013076 Key, Woodruff #3 1

172 BP 12190182 Screw, Pinion Shaft Hub 1

173 BP 11192165 Ball, Steel 1

174 BP 11192054 Spring, Compression 1

175 BP 12201033 Assembly, Quill Feed Handle 1

4-10 M-508

Page 69

Item Part Number Description Qty

176 BP 12190079 Hub, Quill Pinion 1

177*** BP 12190066 Cover, Spring 1

178*** BP 11192020 Spring, Clock 1

179*** BP 28007150 Pin, Outside Clock Spring 1

180 BP 28007064 Pinion, Quill (see BP 12190108) 1

183 BP 12190085 Lever, Reverse Trip Ball 1

184 BP 12190086 Plunger, Feed Reverse Trip 1

185 BP 12190087 Screw, Reverse Trip Ball Lever 1

186 BP 11192207 Gear, Worm 1

187 5 0001465 Key, Woodruff #405 1

188 BP 11011370 Screw, Socket Hd Set, .250”-UNC x 20 x .375” 1

189 BP 12190850 Shaft, Adjustable Worm 1

192* BP 12190051 Housing, Quill (see BP 12194541) 1

193 BP 11193111 Cup, Oil 1

196 BP 12190162 Key, Worm Shaft, Sq, .125” x 5/16” 1

*Items 10, 36, 37 and 40 sold as assembly BP 12193440.

**Items 32, 33, 34 and 35 sold as assembly BP 12193544.

***Items 177, 178 and 179 sold as assembly BP 12193437.

M-508 4-11

Page 70

BASIC MACHINE

TI5727

Figure 4.4 - Basic Machine Assembly

4-12 M-508

Page 71

BASIC MACHINE

Item Part Number Description Qty

1 BK 0001500C141 Body 1

2 BK 0001500C103 Column 1

3 BK 0001500C139 Elevating screw nut (Inch) 1

4 BK 0001500C137 Elevating screw (Inch) 1

5 BK 0001500C077 Bevel gear (Big) 1

6 BK 0001500C175 Knee 1

7 BK 0001500C096 Bevel gear (Small) 1

8 BK 0001500C094 Elevating shaft 1

9 BK 0001500C092 Bearing Housing 1

10 BK 0001500C090 Bearing Cap 1

11 BK 0001500C088 Dial holder 1

12 BK 0001500C1381 Dial with 100 graduation (Inch) 1

13 BK 0001500D021 Dial nut 1

14 BK 0001500C085 Gear shaft clutch insert 1

15 BK 0001500C084 Knee knob 1

16 BK 0001500C083 Ball crank handle lever 1

17 BK 0001500C055 Knee clamp 1

18 BK 0001500C041 Clamp adjusting screw 2

19 BK 0001500C044A Scraper set 1

20 BK 0001500C044B Scraper set 1

21 BK 0001500C0611 Dustproof cover 1

22 BK 0001500C060A1 Dustproof cover 1

23 BK 0001500C118 Spider 1

24 BK 0001500C124 Turret 1

25 BK 0001500C120 Ram pinion 1

26 BK 0001500C126 Ram lock plunger 2

27 BK 0001500C037 Table lock bolt handle 4

28 BK 0001500C110 Gib lock screw 2

29 BK 0001500C128 Ram pinion set 1

30 BK 0001500C127 Locking bolt 4

31 BK 000146603 Nut, 1/2" 1

32 BK 0001500C172 Ram 1

33 BK 0001500C002 Ram adaptor 1

34 BK 0001500C001 Tilting worm 1

35 BK 0001500C011 Hook 1

36 BK 0001500C008 Vertical adjusting worm shaft 1|

37 BK 0001500C019 Adaptor locking bolt 3

38 BK 0001500C004 Adaptor pivot stud locknut 1

39 BK 000284001 Washer, M14 3

40 BK 0001500C017 Head housing shaft 1

41 BK 000823126 Snap Ring, M26 2

44 BK 000631702 Key, 5 X 5 X 50 1

45 BK 0001500C006 Worm 1

46 BK 0001500C012 Worm thrust washer 1

47 BK 0001500C003 Adaptor scale 1

48 BK 0001500C125 Column side cover 2

49 BK 0001500C130 Oil filter 2

50 BK 000631703 Key, 5 X 5 X 15 2

M-508 4-13

Page 72

Item Part Number Description Qty

51 BK 000026602 Bearing 1

52 BK 0001500C076 Washer 5

53 BK 000026601 Bearing 2

54 BK 000146602 Nut, 3/8 2

55 BK 000033804 Hexagon socket screw 3

56 BK 0001500C170B Leveling screw 4

57 BK 0001800C146 Leveling pads 4