Hardinge 16C Mounting Instructions

MOUNTING INSTRUCTIONS

and

PARTS LIST

for

16C

The dead length work stop makes it possible to accurately locate and hold parts that have a

previously machined shoulder. The soft, machineable stop plates can be bored in your shop to the

appropriate size for nearly instantaneous use. The work stop can be mounted on any Hardinge

machine that has a

A2-5

spindle.

DEAD LENGTH WORK STOP

Mounting Instructions:

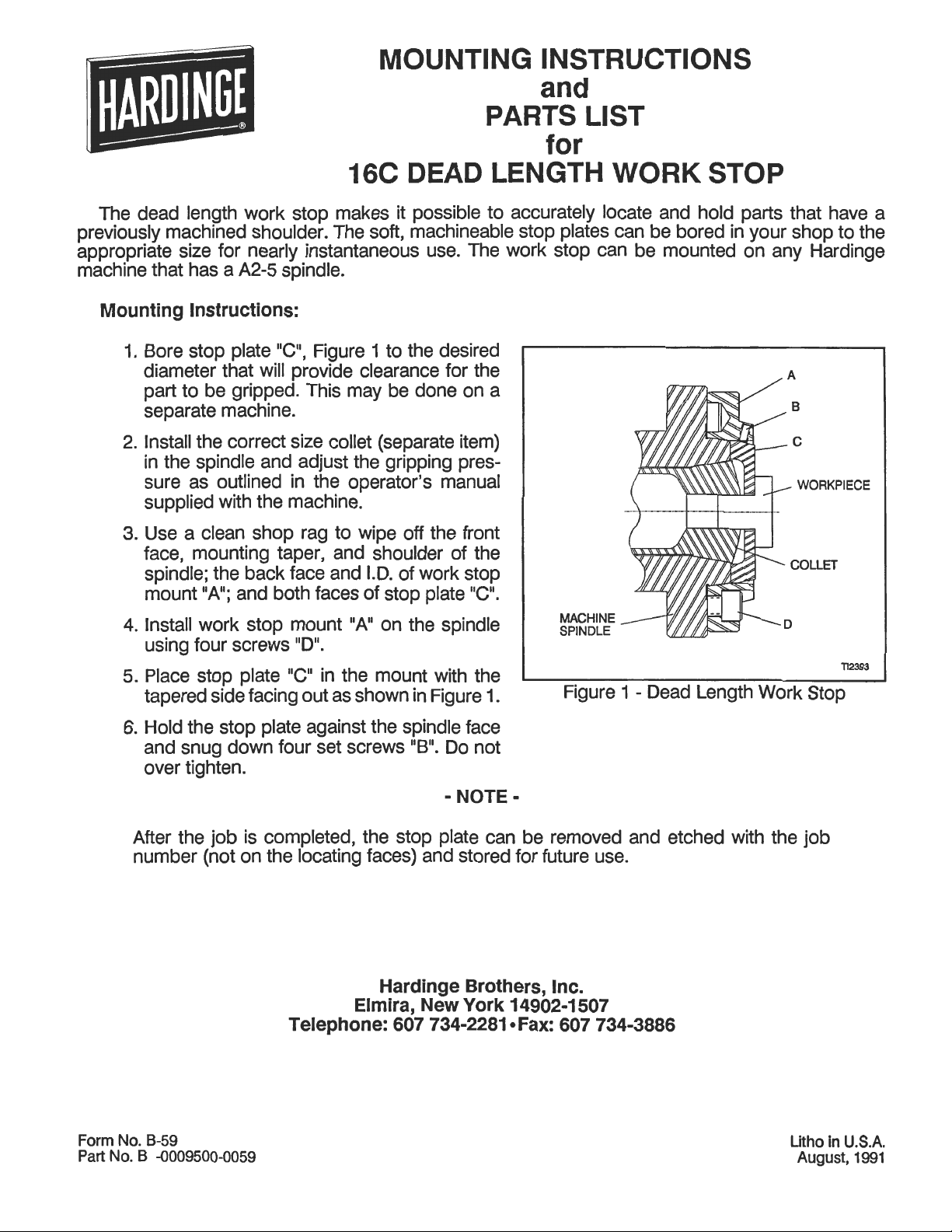

1.

Bore stop plate "C", Figure 1 to the desired

diameter that will provide clearance for the

part to be gripped. This may be done on a

separate machine.

2.

Install the correct size collet (separate item)

in the spindle and adjust the gripping pressure as outlined in the operator's manual

supplied with the machine.

3.

Use a clean shop rag to wipe off the front

face, mounting taper, and shoulder of the

spindle; the back face and I.D. of work stop

"A";

mount

4.

Install work stop mount

using four screws

and both faces of stop plate "C".

"A"

on the spindle

"DM.

MACHINE

SPINDLE

-

COLLET

D

5.

Place stop plate "C"

tapered side facing out as shown in Figure

6.

Hold the stop plate against the spindle face

and snug down four set screws

over tighten.

After the job is completed, the stop plate can be removed and etched with the job

number (not on the locating faces) and stored for future use.

in

the mount with the

Hardinge Brothers,

Elmira,

Telephone:

1.

"B".

Do not

-

NOTE

New

York

607 734-2281

Figure

=

Inc.

14902-1 507

@Fax:

607 734-3886

1

-

Dead Length Work Stop

Form No. B-59

Part

No. B -0009500-0059

in

Litho

August, 1991

U.S.A.

16C

(SEPARATE ITEM)

COLLET

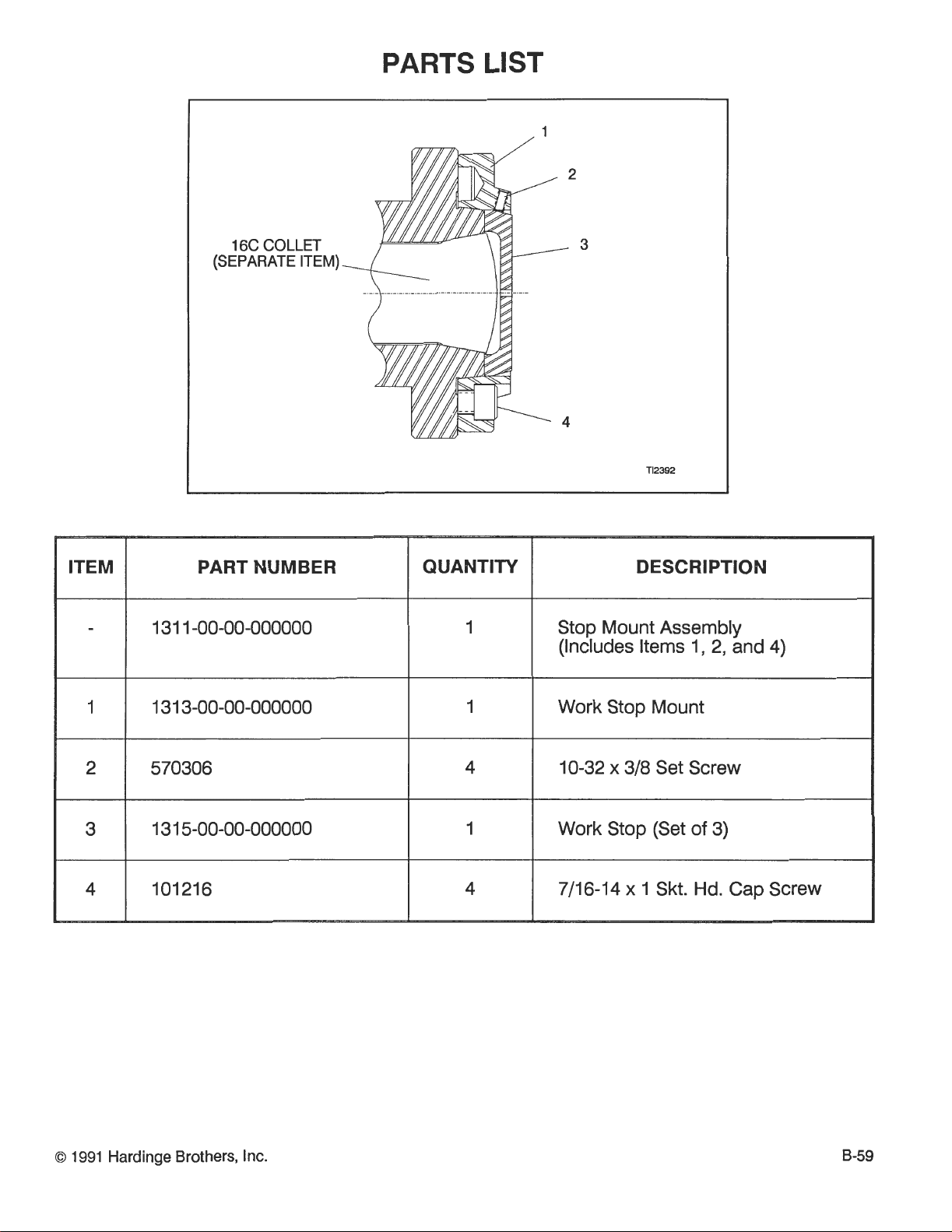

PARTS LIST

ITEM PART NUMBER

QUANTITY

DESCRIPTION

Stop Mount Assembly

I,

2,

(Includes Items

and

Work Stop Mount

10-32 x 318

Work Stop (Set of

7/16-14

Set Screw

3)

x

1

Skt. Hd. Cap Screw

4)

O

1991 Hardinge Brothers, Inc.

Loading...

Loading...