HardiePlank® Lap Siding

EFFECTIVE SEPTEMBER 2019

IMPORTANT: FAILURE TO FOLLOW JAMES HARDIE WRITTEN INSTALLATION INSTRUCTIONS AND COMPLY WITH APPLICABLE BUILDING CODES MAY VIOLATE LOCAL LAWS, AFFECT

BUILDING ENVELOPE PERFORMANCE AND MAY AFFECT WARRANTY COVERAGE. FAILURE TO COMPLY WITH ALL HEALTH AND SAFETY REGULATIONS WHEN CUTTING AND INSTALLING

THIS PRODUCT MAY RESULT IN PERSONAL INJURY. BEFORE INSTALLATION, CONFIRM YOU ARE USING THE CORRECT HARDIEZONE® PRODUCT INSTRUCTIONS BY VISITING

HARDIEZONE.COM OR CALL 1-866-942-7343 (866-9-HARDIE)

CUTTING INSTRUCTIONS

STORAGE & HANDLING:

Store flat and keep dry and covered prior to

installation. Installing siding wet or saturated may

result in shrinkage at butt joints. Carry planks on

edge. Protect edges and corners from breakage.

James Hardie is not responsible for damage caused

by improper storage and

handling of the

OUTDOORS

1. Position cutting station so that airflow blows dust away from the

user and others near the cutting area.

2. Cut using one of the following methods:

a. Best: Circular saw equipped with a HardieBlade

and attached vacuum dust collection system. Shears

(manual, pneumatic or electric) may also be used, not

recommended for products thicker than 7/16 in.

b. Better: Circular saw equipped with a dust collection feature

(e.g. Roan

c. Good: Circular saw equipped with a HardieBlade saw blade.

®

saw) and a HardieBlade saw blade.

®

saw blade

product.

IMPORTANT: The Occupational Safety and Health Administration (OSHA) regulates workplace exposure to silica dust. For construction sites, OSHA has deemed

that cutting fiber cement with a circular saw having a blade diameter less than 8 inches and connected to a commercially available dust collection system per

manufacturer’s instructions results in exposures below the OSHA Permissible Exposure Limit (PEL) for respirable crystalline silica, without the need for additional

respiratory protection.

If you are unsure about how to comply with OSHA silica dust regulations, consult a qualified industrial hygienist or safety professional, or contact your James

Hardie technical sales representative for assistance. James Hardie makes no representation or warranty that adopting a particular cutting practice will assure

your compliance with OSHA rules or other applicable laws and safety requirements.

IMPORTANT: To prevent damage to the drip edge, extra care should be taken when removing planks from the pallet, while handling, and when installing with a lap gauge. Please see

additional handling requirements on page 4.

INDOORS

DO NOT grind or cut with a power saw indoors. Cut using shears (manual, pneumatic or

electric) or the score and snap method, not recommended for products thicker than 7/16 in.

- DO NOT dry sweep dust; use wet dust suppression or vacuum to collect dust.

- For maximum dust reduction, James Hardie recommends using the “Best” cutting

practices. Always follow the equipment manufacturer’s instructions for proper operation.

- For best performance when cutting with a circular saw, James Hardie recommends

using HardieBlade

- Go to jameshardiepros.com for additional cutting and dust control recommendations.

®

saw blades.

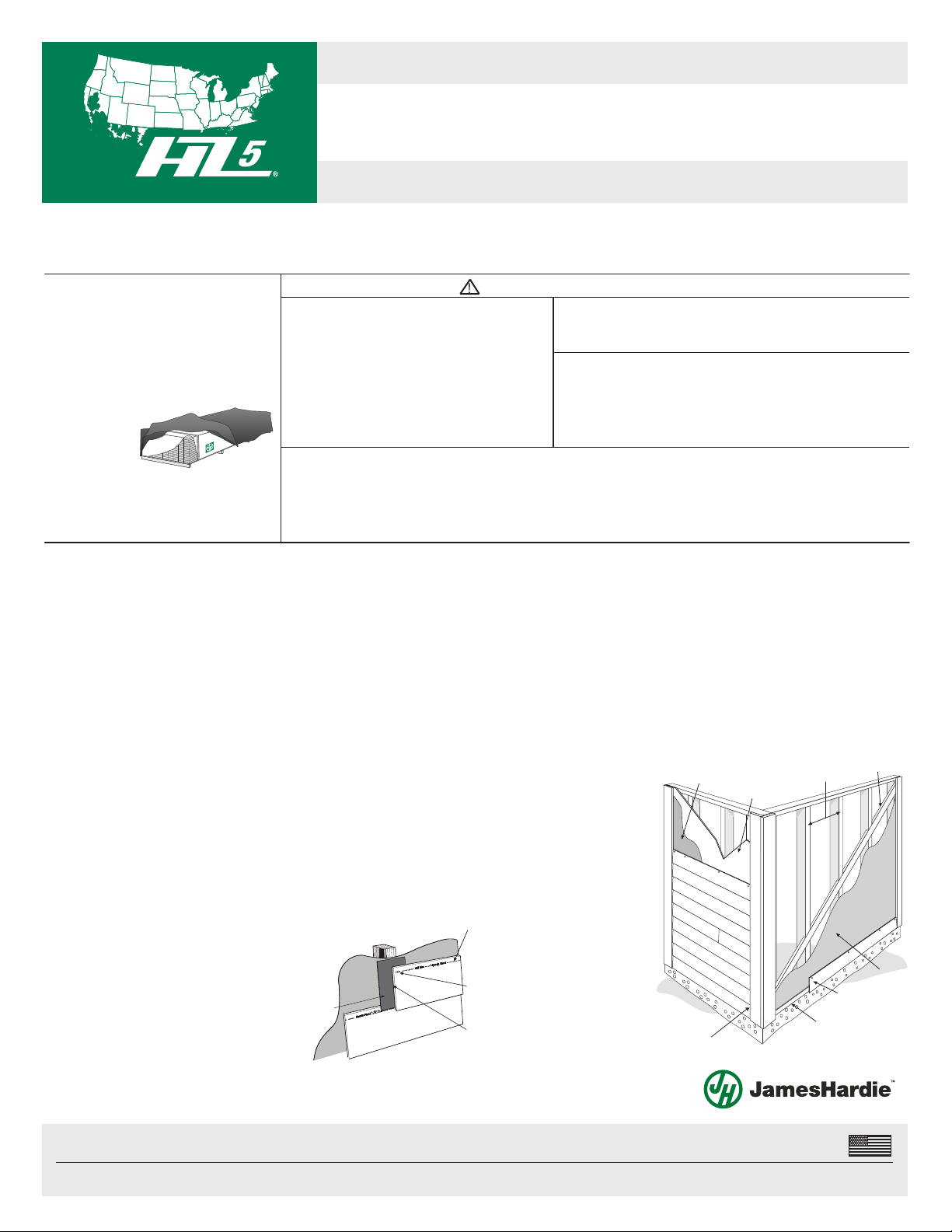

GENERAL REQUIREMENTS:

• HardiePlank® lap siding can be installed over braced wood or steel studs, 20 gauge (33 mils) minimum to 16 gauge (54 mils) maximum, spaced a maximum of 24 in o.c. or directly to

minimum 7/16 in thick OSB sheathing. See General Fastening Requirements. Irregularities in framing and sheathing can mirror through the finished application. Correct irregularities

before installing siding.

• Information on installing James Hardie products over non-nailable substrates (ex: gypsum, foam,etc.) can be located in JH Tech Bulletin 19 at www.jamehardie.com

• A water-resistive barrier is required in accordance with local building code requirements. The water-resistive barrier must be appropriately installed with penetration and junction flashing

in accordance with local building code requirements. James Hardie will assume no responsibility for water infiltration. James Hardie does manufacture HardieWrap® Weather Barrier, a

non-woven non-perforated housewrap¹, which complies with building code requirements.

• Adjacent finished grade must slope away from the building in accordance with local building codes - typically a minimum of 6 in. in

the first 10 ft..

• Do not use HardiePlank lap siding in Fascia or Trim applications.

• Do not install James Hardie products, such that they may remain in contact with standing water.

• HardiePlank lap siding may be installed on flat vertical wall applications only.

• For larger projects, including commercial and multi-family projects, where the span of the wall is

significant in length, the designer and/or architect should take into consideration the coefficient of thermal expansion and

moisture movement of the product in their design. These values can be found in the Technical Bulletin “Expansion Characteristics

of James Hardie® Siding Products” at www.jameshardie.com.

• James Hardie Building Products provides installation /wind load information for buildings with a maximum mean roof height of 85

feet. For information on installations above 60 feet, please contact JH technical support.

INSTALLATION:

JOINT TREATMENT

One or more of the following joint treatment options are

required by code (as referenced 2009 IRC R703.10.2)

A. Joint Flashing (James Hardie recommended)

B. Caulking* (Caulking is not recommended

for ColorPlus for aesthetic reasons as the

Caulking and ColorPlus will weather differently.

For the same reason, do not caulk nail heads on

ColorPlus products.)

joint

flashing

water-

resistive

barrier

stud

Figure 2

Nail line (If nail line is not

present, place fastener

between 3/4 in. & 1 in.

from top of plank)

Nail 3/8 in. from

edge of plank

Install planks in

moderate contact

at butt joints

Leave appropriate gap between

planks and trim, then caulk.*

C. “H” jointer cover

Double Wall

Construction

water-resistive

barrier

plywood or

OSB sheathing

Figure 1

Single Wall

Construction

24 in. o.c. max.

fastener

Install a 1 1/4 in. starter strip to

ensure a consistent plank angle

let-in bracing

water-resistive

barrier

Note: Field painting over caulking may produce a sheen difference when compared to the field painted PrimePlus. *Refer to Caulking section in these instructions.

¹For additional information on HardieWrap® Weather Barrier, consult James Hardie at 1-866-4Hardie or www.hardiewrap.com

SELECT CEDARMILL© | SMOOTH | BEADED CEDARMILL© | BEADED SMOOTH

Visit jameshardiepros.com for the most recent version.

HS11117 P1/4 09/19

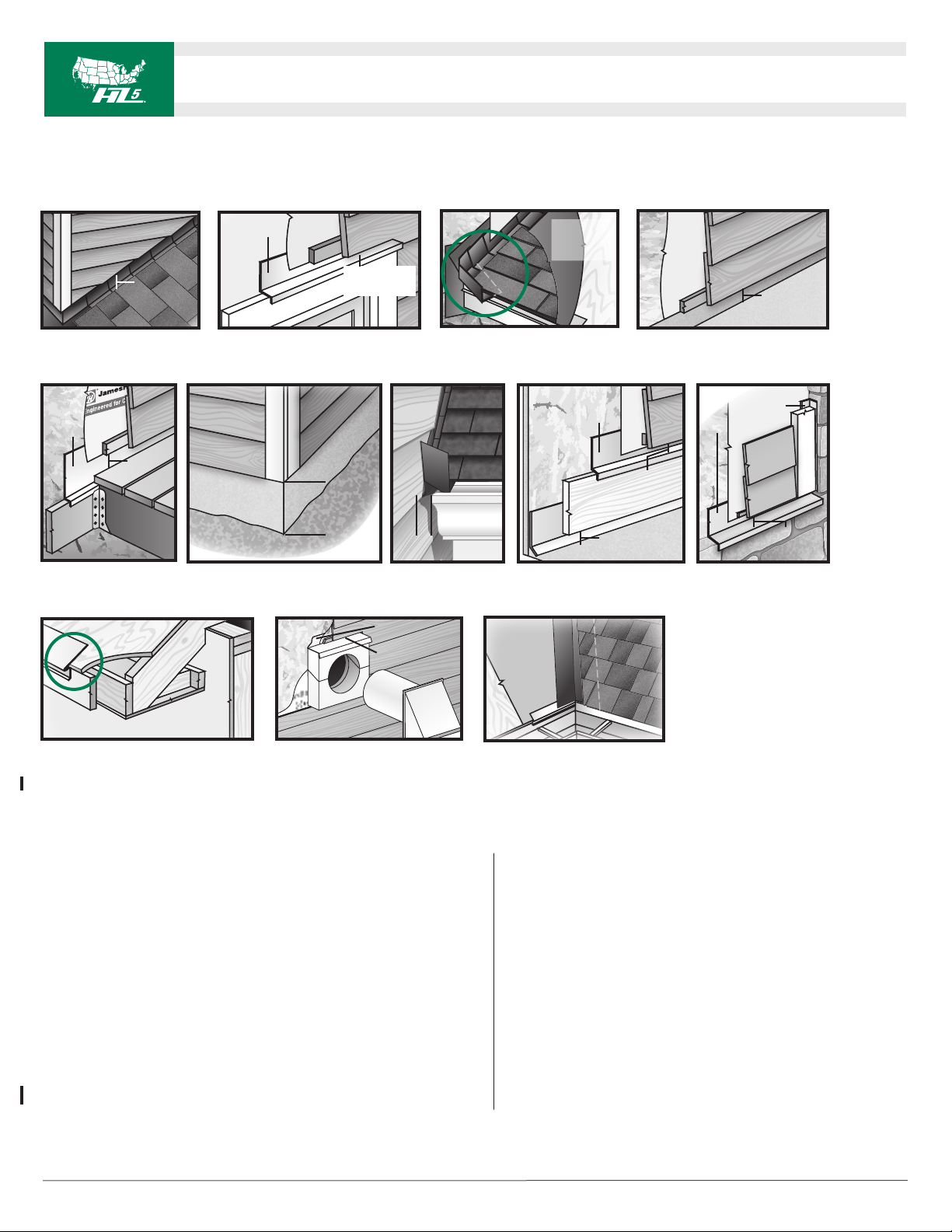

CLEARANCE AND FLASHING REQUIREMENTS

HardiePlank® Lap Siding

Figure 3

Roof to Wall

Figure 7

Deck to Wall

Z-Flashing

Figure 12

Drip Edge

Min. 2 in.

Min.

2 in.

Figure 4

Horizontal Flashing

Z-Flashing

Figure 8

Ground to Siding

Figure 13

Block Penetration

6 in.

Min. ¼ in.

Do not caulk

Figure 9

Gutter to Siding

Figure 5

Kickout Flashing

1in.

Figure 14

Valley/Shingle Extension

As required

by IRC code

min 4 in. x 4 in.

Figure 10

Sheltered Areas

Z-Flashing

Min. ½ in.

Figure 6

Slabs, Path, Steps to Siding

Min. 2 in.

Figure 11

Mortar/Masonry

L-Flashing

Z-Flashing

Min. ¼ in.

Min. ¼ in.

Z-Flashing

Min. ¼ in.

Do not caulk

FASTENER REQUIREMENTS*

Refer to the applicable ESR report online to determine which fastener meets your wind load design criteria.

Blind Nailing is the preferred method of installation for HardiePlank

be used in conjunction with Blind nailing (Please see JH Tech bulletin 17 for exemption when doing a repair).

BLIND NAILING

Nails - Wood Framing

• Siding nail (0.09 in. shank x 0.221 in. HD x 2 in. long)

• 11ga. roofing nail (0.121 in. shank x 0.371 in. HD x 1.25 in. long)

Screws - Steel Framing

• Ribbed Wafer-head or equivalent (No. 8 x 1 1/4 in. long

x 0.375 in. HD) Screws must penetrate 3 threads into metal framing.

Nails - Steel Framing

• ET & F Panelfast

Nails must penetrate minimum 1/4 in. into metal framing.

OSB minimum 7/16 in.

• Siding nail (0.09 in. shank x 0.215 in. HD x 1-1/2 in. long

• Ribbed Wafer-head or equivalent (No. 8 x 1 5/8 in. long x 0.375 in. HD).

®

nails or equivalent (0.10 in. shank x 0.313 in. HD x 1-1/2 in. long)

®

lap siding products. Face nailing should only be used where required by code for high wind areas and must not

FACE NAILING

Nails - Wood Framing

• 6d (0.113 in. shank x 0.267 in. HD x 2 in. long)

• Siding nail (0.09” shank x 0.221” HD x 2” long)

Screws - Steel Framing

• Ribbed Bugle-head or equivalent (No. 8-18 x 1-5/8 in. long x

0.323 in. HD) Screws must penetrate 3 threads into metal framing.

Nails - Steel Framing

• ET & F pin or equivalent (0.10 in. shank x 0.25 in. HD x 1-1/2 in. long)

Nails must penetrate minimum 1/4 in. into metal framing.

OSB minimum 7/16 in.

• Siding nail (0.09 in. shank x 0.221 in. HD x 1-1/2 in. long)

Extend shingles

at least 1 in.

out from the

fascia when

gutters are

present

*Also see General Fastening Requirements; and when considering alternative fastening options refer to James Hardie's Technical Bulletin USTB 5 - Fastening Tips for HardiePlank Lap Siding.

HS11117 P2/4 09/19

HardiePlank® Lap Siding

FASTENER REQUIREMENTS continued

24”

O.C. max

Nail Line

Water Resistive

Barrier

1 1/4” min.

Overlap

Stud

Blind Nail

Figure 14

min. 1 1/4 in.

overlap

Figure 15

Minimum overlap

for Both Face

and Blind Nailing

Joint

Flashing

Stud

3/4”-1”

24”

O.C. max

Face Nail

Water Resistive

Barrier

1 1/4” min.

Overlap

Laminate sheet to be removed immediately after installation of each course for ColorPlus® products.

Pin-backed corners may be done for aesthetic purposes only. Finish nails are recommended for pin-backs. Headed siding nails are allowed. Place pin-backs

no closer than 1 in. from plank ends and 3/4 in. from plank edge into min. 3/8 in. wood structural panel. Pin-backs are not a substitute for blind or face nailing.

GENERAL FASTENING REQUIREMENTS

Fasteners must be corrosion resistant, galvanized, or stainless steel. Electro-galvanized

are acceptable but may exhibit premature corrosion. James Hardie recommends the

use of quality, hot-dipped galvanized nails. James Hardie is not responsible for the

corrosion resistance of fasteners. Stainless steel fasteners are recommended when

installing James Hardie

humid climates.

®

products near the ocean, large bodies of water, or in very

PNEUMATIC FASTENING

James Hardie products can be hand nailed or fastened with a pneumatic tool.

Pneumatic fastening is highly recommended. Set air pressure so that the

fastener is driven snug with the surface of the siding. A flush mount

attachment on the pneumatic tool is recommended. This will help control the

depth the nail is driven. If setting the nail depth

proves difficult, choose a setting that under drives

the nail. (Drive under driven nails snug with a

Manufacturers of ACQ and CA preservative-treated wood recommend spacer materials

or other physical barriers to prevent direct contact of ACQ or CA preservative-treated

wood and aluminum products. Fasteners used to attach HardieTrim Tabs to preservative-treated wood shall be of hot dipped zinc-coated galvanized steel or stainless steel

and in accordance to 2009 IRC R317.3 or 2009 IBC 2304.9.5

SNUG FLUSH

DO NOT DO NOT

smooth faced hammer - Does not apply for

installation to steel framing).

DO NOT USE

• Consult applicable product evaluation or listing for correct fasteners type and

placement to achieve specified design wind loads.

• NOTE: Published wind loads may not be applicable to all areas where Local Building

Codes have specific jurisdiction. Consult James Hardie Technical Services if you are

unsure of applicable compliance documentation.

• Drive fasteners perpendicular to siding and framing.

• Fastener heads should fit snug against siding (no air space).

• NOTE: Whenever a structural member is present, HardiePlank should be fastened with

even spacing to the structural member. The tables allowing direct to OSB or plywood

should only be used when traditional framing is not available.

UNDER

DRIVE

IF, THEN IF, THEN ADDITIONAL NAIL

WOOD

FRAME

STEEL

FRAME

OVER

DRIVE

FACE

NAIL

SLANT

AL

ALUMINUM

FASTENERS

CLIPPED

HEAD NAILS

CUT EDGE TREATMENT

Caulk, paint or prime all field cut edges. James Hardie touch-up kits are required to

touch-up ColorPlus products.

CAULKING

For best results use an Elastomeric Joint Sealant complying with ASTM C920 Grade NS,

Class 25 or higher or a Latex Joint Sealant complying with ASTM C834. Caulking/Sealant

HAMMER

FLUSH

REMOVE &

REPLACE

COUNTERSINK

& FILL

STAPLES

must be applied in accordance with the caulking/sealant manufacturer’s written instructions.

Note: some caulking manufacturers do not allow "tooling".

PAINTING

DO NOT use stain, oil/alkyd base paint, or powder coating on James Hardie® products. Factory-primed James Hardie products must be painted within 180 days of installation.

100% acrylic topcoats are recommended. Do not paint when wet. For application rates refer to paint manufacturers specifications. Back-rolling is recommended if the siding

is sprayed.

HS11117 P3/4 09/19

HardiePlank® Lap Siding

COLORPLUS® TECHNOLOGY CAULKING, TOUCH-UP & LAMINATE

• Care should be taken when handling and cutting James Hardie ColorPlus® products. During installation use a wet soft cloth or soft brush to gently wipe off any

residue or construction dust left on the product, then rinse with a garden hose.

• Touch up nicks, scrapes and nail heads using the ColorPlus

If large areas require touch-up, replace the damaged area with new HardiePlank

• Laminate sheet must be removed immediately after installation of each course.

• Terminate non-factory cut edges into trim where possible, and caulk. Color matched caulks are available from your ColorPlus

®

Technology touch-up applicator. Touch-up should be used sparingly.

®

lap siding with ColorPlus® Technology.

®

product dealer.

• Treat all other non-factory cut edges using the ColorPlus Technology edge coaters, available from your ColorPlus product dealer.

Note: James Hardie does not warrant the usage of third party touch-up or paints used as touch-up on James Hardie ColorPlus products.

Problems with appearance or performance arising from use of third party touch-up paints or paints used as touch-up that are not James Hardie touch-up will not be covered

under the James Hardie ColorPlus Limited Finish Warranty.

PAINTING JAMES HARDIE® SIDING

COVERAGE CHART/ESTIMATING GUIDE

Number of 12 ft. planks, does not include waste

7 1/4

100

117

133

150

167

183

200

217

233

250

267

283

300

317

333

®

LAP SIDING WIDTH

7 1/2

6

6 1/4

17

33

50

67

83

112

128

144

160

176

192

208

224

240

256

272

288

304

320

8

104

119

133

148

163

178

193

207

222

237

252

267

281

296

8 1/4

15

30

44

59

74

89

6 3/4

16

32

48

64

80

96

100

114

129

143

157

171

186

200

214

229

243

257

271

286

9 1/4

9 1/2

7

14

29

43

57

71

86

100

113

125

138

150

163

175

188

200

213

225

238

250

8

13

25

38

50

63

75

88

8 1/4

100

113

125

138

150

163

175

188

200

213

225

238

250

12

10 3/4

13

25

38

50

63

75

88

HARDIEPLANK

SQ

(1 SQ = 100 sq.ft.)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

5 1/4

100

125

150

175

200

225

250

275

300

325

350

375

400

425

450

475

500

6 1/4

4

25

50

75

100

120

140

160

180

200

220

240

260

280

300

320

340

360

380

400

5

20

40

60

80

This coverage chart is meant as a guide. Actual usage is subject to variables such as building design.

James Hardie does not assume responsibility for over or under ordering of product.

102

112

121

130

140

149

158

167

177

186

9

19

28

37

47

56

65

74

84

93

AND TRIM PRODUCTS WITH

COLORPLUS

When repainting ColorPlus products, James

Hardie recommends the following regarding

surface preparation and topcoat application:

• Ensure the surface is clean, dry, and free of any

dust, dirt, or mildew

• Repriming is normally not necessary

• 100% acrylic topcoats are recommended

• DO NOT use stain, oil/alkyd base paint, or

powder coating on James Hardie

• Apply finish coat in accordance with paint

manufacturers written instructions regarding

coverage, application methods, and application

temperature

• DO NOT caulk nail heads when using ColorPlus

products, refer to the ColorPlus touch-up

section

®

TECHNOLOGY

®

Products.

ADDITIONAL HANDLING REQUIREMENTS

Pull from across the stack

Do not go down the stack

IMPORTANT: To prevent damage to the drip edge, extra care should be

taken when removing planks from the pallet, while handling, and

when installing with a lap gauge. Planks are interlocked together on

the pallet, therefore they should be removed from the pallet

horizontally (side to side) to allow planks to unlock themselves from

one another.

HS11117 P4/4 09/19

DANGER: May cause cancer if dust from product is inhaled. Causes damage to lungs and respiratory system through prolonged or repeated inhalation of dust from product. Refer to the current product Safety Data Sheet before use.

The hazard associated with fiber cement arises from crystalline silica present in the dust generated by activities such as cutting, machining, drilling, routing, sawing, crushing, or otherwise abrading fiber cement, and when cleaning

up, disposing of or moving the dust. When doing any of these activities in a manner that generates dust you must (1) comply with the OSHA standard for silica dust and/or other applicable law, (2) follow James Hardie cutting

instructions to reduce or limit the release of dust; (3) warn others in the area to avoid breathing the dust; (4) when using mechanical saw or high speed cutting tools, work outdoors and use dust collection equipment; and (5) if no

other dust controls are available, wear a dust mask or respirator that meets NIOSH requirements (e.g. N-95 dust mask). During clean-up, use a well maintained vacuum and filter appropriate for capturing fine (respirable) dust or use

wet clean-up methods - never dry sweep.

SILICA WARNING

WARNING: This product can expose you to chemicals including respirable crystalline silica, which is known to the State of California to cause cancer. For more information go to P65Warnings.ca.gov.

RECOGNITION: In accordance with ICC-ES Evaluation Report ESR-2290, HardiePlank® lap siding is recognized as a suitable alternate to that specified in the 2006, 2009, 2012 & 2015 International Residential Code for One and Two-Family

Dwellings, and the 2006, 2009, 2012 & 2015 International Building Code. HardiePlank lap siding is also recognized for application in the following: City of Los Angeles Research Report No. 24862, State of Florida Product Approval FL#13192,

Miami-Dade County Florida NOA No. 17-0406.06, U.S. Dept. of HUD Materials Release 1263f, Texas Department of Insurance Product Evaluation EC-23, City of New York MEA 223-93-M, and California DSA PA-019. These documents should

also be consulted for additional information concerning the suitability of this product for specific applications.

© 2019 James Hardie Building Products, Inc. All rights reserved TM, SM and ®

denote trademarks or registered trademarks of James Hardie Technology Limited.

Product warranties, safety information and additional installation

information are available at jameshardiepros.com

Loading...

Loading...