Page 1

RANGER 2500

TR2

Original in french

Instruction manual

67788101-100 - Version 1.00

GB - 11.2013

www.hardi-international.com

Page 2

Thank you for choosing HARDI crop protection equipment. This product's

reliability and effectiveness depend on the care that you take with it. The first step

is to read this user manual carefully. It contains essential information that will

allow you to use and maintain this quality product effectively.

The original user manual was written and published in French. All other foreign language versions are translations

from the original. In the event of contradictions, inaccuracies or digressions between the original French version

and other foreign language versions, the French original will take precedence.

The illustrations, technical information and specifications provided in this manual are correct to our knowledge at

the time of printing. Since HARDI EVRARD SAS operates a policy of constant product improvement, we reserve

the right to modify the design, characteristics, components, specifications and maintenance instructions at any

time, without prior notice.

HARDI EVRARD does not accept any liability for equipment sold prior or subsequent to such modifications.

HARDI EVRARD has taken every care in writing this manual to ensure it is as complete and accurate as possible.

However, it cannot be held liable for any omissions or inaccuracies.

Since this manual covers a range of models, the characteristics or equipment described may differ from those

available in some countries. Take note only of the paragraphs that relate to your model.

Published and printed by HARDI EVRARD S.A.S.

Page 3

Sommaire

1 - EC declaration

EC Declaration of Conformity ................................................................................................................7

2- Safety instructions

3 - Description

General information ............................................................................................................................13

Using the sprayer ................................................................................................................................................................................................ 13

Driving on the road ............................................................................................................................................................................................ 13

Tank ............................................................................................................................................................................................................................. 13

Chassis ........................................................................................................................................................................................................................ 13

General view .......................................................................................................................................................................................................... 14

Identification plates ........................................................................................................................................................................................... 15

Spraying system ..................................................................................................................................16

Pump .......................................................................................................................................................................................................................... 16

Valves and pictograms ..................................................................................................................................................................................... 16

Regulation ............................................................................................................................................................................................................... 17

Diagrams - spraying system ......................................................................................................................................................................... 17

Filters ........................................................................................................................................................................................................................... 17

Cyclone Filter (optional) .................................................................................................................................................................................. 17

TurboFiller ................................................................................................................................................................................................................ 18

Boom ...................................................................................................................................................20

Boom and terminology ................................................................................................................................................................................... 20

Equipment ...........................................................................................................................................21

Hitch with hydraulic drawbar (optional) .............................................................................................................................................. 21

Step .............................................................................................................................................................................................................................. 21

Platform ..................................................................................................................................................................................................................... 21

Main tank gauge .................................................................................................................................................................................................. 22

Boom pressure gauge ...................................................................................................................................................................................... 22

Storage box (optional) ..................................................................................................................................................................................... 22

External cleaning equipment (optional) ............................................................................................................................................... 23

TR2 Y version control unit .............................................................................................................................................................................. 23

'Sprayll' spraying control ................................................................................................................................................................................ 24

'Hydraulic' control ............................................................................................................................................................................................... 24

4 - Sprayer set-up

General information ............................................................................................................................25

Precautions before use .................................................................................................................................................................................... 25

Unloading the sprayer ..................................................................................................................................................................................... 25

Lifting the sprayer with a jack ..................................................................................................................................................................... 25

Support leg ............................................................................................................................................................................................................. 26

Transmission shaft ..............................................................................................................................27

User safety ............................................................................................................................................................................................................... 27

Connecting the transmission shaft .......................................................................................................................................................... 27

Mechanical equipment ........................................................................................................................29

Hitches ....................................................................................................................................................................................................................... 29

Articulated hitch with tilt correction (optional) ............................................................................................................................... 29

Track width, axles and wheels .............................................................................................................30

Modifying the track width ............................................................................................................................................................................. 30

Tyre inflation pressures .................................................................................................................................................................................... 30

Brakes ..................................................................................................................................................31

Parking and safety brake ................................................................................................................................................................................. 31

Hydraulic braking ................................................................................................................................................................................................ 31

Hydraulic system .................................................................................................................................32

General information .......................................................................................................................................................................................... 32

Version TR2 Y hydraulic connection ........................................................................................................................................................ 32

Version TR2 V and TR2 Z hydraulic connection ................................................................................................................................ 32

Open centre hydraulic block (optional) ................................................................................................................................................ 33

Electrical connections ..........................................................................................................................34

3

Page 4

Sommaire

Installing the control unit supports ......................................................................................................................................................... 34

Electrical supply ................................................................................................................................................................................................... 34

Sprayer speed sensor ........................................................................................................................................................................................ 35

Road signalling ..................................................................................................................................................................................................... 35

Spraying system ..................................................................................................................................36

Use of electrical EVC adjustment .............................................................................................................................................................. 36

5 - Operation

Boom ...................................................................................................................................................37

Safety instructions .............................................................................................................................................................................................. 37

TR2 Y boom hydraulic controls .................................................................................................................................................................. 37

TR2 V and TR2 Z boom hydraulic controls .......................................................................................................................................... 39

Equipment ...........................................................................................................................................40

Articulated hitch with hydraulic tilt correction (optional) ......................................................................................................... 40

Driving technique with the articulated hitch .................................................................................................................................... 40

Spraying system ..................................................................................................................................41

General information .......................................................................................................................................................................................... 41

Filling/cleaning zone - Rules ........................................................................................................................................................................ 41

Filling the main tank .......................................................................................................................................................................................... 41

Filling via the opening in the tank ............................................................................................................................................................ 42

Filling the rinsing tank ...................................................................................................................................................................................... 42

Filling the hand wash tank ............................................................................................................................................................................ 43

Water filling device ............................................................................................................................................................................................ 43

Safety instructions - Agro-pharmaceutical products .................................................................................................................... 44

Parking the sprayer ............................................................................................................................................................................................ 44

Adding products through the opening in the tank ...................................................................................................................... 45

Adding liquid products via the TurboFiller ......................................................................................................................................... 45

Adding powder products via the TurboFiller .................................................................................................................................... 46

Cleaning the TurboFiller ................................................................................................................................................................................. 46

Agitation prior to resuming treatment .................................................................................................................................................. 47

Spray controls ........................................................................................................................................................................................................ 48

Quick guide - Operation ................................................................................................................................................................................. 48

Cleaning ...............................................................................................................................................49

General information .......................................................................................................................................................................................... 49

Quick guide - Cleaning .................................................................................................................................................................................... 50

Cleaning the tank and the spraying system ....................................................................................................................................... 50

Cleaning and maintaining the filters ...................................................................................................................................................... 51

Using the rinsing tank and the rotating nozzle. ............................................................................................................................... 51

Boom purge (optional) .................................................................................................................................................................................... 53

Dead volume ......................................................................................................................................................................................................... 53

Using the drain ..................................................................................................................................................................................................... 54

6 - Maintenance

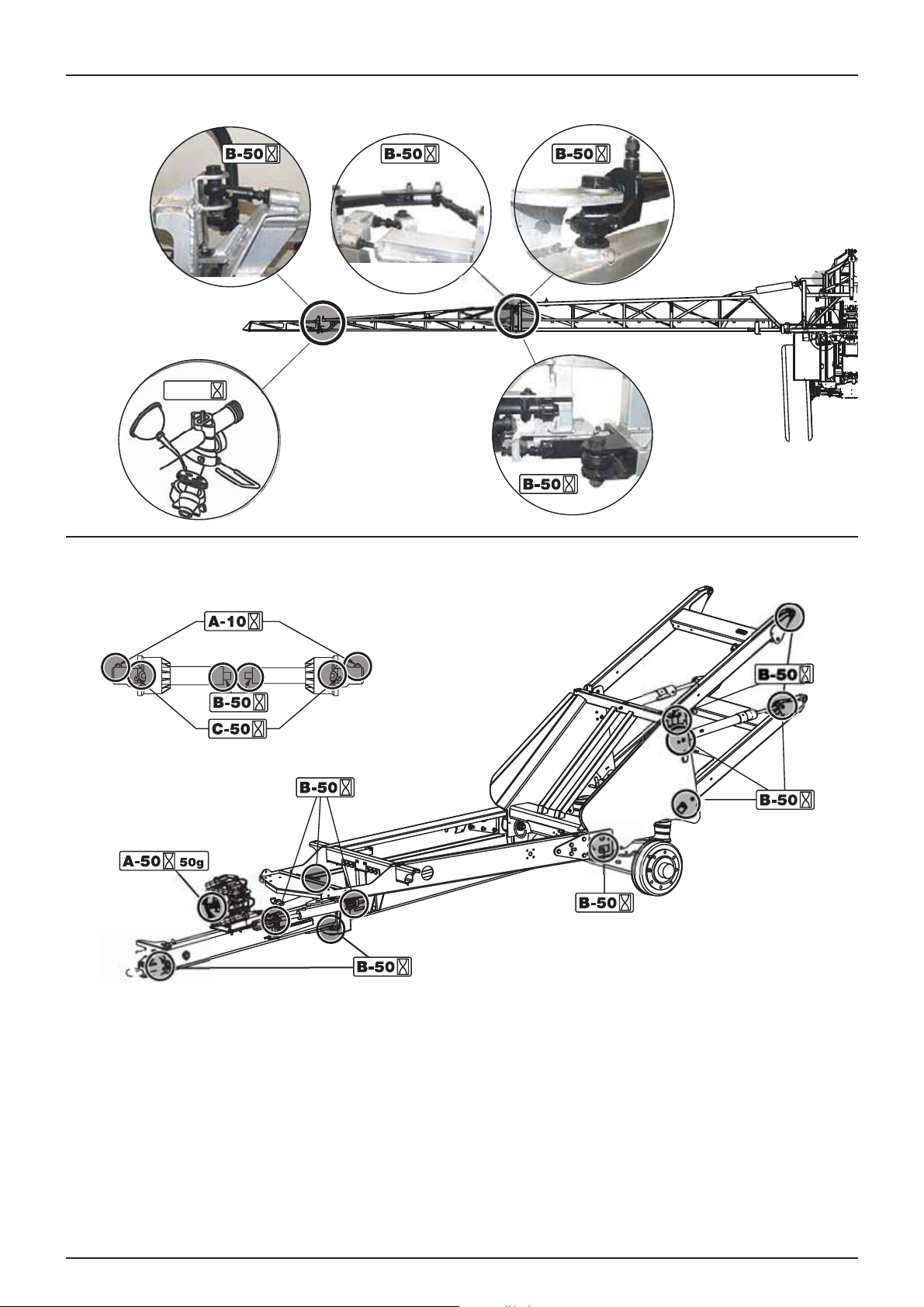

Greasing ..............................................................................................................................................55

General information .......................................................................................................................................................................................... 55

Recommended lubricants ............................................................................................................................................................................. 55

Power take-off lubrication points and frequency ........................................................................................................................... 55

Boom lubrication points and frequency .............................................................................................................................................. 56

Chassis lubrication points and frequency ............................................................................................................................................ 56

Maintenance cycle ...............................................................................................................................57

Every 10 hours - Spraying system ............................................................................................................................................................. 57

Every 10 hours - Boom filters (optional) ................................................................................................................................................ 57

Every 10 hours - Cyclone filter ..................................................................................................................................................................... 58

Every 10 hours - Brakes (optional) ............................................................................................................................................................ 58

Every 50 hours - Transmission shaft ........................................................................................................................................................ 58

Every 50 hours - Tyre pressure .................................................................................................................................................................... 58

Every 250 hours - Wheel nuts and bolts ............................................................................................................................................... 58

Every 250 hours - Hydraulic system ......................................................................................................................................................... 59

Every 250 hours - Pipes and lines .............................................................................................................................................................. 59

4

Page 5

Sommaire

Every 250 hours - Hydraulic brakes (optional) ................................................................................................................................... 59

Every 250 hours - Parking brake check .................................................................................................................................................. 59

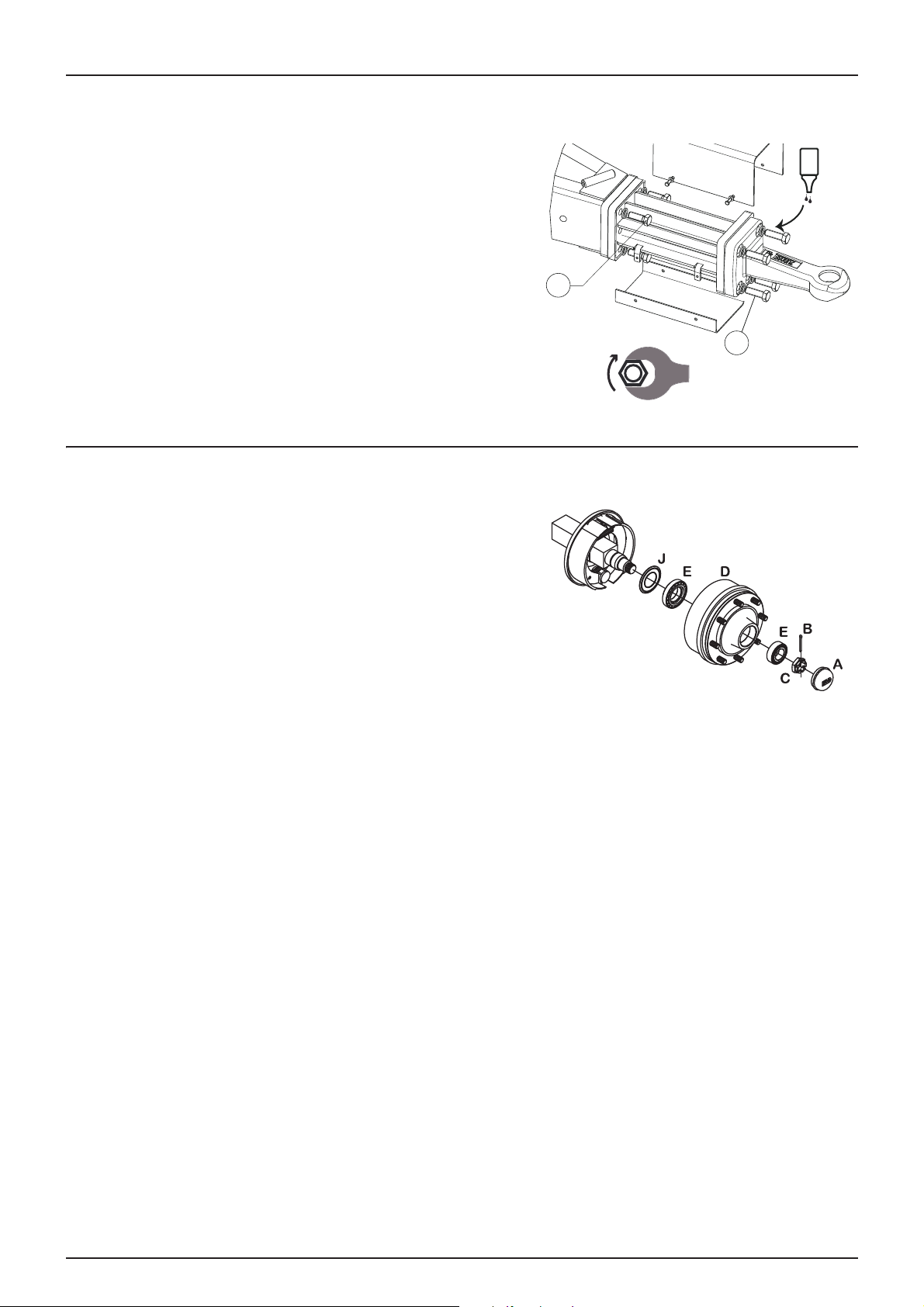

Every 250 hours - Wheel bearings ............................................................................................................................................................ 60

Every 1,000 hours - Wheel bearings (unbraked) .............................................................................................................................. 60

Every 1,000 hours - Hitch extension ........................................................................................................................................................ 61

Every 1,000 hours - Wheel bearings and brakes .............................................................................................................................. 61

Occasional maintenance ......................................................................................................................63

Checking/replacing the regulation valve piston ............................................................................................................................. 64

Checking/replacing valve gaskets on EVC valves ........................................................................................................................... 64

Adjusting the gauge ......................................................................................................................................................................................... 64

Replacing the steel cable on the gauge ............................................................................................................................................... 65

Replacing the drain valve gasket .............................................................................................................................................................. 65

Adjusting the 3-way valves ........................................................................................................................................................................... 65

Spray lines and connectors ........................................................................................................................................................................... 66

Replacing bulbs ................................................................................................................................................................................................... 66

Replacing the boom lights bulbs (optional) ...................................................................................................................................... 66

Replacing tyres ..................................................................................................................................................................................................... 67

Operating the safety valve ....................................................................................................

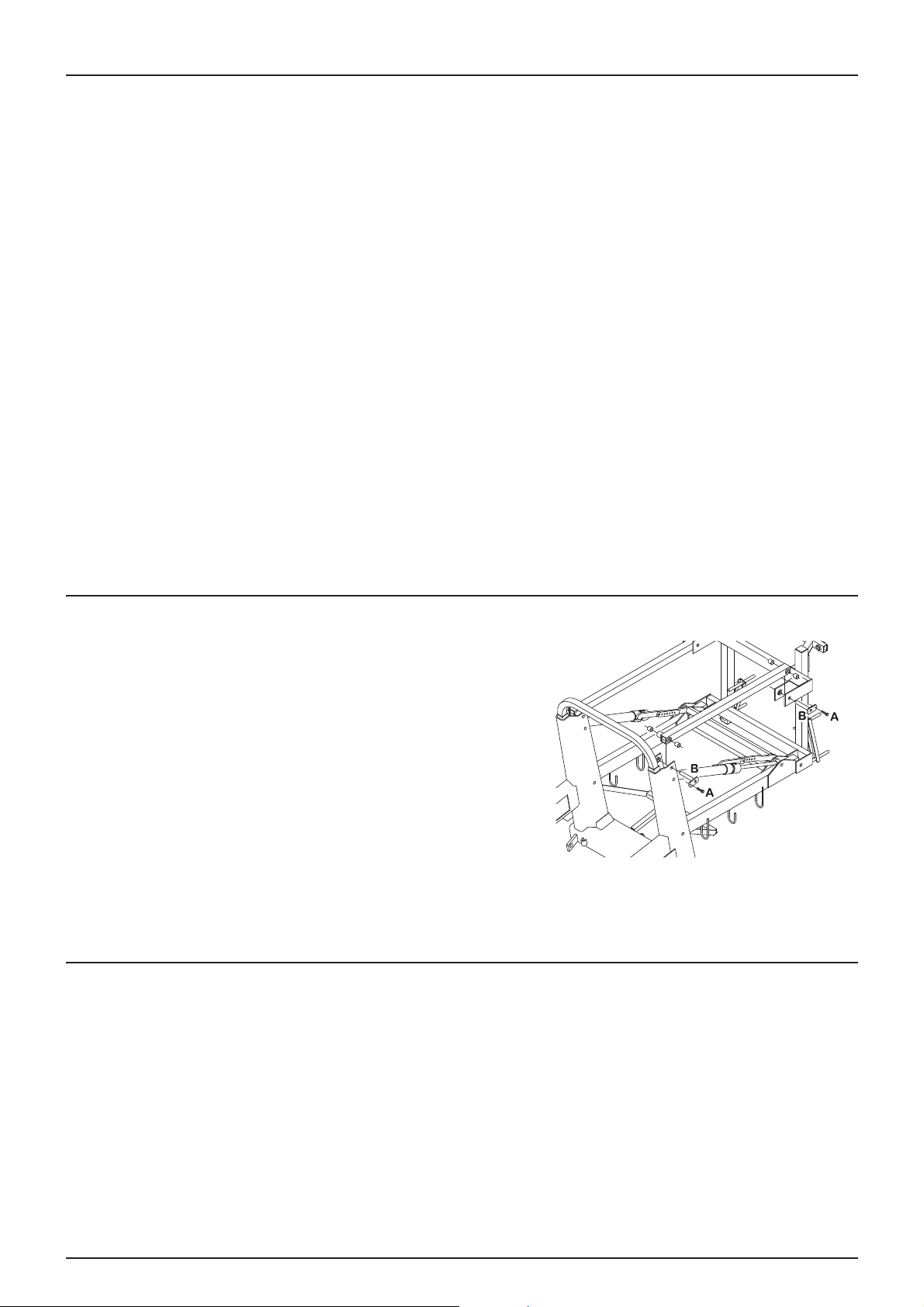

Adjusting the boom - general information ........................................................................................................................................ 69

Anti-yaw device ................................................................................................................................................................................................... 69

Central frame locking device ....................................................................................................................................................................... 69

Horizontally aligning the inner arms with the central frame ................................................................................................... 70

Adjusting the height of the boom on the transport supports ............................................................................................... 70

Adjusting the boom open/close ............................................................................................................................................................... 70

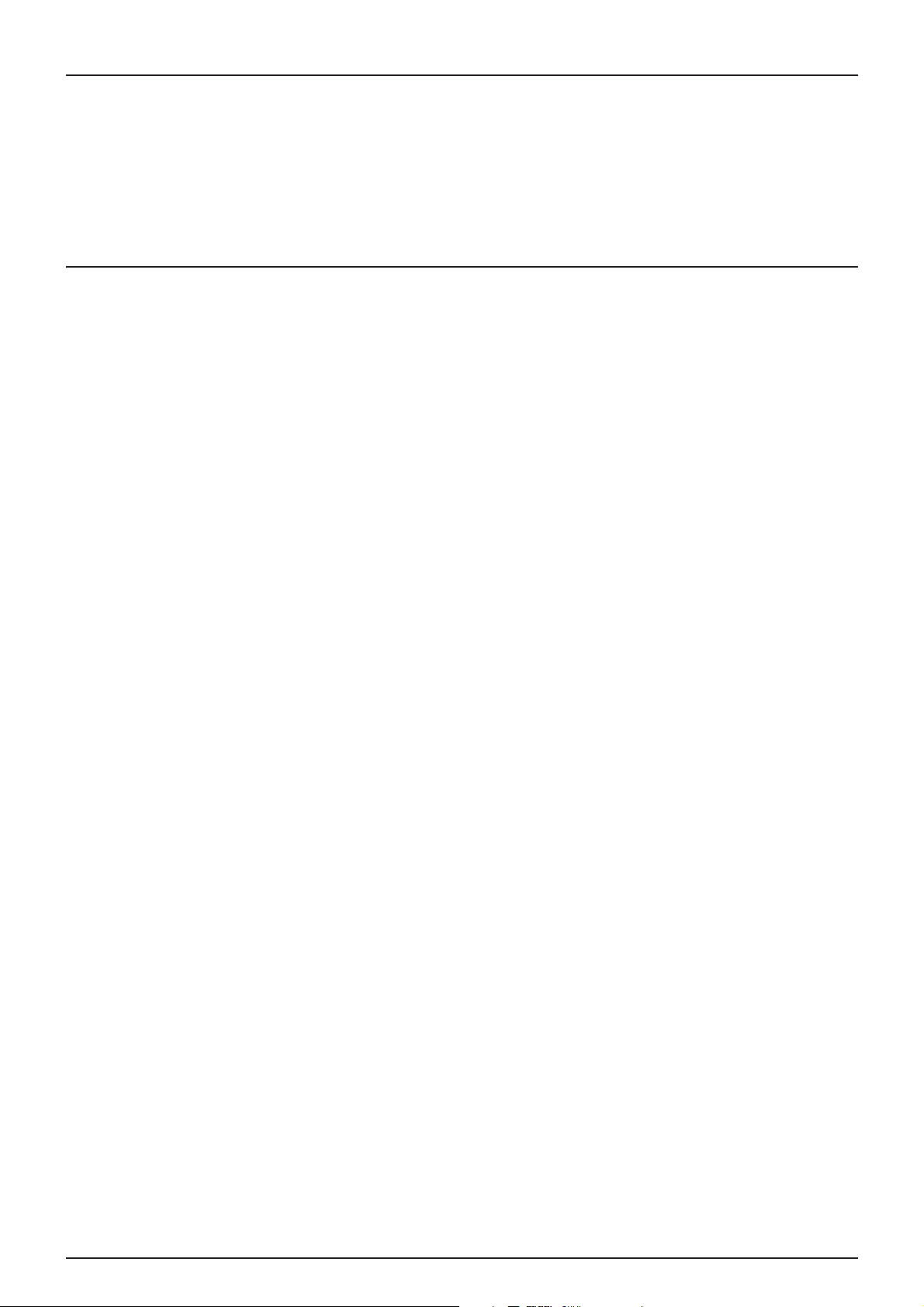

Winter storage .....................................................................................................................................71

Storage procedure ............................................................................................................................................................................................. 71

........................................................................ 68

7 - Fault finding

Operating incidents .............................................................................................................................73

General information .......................................................................................................................................................................................... 73

Spraying system ................................................................................................................................................................................................... 74

Hydraulic functions - Z boom ..................................................................................................................................................................... 75

Mechanical problems ..........................................................................................................................76

Backup operation - Spraying system ...................................................................................................................................................... 76

8 - Technical specifications

Dimensions ..........................................................................................................................................77

General information .......................................................................................................................................................................................... 77

Overall dimensions ............................................................................................................................................................................................ 77

Weight ....................................................................................................................................................................................................................... 77

Conversion factors, SI units into imperial ............................................................................................................................................. 77

Specifications ......................................................................................................................................................................................................... 78

Pump model 363/10.0 ..................................................................................................................................................................................... 78

Temperature and pressure ranges ........................................................................................................................................................... 78

Filters and nozzles .............................................................................................................................................................................................. 78

Reservoir specifications ................................................................................................................................................................................... 78

Tyre specifications .............................................................................................................................................................................................. 78

Raw materials and recycling ................................................................................................................79

Disposing of the sprayer ................................................................................................................................................................................. 79

Spraying system schematic diagrams .................................................................................................80

Basic spraying system ....................................................................................................................................................................................... 80

Spraying system with options ..................................................................................................................................................................... 81

Electrical connections ...................................................................................................................................................................................... 82

Road signalling ..................................................................................................................................................................................................... 82

Spray II unit electrical connections .......................................................................................................................................................... 82

EVC operating unit ............................................................................................................................................................................................. 83

TR2 Y version diagrams ................................................................................................................................................................................... 84

TR2 Y version diagrams ................................................................................................................................................................................... 85

5

Page 6

Sommaire

Index

Index ....................................................................................................................................................87

6

Page 7

EC Declaration of Conformity

The manufacturer:

Production unit

HARDI-EVRARD

301 rue du 21 mai 1940 - Beaurainville

France

1 - EC declaration

declares that the following equipment:

RANGER TR2 Y - RANGER TR2 V - RANGER TR2 Z

- Complies with all the relevant requirements in machinery directive 2009/127/EC, modifying directive 2006/42/EC.

- The requirements of Council Directive 2004/108/EC (EMC).

Beaurainville 01.06. 2013

Managing Director

HARDI EVRARD

7

Page 8

1 - EC declaration

8

Page 9

2- Safety instructions

User safety

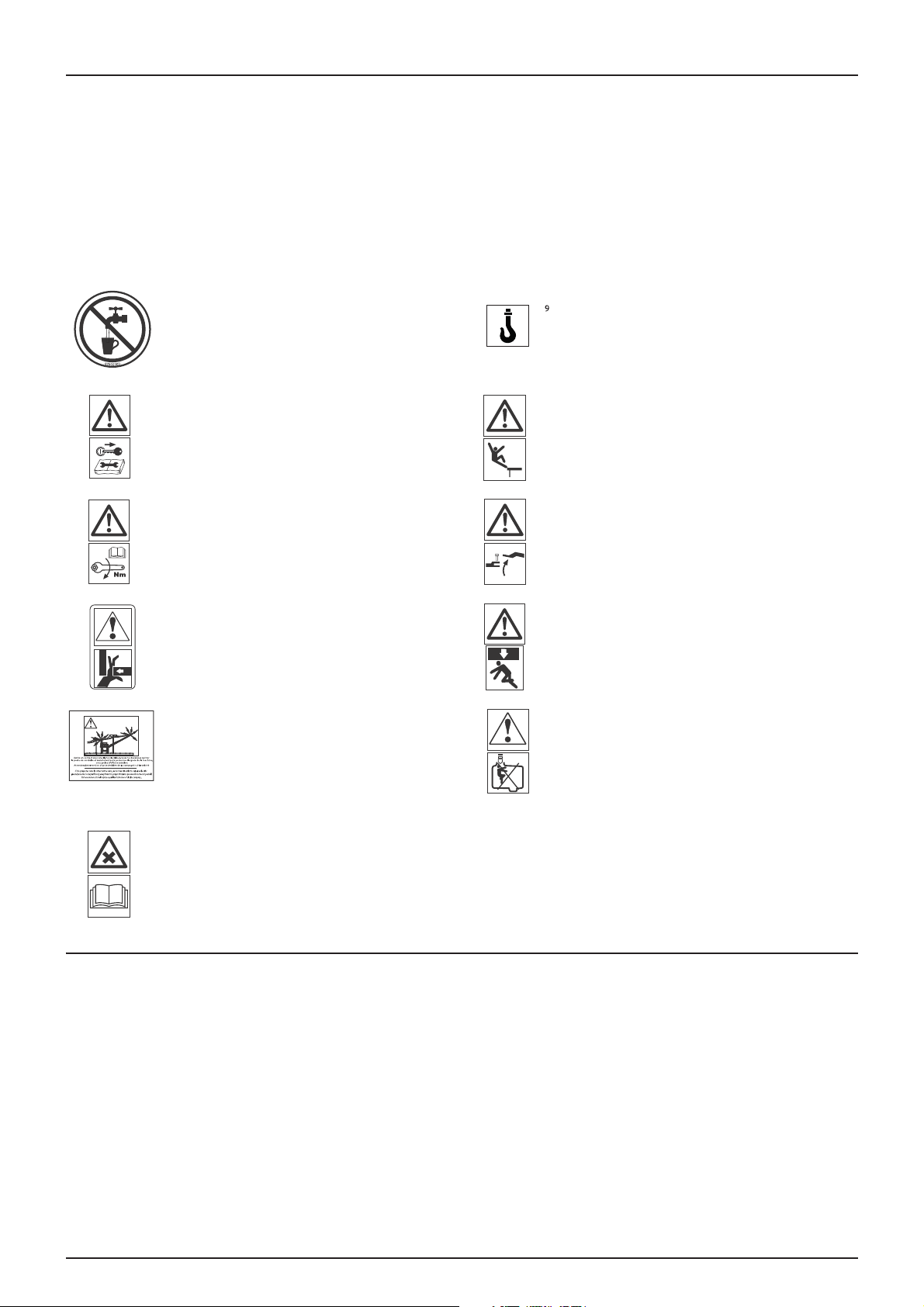

Symbols

These symbols are used throughout this manual, indicating that the reader should pay particular attention to certain points.

The meanings of the four symbols are as follows.

This symbol means DANGER. Be extremely careful, your safety is at stake!

€

This symbol means WARNING. Pay close attention, your safety might be at stake!

±

This symbol means IMPORTANT. It will guide you in the most effective, trouble-free and safe use of your sprayer!

This symbol means NOTE.

÷

Recommendations to users of treatment products

This sprayer was designed and manufactured by HARDI EVRARD to operate in conjunction with treatment products selected

by you. For the correct operation of your sprayer, we ask you to adhere strictly to our recommendations, as set out in the

User Manual which was given to you when you purchased the sprayer.

But it is your responsibility alone as the user to comply strictly with the recommendations given by the manufacturers of the

treatment products you use.

In particular, it is strongly recommended that every user should:

• Carefully read the manufacturer's labels on the treatment product(s) used and follow the instructions given (dosage,

personal protection equipment, etc.);

• Only mix together products whose compatibility is expressly recognised by the manufacturer of the phytosanitary

products;

• Avoid mixing in air when filling your sprayer's tank and so prevent the formation of foam and problems with overflows;

• Follow the precautions for use and warnings given by the phytosanitary product manufacturer for the storage of the

treatment products and always use locked premises with no access for children or animals;

• Take precautions relating to the re-processing of packaging, following the recommendations given by phytosanitary

product manufacturers;

• Respect untreated areas;

• Contact the phytosanitary product's manufacturer (or its representative), if there is any doubt or missing information.

Before using the sprayer, also read the following supplementary recommendations and safety instructions:

• Read this instruction manual carefully before using the equipment. Anyone likely to use it must also read the manual.

If there are any points in the manual which you do not understand, contact your dealer to obtain additional

information before you use the equipment.

• Legislation may require the operator to be in possession of a proficiency certificate in the use of the equipment.

Comply with current legislation.

• The driver's seat constitutes the work station during treatment.

• Wear protective clothing. Clothing may vary, depending on the phytosanitary products used. Comply with current

legislation.

After treatment, wash and change your clothes. Clean the equipment, as it may have become dirty.

• You should neither eat, drink nor smoke while using or maintaining your equipment.

In the event of poisoning, call a doctor or the emergency medical service, (see the information on the packaging for

the products used).

9

Page 10

2- Safety instructions

Filling and application

• No one should remain within the sprayer's operating perimeter. Be careful not to injure anyone or damage anything

when manoeuvring the equipment, especially when reversing.

• Slow down when driving over uneven ground; the sprayer could become unbalanced and tip over.

• Keep children away from the sprayer!

• Do not attempt to enter the tank.

• Do not pass underneath the equipment, unless it has been made secure. The boom is secure when it rests on the

transport supports.

• For more information, refer to the Application Techniques Manual.

Use

This HARDI EVRARD trailed sprayer is intended exclusively for use in agricultural work, i.e. the application of phytosanitary

products and liquid fertilisers.

Any other use is considered to be outside the scope of normal use and is therefore prohibited.

• Check the pressure using clean water before adding the products to the tank. Never disassemble the tubes while the

sprayer is in operation.

• DANGER! Do not exceed the pump's maximum recommended rotation speed.

• Rinse and clean equipment after use and before carrying out any maintenance.

• Never do any maintenance or make any repairs while the equipment is in operation. Always replace safety equipment

and other guards immediately maintenance work or repairs are complete.

• Disconnect the electrical supply before doing any maintenance and de-pressurise the equipment after use and before

maintenance.

• If you are using an arc welding set on any part of the sprayer, you must disconnect the electrical supply from the

battery before starting welding. Ensure that no inflammable or explosive material is in the vicinity of the welding.

• Do not use external cleaning equipment if parts of the equipment are damaged, in particular safety equipment, highpressure hoses, etc.

• You should take all precautions against the risks associated with unintentional contact with overhead power lines. A

sticker in the tractor cab draws the user's attention to the risk of contact with overhead power lines.

Using the sprayer

This HARDI EVRARD self-propelled sprayer is intended exclusively for use in agricultural work, i.e. the application of

phytosanitary products and liquid fertilisers.

Any other use is considered to be outside the scope of normal use and is therefore prohibited.

Operator qualification

The machine must be used and maintained by persons who are familiar with all the particular characteristics of using it

safely.

Before using your machine, familiarise yourself with all the controls. When you are working, you will not have time to do this.

Ensure that you have the necessary skills to protect crops and the environment when handling and spraying phytosanitary

products. For more information on personal protection and protecting the environment, refer to the APPLICATION

TECHNIQUES manual.

10

Page 11

2- Safety instructions

DANGER !

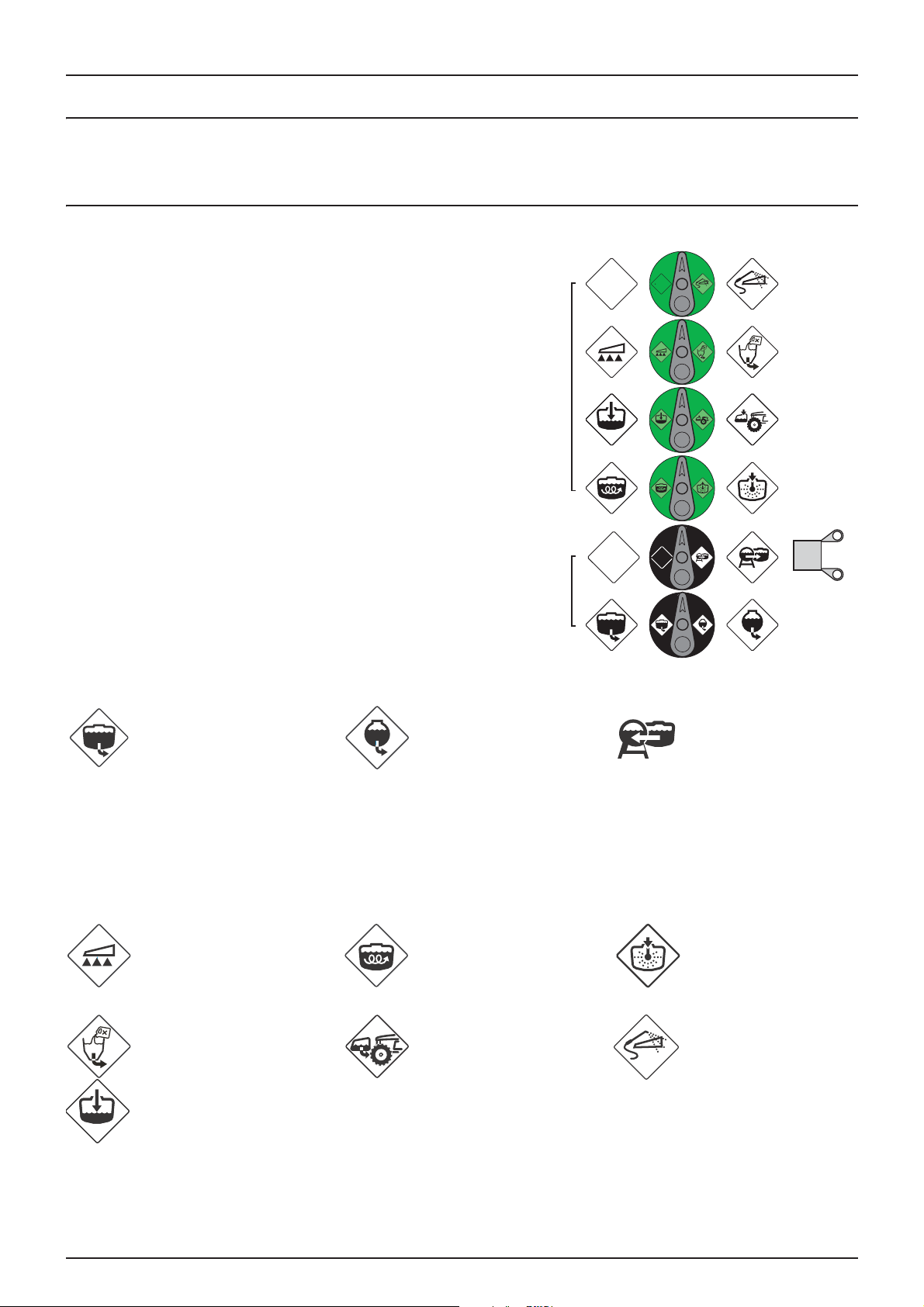

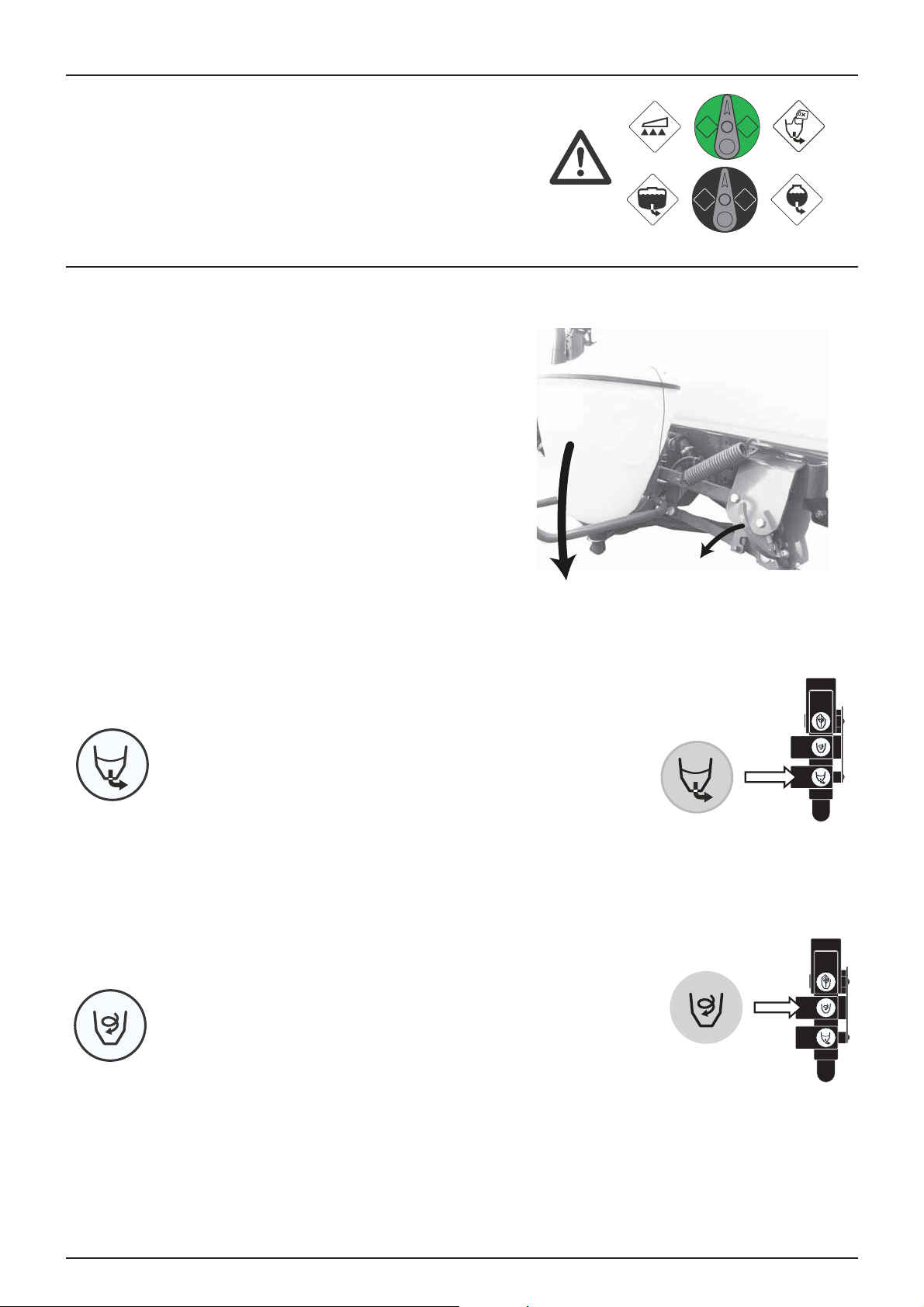

Safety pictograms

Safety pictograms indicate the various parts of the sprayer that could present a risk to your safety. These pictograms must

be complied with by anyone working on or close to the machine.

The safety pictograms must always be clean and readable. Worn or damaged stickers must be replaced. Your distributor can

supply you with new stickers.

NOTE! The list of warnings given below may vary according to the equipment.

÷

Clean water not for drinking!

Fill the rinsing tank and the hand wash tank

with clean water only.

This water must not be drunk.

Service!

Stop the engine and remove the ignition key

before doing any maintenance or repairs.

Service!

Tighten to the torque indicated in the user

manual.

Risk of crushing!

Keep hands out.

Risk of electrocution!

Keep well away from power lines.

Anchor point!

Risk of falling!

Do not stand on the platform or ladder during

use.

Risk of tipping over!

Be careful when uncoupling the sprayer.

Risk of crushing!

Do not stand under a raised and unsecured

load.

Risk of intoxication!

Entering the tank prohibited!

Handling phytopharmaceutical products!

Read recommendations relating to the

preparation of products carefully prior to

using the equipment. Follow the instructions

and safety advice during operation.

Regulations on the use of phytosanitary effluent

For more information on the use of effluent, refer to the APPLICATION TECHNIQUES manual in the 'Environmental Protection'

section.

11

Page 12

2- Safety instructions

12

Page 13

3 - Description

General information

Using the sprayer

This HARDI sprayer was designed for the application of phytopharmaceutical products and liquid fertilisers. It should be

used for this function only. Its use for other purposes is prohibited. If current regulations do not require you to obtain an

approved application certificate, it is still strongly recommended that you keep up to date your knowledge of protecting

crops and handling phytopharmaceutical products, to ensure the safety of persons and the environment during treatment.

Driving on the road

When you drive on a public road, you must follow the Highway Code and/or any other regulation applicable, especially

where required equipment is concerned, such as lighting, signalling, etc.

IMPORTANT! The maximum permitted speed for a tractor hitched to a towed sprayer is 25k.p.h. (French law). This

speed may differ in other countries. Check on the maximum permitted speed with the relevant authorities.

Ta nk

Made of impact-resistant polythene, resistant to UV light and chemicals, the main tank is round in shape to facilitate

cleaning. The manhole is accessible from the platform. This provides easy access for filling, cleaning the tank, etc. The sprayer

also has a rinsing tank and a hand wash tank. An optional gauge, easy to read and visible from the tractor cab, can be fitted

beside the platform.

Nominal capacity 2,500 litres.

Chassis

Compact and extremely robust, it is covered with an electrostatic lacquer which is resistant to chemicals and weather.

Bolting is treated with Delta-Magni against corrosion.

13

Page 14

3 - Description

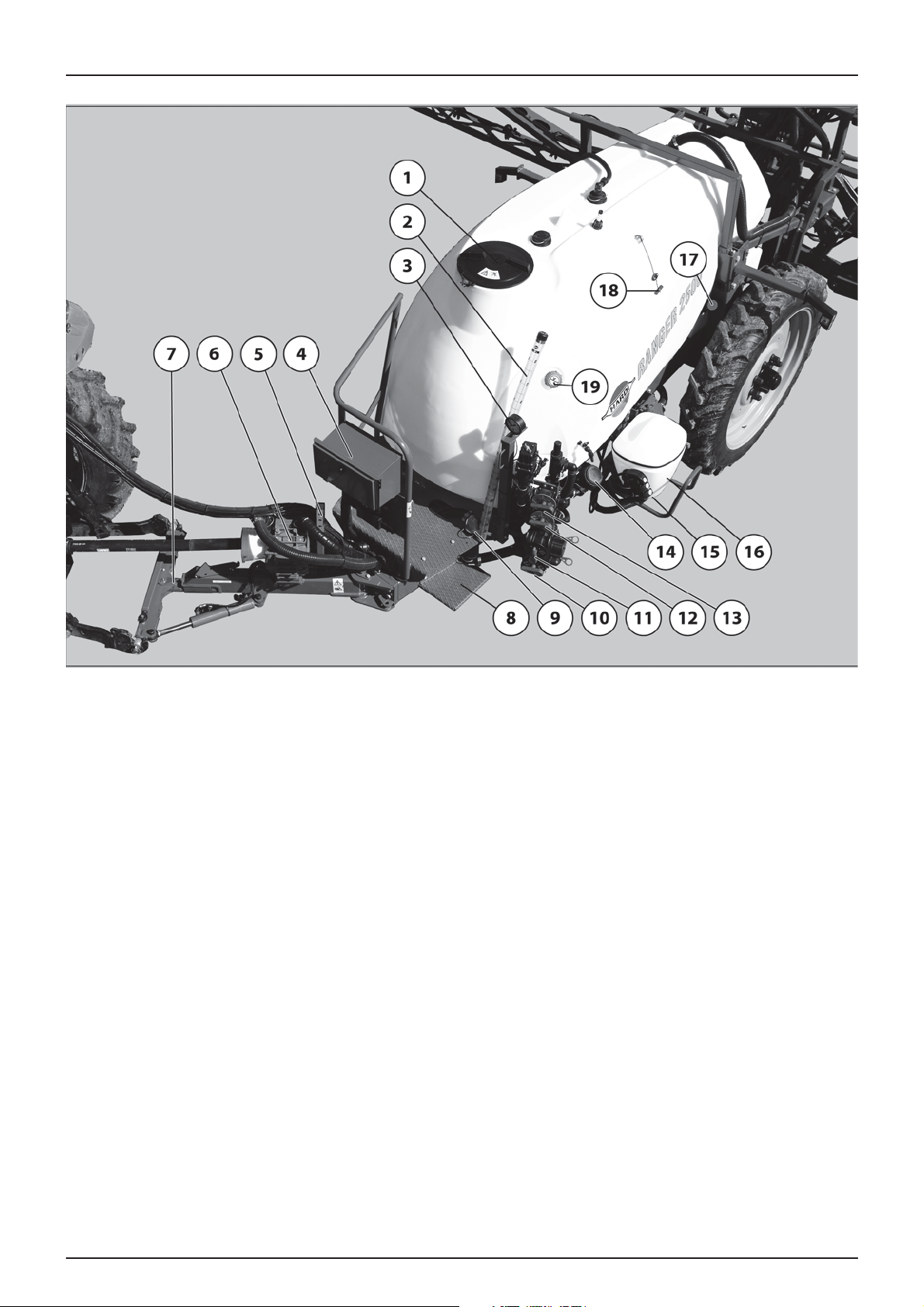

General view

1. Main tank cover

2. Main tank gauge

3. Pressure gauge

4. Storage box (optional)

5. Support leg

6. Pump

7. Hitch

8. Step

9. Suction filter

10. Suction valve

11. External filling valve

12. Agitation valve

13. Pressure valve

14. Cyclone filter

15. TurboFiller controls

16. TurboFiller

17. Rinsing tank cover

18. Drain valve control

19. Hand wash tank cover

14

Page 15

Identification plates

3 - Description

An identification plate, fixed to the chassis, indicates the manufacturer's

name, the model, the weight when empty, maximum height and the

maximum pressure in the hydraulic system (where there is one) and

spraying system.

The SERIAL NO. is the number for the complete equipment.

The chassis, boom frame and other main steel components also carry

identification plates showing the model and the part no. (not shown).

REFERENCE NO.: is the reference number for the basic chassis.

*1A500*- RG25- ALS

HARDI-INTERNATIONAL A/S

Marque : EVRARD

Type Variante Version

Année fabrication

Masses maximales admissibles

Essieu 1/attelage

Essieu 2

Essieu 3

RG25 ALS

2012

1200

4500

HELGESHOJ ALLE 38. DK263, DENMARK

kg

kg

kg

1A500

N° de série

2310

PV

5080

PTAC

PTRA

Réceptionné le

par la DRIRE

11/05/2012

GRAVELINES

kg

kg

kg

The CE identification plate fixed to the chassis shows the sprayer's

manufacturer, model and serial number.

15

Page 16

3 - Description

Spraying system

Pump

Six diaphragm pump, model 363 Standard = 540 rpm (6 splines). The design of the diaphragm pump is simple, with easily

accessible valves and diaphragms which isolate the moving parts from the mixture.

Valves and pictograms

The valves and pictograms are identified by a different colour for

different functions. The pictograms facilitate the operation of the valves.

The modular MANIFOLD principle facilitates the addition of optional

suction and discharge equipment. A return valve may be fitted on the

suction valve to improve draining of the sprayer prior to cleaning.

To activate a function, simply turn the handle to the desired function.

B

A. Suction valves (main and rinsing tanks, external suction).

B. Pressure valves (spraying, agitation, incorporation of products, tank

rinsing and equipment cleaning).

A

Suction MANIFOLD valves (A) - black disc

The arrow indicates the active function. Turn the handle to point the

arrow to the pictogram of the function required. If the arrow points to a

position without a pictogram (function not used), the valve is closed.

From the main tank From the rinsing tank From an external source

IMPORTANT! If a valve is difficult to turn or, conversely, turns too easily (= leak) - it should be checked. For more

information, refer to the "Maintenance" section.

Pressure MANIFOLD valves (B) - green disc

The arrow indicates the active function. Turn the handle to point the arrow to the pictogram of the function required. If the

arrow points to a position without a pictogram (function not used), the valve is closed.

To the spraying boom To the main tank agitation To the tank rinsing nozzle

To the product filler To a front tank External cleaning gun

16

Main tank filling

Page 17

3 - Description

Electrically controlled MANIFOLD valves (optional)

One or more Manifold valves may be fitted with an electrical control from a unit in the cab. To operate them manually, the

motor(s) must be disconnected from the power.

Regulation

The sprayer is equipped with EVC regulation.

Regulation is by EVC - Electrical valve control. The O/C (open/closed) control acts directly on the distribution valves,

providing a very quick response time. The setting unit, modular in design, is controlled electrically from a control unit in the

cab.

Diagrams - spraying system

Refer to sections Basic spraying system page 80 and Spraying system with options page 81

Filters

A suction filter is fitted on the left hand side of the sprayer, just in front of the MANIFOLD valves, recognisable by its red elbow

connection.

A Cyclone pressure filter is located on the left hand side of the equipment, just behind the Manifold valves. It has a built-in

self-cleaning function.

Optional boom filters can be fitted on each section..

All nozzles are fitted with filters.

All filters must be in good condition, in position and cleaned regularly. Take care with the choice of mesh size (see

"Application Techniques" manual).

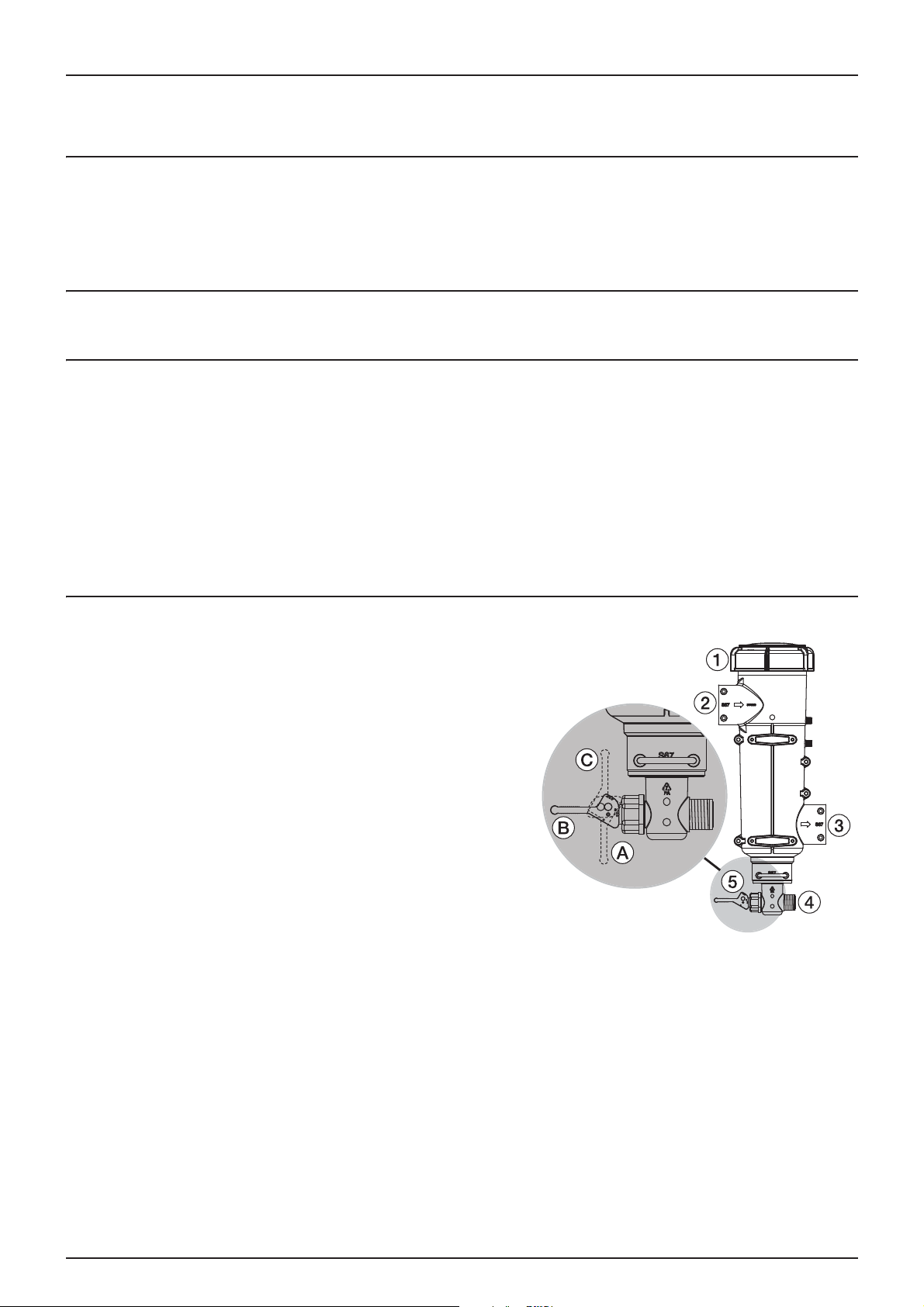

Cyclone Filter (optional)

With the Cyclone filter, all impurities contained in the mixture are

returned to the tank.

Operating diagram

1. Filter cover

2. Intake for the mixture from the pump

3. Outlet to the boom

4. Tank return

5. Return valve

The valve (5) has three positions identified by dots on the side of the

lever.

A. This position is marked with a dot: No return to tank. Position used

to rinse the boom when the tank is full. Or to have the pump's full

capacity available.

B. This position is marked with two dots: Normal working position. With a return to tank to prevent any blockage during

treatment. Position also used to rinse the boom when the tank is empty.

C. This position is marked with three dots: Turbo function to unblock the filter. Lift and hold the lever for a few moments.

The increased return to the tank cleans the filter.

IMPORTANT! The use of position C does not guarantee that the filter is clean. Check the condition of the filter and

clean it regularly. If necessary see Every 10 hours - Cyclone filter page 58.

17

Page 18

3 - Description

A

B

DANGER! Never open the Cyclone filter before valves (1) and (2)

€

are closed (turned to the neutral position). Otherwise, the

mixture could escape and splash you through the filter cover.

TurboFiller

Before use

Pull the lever (A) to unlock.

Use the handle (B) to lower the TurboFiller until it locks in the down

position.

After use

Use the handle to lift the TurboFiller back to the upper position

until it locks into place.

WARNING! Before using the unlocking lever (A), you must hold

±

the handle to prevent any unwanted movement of the

TurboFiller!

TurboFiller suction valve

The locked opening valve is used simultaneously with the TurboFiller. It is opened just

before pouring the products into the filler.

Adding products without using the Turbo deflector.

Turbo deflector control

When locked in the open position, this valve activates a continuous vortex at the bottom

of the TurboFiller hopper.

Turbo deflector control

18

Page 19

Package and drum rinsing control

The upper lever has two functions:

1. When the TurboFiller lid is open, it can be used to clean empty packages by turning

drums upside down over the rotary rinsing nozzle in the middle of the hopper.

When the TurboFiller lid is closed, it rinses the hopper after the products have been added

to the tank.

Rinsing product packaging and drums

For more information on using the rinsing control, refer to section Cleaning the TurboFiller page 46

3 - Description

19

Page 20

3 - Description

AB C

D

Boom

Boom and terminology

The sprayer is equipped with a TR2 boom. It is held by trapeze arms fixed to the tank's chassis.

The trapeze arms allow the boom to remain horizontal when unfolded and protect it from impacts and vibrations on uneven

terrain. They ensure the longevity of the boom and improve its stability, resulting in more accurate application.

Booms are available in 18, 20, 21, 22 and 24m working widths. All booms are fitted with folding end arms.

The terminology for dual-fold booms is as follows

A - Folding end arm

B - Outer arm

C - Inner arm

D - Central section

Model

Equipment

Function control Tractor valve

Independent folding of

the ends

Hydraulic tilt corrector

Boom tilt

1 single acting control valve

Tractor valves

1 double acting control valve

TR2 Y TR2 V TR2 Z

control

optional

Tractor valve

control

By hydraulic solenoid valves

and unit in the cab

no yes

yes

no

1 single acting control valve

+

+

free return

yes

20

Page 21

Equipment

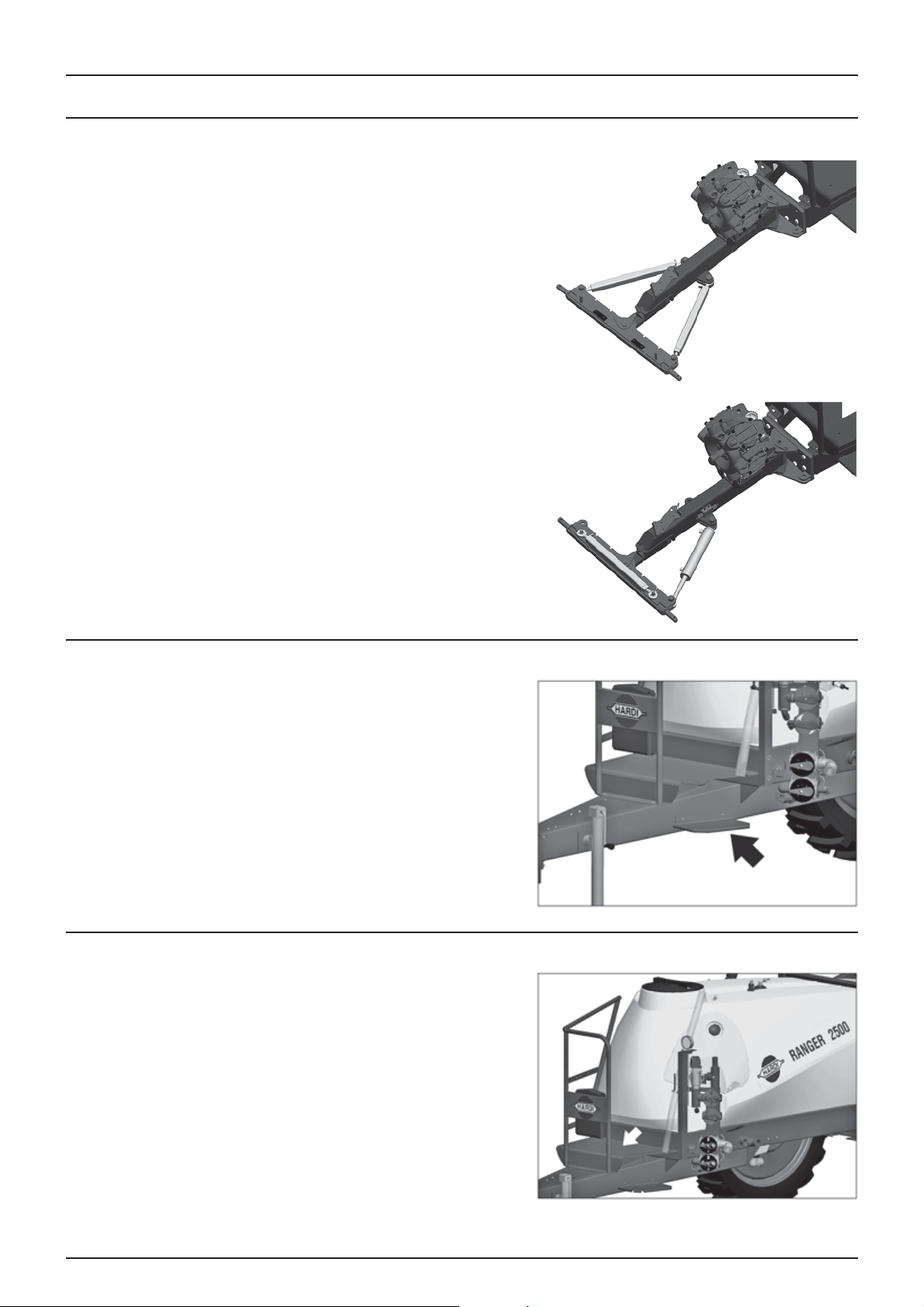

Hitch with hydraulic drawbar (optional)

The sprayer can be equipped with a hitch with a hydraulic drawbar. This

allows the sprayer to be turned a little later when the tractor starts to

turn at headlands, compared to a conventional hitch tongue. This results

in a tighter turning circle, allowing the size of headlands to be reduced.

It also makes traces in the headlands easier to follow.

The articulated hitch with tilt correction has an offset correction device.

The hitch carries out the same function but the tilt correction allows it to

also be used on slopes.

IMPORTANT! The offset correction is controlled by the tractor's

hydraulic control valves.

3 - Description

Step

A step on the left hand side of the sprayer gives access to the platform.

Platform

The platform provides access to the lids on the hand wash tank and the

main tank.

21

Page 22

3 - Description

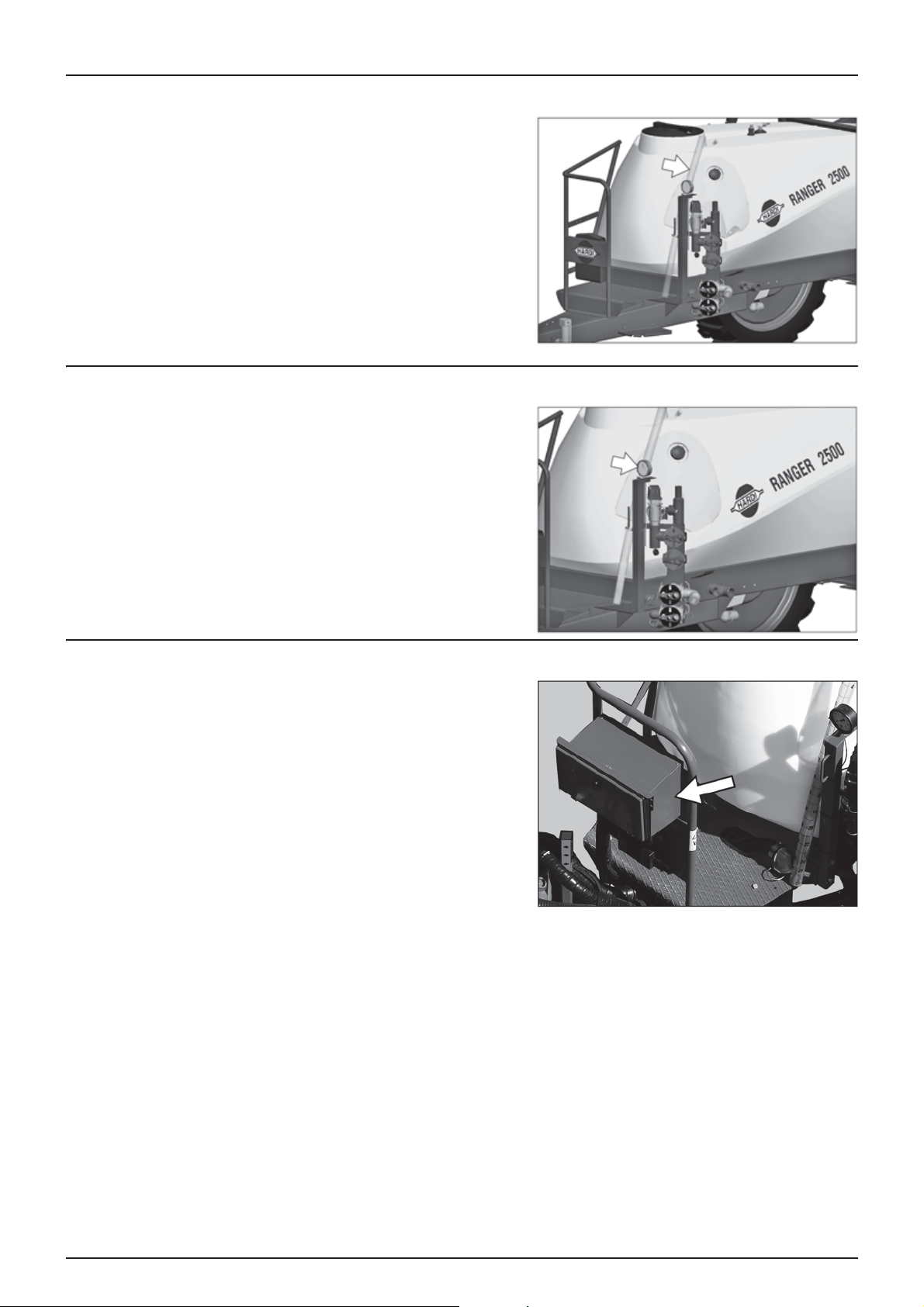

Main tank gauge

The gauge indicates the level of the mixture in the main tank. The scale

is written in litres or Imp./US gallons (for some countries).

The gauge is only an indication of the level in the tank. The total

variation in the accuracy of the level is 7.5% for a tank filled to less than

20% of its capacity. For a tank filled to more than 20%, the accuracy

variation is 5%.

IMPORTANT! For greater accuracy, a filling meter can be fitted as

an option.

Boom pressure gauge

The pressure gauge is located on the platform, above the Manifold

valves. It measures the working pressure in the boom's pipes right next

to the nozzles.

The flow rates shown in the nozzle flow tables are always calculated

according to the pressure measured at the nozzles. When calibrating, as

when working, the pressure should be set using this gauge.

Storage box (optional)

A storage box can be fitted to the platform rail. It is intended for the

storage of protective equipment such as clean clothing, soap for hand

washing, etc. The box is divided into two compartments, allowing clean

items to be separated from dirty ones.

WARNING! Although the box is intended for storing clean items,

±

it should never be used for storing food, drinks or any other

consumable.

22

Page 23

3 - Description

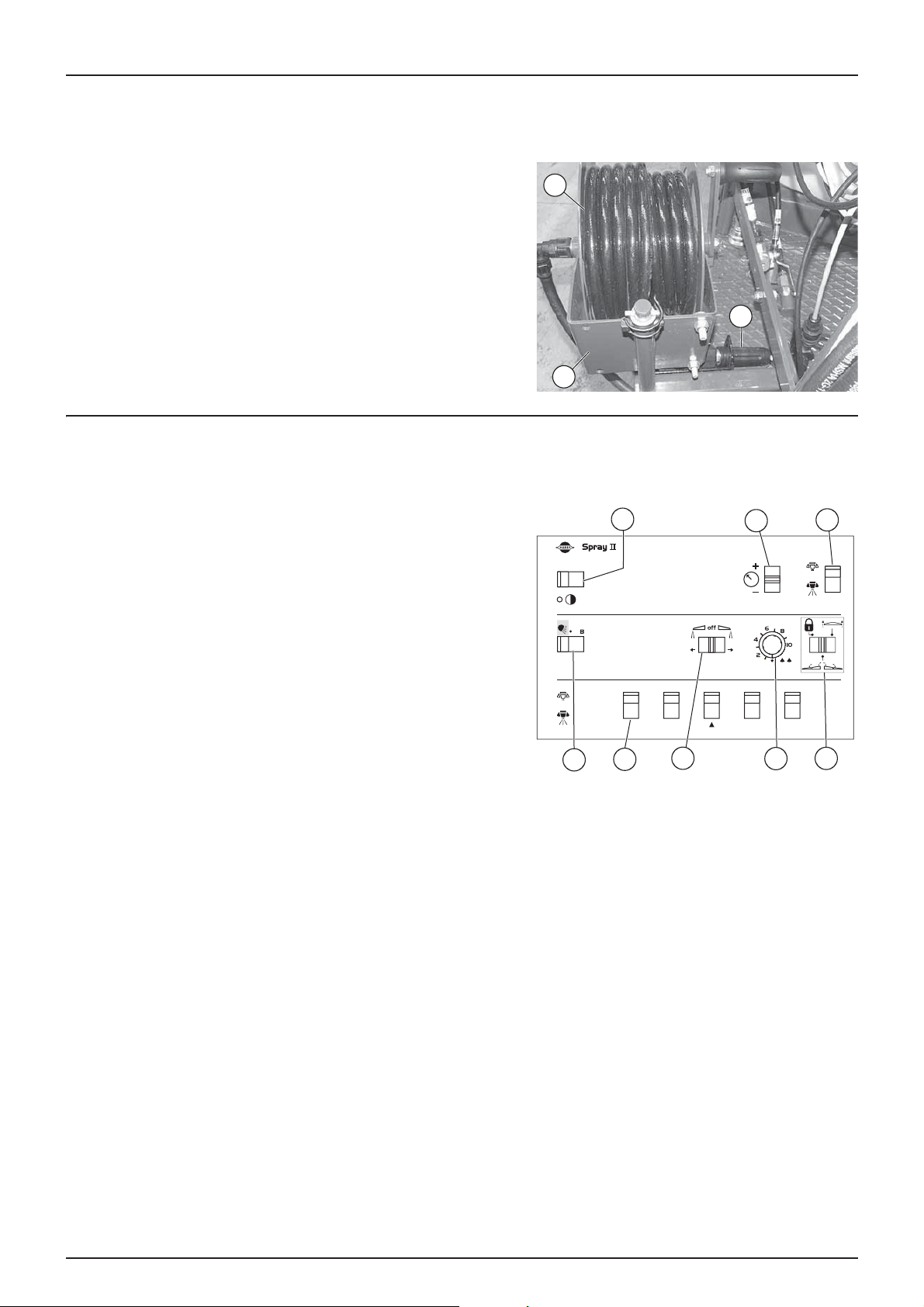

1

7

5

4

6

8

2

3

External cleaning equipment (optional)

This equipment comprises a reel with a hose and a spray gun for rinsing the sprayer with clean water while still in the field.

The external cleaning equipment is located to the right of the sprayer.

1. Reel

2. Spray gun

3. Rotating hose reel bracket

For information on using the hose reel, refer to the relevant section.

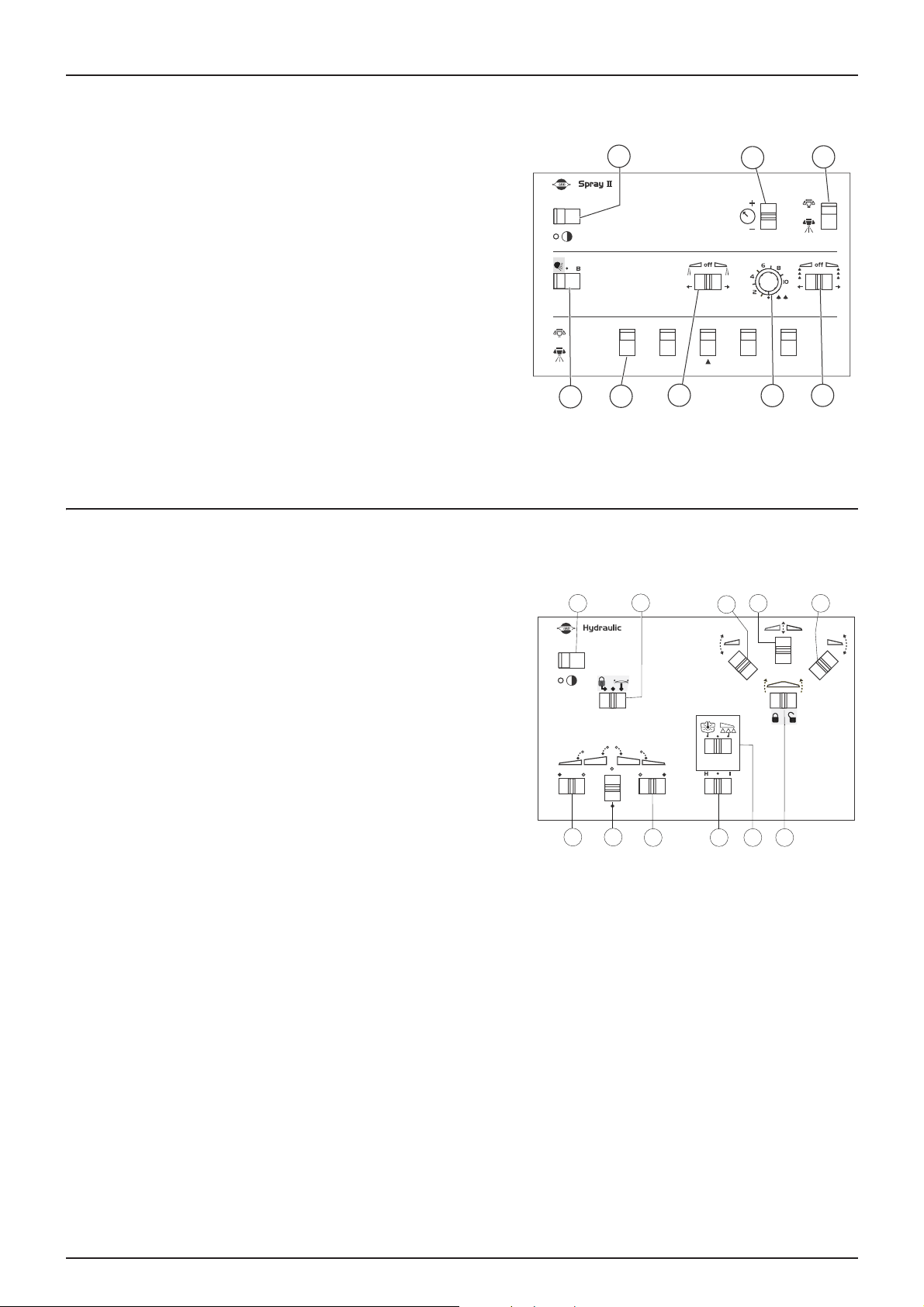

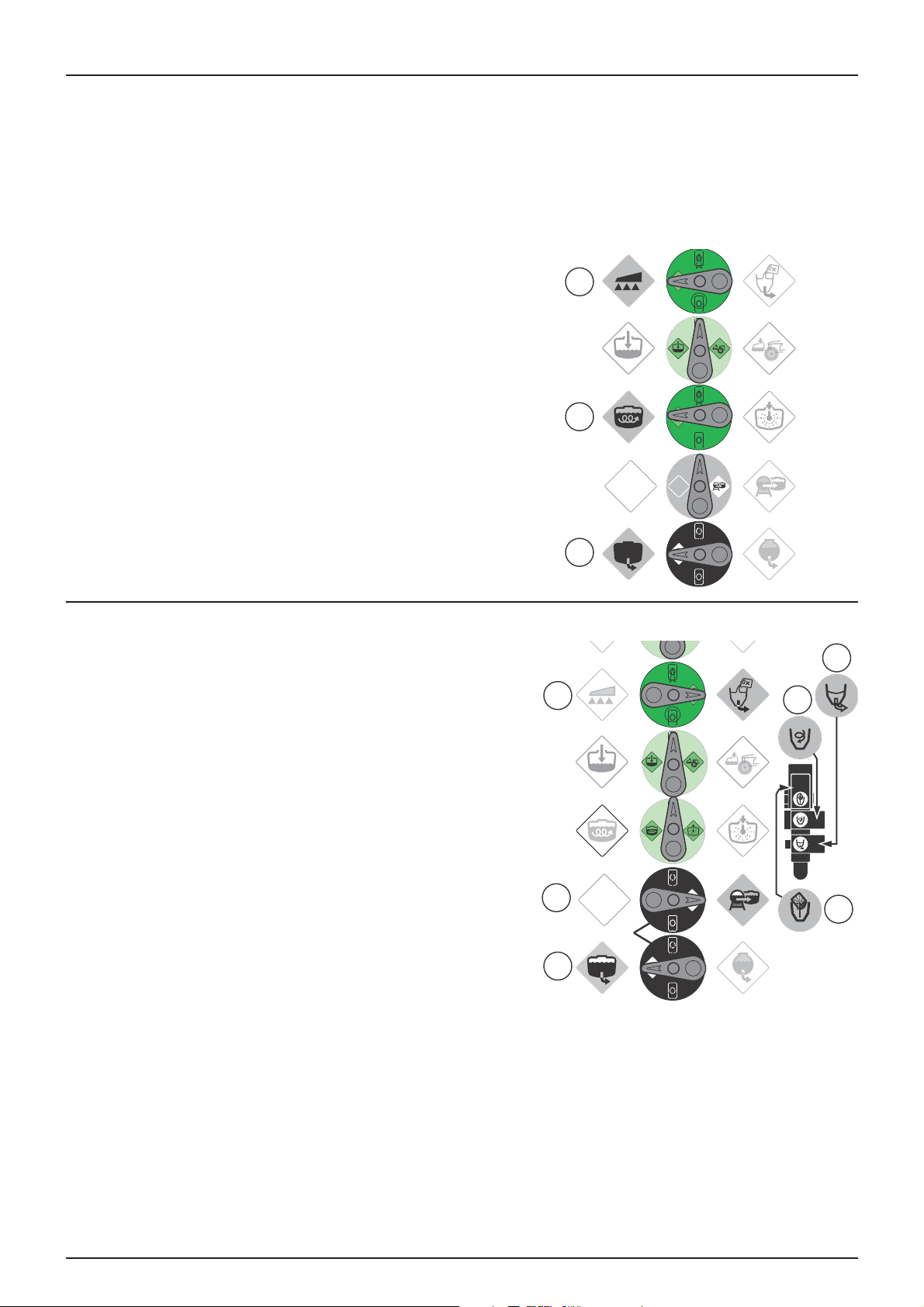

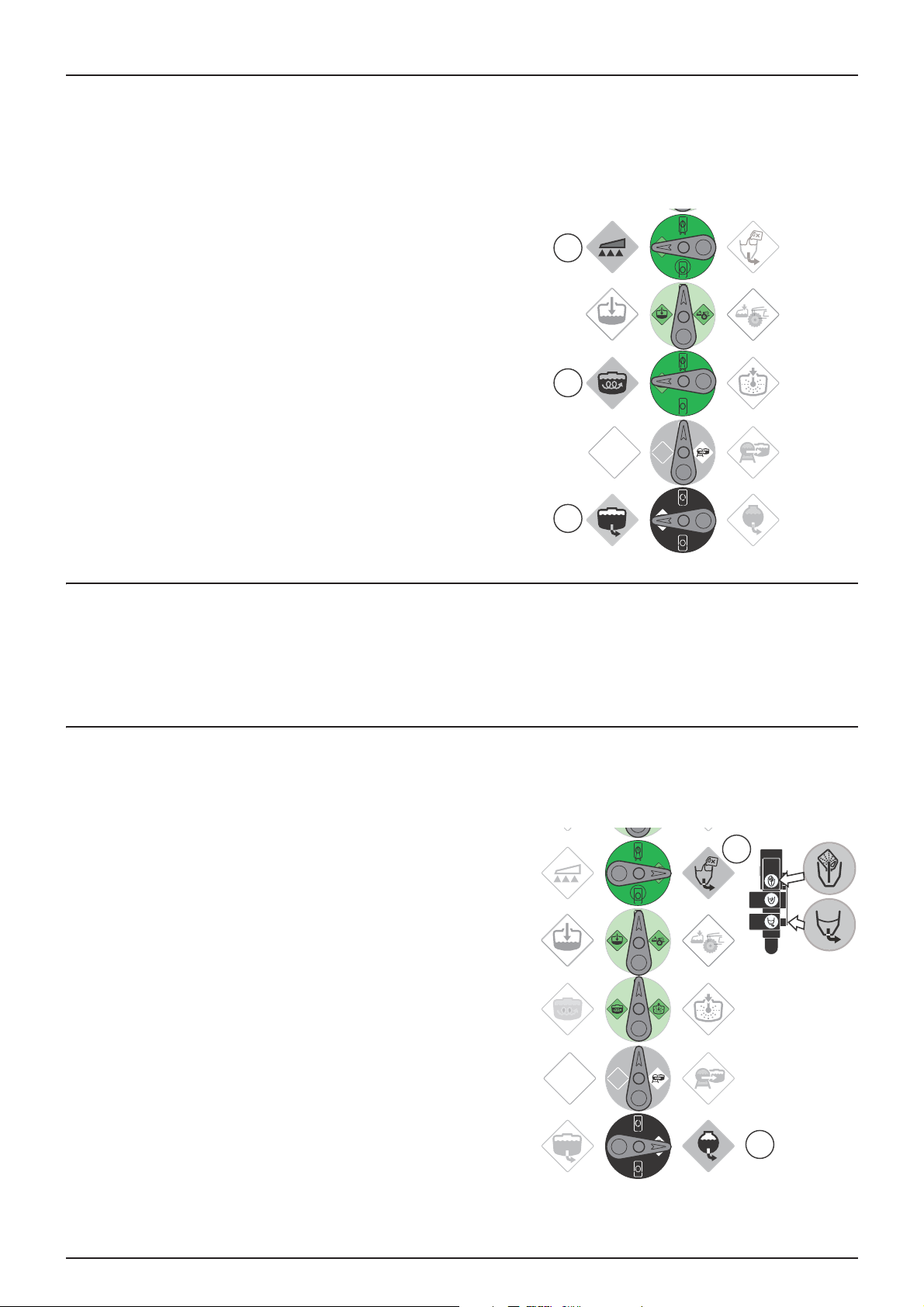

TR2 Y version control unit

'Sprayll' hydraulic and spraying control

The switches on the Spraying unit control the following functions:

1

2

3

1. Switching on the unit.

2. Regulating the working pressure. Regulates the working pressure.

3. General spraying Open/Closed. Opens or closes all sections.

Closed position at the top and Open position at the bottom.

4. End nozzles (Left/OFF/Right). If end nozzles are fitted, opens them

on each side. Closed position in the middle.

5. Not used

6. Central frame locking selection - Boom Open/Closed - Tilt

7. Individual spray section control valves Open/Closed.

Closed position at the top and Open position at the bottom.

8. Boom lights (optional)/Tank bottom dilution (optional)

For more information on using the spraying functions, refer to section Spray controls page 48

For more information on using the hydraulic functions, refer to section TR2 Y boom hydraulic controls page 37

23

Page 24

3 - Description

1

7

5

4

6

8

2

3

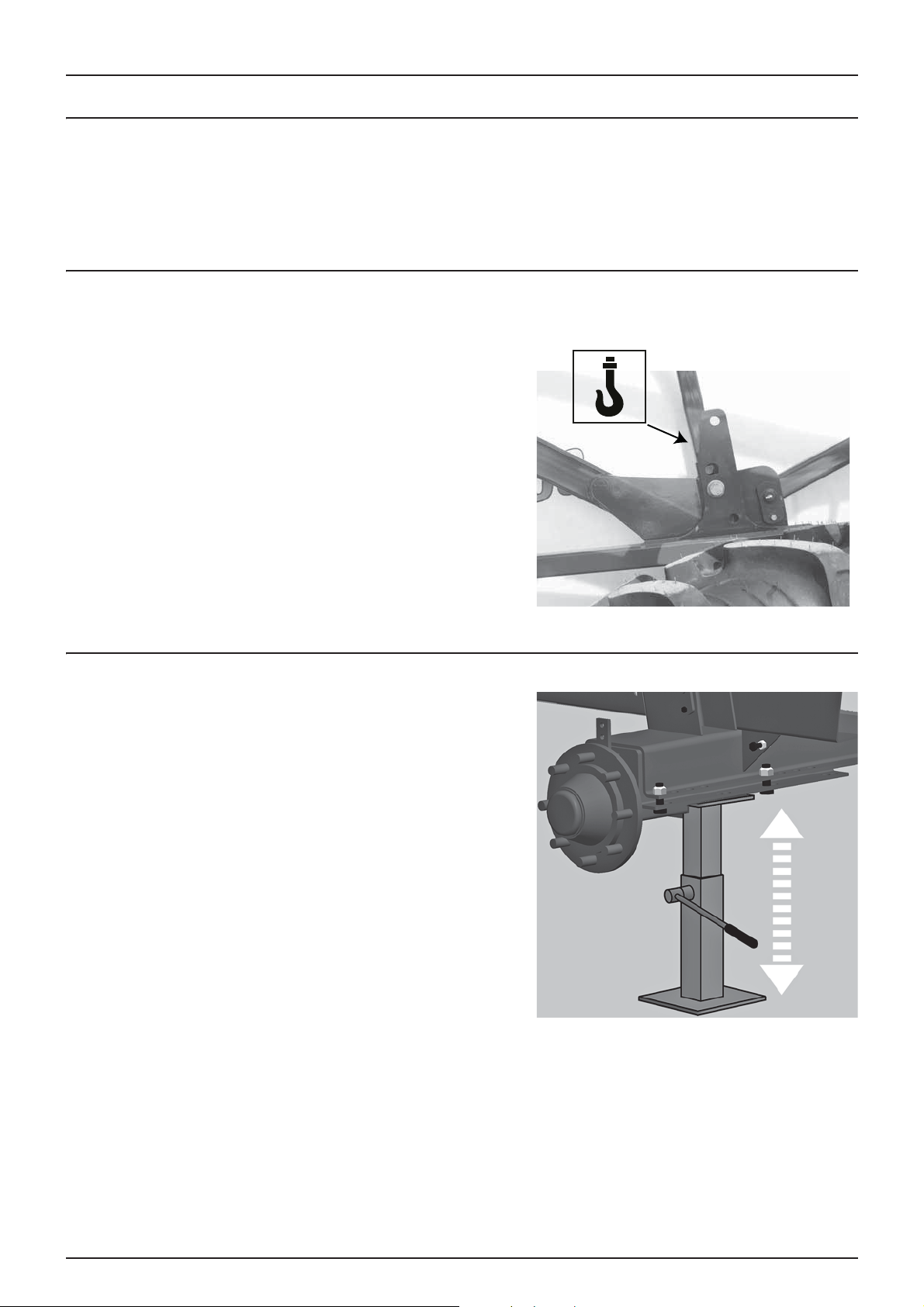

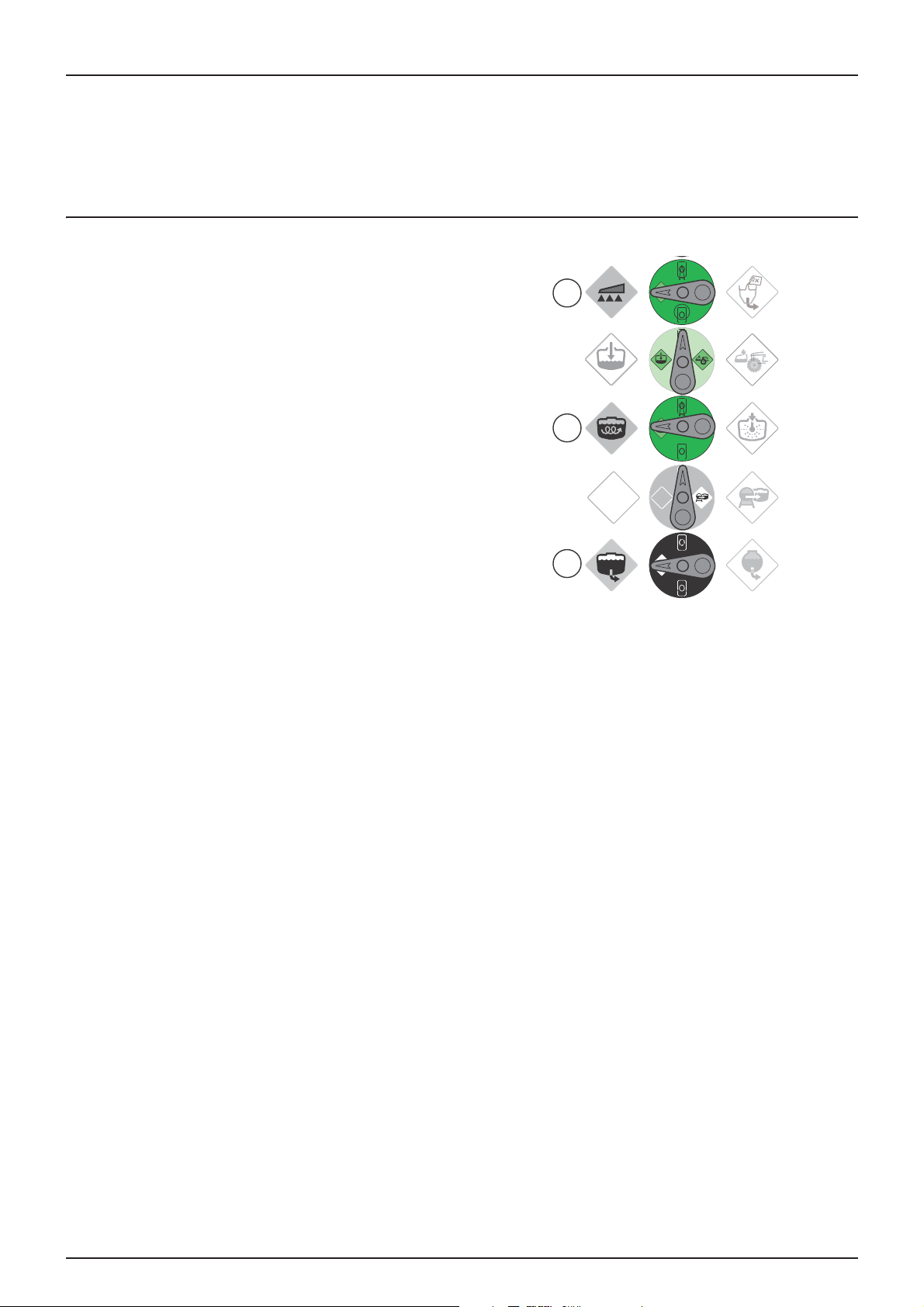

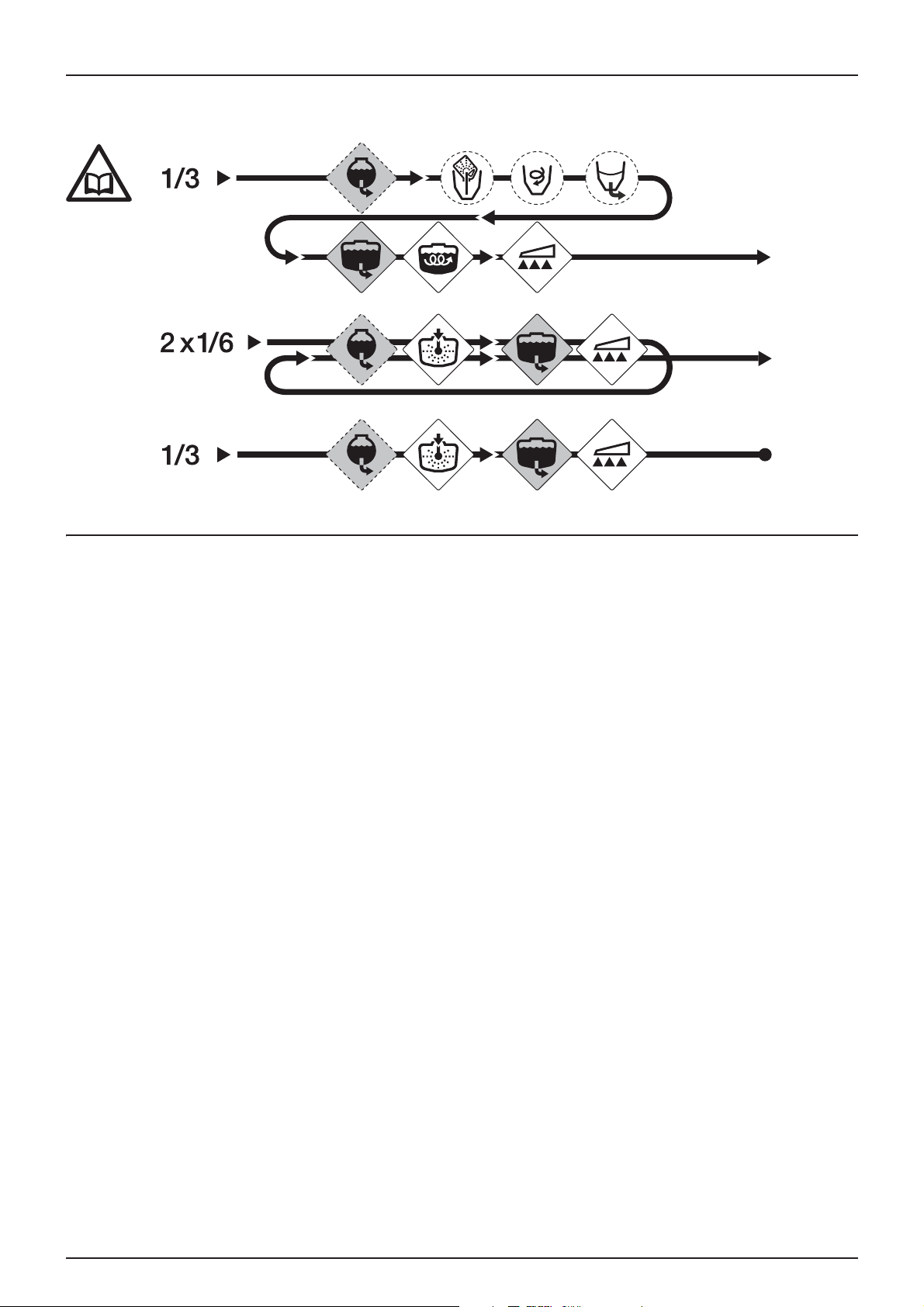

'Sprayll' spraying control

The switches on the spraying control unit control the following functions

1. Switching on the unit.

2. Regulating the working pressure. Regulates the working pressure.

3. General spraying Open/Closed. Opens or closes all sections.

Closed position at the top and Open position at the bottom.

4. End nozzles (Left/OFF/Right). If end nozzles are fitted, opens them

on each side. Closed position in the middle.

5. Not used

6. Not used.

7. Individual spray section control valves Open/Closed.

Closed position at the top and Open position at the bottom.

8. Boom lights (optional).

For more details on using the spraying functions, refer to section Spray controls page 48

'Hydraulic' control

The switches on the hydraulic control unit control the following functions:

1. M/A supply

2. Selection of central frame locking or tilt correction

3. Left boom tilt - TR2 Z version only

4. Boom raise/lower

5. Right boom tilt - TR2 Z version only

6. Fold out/fold in left arm

7. Inner arm simultaneous fold out/fold in

8. Fold out/fold in right arm

9. Hydraulic drawbar

10. Tank bottom dilution (optional)

11. Central frame locking/tilt correction control

For more information on using the hydraulic functions, refer to section TR2 V and TR2 Z boom hydraulic controls page 39

1

6

2

H2o

7

8

3

H2o

9

4 5

11

10

24

Page 25

4 - Sprayer set-up

General information

Precautions before use

Although the sprayer is factory protected with a resistant coating on its metal parts, nuts and bolts etc., it is recommended

that you apply a coat of anti-corrosion oil (Castrol Rustillo or Shell Ensis Fluid) to all metal parts, to prevent agropharmaceutical products and liquid fertilisers from discolouring the paintwork.

If you do this before you use the equipment for the first time, future cleaning will be easier and the paintwork will not dull.

Re-apply the treatment regularly, as soon as the protective film disappears.

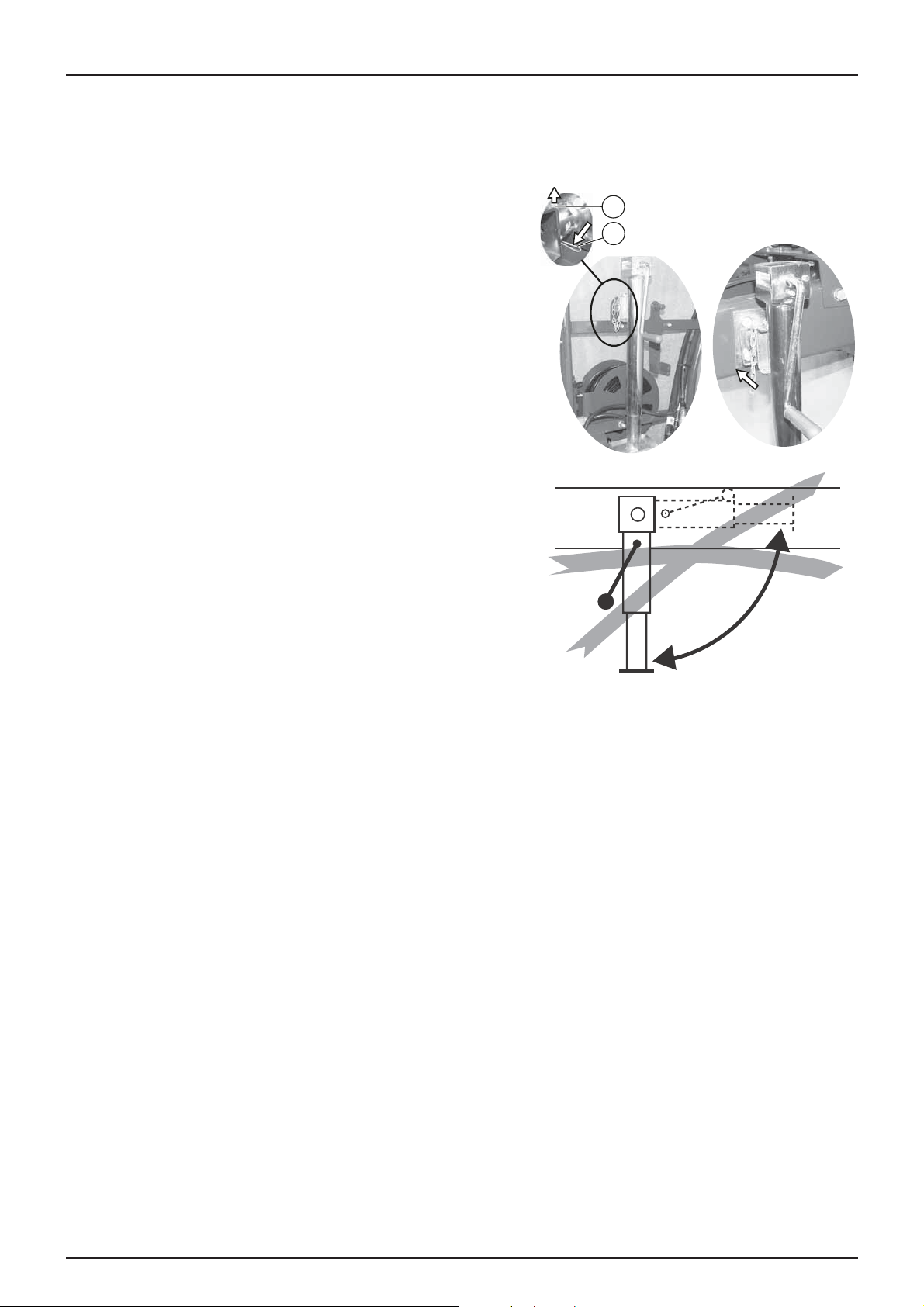

Unloading the sprayer

Unloading may require the use of a crane or forklift truck. If this is the

case, use the anchor points provided for this purpose. Ensure the slings

or chains used can support the load.

IMPORTANT! only lift the sprayer when the tanks are empty.

Lifting the sprayer with a jack

To change a wheel, replace a bearing, etc., lift the sprayer by positioning

the jack under the axle as shown.

DANGER! The sprayer must be placed on firm level ground, so

€

that it will not fall off the jack.

IMPORTANT! For greater safety, chock the opposite wheel!

25

Page 26

4 - Sprayer set-up

Support leg

NOTE! The strength of the support leg and the jack is designed to support the weight on the hitch tongue, on flat

÷

ground, when the tank is full.

To position the support leg:

1. Remove the pin (1) and pull the shaft (2)

2. Position the support leg with the shaft on the hitch tongue,

replace the pin

3. Turn the handle to lower the support leg to the ground.

4. When the leg is fully supporting the sprayer, you can unhitch the

sprayer from the tractor.

When the sprayer is hitched to the tractor, the leg is positioned on the

support provided for this purpose.

2

1

26

Page 27

4 - Sprayer set-up

Transmission shaft

User safety

1. ALWAYS SWITCH OFF THE ENGINE before connecting the transmission shaft to the tractor's PTO drive - most PTO drive

can be rotated by hand to make it easier to align the splines.

2. When you connect the shaft, check that it is LOCKED. Push and pull the shaft until it engages.

3. Keep guards and chains in good condition and check that all rotating parts are properly protected, including the

journal crosses at each end of the shaft. Do not use the transmission shaft without guards.

4. Do not touch the transmission shaft while it is rotating. Do not climb on it. Safety distance: 1.50m. NEVER step over a

rotating shaft to get to the other side of the equipment.

5. To prevent guards from being pushed out of the way, attach safety chains but leave sufficient slack.

6. Check that the guards around the tractor's PTO drive and shaft on the equipment side are in good condition.

7. ALWAYS STOP THE ENGINE and remove the ignition key before doing any maintenance or repair to the shaft or the

equipment.

DANGER! UNGUARDED ROTATING TRANSMISSION SHAFTS ARE A DANGER TO LIFE.

€

Connecting the transmission shaft

Always check the manufacturer's user manual before connecting the

transmission shaft!

When you connect the shaft for the first time, follow this procedure:

1. Hitch the sprayer to the tractor and position it with the tractor and

the PTO drive on the spray pump side as close as possible.

2. Stop the engine and remove the ignition key.

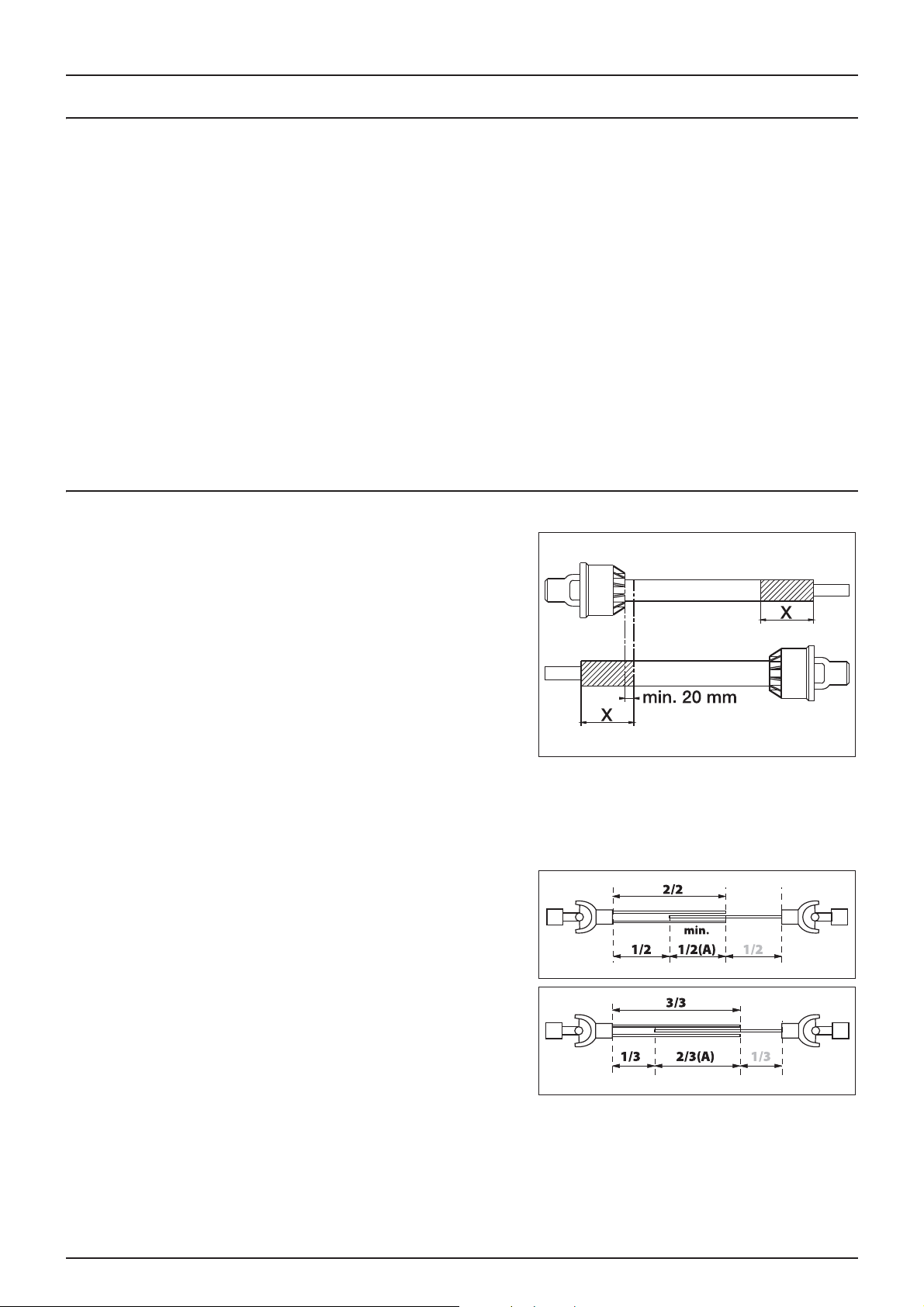

3. To shorten the transmission shaft, separate the two parts of the

shaft. Fit the two parts on the tractor side and sprayer side and

measure by how much you need to shorten the shaft. Mark the

guards, so that they can be shortened by the same amount.

WARNING! Only shorten the shaft if absolutely necessary!

±

WARNING! The shaft must always have a minimum overlap of half its length!

±

The overlap (A) recommended between the two parts of the shaft

equals two thirds of its total length. The minimum overlap (A) must be

half the length.

DANGER! Since transmission shafts are potentially dangerous,

€

always consult the manufacturer's user manual before making

any modification.

27

Page 28

4 - Sprayer set-up

The transmission shaft's speed is limited to 540 rpm.

A pictogram reminds you of the dangers and the speed limit relating to transmission shafts. A speed greater than

€

540 rpm could cause serious injury by damaging components on the sprayer or the transmission shaft.

28

Page 29

4 - Sprayer set-up

Mechanical equipment

Hitches

The hitch is equipped with a ring as standard, or with an optional articulated system with or without offset correction.

All hitches are fixed using six bolts secured by locknuts under the sprayer, close to the rear axle. Also, the hitch is supported

by two bolts secured by locknuts under the platform.

Ring hitches have an extension piece, secured with six bolts.

1. Ring hitch

2. Extension

3. Ring hitch fixing screw on the extension

4. Ring

For more information, refer to section Every 1,000 hours - Hitch

extension page 61

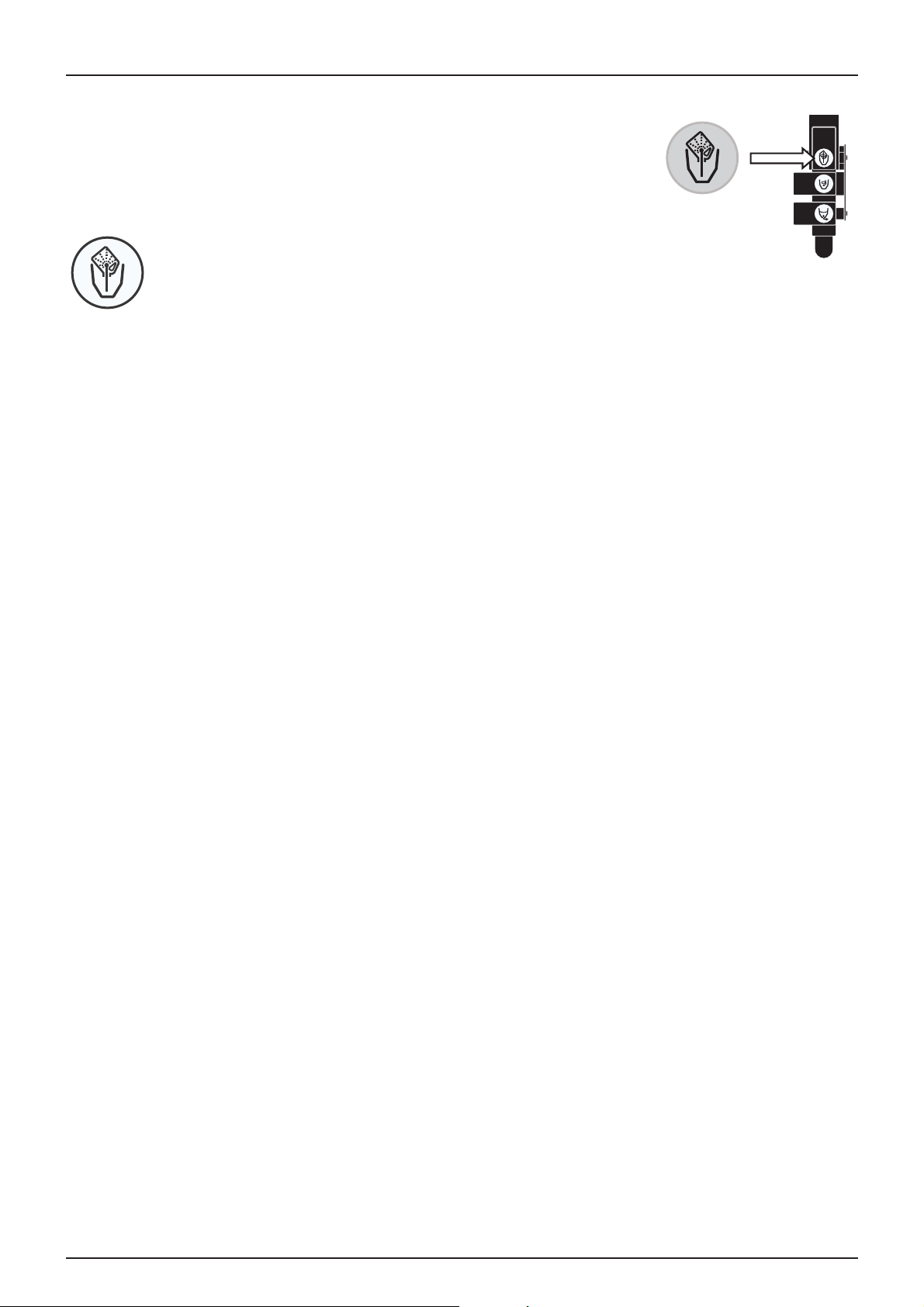

Articulated hitch with tilt correction (optional)

When the sprayer is hitched to the tractor, move the tie-rods from

position (B) to position (A).

Position of tie-rods:

A. Spraying.

B. Driving on the road.

DANGER! While driving on public roads, the tie rods must be in

€

position (B). If this is not the case, the sprayer could tip on bends

or when turning.

2

1

Where the articulated hitch is equipped with an offset corrector, remove

the tie rod from position (D) and store it in position (B). Pivot the cylinder

from position (C) to position (A).

Position of the tie-rod/cylinder:

A. Spraying with offset correction.

B. Tie-rod storage (not used during work).

C. Driving on the road.

D. Driving on the road.

DANGER! While driving on public roads, the cylinder and tie rods

€

must be in positions (C) and (D). If this is not the case, the sprayer could tip on bends or when turning.

WARNI NG! To pre vent any dama ge to the drawbar or chassis, the cy linder should not be under pressure when driving

±

on the roads (C).

29

Page 30

4 - Sprayer set-up

Track width, axles and wheels

Modifying the track width

The sprayer's track width can be modified in stages.

The tables show the track widths possible, twice the distance the axle (X)

can slide from the middle of the sprayer (C) and the position of the

wheel discs (A) and (B).

Wheel discs Offset Consequences for the track

width

ANegative Narrower

B Positive Wider

Modification procedure

1. Measure the track width (centre of the right tyre to the centre of

the left tyre). The increase or decrease in track width must be

divided between the two sides.

2. Hitch the sprayer to the tractor and engage the parking brake.

3. Place chocks in front of and behind the right hand wheel. Lift up

the left wheel and make the equipment secure.

4. Loosen the bolts (A) on the left stub-axle.

5. Loosen the setting screw on the hand brake control lever.

6. Slide the axle. If necessary, use tools to assist.

7. Tighten the bolts (A) to a torque of 250Nm.

8. Repeat the operation for the right hand wheel.

9. Check that the distance from the centre of the tyre to the centre of

the chassis is the same on both sides.

10. Tighten the bolts, including those on the wheels, to the indicated

torques after 8 hours of work.

IMPORTANT! The wider the track width, the more stable the sprayer. We recommend that you work with the widest

possible track width.

WARNING! Position the jack under the axle and lift the wheel, so that there is no weight on the flanges, before

tightening them to the specified torque.

Tyre inflation pressures

Check tyre pressures. Refer to section Tyre specifications page 78

An incorrectly inflated tyre could burst and will wear more quickly.

±

30

Page 31

Brakes

a0

b1

b0

a1

X

Parking and safety brake

There are two operating modes for the parking brake, determined by

the position of the pawl (A). To change from one mode to the other, turn

the pawl.

Position Pressure position Function

1 Pressing against the ratchet To release the hand brake

2 Tip clear of the ratchet To engage the hand/safety brake

To release the hand brake

• Put the pawl in position 1.

• Pull the lever gently forward to release the yoke from the toothed

wheel, then push the lever fully backwards.

To engage the hand brake

• Put the pawl in position 2.

• Pull the lever firmly forward until it is fully engaged.

Safety brake:

• Put the pawl in position 2.

4 - Sprayer set-up

• Adjust and solidly fix the link on the parking brake wire to a fixed

point on the tractor. If the sprayer accidentally comes unhitched

whilst moving, the wire will activate the parking brake before

breaking.

IMPORTANT! For the safety brake to operate correctly without

damaging the hand brake, use a wire with a break link.

WARNING! Release the parking brake before moving.

±

Hydraulic braking

How the hydraulic braking device is fitted depends on the tyres used.

If they are changed, it is essential that you use the brake control cylinder

fixing points indicated.

Tyres Distance (X) in mm Brake cylinder position

270/95R38

other tyres 180 b0 - b1

See section Tyre specifications page 78.

152 a0 - a1

X

31

Page 32

4 - Sprayer set-up

Vers distributeur

simple effet

Vers distributeur

double effet

Frein

hydraulique

1

2

3

4

RETUR

RETUR

TRYK

TRYK

Hydraulic system

General information

Check the cleanliness of the oil intakes before you connect them!

After manoeuvring the boom and filling the oil system, check the level of hydraulic oil in the tractor and top up if necessary.

The hydraulic hoses' connection to the tractor differs according to the configuration of the sprayer. For more information,

refer to section Boom and terminology page 20

Check that the hydraulic system on your tractor is compatible with the RANGER TR2 system. If you are in any doubt,

±

consult your HARDI-EVRARD dealer.

If controlled by a double acting control valve on the tractor, failure to comply with the oil's direction of circulation

±

could cause uncontrolled movements of the boom.

DANGER! Commissioning the hydraulic system must be performed with great care. There could be air in the system

€

that would cause undesirable movements of the boom.

DANGER! Hydraulic leaks: Never attempt to identify the location of a leak in the hydraulic system with your bare

€

hands. The high pressure could cause oil to penetrate the skin.

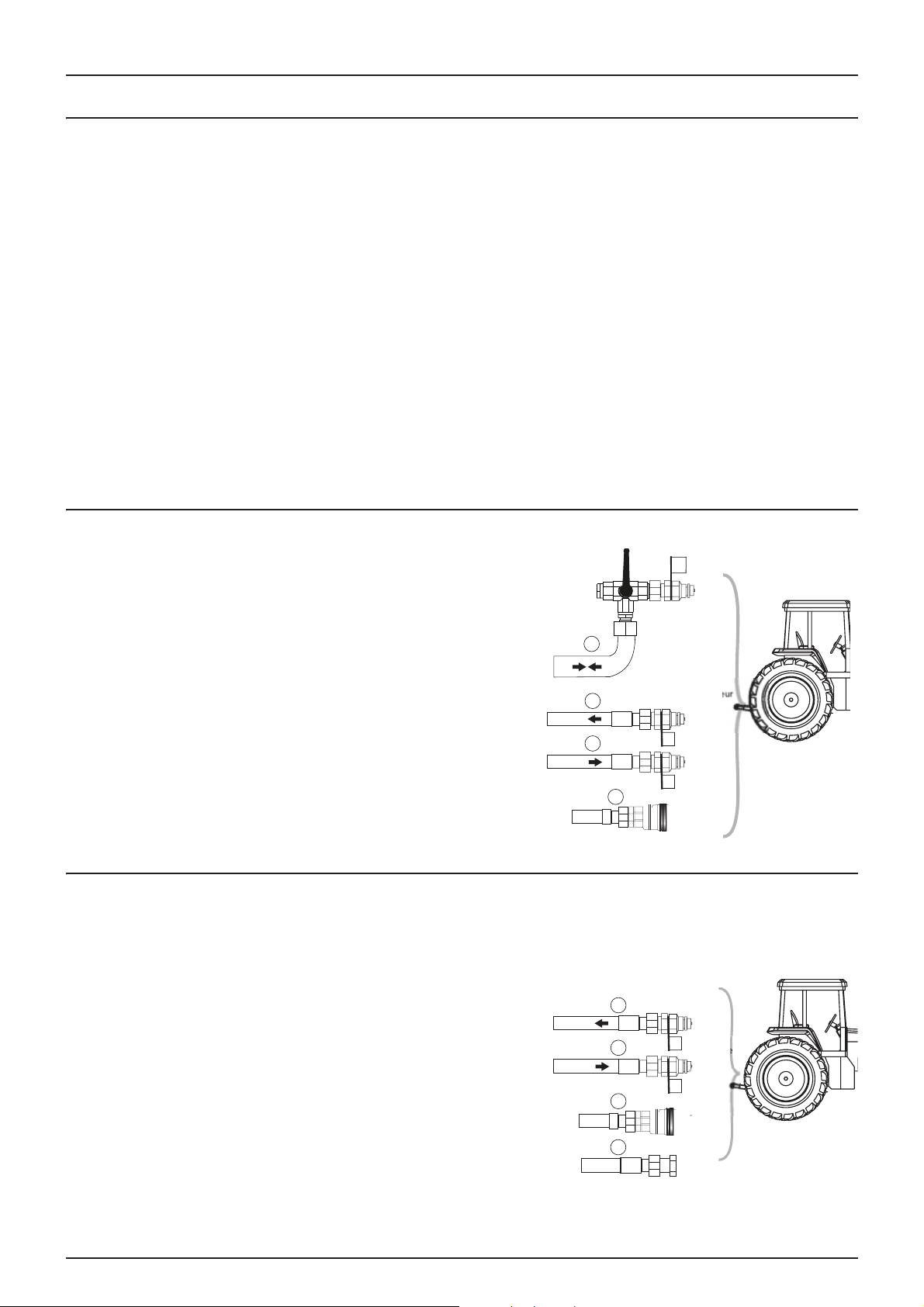

Version TR2 Y hydraulic connection

1. Hose (TRYK/RETUR) with isolation valve connected to a single

acting control valve for controlling the raising/lowering of the

boom.

2. Hose (TRYK) connected to the outlet of a doubling acting control

valve.

3. Hose (RETUR) connected to a double acting control valve

for controlling the opening and closing of the boom or the tilt

control.

4. Hydraulic brake hose.

For the detailed use of the hydraulic controls, refer to section

÷

TR2 Y boom hydraulic controls page 37

Version TR2 V and TR2 Z hydraulic connection

The hydraulic system requires: a single acting control valve and a free return to control the boom's folding/unfolding

functions. The hydraulic hoses are marked with an arrow which indicates the direction of circulation of the oil.

The hydraulic system requires an oil flow of between 25 and

30 litres/minute and a minimum pressure of 170 bar.

RETUR

1

TRYK

2

3

4

Vers distributeur

double effet

Frein

hydraulique

Load Sensing (LS)

1. Hose (TRYK) connected to the outlet of a single acting control

valve

2. Hose (RETUR) connected to a free return

3. Hydraulic brake hose

4. Load Sensing (LS) hose (optional)

÷

For the detailed use of the hydraulic controls, refer to section

TR2 V and TR2 Z boom hydraulic controls page 39.

32

Page 33

Open centre hydraulic block (optional)

If the tractor's hydraulic system is of the open centre or load sensing

type, an open centre hydraulic block is required.

The valve (1) on the side of the block is factory set for an open centre. But

if the tractor has a closed centre (and/or load sensing) system, this valve

must be screwed all the way in.

Some tractors can use load sensing (LS) without connecting an external

load sensor. But if the optimum load control pressure is not reached, an

external load sensor (3) must be fitted. Ask your tractor dealer for the

correct setting and connection.

WARNING! The valves must be adjusted according to the model

±

of tractor before you operate the hydraulics. If you do not know

what type of hydraulic system your tractor has, contact your

dealer.

Settings table for the valves on the block:

Valve no. 1 2 3 (LS port )

Open centre Unscrewed Unscrewed Free

Closed centre Screwed Screwed Free

Load sensing (LS) Screwed Unscrewed Connected

4 - Sprayer set-up

*if the tractor requires a pressure discharge, consult your tractor dealer.

WARNING! Always check that the valve (1) to select open centre/closed centre is indeed fully screwed in or

±

unscrewed. Failure to do this could result in vital components in the tractor's hydraulic pump being damaged.

WARNING! It is essential that the load sensor connectors are always kept perfectly clean. Failure to ensure that this is

±

the case could result in impurities entering the pump and damaging its components.

33

Page 34

4 - Sprayer set-up

Electrical connections

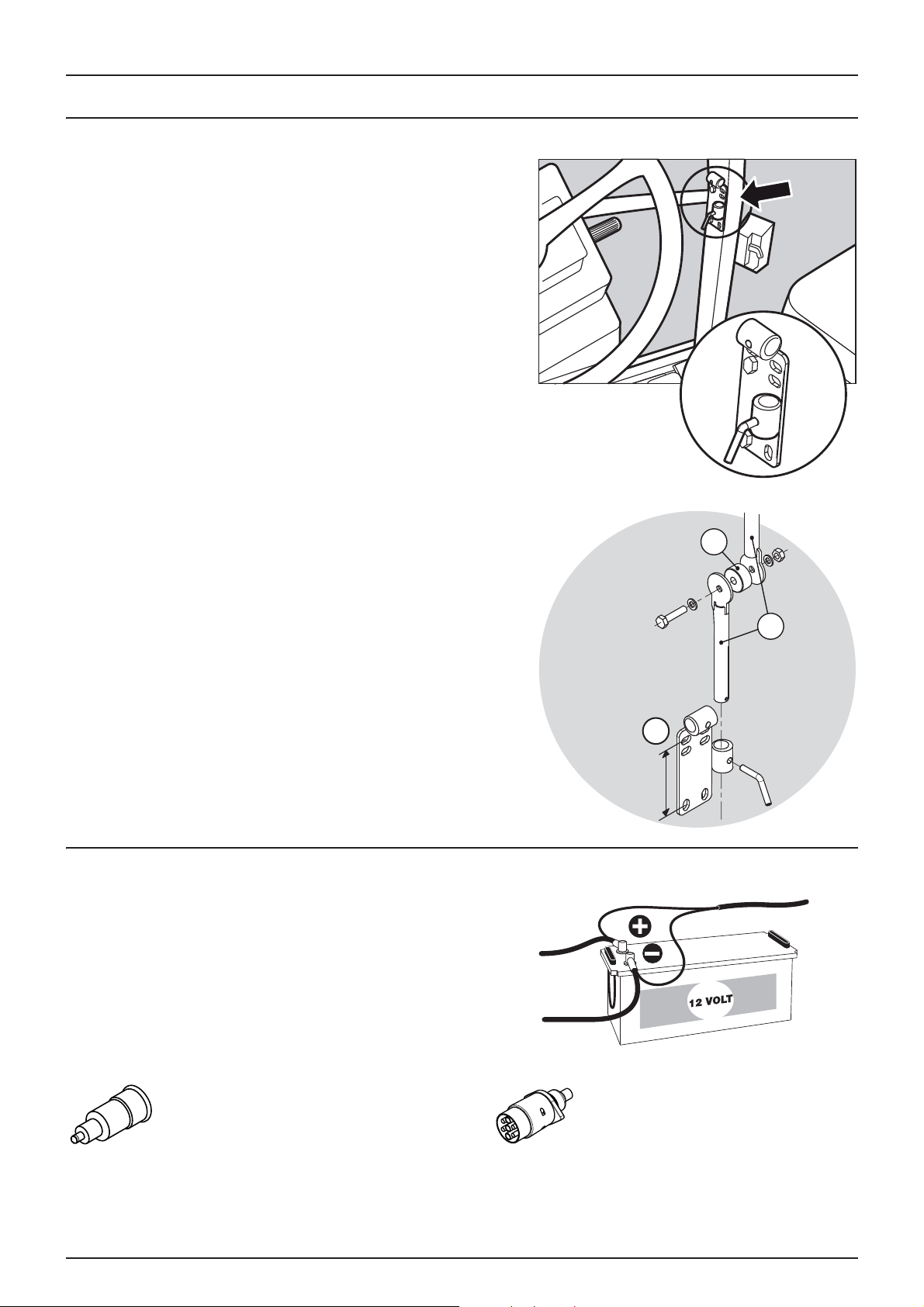

Installing the control unit supports

Position the control units in the most suitable place in the tractor cab.

The best position is to the right of the driver's seat.

The support (A) supplied is drilled with holes spaced at 100 and 120mm

and is suitable for most tractors. Tapped fixing holes are sometimes

concealed inside the front post protector. See the tractor's user manual

for the fixings in the cab.

Three tubes (B) are supplied. You can use 1, 2 or all 3 of them. They can

be bent and shortened. A spacer (C) is also supplied to allow for other

types of fitting. It is up to you to choose the best solution for your tractor.

The tube (B) is adjustable, so that, when correctly oriented, all the units

will be in line.

Electrical supply

Power required: 12V DC. Always check the polarity! To ensure sufficient

power and correct operation of the electrical equipment, use the

correct size of cables and fuses. The plugs supplied comply with the

most recent standards for tractors. If they do not fit, remove them and

connect the wires directly to the socket on the tractor.

C

B

A

100 -120mm

The number and type of plugs can vary for the same sprayer, depending

on its equipment.

CIGARETTE LIGHTER

The spraying control unit requires:

2.5mm² cable, 10 Amp fuse

The hydraulic control unit requires:

4.0mm² cable, 16 Amp fuse

34

ROAD SIGNALLING SOCKET

Page 35

Sprayer speed sensor

The speed sensor and holed disc are located in the sprayer's right side

wheel.

It works by induction and has to pass over a metal projection to trigger

a signal. A holed disc is used to do this. It has to be adjusted so that it

senses in the middle of the disc's holes (when vertical). The

recommended distance between the metal part and the sensor (A) is

between 3 and 6mm. Check that this is so over the whole circumference.

IMPORTANT! Correct operation is indicated by a constant flashing

of the sensor when you turn the holed disc.

Road signalling

4 - Sprayer set-up

Connect the plug to the 7-pin socket on the tractor and check the operation of the rear lights, stop lights, side lights and

indicators on each side before moving off.

The wiring complies with ISO 1724. See section Electrical connections page 82.

IMPORTANT! SWITCH OFF working lights when driving on public roads!

35

Page 36

4 - Sprayer set-up

Spraying system

Use of electrical EVC adjustment

Before spraying, it is necessary to adjust the setting using clean water

(no agro-pharmaceutical products).

1. Select the appropriate nozzles for the treatment by turning the

Triplet nozzle holder. Check that all the nozzles are of the same

type and size. Refer to the "Application Techniques" manual.

2. Set the On/Off switch to On on the spraying control unit.

3. Set all the switches on the sections to ON on the spraying control

unit.

4. Lower the pressure regulation switch until the emergency lever on

the control valve stops turning (minimum pressure).

5. While stationary, rotate the PTO drive and with it the pump at the

planned speed. The PTO drive should rotate at between 300 and 600 rpm (pump 540 rpm) or between 650 and

1,100 rpm (pump 1,000 rpm).

6. Lift the pressure setting switch on the spraying control unit until the pressure gauge indicates the required pressure.

PRESSURE COMPENSATION SETTING:

7. Close the first section on the spraying control unit.

8. Turn the compensation screw until the pressure gauge indicates the required pressure again.

9. Open the section again.

10. Set the other sections one by one, using the same method.

IMPORTANT! A NEW PRESSURE COMPENSATION SETTING WILL BE NECESSARY IF:

1. YOU USE NOZZLES OF A DIFFERENT SIZE

2. THE FLOW THROUGH THE NOZZLES INCREASES DUE TO WEAR

36

Page 37

5 - Operation

Boom

Safety instructions

The boom must never be unfolded/folded while the sprayer is moving. Only use the unfolding/folding functions when the

sprayer is stationary. Any failure to comply with this rule could damage the boom.

DANGER! Before unfolding the boom, hitch the sprayer to the tractor to prevent it tipping over.

€

DANGER! Before unfolding or folding the boom, check that nothing and no one is within its field of movement.

€

DANGER! When you are close to high voltage lines, follow the advice below very carefully:

€

Never unfold/fold the boom close to overhead power lines.

It could touch the lines during accidental movements.

IMPORTANT! A warning sticker (ref. 978448) is delivered with the

equipment. Display this in the cab, visible from the driver's seat.

IMPORTANT! The boom must be unfolded/folded on even

ground.

TR2 Y boom hydraulic controls

WARNING! Before using the unfolding/folding functions, check that the frame is locked in place.

±

WARNING! The boom unfolding/folding functions must only be used when the sprayer is stationary. Otherwise the

±