Page 1

N-SERIES 3-PT SPRAYER

DIAPHRAGM

Operator's Manual

67302903 (08/10)

Page 2

Page 3

HARDI

N-SERIES 3-PT SPRAYER

DIAPHRAGM

Operator's Manual

67302903 (08/10)

HARDI® reserves the right to make changes in design,

material, or specifi cation without notice thereof.

HARDI® and other product names are registered trademarks

of HARDI® Inc. in the U.S. and in other countries.

Page 4

TABLE OF CONTENTS

1.0 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.0 SAFETY INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 Follow Safety Instructions . . . . . . . . . . . . . . . . . . . . 9

2.2 Operating the Sprayer Safely . . . . . . . . . . . . . . . . . 9

2.3 Handling Chemical Products Safely . . . . . . . . . . . . 11

2.4 Local Poison Information Center. . . . . . . . . . . . . . . 12

3.0 HOOKING UP THE SPRAYER . . . . . . . . . . . . . . . . . . . . . . 13

3.1 P.T.O. Shaft Operator Safety . . . . . . . . . . . . . . . . . . 14

3.2 Installation Of P.T.O. Shaft. . . . . . . . . . . . . . . . . . . . 14

3.3 Power Supply (electric controls only) . . . . . . . . . . . 16

3.4 Control box (electric controls only) . . . . . . . . . . . . . 17

4.0 OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . 18

4.1 Filling The Main Tank (all models). . . . . . . . . . . . . . 18

4.2 Filling The Clean Water Tank (optional). . . . . . . . . . 18

4.3 EC-3 Standard Plumbing Diagram . . . . . . . . . . . . . 19

4.4 EC-3 Plumbing Diagram w/optional Rate Controller 20

4.5 Adjustment of the EC-3 Electric Controls . . . . . . . . 21

4.6 ET-3 Manual Control Plumbing Diagram. . . . . . . . . 23

4.7 Adjustment of the ET-3 Manual Controls. . . . . . . . . 24

4.8 ET-2 Manual Control Plumbing Diagram. . . . . . . . . 26

4.9 Adjustment of the ET-2 Manual Controls. . . . . . . . . 27

4.10 BK-3 Manual Control Plumbing Diagram . . . . . . . . 29

4.11 Adjustment of the BK-3 Manual Controls . . . . . . . . 30

4.12 Operation Of The Tank Drain Valve (all models) . . . 33

4.13 Adjustment of Air Pressure in Pressure Damper

(All models). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.14 Self Cleaning Filter (optional) . . . . . . . . . . . . . . . . . 34

4.15 Unfolding/Folding Boom

(All models with standard booms). . . . . . . . . . . . . . 35

4.16 Boom Height Adjustment

(All models with standard booms). . . . . . . . . . . . . . 36

2 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 5

5.0 NOZZLE SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5.1 Boom Nozzle Selection

(All models with standard booms). . . . . . . . . . . . . . 37

5.2 Giant End Nozzle Selection (Pasture Sprayer only) 40

5.3 Spraygun Nozzle Selection (All models). . . . . . . . . 42

5.4 Calibration (All models with standard booms). . . . . 43

5.5 Calibration (Pasture sprayer model only) . . . . . . . . 47

6.0 MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.1 Cleaning The Sprayer . . . . . . . . . . . . . . . . . . . . . . . 51

6.2 Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.3 Nozzles And Fittings . . . . . . . . . . . . . . . . . . . . . . . . 54

6.4 Replacement Of P.T.O. Shaft Protection Guards. . . 55

6.5 Replacement Of P.T.O. Shaft Cross Journals . . . . . 55

6.6 Changing the Valves and Diaphragms (all pumps). 56

6.7 Breakaway Clutch Adjustment (MB Boom only) . . . 57

6.8 Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.0 OFF-SEASON STORAGE. . . . . . . . . . . . . . . . . . . . . . . . . . 61

7.1 Preparation after Off-Season Storage. . . . . . . . . . . 62

8.0 ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.1 Clean Water Dispenser (optional) . . . . . . . . . . . . . . 63

8.2 Spraygun And Hose wrap (optional). . . . . . . . . . . . 63

8.3 Maverick Rate Controller (optional). . . . . . . . . . . . . 64

8.4 Large 4" Pressure Gauge (optional) . . . . . . . . . . . . 64

8.5 Chemical Filler (optional) . . . . . . . . . . . . . . . . . . . . 65

8.6 Chemical Filler Bag & Bottle Rinse Kit (optional) . . 65

8.7 SMV Sign Kit (optional). . . . . . . . . . . . . . . . . . . . . . 66

9.0 TROUBLESHOOTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.1 General Spray Systems . . . . . . . . . . . . . . . . . . . . . 67

10.0 TECHNICAL SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . 69

10.1 Dimensions and weights. . . . . . . . . . . . . . . . . . . . . 69

10.2 Power consumption. . . . . . . . . . . . . . . . . . . . . . . . . 69

11.0 WARRANTY POLICY AND CONDITIONS . . . . . . . . . . . . 70

12.0 NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

3HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 6

HARDI

Dear Owner,

Thank you for purchasing a HARDI

increasing family of HARDI® sprayer owners.

Our sprayers and accessories are rapidly becoming a familiar sight

on North American farms. We believe that this results from growers

becoming increasingly conscious of crop protection input costs and the

vital need for cost effective spray application equipment.

Please take the time to thoroughly read the Operator’s Manual before

using your equipment. You will fi nd many helpful hints as well as

important safety and operation information.

Some of the features on your HARDI® sprayer were suggested by

growers. There is no substitute for “on farm” experience and we invite

your comments and suggestions. If any portion of this instruction book

remains unclear after reading it, contact your HARDI® dealer or service

personnel for further explanation before using the equipment.

For Product, Service or Warranty Information:

- Please contact your local HARDI® dealer.

To contact HARDI® directly:

- Please use the HARDI® Customer Service number: 1-866-770-7063

- Or send your email to CUSTSERV@hardi-us.com

®

product and welcome to the ever-

Visit us online at: www.hardi-us.com

HARDI® NORTH AMERICA INC.

1500 West 76th St.

Davenport, Iowa 52806

Phone: (563) 386-1730

Fax: (563) 386-1710

Sincerely,

Dale M. Szuminski

President

4 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

337 Sovereign Rd.

London, Ontario N6M 1A6

Phone: (519) 659-2771

Fax: (519) 659-2821

Page 7

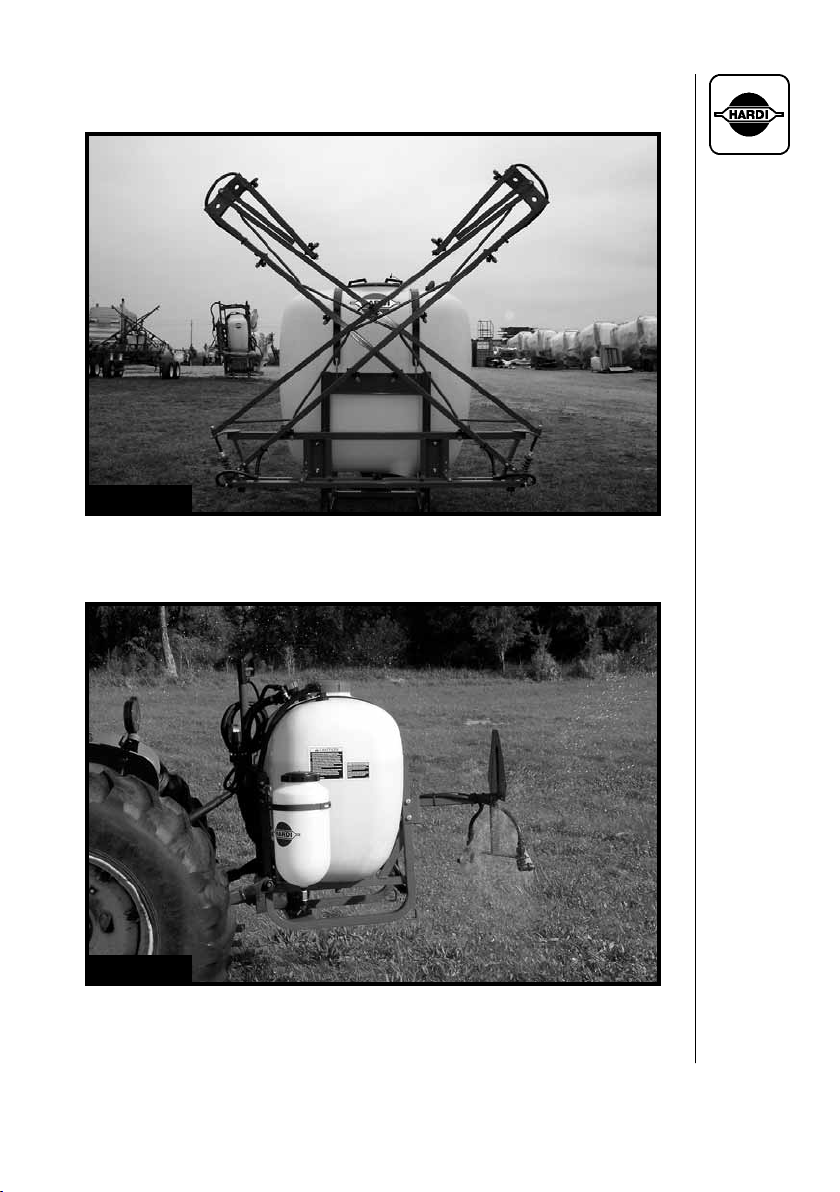

Fig. 1

N155 GALLON 3-PT WITH 26' MB BOOM

Fig. 2

N105 GALLON 3-PT PASTURE SPRAYER MODEL

5HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 8

1.0 INTRODUCTION

We congratulate you for choosing a HARDI

®

plant protection product.

The reliability and effi ciency of this product depends on your care. The

fi rst step is to carefully read and pay attention to this operator's manual.

It contains essential information for the effi cient use and long life of this

quality product.

As this instruction book covers all N-series models, please pay

attention to the sections dealing with your specifi c model.

This manual covers the HARDI

®

N-series 3-PT sprayers, available in

105, 155 or 210 gallon (400 L, 600 L or 800 L) capacities. They are

equipped with a HARDI® 603, 1203 or 1303 diaphragm pump (540

RPM P.T.O. drive), 3-PT frame and tank with electrical (EC) or manual

(ET or BK) controls. Available standard booms include:

N105: 20' MB, 26' MB

N155: 20' MB, 26' MB, 33' MB, 40' MB

N210: 20' MB, 26' MB, 33' MB, 40' MB

Other boom options include: No boom (spray gun only), pasture

sprayer nozzles (30', 40', 50' spray width), VS8D 1-Row Berry Boom or

VII 2-Row Berry Boom.

The heart of your sprayer is the diaphragm pump. The design is simple,

resulting in low maintenance requirements and guaranteed pump life.

The bearings and crankshaft are grease lubricated and are therefore

protected from spray solution if any diaphragm fails in service. A drain

hole is located in the base of the crank case to facilitate the draining of

any foreign matter. The pump is self-priming and can be run dry without

damage.

The EC-3 electric control unit consists of: Electrically operated master

on/off valve, electrically operated boom distribution valves, manual

pressure adjustment valve, 2-1/2" pressure gauge, and adjustable

pressure agitation.

The ET-2/ET-3 manual control unit consists of: Manual pressure

adjustment valve, boom distribution valves, 2-1/2" pressure gauge, and

adjustable pressure agitation.

Note: ET-2 control is used on pasture sprayer model

6 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 9

The BK-3 manual control unit consists of: On/off function, distribution

valves with pressure equalization, manual pressure adjustment valve,

pressure fi lter with 2-1/2" pressure gauge and HARDI-MATIC. The

HARDI-MATIC is a mechanical rate controller that ensures a constant

volume of spray solution per acre at varying speeds in the same gear.

The tanks, made of impact proof and chemical resistant poly eth yl ene,

have a purposeful design with rounded contours and a large deep

sump to allow for ef fi cient cleaning and draining. The tanks are

equipped with a top suction fi lter for easy service and a top operated

tank drain.

All standard booms (20', 26', 33' or 40' MB) feature ISO fl at fan nozzles

with 20" spacing. The 40' MB boom features a self-levelling trapeze

center.

The pasture sprayer model includes a height adjustable offset nozzle

bracket bolted to the rear of the 3-PT frame for mounting either two

HARDI

®

Giant End Nozzles or two "Boom Buster" nozzles (Evergreen

Products, Inc.). The two HARDI® Giant End Nozzles provide a

consistent spray pattern and droplet distribution. They are available

in three different sizes ranging from 3.22 - 9.38 GPM (12.7 - 36 l/min)

between 20 - 70 PSI (1.5 - 5 bar) spray pressure. Under optimal

spraying conditions, the maximum spray swath covered by the two

opposite mounted HARDI® Giant End Nozzles is 30', 40' or 50' (10m,

12m or 16m).

Available options include:

Spray Mate II Rate Controller (requires electric EC control)

Remote control cable (for manual BK control only)

Self cleaning fi lter (with 50 mesh fi lter)

4 gallon (15 L) clean water dispenser

Chemical fi ller with optional bag & bottle rinse

4" pressure gauge

Hose wrap with 25' of 3/8" hose and a model 60L HARDI® spray gun

Hose reel with 160' of 3/8" hose and a model 60L HARDI® spray gun*

Hose reel with 275' of 5/8" hose and a model 60L HARDI® spray gun**

Hydraulic boom vertical fold (40' MB boom only)

SMV Sign kit

* Not available on N210 with boom

** Not available with boom

7HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 10

2.0 SAFETY INFORMATION

WARNING

ALWAYS READ OPERATOR'S MANUAL BEFORE

USING EQUIPMENT

DO NOT REMOVE ANY SAFETY DEVICES OR

SHIELDS. NEVER SERVICE, CLEAN OR REPAIR A

MACHINE WHILE IT IS OPERATING

WARNING

ALWAYS WATCH FOR THIS SYMBOL TO POINT OUT

IMPORTANT SAFETY PRECAUTIONS

IT MEANS ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

8 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 11

RECOGNIZE SAFETY INFORMATION

This is the Safety-alert symbol. When you see

this symbol on your machine or in this manual,

be alert to the potential for per son al injury.

Follow recommended precautions and safe

operating practices.

2.1 Follow Safety Instructions

- Carefully read all the safety messages in this manual and the safety

labels fi tted to the machine. Keep safety labels in good condition.

Replace missing or damaged safety labels. Be sure that new equipment components include any current safety labels. Replacement

safety labels are available from your authorized HARDI® dealer.

- Learn how to operate the sprayer and how to use the controls

prop erly. Do not let anyone operate the machine without proper

instructions.

- Keep your sprayer in proper working condition. Unauthorized modi-

fi cations or use may impair the function and/or safety and affect the

machine's life.

- If you do not understand any part of this manual and need assis-

tance, please contact your authorized HARDI® dealer.

2.2 Operating The Sprayer Safely

1. Read the complete manual carefully and become familiar with the

operation of the equipment before initial operation in each spraying

season. Failure to do so may result in possible over or under-application of spray solution which may drastically affect crop production

and lead to personal injury.

2. Before starting the engine on the tractor unit, be sure all operating

controls are in the off or neutral position (including spray controls)

and disengage the tractor power train.

3. Operate spray functions only when seated in the operator’s seat.

4. One of the most frequent causes of personal injury or death results

from persons falling off or being run over. Do not permit others to

ride on or in. Only one person, the operator, should be on the machine when in operation.

9HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 12

5. Before leaving the tractor seat, stop the engine, put all controls in

neutral, and put the transmission control lever in the park position or

neutral with the brakes locked. Read the tractor operations manual

for added safety precautions.

6. P.T.O. driven equipment can cause serious injury. Before working

on or near the P.T.O. shaft, servicing or cleaning the equipment, put

P.T.O. lever in the DISENGAGE position and stop the engine.

7. Keep hands, feet & clothing away from moving parts.

8. Wear relatively tight and belted clothing to prevent from being caught

on some part of the machine.

9. Slow down when turning.

10. Always keep children away from your sprayer and/or tractor unit.

11. Slow moving tractors and spray equipment can create a hazard

when on public roads. Avoid personal injury or death resulting

from any accidents by using fl ashing lights. Local regulations may

require installation of fl ashing warning lights.

12. Understand service procedures before undertaking any mainte-

nance. Never lubricate, service, or adjust the machine while it's

moving. Securely support any components before working on

them.

13. Keep all parts in good condition and properly installed. Fix dam-

aged parts immediately. Replace worn or broken parts. Remove

excessive buildup of grease, oil or debris.

10 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 13

2.3 Handling Chemical Products Safely

1. Direct exposure to hazardous chemicals can cause serious injury.

These chemicals can include lubricants, coolants, paints, adhesives

and agricultural chemicals. Material Safety Data Sheets (M.S.D.S.)

are available for all hazardous chemicals which inform the user of

specifi c details including, physical and health hazards, safety procedures, and emergency response techniques.

2. Protective clothing such as rubber gloves, goggles, coveralls and

respirator must be worn while handling chemicals. All protective

clothing should be kept in excellent condition and cleaned regularly

or discarded.

3. If chemicals come in contact with any exposed skin areas, wash immediately with clean water and detergent. Never place nozzle tips or

any other components that have been exposed to chemicals to lips

to blow out obstructions. Use a soft brush to clean spray nozzles.

4. Dedicate an area to fi ll, fl ush, calibrate and decontaminate sprayer

where chemicals will not drift or run off to contaminate people, animals, vegetation, water supply, etc. Locate this area where there is

no chance of children coming in contact with this residue.

5. Decontaminate equipment used in mixing, transferring and applying

chemicals after use. Follow the instructions on the chemical label for

the correct procedure required. Wash spray residue from outside of

the sprayer to prevent corrosion.

6. Extreme care should be taken in measuring spray products. Powders

should be used in suitable sized packages or weighed accurately.

Liquids should be poured into a suitable graduated container. Keep

chemical containers low when pouring. Wear a fi ltered respirator

and let the wind blow away from you to avoid dust and/or splashes

contacting the skin or hair.

7. Store chemicals in a separate, plainly marked locked building. Keep

the chemical in its original container with the label intact.

8. Dispose all empty containers after rinsing in accordance with local

regulations & by-laws. Dispose of all unused chemicals and left over

fertilizer in an approved manner

9. Keep a fi rst aid kit and fi re extinguisher available at all times when

handling chemicals.

11HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 14

2.4 Local Poison Information Center

If you live anywhere in the United States, the following toll free number

will connect you to your Local Poison Information Center.

PHONE NO. 1 - 8 0 0 - 2 2 2 - 1 2 2 2

If you live outside the United States, fi nd the number f or the poison control

center in your phone book and write it in the space below:

PHONE NO. _________ - _________ - _____________

Keep a list, in the space provided below, of all the chemicals that you

have in use.

1. __________________________________________________

2. __________________________________________________

3. __________________________________________________

4. __________________________________________________

5. __________________________________________________

6. __________________________________________________

7. __________________________________________________

8. __________________________________________________

9. __________________________________________________

10. __________________________________________________

12 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 15

3.0 HOOKING UP THE SPRAYER

WARNING: MAKE SURE THAT YOUR TRACTOR HAS SUFFICIENT

HORSEPOWER, BRAKING ABILITY AND CARRYING

CAP ACITY T O SAFEL Y CONTROL THE TRACTOR WITH

THE SPRAYER MOUNTED.

Check your tractor operator's manual for 3 point lifting capacity (See

section 10.1 for approximate weight of your N-series model sprayer

and section 10.2 for minimum tractor power requirements).

1. Attach lower lift arms.

2. Attach P.T.O. shaft (See sections 3.1 and 3.2).

3. Attach top link.

IMPORTANT: Make absolutely sure that the correct 3 point hitch

pins are used and that they are securely installed.

4. Raise sprayer from ground and adjust 3 point linkage so that tank is

level in the raised position (ensure that the sprayer tank is level from

side to side as well as front to back).

5. Also follow these general recommendations:

• Increase tire pressure if necessary (refer to tractor operator's

manual) to compensate for the added weight.

• Make sure that no parts of the sprayer come into contact with the

tractor.

• Be careful when fi lling the sprayer for the fi rst time.

• Travel at slower speeds when driving with a full tank.

13HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 16

3.1 P.T.O. Shaft Operator Safety

WARNING: ALWAYS STOP ENGINE BEFORE ATTACHING THE

TRANSMISSION SHAFT TO TRACTOR P.T.O. - MOST

TRACTOR P.T.O. SHAFTS CAN BE ROTATED BY HAND

TO FACILITATE SPLINE ALIGNMENT, WHEN ENGINE

IS STOPPED.

When attaching the shaft, make sure that the snap lock is FULLY

ENGAGED - push and pull shaft until it locks.

WARNING: ROTATING TRANS MIS SION SHAFTS WITHOUT

PROTECTION GUARDS ARE FATAL.

Always keep protection guards and chains intact and make sure that

it covers all rotating parts, in clud ing CV-joints at each end of the shaft.

Do not use with out protection guard.

Do not touch or stand on the transmission shaft when it is rotating

- safety distance: min 5' (1.5 meters).

Prevent protection guards from rotating by attaching the chains,

al low ing suffi cient slack for turns.

Make sure that protection guards around tractor P.T.O. and im ple ment

shaft are intact. Check every 40 hours.

Always STOP ENGINE and re move the ignition key before car ry ing out

main te nance or repairs to the trans mis sion shaft or im ple ment.

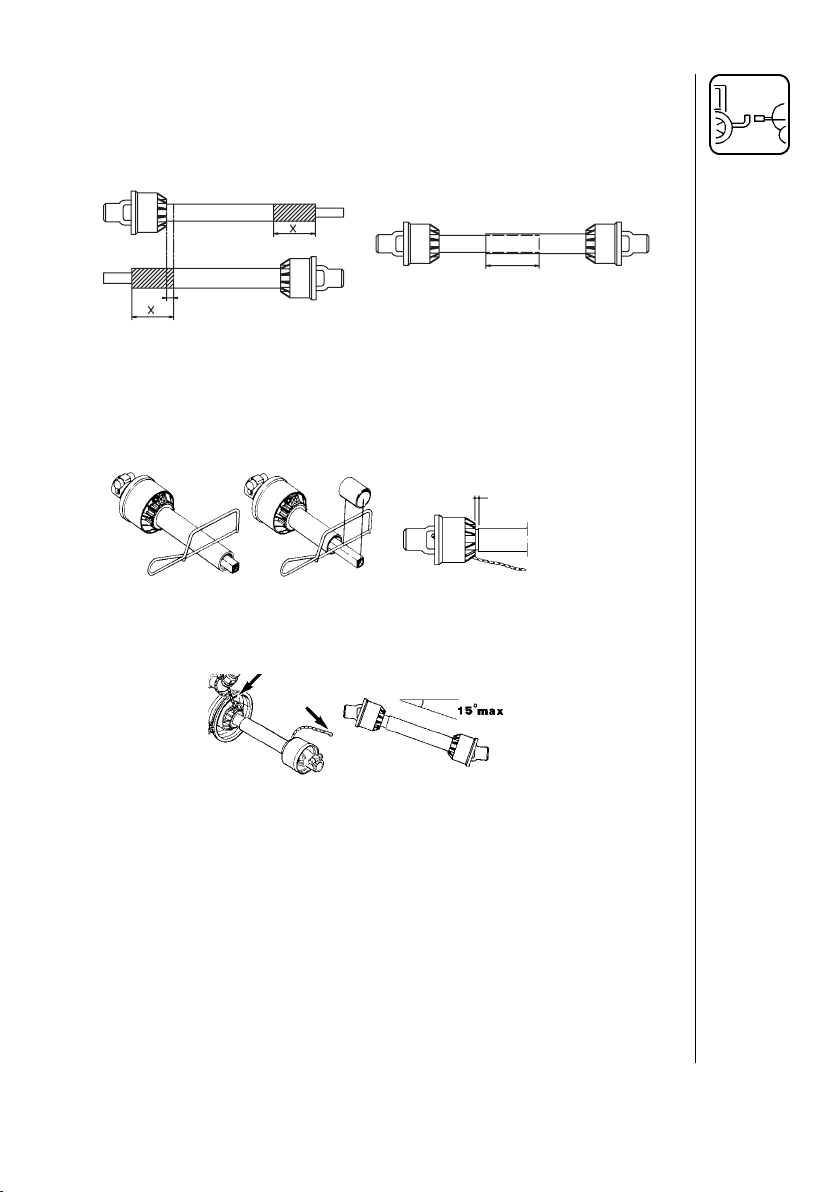

3.2 Installation Of P.T.O. Shaft

WARNING: THE P.T.O. SHAFT ANGLE WILL CHANGE WHEN

RAISING AND LOWERING THE 3 POINT LINKAGE.

TO PREVENT EXCESSIVE LOADING AND BINDING

ON THE P.T.O. SHAFT, IT MAY BE ADVISABLE TO

LEAVE THE P.T.O. SHAFT DISCONNECTED UNTIL

THIS OPERATION IS COMPLETED. THEN P.T.O. SHAFT

ADJUSTMENTS CAN BE MADE.

Initial in stal la tion of the shaft is done as fol lows:

1. Attach spr ayer to tractor and set sprayer in the position with shortest

distance between the tractor and spray er pump P.T.O. shafts.

2. Stop engine and remove ig ni tion key.

14 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 17

3.2 Installation Of P.T.O. Shaft (continued)

3. If P.T.O. shaft must be short ened, pull the shaft apart. Fit the two

shaft parts at tractor and spray er pump and measure how much it is

necessary to shorten the shaft. Mark the protection guards.

min. 3/4" (20mm)

Note: The shaft must al ways have a minimum over lap of 6" (150 mm)

(Fig. 3).

4. Shorten the two parts equal ly. Use a saw, and fi le the profi les

af ter wards to re move burrs (Fig. 4).

5. Grease the profi les, and reas sem ble the male and female parts.

6. Fit the shaft to tractor and spray er pump.

Note: Female part to wards tractor. Fit the chains to prevent the

pro tec tion guards from r

otating with the shaft.

Fig. 3

min. 3/4" (20mm)

Fig. 4

Fig. 5

min. 6" (150mm)

7. To ensure long life of the P.T.O. shaft, try to avoid work ing an gles

great er than 15° (Fig. 5).

15HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 18

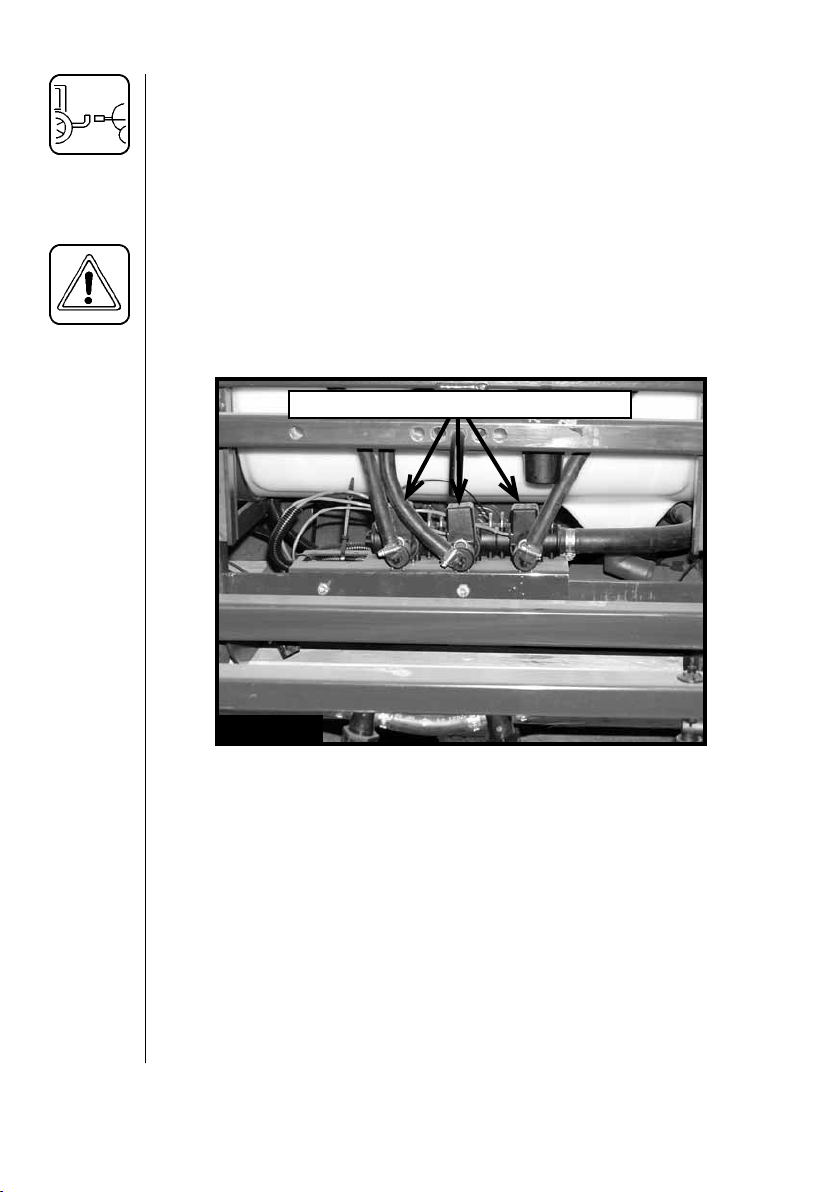

3.3 Power Supply (electric controls only)

A 12 Volt DC power supply is required to operate the electrical boom

distribution valve solenoids (Fig. 6). Connect the power supply wiring

harness as follows:

Red wire to positive (+) and Black wire to negative (-).

IMPORTANT: Do not connect to the starter motor or generator/alternator. Warranty is void if this is done.

The power supply wiring harness is equipped with a 7.5 Amp inline

fuse to protect the control box.

DISTRIBUTION V AL VE SOLENOIDS

Fig. 6

16 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 19

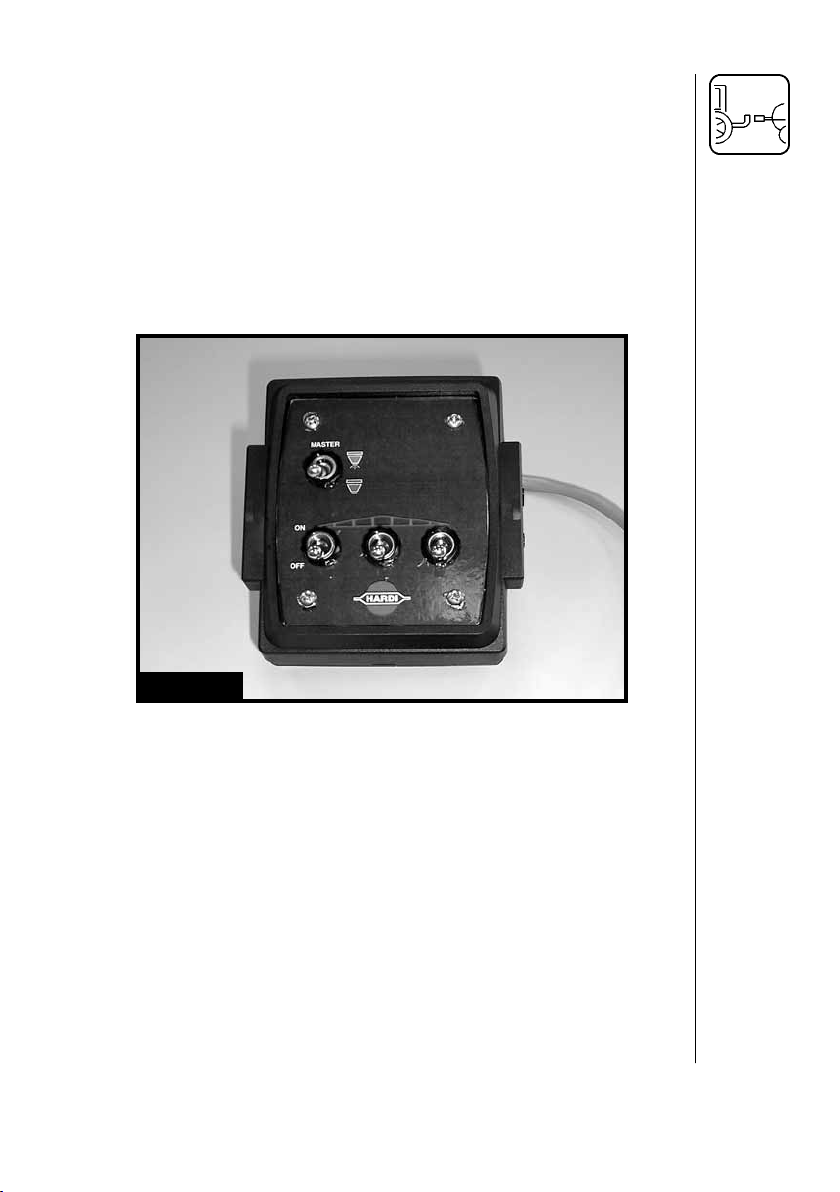

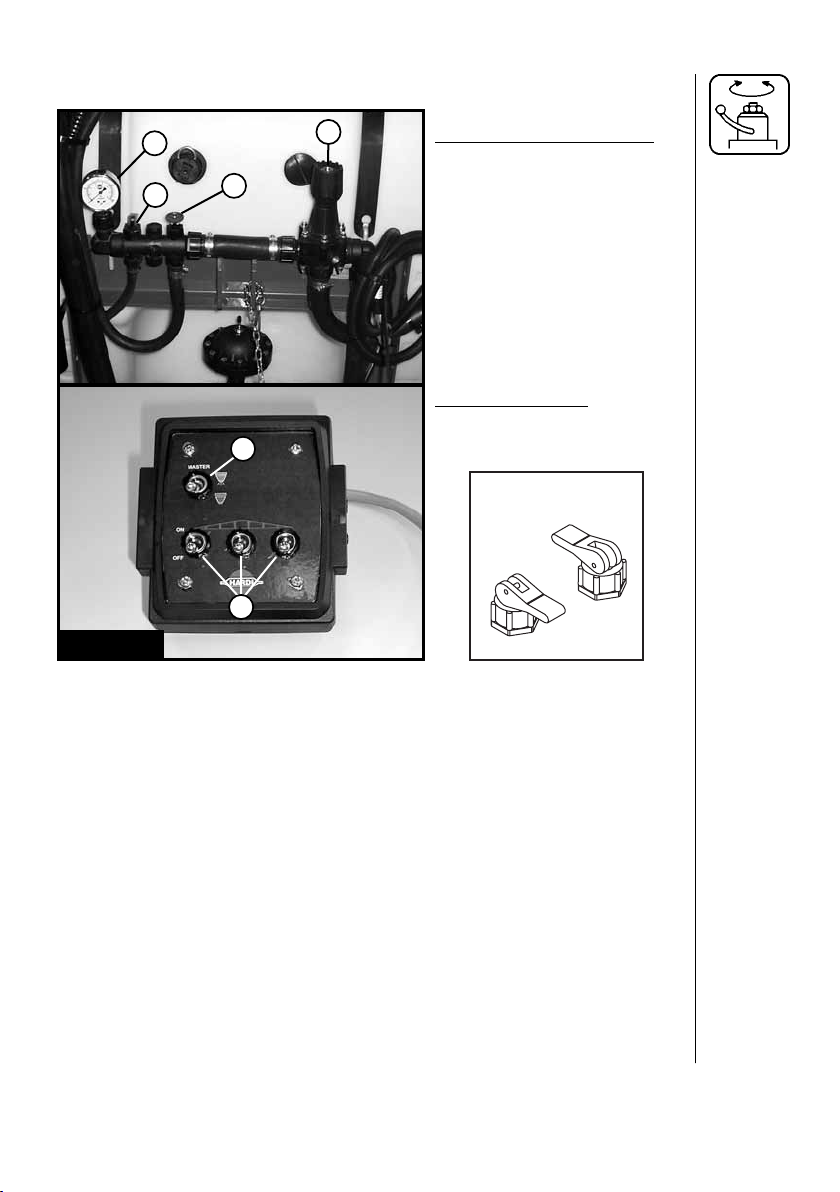

3.4 Control box (electric controls only)

The HARDI® N-series 3-PT sprayer equipped with electric controls

uses an electrical control box for master on/off control and individual

boom section on/off control. An optional rate controller box is also

available.

1. Mount the control box in a convenient location near the operator.

2. Route the power supply (installed in section 3.3) to the small plug on

the control box.

3. Route the main wiring harness from the sprayer to the large plug on

the control box.

Fig. 7

17HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 20

4.0 OPERATING INSTRUCTIONS

4.1 Filling The Main Tank (all models)

Water is fi lled into the tank by re mov ing the tank lid located at the

center of sprayer tank. It is rec om mend ed to use water as clean as

possible for spraying pur pos es. Fill water through the strainer basket

(optional) to pre vent foreign par ti cles from entering the tank.

WARNING: DO NOT LET THE FILLING HOSE ENTER THE TANK.

KEEP IT OUT SIDE THE TANK, POINTING TO WARDS

THE FILLING HOLE (FIG. 8). IF THE END OF THE

HOSE IS BENEATH THE SURFACE OF THE

TANK CONTENTS AND THE WATER SUPPLY

STOPS, CHEMICALS

MAY BE SIPHONED

BACK AND CONTAMINA TE THE WA TER

SUPPLY SOURCE

AND LINES.

4.2 Filling The Clean Water Tank (optional)

Unscrew the clean water tank lid and fi ll with clean water only.

IMPORTANT: The water from this tank is only for hand washing,

cleaning blocked nozzles, etc.

Fig. 8

WARNING: ALTHOUGH THE HANDWASH T ANK IS

ONL Y FILLED WITH CLEAN WATER,

THE WATER MUST NEVER BE USED

FOR DRINKING, DUE TO THE SMALL

RISK OF CONTAMINATION WHILE

FILLING, ETC.

Fig. 9

18 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 21

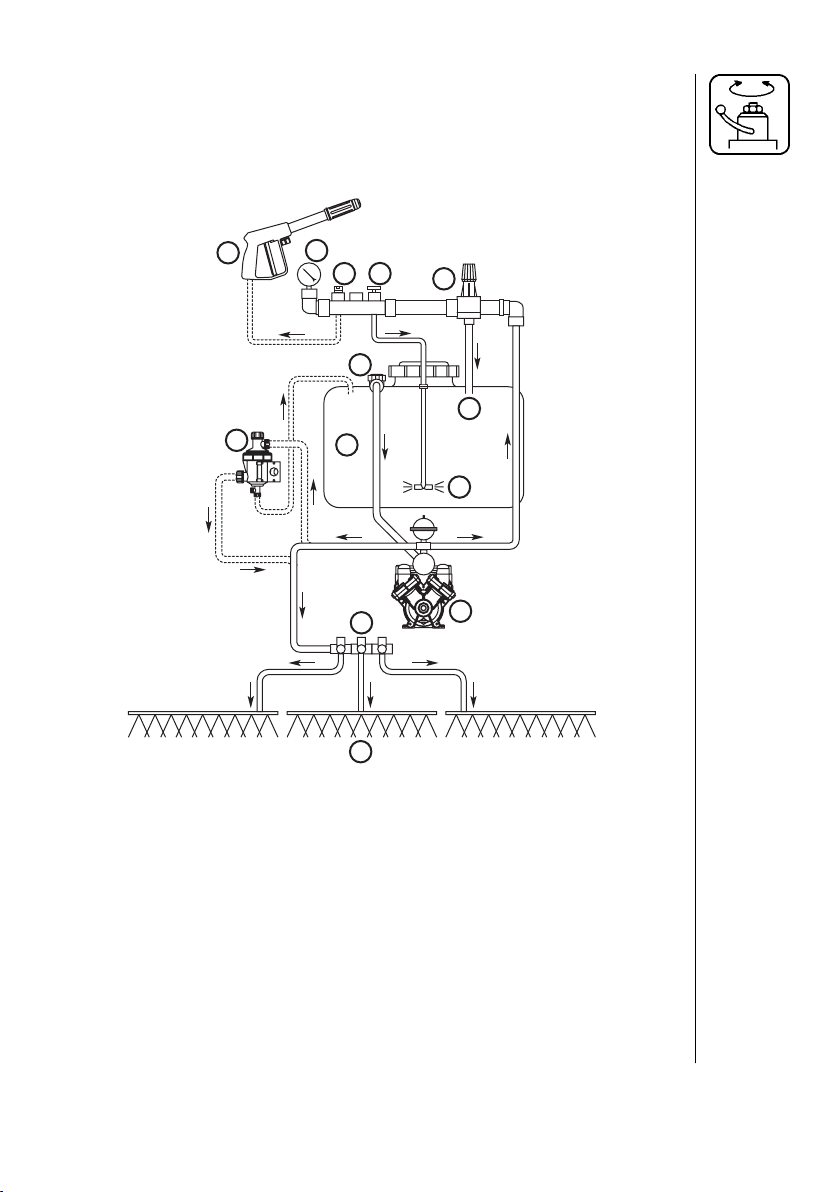

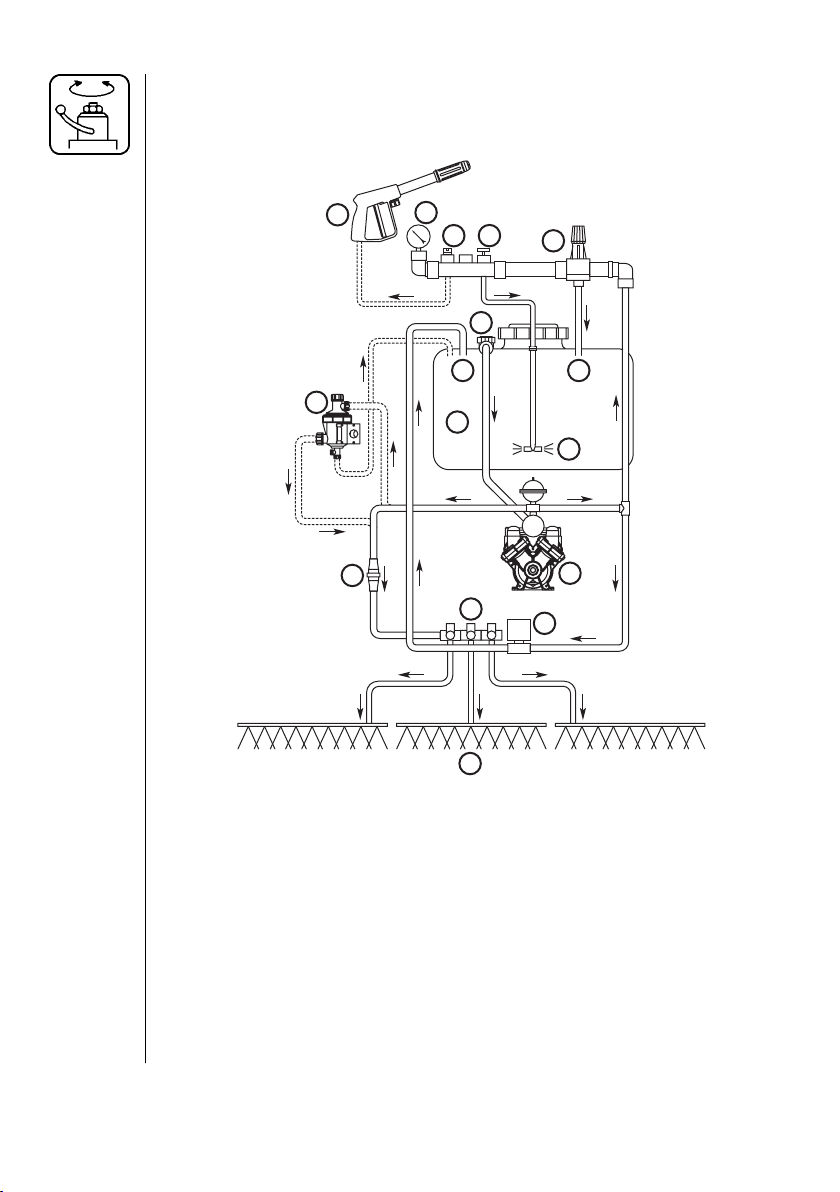

4.3 EC-3 Standard Plumbing Diagram

Review and study the following diagram. By following the fl ow through

the diagram, you will better understand the various functions of your

sprayer system.

7

11

6

4

5

1

9

12

13

3

10

8

2

Fig. 10

1. Top Suction 8. Agitation

2. Diaphragm Pump 9. Tank

3. Pressure Control Valve 10. Bypass Return

4. Agitation Valve 11. Self-Cleaning Filter (optional)

5. Spraygun Valve (optional) 12. Boom Distribution Valves

6. System Pressure Gauge 13. Boom

7. Spraygun (optional)

19HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 22

4.4 EC-3 Plumbing Diagram w/optional Rate Controller

Review and study the following diagram. By following the fl ow through

the diagram, you will better understand the various functions of your

sprayer system.

7

11

14

6

4

5

1

10

9

12

13

3

10

8

2

15

Fig. 11

1. Top Suction 9. Tank

2. Diaphragm Pump 10. Bypass Returns

3. Pressure Relief Valve* 11. Self-Cleaning Filter (optional)

4. Agitation Valve 12. Boom Distribution Valves

5. Spraygun Valve (optional) 13. Boom

6. System Pressure Gauge 14. Flowmeter

7. Spraygun (optional) 15. Pressure Regulator

8. Agitation

*Turn Pressure Relief Valve clockwise all the way in when used with

the optional Rate Controller. Refer to Maverick Operator's manual for

adjustment of the controls.

20 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 23

4.5 Adjustment of the EC-3 Electric Controls

2

4

3

1

SPRAYER CONTROLS:

1. Pressure control valve

2. System Pressure gauge

3. Agitation valve

4. Spraygun valve (optional)

CONTROL BOX:

5. Master On/Off Switch

5

6. Distribution Switches

SPRAYGUN

VAL VE

OFF

6

Fig. 12

ON

Boom Operation

1. Choose the correct nozzle. Make sure that all nozzles are the same

type and capacity. Refer to section 5.0 for nozzle selection and

calibration.

2. Locate your sprayer in a suitable location to spray water from the

boom. Fill the tank with clean water (see section 4.1).

3.

Turn the Pressure Control Valve 1 (Fig. 12) counter clockwise all the

way out.

4. Set Master On/Off boom switch 5 and individual boom switches 6

(Fig. 12) "ON". Set spraygun valve 4 (Fig. 12) "OFF".

5. With the tractor in neutral, engage the P.T.O. to start the pump.

Adjust the R.P.M.'s to normal operating speed.

6. Increase pressure by turning Pressure Control Valve 1 (Fig. 12)

clockwise. Adjust until the pressure gauge 2 (Fig. 12) reaches the

desired pressure (turn Pressure Control Valve counter clockwise to

decrease pressure).

21HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 24

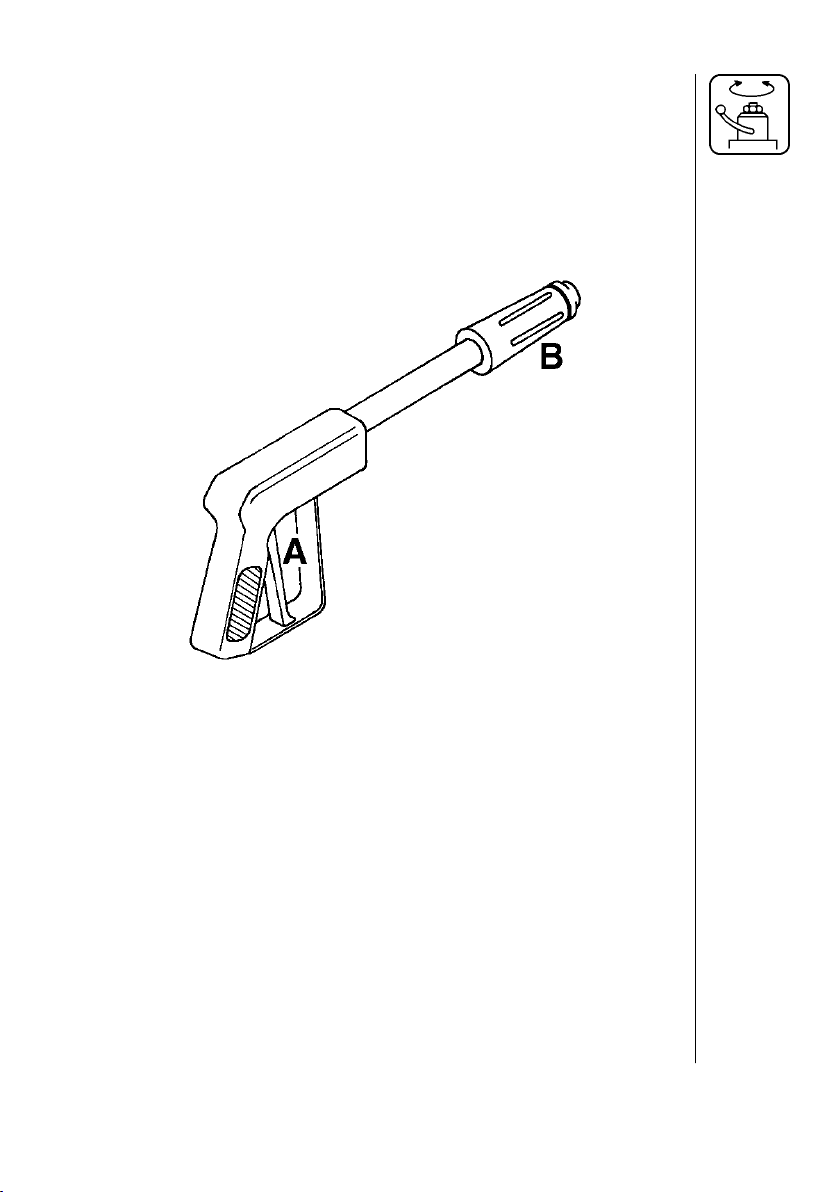

Operating the Spraygun (optional)

7. Set spraygun valve 4 (Fig. 12) "ON" and set Master On/Off boom

switch 5 (Fig. 12) "OFF".

8. Then depress the red handle A (Fig. 13) to spray fl uid from the

spraygun. Check the pressure on the system pressure gauge 2 (Fig.

12) and follow step 6 to adjust.

9. To adjust the spray pattern, turn the black handle B (Fig. 13) OUT for

a narrow spray pattern for long distances and IN for a wide pattern

for more coverage at close distances.

Fig. 13

Agitation Adjustment

Ag i ta tion is nec es sary to keep the so lu tion in your tank prop er ly mixed.

Con sult your chem i cal sup pli er for the rec om mend ed amount of ag i ta tion.

In gen er al, max i mum agitation is required but some products tend to

foam easily. To reduce foaming in some instances anti-foaming agents

may be added to the tank (Refer to chemical label). When running low

liquid levels in the tank, agitation may be reduced to fa cil i tate pump

priming and avoid pressure fl uc tu a tions. Make sure that you have ad just ed the agitation properly before sprayer calibration.

Turn the agitation valve 3 (Fig. 12) clockwise to reduce the agitation

fl ow. Turn the valve counter-clockwise to in crease the agitation fl ow.

22 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 25

4.6 ET-3 Manual Control Plumbing Diagram

Review and study the following diagram. By following the fl ow through

the diagram, you will better understand the various functions of your

sprayer system.

7

6

13

5 12

9

4

3

1

10

8

2

11

Fig. 14

1. Top Suction 8. Agitation

2. Diaphragm Pump 9. Tank

3. Pressure Control Valve 10. Bypass Return

4. Agitation Valve 11. Self-Cleaning Filter (optional)

5. Spraygun Valve (optional) 12. Boom Distribution Valves

6. System Pressure Gauge 13. Boom

7. Spraygun (optional)

23HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 26

4.7 Adjustment of the ET-3 Manual Controls

3

1

2

5

Fig. 15

4

1. Pressure control valve

2. Distribution valves

3. System pressure gauge

4. Agitation valve

5. Spraygun valve (optional)

ON

OFF

Boom Operation

1. Choose the correct nozzle. Make sure that all nozzles are the same

type and capacity. Refer to section 5.0 for nozzle selection and

calibration.

2. Locate your sprayer in a suitable location to spray water from the

boom. Fill the tank with clean water (see section 4.1).

3.

Turn the Pressure Control Valve 1 (Fig. 15) counter clockwise all the

way out.

4. Set the three distribution valves 2 (Fig. 15) to the ON position. Set

spraygun valve 5 (Fig. 15) to the OFF position.

5. With the tractor in neutral, engage the P.T.O. to start the pump.

Adjust the R.P.M.'s to normal operating speed.

6. Increase pressure by turning Pressure Control Valve 1 (Fig. 15)

clockwise. Adjust until the pressure gauge 3 (Fig. 15) reaches the

desired pressure (turn Pressure Control Valve counter clockwise to

decrease pressure).

24 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 27

Operating the Spraygun (optional)

7. Set the three distribution valves 2 (Fig. 15) to the OFF position. Set

spraygun valve 5 (Fig. 15) to the ON position.

8. Then depress the red handle A (Fig. 16) to spray fl uid from the

spraygun. Check the pressure on the system pressure gauge 3 (Fig.

15) and follow step 6 to adjust.

9. To adjust the spray pattern, turn the black handle B (Fig. 16) OUT for

a narrow spray pattern for long distances and IN for a wide pattern

for more coverage at close distances.

Fig. 16

Agitation Adjustment

Ag i ta tion is nec es sary to keep the so lu tion in your tank prop er ly mixed.

Con sult your chem i cal sup pli er for the rec om mend ed amount of ag i ta tion.

In gen er al, max i mum agitation is required but some products tend to

foam easily. To reduce foaming in some instances anti-foaming agents

may be added to the tank (Refer to chemical label). When running low

liquid levels in the tank, agitation may be reduced to fa cil i tate pump

priming and avoid pressure fl uc tu a tions. Make sure that you have ad just ed the agitation properly before sprayer calibration.

Turn the agitation valve 4 (Fig. 15) clockwise to reduce the agitation

fl ow. Turn the valve counter-clockwise to in crease the agitation fl ow.

25HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 28

4.8 ET-2 Manual Control Plumbing Diagram

Review and study the following diagram. By following the fl ow through

the diagram, you will better understand the various functions of your

sprayer system.

7

6

13

5 12

4

3

1

10

9

8

2

11

Fig. 17

1. Top Suction 8. Agitation

2. Diaphragm Pump 9. Tank

3. Pressure Control Valve 10. Bypass Return

4. Agitation Valve 11. Self-Cleaning Filter (optional)

5. Spraygun Valve (optional) 12. Boom Distribution Valves

6. System Pressure Gauge 13. Pasture Sprayer Nozzles

7. Spraygun (optional)

26 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 29

4.9 Adjustment of the ET-2 Manual Controls

3

1

2

5

Fig. 18

4

1. Pressure control valve

2. Distribution valves

3. System pressure gauge

4. Agitation valve

5. Spraygun valve (optional)

ON

OFF

Operating the Pasture Sprayer Nozzles

1. Choose the correct pasture sprayer nozzles (Section 5.2). Make sure

that both nozzles are the same type and capacity.

2. Locate your sprayer in a suitable location to spray water from the

boom. Fill the tank with clean water (see section 4.1).

3.

Turn Pressure Control Valve 1 (Fig. 18) counter clockwise all the way.

4. Set the two distribution valves 2 (Fig. 18) to the ON position. Set

spraygun valve 5 (Fig. 18) to the OFF position.

5. With the tractor in neutral, engage the P.T.O. to start the pump.

Adjust the R.P.M.'s to normal operating speed.

6. Increase pressure by turning Pressure Control Valve 1 (Fig. 18)

clockwise. Adjust until the pressure gauge 3 (Fig. 18) reaches the

desired pressure (turn Pressure Control Valve counter clockwise to

decrease pressure).

27HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 30

Operating the Spraygun (optional)

7. Set the two distribution valves 2 (Fig. 18) to the OFF position. Set

spraygun valve 5 (Fig. 18) to the ON position.

8. Then depress the red handle A (Fig. 19) to spray fl uid from the

spraygun. Check the pressure on the system pressure gauge 3 (Fig.

18) and follow step 6 to adjust.

9. To adjust the spray pattern, turn the black handle B (Fig. 19) OUT for

a narrow spray pattern for long distances and IN for a wide pattern

for more coverage at close distances.

Fig. 19

Agitation Adjustment

Ag i ta tion is nec es sary to keep the so lu tion in your tank prop er ly mixed.

Con sult your chem i cal sup pli er for the rec om mend ed amount of ag i ta tion.

In gen er al, max i mum agitation is required but some products tend to

foam easily. To reduce foaming in some instances anti-foaming agents

may be added to the tank (Refer to chemical label). When running low

liquid levels in the tank, agitation may be reduced to fa cil i tate pump

priming and avoid pressure fl uc tu a tions. Make sure that you have ad just ed the agitation properly before sprayer calibration.

Turn the agitation valve 4 (Fig. 18) clockwise to reduce the agitation

fl ow. Turn the valve counter-clockwise to in crease the agitation fl ow.

28 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 31

4.10 BK-3 Manual Control Plumbing Diagram

Review and study the following diagram. By following the fl ow through

the diagram, you will better understand the various functions of your

sprayer system.

12

7

10

9

13

6

1

10

14

3

8

2

4

5

11

Fig. 20

1. Top Suction 8. Agitation

2. Diaphragm Pump 9. Tank

3. HARDI-MATIC 10. Bypass Returns

4. Agitation Valve 11. Self-Cleaning Filter (optional)

5. Spraygun Valve (optional) 12. Boom Distribution Valves with

6. Pressure Filter with pressure equalization

pressure gauge 13. Boom

7. Spraygun (optional) 14. On/Off Valve

29HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 32

4.11 Adjustment of the BK-3 Manual Controls

2

A

6

5

B

B

3

4

A

Fig. 21

1. Choose the correct nozzle. Make sure that all nozzles are the same

type and capacity. Refer to section 5.0 for nozzle selection and

calibration.

2. Locate your sprayer in a suitable location to spray water from the

boom. Fill the tank with clean water (see section 4.1).

3. Open or close lever 1 (Fig. 21) depending on whether pressure

agitation is required (Remember pressure agitation takes 5% to 10%

of pump output).

4. Turn main On/Off handle 2 (Fig. 21) to ON position A.

5. Set all hand levers 3 (Fig. 21) on the distribution valves to ON

position A.

6. Turn the HARDI-MATIC valve 4 (Fig. 21) counter-clockwise all the

way out.

7. With the tractor in neutral, engage the P.T.O. to start the pump.

Adjust the R.P.M.'s to normal operating speed.

1

Note: The P.T.O. revolutions must be kept between 300-600 R.P.M. for

the HARDI-MATIC to function properly.

8. Increase pressure by turning the HARDI-MATIC valve 4 (Fig. 21)

clockwise. Adjust until the pressure gauge 6 (Fig. 21) reaches the

desired pressure (turn HARDI-MATIC valve counter clockwise to

decrease pressure).

30 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 33

Adjustment of Pressure Equalization

Note: Adjust the constant boom section pressure one section at a time

as follows: (Start with the valve turned closed before adjusting).

9. Place the fi rst boom distribution valve lever 3 (Fig. 21) in the OFF

position B.

10. Turn the adjusting screw 5 (Fig. 21) until the pressure gauge 6

(Fig. 21) again shows the same pressure as in step 8 (Turn the

screw clockwise for higher pressure, counter clockwise for lower

pressure).

11. Turn the boom distribution valve lever 3 (Fig. 21) back to the ON

position A.

12. Repeat steps 9 through 11 for the remaining boom section valves.

Note: Hereafter adjustment of the constant boom pressure will only be

needed if you change to nozzles with other capacities, but not

required if only changing pressure or application rate using the

same nozzles.

Operating the Control Unit while driving

13. In order to shut off the entire boom, turn the ON/OFF handle 2 (Fig.

21) to OFF position B. This returns the pump output to the tank

through the return system. The diaphragm anti-drip valves ensure

instantaneous closing of all nozzles.

In order to shut off one or more boom sections, turn the boom

distribution lever(s) 3 (Fig. 21) of the unneeded boom section(s)

to OFF position B. The constant pressure device ensures that

the pressure does not increase in the section(s) which are still

operating.

31HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 34

Operating the Spraygun (optional)

14. Set the three distribution valves 3 (Fig. 21) to the OFF position. Set

spraygun valve 5 (Fig. 20) to the ON position.

15. Then depress the red handle A (Fig. 22) to spray fl uid from the

spraygun. Check the pressure on the system pressure gauge 6

(Fig. 21) and follow step 8 to adjust.

16. To adjust the spray pattern, turn the black handle B (Fig. 22) OUT

for a narrow spray pattern for long distances and IN for a wide

pattern for more coverage at close distances.

Fig. 22

32 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 35

4.12 Operation Of The Tank Drain Valve (all models)

WARNING: BEFORE USING THE TANK DRAIN, VERIFY THAT

DISPOSAL OF WASTE IS DONE ACCORDING TO

CHEMICAL LABEL INSTRUCTIONS AND LOCAL

REGULATIONS.

The HARDI

®

N-series 3-PT sprayer is equipped with a top operated

tank drain valve.

The top operated tank drain valve handle is located near the tank

lid. To open the drain valve, turn the red drain valve handle (Fig. 23)

counter-clockwise.

To close the drain valve, turn the handle (Fig. 23) clockwise.

TOP OPERATED TANK DRAIN

To open

Fig. 23

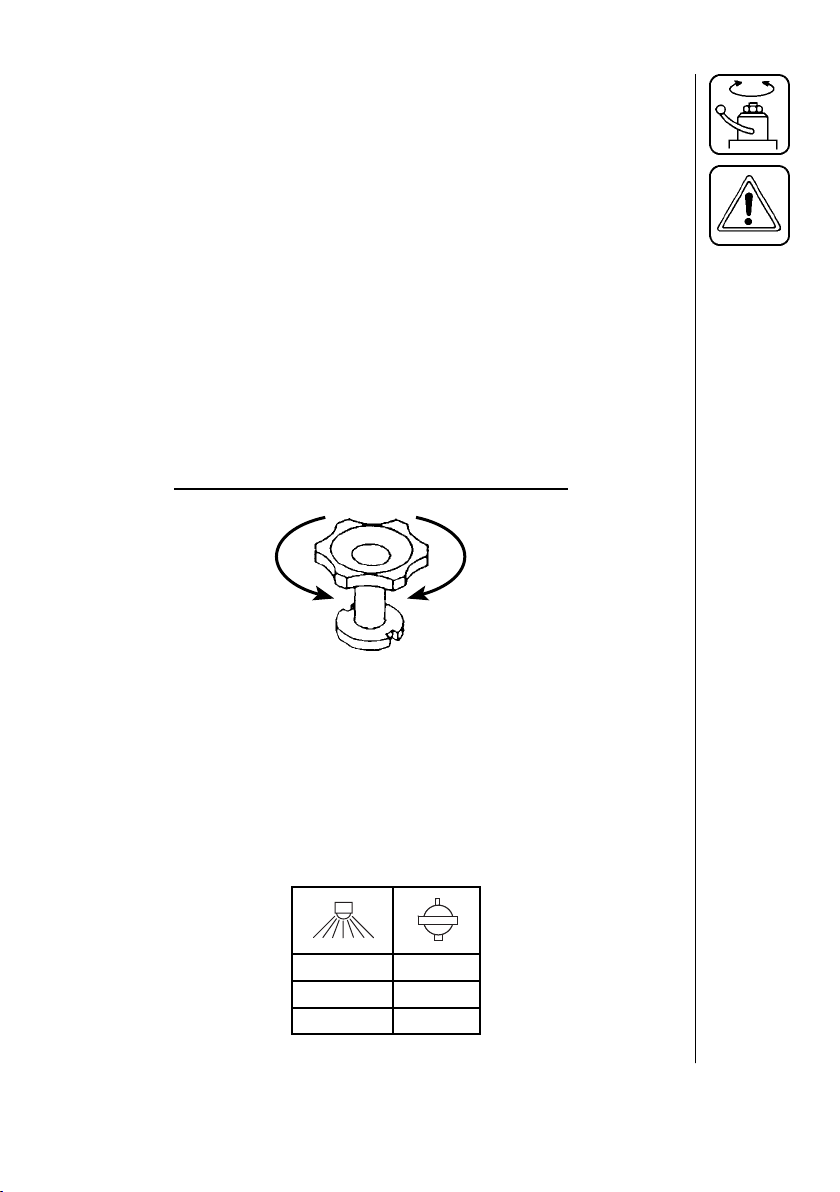

4.13 Adjustment of Air Pressure in Pressure Damper

(All models)

The air pressure in the damper on the HARDI® diaphragm pump is factory preset at 30 psi (2 bar). This is suitable for nozzle spray pressures

between 45 psi (3 bar) and 225 psi (15 bar). If different nozzle pressures are required, set pressure damper at pressures indicated.

To close

PSI (BAR) PSI (BAR)

20-45 (1-3) 0-15 (0-1)

45-255 (3-15) 15-45 (1-3)

33HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 36

4.14 Self Cleaning Fil ter (optional)

This fi lter automatically fl ushes out par ticles and chemical deposits,

re duc ing routine main te nance, nozzle plugging and operator exposure.

No ad just ments are required but different mesh screens may be installed

for various types of products. The mesh size of the fi l ter in use should

al ways be small er than the fl ow av er age of the noz zles used.

Self-Cleaning Filter

Operating Diagram

1. From pump

2. Double fi lter screen

3. Guide cone

4. To operating unit

5. Replaceable restrictor

6. Return to tank

Choice Of Correct Restrictor for S.C.F.

It is important to have a large fl ow though the self clean ing fi lter. This

is achieved by choos ing the restrictor size in re la tion to the liquid

con sump tion of the spray boom.

The hose (A) is un screwed from the self-clean ing

fi lter . Be careful not to lose the seal ball or spring

when the restrictor is put in the hose and the hose

is re fi t ted. If the re quired working pres sure can not

be ob tained, the restrictor is too large. 4 Restrictors

are supplied. Use the green one (larg est or i fi ce) fi rst.

Choose the next smaller restrictor. Start with a black

one, then a white and fi nal ly a red one.

34 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 37

4.15 Unfolding/Folding Boom

(All models with standard booms)

Unfolding boom into operating position

1. Remove transport lock pins A (Fig. 24) and swing boom into

operating position. Store transport lock pins in original locations so

they don't get lost.

2. Lift outer boom sections up and over to horizontal position (not

necessary for 20' MB boom). Carefully check that feed hoses do not

interfere with spray pattern.

3. Remove trapeze lock pin B (Fig. 24) to allow for self-leveling boom

feature (40' MB boom only).

Note: The trapeze lock pin may also be used to lock the boom in a

tilted position (40' MB boom only).

A

B

Fig. 24

Folding boom into transport position

1. Replace trapeze lock pin B (Fig. 24) in center position (40' MB boom

only).

2. Fold outer boom section over to rest on inner boom section (not

necessary for 20' MB boom).

3. Remove transport lock pins A (Fig. 24) and fold boom into transport

position. Secure with transport lock pins A (Fig. 24).

WARNING: MAKE ABSOLUTELY CERTAIN BOOM TRANSPORT LOCK

PINS ARE INST ALLED AND SECURED WITH CLIP PINS

BEFORE TRANSPORTING THE SPRA YER.

35HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 38

4.15 Boom Height Adjustment

(All models with standard booms)

Correct boom height is very important in order to achieve the most

optimal spray pattern. Small adjustments of the boom height can usually be made with the 3-point suspension from the tractor - raising or

lowering the sprayer.

In crops where greater adjustments are needed, the boom height can

be changed manually by removing the 4 bolts holding the boom to the

frame.

Note: This is best done by 2 people or with a mechanical hoist.

36 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 39

5.0 NOZZLE SELECTION

Correct selection of nozzles and calibration of the sprayer are critical to

achieve accurate and cost effective use of farm crop protection prod ucts.

Your HARDI® N-series sprayer has been supplied with standard nozzles. Should you wish a different application rate or different type of

nozzle, HARDI® manufactures a nozzle for virtually every need.

IMPORTANT: Always consult your chemical supplier for rec om mend ed chemical rate and water application rate. Always wear

protective gloves when handling nozzles.

5.1 Boom Nozzle Selection

(All models with standard booms)

The following tables show what types of spray nozzles are suitable for

different applications. It is important to use the correct nozzle.

HARDI® ISO COLOR TIPS™

110 degree fl at fan, one piece

cap and nozzle; color coded for

fl ow rate se lec tion.

For herbicides, insecticides, and

fertilizer applications. 50, 80, and

100 mesh screens are normally

used.

F110

HARDI® ISO LowDrift COLOR

TIPS™ 110 degree fl at f an, one

piece cap and nozzle, 1553 solid

stream nozzle; color coded for

fl ow rate selection.

In-Line Filters will normally be

used.

LD110

37HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 40

HARDI® INJET™ NOZZLES; air

inclusion nozzles with removable

restrictor. Color coded for fl ow

rate selection. In-Line Filters will

normally be used.

FLAT SPRAY NOZZLES in 65

degree, 80 degree, and 110

degree spray angles. For her bi cides, insecticides, and fertilizer

applications. 50, 80, and 100

mesh screens are normally

used.

FLOOD NOZZLES set at 40°

spacing. Designed for high

vol ume application.

HOLLOW CONE NOZZLES

for high pressure and high

vol ume insecticide application

in row crops. 1553 nozzles are

AL WA YS used with swirl plates

shown below EXCEPT when

used as solid stream nozzles.

50, 80, or 100 mesh screens

are normally used with these

nozzles

SWIRL PLA TE used in con junc tion with cone nozzle to create

desired spray pattern. These

swirls work with 1553 series

cone nozzles. Grey , blue, or black

swirls are used to create hollow

cone effect. White swirls are used

to create full cone effect.

4665-65 degree

2080-80 degree

4110-110 degree

Part # 330013-

O-ring

4598

1553

Must add swirl

to produce

hollow cone

pattern

Grey

Blue

Black

White

38 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 41

HOLLOW CONE CERAMIC

NOZZLES for high pressure

and high volume fungicide and

insecticide application.

LARGE DROPLET HOLLOW

CONE NOZZLE for use where

drift must be kept to a minimum.

These nozzles must always be

fi tted with 1553 nozzles and g re y

swirl plates. 50, 80 or 100 mesh

screens are normally used with

these nozzles.

LARGE DROPLET FLA T SPRAY

TIP IN 150 DEGREE SPRAY

ANGLE. Always used in conjunc-

tion with 1553-14-16-18 or 20

cone nozzle. 50, 80 or 100 mesh

screens are normally used with

these nozzles.

SOLID STREAM NOZZLE for

high volume liquid fertilizer

ap pli ca tion. In this application, the

1553 nozzle is always used with

330013 o-ring and 50, 80 or 100

mesh screens.

HARDI® QUINTASTREAM

5 HOLE LIQUID FERTILIZER

NOZZLE Five streams of liquid

are distributed at different angles

and fl ows. Highest fl ow is from

the middle stream and lowest in

the outer; overlapping streams.

This allows for boom mov ements

that do not infl uence distribution.

Boom heights of 20" can be used

as safely as 30".

1299

371077

371551

1553 less swirl

372011

thru

372019

39HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 42

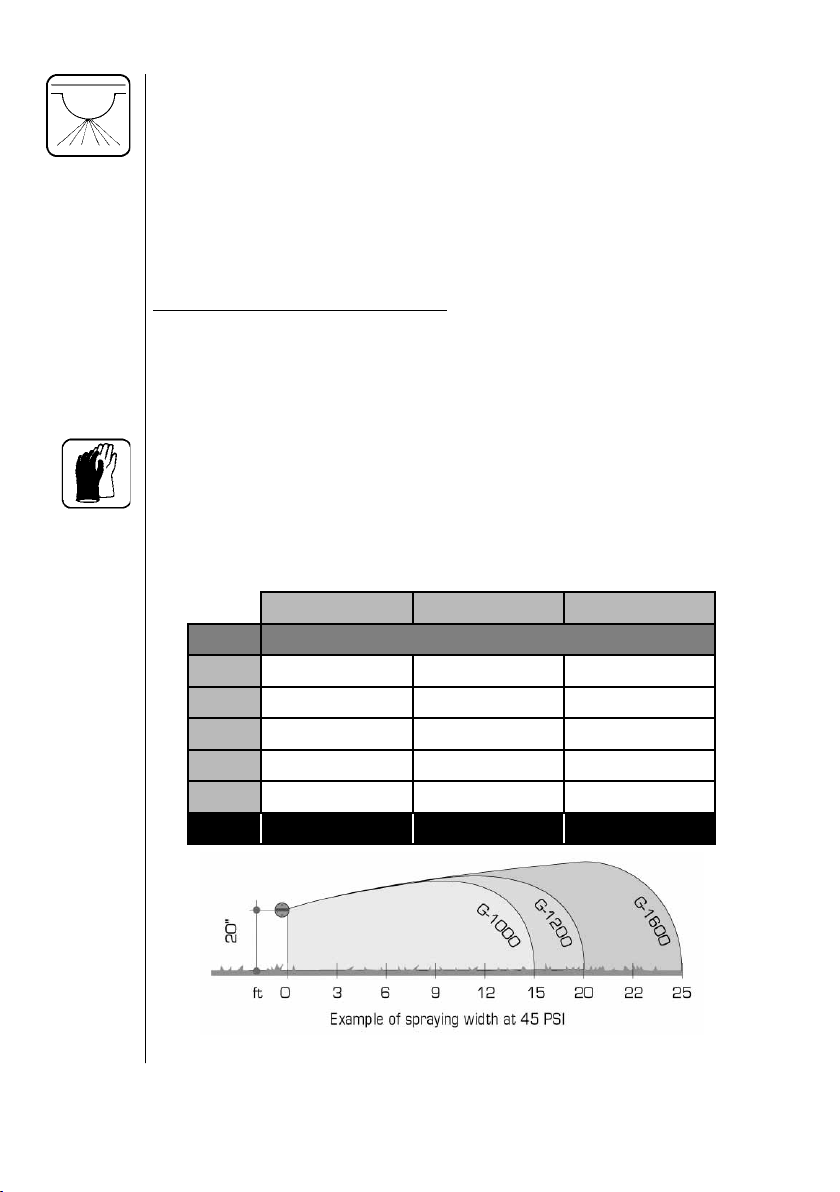

5.2 Giant End Nozzle Selection (Pasture Sprayer only)

The two opposite mounted HARDI® Giant End Nozzles are available in

three different sizes and provide a maximum spray width of 30', 40' or

50' (10m, 12m or 16m) under optimal spraying conditions at the recommended 20" (50 cm) nozzle spray heights (Fig. 25).

For sprayers equipped with "Boom Buster" nozzles (Evergreen Products, Inc.), consult the supplied nozzle application chart.

Giant End Nozzle characteristics:

• Off center spray nozzle

• Pressure range: 20 to 70 PSI

• Spray width up to 25 ft. (per nozzle)

• SYNTAL precision molded thermoplastic

IMPORTANT: Always consult your chemical supplier for rec om mend ed chemical rate and water application rate. Always wear

protective gloves when handling nozzles.

The following tables show which HARDI® Giant End Nozzles are suitable for different applications. It is important to use the correct nozzle.

G-1000 Red G-1200 White G-1600 Blue

PSI GPM

20 3.224 3.762 5.015

30 3.949 4.607 6.143

40 4.560 5.320 7.093

50 5.098 5.948 7.930

70 6.032 7.037 9.383

Part # 371556 371557 371558

Fig. 25

40 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 43

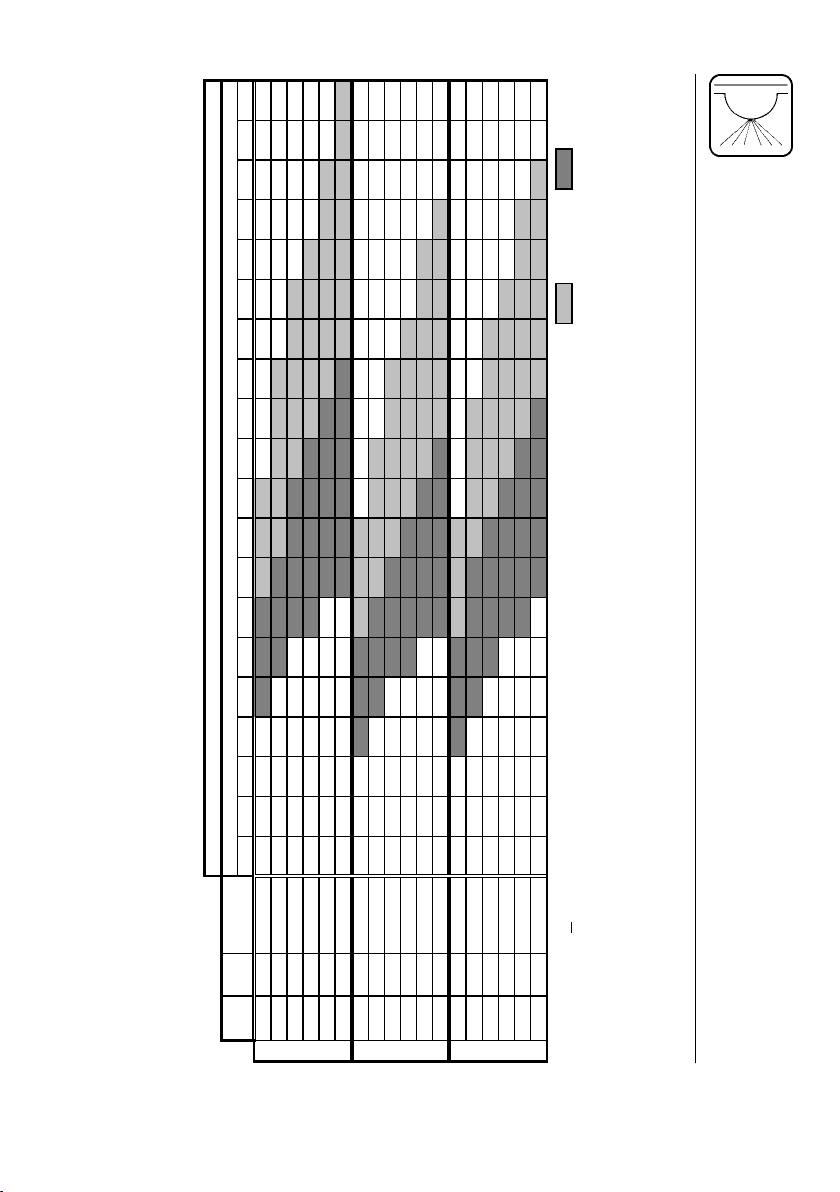

(

GALLONS PER ACRE

)

SPEED (MPH)

15-25 GPA

10-15 GPA

APPLICATION RATE

1234567891011121314151617181920

‡

Use the following table to quickly determine which nozzle and spraying speed will work best for a wide range of

Note: Using this chart will bring you very close to your desired application rate. However, you must calibrate

application rates.

your sprayer with clean water before applying chemicals (Section 5.5).

SPRAY

WIDTH (ft)

†

GPM

20 3.224 30.0 106.4 53.2 35.5 26.6 21.3 17.7 15.2 13.3 11.8 10.6 9.7 8.9 8.2 7.6 7.1 6.6 6.3 5.9 5.6 5.3

PSI*

30 3.949 30.0 130.3 65.2 43.4 32.6 26.1 21.7 18.6 16.3 14.5 13.0 11.8 10.9 10.0 9.3 8.7 8.1 7.7 7.2 6.9 6.5

40 4.560 30.0 150.5 75.2 50.2 37.6 30.1 25.1 21.5 18.8 16.7 15.0 13.7 12.5 11.6 10.7 10.0 9.4 8.9 8.4 7.9 7.5

50 5.098 30.0 168.2 84.1 56.1 42.1 33.6 28.0 24.0 21.0 18.7 16.8 15.3 14.0 12.9 12.0 11.2 10.5 9.9 9.3 8.9 8.4

60 5.575 30.0 184.0 92.0 61.3 46.0 36.8 30.7 26.3 23.0 20.4 18.4 16.7 15.3 14.2 13.1 12.3 11.5 10.8 10.2 9.7 9.2

G-1000 RED

70 6.032 30.0 199.1 99.5 66.4 49.8 39.8 33.2 28.4 24.9 22.1 19.9 18.1 16.6 15.3 14.2 13.3 12.4 11.7 11.1 10.5 10.0

20 3.762 40.0 93.1 46.6 31.0 23.3 18.6 15.5 13.3 11.6 10.3 9.3 8.5 7.8 7.2 6.7 6.2 5.8 5.5 5.2 4.9 4.7

30 4.607 40.0 114.0 57.0 38.0 28.5 22.8 19.0 16.3 14.3 12.7 11.4 10.4 9.5 8.8 8.1 7.6 7.1 6.7 6.3 6.0 5.7

40 5.320 40.0 131.7 65.8 43.9 32.9 26.3 21.9 18.8 16.5 14.6 13.2 12.0 11.0 10.1 9.4 8.8 8.2 7.7 7.3 6.9 6.6

50 5.948 40.0 147.2 73.6 49.1 36.8 29.4 24.5 21.0 18.4 16.4 14.7 13.4 12.3 11.3 10.5 9.8 9.2 8.7 8.2 7.7 7.4

60 6.500 40.0 160.9 80.4 53.6 40.2 32.2 26.8 23.0 20.1 17.9 16.1 14.6 13.4 12.4 11.5 10.7 10.1 9.5 8.9 8.5 8.0

70 7.037 40.0 174.2 87.1 58.1 43.5 34.8 29.0 24.9 21.8 19.4 17.4 15.8 14.5 13.4 12.4 11.6 10.9 10.2 9.7 9.2 8.7

G-1200 WHITEG-1600 BLUE

20 5.015 50.0 99.3 49.6 33.1 24.8 19.9 16.5 14.2 12.4 11.0 9.9 9.0 8.3 7.6 7.1 6.6 6.2 5.8 5.5 5.2 5.0

30 6.143 50.0 121.6 60.8 40.5 30.4 24.3 20.3 17.4 15.2 13.5 12.2 11.1 10.1 9.4 8.7 8.1 7.6 7.2 6.8 6.4 6.1

40 7.093 50.0 140.4 70.2 46.8 35.1 28.1 23.4 20.1 17.6 15.6 14.0 12.8 11.7 10.8 10.0 9.4 8.8 8.3 7.8 7.4 7.0

50 7.930 50.0 157.0 78.5 52.3 39.3 31.4 26.2 22.4 19.6 17.4 15.7 14.3 13.1 12.1 11.2 10.5 9.8 9.2 8.7 8.3 7.9

60 8.666 50.0 171.6 85.8 57.2 42.9 34.3 28.6 24.5 21.4 19.1 17.2 15.6 14.3 13.2 12.3 11.4 10.7 10.1 9.5 9.0 8.6

70 9.383 50.0 185.8 92.9 61.9 46.4 37.2 31.0 26.5 23.2 20.6 18.6 16.9 15.5 14.3 13.3 12.4 11.6 10.9 10.3 9.8 9.3

Fig. 26

† GPM per nozzle

the nozzle ‡ Spray width is the total width (2 nozzles) at 20" spray height

* PSI is the pressure at

41HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 44

5.3 Spraygun Nozzle Selection (All models)

The 1099-20 nozzle (HARDI® ref. no. 371314) is the standard nozzle

for the spraygun. This nozzle supplies the following rates in U.S. gallons per minute at the given pressures:

GPM

NOZZLE

1099-20

PSI

20

30

40

50

60

70

100

150

200

0.678

0.829

0.956

1.068

1.169

1.261

1.504

1.840

2.123

0.538

0.661

0.766

0.857

0.940

1.018

1.222

1.500

1.736

Other size 1099 nozzles are available from your HARDI

®

Dealer.

42 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 45

5.4 Calibration (All models with standard booms)

WARNING: ALWAYS CALIBRATE YOUR SPRAYER WITH CLEAN

WATER ONLY! IN ADDITION, WEAR PROTECTIVE

CLOTHING WHEN CALIBRATING YOUR SPRAYER!

Why must you calibrate a sprayer?

A nozzle selection chart will tell you what application rate you should

expect. V ariations due to nozzle wear, errors in pressure adjustment, and

tractor speedometer can result in a possible error in application rate.

How do you calibrate a sprayer?

Calibration kits are available from HARDI

®

, #818493 for US gallons &

#818492 for metric calibration.

Following are some tips to remember when using the calibration kit

method:

• When determining the length of time required to drive the recommended

distance, drive in actual fi eld conditions with a half-full tank.

• Repeat the test several times, each time avoiding the tracks from the

previous test. Take the average of the times recorded.

• Calibration of the sprayer should be completed at the beginning of the

season and repeated after every 2 to 3 full days of spraying, and every

time you change volume rate or use new nozzles.

• Before you calibrate, check the fl ow of each nozzle. If it puts out more

than 10% of its original volume, replace it.

Select your calibration method: Ounce method or Formula method.

Then follow the steps described in the corresponding section(s):

43HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 46

Ounce Method

1. Determine how long it takes to cover the test strip. Use the following

chart to determine the length of your test strip. Row width f or broadcast

application is equal to your nozzle spacing. For your drop nozzle or

band application, use row spacing.

Row width or nozzle spacing (in.) Distance (ft.)

40 102

38 107

36 113

34 120

32 127

30 136

28 146

26 157

24 170

22 185

20 204

18 227

16 255

14 291

2. Measure the amount of time it takes you to travel the test strip when

throttle is set at spraying speed.

3. In a container (with oz. measurements), catch the spra y from one nozzle

for that amount of time. F or drop or band nozzles, catch the spra y from

all nozzles for the row.

4. Read the ounces in the container. That is the actual U.S. GPA applied.

(ounces = GPA)

44 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 47

Formula Method

1. Check your spraying speed. Measure a test strip of at least 200 feet

(300 feet is ideal). T rav el the distance at the speed you plan on spraying

and record the time it takes to trav el the distance. Read from the chart

or use the formula to fi nd your exact travel speed.

Travel Time (in seconds)

Speed in MPH 200 ft. 300 ft.

3.0 45 68

3.5 39 58

4.0 34 51

Formula: 4.5 30 45

distance (ft.) x 0.68

seconds 6.0 23 34

7.0 19 29

7.5 18 27

8.0 17 26

9.0 15 23

= MPH

5.0 27 41

2. Calculate the required nozzle output. Use either the nozzle wheel (if

nozzle spacing is 20 inches), or this formula:

Formula: Formula:

5940

GPA x MPH x W (in.)

GPM =

GPM =

10 x 7 x 20

5940

= .24 GPM

Note: W= • Nozzle spacing (in inches) for broadcast application.

• Row spacing (in inches) divided by number of nozzles

per row for drop nozzle application.

• Sprayed band width or swath width (in inches) for band

application divided by number of nozzles per band.

• Note that on the nozzle wheel, W = 20 inches.

3. Set correct pressure. Read the required pressure from the nozzle table

in the nozzle catalogue or nozzle wheel. With clean water in the tank

and line, turn on the sprayer and set the target pressure. Collect the

spray from one nozzle for one minute in a container. Adjust pressure

until you collect the precise GPM called for.

45HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 48

Calibration For Carriers Other Than Water

Use the following water rate conversion chart to determine the right

conversion factor. When you've determined the new converted GPM or

GPA, you can follow the steps on either the pressure or ounce method

of calibration.

Weight of solution Specifi c Gravity Conversion Factors

7.00 lbs/gal .84 .92

8.00 lbs/gal .96 .98

8.34 lbs/gal-water 1.00 1.00

9.00 lbs/gal 1.08 1.04

10.00 lbs/gal 1.20 1.10

10.65 lbs/gal-28% N 1.28 1.13

11.00 lbs/gal 1.32 1.15

12.00 lbs/gal 1.44 1.20

14.00 lbs/gal 1.68 1.30

Example: 20 GPA of 28% N

Then GPA (solution) x conversion factor = GPA (water)

20 GPA (28% N) x 1.13 = 22.6 GPA (water)

Calibrate for 22.6 GPA of water

For conversion to Imperial gallons per acre, multiply U.S. GPA by .833

For conversion to liters per hectare, multiply U.S. GPA by 9.34

For conversion to liters per acre, multiply U.S. GPA by 3.78

Formula for tractor speed: Distance (in feet) x .682

= MPH

Second

46 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 49

5.5 Calibration (Pasture sprayer model only)

WARNING: ALWAYS CALIBRATE YOUR SPRAYER WITH CLEAN

WATER ONLY! IN ADDITION, WEAR PROTECTIVE

CLOTHING WHEN CALIBRATING YOUR SPRAYER!

Why must you calibrate a sprayer?

A nozzle selection chart will tell you what application rate you should

expect. Variations due to nozzle wear, errors in pressure adjustment,

and tractor speedometer can result in a possible error in application

rate.

How do you calibrate a sprayer?

Calibration kits are available from HARDI®, #818493 for US gallons &

#818492 for metric calibration.

Following are some tips to remember when using the calibration kit

method:

• When determining the length of time required to drive the recom-

mended distance, drive in actual fi eld conditions with a half-full tank.

• Repeat the test several times, each time avoiding the tracks from the

previous test. Take the average of the times recorded.

• Calibration of the sprayer should be completed at the beginning of

the season and repeated after every 2 to 3 full days of spraying, and

every time you change volume rate or use new nozzles.

• Before you calibrate, check the fl ow of each nozzle. If it puts out more

than 10% of its original volume, replace it.

47HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 50

Formula Method

1. Check your spraying speed. Measure a test strip of at least 200

feet (300 feet is ideal). Travel the distance at the speed you plan on

spraying and record the time it takes to travel the distance. Read

from the chart or use the formula to fi nd your exact travel speed.

Travel Time (in seconds)

Speed in MPH 200 ft. 300 ft.

3.0 45 68

3.5 39 58

4.0 34 51

Formula: 4.5 30 45

Distance (ft.) x 0.68

= MPH

5.0 27 41

Time (sec.) 6.0 23 34

7.0 19 29

7.5 18 27

8.0 17 26

9.0 15 23

2. After determining your forward speed and choosing your application

rate according to the recommendations on the chemical container,

use the following formula to calculate the total nozzle capacity:

Formula:

Total GPM =

W (ft.) x GPA x MPH

495

Note: W = Total measured sprayed width (ft.) at operating pressure.

3.

To initially calculate which nozzle to use, let W = 30 ft., 40ft. or 50 ft.

for HARDI® Giant End Nozzles G-1000 Red, G-1200 White or G1600 Blue, respectively (Fig. 24 & Fig. 25).

Example: Total sprayed width: 40 ft. (G-1200 White nozzles)

Application rate: 20 GPA

Forward speed: 7 mph

11.3 GPM =

40 ft. x 20 GPA x 7 mph

495

48 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 51

Calibration (continued)

4. Divide the total nozzle capacity by 2 (the number of nozzles) to get

the GPM needed per nozzle to match the speed, pressure and width

used in the calculations (Example: 11.3 ÷ 2 = 5.65 GPM).

Capacity of single nozzle in GPM =

Number of nozzles

5. For HARDI® Giant End Nozzles, use the nozzle chart (Fig. 25) to

fi nd the nozzle with the closest desired output and pressure. (The G1200 White nozzle at 50 PSI is the closest for this example at 5.948

GPM).

IMPORTANT: Al ways check actual sprayed width at operating

pressure once the correct nozzle has been chosen. Locate the

sprayer in a suitable location and use clean water to check.

6. If the measured sprayed width at operating pressure differs from the

value used in step 2, re-calculate the total nozzle capacity using the

measured sprayed width. Divide by 2 to get the nozzle capacity in

GPM needed per nozzle (step 4). This will be the corrected nozzle

capacity in GPM required from each nozzle for proper application

rate.

7. Double-check the nozzle output with a measuring jug (using clean

water at operating pressure). If the measured nozzle output matches

the required calculated output, calibration is complete.

8. If necessary, use the following formulas to adjust either the spraying

speed or operating pressure to achieve proper calibration.

Total GPM

New speed (MPH) =

Measured output (GPM)

New pressure (PSI) =

Measured output (GPM)

Note: If the operating pressure is changed, the actual spraying width

will need to be checked again. If spraying width differs, repeat

steps 6-8.

Desired output (GPM) x Previous speed (MPH)

Desired output (GPM) x Previous pressure (PSI)

49HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 52

Calibration For Carriers Other Than Water

Use the following water rate conversion chart to determine the right

conversion factor. When you've determined the new converted GPM or

GPA, you can follow the steps in the formula method of calibration.

Weight of solution Specifi c Gravity Conversion Factors

7.00 lbs/gal .84 .92

8.00 lbs/gal .96 .98

8.34 lbs/gal-water 1.00 1.00

9.00 lbs/gal 1.08 1.04

10.00 lbs/gal 1.20 1.10

10.65 lbs/gal-28% N 1.28 1.13

11.00 lbs/gal 1.32 1.15

12.00 lbs/gal 1.44 1.20

14.00 lbs/gal 1.68 1.30

Example: 20 GPA of 28% N

Then GPA (solution) x conversion factor = GPA (water)

20 GPA (28% N) x 1.13 = 22.6 GPA (water)

Calibrate for 22.6 GPA of water

For conversion to Imperial gallons per acre, multiply U.S. GPA by .833

For conversion to liters per hectare, multiply U.S. GPA by 9.34

For conversion to liters per acre, multiply U.S. GPA by 3.78

Formula for tractor speed: Distance (in feet) x .682

= MPH

Second

50 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 53

6.0 MAINTENANCE

IMPORTANT: Always clean the sprayer at the end of your workday

or before servicing is done to avoid unnecessary contact with

chemicals.

In order to derive full benefi t from the sprayer for many years, the fol low ing few, but im por tant rules should be followed.

6.1 Cleaning The Sprayer

Guidelines

Read the whole label for the chem i cal used. Take note of any par tic u lar

in struc tions regarding rec om mend ed protective clothing, de ac ti vat ing

agents, etc. Read the de ter gent and de ac ti vat ing agent labels. If clean ing pro ce dures are given, follow them closely.

Be familiar with local leg is la tion regarding disposal of pes ti cides washings, man da to ry de con tam i na tion meth ods, etc. Contact the ap pro pri ate body (e.g. Dept. of Ag ri cul ture).

Cleaning starts with cal i bra tion, as a well cal i brat ed spray er will en sure

a min i mal amount of re main ing spray liquid.

It is good practice to clean the spray er immediately after use, there by

ren der ing the spray er safe and ready for the next ap pli ca tion. This also

pro longs the life of the com po nents.

It is sometimes necessary to leave spray liquid in the tank for short

pe ri ods - over night, or until the weather becomes suitable for spray ing

again. Unauthorized per sons and animals must not have ac cess to the

sprayer under these circumstances.

If the product applied is cor ro sive, it is recommended to coat all metal

parts of the sprayer before and after use with a suit able rust in hib i tor.

Remember: Clean sprayers are safe spray ers.

Clean sprayers are ready for action.

Clean sprayers can not be dam aged by chemicals and

their solvents.

51HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 54

Cleaning

1. Dilute remaining spray liquid in the tank with at least 10 parts water

and spray the liquid out in the fi eld you have just sprayed.

Note: It is ad vis able to in crease the forward speed (dou ble if possible)

and reduce the pressure.

2. Select and use the ap pro pri ate protective clothing. Select detergent

suitable for cleaning and suit able de ac ti vat ing agents if necessary.

3. Rinse and clean sprayer and tractor ex ter nal ly. Use de ter gent if

necessary.

4. Remove all fi lters and clean them. Be careful not to damage the

mesh. Replace fi lters when the sprayer is completely clean.

5. With the pump running, rinse the inside of the tank. Re mem ber the

tank roof. Rinse and operate all com po nents and any equipment that

has been in contact with the chemical.

6. After spraying the liquid out again in the fi eld, stop the pump and fi ll

at least 1/5 of the tank with clean wa ter. Note that some chemicals

require the tank to be com plete ly fi lled. Add appropriate detergent

and/or deactivating agent, e.g. Washing soda or Triple ammonia.

Note: If a cleaning pro ce dure is given on the chemical label, follow it

closely.

7. Start the pump and op er ate all controls en abling the liquid to come

in contact with all the components. Leave the dis tri bu tion valves until

last. Some detergents and de ac ti vat ing agents work best if left in the

tank for a short period. Check the label.

8. Drain the tank and let the pump run dry. Rinse inside of tank, again

letting the pump run dry.

9. Stop the pump. If the chemicals used have a tendency to block

nozzles, re move and clean them now.

10. Replace all fi lters and noz zles and store the sprayer. If, from previ-

ous experiences, it is noted that the solvents in the chemicals are

particularly ag gres sive, store the sprayer with the tank lid open.

Note: If the sprayer is cleaned with a high pres sure cleaner we recom-

mend lu bri ca tion of the entire machine (Section 6.8).

52 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 55

6.2 Filters

IMPORTANT: Wear protective clothing when servicing & handling

components that have been in contact with spray liquid.

Clean fi lters ensure :

• Sprayer components such as valves, diaphr agms and operat ing unit

are not hindered or damaged during operation.

• Nozzle blockages do not occur while spray ing.

• Long life of pump. A blocked suction fi lter will result in pump cavitation.

Suction fi lter

The main fi lter protecting spray er com po nents is

the suc tion fi l ter at the top of the tank. Check

it reg u lar ly. Make sure the O-ring on the

fi lter housing is in good condition and

lubricated*.

Pressure fi lter (BK-3 Control Unit only)

The BK-3 Control unit is equipped with a built-in pressure fi lter.

Unscrew the base to check and clean the fi lter. Make sure the O-ring

on the fi lter housing is in good condition and lubricated*.

*HARDI

®

recommends using a vegetable based oil to prolong the life of

the O-ring.

53HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 56

ISO Nozzle

Size

Pink (075)

Orange (01)

Green (015)

Yellow (02)

Suction Filter Self Cleaning

Filter (optional)

50 100 100 100

Nozzle

Screen

Inline Filters

(optional)

Lilac (025)

Blue (03)

Red (04)

& Larger

*Standard mesh

50 80 80 80

30* 50* 50* 50*

6.3 Nozzles And Fittings

Poor seals are usually caused by:

• Missing O-rings or gaskets

• Damaged or incorrectly seated O-rings

• Dry or deformed O-rings or gaskets

• Foreign materials

Therefore, in case of leaks; DO NOT overtighten. Disassemble, check

condition and position of O-ring or gasket, clean, lubricate and reassemble. For radial type seals (O-ring) hand tighten only, do not use

pliers (Fig. 27).

The O-rings need to be lubricated ALL THE WA Y AROUND before fi tting on to the nozzle tube.

Fig. 27

HARDI® recommends using a vegetable based oil to prolong the life of

the O-ring.

54 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 57

6.4 Replacement Of P.T.O. Shaft Protection Guards

The replacement of defective pro tec tion guards is easy to do.

1. The retaining ring A (Fig. 28) holds the base cone B (Fig. 28) and

shield bell C (Fig. 28) to the shield tube D (Fig. 28).

2. Locate the three white tabs on the retaining ring A (Fig. 28) visible

through holes on the shield bell C (Fig. 28). Pushing these tabs will

release the retaining ring A (Fig. 28).

3. Remove the base cone B (Fig. 28) and shield bell C (Fig. 28) from

the shield tube D (Fig. 28).

4. Assemble again in reverse order, using new parts where necessary.

5. Apply grease (Section 6.8).

Use only genuine HARDI

B

A

C

®

spare parts to service the P.T.O. shaft.

D

C

B

A. Retaining Ring

A

B. Base Cone

C. Shield Bell

Fig. 28

D. Shield tubes

6.5 Replacement Of P.T.O. Shaft Cross Journals.

1. Remove protection guard as described pre vi ous ly.

2. Remove circlip rings.

3. Press the cross journal sidewards, use ham mer and punch if necessary.

4. Remove needle bearing cups and cross journal can now be re moved.

5. Carefully remove nee dle bearing cups from new cross journal and

install it in re verse order. Before fi tting the nee dle bearing cups

again, check that nee dles are placed cor rect ly. Avoid dust and dirt in

the new bear ings.

55HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 58

6.6 Changing the Valves and Diaphragms (all pumps)

Note: It is recommended that if one or more diaphragms and or valves

need replacing, they should all be replaced. Complete rebuild kits are

available from HARDI® (check the table below for part numbers).

Pump model 603 1203 1303

Hardi® Part No. 750656 750696 750175

1. Remove the valve cover 1. Before changing the valves 2, note the

orientation of the valves so that they are replaced correctly.

2. It is recommended to use new O-rings 3 when changing or checking

valves.

3. Remove diaphragm covers 4 to gain access to the diaphragms.

4. Remove the diaphragm bolts 5. The diaphragms 6 may now be

changed.

5. If fl uids have reached the crankcase, regrease the pump thoroughly.

Also make sure the drain hole at the bottom of the pump is not

blocked.

6. Reassemble with torque settings shown below.

Pump

Model

603 34 (46) 18.5 (25) 37 (50)

1203/1303 45 (60) 45 (60) 50 (70)

Valve Cover

Ft/lb (Nm)

Diaphragm

Bolt Ft/lb (Nm)

Diaphragm

Cover

4

4

1

5

6

Model 1203

(603 similar)

56 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

2

3

5

6

Model 1303

1

2

3

Page 59

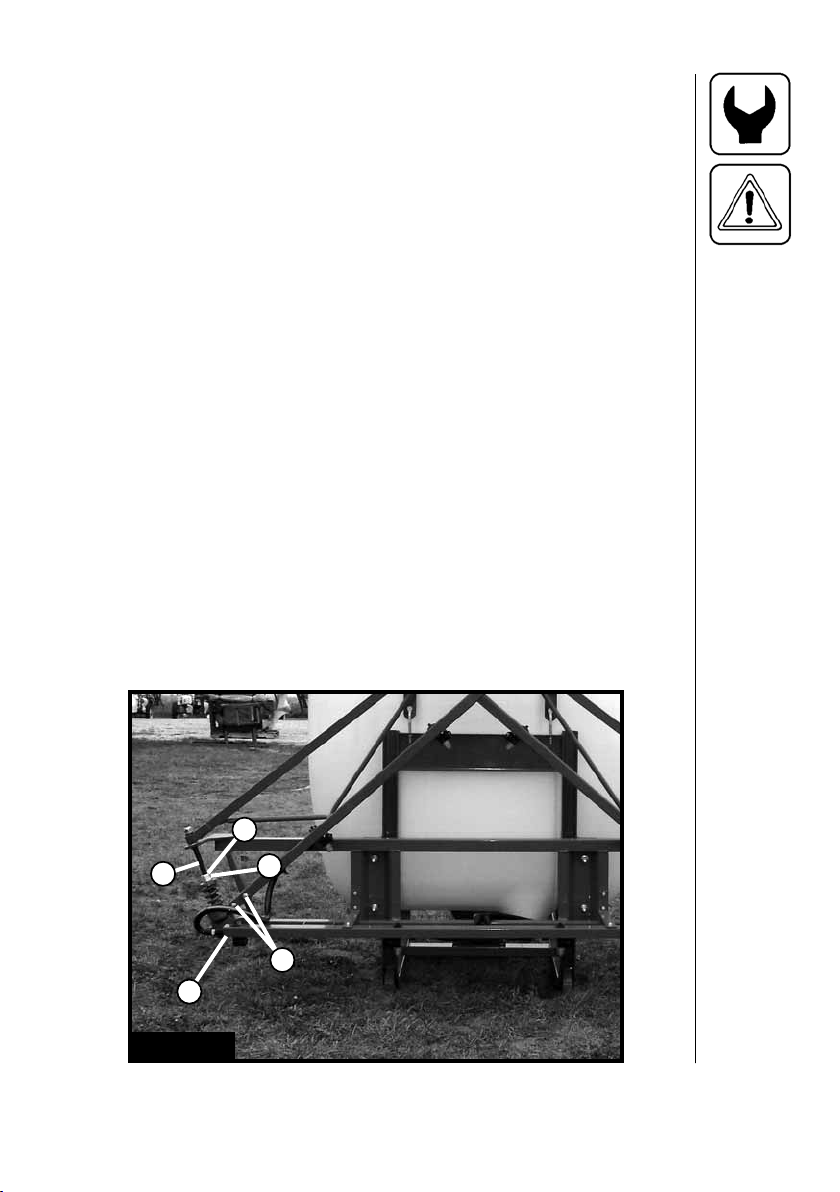

6.7 Breakaway Clutch Adjustment (MB Boom only)

WARNING: NEVER PLACE FINGERS INTO OPEN BREAKAWAY

CLUTCH OR YOU MAY BE INJURED SHOULD CLUTCH

SNAP CLOSED! DO NOT TIGHTEN THE BREAKAWAY

CLUTCH MORE THAN WHAT IS NECESSARY! OVER

TIGHTENING CAN CAUSE DAMAGE TO THE BOOM!

IMPORTANT: Properly lubricate clutch assembly before adjusting the

tension. Breakawa y clutch cap scre ws (A) (Fig. 29) must be torqued

to 40 Ft/lb (55 N-m) every week (40 hours) to prevent boom damage.

Lubricate every day (8 hours) to ensure maximum perf ormance and

life.

The tension on the clutch for the breakaway wing section can be

adjusted by loosening or tightening nut C (Fig. 29).

1. Check that the lower nut D (Fig. 29) is fully tightened.

2. The breakaway wing section should pivot around the axle shaft E

(Fig. 29). Make sure wing section is free to move.

3. Loosen jam nut B (Fig. 29).

4. If the breakaway clutch releases too easily, tighten nut C (Fig. 29).

If the breakaway clutch releases too stiffl y, loosen nut C (Fig. 29).

Clutch is properly tensioned when breakaway wing section returns

to alignment with center section after breaking away.

5. Tighten jam nut B (Fig. 29) after adjustment.

E

D

Fig. 29

B

C

A

57HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 60

6.8 Lubrication

Recommended lubrication is shown in following tables.

Use ball bearing grease (lithium grease No. 2)

Note: If the sprayer is cleaned with a high pressure cleaner or fertilizer

has been used, we recommend lubrication of all sections.

Position on

sprayer

Oil

Sprayer Boom

2

Fig. 30

N-series sprayer lubrication points

Grease

Operation

hours

3

1

Page to find more

information

Winter protection

or off-season

storage

4

5

1. Pump

2. PTO

3. Agitation Control

4. MB Boom

5. Trapeze (40' MB only)

58 HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 61

1X40

2

56

X

X

X

10

50

A

B

340

55

55

59HARDI® N-SERIES 3-PT SPRAYER DIAPHRAGM OPERATOR'S MANUAL

Page 62

48X57

58X