Page 1

MERCURY COVAMAX

Operator Instruction Manual

67002404-100

HAU - 08.2009

www.hardi.com.au

Page 2

We congratulate you for choosing a HARDI plant protection product. The reliability and efficiency of this product

depends upon your care. The first step is to carefully read and pay attention to this instruction book. It contains

essential information for the efficient use and long life of this product.

As this instruction book covers all versions of the equipment which are available in certain countries only,

including all hydraulic variations, and all operating units, please pay attention to the paragraphs dealing precisely

with your model.

This book is not

is to be read in conjunction with the “Spray Technique” book and any other manuals supplied with your sprayer.

Illustrations, technical information and data in this book are to the best of our belief correc t at the time of printing.

As it is HARDI Australia policy to improve our products, we reserve the right to make changes in design, features,

accessories, specifications and maintenance instructions at any time and without notice.

HARDI Australia is without any obligation in relation to implements purchased before or after such changes.

HARDI Australia cannot undertake any responsibility for possible omissions or inaccuracies in this publication,

although everything possible has been done to make it complete and correct.

Published by HARDI Australia

Copyright © HARDI Australia 2009

designed to be a maintenance manual, its main purpose is to supply operational information and

Page 3

Welcome

Section 1

Operator Safety

Section 1

Table of Contents

WELCOME MESSAGE 2

INTRODUCTION 1

SAFETY ALERT ICONS 1

SPRAY DRIFT 1

MECHANICAL SAFETY 2

DISPOSAL OF CHEMICAL CONTAINERS 2

CHEMICAL SAFETY 3

Safety Equipment 3

Contaminated Clothing and Equipment 3

Australian Safety Standards 3

Chemical Information 3

SPRAYER SAFETY 4

Operations 4

Service and Maintenance 4

ELECTRICAL SAFETY 5

During Sprayer Use 5

Operation of Electrical Components 5

TOC. 1

Page 4

Table of Contents

Description

Section 3

INTRODUCTION 1

GENERAL INFO 2

Work Zones 3

Sprayer Details 3

Identification Plate 4

Further documents 4

Road worthiness 4

Chassis 4

Tanks 5

Drawbars 6

Standard Duty Wide Angle Drawbar 6

Heavy Duty Wide Angle Drawbar 6

Fluid System 7

Main Product Pump 7

Manifold System 8

Filters 8

BoomZone Selection Valves 9

Operating Units 10

MC/2 Manual Operating Unit 10

CB/2 Electric Control Unit 10

EVC Operating Control Unit 11

HARDI CB/2 Switchbox 12

HARDI Spray 2 Switchbox 12

HC 2500 Display 12

HC 5500 Display 12

Air Flow Delivery System 13

Centrifugal Blower Unit 13

4-Way Distribution Stack 13

Flexible Delivery Hoses & Boom Tubes 13

Outlet Delivery Spouts & Nozzles 13

Gearbox 14

TOC. 2

Axles 15

Track Adjustment 15

Wheel Types 16

Page 5

Table of Contents

Suspension 17

Powder Mixer - Chemical Induction 18

Boom 19

Lift 20

Fold 20

Tilt 20

Breakaway Arms 21

Adjustable Nozzles & Independent control 21

Sprayer Set-Up

Section 4

Introduction 1

Safety 1

Transporting Mistblower 2

Truck transport 2

Connecting Mistblower to tractor 3

Adjusting drawbar length 3

Hitching Drawbar 4

Sprayer levelling with wide angle drawbar 5

Connecting Hydraulics 6

Brakes 7

Fitting PTO Shaft 9

Jockey Wheel 11

Drawbar Safety Chains 11

Connecting Controls 12

Boom Adjustments 14

Boom Width - Row Spacing 14

Crop Height Adjust 14

Adjustable Boom Tube Length & nozzle positioning 15

TOC. 3

Page 6

Table of Contents

Sprayer Operation

Section 5

Introduction 1

Fluid Delivery 1

Pump Operation 1

Controller Units 2

Adjusting Braglia CB/2 Pressure equalisation 2

Adjusting HARDI EVC Pressure equalisation 3

Filters 4

Air Delivery 5

Gearbox 5

Blower Unit, Distribution Stack & Outlet Spouts 5

Boom Operations 6

Lift 6

Individual Fold & Manual Hydraulic Tilt 6

Electric over Hydraulic Tilt (EOH) 6

Filling of water 7

Filling the clean water tank 8

Cleaning 8

Introduction 8

Cleaning Guidelines 8

Rinsing boom and fluid system 9

TOC. 4

De-contamination 10

Diagrams 11

Fluid System 11

Air Flow Delivery 12

External Fill 13

Agitation 14

Powder Mixing Option 15

Spray Distribution 16

Pressure Regulation & Pressure Relief 17

Page 7

Maintenance

Section 6

Table of Contents

Introduction 1

Before you get started... 1

Spare parts 1

Lubrication 2

General info 2

Recommended lubricants 2

Transmission Shaft (PTO) lubrication 2

Drawbar lubrication 3

Boom lubrication 3

Axle lubrication 3

O-Ring and Filter lubrication 4

Gearbox lubrication 4

Pump Maintenance 4

Servicing 5

10 Hour Servicing 5

50 Hour Servicing 7

250 Hour Servicing 8

1000 Hour Servicing 9

Occasional Maintenance 10

Boom Tube Fittings 11

Check for EVC Pressure Regulator 12

Cone Check for Distribution valves 12

Drain Valve Seal Replacement 13

Drain Valve Cord Replacement 13

Tyre Changing 14

Flow Meter Inspection 14

Off Season Maintenance 15

Maintenance Schedule 16

TOC. 5

Page 8

Table of Contents

Fault Finding

Section 7

Operational Problems 1

Introduction 1

It is good practice to start by checking these basics: 1

Prevention 1

Sensors 4

Flow Sensor Inspection 4

Technical Specifications

Section 8

Weights and Measures 1

Conversion factors: Metric to Imperial units 2

Filter mesh specifications 2

Recommended Tyre Sizes & Load Ratings 2

Tightening Hydraulic Fittings 3

Tightening O-Ring Fittings 3

Tightening Flare Type Fittings 3

TOC. 6

Torque Specifications 4

Spare part information 7

Page 9

Warrant y

Section 9

Table of Contents

Materials and recycling 7

Disposal of the sprayer 7

Further information 7

Warranty policy & conditions 1

Risk Assessment

Section 10

Entanglement 1

Cutting, Stabbing, Puncturing or Striking 1

Shearing 1

Crushing 2

Electrical 3

Explosion 3

Friction 3

Pressure 4

Slips, Trips & Falls 4

Ergonomics 5

Suffocation 5

High Temperature or Fire 5

Other Hazards 6

Condition / Stability 6

Environment 7

Abnormal Situations 7

Systems of Work 8

TOC. 7

Page 10

Table of Contents

TOC. 8

Page 11

MERCURY COVAMAX

Operator Instruction Manual

67002404- 100

HAU - 08.2009

1 - Welcome

HARDI Australia

534-538 Cross Keys Road Cavan

South Australia, 5094

1. 1

Page 12

1 - Welcome

WELCOME MESSAGE

To our valued customer:

Congratulations on your purchase and thank you for choosing the HARDI “COVAMAX” Mistblower. This “Operator

Instruction Manual” covers the Safety, Operation and Maintenance procedures for the 2300, 3300 & 3800 Litre

models, and is to be read in conjunction with the “Mistblowing Techniques” manual supplied with your sprayer.

This book is not

is to be read in conjunction with the “Spray Technique” book and any other manuals supplied with your sprayer.

WARNING: Any persons intending to use this equipment, or any of it’s parts or systems must read and

±

understand these publications (plus any related material) paying close attention to the safety warnings prior

to operation.

In addition, all operators must be competent, have undergone appropriate training and hold correct licenses

where applicable, as required by state and federal law. The safety sections and warnings in this publication and all

related material must be thoroughly read and understood before attempting to operate this equipment.

DANGER: Failure to comply with the above may result in personal injury, death or damage to the

€

equipment,property, crops or the environment.

Attention: The technical data contained herein is to the best knowledge of HARDI Australia Pty Ltd correct at the time

μ

of publishing. HARDI Australia Pty Ltd reserves the right to make changes in design, features, accessories,

specifications and instructions at any time without prior notice and is without obligation in relation to products

purchased before or after such changes and assumes no responsibility for any errors, inaccuracies or omissions.

Please visit our web site at: www.hardi.com.au for more information about research and development, our

product range, spraying techniques and crop protection. For sales, service and spare parts information contact

your local HARDI dealer.

Copyright: Design, text, illustrations and layout in this manual are produced and published by HARDI Australia Pty

Ltd and are protected by copyright law. Copyright © August 2009 HARDI Australia Pty Ltd.

designed to be a maintenance manual, its main purpose is to supply operational information and

1. 2

Page 13

2 - Safety

Operator Safety

INTRODUCTION

This manual contains safety information which could prevent crop damage, personal injury or death. It is highly

recommended that all operators intending to use this equipment read and understand this manual and related

literature. Safety information in each section must be read carefully, and if any doubt contact your HARDI dealer

for further information.

SAFETY ALERT ICONS

Safety information in this manual is highlighted by the following icons according to the level of potential risk:

DANGER: This indicates the highest level of hazard alert. Failure to comply with the information contained

€

here could result in personal injury or death.

WARNING: This indicates that mandatory action is required. Failure to comply with the information

±

contained here could result in damage to crops, the equipment and/or the environment.

Attention: This indicates practical information regarding safe and effective use of the equipment and its systems.

μ

Note: This indicates general information that can provide the reader with a higher level of understanding.

÷

SPRAY DRIFT

WARNING: Serious crop damage can occur as a result of spray drift. Certain climatic conditions can increase

±

the risk of spraydrift onto neighbouring crops.

Although calibration information is provided in the Mistblowing Techniques Manual it is vitally important that you

read the chemical manufacturer’s recommendations for the correct use of their product.The manufacturers label

will also state the products limitations and warnings.

Wind speed, temperature, humidity and chemical properties should all be considered when determining if

conditions are suitable for spraying. Contact your local Department of Primary Industries for details of relevant

publications explaining the risks and how best to minimise them. It is the responsibility of the sprayer operator to

make sure that the spraying conditions are suitable for the application of the chemical to be used.

WARNING: After changing chemicals or crops it is essential that the entire sprayer be flushed. This includes

±

disconnecting hoses from the filters and pressure relief valve and cleaning residue and sediment in the

hoses, valves and filters. Failure to do so may potentially lead to serious crop damage.

Attention: Remove and store safety wear and clothing after spraying to prevent contamination of the cabin.

±

Dispose of, or clean appropriately. If poisoning occurs identify the chemicals and seek medical advice

urgently.

2. 1

Page 14

2 - Safety

MECHANICAL SAFETY

DANGER: Never operate any part of the equipment if any of it’s components or safety shields are damaged.

€

Never service or repair the equipment while it’s operating and replace all safety devices and shields after

service procedures.

DANGER: Always de-pressurise the equipment and disconnect the power after each use and before

€

servicing. Make sure all hydraulics are in the recommended position. Do not walk under any part of the

sprayer or the boom unless it is properly secured.

DANGER: Never attempt to enter a tank or allow some one else to do so for any reason.

€

DANGER: No persons are allowed in the operations area of the sprayer. Keep unauthorised persons and

€

children away from the equipment at all times. Do not allow any one to ride on the equipment while it is

operating.

DANGER: Do not exceed the max. recommended RPM for any part of this equipment.

€

DANGER: Local laws may require operators to be certified before using spray equipment and some

€

chemicals. Consult your local authorities before commencing operation.

WARNING: When using an arc welder disconnect any power leads to the sprayer prior to welding and remove

±

any flammable or explosive material from the area.

WARNING: Although every effort has been made to include as much safety information as practical, it is

±

impossible to anticipate every hazardous scenario. It is therefore the responsibility of the operator to

exercise safe operating practices.

WARNING: This equipment is intended for the application of crop protection chemicals and liquid fertilisers

±

only. HARDI Australia does not authorise or endorse it’s use for any other purpose.

DISPOSAL OF CHEMICAL CONTAINERS

Please note that in addition to normal safe operating practices, and in the interests of a cleaner and safer

environment HARDI Australia supports the “drumMUSTER” chemical drum recycling program:

• Rinse empty drums immediately after use.

• Remove lids to allow drums to dry completely.

• Recycle with “drumMUSTER”

WARNING: Used chemical containers pose a severe threat to persons, animals and the environment. Before

±

disposal, contact the Environmental Protection Authority or the Department of Primary Industries in your

area for more information.

2. 2

Page 15

2 - Safety

1

2

3

4

5

6

CHEMICAL SAFETY

DANGER: Avoid risk of chemical contamination. Always read chemical labels and pressure test the

€

equipment with clean water prior to filling. Never eat, drink or smoke when spraying or working with

contaminated equipment.

DANGER: Never drink from any of the sprayer's tanks.

€

DANGER: Never assume that the contents of any tank is safe to drink.

€

DANGER: Chemical contamination poses a serious health risk. It is the responsibility of the operator to make

€

sure safe work practices are observed and correct safety equipment and clothing is used.

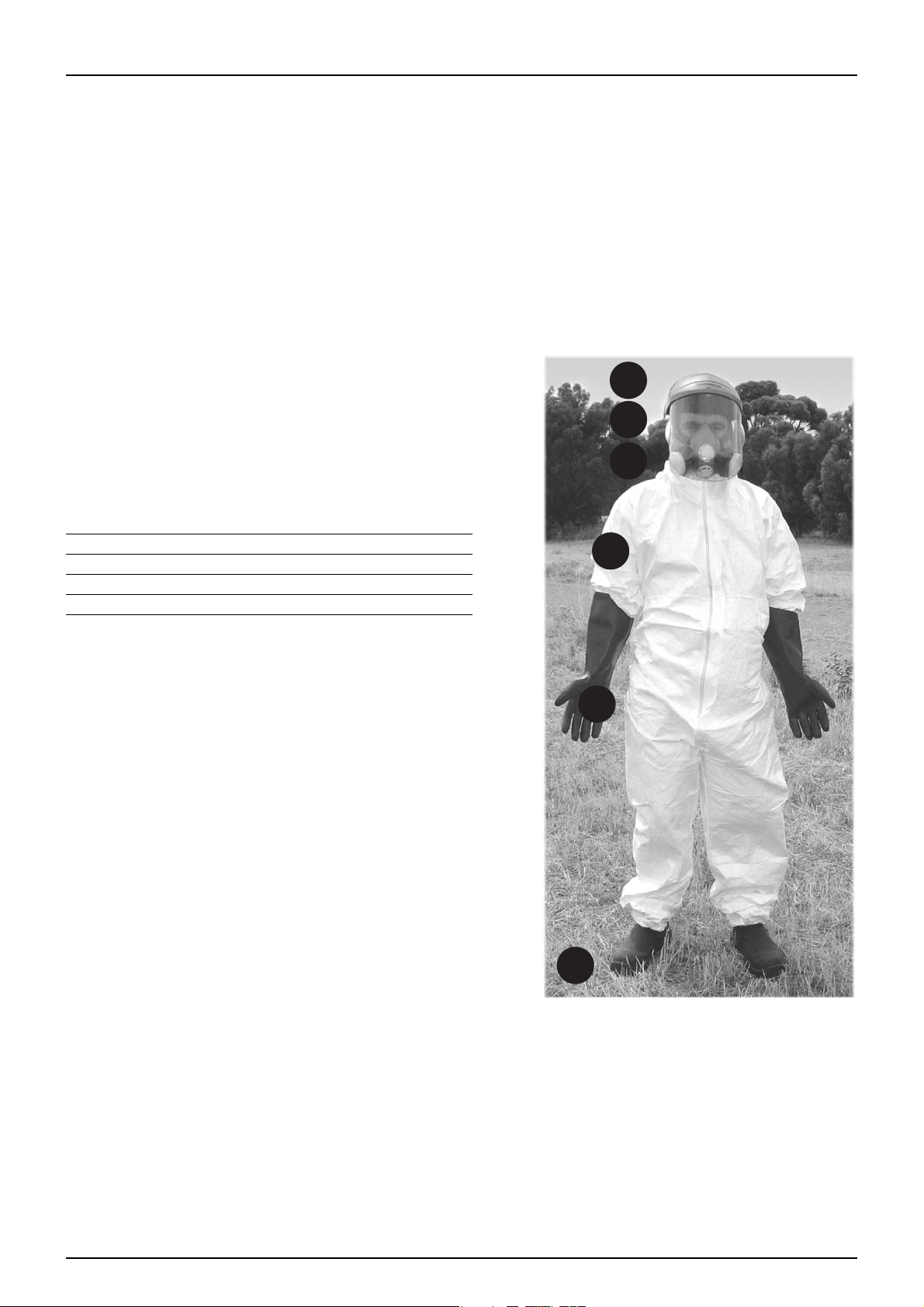

Safety Equipment

Depending on the type of chemical used, some or all of the

following protective clothing and equipment will be required (see

diagram to right).

1. Hearing Protection

2. Eyes and Face Protection

3. Respirator

4. Chemical Resistant Overalls

5. Chemical Resistant Gloves

6. Chemical Resistant Boots

Contaminated Clothing and Equipment

Contaminated clothing should be carefully removed, safely

isolated and then appropriately laundered or disposed of, taking

care not to contaminate other work areas. Tools and equipment

used must also be safely isolated and carefully washed and

decontaminated.

Australian Safety Standards

Protective clothing and equipment must conform to Australian

Safety Standards and must always be used when handling

chemicals, operating the sprayer and during the cleaning and

decontamination process.

Chemical Information

Always read the chemical manufacturer’s labels as they contain

critical information about your safety and the environment. Always consider the environment when disposing of

chemical residue (see section on decontamination). Chemical labels are registered by the National Registration

Authority. Laws vary from state to state regarding the purpose for which a chemical may be used so consult your

local authorities.

DANGER: Agricultural chemicals can be dangerous. Always read chemical labels and carefully follow safety

€

recommendations to the letter.

Attention: Please refer to the chapter on “Cleaning and De-contamination” in the Operation section of this manual

μ

for further information.

2. 3

Page 16

2 - Safety

SPRAYER SAFETY

Operations

For your safety:

DANGER: Secure the discharge lines before starting the pump. An insecure line may whip causing personal

€

injury and/or property damage.

DANGER: Never operate this vehicle on public roads at high speeds with product in the product tank.

€

Driving at high speeds with product in the tank will overload the tyres, causing tyre failure leading to loss of

control. Losing control can result in death or serious injury.

DANGER: Do not use these pumps for pumping water or other liquids for human or animal consumption.

€

WARNING: Do not pump at pressures higher than the maximum recommended pressure.

±

WARNING: Empty all product from the product tank before leaving the field. Do not attempt to drive this

±

vehicle at high speeds with product in the tank. Fill product tank once you have reached the area of

operation.

WARNING: Turn on the hazard lights and road lights if fitted before entering onto a public road. Keep them

±

on while travelling on the road.

WARNING: Check hoses for wear or worn condition before each use. Make certain that all connections are

±

tightly secured.

Attention: Periodically inspect the product pump and the system components. Perform routine maintenance as

μ

required.

SERVICE AND MAINTENANCE

For your safety:

DANGER: Release all pressure within the system before servicing any component.

€

DANGER: Drain all fluids from the system before servicing any component. Flush with water.

€

WARNING: Disconnect power before servicing.

±

WARNING: Use only pipe, hose and fittings rated for the maximum psi rating of the pump.

±

2. 4

Page 17

ELECTRICAL SAFETY

DANGER

BEWARE OF OVERHEAD

ELECTRICAL LINES

ELECTROCUTION

SERIOUS INJURY OR DEATH

During Sprayer Use

Beware of overhead power lines!

DANGER: Operating agricultural machinery near power-

€

lines presents a potentially fatal hazard. It is the

responsibility of the operator to make sure that minimum

safe clearances are strictly observed, in particular when

transporting the implement, spraying, raising, tilting or

lowering the boom. Also be aware that during hot or windy

weather sagging or swaying of power lines can reduce safe

working clearances.

2 - Safety

Operation of Electrical Components

For Your Safety:

DANGER: Never operate this machine with a damaged electrical cord. Disconnect from electrical supply if

€

machine is not working properly or cord is damaged.

DANGER: Do not attempt to bypass a fuse. If a fuse is no longer serviceable, a shock or short hazard may

€

exist.

DANGER: All electrical components generate heat. To avoid serious burns, never touch internal components

€

immediately after use.

DANGER: Disassembly or attempted repairs, if accomplished incorrectly can create electrical shock and/or

€

short hazards. Only qualified personnel should perform repair service.

DANGER: Some electrical components can store energy after the unit is shut down. Be sure to completely

€

de-energize all electrical components, discharging all stored energy before beginning any service work.

WARNING: Never replace original fuses/breakers with a higher amperage fuses/breakers.

±

WARNING: Never attempt to replace electrical wires and cables with smaller gauge wire and cable.

±

Attention: Do not attempt to operate this machine without the appropriate fuses and breakers in place.

μ

Attention: Inspect all components for damage after any electrical problem.There are additional hazards associated

μ

with the service and maintenance of electrical components

2. 5

Page 18

2 - Safety

2. 6

Page 19

3 - Description

INTRODUCTION

The MERCURY COVAMAX, available in 2300ltr, 3300ltr & 3800ltr models is designed to deliver features that will

enable greater control over your mistblowing needs, while minimising undesirable conditions such as spray drift.

The over row boom completely envelops the vine row delivering superior spray coverage with significantly less off

target drift. The swivel outlets give easy directional control of the spray to the target ensuring converging air

generates the canopy turbulence required for uniform spray deposition.

The COVAMAX is powered by a large fan capacity ducted air delivery system requiring only 35HP to drive. The air

is carried through the 8 inch air tubing which significantly increases air delivery.

The hydraulic boom design is a simple but sturdy construction utilising maintenance free no grease bushes for

trouble free operation. The boom is a perfect platform for supporting the COVAMAX air delivery system. It is width

adjustable and provides for optional wing tilt operation.

Flexibility of the COVAMAX allows the sprayer to be adjusted to suit varying vine canopies. Individual ball in socket

air outlet design provides for smooth rotation and easy adjustment into the right position. Fluid delivery to each

section is activated by its own valve and each air outlet can be independently turned on and off.

Up to five nozzles can be fitted to each outlet, giving a maximum of fifty nozzles per row! This allows the COVAMAX

to be used in both high and low volume application situations.

The MERCURY COVAMAX can be supplied with chassis suspension for smoother ride and a wide angle drawbar for

confined headlands, allowing the sprayer to track directly behind the tractor.

1. 1

Page 20

3 - Description

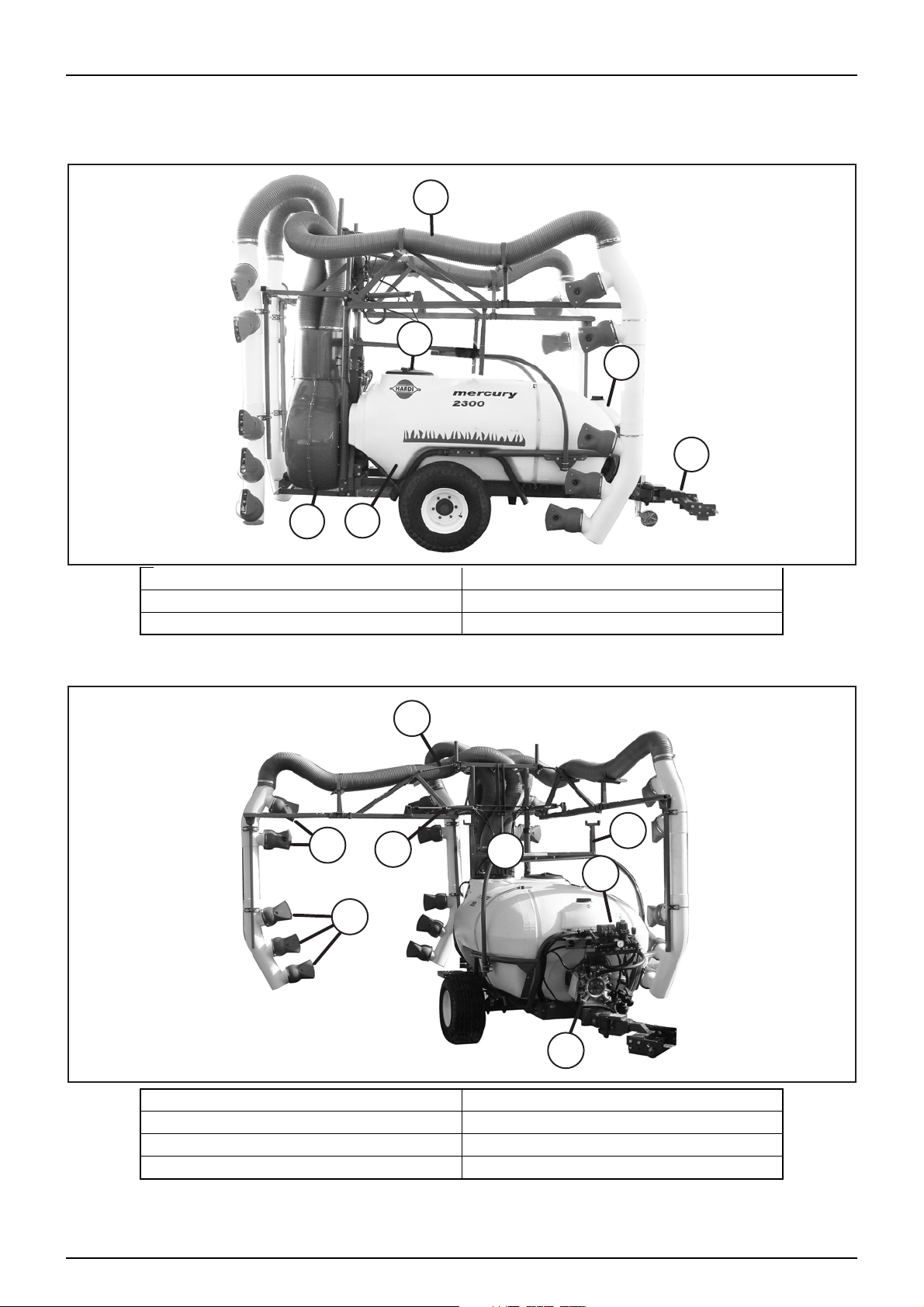

1

2

4

3

5

6

10

8

11

9

14

13

12

7

GENERAL INFO

View 1

View 2

1. Boom & Spouts 2. Handwash Tank

3. Drawbar 4. Main Tank

5. Blower Fan 6. Tool Box & Main Tank Lids

1. 2

7. EC Control Valves 8. Tilt Cylinder (If fitted)

9. Upper Nozzle Spouts - Outer Arm 10. Lower Nozzle Spouts - Outer Arm

11. Fold Cylinder 12. Lift Cylinder

13. Boom Transport Brackets 14. Main Pump

Page 21

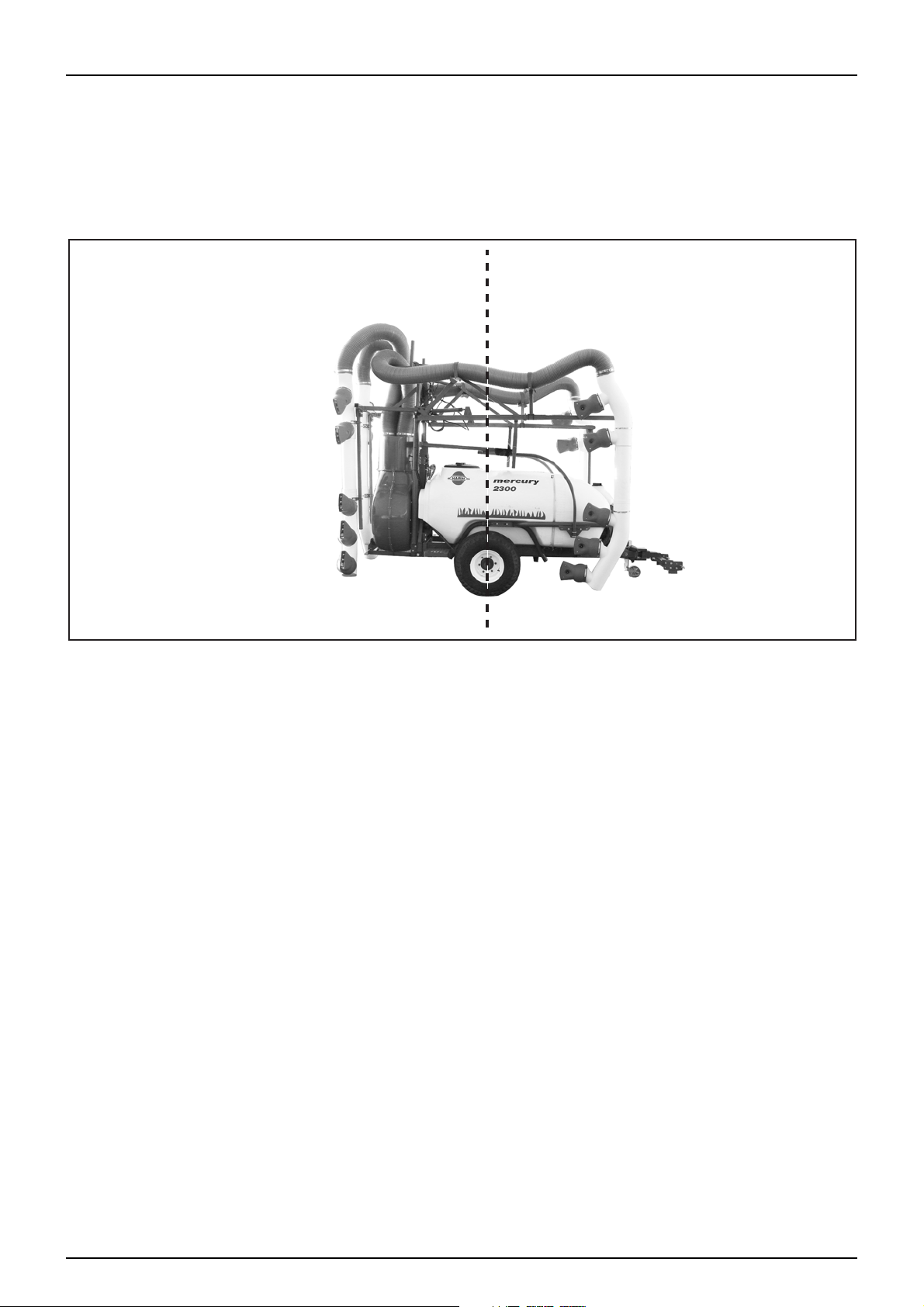

3 - Description

WORKING ZONEAPPLICATION ZONE

Control Valves

Level Indicators

Handwash Tank

Pressure Gauge

Suction Filter

Pump

Drawbar

PTO Connect

Boom

Tank Lid

Toolbox

Blower Fan

Gearbox

Powder Mixer

Spray Spouts

Pressure Filters

Zone Selection Valves

Work Zones

The trailed HARDI MERCURY COVAMAX mistblowers are divided into two different zones.

Working zone: with ease of use in mind; all the elements for regulating the water circuit are located

at the front of the machine.

Application zone: with operator safety in mind; all the parts that come into contact with chemical

products have been located at the rear of the machine.

Sprayer Details

It is important to record details of your sprayer for future reference. These details may help to identify your sprayer

when requiring spare parts or replacement documentation.

Please record your sprayer’s details here:

Model

Serial Number

Capacity

Date of delivery

Dealer

1. 3

Page 22

3 - Description

HARDI INTERNATIONAL A/S

REFERENCE:

Identification Plate

The identification plate is located on the front right-hand side and

is riveted to the frame. The reference number is engraved to aid

identification of the trailer.

The machine number helps to provide details of the trailers history

and equipment fitted for later reference when dealing with issues

such as warranty or spare parts ordering.

Further documents

Upon delivery please make sure your sprayer’s documentation is complete. Your HARDI Dealer should spend time

to check your new equipment with you and give a detailed explanation of the sprayer’s systems and functions.

Please take the time also to fill out your warranty form and return it to HARDI Australia within fourteen days of

delivery.

Road worthiness

When driving on public roads and other areas where the highway code applies, or areas where there are special

rules and regulations for marking and lights on implements, you should observe these and equip implements

accordingly.

Chassis

Manufactured with high tensile profiles which proportion the machine with great durability and resistance to

breakages and vibrations. During the manufacturing process, and to protect it from corrosion, the chassis is first

sandblasted to provide a clean surface, it is then pre-treated by dipping the frame in an iron phosphate bath

followed by a polymer sealant, it is then coated with a poly-zinc protectant and finished with a powdercoat.

1. 4

Page 23

3 - Description

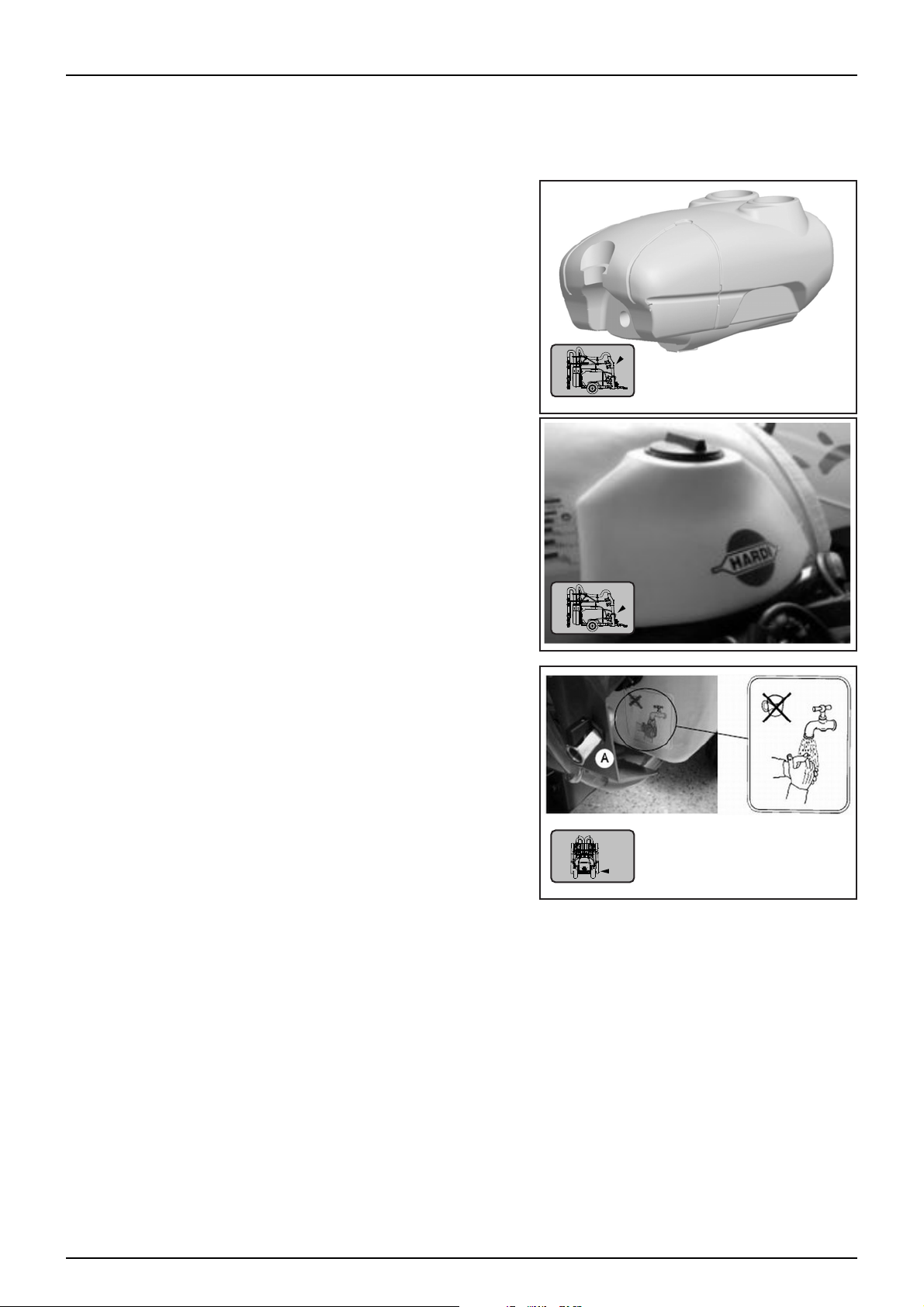

Ta nk s

The COVAMAX mistblowers are available in 3 tank capacities with a range of options, the tank capacities are:

2300 litre 3300 litre 3800 litre

The tanks are made of a UV, chemical and Impact resistant

polyethylene. The main tank is designed for easy cleaning and

rounded corners to aid agitation and prevent chemical from

becoming trapped in tight spots.

The main tank also features a fluid level indicator.

The Handwash tank has a nominal capacity of 15 litres. and is

situated at the front of the sprayer. The outlet for the handwash

tank is located at the lower left hand area of the main tank just

behind the suction filter.

DANGER: The “clean water” tank is intended for hand washing etc. only and must not to be used for drinking

€

water.

1. 5

Page 24

3 - Description

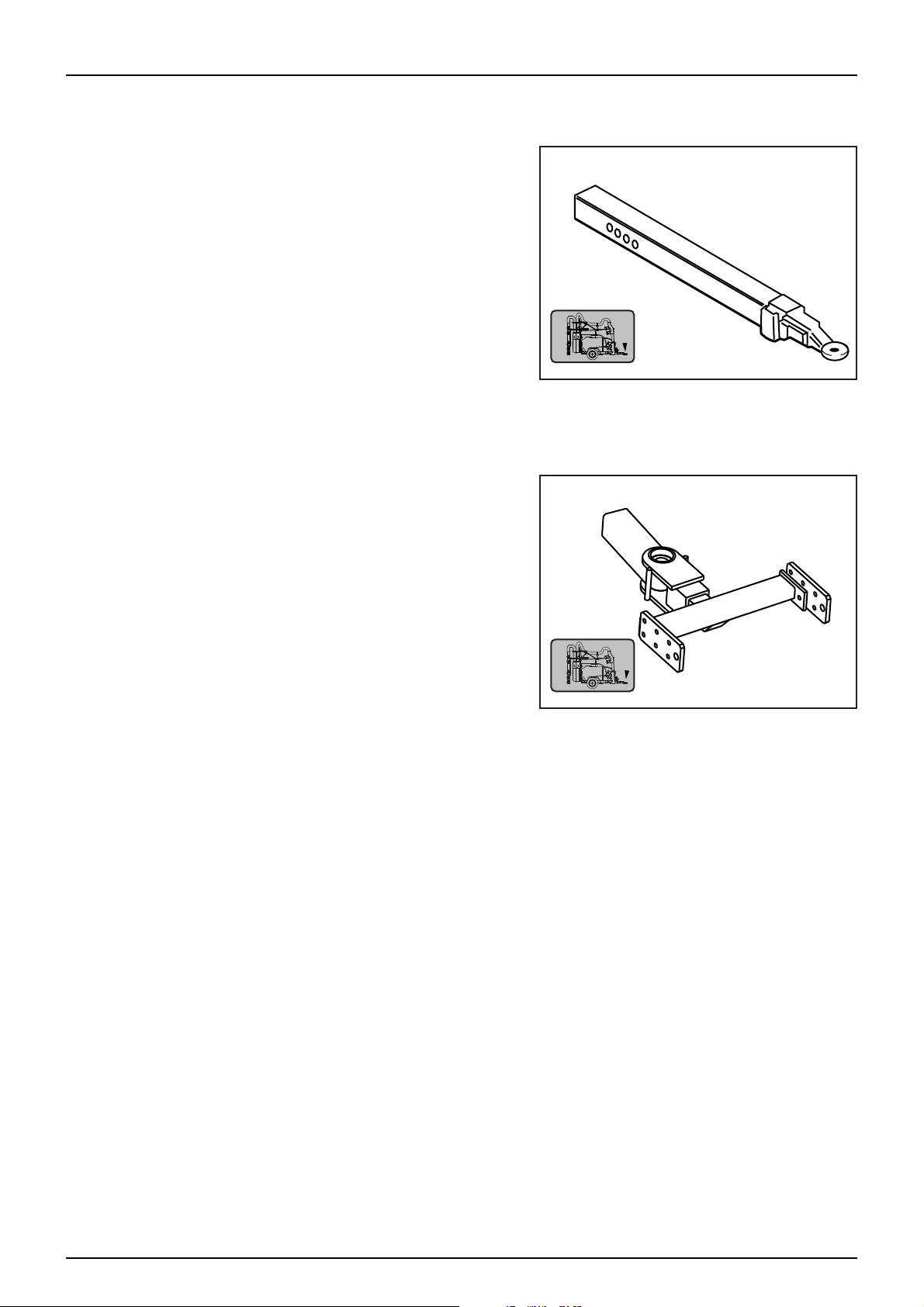

Drawbars

Standard Duty Wide Angle Drawbar

The standard drawbar is coupled to the tractor’s hitching point.

Before connecting the PTO make sure that the drawbar is properly

secured and check that the tractor’s wheels do not touch the

mistblower when turning. The length of the drawbar is adjustable

(see Sprayer Setup section for “Changing the drawbar length”).

Attention: Before connecting the PTO make sure that the

μ

diameter and number of splines on the driveshaft is the

same as that of the tractor’s output shaft. Make sure that the

tractor’s PTO output speed is matched to the speed of the

product pump.

Heavy Duty Wide Angle Drawbar

This drawbar is coupled to the tractor’s linkage.

Check that the tractor’s wheels do not touch the mistblower when

turning. Unlike a standard drawbar, it permits greater turning

angles, but a transmission shaft with CV joint is needed on the

mistblower side.

The length of the drawbar is adjustable (see Sprayer Setup section

for “Changing the drawbar length”).

1. 6

Page 25

3 - Description

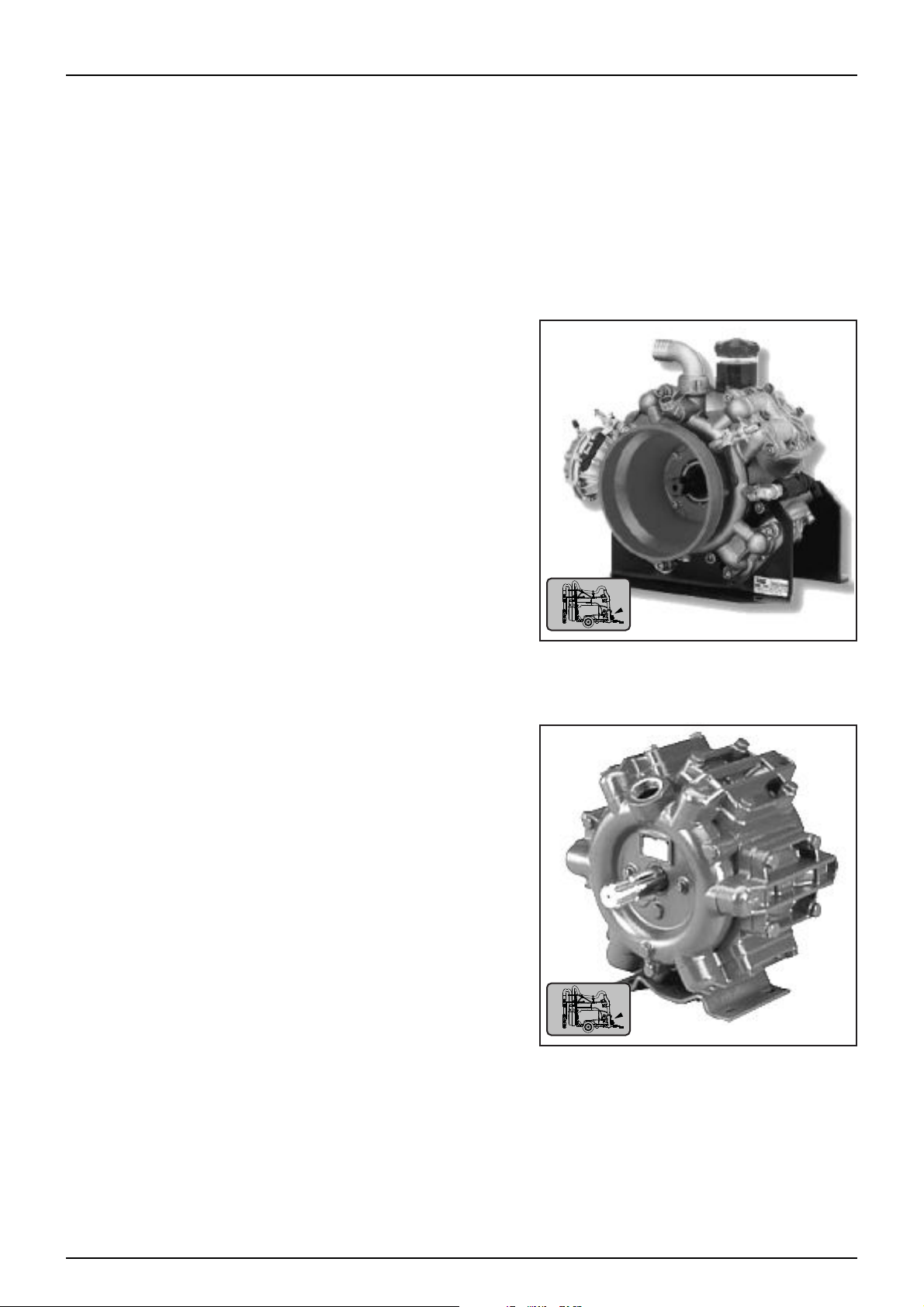

BHS200 Product Pump

363 Product Pump

Fluid System

Main Product Pump

The main product pump is available in two different models;

• AR Pumps BHS200 - Four Diaphragm Brass Head High Pressure Pump

• HARDI 363 - Six Diaphragm Positive Displacement Pump

BHS200 Pump

High pressure diaphragm pumps with positive displacement, external bronze manifolds and brass heads with 4

diaphragms. It has a maximum pressure of 50 bar (775 PSI) and operating at 550 RPM will deliver 193.7 litres per

minute.

• Four diaphragm positive displacement pump

• High Pressure 50 bar (725 PSI)

• 193.7 Litres per min delivery rate.

• Self priming

• Oil bath lubrication

• Cast alloy construction

363 Pump

The Hardi 363/7 pump has a 6 splined 1 3/8” shaft for connection to the tractor PTO. The normal operating

revolutions are 540 RPM. The HARDI 363 is a self priming diaphragm pump with 6 diaphragms and a maximum

pressure of 20 bar (294 PSI).

• Six diaphragm positive displacement radial pump with base

plate.

• Self-priming.

• Can rotate clockwise or anti-clockwise.

• One grease point for lubrication.

• Dry sump to simplify maintenance.

• Polyurethane diaphragms and seals.

• Cast iron crankcase and covers.

• Stainless steel bolts and plates for diaphragms.

• 1 1/2” suction port, 1” pressure port.

• Capacity range of 140 l/pm @ 0 bar to 122 l/pm @ 20 bar

1. 7

Page 26

3 - Description

Fluid Manifold System

Control of the fluid flow and functions is carried through a distribution manifold. This manifold consists of control

valves (MC/2, CB/2 or EVC), pressure regulators, flowmeter (option), pressure relief and control taps for activation

of agitation and if fitted the powdermixer option.

Filters

The filters fitted to the MERCURY COVAMAX include a suction filter and two optional pressure filters;

Suction Filter

The suction filter captures impurities in the liquid system in order to protect the machines’ components. It is

located at the front of the sprayer in the lower left hand side next to the main pump.

The tap on the top of the suction filter controls the selection source for fluid flow. The source tap can be turned to

open the valve to accept an external source supply or to supply from the main tank contents, the tap may also be

turned to an ‘OFF’ position by turning the handle to 90 degrees between the two source options for servicing the

filter when the tank has liquid inside.

1. 8

Page 27

3 - Description

x2

x2

Pressure Filters (Optional)

The sprayer is fitted with two inline pressure filters which

independently filter each side of the boom. These filters are

located directly in front of the fan and are connected immediately

before the boomzone selection valves.

BoomZone Selection Valves

Located immediately after the pressure filters are valves that control the flow to the boom sections. Each valve

controls flow to the left and right side - inner or outer boom sections.

1. 9

Page 28

3 - Description

1

2

Operating Units

MC/2 Manual Operating Unit

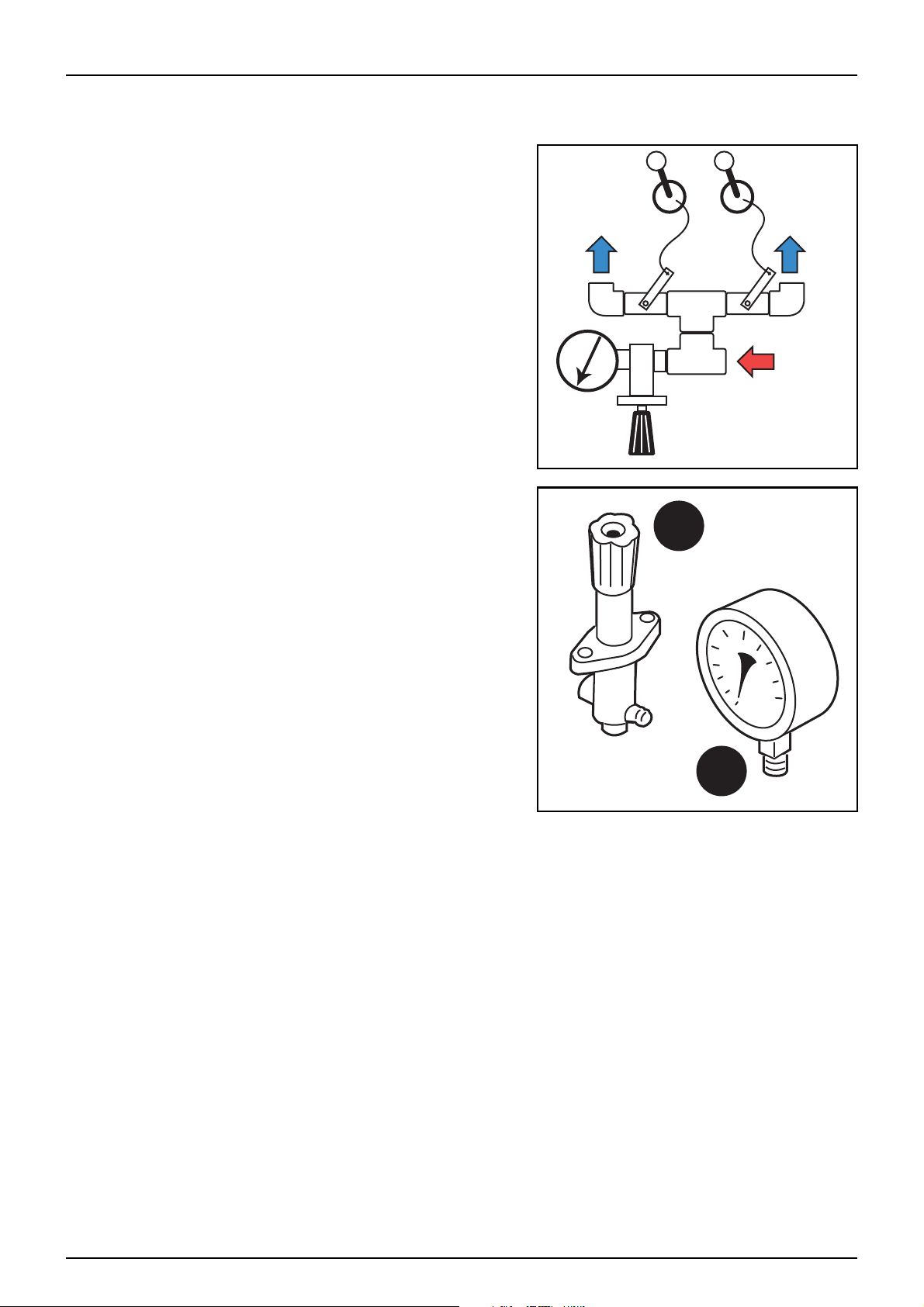

The MC/2 Manual operating unit consists of a pressure valve (1)

and a pressure gauge (2). These are connected on to the end of the

supply manifold and serve to regulate and read the system

pressure.

With the use of two control handles connected to the tractor’s

cabin, control of the left and right side spray zones can be

manually operated as required.

1. 10

Page 29

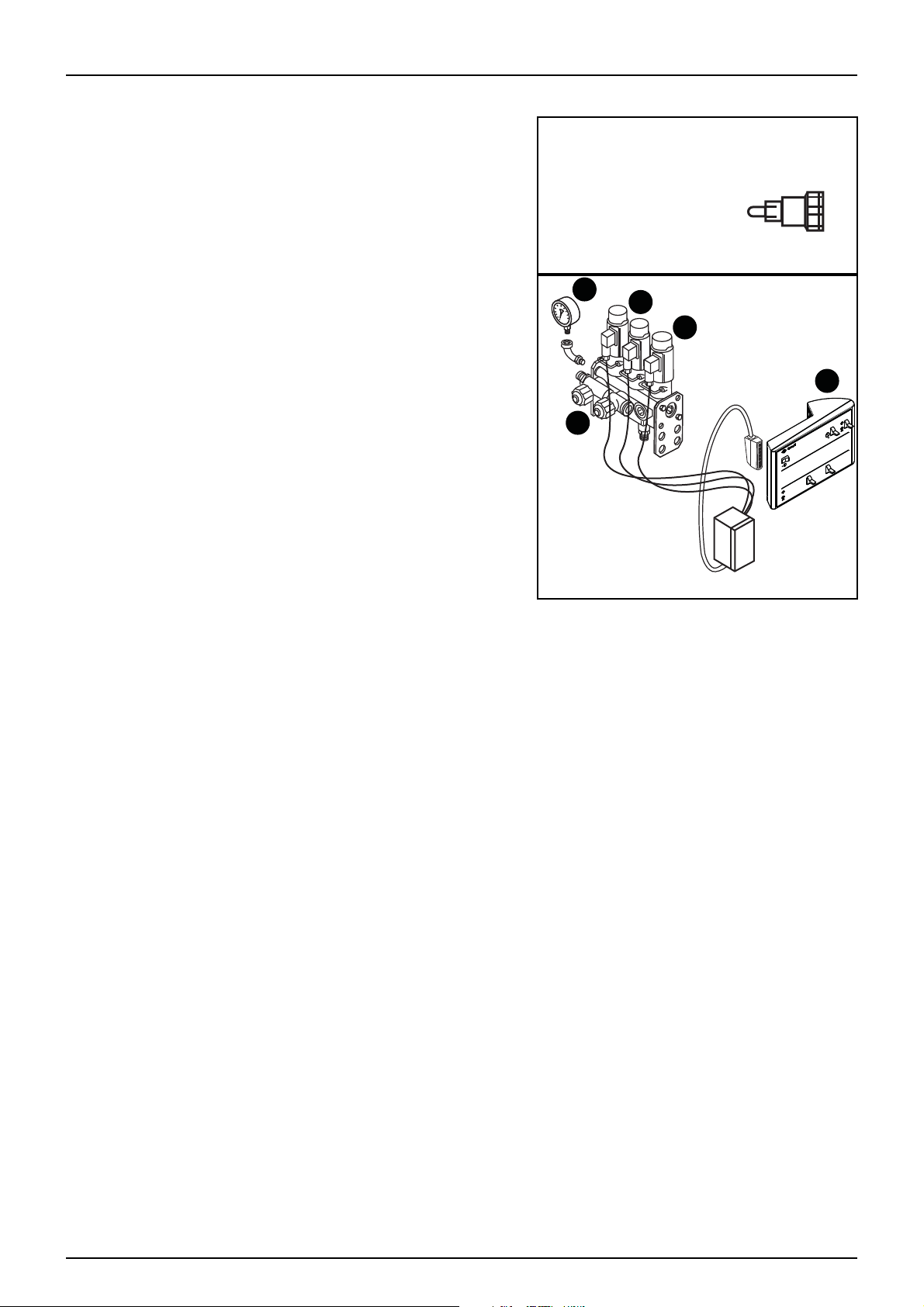

CB/2 Electric Control Unit

Brown wire (+)

Blue Wire (-)

12V

+

-

1

2

3

4

5

Through an electrical control box the incorporated switches are

operated to select the sector that you want to open, and to raise or

lower the pressure.

Its constituent elements are:

• Pressure Gauge

• Electro Valves for section control

• Electro Valve for pressure control

• Spray Box 2 (pressure, section ON/OFF)

• Pressure Equaliser Valves

The power requirement is 12V DC. Be very careful with the

μ

po la rity as ther e i s a ris k of da ma ging the circuit of the control box

or some of the electro-valves.

3 - Description

1. 11

Page 30

3 - Description

EVC Operating Control Unit

The EVC control unit is constructed of modules and consists of;

• Pressure Relief Valve

• Pressure Regulator

• Pressure Gauge

• Flowmeter (fitted on electronic control)

• Section distribution valves

• Constant Pressure Equalisation valves

Pressure Relief valve

The pressure relief valve mounted to the end of the fluid

distribution manifold enables control of the maximum liquid system pressure.

EVC Pressure Regulation Valve

The pressure regulator controls the system pressure allowing excess fluid to bypass back to the main tank.

Pressure Gauge

The pressure gauge gives a visual indication of the system pressure and can easily be viewed from the tractor cab.

Section Distribution Valves

The distribution valves offer independent control of fluid flow to the boom sections enabling operation of either

left wing, right wing for versatile application of chemical product.

Constant Pressure Equalisation Valves

Mounted underneath the distribution valves is an adjuster that controls the constant pressure for the distribution

valves, this helps to maintain a constant system pressure when the distribution valves are opened or closed.

1. 12

Page 31

HARDI Spray 2 Switchbox

The Spray 2 controller is connected in combination with either the

HC 2500 or the HC 5500 and allows for operator control of spray

zone selection and remote pressure regulation

Automatic Rate Controller Options

HC 2500 Display

The HC 2500 display provides user feedback of spray application in

addition to visual and audio alarms that notify the operator when

conditions have changed

HC 5500 Display

3 - Description

Like the HC 2500, the HC 5500 display gives valuable feedback to

the operator. The HC 5500 offers more control for features such as

application rate programmability, preset keys, remaining volumes,

etc

Note: Please refer to the seperate operator instruction

÷

manuals that are supplied with your controller options for

detailed information on controller usage.

1. 13

Page 32

3 - Description

AIR INLET

AIR INLET

Air Flow Delivery System

The air flow delivery system includes the following;

• Centrifugal Blower Unit

• 4-way Distribution Stack

• Flexible Delivery hoses

• Boom delivery tubes

• Outlet Delivery Spouts &Nozzles

Centrifugal Blower Unit

The MERCURY COVAMAX is fitted with an HF600 Twin Row

Centrifugal Blower. The blower turbine wheel is a robust, onepiece design made from aluminium. The blower unit draws air

from both sides of the turbine wheel and supplies an air flow of

25000 m3/h which is delivered to a 4 distribution stack.

The blower unit is speed controlled via the gearbox and PTO revs,

it delivers air through the distribution stack and out to the boom

nozzles.

The blower unit draws air from the front and rear of the machine

that is then divided and directed into the boom tubes by the

distribution stack.

Warning: Do not put hands or other objects near fan. Fan

±

operates at high speeds and can draw nearby objects into

the blower intake.

Warning: Wear approved hearing protection when

±

operating blower unit.

4-Way Distribution Stack

The 4-way distribution stack separates the airflow from the blower

unit and evenly distributes it to the boom tubes

Flexible Delivery Hoses & Boom Tubes

The flexible delivery hoses enable boom movement and air

delivery to the boom tubes. The boom tubes are adjustable to suit

the required vertical placement of nozzles, they also support the

nozzle assemblies.

Outlet Delivery Spouts & Nozzles

The outlet spout assemblies provide the operator with individual

ON/OFF nozzle capability in addition to individual positioning of

the spouts to enable directing of spray output.

1. 14

Page 33

3 - Description

1 2 3

Gearbox

Warning: Make sure that PTO shaft has come to a complete

±

stop before changing gears on gearbox

Fitted to the MERCURY COVAMAX is a two speed gearbox. This gearbox is mounted directly in front of the fan unit

and controls fan speed between the PTO shaft and the blower by positioning the lever in one of three positions;

• Position 1 -Slow speed 540/1890RPM (1:3.5 Ratio)

• Position 2 - Neutral (disengaged drive)

• Position 3 - Fast speed 540/2380RPM (1:4.4 Ratio)

1. 15

Page 34

3 - Description

STANDARD BRAKED

STANDARD

STEPPED BRAKED

STEPPED

Axles

Axle options for the MERCURY COVAMAX are either in the form of a straight axle or a stepped axle and vary

depending on sprayer size.

The straight axle is adjustable for track width and for placement forward and aft on the sprayer.

The stepped axle provides the same adjust ability as the straight

axle but with the stepped axle further changes to ride height can be made with the repositioning of the axle to

enable higher ground clearance if desired.

The half-axles are mounted in a housing that

is bolted to the frame. This has five different

settings to improve the stability of the

machine when necessary.

Track Adjustment

In order to obtain a wider track gauge or

greater stability on sloping terrain it is

possible to lengthen the half-axles of the

HARDI MERCURY mistblower on all its

versions.

DANGER: Raise the mistblower frame and prevent it from moving. Carry out this operation with empty tanks.

€

•Loosen the nuts and bolts on the axle housing.

•Extend the half-axle to the desired length without exceeding the maximum.

•Tighten the nuts and bolts again until the half-axle is sufficiently secured.

•Make sure that the two axles have been lengthened to the same amount in reference to the centreline of

the sprayer.

1. 16

Page 35

3 - Description

LIQUID FILLING NOT ALLOWED

WITH IMPLEMENT TYRES PROVIDED

Wheel Types

HARDI MERCURY COVAMAX mistblowers possess a wide range of interchangeable wheels to make it possible

to adapt the equipment to the particularities of the terrain.

Warning: The mistblower’s wheels are IMPLEMENT type and

±

cannot exceed 40 km/h. when fully loaded.

Warning: Tyres MUST NOT BE LIQUID-FILLED.

±

HARDI will not be held responsible for the consequences or

damage that this practice may have on its mistblowers.

Note: Always maintain the recommended pressure to get

÷

normal wear and life from the mistblower’s wheels, and to

avoid punctures and unnecessary strain.

Wheels & Tyres

A 12.5/80 x 15.3 x 14 PLY Std on 2300l

A 12.5/80 x 15.3 x 14 PLY Std on 3300l

B 400/60 x 15.5 x 14 PLY Std on 3800l

Options for 3800l

C 400/55 x 22.5 x 14 PLY (Flotation Tyre)

In areas of difficult access with many slopes, or for working on tall crops, always choose a wheel that guarantees

sufficient ground clearance.

The mistblowers tyres should always be at the correct pressure as they act as a suspension system when the tank

is full, making the whole assembly less rigid. Refer to the tyre pressure specified by the tyre manufacturer when

inflating.

1. 17

Page 36

3 - Description

ACTIVE SUSPENSION PASSIVE SUSPENSION

Suspension

The frames of Covamax machines can be fitted with a unique and exclusive torsion suspension system that is

capable of smoothing and absorbing irregularities in the terrain. This system improves safety on long trips over

rough terrain and reduces time spent on trips for filling, etc...

The suspension is ACTIVE when the machine is load-free, and it gets lower as the tank is filled. When the tank of the

mistblower reaches half-full, the suspension is PASSIVE, as the machine will only tilt if there is a very pronounced

unevenness in the terrain.

Note: Use of the suspension with the ring drawbar is recommended for those machines which frequently

÷

cover long distances over uneven terrain.

1. 18

Page 37

Powder Mixer - Chemical Induction

Agitation

Powder Mixer

Not Used

3 - Description

The powder mixer option supplies liquid to an outlet in the base of the powder mixer basket, this helps to dissolve

dry chemical in the basket.

DANGER: Do not operate the powder mixing feature with the lid removed as chemical product may be forced

€

from the basket and cause chemical contamination to surrounding areas or contact with operator.

Activate the powder mixer by turning the tap handle for powder mixing ON when the pump is running, this will

draw main tank liquid through the manifold and into the powder mixer basket. Turn the tap OFF when not in use.

1. 19

Page 38

3 - Description

Boom

The boom fitted to the MERCURY COVAMAX has numerous features that enable flexibility for operators when

setting up and operating. Some of the benefits are;

• Lift

• Fold

• Tilt

• Breakaway Arms

• Adjustable nozzle positioning and directing

• Low maintenance

1. 20

Page 39

3 - Description

Lift

The lift mechanism consists of a single double acting cylinder with two telescoping uprights that support and

guide the boom centre

Fold

Boom folding is independently operable through two double acting cylinders enabling the flexibility to open and

close boom wings for one side at a time.

Til t

The MERCURY COVAMAX has two options available for tilting of the boom;

• Electric over Hydraulic (EOH)

• Manual Hydraulic

Electric over Hydraulic (EOH)

The electric tilt option allows independent tilting of the boom wings and connection to the tractor using fewer

hydraulic outlets

Manual Hydraulic Tilt

Manual Hydraulic Tilt is available as an option to perform actions similar to the electric tilt option, however the

manual tilt option requires the use of two additional hydraulic circuits on the tractor.

1. 21

Page 40

3 - Description

ON/OFF VALVE

Breakaway Arms

To minimise damage to equipment or crops should the boom

collide with an object, a breakaway feature is incorporated into the

boom. A pivoting hinge mounted on a rear spar of the boom centre

allows the boom tubes to independently move out should the

boom arm come in contact with an object.

Adjustable Nozzles & Independent control

The nozzle bodies fitted to the Covamax allow for greater control

of fluid flow and spray dispersion.

Each nozzle body contains an ON/OFF valve that enables liquid

flow to be stopped at the nozzle manifold in each nozzle body.

1. 22

Page 41

4 - Set Up

Sprayer Set-Up

Introduction

This section of the manual deals with taking delivery and preparing the new sprayer for service in the field. It

contains important information to help you get started, plus mandatory safety information. Please make sure that

anyone intending to use the equipment carefully reads and understand the contents, plus any related

documentation.

Safety

Safety during set-up, service and maintenance procedures requires awareness, preparation and common sense.

μ

Preparing the sprayer for service in the field involves:

• -Unloading the sprayer from transport

• -Connection and testing of Mechanical components

• -Connection and testing of Electrical wiring and systems

• -Connection and testing of Hydraulic hoses and systems

• -Installation of mounting brackets and electronic components in the cabin

• -Reading and interpreting technical information and illustrations

• -Testing of Fluid systems

Below is a list of safety issues which must be observed before commencing set-up:

Before carrying out any set-up procedures observe the following:

• -Make sure your work area has lifting and safety equipment of a suitable load bearing capacity.

• -Always wear safety eye protection, overalls, safety boots and gloves where appropriate.

• -Keep animals and people away from the service area at all times unless involved in the procedure.

• -Keep children away.

• -If necessary clean and de-contaminate the sprayer and use chemical safety gear (see “Chemical Safety”

section 2).

• -Position the sprayer on a suitable flat surface with enough room for the boom to operate.

• -Never perform set-up, service or maintenance procedures with the engine or PTO running.

• -Turn the tractor engine off, place in park with the hand brake on and remove the ignition key!

• -Fit wheel chocks in front and behind of each wheel.

• -Always use suitable safety stands when supporting the sprayer off the ground.

• -Always re-fit all safety equipment and shields after service procedures.

• -Think each job through before commencing work and assess any potential risk.

• -Avoid working alone or at least have some-one check on you periodically.

• -Carry a mobile phone on you for emergencies.

• -Isolate any power source and clear the area of any flammable material before using an arc welder.

• -If any procedure is unclear or requires facilities which are not available, refer the job to your HARDI dealer.

4. 1

Page 42

4 - Set-Up

Transporting Mistblower

Truck transport

Preparing Mistblower for transport

To prepare the mistblower for transport consider the following points;

• Mistblower is emptied

• Mistblower is clean and decontaminated

• Items such as boom arms are secured to prevent movement during transit

• Carry out visual inspection to make sure that no items can come loose during transit

Securing Mistblower for transport

When secur ing the m istbl ower on to a truck trailer, ma ke sure the trailer is of adequate size and properly placarded

with safety signs should they be required.

Do not allow heavy objects to be loaded on top of the mistblower as this may cause damage to mistblower

components or surface finishes.

Tie down the mistblower adequately to prevent movement during transport.

Loading or Unloading the mistblower from a truck

When loading or unloading the mistblower from a truck trailer with the aid of a block and tackle or crane, use the

lifting points shown in the illustration, and make sure that the straps or cords used for the purpose are strong

enough and comply with Australian Safety Standards.

4. 2

Page 43

Connecting Mistblower to tractor

B

C

A

Connecting the mistblower requires the following;

• Adjusting drawbar length

• Hitching drawbar to tractor

• Connecting hydraulics to tractor

• Sizing & Fitting PTO shaft

• Un-mounting Jockey Wheel

• Connecting control box (if fitted)

Adjusting drawbar length

Both drawbar designs have the ability to be adjusted. The basic steps to follow are;

• Support mistblower on jockey wheel

• Loosen bolts (C) where the drawbar passes through the

chassis

4 - Set Up

• Remove nut & bolt (B)

• Slide drawbar in or out of the frame to desired position

• Refit nuts & bolts (B) and tighten lockbolts (C) sufficiently to

prevent movement

Additional adjustments can be made by altering hole positions of plates (A) on wide angle drawbar

Attention: Make sure the bolt passes through both the holes in the frame and the holes in the drawbar as shown (B)

μ

and that locknuts (C) are securely tightened.

4. 3

Page 44

4 - Set-Up

Hitching Drawbar

Depending on the type of drawbar fitted to your sprayer, one of two connection methods will be used;

• Standard Drawbar - direct connect to trailer hitch

• Wide Angle Drawbar - connected to linkage arms

Standard Drawbar

The standard drawbar is hitched to the tractor and secured with a

pivot pin

Wide Angle Drawbar

The wide angle drawbar is directly connected to the linkage arms

which can be used to change the sprayer height for levelling the

mistblower.Of the two hitch types this is the one that permits the

greatest turning angles.

4. 4

Page 45

4 - Set Up

Sprayer levelling with wide angle drawbar

By having the drawbar hitched to the tractors linkage arms it provides the ability to level the sprayer as shown

below, this will provide a better ride and more accurate readings when using items such as the sight gauge.

4. 5

Page 46

4 - Set-Up

Connecting Hydraulics

The hydraulic hoses supplied with your mistblower will vary depending on the options you have fitted. As a

standard there will be six hydraulic hoses supplied, two will control the boom lift function and four for the

independent boom fold functions. There is also the possibility of a further four hoses that control hydraulic tilt

function if it has been fitted to your machine.

If Electric over Hydraulic (EOH) Tilt is fitted as an option, the supplied number of hydraulic hoses is reduced to only

four hoses, two hoses control the boom lift function and two supply the EOH hydraulic manifold, the EOH

switchbox controls operate the independent boom fold and tilt operations through electronic control of hydraulic

solenoids.

Connect the required hoses into the hydraulic outlets on the rear of your tractor. The cylinders used for lift, fold and

tilt features all require double acting hydraulic outlets.

Hydraulics hoses are marked for identifying which hoses are for

which function. They are generally labelled with either named tags

(lift/fold/etc) or have different coloured cable ties attached to the

hoses as shown. For each cylinder one hose connects to the

pressure line (P) and the other connects to the tank line (T).

4. 6

Page 47

4 - Set Up

PROPORTIONAL BRAKE OUTLET

LEFT/RIGHT DISTRIBUTION

MISTBLOWER

BRAKE ASSEMBLY

PISTON

SUPPORT

BRAKE LEVER

AXLE ROD

DIRECTION

BRAKE SHOE DIAGRAM

TRACTOR

OPTION 1. Quick ttings

Tractor

male

Mistblower

female

Protector nut

Brakes

Brakes are available for all MERCURY COVAMAX models, it consists of a hydraulic braking system with two options

available to stop the mistblower.

Tractors with a proportional brake outlet are suitable for the

mistblower’s hydraulic braking system, because they permit

progressive braking before the wheels are blocked in the case of

emergency.

Attention: The tractor’s proportional outlet should be adjusted to

μ

a maximum of 150 bar (2175 p.s.i.).

4. 7

Page 48

4 - Set-Up

DANGER

ROTATING DRIVESHAFT

SERIOUS INJURY OR DEATH

Do not operate without guards tted

or driveshaft connected at both ends

Make sure guards turn on driveshaft

Inspect driveshaft daily

Fitting PTO Shaft

In order to maintain drive to the sprayer’s pump whilst allowing for changes in length the transmission shaft is

divided into two halves with matching profiles.

The geometric shape of the profiles locks them together on the rotational axis whilst allowing free lateral

movement to absorb changes in length as the implement and tractor move in relation to each other.

Transmission Shaft - Operator Safety

• Always STOP ENGINE before attaching the transmission shaft to tractor P.T.O. - most tractor P.T.O. shafts can

be rotated by hand to facilitate spline alignment, when engine is stopped.

• When attaching the shaft, make sure that the lock is FULLY ENGAGED - push and pull shaft until it locks.

• Always keep protection guards and chains intact and make sure that it covers all rotating parts, including CV-

joints at each end of the shaft. Do not use without protection guard.

• Do not touch or stand on the transmission shaft when it is rotating - safety distance: 5’ (1.5 meter)

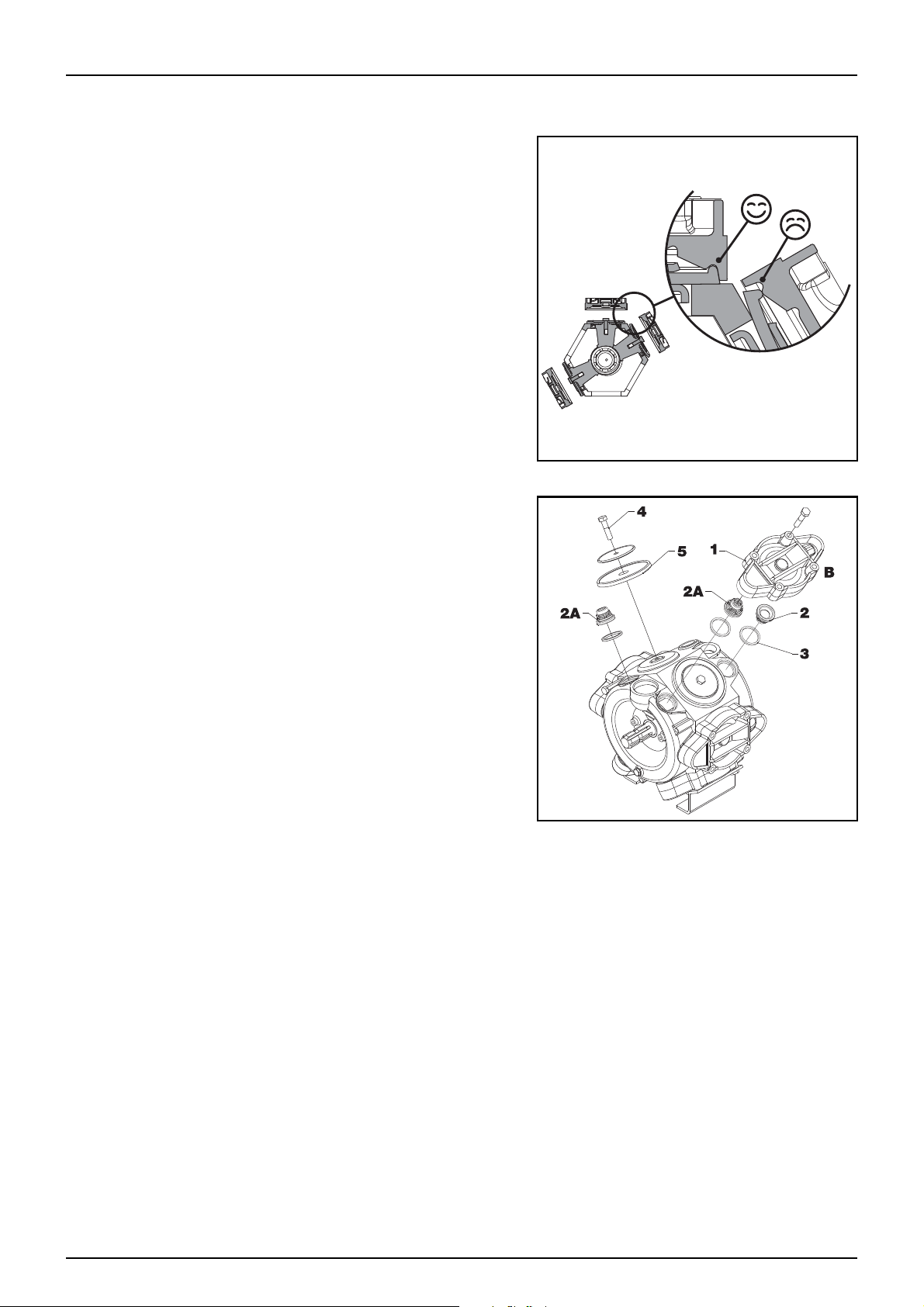

• Prevent protection guards from rotating by attaching the chains allowing sufficient slack for turns.

• Make sure that protection guards around tractor P.T.O. and implement shaft are intact.

• Always STOP ENGINE and remove the ignition key before carrying out maintenance or repairs to the

transmission shaft or implement.

DANGER: ROTATING TRANSMISSION SHAFTS - DO NOT USE WITHOUT PROTECTION GUARDS.

€

DANGER: PTO SHAFTS CAN SERIOUSLY INJURE. KEEP CLEAR OF ROTATING PARTS!

€

Transmission Shaft - Installation

First installation of the transmission shaft is done in the following way:

• Attach sprayer to tractor and set PTO angle to a maximum of 15 degrees, position with shortest distance

between the tractor and sprayer pump P.T.O. shafts.

• Stop engine and remove ignition key.

• If transmission shaft must be shortened, the shaft is pulled apart (see PTO Shaft Length reduction)

WARNING: The shaft must always have a minimum overlap of 30%.

±

• The PTO shaft connects between the tractor output spline and the pump input spline.

4. 8

Page 49

PTO Shaft length reduction

x

x

min. 20mm

1/3 1/3 1/3

A B C D E

A. Universal joint

B. Safety guard

C. Female section

D. Male section

E. Splined coupling

WARNING: The shaft must always have an overlap (A) of

±

minimum 1/3 of the length.

Fit the two shaft parts at tractor and sprayer pump and measure

how much it is necessary to shorten the shaft. Mark the protection

guards.

• The two parts are shortened equally. Use a saw, and file the

profiles afterwards to remove burrs.

• Grease the profiles and assemble male and female parts

again.

• Fit the shaft to tractor P.T.O. and sprayer pump shaft.

• Fit the chains to prevent the protection guards from rotating

with the shaft.

4 - Set Up

• To ensure long life of the transmission shaft, try to avoid

working angles greater than 15°.

4. 9

Page 50

4 - Set-Up

Position 1

Position 2

Jockey Wheel

The jockey wheel allows the mistblower to be coupled to or

uncoupled from the tractor. It should be in position 1 when the

mistblower is uncoupled, and in position 2 when it is coupled to

the tractor. In this position the jockey wheel is fixed to the

mistblower’s frame by two spring pins.

The jockey wheel is secured in place with two pins that enable it to

be fixed to the frame and held with two spring clips.

The height of the machine can be altered by turning the handle of

the jockey wheel.

Drawbar Safety Chains

Due to weight distribution when the MERCURY COVAMAX is

working in the unfolded position, a chain and brace is fitted to the

wide angle drawbar to prevent the sprayer from tipping up when

rearward weight conditions are present.

The brace is attached to the side plates of the drawbar hitch and a

chain with shackle is connected to the rear of the tractor.

Maintain enough slack in the chain to prevent it from binding

during operation but taught enough to perform the task.

Isolate the hydraulic linkage arm lifting mechanism after chain is

fitted to the top link pin.

Warning: Operation of the hydraulic 3 point linkage arms

±

lifting mechanism after the chain has been fitted will cause

the brace to bend or tractor link arms to reach stall point in

hydraulics and may cause damage to the sprayer or tractor.

4. 10

Page 51

4 - Set Up

Connecting Controls

The following optional extras will all require further setup and connections between the mistblower and the

tractor;

• Electric over hydraulic tilt

• EVC & CB/2 fluid control

The control box options to accompany these extras are;

• HC2500

• HC5500

Note: Please refer to the controller specific handbook supplied with your sprayer for detailed information on

÷

connection and operation.

Electric over Hydraulic Tilt

Th is o pti ona l ex tra allows the til t an d fo ld f unc tion s of the boo m to be r emo tel y cont rol led fro m th e tr actor c ab a nd

to reduce the number of hydraulic hose connections at the tractor, this may be useful when there are not enough

outlets available for connecting manual tilt hydraulic control.

EVC Fluid Control

Connection for HARDI EVC or Braglia CB/2 controller options is via a 39 pin plug which connects directly to either

a HC2500 or HC5500 HARDI Controller

4. 11

Page 52

4 - Set-Up

HARDI Spray2 Switchbox

The HARDI Spray2 Switchbox is used for the control of fluid in

conjunction with the EVC fluid components and CB/2

The Spray 2 controller is connected in combination with either the

HC 2500 or the HC 5500 and allows for operator control of spray

zone selection and remote pressure regulation

HC2500 & HC5500 Displays

The HC 2500 and HC 5500 displays offer spray data to the user

depending on which transducer options are fitted to the sprayer.

Note: Please refer to the controller specific handbook

÷

supplied with your sprayer for detailed information on

connection and operation.

4. 12

Page 53

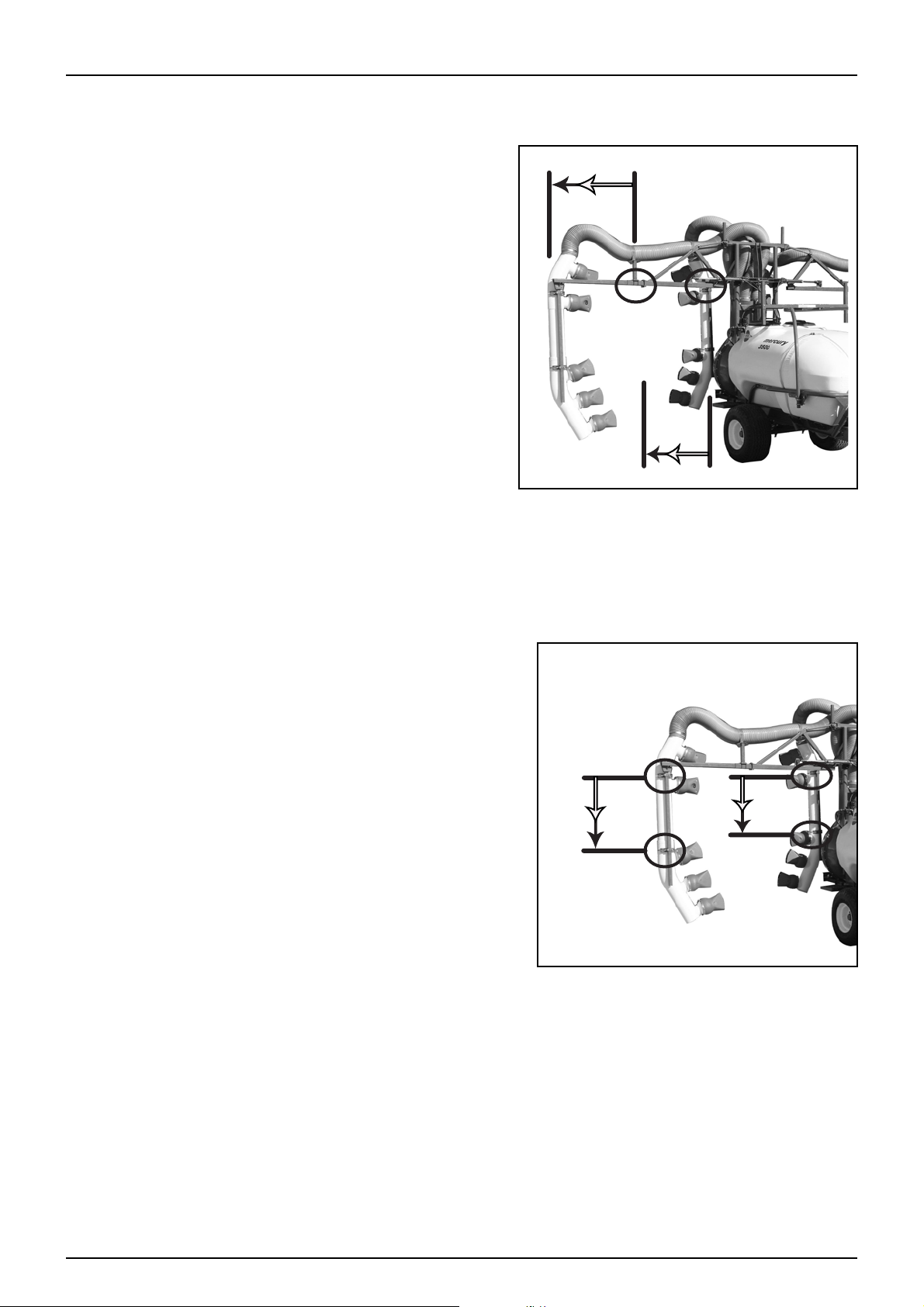

Boom Adjustments

Boom Width Adjustment

Crop Height Adjustment

Boom Width - Row Spacing

The position of the out reaching arms can be regulated to alter

the width of the boom, in order to adapt the machine to match

the row spacing. Adjustment is achieved by loosening clamps

on the horizontal bar and extending or shortening the

telescopic tubes to the desired width. Once the required

position has been chosen retighten clamps to prevent any

movement of the bar.

4 - Set Up

Note: Both the inner and outer boom sections may be repositioned to suit user requirements.

÷

Crop Height Adjust

As with the adjustment it is also possible to adjust the crop height.

Vertical delivery tubes are clamped to the vertical boom member.

By loosening the clamps the whole tube assembly can be

repositioned higher or lower to suit current crop heights.

Note: Both the inner and outer boom sections tube lengths

÷

may be altered to suit user requirements.

4. 13

Page 54

4 - Set-Up

Adjustable Boom Tube Length & nozzle positioning

The boom tubes and nozzles for the MERCURY COVAMAX include features that enable the operator to set the

machine to suit their particular spray application needs. These features are;

• Boom Tube length adjustment

• Positional Nozzles

Boom Tube Adjustment

The boom tubes are able to be trimmed to length to suit your

spraying needs. By removing the band clamp fitted to the lower

section of the boom tubes and then removing the lower section,

the upper section may be cut to the desired length then

reassembled with the lower section.

Located inside the boom tubes and nozzle shrouds are fluid supply

lines and nozzle body assemblies. Care should be taken not to

damage any of these items when making adjustments to the boom

tubes.

Nozzle Positioning

The ball and socket joint design of the nozzles allows for

independent positioning of the nozzles to aid even dispersion of

spray to gain better results in your spray application.

Fluid Hoses

The high pressure tubes inside the booms that feed fluid to the

nozzle bodies are all connected through the use of ‘push-in’ quick

release fittings similar to the picture shown. To disconnect a tube

from the fitting, push the plastic ring in towards the body of the

fitting and pull the tube out of the fitting. If the tube will not

release try slightly pushing the tube into the fitting then back out

again while making sure the plastic ring is pushed in.

4. 14

Page 55

5 - Operation

Introduction

The HARDI MERCURY mistblower is designed for the application of chemical crop protection products and liquid

fertilizers.

The equipment can only be used for this purpose. Using the mistblower for any other purpose is not permitted.

If there is no particular local law that compels the operator to be qualified in the use of chemical products, it is

highly recommended to be familiar with the basic techniques in the use of chemical products, so as to avoid the

risk of contamination of persons as well as the environment.

Operation of the mistblower can be considered in two parts;

• Fluid Delivery

• Air Delivery

Fluid Delivery

Pump Operation

Pump operation is controlled by the power take-off connection at the tractor. An input shaft on the pump

transmits the rotary motion from the PTO to drive the pump. The output shaft at the rear of the pump provides a

ratio drive of 1:1 to the gearbox input shaft via a secondary driveshaft permanently mounted through a cavity in

the main tank.

Suction

Suction from an external source is available through connection to the suction filter camlock fitting.

Pressure

When the main tank has fluid contents, the pump will provide pressurised fluid for spray operations. The

pressurised flow can be used for agitation and powder mixing or output to the boom controls for regulated spray

application.

5. 1

Page 56

5 - Operation

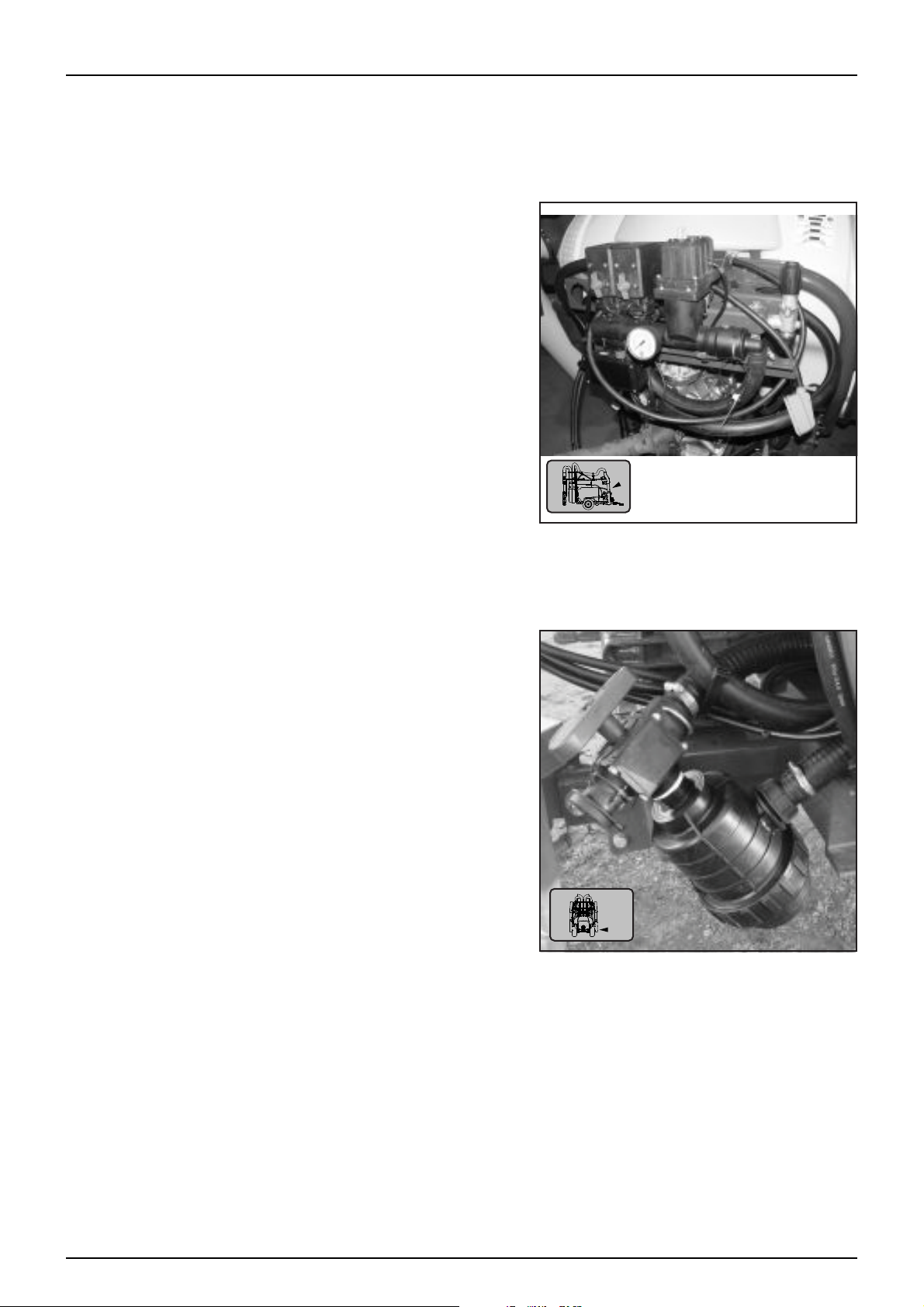

Adjusting Pressure equalisation

Pressure equalisation on machines fitted with HARDI EVC or

Braglia CB/2 control units are adjusted using these steps;

• With the boom section valves open, run the sprayer at normal

average spraying pressure.

• Note the reading on the pressure gauge (B)

• Close the first section valve (1) by turning off at the

switchbox.

• When system pressure has stabilised, adjust the first

equalisation valve (A) until the original spraying pressure is

restored, then reopen the valve at switchbox.

• Repeat the procedure until both valves have been balanced.

μ

Attention: After service procedures it is recommended to recalibrate equipment before spraying. The equalisation procedure

is generally only required after servicing, changing nozzle size or

when compensating for worn nozzles.

5. 2

Page 57

Filters

There are two types of filters employed on the MERCURY COVAMAX

• Suction Filter

• Pressure Filters (Optional)

Operation of the suction filter is by turning the handle to point

towards the desired fluid source.

5 - Operation

Pressure filters are simple inline filters that do not require any

opening or closing.

Maintenance requirements for both filter types is covered in the

maintenance section of this manual.

5. 3

Page 58

5 - Operation

1 2 3

Air Delivery

Gearbox

The gearbox fitted to the MERCURY COVAMAX has two speeds,

• Position 1 - Slow speed 540/1890RPM (1:3.5 Ratio)

• Position 2 - Neutral (disengaged drive)

• Position 3 - Fast speed 540/2380RPM (1:4.4 Ratio)

±

÷

Blower Unit, Distribution Stack & Outlet Spouts

The HF600 blower unit takes its drive from the gearbox output to turn the blower wheel. Air is drawn in from the

rear of the blower and forced up through the distribution stack. Airflow is then carried through the boom tubes to

the outlet spouts where it blends with the spray solution from the spray nozzles.

Airflow quantity is controlled by the gearbox setting which determines the fan speed.

Warning: Make sure that PTO shaft has come to a complete stop before changing gears on gearbox

Note: If the gearbox will not engage it is most likely that

the gear teeth are clashing. Move the gearbox lever to the

off (neutral) position and turn over the PTO, when PTO has

come to a stop attempt to engage gearbox again.

5. 4

Page 59

5 - Operation

Boom Operations

The boom can carry out the following functions depending on which options have been selected;

• Lift

• Individual Fold & Manual Hydraulic Tilt

• Individual Tilt - Electric over Hydraulic (EOH)

Lift

Lift is connected and operated by the tractor hydraulics.

Individual Fold & Manual Hydraulic Tilt

If no tilt option or manual hydraulic tilt is fitted then the fold function is made by connecting the four hydraulic fold

hoses and four manual hydraulic tilt hoses to the double acting outlets on the tractor. Fold and Tilt control is then

operated by the tractor hydraulics.

Electric over Hydraulic Tilt (EOH)

If EOH tilt is optioned on the machine the method of fold will vary.

If EOH tilt is optioned on the machine the control for tilt and fold is

via the supplied switchbox which operates the electric controls

used. Both tilt & fold are operated individually for each side.

5. 5

Page 60

5 - Operation

A B

1

2

3

Filling of water

The tank should normally be filled 1/3 with water before adding

chemicals. Always follow the instructions on the chemical label.

±

Filling - Main Tank

To fill the tank with water, remove the lid found on top of the tank;

this is located at the back on the left hand side. The use of water as

clean as possible is recommended for mistblowing tasks. Always

fill the tank with the upper filter correctly in place to prevent

impurities from entering the tank.

±

WARNING: If the sprayer is put aside with liquid in the main

tank all liquid control valves must be closed.

WARNING. Do not place the filling hose inside the tank (A). Keep it out of the tank (B) at all times and only

point it towards the inside. If the hose were inside the tank and the pressure from the water supply point

dropped, the chemical products could be siphoned from the tank to the water supply, contaminating the

water supply.

Emptying - Main Tank

To empty the tank with the drain valve, pull the red handle located on the upper left -hand side. The valve is springloaded to return it to the closed position, but it can be kept open by attaching the cord to the locking tab. To shut

it off again, let go of the red handle and the valve will close automatically.

If the tank is not completely emptied, it can be fully drained pulling on the tank drain handle to open the drain

valve, by connecting a hose with HARDI camlock fitting to the tank drain outlet (3) contents may be safely drained

to a container for safe disposal.

5. 6

Page 61

Filling the clean water tank

A clean water tank for hand washing is fitted to the front of the

sprayer just above the product pump.

To fill the clean water tank:

1. Remove the lid and fill with clean water.

2. Replace the lid.

The clean water is accessible by operating the ball valve tap

located below the tank on the left hand side of the machine.

Clean water tank capacity:....................................15 litres

5 - Operation

±

WARNING: The clean water tank is for washing hands and cleaning blocked nozzles only. Never drink from

this, or any other tank. Chemical contamination poses a serious health risk. If poisoning occurs note the

chemical(s) involved and seek medical advice immediately.

Cleaning

Introduction

The best performance and service life can be expected when the sprayer is properly cleaned and maintained. Clean

sprayers are safe and ready for action. Clean sprayers are less likely to be damaged by pesticides and their solvents.

€

÷

Cleaning Guidelines

DANGER: Agricultural chemicals can be dangerous. Read chemical labels and carefully follow safety

recommendations to the letter. Always use appropriate safety clothing and equipment (see section 2 of

this manual for further information).

Note: Read instructions for cleaning carefully before starting on the job. This includes the instructions on

the chemical label which must be observed. Further information such as local restrictions on the disposal

of chemical washings and licensing for operators specific to your area can be obtained from the

Department of Primary Industries and the Environmental Protection Agency.

• Read the whole chemical label. Take note of any particular instructions regarding recommended protective

clothing, deactivating agents, etc. Read the detergent and deactivating agent labels. If cleaning procedures

are given, follow them closely.

• Be familiar with local legislation regarding the disposal of chemical washings, mandatory decontamination

methods, etc. Contact the appropriate department, e.g. Department of Primary Industries / Environmental

Protection Agency.

• Legislation demands that you prevent seepage or run off of residue into streams, water courses, ditches,

wells, springs, etc. The washings from the cleaning area must not enter sewers. Drainage must be confined to

an approved catchment.

• Cleaning starts with accurate calibration. A well calibrated sprayer will ensure the minimum amount of spray

solution remains in the tank once the spray job is completed.

• It is good practice to clean and decontaminate the sprayer immediately after use, rendering the sprayer safe

and ready for the next spray job. This also prolongs the life of the components. Be aware that if chemicals are

left to dry out on the sprayers surfaces, they become much more difficult to remove.

• It is sometimes necessary to leave spray liquid in the tank for short period s, e .g. ove rnig ht, o r unt il th e wea ther

improves. Animals and unauthorised persons must not have access to the sprayer under these circumstances.

• If the product to be used is corrosive (ie: liquid fertiliser) apply a coat of a suitable rust inhibitor before and

after the job.

5. 7

Page 62

5 - Operation

Rinsing boom and fluid system

Rinsing the entire liquid system

The complete rinse decontamination process should use the following;

• Full Tank - Cycle and drain

• 1/3 Tank - Cycle and drain

• 1/3 tank - Cycle and drain

• Full Tank - Cycle and drain

The following process should be followed as a minimum;

1. Empty the sprayer by draining solution from the main tank as much as possible.

2. Completely refill the main tank with clean water to aid cleaning of the inside walls of the tank.

3. Turn pump ‘ON’

4. Turn the agitation tap ‘ON’ to cycle the clean water through the agitation lines. Turn tap ‘OFF’ after cycling for

several minutes.

5. Turn the powder mixer tap ‘ON’ to clean the powder mixer lines. Turn tap ‘OFF’ after cycling for several

minutes.

6. Open the section control valves, boom zone valves and outlet nozzle valves to allow clean water to spray

through boom lines and nozzles.

7. Clean the pressure relief line by turning the pressure regulation to the lowest setting and close both section

valves, this will pressurise the manifold and activate the pressure relief valve allowing clean water through

the valve and back to tank.

8. After operating all fluid components, turn ‘OFF’ the main pump and drain the tank completely.

9. Refill the main tank with clean water to 1/3 full and repeat steps 3-8.

10. Repeat step 8.

11. Repeat steps 2-8.

±

WARNING: To avoid over-dosing the crop, spray out diluted residues over as large an area as possible by

increasing your forward speed (to double if possible) and set your working pressure to somewhere around

1.5 bar (20 psi).

5. 8

Page 63

De-contamination

Introduction

A complete cleaning and storage procedure consists of six steps:

1. Read Labels 2. Flush 3. Drain4. Decontaminate 5. Inspect6. Store

5 - Operation

±

±

In addition to the cleaning information previously described, complete sprayer cleaning includes “Decontamination” which is essential to reduce risk to other crops sprayed and makes sure the sprayer is safe and

ready for the next spray job. Always remember, if it’s not clean, it’s not safe!

It is therefore necessary to neutralise any chemical residues left within the sprayer’s fluid system, before changing

crops, chemicals or off-season storage. This includes the main tank, flush tank, chemical induction system, all

hoses, valves, spray lines, nozzles and the external surfaces of the sprayer.

De-contamination agents

Some chemicals require particular neutralising agents and stringent decontamination procedures to make sure

particles that may have adhered to sprayer system surfaces are rendered neutral before spraying a new crop or

changing chemicals.

Chemical labels contain important information regarding safety, cleaning, neutralising agents and

decontamination procedures. Read them and take note of recommended de-activating agents and follow their

instructions to the letter.

±

WARNING: Always use personal safety equipment and clothing, and make sure contaminated equipment

and clothing is stored, cleaned, or disposed of in an appropriate manner (See “Chemical Safety” in section

2 of this manual).

WARNING: In-field rinsing can never take the place of a thorough decontamination. Always refer to

Chemical suppliers decontamination instructions for recommended decontamination procedures.

WARNING: Local laws may vary from state to state regarding the use and disposal of certain agricultural

chemicals. Contact your local authorities for details. Information can also be obtained from the

Department of Agriculture, the Department of Primary Industries or the Environmental Protection

Authority.

±

Decontamination:

After your sprayer has been rinsed it is time to decontaminate it. Using the recommended decontamination agent

and dose listed on the product label (personal protective equipment is essential). Be sure to decontaminate both

the interior and exterior of the machine, running the de-contaminating solution right through the fluid system and

boom structure and out the nozzles.

As most chemicals used have a tendency to block nozzles and filters, remove and clean in the appropriate

decontamination solution with a soft brush. Check also for sediment on the pressure side of the safety valve.

WARNING: Contamination of one chemical to another can adversely affect chemical properties and

damage or destroy your next crop. The sprayer must be cleaned and decontaminated when changing

chemicals or crops.

5. 9

Page 64

5 - Operation

Diagrams

Fluid System

OFF ON

15

15

18 19

17

16

Main Tank Supply - Suction

Fluid under pressure

External Fill Source

Rinse Tank Supply / External Fill

Bypass

Mercury Covamax Liquid System

Line

13 Distribution Valves (EVC or CB/2)

14 Pressure Filters

15 Boom Spray Zone Selector Valves

16 Left Boom Outer Nozzles

17 Left Boom Inner Nozzles

18 Right Boom Inner Nozzles

19 Right Boom Outer Nozzles

20 Pressure Agitation Line

4

5

20

21

1

21 Bypass Agitation Line

22 Pressure Relief Bypass

5. 10

14

14

13 13

12 11

9

10

Main Tank

1

2 Handwash

3 Handwash Tank Outlet

4 Powder Mixer (Option)

5 Agitators

6 Suction Filter

7 External Source

8 Main Pump

9 Manual Pressure Relief

10 Manifold

11 Pressure Regulator

12 Flow Meter (Option)

2

3

6

22

7

8

Page 65

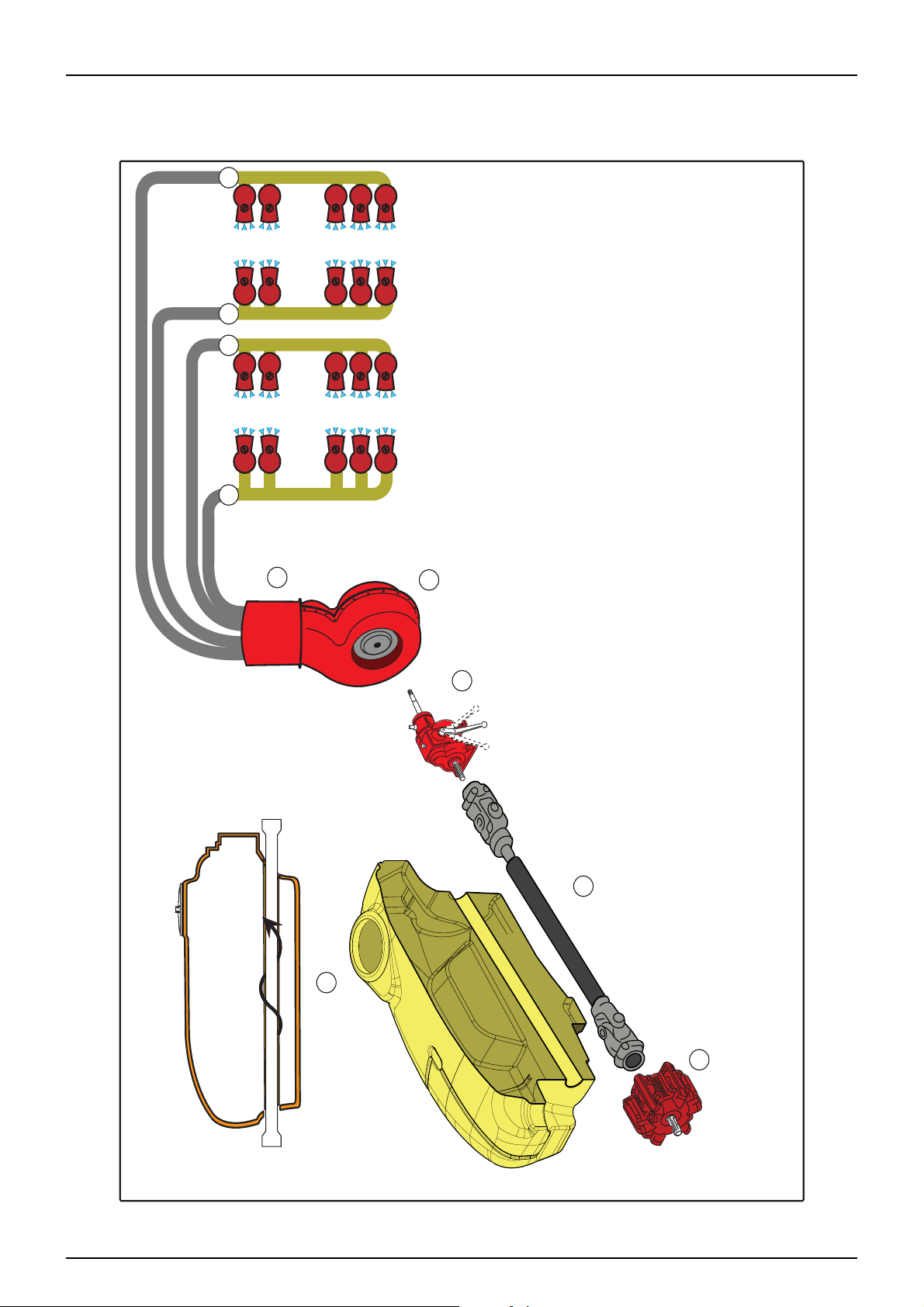

Air Flow Delivery

5 - Operation

7 8 9 10

Product Pump

1

2 Drive Shaft

3 Main Tank

4 Gearbox

5 Blower Fan

6 Distribution Stack

7 Left Boom Outer Nozzles

6