Page 1

Contents

Description .................................................................2

Operation diagram ..................................................... 4

Connecting the sprayer .............................................. 5

Operating instructions ................................................7

Operation of the MB boom....................................7

Operation of the HB boom .................................... 8

Operation of trapeze ............................................. 9

Adjustment of the operating unit ......................... 10

Drain valve operation ..........................................11

Maintenance.............................................................12

Lubrication ..........................................................12

Re-adjustment of the boom................................. 18

Changing of valves and diaphragms................... 20

Changing of ball seat in operating unit................ 22

Off-season storage .............................................23

Operational problems............................................... 24

Technical specifications ...........................................27

Pictorial symbols ......................................................29

Spare parts...............................................................30

LX -

MB/HB

Instruction book

673514-GB-92/03

HARDI INTERNATIONAL A/S reserve the right to make changes in design or to add new features without any

obligation in relation to implements purchased before or after such changes.

1

Page 2

We congratulate you for choosing a HARDI plant protection product. The reliability and efficiency of this product depend on your care.

The first step is to carefully read and pay attention to this instruction

book. It contains essential information for the efficient use and long life

of this quality product.

As the instruction book covers all LX models, please pay attention to

the paragraphs dealing with precisely your model. This book is to be

read in conjunction with the Spray Technique book.

Description

The Hardi LX models consist of a pump, frame with tank of 600, 800,

1000 or 1200 litre capacity, BK operating unit, 10, 12, 15, 16 or 18

metre trapeze suspended booms and transmission shaft.

The design of the diaphragm pump is simple, with easily accessible

diaphragms and valves that ensures liquid does not come in contact

with the vital parts of the pump.

The tank, made of impact-proof and chemical resistant polyethylene,

has a purposeful design with no sharp edges for easy cleaning and

efficient agitation. A suction filter is located at the top of the tank. This

facilitates filter inspection even if the tank is filled with spray liquid. To

ensure safe operation, the drain valve is also located at the top of the

tank.

The BK 180 K operating unit consists of; pressure agitator, safety

valve, on/off function, pressure filter with pressure gauge, distribution

valves with pressure equalization device and HARDI-MATIC.

HARDI-MATIC ensures a constant volume per hectare of the liquid at

varying speed in the same gear. The number of revolutions on the

P.T.O. must be kept between 300-600 r/min.

2

Page 3

LX-MB

LX-HB

The MB spray boom (10 or 12 metre) or the HB spray boom (12, 15,

16 or 18 metre) is fitted. The boom is supported by a trapeze which

protects the boom against vibrations and shocks when driving on

uneven ground. This ensures longer boom life and improves boom

stability for an optimal spray pattern. Height adjustment of the boom is

hydraulic. The boom is fitted with spring loaded breakaways at the

pivots.

Identification plate

An identification plate fitted on the frame indicates model, year of

production and serial number, and country of origin.

3

Page 4

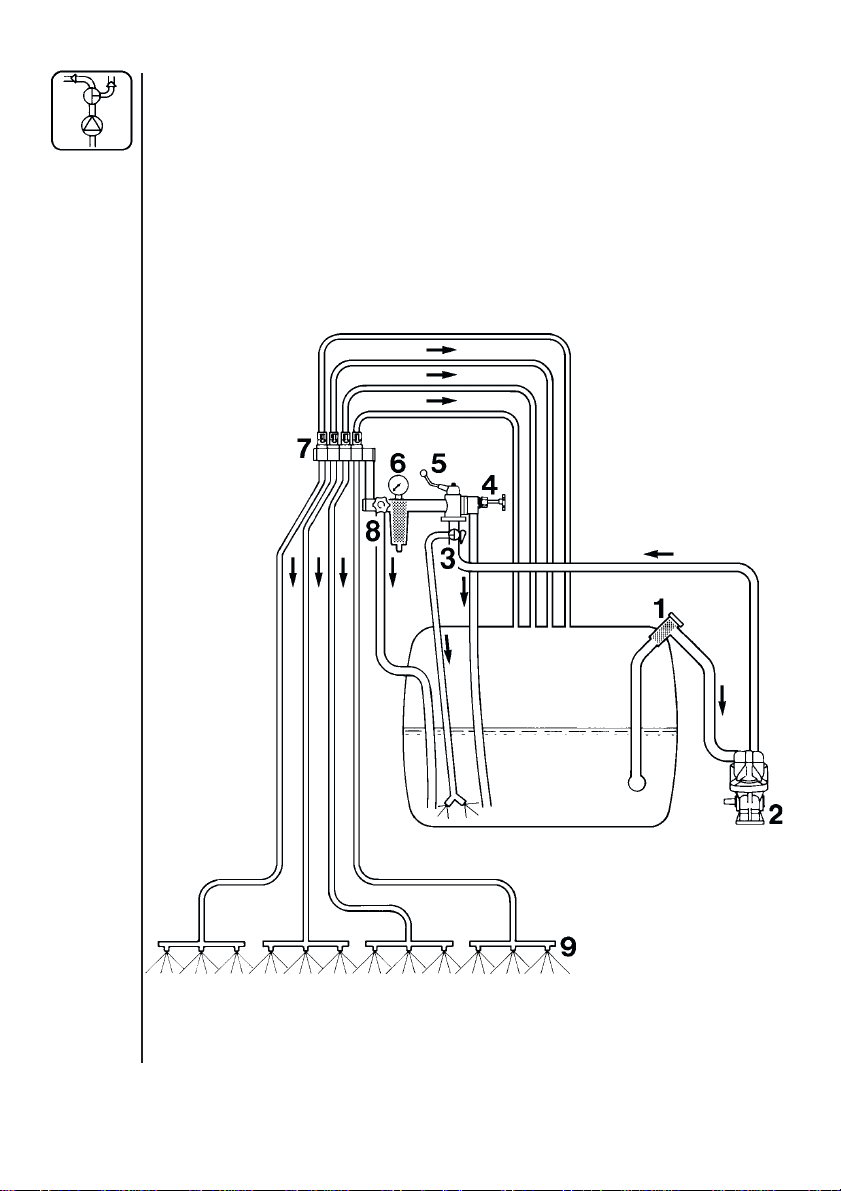

Operation diagram

1. Suction filter

2. Pump

3. Pressure agitator valve

4. Safety valve

5. On/off valve

6. Pressure filter with pressure

gauge

7. Distribution valve with pressure

equalization

MB boom - 3 sections

HB boom - 4 sections

8. HARDI-MATIC

9. Sprayer boom

4

Page 5

Connecting the sprayer

The sprayer is designed for three point

suspension and is equipped with 28

mm pivots (category II). On 600 litre

model, 22 mm (category I) pivots are

fitted.

On models 800, 1000 and 1200 l the

pivot position can be altered 120 mm.

For HB boom - For increased stability

when the sprayer is detached, retractable supports are located under the

frame. Extend before detaching.

Retract after attached.

WARNING: Note the weight of the sprayer.

See section on Technical specifications.

Generally it is recommended to:

1. Add ballast to front of tractor.

2. Increase tyre pressure (see tractor

instruction book).

3. Travel at slower speeds when driving with

a full tank.

(The tractor will have decreased braking

efficiency.)

4. Be careful when filling/lifting the sprayer the first time.

120mm

HB

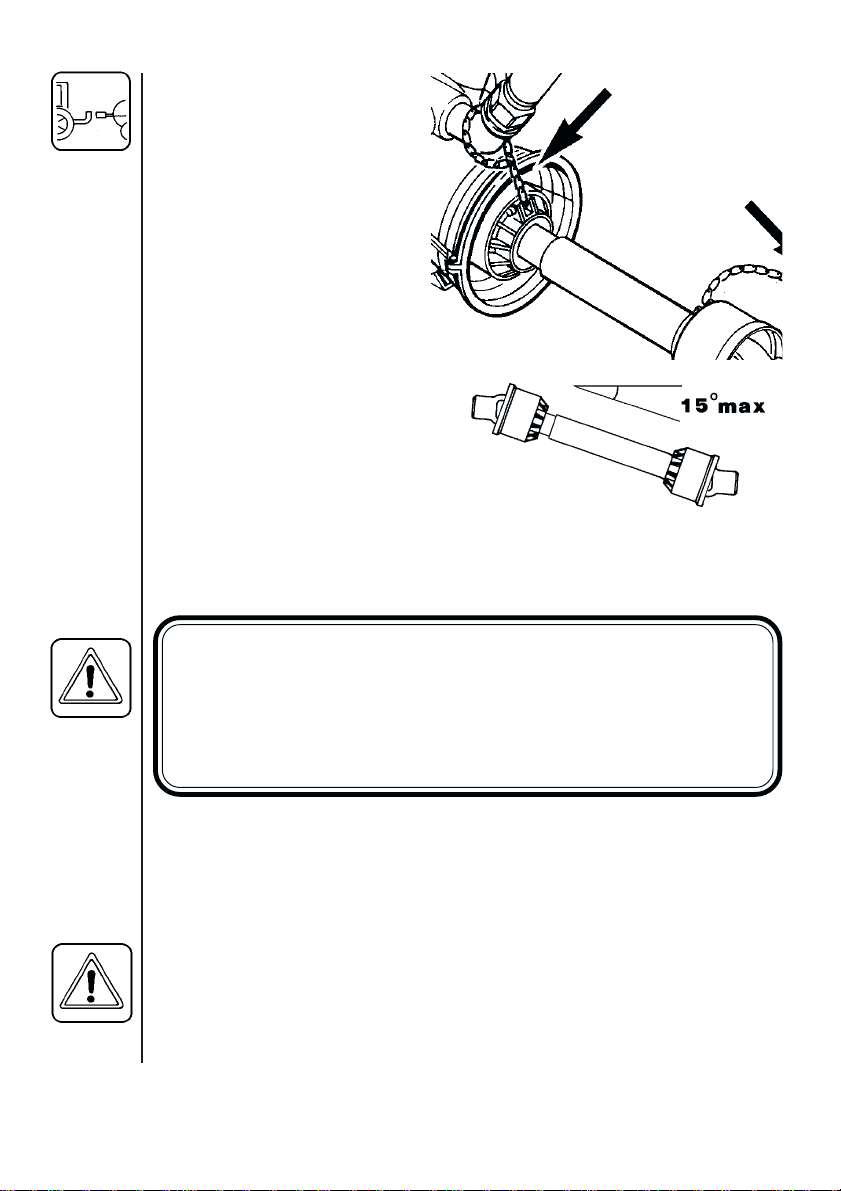

When connecting the sprayer to the tractor the length of the transmission shaft should be checked and if necessary shortened. There

should be at least 10 mm free play between the male and female parts

when the shaft is horizontal.

5

Page 6

It is important for the personal

safety of the operator that the

transmission shaft is intact.

The protection guards must

cover the whole shaft. This

includes the universal cross

covers at each end of the

shaft. The chains are connected so that the protection

guards do not rotate with the

shaft.

To ensure long life of the

transmission shaft, try to avoid

working angles greater than 15°.

Hydraulics

Hydraulic connection necessitates one single acting outlet. The system

will require a capacity of approx. 2 litres and a minimum pressure of

100 bar.

WARNING

INITIAL RAISING AND LOWERING SHOULD BE DONE CAUTIOUSLY; THERE MAY BE A LITTLE AIR IN THE SYSTEM

AND THIS MAY CAUSE ERRATIC MOVEMENTS. THEREFORE TAKE CARE THAT NO PERSONS OR OBJECTS ARE

HURT OR DAMAGED IN THE PROCESS OF TESTING.

Rear lights (if fitted)

Connect plug for rear lights to the tractors 7-poled socket and check

that rear lights, stop lights and turning indicators work properly before

driving anywhere.

Roadworthyness

When driving on public roads and other areas where the highway code

applies, or areas where there are special rules and regulations for

marking and lights on implements, you should observe these and

equip implements accordingly.

6

Page 7

Operating instructions

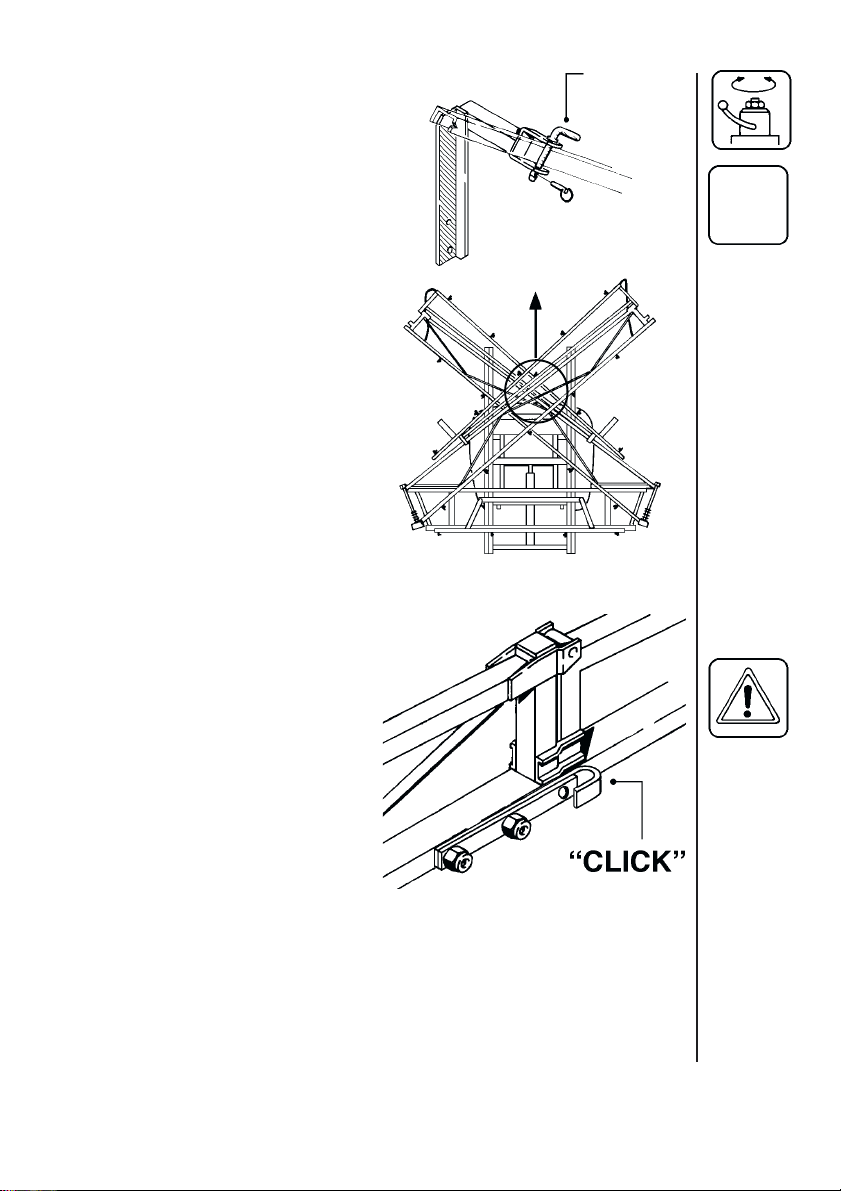

Operation of the MB boom

Remove boom transport lock pins

A. When unfolding (or folding) the

initial force to release the spring

loaded breakaways will be higher

than the actual unfolding/folding.

CAUTION: The breakaways must

be correctly tensioned and lubricated. (see section on Re-adjustment of the boom).

A

MB

When unfolding outer sections,

ensure the outer boom locks click

into place.

Reverse procedure to fold.

7

Page 8

Operation of the HB boom

HB

*

➀ Remove the transport safety wire (

part. Fold arm down to tighten wire.

➁ Lift spring-loaded lock.

➂ Turn the lock 90°.

√ Lock the intermediate and central parts.

➄ Unfold outer section. Fold arm down to

tighten wire.

≈ For 16 and 18 metre unfold

breakaway ensuring the locks

click into place.

) and unfold the intermediate

*

CAUTION: The breakaways must be correctly tensioned and lubricated. (see section on Re-adjustment of the boom)

To fold the order is A - B - C - D - E - F. Remember to reattach safety

wire at transport bracket around boom.

8

Page 9

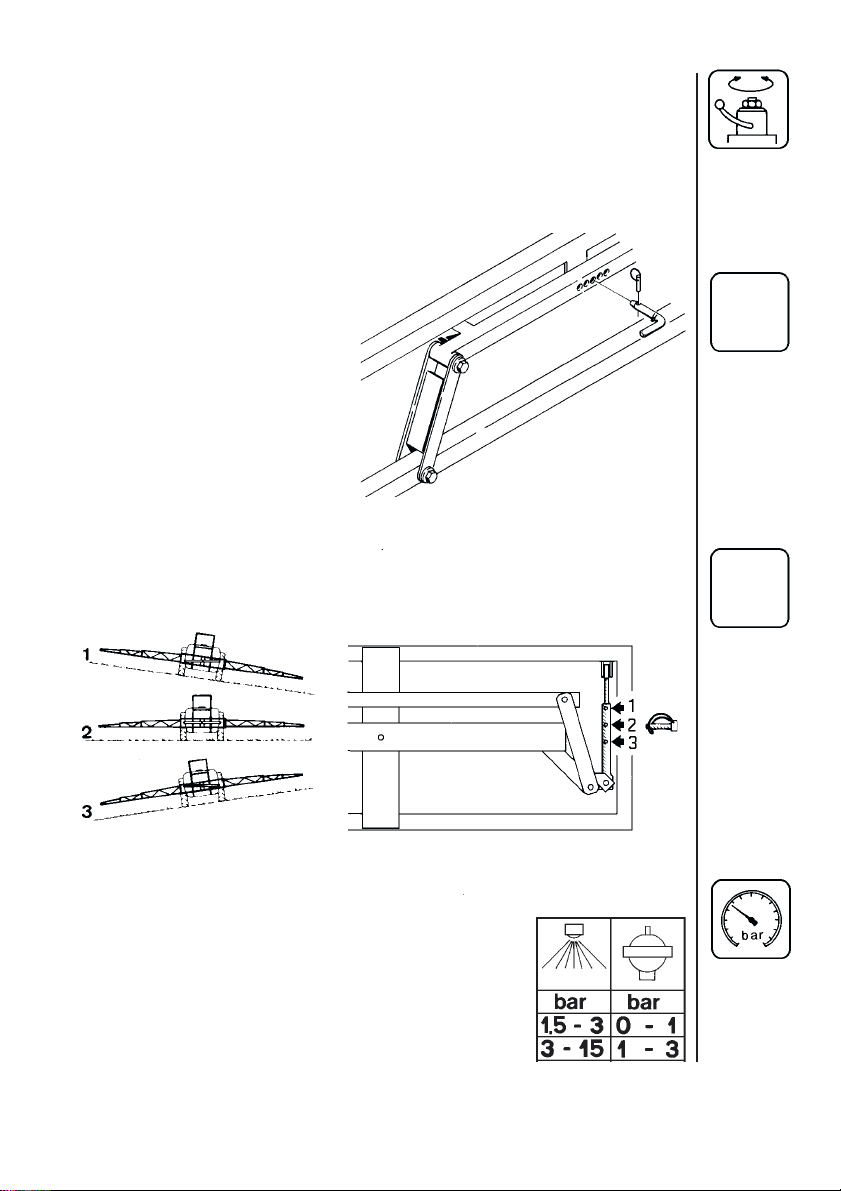

Operation of trapeze

The trapeze suspension must be correctly adjusted and regularly

lubricated, if it is going to operate satisfactorily.

The primary function of the suspension is to protect the boom against

vibrations and shocks. It also helps maintain it a uniform height above

the target.

For MB boom - Under normal

field operation, remove trapeze

lock pin C. Replace pin to block

function, for example before

folding the boom or when

spraying on sloping terrain.

For HB boom - Under normal conditions the trapeze is always active.

When spraying on flat fields, use pos. 2. On sloping terrain the boom

can be slanted (pos. 1 or 3) and still maintain an active trapeze.

C

MB

HB

Pulsation damper (if fitted)

The air pressure in the pulsation damper is preset

at the factory to 2 bar. This covers spray working

pressures between 3 and 15 bar. When using

spray pressures outside this range, the air pressure

should be adjusted as shown in the diagram. The

diagram is also embossed on the damper.

9

Page 10

Adjustment of the operating unit

10

1. Open or close lever 4 depending on whether pressure agitation is

required. (Remember pressure agitation takes 5% to 10% of pump

output).

2. Turn main on/off handle 2 to spraying position A.

3. Set all hand levers 3 on the distribution valve to spraying position A.

4. Turn the HARDI-MATIC valve 6 anti-clockwise to its extreme position.

5. Turn the safety valve 1 clockwise to maximum pressure.

6. Put the tractor in neutral and set the engine revolutions and thereby

the number of revolutions of the pump corresponding to the intended

travelling speed. Remember the number of revolutions on the P.T.O.

must be kept between 300-600 r/min.

Page 11

Adjust the HARDI-MATIC valve 6 so that the pressure gauge indicates

the recommended pressure.

ADJUST THE PRESSURE EQUALIZATION SECTIONS AS FOLLOWS:

7. Note the pressure and place the first lever 3 on the distribution valve

in position B (off position).

8. Turn the corresponding adjust screw 5 until the pressure gauge

again shows the same pressure (turn the screw clockwise for higher

pressure, anti-clockwise for lower pressure).

9. Adjust the other sections of the distribution valve in the same way.

NB: HEREAFTER ADJUSTMENT OF PRESSURE EQUALIZATION

WILL ONLY BE NEEDED IF YOU CHANGE TO NOZZLES WITH

OTHER CAPACITIES.

10. Operating the control unit while driving:

To close the entire boom, turn the handle 2 to position B. This takes

the pressure off the pump. The liquid will then return to the tank via the

return system. The diaphragm anti-drip valves ensure instantaneous

closing of all nozzles. In order to close part of the boom, move lever 3

of the distribution valve to position B (off position) for the section or

sections to be closed. The pressure equalization device ensures that

the pressure does not rise in the sections which are to remain open.

Drain valve operation

Pressure filter

The operating unit has an in-built pressure filter. It is not necessary to

dismantle the filter to clean it. When cleaning the sprayer (clean water

circulating in the tank), open the drain valve to flush the filter;

To open : A

To close : B

Tank drain

To open : A

To close : B

11

Page 12

Maintenance

In order to derive full benefit from the sprayer for many years the

following few but important rules should be kept:

Cleaning the sprayer - see Spray Technique book.

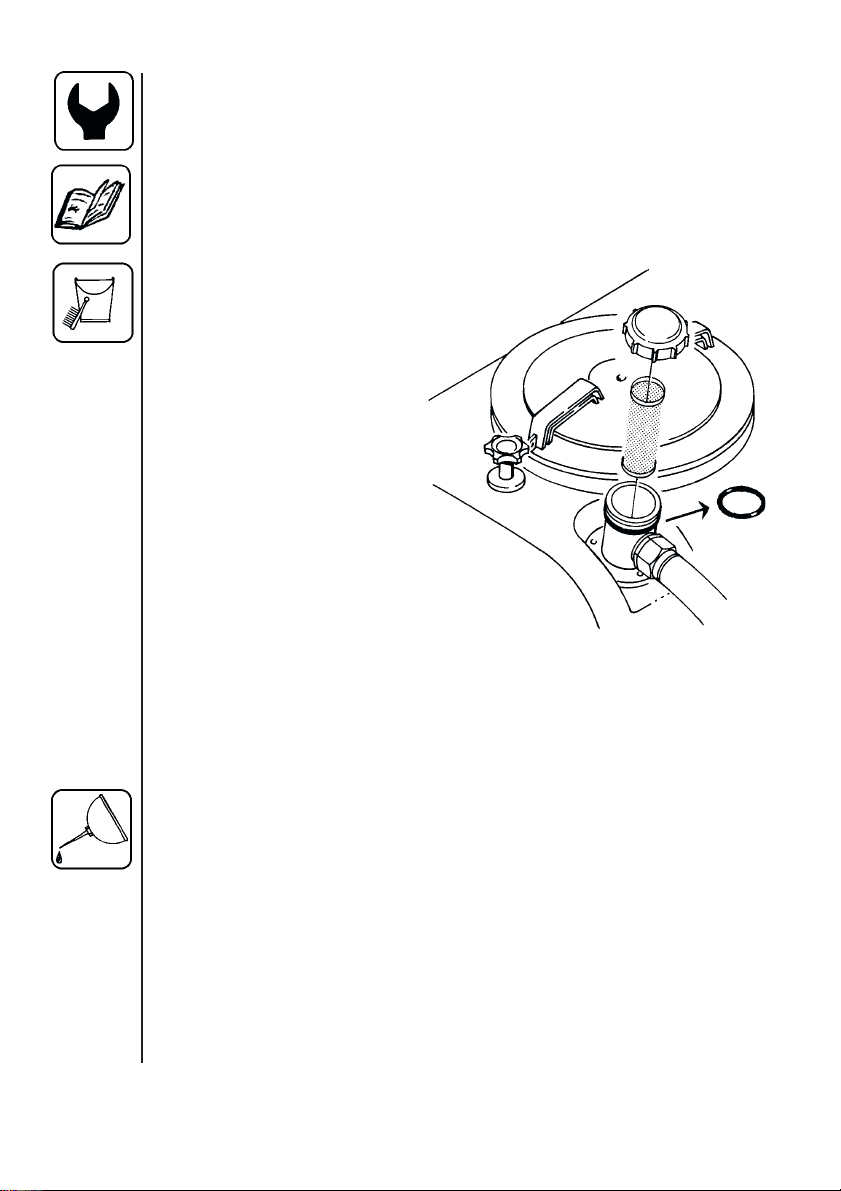

Filters

Clean filters ensure :

• Sprayer components such

as valves, diaphragms

and operating unit are not

hindered or damaged

during operation.

• Nozzle blockages do not

occur whilst spraying.

• Long life of pump. A

blocked suction filter will

result in pump cavitation.

The main filter protecting

sprayer components is the

suction filter at the top of the

tank. Check it regularly.

Ensure the O-ring on filter housing is in good condition and lubricated.

12

The operating unit has an in-built pressure filter. See section on Drain

valve operation.

Lubrication

Recommended lubrication is shown in following tables. Use ball

bearing grease (lithium grease No.2)

NOTE: If the sprayers are cleaned with a high pressure cleaner or it

has been used to spray fertilizer, we recommend lubrication of the

entire machine.

Page 13

Position on sprayer

5

Oil

Grease

Operation hours

Page to find more

information

Winter protection or

off-season storage

8

12

11

9

3

10

1-2

13

Page 14

1X 40

1X 40

2

AX 12

BX40

3X 20

20

6

10

11

22

14

Page 15

MB

4X40

MB

5X40

MB

6X40

19

9

18

7X 40

MB

18

15

Page 16

HB

8X 40

HB

9

AX 40

BX 40

HB

19

A

B

9

A

B

A

B

A

B

19

10

AX 40

BX 40

16

B

A

B

A

B

A

Page 17

HB

11 X 40

12

AX 40

BX40

HB

19

A

A

18

B

17

Page 18

Re-adjustment of the boom

After having used the sprayer for some days the boom should be

adjusted as follows:

When adjusting the sprayer must be on level ground with unfolded

boom. For MB booms - Remove the lock pin for trapeze.

MB

HB

MB

Boom breakaway

The function of the breakaway is to prevent or reduce

boom damage if it should

strike an object or the ground.

If it is overtight, it will not

function. If it is too loose, it

will yawn (forward and back

movement) under spraying.

Lubricate coupling before

adjusting spring tension.

Slacken screw nut A to

decrease breakaway resistance. Do not overtighten;

better to loose than overtight.

Again minor adjustments in

the field may be necessary.

For MB boom - Ensure also

channel bolts B are tight.

Outer section

The hinge should be firm. If

overtight it is difficult to fold.

To adjust, tighten or loosen

nuts C.

MB

HB

MB

A

C

C

18

Page 19

Boom lift.

The boom lift should be adjusted so the boom can freely

move up and down when the lift

cylinder is actuated. Do not

tighten so much that the lift

cannot work unhindered.

For MB boom - Adjust D so the

space E is about equal at all 4

points.

MB

MB

E

D

For HB boom - Loosen lock

nuts F and adjust bolts G.

Retighten lock nuts.

Trapeze suspension

For the trapeze to function it

must not be overtight. If it is too

loose the boom will yawn. This

results in a poor spray distribution.

Adjustment is made after

having lubricated all pivot and

friction points (see section on

Lubrication).

Adjust trapeze bolts H so it is

not to tight nor to loose. Minor

adjustment in the field may be

necessary.

Wire tension - HB boom only.

Slack wires result in excessive

boom yawn. To adjust, loosen

rigging screw lock nuts and

turn. If overtightened it will not

be possible to fold arm down.

HB

MB

HB

H

H

F

G

F

HB

G

MB

HB

19

Page 20

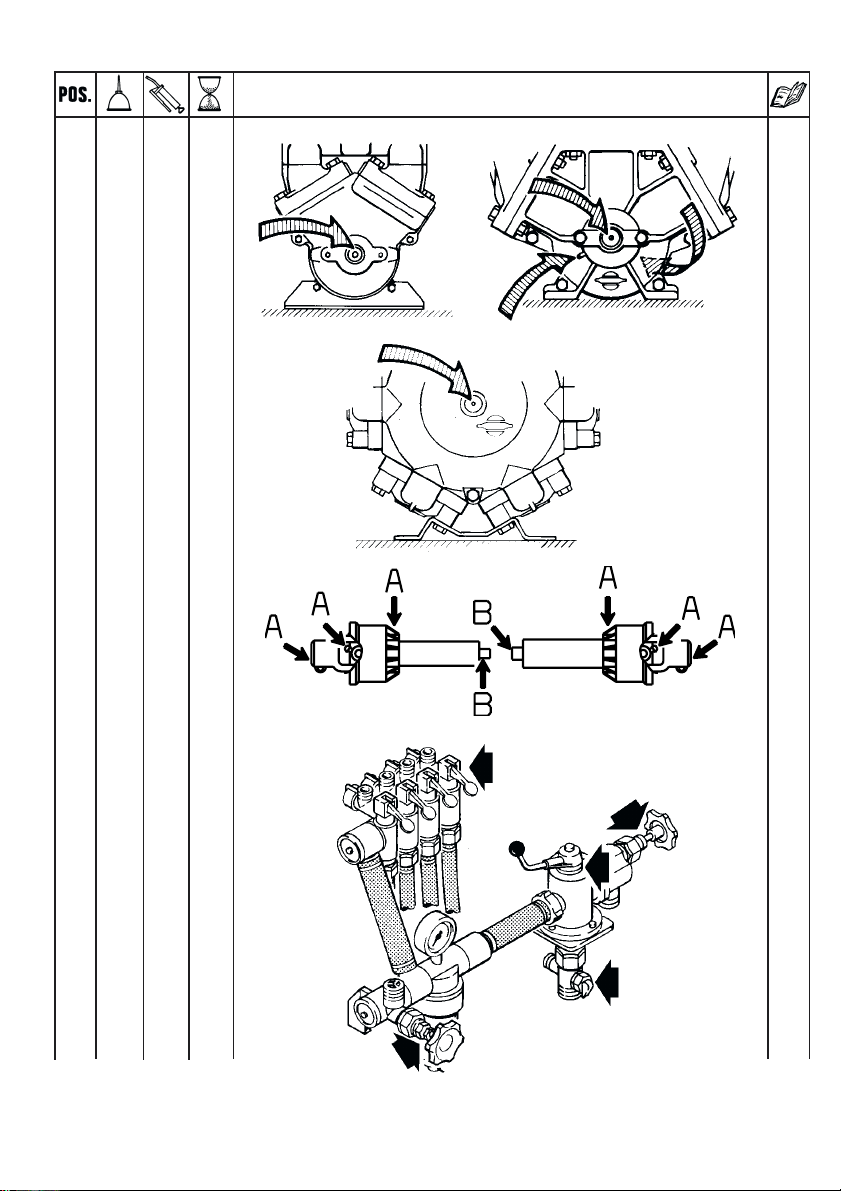

Changing of valves and diaphragms

Valves

Dismantle valve compartment 1. Before changing the valves 2 note the

orientation of the valves so that they may be replaced correctly.

Important: For model 361 one special valve with red flap 2A is to be

placed in the valve opening shown.

It is recommended to use new gaskets 3 when changing or checking

the valves.

Diaphragms

Remove the diaphragm cover 4 after having dismantled the valve

compartment as indicated above. The diaphragm 5 may then be

changed. If fluids have reached the crankcase, re-grease the pump

thoroughly. Check also the drain hole at the bottom of the pump is not

blocked.

Model 1202

20

Page 21

Model 1302

Model 361

21

Page 22

Changing of ball seat in operating unit

If problems with on/off valve occurs (dripping nozzles when on/off

valve is closed), the ball and ball seat should be checked.

Remove the 2 bolts fixing the

on/off-pressure valve unit to

the bracket, unscrew the

union nut A and pull the on/

off-pressure valve away from

the distribution valves.

Check the ball for sharp

edges and scratches and

check the ball seat for

cracks and wear - replace if necesary.

A

Nozzle tubes and fittings

Poor seals are usually caused by;

• missing O-rings or gaskets

• damaged or incorrectly seated O-rings

• dry or deformed O-rings or gaskets

• foreign bodies

Therefore, in case of leaks: DO NOT overtighten.

Disassemble, check condition and position of Oring or gasket, clean lubricate and reassemble.

For radial connections only hand tighten them.

22

Lubricate ALL THE WAY ROUND before fitting.

For face connections, a little mechanical leverage may be used.

Page 23

Level indicator

Depending on products used, it can become difficult

to see the red sphere inside the level indicator tube.

Note that the tube can be replaced when necessary.

Off-season storage

When the spraying season is over you should devote

some extra time to the sprayer before it is stored.

Hoses

Check that none of the hoses are caught or have sharp bends.

A leaky hose can give an annoying delay in the middle of the spraying

job. Therefore check all the hoses and change if there is any doubt

about the durability.

Paint

Some chemicals are very hard on paints. It is therefore well advised to

remove rust, if any, and then touch up the paint.

Tank

Check that no chemical residues are left from the last spraying. Chemical residues must not be left in the tank for a long time. It will reduce

the life of the tank. See Spray Technique book - Cleaning the sprayer.

Operating unit

Take care that the safety valve is

completely loosened. The spring is

thereby relieved and operation difficulties are avoided at starting-up next

season.

23

Page 24

Transmission shaft

Check that the transmission shaft fulfills its security purpose, e.g. that

shields and protective tubes are intact.

Anti-freeze precaution

If the sprayer is not stored in a frost- proof place you should take the

following precautions: Put at least 10 litres of 33% anti-freeze mixture

in the tank and let the pump run a few minutes so that the entire

system including spray hose are filled. Remove the glycerine filled

pressure gauge and store it frost free in vertical position.

The anti-freeze solution also hinders the O-rings and gaskets from

drying out.

Operational problems

In cases where breakdowns have occurred the same factors always

seem to come into play:

• Minor leaks on the suction side of the pump will reduce the pump

capacity or stop the suction completely.

• A clogged suction filter will hinder or prevent suction so that the

pump does not operate satisfactorily.

• Clogged up pressure filters will result in increasing pressure at the

pressure gauge but lower pressure at the nozzles.

• Foreign bodies stuck in the pump valves with the result that these

cannot close tightly against the valve seat. This reduces pump

efficiency.

• Poorly reassembled pumps, especially diaphragm covers will allow

the pump to suck air resulting in reduced or no capacity.

24

Therefore ALWAYS check:

1. Suction, pressure and nozzle filters are clean.

2. Hoses for leaks and cracks, paying particular attention to suction

hoses.

3. Gaskets and O-rings are present and in good condition.

4. Pressure gauge is in good working order. Correct dosage depends

on it.

5. Operating unit functions properly. Use clean water to check.

Page 25

Fault Probable cause Control / remedy

Liquid system

No spray from

boom when

turned on.

Air leak on suction.

Check if red suction lid/O-ring are

sealing.

Check suction tube and fittings.

Check tightness of pump diaphragm

and valve covers.

Lack of

pressure.

Pressure

dropping.

Air in system.

Suction/pressure

filters clogged.

Incorrect assembly.

Pump valves blocked

or worn.

Defect pressure

gauge.

Filters clogging.

Nozzles worn.

Tank is airtight.

Sucking air towards

end of tank load.

Fill suction hose with water for initial

prime.

Clean filters.

Check yellow suction pipe is not

obstructed or placed too near the

tank bottom.

Agitation nozzles not fitted.

Too little distance between yellow

suction pipe and tank bottom.

Check for obstructions and wear.

Check for dirt at inlet of gauge.

Clean all filters. Fill with cleaner

water.

If using powders, make sure

agitation is on.

Check flow rate and replace

nozzles if it exceeds 10%.

Check vent is clear.

Excessive agitation, turn off.

Returns inside tank need relocation.

25

Page 26

Fault Probable cause Control / remedy

Pressure

increasing

Pressure filters

beginging to clog.

Clean all filters.

Formation of

foam.

Liquid leaks

from bottom of

pump.

Agitation nozzles

clogged.

Air is being sucked

into system.

Excessive liquid

agitation.

Damaged diaphragm.

Check by turning agitation off/on.

Check tightness / gaskets / O-rings

of all fittings on suction side.

Turn agitation off.

Reduce pump r/min.

Ensure returns inside tank are

present.

Use foam damping addative.

Replace. See Changing of valves

and diaghragms.

26

Page 27

Technical specifications

Measure and weights

LX-MB

Tank Spraying Pump Measure Weight

size width model a x b x c

lm cm kg

10 1202 160 x 226 x 220 309

600 10 1302 160 x 226 x 220 316

12 1302 160 x 226 x 220 324

10 1302 160 x 226 x 220

800 12 1302 160 x 226 x 220

12 361 160 x 226 x 220 404

1000 12 1302 176 x 226 x 220 396

12 361 176 x 226 x 220 418

1200 12 1302 185 x 226 x 220 450

12 361 185 x 226 x 220 468

LX-HB

Tank Spraying Pump Measure Weight

size width model a x b x c

lm cm kg

12 1302 245 x 248 x 215 655

12 361 245 x 248 x 215 679

800 15 1302 330 x 248 x 215 663

15 361 330 x 248 x 215 671

16 361 330 x 248 x 215 683

18 361 330 x 248 x 215 707

12 1302 245 x 248 x 215 693

12 361 245 x 248 x 215 717

1000 15 1302 330 x 248 x 215 701

15 361 330 x 248 x 215 709

16 361 330 x 248 x 215 721

18 361 330 x 248 x 215 745

12 1302 245 x 248 x 215 713

12 361 245 x 248 x 215 737

1200 15 1302 330 x 248 x 215 721

15 361 330 x 248 x 215 729

16 361 330 x 248 x 215 741

18 361 330 x 248 x 215 765

a

c

b

27

Page 28

Power consumption and capacity

1202/9.0

bar l/min kW l/min kW l/min kW l/min kW l/min kW

0 56 0,91 72 1,28 93 1,52 99 1,63 112 1,79

5 40 1,11 53 1,36 66 1,60 71 1,71 79 1,86

10 38 1,38 52 1,74 64 1,79 69 1,87 77 2,07

15 37 1,60 50 1,97 62 2,32 67 2,48 75 2,76

Rotation per min. r/min Capacity l/min Suction height 0,0 m

Power consumption kW Max. pressure 15 bar Weight 24,0 kg

1302/9.0

bar l/min kW l/min kW l/min kW l/min kW l/min kW

0 63 0,90 84 1,19 103 1,51 114 1,61 125 1,80

5 58 0,94 79 1,29 96 1,61 105 1,75 116 1,93

10 56 1,30 76 1,80 94 2,30 101 2,48 111 2,72

15 55 1,80 74 2,22 93 2,92 99 3,18 109 3,54

Rotation per min. r/min Capacity l/min Suction height 0,0 m

Power consumption kW Max. pressure 15 bar Weight 35,0 kg

361/9.5

bar l/min kW l/min kW l/min kW l/min kW l/min kW

0 95 0,92 127 1,33 158 1,56 171 1,69 189 1,85

5 92 1,49 123 1,93 151 2,38 165 2,63 183 2,98

10 91 2,22 120 2,89 148 3,69 163 4,02 180 4,74

15 89 3,03 119 3,92 148 4,90 160 5,40 177 6,15

Rotation per min. r/min Capacity l/min Suction height 0,0 m

Power consumption kW Max. pressure 15 bar Weight 54,0 kg

300 400 500 540 600

300 400 500 540 600

300 400 500 540 600

r/min

r/min

r/min

28

Page 29

Filters and nozzles

Pos. Mesh/ Description/

colour nozzle

2

Pictorial symbols

Description

Function

Connection

Warning

3 - 4

1 30 Suction filter

1

2 50 Pressure filter

3 50 blue Nozzle 4110-16

4 50 blue Nozzle 4110-20

Pressure

Cleaning

Lubrication

Winter storage

Operating

Service/adjustment

Liquid flow

MB

Operational problems

Technical

specifications

Specific boom type

29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Notes:

48

32

Loading...

Loading...