Hardi NEPTUN iEF820, NEPTUN iEF750, NEPTUN EF920, NEPTUN iEF920, NEPTUN AB820 Instruction Book

...Page 1

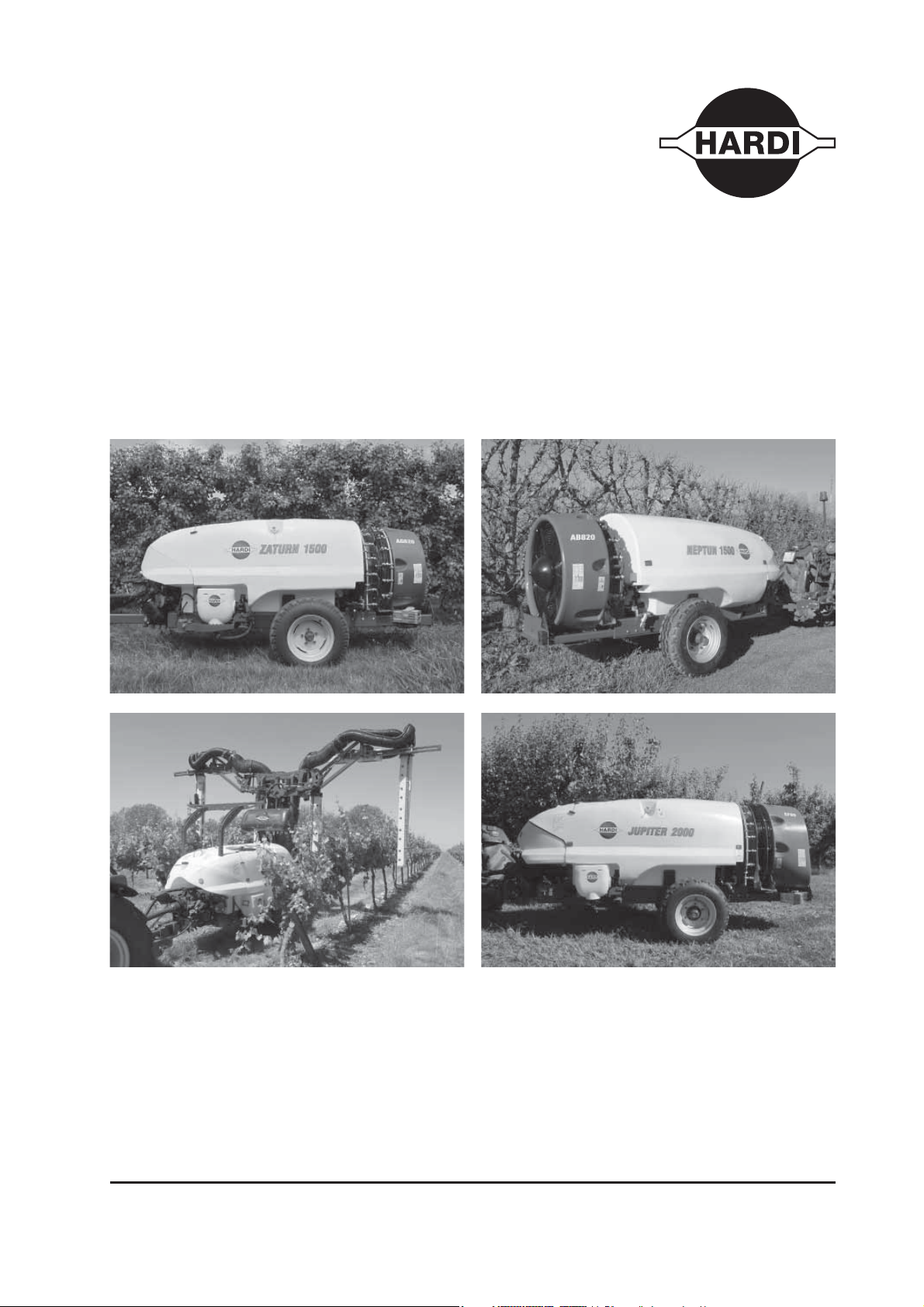

NEPTUN

ZATURN

JUPITER

Original

Instruction book

67030102-110 - version 1.10

GB - 05.2016

www.hardi.es

www.hardi-international.com

Page 2

Congratulations for choosing a HARDI crop protection product. The reliability and effi ciency

of this machine depend entirely on the care it receives. The fi rst step is to carefully read and

pay attention to this instruction book. It contains essential information on correctly using and

ensuring a long useful life of this quality product.

As this instruction book includes all versions of the equipment, including the entire diff erent

hydraulic boom and operating unit versions, please pay particular attention to the paragraphs

dealing with your specifi c model.

This book should be read in conjunction with the ‘Spraying Techniques’ booklet.

The original instruction book is approved and published in English. All other languages are

translations of the original. In the event of any confl icts, inaccuracies or deviations between

the English original and other languages the English version shall prevail.

Since it is ILEMO-HARDI S.A.U. policy to continually improve our products, we reserve the right

to make changes in the design, accessories, specifi cations and maintenance instructions at

any time and without notice.

ILEMO-HARDI S.A.U. is exempt from any obligation as regards instruments purchased before

or after such changes. ILEMO-HARDI S.A.U. cannot undertake any responsibility for possible

omissions or inaccuracies in this publication, although it has done everything in its power to

make this information as complete and correct as possible.

As this instruction book covers models, specifi cations or equipment that are only available in

certain countries, please pay particular attention to the paragraphs dealing with your specifi c

model.

Published and printed by ILEMO-HARDI S.A.U.

Page 3

Table of Contents

1 - EC Declaration

EC Declaration of Conformity .............................................................................................................. 5

2 - Safety

Operator safety ................................................................................................................................... 7

Symbols .................................................................................................................................................................................................................................................................7

Precautions ..........................................................................................................................................................................................................................................................7

3 - Description

General information ............................................................................................................................ 9

Overview ..............................................................................................................................................................................................................................................................9

Use of the mist blower ..............................................................................................................................................................................................................................11

Roadworthiness ............................................................................................................................................................................................................................................ 11

Identifi cation plate ......................................................................................................................................................................................................................................11

Chassis .................................................................................................................................................................................................................................................................11

Tank .......................................................................................................................................................................................................................................................................12

Liquid system .................................................................................................................................... 13

General information ...................................................................................................................................................................................................................................13

The liquid circuit ...........................................................................................................................................................................................................................................13

Diaphragm pump ........................................................................................................................................................................................................................................ 13

Valves ...................................................................................................................................................................................................................................................................13

Valves and symbols .....................................................................................................................................................................................................................................13

Manifold system ............................................................................................................................................................................................................................................14

Blue valve – Blue disc = Return valve ..............................................................................................................................................................................................14

Circuit Diagram .............................................................................................................................................................................................................................................. 15

Suction fi lter ....................................................................................................................................................................................................................................................15

Safety valve.......................................................................................................................................................................................................................................................16

Pressure manifold ......................................................................................................................................................................................................................................... 16

Suction and pressure pulsation dampers ..................................................................................................................................................................................... 16

Agitator ...............................................................................................................................................................................................................................................................16

Operating unit ................................................................................................................................................................................................................................................17

BK/2 ...................................................................................................................................................................................................................................................................... 17

MC/2 operating unit ................................................................................................................................................................................................................................... 17

BS/2 ......................................................................................................................................................................................................................................................................17

SV operating unit .......................................................................................................................................................................................................................................... 17

SA operating unit .........................................................................................................................................................................................................................................17

CA operating unit ......................................................................................................................................................................................................................................... 17

CB operating unit ......................................................................................................................................................................................................................................... 17

Filters ....................................................................................................................................................................................................................................................................17

Powder mixer ..................................................................................................................................................................................................................................................17

TurboFiller ........................................................................................................................................................................................................................................................ 18

Axial blower units ............................................................................................................................. 19

Technical information ................................................................................................................................................................................................................................19

EF820, EF920, AB750, AB820, AB920, AG820, AG920, IAG820, IAG920, SF65, SF85 and XF90 .......................................................................19

Air fl ow for axial air kits .............................................................................................................................................................................................................................21

Defl ectors .......................................................................................................................................................................................................................................................... 22

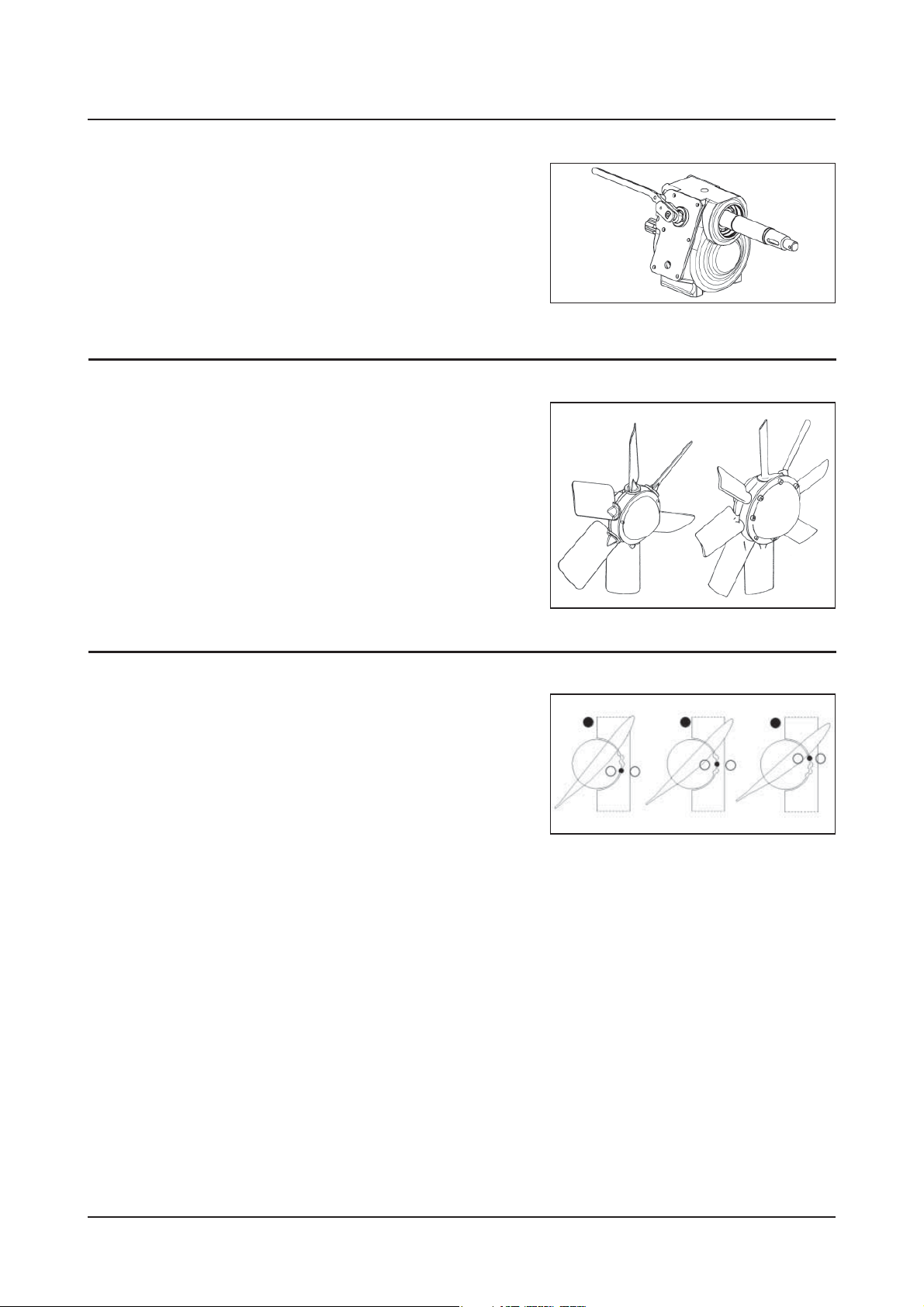

Gearbox ..............................................................................................................................................................................................................................................................23

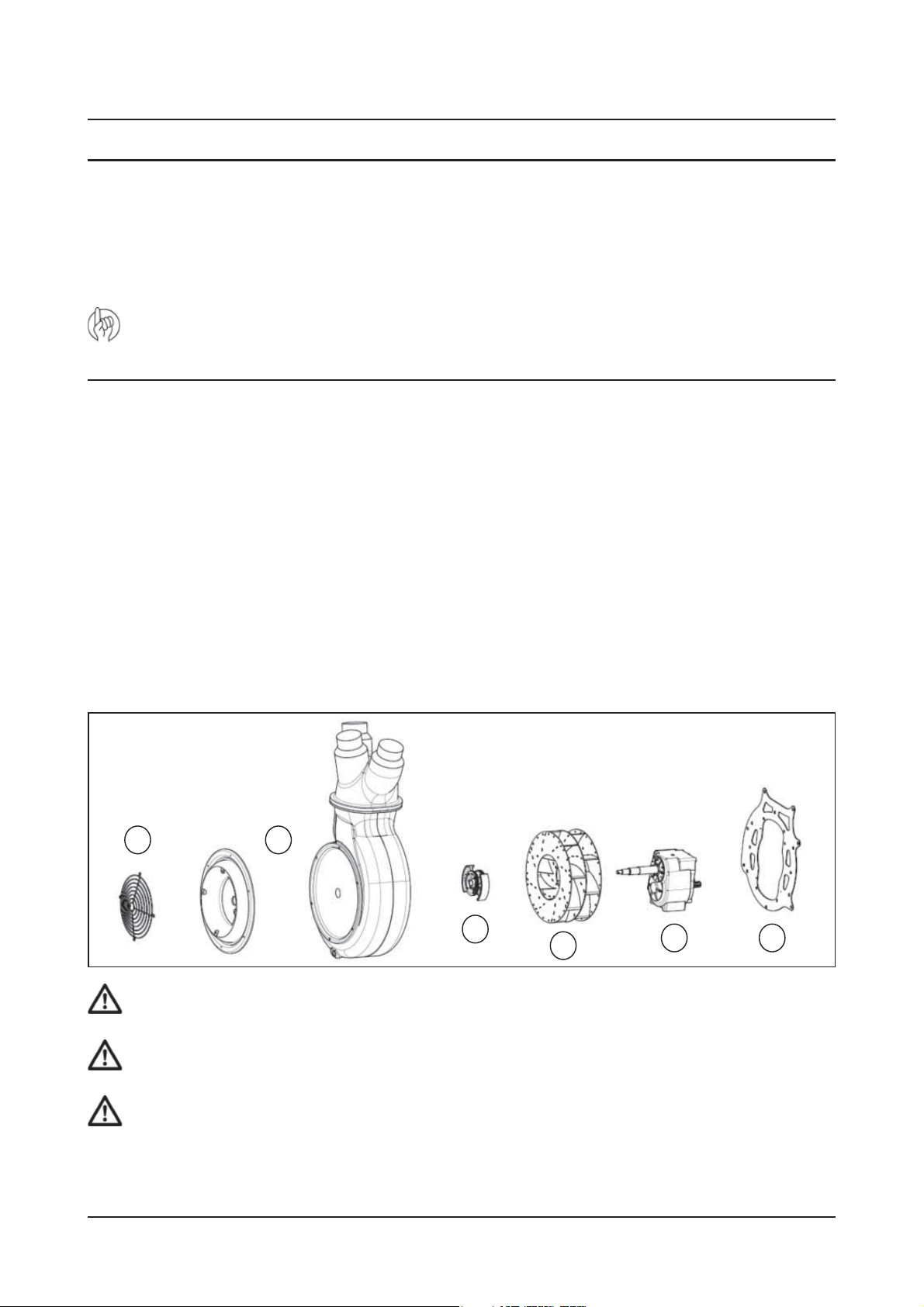

Fan .........................................................................................................................................................................................................................................................................23

Specifi c for SF and XF axial fans .........................................................................................................................................................................................................23

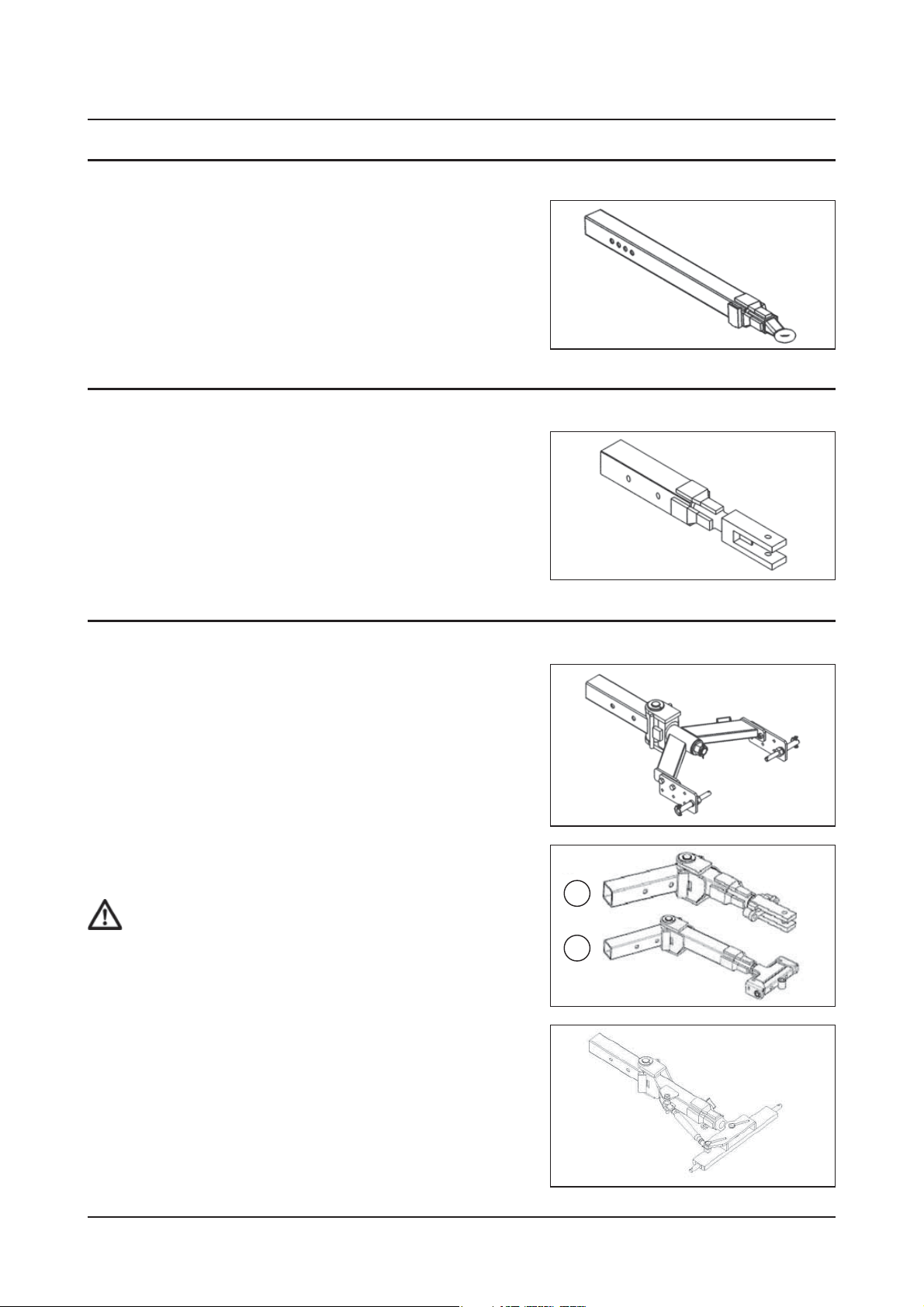

Centrifugal Blower Units (Turbines) .................................................................................................. 24

General information ...................................................................................................................................................................................................................................24

HF540 (TS3 P540 / TS6 P540 Single)...............................................................................................................................................................................................24

HF540D (TD3-P540 Double) ...............................................................................................................................................................................................................24

HF640D (TD3-P640 Double) ..............................................................................................................................................................................................................24

Protective grid ................................................................................................................................................................................................................................................25

Gearbox ..............................................................................................................................................................................................................................................................26

HF540, HF540D and HF 640D Turbines ..........................................................................................................................................................................................26

Clutch (All blower types) .........................................................................................................................................................................................................................26

Equipment ......................................................................................................................................... 27

Ring drawbar ...................................................................................................................................................................................................................................................27

Fork drawbar ...................................................................................................................................................................................................................................................27

Turnable drawbar .........................................................................................................................................................................................................................................27

1

Page 4

Table of Contents

Wedges ...............................................................................................................................................................................................................................................................28

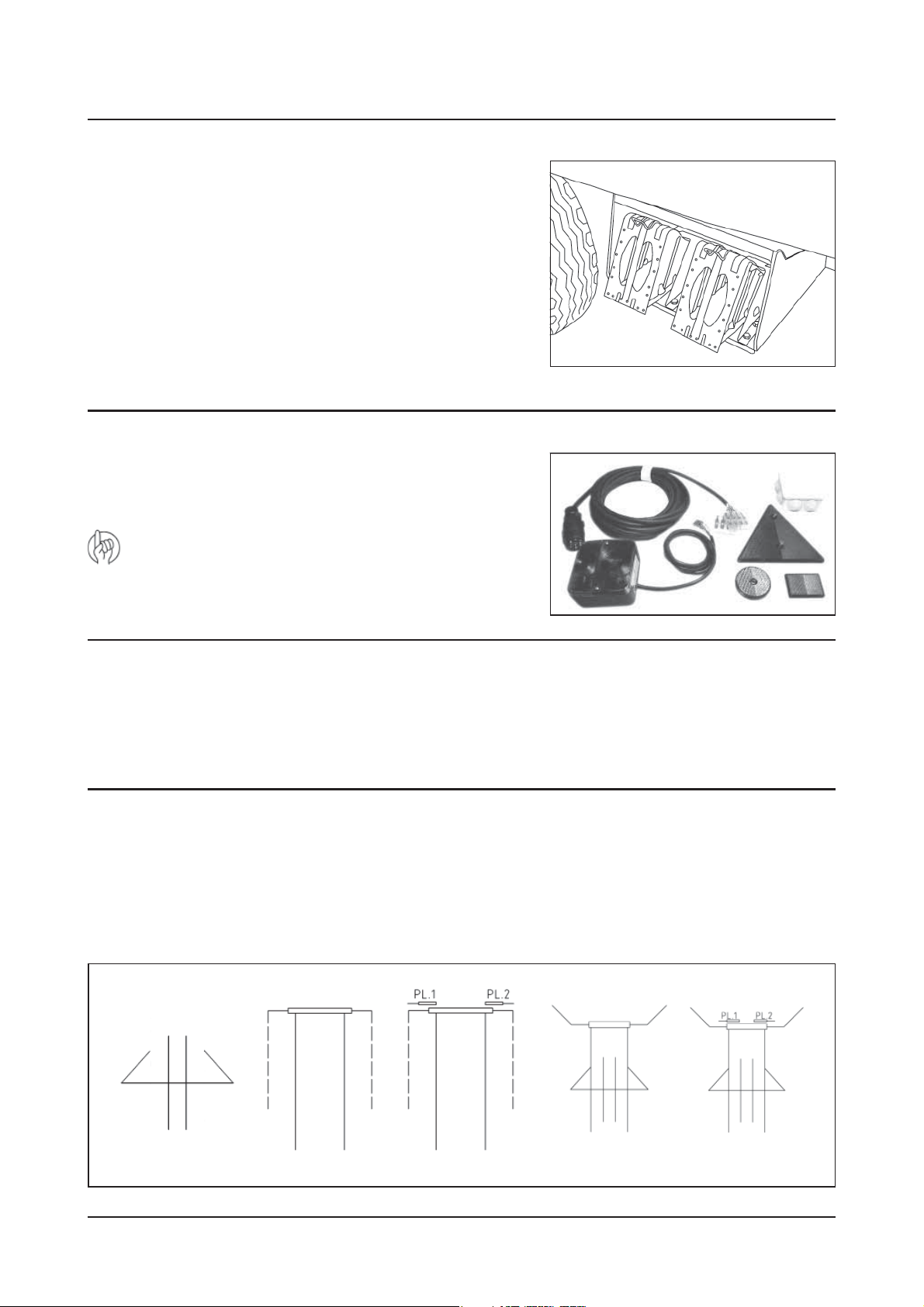

Light kit ............................................................................................................................................................................................................................................................... 28

Booms..................................................................................................................................................................................................................................................................28

The LINER boom .........................................................................................................................................................................................................................................28

The ATLAS boom ..........................................................................................................................................................................................................................................29

The BOXER boom .........................................................................................................................................................................................................................................30

The CRONOS boom .................................................................................................................................................................................................................................... 31

Break away clutch ........................................................................................................................................................................................................................................32

Particularly for CRONOS boom ............................................................................................................................................................................................................ 32

Pneumatic spray system .......................................................................................................................................................................................................................... 33

Hydropneumatic spray system ............................................................................................................................................................................................................ 33

IRIS system, continuation of Hydro pneumatic system ......................................................................................................................................................34

4 - Starting up

General information .......................................................................................................................... 35

Unloading the mistblower from the truck ...................................................................................................................................................................................35

Before starting up for the fi rst time ................................................................................................................................................................................................... 35

Counterweights ............................................................................................................................................................................................................................................35

Mechanical connections .................................................................................................................... 36

Adjusting the drawbar length ..............................................................................................................................................................................................................36

Jockey wheel ................................................................................................................................................................................................................................................... 36

Connecting the fork drawbar ...............................................................................................................................................................................................................36

Connecting the ring drawbar ...............................................................................................................................................................................................................36

Connecting the articulated drawbars .............................................................................................................................................................................................37

Lock device on turnable drawbar ...................................................................................................................................................................................................... 37

Coupling the driveshaft............................................................................................................................................................................................................................38

Hydraulic connections ....................................................................................................................... 39

General information ...................................................................................................................................................................................................................................39

Tractor requirements ..................................................................................................................................................................................................................................39

Electrical connections ....................................................................................................................... 40

General information ...................................................................................................................................................................................................................................40

Operating unit ................................................................................................................................................................................................................................................40

Rate controller................................................................................................................................... 41

Rate controller DB 3610 ............................................................................................................................................................................................................................ 41

Rate controller DB 3620 ............................................................................................................................................................................................................................ 42

Fluid circuit ....................................................................................................................................... 43

Suction fi lter ....................................................................................................................................................................................................................................................43

Pressure damper ...........................................................................................................................................................................................................................................43

Diaphragm pump ........................................................................................................................................................................................................................................ 43

Defl ectors .......................................................................................................................................................................................................................................................... 44

Booms ............................................................................................................................................... 47

General information ...................................................................................................................................................................................................................................47

FIX ..........................................................................................................................................................................................................................................................................47

START ...................................................................................................................................................................................................................................................................47

ATLAS START ....................................................................................................................................................................................................................................................48

ATLAS AGILE ..................................................................................................................................................................................................................................................... 48

ATLAS SOLID FIX and ATLAS SOLID FIX GV.................................................................................................................................................................................. 48

ATLAS SOLID CONVERT and ATLAS SOLID GV CONVERT ..................................................................................................................................................... 48

BOXER START ...................................................................................................................................................................................................................................................49

BOXER SOLID VERTICAL FIX or CONVERT ..................................................................................................................................................................................... 49

BOXER SOLID HORIZONTAL ...................................................................................................................................................................................................................49

Adjustment of BOXER boom ................................................................................................................................................................................................................. 50

CRONOS BOOM .............................................................................................................................................................................................................................................50

SOLID ...................................................................................................................................................................................................................................................................50

RIDER ....................................................................................................................................................................................................................................................................51

VARIA ....................................................................................................................................................................................................................................................................51

CRONOS GV ....................................................................................................................................................................................................................................................51

General for all boom models ................................................................................................................................................................................................................52

Break away clutch ....................................................................................................................................................................................................................................... 52

Adjustment of hydraulic fold ................................................................................................................................................................................................................ 52

Transport bracket ........................................................................................................................................................................................................................................ 53

Adjustment of upright ............................................................................................................................................................................................................................. 53

2

Page 5

Table of Contents

Adjustment of out spray device .......................................................................................................................................................................................................... 53

The hydraulic version .................................................................................................................................................................................................................................54

Adjustment of inner 4 spray device .................................................................................................................................................................................................. 54

Hydraulic adjustment of the Convert brackets ........................................................................................................................................................................55

IRIS system setup ..........................................................................................................................................................................................................................................55

Cannons .............................................................................................................................................................................................................................................................56

Calibration.........................................................................................................................................................................................................................................................56

5 - Operation

Blower unit ........................................................................................................................................ 57

Safety information .......................................................................................................................................................................................................................................57

Selecting the gear ........................................................................................................................................................................................................................................57

While moving the Sprayer ...................................................................................................................................................................................................................... 58

Adjusting the fan A6820 and SF65/SF85 and XF90 ................................................................................................................................................................ 59

Single side blinds (Optional) .................................................................................................................................................................................................................59

Fluid circuit ....................................................................................................................................... 60

Filling/washing location requirements ...........................................................................................................................................................................................60

Filling with water .......................................................................................................................................................................................................................................... 60

Filling through tank lid .............................................................................................................................................................................................................................. 61

Filling the rinsing tank ...............................................................................................................................................................................................................................61

Rinsing nozzle ................................................................................................................................................................................................................................................. 61

Filling the clean water tank ....................................................................................................................................................................................................................62

Drain valve ........................................................................................................................................................................................................................................................ 62

Manifold system ............................................................................................................................................................................................................................................62

Filling liquid chemicals by HARDI TurboFiller (optional) ...................................................................................................................................................... 63

TurboFiller rinsing.........................................................................................................................................................................................................................................64

Power supply...................................................................................................................................................................................................................................................65

Installation of control unit brackets .................................................................................................................................................................................................. 65

Adjusting the BK/2 Operating Unit ................................................................................................................................................................................................... 66

MC/2 operating unit ................................................................................................................................................................................................................................... 66

BS2 operating unit ...................................................................................................................................................................................................................................... 67

SV operating unit .......................................................................................................................................................................................................................................... 67

CA operating unit ......................................................................................................................................................................................................................................... 68

The SA Operating unit, is either 2, 4 or more section ............................................................................................................................................................ 68

CB operating unit ......................................................................................................................................................................................................................................... 68

CB operating unit with bypass valve ................................................................................................................................................................................................ 69

Control boxes ..................................................................................................................................................................................................................................................69

FB 3605 ...............................................................................................................................................................................................................................................................69

FB 3610 ...............................................................................................................................................................................................................................................................69

FB 3620 ...............................................................................................................................................................................................................................................................69

HB 3610 ..............................................................................................................................................................................................................................................................70

The Joystick S selector .............................................................................................................................................................................................................................70

HB 3620 ..............................................................................................................................................................................................................................................................71

Cannon L-M-T .................................................................................................................................................................................................................................................71

Hydraulic control of the CANNON ...................................................................................................................................................................................................71

The hydraulic adjustment ......................................................................................................................................................................................................................72

Vegetation sensor is optionally equipped .................................................................................................................................................................................... 72

Rate controller DB3610 ..........................................................................................................................................................................................................................73

Rate controller DB3620 ..........................................................................................................................................................................................................................74

Extended joystick .........................................................................................................................................................................................................................................75

Example of speed and pressure limit settings ...........................................................................................................................................................................75

Cleaning ............................................................................................................................................ 76

General information ...................................................................................................................................................................................................................................76

Cleaning and maintaining the fi lters ...............................................................................................................................................................................................76

Cleaning the tank and liquid system ...............................................................................................................................................................................................77

Use of rinsing tank and rinsing nozzles (optional) ................................................................................................................................................................... 77

6 - Maintenance

Lubrication ........................................................................................................................................ 80

General information ...................................................................................................................................................................................................................................80

Lubricating and greasing the mistblower ....................................................................................................................................................................................80

Suitable lubricants ....................................................................................................................................................................................................................................... 81

3

Page 6

Table of Contents

Transmission shaft .......................................................................................................................................................................................................................................83

Tank transmission shaft ...........................................................................................................................................................................................................................83

Diaphragm pump ........................................................................................................................................................................................................................................ 83

Filters and fi ttings ......................................................................................................................................................................................................................................... 84

Fork drawbar ...................................................................................................................................................................................................................................................84

Ring drawbar ...................................................................................................................................................................................................................................................84

Articulated drawbar .................................................................................................................................................................................................................................... 85

Axles with brake ............................................................................................................................................................................................................................................ 85

Service and maintenance intervals ................................................................................................... 86

General information ...................................................................................................................................................................................................................................86

Every 10 working hours – Spray circuit ..........................................................................................................................................................................................86

Every 10 working hours – Suction fi lter .........................................................................................................................................................................................86

Every 10 hours of operation – Pressure fi lters ............................................................................................................................................................................87

Every 10 working hours – Nozzles ..................................................................................................................................................................................................... 87

Every 50 working hours – Transmission shaft, chassis, air pressure and diaphragm pump ......................................................................... 88

Every 100 working hours – Drawbar ................................................................................................................................................................................................88

Every 250 working hours – Wheels, brakes, hoses and gearbox ....................................................................................................................................88

Every 1000 working hours – Full service ........................................................................................................................................................................................88

Every 1000 working hours - Gearbox oil change .....................................................................................................................................................................88

Every 1000 working hours - Fan clutch inspection ................................................................................................................................................................. 89

Annual maintenance of tank PTO ..................................................................................................................................................................................................... 90

Occasional maintenance ................................................................................................................... 91

Replacing the 321 valves and diaphragms .................................................................................................................................................................................. 91

SV operating unit .......................................................................................................................................................................................................................................... 91

CB Section valve ............................................................................................................................................................................................................................................92

Cleaning the air kit .....................................................................................................................................................................................................................................94

Tank level indicator adjustment .......................................................................................................................................................................................................... 95

Replacing the valves and 364 and 464 diaphragms ..............................................................................................................................................................95

Grease Gun Calibration ............................................................................................................................................................................................................................. 96

Greasing the Pump .....................................................................................................................................................................................................................................96

Service and Maintenance Intervals ................................................................................................... 97

50 Hours Service - Greasing the Pump ........................................................................................................................................................................................... 97

Occasional Maintenance ................................................................................................................... 98

Lifting and Removing the Pump ........................................................................................................................................................................................................ 98

Pump Valves and Diaphragms Renewal ........................................................................................................................................................................................98

Adjusting the 3-way valve ...................................................................................................................................................................................................................100

Replacing the driveshaft protector guard ................................................................................................................................................................................. 100

Replacing the driveshaft crossheads ............................................................................................................................................................................................100

Replacing the seal on the drain valve...........................................................................................................................................................................................101

Storing the mistblower at the end of the season ................................................................................................................................................................. 101

Preparing the machine for use after storage ........................................................................................................................................................................... 102

7 - Troubleshooting

Operational problems ..................................................................................................................... 103

General information ................................................................................................................................................................................................................................ 103

Fluid circuit .................................................................................................................................................................................................................................................... 104

Blower unit ....................................................................................................................................................................................................................................................105

Electrical problems ......................................................................................................................... 106

Emergency function – Fluid circuit ................................................................................................................................................................................................ 106

8 - Technical specifi cations

Axial dimensions and weight .......................................................................................................... 107

Turbines dimensions and weight .................................................................................................... 110

Conversion factors (SI to Imperial) .................................................................................................................................................................................................. 112

Specifi cations .................................................................................................................................. 113

Pump model 363/7 .................................................................................................................................................................................................................................. 113

Pump model 321/10 ............................................................................................................................................................................................................................... 113

Filters and nozzles ..................................................................................................................................................................................................................................... 113

Temperature and pressure range .................................................................................................................................................................................................... 113

Materials and recycling ................................................................................................................... 114

Disposing of the mistblower .............................................................................................................................................................................................................. 114

Index

4

Page 7

EC Declaration of Conformity

Manufacturer: ILEMO HARDI S.A.U.

Polígono Industrial El Segre, 712, 713

25191 Lleida

SPAIN

Declares the following product(s):

NEPTUN

1 - EC Declaration

ZATURN

JUPITER

- were manufactured in conformity with the applicable provisions of the Directive 2006/42/EC on machinery, and

- all the applicable provisions of the Council Directive 2004/108/EC (EMC)

Lleida, March 2015

Josep Maria Godia

Technical Director

ILEMO HARDI S.A.U.

5

Page 8

6

Page 9

2 - Safety

Operator safety

Symbols

These symbols are used in the book and require special attention. The meaning of the four symbols is:

This symbol means DANGER. Be alert as your safety is involved!

This symbol means WARNING. Be alert as your safety may be involved!

This symbol means ATTENTION. This will guide you on how to correctly and safely use the sprayer equipment.

This symbol means NOTE.

Precautions

Please note these precautions and safe operating practices before using the sprayer.

General information

Read and fully understand this instruction book before using the equipment. It is also equally important that other

operators of the equipment read and understand this book.

If you do not fully understand any part of this instruction book after reading it, please contact your HARDI distributor

for further information before using the equipment

.

Local law may demand the operator to be certifi ed to use this spray equipment. Comply with the law.

The tractor seat is the safest area when handling the equipment.

Wear protective clothing. Protective clothing may vary according to the chemical product being used. Comply with regulations.

Wash and change clothes after spraying. Clean the tools if they have become contaminated.

Do not eat, drink or smoke while spraying or working with contaminated equipment.

In the event of poisoning, immediately seek medical advice. Remember to identify the chemicals used.

Filling and spraying

Be careful not to hit persons or objects while manoeuvring the spraying equipment, especially when reversing.

Slow down when driving over uneven terrain as the machine could overturn.

Keep children away from the sprayer.

Do not attempt to enter the tank.

Do not climb over the sprayer unless it has been securely fastened. The boom is only secure when it is placed in the

transport brackets.

7

Page 10

2 - Safety

Service

Always pressure test with clean water before fi lling with chemicals. Do not remove the hose if the machine is turned

on.

DANGER! Do not exceed the maximum recommended r.p.m.

Rinse and wash out the equipment after use and before servicing.

Do not remove the hose if the machine is turned on. Always replace all safety devices or shields immediately after

servicing.

Disconnect the power supply before servicing, and de-pressurise the equipment after use and servicing.

If an arc welder is used on the equipment, disconnect any power leads before welding.

Remove all infl ammable or explosive materials from the area.

The External Cleaning Device should not be used if any part of the equipment has been damaged, including safety

devices, high-pressure hoses, etc.

8

Page 11

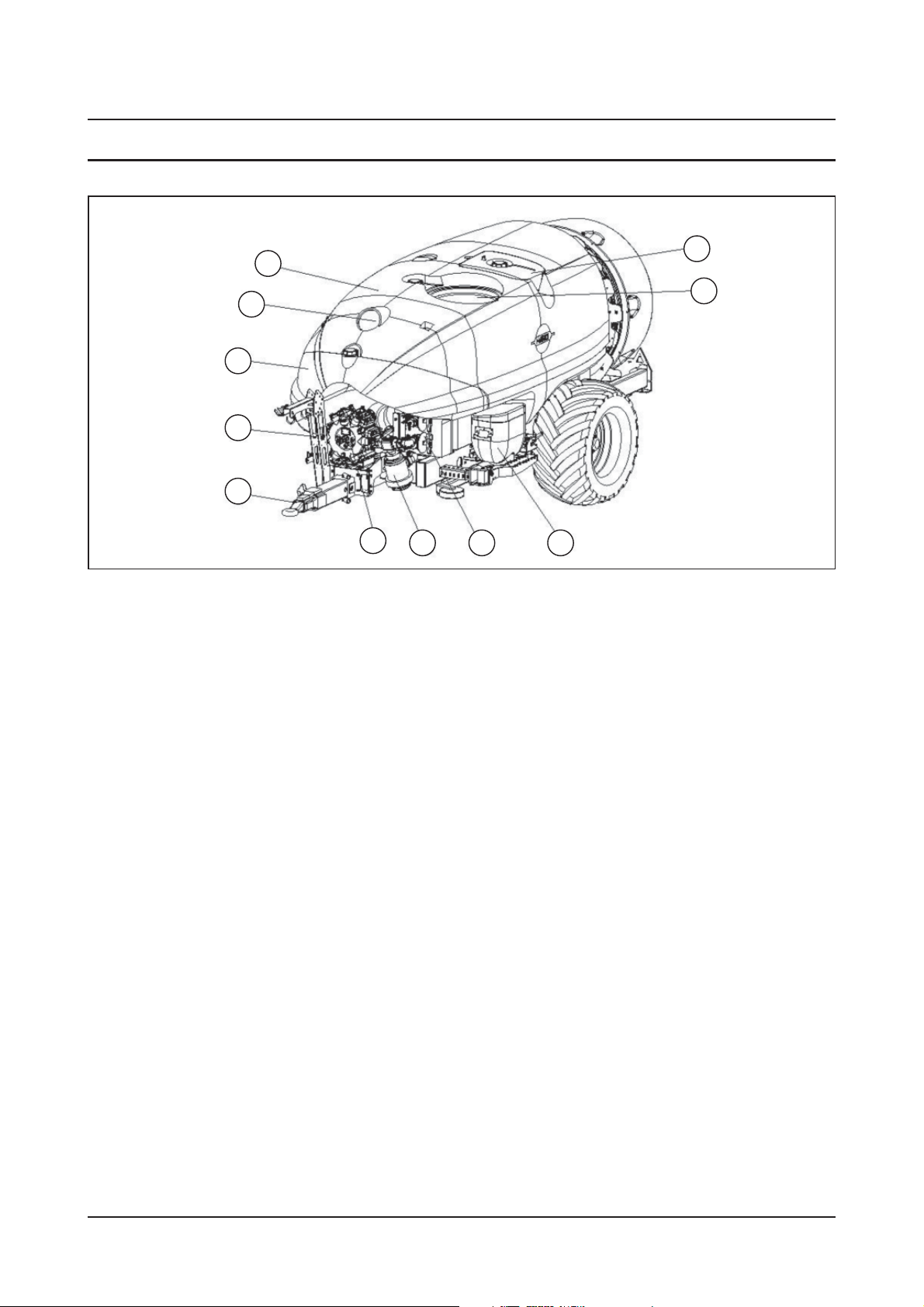

General information

Overview

3 - Description

1

2

6

11

10

5

1. Main tank

2. Level indicator, optionally on top of the tank

3. Manifold valves

4. Suction fi lter

5. Pump

6. Rinsing tank

7

8

4

3

7. Clean water tank

8. Main lid and strainer

9. TurboFiller

10. Drawbar

11. Operating unit

9

9

Page 12

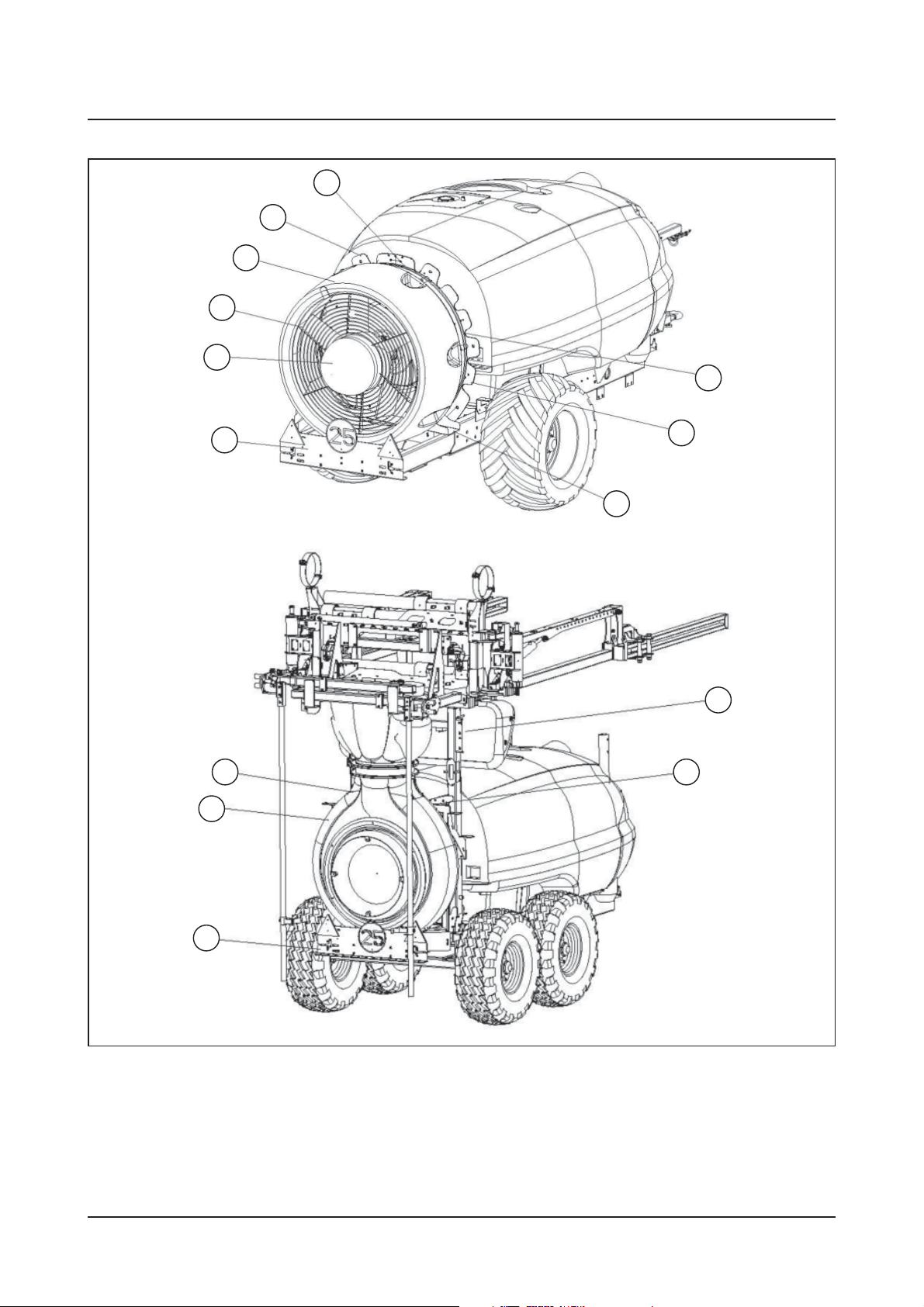

3 - Description

13

14

15

17

12

18

13

16

12

19

20

21

17

16

12. Chassis

13. Fan house

14. Grid and air guide

15. Centre cover

16. Bumper and light bar

10

17. Gear box fi lling point

18. Air outlet

19. Spray line

20. Adjustable bottom defl ector

21. Operating unit and hydraulic valves

Page 13

3 - Description

Use of the mist blower

The HARDI mist blower is designed for applying chemical products used for crop protection. This equipment may only be

used for this purpose. The use of this equipment for other purposes is not allowed. If there is no special law in your region

which obliges the user to have a permit, it is recommended to be well-prepared for protecting crops in a correct way and

for handling chemical products safely so as to avoid unnecessary risks to people and the environment while spraying takes

place.

For environmental issues the air kit is off ered with option to close either left or right side of the air stream from the blower.

These blinds, are mandatory in some sensitive areas, to avoid chemical contaminated air, blowing towards river sides and

water channels

Roadworthiness

When driving on public roads and other places where the road safety code or where there are other special rules and

regulations for marking and lights on machinery, the machine must be equipped to comply with these regulations.

ATTENTION! For models not fi tted with brakes the maximum speed is 25 km/h and 40 km/h for those with. This

could vary according to local legislation. Contact your local authorities to fi nd out the current maximum speed

limits.

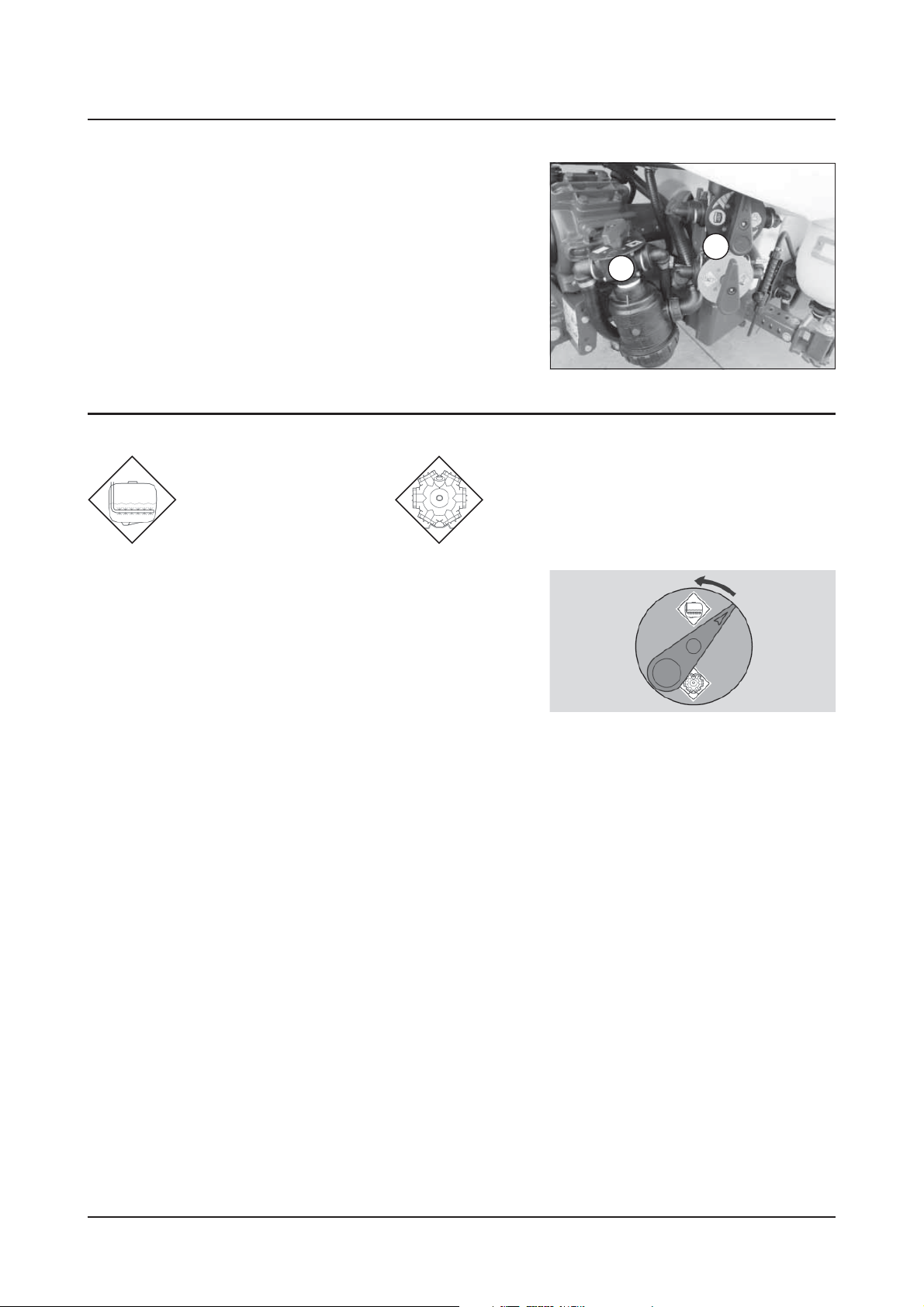

Identifi cation plate

The identifi cation plate is located on the front right-hand side of the

machine and is riveted to the chassis. It indicates the make, model, serial

number, and date of manufacture.

The serial number is also engraved onto the chassis. The number is

found above the identifi cation plate, as indicated in the picture. The

serial number consist of fi ve digits.

Chassis

The monoblock cold-pressed metal chassis is highly durable and built to last under everyday use under extreme conditions.

It is manufactured using only the most advanced laser cutting and automated soldering processes. To protect against

corrosion it is coated with a polyurethane bi-component paint on top of a highly adherent, steel blasted base.

11

Page 14

3 - Description

Tank

The main tank made of impact-proof, UV-resistant and chemical resistant polyethylene has a purposeful design with no

sharp corners for easy cleaning. Nominal contents are 1000, 1500, 2000 or 3000 l. A large, easy to read tank contents

indicator is placed on the front - right-hand side and another one is placed on the left side. First one is visible from the

tractor cabin. The fi lling hole is accessible from the left-hand side. This ensures an easy access for the fi lling of spray liquid,

cleaning of the tank, etc. The mistblower is equipped with a clean water tank integrated with the main tank design.

12

Page 15

3 - Description

Liquid system

General information

All the suction system functions are operated via a 3-way valve. The pressure valve is also to be found in the pressure circuit.

The low pressure circuit is called HLC (Hardi Liquid Circuit).

The liquid circuit

Consist of manifold system in the working zone (front part) where pressure manifold receives liquid from the pump, and

distributes to the diff erent options on the sprayer – to the operating unit, to the TurboFiller, to the bottle cleaner, to the

Powder mixer in strainer etc., all according to confi guration of options. The suction manifold in same area allows suction

from main tank, rinsing tank or external water source, if fi tted, depending on its confi guration.

The pressure side of the liquid circuit is fi tted with a safety valve to protect the circuit against misuse of excessive pressure.

See chapter “Safety valve”

Diaphragm pump

Pumps with a diaphragm: Models 321/10 (max. 20 bar) or 363/7 (max. 20 bar)

They are low pressure and robustly built. Use only grease for lubrication. The 363 model has six diaphragms and the 321

has two. This type of pump is self-priming, works without oil and can run dry as long as necessary.

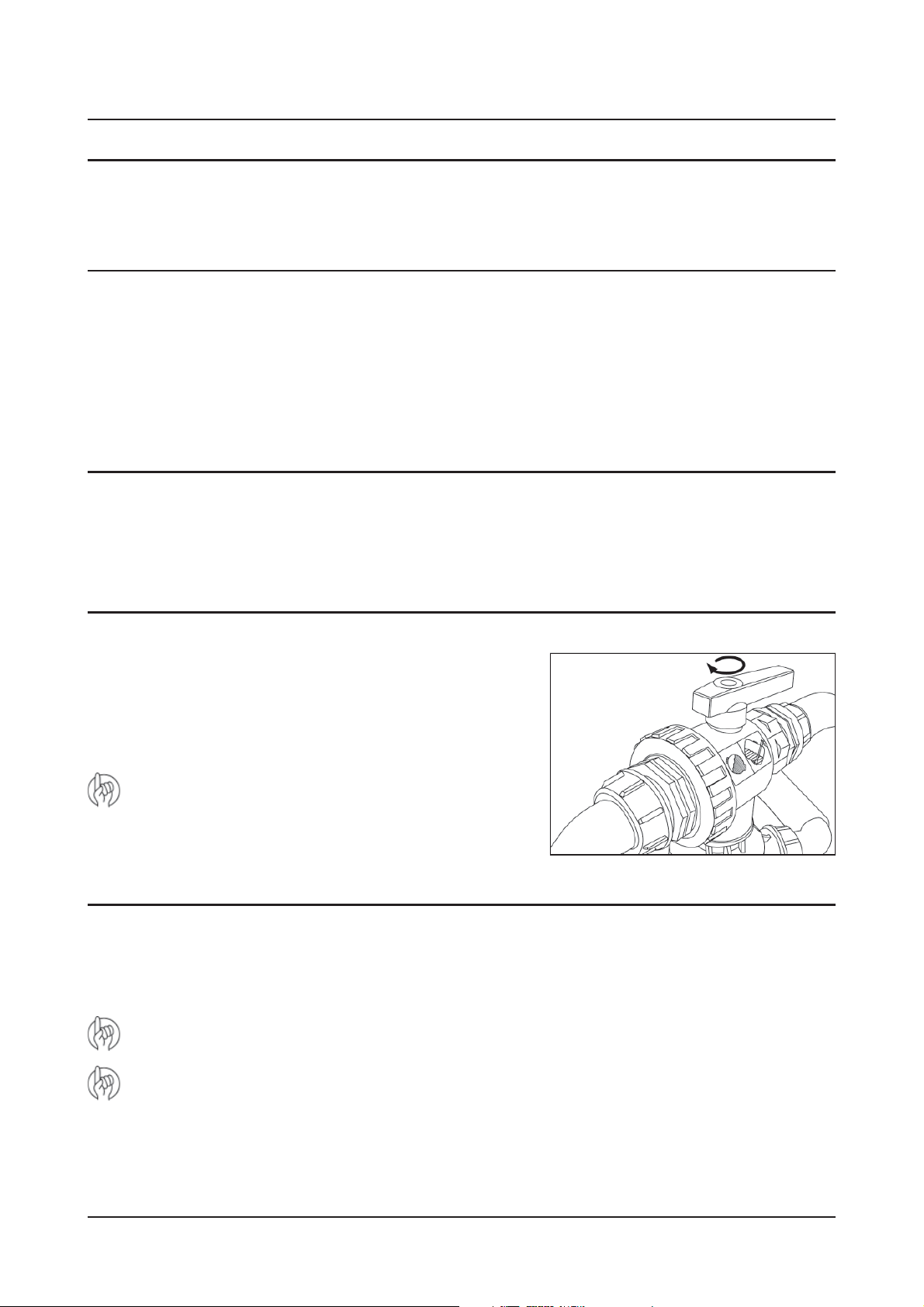

Valves

The suction valve is located above the pump and is used to select where

to suck liquid from. Either suction from the main tank for spraying or

from the rinse tank for internal cleaning of the liquid circuit. The function

is selected by turning the handle of the valve towards the desired

function.

ATTENTION! If one of the handles is too tight - or too loose (=liquid

loss) - the valve needs to be serviced. For more information, see

section on “Maintenance”.

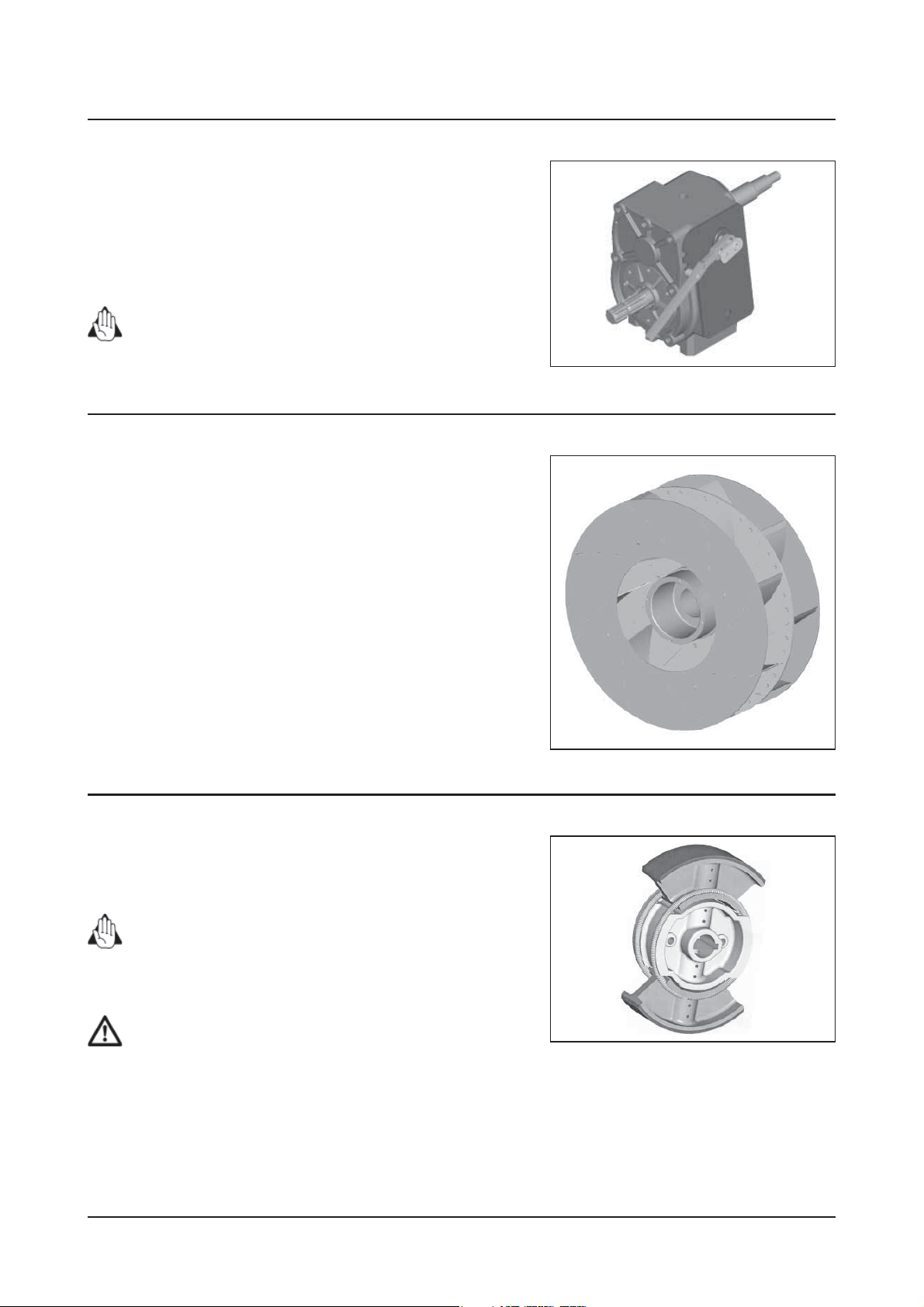

Valves and symbols

The valves are identifi ed by coloured discs fi tted on the valves themselves. The symbols correspond to the optional

accessories, and are located on the discs for quick identifi cation and handling. To activate/open a function, turn the lever

to the desired function.

ATTENTION: Only the functions to be used should be activated – the other valves should always be kept closed.

ATTENTION: If the handle of a MANIFOLD valve is too tight – or too loose (loss of fl uid)– the valve needs to be

serviced. For more information, see the section on ‘Maintenance’.

13

Page 16

3 - Description

Manifold system

The functions of the spray circuit are operated via the centrally situated

MANIFOLD with colour coded plates and pictorial symbols for easy

operation.

The modular valve system facilitates the addition of optional extras on

both pressure (A) and suction (B) for agitation and for rinsing nozzle

(optional equipment).

Blue valve – Blue disc = Return valve

Towards agitation Towards the suction pump

The position of the return MANIFOLD valve determines where the excess

fl ow from the fl uid circuit goes. When the arrow on the handle points

to a symbol, the excess fl uid will be fully sent towards that function (the

example shows agitation). This valve does not have the ‘0’ position.

A

B

14

Page 17

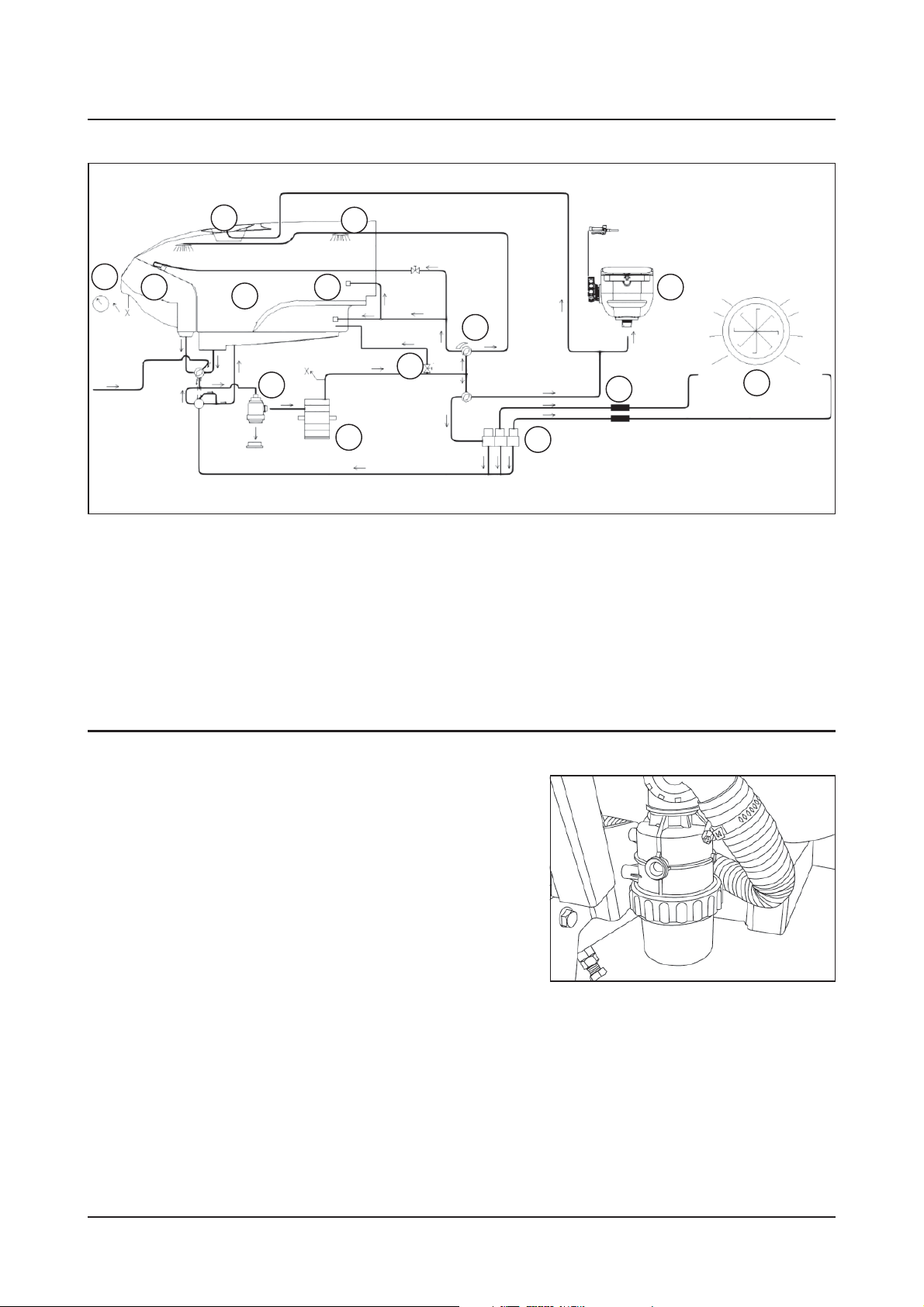

Circuit Diagram

3 - Description

3

6

2

1

10

11

5

4

1. Main tank

2. Rinsing tank

3. Powder mixer or bottle cleaner (optionally)

4. Pump

5. Suction fi lter

6. Manometer

7. Safety valve

9

8

7

13

14

12

8. Manifold valves

9. TurboFiller

10. Rinsing nozzles

11. Ventury agitation nozzles

12. Operating unit

13. Inline fi lters

14. Spray line

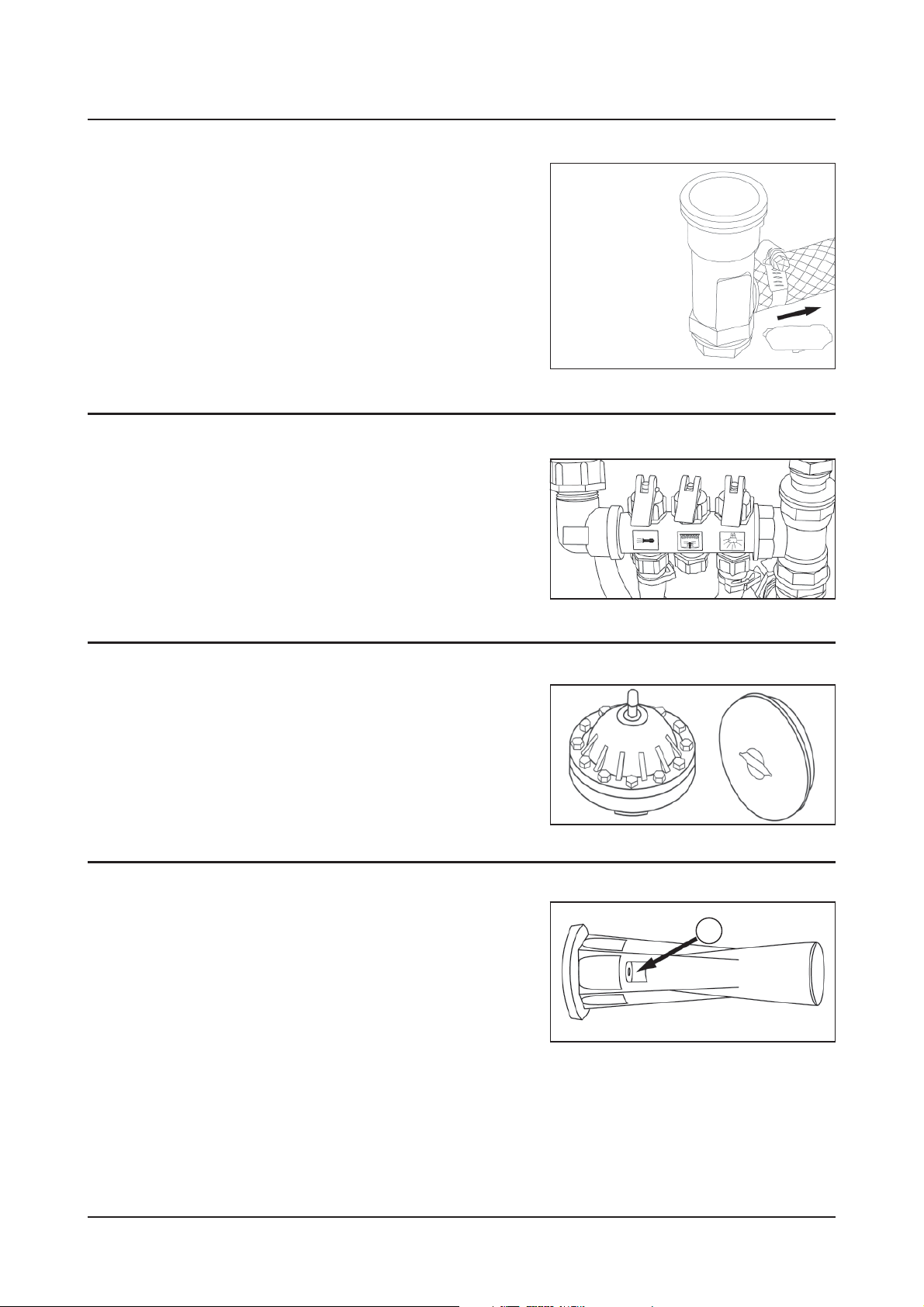

Suction fi lter

The suction fi lter is located underneath the three-way suction valve.

15

Page 18

3 - Description

Safety valve

It is made of cast iron and is situated at the front of the machine next

to the operating unit. From this manifold it is possible to activate the

agitator and the rinsing nozzle for internal cleaning (optional), as well as

the Turbofi ller (optional) or powder mixer. Do only open the manifold

valve in order to send pressure to the desired device, as in the example

given: the Turbofi ller.

Pressure manifold

It is made of plastic and is situated on the front of the machine next

to the operating unit. From this manifold it is possible to activate the

agitator and the rinsing nozzle for internal cleaning (optional).

MAX. 20 bar

(HLC)

MAX. 40 bar

(HPC)

Suction and pressure pulsation dampers

The 321 pump is fi tted with a pulsation damper on suction and pressure

sides. The pressure side damper is pressurized. The dampers will reduce

pulsations and secure an even fl ow from the pump.

Agitator

At the front and on each side of the inside of the tank there are two

ventury-shaped agitators. The agitators are activated by a valve on the

pressure manifold.

Each agitator has a Ø 3mm nozzle (D).

D

16

Page 19

3 - Description

Operating unit

Your sprayer will be equipped with operating unit accordingly to country specifi cations.

The mistblower can be equipped with following types of operating units: MC/2, CB/2, SV and CB.

BK/2

Manual operating unit with pressure equalisation. Optionally remote operated by cable

MC/2 operating unit

It has two section valves which control RH and LH sides. The section valves are remote controlled from the tractor cab by

via two bowden cables.

BS/2

Manual operating unit, placed near drivers position. Allows pressure regulation, section controls , and manometer

incorporated.

SV operating unit

It has 2 or 4 section valves. It uses solenoid valves for on/off of each section. The SV operating unit has no pressure

equalization device. Pressure regulation is done manually in the working zone.

SA operating unit

Remote operated solenoid sections valves with manual pressure regulation

CA operating unit

Remote operated solenoid sections with pressure equalisation device and manual pressure regulation

CB operating unit

Electrical remote pressure regulation, section valves by means of motor valves with pressure equalization device.

Filters

The pressure fi lters are located on the bumper next to the air outlet

nozzle. In the HLC circuit the fi lters are made of plastic and in the HPC

circuit they are made of brass.

All fi lters should be kept in good condition and cleaned regularly. Make

sure you to use correct combinations of fi lter and mesh size. The mesh

size should always be less than the average of the total fl ow from the

nozzles.

Powder mixer

This is used to rinse the fi lter basket in tank’s fi lling hole when adding

powdered products that do not dissolve properly or form lumps in

contact with the water in the tank.

After using the powder mixer it must be disengaged as it uses a large

amount of the available pump capacity..

17

Page 20

3 - Description

TurboFiller

Chemical inductor, TurboFiller (optional)

The TurboFiller allows fi lling of both powder and liquid spray chemicals

safe and conveniently when standing next to the machine.

The Turbofi ller is neatly stowed under the main tank when not in use..

ATTENTION! Local legislation may require chemicals to be fi lled

using a chemical inductor - Always follow local legislation in

force at any time.

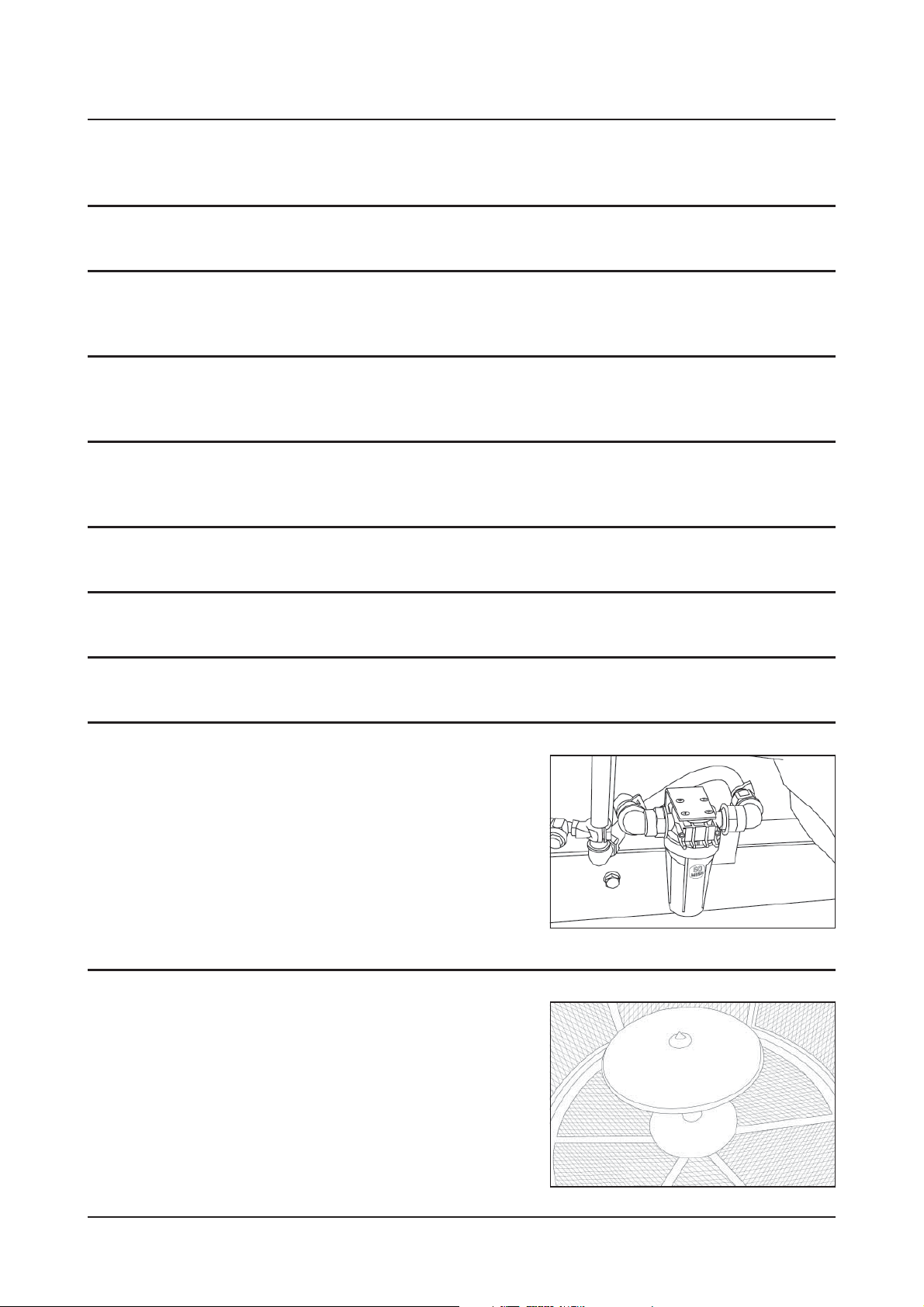

TurboFiller suction valve

The valve is used simultaneously with the TurboFiller. The valve has 2

settings: In the position A, indicated on the picture, it is closed. Open the

valve when chemicals are to be fi lled into the TurboFiller.

A

Turbo Defl ector valve

This Turbo Defl ector valve activates the Vortex fl ushing of the TurboFiller.

Lift the lever to lock it in open position for continuous liquid rotation in

the hopper.

Start Turbo Defl ector

Chemical Container Rinsing lever

The upper lever is used for two purposes:

When the TurboFiller lid is open: For rinsing empty containers. Place

the container over the rotating fl ushing nozzle in the middle of the

TurboFiller to rinse the inside of the container.

When the TurboFiller lid is closed: Use the Chemical Container Rinsing

lever to rinse the hopper when the fi lling of chemicals is completed.

Chemical Container Rinsing

DANGER! Do not press the lever unless the multi-hole nozzle is covered by a container as spray liquid may otherwise

hit the operator.

18

Page 21

3 - Description

Axial blower units

Technical information

The air kits fi tted on the HARDI ZATURN mist blowers are the AG820 and AG920, both having a polyethylene housing

and fan blades made of a hardened synthetic material. Their aerodynamic shape off er a high quantity and perfect air

distribution, low noise levels and low power consumption when adjusted to standard levels. The fan clutch enables a

smooth start and stop.

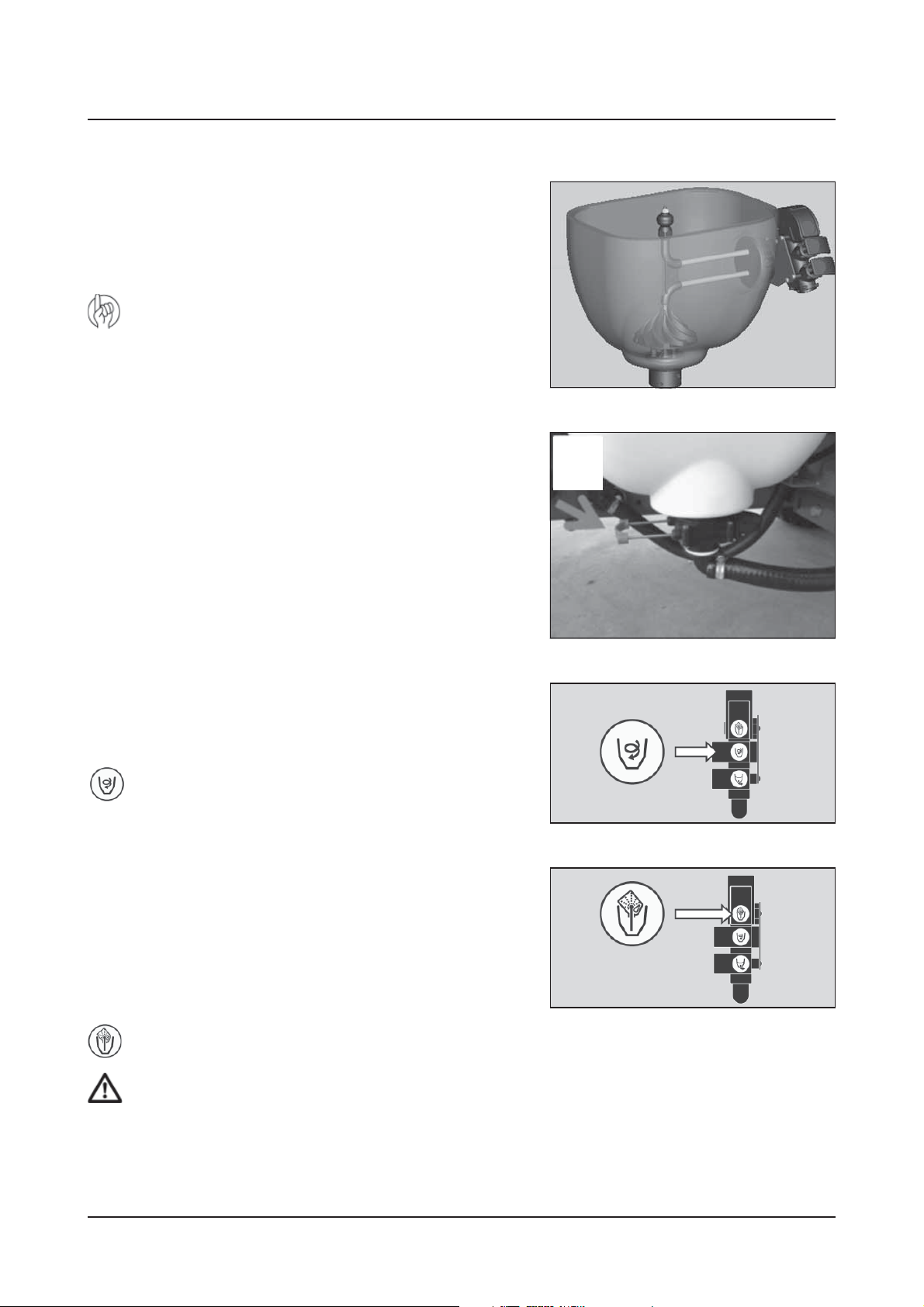

EF820, EF920, AB750, AB820, AB920, AG820, AG920, IAG820, IAG920, SF65, SF85 and XF90

The air kits are fi tted with a grid with air guides at the air intake, which forms the air fl ow before reaching the fan, to

decrease the imbalance in the airfl ow. The fan is either 820 or 920 mm of diameter and is fi tted with blades made of a

hardened synthetic material. This reduces the power consumption to a minimum as a result of low material density.

There is a channel between the air intake and the cone of the air kit which increases the air speed through the outlet, and

ensures that a high uniformity in air distribution is achieved.

EF

I EF

AB

19

Page 22

3 - Description

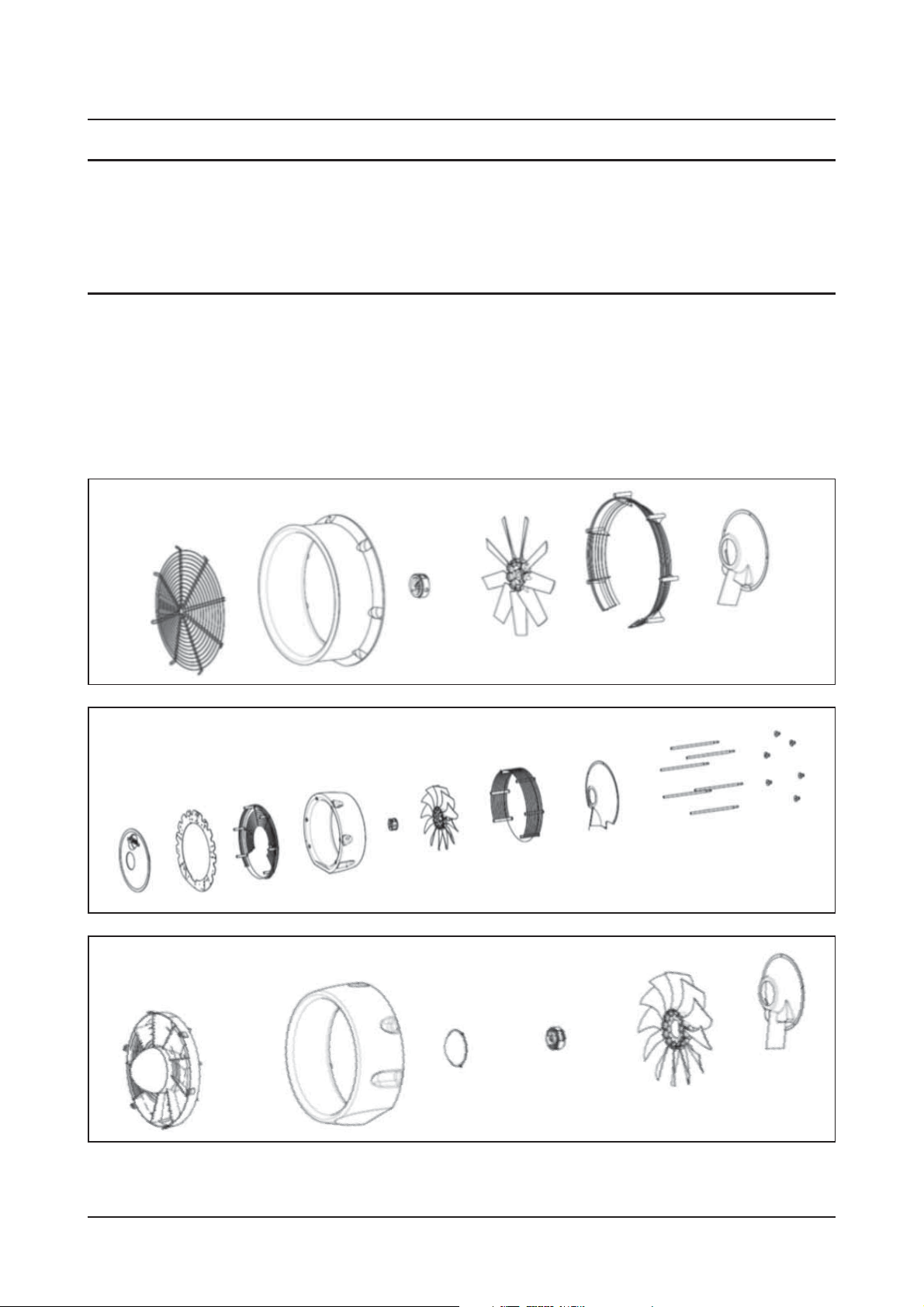

AG

I AG

SF

XF

NEVER exceed 540 r.p.m. on the tractor P.T.O.! The fan may explode if overspeeded!

KEEP AWAY from the air inlets and outlets while the fan is on. Some objects may be shot out of the air outlet or a

piece of clothing could be sucked into the air inlet.

The fan is the most dangerous part of the machine. Do not try to replace any of the parts without consulting your

HARDI dealer fi rst. Any service job or modifi cations on fan and air kit is to be carried out by your HARDI dealers

qualifi ed technicians.

20

Page 23

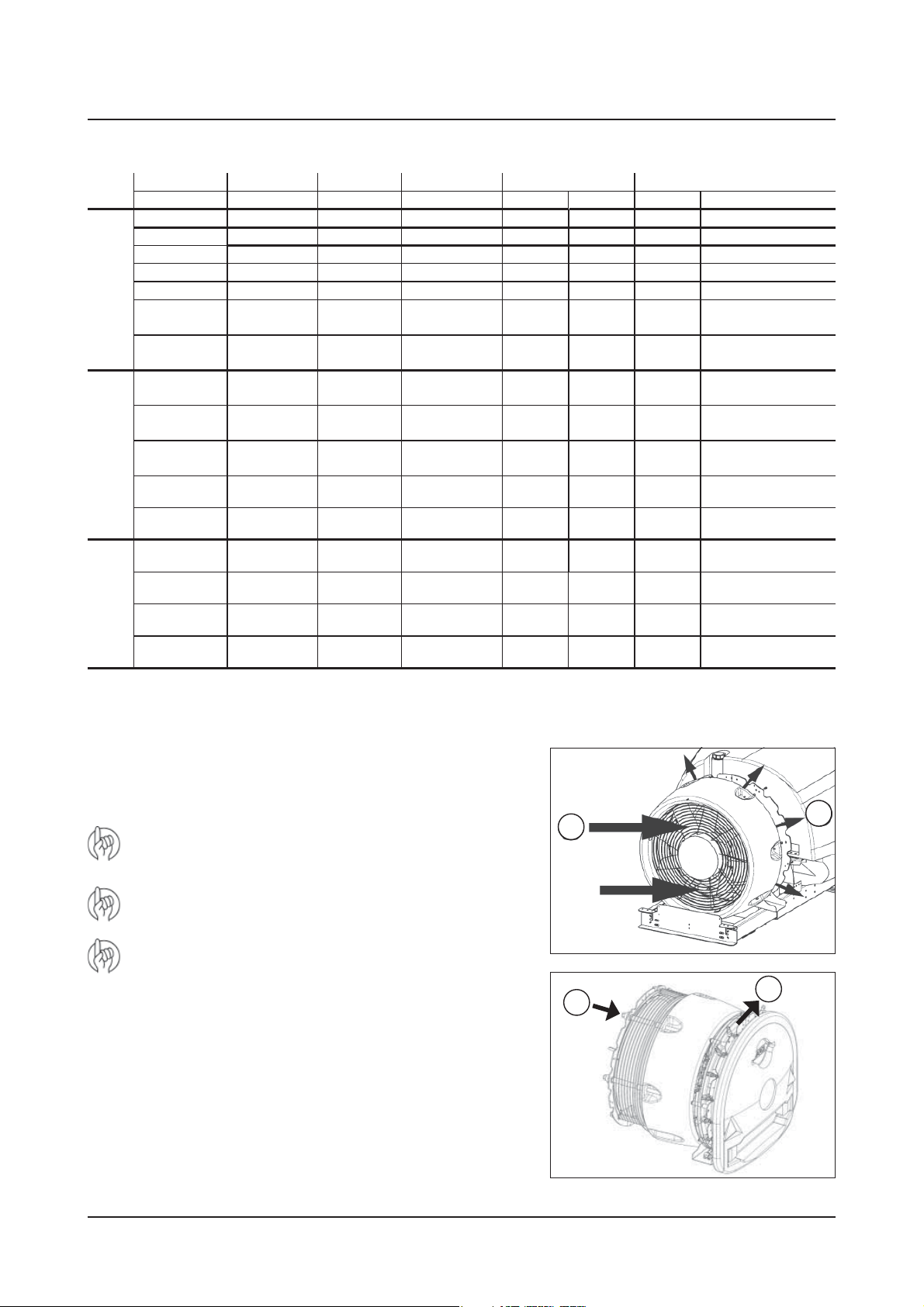

Air fl ow for axial air kits

Blower unit Speed Relationship Fan diameter Power Air ow

iEF750 1 gear 1:4.4 750 mm / 30” 25 35 28.000 16.500

EF820 1 gear 1:4.4 820 mm / 32” 25 35 35.000 21.000

iEF820 1 gear 1:4.4 820 mm / 32” 25 35 31.000 18.000

EF920 1 gear 1:4.4 920 mm / 36” 33 45 45.000 26.000

iEF920 1 gear 1:4.4 920 mm / 36” 33 45 40.000 23.000

AB820

NEPTUN

AB920

iAB750

iAG820

AG820

ZATURN

AG920

iAG920

SF65

SF85

XF90

low pitch

JUPITER

XF90

Medium pitch

1st low

2nd high

1st low

2nd high

1st low

2nd high

1st low

2nd high

1st low

2nd high

1st low

2nd high

1st low

2nd high

1st low

2nd high

1st low

2nd high

1st low

2nd high

1st low

2nd high

1:3.5

1:4.4

1:3.5

1:4.4

1:3.5

1:4.4

1:3.5

1:4.4

1:3.5

1:4.4

1:3.5

1:4.4

1:3.5

1:4.4

1:3.5

1:4.4

1:3.5

1:4.4

1:3.5

1:4.4

1:3.5

1:4.4

820 mm / 32”

920 mm / 36”

750 mm / 32”

820 mm / 32”

820 mm / 32”

920 mm / 36”

920 mm / 36”

820 mm / 32”

920 mm / 36”

920 mm / 36”

920 mm / 36”

3 - Description

kW Hp m3/h cubic foot/minute

25

32

27

33

19

25

26

30

27

33

30

36

30

36

41

40

37

44

37

42

44

52

35

44

38

45

27

35

36

42

38

45

42

50

42

50

56

55

51

60

50

58

60

70

36.000

43.000

42.000

50.000

26.000

33.000

34.000

40.000

43.000

50.000

51.000

60.000

46.000

54.000

55.000

65.000

72.000

85.000

70.000

80.000

85.000

100.000

21.000

25.000

25.000

29.000

15.000

19.000

20.000

24.000

25.000

29.000

30.000

35.000

30.000

35.000

32.000

38.000

42.000

50.000

41.000

47.000

50.000

60.000

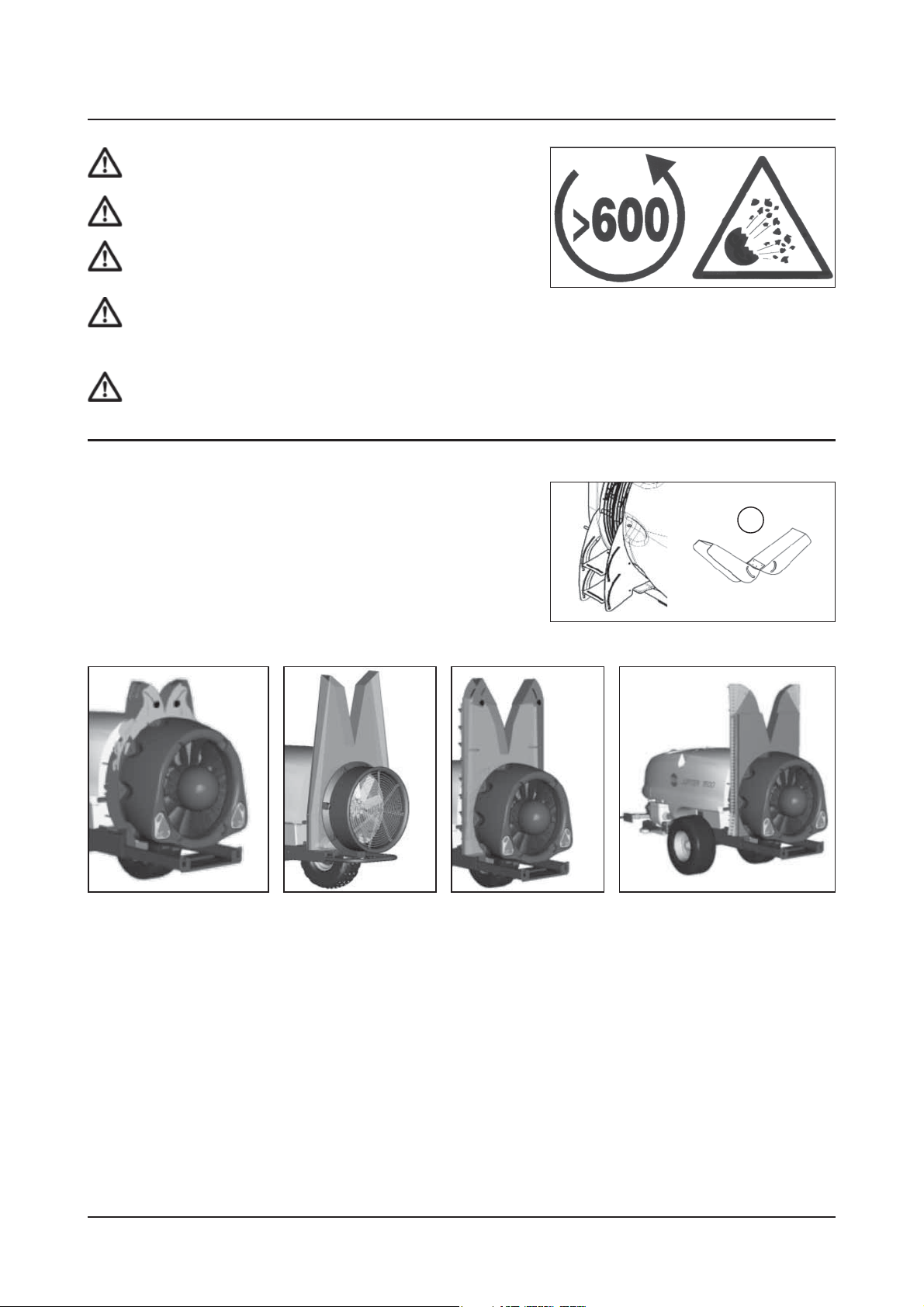

Protective grid

The air kits are fi tted with protection grids. They are fundamental for

avoiding accidents and for stopping foreign bodies from getting inside

the air kit.

Tractor driver’s seat is the intended working place during

operation.

This product is designed to be used in agriculture orchard

application.

Do never pass 540 rpm on tractor PTO

Invers air inhalation

A is air inhale and B is air out let

A

B

B

A

21

Page 24

3 - Description

DANGER! It is strictly forbidden to use the blower unit without

the protective grid.

DANGER! Do not approach the fan when in use.

DANGER! Do not introduce foreign bodies through the grid,

regardless of whether the fan is in use or not.

DANGER! During the working day, protect your hearing from the

noise produced with EN 352-1:1992 approved hearing protection

or similar.

DANGER! If you notice vibrations or unusual noise, stop the fan

immediately and consult your HARDI dealer.

Defl ectors

Axial air sprayer known as well as air sprayers can optionally be equipped

with mentioned defl ectors.

Defl ectors contribute to an increased effi cacy in the spray job, as they