Page 1

The Sprayer

Operator’s Manual

CONTROLLER

ISOBUS VT

Instruction book - SW 3.XX

67023603 - Version 1.10

US - 06.2015

Page 2

Page 3

CONTROLLER

ISOBUS VT

Instruction book - SW 3.XX

67023603 - Version 1.10

US - 06.2015

HARDI® reserves the right to make changes in design, material, or specification without notice thereof.

HARDI® and other product names are registered trademarks of HARDI® Inc. in the U.S. and in other countries.

Page 4

Page 5

Table of contents

1 - Welcome

Welcome letter ......................................................................................................................................1

2 - Safety notes

Operator safety .....................................................................................................................................1

Symbols ........................................................................................................................................................................................................................ 1

Precautions ................................................................................................................................................................................................................ 1

3 - Description

Introduction ..........................................................................................................................................1

About the ISOBUS VT system .........................................................................................................................................................................1

System description ................................................................................................................................2

Overall description ................................................................................................................................................................................................ 2

Terminals and boxes ..............................................................................................................................3

Types of terminals .................................................................................................................................................................................................. 3

ISOBUS Terminal layout ...................................................................................................................................................................................... 4

Soft keys menu tree .............................................................................................................................................................................................. 6

SetBox ............................................................................................................................................................................................................................ 7

HC 6300 Grip ............................................................................................................................................................................................................. 8

General keystrokes ................................................................................................................................................................................................ 8

Extended menu ................................................................................................................................................................................................... 10

Functions .............................................................................................................................................11

Auto functions general info .......................................................................................................................................................................... 11

End nozzles (Fence line) (optional) .......................................................................................................................................................... 11

DynamicFluid4 pressure regulation ........................................................................................................................................................ 12

SafeTrack (Trailed sprayers only) ................................................................................................................................................................ 14

HARDI® AutoSectionControl (optional) ................................................................................................................................................. 14

Menus ..................................................................................................................................................15

Full menu structure ........................................................................................................................................................................................... 15

4 - System setup

Tractor installation ................................................................................................................................1

Installation of control unit brackets ............................................................................................................................................................ 1

Printer ............................................................................................................................................................................................................................ 1

Speed transducer for sprayer .........................................................................................................................................................................2

How to set clock ..................................................................................................................................................................................................... 2

Initial settings ........................................................................................................................................3

System start-up ....................................................................................................................................................................................................... 3

Display readout ....................................................................................................................................................................................................... 3

ESC key for ISOBUS terminals .........................................................................................................................................................................3

Working in the field ...............................................................................................................................4

Set up before spray job ...................................................................................................................................................................................... 4

Volume rate ............................................................................................................................................................................................................... 5

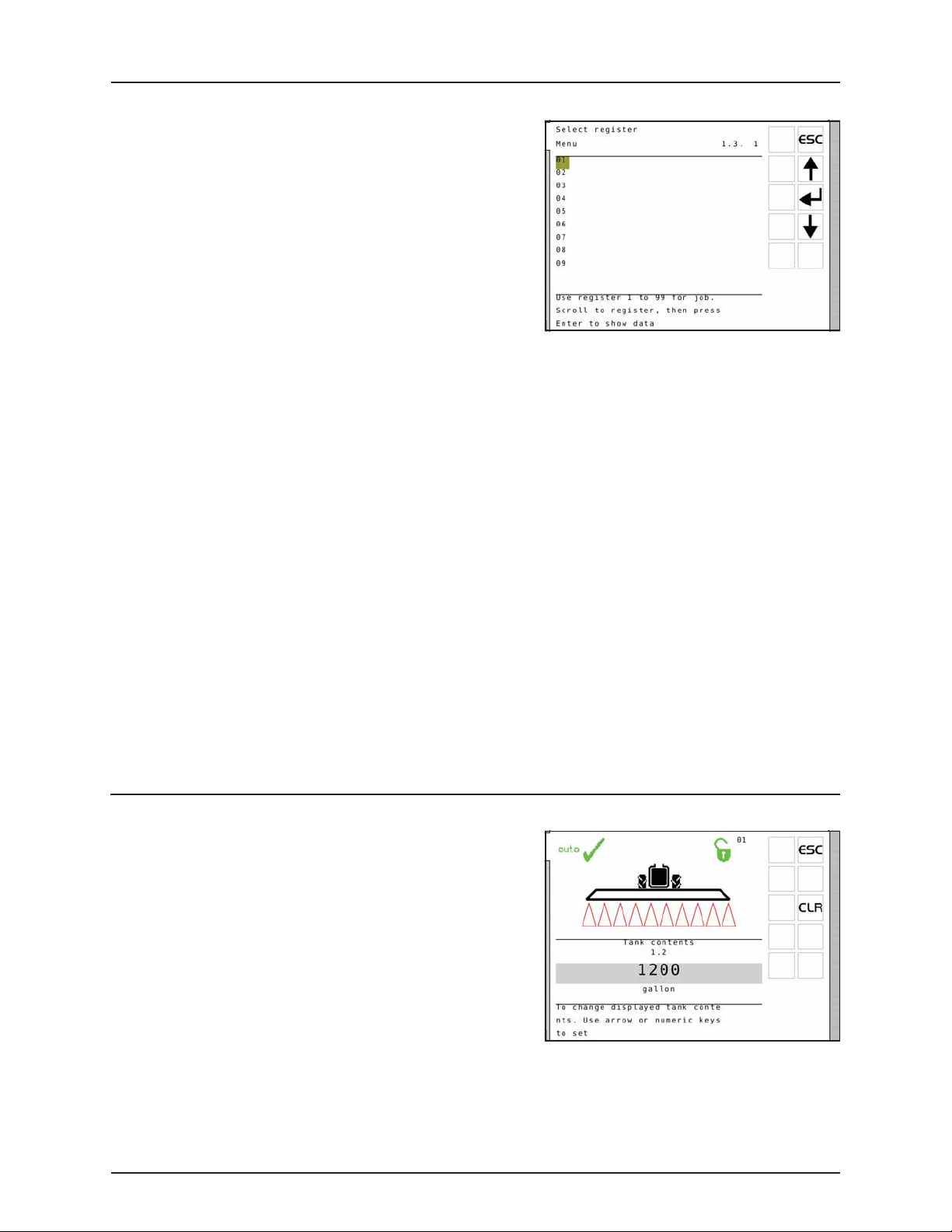

Register readout and selection .....................................................................................................................................................................6

Tank contents ........................................................................................................................................................................................................... 6

TWIN Preset ................................................................................................................................................................................................................ 7

Spraying with DynamicFluid4 pressure regulation .......................................................................................................................... 7

Spraying with FlexCapacity pump .............................................................................................................................................................. 8

5 - Menu 1 Daily settings

Menu 1 Daily settings ............................................................................................................................1

Menu 1.1 Volume rate ......................................................................................................................................................................................... 1

Menu 1.2 Tank contents ....................................................................................................................................................................................1

Menu 1.3 Select register ....................................................................................................................................................................................1

TOC. 1

Page 6

Table of contents

6 - Menu 2 Setup

Menu 2 Setup .........................................................................................................................................1

General info ............................................................................................................................................................................................................... 1

Menu 2.1 Display readout ................................................................................................................................................................................. 1

Menu 2.2 Auto functions ................................................................................................................................................................................... 2

Menu 2.3 Variable Rate Application (VRA) / Remote / HARDI® AutoSectionControl ................................................... 3

Menu 2.4 Set clock ................................................................................................................................................................................................3

Menu 2.5 Alarms ..................................................................................................................................................................................................... 3

7 - Menu 3 Calibration

Menu 3 Calibration ................................................................................................................................1

Menu 3.1 Speed calibration ............................................................................................................................................................................. 1

Menu 3.2 Flow calibration ................................................................................................................................................................................ 3

Menu 3.3 Boom ....................................................................................................................................................................................................... 6

Menu 3.4 Regulation user setup ................................................................................................................................................................... 8

Menu 3.5 Tank gauge ....................................................................................................................................................................................... 11

Menu 3.6 Track ...................................................................................................................................................................................................... 14

8 - Menu 4 Toolbox

Menu 4 Toolbox .....................................................................................................................................1

Menu 4.1 Measure ................................................................................................................................................................................................. 1

Menu 4.2 Service intervals ................................................................................................................................................................................ 1

Menu 4.3 Service interval reset ...................................................................................................................................................................... 1

Menu 4.4 Reserved ................................................................................................................................................................................................ 1

Menu 4.5 Test ...........................................................................................................................................................................................................2

Menu 4.6 Speed simulation ............................................................................................................................................................................. 2

Menu 4.7 Emergency ........................................................................................................................................................................................... 3

Menu 4.8 Computer CAN status ................................................................................................................................................................... 3

9 - Menu 5 Logbook

Menu 5 Logbook ....................................................................................................................................1

Menu 5.1 Print .......................................................................................................................................................................................................... 1

Menu 5.2 Data dump ........................................................................................................................................................................................... 2

10 - Maintenance

Off-season storage ................................................................................................................................1

Storage ......................................................................................................................................................................................................................... 1

11 - Fault finding

Operational problems ...........................................................................................................................1

Fault finding the system .................................................................................................................................................................................... 1

Checks for clogging .............................................................................................................................................................................................. 2

Checks for external leak .....................................................................................................................................................................................2

Location of components (trailed sprayers) ............................................................................................................................................ 3

Location of components (self-propelled sprayers) ........................................................................................................................... 4

Fault codes ................................................................................................................................................................................................................. 5

Emergency operation ..........................................................................................................................15

In an emergency situation ............................................................................................................................................................................ 15

Operation when a sensor fails ..................................................................................................................................................................... 15

12 - Testing and fine tuning

Testing and fine tuning .........................................................................................................................1

Fine tuning the flow constant - PPU .......................................................................................................................................................... 1

Pin & Wire connection ........................................................................................................................................................................................1

Testing flow transducer .....................................................................................................................................................................................2

Testing speed transducer ................................................................................................................................................................................. 2

TOC. 2

Page 7

Table of contents

13 - Technical specifications

Specifications ........................................................................................................................................1

Specifications ............................................................................................................................................................................................................ 1

Flow ranges for the flow transducers ........................................................................................................................................................ 1

Electrical connections ............................................................................................................................2

Types of plugs and fuses ................................................................................................................................................................................... 2

Materials and recycling .........................................................................................................................3

Disposal of electronics ........................................................................................................................................................................................ 3

Packaging information ....................................................................................................................................................................................... 3

Charts ....................................................................................................................................................4

Chart for recording values ................................................................................................................................................................................ 4

14 - Warranty

Warranty policy and conditions ............................................................................................................1

TOC. 3

Page 8

Table of contents

TOC. 4

Page 9

1 - Welcome

Welcome letter

Dear New HARDI® Owner,

Thank you for purchasing your new HARDI® product and welcome to the ever-increasing family of proud HARDI® owners.

HARDI® is the leading sprayer company in offering growers strong, reliable products made for the widest range of

applications worldwide. Quality, reliability, and resale value make the HARDI® product line the preferred product line of

customers both in North America as well as worldwide. Our guiding principle is to provide the highest level of customer

satisfaction and long term value in the marketplace today. We have developed a very high level of customer loyalty in the

marketplace which we are very proud of and strive every day to maintain and to continue to grow.

HARDI® is your specialist in spraying and we spend all of our time and keep all of our focus on spraying. We do not share our

resources between other types of products or compromise on anything in providing the best quality sprayers to the market

today. We can provide the latest in technology with our products if desired, or allow them to operate with the technology

that you already use on other products in most cases. You get to decide that, and what best suits your needs. We feel that

you, our customer, are the best suited to answer that question for your operation. Either way, you decide, and we will try and

help make it happen for you.

Our broad spectrum of product offerings, from the ruggedly simple models we build to our highly sophisticated models,

the built-in HARDI® strength and reliability ensures a low cost of ownership. HARDI® sprayers are all based on a functional

design concept of being as simple to operate as possible and to meet our customers’ requirements for all their application

needs.

Please take the time to thoroughly read the Operator’s Manual before using your equipment. You will find many helpful hints

as well as important safety and operation information.

Some of the features on your HARDI® sprayer were suggested by growers. There is no substitute for “on farm” experience

and we invite your comments and suggestions. If any portion of this instruction book remains unclear after reading it,

contact your HARDI® dealer or service personnel for further explanation before using the equipment.

For Product, Service or Warranty Information please contact your local HARDI® dealer.

- Please use the HARDI® Customer Service number: 1-866-770-7063

- Or send your email to CUSTSERV@hardi-us.com

HARDI® NORTH AMERICA INC.

Visit us online at: www.hardi-us.com

1500 West 76th St.

Davenport, Iowa 52806

Phone: (563) 386-1730

Fax: (563) 386-1280

Sincerely,

Wayne Buchberger

President

1.1

Page 10

1 - Welcome

1.2

Page 11

2 - Safety notes

Operator safety

Symbols

These symbols are used throughout the book to designate where the reader needs to pay extra attention.

This symbol means DANGER. Be very alert as your safety is involved!

€

This symbol means WARNING. Be alert as your safety can be involved!

±

This symbol means ATTENTION. This guides to better, easier and safer operation of your sprayer!

This symbol means NOTE.

÷

Precautions

Note the following recommended precautions and safe operating practices before using the sprayer.

General info

Read and understand this instruction book before using the equipment. It is equally important that other operators

€

of this equipment read and understand this book.

If any portion of this instruction book remains unclear after reading it, contact your HARDI® dealer for further

€

explanation before using the equipment.

Keep children away from the equipment.

€

Press the keys with the underside of your finger. Avoid using your fingernail.

€

Local law may demand that the operator is certified to use spray equipment. Adhere to the law.

€

Tractor driver’s seat is the intended working place during operation.

€

Service

Test with clean water prior to filling with chemicals. Rinse and wash equipment after use and before servicing.

€

Never service or repair the equipment while it is operating. Always replace all safety devices or shields immediately

€

after servicing.

Turn electrical power off before connecting and disconnecting the display and transducers, servicing or using a

€

battery charger.

If an arc welder is used on the equipment or anything connected to the equipment, disconnect power leads before

€

welding. Remove all flammable or explosive material from the area.

Do not use a high pressure cleaner to clean the electronic components.

€

2.1

Page 12

2 - Safety notes

2.2

Page 13

3 - Description

Introduction

About the ISOBUS VT system

The ISOBUS VT is for use in agricultural and horticultural production. The components are developed to last many years

under agricultural conditions.

The system has a non-volatile memory without battery which simplifies storage. All parameters in the menus are saved in

the memory and are not lost when the power is disconnected.

Main components Location

ISOBUS terminal Tractor/Self-propelled

HC 6300 Grip Tractor/Self-propelled

HC 6400 SetBox/Spray Center Tractor/Self-propelled

HC 6100 JobCom Sprayer/Self-propelled

HC 6200 FluidBox/Outside Box Sprayer/Self-propelled

The transducers utilized are chosen for long service life and good signal quality. The speed and flow transducers have a builtin diode that will flash to indicate when it’s functioning, to aid servicing.

Optional transducers include pressure and revolutions readout. Other options include a 12 Volt printer.

Working pictures will be shown in different colors, depending on the function used.

Display readouts

Among many possible display readouts, are:

• Volume rate.

• Speed.

• Liquid rate per minute.

• Total covered area.

• Total volume sprayed.

• 99 trip registers. It includes a total register that summarizes data from the 98 trip registers.

The system is also compatible with Variable Rate Application (VRA) and is prepared for communication with Precision

Farming tools (e.g. HARDI® AutoSectionControl). Data dump of registers and configuration to a personal computer

are possible.

Functions include

• Correct area with closure of up to 13 spray boom sections.

• Many alarm functions and possibility for audio/visual alarm etc.

• Many warnings depending on operation. Alarms and warnings is shown in the bottom left 1/4 corner of the display

on some VT screens. HC 9500 will show alarms in top of the screen.

3.1

Page 14

3 - Description

System description

Overall description

The precise wiring setup can vary, depending on the terminal mounted.

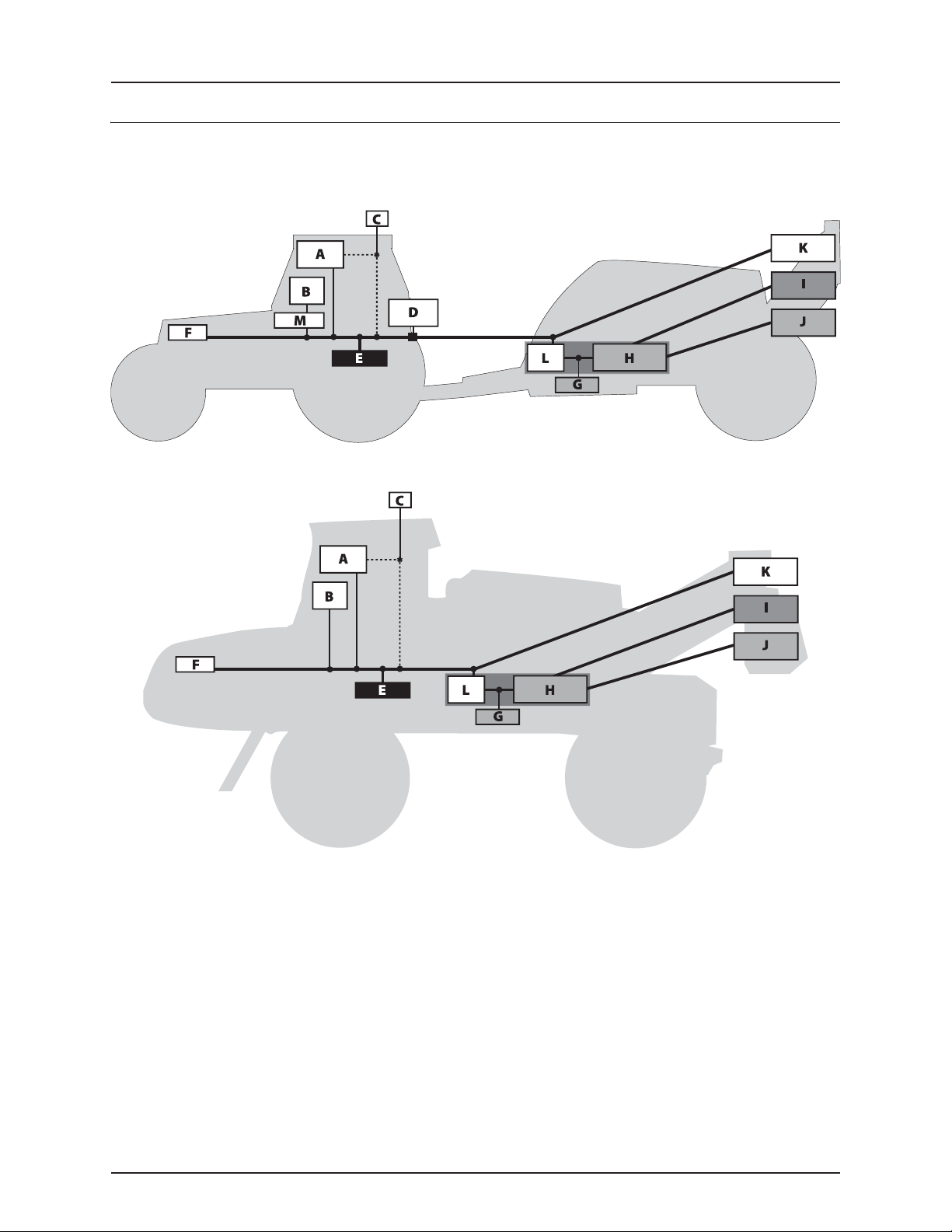

ISOBUS system (trailed)

ISOBUS system (self-propelled)

A. HC 9500 or VT Terminal.

B. SetBox and Grip.

C. GPS antenna (optional).

D. IBBC connector.

E. Vehicle bus.

F. ISOBUS.

G. FluidBox (i-sprayers only).

3.2

H. JobCom (Implement ECU).

I. Center section junction box.

J. Hydraulics block.

K. AutoHeight UC5.

L. ISOBUS bridge.

M. Cabin connector.

Page 15

Terminals and boxes

Types of terminals

This software can run with two types of ISOBUS display terminals.

ISOBUS terminals with physical buttons

ISO terminals with physical function buttons, e.g. the Massey Ferguson

terminal shown.

• Conventional or touch screen and physical buttons.

• Function buttons are graphical but are operated by physical

buttons on the terminal.

• The software runs as a Virtual Terminal (VT) into the terminal

software.

ISOBUS terminals with touchscreen interface

HARDI® HC 9500 or similar ISO terminals with touchscreen interface. The

HC 9500 is shown.

• Touchscreen and no buttons (except ON/OFF).

• Function buttons are graphical and operated by pressing the

touch screen.

• The software runs as a Virtual Terminal (VT) into the terminal

software.

3 - Description

3.3

Page 16

3 - Description

ISOBUS Terminal layout

The ISOBUS terminal layout is described as follows:

ISOBUS virtual terminal buttons

1. Scroll up, increase a value or volume rate.

2. Enter menu.

3. Scroll down, decrease a value or volume rate.

4. Preset keys.

5. Soft menus.

6. Escape a menu.

7. Scroll up.

8. Enter menu or confirm a value.

9. Scroll down.

3.4

Page 17

Display symbols

These symbols are common on VT (Virtual Terminal) displays.

1. The 1st Line is for status symbols, register number and alarm

number. All status symbols will be displayed here.

ATTENTION! If an error occurs, alarm/warning error number will

be shown instead of register number. The alarm/warning

number can be recognized by the exclamation sign in front of the

number.

2. The 2nd Line is for boom status, foam marker and end nozzle

indications.

3. ISOBUS: The bottom half has 6 boxes with selectable information.

NOTE! See “Menu 2.1 Display readout” on page 6.1 for setup of

÷

the display readouts in the bottom half of the terminal display.

1st line status icons

3 - Description

All “OK” Information Warning Stop (critical) Over or under

Volume rate

Automatic

Track Crab left Track Crab right Track Lock Track Automatic Track Manual

Options A on Options B on Options both on Options both off

TWIN Preset 1 TWIN Preset 2 TWIN Manual

Auto mode

Nozzle size

calculated

Manual mode

Nozzle size

calculated

Increment steps

mode

Nozzle size

calculated

Variable rate (GPS)

active

Auto mode

No flow to sections

Manual mode

No flow to sections

Increment steps

mode

No flow to sections

Volume rate Manual Pendulum Locked Pendulum

Auto mode

Nozzle size not

calculated

Manual mode

Nozzle size not

calculated

Increment steps

mode

Nozzle size not

calculated

application

Unlocked

3.5

Page 18

3 - Description

A. Preset keys

Vital information while spraying is quick and easy

to access.

Pressing the button will enter a submenu with the

preset keys.

B. Soft keys

Soft keys control optional features. Press the soft

key button to activate a submenu with further

features.

ATTENTION! The number of levels in the soft

key menu system depends on the number

of functions - see also “Soft keys menu tree”

below.

C. Navigation keys

The navigation keys are initially used for set up in the menu system by coding in values. The navigation keys can change the

volume rate in a set percentage or fixed volume rate. Other keys appear as needed on the ISOBUS Terminal.

ISOBUS Description

This key appears whenever necessary at respective menus, etc.

See “ESC key for ISOBUS terminals” on page 6.1 for setup of this

button.

This key appears whenever necessary at respective menus, etc. Used to scroll up.

Used to escape back to previous screen.

This key appears whenever necessary at respective menus, etc. Used to enter a menu or confirm a value.

This key appears whenever necessary at respective menus, etc. Used to scroll down.

This is normally a key in the standard numeric keypad of the specific

terminal.

D. Numeric keys

Used to clear a value or register.

The keys will be the standard numeric keypad for the specific ISOBUS terminal.

Soft keys menu tree

LEVEL 1 LEVEL 2 LEVEL 3 LEVEL 4

ICON FUNCTION ICON FUNCTION ICON FUNCTION

F1 EndNozzles F1 Left ON Work screen

F2 Left OFF

F3 Right OFF Work screen

F4 Right OFF

3.6

Page 19

3 - Description

SetBox

The SetBox controls secondary functions. The keys are grouped into control areas to simplify operator understanding.

NOTE! Self-propelled sprayers do not have a SetBox as the controls are built-in to the cabin.

÷

1. Power ON/OFF.

2. Pendulum unlock.

3. Pendulum lock.

4. Inner wing fold.

5. Inner wing unfold.

6. 1st outer wing fold.

7. 1st outer wing unfold.

8. 2nd outer wing fold.

9. 2nd outer wing unfold.

10. Automatic volume rate selector.

11. Manual pressure control.

12. Foam marker regulation.

13. Foam marker Left/Right selector.

14. DynamicCenter adjustment (increments).

15. DynamicCenter outer positions 1 or 5.

16. Optional function A-B.

17. HeadlandAssist automatic.

18. HeadlandAssist boom align.

19. SafeTrack manual control (if installed).

20. SafeTrack align selector (if installed).

21. SafeTrack automatic selector (if installed).

ATTENTION! Button 1 has different function on ISOBUS sprayers as this turns the JobCom ON/OFF.

ATTENTION! Buttons 17 and 18 can have different functions if the sprayer is equipped with AutoHeight.

ATTENTION! The Grip cannot be switched ON/OFF separately. It is automatically switched ON when tractor power is

turned ON (ISOBUS).

3.7

Page 20

3 - Description

HC 6300 Grip

The Grip is an ergonomic remote unit that can be easily mounted inside

the tractor cabin. All common functions required during normal

spraying can be operated with the Grip. Also the Grip controls some

optional functions.

ATTENTION! The Grip cannot be switched ON/OFF separately. It is

automatically switched ON when tractor power is turned ON

(ISOBUS).

A. Status LED.

B. Boom section controls (up to 13).

C. Main ON/OFF.

D. Tilt.

E. Boom height.

F. Boom slant.

G. Not used.

H. TWIN presets.

General keystrokes

The first steps to choose a menu are shown below. See also “Full menu structure” on page 3.15.

Menu selection

1. Press {Menu} Virtual Terminal button to proceed into the menu.

2. Navigate to desired submenu using arrows.

3. In the menu, the current selection is marked with a colored bar.

4. Move the menu colored bar up and down by using the {up} and

{down} arrows.

NOTE! A maroon colored bar indicates current setting.

÷

5. Confirm selection by pressing the enter arrow.

ATTENTION! Press {ESC} to leave the menu without changing values.

NOTE! There is help text for each menu in the bottom of the display. The displayed help text corresponds to the

÷

location of the colored bar on the Virtual Terminal.

3.8

Page 21

Menu editing example: Tank contents ISOBUS VT

1. At main ISOBUS VT screen select {Menu} to

enter menus.

2. With “Daily Settings” highlighted, select

{Enter} to confirm.

3 - Description

3. Scroll to “Tank contents” with {up} or {down}

arrows and select enter to confirm.

3.9

Page 22

3 - Description

ATTENTION! The procedure for the following two steps can vary between ISOBUS terminals. Procedure for HC 9500

terminal is shown here.

4. Select the value field to enter a value.

5. Enter the new tank contents value on the

numeric key pad and select check mark to

confirm.

Extended menu

This menu has been set up by your HARDI® Service center. It contains parameters that are typically set only once, normally

before the Controller is used.

• For ISOBUS terminals the extended menu is accessible from menu 2.8 and requires a pin code to enter.

ATTENTION! Unless instructed, do not tamper with the settings and values in these menus. Doing so may void

warranty.

3.10

Page 23

3 - Description

Functions

Auto functions general info

The Soft key buttons are used for the End Nozzle functions.

ATTENTION! Refer to “B. Soft keys” on page 3.6 for information about how to enter the soft keys.

End nozzles (Fence line) (optional)

If End nozzles/Bi-jet are fitted, set the value to the equivalent coverage by the boom nozzles. E.g. End nozzle coverage is 5

feet. This is equal to [03 Boom nozzles]. Choose End Nozzles by pressing F1.

• When end nozzle is active, it will be shown in the display with two icons at the ends of the boom line.

• Set up of end nozzles/Bi-jet can be done from menu 3.3.4.

ATTENTION! It is important that the volume applied from the end nozzle or Bi-jet matches the volume applied under

the boom. This is a comparison of volume per minute per length. (Liter/min/meter).

When the end nozzle or Bi-jet is active, the area covered and volume sprayed is calculated and registered. If “Active

boom size” is displayed, it will show an increase when the end nozzle or Bi-jet is activated.

3.11

Page 24

3 - Description

DynamicFluid4 pressure regulation

Traditional fluid regulation starts when the nozzles are opened. With DynamicFluid4 the regulation is a continuous process

that continues even if the nozzles are closed. Two ceramic discs regulate the pressure and ensures quick reaction and zero

leakages. Sprayer speed, P.T.O. RPM and number of sections activated are parameters used, and the benefit is more precise

application rates from the second the sprayer begins spraying.

The DynamicFluid4 uses feed forward technology based on 5 sensors that feed the JobCom computer with data necessary

for optimal regulation. It auto-primes at start-up, starts and moves the valve towards the final position immediately after the

operator makes changes. E.g. when section valves are opened or closed, the regulation valve is started the same time the

section valve motors are started. This avoids overpressure situations e.g. after running empty and refill of main tank.

The 5 sensors are also back-up for each other and ensures the system can continue regulation even if one or more sensor

signals fail. Sensors used are:

• Sprayer speed sensor

• Flow sensor

• Pressure sensor

• Pump r.p.m. sensor

• Regulation valve opening angle sensor

The DynamicFluid4 pressure regulation features are:

• Very fast and accurate regulation when all sensors are ok, setup in menus are correct and pump, filters and valves are

in good condition.

• Quick reacting valve when sections are turned ON/OFF and at speed changes.

• Optimized AutoSectionControl feature that predicts when boom sections will open and nozzle pressure.

• Optimized for different P.T.O. systems.

• Nozzle surveillance. No setup or tuning required for nozzle change.

• Warning in display if failures occur on boom plumbing, such as severe clogging of line or nozzle filters or large leakages

on hoses and fittings.

• All functions continue working, although with degraded performance (Limp home modes), if:

Faults occur in fluid system, e.g. pump defects, clogged filters, leaking valves.

Sensor failure appears on pressure sensor, flow sensor or RPM sensor.

There is wrong setup of sprayer data in menus.

• Emergency mode if angle sensor or speed sensor fails.

Screen icons

The sprayer driver selects one of three modes Auto, Manual or Increment steps. The sprayer computer detects one of three

regulation modes Drop, Question mark or calibration jug. This makes 9 modes in total.

Auto Manual Increment steps

When Automatic

Volume Rate button is

pressed on the SetBox.

When one of the

Manual pressure

control buttons is

pressed on the SetBox.

When the Volume Rate

is changed in steps

with %-up or %-down

buttons on the

Ter mi nal .

Calibration jug

There is flow to section valves.

Nozzle size (L/min at 3 bar) has been calculated.

Drop

There is no flow to section valves.

The pump is not started or the pressure SmartValve is set to other function than spraying.

Question mark

There is flow to section valves but pressure and flow has not yet been stable, therefore

the nozzle size (L/min at 3 bar) has not been calculated.

The system uses the previously stored nozzle size.

3.12

Page 25

Regulation valve function diagram

ATTENTION! Auto mode icons shown, but could be Manual or

Increment steps icons, depending on driver selection.

3 - Description

Spray job begins

Start condition:

Controller is turned OFF. Pump is turned OFF.

Pressure SmartValve to Pressure draining/Tu rboFiller,

suction SmartValve to Main tank, have water in Main

tank.

Driver action

Turn the controller ON.

Controller reaction

Controller detects no pressure or flow.

Starts in auto mode. Sets regulation valve to safe angle, to

avoid overpressure at pump start and to ensure that software

detects that pump is started (avoid hanging).

Driver action

Turn the pump ON.

Controller reaction

Headland (boom is closed)

Software uses nozzle size and feed for ward to

prepare for opening of boom.

Max. pressure limit is disabled, because last

saved nozzle size is reliable and therefore

software “dare” to close regulation valve

completely.

Driver action

Turn main OFF at headland. (go up)

Turn main ON to spray. (go down)

Headland (boom is closed)

for over 5 min

Boom is closed for a longer

period, operator could have

changed to other nozzle size.

Last saved nozzle size

becomes unreliable.

Software enable max. pressure

limit.

Controller action

Controller detects no pressure or flow, Stay in safe

position.

Driver action

Turn pressure SmartValve to Spraying.

Controller reaction

Headland (boom is closed)

Controller detects pressure at armature and bypass flow back

to tank. Software uses last saved nozzle size and feed forward

to prepare for opening of boom.

Max. pressure limit is enabled, because last saved nozzle size

is unreliable and therefore software will not close regulation

valve completely. PrimeFlow booms are primed.

Driver action

Turn main OFF at headland. (go up)

Turn main ON to spray. (go down)

3.13

Page 26

3 - Description

Controller reaction

Spraying (boom is open)

Boom is open and sprays.

Both flow measurement and pressure

measurement are good, and the actual

nozzle size is calculated.

The actual nozzle size is used to adjust to

correct liter/ha.

Flow and pressure are

good

Both flow measurement and

pressure measurement are

good.

Software disables max.

pressure limit.

Controller reaction

Spraying (boom is open)

Boom is open and sprays.

Software uses last saved nozzle size and pressure sensor to

adjust to correct liter/ha.

Max. pressure limit is enabled to avoid overpressure in case

operator had changed to smaller nozzles.

SafeTrack (Trailed sprayers only)

SafeTrack is a steering mechanisms for the trailed HARDI® sprayers. When using a track system, sprayer stability is a common

concern. Many factors influence the sprayer and conditions where the sprayer might tip over have to be dealt with.

The factors that the driver can influence with are

• Driving behavior

• Field conditions

• Tire width

• Tire pressure

Read sprayer’s instruction book for further information. If unsafe driving occurs, an alarm will be triggered and the sprayer

will align. Be aware that the alarm cannot be turned off as long as unsafe driving still occurs!

ATTENTION! If necessary, the level of security can be adjusted - please contact your local HARDI® dealer.

DANGER! The system has been calibrated during driving on flat fields. Special attention should be made when driving

€

in hilly conditions.

DANGER! When driving on fields with deep tracks, then the speed must be decreased.

€

HARDI® AutoSectionControl (optional)

HARDI® AutoSectionControl will:

• manage the sections when driving over sprayed area, like into a headland or wedge or around obstacles like trees, etc.

• automatically record the area sprayed, when spraying.

In a typical situation where the headland is sprayed first, HARDI® AutoSectionControl will now automatically close the

sections if the operator passes over a sprayed area.

ATTENTION! Variable Rate Application needs to be enabled for AutoSectionControl to work - refer to “Menu 2.3

Variable Rate Application (VRA) / Remote / HARDI® AutoSectionControl” on page 6.3.

ATTENTION! For more information about AutoSectionControl, see the AutoSectionControl instruction book. On

ISOBUS terminals AutoSectionControl can be an integrated part - if so, refer to the ISOBUS terminal instruction book.

3.14

Page 27

3 - Description

grey box

Menus

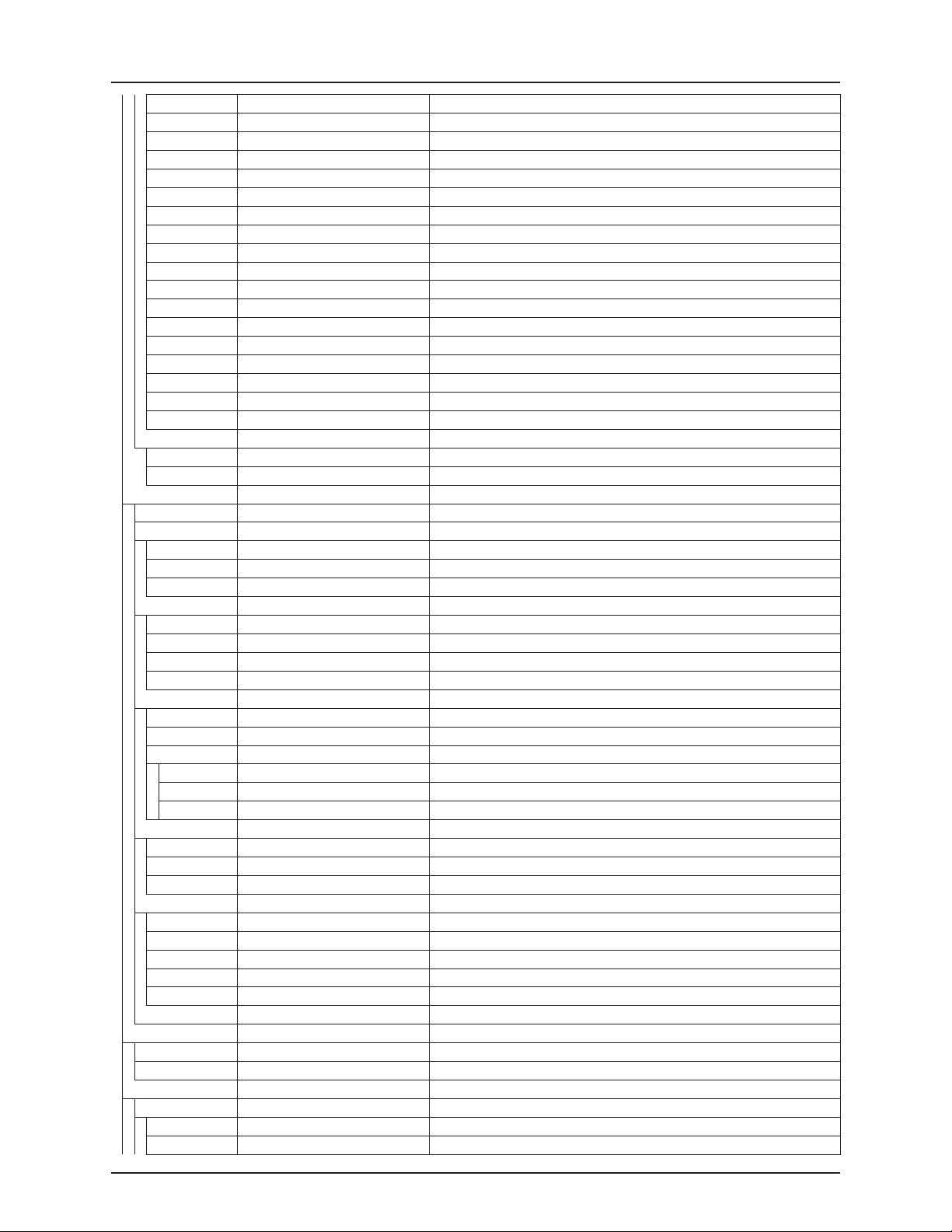

Full menu structure

NOTE! Blank fields are menus without name or description.

÷

NOTE! Menus marked with a are not for ISOBUS terminals.

÷

Menu number Menu name Description / Help text

1 Daily settings Most used settings e.g. desired rate, tank contents and register number

1. 1 Volume rate Use arrow keys or numeric keys to set the desired volume rate

1. 2 Tank contents To change displayed tank contents. Use arrow keys or numeric keys to set

1. 3 Select register Use register 1 to 99 for job. Scroll to register, then press Enter to show data

1. 3. 1

1. 3. 1. 1 Show register spray data 1 Press C for 5 sec to reset register. Enter to see screen 2, ESC to leave

1. 3. 1. 1. 1 Start date

1. 3. 1. 1. 2 Start time

1. 3. 1. 1. 3 End date

1. 3. 1. 1. 4 End time

1. 3. 1. 2 Show register spray data 2 Press C for 5 sec to reset register, Enter to see screen 1, ESC to leave

1. 3. 1. 2. 1 Volume applied

1. 3. 1. 2. 2 Area covered

1. 3. 1. 2. 3 Average spray speed

1. 3. 1. 2. 4 Maximum spray speed

1. 3. 1. 2. 5 Travelled spray dist

1. 3. 1. 2. 6 Time used spraying

1. 3. 1. 2. 7 Work rate

1. 3. 1. 2. 8 Average volume rate

1. 4 Volume rate: Preset high Rate selected with1 press on the arrow up-key

1. 5 Volume rate: Preset low Rate selected with1 press on the arrow down-key

2 Setup Customizing of display, automatic functions, clock, alarms, registers, etc

2. 1 Display readout Customizes the 4 small display readouts

2. 1. 1 Show upper middle

2. 1. 1. 01 Programmed volume rate Shows Programmed volume rate

2. 1. 1. 02 Boom flow Boom flow rate per minute sprayed out through the boom

2. 1. 1. 03 time Actual time

2. 1. 1. 04 Work rate Rate shown in hectare per hour or acre per hour

2. 1. 1. 05 Actual volume rate Actual rate in liter per hectare or gallon per acre

2. 1. 1. 06 Tank contents Main tank contents

2. 1. 1. 07 Speed Driving speed

2. 1. 1. 08 Volume sprayed Readouts for Volume sprayed in currently active register

2. 1. 1. 09 Area sprayed Readouts for Area sprayed in currently active register

2. 1. 1. 10 Active boom size Active boom size including end nozzle

2. 1. 1. 11 Pressure Displays spray pressure if sensor is fitted

2. 1. 1. 12 Fan speed Displays Twin fan speed if sensor is fitted

2. 1. 1. 13 Wind Speed Displays wind speed if sensor is fitted

2. 1. 1. 14 Pendulum lock status Displays reading of pendulum lock sensor if fitted

2. 1. 1. 15 Pendulum unlock status Displays reading of pendulum unlock sensor if fitted

2. 1. 1. 16 Dynamic center position Displays Dynamic center position sensor if fitted

2. 1. 1. 17 Spray pump rev Displays revolutions if sensor is fitted

2. 1. 1. 18 Extra sensor 1F Readout from extra sensor 1 frequency

2. 1. 1. 19 Extra sensor 2F Readout from extra sensor 2 frequency

2. 1. 1. 20 Extra sensor 3A Readout from extra sensor 3 analog

2. 1. 1. 21 Extra sensor 4A Readout from extra sensor 4 analog

2. 1. 1. 22 Voltmeter Displays system voltage. Useful when fault finding

2. 1. 1. 23 Agitation Agitation valve opening

3.15

Page 28

3 - Description

2. 1. 1. 24 RinseTank content RinseTank calculated content

2. 1. 1. 25 Slant angle Headland assist angle sensor

2. 1. 1. 26 Boom height Headland assist height sensor

2. 1. 1. 27 Reserved R R

2. 1. 1. 28 Reserved R R

2. 1. 1. 29 Reserved R R

2. 1. 1. 30 Reserved R R

2. 1. 1. 31 Reserved R R

2. 1. 1. 32 Reserved R R

2. 1. 1. 33 Nozzle size flow at 3 bar (45 psi) Calculated nozzle flow at 3 bar (45 psi)

2. 1. 1. 34

2. 1. 1. 35

2. 1. 1. 36

2. 1. 1. 37 PF bus + Voltage on PrimeFlow databus +

2. 1. 1. 38 PF bus - Voltage on PrimeFlow databus -

2. 1. 2 Show upper right

2. 1. 2. 01 Programmed volume rate Shows Programmed volume rate

2. 1. 2. 02 Boom flow Boom flow rate per minute sprayed out through the boom

2. 1. 2. 03 time Actual time

2. 1. 2. 04 Work rate Rate shown in hectare per hour or acre per hour

2. 1. 2. 05 Actual volume rate Actual rate in liter per hectare or gallon per acre

2. 1. 2. 06 Tank contents Main tank contents

2. 1. 2. 07 Speed Driving speed

2. 1. 2. 08 Volume sprayed Readouts for Volume sprayed in currently active register

2. 1. 2. 09 Area sprayed Readouts for Area sprayed in currently active register

2. 1. 2. 10 Active boom size Active boom size including end nozzle

2. 1. 2. 11 Pressure Displays spray pressure if sensor is fitted

2. 1. 2. 12 Fan speed Displays Twin fan speed if sensor is fitted

2. 1. 2. 13 Wind Speed Displays wind speed if sensor is fitted

2. 1. 2. 14 Pendulum lock status Displays reading of pendulum lock sensor if fitted

2. 1. 2. 15 Pendulum unlock status Displays reading of pendulum unlock sensor if fitted

2. 1. 2. 16 Dynamic center position Displays Dynamic center position sensor if fitted

2. 1. 2. 17 Spray pump rev Displays revolutions if sensor is fitted

2. 1. 2. 18 Extra sensor 1F Readout from extra sensor 1 frequency

2. 1. 2. 19 Extra sensor 2F Readout from extra sensor 2 frequency

2. 1. 2. 20 Extra sensor 3A Readout from extra sensor 3 analog

2. 1. 2. 21 Extra sensor 4A Readout from extra sensor 4 analog

2. 1. 2. 22 Voltmeter Displays system voltage. Useful when fault finding

2. 1. 2. 23 Agitation Agitation valve opening

2. 1. 2. 24 RinseTank content RinseTank calculated content

2. 1. 2. 25 Slant angle Headland assist angle sensor

2. 1. 2. 26 Boom height Headland assist height sensor

2. 1. 2. 27 Reserved R R

2. 1. 2. 28 Reserved R R

2. 1. 2. 29 Reserved R R

2. 1. 2. 30 Reserved R R

2. 1. 2. 31 Reserved R R

2. 1. 2. 32 Reserved R R

2. 1. 2. 33 Nozzle size flow at 3 bar (45 psi) Calculated nozzle flow at 3 bar (45 psi)

2. 1. 2. 34

2. 1. 2. 35

2. 1. 2. 36

2. 1. 2. 37 PF bus + Voltage on PrimeFlow databus +

2. 1. 2. 38 PF bus - Voltage on PrimeFlow databus -

2. 1. 3 Show lower middle

2. 1. 3. 01 Programmed volume rate Shows Programmed volume rate

2. 1. 3. 02 Boom flow Boom flow rate per minute sprayed out through the boom

3.16

Page 29

2. 1. 3. 03 time Actual time

2. 1. 3. 04 Work rate Rate shown in hectare per hour or acre per hour

2. 1. 3. 05 Actual volume rate Actual rate in liter per hectare or gallon per acre

2. 1. 3. 06 Tank contents Main tank contents

2. 1. 3. 07 Speed Driving speed

2. 1. 3. 08 Volume sprayed Readouts for Volume sprayed in currently active register

2. 1. 3. 09 Area sprayed Readouts for Area sprayed in currently active register

2. 1. 3. 10 Active boom size Active boom size including end nozzle

2. 1. 3. 11 Pressure Displays spray pressure if sensor is fitted

2. 1. 3. 12 Fan speed Displays Twin fan speed if sensor is fitted

2. 1. 3. 13 Wind Speed Displays wind speed if sensor is fitted

2. 1. 3. 14 Pendulum lock status Displays reading of pendulum lock sensor if fitted

2. 1. 3. 15 Pendulum unlock status Displays reading of pendulum unlock sensor if fitted

2. 1. 3. 16 Dynamic center position Displays Dynamic center position sensor if fitted

2. 1. 3. 17 Spray pump rev Displays revolutions if sensor is fitted

2. 1. 3. 18 Extra sensor 1F Readout from extra sensor 1 frequency

2. 1. 3. 19 Extra sensor 2F Readout from extra sensor 2 frequency

2. 1. 3. 20 Extra sensor 3A Readout from extra sensor 3 analog

2. 1. 3. 21 Extra sensor 4A Readout from extra sensor 4 analog

2. 1. 3. 22 Voltmeter Displays system voltage. Useful when fault finding

2. 1. 3. 23 Agitation Agitation valve opening

2. 1. 3. 24 RinseTank content RinseTank calculated content

2. 1. 3. 25 Slant angle Headland assist angle sensor

2. 1. 3. 26 Boom height Headland assist height sensor

2. 1. 3. 27 Reserved R R

2. 1. 3. 28 Reserved R R

2. 1. 3. 29 Reserved R R

2. 1. 3. 30 Reserved R R

2. 1. 3. 31 Reserved R R

2. 1. 3. 32 Reserved R R

2. 1. 3. 33 Nozzle size flow at 3 bar (45 psi) Calculated nozzle flow at 3 bar (45 psi)

2. 1. 3. 34

2. 1. 3. 35

2. 1. 3. 36

2. 1. 3. 37 PF bus + Voltage on PrimeFlow databus +

2. 1. 3. 38 PF bus - Voltage on PrimeFlow databus -

2. 1. 4 Show lower right

2. 1. 4. 01 Programmed volume rate Shows Programmed volume rate

2. 1. 4. 02 Boom flow Boom flow rate per minute sprayed out through the boom

2. 1. 4. 03 time Actual time

2. 1. 4. 04 Work rate Rate shown in hectare per hour or acre per hour

2. 1. 4. 05 Actual volume rate Actual rate in liter per hectare or gallon per acre

2. 1. 4. 06 Tank contents Main tank contents

2. 1. 4. 07 Speed Driving speed

2. 1. 4. 08 Volume sprayed Readouts for Volume sprayed in currently active register

2. 1. 4. 09 Area sprayed Readouts for Area sprayed in currently active register

2. 1. 4. 10 Active boom size Active boom size including end nozzle

2. 1. 4. 11 Pressure Displays spray pressure if sensor is fitted

2. 1. 4. 12 Fan speed Displays Twin fan speed if sensor is fitted

2. 1. 4. 13 Wind Speed Displays wind speed if sensor is fitted

2. 1. 4. 14 Pendulum lock status Displays reading of pendulum lock sensor if fitted

2. 1. 4. 15 Pendulum unlock status Displays reading of pendulum unlock sensor if fitted

2. 1. 4. 16 Dynamic center position Displays Dynamic center position sensor if fitted

2. 1. 4. 17 Spray pump rev Displays revolutions if sensor is fitted

2. 1. 4. 18 Extra sensor 1F Readout from extra sensor 1 frequency

2. 1. 4. 19 Extra sensor 2F Readout from extra sensor 2 frequency

2. 1. 4. 20 Extra sensor 3A Readout from extra sensor 3 analog

3 - Description

3.17

Page 30

3 - Description

2. 1. 4. 21 Extra sensor 4A Readout from extra sensor 4 analog

2. 1. 4. 22 Voltmeter Displays system voltage. Useful when fault finding

2. 1. 4. 23 Agitation Agitation valve opening

2. 1. 4. 24 RinseTank content RinseTank calculated content

2. 1. 4. 25 Slant angle Headland assist angle sensor

2. 1. 4. 26 Boom height Headland assist height sensor

2. 1. 4. 27 Reserved R R

2. 1. 4. 28 Reserved R R

2. 1. 4. 29 Reserved R R

2. 1. 4. 30 Reserved R R

2. 1. 4. 31 Reserved R R

2. 1. 4. 32 Reserved R R

2. 1. 4. 33 Nozzle size flow at 3 bar (45 psi) Calculated nozzle flow at 3 bar (45 psi)

2. 1. 4. 34

2. 1. 4. 35

2. 1. 4. 36

2. 1. 4. 37 PF bus + Voltage on PrimeFlow databus +

2. 1. 4. 38 PF bus - Voltage on PrimeFlow databus -

2. 1. 5 Show ESC softkey to leave ISObus terminal can have a separate ESC key or use an ESC softkey

2. 1. 5. 1 Show ESC as softkey Choose this to show ESC key as softkey on ISObus terminal

2. 1. 5. 2 Do not show ESC as softkey Choose this if ISObus terminal has a separate ESC key.

2. 2 AUTO functions Set up for Auto ON/OFF, Foam marker, HeadlandAssist and optional A/B

2. 2. 1 Main ON/OFF For automatic operation of the main ON/OFF function at a pre-set speed

2. 2. 2 Foam marker To operate via the main ON/OFF function and automate side choice

2. 2. 2. 1 Disable It will only follow the manual setting of the switch on the SetBox

2. 2. 2. 2 Same side It will automatically activate the same side for race-track spraying

2. 2. 2. 3 Change side It will automatically change side for up and back spraying

2. 2. 3 Dual Line To set up lower and upper trigger limits for the operation of line A and line B

2. 2. 3. 1 Lower pressure level Key in pressure level to switch Dual Line to smaller nozzles

2. 2. 3. 2 Upper pressure level Key in pressure level to switch Dual Line to bigger nozzles

2. 2. 3. 3 From A to B speed level Key in speed to switch Dual Line from A to B

2. 2. 3. 4 From B to A+B speed level Key in speed to switch Dual Line from B to A+B

2. 2. 4 HeadlandAssist setup Boom lift and lower automatically when switching main ON/OFF function

2. 2. 4. 1 ON/OFF delay Distance delay so the boom will lift or lower via the main ON/OFF

2. 2. 4. 2 Boom height at headlands Key in 0 to disable HeadlandAssist Key in a height to enable

2. 2. 4. 3 Slant mirror or in steps Activate headland assist slant mirror or slant in steps.

2. 2. 4. 3. 1 Slant mirror and steps disable Traditional slant. No slant mirror. No slant in steps.

2. 2. 4. 3. 2 Slant mirror enable Activate opposite slant at headlands. Slant in steps not possible.

2. 2. 4. 3. 3 Slant in steps enable Activate slant in steps. Set step size in 2.2.4.4. Slant mirror not possible.

2. 2. 5 TWIN preset shift auto / man Shifts automatically at main ON/OFF or manually at keypress

2. 2. 5. 1 Manual shift at keypress Upon keypress it will change to the other preset value

2. 2. 5. 2 Auto shift at main ON/OFF It will automatically change to the other preset value

2. 2. 5. 3 TWIN controls disabled TWIN fan, angle and preset controls are disabled

2. 2. 6 AutoAgitation select level Powerful or soft no Agitation

2. 2. 6. 1 Powerful AutoAgitation Recommended for powder

2. 2. 6. 2 Soft AutoAgitation Recommended for liquid chemical

2. 2. 6. 3 No agitation Never use if sedimentation occurs. Recommended for liquid fertilizer.

2. 2. 6. 4 Fixed agitation Valve is positioned

2. 2. 6. 5 Agitation switch Switch increase or decrease agitation

2. 2. 7 AutoAgitation fixed level Key in position of agitation valve for FluidBox key and fixed level

2. 3 VRA / Remote control Variable Rate Application by RS232 Auto Section Control

2. 3. 1 VRA / Remote control disable Variable Rate Application / Remote control disabled. Dish icon disappear

2. 3. 2 VRA / Remote control enable by RS232 data port control enabled. Dish icon will be shown

2. 4 Set clock Change date and clock time

2. 4. 1 Time format (12 or 24 hour) Choose between a 12 hour or 24 hour clock

2. 4. 1. 1 12 hour format You have chosen 12 hours as your time unit

2. 4. 1. 2 24 hour format You have chosen 24 hours as your time

3.18

Page 31

3 - Description

2. 4. 2 Set time Set the actual time. Use arrow keys or numeric keys, then press Enter

2. 4. 3 Set date and month Set date and month. Use arrow keys or numeric keys, then press Enter

2. 4. 4 Set year Set year. Use arrow keys or numeric keys, then press Enter

2. 5 Alarms Different alarms can be set up. Choices will be listed

2. 5. 01 Volume rate alarm Over or under application alarm

2. 5. 01. 1 High volume rate limit Over application warning for volume rate when over in 20 seconds

2. 5. 01. 2 Low volume rate limit Under application warning for volume rate when under in 20 seconds

2. 5. 02 Tank contents at minimum Warning given when tank contents is below this volume

2. 5. 03 Spray pressure High and low spray pressure alarm

2. 5. 03. 1 High spray pressure limit Warning given when spray pressure is above value

2. 5. 03. 2 Low spray pressure limit Warning given when under this pressure

2. 5. 04 Fan speed alarm High and low r/min alarm

2. 5. 04. 1 High fan revolutions limit Warning given when over this value

2. 5. 04. 2 Low fan revolutions limit Warning given when under this value

2. 5. 05 Speed alarm Speed maximum and minimum alarm

2. 5. 05. 1 Maximum speed value Warning will be given if spraying over this value

2. 5. 05. 2 Minimum speed value Warning will be given if spraying under this value

2. 5. 06 Wind speed Displays wind speed if sensor is fitted

2. 5. 07 PTO r/min alarm PTO revolutions maximum and minimum alarm

2. 5. 07. 1 Maximum value Alarm value for the maximum revolutions on the PTO

2. 5. 07. 2 Minimum value Alarm value for the minimum revolutions

2. 5. 08 R/minute alarm Revolutions maximum and minimum alarm

2. 5. 08. 1 Maximum value Alarm value for the maximum revolutions on the PTO

2. 5. 08. 2 Minimum value Alarm value for the minimum revolutions

2. 5. 09 Reserved

2. 5. 09. 1 Reserved

2. 5. 09. 2 Reserved

2. 5. 10 R/minute alarm Revolutions maximum and minimum alarm

2. 5. 11 R/minute max Value (PPU) maximum and minimum alarm

2. 5. 13 R/minute min Value (Volt) maximum and minimum alarm

2. 5. 15 Sections OFF warning Main ON/OFF is switched to ON and some sections are switched to OFF

2. 5. 15. 1 Enabled Press Enter to enable warning when sections are OFF

2. 5. 15. 2 Disabled Press Enter to disable warning

2. 5. 16 Audio level Audio steps for alarm volume. 0 is for no sound

2. 5. 16. 0 Sound step 0 0 = no sound, 5 is maximum volume

2. 5. 16. 1 Sound step 1 0 = no sound, 5 is maximum volume

2. 5. 16. 2 Sound step 2 0 = no sound, 5 is maximum volume

2. 5. 16. 3 Sound step 3 0 = no sound, 5 is maximum volume

2. 5. 16. 4 Sound step 4 0 = no sound, 5 is maximum volume

2. 5. 16. 5 Sound step 5 0 = no sound, 5 is maximum volume

2. 6 Register names Register set up. Once done, a name can be copied and edited

2. 6. 1 up to 99 Register name Toggle numeric keyboard to key in Register name

2. 7 Setup display Setup for brightness, contrast and day/night colors

2. 7. 1 Choose day/night colors Color change makes the display easier to read at day and night

2. 7. 1. 1 Day colors Select this for day-time spraying Black text on white background

2. 7. 1. 2 Night colors Select this for night-time spraying White text on black background

2. 7. 2 Setup brightness Brightness can be stepped

2. 7. 2. 1 High brightness Maximum setting

2. 7. 2. 2 Medium Medium setting

2. 7. 2. 3 Low brightness Minimum setting

2. 8 Extended menu Extended menu for dealers setup to match features on sprayer

3 Calibration Basic calibration,e.g. speed, boom, regulation constant, tank and track

3. 1 Speed calibration Sprayer, tractor, Alpha or radar speed input. Calibration of selected sensor

3. 1. 1 Sprayer speed Speed sensor mounted on trailed sprayer Connected to armature junction box

3. 1. 1. 1 Sprayer speed constant Shows and permits change to the constant, Pulses Per Unit (meter / feet)

3. 1. 1. 2 Sprayer speed practical Preferred method. Do in field with spray tank half full for most accurate result

3.19

Page 32

3 - Description

3. 1. 1. 2. 1 Sprayer practical Measure up a distance more than 70 meters or 200 feet. Then drive distance

3. 1. 1. 2. 2 Now key in the exact distance, measured by a measuring tape

3. 1. 1. 2. 3 This is the new constant (pulses per meter or feet)

3. 1. 2 Tractor Alpha speed Alpha, or sensor located on tractor Sensor cable connected to Terminal

3. 1. 2. 1 Tractor speed constant

3. 1. 2. 2 Tractor practical Preferred method. Do in field with spray tank half full for most accurate result

3. 1. 3 Radar speed Choose if radar speed sensor is used

3. 1. 3. 1 Radar speed constant Shows and permits change to the constant, Pulses Per Unit (meter / feet)

3. 1. 3. 2 Radar practical Preferred method. Do in field with tank half full for most accurate result

3. 1. 3. 2. 1 Measure up a distance more than 70 meters or 200 feet. Then drive distance

3. 1. 3. 2. 2 Now key in the exact distance, measured by a measuring tape

3. 1. 3. 2. 3 This is the new constant (pulses per meter or feet)

3. 2 Flow calibration Flow sensor calibration. Theoretical (PPU), Nozzle Tank method PrimeFlow

3. 2. 1 PPU theory method EU: dia/ca PPU: Ø13/120, Ø20/60, Ø36/17 US: dia/ca PPU: Ø13/485, Ø20/225, Ø36/60

3. 2. 2 Nozzle method Practical flow calibration, by checking the actual nozzle output per minute

3. 2. 2. 1 Nozzle method measure the flow per minute from a number of nozzles. Press Enter.

3. 2. 2. 2 Nozzle method Key in the averaged actual flow value and press Enter

3. 2. 2. 3 Nozzle method This is the PPU constant from the volume previously just measured

3. 2. 2. 4 Open all sections

3. 2. 2. 5 Close end nozzles, Bi-jet nozzles

3. 2. 3 Tank method Practical flow calibration done by emptying over half the tank

3. 2. 3. 1 Tank method The sprayed amount is counted up when the sections are opened

3. 2. 3. 2 Tank method Press Enter. The shown volume is adjusted to match the actual volume

3. 3 Boom setup Boom width, number of sections and number of nozzles for each section

3. 3. 1 Width The total spray boom width. Include end nozzles if fitted

3. 3. 2 Number of sections The number of spray boom sections. Key in, then press Enter

3. 3. 3 Nozzles / sections To set up no. of nozzles per section. Screens for each section will appear

3. 3. 3. 01 Section 1 Use arrow keys or numeric keys, then press Enter to set up section 1

3. 3. 3. 02 Section 2 Use arrow keys or numeric keys, then press Enter to set up section 2

3. 3. 3. 03 Section 3 Use arrow keys or numeric keys, then press Enter to set up section 3

3. 3. 3. 04 Section 4 Use arrow keys or numeric keys, then press Enter to set up section 4

3. 3. 3. 05 Section 5 Use arrow keys or numeric keys, then press Enter to set up section 5

3. 3. 3. 06 Section 6 Use arrow keys or numeric keys, then press Enter to set up section 6

3. 3. 3. 07 Section 7 Use arrow keys or numeric keys, then press Enter to set up section 7

3. 3. 3. 08 Section 8 Use arrow keys or numeric keys, then press Enter to set up section 8

3. 3. 3. 09 Section 9 Use arrow keys or numeric keys, then press Enter to set up section 9

3. 3. 3. 10 Section 10 Use arrow keys or numeric keys, then press Enter to set up section 10

3. 3. 3. 11 Section 11 Use arrow keys or numeric keys, then press Enter to set up section 11

3. 3. 3. 12 Section 12 Use arrow keys or numeric keys, then press Enter to set up section 12

3. 3. 3. 13 Section 13 Use arrow keys or numeric keys, then press Enter to set up section 13

3. 3. 4 End nozzles and Bi-jet nozzles If end nozzles are fitted. Set value to equivalent coverage by boom nozzles

3. 3. 4. 1 None If no end nozzles or Bi-jet nozzles are fitted, select this

3. 3. 4. 2 End nozzles fitted Select if end nozzles are fitted

3. 3. 4. 2. 1 End nozzles Key in 'n', number of regular nozzles equivalent to the end nozzle coverage

3. 3. 4. 3 Bi-jet fitted Select if Bi-jet nozzles are fitted

3. 3. 4. 3. 1 Bi-jet end nozzles

3. 3. 5 Length hitch to axle for ASC Length from hitch to axle on sprayer for AutoSectionControl for ISObus

3. 3. 6 Length axle to boom for ASC Length from axle on sprayer to boom for AutoSectionControl for ISObus

3. 4 Regulation user setup Setup of pressure filter, nozzle, ASC default

3. 4. 1 Flow sensor restriction Flow to obtain 1 bar (15 psi) pressure drop over pressure filter and flow sensor

3. 4. 2 Simulated speed value Type in speed for priming at stand still and when both flow and pressure are defect

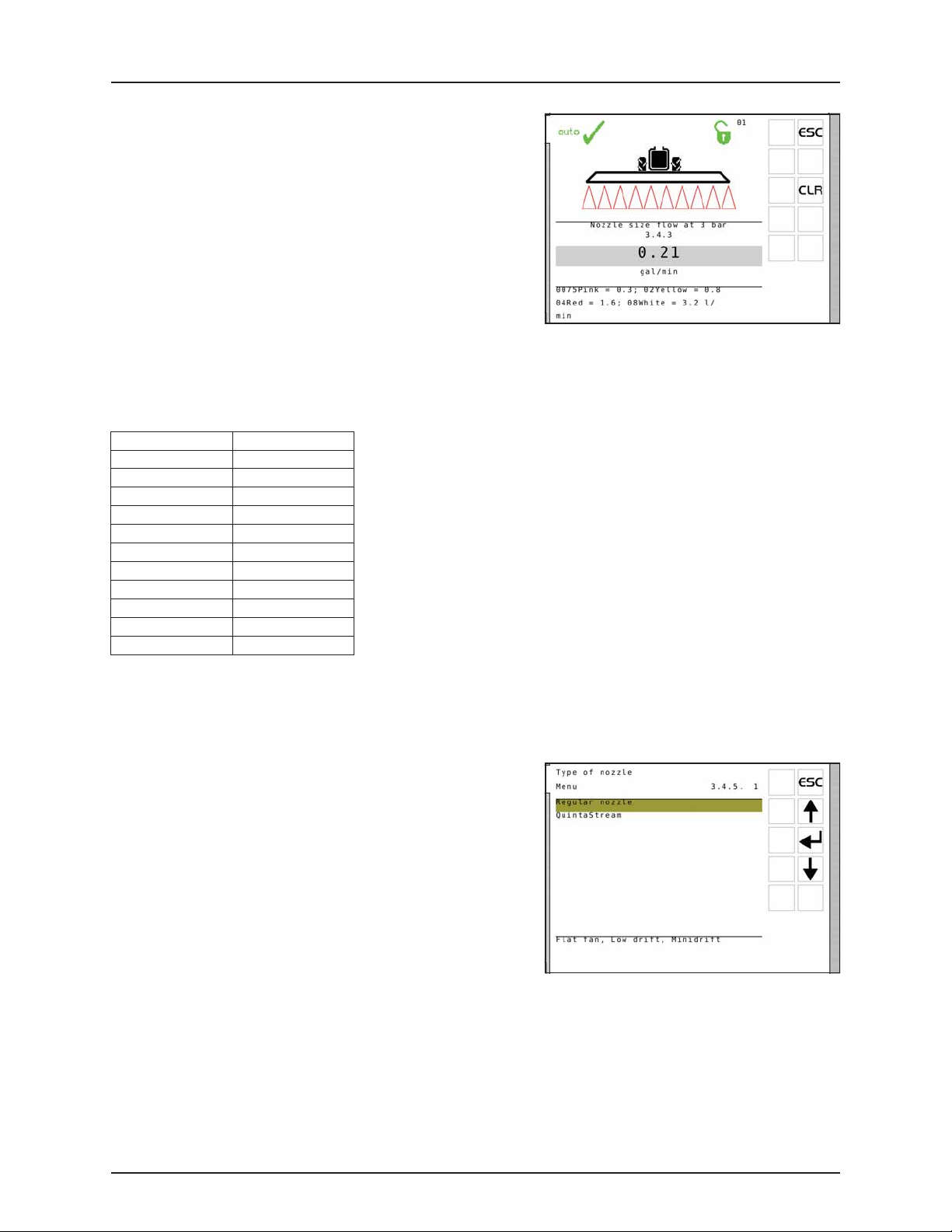

3. 4. 3 Nozzle size flow at 3 bar (45 psi) 0075Pink = 0.3 02Yellow = 0.8 04Red = 1.6 08White = 3.2 l/min

3. 4. 4 Dual line second nozzle 0075Pink = 0.3 02Yellow = 0.8 04Red = 1.6 08White = 3.2 l/min

3. 4. 5 Type of nozzle Select Regular or QuintaStream nozzle

3. 4. 5. 1 Regular nozzle Flat fan, Low drift, Minidrift

3. 4. 5. 2 QuintaStream QuintaStream fertilizer nozzle

3. 4. 6 Regulation parameter Code for special machines or applications, consult your dealer

3.20

Page 33

3 - Description

3. 5 Tank gauge calibration Setup density of chemical or fertilizer. Calibration for tank size and shape

3. 5. 1 Adjustment of specific gravity Enter weight of liquid fertilizer divided by weight of water (e.g. 1.10 to 1.30)

3. 5. 2 Calibration of Tank gauge Calibrate if factory calibration is not adequate. Disable SafeTrack

3. 5. 2. 1 Water level Fill up the tank to the max level, then press Enter

3. 5. 2. 2 Water level Level the sprayer, then press Enter

3. 5. 2. 3 Water level Empty sprayer through main flow meter at boom. Computer will register flow

3. 5. 2. 4 Water level Key in true volume from flowmeter. Computer will calculate table

3. 5. 3 Select factory calibration Select preloaded factory calibration for Hardi® tanks or custom calibration

3. 5. 3. 1 Custom calibration of gauge Tank gauge table from custom Calibration

3. 5. 3. 2 CME 3300 factory calibration Factory tank gauge table for CME 3300

3. 5. 3. 3 CME 4500 factory calibration Factory tank gauge table for CME 4500

3. 5. 3. 4 CME 7000 factory calibration Factory tank gauge table for CME 7000

3. 5. 3. 5 CME 9000 factory calibration Factory tank gauge table for CME 9000 AUS

3. 5. 3. 6 Alpha 2500 factory calibration Factory tank gauge table for Alpha 2500

3. 5. 3. 7 Alpha 3500 factory calibration Factory tank gauge table for Alpha 3500

3. 5. 3. 8 Alpha 4100 factory calibration Factory tank gauge table for Alpha 4100

3. 5. 3. 9 Alpha 3000 factory calibration Factory tank gauge table for Alpha 3000

3. 5. 3. 10 CME 5x00 factory calibration Factory tank gauge table for CME 5x00 AUS

3. 5. 3. 11 CME 7x00 factory calibration Factory tank gauge table for CME 7x00 AUS

3. 5. 3. 12 Saritor 4000 factory cal Factory tank gauge table for Saritor 4000

3. 5. 3. 13 Saritor 5000 factory cal Factory tank gauge table for Saritor 5000

3. 5. 3. 14 Navigator 3000 factory cal Factory tank gauge table for Navigator 3000

3. 5. 3. 15 Navigator 4000 factory cal Factory tank gauge table for Navigator 4000

3. 5. 3. 16 CME 5500 factory cal Factory tank gauge table for CME 5500 EU US

3. 5. 3. 17 CME 10,000 factory cal Factory tank gauge table for CME 10,000

3. 5. 3. 18 Navigator 5000 factory cal Factory tank gauge table for Navigator 5000

3. 5. 3. 19 Navigator 6000 factory cal Factory tank gauge table for Navigator 6000

3. 5. 3. 20 Presidio 2700 factory cal Factory tank gauge table for Presidio 2700 EU US

3. 5. 4 Offset at empty MainTank Actual frequency. Accept if empty. Or key in recorded empty-frequency

3. 5. 4. 1 TankGauge Offset,

3. 6 Track calibration Track width, tractor drawbar length, damping, alignment, sensitivity set up

3. 6. 1 Track width Track width of the sprayer wheels measured center to center

3. 6. 2 Tractor drawbar Tractor drawbar length is length from tractor rear axle to pin-bolt

3. 6. 3 Dead zone for regulation Increase for high speed. Decrease for high accuracy

3. 6. 4 Damping of hydraulics Increase for smooth drive and high speed. Decrease for high accuracy

3. 6. 5 Align offset + right - left Alignment of sprayer. Positive value moves sprayer right, negative left

3. 6. 6 Calibrate sensitivity Adjustment of track sensitivity in relation to the tractor hydraulics

3. 6. 6. 01 Sensitivity tractor hydraulic Press ESC to abort. Press Enter to start calibration of offset and gain

3. 6. 6. 02 Finding offset right side Press hold 'steer to right' button. Computer will activate valve to find offset

3. 6. 6. 03 Offset right side is Ok

3. 6. 6. 04 Finding offset right failed Press Enter to return to Track calibration menu

3. 6. 6. 05 Finding offset left side Press hold 'steer to left' button. Computer will activate valve to find offset

3. 6. 6. 06 Offset left side is Ok

3. 6. 6. 07 Finding offset left failed Press Enter to return to Track calibration menu

3. 6. 6. 08 Finding gain right side Press hold 'steer to right' button. Computer will activate valve and find gain

3. 6. 6. 09 Gain right side is Ok

3. 6. 6. 10 Find gain right side failed Press Enter to return to Track calibration menu

3. 6. 6. 11 Finding gain left side Press hold 'steer to left' button. Computer will activate valve and find gain

3. 6. 6. 12 Gain left side is Ok Calibration is OK. Press Enter to return to Track calibration menu

3. 6. 6. 13 Finding gain left side failed Press Enter to return to Track calibration menu

3. 6. 6. 14 Stop driving Stop driving

3. 6. 6. 15 Switch to auto Switch to auto track

4 Toolbox Helpful tools e.g. measure distance and area, service intervals, test etc

4. 1 Measure To measure distance and area. Setup working width

4. 1. 1 Measure Distance This is a simple electronic 'measuring tape'. You can measure distance

4. 1. 1. 1 Measure Distance Measure stopped. Press C to clear, Enter to start and ESC to exit

3.21

Page 34

3 - Description

4. 1. 1. 2 Measure Distance Measure started. Press Enter to stop and ESC to exit

4. 1. 2 Measure Area If the implement width is Entered, area can also be measured

4. 1. 3 Setup working width Key in the implement working width

4. 1. 4 Stop-watch The clock can be used as a stop watch

4. 1. 4. 1 Stopwatch: Not active Press C to clear. Press Enter to start, Esc to exit

4. 1. 4. 2 Stopwatch: Active Press Enter to stop and edit. Press Esc to exit. Stopwatch will continue

4. 1. 5 Alarm clock The clock can be set as an alarm clock

4. 1. 5. 1 Alarm clock: Not active Key in time. Press C to clear. Press Enter to start. Press ESC to exit.

4. 1. 5. 2 Alarm clock: Active Press Enter to stop and edit. Press Esc to exit. Alarm clock will continue

4. 2 Service interval: Hours until Work hours remaining for each part until next service is recommended

4. 2. 1 10 hrs Check filters

4. 2. 2 50 hrs Grease boom

4. 2. 3 250 hrs Grease center

4. 2. 4 Misc. service

4. 2. 5 10 hrs Check nozzles

4. 3 Service interval reset Reset timer counter when service has been carried out

4. 3. 1 Check filters reset Press Enter to reset hour counter, ESC to leave unchanged

4. 3. 2 Grease boom reset Press Enter to reset hour counter, ESC to leave unchanged

4. 3. 3 Grease track and center Press Enter to reset hour counter, ESC to leave unchanged

4. 3. 4 Miscellaneous service Press Enter to reset hour counter, ESC to leave unchanged

4. 3. 5 Check nozzles Press Enter to reset hour counter, ESC to leave unchanged

4. 4 Reserved R R

4. 5 Test of sensors Test screens for buttons, sensor readings PrimeFlow status Valve friction

4. 5. 1 Flow Speed Optional sensors Activate function to monitor sensor (e.g. drive forwards, start flow)

4. 5. 1. 1 Pressure

4. 5. 1. 2 Fan Speed

4. 5. 1. 3 Tank gauge

4. 5. 1. 4 Boom sensor

4. 5. 1. 5 Pressure regulation feedback

4. 5. 1. 6 Flow

4. 5. 1. 7 Speed

4. 5. 2 Active keys Push key to see if a count is registered. If yes, the key or switch function is OK

4. 5. 2. 1 Keys on Terminal

4. 5. 2. 2 Keys on SetBox

4. 5. 2. 3 Keys on Grip

4. 5. 2. 4 Keys on FluidBox

4. 5. 3 PrimeFlow test PrimeFlow test for nozzles and PrimeFlow computers on boom

4. 5. 3. 1 to 125 PrimeFlow computer status Press Arrow DOWN to see next SMCU Arrow UP to see previous

4. 5. 3. 1. 1 Total SMCU’s

4. 5. 3. 1. 2 Total nozzles

4. 5. 3. 1. 3 This SMCU position

4. 5. 3. 1. 4 Nozzle order

4. 5. 3. 1. 5 Nozzle no short cab.

4. 5. 3. 1. 6 Nozzle medium cable

4. 5. 3. 1. 7 Nozzle no long cable

4. 5. 3. 1. 8 Count of data error

4. 5. 3. 1. 9 Count of power error

4. 5. 4 Input test See computer readings of sensors Frequency, switch, analog inputs

4. 5. 4. 1 Frequency 1 Speed, Flow Test of frequency input sensors: Speed, Flow, Tank gauge, Fan

4. 5. 4. 1. 1 Speed

4. 5. 4. 1. 2 Flow to sections

4. 5. 4. 1. 3 Flow from rinse tank

4. 5. 4. 1. 4 FlexCap pump RPM

4. 5. 4. 1. 5 Tank gauge

4. 5. 4. 1. 6 Wind Speed

4. 5. 4. 1. 7 Fan speed

4. 5. 4. 1. 8 PTO pump RPM

3.22

Page 35

3 - Description

4. 5. 4. 1. 9 Speed to terminal

4. 5. 4. 2 Freq. 2 input Extra Test of frequency 2 sensors: Extra Regulation, agitation valve

4. 5. 4. 2. 1 Regulation valve

4. 5. 4. 2. 2 Agitation valve

4. 5. 4. 2. 3 Boom folded Left