Page 1

BOSS/HERON

Instruction book

673791

GB - 04.2002

www.hardi-international.com

Page 2

We congratulate you for choosing a HARDI plant protection

product. The reliability and efficiency of this product depend

upon your care. The first step is to carefully read and pay attention to this instruction book. It contains essential information

for the efficient use and long life of this quality product.

llustrations, technical information and data in this book are to the best of our belief

correct at the time of printing. As it is HARDI INTERNATIONAL A/S policy permanently to

improve our products, we reserve the right to make changes in design, features,

accessories, specifications and maintenance instructions at any time and without notice.

HARDI INTERNATIONAL A/S is without any obligation in relation to implements

purchased before or after such changes.

HARDI INTERNATIONAL A/S cannot undertake any responsibility for possible omissions

or ina ccurac ies in this pub lic ati on, alt hou gh e ver ything p oss ible has been do ne to ma ke

it complete and correct.

.As this instruction book covers more models and features or equipment, which are

available in certain countries only, please pay attention to paragraphs dealing with

precisely your model.

Published and printed by HARDI INTERNATIONAL A/S

Page 3

Contents

EC Declaration of Conformity................................................... 2

Operator safety ........................................................................ 3

Description ............................................................................... 4

Function diagram ..................................................................... 5

Connecting the sprayer............................................................5

Transmission shaft ............................................................. 6

Mechanical remote control - HR only ................................. 8

Rear lights (if fitted) ............................................................ 8

Roadworthyness ................................................................ 8

Operating instructions .............................................................. 8

Filling the tank .................................................................... 8

Unfolding and folding the boom.......................................... 9

Boom height ....................................................................... 9

Pulsation damper ............................................................... 9

Adjustment of the BK controls..........................................10

Maintenance .......................................................................... 12

Cleaning the sprayer ........................................................ 12

Filters ............................................................................... 14

Lubrication ....................................................................... 15

Re-adjustment of the boom..............................................18

Recommended tyre pressure (only HR)........................... 18

Wheel nuts and bearings (only HR) ................................. 19

Changing of valves and diaphragms................................19

Changing the ball seat in operating unit........................... 20

Nozzle tubes and fittings .................................................. 20

Off-season storage........................................................... 21

Operational problems............................................................. 22

Technical specifications.......................................................... 24

Pictorial symbols .................................................................... 26

Assembly................................................................................ 27

Spare parts ............................................................................ 45

BOSS/HERON

Instruction book

673791-GB-04/2002

HARDI INTERNATIONAL A/S reserve the right to make changes in design or to add new features without

any obligation in relation to implements purchased before or after such changes.

1

Page 4

EC Declaration of Conformity

Manufacturer,

HARDI INTERNATIONAL A/S

Helgeshøj Allé 38

DK 2630 Taastrup

DENMARK

Importer,

declare that the following product;

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Adhere extra shipping package labels to inside cover.

A. was manufactured in conformity with the provisions in the COUNCIL

DIRECTIVE of 14 June 1989 on mutual approximation of the laws of the

Member States on the safety of machines (89/392/EEC as amended by

directives 91/368/EEC and 93/368/EEC) with special reference to Annex 1

of the Directive on essential safety and health requirements in relation to

the construction and manufacture of machines.

B. was manufactured in conformity with the standards current at that time

that implements a harmonised standard in accordance with Article 5 (2) and

other relevant standards.

Taastrup 03.04.2002

Lars Bentsen

Product Development Manager

HARDI INTERNATIONAL A/S

2

Page 5

Operator safety

Watch for this symbol . It means WARNING, CAUTION,

NOTE. Your safety is involved so be alert!

Note the following recommended precautions and safe operating

practices.

Read and understand this instruction book before using the

equipment. It is equally important that other operators of this

equipment read and understand this book.

Local law may demand that the operator be certified to use spray

equipment. Adhere to the law.

Pressure test with clean water prior to filling with chemicals.

Wear protective clothing.

Rinse and wash equipment after use and before servicing.

Depressurize equipment after use and before servicing.

Never service or repair the equipment whilst it is operating.

Disconnect electrical power before servicing.

Always replace all safety devices or shields immediately after

servicing.

If an arc welder is used on the equipment or anything connected

to the equipment, disconnect power leads before welding. Remove all inflammable or explosive material from the area.

Do not eat, drink or smoke whilst spraying or working with contaminated equipment.

Wash and change clothes after spraying.

Wash tools if they have become contaminated.

In case of poisoning, seek doctor or ambulance. Remember to

identify chemicals used.

Keep children away from the equipment.

Do not attempt to enter the tank.

If any portion of this instruction book remains unclear after read-

ing it, contact your HARDI dealer for further explanation before

using the equipment.

3

Page 6

We congratulate you for choosing a HARDI plant protection product.

The reliability and efficiency of this product depend on your care. The

first step is to carefully read and pay attention to this instruction

book. It contains essential information for the efficient use and long life

of this quality product.

As the instruction book covers all BOSS (BS) and HERON (HR) models, please pay attention to the paragraphs dealing with precisely your

model. This book is to be read in conjunction with the

“Spray Technique” book.

Description

The HARDI BS/HR sprayer is for the application of plant protection

chemicals. They consist of pump, operating unit, frame with tank and

spray boom.

The design of the diaphragm pump is simple, with easily accessible

diaphragms and valves that ensures liquid does not contact the vital

parts of the pump.

The tank, made of impact-proof and chemical resistant polyethylene,

has a purposeful design with no sharp corners, for easy cleaning.

The BK operating unit consists of; pressure agitator valve, safety valve,

main ON/OFF valve, pressure filter with pressure gauge, distribution valves

with pressure equalization and HARDI-MATIC pressure control valve.

HARDI-MATIC ensures a constant volume per hectare of the liquid

(l/ha) at varying speed in the same gear when the number of P.T.O. revolutions is between 300-600 r/min (800-1100 r/min for 1202/6.0 pumps).

The manually folded 6, 8 or 10 metre SB spray boom is fitted. It is

fitted with a spring loaded breakaway at the pivots and TRIPLET

SNAP-FIT nozzle bodies with COLOR TIP nozzles.

Identification plates

An identification plate fitted on the frame and pump is to indicate

model, year of production with serial number and country of origin. If

ordering spare parts, inform your dealer of these so the right model

and version are described.

4

Page 7

Function diagram

1a.Suction filter, BS 300

1b.Suction filter, BS/HR 800

2. Pump

3. Safety valve

4. Main ON/OFF valve

5. Pressure filter with pressure gauge

6. Distribution valves with pressure

equalization and extra valve for

spraygun

7. Pressure control valve with

HARDI MATIC

8. Sprayer boom

6

4

7

3

5

1b

1a

2

8

Connecting the sprayer

The BS 300 sprayer is designed for Cushman and Jacobsen tractors

and fitting brackets must be used. For other tractors special hitching

brackets must be manufactured.

T056-0001

The BS 800 sprayer is designed for TORO Workman 3200/3300.

The HR 800 sprayer can be connected to the tractor drawbar. The

standard drawbar is forked. Alternatively, a drawbar with ball hitch can

be supplied. Max driving speed for HR 800 is 25 km/h.

The standard pump is made for 540 r/min PTO. An alternative is model

1202 pump for 1000 r/min PTO.

5

Page 8

Transmission shaft

Operator safety

To avoid accidents and personal injuries, note the following recommended precautions and safe operation practices.

Always STOP ENGINE before attaching the transmission shaft to

tractor P.T.O. - most tractor P.T.O. shafts can be rotated by hand to

facillitate spline alignement, when engine is stopped.

When attaching the shaft, make sure that the snap lock is FULLY

ENGAGED - push and pull shaft until it locks.

WARNING: ROTATING TRANSMISSION SHAFTS WITHOUT PROTECTION GUARDS ARE FATAL.

Always keep protection guards and chains intact and make sure that it

covers all rotating parts, including CV-joints at each end of the shaft.

Do not use without protection guard.

Do not touch or stand on the transmission shaft when it is rotating safety distance: 1.5 meter.

Prevent protection guards from rotating by attaching the chains allowing sufficient slack for turns.

Make sure that protection guards around tractor P.T.O. and implement

shaft is intact.

Always STOP ENGINE and remove the ignition key before carrying out

maintenance or repairs to the transmission shaft or implement.

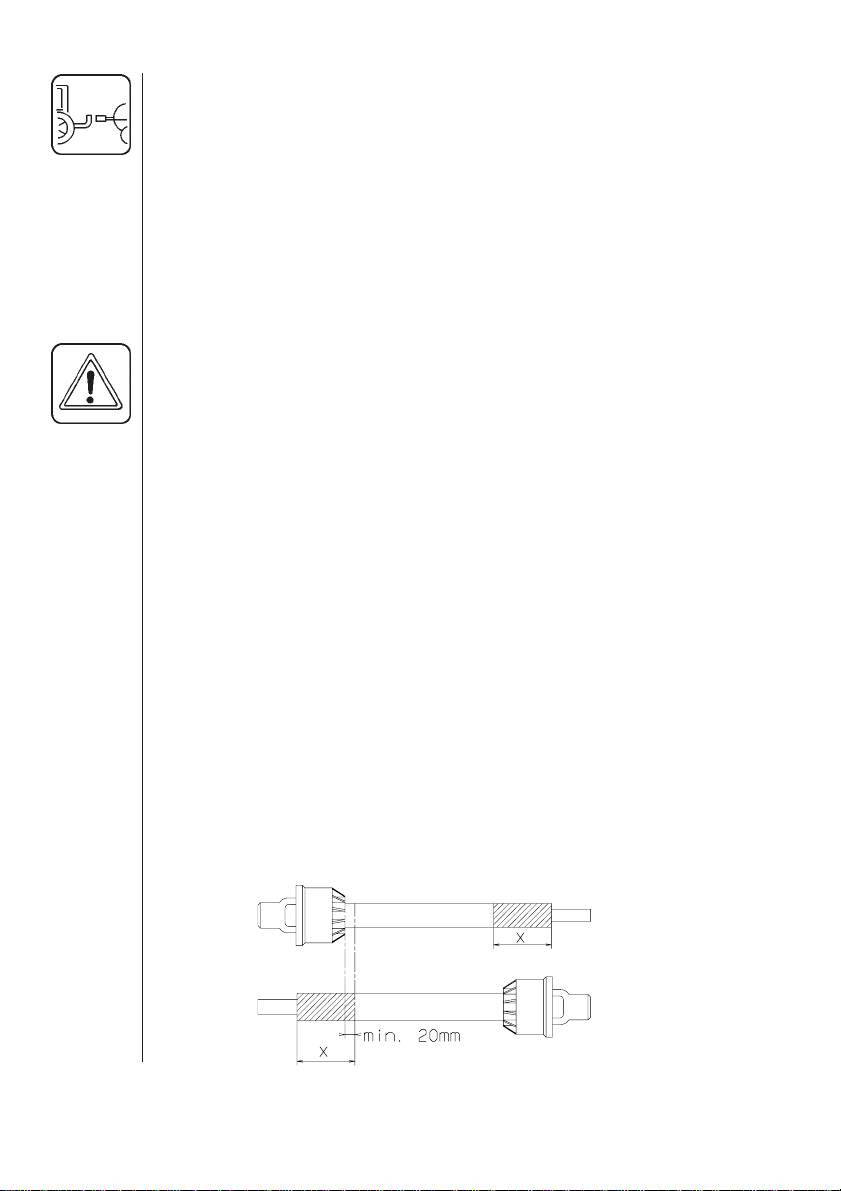

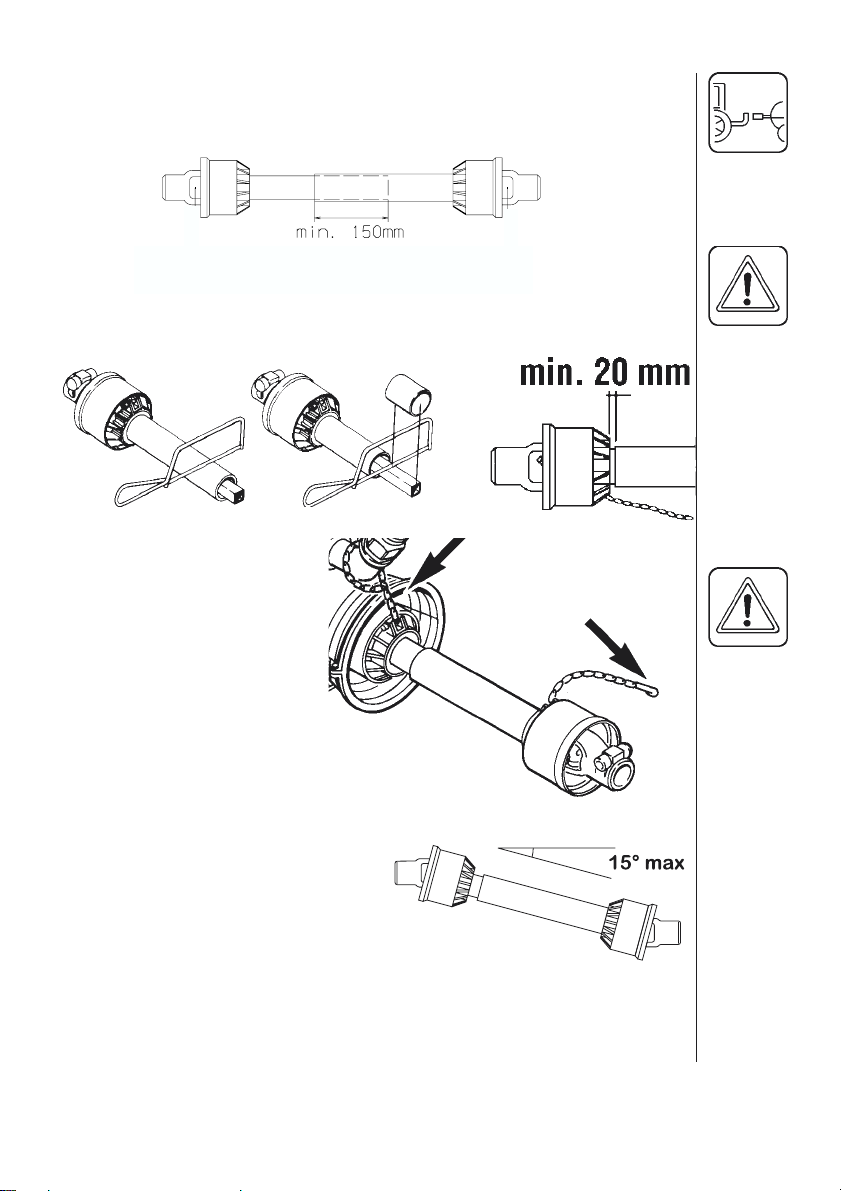

Installation of transmission shaft

Initial installation of the shaft is done as follows:

1. Attach sprayer to tractor and set sprayer in the position with short-

est distance between the tractor and sprayer pump P.T.O. shafts.

2. Stop engine and remove ignition key.

T259-0004

6

Page 9

3. If transmission shaft must be shortened, the shaft is pulled apart. Fit

the two shaft parts at tractor and sprayer pump and measure how

much it is necesary to shorten the shaft. Mark the protection guards.

T259-0004

NOTE: The shaft must always have a minimum overlap 150 mm.

4. The two parts are shortened equally. Use a saw, and file the profiles

afterwards to remove burrs.

5. Grease the profiles, and assemble male and female parts again.

T259-0005

6. Fit the shaft to tractor

and sprayer pump.

NOTE: Female part

towards tractor.

Fit the chains to prevent

the protection guards to

rotate with the shaft.

7. To ensure long life of the

transmission shaft, try to

avoid working angles

greater than 15°.

8. Transmission shafts with

cone must be fitted by

tightening the Allen

screw to a torque of

40 Nm. Check again after

2 minutes use.

T259-0007

7

Page 10

Mechanical remote control - HR only

The operating unit remote control is fitted at a convenient place in the

tractor cabin.

Rear lights (if fitted)

Connect plug for rear lights to the tractors 7-poled socket and check

that rear lights, stop lights and direction indicators work properly before

driving anywhere.

The wiring is in ISO accordance. See section on Technical specifications.

Roadworthyness

When driving on public roads and other areas where the highway code

applies, or areas where there are special rules and regulations for

marking the lights on implements, you should observe these and equip

implements accordingly.

Operating instructions

Filling the tank

It is recommended to use as clean water as possible for spraying

purposes. Always fill water through the strainer basket to prevent

foreign particles from entering the tank. An overhead tank can be used

in order to obtain high filling capacity.

WARNING: Do not let the filling hose enter the tank. Keep it outside

the tank, pointing towards the filling hole.

If the hose is lead into the tank and the water pressure drops at the

water supply plant, chemicals may be syphoned back and contaminate

the water supply lines, plant and well.

8

Page 11

Unfolding and folding the boom

The boom is operated as follows:

1. Remove boom transport

lock pins A.

2. Swing the boom down.

When unfolding (or folding)

the initial force to release

the spring loaded breakaway will be higher than the

actual unfolding/folding.

CAUTION: The breakaway

must be correctly tensioned

and lubricated.

(See section on Re-adjustment of the boom).

3. Unfold the outer sections.

Do not let the outer sections fall into place.

4. Reverse procedure to fold.

A

Boom height

Correct boom height is very important in order to obtain optimum distribution of the liquid (see “Spray Technique” book).

The boom height can be manually adjusted by removing the 4 bolts

keeping the boom on the frame.

NOTE: This is best done by 2 persons or by means of a hoist.

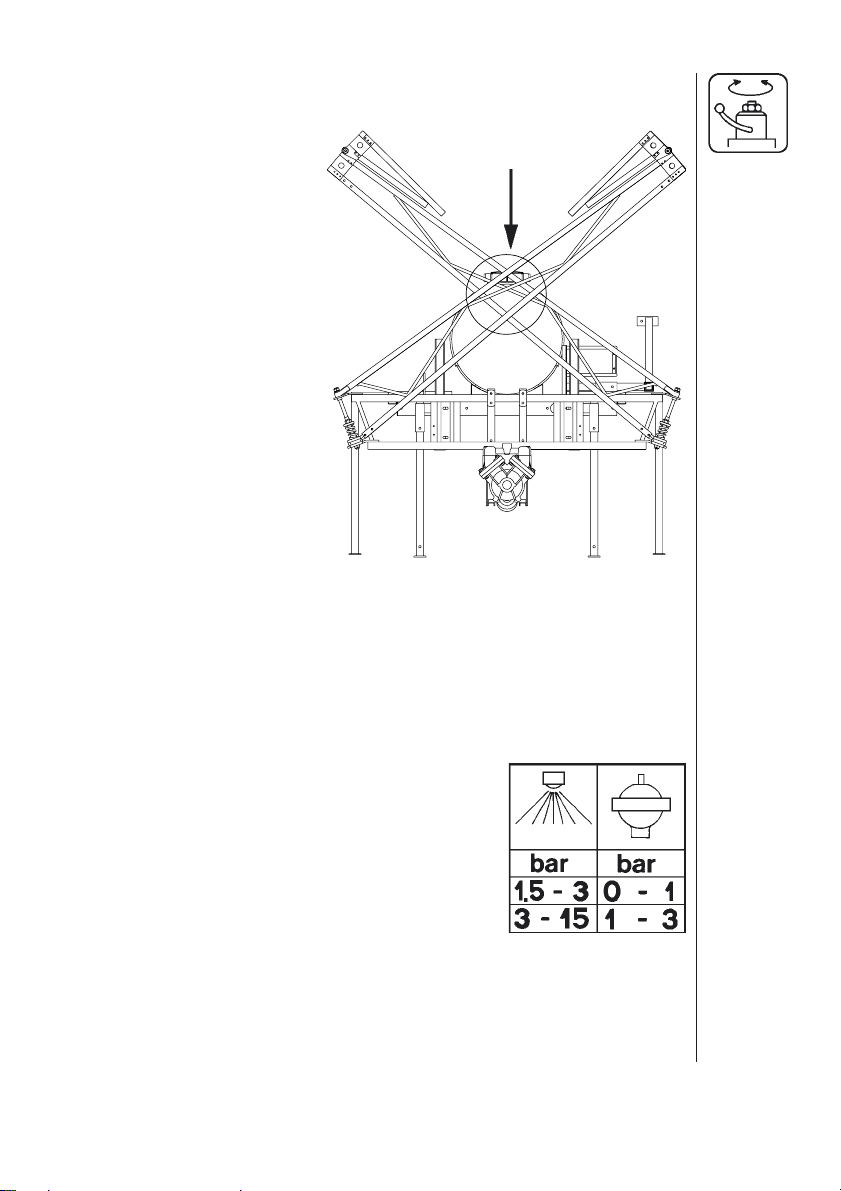

Pulsation damper

The air pressure in the pulsation damper is factory preset at 2 bar to cover spray working pressures between 3 and 15 bar. When using spray

pressures outside this range, the air pressure

should be adjusted as shown in the diagram. The

diagram is also embossed on the damper.

9

Page 12

2

B

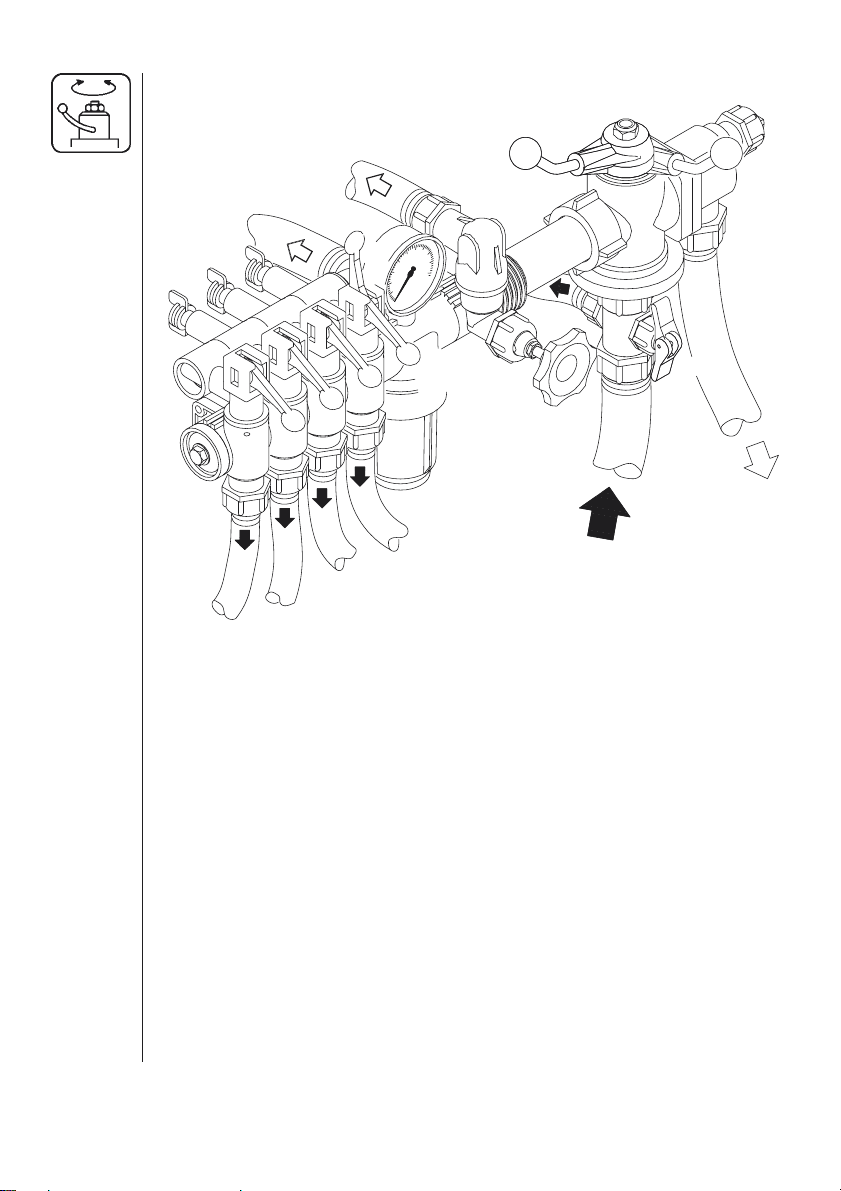

Adjustment of the BK controls

A

B

5

3

A

4

1

6

1. Choose the correct nozzle. Turn the TRIPLET nozzle bodies to the

suitable nozzle for the spray purpose. Make sure that all nozzles are

the same type and capacity. See “Spray Technique” book.

2. Open or close lever 1 depending on whether pressure agitation is

required. (Remember pressure agitation takes 5% to 10% of pump

output).

3. Turn main ON/OFF handle 2 to ON position A.

4. Set all hand levers 3 on the distribution valve to ON position A.

5. Turn the HARDI-MATIC valve 4 anti-clockwise to its extreme position.

6. Put the tractor in neutral and adjust the P.T.O. thereby the number

of revolutions of the pump corresponding to the intended travelling

speed.

NOTE: For units with 540 r/min P.T.O., the revolutions must be kept

between 300-600 r/min.

NOTE: For units with 1000 r/min P.T.O., the revolutions must be

kept between 800-1100 r/min.

7. Adjust the HARDI-MATIC valve 4 so that the pressure gauge indi-

cates the recommended pressure.

T020-0025

10

Page 13

ADJUSTMENT OF PRESSURE EQUALIZATION:

8. Place the first lever 3 on the distribution valve in OFF position B.

9. Turn the adjusting screw 5 until the pressure gauge again shows the

same pressure.

10.Adjust the other sections of the distribution valve in the same way.

Hereafter adjustment of pressure equalization will only be needed if

you change to nozzles of other capacities.

OPERATING THE CONTROL UNIT WHILE DRIVING:

11.To stop the liquid flow to the boom turn the ON/OFF handle 2 to

OFF position B. This returns the pump output to the tank through

the return system. The diaphragm anti-drip valves ensure instantaneous closing of all nozzles.

To stop the liquid flow to one or more boom sections, turn lever 3 of

the distribution valve to OFF position B for the section to be closed.

The pressure equalization ensures that the pressure does not rise in

the sections which are to remain open.

OPERATING THE EXTRA VALVE

12.A spray gun can be connected to the control unit. When using this

function, set hand levers 3 for the boom section to OFF position B.

Screw the adjusting screws 5 in to prevent liquid returing to the tank.

Set hand lever 6 to ON position A.

Operation of the tank drain valve (only 800 l tank)

To open: A

To close: B

Spray Technique - see separate book.

Optional Extras - see separate books.

11

Page 14

Maintenance

In order to derive full benefit from the sprayer for many years the following few but important rules should be kept:

Cleaning the sprayer

Guidelines

Read the whole label of the chemical. Take note of any particular

instructions regarding recommended protective clothing, deactivating

agents, etc. Read the detergent and deactivating agent labels. If cleaning procedures are given, follow them closely.

Be familiar with local legislation regarding disposal of pesticides

washings, mandatory decontamination methods, etc. Contact the

appropriate body, eg. Dept of Agriculture.

Pesticide washings can usually be sprayed out on a soakaway. This is

an area of ground that is not used for cropping. You must avoid seepage or run-off of residues into streams, water courses, ditches, wells,

springs, etc. The washings from the cleaning area must not enter

sewers. Drainage must lead to a soakaway.

Cleaning starts with the calibration, as a well calibrated sprayer will

ensure the minimal amount of remaining spray liquid.

It is good practice to clean the sprayer immediately after use thereby

rendering the sprayer safe and ready for the next pesticide application.

This also prolongs the life of the components.

12

It is sometimes necessary to leave spray liquid in the tank for short

periods, eg. overnight, or until the weather becomes suitable for spraying again. Unauthorized persons and animals must not have access to

the sprayer under these circumstances.

If the product applied is corrosive, it is recommended to coat all metal

parts of the sprayer before and after use with a suitable rust inhibitor.

Remember: Clean sprayers are safe sprayers.

Clean sprayers are ready for action.

Clean sprayers can not be damaged by pesticides and

their solvents.

Cleaning

1. Dilute remaining spray liquid in the tank with at least 10 parts water

and spray the liquid out in the field you have just sprayed.

Page 15

NOTE: It is advisable to increase the forward speed (double if possible) and reduce the pressure. For S4110 nozzles, pressure may

be reduced to 1.5 bar.

2. Select and use the appropriate protective clothing. Select detergent

suitable for cleaning and suitable deactivating agents if necessary.

3. Rinse and clean sprayer and tractor externally. Use detergent if

necessary.

4. Remove tank and suction filters and clean. Be careful not to damage

the mesh. Replace suction filter top. Replace filters when the

sprayer is completely clean.

5. With the pump running, rinse the inside of the tank. Remember the

tank roof. Rinse and operate all components and any equipment

that has been in contact with the chemical. Before opening the

distribution valves and spraying the liquid out, decide whether this

should be done in the field again or on the soakaway.

6. After spraying the liquid out, stop the pump and fill at least 1/5 of the

tank with clean water. Note that some chemicals require the tank to

be completely filled. Add appropriate detergent and/or deactivating

agent, eg. Washing soda or Triple ammonia.

NOTE: If a cleaning procedure is given on the chemical label, follow

it closely.

7. Start the pump and operate all controls enabling the liquid to come

in contact with all the components. Leave the distribution valves

until last. Some detergents and deactivating agents work best if left

in the tank for a short period. Check the label.

If fitted the Self-Cleaning Filter can be flushed by removing the

bypass hose from the bottom of the filter. Stop the pump and remove the hose. Start the pump for a few seconds to flush filter. Be

careful not to loose the restrictor nozzle.

8. Drain the tank and let pump run dry. Rinse inside of tank, again

letting the pump run dry.

9. Stop the pump. If the pesticides used have a tendency to block

nozzles and filters, remove and clean them now. Check also for

sediment on the pressure side of the safety valve for the Self-Cleaning Filter.

10. Replace all the filters and nozzles and store the sprayer. If, from

previous experiences, it is noted that the solvents in the pesticide

are particularly aggressive, store the sprayer with the tank lid open.

NOTE: If the sprayer is cleaned with a high pressure cleaner we

recommend lubrication of the entire machine.

13

Page 16

Filters

Clean filters ensure :

• Sprayer components such as valves, diaphragms and operating unit

are not hindered or damaged during operation.

• Nozzle blockages do not occur whilst spraying.

• Long life of pump. A blocked suction filter will result in pump cavitation.

Suction filter

The main filter protecting sprayer components is the suction filter.

Check it regularly.

The BS 300 sprayer has a suction filter placed in the bottom of the tank.

The BS/HR 800 has a suction filter placed in the top of the tank.

BK Pressure filter / In Line Filters (if fitted)

The BK operating unit has an in-built pressure filter. Unscrew the filter

bowl to inspect and clean the filter.

The boom may be equipped with In Line Filters. Unscrew the filter bowl

to inspect and clean the filter.

Alternative filters are available. See section on Technical specifications

- Filters and nozzles.

14

Page 17

Lubrication

Recommended lubrication is shown in following table. Use ball bearing

grease (lithium grease No. 2).

Note: If the sprayers are cleaned with a high pressure cleaner or fertilizer has been used, we recommend lubrication of all sections and all

metal parts by means of corrosion protective oil.

5

Position on sprayer

Operation hours

4

Oil

Grease

5

1

Page to find more

information

Winter protection/

off-season storage

3

2

15

Page 18

1X40

2

AX8

AX40

3X 40

17

6

9

16

T200-0001

Page 19

4X40

5X 40

HR only

X

1000

or once a year

16

16

17

Page 20

Re-adjustment of the boom

After having used the sprayer for some days the boom should be

adjusted according to the following instructions:

Carry adjustments out in the following order.

NOTE: Tractor and sprayer must be on level ground.

Sprayer must be lubricated. See section on Lubrication.

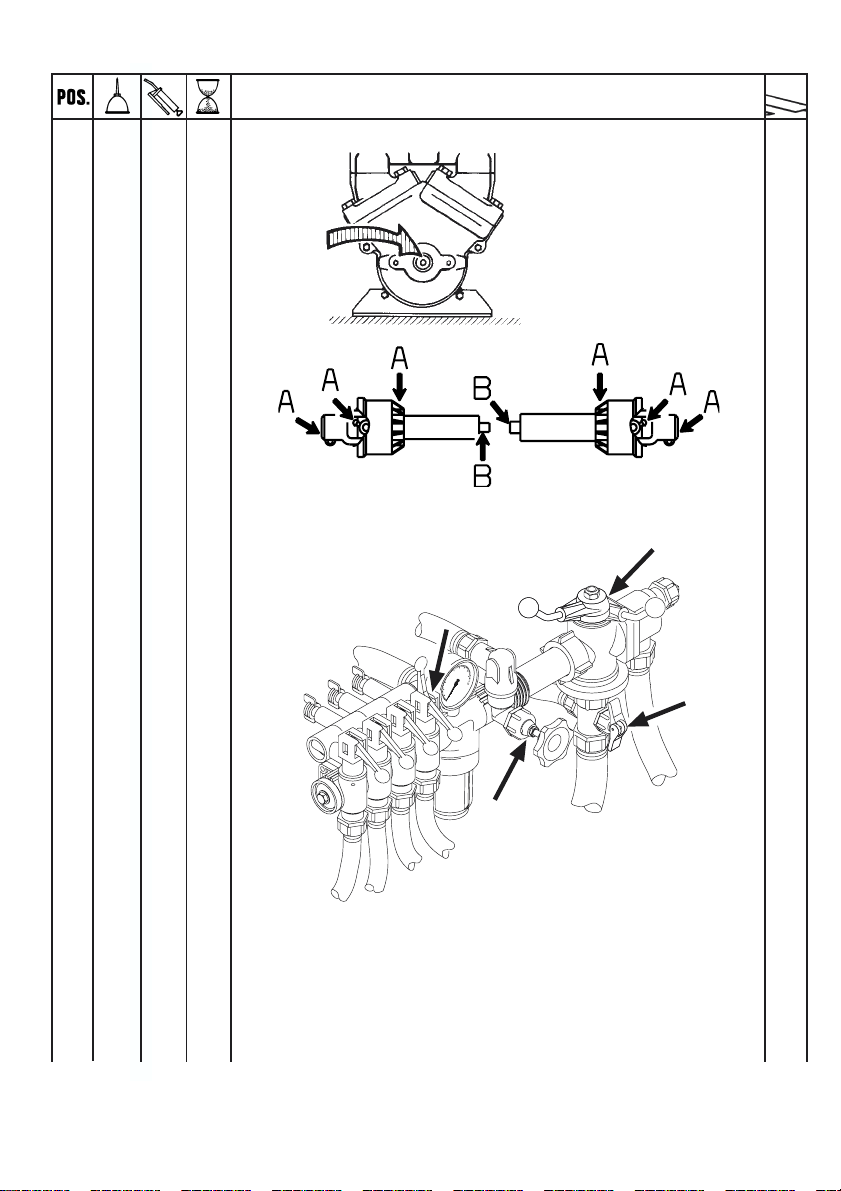

Boom breakaway

The function of the breakaway is

to prevent or reduce boom damage if it should strike an object or

the ground. If it is too tight, it will

not function. If it is too loose, it will

yaw (forward and back movement).

Slacken screw nut A to decrease

breakaway resistance. Do not

tighten excessively; better too

loose than too tight. Again minor

adjustments in the field may be

necessary.

Ensure also channel bolts B are

tight.

C

18

Outer section (8 and 10 m only)

The hinge should be firm. If too

tight it is difficult to fold. To adjust, tighten or loosen nuts C.

Recommended tyre pressure (only HR)

The tyres should not run under-inflated. This only promotes instability

and rapid wear.

Tyre size : 26" x 12"

Pressure :1.6 bar (24 p.s.i.)

The pressure is specified for a full loaded trailer.

Remember it is easier to let off a little pressure for a specific use than

to re-inflate a tyre in mid-field.

Page 21

Wheel nuts and bearings (only HR)

Check wheel nut tension after the first 8 working hours, hereafter every

50 hours.

Check roller bearing slack after the first 8 hours and 50 hours.

Thereafter every 100 hours.

If necessary, adjust as follows

1. Jack wheel up. It is best to remove the wheel.

2. Remove hub cap A and split pin B.

3. Shaft nut C is tightened until slight

rotation resistance of drum is noted.

4. Now loosen shaft nut until first split

pin hole is visible.

5. Insert split pin and replace hub cap.

After 1000 hours or once a year, the

axle bearings are greased.

Changing of valves and diaphragms

Valves

Remove valve cover 1. Before changing the valves 2 note their orientation so they are replaced correctly.

It is recommended to use new gaskets 3 when changing or checking

the valves.

19

Page 22

Diaphragms

Remove the diaphragm cover 4. The diaphragm 5 may then be

changed. If fluids have reached the crankcase, re-grease the pump

thoroughly. Check also the drain hole at the bottom of the pump is not

blocked. Reassemble with the following torque setting.

Pump Valve cover Diaphragm Diaphragm

Model Nm cover Nm bolt Nm

1302 45 50 25

1202 70 70 60

1 Nm = 0.74 ft-lb

Changing the ball seat in operating unit

If the main ON/OFF valve does not seal properly

(dripping nozzles when main ON/OFF valve

is closed), the ball and seat should

be checked.

Remove the 2 bolts fixing

the main ON/OFF-pressure valve unit to the

bracket, unscrew the

union nut A and pull the

valve away from the distribution valves.

Check the ball for sharp edges and scratches, and check the ball seat

for cracks and wear - replace if necessary.

A

Nozzle tubes and fittings

Poor seals are usually caused by;

• missing O-rings or gaskets

• damaged or incorrectly seated O-rings

• dry or deformed O-rings or gaskets

• foreign bodies

T199-0001

20

Page 23

Therefore, in case of leaks: DO NOT overtighten. Disassemble, check

condition and position of O-ring or gasket, clean lubricate and reassemble. The O-ring should be lubricated ALL THE WAY ROUND

before fitting on to the nozzle tube.

For radial connections only hand tighten.

For axial connections, a little me-

chanical leverage may be used.

T199-0002

Off-season storage

When the spraying season is over you should devote some extra time

to the sprayer before it is stored.

Hoses

Check that none of the hoses are cut or have sharp bends.

A leaky hose can give an annoying delay in the middle of the spraying

job. Therefore check all the hoses and replace them if there is any

doubt about the durability.

Paint

Some chemicals are very rough on paints. It is therefore well advised

to remove rust, if any, and then touch up the paint.

Tank

Check that no chemical residues are left from the last spraying. Chemical residues must not be left in the tank for a long time. It will reduce

the life of the tank. See section on Cleaning the sprayer.

Transmission shaft

Check that the shaft fullfils its security purpose, e.g. that shields and

protective tubes are intact.

Anti-freeze precaution

If the sprayer is not stored in a frost free place you should take the

following precautions: Put at least 10 litres of 33% anti-freeze mixture

in the tank and let the pump run a few minutes so that the entire system including spray hose are filled. The anti-freeze solution also hinders the O-rings and gaskets from drying out.

Remove the glycerine filled pressure gauge and store it frost free in

vertical position.

21

Page 24

Operational problems

In cases where breakdowns have occurred the same factors always

seem to come into play:

• Minor leaks on the suction side of the pump will reduce the pump

capacity or stop the suction completely.

• A clogged suction filter will hinder or prevent suction so that the

pump does not operate satisfactorily.

• Clogged up pressure filters will result in increasing pressure at the

pressure gauge but lower pressure at the nozzles.

• Foreign bodies stuck in the pump valves with the result that these

cannot close tightly against the valve seat. This reduces pump

efficiency.

• Poorly reassembled pumps, especially diaphragm covers will allow

the pump to suck air resulting in reduced or no capacity.

Therefore ALWAYS check

1. That suction, pressure and nozzle filters are clean.

2. Hoses for leaks and cracks, paying particular attention to suction

hoses.

3. Gaskets and O-rings are present and in good condition.

4. Pressure gauge is in good working order. Correct dosage depends

on it.

5. Operating unit functions properly. Use clean water to check.

22

Fault Probable cause Control / remedy

Liquid system

No spray from

boom when

turned on.

Air leak on suction.

Air in system.

Suction/pressure

filters clogged.

Check if red suction lid/O-ring are

sealing.

Check suction tube and fittings.

Check tightness of pump diaphragm

and valve covers.

Fill suction hose with water for initial

prime.

Clean filters.

Check yellow suction pipe is not

obstructed or placed too near the

tank bottom (only 800 l tank).

Page 25

Fault Probable cause Control / remedy

Lack of

pressure.

Pressure

dropping.

Pressure

increasing

Formation of

foam.

Incorrect assembly.

Pump valves blocked

or worn.

Defect pressure

gauge.

Filters clogging.

Nozzles worn.

Tank is airtight.

Sucking air towards

end of tank load.

Pressure filters

beginging to clog.

Agitation nozzles

clogged.

Air is being sucked

into system.

Excessive liquid

agitation.

Agitation nozzles not fitted.

Too little distance between yellow

suction pipe and tank bottom (only

800 l tank).

Check for obstructions and wear.

Check for dirt at inlet of gauge.

Clean all filters. Fill with cleaner

water.

If using powders, make sure

agitation is on.

Check flow rate and replace nozzles

if it exceeds 10%.

Check vent is clear.

Exessive agitation, turn off.

Returns inside tank need relocation.

Clean all filters.

Check by turning agitation off/on.

Check tightness / gaskets / O-rings

of all fittings on suction side.

Turn agitation off.

Reduce pump r/min.

Ensure returns inside tank are

present.

Liquid leaks

from bottom of

pump.

Damaged diaphragm.

Use foam damping addative.

Replace. See Changing of valves

and diaghragms.

23

Page 26

Technical specifications

Measure and weight

AB

C

C

24

AB

Model Boom width Pressure Dimension

BS 300 6 SB 15 265 x 195 x 192/225

BS 300 8 SB 15 265 x 195 x 237/270

HR 800 6 SB 15 310/350 x 195 x 180/230

HR 800 8 SB 15 310/350 x 195 x 225/275

m max. bar A x B x C

Weight:

BS 300: from 172 - 213.5 kg depending on model

BS 800: from 234 - 256 kg depending on model

Page 27

Pump power consumption and capacity

1202/6.0

bar l/min kW l/min kW l/min kW l/min kW l/min kW

0 46 58 72 95 112

531 39 47 62 77

10 30 37 44 59 73

15 28 35 42 55 69

Rotation per min. r/min Capacity l/min Suction height 0,0 m

Power consumption kW Max. pressure 15 bar Weight 24,0 kg

1202/9.0

bar l/min kW l/min kW l/min kW l/min kW l/min kW

0 56 0,91 72 1,28 93 1,52 99 1,63 112 1,79

5 40 1,11 53 1,36 66 1,60 71 1,71 79 1,86

10 38 1,38 52 1,74 64 1,79 69 1,87 77 2,07

15 37 1,60 50 1,97 62 2,32 67 2,48 75 2,76

Rotation per min. r/min Capacity l/min Suction height 0,0 m

Power consumption kW Max. pressure 15 bar Weight 24,0 kg

1302/9.0

bar l/min kW l/min kW l/min kW l/min kW l/min kW

0 63 0,90 84 1,19 103 1,51 114 1,61 125 1,80

5 58 0,94 79 1,29 96 1,61 105 1,75 116 1,93

10 56 1,30 76 1,80 94 2,30 101 2,48 111 2,72

15 55 1,80 74 2,22 93 2,92 99 3,18 109 3,54

Rotation per min. r/min Capacity l/min Suction height 0,0 m

Power consumption kW Max. pressure 15 bar Weight 35,0 kg

400 500 600 800 1000

300 400 500 540 600

300 400 500 540 600

r/min

r/min

r/min

Rear lights connection diagram

Position Wire colour

1. LH direction indicator Yellow

2. Free Blue

3. Frame White

4. RH direction indicator Green

5. RH rear position lamp Brown

6. Stop lamps Red

7. LH rear position lamp Black

1

6

5

2

7

3

4

25

Page 28

Filters and nozzles

30 mesh suction filter

(only BS/HR 800)

50 mesh operating

unit/pressure filter

Mesh 30 50 80 100

GBRY

0.58 0.30 0.18 0.15

G= Green B= Blue R= Red Y= Yellow

50 mesh nozzle filters

Temperature and pressure ranges

Operating temperature range : 2° to 40° C.

Operating pressure for safety valve : 15 bar

Materials and recycling

Tank HDPE

Hoses PVC

Fittings PA

Disposal of the sprayer

When the equipment has completed its working life, it must be thoroughly cleaned. The tank, hose and synthetic fittings can be incinerated at an authorized disposal plant. The metallic parts can be

scrapped. Always follow local legislation regarding disposal.

26

Pictorial symbols

Description

Function

Connection

Warning

Operating

Service/adjustment

Liquid flow

Pressure

Cleaning

Lubrication

Winter

storage

Operational

problems

Technical specifications

EC Declaration

of Conformity

Page 29

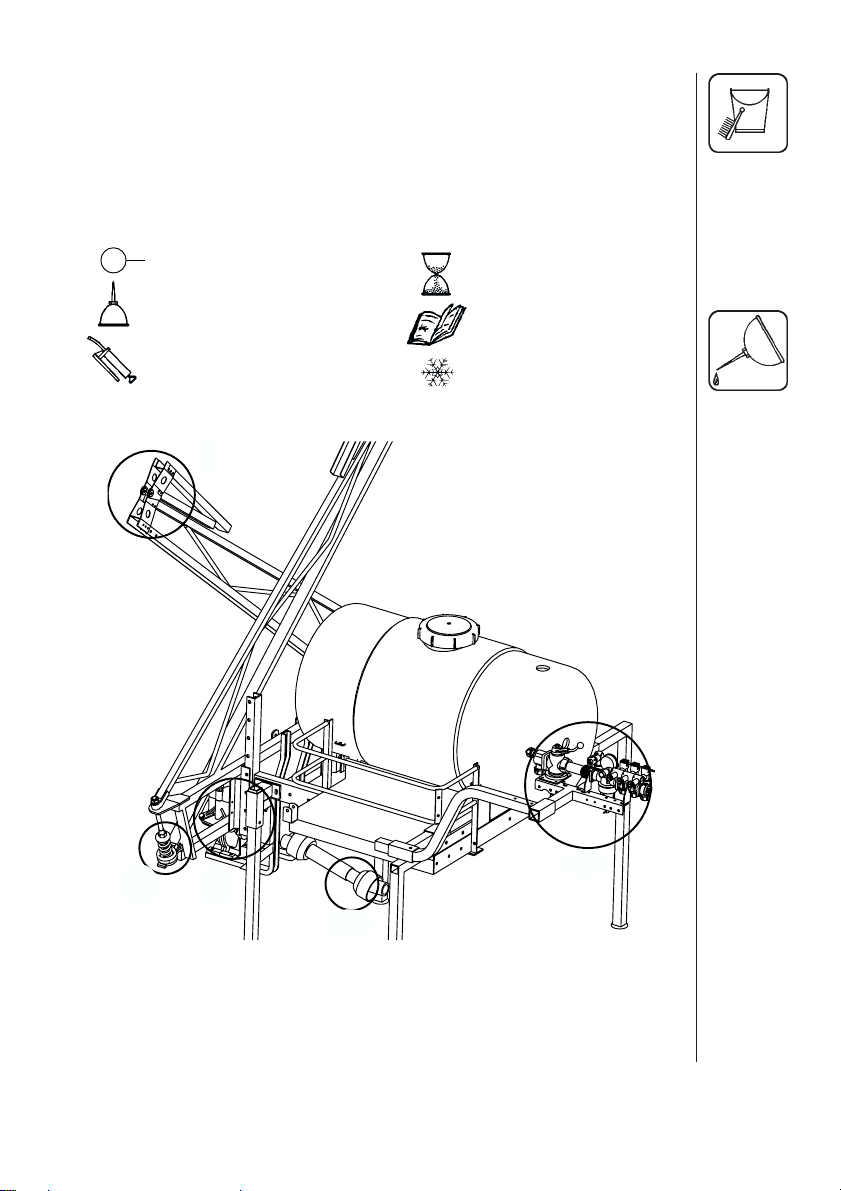

Assembly

Preassembly information

The sprayer is supplied ex-works in shipping packages (SP). Number

of SP’s per sprayer varies depending on model.

As this covers all BS/HR models, please note the fittings covering

exactly your model.

NOTE: Removal of the plastic bag covering the tank is easiest done

before assembly.

Some components are shipped within the tank. Check inside.

To verify connection of hoses, a function diagram is included on the

last page.

Packaging information

Materials used for packaging are environmentally compatible. They

can be safely deposited or they can be burnt in an incinerator.

Recycling

Cardboard: Can recycle up to 99% and therefore should be put into

the waste collection system.

Polystyrene foam: Can be recycled. Fluorocarbons (CFC) not used in

foam production. Polyethylene: Can be recycled.

NOTE: Use O-rings where indicated. Lubricate them with non-mineral

lubricant (silicon oil) before assembly. Where O-rings are not indicated,

use sealing tape.

Check that all shipping packages are present.

T159-0001

27

Page 30

BS 300 sprayer

1. Fit rear brackets for support legs.

The 4 legs to be mounted in

brackets and platform. Use crane

or be 2 persons for the job. Lock

with split bolts for your safety.

T142-0016

28

2. Remove plastic protection

from the tank. Use profile

strips before the tank is

placed in its frame. Strips

and tank are fixed with

tank straps. Remember

the socket in one end of

the tank must point forward.

T142-0019

Page 31

3. Fit straight bracket in right hand side of

platform and then S-shaped bracket and

operating unit arm.

4. Main ON/OFF handle

1B is closed. Put ball

into the handle and

turn it to working

position 1A, whereby

the ball disappears

into the operating unit.

Fit ball seat on distribution valves which

are tightened to the

main ON/OFF part. Fit

the operating unit with

snap screws and

plastic nuts.

T140-0023

T140-0022

29

Page 32

5. Screw pressure gauge on with teflon

tape to filter body . Do not overtighten.

See back of gauge. Remember to

pierce casing after installation.

6. Fit angle bracket

to frame and fit

central section to

angle bracket.

Clamp and nozzle

screen are placed

on central section.

Mount 6 m SB

outer section or

8 m SB intermediate/outer

sections.

Be careful when

folding the boom

for the first time

(see section on

Re-adjustment

of the boom).

T140-0005

30

T153-0004

Page 33

8m SB

T153-0005

6m SB

M10x65

7. Tighten transport bracket

of sprayer boom:

6 m SB: First fold right outer

section - fit lock.

8 m SB: Fit transport bracket on

central section.

8. Use sealing tape on pump suction

and pressure fittings. Mount pulsation dampers (O-ring diameter

30/26x2).Fit bottom half of the

yellow protection guard. Lubricate

conical shaft, connect the transmission shaft and fit upper part of

guard. Recheck the grub screw

is tight after 5 min. of usage.

A. Suction from tank

B. Pressure to operating

unit

T153-0006

T141-0008

31

Page 34

9. For model 1202 pump, use pump socket with reinforcement which

must be placed outward. Tighten pump socket to central section.

Fix the chain of the transmission shaft to prevent the protection

tubes from rotating.

T141-0006

10.Nozzle tubes are

supplied with one

lock nozzle saddle per tube A.

The rest can slide

lengthwise B

allowing for extension and

contraction.

32

A

B

T145-0010

Page 35

11.Tubes and hoses are connected. Fit tubes using synthetic nut.

Press down (1), turn (2). Do not over-tighten. Fit filter and COLOR TIPS.

REMEMBER: Lubricate O-rings before fitting.

8m SB

6m SB

8m SB

T145-0012

T145-0011

T145-0013

12.Adjust mounting

bracket of tank

frame to your tractor.

Connect the sprayer.

Shorten, if necessary, the transmission shaft.

Adjust operating

unit bracket.

T145-0009

33

Page 36

A. Suction hose of pump

B. Pressure hose of pump

C.By-pass to main ON/OFF valve

H.By-pass to HARDI-MATIC

E. By-pass for pressure equalization

valves

F. Feed hoses for boom

Secure hoses with plastic straps.

Check they do not foul. Shorten

if necessary.

Test the sprayer with clean water

and check for leaks. Tighten if

necessary.

T145-0008

34

T142-0017

Page 37

BS 800 sprayer

1. Fit front and

rear support legs

to mainframe. Use

crane or be 2 persons for

the job.

Lock with split bolts for your safty.

2. Tighten bracket and hole profile

together with the tank frame and

mainframe.

3. Fit footboard on the right side of

mainframe.

T142-0018

T142-0006

35

Page 38

4. Fit bracket to the right

front support, then fold

away mechanism and

operating unit arm.

(If equiped fit Foam

marker bracket).

5. Fit angle brackets to frame and

central section to angle brackets. Fit clamp and nozzle

screen to central section. Mount

intermidiate/outer

sections.

Be careful when

folding the boom

for the first time.

(See section

on readjustment of the

boom).

T142-0007

36

T153-0001

Page 39

6. Tighten boom

transport bracket.

M10x65

First fold right hand

intermidiate/outer

sections.

Fit lock.

7. 10 m SB ONLY: Fit

outer section locks.

T153-0006

8. See BS 300 point 8

9. Fit pump bracket to central section.

Note: The reinforcement must be

placed outward. Fix the chain of

the transmission shaft to prevent

the protection tubes from rotating.

10m SB

T153-0007

T141-0006

37

Page 40

10. See BS 300 punkt 10 and 11

11. Close main ON/OFF

handle (1B) on the

operating unit. Put the

ball into the handle

and turn it to working

position, Whereby the

ball dissapears into the

operating unit. Fit ball

seat on distribution

valves which are tightened to the main ON/

OFF. part. Use screws

and plastic nuts to fit

the operating unit.

T140-0007

12. Use sealing tape

on the pressure

gauge. See back

of pressure gauge.

Pierce casing and

fit gauge.

Do not tighten

by twisting the

gauge casing use spanner. Do

not overtighten.

38

T140-0022

T140-0005

Page 41

13. Fit hoses to operating unit and tank.

A Pump suction hose.

B Pump pressure hose.

C By-pass to main ON/OFF handle.

D Pressure agitation.

E By-pass to pressure equalization.

F Feed hoses to boom

H By-pass to HARDI MATIC

Secure hoses with plastic straps.

Check that hoses do not foul in spraying or transport position.

T142-0020

39

Page 42

14. Fit mounting bracket to frame

of vehicle. Connect sprayer to

vehicle. Shorten if necessary,

the transmission shaft. See

instruction book on connecting the sprayer.

15. The sprayer is tested with water at high pressure in order to reveal possible

leakages. Leakages must be sealed.

Optional extras:

16. Bracket for hose

reel is fitted on

the left side of

the rear tankframe support.

T142-0007

40

T164-0004

Page 43

17. The HARDI FILLER is fitted on the left side of the mainframe.

T164-0005

18. Bracket for 15L

clean water tank

is to be fitted on

the left side of the

front tankframe

support.

T164-0006

41

Page 44

19.Bracket for Foammarker tanks is to

be fitted on the right

side of the rear

tankframe support.

T164-0007

20. HARDI® Nozzle

Booklet.The self

cleaning filter is

fitted to the

operating unit

arm using the ushaped clamp.

42

T164-0008

Page 45

HR 800 sprayer

1. Fit wheels and nose wheel on

frame. Fit hole profile 40 x 40 mm

(length 2.2 m) on frame with

U-bracket. Place rear A

and front B

trestles and

then pump

bracket C.

2. Tighten bracket and hole profile D together

with tank frame and trestle. The position of

tank/trestles can be changed according to

wish - tighten U-brackets E on frame.

C

43

Page 46

3. See BS 800 point 6.

4. See BS 800 point 7 and 8.

5. Place tubes and hoses. Do not forget to lubricate. Fit tubes with synthetic

nut. Press 1 down and turn 2. Do not overtighten. Fit filter and COLOR TIPS.

10m SB

8m SB

T145-0012

6. See BS 300 point 8.

7. See BS 800 point 12,13 and 14.

T145-0011

6m SB

T145-0013

44

Page 47

1202/foot A10

45

Page 48

A12 1302/foot47Unit BK 180K (92) B9

46

Page 49

Page 50

B10 Distributor BK180K (92)

48

Page 51

Damper HJ73 B300

49

Page 52

D2 SB 6/8/10 m

50

Page 53

Boom tube TRIPLET SNAP-FIT D904

51

Page 54

H106 PS 300

52

Page 55

TPS 800 H107

53

Page 56

H108 PU/TPS 80055Shaft (94) K604

54

Page 57

HELGESHØJ ALLÉ 38 • DK 2630 TAASTRUP • DENMARK

HARDI INTERNATIONAL A/

0396

EN 1152 / ISO 5674

POS.

AX 8

BX 40

rpm kW Nm

540 12 210

1000 18 172

S

HARDI

978389

Page 58

56

Page 59

Spare parts

To see updated spare part information the website

www.agroparts.com can be visited. Here all parts

information can be accessed when free registration

has been made.

Page 60

HARDI INTERNATIONAL A/S

Helgeshøj Allé 38 - DK 2630 Taastrup - DENMARK

Loading...

Loading...