Page 1

The Sprayer

Operator’s Manual

CONTROLLER

HC 8600/9600

Instruction book - SW 1.X

67025303 - Version 1.00

US - 03.2017

Page 2

Page 3

CONTROLLER

HC 8600/9600

Instruction book - SW 1.X

67025303 - Version 1.00

US - 03.2017

HARDI® reserves the right to make changes in design, material, or specification without notice thereof.

HARDI® and other product names are registered trademarks of HARDI® Inc. in the U.S. and in other countries.

Page 4

Page 5

Table of Contents

Table of Contents

1 - Welcome

Welcome letter ......................................................................................................................................7

HC 8600 and HC 9600 .............................................................................................................................8

About this Instruction Book ............................................................................................................................................................................. 8

Differences between the Controllers ........................................................................................................................................................8

2 - Safety Notes

Operator Safety .....................................................................................................................................9

Symbols ........................................................................................................................................................................................................................ 9

Precautions ................................................................................................................................................................................................................ 9

3 - Description

Display .................................................................................................................................................11

General info ............................................................................................................................................................................................................ 11

System Uses ............................................................................................................................................................................................................ 11

System Features ................................................................................................................................................................................................... 11

Display Hardware ................................................................................................................................................................................................ 12

USB Flash Drive ..................................................................................................................................................................................................... 13

ISOBUS Technology ........................................................................................................................................................................................... 13

Color Touch Screen ........................................................................................................................................................................................... 13

Gestures .................................................................................................................................................................................................................... 14

Screen Icon Conventions ............................................................................................................................................................................... 15

Initial Start-up .....................................................................................................................................16

General info ............................................................................................................................................................................................................ 16

Initial Setup Wizard ............................................................................................................................................................................................ 16

Home Screen Layout ........................................................................................................................................................................................ 17

Status Indicators .................................................................................................................................................................................................. 18

Map Screen ..........................................................................................................................................19

Work Screen ........................................................................................................................................................................................................... 19

Map Toolbox ........................................................................................................................................22

Legend Settings ................................................................................................................................................................................................... 22

Map Options .......................................................................................................................................................................................................... 23

Map Shift .................................................................................................................................................................................................................. 24

Split-Screen Map ................................................................................................................................................................................................. 26

Markers tab .............................................................................................................................................................................................................. 27

Video ........................................................................................................................................................................................................................... 27

AgFiniti ................................................................................................................................................28

General Info ............................................................................................................................................................................................................ 28

AgFiniti Mobile Connection Types ........................................................................................................................................................... 28

Miscellaneous ......................................................................................................................................29

About AutoTerrain/AutoHeight ................................................................................................................................................................. 29

Glossary of Application Settings ................................................................................................................................................................ 29

4 - System setup

Installation ..........................................................................................................................................31

Installation Instructions ................................................................................................................................................................................... 31

Cable connections ............................................................................................................................................................................................. 32

Initial Start-up .....................................................................................................................................35

General info ............................................................................................................................................................................................................ 35

Advanced Options ............................................................................................................................................................................................. 35

Location Specific Setup ................................................................................................................................................................................... 36

Single Display ........................................................................................................................................................................................................ 37

Multiple Displays ................................................................................................................................................................................................. 39

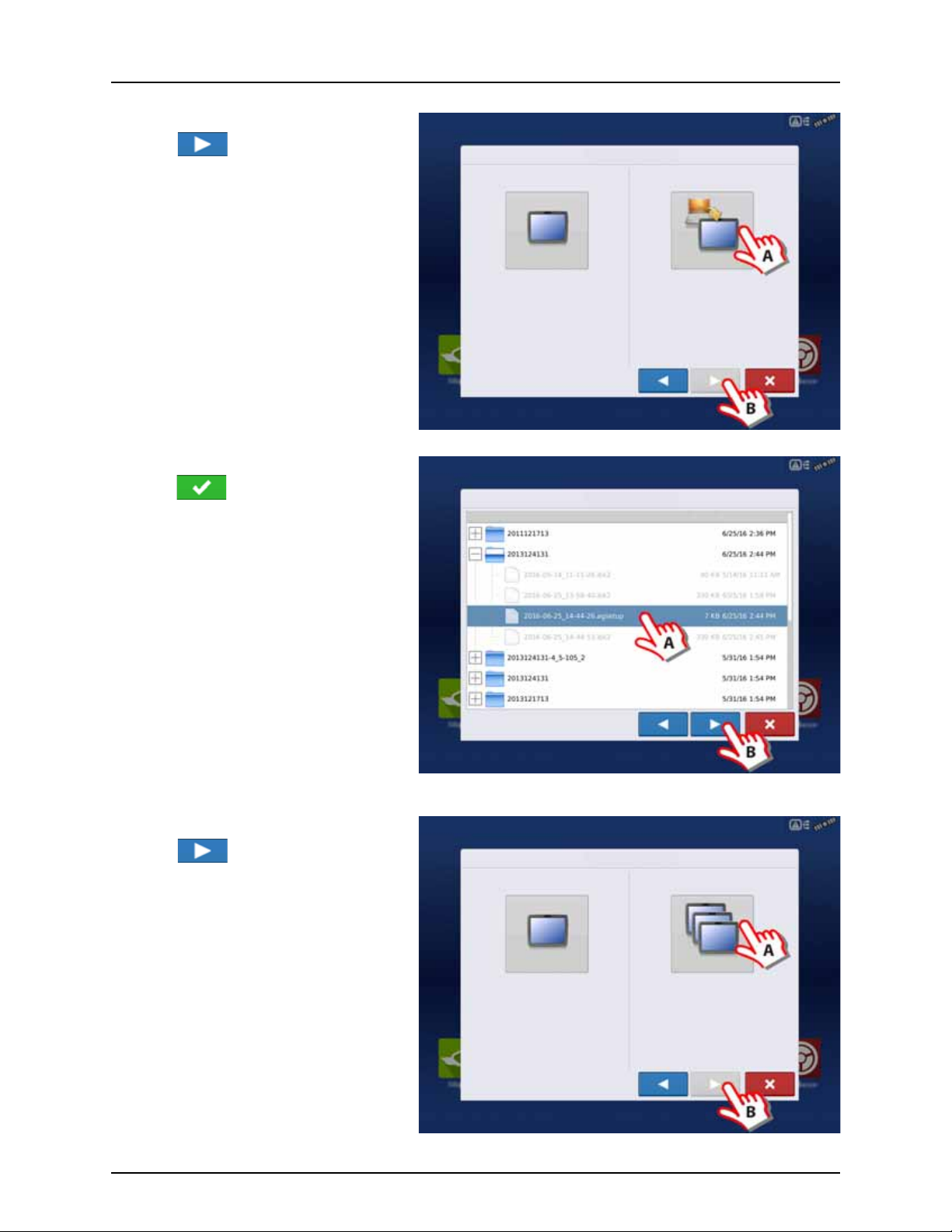

Import Setup Data .............................................................................................................................................................................................. 43

Home Screen ......................................................................................................................................................................................................... 44

Universal Terminal ..............................................................................................................................45

Universal Terminal together with HC 8600/HC 9600 ................................................................................................................... 45

General info about Universal Terminal .................................................................................................................................................. 45

Enable Universal Terminal and Task Controller ................................................................................................................................ 45

3

Page 6

Table of Contents

Quick Setup Guide ...............................................................................................................................48

General Info ............................................................................................................................................................................................................ 48

Before Setup ........................................................................................................................................................................................................... 48

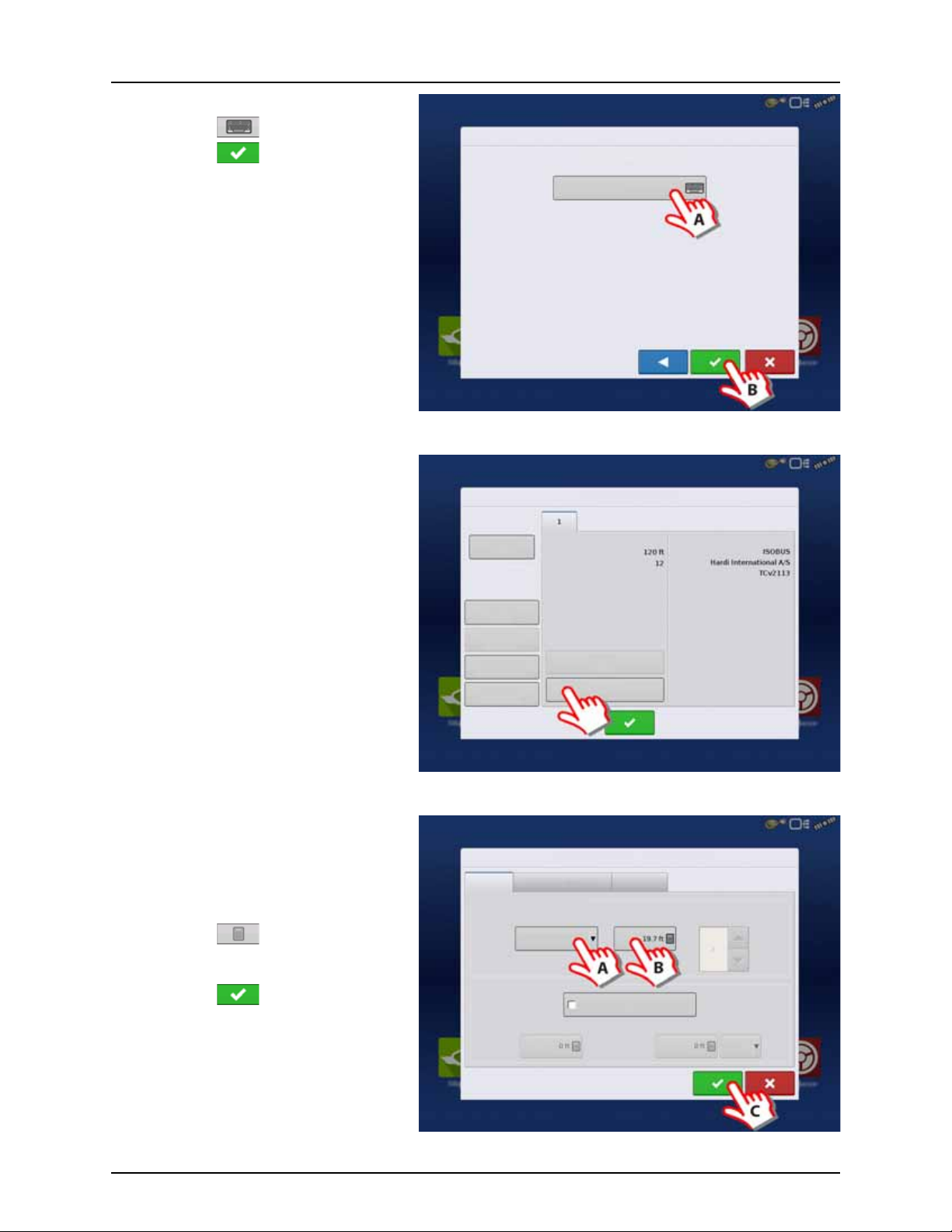

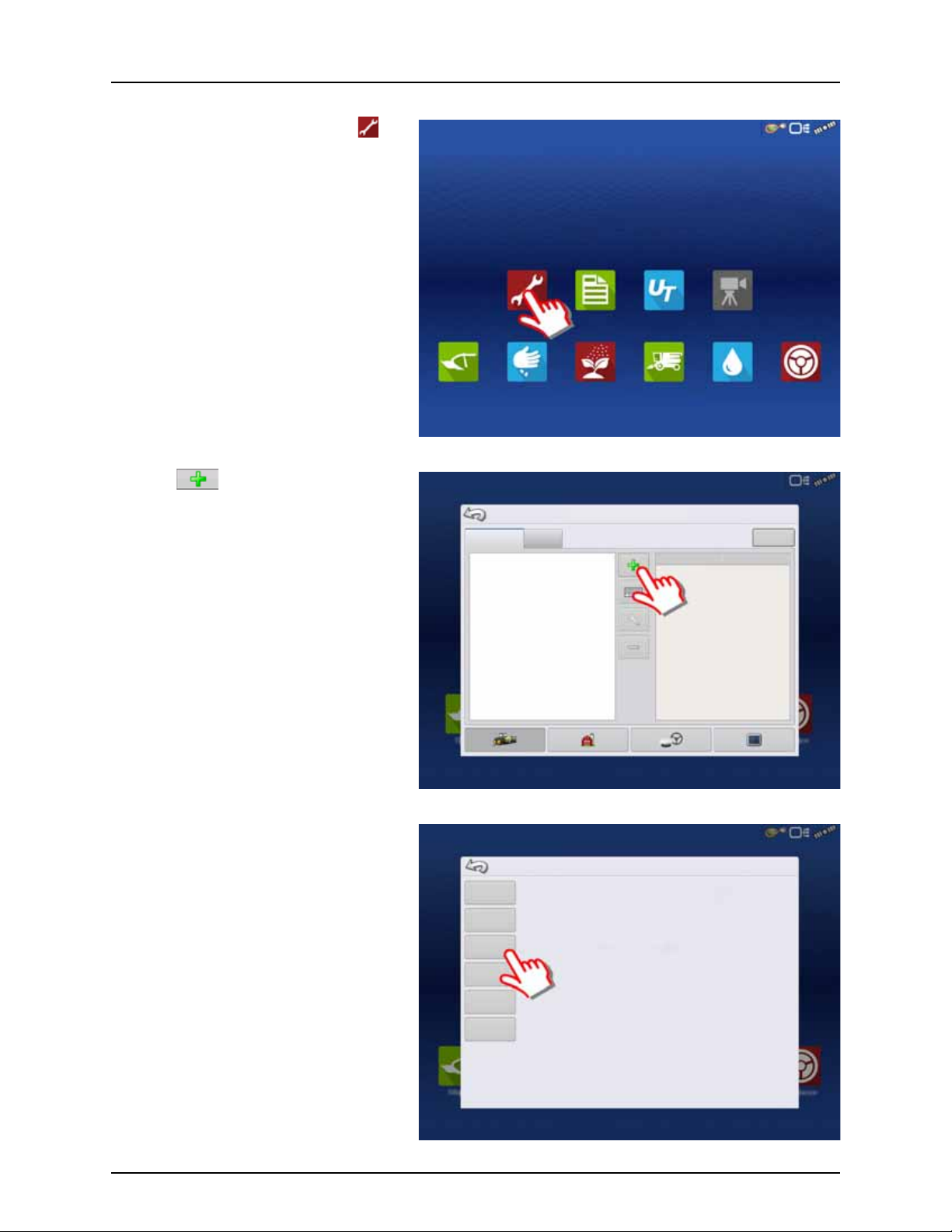

Configuration for Trailer and Lift sprayers ........................................................................................................................................... 48

Configuration for Self-Propelled sprayers ............................................................................................................................................ 60

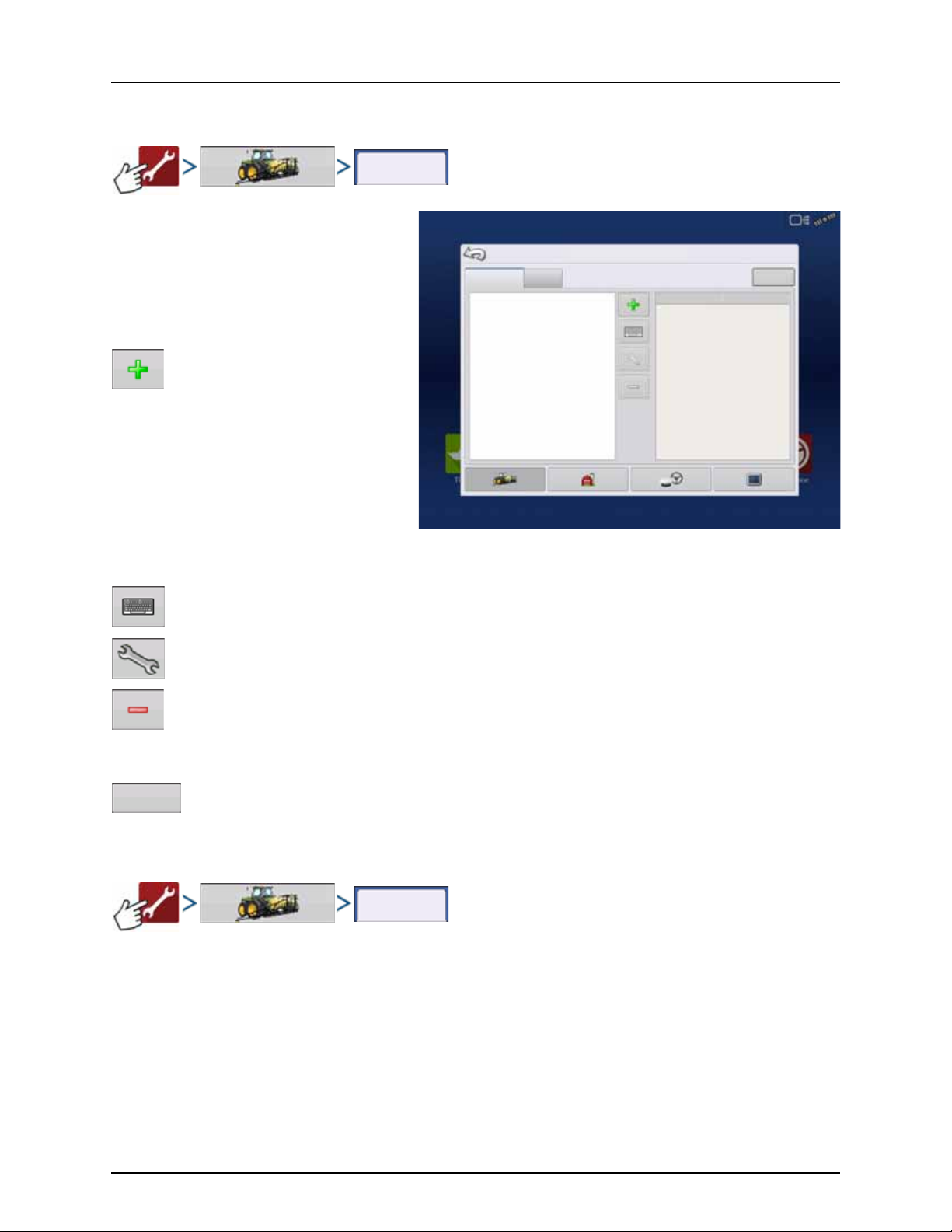

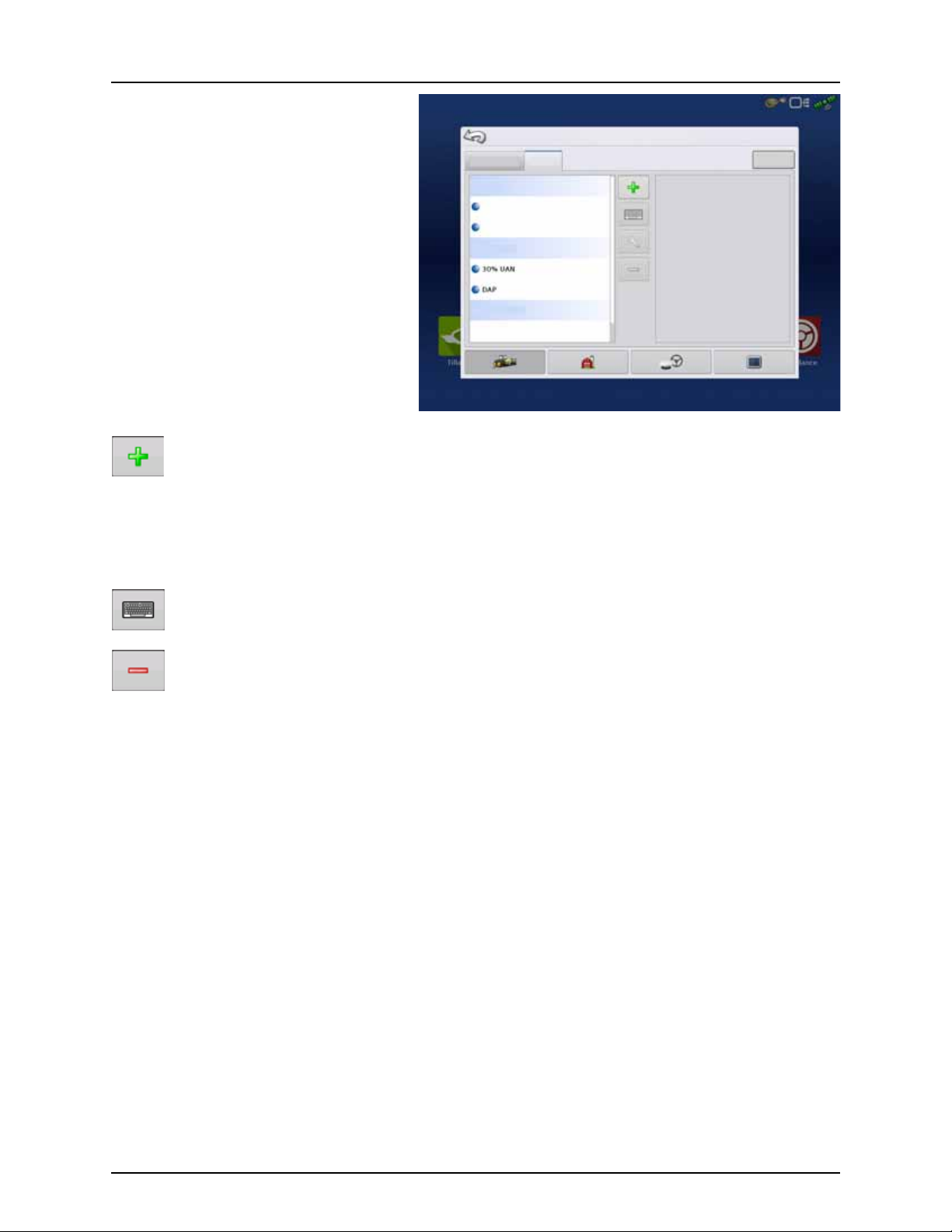

Product setup ........................................................................................................................................................................................................ 68

Configuration ......................................................................................................................................71

Setup buttons ....................................................................................................................................................................................................... 71

Equipment Setup ................................................................................................................................................................................................ 72

Management button ........................................................................................................................................................................................ 74

Edit User Profile .................................................................................................................................................................................................... 78

Permissions tab .................................................................................................................................................................................................... 78

Permission Level for Operators .................................................................................................................................................................. 79

Accessing Setup Menus .................................................................................................................................................................................. 81

Accessing Data Transfer .................................................................................................................................................................................. 82

Forgotten Passwords ........................................................................................................................................................................................ 83

Display Button ....................................................................................................................................................................................................... 84

Settings ................................................................................................................................................89

Speed Input Settings ........................................................................................................................................................................................ 89

Automatic Swath Control (AutoSectionControl) ............................................................................................................................ 90

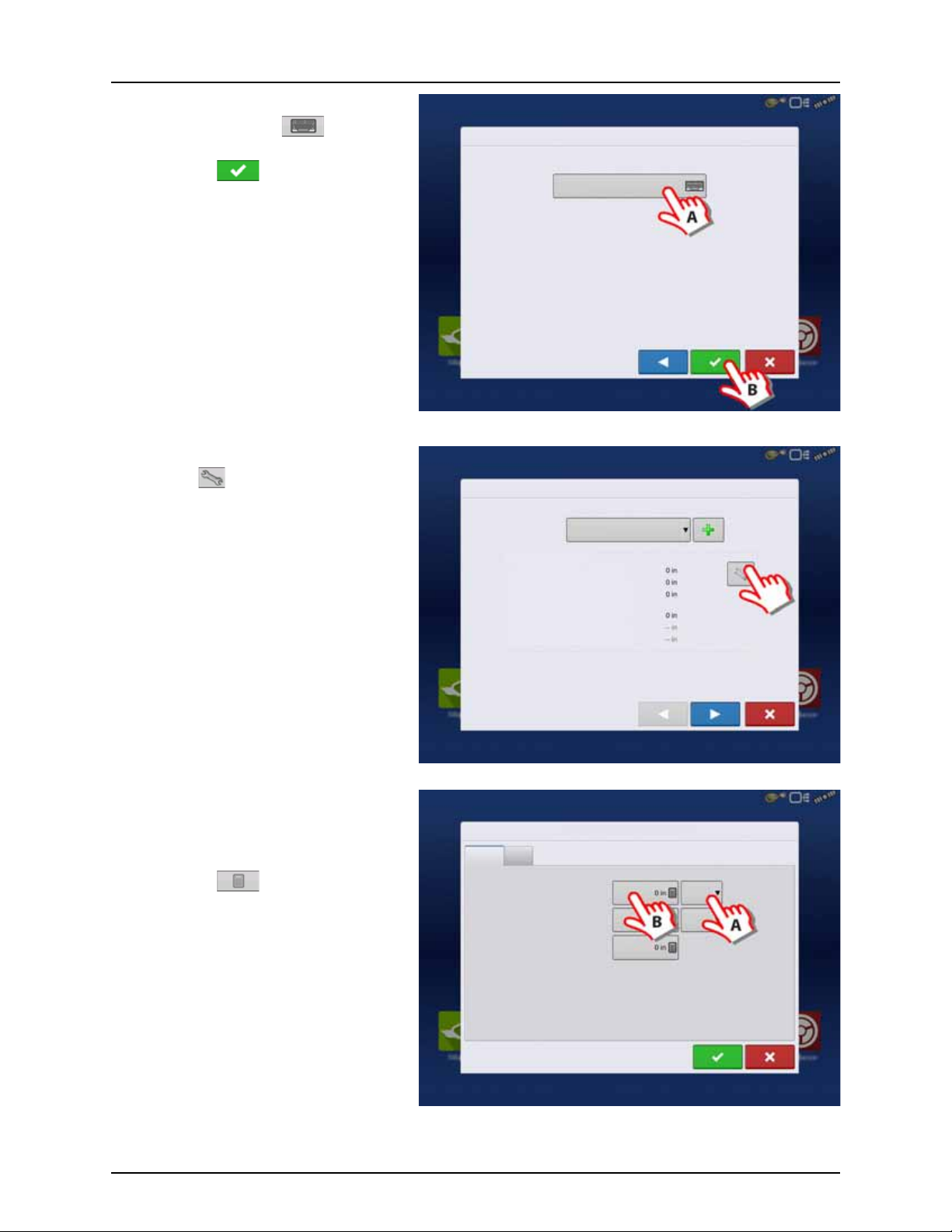

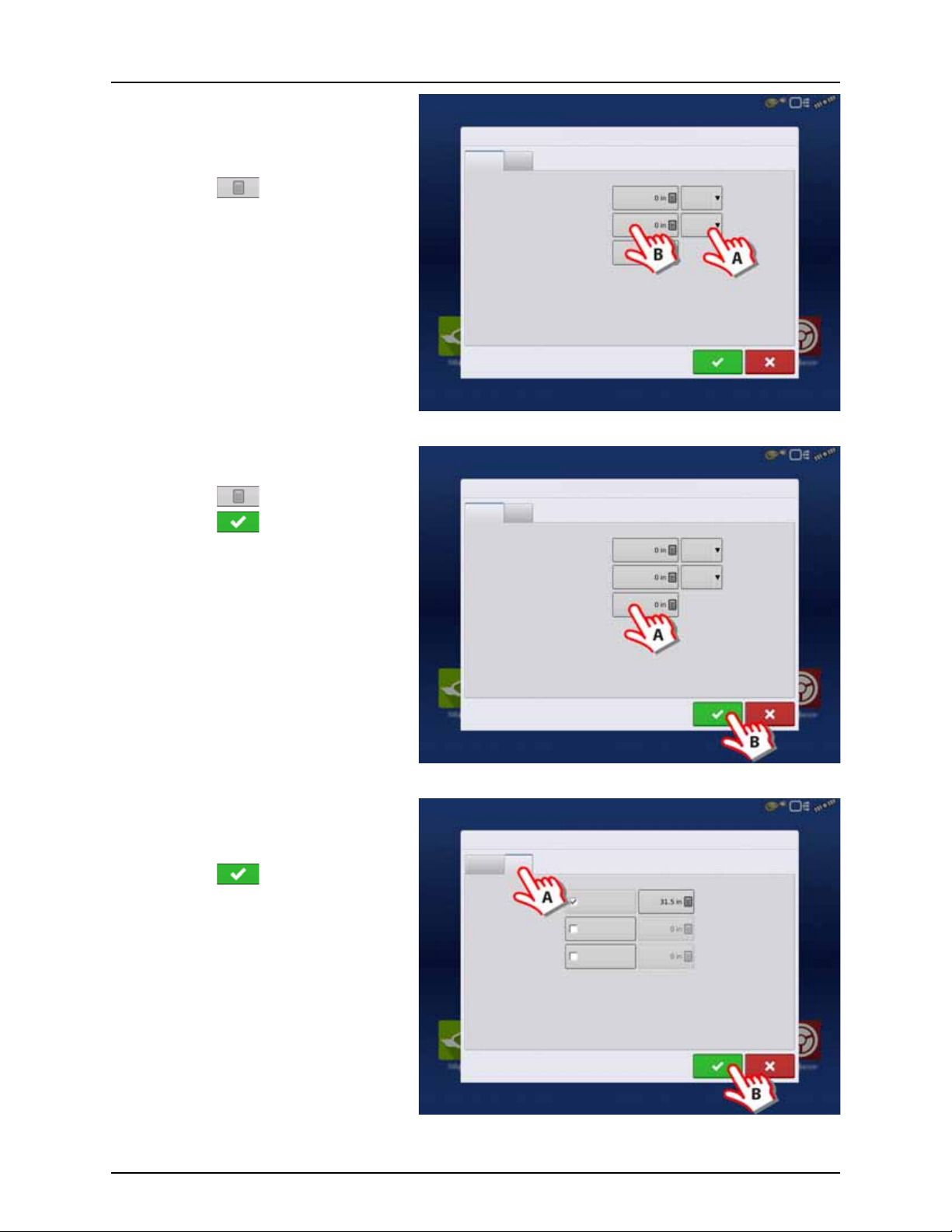

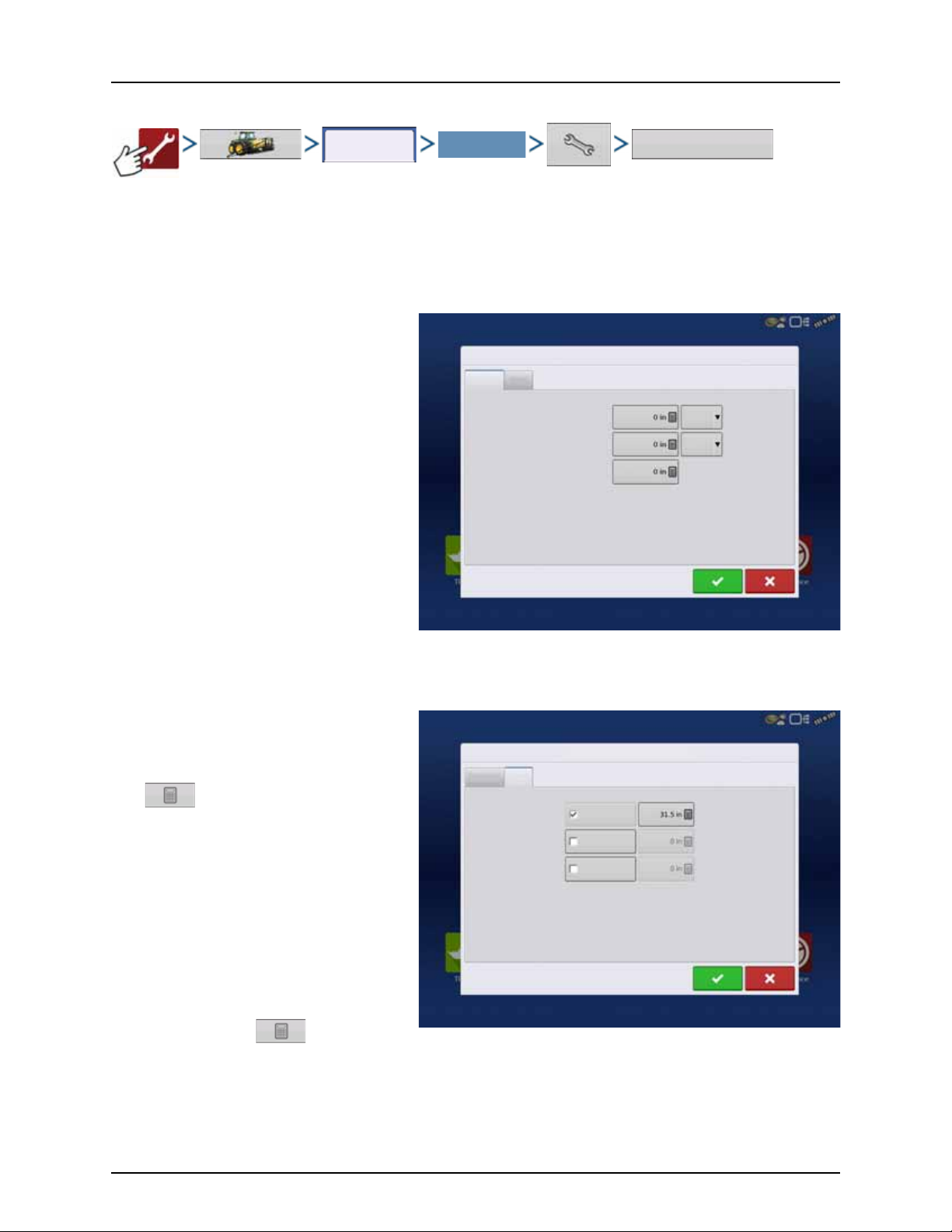

Vehicle Offsets ....................................................................................................................................................................................................... 91

GPS Guidance/Steering Control ..........................................................................................................93

Setup ........................................................................................................................................................................................................................... 93

WAAS/EGNOS Settings .................................................................................................................................................................................... 95

TerraStar Settings ................................................................................................................................................................................................ 95

RTK External Settings ........................................................................................................................................................................................ 96

RTK Settings - NTRIP .......................................................................................................................................................................................... 96

RTK Settings - 400 MHz .................................................................................................................................................................................... 98

RTK Settings - 900 MHz .................................................................................................................................................................................... 98

Upgrade Receiver ............................................................................................................................................................................................... 99

Serial Port Settings .............................................................................................................................................................................................. 99

Lightbar Settings .............................................................................................................................. 101

Setup .........................................................................................................................................................................................................................101

Guidance Tab on Mapping Toolbox .....................................................................................................................................................101

New Pattern - Straight ....................................................................................................................................................................................102

New Pattern - Adaptive Curve ..................................................................................................................................................................103

New Pattern - Identical Curve ...................................................................................................................................................................104

New Pattern - Pivot ..........................................................................................................................................................................................105

New Pattern - SmartPath ..............................................................................................................................................................................107

AutoSave ................................................................................................................................................................................................................110

Manage Patterns ...............................................................................................................................................................................................110

Pattern Groups ....................................................................................................................................................................................................111

Guidance Options .............................................................................................................................................................................................113

Liquid Rate Control ........................................................................................................................... 118

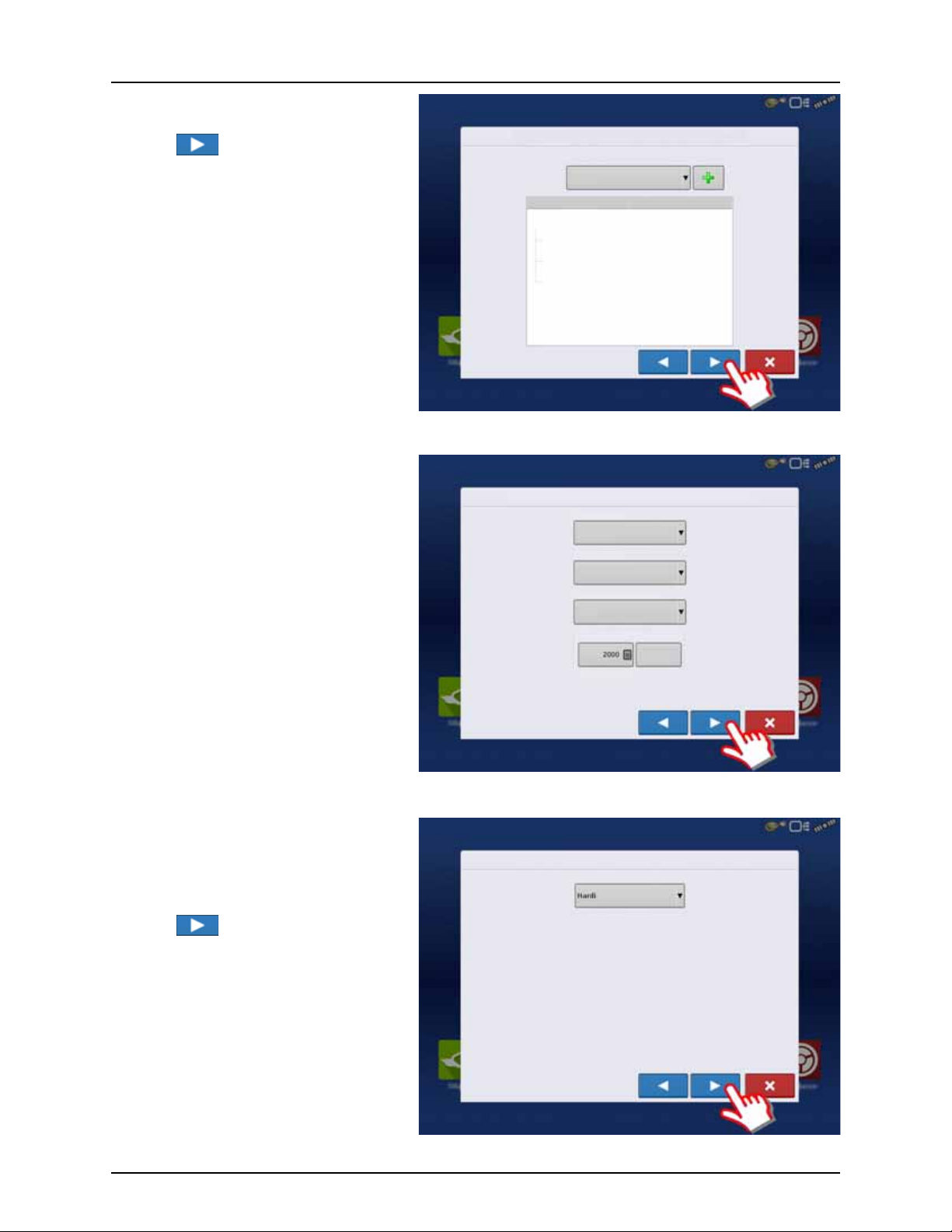

Creating Products .............................................................................................................................................................................................118

Creating Single Products ..............................................................................................................................................................................118

Creating Product Templates ......................................................................................................................................................................118

Configure Product Mix ...................................................................................................................................................................................120

Create Configuration ......................................................................................................................................................................................122

Load Configuration ............................................................................................................

Implement Offsets ............................................................................................................................................................................................122

Equipment Settings .........................................................................................................................................................................................123

Configuration Setup ........................................................................................................................................................................................124

Rate Control: Product Control Toolbox ...............................................................................................................................................125

Loading Prescriptions .....................................................................................................................................................................................129

Shape File Conversion ...................................................................................................................................................................................130

..............................................................................122

4

Page 7

Table of Contents

AgFiniti ............................................................................................................................................. 132

Display Access Point connection type ................................................................................................................................................132

AgFiniti Mobile ...................................................................................................................................................................................................135

Filters .........................................................................................................................................................................................................................136

Stat Cards ...............................................................................................................................................................................................................136

Zoom Options .....................................................................................................................................................................................................138

Summary Reports .............................................................................................................................................................................................138

Menu button ........................................................................................................................................................................................................139

AgFiniti Display Settings ...............................................................................................................................................................................140

Logging into an AgFiniti Account ..........................................................................................................................................................140

Logout and De-register Display ...............................................................................................................................................................140

Mobile Management ......................................................................................................................................................................................140

File Transfer ...........................................................................................................................................................................................................140

Remote Support ................................................................................................................................................................................................141

Remote Support Pre-authorization .......................................................................................................................................................141

Remote Support Permissions Options ................................................................................................................................................141

Cellular iPad as Personal Hotspot Connection ...............................................................................................................................142

Shared Wi-Fi Network Connection ........................................................................................................................................................145

Data Management ............................................................................................................................ 148

Data Transfer screen ........................................................................................................................................................................................148

Display Backups .................................................................................................................................................................................................148

Upgrade Firmware ...........................................................................................................................................................................................149

Importing Logged Data ................................................................................................................................................................................149

Exporting Logged Data .................................................................................................................................................................................150

Manual Sync .........................................................................................................................................................................................................150

5 - Operation

Map Screen ....................................................................................................................................... 151

Configuration Setup Screen .......................................................................................................................................................................151

Mapping Toolbox .............................................................................................................................................................................................151

Boundary ................................................................................................................................................................................................................153

Field Operations ............................................................................................................................... 155

Operator Selection ...........................................................................................................................................................................................155

Operator Log Out ..............................................................................................................................................................................................155

Menu Buttons ......................................................................................................................................................................................................155

Events .......................................................................................................................................................................................................................156

Setup Event ...........................................................................................................................................................................................................156

GPS Button ............................................................................................................................................................................................................159

Work Screen Operations ...............................................................................................................................................................................160

Heading Change Button ..............................................................................................................................................................................160

Rate Control Settings ......................................................................................................................................................................................161

Display Item Selection ...................................................................................................................................................................................162

Boom Height Control Options ..................................................................................................................................................................162

Headlands ..............................................................................................................................................................................................................163

Topography ..........................................................................................................................................................................................................167

Finalize Event .......................................................................................................................................................................................................170

Reports ............................................................................................................................................. 171

Summary Report ................................................................................................................................................................................................171

Event Summary ..................................................................................................................................................................................................173

Smart Reports™ (HC 9600 only) ................................................................................................................................................................175

6 - Maintenance

General info ...................................................................................................................................... 181

Service ......................................................................................................................................................................................................................181

Fuse Installation and Replacement ........................................................................................................................................................181

System and Upgrades ....................................................................................................................................................................................181

5

Page 8

Table of Contents

7 - Fault finding

Devices ............................................................................................................................................. 183

CAN Diagnostics ................................................................................................................................................................................................183

ISOBUS .............................................................................................................................................. 185

ISOBUS Universal Terminal ..........................................................................................................................................................................185

UT Alarms and Trouble Codes ..................................................................................................................................................................186

ISOBUS Modules ............................................................................................................................... 187

Modules not found ..........................................................................................................................................................................................187

ISOBUS Configuration Mismatch ............................................................................................................................................................188

GPS ................................................................................................................................................... 189

GPS Information .................................................................................................................................................................................................189

GPS Information - General Tab .................................................................................................................................................................189

GPS Messages ......................................................................................................................................................................................................191

Satellite Plot ..........................................................................................................................................................................................................192

GPS Information .................................................................................................................................................................................................193

8 - Technical specifications

Specifications ................................................................................................................................... 197

Technical Specifications ................................................................................................................................................................................197

Sprayer Offsets ....................................................................................................................................................................................................197

Appendix .......................................................................................................................................... 198

Current File Formats ........................................................................................................................................................................................198

Legacy File Formats .........................................................................................................................................................................................198

12 - Warranty

Warranty policy and conditions ....................................................................................................... 201

Index

Index ................................................................................................................................................. 203

6

Page 9

1 - Welcome

Welcome letter

Dear New HARDI® Owner,

Thank you for purchasing your new HARDI® product and welcome to the ever-increasing family of proud HARDI® owners.

HARDI® is the leading sprayer company in offering growers strong, reliable products made for the widest range of

applications worldwide. Quality, reliability, and resale value make the HARDI® product line the preferred product line of

customers both in North America as well as worldwide. Our guiding principle is to provide the highest level of customer

satisfaction and long term value in the marketplace today. We have developed a very high level of customer loyalty in the

marketplace which we are very proud of and strive every day to maintain and to continue to grow.

HARDI® is your specialist in spraying and we spend all of our time and keep all of our focus on spraying. We do not share our

resources between other types of products or compromise on anything in providing the best quality sprayers to the market

today. We can provide the latest in technology with our products if desired, or allow them to operate with the technology

that you already use on other products in most cases. You get to decide that, and what best suits your needs. We feel that

you, our customer, are the best suited to answer that question for your operation. Either way, you decide, and we will try and

help make it happen for you.

Our broad spectrum of product offerings, from the ruggedly simple models we build to our highly sophisticated models,

the built-in HARDI® strength and reliability ensures a low cost of ownership. HARDI® sprayers are all based on a functional

design concept of being as simple to operate as possible and to meet our customers’ requirements for all their application

needs.

Please take the time to thoroughly read the Operator’s Manual before using your equipment. You will find many helpful hints

as well as important safety and operation information.

Some of the features on your HARDI® sprayer were suggested by growers. There is no substitute for “on farm” experience

and we invite your comments and suggestions. If any portion of this instruction book remains unclear after reading it,

contact your HARDI® dealer or service personnel for further explanation before using the equipment.

For Product, Service or Warranty Information please contact your local HARDI® dealer.

- Please use the HARDI® Customer Service number: 1-866-770-7063

- Or send your email to CUSTSERV@hardi-us.com

HARDI® NORTH AMERICA INC.

Visit us online at: www.hardi-us.com

1500 West 76th St.

Davenport, Iowa 52806

Phone: (563) 386-1730

Fax: (563) 386-1280

Sincerely,

Wayne Buchberger

President

7

Page 10

1 - Welcome

HC 8600 and HC 9600

About this Instruction Book

This ins tru cti on boo k is writt en for the us e wi th the HAR DI® HC 860 0 and H C 96 00 con troll ers re specti vely. Sinc e mo st men us

are nearly identical for both, we have chosen to illustrate this book with HC 9600 illustrations. On the HC 9600 many menu

screens will appear as part of the screen (pop-up dialogue boxes), but will appear full screen on the HC 8600 controller.

Because of the physical size of controllers, some dialogue boxes will appear with a bit different layout on HC 8600, but with

same contents as the HC 9600 screen.

Differences between the Controllers

The controllers differ in the following:

• Display sizes

• Menu layouts

• Features available:

Display Features HC 8600 HC 9600

Display Size 8 in. 12 in.

Swipe Gesture Yes Yes

Coverage Mapping Yes Yes

Split Screen Not Available Yes

Data Logging Yes Yes

AutoSectionControl (AutoSwath) Yes Yes

Headlands Yes Yes

Multiple Product Control Yes Yes

Camera Support 4 4

AgFiniti Mobile Yes Yes

USB Port 1 2

Guidance & Steering

Lightbar Guidance Yes Yes

Mechanical Assisted Steering Yes Yes

Hydraulic Assisted Steering Yes Yes

GLIDE, SBAS (WAAS/EGNOS), TerraStar, RTK Yes Yes

SmartPath Yes Yes

Tram line s Yes Yes

StableLoc Yes Yes

Application Control

Liquid Product Application Control 10 sections 10 sections

ISOBUS Liquid Control Module 36 sections 36 sections

Variable Rate Application Yes Yes

Chemical Injection Yes Yes

Boom Height Control Yes Yes

Smart Report™ Not Available Yes

AutoSectionControl (AutoSwath) based on Previously Applied Maps Yes Yes

Container Sequencing Not Available Yes

Dry Product Application Control Yes Yes

Closed Loop Spinner Speed Control Yes Yes

Strip-Till Yes Yes

Air Seeder Support Yes Yes

OptRx® Crop Sensors Not Available Yes

Multiple Product Application (Liquid or Granular) up to 3 up to 8

ISOXML Data Export Yes Yes

ISOBUS

ISOBUS Universal Terminal Yes Yes

Task Controller Yes Yes

8

Page 11

2 - Safety Notes

Operator Safety

Symbols

These symbols are used thorough the book to designate where the reader needs to pay extra attention.

This symbol means DANGER. Be very alert as your safety is involved!

€

This symbol means WARNING. Be alert as your safety can be involved!

±

This symbol means ATTENTION. This guides to better, easier and safer operation of your sprayer!

μ

This symbol means NOTE.

÷

Precautions

Note the following recommended precautions and safe operating practices before using the sprayer.

General info

Read and understand this instruction book before using the equipment. It is equally important that other operators

€

of this equipment read and understand this book.

If any portion of this instruction book remains unclear after reading it, contact your HARDI® dealer for further

€

explanation before using the equipment.

Keep children away from the equipment.

€

Press the keys with the underside of your finger. Avoid using your fingernail.

€

Local law may demand that the operator is certified to use spray equipment. Adhere to the law.

€

Tractor driver’s seat is the intended working place during operation.

€

Service

Test with clean water prior to filling with chemicals. Rinse and wash equipment after use and before servicing.

€

Never service or repair the equipment while it is operating. Always replace all safety devices or shields immediately

€

after servicing.

Turn electrical power off before connecting and disconnecting the display and transducers, servicing or using a

€

battery charger.

If an arc welder is used on the equipment or anything connected to the equipment, disconnect power leads before

€

welding. Remove all flammable or explosive material from the area.

Do not use a high pressure cleaner to clean the electronic components.

€

9

Page 12

2 - Safety Notes

10

Page 13

3 - Description

Display

General info

The display is a full-featured, year-round hub of any precision farming operation. A full-color, high-brightness, highresolution touchscreen display is easy to read and offers powerful, year-round precision farming tools. Built-in manual

guidance, full-screen mapping, planter and application control, yield monitoring, real-time data logging and automated

steering make up the core functionality of the display.

ATTENTION! This manual only describes functions relevant for spray use with a HARDI® sprayer.

μ

WARNING! Read manual completely before operating display. Understand and follow all operating and safety

±

instructions for proper use of this display. Failure to use display properly could result in an impairment of the safety

features of this product.

System Uses

• Manual Guidance

• AutoTerrain/AutoHeight UC5

• Hydraulic automated steering

• Video Camera Inputs

• Mapping tillage operations

• Mapping and logging product application

• Mapping of all field boundaries, sub-boundaries, waterways and terraces

• Grain yield monitoring

• Variety logging

• Granular and liquid fertilizer application

• Liquid spray system control

• NH3 application control

• Application control of multiple bin spinner spreaders

System Features

• Sunlight-readable screen

• Rugged sealed enclosure

• Compatible with most NMEA GPS receivers

• HARDI® ISOBUS product control using industry standard CAN-bus interface

• Adjustable volume control

• Perspective 3D View Map

• Report preview

• Automatic field selection

• Automated module firmware upgrade

• Advanced GPS Diagnostics

• USB media slot

• 28-pin plug for JobCom connection

• 28-pin auxiliary connection

• RAM mounting bracket

11

Page 14

3 - Description

Display Hardware

Rear

A. Speaker

The built-in speaker is used for audible warnings. The volume can

be adjusted through the display setup routine.

B. WiFi

802.11 communication.

C. RAM mount

D. HDMI OUT (HC 9600 only)

E. Ethernet Connection

4-pin connection used for communication with ParaDyme,

GeoSteer, SteerCommand, OnTrac3.

F. 19-pin auxiliary connection

Used for camera input.

G. 19-pin plug

The 19-Pin round display connector contains CAN, RS-232 serial, and system

power and ground connections. It is compatible with some certain other

displays.

H. Power/Reset switch

The Power/Reset switch is used for turning the display on and off in

installations where the system is connected to a continuous power supply.

If the display ever stops responding, the manual power switch may be held

in for five seconds to restart the system. Only do this as a last resort, data loss

could occur during times of improper shutdown.

Front and Side

I. Built in lightbar

For guidance.

J. Light sensitivity sensor

Used to automatically dim the display during nighttime or lowlight situations.

K. Power light

The power light displays one of three states:

Green = ON

Pulses amber = Standby Mode

Solid amber = Running on battery power

L. Side mount USB media slots

• 2 slots for HC 9600

• 1 slot for HC 8600

Used for data transfer in and out of the display.

Used to charge mobile devices up to 1.2 amps.

12

Page 15

3 - Description

USB Flash Drive

The display utilizes a USB Flash Drive slot that you can use to save and transfer your data in and out of the display.

ISOBUS Technology

The ISOBUS system uses Controller Area Network (CAN) technology. CAN systems are comprised of individual modules, each

with their own high speed processor, connected through a high-speed communications cable.

CAN has many benefits:

• Greater ability to configure and expand the system.

• Compatibility.

• Simpler installations with less wiring.

• Increased system dependability.

Color Touch Screen

Here are a few key things to remember if you are new to using a touch screen device:

• Do not use any sharp objects for running the touch screen device, this could result in damage to the display. Using the

tip of a finger is the recommended method of operating the display touch screen.

• Do not use any harsh chemicals to clean the touch screen. Using a damp soft cloth or an anti-static wipe made

specifically for cleaning computer displays is the correct way to clean the screen and the enclosure.

• The display uses a capacitive screen that is heat sensitive. It requires only a brief, gentle touch to operate correctly. A

common mistake is to try to navigate too quickly through the system using firm taps instead of gentle presses.

13

Page 16

3 - Description

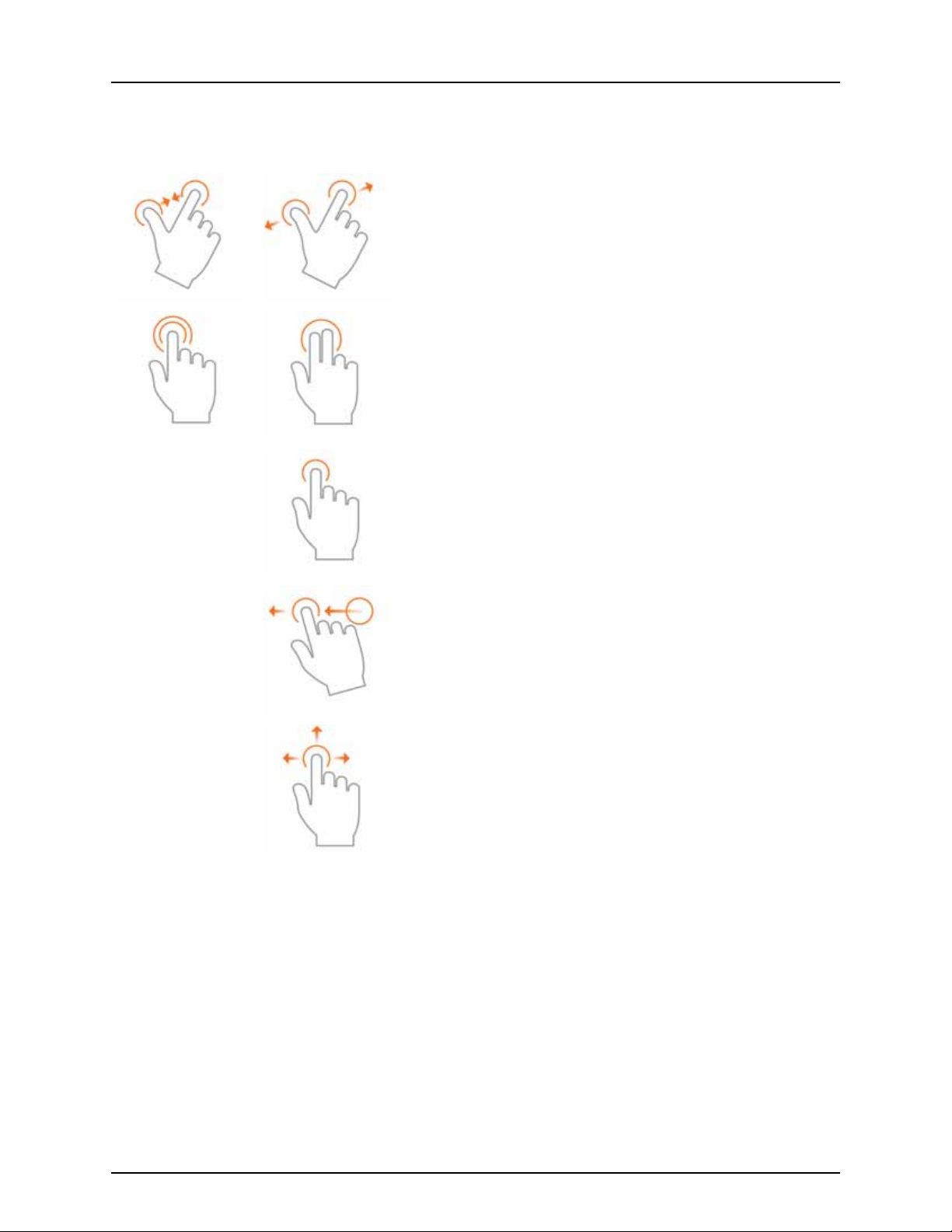

Gestures

As with any smart phone or pad you can use gestures. These gestures will allow you to navigate around the map screens,

select items and make various changes. The most common gestures are outlined below.

Pinch In and Out

Using two fingers touch the screen and pinch in and out to adjust the

zoom level of your map. If zoomed out enough field coins will begin to

appear and allow you to view other maps. If zooming in far enough you

should begin to see row by row data on applicable fields.

Tap to Zoom

By tapping on the map you can quickly control the zoom level of your map.

Quickly double tap with one finger to zoom in and tap with two fingers

together to zoom out.

Tap

Tap items to select them. You can also tap on your map to set a manual

location within the field and view its specific data in the stat cards.

Swipe

Swipe your finger to see additional menus on certain items.

Pan

Tap and hold your finger on the screen to pan around your mapped data

while maintaining the same zoom level.

14

Page 17

3 - Description

Symbols

Screen Icon Conventions

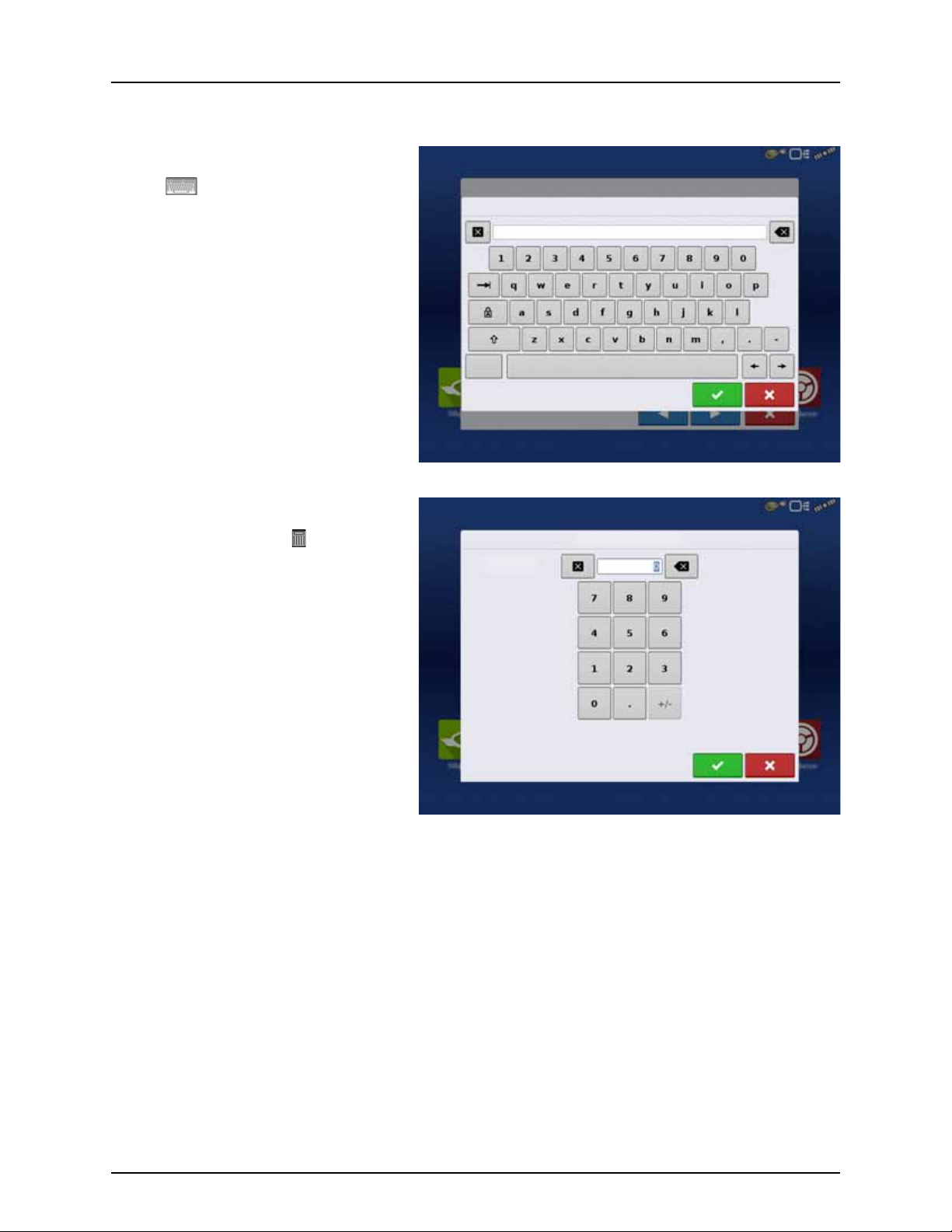

The following control buttons are made available for entering names and calibration values into the system.

An on-screen Keyboard is made available when

appropriate for use during all setup processes.

Press the button to access the on-screen text

entry screen.

An on-screen Numeric Keypad is made available

for changing configuration settings and

calibration numbers. Press the button to access

the on-screen numeric entry screen.

15

Page 18

3 - Description

Initial Start-up

General info

An Initial Setup wizard is presented on start-up. The wizard is presented if the display is brand new out-of-the-box.

NOTE! Not all of the following parts may be required to follow - it depends on your specific setup.

÷

Once the wizard is completed, it is not shown again unless the display memory is cleared.

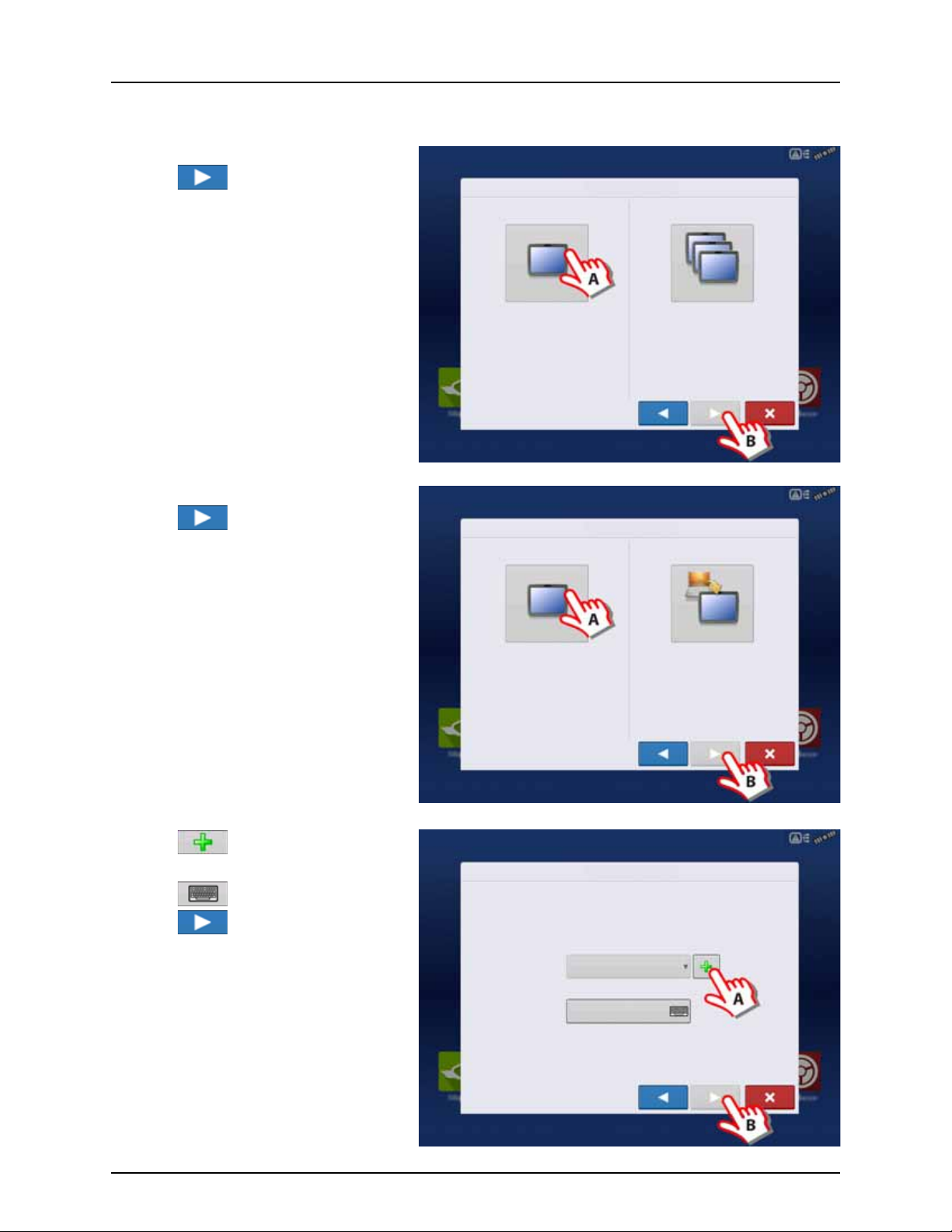

Initial Setup Wizard

The Initial Setup wizard will take you through the following setup items:

Time\Date, Time Zone, Unit System, Language

• Advanced Options. See “Advanced Options” on page 35.

• Restore Backup.

• Upgrade Firmware.

• Unlock Display Features.

Single or Multiple Display Setup

• Single

Use single display if this is the only display that is getting setup.

• Multiple Display

Use multiple display if there is more than one display in the operation and the plan is to share management data

between displays. After initial setup is complete, enter management information and create an .agsetup file.

NOTE! Using the Restore backup option is not the proper method to get multiple displays set up to be the same. Use

÷

the .agsetup file.

It is acceptable to complete the Initial Setup wizard and then upgrade. Setup information will not change.

• On a “clean” display going out for service, to stand in for a failed display, the customer should use the Restore backup

option in the Initial Setup wizard.

ATTENTION! The business created on the first display, and any other management and equipment items, will be

μ

imported to the additional displays.

16

Page 19

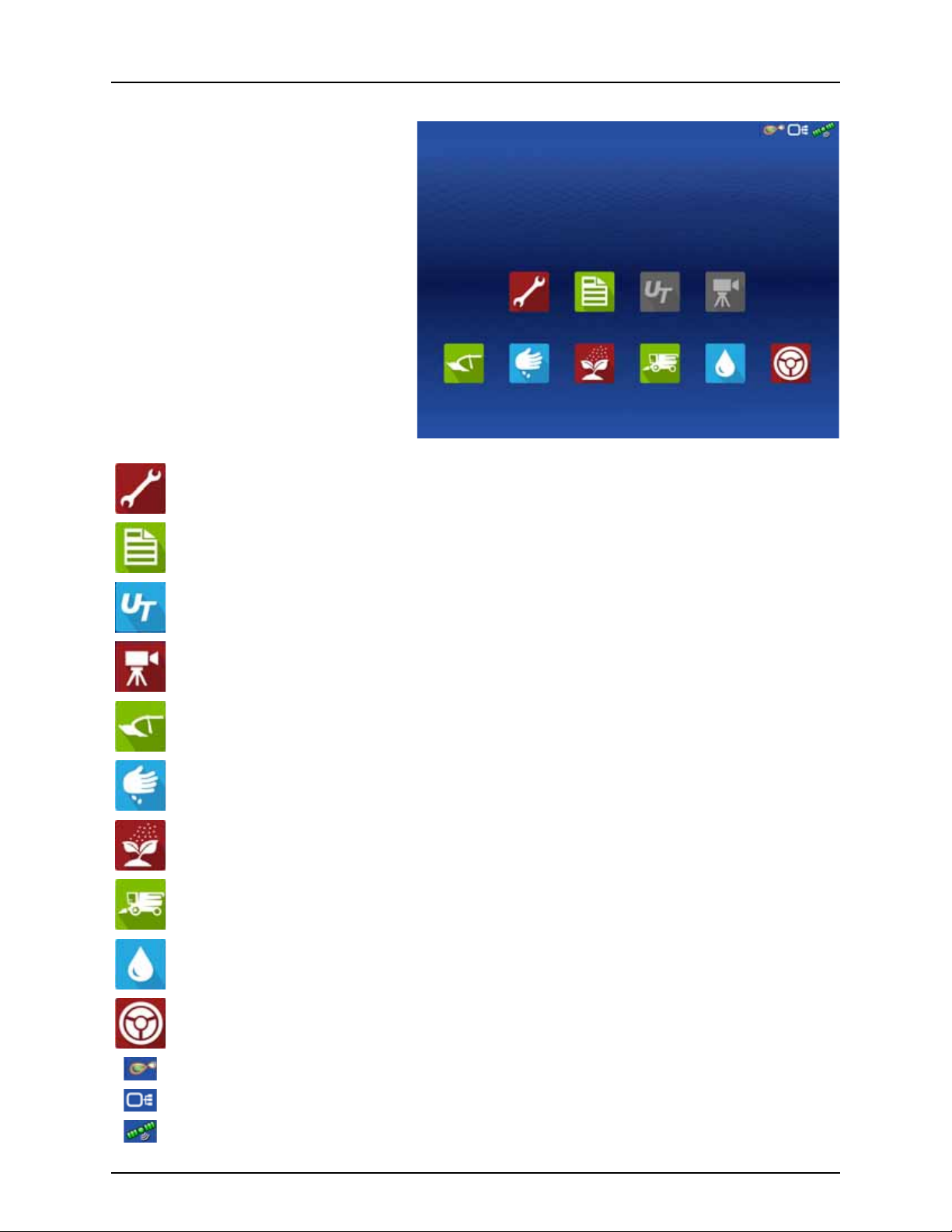

Home Screen Layout

Setup

Summary

Universal

Ter mi na l

Camera

Harvest

Tillage

Planting

Application

Water

Management

Guidance

Setup Access display’s setup items.

3 - Description

Summary Used to access previously logged data, maps, reports.

Universal Terminal Used to interact with UT based ECU’s. It must be enabled in setup.

Camera View cameras attached to the display. It must be enabled in setup.

Tillage Create configuration or start operation specific to tillage.

Planting Create configuration or start operation specific to planting.

Application Create configuration or start operation specific to application.

Harvest Create configuration or start operation specific to harvest.

Water Management Create configuration or start operation specific to water management.

Guidance Used to start guidance steering only operation.

AgFiniti Status Indicator

Devices Status Indicator

Satellites Status Indicator

17

Page 20

3 - Description

GNSS

CAN

Operator

Data Transfer

Remote

Most of the functionality of the display is not available until the basic setup process is completed.

You must complete these initial configuration steps for the Run Time Environment to be active:

• Equipment Operating Configuration.

You can access Configuration Setup by pressing or pressing an app specific to a field operation.

• Product setup.

• Start Field Operation.

Status Indicators

Status Indicators are used to show different states of external equipment connected

to the display (for example: , , and ) and provides easy access to data transfer and

diagnostic features of the display.

18

Page 21

8.99 ac

Field

Boundary

Spray Pump

Wheel Speed

Volta ge

Water

Flow:

Container:

Sensitivity:

Targ et H eigh t:SoilMode:

Tank Vol ume

Headlands

Top og ra ph y

3 - Description

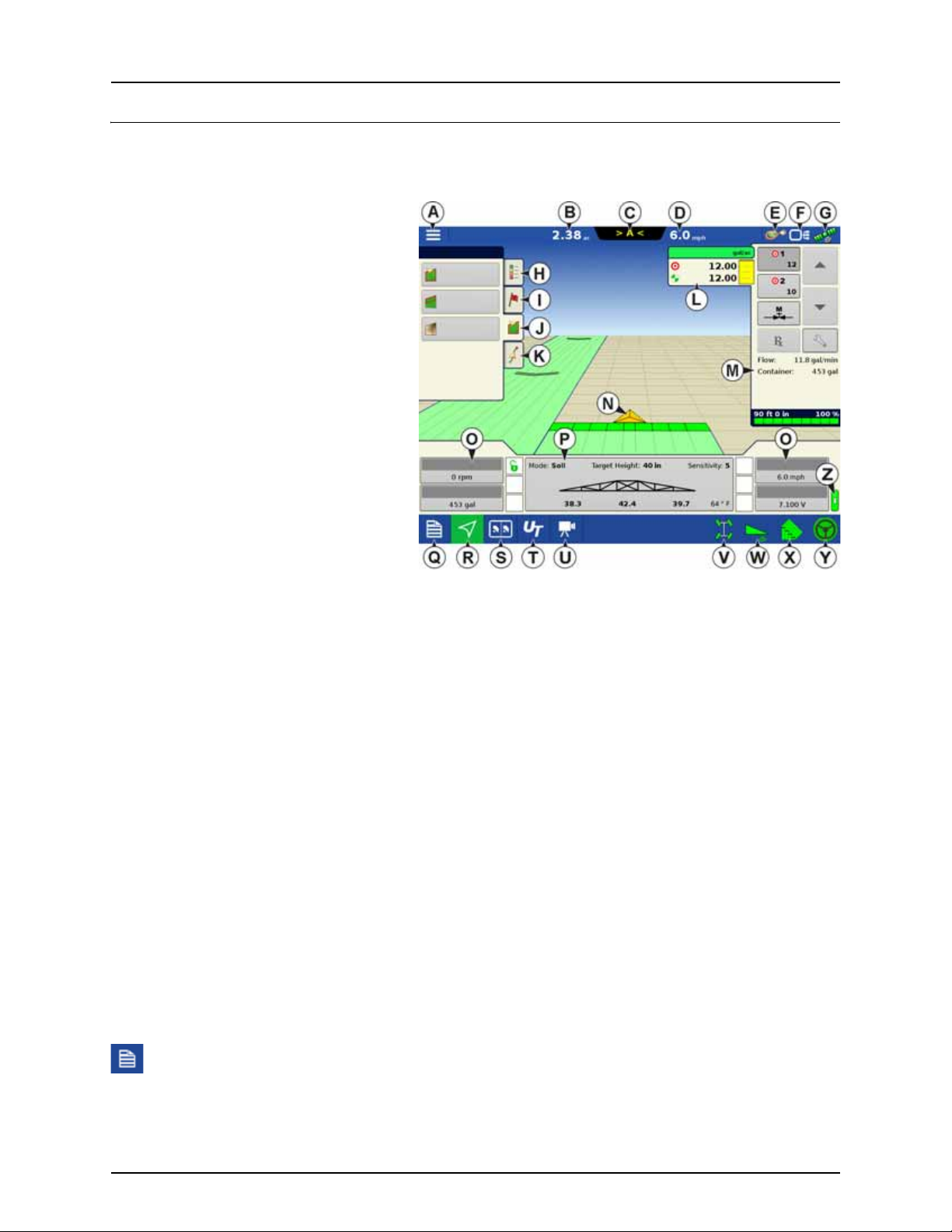

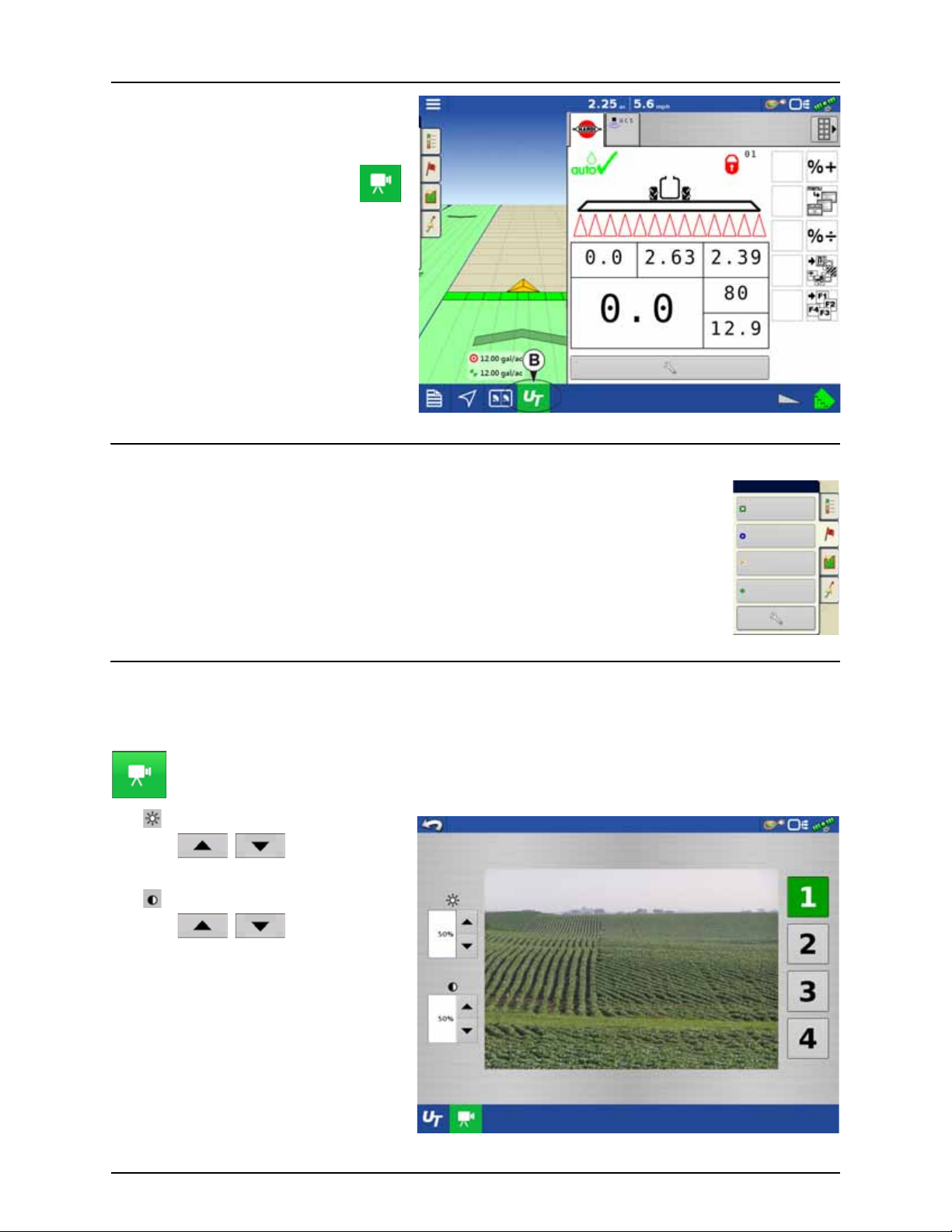

Map Screen

Work Screen

The appearance of the Map screen varies, depending upon which operation you are performing, and your specific operating

configuration.

A. Menu

B. Area Covered

C. Path Indicator

D. Speed

E. AgFiniti Status Indicator

F. Diagnostics Status Indicator

G. GNSS Satellite Status Indicator

H. Legends Tab

I. Markers Tab

J. Field Operations Tab

Guidance Tab

K.

L. Product Tab

M. Product Control Toolbox

N. Vehicle Icon

O. Equipment Tab

P. AutoTerrain/AutoHeight Settings

Q. Summary Screen

R. Map Views

S. Split-Screen (HC 9600 only)

T. Universal Terminal

U. Video Button

V. 4-Wheel Steer Logging Button

W. AutoTerrain/AutoHeight ON/OFF

X. AutoSectionControl (Autoswath)

Y. AutoSteer Button

Z. Main ON/OFF Switch Status

The task bar displays function buttons to the left (Q to U), and status indicators to the right ( V to Y) relating to various

functions of the display. These buttons are shown in front of a green background when function is enabled or you are at that

screen; otherwise they are shown in front of a blue background.

Buttons and indicators are explained in the following:

Equipment Tabs

Different Display Items can be selected by pressing the Equipment tabs (O).

Summary Screen

Pressing the Summary screen button takes you to the Summary Report screen. See “Summary Report” on page 171.

19

Page 22

3 - Description

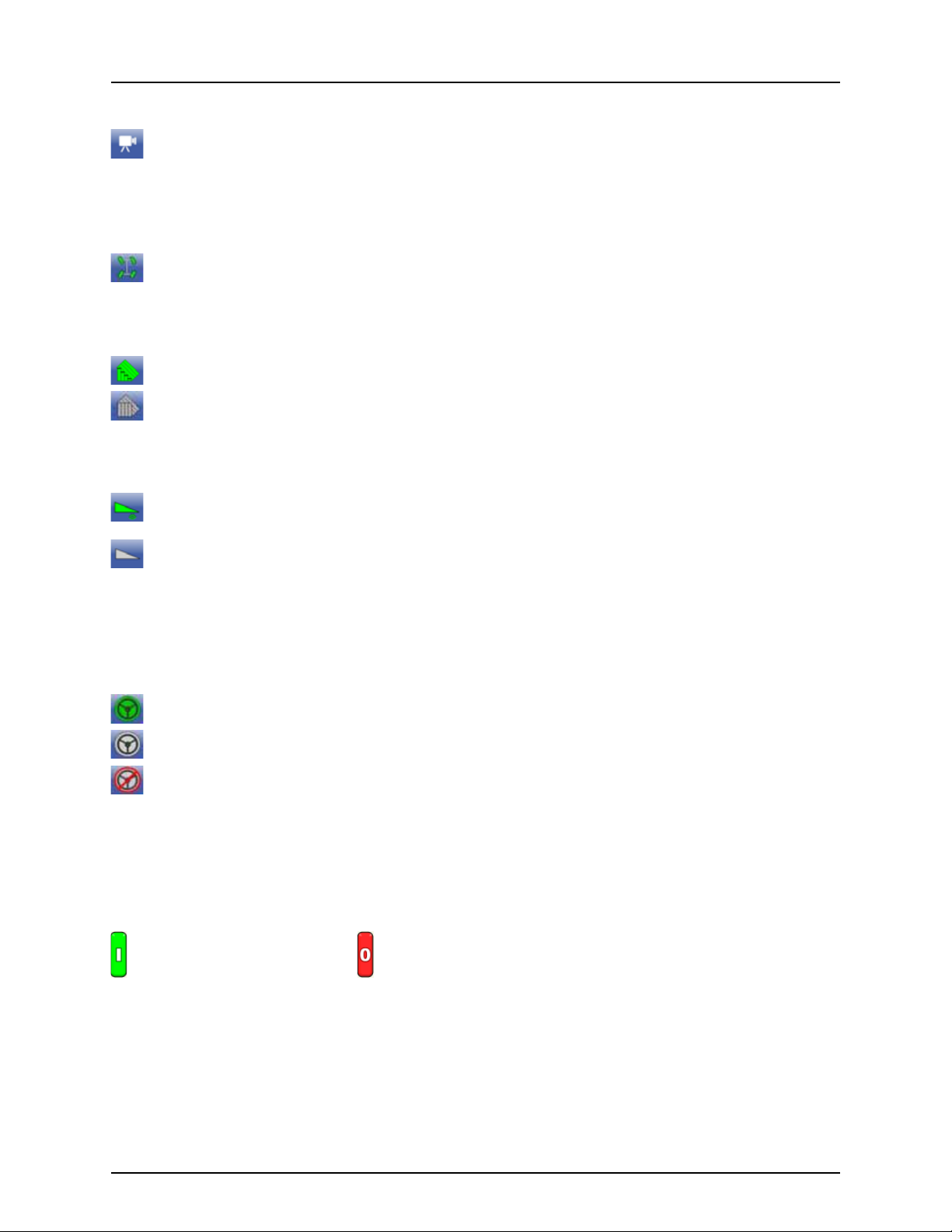

Video Button

Pressing this button takes you to the video screen. Pressing this button repeatedly cycles through the video inputs.

NOTE! For more information on the Video screen, see “Video” on page 27.

÷

4-wheel Steer Button (Self-Propelled only)

Activates logging of 4-wheel steering for AutoSectionControl.

AutoSwath Button

Pressing this button turns the AutoSwath (AutoSectionControl) feature on and off.

AutoSwath - ON

AutoSwath - OFF

AutoTerrain/AutoHeight button

The AutoTerrain/AutoHeight Engage button enables boom height control.

AutoTerrain/AutoHeight Engage - Enabled (Automatic Mode)

• When enabled the display beeps three times.

AutoTerrain/AutoHeight Engage - Disabled (Manual Mode)

• When you disable Automatic Mode on any part of the boom and the display switches to Manual Mode, this

button turns gray and the display beeps twice.

• If less than the full boom remains in Manual Mode, the display will continue beeping twice every three seconds.

AutoSteer Button

The Engage icon status of the AutoSteer system. The appearance of this icon displays the following:

AutoSteer is ON and ready to use.

AutoSteer is OFF but ready to engage.

AutoSteer is OFF and unable to engage.

NOTE! For more information, see “Steering” on page 115.

÷

Master Switch Status

This bar shows that the Master Switch is active.

Master Switch - ON (GREEN) Master Switch - OFF (RED)

20

Page 23

GPS Signal Indicator

The GPS button in the upper right-hand corner of the Map screen, displays the following colors:

Differential GPS

Green if you are receiving a differential GPS signal

GPS - No differential

Ye l l ow if you are receiving GPS, but no differential signal

No GPS

Gray if you are receiving no GPS signal.

Device Information button

Opens screens that display Device Information, Memory, Display, and display diagnostics.

NOTE! For more information, See “CAN Diagnostics” on page 183.

÷

3 - Description

Vehicle Icons

Vehicle Icon - When Zoomed Out

This gold colored triangle indicates the display is in “zoom to extent” mode. When in “zoom to extent” mode the

vehicle implement does not appear, but logged data will still populate on the map.

Vehicle Icon - logging

If the vehicle is logging, the implement icon appears with a green bar below it.

Vehicle Icon - logging (with all sections ON)

If the vehicle is logging data from an implement split into sections, (for instance during a planting or application

operation), then these sections appear in the implement icon.

Vehicle Icon - not logging

If the vehicle is not logging data, then the implement icon appears with a gray bar.

Vehicle Icon - Master Switch Off

When the master switch is off, the vehicle will show a thinner red bar.

21

Page 24

3 - Description

Corn

Yield

Legend

Save as Product Legend

Reset to Default

Legend

Automatic

Legend

Legend Settings

Attribute: Rate

Average

Color Scheme

Range Spacing

Range

Green-Yellow-Red

Legend

Map Toolbox

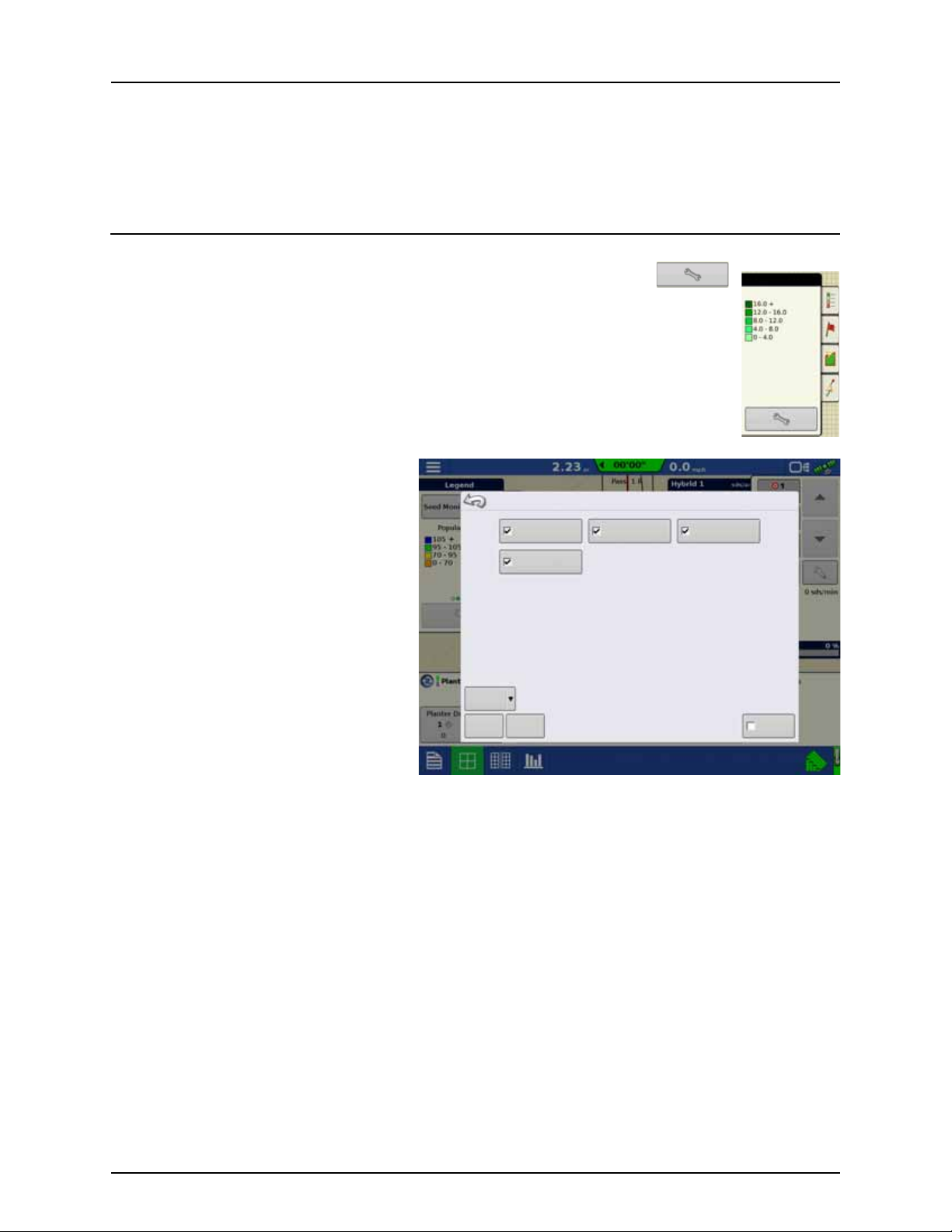

Legend Settings

The Legend Settings screen allows you to change the default legend. On the map legend tab, press

anywhere on the legend and the legend settings screen appears.

NOTE!

÷

• The Legend Settings screen can also

be accessed by pressing the Edit

Legend button on the Setup screen’s

Product tab.

• Legend settings changes that are

made at the Legend Settings screen

will affect all regions.

The Legend Settings screen includes the following

items:

• Attribute

Appears at the top left of the Legend Settings screen. Attributes shown for Harvest include Yield and Moisture. The

Rate attribute is shown for Planting and Application operations. You can adjust the color scheme, spacing and ranges

as they appear on the map screen, by using the buttons described below.

• Average

The Average button changes the average rate for the legend. Press to specify the average of the ranges

shown on the map legend.

• Range Spacing

The Range Spacing button changes the difference between the rates in one color range. Press to edit the

legend range spacing value, which is the total number of units represented by a particular color.

• Ranges

The Ranges / change the number of range increments displayed in the legend.

• Color Scheme

The Color Scheme can be modified by using the drop-down list. Choices include the following:

• Green-Yellow-Red

• Single Hue (blues or greens)

• Rainbow

• Reset to Default Legend

Resets the legend to the default settings.

22

Page 25

3 - Description

Water

RATE

Load

Reference

Map Options

Data

Perspe ctive

Row Outlines

Grid

Trave l Direc tion

Clear Map

Map Shift

Follo w View

Legend

• Automatic Legend

If the “Automatic Legend” check box is selected, the average automatically sets itself to the field average and updates

as the field average changes.

• Save as Product Legend

Select the “Save as Product Legend” check box if you wish to set the current legend as the default legend for all regions

of the same product.

Map Options

Here you can toggle mappable items, load references, or clear map. Press the Legend Setup

and the Map Options screen appears.

Clear Map

•

Permanently removes on-screen map from

the active field operation, but the log data

will still be exported to the USB drive.

WARNING! Once you clear the map, this

±

information cannot be retrieved.

• Load Reference

Loads a list of maps of previous operations

performed in that field. For each operation,

you can view As-Applied or Coverage

attributes; and Varieties if you are performing

a Planting operation.

23

Page 26

3 - Description

Map Shift

Map Shift

Reference Point Set

Going Back to Reference Point

Map Shift

Map Shift is used to shift the onscreen map and account for time base inaccuracies with lower accuracy GPS

receivers. This is done by doing a quick survey and creating a reference point. Any time the user would like to

adjust the map to fix GPS drift inaccuracies, they can go back to the reference point and perform a survey to

shift to the current position.

Map Shift General Guideline

For Map Shift to be successful, it is suggested that a reference point be set before beginning a field operation. That way any

time the vehicle leaves the field or is shut down for an extended period of time, the reference point can be used upon

returning to the field operation.

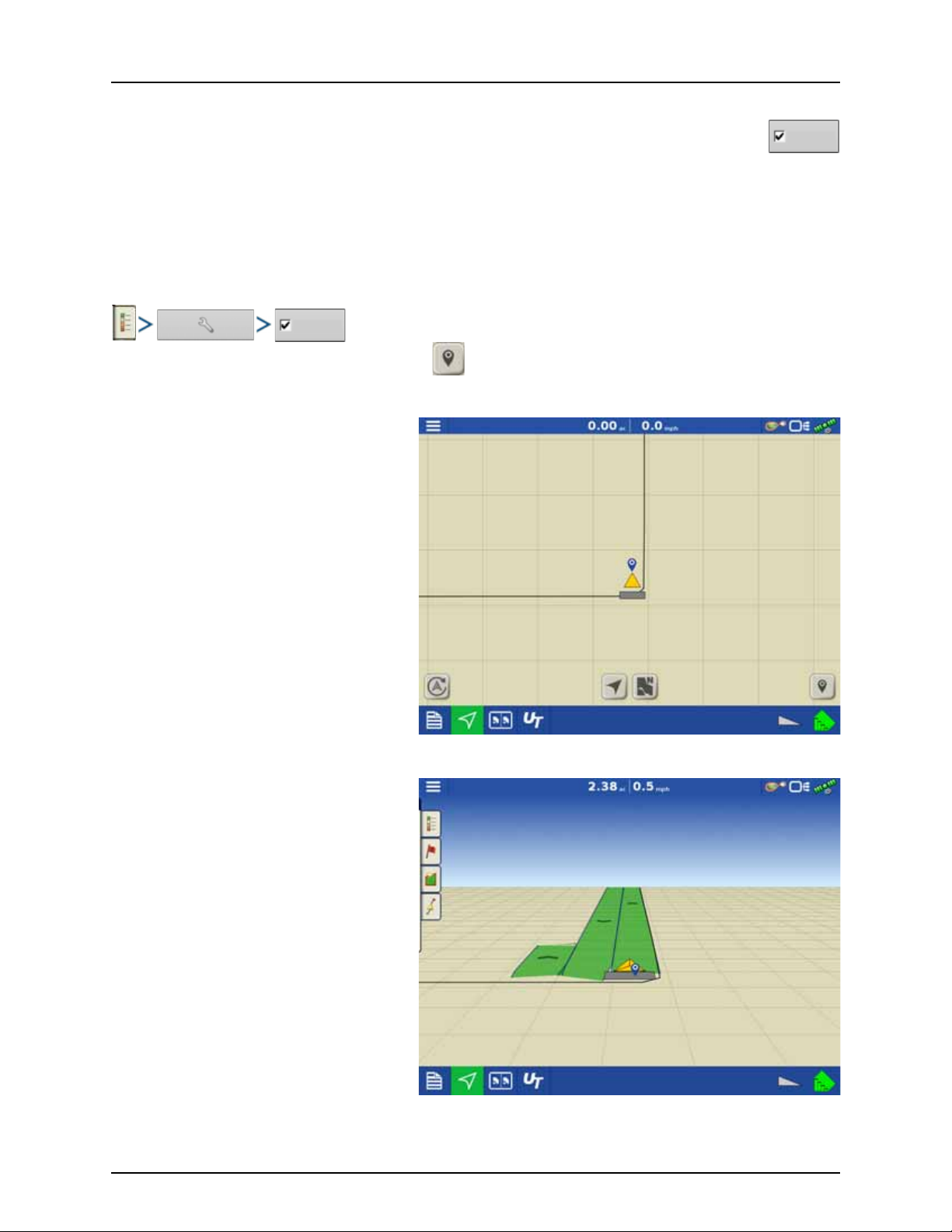

Enable Map Shift

With the map shift option checked, the map shift icon will become available when in full screen view on the mapping

screen.

Shifting the Map

1. Press the map shift icon to access Map Shift

Options.

2. Determine a good location to create a

reference point. For Map shift to work

properly, it is vital that the GPS receiver be

able to get back to the exact same point each

time a shift is required.

3. Once a spot is located, press “Set” on the Map

Shift options page to begin the 10 second

survey.

4. Once the survey is complete, the reference

point will be set. On the Mapping Screen, the

reference point is shown by a blue pin drop.

24

Page 27

5. When a map shift is required, go back to the

Shifting Map

Map Shift Options

Set saves a reference point

Shift moves the map to match the current position

Ensure GPS receiver is always at the same location is was when the reference point

was created

Reference point

Latitude:

Longitud e:

Current Position

In Progress

Positi on Surve y

Time Remaining: 9 s

Clear Set

Clear Shift

Cancel

set reference point and make sure the GPS

antenna is back in the original location.

6. Access the Map Shift Options menu and

press the “Shift” button.

3 - Description

7. “Shift” will start a 10 second survey and

update the map with the new current

position.

8. Any time a reference point or shift needs

cleared, it can be accomplished via Map Shift

Options.

25

Page 28

3 - Description

Legend Legend

Water Wat er

Rate

Perspective

Follow View

Top -D ow n

Follow View

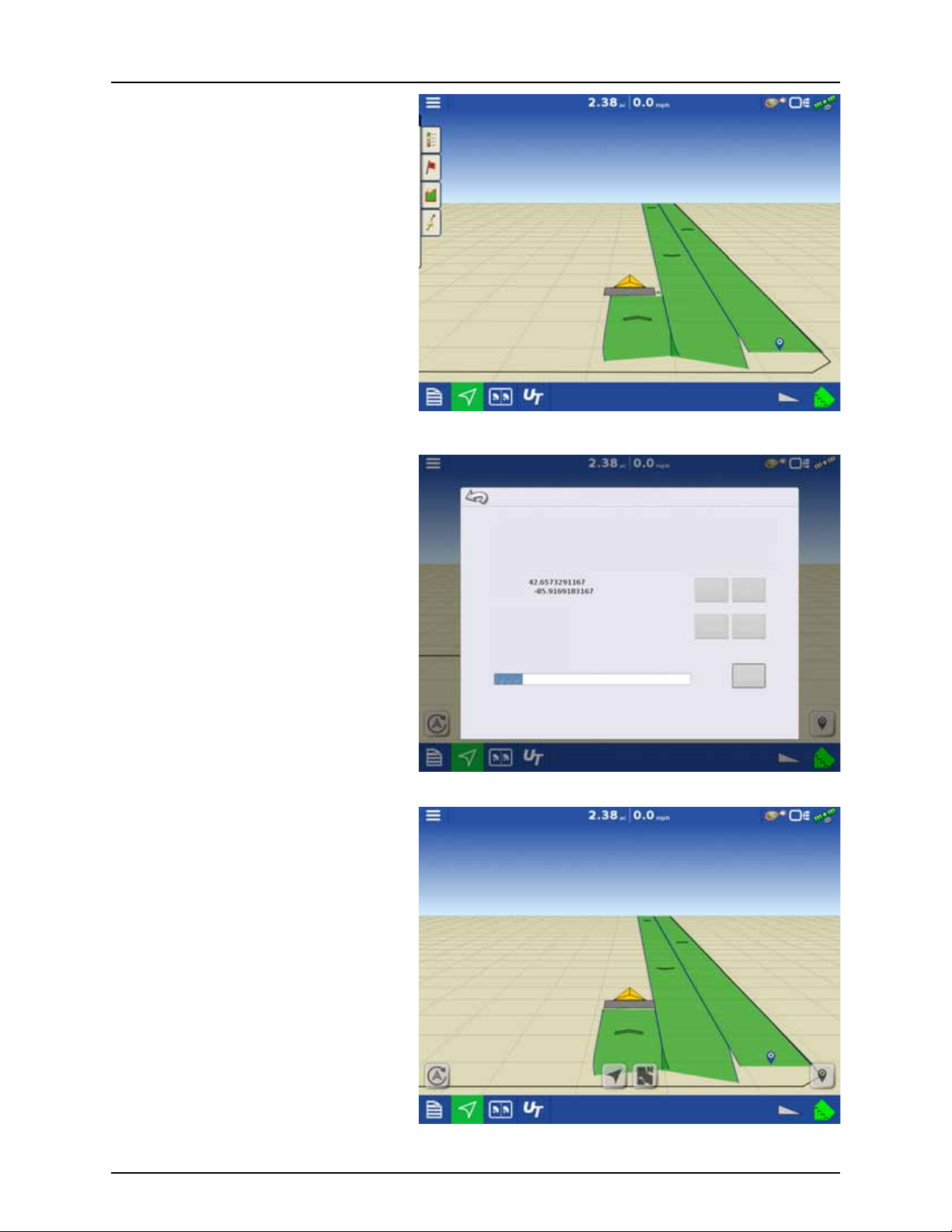

Split-Screen Map

The HC 9600 has the capability of showing multiple views at the same time from the map screen. This has multiple uses like

showing guidance in perspective view and zoom extents view at the same time, splitting the screen between guidance and

Universal Terminal, or watching two products at the same time like planting and liquid application.

Maps can be selected individually from the legend

drop-down.

Map views can be changed by tapping anywhere

in the center of the left/right side map then

choosing from one of the views buttons (A).

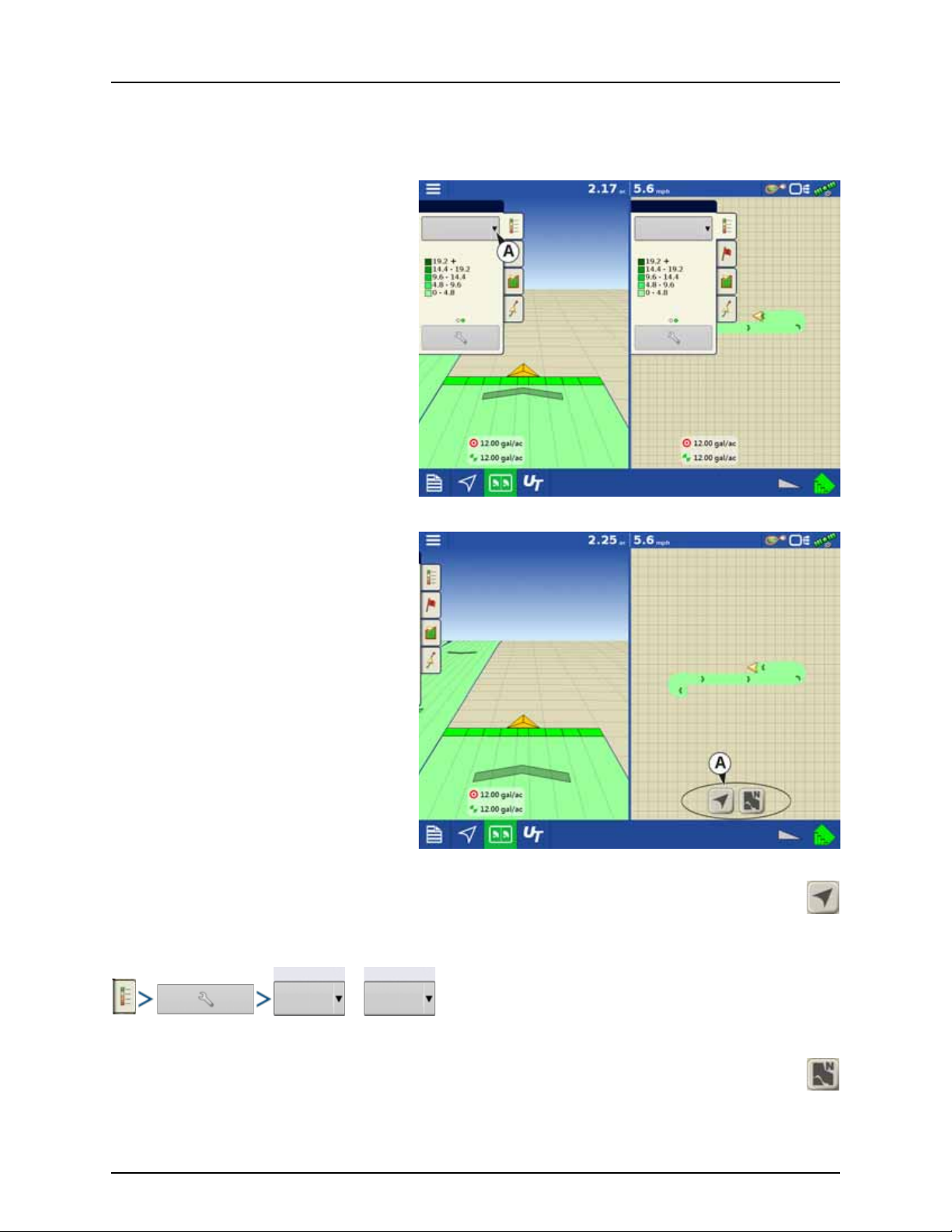

Follow View

Sets the map to follow the vehicle icon. The default Follow View can be set to either Perspective view or Top-Down

view.

Setting the Follow View mode:

or

North Oriented View

Zooms the map out to the full extent of the field boundary or mapped area and orients the map north, regardless of

the vehicle’s direction of travel.

26

Page 29

3 - Description

Volume rate

gal/acre

PF bus + PF bus -

Volt Volt

Agitation

%

Voltmeter

Volt

Volume rate

gal/acre

Markers

Rock

Washo ut

Weeds

Trees

By pressing the UT button (B) from the map screen,

the display will split the screen between Map

screen and Universal Terminal.

In same manner with Cameras attached,

pressing the video button will split the

screen between the active map and the

video page.

Markers tab

Markers are a collection of point objects that are available on the Map Markers tab of the Mapping

toolbox. Map markers allow you to map points on the go in order to identify specific features within a

field. Press an individual marker to indicate a Map Marker on the Map screen.

If all of the Markers that you created are not immediately visible in this screen, swipe the tab to view

more markers that you created.

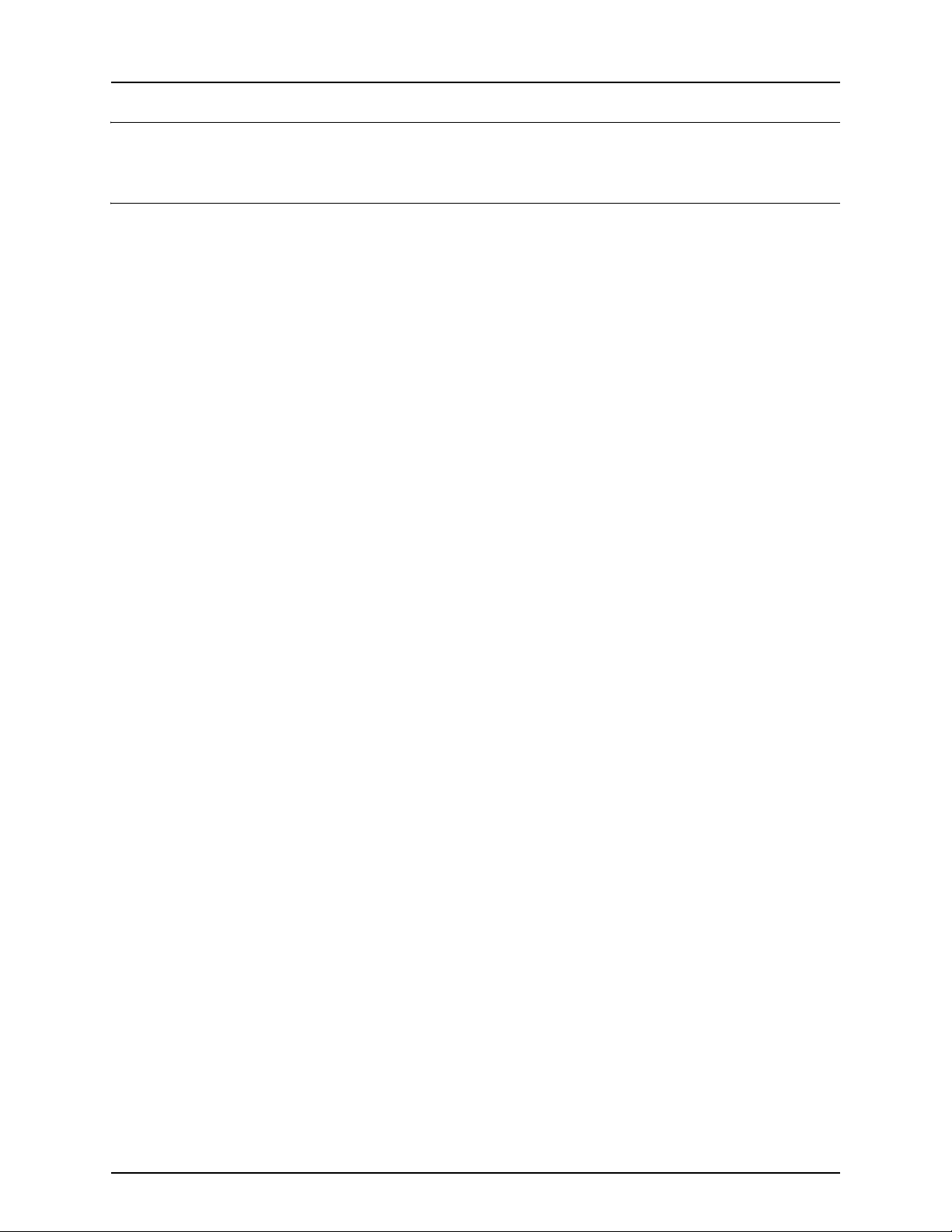

Video

NOTE! Video is only available when enabled in the Console Setup menu - see “Display Button” on page 84.

÷

Video button. Camera is available from the Home or Map screen. Press video button and the Video screen appears.

• Brightness

Press / to increase or

decrease the brightness of the video input.

• Contrast

Press / to increase or

decrease the contrast of the video input.

• Camera Number Selection

The display can receive input from up to four

video cameras. Press the numbered buttons

to switch views between video cameras.

NOTE! You can adjust the brightness and

÷

contrast of each input individually.

27

Page 30

3 - Description

AgFiniti

General Info

AgFiniti is a platform to provide users with the ability to quickly and easily transfer data, view their display remotely, and take

logged data with you when you leave the cab.

AgFiniti Mobile

AgFiniti Mobile is Ag Leader’s native iOS app. It provides the ability to take maps and summary information from the cab

instantly and access it on an iPad anywhere. The app allows for a direct connection to the display, reducing the need for a

modem or Wi-Fi hotspot in the cab and provides a simple, direct connection to access data. AgFiniti Mobile also allows for

multiple display connections, allowing for operations with multiple displays to have their logged data all in one iPad. Lastly,

it is a permanent storage solution; data imported into Mobile will remain there until removed by the user or the app is

uninstalled. See “AgFiniti Mobile” on page 135.

File Transfer

AgFiniti File Transfer is a wireless file transfer solution. It allows the user the ability to both access and export data to and from

the cloud. This results in data being accessible anywhere without requiring a USB drive. You can export prescriptions and

management information from SMS and have them instantly accessible in your tractor by using AgFiniti File Transfer. File

Transfer also allows for the sharing of data with other users and trusted advisors, again, without having to hand them a

physical drive. File Transfer requires an annual license. See “File Transfer” on page 140.

Remote Support

AgFiniti Remote Support grants the ability to remotely view a display from the AgFiniti website on supported browsers. This

allows for faster, more effective troubleshooting due to the user being able to view the display and not relying on secondhand descriptions. This can result in less downtime and fewer frustrations when issues do occur. This can also help when

setting up displays for the first time and provides an avenue for getting help in a more efficient manner. Remote Support

requires an annual license. See “Remote Support” on page 141.

AgFiniti Mobile Connection Types

Display Access Point Mode

This connection type turns your HC 8600/9600 display into a wireless access point that all compatible iPads can connect to.

When using this connection type, every time an iPad is within range of your HC 8600/9600 display, AgFiniti Mobile will

automatically download new data while the app is running.

See “Display Access Point connection type” on page 132 for step by step instructions to make this connection type.

Wi-Fi Network

Connection scenarios:

• Transferring information when both devices are connected to the same home/office Wi-Fi network

• A hotspot (i.e. Jetpack) device is used in the cab to provide internet

When both the HC 8600/9600 display and your iPad are connected to the same network, for example your home Wi-Fi

network, they will be able to recognize one another and transfer data in the same fashion as the other two connection types.

If you already have a Wi-Fi network present in the cab of your vehicle, this connection can be utilized. To use this connection

type, the HC 8600/9600 display and AgFiniti Mobile need to be on the same wireless network.

See “Cellular iPad as Personal Hotspot Connection” on page 142 for step by step instructions to make this connection type.

Cellular iPad as Personal Hotspot

Connection scenarios

• Only Cellular iPads when HC 8600/9600 is accessing AgFiniti Cloud

Cellular based iPads have the ability to act as a personal hotspot. This allows HC 8600/9600 to both access the AgFiniti cloud

and directly transfer information from the HC 8600/9600 display to AgFiniti Mobile, both through the iPad’s cellular

connection and Wi-Fi hotspot. This connection type would need to be used to access AgFiniti cloud. For example you may

need to download an .agsetup file (for prescriptions) from AgFiniti cloud or to use remote support.

See “Cellular iPad as Personal Hotspot Connection” on page 142 for step by step instructions to make this connection type

NOTE! Using this connection type to transfer data directly from the HC 8600/9600 display to your iPad will not utilize

÷

your cellular data. The connection is over Wi-Fi and therefore does not use cellular data. If you use your iPad to

connect to AgFiniti Cloud to download data, then cellular data will be used.

28

Page 31

3 - Description

Miscellaneous

About AutoTerrain/AutoHeight

For the use of AutoTerrain/AutoHeight together with HC 8600/9600, please refer to the specific AutoTerrain/AutoHeight UC5

instruction books.

Glossary of Application Settings

Configuration Settings

• Rate Outside of Field

Rate that will be used outside of the field boundary.

• Zero stops product application.

• Last Good uses the previous rate before exiting the boundary.

• Rx Default uses the default rate written in the prescription file loaded.

• Rate Change Look-Ahead

Compensates for any delay in the control system when changing between different product flow rates during variable

rate application. This setting can be thought of as a “look ahead” value when using a variable rate prescription.

The display will send the signal to change rates before hitting a transition line so that the applied rate is correct when

crossing into the new management zone.

• The typical setting range for this is 0-1 seconds.

Speed Input Settings

• Primary Speed Source

Main source used by the display.

• Backup Speed Source

If the primary speed source fails, the display will use the backup if one is available.

• Manual Speed

If both of the sources are unavailable, manual speed can be used in order for the control channel to provide application.

Manual speed setting is for use during static machine testing or by the control system in the absence of primary and

backup speed signals.

Automatic Swath Control Settings

• Turn-On Look-Ahead

Determines how far ahead the system looks to turn the swath sections back on. This setting compensates for any delay

in the product control system when the sections are turned on.

• Turn-Off Look-Ahead

Determines how far ahead the system looks to turn the swath sections off. This setting compensates for delay in the

product control system when the boom sections are turned off.

• Outside Boundary Option

Determines the behavior of the sections when exiting the field boundary or prescription-mapped area.

• Coverage Option

Based on the coverage option selected, this setting determines the behavior of the swath section when

entering/exiting an already applied area or field boundary.

Options available include:

• Minimize Skip

• Minimize Overlap

• User Defined Percentage.

Run Screen

• AutoSwath (AutoSectionControl)

Use to enable/disable automatic control of boom section on/off state based upon field boundaries, prescription files,

and previously applied areas.

29

Page 32

3 - Description

30

Page 33

4 - System setup

Installation

Installation Instructions

Mount the display to a secure support inside the vehicle cab. When choosing a mounting location consider if the display:

• is readily accessible to the machine operator.

• does not obstruct the machine operator's normal driving view.

• does not interfere with or limit access to any of the existing machine controls.

• is fitted so the ISOBUS system cabling is routed and secured without interfering with existing machine controls.

WARNING! If drilling holes is required during the mounting process, care must be taken to ensure that damage is not

±

done to existing vehicle wiring, mechanical, or cab structure. Refer to vehicle manufacturer documentation for

specific details on your equipment. Follow all OEM instructions, cautions, and warnings when working around

equipment.

Components of Ram mount kit:

• 9600 Display: HARDI® Part #72802400

• 8600 Display: HARDI® Part #73156900

A. RAM Base

B. RAM Arm

C. Base

31

Page 34

J02

J04

P01

J03

J01

J05

J06

J04

J06

J10

J09

J01

J03

A

G

C

J07

J08

P02

M

J01

P01

J02

P01

D

J03

P02

P03

J06

J07

F01

J02 J01

J05 J06

J01

J02

H1

H

F

B

4 - System setup

Cable connections

Non ISOBUS Tractor

A. 26069200/4004664-1

Display cable, Guidance activation - 3.8m

J01 - Display Main

J06 - Guidance Activation

P01 - Power IN

J05 - CAN A

J04 - GPS

J03 - ISOBUS

J02 - Digital I/O

J07 - Display Ethernet

J08 - Ethernet Out

C. 26040900/ 4002820-1

Power, display/guidance

J04 - Power 5A

J06 - Power 15A

J09 - Battery ground

J10 - Battery power

J01 - Fuse, 5A blade style

J03 - Fuse, 15A blade style

B. 26069400/ 4004666-1

ISOBUS Retrofit cable

P01 - Display cable

P03 - ISOBUS out

J07 - ECU Power

J03 - IBBC Relay Module

P02 - IBBC Relay Module

F01 - Fuse, 5A Blade style

J06 - Battery power

D. 26040500/ 4002825

ISOBUS Termination Assembly

J02 - ISOBUS

J01 - Active terminator

F. 26040600/ 4002827-16

ISOBUS Power Cable

H. 26040300/ 4002826

ISOBUS IBBC

M. 26069900/ 4004668-1

ISOBUS Joystick Tee cable

J01 - ISO CAN Out

P01 - ISO CAN IN

P02 - Grip Connector

J02 - Jumper

G. 26031500

HARDI® Grip and SetBox cable

Grip and SetBox kit include the cable G.

Display cable kit 83365003 includes cables:

A, C, D and M.

Tractor ISOBUS kit 83365103 includes cables:

B, D, F and H.

32

Page 35

J02