Page 1

Content

Glossary and pictorials symbols ................................................. 2

Operator safety ........................................................................... 3

Description .................................................................................. 3

Fitting the system ........................................................................ 4

Power supply ........................................................................ 6

Scanbox ................................................................................ 7

Display .................................................................................. 7

Transducer colour codes and plug assembly........................ 8

Speed transducer.................................................................. 8

Flow transducer .................................................................... 9

Optional transducers ............................................................10

Start-up ...................................................................................... 11

Reading chosen volume rate ............................................... 11

HM 1500: Changing the desired volume rate for alarm ....... 11

HC 2500: Changing the volume rate.................................... 11

Menus ....................................................................................... 13

General keystroke ................................................................13

Keystroke menu tree chart ...................................................14

Main menu .......................................................................... 15

Display readout ....................................................................16

Tank contents ...................................................................... 17

Calibration ........................................................................... 18

Alarms ..................................................................................23

Sensor test .......................................................................... 25

Area meter .................................................................................26

Mistblowers and HM 1500/HC 2500 ..........................................26

Storage ......................................................................................27

Emergency operation ................................................................ 27

Fault finding .........................................................................27

Technical specifications ............................................................ 29

Chart for recording values......................................................... 30

Extended menu ......................................................................... 30

EC Declaration of Conformity ................................................... 32

Parts.......................................................................................... 33

Controller 2500 &

Monitor 1500 ver. 1.13

Instruction book

673294-GB-2002/09

HARDI INTERNATIONAL A/S is without any obligation in relation to implements purchased before or after such

changes.

HARDI INTERNATIONAL A/S cannot undertake any responsibility for possible omissions or inaccuracies in this

publication, although everything possible has been done to make it complete and correct.

Published and printed by HARDI INTERNATIONAL A/S.

1

Page 2

We congratulate you for choosing a HARDI plant protection product.

The reliability and efficiency of this product depend on your care.

Read and pay attention to this instruction book. It contains information for the efficient use and long life of this quality product.

Glossary and pictorials symbols

HM 1500 HARDI Monitor 1500.

HC 2500 HARDI Controller 2500.

Scanbox Junction box for HM 1500 and HC 2500.

Transducer Device that transforms variations to a signal.

Also called a sensor.

[ x ] or [ y ] Variable figures.

PPU Pulses per unit. For flow calibration.

The unit measure is litre.

UPP Unit per pulse. For speed calibration.

The unit measure is metre.

PPR Pulses per revolution. For revolutions calibration.

BK HARDI manual control unit.

BK/EC HARDI manual control unit (with electric on/off and

pressure regulation).

EC HARDI electric control unit.

EVC, ESC or CB Electric control unit (without main valve).

Description/Notes

Warning

Assembly

Operation/Use

NOTE: Text shown in square brackets or in the rectangular window will

be seen on the display.

E.g. [ MAIN MENU ]

Winter storage

Operational problems

Technical specifications

EC Declaration of Conformity

MAIN MENU

Display readout

2

Page 3

Operator safety

Watch for the WARNING symbol

be alert! Note the following recommended precautions and safe

operating practices.

Read and understand this instruction book before using the equip-

ment. It is equally important that other operators of this equipment

read and understand this book.

Turn electrical power off before connecting and disconnecting the

display and transducers, servicing or using a battery charger.

If an arc welder is used on the equipment or anything connected to

the equipment, disconnect power leads before welding.

Test with clean water prior to filling with chemicals.

Keep children away from the equipment.

Do not use a high pressure cleaner to clean the electronic

components.

Press the keys with the underside of your finger. Avoid using your

fingernail.

If any portion of this instruction book remains unclear after reading

it, contact your HARDI dealer or HARDI service personnel for

further explanation before using the equipment.

. Your safety is involved so

Description

The HARDI Monitor 1500 and HARDI Controller 2500 are for use in

agricultural and horticultural production. HM 1500 is a monitor whereas

HC 2500 permits automatic control of application rate.

Main components are:

• Display

• Scanbox junction box

• Flow transducer

• Speed transducer

The matrix display has two lines permitting two lots of information to be

shown at the same time. Display readout includes dosage applied,

speed, liquid rate per minute, total covered area, total volume sprayed

and 9 trip tellers for area covered and volume sprayed. It is illuminated

internally so readout is possible even for night-time work.

3

Page 4

Functions include correct area with closure of up to 8 spray boom

sections, alarm functions for dosage and minimum tank contents and

possibility for audio/visual alarm.

The transducers utilised are chosen for long service life and good

signal quality. Speed, area switch and revolutions transducer is the

same component. The flow transducer has a diode built into the

housing to aid servicing. As the rotor turns, the diode will flash thereby

indicating it functions.

The system has a non-volatile memory with no battery which simplifies

storage. All parameters in the menus are saved in the display’s

memory and are not lost when the power is disconnected.

The materials and electronics for the components have been developed to last many years under agricultural conditions.

Options include a 4-20 mA transducer (e.g. pressure), revolutions

transducer, area meter transducer and switch box for boom sections

when used with BK or BK/EC control unit (only for HM 1500).

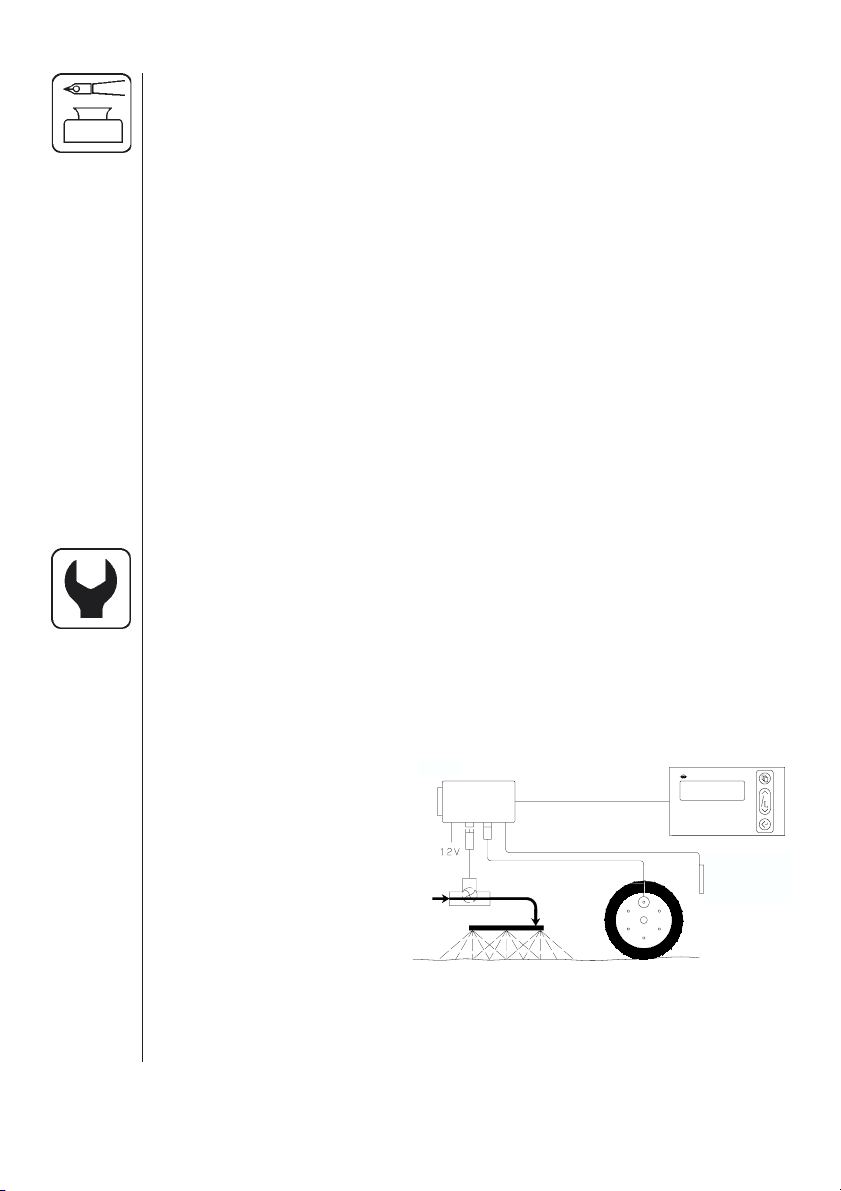

Fitting the system

Please note the configuration and connections for your system.

HM 1500 Monitor with manual control unit (BK, BK/EC)

The active boom width is always the total boom width.

The system can not automatically calculate correctly when one or more

boom sections are turned off.

1. HM 1500 display

2. Display connector cable

4.

3.

2.

1.

3. Scanbox (fuse inside)

4. On/off switch

5. Speed transducer

6. Flow transducer

7.

6.

8.

5.

7. To 12 Volt power supply

8. Switch box connector

cable (not used)

4

Page 5

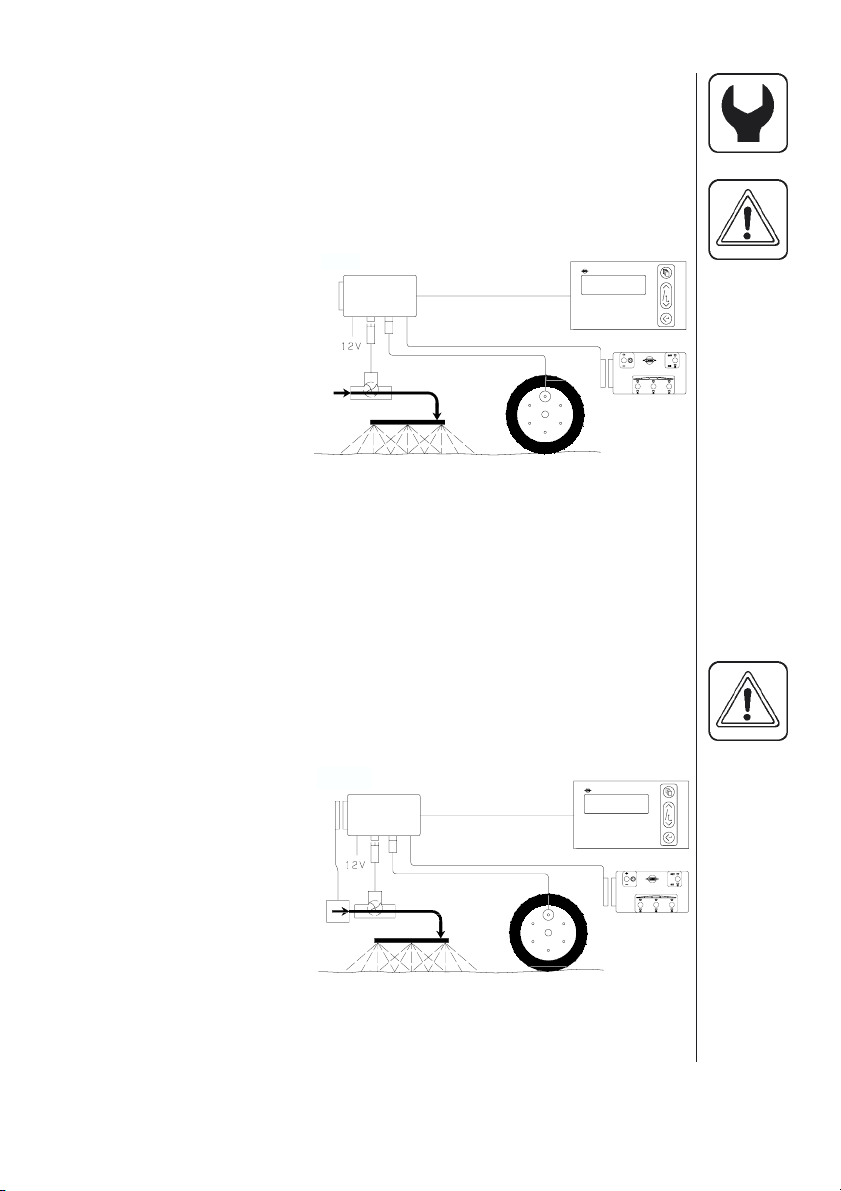

HM 1500 Monitor with manual control unit (BK, BK/EC)

and switch box for boom sections

Active boom width is calculated automatically.

The control box switches are set to correspond with the boom sections.

NOTE: Extended menu setting:

[ Control box ] is [ Connected ].

See “Extended menu”.

1. HM 1500 display

4.

3.

2.

1.

2. Display connector cable

3. Scanbox (fuse inside)

4. On/off switch

5. Speed transducer

6. Flow transducer

7.

6.

8.

5.

9.

7. To 12 Volt power supply

8. Switch box connector

cable

9. Switch (control) box

HM 1500 Monitor with electric control unit

(EC, EVC, ESC, CB)

Active boom width is calculated automatically when the boom sections

are operated.

NOTE: Extended menu setting:

[ Control box ] is [ Connected ].

[ ON/OFF valve ] is [ Not present ] for EVC, ESC and CB.

See “Extended menu”.

1. HM 1500 display

4.

2. Display connector cable

3. Scanbox (fuse inside)

4. On/off switch

5. Speed transducer

11.

7.

6. Flow transducer

7. To 12 Volt power supply

10.

8. Control box connector

cable

9. Control box for electric control unit

10. Electric control unit

11. Connector cable from control unit

3.

6.

2.

1.

8.

5.

9.

5

Page 6

HC 2500 Controller with electric control unit

(EC, EVC, ESC, CB)

Active boom width is calculated automatically when the boom sections

are operated.

NOTE: Extended menu setting:

[ ON/OFF valve ] is [ Not present ] for EVC, ESC and CB.

See “Extended menu”.

1. HC 2500 display

2. Display connector cable

3. Scanbox (fuse inside)

4. On/off switch

5. Speed transducer

11.

4.

7.

3.

6.

2.

1.

8.

5.

6. Flow transducer

7. To 12 Volt power supply

10.

8. Control box connector

cable

9. Control box for electric control unit

10. Electric control unit

11. Connector cable from control unit

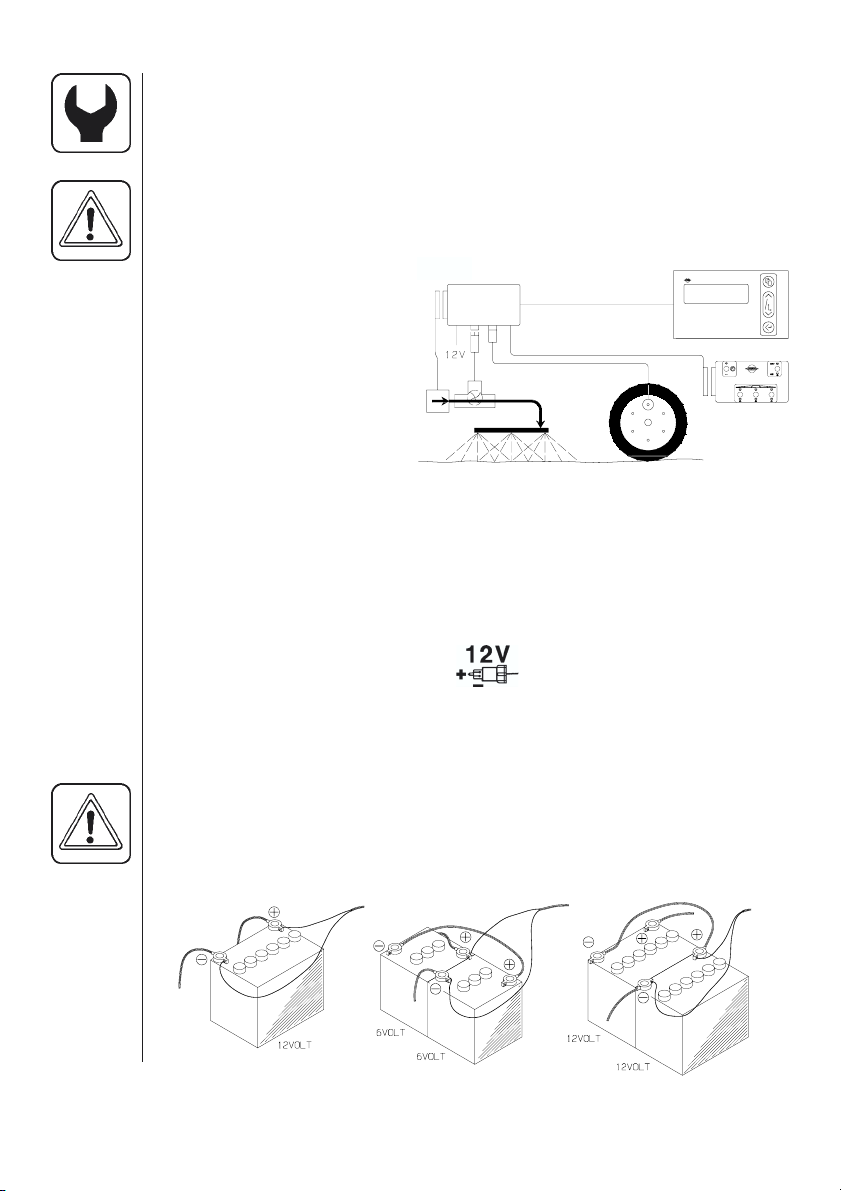

Power supply

The power supply is 12 Volt DC.

Brown wire is positive “ ⊕ ”.

Blue wire is negative “ - ”.

Power supply must come directly from the battery. The wires must

have a cross-sectional area of at least 1.0 mm2 to ensure sufficient

power supply.

NOTE: Do not connect to the starter motor or generator/alternator.

Warranty is void if this is done.

9.

Use the HARDI Electric distribution box (Ref. no. 817925) if the tractor

has a doubtful wiring.

T165-0002

6

Page 7

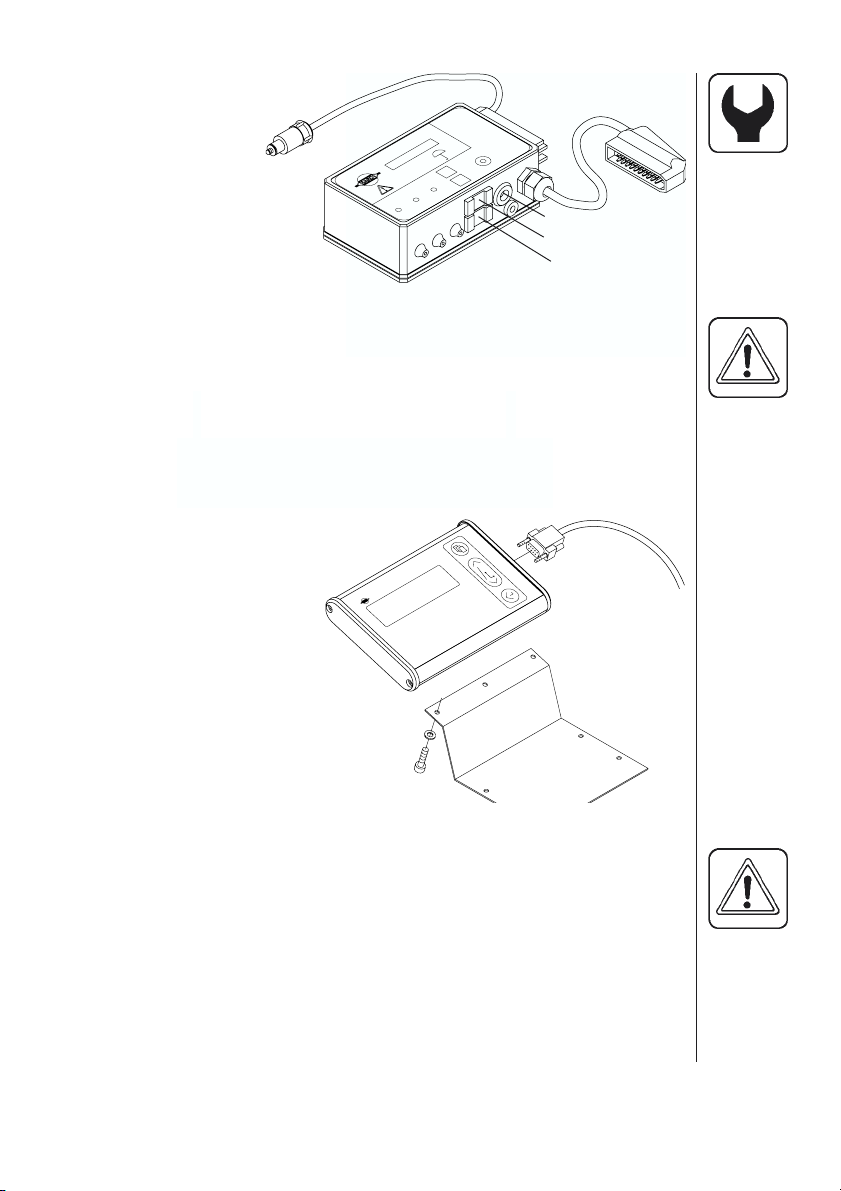

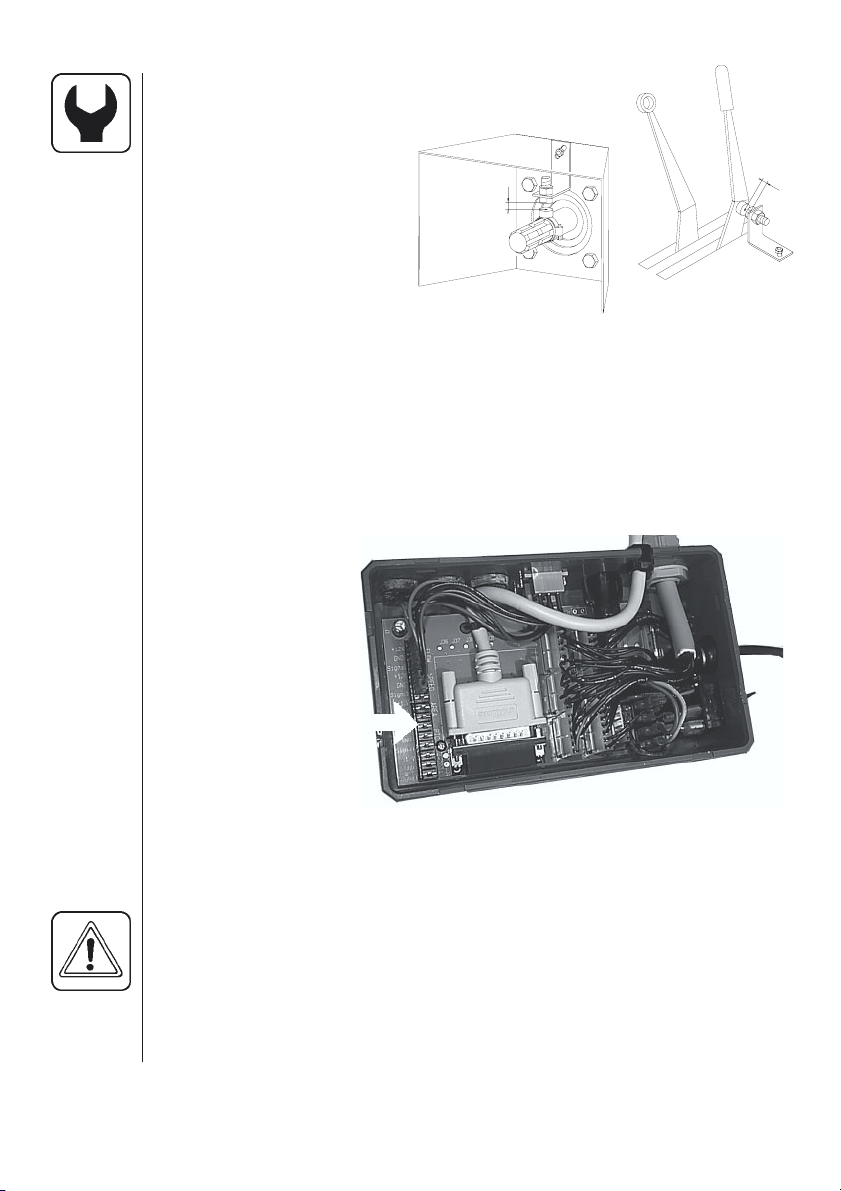

Scanbox

The box is not water

proof and must be

protected from

moisture. Place in the

tractor cabin for example,

behind the driver seat.

It should be secured from

12 Volt Max. 5 Amp

Flow

Speed

movement.

NOTE: If the tractor is without a cabin, it is recommended to cover the

Scanbox and display with a rain protection bag. This is available as an

optional extra.

Fuses are located inside the box.

Fuse 1.25 T Amp Slow acting (HARDI ref. no. 261589)

The 2-pole 12 Volt socket has a maximum rating of 5 ampere.

Fuse 5.0 Amp Quick acting (HARDI ref. no. 261762)

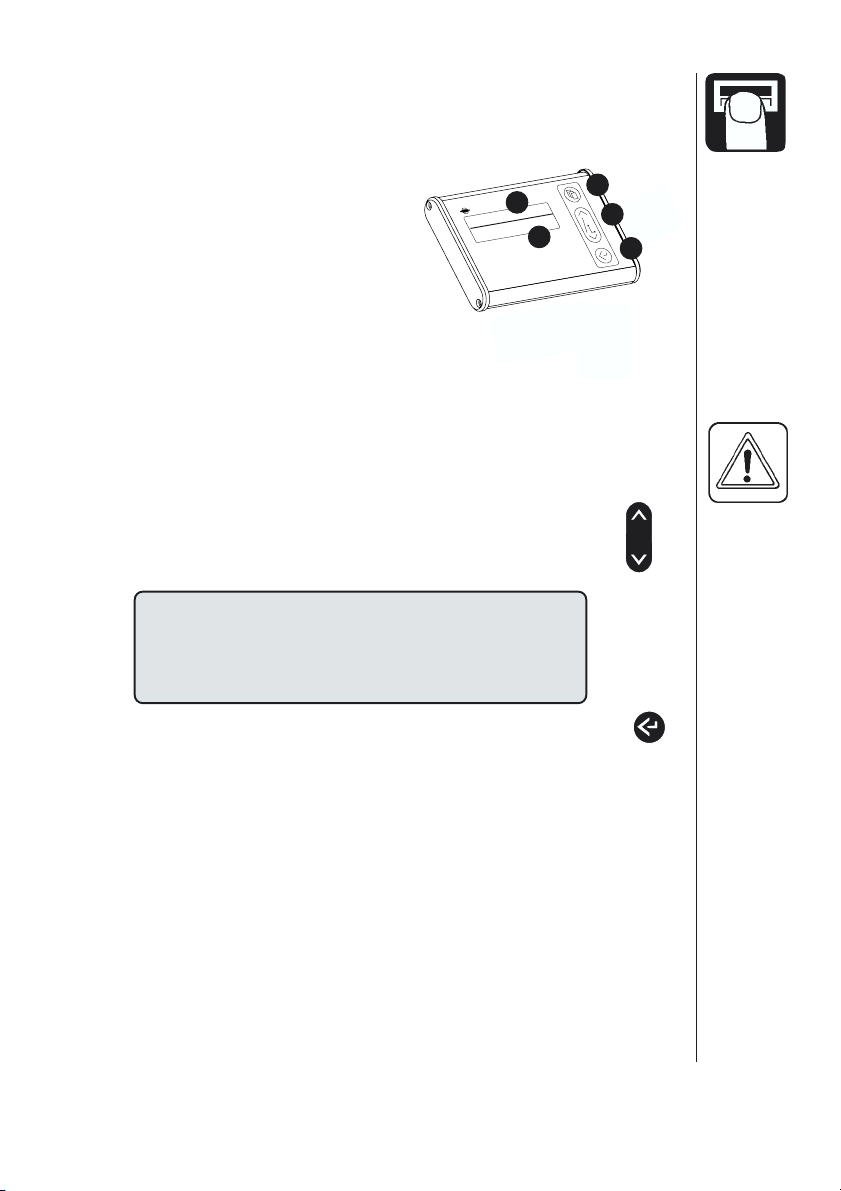

Display

The display is fitted in the

tractor cabin at a convenient

place. Use only the supplied

screws.

The mounting plate (A) is

utilised to fit the display together

with the switch box. The display can

also be fitted to a flat surface with

“Velcro” tape.

C

ABA

Place “ Quick guide” sticker at C

NOTE: Power must be disconnected before plug (B) is connected to

the display.

7

Page 8

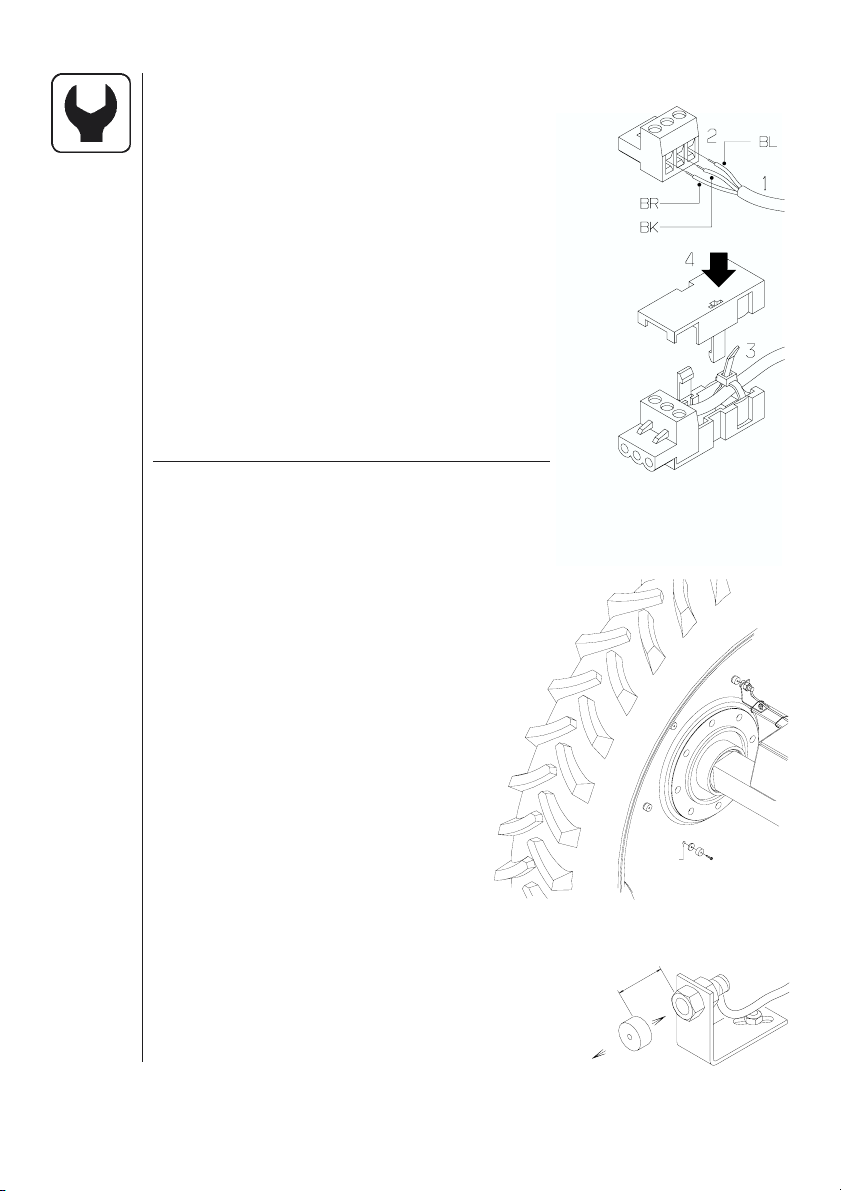

Transducer colour codes and plug assembly

1. Shorten cable to a suitable length.

2. Assemble as shown.

3. Run tie strap through hole under cable

grip and secure cable to plug housing.

4. Trim tie strap length and assemble the

housing. Tag the speed transducer by

folding the identification sticker around

the cable.

5. Secure plug housing with a tie strap.

HARDI transducers colour codes are as

follows. Includes speed, flow, area meter,

revolutions and pressure transducers.

Wire colour Code Connection for transducer

Brown BR 12 Volt supply

Black BK GND

Blue BL Signal

Speed transducer

Speed transducer is fitted as shown.

Hole size is 4.5 mm.

Magnets must be placed an equal

distance (and at least 150 mm) from one

another.

T165-0003

Recommended number of magnets

fitted are as follows:

Tractor front wheel

(rim size up to 20”) ........................ 4

Tractor rear wheel

(rim size over 20”) .........................6

4.5 mm

3

/16

Transmission drive-shaft ...............1

The south side of the magnet must

face the transducer.

Distance between them must be 5 to 7 mm.

T165-0004

1

5-7 mm

-

8

1

/

N

4

/

S

8

Page 9

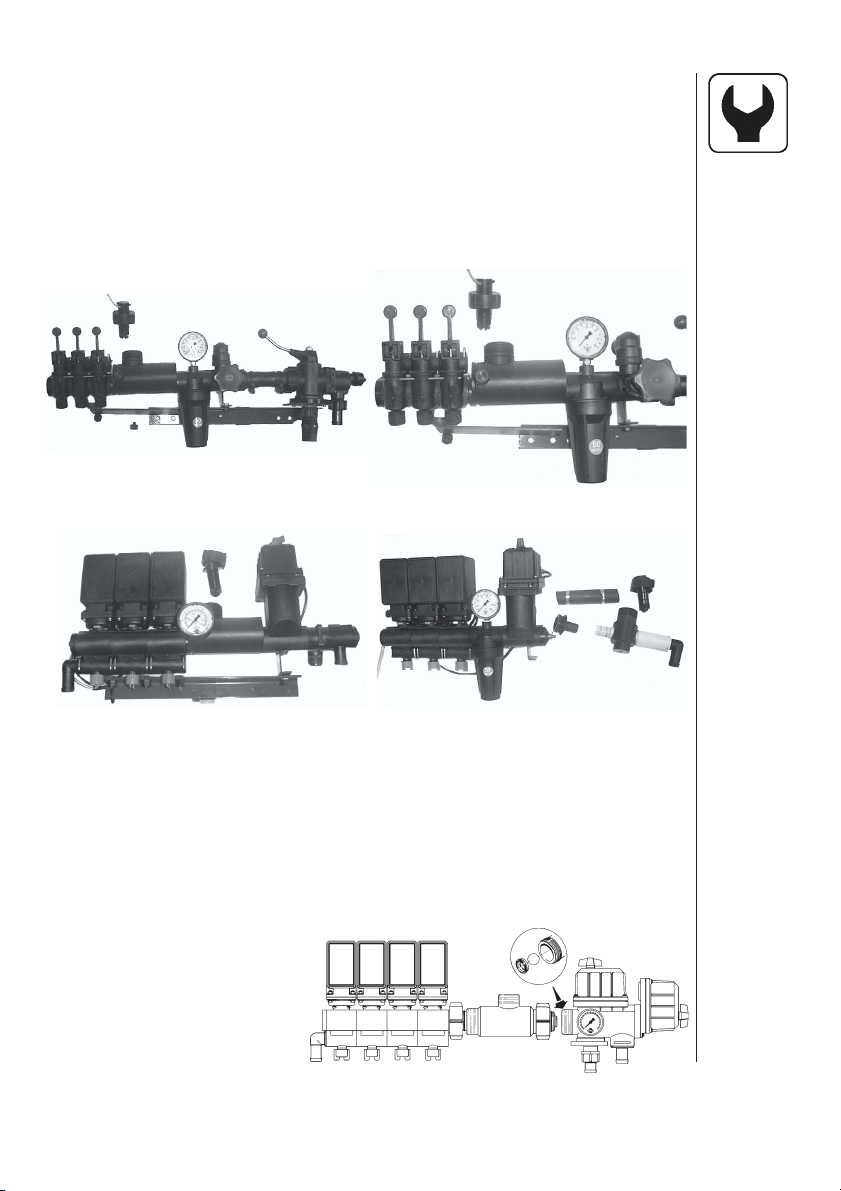

Flow transducer for BK, EVC and ESC control unit

For BK and EVC control unit, the housing is fitted just prior to the

distribution valves. Flow transducer is fitted to the housing and connected to the Scanbox with the a 3 poled plug.

For ESC control unit, the flow housing is fitted just prior to the control

unit on the delivery hose from the pump. Flow transducer is fitted to the

housing and connected to the Scanbox with the a 3 poled plug.

BK BK

EVC

ESC

Flow transducer EC control unit

1. The distribution valve unit is detached from the main ON/OFF

valve unit. Note the orientation of the ball seat and remove it from

the distribution valve unit.

2. Mount the flow transducer housing just before the distribution

valves.

3. Attach distribution valves with flow housing with the ball seat on

the end to main ON/OFF valve unit.

4. Flow transducer is fitted

to the housing and

connected to the

Scanbox with the

a 3 poled plug.

9

Page 10

Optional transducers

Revolutions and area-meter transducer

The south side of the

magnet must face the

transducer.

Distance between them

5-7 mm

must be 5 to 7 mm.

An adjustable hose clamp

drilled with a 4.5 mm hole

can be used to attach the

T165-0005

magnet to the shaft.

Analog transducer

Input is 4 to 20 mA.

Transducer cables are fed through the Scanbox grommets. Connection

is directly to the Scanbox circuit board.

NOTE: A 2 metre cable extension set with plugs and sockets is avail-

able. HARDI ref. no. is 741610.

5-7 mm

T165-0006

10

Connection pins

Cables

All the cables and wires must be routed so they do not get pinched,

snagged or melted. The transducer cables should be shortened if

necessary.

NOTE: Although the system meets standards EN 50081-1 (1992) for

generic emission and EN 50082-2 (1995) for generic immunity, some

communication systems (e.g. 2 way radio, cellular telephones) may

cause interference with the sprayer computer. Keep communication

system units and cabling away from the sprayer computer units and

cabling. If interference is noted, avoid using the communication system.

Page 11

Start-up

After connecting the plugs, the power is turned on at the Scanbox.

Model, version number and boom sections and size is displayed briefly.

Display

1. Matrix display, upper line.

2. Matrix display, lower line.

3. Key for menu.

4. Arrow keys.

• For programmed application rate.

With HM 1500, the value is used for the dose alarm.

• To get to (scroll).

• To alter a parameter.

5. Key to accept or get out of a menu.

NOTE: Press the keys with the underside of your finger.

Avoid using your fingernail.

1

3

4

2

Reading chosen volume rate

To read the chosen volume rate, press briefly either arrow keys

on the display. The chosen rate is shown.

CHANGE VOL. RATE

xxx L/ha

The main picture will return again after 5 seconds or if you press

accept key.

5

HM 1500: Changing the desired volume rate for alarm

The desired rate must be entered if you wish to operate with the alarm.

Press either arrow keys on the display. The rate per area is shown.

If the key is pressed again it will raise or lower the chosen rate.

When the key is released the display shows the new rate for a moment

and then returns to the main picture.

HC 2500: Changing the volume rate

The rate can be changed:

• Automatically, by changing the desired rate on the HC 2500 display.

• Manually, by raising and lowering the pressure on the control box.

11

Page 12

Automatic dosage

To alter the chosen application rate, press either arrow keys on the

display. The chosen quantity applied per area unit is shown. If the key

is pressed again it will raise or lower the chosen rate. When the key is

released the display shows the new rate for a moment and then

returns to the main picture.

NOTE: A minimum speed of 2.0 km/h is needed before the system will

regulate automatically.

Manual dosage

To dose in manual mode, use the pressure switch on the control box.

With HC 2500, the manual mode is indicated on the bottom line with a

flashed text [ MAN. ] over the displayed information. Bottom line is

cleared when [ MAN. ] is displayed.

MAN.

To go from manual to automatic dosage, briefly touch the arrow key

on the HC 2500.

Reading and reset of area trip

Area trip from 1 to 8 (Y) can be used for individual areas.

Area trip 0 is a tally of area trips 1 to 8. The treated area is memorised

when the system is switched off.

12

Area xxxx. xx ha

Y xxxxx L

1. Press enter key for area covered and volume sprayed.

2. Press enter key again to return. If is not pressed again it will return

to the main picture after 15 seconds.

To reset the active register press the enter key continuously and a

5 second countdown will commence.

Reset of a register can be stopped if the enter key is released.

Alarms

Alarm warnings [ Vol. rate alarm ] or [ Tank alarm ] are flashed for

3 seconds at a time on the top line over the displayed information.

Page 13

Menus

Parameter selection is carried out from the menu key.

The menus can be scrolled to and fro with the arrow keys.

The upper line, in capital letters, displays the menu you are in.

The lower line, in small letters, displays the choices you have. When the

chosen menu is shown, press the menu key again to open the menu.

When modifying a parameter, prolonged pressure on the arrow key will

generally cause the data shown on the display to alter faster.

After the parameter is modified, press the accept key.

The display then changes back to the previous picture.

Press the accept key until the display returns to the main display.

There are 2 menu systems, the operator menu for general use and an

extended menu for initial set-up of the system. To access the extended

menu, press both arrow keys at the same time until the menu changes.

General keystroke

Press to enter menus.

Press to find desired menu.

Press to enter menu.

Press to find desired sub-menu or alter parameter.

Press to continue in the menu if needed.

Press to accept and exit the menu.

Press Repeat to exit the menus and go back to the normal display

function.

13

Page 14

Keystroke menu tree chart

Press to read or alter (HC 2500) chosen volume rate.

Press to read or reset area trip.

Display readout

Tank contents

Main menu

Calibration

Volume rate

Program : Actual

Tank contents

Flow rate

Optional sensor

Revolutions

Speed

Active boom size

Flow calibration

Speed calibration

Revolutions

Boom sections/size

14

Alarms

Area/volume trip

Sensor test

Volume rate

Tank

Area 0 to 8

Flow

Speed

Area switch test

Revolutions

Optional sensor

Page 15

Main menu

The upper line will read [ MAIN MENU ].

The lower line displays the choices.

MAIN MENU

Display readout

To choose what is to be displayed on screen.

Tank contents

To change the indicated tank contents.

Calibration

To access calibration menus.

Alarms

To set alarm parameters.

Area/volume trip

To select register to record or read area covered and volume sprayed.

Sensor test

To test that the transducers function.

15

Page 16

Display readout

It is possible to freely choose which function is to be shown on the

upper or lower line of the display.

Show here

Show here

To choose where to show information.

Press arrow key to move [ Show here ] from the upper to lower line.

Press menu key to continue.

The upper line will read [ DISPLAY READOUT ].

The lower line displays the choices.

DISPLAY READOUT

Volume rate

To show the actual application rate.

Program:Actual

16

To show the programmed and actual application rate.

Tank contents

To show the tank contents.

If two tanks are used, the tank contents is the total contents.

Flow rate

To show the flow rate.

Page 17

Optional sensor

To show readout from optional analog transducer.

Revolutions

To show revolutions.

Speed

To show driving speed.

Active boom size

To see the active boom size.

Tank contents

If the sprayer is partially refilled or refilled the tank contents can be

adjusted.

See Extended menu to set tank size.

TANK CONTENTS

xxxx L

Press menu key and use arrow keys to raise or lower value.

17

Page 18

Calibration

It is necessary to set the correct boom width and calibrate the flow and

speed transducer before using the system. Calibration of the optional

revolutions transducer is necessary if it is fitted.

Boom size

CALIBRATION

Boom size set

For setting of number of boom sections and width.

Correct work width for each boom section is necessary

to calculate dosage and area covered.

Method

BOOM SIZE SET

Total sections x

1. Use arrow key to set number of boom sections and press menu key.

Maximum number of sections is 8. Press menu key to continue.

For mistblowers, number of sections is typically 2.

18

Sec. y Size x . xx m

2. Use the arrow key to increase or decrease section work width.

Press menu key to continue to next boom section.

After the last section, press the accept key.

The display will briefly show the total width.

Flow calibration

CALIBRATION

Flow calibration

Page 19

The flow transducer can be calibrated theoretically or with two practical

methods. For the sake of accuracy, the practical methods are preferred. Practical calibration is done with clean water. The Flow Tank

method is more time consuming, but is more accurate than the Flow

Nozzle method.

When changing to nozzles with more than a 100% increase or decrease

in output, it is recommended to re-calibration the flow transducer.

Calibration is recommended to be carried out at least once during the

spraying season.

Use the chart at the back of the book to record the values.

Flow constant

FLOW CALIBRATION

Flow constant

To change the flow constant theoretically.

During theoretical flow calibration the number of pulses per unit are

shown on the display.

For example, [ 120.0 PPU ] indicates the number of pulses which

theoretically come from the flow transducer whilst 1 litre of liquid

passes through. Approximate PPU values for different flow housings

are as follows:

Housing Code for Flow range PPU Orifice

housing l/min value mm

BK White 5 - 150 105.0 13.5

BK & EVC One outside groove 5 - 150 120.0 13.5

BK Black 10 - 300 60.0 20.0

EC White 5 - 150 118.0 13.5

EC Black 10 - 300 59.0 20.0

EC S/67 One outside groove 5 - 150 128.0 13.5

S/67 Two outside grooves 35 - 600 125.0 36.0

FLOW CONSTANT

xxx.x PPU

19

Page 20

Nozzle method

FLOW CALIBRATION

Nozzle method

During practical flow calibration the individual nozzle output on the

display is compared to the actual individual nozzle output.

The output displayed is corrected to read the actual output. For correct

calibration it is necessary to know the number of nozzles on the boom.

Method

NOZZLE METHOD

Total Nozzles xxx

1. The number of nozzles is set with the arrow key to read the actual

number of nozzles to spray. Press the menu key to continue.

2. Open all boom sections.

3. Turn the main ON/OFF valve on.

The display unit will then show the individual nozzle output per minute.

20

Flow xx.xx L/min

4. Using a HARDI calibration jug, check the actual nozzle output

per minute. It is recommended that an average of several nozzles

be taken.

5. Correct the output shown on the display with the arrow key to read

the average output measured with the calibration jug.

The display will briefly show the new calibration value PPU when

returning to the main display picture.

Page 21

Tank method

FLOW CALIBRATION

Tank method

During practical flow calibration the tank is partly emptied through the

nozzles. Whilst emptying, the display calculates the quantity emptied

on the basis of the actual calibration value (PPU). The quantity displayed is compared with the quantity actually dosed.

This can be according to the tank contents level indicator or by weight

difference before and after. The quantity displayed is corrected to read

the quantity actually dosed.

Method

1. Place the tank on level ground and fill up with water until the level

reaches a unique mark on the tank contents level indicator, e.g.

1000 litres.

2. Open all boom sections.

3. Open menu and turn the main ON/OFF valve on.

TANK METHOD

Sprayed xxxxL

The display unit will then begin to count the volume

being emptied through the nozzles.

4. When for example, 600 litres have been emptied out, as shown by

the tank contents level indicator, the main ON/OFF valve can be

turned off.

5. Correct the volume shown on the display with the arrow key to read

the volume shown on the tank contents level indicator. The display

will briefly show the new calibration value PPU when returning to

the main display picture.

21

Page 22

Speed calibration

CALIBRATION

Speed Calibration

The speed transducer can be calibrated theoretically or practically.

The practical method is recommended.

Speed constant

SPEED CALIBRATION

Speed constant

The theoretical speed constant, units per pulse (UPP), is the distance

in metre on the circumference of the wheel between magnets.

For example, if the wheel circumference is 2.00 m and

4 magnets are fitted, UPP is 0.5000.

SPEED CONSTANT

0.5 m

22

xxxxx UPP

Speed practical

SPEED CALIBRATION

Practical

Practical calibration of speed is done by driving a measured distance

and correcting the display so that the actual and the calculated

distances are the same.

Theoretical speed calibration should be carried out before practical

speed calibration.

Calibration should take place in the field with a half full tank and normal

working tyre pressure in order to obtain the wheel’s real “working radius”.

Page 23

Method

1. Measure a distance not less than 75 metres.

2. Park the tractor at the start of the measured distance.

3. Open menu. When zero distance [ 0 m ] shows, drive the meas-

ured distance.

PRACTICAL

Measured xxx m

4. Correct the distance shown on the display with the arrow key to

read the actual distance

Revolutions calibration

CALIBRATION

Revolutions cal.

For calibration of revolutions transducer.

REVOLUTIONS CAL.

x.x PPR

The constant, pulse per revolution (PPR), is

the number of pulses for one revolution.

For example, if one magnet is fitted, the PPR is 1.0.

Alarms

There are 2 alarms, a tank alarm for low tank contents and a volume

rate alarm for over or under application. When outside the alarm

parameters, the relevant warning will flash. A beeper can also be

activated.

ALARMS

Tank alarm

Low tank contents alarm.

23

Page 24

Activated at xx %

Suggested setting is 10%. For no alarm, set at 0 %.

Audio off

The beeper can be activated [ on ] or de-activated

[ off ] by pressing the arrow key.

ALARMS

Vol. rate alarm

Volume rate alarm for over or under application

for more than 20 seconds.

Activated at xx %

Suggested setting is 5%. For no alarm, set at 0 %.

24

Audio off

The beeper can be activated [ on ] or de-activated

[ off ] by pressing the arrow key.

Area/volume trip

It is possible to choose up to 9 area trip meters (0 to 8). [ Area 0 ] is a total

for all areas treated. When any of the other areas are used, the treated

area and volume will also be registered automatically in [ Area 0 ].

AREA/VOLUME TRIP

Area x

For reset of [ Area / Volume Trip ], see “Reset of area trip”.

Page 25

Sensor test

All readouts are in accumulated counts, i.e. one signal gives one

count, except for the optional (analog) transducer that is read in milliampere. Follow instructions on the display.

SENSOR TEST

Flow test

To test the flow sensor.

Spin rotor xxx

Remove transducer from flow housing and spin rotor.

Every second magnet will give a count, indicating correct function.

See also “Testing flow transducer”.

Speed test

To test the speed sensor.

Drive slowly xxx

Every magnet will give a count, indicating correct function.

See also “Testing speed transducer”.

Area switch test

To test the area-meter switch.

Magnet To Sens. Off

Without magnet.

25

Page 26

Magnet To Sens. On

With the south side of the magnet facing the transducer

at a distance of 5 to 7 mm. This indicates correct function.

Revolutions test

To test the revolutions sensor

Turn slowly xxx

Every magnet will give a count, indicating correct function.

Optional sensor

To test the optional transducer.

Area meter

For HM 1500 with manual control unit, the area

meter will register area continuously when the

sprayer is disconnected. When the south side of the

magnet is located directly in front of the transducer,

the area meter will stop registering area.

5-7 mm

26

When using a HM 1500 with manual control unit

and switch box, or HC 2500 with EC control box, all

the switches must be turned on.

If you do not want to utilise the area meter transducer, the main on/off

switch can be used to start and stop the area register.

T165-0006

Mistblowers and HM 1500/HC 2500

Points to note if the system is used on a mistblower.

• Work width is the same as the spray width of the mistblower.

• Not active switches on the control box are set to zero work width.

• Use the Tank method to calibrate the flow transducer.

• Blower fan revolutions can be read in the revolutions readout.

Page 27

Storage

When the tractor and sprayer is parked, disconnect the power supply

to the Scanbox. This will stop the system from using power.

The display and Scanbox should be protected from moisture and

should be removed if the tractor does not have a cabin.

Emergency operation

The system is added to a standard electric control unit without any

modifications to the wiring. Should there be a problem when using the

HC 2500 disconnect the Scanbox from the control unit and connect the

cable from the control unit to the control box.

Spraying can now be continued.

Fault finding

Fault Cause Remedy

No start-up. Check polarisation is correct.

Blinking back-light. Poor power supply. Check battery, cabling and

No “bip” sound at start-up. connections.

Displayed area larger Field was not rectangular.

than actual area. “Tramlines” narrower than Measure “tramline” width.

Displayed volume larger Pressure equalisation valve Replace seals

than actual volume. leaks.

Check the fuse in the Scanbox. Change fuse. (use 1.25 T Amp).

spray width.

.

Fine tuning the flow constant - PPU

Calibration of the flow transducer is carried out with clean water but

small changes may occur when adding pesticides or fertiliser.

This will effect the final readings. This is typically noted when the

volume displayed on the display does not equal the actual known

volume that was sprayed out. The below formula can be used to

“fine tune” the flow transducer PPU.

New PPU =

Original PPU x Displayed Volume

Sprayed Volume

For example, the spray tank is filled with 2400 litres of spray liquid.

When sprayed out, the display showed a total of 2300 litres.

(Original PPU = 120.0)

New PPU =

120.0 (Original PPU) x 2300 (Displayed Volume) = 115.0

2400 (Sprayed Volume)

27

Page 28

Note the relation is inverse:

• To raise the displayed volume, the PPU is lowered.

• To lower the displayed volume, the PPU is raised.

Testing flow transducer (Ref. no. 728816)

Wire connections: BROWN wire to positive of 12 volt battery.

BLACK wire to negative.

BLUE wire to multimeter positive.

1. Check the rotor turns freely.

2. Each vane in the rotor has a magnet in it

N

S

with the pole facing out.

Check that the 4 magnets are present.

S

N

3. Check every second magnet has the

same pole orientation so the rotor

magnets are N - S - N - S.

4. Connect negative from multimeter to

negative of battery.

T045-0003

5. Set multimeter to DC volt.

6. By turning the mill wheel slowly, this will register approx. 8.0 +/- 1 volt

with the diode on and 0.3 +/- 0.1 volt with the diode off with every

second magnet.

Testing speed transducer (Ref. no. 729058)

Wire connections: BROWN wire to positive of 12 volt battery.

BLACK wire to negative.

BLUE wire to multimeter.

4

1

1. Connect negative from multimeter to

negative of battery.

5-7 mm

-

8

1

/

/

2. Set multimeter to DC volt.

3. By bringing the south pole of a magnet

(distance 5 mm +/- 2 mm) by the trans

ducer, this will register 0.3 +/- 0.1 volt.

S

N

T165-0004

4. By removing the magnet, this will register 7 .0 +/- 1.0 volt.

28

Page 29

Technical specifications

Supply voltage 12 Volt DC

Minimum supply 11 Volt DC

Maximum supply 16 Volt DC

Maximum peak 20 Volt DC

Ambient temperature – 10° C to + 55° C

Memory Flash PROM non-volatile

Digital transducers Square signal

Update frequency 4 times per second

Trigger high 5.0 to 12.0 Volt DC

Trigger low 0.0 to 0.5 Volt DC

Analog transducers

Supply Loop

Input 4 to 20 mA

Minimum speed for volume regulation 2.0 km/h

Flow ranges for the flow transducers

Identification code Orifice Flow

White 13.5 mm 5 to 150 l/min

Black 20.0 mm 10 to 300 l/min

One outside groove 13.5 mm 5 to 150 l/min

Two outside grooves 36.0 mm 35 to 600 l/min

Pressure drop over 13.5 mm orifice is 1 bar at 150 l/min.

Packaging information

Materials used for packaging are environmentally compatible.

They can be safely deposited or they can be burnt in an incinerator.

Recycling

Cardboard: Can recycle up to 99% and therefore should be put into

the waste collection system.

Polyethylene: Can be recycled.

When the HM 1500 / HC 2500 has completed its working life, it must

be thoroughly cleaned. The synthetic fittings can be incinerated.

The printed circuit boards and metallic parts can be scrapped.

29

Page 30

Chart for recording values

Menu Function 1 - Values 2 - Values 3 - Values

Nozzle /Colour

[ Flow constant ] Flow PPU

[ Speed constant ] Speed UPP

Extended menu

Access the extended menu by pressing both arrow keys at the same

time until the menu changes.

The extended menu written in English only.

NOTE: Re-start the system after leaving the Extended menu.

Menu Function [ choices ]

[ Language ] To select language.

[ GB, DK, F, E, D, Cz, SF, NL, I, S ]

[ Unit ] To set unit of measurement. [ Metric, USA ]

[ ON/OFF valve ] To select EC or EVC/ESC/CB control unit.

[ Present, not present ]

[ Pressure system ] To select pressure system.

[ Equalisation, No equalisation ]

[ Control box ] To indicate control box connection to Scanbox.

[ Connected, Not connected ]

[ Tank volume max ] To pre-set tank volume indicated at start-up.

[ Analog adjust ] To calibrate the optional transducer.

[ max., min., offset in mA ]

[ Analog unit text ] To choose the unit of measurement.

[ Bar, PSI, deg C, deg F, % R.H ]

[ Regulation con. ] For the sensitivity of the pressure regulation

valve.

[ Change SW ver. ] To permit change or update of software.

[ Master reset ] For factory use only.

[ Area totals ] To see total area covered and volume sprayed.

[ Scanbox] For factory use.

30

Page 31

Default setting

Text For HC 2500* For HM 1500**

[ Language ]GB GB

[ Unit ] Metric Metric

[ ON/OFF valve ] Present Present

[ Pressure system ] Equalisation Equalisation

[ Control box ] Connected Not Connected

[ Tank size ] 2000 l 2000 l

[ Analog adjustment ] max. 10 max. 10

min. 0 min. 0

offset in mA 0 mA offset in mA 0 mA

[ Analog unit text ] Bar Bar

[ Regulation con. ]0% 0%

[ Flow PPU ] 120.0 120.0

[ Speed UPP ] 1.0000 1.0000

HC 2500*

For EVC, ESC or CB control unit set:

[ ON/OFF valve ] to [ Not present ]

HM 1500**

For BK, BK/EC or EC control unit with switch (control) box for boom sections set:

[ Control box ] to [ Connected ]

For EVC, ESC or CB control unit set:

[ ON/OFF valve ] to [ Not present ]

[ Control box ] to [ Connected ]

NOTE: Re-start the system after leaving the Extended menu.

31

Page 32

EC Declaration of Conformity

Manufacturer,

HARDI INTERNATIONAL A/S

Helgeshøj Allé 38

DK 2630 Taastrup

DENMARK

Importer,

declare that the following product;

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Adhere extra shipping package labels to inside cover.

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

32

was manufactured in conformity with the provisions in the EMC directive 89/336/EEC, EN 50081-1 (1992) (generic emission) and EN

50082-2 (1995) (generic immunity).

Taastrup 15/09/2002

Lars Bentsen

Product Development Manager

HARDI INTERNATIONAL A/S

Page 33

333435

Page 34

Page 35

Page 36

36

Loading...

Loading...