Page 1

ESTATE SPRAYERS

GAS ENGINE

Operator's Manual

67301103 (6/01)

Page 2

Page 3

ESTATE SPRAYERS

GAS ENGINE

Operator’s Manual

67301103 (6/01)

HARDI® reserves the right to make changes in design,

material, or specification without notice thereof.

®

and other product names are registered trademarks

HARDI

of HARDI

®

Inc. in the U.S. and in other countries.

1

Page 4

TABLE OF CONTENTS

1.0 INTRODUCTION................................................................................ 4

2.0 SAFETY INFORMATION................................................................... 6

Follow Safety Instructions ..................................................................

2.1

Operating The Sprayer Safely ...........................................................

2.2

2.3 Handling Chemical Products Safely ............................................. 8

2.4 Local Poison Information Center .................................................. 9

3.0 HOOKING UP THE SPRAYER ....................................................... 10

4.0 OPERATING THE SPRAYER ......................................................... 11

Controls ...........................................................................................

4.1

ET Manual Control Operation ..........................................................

4.2

4.3

M600 Brass Manual Control Operation ...........................................

5.0 NOZZLE SELECTION ..................................................................... 16

5.1 Handgun Nozzle Selection ......................................................... 16

5.2 Boom Nozzle Selection .............................................................. 16

6.0 CALIBRATION ................................................................................ 18

6.1 Calibration (Ounce Method) ....................................................... 19

7.0 MAINTENANCE............................................................................... 19

7.1 Cleaning The Sprayer ................................................................ 19

7.2 Lubrication .................................................................................. 21

7.3 Nozzle Filters .............................................................................. 22

7.4 Nozzle Tubes and Fittings .......................................................... 22

7.5 Pump Maintenance .................................................................... 22

7.6 Boom Maintenance .................................................................... 23

8.0 STORAGE ....................................................................................... 24

8.1 Preparation After Storage ........................................................... 24

9.0 TROUBLESHOOTING..................................................................... 25

10.0 TECHNICAL SPECIFICATIONS ................................................... 26

10.1 HARDI

10.2 Sprayer Specifications .............................................................. 27

10.3 Safety Decals ........................................................................... 27

11.0 PARTS DRAWINGS ...................................................................... 28

12.0 WARRANTY POLICY AND CONDITIONS ................................... 41

13.0 NOTES ........................................................................................... 43

®

Diaphragm Pump Specifications ................................ 26

11

12

14

7

7

2

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 5

Dear Owner,

Thank you for purchasing a HARDI® product and welcome to the everincreasing family of HARDI® equipment owners.

Our sprayers and accessories are rapidly becoming a familiar sight on

North American farms and estates. We believe that this results from

growers becoming increasingly conscious of crop protection input costs

and the vital need for cost effective application equipment.

Please take the time to thoroughly read the Operator’s Manual before

using your equipment. You will find many helpful hints as well as

important safety and operation information.

Some of the features on your HARDI® Estate Sprayer were suggested

by growers. There is no substitute for “on farm” experience and we

invite your comments and suggestions.

Please address your correspondence to the Service Manager at one of

these branches:

HARDI® MIDWEST

1500 West 76th St.

Davenport, Iowa 52806

Phone: (319) 386-1730

Fax: (319) 386-1710

Sincerely,

Tom L. Kinzenbaw

President

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

®

GREAT LAKES

HARDI

290 Sovereign Rd.

London, Ontario N6M 1B3

Phone: (519) 659-2771

Fax: (519) 659-2821

®

WEST COAST

HARDI

5646 W. Barstow, Suite 101

Fresno, California 93722

Phone: (559) 271-3106

Fax: (559) 271-3107

3

Page 6

1.0 INTRODUCTION

We congratulate you for choosing a HARDI® plant protection product.

The reliability and efficiency of this product depends on your care. The

first step is to carefully read and pay attention to this operator’s

manual. It contains essential information for the efficient use and long

life of this quality product.

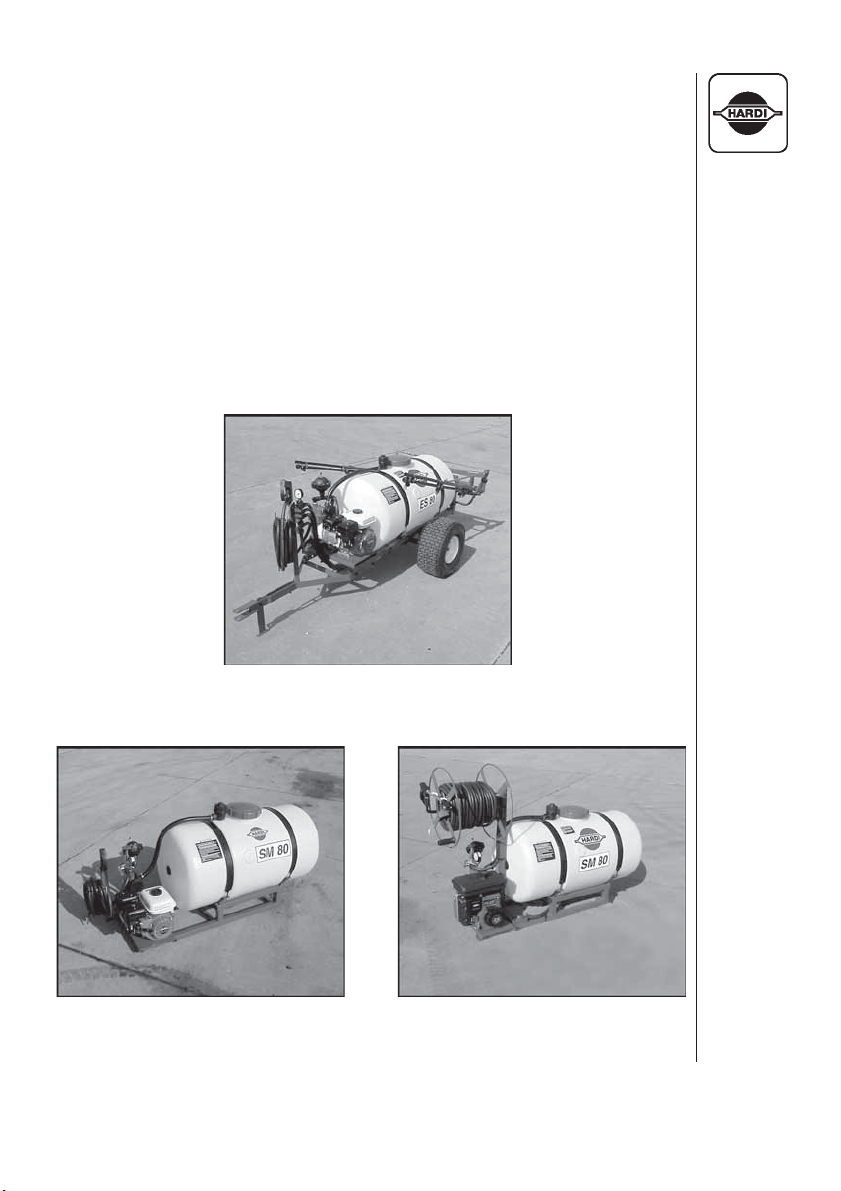

This manual covers the HARDI

& Stratton or Honda gas engines directly coupled to HARDI® 500 or

600 diaphragm pumps. These sprayers include the ES 50, ES 80, SM

50 and SM 80 models.

The heart of your sprayer is the diaphragm pump. The design is

simple, resulting in low maintenance requirements and guaranteed

pump life. The bearings and crankshaft are grease lubricated and are

therefore protected from spray solution if any diaphragm fails in service. A drain hole is located in the base of the crank case to facilitate

the draining of any foreign matter. The pump is self-priming and can be

run dry without damage.

The ES 50 and ES 80 sprayers are equipped with the ET manual

control which features: on/off control for boom and handgun, pressure

adjustment, pump bypass agitation, remote pressure safety valve and

a 2-1/2” pressure gauge.

®

Estate Sprayers equipped with Briggs

The SM 50 and SM 80 sprayers are equipped with the M600 Brass

manual control which features: on/off control for handgun/(optional

boom), pressure adjustment, pump bypass agitation, integral pressure

safety valve and a 2-1/2” pressure gauge.

The tanks, made of impact proof and chemical resistant polyethylene,

have a purposeful design with rounded contours which allows for

efficient cleaning and draining. They are designed with a large deep

sump so that they can be completely emptied even when the sprayer is

used on slopes. A drain plug is provided in the sump to assist cleaning

of the tank. The tanks are equipped with a top suction filter which can

be inspected and cleaned without emptying the tank.

Also covered in this manual are the 6’ FD and 14’ HD booms which

feature fore and aft breakaways. The 6’ FD boom folds vertically and

the 14’ HD boom folds horizontally forward. Both booms feature ISO

flat fan nozzles with 20” spacing.

4

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 7

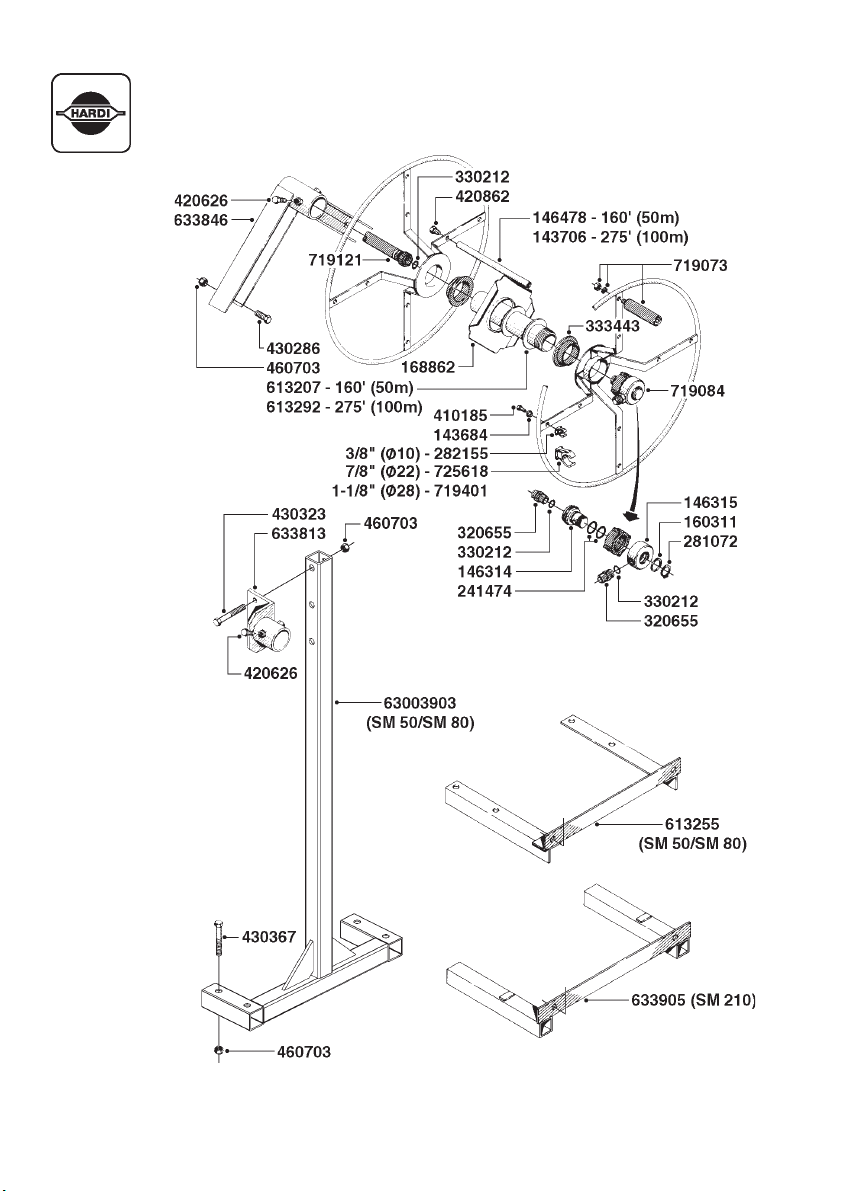

The frame and boom of your estate sprayer are finished with a powder

coat paint which provides maximum protection from chemicals and

rust.

The model 60L spraygun features an adjustable spray nozzle for

varying the spray width. The standard spraygun features 25’ of 1/2”

hose on the hose wrap (optional 40’).

Since this book covers options available for several different Estate

Sprayers, please pay attention to the sections dealing specifically with

your model.

ES 80 with 14‘ HD Boom

SM 80 with Spraygun

and Hose Wrap

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

SM 80 with Spraygun

and Hose Reel

5

Page 8

2.0 SAFETY INFORMATION

WARNING!

ALWAYS READ THE OPERATOR’S MANUAL BEFORE

USING THIS EQUIPMENT

DO NOT REMOVE ANY SAFETY DEVICES OR

SHIELDS. NEVER SERVICE, CLEAN OR REPAIR A

MACHINE WHILE IT IS OPERATING

WARNING!

ALWAYS WATCH FOR THIS SYMBOL TO POINT OUT

IMPORTANT SAFETY PRECAUTIONS

IT MEANS ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

6

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 9

RECOGNIZE SAFETY INFORMATION

This is the Safety-alert symbol. When you see this

symbol on your machine or in this manual, be alert

to the potential for personal injury.

Follow recommended precautions and safe operating practices.

2.1 Follow Safety Instructions

1. Carefully read all the safety messages in this manual and the

safety labels fitted to the machine. Keep safety labels in good

condition. Replace missing or damaged safety labels. Make sure

that new equipment components include any current safety labels.

Replacement safety labels are available from your authorized

HARDI® dealer.

2. Learn how to operate the sprayer and how to use the controls

properly. Do not let anyone operate the sprayer without proper

instructions.

3. Keep your sprayer in proper working condition. Unauthorized

modifications or use may impair the function and/or safety and

affect the machine’s life.

4. If you do not understand any part of this manual and need assistance, please contact your authorized HARDI® dealer.

2.2 Operating The Sprayer Safely

1. Read the complete manual carefully and become familiar with the

operation of the equipment before initial operation in each spraying season. Failure to do so may result in possible over or under

application of spray solution and may lead to personal injury.

2. Always keep children away from your estate sprayer.

3. Never pull your estate sprayer behind a truck on public roads.

Load the sprayer onto a trailer or into the back of a truck for

transporting.

4. Understand service procedures before undertaking any maintenance. Never lubricate, service, or adjust the machine while it’s

moving. Securely support any components before working on

them.

5. Keep all parts in good condition and properly installed. Repair

damaged parts immediately. Replace worn or broken parts.

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

7

Page 10

2.3 Handling Chemical Products Safely

1. Direct exposure to hazardous chemicals can cause serious injury.

These chemicals can include lubricants, coolants, paints, adhesives and agricultural chemicals. Material Safety Data Sheets

(M.S.D.S.) are available for all hazardous chemicals which inform

the user of specific details including, physical and health hazards,

safety procedures, and emergency response techniques.

2. Protective clothing such as rubber gloves, goggles, coveralls and

respirator must be worn while handling chemicals. All protective

clothing should be kept in excellent condition and cleaned regularly or discarded.

3. If chemicals come in contact with any exposed skin areas, wash

immediately with clean water and detergent. Never place nozzle

tips or any other components that have been exposed to chemicals to lips to blow out obstructions. Use a soft brush to clean

spray nozzles.

4. Dedicate an area to fill, flush, calibrate and decontaminate sprayer

where chemicals will not drift or run off to contaminate people,

animals, vegetation, water supply, etc. Locate this area where

there is no chance of children coming in contact with this residue.

5. Decontaminate equipment used in mixing, transferring and

applying chemicals after use. Follow the instructions on the

chemical label for the correct procedure required. Wash spray

residue from outside of the sprayer to prevent corrosion.

6. Extreme care should be taken in measuring spray products.

Powders should be used in suitable sized packages or weighed

accurately. Liquids should be poured into a suitable graduated

container. Keep chemical containers low when pouring. Wear a

filtered respirator and let the wind blow away from you to avoid

dust and/or splashes contacting the skin or hair.

7. Store chemicals in a separate, plainly marked locked building.

Keep the chemical in its original container with the label intact.

8. Dispose all empty containers after rinsing in accordance with local

regulations & by-laws. Dispose of all unused chemicals and left

over fertilizer in an approved manner

9. Keep a first aid kit and fire extinguisher available at all times when

handling chemicals.

8

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 11

2.4 Local Poison Information Center

PHONE NO. _________ - _________ - _____________

Find the phone number for the poison control center in your phone book

and write it in the space above.

Keep a list, in the space provided below, of all the chemicals that you have

in use.

1. ___________________________________________________

2. ___________________________________________________

3. ___________________________________________________

4. ___________________________________________________

5. ___________________________________________________

6. ___________________________________________________

7. ___________________________________________________

8. ___________________________________________________

9. ___________________________________________________

10. ___________________________________________________

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

9

Page 12

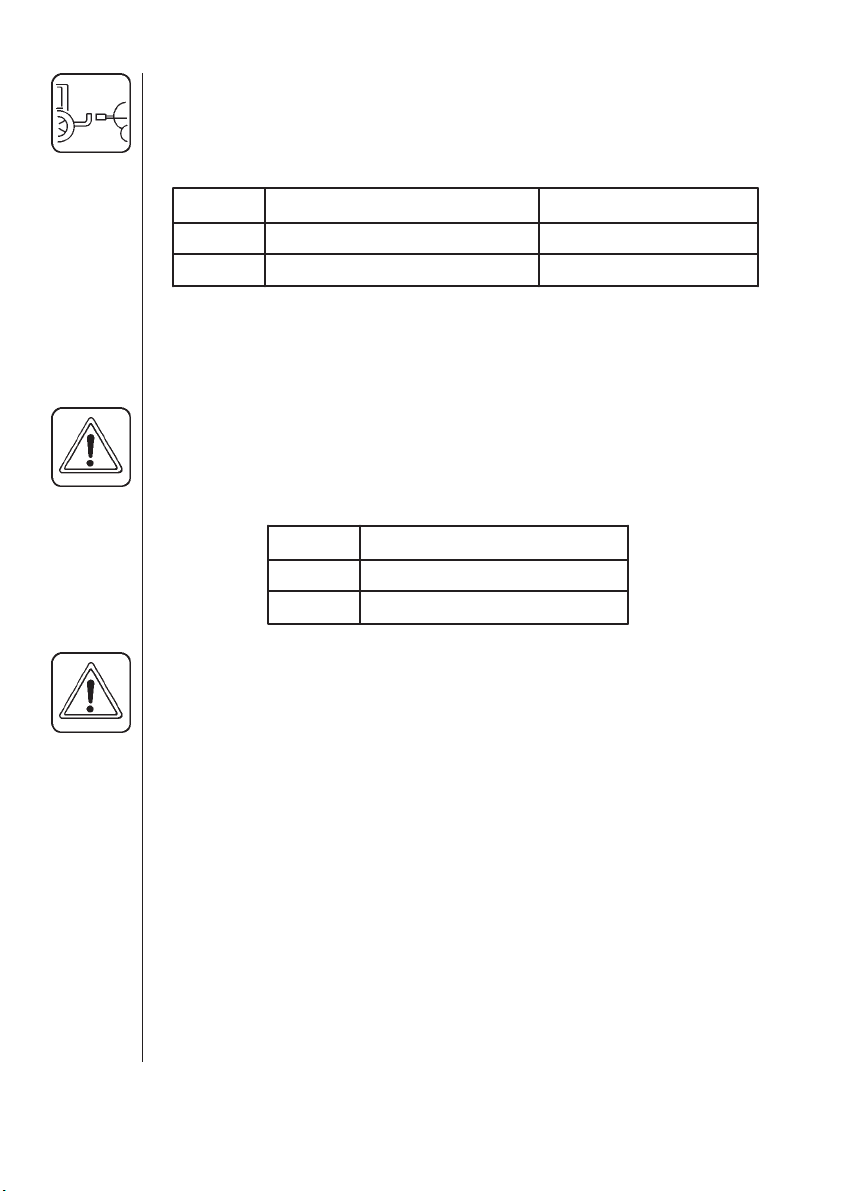

3.0 HOOKING UP THE SPRAYER

TOW VEHICLE REQUIREMENTS:

Lawn & Garden tractor or ATV with a drawbar with sufficient horsepower and braking ability to safely control the following specifications:

Sprayer

ES 50

ES 80

1. ES 50 and ES 80: Attach sprayer tongue to drawbar with the

correct size drawbar pin and install safety clip.

SM 50 and SM 80: Secure sprayer to bed of truck/utility vehicle.

WARNING:

MAKE SURE THAT YOUR SKID MOUNT SPRAYER IS

634

940

Tongue Weight (lbs.)Total Loaded Weight (lbs.)

92

66

PROPERLY SECURED AND THAT YOUR TRUCK/UTILITY

VEHICLE HAS SUFFICIENT CARRYING CAPACITY FOR YOUR

SPRAYER PLUS THE WEIGHT OF THE SPRAY LIQUID.

IMPORTANT:

Sprayer

SM 50

SM 80

The HARDI® Estate sprayers equipped with gas en-

Total Loaded Weight (lbs.)

616

852

gines are shipped from the factory without oil in the engine crankcase

or reduction gearbox.

2. Before operating the gas engine, you must:

A. Check the engine crankcase oil level.

B. Check the reduction gearbox oil level.

C. Fill the gas tank.

D. Make sure engine air filter is not plugged.

3. Refer to gas engine operating manual for oil change and maintenance information.

4. Tire pressure should be 10 PSI (ES 50, ES 80 only).

10

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 13

4.0 OPERATING THE SPRAYER

WARNING:

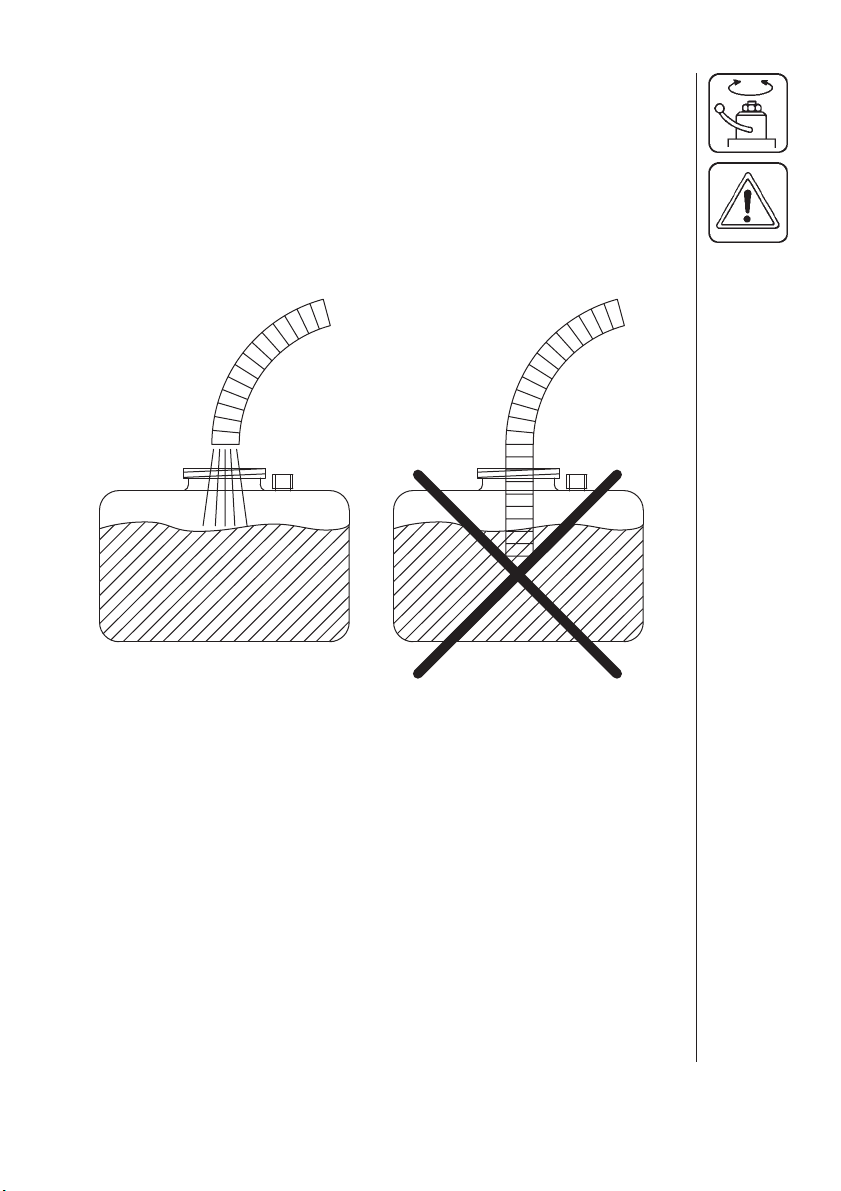

WATER ONLY. ALWAYS FILL WATER THROUGH THE STRAINER

BASKET TO PREVENT FOREIGN PARTICLES FROM ENTERING

THE TANK. NEVER LET THE FILLING HOSE ENTER THE TANK.

CHEMICALS MAY CONTAMINATE THE WATER SUPPLY LINES,

PLANT AND/OR WELL.

ALWAYS FILL YOUR ESTATE SPRAYER WITH CLEAN

4.1 CONTROLS

The ES and SM series estate sprayers use different controls for

operating. The ES 50 and ES 80 sprayers use the ET manual control

(Section 4.2), while the SM 50 and SM 80 use the M600 brass manual

control (Section 4.3).

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

11

Page 14

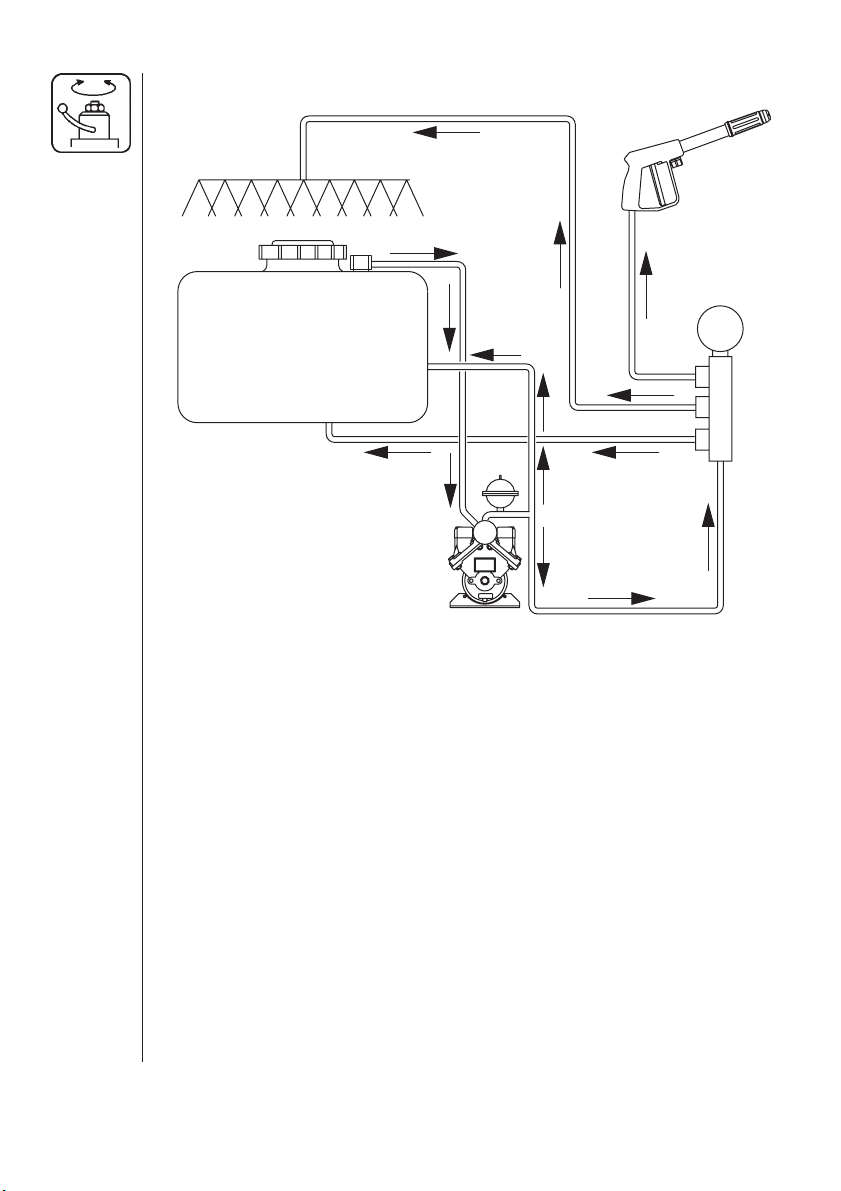

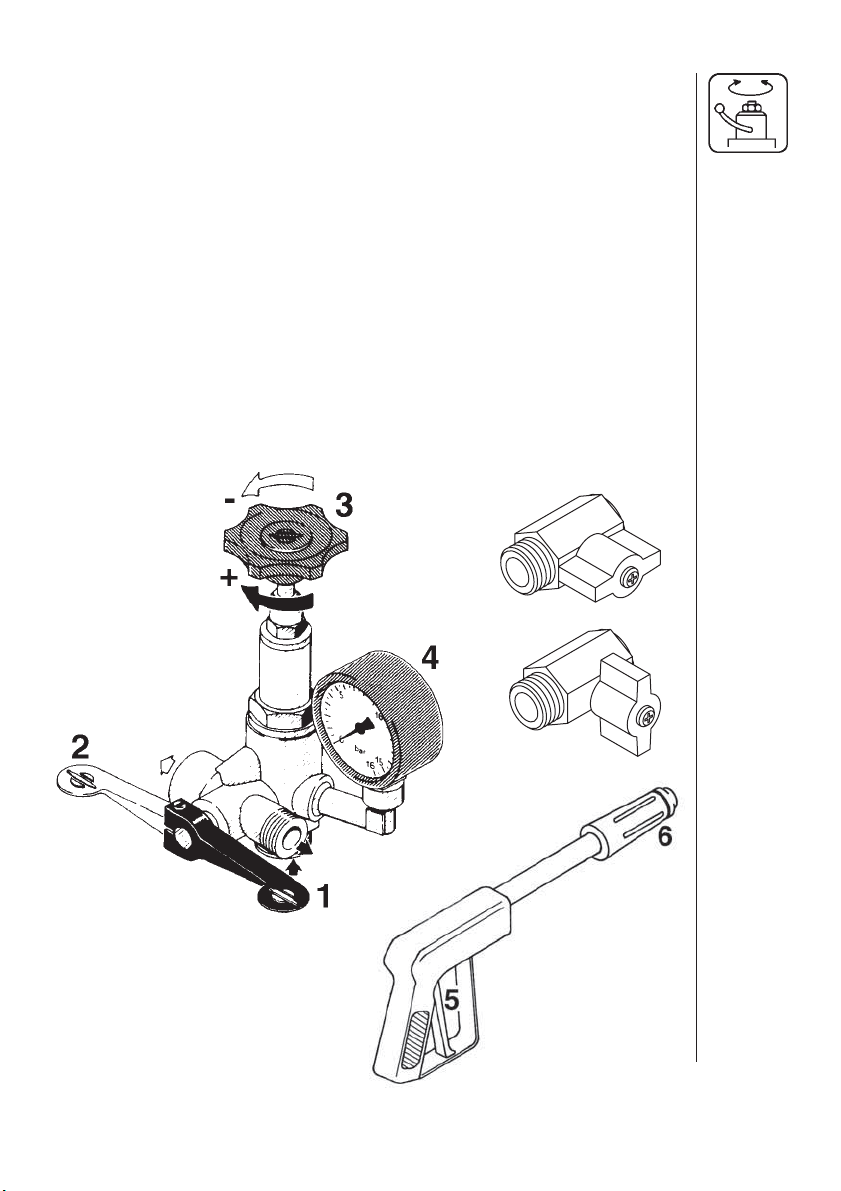

4.2 ET MANUAL CONTROL OPERATION (ES 50/80)

C

D

TANK

E

F

A. 500/600 Pump

B. Distribution Valves

C. Spraygun

D. Boom

E. Safety Valve

F. Agitation

Fluid System Overview

When the 500/600 pump A (Fig 1) is running, pressurized fluid flows

from the tank to the distribution valves B (Fig 1). Fluid that is not

required for use by the boom or spraygun is returned to the tank

through the bypass line and agitation nozzle F (Fig 1). When the boom

valve is open, fluid flows to the boom D (Fig 1). When the spraygun

valve is open and the red handle on the spraygun is depressed, fluid

flows to the spraygun C (Fig 1). If the boom and spraygun valves are

off and the pressure valve is set too low to handle the output from the

pump, the safety valve E (Fig 1) opens to allow the fluid to return to the

tank.

Fig. 1

A

B

12

Boom Operation

1. Locate your sprayer in a suitable location to spray water from the

boom and/or handgun.

2. Fill the tank with clean water.

3. Turn dial 1 (Fig. 2) counter clockwise all the way out.

4. Set boom switch 2 (Fig. 2) on and spraygun switch 3 (Fig. 2) off.

5. Start the engine.

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 15

6. Increase pressure by turning dial 1 (Fig. 2) clockwise. Watch the

pressure gauge 4 (Fig. 2) until the desired pressure is reached

(turning dial 1 (Fig. 2) counter clockwise decreases pressure).

NOTE: Refer to Section 5.0 for nozzle selection and calibration.

Spraygun Operation

7. To operate the spraygun, turn switch 2 (Fig. 2) off and switch 3

(Fig. 2) on. Then depress the red handle 5 (Fig. 2) to spray water

from the spraygun. Check the pressure on gauge 4 (Fig. 2) and

follow step 6 to adjust.

8.

To adjust the spray pattern, turn the black handle 6 (Fig. 2)

OUT for

a narrow spray pattern for long distances and IN for a wide pattern

for more coverage at close distances.

ON

Fig. 2

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

OFF

13

Page 16

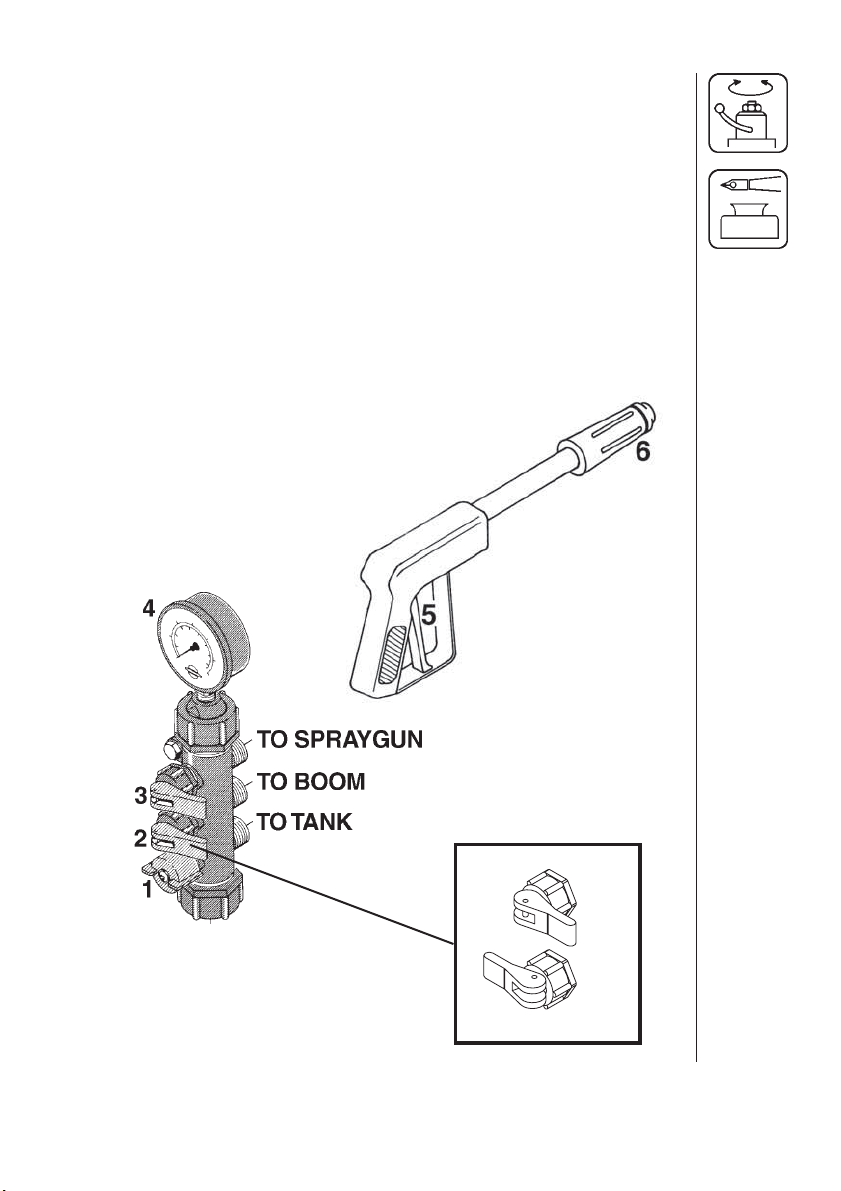

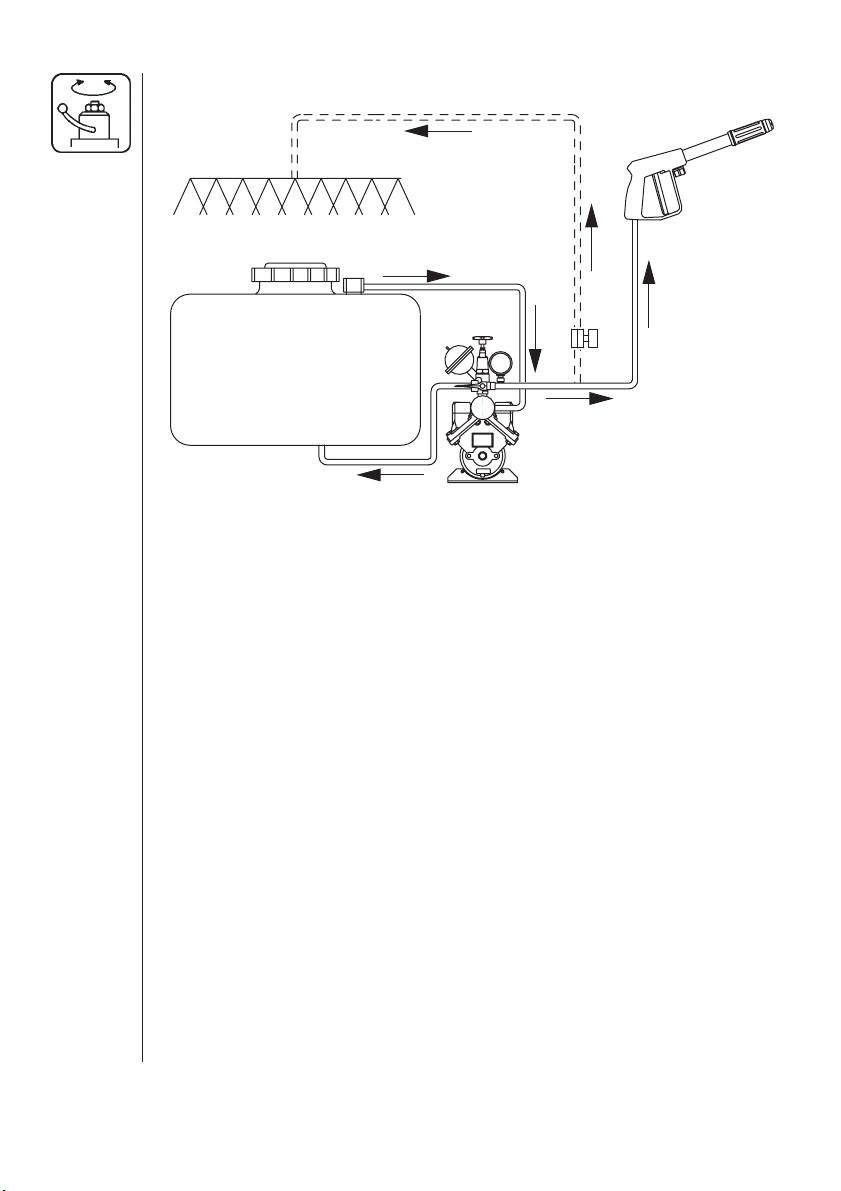

4.3 M600 BRASS MANUAL CONTROL OPERATION (SM 50/80)

C

F*

TANK

B

E*

D

Fig. 3

A. 500/600 Pump

B. M600 Control

C. Spraygun

Fluid System Overview

When the 500/600 pump A (Fig 3) is running, pressurized fluid flows

from the tank to the M600 brass manual control B (Fig 3). When the

main ON/OFF valve is “OFF”, fluid is returned to the tank through the

bypass line and agitation nozzle D (Fig 3). When the main ON/OFF

valve is “ON” and the red handle on the spraygun is depressed, fluid

flows to the spraygun C (Fig 3). Optional boom: when main ON/OFF

valve is “ON” and boom valve E* (Fig 4) is open, fluid flows to the

boom F* (Fig 3).

Spraygun/(Optional Boom) Operation

1. Locate your sprayer in a suitable location to spray water from the

spraygun (and/or optional boom).

2. Fill the tank with clean water.

3. Turn main ON/OFF handle to spraying position 1 (Fig 4).

4. Turn dial 3 (Fig 4) counter clockwise all the way out. This relieves

the pressure on the springs and minimizes start-up problems.

(If optional boom is installed, make sure boom valve 7 (Fig 4) is

closed).

5. Start the engine.

D. Agitation - (Control Valve Bypass)

E*. Boom Valve (Optional)

F*. Boom (Optional)

A

14

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 17

6. Increase pressure by turning dial 3 (Fig 4) clockwise. Watch the

pressure gauge 4 (Fig. 4) until the desired pressure is reached

(turning dial 3 (Fig 4) counter clockwise decreases pressure).

7. To operate the spraygun, depress the red handle 5 (Fig 4) to spray

water from the spraygun. Check the pressure on gauge 4 (Fig 4)

and follow step 6 to adjust.

8.

To adjust the spray pattern, turn the black handle 6 (Fig 4)

a narrow spray pattern for long distances and IN for a wide pattern

for more coverage at close distances.

9. To stop liquid flow to the spraygun (and optional boom), turn main

ON/OFF handle to position 2 (Fig 4). The entire fluid flow from the

pump will then return to the tank through the by-pass line.

10. To operate optional boom, turn main ON/OFF handle to spraying

position 1 (Fig 4) and open boom valve 7 (Fig 4) to spray water

from the boom. Check the pressure on gauge 4 (Fig 4) and follow

step 6 to adjust.

OUT for

OPEN

7

CLOSED

Fig. 4

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

15

Page 18

5.0 NOZZLE SELECTION

As standard equipment with your estate sprayer, nozzles have been

provided for both the handgun and boom.

5.1 Handgun Nozzle Selection

The 1099-20 nozzle (HARDI® ref. no. 371314) is the standard nozzle

for the handgun. This nozzle supplies the following rates in U.S.

gallons per minute at the given pressures:

GPM

NOZZLE

1099-20

PSI

20

30

40

50

60

70

100

150

200

0.678

0.829

0.956

1.068

1.169

1.261

1.504

1.840

2.123

0.538

0.661

0.766

0.857

0.940

1.018

1.222

1.500

1.736

Other size 1099 nozzles are available from you HARDI® Dealer.

5.2 Boom Nozzle Selection

ISO F-03-110 BLUE nozzles (HARDI® ref. no. 371767) are standard

on the 6’ boom and 14’ boom for gas engine driven systems. If you

find by using the following directions and nozzle chart, that these

nozzles are not the correct size for your spraying needs, other nozzles

are available from your HARDI® Dealer.

NOTE: A Calibration & Nozzles Manual (HARDI® ref. no. 67000103) is

available from your HARDI® dealer which contains more detailed

information for calibration and nozzle selection.

TO USE THE FOLLOWING CHART:

16

1. You must know your desired forward speed (example 3 MPH).

2. You must know the pressure (PSI) you want to spray at (example

30 PSI).

3. You must know your desired application rate (example 16 gallons

per acre).

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 19

KNOWING THESE THREE FACTS, PROCEED AS FOLLOWS:

1. Locate the correct speed column on the chart below (example 3

M.P.H.).

2. Find the number in that column which is closest to your desired

application rate and is also opposite the desired pressure (example

16.8 GPA is closest to 16 GPA and opposite 30 PSI).

3. For this example, you would select the F-02-110 YELLOW nozzle.

NOTE: Using this chart will bring you very close to your desired application rate. However, for final pressure setting, you must calibrate your

sprayer (Section 6.0).

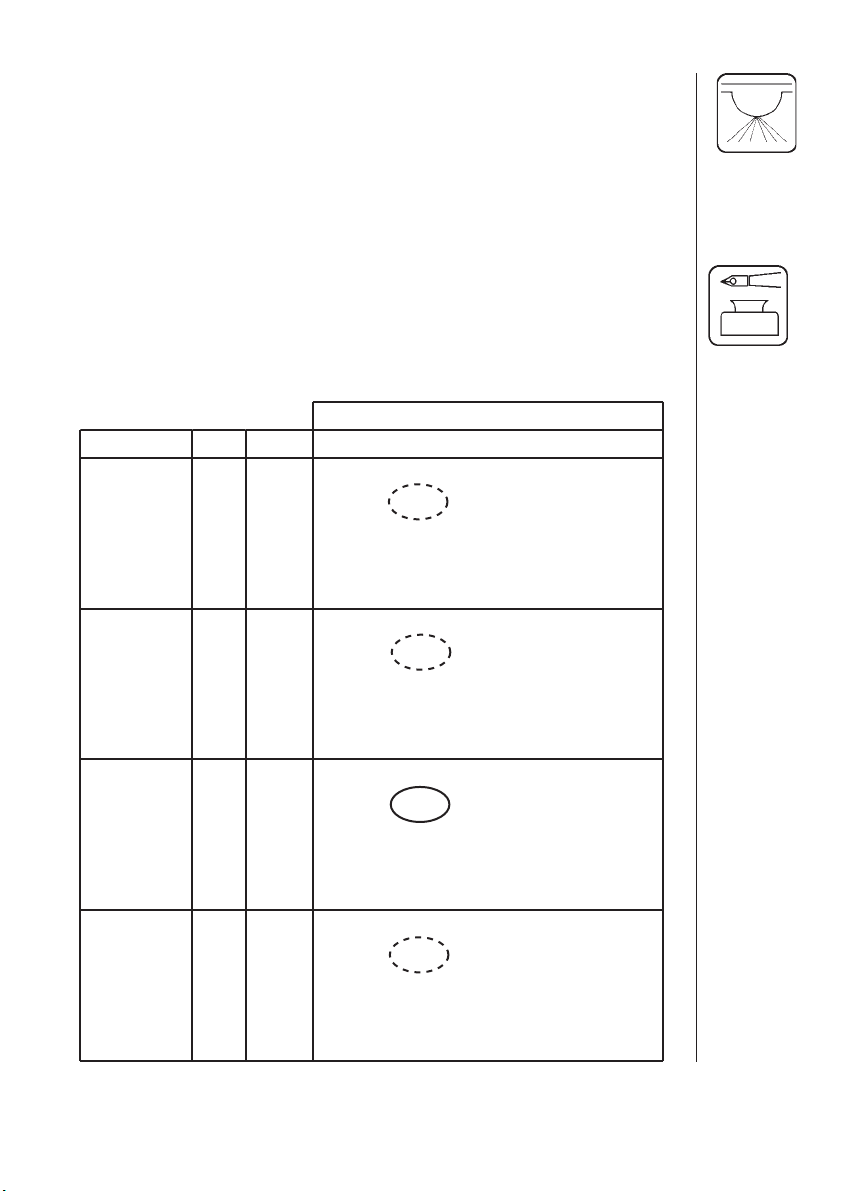

HARDI® ISO F-110 SPRAY SYNTAL NOZZLES

GPA at MPH

NOZZLE PSI 3

GPM 6

20 0.071

ISO

F-01-110

ORANGE

(371764)

30

40

50

60

0.087

0.100

0.113

0.122

2

10.5

12.9

14.8

16.8

18.1

MPH

MPH

7.0

8.6

9.9

11.2

12.1

4

MPH

5.3

6.5

7.4

8.4

9.1

5

MPH

4.2

5.2

5.9

6.7

7.2

MPH

3.5

4.3

5.0

5.6

6.0

20 0.11

ISO

F-015-110

GREEN

(371765)

ISO

F-02-110

YELLOW

(371766)

ISO

F-03-110

BLUE

(371767)

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

30

40

50

60

20

30

40

50

60

20

30

40

50

60

0.13

0.15

0.17

0.18

0.14

0.17

0.20

0.23

0.24

0.21

0.26

0.30

0.34

0.37

16.3

19.3

22.2

25.2

26.7

20.8

25.2

29.7

34.1

35.6

31.1

38.6

44.6

50.5

54.9

10.9

12.9

14.8

16.8

17.8

13.9

16.8

19.8

22.8

23.8

20.8

25.7

29.7

33.7

36.6

8.2

9.7

11.1

12.6

13.3

10.4

12.6

14.8

17.1

17.8

15.6

19.3

22.3

25.2

27.5

6.5

7.7

8.9

10.1

10.7

8.3

10.1

11.9

13.7

14.3

12.5

15.4

17.8

20.2

22.0

5.4

6.4

7.4

8.4

8.9

6.9

8.4

9.9

11.4

11.9

10.4

12.9

14.8

16.8

18.3

17

Page 20

6.0 CALIBRATION

WARNING:

WATER ONLY! WEAR PROTECTIVE CLOTHING SUCH AS RUBBER GLOVES, GOGGLES AND COVERALLS.

Why must you calibrate a sprayer?

A nozzle selection chart will tell you what application rate you should

expect. Variations due to nozzle wear, errors in pressure adjustment,

and tractor speedometer can result in a large error in application rate.

How do you calibrate a sprayer?

Calibration kits are available from HARDI®, #818493 for U.S. Gallons

and #818492 for metric calibration. For accurate calibration, the

sprayer is driven a specific distance at spraying speed and the length

of time is recorded. The operator then measures the amount of water

sprayed from one nozzle at spraying pressure for the same length of

time noted. The amount of water sprayed provides a direct reading of

application rate. Slight adjustments are then made by varying the

pressure.

Here are some tips to remember when using the calibration kit method:

1. Calibrate with clean water only.

2. Follow the instructions in the calibration kit carefully.

3. Before calibration, check the flow of each nozzle. If it puts out more

than 10% of its original volume, replace it.

4. When determining the length of time required to drive a recommended distance, drive in actual field or lawn conditions with a half full

sprayer. Repeat the test several times, then take the average of the

times recorded.

5. Calibration of the sprayer should be completed at the beginning of

the season and repeated every 2 to 3 full days of spraying, and every

time you change volume rate or use different nozzles.

ALWAYS CALIBRATE YOUR SPRAYER WITH CLEAN

18

NOTE: A Calibration & Nozzles Manual (HARDI® ref. no. 67000103) is

available from your HARDI® dealer which contains more detailed

information for calibration and nozzle selection.

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 21

6.1 Calibration (Ounce Method)

If you do not wish to use the calibration kit method, the following

method may be used. All you need is a tape measure, stop watch and

a container that accurately measures U.S. fluid ounces.

1. Fill the sprayer tank approximately half full with clean water.

2. Set up two stakes, 204 ft. apart in actual spraying conditions.

3. While driving at spraying speed, note the length of time required to

drive 204 ft. Repeat several times and take the average of the times

recorded.

4. With the sprayer operating at intended spraying pressure, collect the

output from one nozzle for the length of time determined in step 3.

The number of U.S. fluid ounces will exactly measure the application

rate.

e.g. 15 U.S. fluid ounces = 15 U.S. gallons per acre

NOTE: This method only works if the nozzle spacing is 20”.

For conversion to Imperial gallons per acre, multiply U.S. GPA x .833

For conversion to liters per hectare, multiply U.S. GPA x 9.34

For conversion to liters per acre, multiply U.S. GPA x 3.78

7.0 MAINTENANCE

WARNING:

PEOPLE AND ANIMALS. NEVER LEAVE A SPRAYER CONTAINING CHEMICALS WHERE IT COULD BE ACCESSED BY UNAUTHORIZED PEOPLE OR ANIMALS.

IMPORTANT:

before servicing to avoid unnecessary contact with chemicals.

In order to derive full benefit from the sprayer for many years, the

following few, but important rules should be followed.

7.1 Cleaning The Sprayer

Read the entire label of the chemical used. Take note of any particular

instructions regarding recommended protective clothing, deactivating

agents, etc. Read the detergent and deactivating agent labels. If

cleaning procedures are given, follow them closely.

UNCLEAN SPRAYERS CAN BE HAZARDOUS TO

Always clean the boom at the end of your workday or

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

19

Page 22

7.1 Cleaning The Sprayer (cont.)

Be familiar with local legislation regarding disposal of agricultural

chemicals, mandatory decontamination methods, etc. Contact the

appropriate office, e.g. Department of Agriculture.

Cleaning starts with calibration as a well calibrated sprayer will ensure

the minimal amount of remaining spray liquid. It is a good practice to

clean the sprayer immediately after use thereby rendering the sprayer

safe and ready for the next application. This also prolongs the life of

the components.

It is sometimes necessary to leave the spray liquid in the tank for short

periods of time (e.g. overnight), or until the weather becomes suitable

for spraying again. Unauthorized persons and animals must not have

access to the sprayer under these circumstances.

Cleaning

1. Dilute the remaining spray liquid in the tank with at least 10 parts

water and spray the liquid out into the field or lawn you have just

sprayed.

2. Select and use the appropriate protective clothing. Select detergent

suitable for cleaning and suitable deactivation agents if necessary.

3. Rinse and clean sprayer and tractor externally. Use detergent if

necessary.

4. Remove all filters and clean them. Be careful not to damage the

mesh. Replace filters when the sprayer is completely clean.

5. With the pump running, rinse the inside of the tank. Remember the

tank roof. Rinse and operate all components and any equipment that

has been in contact with the chemical.

6. After spraying the liquid out again in the field or lawn, stop the pump

and fill at least 1/5 of the tank with clean water. Note that some

chemicals require the tank to be completely filled. Add appropriate

detergent and/or deactivating agent, e.g. Washing soda or Triple

ammonia.

20

NOTE: If a cleaning procedure is given on the chemical label, follow it

closely.

7. Start the pump and operate all controls enabling the liquid to come

in contact with all the components. Leave the distribution valves until

last. Some detergents and deactivating agents work best if left in the

tank for a short period. Check the label.

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 23

8. Drain the tank and let the pump run dry. Rinse inside of tank, again

letting the pump run dry.

9. Stop the pump. If the chemicals used have a tendency to block

nozzles, remove and clean them now.

10. Replace all filters and nozzles and store the sprayer. If, from

previous experiences, it is noted that the solvents in the chemicals

are particularly aggressive, store the sprayer with the tank lid open.

NOTE: If the sprayer is cleaned with a high pressure cleaner, we

recommend lubrication of the entire machine.

7.2 Lubrication

Every 40 hours of operation, new grease should be applied to the

pump and boom. Use a high quality multi-purpose lithium based

grease. When greasing the pump, use only 2 to 3 pumps from a

grease gun. For easier application of grease to the boom, place the

wing in the breakaway position. Also oil the M600 control as shown

every 40 hours of operation.

WARNING:

NEVER PLACE FINGERS IN BREAKAWAY CLUTCH.

TO PREVENT SERIOUS INJURY FROM CRUSHING,

14‘ HD Boom

Grease

Grease

Pump

Grease

M600

Control

6‘ FD Boom

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

21

Page 24

7.3 Nozzle Filters

WARNING:

WITHOUT WEARING CHEMICAL RESISTANT GLOVES AND

SAFETY GOGGLES.

Each nozzle assembly is equipped with a 50 mesh filter screen as

standard. A properly maintained suction filter will eliminate plugging of

the screens and nozzles.

NEVER SERVICE YOUR CONTAMINATED NOZZLES

7.4 Nozzle Tubes and Fittings

Poor seals are usually caused by:

• Missing O-rings or gaskets

• Damaged or incorrectly seated O-rings

• Dry or deformed O-rings or gaskets

• Foreign materials

Therefore, in case of leaks; DO NOT overtighten any fittings (Fig 5).

Disassemble, check the condition and position of the O-ring or gasket,

clean, lubricate and then reassemble. For radial seals (O-ring) (Fig 5),

only hand tighten the fittings. Do not use pliers or wrenches.

The O-rings need to be lubricated ALL THE WAY AROUND before

fitting on to the nozzle.

22

Fig. 5

HARDI® recommends using a vegetable based oil to prolong the life of

the O-ring.

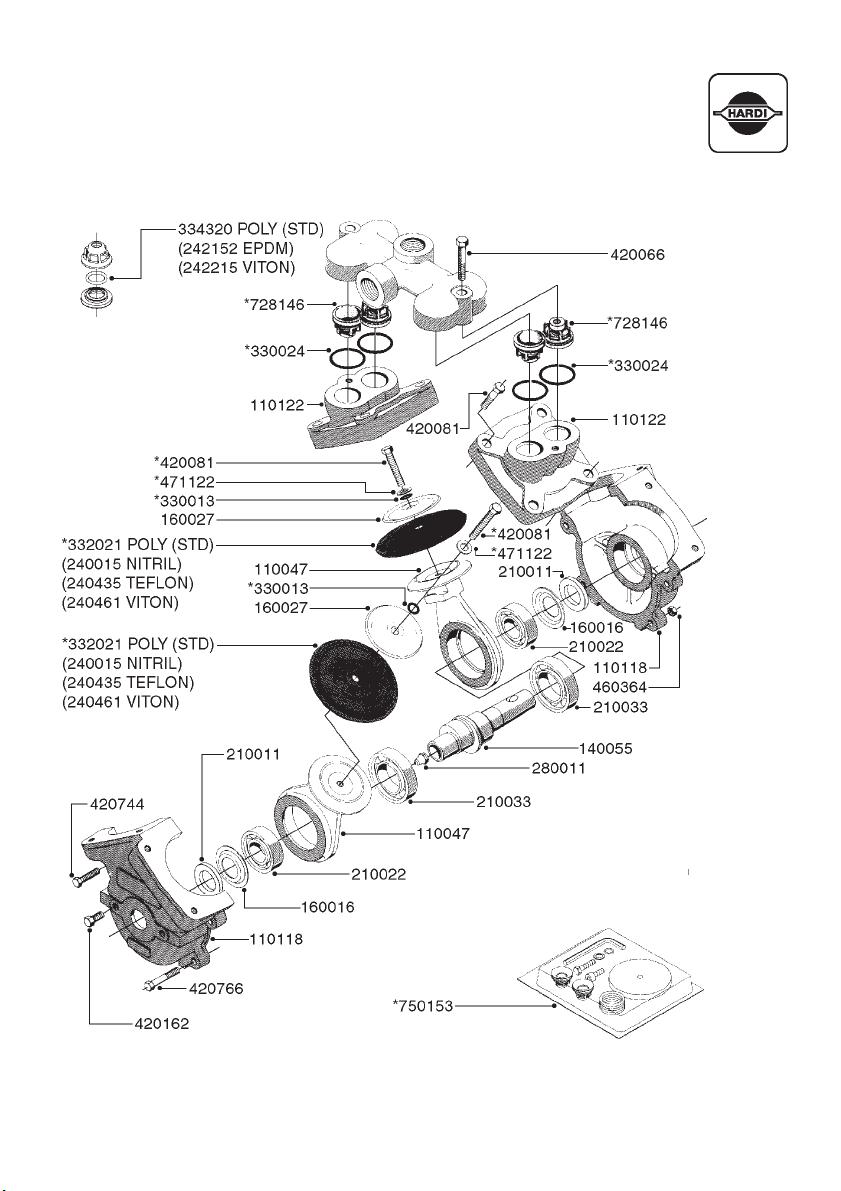

7.5 Pump Maintenance

Changing the valves

Remove valve cover 1 (Fig 6). Before changing the valves 2 (Fig 6),

note the orientation of the valves so that they may be replaced

correctly. It is recommended to use new seals 3 (Fig 6) when changing

or checking the valves.

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 25

Changing the diaphragms

Remove the diaphragm cover 4 (Fig 6) after removing the valve cover.

The diaphragm 5 (Fig 6) may then be changed. If fluids have reached

the crankcase, re-grease the pump thoroughly. Also make sure the

drain hole at the bottom of the pump is not blocked. Use the following

torque chart when re-tightening bolts:

Diaphragm Bolt - 18.5 Ft/Lbs

Diaphragm Cover Bolts - 37 Ft/Lbs

Valve Cover Bolts (500) - 22 Ft/Lbs

Valve Cover Bolts (600) - 34 Ft/Lbs

Fig. 6

Model 600

7.6 Boom Maintenance

The 6’ FD boom breakaway should be

adjusted tightly enough so that the boom

stays securely in the upright (folded)

position during transport, yet loosely

enough that the boom easily swings back

if an obstacle is hit. Adjustment is made

by tightening or loosening the spring

tension bolt (Fig 7).

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Model 500

Spring Tension

Bolt

Fig. 7

23

Page 26

8.0 STORAGE

When the spraying season is over, you should devote some extra time

to the sprayer. If chemical residues are left over in the sprayer for long

periods, it can reduce the life of the individual components. To

preserve the sprayer and protect the components, carry out the

following off-season storage program:

1. Clean the sprayer completely - inside and outside - as described in

Section 7.1 “Cleaning The Sprayer“. Make sure that all valves,

hoses and auxiliary equipment have been cleaned with detergent

and flushed with clean water afterwards, so no chemical residues

are left in the sprayer.

2. Replace any damaged seals and repair any leaks.

3. Empty the sprayer completely and let the pump work for a few

minutes. Operate all valves and handles to drain as much water out

of the spraying circuit as possible. Let the pump run until air is

coming out of all nozzles.

4. Fill the tank with 3 - 5 gallons of an ethylene glycol base anti-freeze

mixture at the ratio for the desired temperature protection. Run the

pump and circulate the anti-freeze through the distribution valves

and boom lines. Spray the handgun into the tank until anti-freeze

sprays out to make sure the line is full of anti-freeze.

NOTE: Never use diesel fuel in a sprayer.

5. When the sprayer is dry, remove rust from any scratches in the paint

and touch up the paint.

6. Lubricate the boom (Section 7.2).

7. Remove the glycerine-filled pressure gauge and store in a vertical

position in a frost-free environment.

8. To protect against dust, the sprayer can be covered by a tarpaulin.

Ensure ventilation to prevent condensation.

24

8.1 Preparation After Storage

After a storage period, the sprayer should be prepared for the next

season in the following way:

1. Remove the cover (If fitted).

2. Fit the pressure gauge again. Seal with Teflon tape.

3. Connect the sprayer to the tow vehicle (Section 3.0).

4. Empty the remaining antifreeze into an approved container.

5. Rinse the entire liquid circuit on the sprayer with clean water. Don’t

forget to flush the boom and handgun lines also.

6. Fill with clean water and check all functions (Section 4.0).

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 27

9.0 TROUBLESHOOTING

Problem

1. Lack of Pressure

2. Pressure jumping

Solution

A. Check that suction filter is

not clogged.

B. Check suction line from tank

to pump for leaks.

C. Check that pressure regula-

tor seat is not damaged.

D. Check pump valves for

obstructions and wear.

Replace valves if necessary.

(Section 7.5)

E. Check pressure gauge.

A. Check that suction filter is

not partially clogged.

B. Check that pressure regula-

tor is functioning properly.

C. Check that non-drip nozzle

diaphragms are functioning

correctly (should open at 10

PSI).

D. Check safety valve for weak

or broken valve spring.

E. Check pressure gauge.

3. Liquid leaks from

bottom of pump

4. No spray from

spraygun or boom

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

A. Replace diaphragm(s).

(Section 7.5)

A. Check suction tube and

fittings.

B. Check suction line from tank

to pump for leaks.

C. Check tightness of pump

diaphragm and valve covers.

(Section 7.5)

25

Page 28

9.0 TROUBLESHOOTING (cont.)

Problem

5. Inadequate weed control

A. Re-calibrate sprayer.

B. Check chemical container

instructions.

C. Did weather conditions affect

application?

D. Take care when driving not to

overlap or miss spraying.

E. Did you stop vehicle in field or

lawn and leave sprayer running?

Solution

10.0 TECHNICAL SPECIFICATIONS

10.1 HARDI® Diaphragm Pump Specifications

PUMP MODEL

Number of Diaphragms

Maximum Pressure

Maximum Flow @540 RPM

4.2 GPM (16 l/min)

500

1

220 PSI (15 Bar)

220 PSI (15 Bar)

8.2 GPM (31 l/min)

600

2

26

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 29

10.2 Sprayer Specifications

Sprayer

Type

ES 50

ES 80

SM 50

SM 80

*

Optional

Tank

Capacity

(Gallons)

50

80

50 (14')

80 (14')

10.3 Safety Decals

Red Reflector Decal - 10533803

Amber Reflector Decal - 10533903

10533003

Boom

Type

(Ft.)

6'

14'

6'

14'

Spray

Width

(Ft.)

6'7"

13'4"

6'7"

13'4"

*

(13'4")*57 x 28 x 49 194

*

(13'4")*68 x 24 x 51 210

Dimensions

L x W x H

(Inches)

85 x 42 x 39

99 x 45 x 40

10533103

Empty

Weight

(lbs.)

264

312

10533203

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

27

Page 30

11.0 PARTS DRAWINGS

500 PUMP

28

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 31

600 PUMP

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

29

Page 32

330757

PUMP & ENGINE

28007203 (Briggs & Stratton 3.5 HP)

28007303 (Honda 4.0 HP)

410347

821041 (500)

821074 (600)

160003

420781

421046

471126

330746

146591

192415

450897

460143

420604

471122

460423

460143

460423

471126

450052

460202

420943

471122

450897

146590

927021 (xFT.)

168846

470046

460143

28014003

28013803

28013903

420744

HONDA

BRIGGS &

STRATTON

30

28008003

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 33

PUMP FITTINGS

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

31

Page 34

ET MANUAL CONTROL

32

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 35

M600 BRASS MANUAL CONTROL

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

33

Page 36

ES 50/80 TANK

34

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 37

ES 50/80 FRAME

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

35

Page 38

SM 50/80 TANK & FRAME

36

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 39

440086

6‘ FD BOOM

460261

440086

410362

240074

322260

725043

371767

(ISO F-03-110 BLUE)

330212

320047

716166

440086

333465

725726 RH

725727 LH

333465

460261

334581

321462

333012

334533

927284 (x FT.)

430874

470282

170775

320482

320386

330013

330783

320187

334533

220749

470282

330212

330676

927284 (x FT.)

334533

TO LEFT SIDE

614704

460703

320084

460423

420604

100305

927284 (x FT.)

927284 (x FT.)

TO CONTROL

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

37

Page 40

14‘ HD BOOM

38

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 41

SPRAYGUN

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

39

Page 42

HOSE REEL

40

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 43

12.0 WARRANTY POLICY AND CONDITIONS

HARDI® INC. , 1500 West 76th Street, Davenport, Iowa USA; 5646 W. Barstow, Fresno, California, USA; and

290 Sovereign Road, London, Ontario, Canada hereinafter called "HARDI

warranty in accordance with the provisions below to each original retail purchaser of HARDI

of its own manufacturer, from an authorized HARDI

such purchaser, free from defects in material and workmanship and that such equipment will be warranted for

a period of one year from the date of delivery to the end user providing the machine is used and serviced in

accordance with the recommendations in the Operator’s Manual and is operated under normal farm

conditions.

®

dealer, that such equipment is at the time of delivery to

®

", offers the following limited

®

new equipment

1. This limited warranty is subject to the following exceptions:

®

a) Parts of the machine not manufactured by HARDI

tires, tubes, electronic controls, and other components or trade accesories, etc.) are not covered by this warranty but are subject to the

warranty of the original manufacturer. Any claim falling into this category will be taken up with the manufacturer concerned.

b) This warranty will be withdrawn if any equipment has been used for

purposes other than for which it was intended or if it has been misused,

neglected, or damaged by accident, let out on hire or furnished by a

rental agency. Nor can claims be accepted if parts other than those

manufactured by HARDI

ment. Further, HARDI

or handling by any common carrier and under no circumstances within

or without the warranty period will HARDI

of use, or damages resulting from delay or any consequential damage.

2. We cannot be held responsible for loss of livestock, loss of crops, loss because of

delays in harvesting or any expense or loss incurred for labor, supplies, substitute

machinery, rental for any other reason, or for injuries either to the owner or to a

third party, nor can we be called upon to be responsible for labor charges, other

than originally agreed, incurred in the removal or replacement of components.

®

have been incorporated in any of our equip-

®

shall not be responsible for damage in transit

, (i.e. engines,

®

be liable for damages of loss

3. The customer will be responsible for and bear the costs of:

a) Normal maintenance such as greasing, maintenance of oil levels, minor

adjustments, etc.

b) Transportation of any HARDI

work is performed.

c) Dealer travel time to and from the machine or to deliver and return the machine

from the service workshop for repair.

®

product to and from where the warranty

d) Dealer traveling costs.

4. Parts defined as normal wearing items, (i.e. tires and V-belts) are not in any way covered

under this warranty.

5. This warranty will not apply to any product which is altered or modified without the express

written permission of HARDI

Dealer.

6. Warranty is dependent upon the strict observance by the purchaser of the following

provisions:

®

and/or repaired by anyone other than an Authorized Service

a) That this warranty may not be assigned or transferred to anyone.

b) That the Warranty Registration Certificate has been correctly completed by dealer

and purchaser with their names and addresses, dated, signed and returned to

the appropriate address as given on the Warranty Registration Certificate.

c) That all safety instructions in the operators manual shall be followed and all safety

guards regularly inspected and replaced where necessary.

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

41

Page 44

7. No warranty is given on second-hand products and none is to be implied.

8. HARDI

9. Subject to the following terms, conditions and contributions, HARDI® extends the warranty on

10. Subject to the following terms, conditions, contributions, HARDI

11. The judgement of HARDI

12. No employee or representative is authorized to change this warranty in any way or grant any

13. Any warranty work performed which will exceed $400.00

®

reserves the right to incorporate any change in design in its products without

obligation to make such changes on units previously manufactured.

polyethylene tanks (excluding fittings, lids and gaskets) to FIVE YEARS. To qualify for this

extended warranty, the tank must be drained and flushed with fresh water after each day of use.

®

’s liability is limited to replacement of the tank, FOB our plant at no cost to the purchaser

HARDI

during the first twelve months; at 20% of the then current price during the second year; at 40%

during the third year; at 60% during the fourth year; and at 80% during the fifth year. This five

year extended warranty is subject, in each instance, to the tank being inspected and approved

for replacement or repair by HARDI

hereunder.

®

HARDI

diaphragm pumps (excluding wearing parts such as diaphragms, valves, etc.) to FIVE

YEARS. To qualify for this extended warranty, the pump must be drained and flushed with fresh

water after each day of use. HARDI

our plants in Davenport, Iowa, USA and London, Ontario, Canada at no cost to the purchaser

during the first twelve months after date of purchase, at 20% of the then current retail price

during the second year; at 40% during the third year; at 60% during the fourth year; and at 80%

during the fifth year. This five year extended warranty is subject, in each instance, to the pump

being inspected and approved for replacement or repair by HARDI

will accept any liability hereunder.

conclusive and the purchaser agrees to accept its decisions on all questions as to defect and

to the exchange of any part or parts.

other warranty unless such change is made in writing and signed by an officer of HARDI

head office.

by the Service Manager.

®

personnel before HARDI® will accept any liability

®

extends the warranty on

®

’s liability is limited to replacement of defective parts, FOB

®

personnel before HARDI

®

in all cases of claims under this warranty shall be final and HARDI

®

MUST be approved IN ADVANCE

®

®

at its

14. Any pump replacement must be approved in advance by the Service Manager.

15. Claims under this policy must be filled with HARDI® within thirty (30) days of work performed or

warranty shall be void.

16. Parts requested must be returned prepaid within thirty (30) days for warranty settlement.

17. Warranty claims must be COMPLETELY filled out properly or will be returned.

DISCLAIMER OF FURTHER WARRANTY

THERE ARE NO WARRANTIES, EXPRESSED OR IMPLIED, EXCEPT AS SET FORTH ABOVE. THERE

ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION OF THE PRODUCT CONTAINED

HEREIN. IN NO EVENT SHALL THE COMPANY BE LIABLE FOR INDIRECT, SPECIAL OR CONSEQUENTIAL DAMAGES (SUCH AS LOSS OF ANTICIPATED PROFITS) IN CONNECTION WITH THE RETAIL

PURCHASER'S USE OF THE PRODUCT.

42

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 45

13.0 NOTES

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

43

Page 46

NOTES

44

HARDI® GAS ENGINE ESTATE SPRAYER OPERATOR’S MANUAL

Page 47

Page 48

For Product, Service or Warranty Information:

- Please contact your local HARDI® dealer.

To contact HARDI® directly:

- Please use the HARDI® Customer Service number: 1-866-770-7063

- Or send your email to: CUSTSERV@hardi-us.com

Visit us online at: www.hardi-us.com

HARDI® NORTH AMERICA INC.

1500 West 76th St.

Davenport, Iowa 52806

Phone: (563) 386-1730

Fax: (563) 386-1710

8550 W. Roosevelt Avenue

Visalia, California 93291

Phone: (559) 651-4016

Fax: (559) 651-4160

337 Sovereign Rd.

London, Ontario N6M 1A6

Phone: (519) 659-2771

Fax: (519) 659-2821

Loading...

Loading...