Page 1

The Sprayer

Operator’s Manual

EAGLE™ SPB/SPC BOOM

Instruction book

67024003 - Version 1.10

US - 06.2015

Page 2

Page 3

EAGLE™ SPB/SPC BOOM

HARDI® reserves the right to make changes in design, material, or specification without notice thereof.

HARDI® and other product names are registered trademarks of HARDI® Inc. in the U.S. and in other countries.

Instruction book

67024003 - Version 1.10

US - 06.2015

Page 4

Page 5

Table of contents

1 - Welcome

Welcome letter ......................................................................................................................................1

2 - Safety notes

Operator safety .....................................................................................................................................1

Symbols ........................................................................................................................................................................................................................ 1

General info ............................................................................................................................................................................................................... 1

Local poison information center ...........................................................................................................2

3 - Description

Boom .....................................................................................................................................................1

Boom types and sizes .......................................................................................................................................................................................... 1

Hydraulic systems .................................................................................................................................................................................................. 1

Boom terminology ................................................................................................................................................................................................ 2

Electrical Hydraulic controls ..................................................................................................................3

General info ............................................................................................................................................................................................................... 3

HV Hydraulic control box (Ranger 550) .................................................................................................................................................... 3

HZ Hydraulic control box (Ranger 550) .................................................................................................................................................... 3

HZ Hydraulic control box (Ranger 2000, Navigator) ........................................................................................................................ 3

HZ Hydraulic control box - 90’/60’ SPC Dual Fold booms (Navigator) ................................................................................. 4

HZ Hydraulic control box - 120’/90’ SPC Dual Fold booms (Navigator) .............................................................................. 4

SetBox controls for sprayers equipped with ISOBUS ....................................................................................................................... 5

HZ Hydraulic controls on the Grip handle (ISOBUS & PRESIDIO) .............................................................................................5

HZ Hydraulic controls on the HARDI® spray center (PRESIDIO) ................................................................................................ 5

4 - Sprayer setup

Hydraulic systems .................................................................................................................................1

General info ............................................................................................................................................................................................................... 1

Requirements - tractor (SPB/SPC HY-model) ........................................................................................................................................ 1

Requirements - tractor (SPB HV-model) ................................................................................................................................................... 1

Requirements - tractor (SPB/SPC HZ-model) ........................................................................................................................................2

HZ hydraulic block ................................................................................................................................................................................................3

Open center hydraulics (trailed - optional equipment) ................................................................................................................. 3

Boom .....................................................................................................................................................4

Suspension effect adjustment (80’-100’ SPC only) ............................................................................................................................ 4

5 - Operation

Boom .....................................................................................................................................................1

Safety info ................................................................................................................................................................................................................... 1

Maneuvering of the SPB booms - HY version (Ranger) .................................................................................................................. 2

Maneuvering of the SPB and SPC booms - HY version (Navigator) .......................................................................................2

Maneuvering of the SPB booms - HV version (Ranger 550) ........................................................................................................ 3

Maneuvering of the SPB booms - HZ version (Ranger 550) ........................................................................................................ 4

Maneuvering of the SPB booms - HZ version (Ranger 2000) ..................................................................................................... 5

Maneuvering of the SPB and SPC booms - HZ version (Navigator) .......................................................................................6

Maneuvering of the 90’/60’ SPC Dual Fold boom (Navigator) ..................................................................................................7

Single-sided folding of the 90’/60’ SPC Dual Fold boom (Navigator) ................................................................................... 8

Maneuvering of the 120’/90’ SPC Dual Fold boom (Navigator) ................................................................................................ 9

Maneuvering of the SPB booms - (Ranger with ISOBUS) ........................................................................................................... 10

Maneuvering of the SPB, SPC & 90’/60’ Dual Fold SPC booms - (Navigator with ISOBUS) ...................................11

Maneuvering of the 120’/90’ Dual Fold SPC booms - (Navigator with ISOBUS) .......................................................... 12

Maneuvering of the SPC booms (PRESIDIO) ...................................................................................................................................... 13

Maneuvering of the 90’/60’ Dual Fold SPC boom (PRESIDIO) ................................................................................................. 14

TOC. 1

Page 6

Table of contents

6 - Maintenance

Lubrication ............................................................................................................................................1

General info ............................................................................................................................................................................................................... 1

Recommended lubricants ............................................................................................................................................................................... 1

45’-60’ SPB & 80’-100’ SPC Boom lubrication & oiling plan .......................................................................................................... 1

120’/90’ & 90’/60’ Dual Fold SPC Boom lubrication & oiling plan ............................................................................................ 2

Service and Maintenance intervals .......................................................................................................3

10 hours service - In-Line filter ....................................................................................................................................................................... 3

10 hours service - Nozzle filters (optional equipment) ................................................................................................................... 3

10 hours service - Spraying circuit ............................................................................................................................................................... 3

250 hours service - Readjustment of the boom ................................................................................................................................. 3

250 hours service - Hydraulic circuit .......................................................................................................................................................... 3

250 hours service - Hoses and tubes ......................................................................................................................................................... 3

Occasional maintenance ........................................................................................................................4

General info ............................................................................................................................................................................................................... 4

Nozzle tubes and fittings ..................................................................................................................................................................................4

Feed pipe snap-lock assembly (T25) .......................................................................................................................................................... 4

Feed pipe clamp assembly (T25) .................................................................................................................................................................. 5

Readjustment boom - general info ............................................................................................................................................................5

Alignment of center and inner wing sections (All booms) .......................................................................................................... 5

Alignment of inner and outer wing sections (All booms) ............................................................................................................ 6

Hydraulic stop valve adjustment (Dual Fold SPC only) .................................................................................................................. 6

Adjusting the front fold cable (All booms) ............................................................................................................................................. 7

Breakaway section adjustment (45’-66’ SPB) ........................................................................................................................................7

Breakaway section adjustment (80’-100’ & Dual Fold SPC) .......................................................................................................... 8

Check/adjust sprocket timing (45’-66’ SPB) ........................................................................................................................................... 8

Adjusting boom level to ground (All booms) ...................................................................................................................................... 9

Adjusting rear cable (All booms) ............................................................................................................................................................... 10

Adjusting center section cables (All except 120’/90’ Dual Fold) ........................................................................................... 10

Yaw rubber dampers (80’-100’ SPC, 90’/60’ Dual Fold SPC) .....................................................................................................11

Yaw rubber dampers (120’/90’ Dual Fold SPC) ................................................................................................................................. 11

Yaw damping (All booms) ............................................................................................................................................................................. 11

7 - Fault finding

Operational problems ...........................................................................................................................1

General info ............................................................................................................................................................................................................... 1

Hydraulic system - I.A.H. .................................................................................................................................................................................... 2

Mechanical problems ............................................................................................................................3

Mechanical problems ......................................................................................................................................................................................... 3

8 - Technical specifications

Specifications ........................................................................................................................................1

Filters and nozzles ................................................................................................................................................................................................. 1

Temperature and pressure ranges .............................................................................................................................................................. 1

Electrical connections ............................................................................................................................2

Plug positions for HZ hydraulics ................................................................................................................................................................... 2

Plug positions for HZ hydraulics (120’/90’ Dual Fold boom) ...................................................................................................... 2

Plug positions for HZ hydraulics (90’/60’ Dual Fold boom) ......................................................................................................... 2

Charts ....................................................................................................................................................3

Boom hydraulics - HY (45’-66’ SPB Ranger) ............................................................................................................................................ 3

Boom hydraulics - HY (45’-66’ SPB & 75’-100’ SPC Navigator) .................................................................................................... 3

Boom hydraulics - HZ (45’-66’ SPB Ranger) ............................................................................................................................................ 4

Boom hydraulics - HZ (45’-66’ SPB & 75’-100’ SPC Navigator) .................................................................................................... 4

Boom hydraulics - 90’/60’ Dual Fold SPC (Navigator) ...................................................................................................................... 5

Boom hydraulics - 120’/90’ Dual Fold SPC (Navigator) ................................................................................................................... 5

Boom hydraulics - 75’-90’ SPC (PRESIDIO) .............................................................................................................................................. 6

Boom hydraulics - 90’/60’ Dual Fold SPC (PRESIDIO) ....................................................................................................................... 6

9 - Warranty

Warranty policy and conditions ............................................................................................................1

TOC. 2

Page 7

1 - Welcome

Welcome letter

Dear New HARDI® Owner,

Thank you for purchasing your new HARDI® product and welcome to the ever-increasing family of proud HARDI® owners.

HARDI® is the leading sprayer company in offering growers strong, reliable products made for the widest range of

applications worldwide. Quality, reliability, and resale value make the HARDI® product line the preferred product line of

customers both in North America as well as worldwide. Our guiding principle is to provide the highest level of customer

satisfaction and long term value in the marketplace today. We have developed a very high level of customer loyalty in the

marketplace which we are very proud of and strive every day to maintain and to continue to grow.

HARDI® is your specialist in spraying and we spend all of our time and keep all of our focus on spraying. We do not share our

resources between other types of products or compromise on anything in providing the best quality sprayers to the market

today. We can provide the latest in technology with our products if desired, or allow them to operate with the technology

that you already use on other products in most cases. You get to decide that, and what best suits your needs. We feel that

you, our customer, are the best suited to answer that question for your operation. Either way, you decide, and we will try and

help make it happen for you.

Our broad spectrum of product offerings, from the ruggedly simple models we build to our highly sophisticated models,

the built-in HARDI® strength and reliability ensures a low cost of ownership. HARDI® sprayers are all based on a functional

design concept of being as simple to operate as possible and to meet our customers’ requirements for all their application

needs.

Please take the time to thoroughly read the Operator’s Manual before using your equipment. You will find many helpful hints

as well as important safety and operation information.

Some of the features on your HARDI® sprayer were suggested by growers. There is no substitute for “on farm” experience

and we invite your comments and suggestions. If any portion of this instruction book remains unclear after reading it,

contact your HARDI® dealer or service personnel for further explanation before using the equipment.

For Product, Service or Warranty Information please contact your local HARDI® dealer.

- Please use the HARDI® Customer Service number: 1-866-770-7063

- Or send your email to CUSTSERV@hardi-us.com

HARDI® NORTH AMERICA INC.

Visit us online at: www.hardi-us.com

1500 West 76th St.

Davenport, Iowa 52806

Phone: (563) 386-1730

Fax: (563) 386-1280

Sincerely,

Wayne Buchberger

President

1.1

Page 8

1 - Welcome

1.2

Page 9

2 - Safety notes

Operator safety

Symbols

These symbols are used throughout the book to designate where the reader needs to pay extra attention.

This symbol means DANGER. Be very alert as your safety is involved!

€

This symbol means WARNING. Be alert as your safety can be involved!

±

This symbol means ATTENTION. This guides to better, easier and safer operation of your sprayer!

This symbol means NOTE.

÷

General info

Before using the sprayer, read the following recommendations and safety instructions.

• Read and understand this instruction book before using the equipment. It is equally important that other operators of

this equipment read and understand this book.

• If any portion of this instruction book remains unclear after reading it, contact your HARDI® dealer for further

explanation before using the equipment.

• Local law may demand that the operator is certified to use spray equipment. Adhere to the law.

• Wear protective clothing. Wash and change clothes after spraying.

• Wash tools if they have become contaminated. Rinse and wash equipment after use and before servicing.

• Never service or repair the equipment while it is operating.

• Always replace all safety devices or shields immediately after servicing.

• Do not eat, drink or smoke while spraying or working with contaminated equipment.

• In case of poisoning, immediately seek medical advice. Remember to identify chemicals used.

• Keep children away from the equipment.

• Be careful not to hit people or surroundings when maneuvering the sprayer, especially when backing.

• Do not fold or unfold boom near overhead wires. Serious injury or death could result if contact is made with electric

wires.

• Slow down when driving in uneven terrain, as the machine might be in risk of turning over.

• Pressure test with clean water prior to filling with chemicals.

• Disconnect electrical power before servicing and depressurize equipment after use and before servicing.

• Do not go under any part of the sprayer unless it is secured. The boom is secure when placed in the transport brackets

with rear transport lock secured.

• If an arc welder is used on the equipment or anything connected to the equipment, disconnect power leads before

welding. Remove all flammable or explosive material from the area.

2.1

Page 10

2 - Safety notes

Local poison information center

If you live anywhere in the United States, the following toll free number will connect you to your Local Poison

€

Information Center.

PHONE NO. 1 - 800 - 222 - 1222

If you live outside the United States, find the number for the poison control center in your phone book and write it

€

in the space below:

PHONE NO._______ - _______ - __________

Keep a list, in the space provided below, of all the chemicals that you have in use.

€

1. _______________________________________________________________________________________________

2. _______________________________________________________________________________________________

3. _______________________________________________________________________________________________

4. _______________________________________________________________________________________________

5. _______________________________________________________________________________________________

6. _______________________________________________________________________________________________

7. _______________________________________________________________________________________________

8. _______________________________________________________________________________________________

9. _______________________________________________________________________________________________

10. ______________________________________________________________________________________________

2.2

Page 11

3 - Description

Boom

Boom types and sizes

The HARDI® EAGLE™ booms are available in the following types and sizes:

SPB sizes: 45’, 50’, 60’ & 66’

The 45’ - 66’ SPB booms are built with the same basic components. There are differences in the outer wing sections to give

the range of boom widths. The 45’ & 50’ booms incorporate the breakaway into the folding hinge point between the inner/

outer wings. The 60’ & 66’ booms include breakaway sections in the outer wing.

SPC sizes: 75’, 80’, 88’, 90’ & 100’

The 75’ - 100’ SPC booms are built with the same basic components as the SPB booms. The main differences are in the size

of the boom steel profiles, the folding hinge area between the inner/outer wings and the type of breakaway sections.

SPC Dual Fold sizes: 90’/60’ & 120’/90’

The SPC booms are also available in Dual Fold models; 90’/60’ & 120’/90’. The outer sections of the dual fold booms fold

vertically to allow for two different spraying widths.

Components cannot be exchanged between the EAGLE™ SPB and SPC booms. Also, the 120’/90’ Dual Fold SPC booms are

equipped with a different center section than the other SPC booms.

Note: Individual boom wing fold is not possible using the 120’/90’ Dual Fold SPC booms.

÷

Hydraulic systems

The HARDI® EAGLE™ booms are available in four different hydraulic system versions; HY, HV, HZ (trailed) & HZ (self-propelled).

1. SPB-HY & SPC-HY

These types of booms are operated directly via the tractor hydraulics. Hydraulic lift cylinders are used for boom height

adjustment and fold cylinders are used for simultaneous boom wing fold and unfold.

2. SPB-HV

This type of boom has the same features as the HY model, but also allows for individual boom wing fold and unfold.

Hydraulic lift cylinders are used for boom height adjustment and fold cylinders are used for individual boom wing fold and

unfold. The SPB-HV hydraulics are controlled with an electrical hydraulic control box.

3. SPB-HZ & SPC-HZ (trailed)

These types of booms have two boom wing tilt cylinders that give the ability to obtain individual boom wing tilt. Hydraulic

lift cylinders are used for boom height adjustment and fold cylinders are used for individual boom wing fold and unfold. The

hydraulics are controlled with various different electrical hydraulic controls depending on the model of sprayer.

4. SPC-HZ (self-propelled)

This type of boom has two boom wing tilt cylinders that give the ability to obtain individual boom wing tilt. Hydraulic lift

cylinders are used for boom height adjustment and fold cylinders are used for simultaneous boom wing fold and unfold.

The hydraulics are controlled with the HARDI® Spray center and the multifunctional Grip handle.

Note: Individual boom wing fold is not possible using the HY Hydraulic system (1) or the HZ self-propelled system (4).

÷

3.1

Page 12

3 - Description

Boom terminology

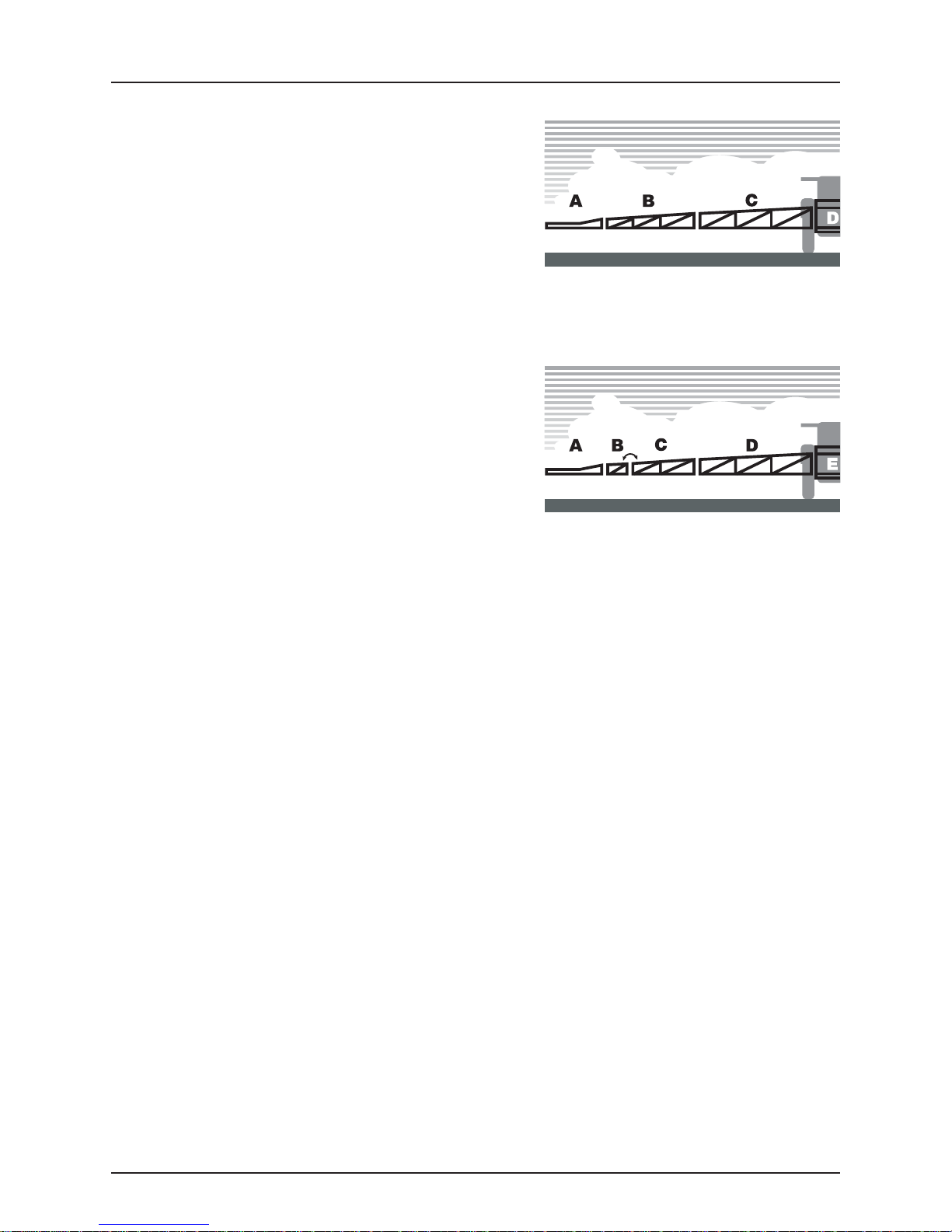

The terminology for the SPB/SPC boom sections is as follows:

A - Breakaway section

B - Outer section

C - Inner section

D - Center section

Note: The outer sections (B) on the 45’ & 50’ SPB booms are also the breakaway sections (A). So A & B are combined.

÷

The terminology for the Dual Fold SPC boom sections is as follows:

A - Breakaway section

B - 2nd Outer section

C - 1st Outer section

D - Inner section

E - Center section

3.2

Page 13

3 - Description

Electrical Hydraulic controls

General info

The electrical controls used to operate the boom hydraulics vary depending on the model of sprayer.

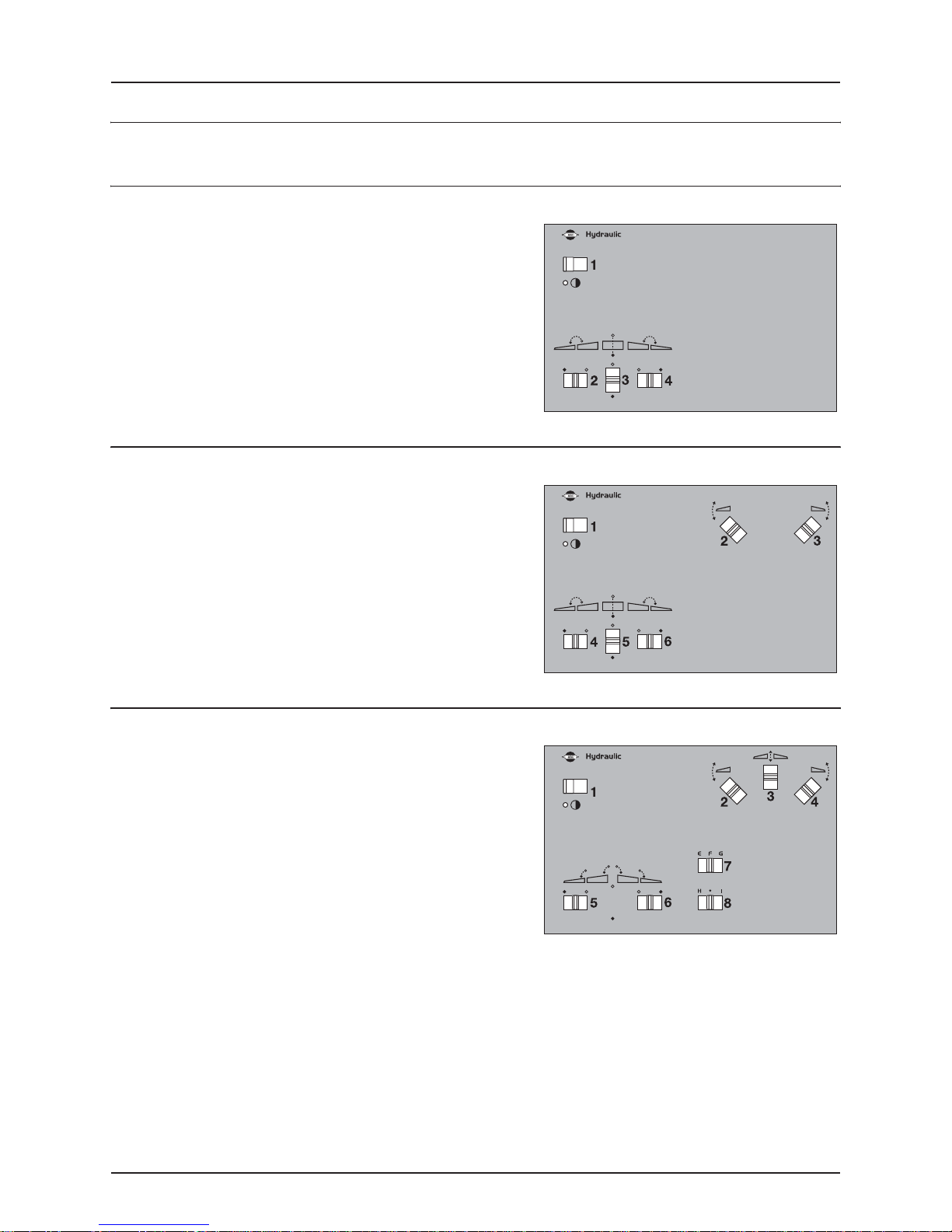

HV Hydraulic control box (Ranger 550)

The switches on the HV hydraulic control box control the following

functions:

1. Power ON/OFF

2. Boom folding (left side)

3. Boom lift raise/lower

4. Boom folding (right side)

HZ Hydraulic control box (Ranger 550)

The switches on the hydraulic control box control the following

functions:

1. Power ON/OFF

2. Boom tilt left

3. Boom tilt right

4. Boom folding (left side)

5. Boom lift raise/lower

6. Boom folding (right side)

HZ Hydraulic control box (Ranger 2000, Navigator)

The switches on the hydraulic control box control the following

functions:

1. Power ON/OFF

2. Boom tilt left

3. Boom lift raise/lower

4. Boom tilt right

5. Boom folding (left side)

6. Boom folding (right side)

7. Optional function

8. Optional function

3.3

Page 14

3 - Description

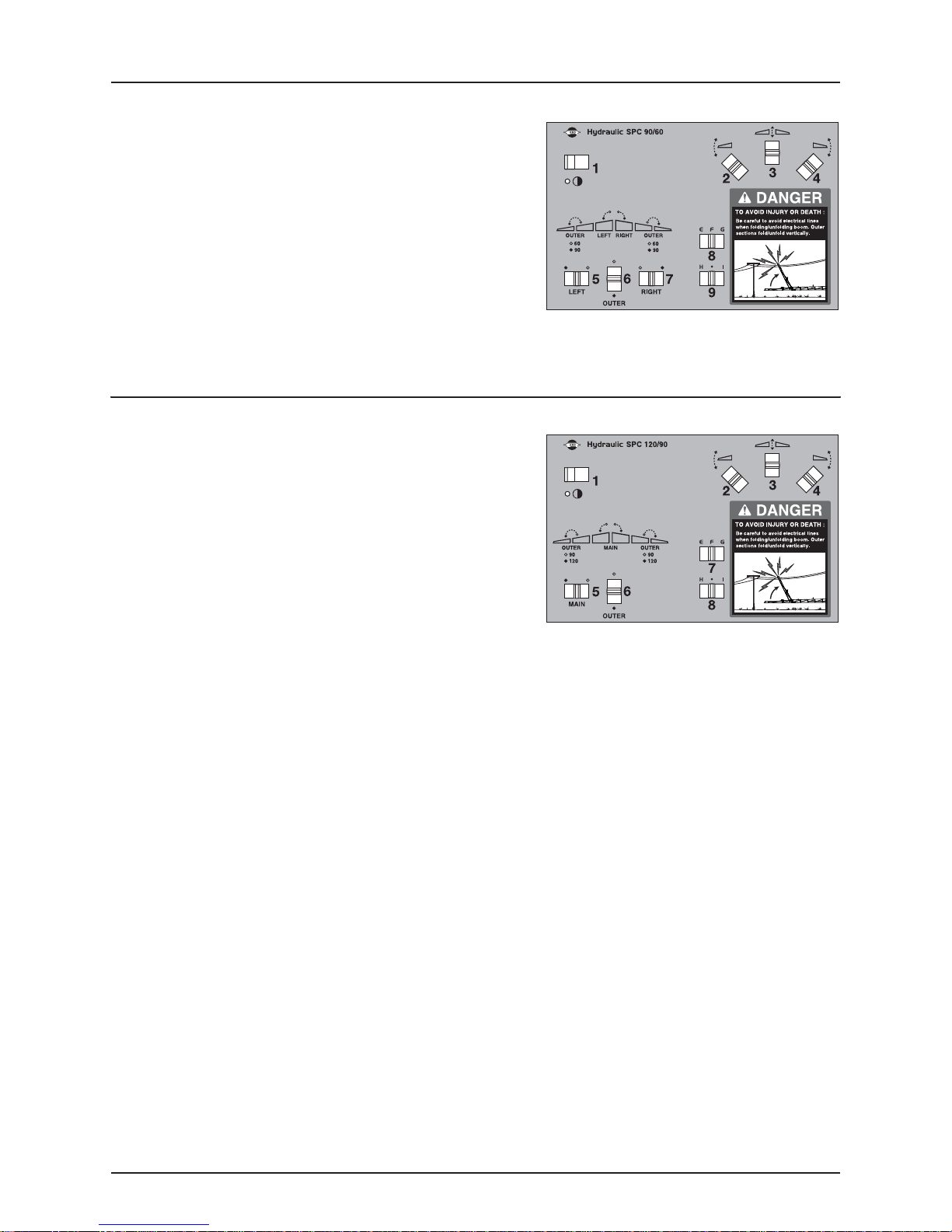

HZ Hydraulic control box - 90’/60’ SPC Dual Fold booms (Navigator)

The switches on the hydraulic control box control the following

functions:

1. Power ON/OFF

2. Boom tilt left

3. Boom lift raise/lower

4. Boom tilt right

5. Boom folding (left)

6. Boom folding (outer)

7. Boom folding (right)

8. Optional function

9. Optional function

HZ Hydraulic control box - 120’/90’ SPC Dual Fold booms (Navigator)

The switches on the hydraulic control box control the following

functions:

1. Power ON/OFF

2. Boom tilt left

3. Boom lift raise/lower

4. Boom tilt right

5. Boom folding (main)

6. Boom folding (outer)

7. Optional function

8. Optional function

3.4

Page 15

3 - Description

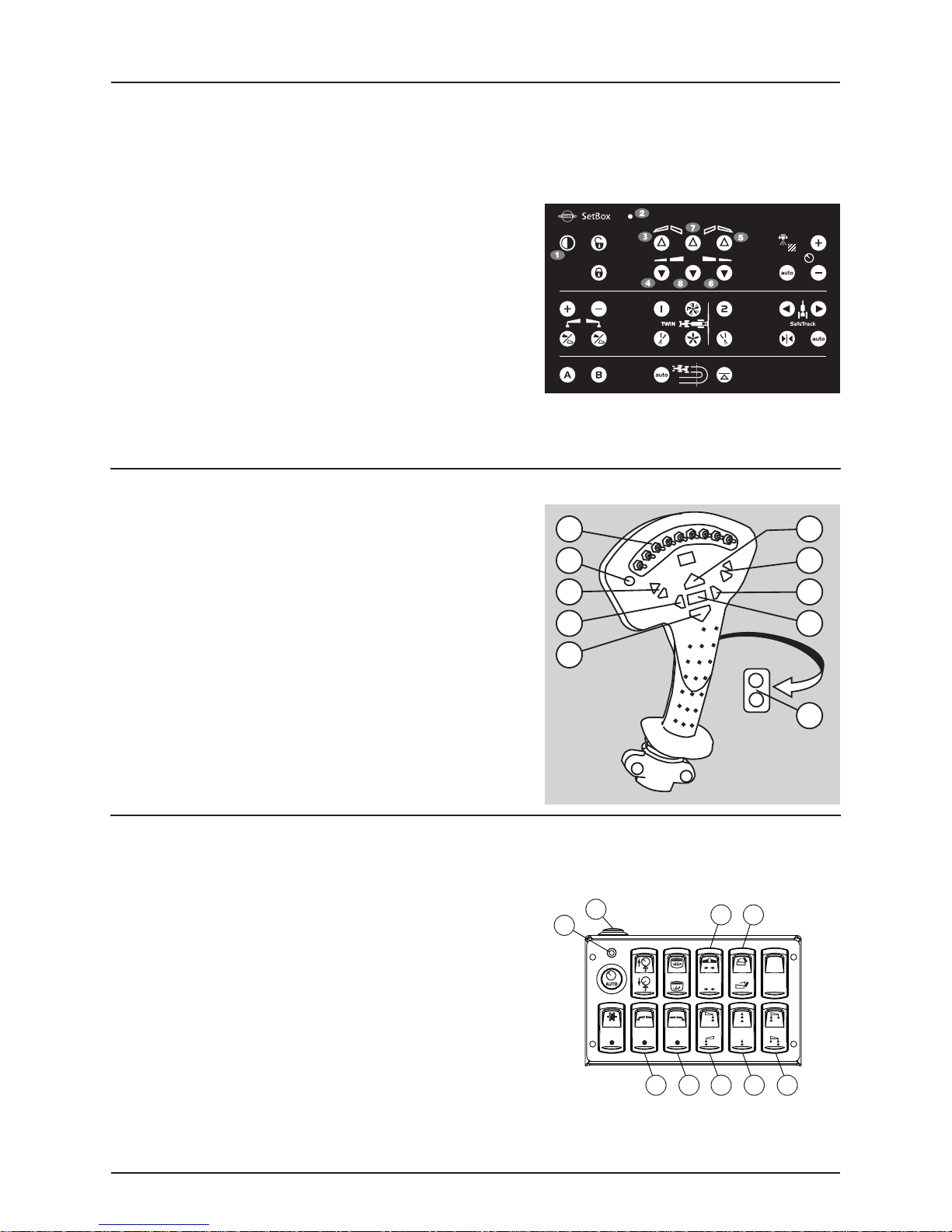

SetBox controls for sprayers equipped with ISOBUS

The SetBox controls secondary functions. The keys are grouped into control areas to simplify operator understanding.

Note: Self-propelled sprayers do not have a SetBox as the controls are built-in to the cabin.

÷

1. Power ON/OFF.

2. Status diode.

3. Left boom fold.

4. Left boom unfold.

5. Right boom fold.

6. Right boom unfold.

7. 2nd outer section fold (Dual Fold booms only).

8. 2nd outer section unfold (Dual Fold booms only).

ATTENTION! The Grip cannot be switched ON/OFF separately. It is automatically switched ON when tractor power is

turned ON (ISOBUS).

HZ Hydraulic controls on the Grip handle (ISOBUS & PRESIDIO)

A. Status LED.

B. Boom section controls.

C. Main ON/OFF.

D. Tilt.

E. Boom height.

F. Boom slant.

G. Not used.

B

A

D

F

E

E

D

F

C

G

HZ Hydraulic controls on the HARDI® spray center (PRESIDIO)

The boom controls on the HARDI® spray center work in combination with the Grip controls. The buttons on the console

control the following functions:

1. Status LED.

2. Main ON/OFF.

3. Unfold/Fold boom.

4. Unfold/Fold second outer section (90’/60’ booms only).

5. Left End Nozzle ON/OFF (optional).

6. Right End Nozzle ON/OFF (optional).

7. Foam Marker Left/Right.

8. Foam Marker blob interval.

9. Foam Marker Inner/Outer (optional).

2

1

5 6 7 8 9

3 4

3.5

Page 16

3 - Description

3.6

Page 17

4 - Sprayer setup

Hydraulic systems

General info

Ensure that snap couplers are clean before connection!

After having operated the boom and the system has been filled with oil, check tractor’s hydraulic oil level and add oil if

necessary.

DANGER! Test of the hydraulic system should be done very cautiously. There may be air trapped in the system which

€

can cause violent movements of the boom.

DANGER! Hydraulic leaks: Never use your fingers to locate a leakage in any part of the hydraulic system. Due to high

€

pressure, hydraulic oil may penetrate the skin.

Requirements - tractor (SPB/SPC HY-model)

Connection requirements are:

• One single acting outlet for the lift function of the spray boom.

• One double acting outlet for the folding function.

Ensure that snap couplers are clean before connection!

The boom’s hydraulic system requires an oil flow of approximately 0.8 GPM (3 liters/min.) and a minimum pressure of 1,950

PSI (130 bar).

ATTENTION! After having operated the boom and the system has been filled with oil, then check tractor’s hydraulic

oil level and add oil if necessary.

WARNING! Due to the variation in tractor hydraulic systems and capacities, care should be exercised when initially

±

operating the sprayer hydraulic cylinders. It is advisable to adjust the hydraulic flow control down to the minimum

rate before operating the system. Adjust/increase the flow control after the system is bled of any air, if necessary.

Requirements - tractor (SPB HV-model)

Connection requirements are:

• One double acting outlet for the lift and folding function of the spray boom.

Ensure that snap couplers are clean before connection!

The hydraulic hoses are marked with arrows and colored tie straps to indicate direction of oil flow. Red tie strap = pressure.

Green tie strap = Return to tank. The hoses must be hooked up to the correct outlet for the hydraulics to function properly

(pressure hose to pressure outlet, return hose to tank outlet).

The boom’s hydraulic system requires an oil flow of approximately 0.8 GPM (3 liters/min.) and a minimum pressure of 1,950

PSI (130 bar).

ATTENTION! After having operated the boom and the system has been filled with oil, then check tractor’s hydraulic

oil level and add oil if necessary.

WARNING! Due to the variation in tractor hydraulic systems and capacities, care should be exercised when initially

±

operating the sprayer hydraulic cylinders. It is advisable to adjust the hydraulic flow control down to the minimum

rate before operating the system. Adjust/increase the flow control after the system is bled of any air, if necessary.

4.1

Page 18

4 - Sprayer setup

Requirements - tractor (SPB/SPC HZ-model)

Connection requirements are:

• One double acting hydraulic outlet for the lift and folding functions of the sprayer.

Ensure that snap couplers are clean before connection!

The hydraulic hoses are marked with arrows and colored tie straps to indicate direction of oil flow. Red tie strap = pressure.

Green tie strap = Return to tank. The hoses must be hooked up to the correct outlet for the hydraulics to function properly

(pressure hose to pressure outlet, return hose to tank outlet).

The boom’s hydraulic system requires an oil flow of approximately 0.8 GPM (3 liters/min.) and a minimum pressure of 1,950

PSI (130 bar).

ATTENTION! After having operated the boom and the system has been filled with oil, then check tractor’s hydraulic

oil level and add oil if necessary.

WARNING! Due to the variation in tractor hydraulic systems and capacities, care should be exercised when initially

±

operating the sprayer hydraulic cylinders. It is advisable to adjust the hydraulic flow control down to the minimum

rate before operating the system. Adjust/increase the flow control after the system is bled of any air, if necessary.

4.2

Page 19

HZ hydraulic block

The hydraulic flow can be adjusted on the HZ hydraulic block if

necessary. First set the hydraulic flow on the tractor so the boom raises

and lowers at the desired speed. Then check the speed of the fold and

tilt functions. If adjustment is necessary, loosen jam nut (A) and turn

throttle valve (B) all the way in using an allen wrench. Then turn throttle

valve (B) back out 1-1/2 turns. If the fold and tilt functions are too slow,

turn throttle valve (B) out more. If the fold and tilt functions are too fast,

turn throttle valve (B) in more. Tighten jam nut (A) when the desired

speed is reached.

Open center hydraulics (trailed - optional equipment)

The open center hydraulic block is needed if the tractor uses open

center hydraulics and/or if load sensing will be used.

The valve (1) on the side of the block is factory set for open center

hydraulics, but if closed center hydraulics will be used (also in

combination with load sensing) then screw in the valve.

Certain tractor models are able to use Load Sensing without connecting

an external sensing line. But if optimal sensing control pressure cannot

be obtained, an external sensing line needs to be mounted (3). Please

consult your tractor dealer for correct setup and correct connection.

Before operating the hydraulics, the valve should be adjusted according

to the specific tractor model. If you have doubt about which type of

hydraulic system your tractor is equipped with, please consult your

tractor dealer.

List of setting combinations for flow element and circuit value:

Valve no. 1 2 3 (LS port)

Open center out out Not conn.

Closed center in in Not conn.

Load sensing (LS) in out* Connected

*if tractor requires pressure relief.

4 - Sprayer setup

A

B

WARNING! Always be sure to fully extract or retract the open/closed center selection valve (1). Failure to do so can

±

result in damages to vital pump parts.

WARNING! It is of essential importance that connectors on sensing line are kept totally clean. Failure to do so can

±

result in impurities entering the pump and thereby cause damages to vital pump parts.

4.3

Page 20

4 - Sprayer setup

Boom

Suspension effect adjustment (80’-100’ SPC only)

The SPC boom features adjustable suspension for 80’-100’ booms. The

spring (A) has two assembly positions as shown on the illustration

below. Position (1) can be used for 80’-90’ booms and position (2) can be

used for 100’ booms.

Moving the assembly position further away from center (e.g. from pos. 1

to pos. 2) gives stiffer trapeze effect. The factory setting is position (1).

4.4

Page 21

5 - Operation

Boom

Safety info

WARNING! The boom must not be folded/unfolded while driving! Never use the folding/unfolding functions before

±

sprayer has been stopped! Failure to do so will cause damage to the boom.

DANGER! When folding or unfolding the boom, make sure that no persons or objects are in the operating area of the

€

boom.

DANGER! Always follow the guidelines listed below when driving

€

in areas with overhead power lines:

• Never use the folding/unfolding functions in areas with overhead

power lines.

• Unintended boom movements can cause contact with overhead

power lines.

ATTENTION! Decal #10533003 is located either on the sprayer’s drawbar (trailed) or inside the cabin (self-propelled).

This label must be visible to the operator when hooking up a trailed sprayer or from the driver’s seat of a self-propelled

sprayer.

ATTENTION! Only fold and unfold the boom on level ground.

5.1

Page 22

5 - Operation

Maneuvering of the SPB booms - HY version (Ranger)

The SPB booms with hydraulic HY-version are operated as follows:

1. Activate the single acting hydraulic outlet to raise the boom and release it from the transport brackets.

2. Activate the double acting hydraulic outlet to unfold the boom. Both wings will now unfold simultaneously.

3. When the boom is completely unfolded, it can be raised or lowered to the desired spray height by activating the single

acting hydraulic outlet.

4. Before attempting to fold the boom back into transport position, it must be raised all the way to the top by activating

the single acting outlet. This will enable the rear cylinder transport lock.

5. The boom is folded by activating the double acting outlet in the opposite direction that was used to unfold the boom.

The boom can now be lowered into the transport brackets.

6. The rear cylinder transport lock will automatically engage when lowering the boom after it has been raised all the way

to the top. To disengage the rear transport lock, simply raise the boom back up a few inches and then lower it again.

WARNING! Ensure that the rear cylinder transport locks are properly engaged before transport.

±

WARNING! The folding function must only be operated when the sprayer is stationary! Failure to do so will damage

±

the boom.

ATTENTION! Only unfold and fold the boom on level ground.

Note: Individual boom wing fold is not possible using the HY Hydraulic system.

÷

Maneuvering of the SPB and SPC booms - HY version (Navigator)

Both SPB and SPC booms with hydraulic HY-version are operated as follows:

1. Activate the single acting hydraulic outlet to raise the boom and release it from the transport brackets.

2. Activate the double acting hydraulic outlet to unfold the boom. Both wings will now unfold simultaneously. Rear

transport hooks disengage automatically.

3. When the boom is completely unfolded, it can be raised or lowered to the desired spray height by activating the single

acting hydraulic outlet.

4. Before attempting to fold the boom back into transport position, it should be raised all the way to the top by activating

the single acting outlet.

5. The boom is folded by activating the double acting outlet in the opposite direction that was used to unfold the boom.

The boom can now be lowered into the transport brackets.

WARNING! Ensure that the rear transport hooks are firmly engaged before transport.

±

WARNING! The folding function must only be operated when the sprayer is stationary! Failure to do so will damage

±

the boom.

ATTENTION! Only unfold and fold the boom on level ground.

Note: Individual boom wing fold is not possible using the HY Hydraulic system.

÷

5.2

Page 23

5 - Operation

Maneuvering of the SPB booms - HV version (Ranger 550)

The switches on the HV hydraulic control box control the following

functions:

1. Power ON/OFF

2. Boom folding (left side)

3. Boom lift raise/lower

4. Boom folding (right side)

To unfold the boom, do the following:

1. Engage the tractor’s double acting remote outlet lever and lock it in the engaged position.

2. Push switch (3) upwards to lift the boom clear of the transport brackets.

3. Push switches (2) and (4) outwards to unfold both wings simultaneously.

4. If only one side of the boom is to be used for spraying, first unfold the boom completely. Then push switch (2) or (4)

inwards to fold the desired side back in. Turn off the spray sections for the folded side on the spray control unit.

5. When the boom is completely unfolded, it can be raised or lowered to the desired spray height by pushing switch (3)

upwards or downwards.

To fold the boom, do the following:

6. Before attempting to fold the boom back into transport position, it must be raised all the way to the top by pushing

switch (3) upwards. This will enable the rear cylinder transport locks.

7. Push switches (2) and (4) inwards to fold the boom. The boom can now be lowered into the transport brackets.

8. The rear cylinder transport locks will automatically engage when lowering the boom after it has been raised all the way

to the top. To disengage the rear transport lock, simply raise the boom back up a few inches and then lower it again.

WARNING! Ensure that the rear cylinder transport locks are properly engaged before transport.

±

WARNING! The folding function (switches 2 & 4) must only be operated when the sprayer is stationary! Failure to do

±

so will damage the boom.

ATTENTION! Only unfold and fold the boom on level ground.

ATTENTION! The SPB-HV booms cannot be operated with tractor’s hydraulic levers.

ATTENTION! It is not advisable to go directly from transport position to spray position with one side only. Both wings

must first be completely unfolded and then one side folded back in.

5.3

Page 24

5 - Operation

Maneuvering of the SPB booms - HZ version (Ranger 550)

The switches on the hydraulic control box control the following

functions:

1. Power ON/OFF

2. Boom tilt left

3. Boom tilt right

4. Boom folding (left side)

5. Boom lift raise/lower

6. Boom folding (right side)

To unfold the boom, do the following:

1. Engage the tractor’s double acting remote outlet lever and lock it in the engaged position.

2. Push switch (5) upwards to lift the boom clear of the transport brackets.

3. Push switches (2) and (3) downwards to lower the individual tilt rams.

4. Push switches (4) and (6) outwards to unfold both wings simultaneously.

5. If only one side of the boom is to be used for spraying, first unfold the boom completely. Then push switch (4) or (6)

inwards to fold the desired side back in. Turn off the spray sections for the folded side on the spray control unit.

6. When the boom is completely unfolded, it can be raised or lowered to the desired spray height by pushing switch (5)

upwards or downwards.

To tilt the boom, do the following:

7. Push switch (2) and/or (3) up or down to tilt the left and/or right wings up or down.

To fold the boom, do the following:

8. Before attempting to fold the boom back into transport position, it must be raised all the way to the top by pushing

switch (5) upwards. This will enable the rear cylinder transport locks.

9. Push switch (4) and (6) inwards to fold the boom.

10. Push switches (2) and (3) upwards to raise the individual tilt rams. The boom can now be lowered into the transport

brackets.

11. The rear cylinder transport locks will automatically engage when lowering the boom after it has been raised all the way

to the top. To disengage the rear transport lock, simply raise the boom back up a few inches and then lower it again.

WARNING! Ensure that the rear cylinder transport locks are properly engaged before transport.

±

WARNING! The folding function (switches 4 & 6) must only be operated when the sprayer is stationary! Failure to do

±

so will damage the boom.

WARNING! Never attempt to fold boom to transport position when wings are tilted. Always let wings down to

±

horizontal position prior to folding.

WARNING! Never attempt to work on or around wing section when tilted up.

±

WARNING! Unexpected boom movements may occur if wings are tilted when folding.

±

WARNING! Never use tilt function when boom is folded into transport position.

±

ATTENTION! Only unfold and fold the boom on level ground.

ATTENTION! The SPB-HZ booms cannot be operated with tractor’s hydraulic levers.

ATTENTION! It is not advisable to go directly from transport position to spray position with one side only. Both wings

must first be completely unfolded and then one side folded back in.

5.4

Page 25

5 - Operation

Maneuvering of the SPB booms - HZ version (Ranger 2000)

The switches on the hydraulic control box control the following

functions:

1. Power ON/OFF

2. Boom tilt left

3. Boom lift raise/lower

4. Boom tilt right

5. Boom folding (left side)

6. Boom folding (right side)

7. Optional function

8. Optional function

To unfold the boom, do the following:

1. Engage the tractor’s double acting remote outlet lever and lock it in the engaged position.

2. Push switch (3) upwards to lift the boom clear of the transport brackets.

3. Push switches (2) and (4) downwards to lower the individual tilt rams.

4. Push switches (5) and (6) outwards to unfold both wings simultaneously.

5. If only one side of the boom is to be used for spraying, first unfold the boom completely. Then push switch (5) or (6)

inwards to fold the desired side back in. Turn off the spray sections for the folded side on the spray control unit.

6. When the boom is completely unfolded, it can be raised or lowered to the desired spray height by pushing switch (3)

upwards or downwards.

To tilt the boom, do the following:

7. Push switch (2) and/or (4) up or down to tilt the left and/or right wings up or down.

To fold the boom, do the following:

8. Before attempting to fold the boom back into transport position, it must be raised all the way to the top by pushing

switch (3) upwards. This will enable the rear cylinder transport locks.

9. Push switches (5) and (6) inwards to fold the boom.

10. Push switches (2) and (4) upwards to raise the individual tilt rams. The boom can now be lowered into the transport

brackets.

11. The rear cylinder transport locks will automatically engage when lowering the boom after it has been raised all the way

to the top. To disengage the rear transport lock, simply raise the boom back up a few inches and then lower it again.

WARNING! Ensure that the rear cylinder transport locks are properly engaged before transport.

±

WARNING! The folding function (switches 5 & 6) must only be operated when the sprayer is stationary! Failure to do

±

so will damage the boom.

WARNING! Never attempt to fold boom to transport position when wings are tilted. Always let wings down to

±

horizontal position prior to folding.

WARNING! Never attempt to work on or around wing section when tilted up.

±

WARNING! Unexpected boom movements may occur if wings are tilted when folding.

±

WARNING! Never use tilt function when boom is folded into transport position.

±

ATTENTION! Only unfold and fold the boom on level ground.

ATTENTION! The SPB-HZ booms cannot be operated with tractor’s hydraulic levers.

ATTENTION! It is not advisable to go directly from transport position to spray position with one side only. Both wings

must first be completely unfolded and then one side folded back in.

5.5

Page 26

5 - Operation

Maneuvering of the SPB and SPC booms - HZ version (Navigator)

The switches on the hydraulic control box control the following

functions:

1. Power ON/OFF

2. Boom tilt left

3. Boom lift raise/lower

4. Boom tilt right

5. Boom folding (left side)

6. Boom folding (right side)

7. Optional function

8. Optional function

To unfold the boom, do the following:

1. Engage the tractor’s double acting remote outlet lever and lock it in the engaged position.

2. Push switch (3) upwards to lift the boom clear of the transport brackets.

3. Push switches (2) and (4) downwards to lower individual tilt rams.

4. Push switches (5) and (6) outwards to unfold the boom. Rear transport hooks disengage automatically.

5. If only one side of the boom is to be used for spraying, first unfold the boom completely. Then push switch (5) or (6)

inwards to fold the desired side back in. Turn off the spray sections for the folded side on the spray control unit.

6. Push switch (3) downwards to lower the boom to correct height above crop or ground level.

To fold the boom, do the following:

1. Push switch (3) upwards to raise the boom to highest possible position.

2. Push switches (5) and (6) inwards to fold the boom. Make sure to fold the boom against the vertical slide pads.

3. Push switches (2) and (4) upwards to raise the individual tilt rams.

4. Push switch (3) downwards to lower the boom until the rear transport hooks are firmly engaged.

5. Push switches (2) and (4) downwards to lower the individual tilt rams until they rest on the transport brackets.

WARNING! Ensure that the boom is clear from the transport brackets before unfolding.

±

WARNING! The folding functions (switches 5 and 6) must only be operated when the sprayer is stationary! Failure to

±

do so will damage the boom.

ATTENTION! The SPB & SPC HZ booms cannot be operated with the tractor’s hydraulic levers.

ATTENTION! It is not advisable to go directly from transport position to spray position with one side only. Both wings

must first be completely unfolded and then one side folded back in.

5.6

Page 27

5 - Operation

Maneuvering of the 90’/60’ SPC Dual Fold boom (Navigator)

The switches on the hydraulic control box control the following

functions:

1. Power ON/OFF

2. Boom tilt left

3. Boom lift raise/lower

4. Boom tilt right

5. Boom folding (left)

6. Boom folding (outer)

7. Boom folding (right)

8. Optional function

9. Optional function

To unfold the boom, do the following:

1. Engage the tractor’s double acting remote outlet lever and lock it in the engaged position.

2. Push switch (3) upwards to lift the boom clear of the transport brackets.

3. Push switches (2) and (4) downwards to lower individual tilt rams.

4. Push switches (5) and (7) inwards to unfold the boom. Rear transport hooks disengage automatically. Boom will be at

90’ working width.

5. Push switch (3) downwards to lower the boom to correct height above crop or ground level.

6. For 60’ working width, push switch (6) upwards to simultaneously fold both of the 2nd outer wings completely in.

7. Remember to set the outer section valves on the spray control unit to match the working boom width.

To fold the boom, do the following:

1. Start with the sprayer stationary and boom completely unfolded in either 90’ or 60’ working width.

2. If at 60’ working width, push switch (6) downwards to simultaneously unfold both of the 2nd outer wings.

3. Push switch (3) upwards to raise the boom to highest possible position.

4. Push switch (5) to the right and (7) to the left to fold the boom. Make sure to fold the boom against the vertical slide

pads.

5. Push switches (2) and (4) upwards to raise the individual tilt rams.

6. Push switch (3) downwards to lower the boom until the rear transport hooks are firmly engaged.

7. Push switches (2) and (4) downwards to lower the individual tilt rams until they rest on the transport brackets.

DANGER! Be careful to avoid electrical lines when folding/unfolding boom. Outer sections fold/unfold vertically.

€

WARNING! Ensure that the boom is clear from the transport brackets before unfolding.

±

WARNING! Never transport sprayer with boom in 60’ working width. The front end of the folded boom will be taller

±

and further forward. Always check for safe clearance from tractor, overhead wires, etc.

WARNING! The folding functions (switches 5, 6 and 7) must only be operated when the sprayer is stationary! Failure

±

to do so will damage the boom.

ATTENTION! There are stop switches located in the hydraulic lines of Dual Fold booms to prevent accidental damage

by folding/unfolding the 2nd outer sections while in transport position. Switch (6) (vertical fold) will only function

when the inner wings (horizontal fold) are completely unfolded in the operating position.

ATTENTION! The 90’/60’ SPC Dual Fold HZ boom cannot be operated with the tractor’s hydraulic levers.

5.7

Page 28

5 - Operation

Single-sided folding of the 90’/60’ SPC Dual Fold boom (Navigator)

It is possible to spray with only one side of the boom unfolded. If this is

desired, start with the boom completely unfolded in either the 90’ or 60’

spraying position. Then push switch (5) or (7) inwards to fold in the left

or right wing only. On the spray control unit also turn off the spray

sections placed on the folded side.

WARNING! Take extra care while operating with one side folded at 60’ working width. The front end of the folded side

±

will be taller and further forward. Always check for safe clearance from tractor, overhead wires, etc.

ATTENTION! It is not advisable to go directly from transport position to spray position with one side only. Both wings

must first be completely unfolded and then one side folded back in.

5.8

Page 29

5 - Operation

Maneuvering of the 120’/90’ SPC Dual Fold boom (Navigator)

The switches on the hydraulic control box control the following

functions:

1. Power ON/OFF

2. Boom tilt left

3. Boom lift raise/lower

4. Boom tilt right

5. Boom folding (main)

6. Boom folding (outer)

7. Optional function

8. Optional function

To unfold the boom, do the following:

1. Engage the tractor’s double acting remote outlet lever and lock it in the engaged position.

2. Push switch (3) upwards to lift the boom clear of the transport brackets.

3. Push switches (2) and (4) downwards to lower individual tilt rams.

4. Push switch (5) to the left to simultaneously unfold the main boom sections. Rear transport hooks disengage

automatically.

5. Push switch (3) downwards to lower the boom to correct height above crop or ground level. Boom will be at 90’

working width.

6. For 120’ working width, push switch (6) downwards to simultaneously unfold the 2nd outer boom sections.

7. Remember to set the outer section valves on the spray control unit to match the working boom width.

To fold the boom, do the following:

1. Start with the sprayer stationary and boom completely unfolded in either 120’ or 90’ working width.

2. If at 120’ working width, push switch 6 upwards to simultaneously fold both of the 2nd outer wings completely in.

3. Push switch (3) upwards to raise the boom to highest possible position.

4. Push switch (5) to the right to fold the boom completely in.

5. Push switches (2) and (4) upwards to raise the individual tilt rams. Make sure the boom is against the vertical slide pads.

6. Push switch (3) downwards to lower the boom until the rear transport hooks are firmly engaged.

7. Push switches (2) and (4) downwards to lower the individual tilt rams until they rest on the transport brackets.

DANGER! Be careful to avoid electrical lines when folding/unfolding boom. Outer sections fold/unfold vertically.

€

WARNING! Ensure that the boom is clear from the transport brackets before unfolding.

±

WARNING! The folding functions (switches 5 and 6) must only be operated when the sprayer is stationary! Failure to

±

do so will damage the boom.

ATTENTION! There are stop switches located in the hydraulic lines of Dual Fold booms to prevent accidental damage

by folding/unfolding the 2nd outer sections while in transport position. Switch (6) (vertical fold) will only function

when the inner wings (horizontal fold) are completely unfolded in the operating position.

ATTENTION! The 120’/90’ SPC Dual Fold HZ boom cannot be operated with the tractor’s hydraulic levers.

Note: Single-sided folding of the 120’/90’ SPC Dual Fold boom is not possible.

÷

5.9

Page 30

5 - Operation

Maneuvering of the SPB booms - (Ranger with ISOBUS)

To unfold the boom, do the following:

1. Press switch (H) to raise the boom clear of the transport brackets.

2. Press switches (B) and (D) to lower individual tilt rams.

3. Press switches (4) and (6) to unfold both wings simultaneously.

4. If only one side of the boom is to be used for spraying, first unfold

the boom completely. Then press switch (3) or (5) to fold the

desired side back in. Turn off the spray sections for the folded side

on the spray control unit.

5. Press switch (I) to lower the boom to correct height above crop or

ground level.

To fold the boom, do the following:

1. Before attempting to fold the boom back into transport position, it

must be raised all the way to the top by pressing switch (H). This

will enable the rear cylinder transport locks.

2. Press switches (3) and (5) to fold the boom.

3. Press switches (A) and (C) to raise the individual tilt rams. The boom

can now be lowered into the transport brackets.

4. The rear cylinder transport locks will automatically engage when

lowering the boom after it has been raised all the way to the top.

To disengage the rear transport lock, simply raise the boom back

up a few inches and then lower it again.

H

C

A

B

E

I

D

F

G

WARNING! Ensure that the rear cylinder transport locks are properly engaged before transport.

±

WARNING! The folding functions (switches 3 - 6) must only be operated when the sprayer is stationary! Failure to do

±

so will damage the boom.

WARNING! Never attempt to fold boom to transport position when wings are tilted. Always let wings down to

±

horizontal position prior to folding.

WARNING! Never attempt to work on or around wing section when tilted up.

±

WARNING! Unexpected boom movements may occur if wings are tilted when folding.

±

WARNING! Never use tilt function when boom is folded into transport position.

±

ATTENTION! Only unfold and fold the boom on level ground.

ATTENTION! The SPB-HZ booms cannot be operated with the tractor’s hydraulic levers.

ATTENTION! It is not advisable to go directly from transport position to spray position with one side only. Both wings

must first be completely unfolded and then one side folded back in.

5.10

Page 31

5 - Operation

Maneuvering of the SPB, SPC & 90’/60’ Dual Fold SPC booms - (Navigator with ISOBUS)

To unfold the boom, do the following:

1. Press switch (H) to raise the boom clear of the transport brackets.

2. Press switches (B) and (D) to lower individual tilt rams.

3. Press switches (4) and (6) to unfold the boom. Rear transport hooks

disengage automatically.

4. If only one side of the boom is to be used for spraying, first unfold

the boom completely. Then press switch (3) or (5) to fold the

desired side back in. Turn off the spray sections for the folded side

on the spray control unit.

5. Press switch (I) to lower the boom to correct height above crop or

ground level.

6. If equipped with 90’/60’ Dual Fold boom, push switch (7) to fold 2nd outer sections in to 60’ working width.

To fold the boom, do the following:

1. If equipped with 90’/60’ Dual Fold boom, start with boom at 90’

working width. If necessary, unfold 2nd outer sections using

switch (8).

2. Press switch (H) to raise the boom to highest possible position.

3. Press switches (3) and (5) to fold the boom. Make sure to fold the

boom against the vertical slide pads.

4. Press switches (A) and (C) to raise the individual tilt rams.

5. Press switch (I) to lower the boom until the rear transport hooks are

firmly engaged.

6. Press switches (B) and (D) to lower the individual tilt rams until they

rest on the transport brackets.

A

B

E

I

H

C

D

F

G

DANGER! Be careful to avoid electrical lines when folding/unfolding Dual Fold boom. Outer sections fold/unfold

€

vertically.

WARNING! Ensure that the boom is clear from the transport brackets before unfolding.

±

WARNING! The folding functions (switches 3 - 8) must only be operated when the sprayer is stationary! Failure to do

±

so will damage the boom.

ATTENTION! There are stop switches located in the hydraulic lines of Dual Fold booms to prevent accidental damage

by folding/unfolding the 2nd outer sections while in transport position. Switches (7) & (8) (vertical fold) will only

function when the inner wings (horizontal fold) are completely unfolded in the operating position.

ATTENTION! The SPB, SPC & Dual Fold SPC HZ booms cannot be operated with the tractor’s hydraulic levers.

ATTENTION! It is not advisable to go directly from transport position to spray position with one side only. Both wings

must first be completely unfolded and then one side folded back in.

5.11

Page 32

5 - Operation

Maneuvering of the 120’/90’ Dual Fold SPC booms - (Navigator with ISOBUS)

To unfold the boom, do the following:

1. Press switch (H) to raise the boom clear of the transport brackets.

2. Press switches (B) and (D) to lower individual tilt rams.

3. Press switch (4) to unfold the boom. Rear transport hooks

disengage automatically.

4. Press switch (I) to lower the boom to correct height above crop or

ground level. Boom will be at 90’ working width.

5. For 120’ working width, press switch (8) to unfold the 2nd outer

sections.

To fold the boom, do the following:

1. Start with boom at 90’ working width. If necessary, fold 2nd outer

sections using switch (7).

2. Press switch (H) to raise the boom to highest possible position.

3. Press switch (3) to fold the boom. Make sure to fold the boom

against the vertical slide pads.

4. Press switches (A) and (C) to raise the individual tilt rams.

5. Press switch (I) to lower the boom until the rear transport hooks are

firmly engaged.

6. Press switches (B) and (D) to lower the individual tilt rams until they

rest on the transport brackets.

A

B

E

I

H

C

D

F

G

DANGER! Be careful to avoid electrical lines when folding/unfolding Dual Fold boom. Outer sections fold/unfold

€

vertically.

WARNING! Ensure that the boom is clear from the transport brackets before unfolding.

±

WARNING! The folding functions (switches 3, 4, 7 & 8) must only be operated when the sprayer is stationary! Failure

±

to do so will damage the boom.

ATTENTION! There are stop switches located in the hydraulic lines of Dual Fold booms to prevent accidental damage

by folding/unfolding the 2nd outer sections while in transport position. Switches (7) & (8) (vertical fold) will only

function when the inner wings (horizontal fold) are completely unfolded in the operating position.

ATTENTION! The 120’/90’ Dual Fold SPC HZ boom cannot be operated with the tractor’s hydraulic levers.

Note: Single-sided folding of the 120’/90’ Dual Fold SPC boom is not possible.

÷

5.12

Page 33

Maneuvering of the SPC booms (PRESIDIO)

To unfold the boom, do the following:

1. Check that the rear transport lock is in the storage position.

2. Press the boom lift button (H) to lift the boom clear of the transport

brackets.

3. Press and hold (B) and (D) to lower individual tilt rams.

4. Press and hold top of switch (3) to unfold the boom.

5. Press and hold the boom down button (I) to lower the boom to

correct height above crop or ground level.

To fold the boom, do the following:

1. Press the boom lift button (H) to lift the boom to highest possible

position.

2. Press and hold bottom of switch (3) to fold the boom.

3. Press buttons (A) and (C) to raise the individual tilt rams until the

transport brackets touch the vertical slide pads.

4. Press the boom down button (I) to lower the boom until it rests on

the rollers and the transport brackets are securely captured by the

transport hooks.

5 - Operation

2

1

5 6 7 8 9

A

B

E

3 4

H

C

D

F

G

I

DANGER! Be careful to avoid electrical lines when folding/unfolding boom.

€

WARNING! The rear transport lock must be in storage position before folding/unfolding the boom. Failure to do so

±

will cause damage to the boom.

WARNING! Ensure that the boom is clear from the transport brackets before unfolding.

±

WARNING! The folding functions (switch 3) must only be operated when the sprayer is stationary! Failure to do so will

±

damage the boom.

Note: Individual boom wing fold is not possible using the Presidio HZ Hydraulic system.

÷

5.13

Page 34

5 - Operation

Maneuvering of the 90’/60’ Dual Fold SPC boom (PRESIDIO)

To unfold the boom, do the following:

1. Check that the rear transport lock is in the storage position.

2. Press the boom lift button (H) to lift the boom clear of the transport

brackets.

3. Press and hold (B) and (D) to lower individual tilt rams.

4. Press and hold top of switch (3) to unfold the boom. Boom will be

at 90’ working width.

5. Press and hold the boom down button (I) to lower the boom to

correct height above crop or ground level.

6. For 60’ working width, press top of switch (4) to fold the 2nd outer

wings completely in.

7. Remember to set the outer section valves on the spray control unit

to match the working boom width.

To fold the boom, do the following:

1. Start with the sprayer stationary and boom completely unfolded in

either 90’ or 60’ working width.

2. If at 60’ working width, press bottom of switch (4) to unfold the

2nd outer wings. Boom will be at 90’ working width.

3. Press the boom lift button (H) to lift the boom to highest possible

position.

4. Press and hold bottom of switch (3) to fold the boom.

5. Press buttons (A) and (C) to raise the individual tilt rams until the

transport brackets touch the vertical slide pads.

6. Press the boom down button (I) to lower the boom until it rests on

the rollers and the transport brackets are securely captured by the

transport hooks.

2

1

5 6 7 8 9

3 4

H

C

A

B

E

D

F

G

I

DANGER! Be careful to avoid electrical lines when folding/unfolding boom. Outer sections fold/unfold vertically.

€

WARNING! The rear transport lock must be in storage position before folding/unfolding the boom. Failure to do so

±

will cause damage to the boom.

WARNING! Ensure that the boom is clear from the transport brackets before unfolding.

±

WARNING! Never transport sprayer with boom in 60’ working width. The front end of the folded boom will be taller

±

and further forward. Always check for safe clearance from tractor, overhead wires, etc.

WARNING! The folding functions (switches 3 & 4) must only be operated when the sprayer is stationary! Failure to do

±

so will damage the boom.

ATTENTION! There are stop switches located in the hydraulic lines to prevent accidental damage to the boom by

folding/unfolding the outer boom while in transport position. Switch (4) for the outer wings (vertical fold) will only

function when the inner wings (horizontal fold) are completely unfolded in the operating position.

Note: Individual boom wing fold is not possible using the Presidio HZ Hydraulic system.

÷

5.14

Page 35

6 - Maintenance

Lubrication

General info

Always store lubricants clean, dry and cool - preferably at a constant

temperature - to avoid contamination from dirt and condensed water.

Keep oil filling jugs, hoppers and grease guns clean, and clean the

lubricating points thoroughly before lubricating. Avoid skin contact with

oil products for longer periods.

Always follow the shown direction concerning recommended quantity.

If no recommended quantity is given, feed lubricator till new grease

becomes visible.

Pictograms in lubrication & oiling plans tell the following:

1. Lubricant to be used (see “Recommended lubricants”).

2. Operating hours before next lubrication.

ATTENTION! If the sprayer is cleaned with a high pressure cleaner, lubrication of the entire machine is recommended.

Recommended lubricants

BALL BEARINGS:

Universal Lithium grease, NLGI No. 2

SHELL RETINAX EP2

CASTROL LMX GREASE

SLIDE BEARINGS:

Lithium grease with

Molybdenumdisulphide or graphite

SHELL RETINAX HD 2 (or HDX 2)

OIL LUB. POINTS:

TOTAL Transmission TM

SAE 80W/90

Castrol EPX 80W/90

SHELL Spirax 80W/90

Mobil Mobilube 80W/90

45’-60’ SPB & 80’-100’ SPC Boom lubrication & oiling plan

6.1

Page 36

6 - Maintenance

120’/90’ & 90’/60’ Dual Fold SPC Boom lubrication & oiling plan

120’/90’

90’/60’

6.2

Page 37

Service and Maintenance intervals

10 hours service - In-Line filter

If the boom is equipped with In-Line Filters, unscrew the filter bowl to

inspect and clean the filter. When reassembling, the O-ring should be

greased.

Alternative filter meshes are available. See section on Technical

specifications - Filters and nozzles.

WARNING! Be careful not to splash out liquid when unscrewing

±

the filter bowl.

WARNING! Always wear protective clothing and gloves before

±

opening the filter!

10 hours service - Nozzle filters (optional equipment)

Check and clean.

6 - Maintenance

10 hours service - Spraying circuit

Fill with clean water, operate all functions and check for leaks using higher spray pressure than normal. Check nozzle spray

patterns visually using clean water.

250 hours service - Readjustment of the boom

See section “Occasional maintenance”.

250 hours service - Hydraulic circuit

Check the hydraulic circuit for leaks and repair if any.

WARNING! Hoses for boom lifting device must be changed after every 5 years of use.

±

250 hours service - Hoses and tubes

Check all hoses and tubes for possible damages and proper attachment. Replace damaged hoses or tubes.

6.3

Page 38

6 - Maintenance

Occasional maintenance

General info

The maintenance and replacement intervals for the following will depend very much on the conditions under which the

sprayer will be operated and are therefore impossible to specify.

Nozzle tubes and fittings

Poor seals are usually caused by:

• Missing O-rings or gaskets

• Damaged or incorrectly seated O-rings

• Dry or deformed O-rings or gaskets

• Foreign bodies

In case of leaks:

DO NOT overtighten. Disassemble, check condition and position of Oring or gasket. Clean, lubricate and reassemble.

The O-ring must be lubricated ALL THE WAY AROUND before fitting on

to the nozzle tube. Use non-mineral lubricant.

For AXIAL connections, a little mechanical leverage may be used.

For RADIAL connections only hand-tighten them.

Feed pipe snap-lock assembly (T25)

Disassembly

1. Screw the union nut (A) completely off.

2. Pull the feed piping and hose barb apart.

3. Take out the O-ring (B).

4. Inspect and oil O-ring (B). Change the O-ring (B) if worn, before

reassembly.

Reassembly

1. Check that the barbed lock ring (C) is fitted to the feed pipe with

barb pointing away from pipe opening.

2. Fit the oiled O-ring (B) on top of the lock ring (C).

3. Push the feed pipe and hose barb together.

4. Screw the union nut (A) on the hose barb and tighten union nut

(A) by hand.

Initial fitting of fittings

ATTENTION! This method can only be used for pipes not fitted

into pipe clamps.

1. Fit the barbed lock ring (C) to the feed pipe with barb pointing

away from pipe opening.

2. Fit the oiled O-ring (B) on top of the lock ring.

3. Screw the union nut (A) partly on the hose barb.

4. Press the feed pipe and hose barb together.

5. Tighten the union nut (A) by hand.

6.4

Page 39

Feed pipe clamp assembly (T25)

A feed pipe can be removed from the pipe clamps the following way:

1. Use a flat bladed screwdriver to pry the cover off the first corner (A).

2. Hold the clamp top with your hand and pry off the opposite corner

(B) with the screwdriver.

3. Pry off the other side of the pipe clamp with the screwdriver.

4. Take out the feed pipe.

Readjustment boom - general info

Before beginning boom adjustments, please go through this check list:

1. The sprayer must be well lubricated (see part about lubrication).

2. Connect the sprayer to the tractor.

Place tractor and sprayer on level ground (horizontal).

3.

4. Unfold boom.

5. Set tilt angle of both wings to horizontal position.

6. Adjustment of hydraulic cylinders are done without pressure in the system.

6 - Maintenance

WARNING! No one is allowed to be under the boom while adjustment is carried out.

±

Alignment of center and inner wing sections (All booms)

1. Unfold the boom and check alignment of the inner section with

the center section.