Page 1

EAGLE 3PT Boom

10521903 (10/91)

Operator’s Manual

Page 2

Page 3

HARDI

EAGLE 3PT Boom

Operator's Manual

105219 (10/99)

HARDI

®

reserves the right to make changes in design,

material, or specification without notice thereof.

HARDI

®

and other product names are registered trademarks

of HARDI

®

Inc. in the U.S. and in other countires.

Page 4

2 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

TABLE OF CONTENTS

1.0 INTRODUCTION 7

2.0 SAFETY INFORMATION 8

3.0 GLOSSARY 13

4.0 ASSEMBLING THE 3PT EAGLE BOOMS 14

4.1

Attaching Center Frame to 3pt Hitch Frame

1

4

4.2 Preparing Wings for Installation 15

4.3 Installing Boom Wings 15

4.4 Mounting Hydraulic Hoses 16

4.5 Installing Center Frame Spray Tube Assembly 17

4.6 Adjusting the Center Section Cables 18

4.7 Attaching Feed Hoses - Two Valve System 19

4.8 Attaching Feed Hoses - Three Valve System 20

4.9 Hydraulic Hook-Up 21

4.10 HZ Hydraulics Joystick Controls 22

4.11 DH Hydraulics (Optional) 23

4.12 Performing Final Inspection 23

5.0 OPERATING THE EAGLE 3PT BOOM 24

5.1 Folding & Unfolding the 3 pt Boom (HY & HT booms only) 24

5.2 Operating the Wing Tilt (If applicable) 25

5.3 Folding & Unfolding Booms (HZ Hydraulics) 25

5.4 Folding One Side Only (HZ Hydraulics only) 26

5.5 Nozzle Selection 26

5.6 Calibration 29

6.0 ADJUSTMENTS 33

6.1 Adjustments & Maintenance Intervals 33

6.2 Checking & Adjusting Sprocket Timing 34

6.3 Alignment of Wing Assemblies 35

6.4 Alignment of Intermediate & Outer Boom Sections 35

6.5 Adjusting Front Fold Cable 36

6.6 Adjusting the Breakaway Clutch 37

6.7 Adjusting Wings Level to Ground 38

6.8 Adjusting the Center Section 39

6.9 Adjusting the Boom Transport Position 39

6.10 Adjusting the Rear Cable 40

7.0 MAINTENANCE 41

7.1 Lubrication 41

7.2 Greasing the Center Frame 41

Page 5

3HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

7.3 Greasing the Suspension/Pivot Linkage 41

7.4 Greasing the Boom 42

7.5 Greasing the Breakaway Clutch 42

7.6 Nozzle Filters 43

7.7 In-Line Filters (optional) 43

7.8 Nozzle Tubes and Fittings 43

7.9 Maintenance of Triplets (when fitted) 44

8.0 PUMP & CONTROLS 45

8.1 P.T.O. shaft Operator Safety 45

8.2 Installation of P.T.O. shaft (361 pump only) 46

8.3 Diaphragm Sprayer Plumbing Diagram 48

8.4 Adjustment of the EC Controls 49

8.5 Adjustment of Constant Pressure 50

8.6 Agitation Adjustment (agitation nozzles only) 51

8.7 Self Cleaning Filter 52

8.8 Checking Ball Seat in EC Controls 53

8.9 Checking the Valve Cone in Distribution Valves 53

8.10Changing the Valves & Diaphrams in a 361/462 Pump 54

8.11Centrifugal Sprayer Plumbing Diagram 55

8.12Operation of the ESC Controls 56

8.13Adjustment of the ESC Controls 57

8.14Agitation Adjustment (agitation nozzles only) 58

8.15Control Box for Electric Control Units 59

9.0 TRANSPORTATION AND STORAGE 60

9.1 Follow Safe Transport and Towing Procedures 60

9.2 Storage of the EAGLE 3-point Boom 61

9.3 Winter Storage 62

10.0 TROUBLESHOOTING 63

10.1 Hydraulic Systems 63

10.2 Mechanical Problems 64

10.3 Hydraulic Schematics 65

10.4 General Spray Systems 67

10.5 Foam Marker 70

10.6 Flush & Rinse™ 71

10.7 Chemical Filler 71

11.0 ACCESSORIES 72

12.0 WARRANTY POLICY AND CONDITIONS 75

Page 6

4 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

Page 7

5HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

Dear Owner,

Thank you for purchasing a HARDI

®

product and welcome to the ever

increasing family of HARDI

®

sprayer owners.

Our sprayers and accessories are rapidly becoming a familiar sight on

North American farms. We believe that this results from growers becoming increasingly conscious of chemical input costs and the vital need for

cost effective chemical application equipment.

Please take the time to thoroughly read the Operator’s Manual before

using your equipment. You will find many helpful hints as well as important

safety and operation information.

Some of the features on your EAGLE 3PT boom were suggested by

growers. There is no substitute for “on farm” experience and we invite your

comments and suggestions.

Please address your correspondence to the Service Manager at one of

these branches:

Sincerely,

Tom L. Kinzenbaw

President

HARDI

HARDI® MIDWEST

1500 West 76th St.

Davenport, Iowa 52806

Phone: (319) 386-1730

Fax: (319) 386-1710

HARDI

®

GREAT LAKES

290 Sovereign Rd.

London, Ontario N6M 1B3

Phone: (519) 659-2771

Fax: (519) 659-2821

HARDI

®

WEST COAST

5646 W. Barstow, Suite 101

Fresno, California 93722

Phone: (209) 271-3106

Fax: (209) 271-3107

Page 8

6 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

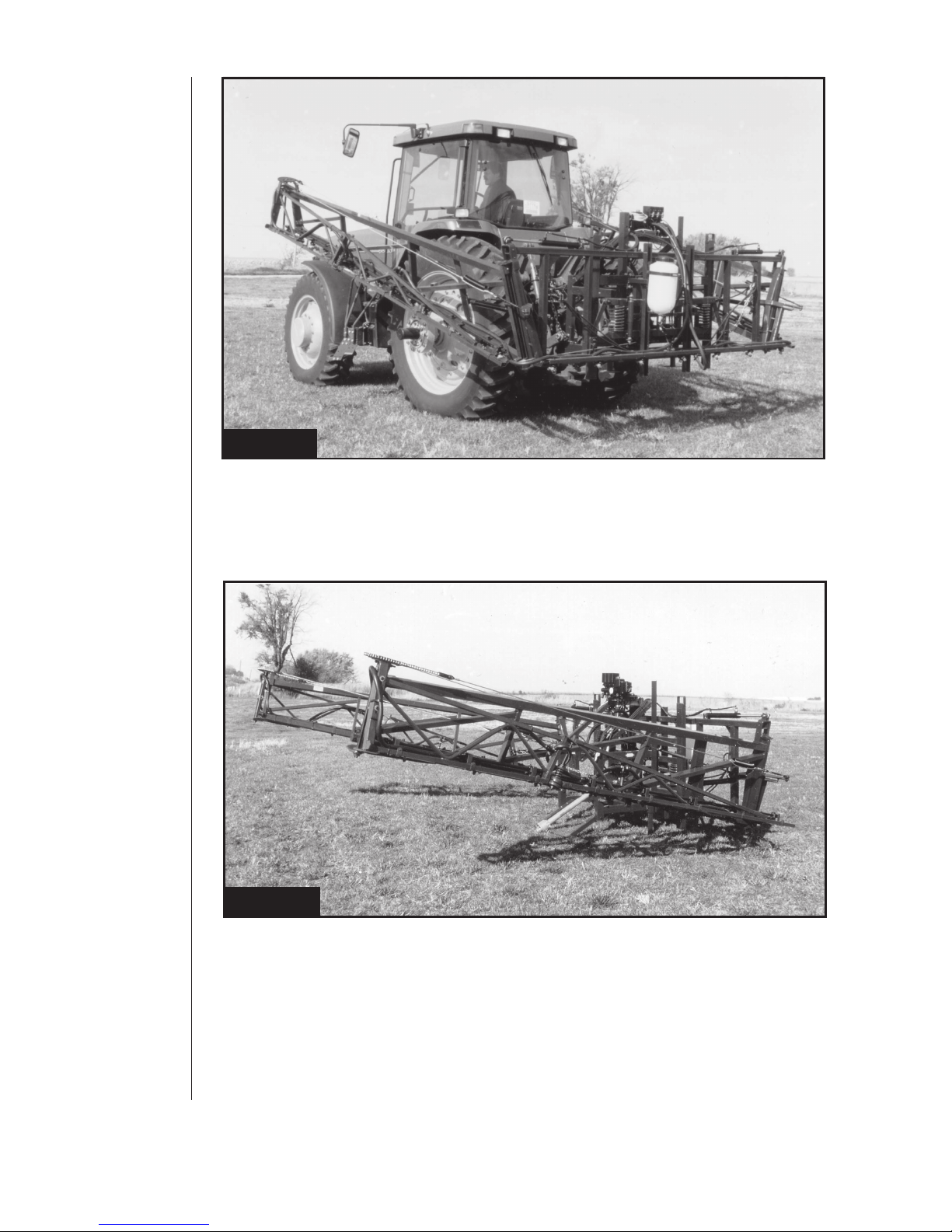

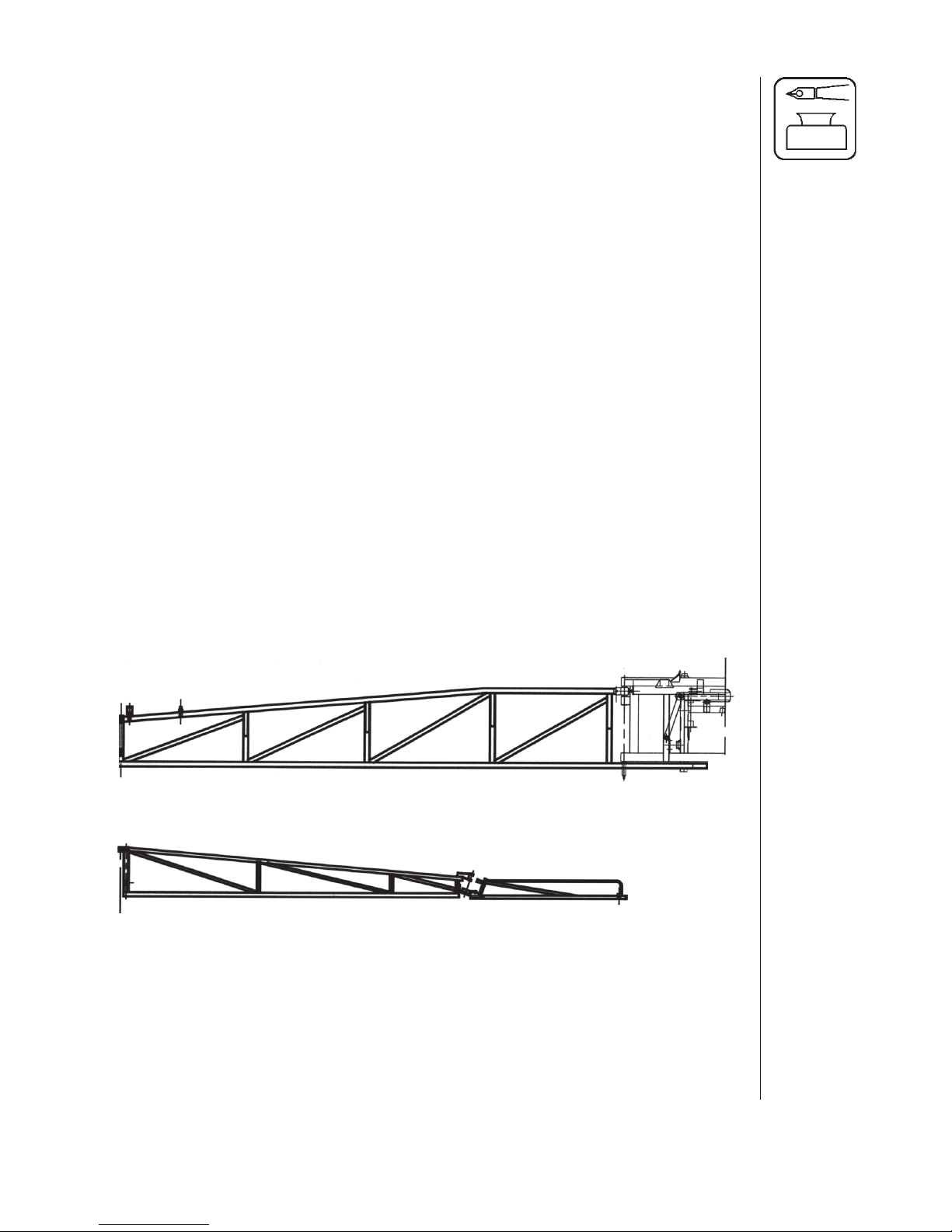

HARDI EAGLE 3PT Boom shown mounted on tractor

Fig. 1

HARDI EAGLE 3PT Boom shown in storage position

Fig. 2

Page 9

7HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

1.0 INTRODUCTION

The EAGLE 3-point boom is a fully suspended hydraulically operated

spray boom featuring self-stabilizing trapeze suspension with coil

springs and a shock absorber to control the rate of boom movement.

The 3-point hitch frame meets the requirements for mounting the

sprayer to a CAT II or CAT III 3 point hitch or CAT II or CAT III-N quick

hitch coupler. The Hitch frame has a pump mounting plate (for PTO

and hydraulic drive pumps) as well as provision for mounting control

units and other accessories.

The 48’ and 60’ EAGLE 3-point boom also has parking stands

attached to the center frame which allows the boom to freestand when

not in use.

Three versions of the EAGLE 3-point boom are available. The “HY”

features simultaneous boom wing folding. The “HT” features

simultaneous wing fold and individual wing tilt through three tractor

double acting outlets. The “HZ” features electric hydraulic wing fold

(same as “HY”) plus individual wing tilt. This will require two tractor

double acting outlets and a 12v power supply. The hydraulic hoses that

attach to the tractor are fitted with 1/2” NPT quick couplers.

The EAGLE 3-point boom can be equipped with either single Snap-fit

or triplet nozzle bodies. Two pump and control systems are available

as options to the 3-point EAGLE boom. The Diaphragm pump system

features a HARDI

®

361 Diaphragm pump and electric control unit with

HARDI-matic, a mechanical rate controller, and a self-cleaning

pressure filter. The Centrifugal pump system features a Ace 206

hydraulically driven pump with an electric control unit. Both systems

are complete with adjustable agitation, constant pressure feature, incab control box, system pressure gauge, and PTO shafts.

Page 10

8 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

2.0 SAFETY INFORMATION

WARNING

ALWAYS READ OPERATORS MANUAL BEFORE

USING EQUIPMENT

DO NOT REMOVE ANY SAFETY DEVICES OR

SHIELDS. NEVER SERVICE, CLEAN OR REPAIR A

MACHINE WHILE IT IS OPERATING

WARNING

ALWAYS WATCH FOR THIS SYMBOL TO POINT OUT

IMPORTANT SAFETY PRECAUTIONS

IT MEANS ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

Page 11

9HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

RECOGNIZE SAFETY INFORMATION

This is the Safety-alert symbol. When you see

this symbol on your machine or in this manual,

be alert to the potential for personal injury.

Follow recommended precautions and safe operating practices.

2.1 Follow Safety Instructions

- Carefully read all the safety messages in this manual and the

safety labels fitted to the machine. Keep safety labels in good

condition. Replace missing or damaged safety labels. Be sure

that new equipment components include any current safety

labels. Replacement safety labels are available from your

authorized HARDI dealer.

- Learn how to operate the spray boom and controls properly. Do

not let anyone operate the machine without proper instructions.

-

Keep your EAGLE 3PT boom in proper working condition.

Unauthorized modifications or use may impair the function and/or

safety and affect the spray boom’s life.

- If you do not understand any part of this manual and need

assistance, please contact your authorized HARDI dealer.

2.2 Operating The EAGLE 3PT Boom Safely

1. Read the complete manual carefully and become familiar with the

operation of the equipment before initial operation of each spraying

season. Failure to do so may result in possible over or under

application of spray solution which may drastically affect crop

production or lead to personal injury.

2. Before starting the engine on the tractor unit, be sure all operating

controls are in the off or neutral position including, but not limited to,

the P.T.O. shaft and or spray controls. Be sure the tractor power

train is disengaged.

3. Operate spray and boom functions only when seated in the

operator’s seat.

Page 12

10 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

4. One of the most frequent causes of personal injury or death results

from persons falling off or being run over. Do not permit others to

ride on or in. Only one person - the operator - should be on the

machine when in operation.

5. Before leaving the tractor seat, stop the engine, put all controls in

neutral, and put the transmission control lever in the park position

or neutral with the brakes locked. Read the tractor operations

manual for added safety precautions.

6. P.T.O. driven equipment can cause serious injury. Before working

on or near the P.T.O. shaft, servicing or cleaning the equipment,

put P.T.O. lever in the DISENGAGE position and stop the engine.

7. Do not fold or unfold boom near overhead wires. Serious injury or

death could result if contact is made with electric wires.

8. Keep hands, feet & clothing away from moving parts.

9. Wear relatively tight and belted clothing to prevent from being

caught on some part of the machine.

10.Slow down when turning, especially with boom extended.

11.Always keep children away from your sprayer and/or tractor unit.

12.Before transporting the sprayer, ensure that the boom is fully folded

and fully locked into transport rests and stops. Ensure all locking

devices are fully engaged whether hydraulic or mechanical.

13.Slow moving tractors and spray equipment can create a hazard

when on public roads. Use flashing lights to avoid personal injury or

death resulting from any accidents. Local regulations may require

installation of warning lights.

14.

Avoid injuries from high pressure fluids penetrating the skin by

relieving system pressure before disconnecting hydraulics or other

lines. Ensure all fittings are tight before applying pressure to the

system.

15.

Understand service procedures before undertaking any

maintenance. Never lubricate, service, or adjust the spray boom

while it’s operating. Securely support any components before

working on them.

16.Keep all parts in good condition and properly installed. Fix

damaged parts immediately. Replace worn or broken parts.

Remove excessive buildup of grease, oil, or debris.

Page 13

11HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

2.3 Handling Chemical Products Safely

1. Direct exposure to hazardous chemicals can cause serious injury.

These chemicals can include lubricants, coolants, paints, adhesives

and agricultural chemicals. Material Safety Data Sheets (M.S.D.S.)

are available for all hazardous chemicals which inform the user of

specific details including, physical and health hazards, safety

procedures,

and emergency response techniques.

2. Protective clothing such as rubber gloves, goggles, coveralls and

respirator must be worn during operation. All protective clothing

should be kept in excellent condition and cleaned regularly or

discarded.

3. If chemicals come in contact with any exposed skin areas, wash

immediately with clean water and detergent. Never place nozzle

tips or any other components that have been exposed to chemicals

to mouth to blow out obstructions. Use a soft brush to clean spray

nozzles.

4. Dedicate an area to fill, flush, calibrate and decontaminate sprayer

where chemicals will not drift or run off to contaminate people,

animals, vegetation, water supply, etc. Locate this area where there

is virtually no chance of children being in contact with this residue.

5. Decontaminate equipment used in mixing, transferring, and

applying chemicals after use. Follow the instructions on the

chemical label for the correct procedure required. Wash spray

residue from outside of the sprayer to prevent corrosion.

6. Extreme care should be taken in measuring spray products.

Powders should be used in suitable sized packages or weighed

accurately. Liquids should be poured into a suitable graduated

container. Keep chemical containers low when pouring. Wear a

filtered respirator and let the wind blow away from you to avoid dust

and/or splashes contacting the skin or hair.

7. Store chemicals in a separate, plainly marked locked building. Keep

the chemical in its original container with the label intact.

8. Dispose all empty containers after rinsing in accordance with local

regulations & by-laws. Dispose of all unused chemicals and left

over fertilizer in an approved manner.

9. Keep a first aid kit and fire extinguisher available at all times when

handling chemicals.

Page 14

12 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

2.4 Local Poison Information Center

PHONE NO. ____________ -____________ -___________________

Find the phone number for the poison control center in your phone

book and write it in the space above.

Keep a list in the space provided below, of all the chemicals that you

have in use.

1. ___________________________________________________

2. ___________________________________________________

3. ___________________________________________________

4. ___________________________________________________

5. ___________________________________________________

6. ___________________________________________________

7. ___________________________________________________

8. ___________________________________________________

9. ___________________________________________________

10. ___________________________________________________

Page 15

13HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

3.0 GLOSSARY

A - Breakaway Section

B - Outer Wing Section

C - Intermediate Wing Section

D - Center Frame

Fig. 3

1)RIGHT HAND AND LEFT HAND SIDES- Are determined by

facing the forward direction of travel.

2) HZ MODELS- An EAGLE 3PT boom with electrically activated

hydraulics. This boom can raise and lower, fold inner or outer

wings simultaneously, and tilt each wing individually.

3)FOLDED BOOM- Refers to the boom in transport position.

4)UNFOLDED BOOM- Refers to the boom in the spraying position.

5)WING- Refers to the folding portion of the boom.

6)LIFT FRAME- Mounts to the upper and lower parallelogram arms.

7)CENTER SECTION- Refers to the portion of the boom that the

wings attach to.The wings move up and down with the center.

8)LINK ARMS- Attaches the Center Section to the Lift Frame.

9)INTERMEDIATE WING- Refers to the inner portion of the wing.

10) OUTER WING- Refers to the outer portion of the wing.

11) BREAKAWAY- Refers to the part of the wing that allows

movement in the event of striking an object.

A

B

C

D

Page 16

14 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

4.0 ASSEMBLING THE 3PT EAGLE BOOMS

WARNING:

USE PROPER LIFTING EQUIPMENT.

LIFTING HEAVY EQUIPMENT INCORRECTLY CAN

CAUSE PERSONAL INJURY OR MACHINE DAMAGE.

FOLLOW ALL RECOMMENDED PROCEDURES FOR

REMOVAL AND INSTALLATION OF COMPONENTS IN

THE MANUAL.

The 3-point EAGLE boom is shipped in 5 parts.

1. Center frame assembly

2. Wing assembly RH

3. Wing assembly LH

4. 3-point hitch frame

5. Boom mount kit

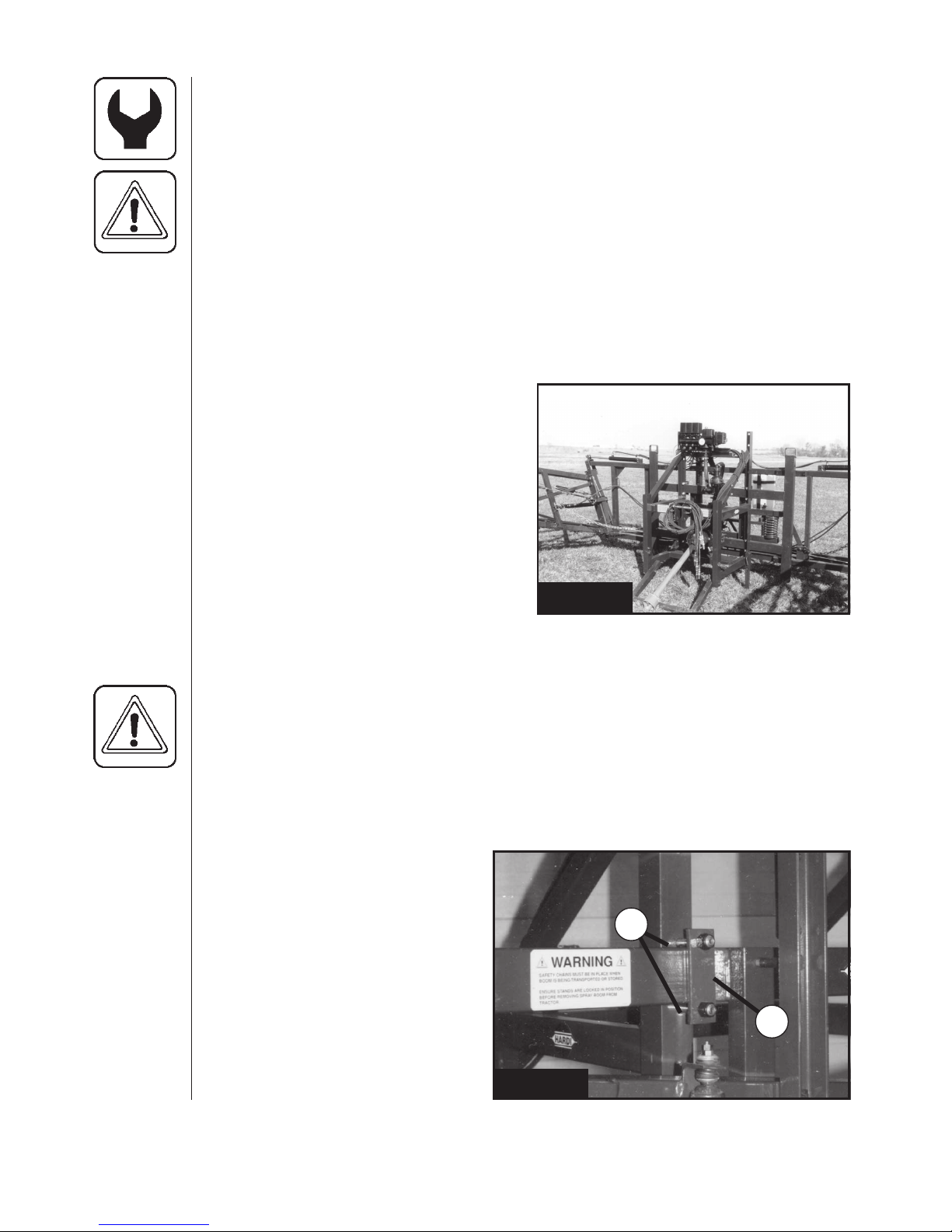

4.1 Attaching Center Frame to 3-point Hitch Frame

WARNING:

CENTER FRAME WILL NOT STAND ON ITS

OWN, EVEN WITH 3PT HITCH FRAME ATTACHED. IT

IS ADVISABLE TO ATTACH THE 3PT HITCH FRAME

TO TRACTOR HITCH BEFORE STARTING TO

ASSEMBLE THE SPRAYER.

Fig. 4

Attach center frame to hitch

frame with 4 (2”x6”x3/8”)

clamping plates (A) and 8 (5/

8”x3-1/2”UNC) bolts & nuts

(B). There are 4 height

positions to chose from

allowing a 10-1/2” (265mm)

variation in spray height

between each setting (Fig 5).

Fig. 5

A

B

Page 17

15HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

4.2 Preparing Wings for Installation

CAUTION:

FOR SAFE HANDLING, TIE INNER & OUTER

BOOM SECTIONS TOGETHER TO PREVENT

ACCIDENTAL UNFOLD DURING INSTALLATION.

1. Tie outer boom sections to inner section.

2. Attach lifting chain at lift point (A) on

inner boom section. Position chain

between vertical and angled boom

members so chain does not move

from this point when boom is lifted.

4.3 Installing Boom Wings

1a. HY BOOM - Fit nut (1) washers (2) to the threaded end of the tie

rod. Fit the rod under tab on mount plates on center frame. Fit

remaining washers and lock nut to the rods.

1b. HZ BOOM - Attach tilt cylinders to center frame using pins and

cotter pins. Remove plugs from cylinder ports and manually

extend cylinders to their full extension. Install 0-ring washers and

restrictor fittings in both ports on hydraulic cylinders. The restrictor

with the small hole is fitted to the fixed (base) end of the hydraulic

cylinder. Fig. 7.

2. Position boom hinge on center frame

with folded boom sections to the front.

3. Attach tie rod/tilt cylinder to hinge pin

and cotter pins.

4. Line up lower hinge pin holes and insert

pin. Insert threaded pin from the front

through the center frame and hinge and

retain with lock nut.

5. Attach safety chain from center section to extended pin on upper

end of hydraulic cylinder - Fit locking ring to pin. This will prevent

boom sections from accidentally unfolding during installation.

6. Repeat steps 3-6 for other wing.

7. Attach equalizer cables to inner boom sections using M12x50mm

bolts and lock nuts.

8. Install 0-ring washers and restrictor fittings in both ports of

hydraulic fold cylinders. Restrictor with small hole goes in the fixed

(base) end of the hydraulic cylinder (Fig 7).

Fig. 6

Fig. 7

Restrictor

Page 18

16 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

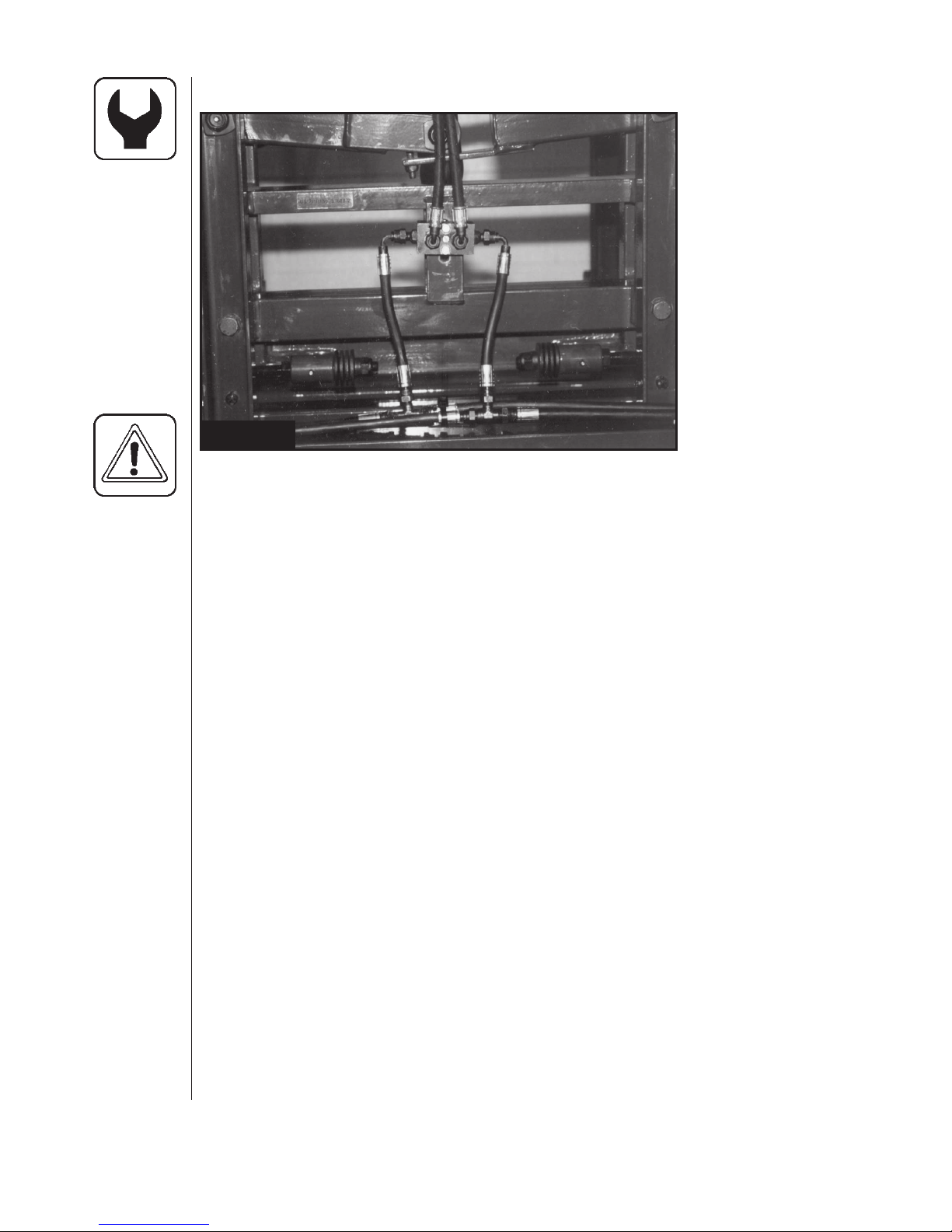

4.4 Mounting Hydraulic Hoses

WARNING:

• BE SURE TO HOOK UP HYDRAULIC LINES PROPERLY!

• MAKE SURE THE HYDRAULIC LINES HAVE NOT BEEN

DAMAGED DURING SHIPPING.

• ESCAPING HYDRAULIC FLUID UNDER PRESSURE CAN

PENETRATE THE SKIN CAUSING SERIOUS INJURY. AVOID

THIS HAZARD BY RELIEVING PRESSURE BEFORE

DISCONNECTING HYDRAULIC LINES.

• ENSURE ALL CONNECTIONS ARE TIGHT BEFORE APPLYING

PRESSURE. SEARCH FOR LEAKS WITH A PIECE OF

CARDBOARD, NOT YOUR HANDS!

• IMPROPER HOOK-UP CAN CAUSE DANGEROUS BOOM

MOVEMENTS AND/OR DAMAGE TO THE SPRAYER

HYDRAULICS.

• DO NOT ALLOW ANYONE NEAR A HYDRAULIC BOOM IN

OPERATION.

• ALWAYS SHUT TRACTOR OFF WHEN CONNECTING,

SERVICING OR ADJUSTING BOOM.

IMPORTANT:

Due to the wide variations in tractor hydraulic

systems and capacities, care should be exercised when initially

operating the sprayer hydraulic cylinders. It is advisable to adjust

the hydraulic flow control down to the minimum rate before

operating the system. Adjust/increase the flow control after the

system is bled of any air, if necessary.

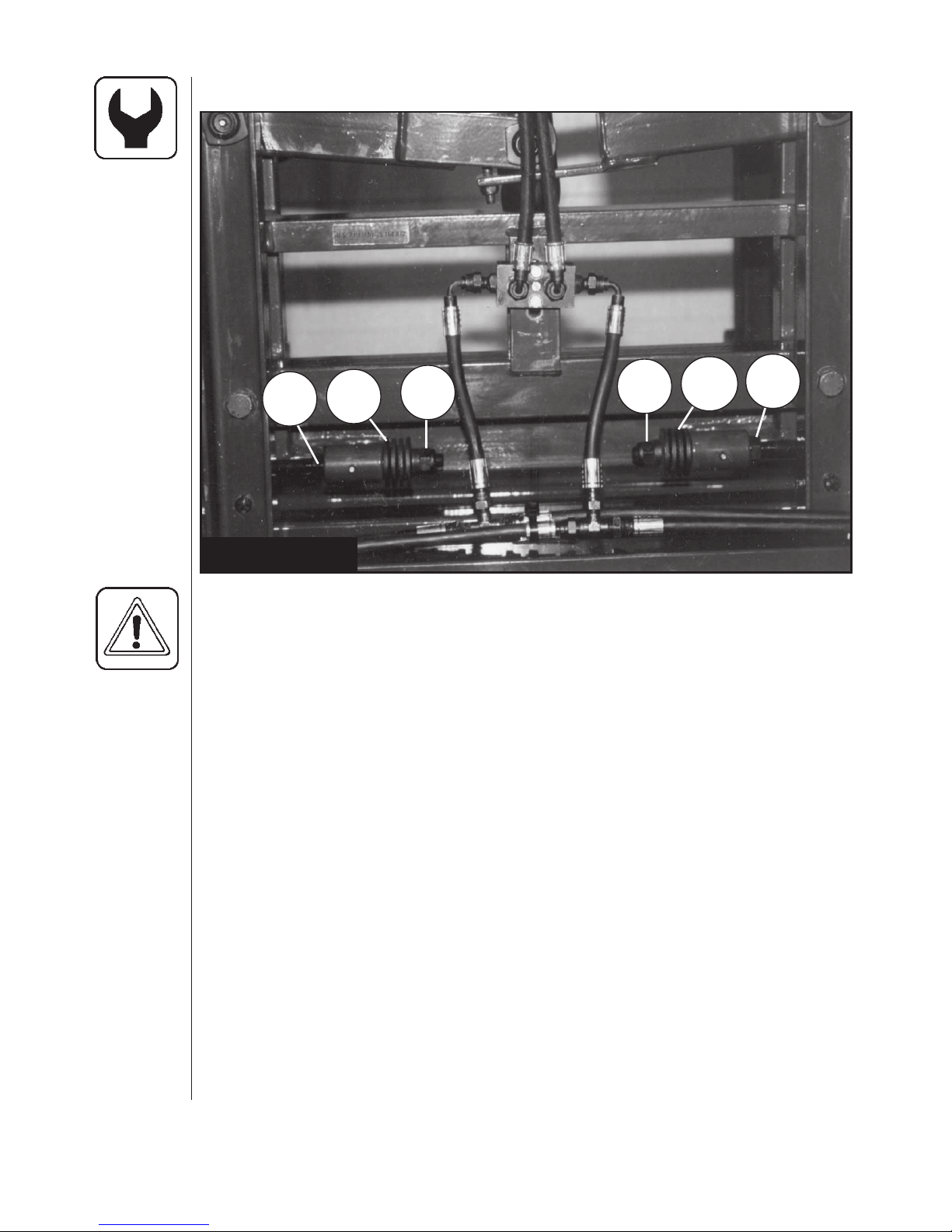

Fig. 8

Page 19

17HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

A/Fold cylinders

1. Route hydraulic hoses to fold cylinders (Section 9.0)

2. Attach hydraulic hoses from right hand side of hydraulic block on

center section to port on the hinge base end of hydraulic fold

cylinders.

3. Attach hydraulic hoses from left hand side of hydraulic block on

center section to the other port on the hydraulic fold cylinders.

4. Disconnect fold cylinder rod (adjustable eye end) from wing section.

5. Ensure cylinder is free for retraction and extension.

6. Connect hydraulic hoses to double acting outlet on tractor.

7. Start tractor engine and cycle fold cylinders by actuating double

acting outlet 10 times to bleed air from hydraulic system.

8. Stop tractor engine, check hydraulic oil level and fill as necessary.

9. Attach fold cylinder rods to boom sections, using previously

removed pins and cotter pins.

B/Tilt cylinders

1. Route hydraulic hoses to fold cylinders (Section 9.0)

2. If hydraulic tilt cylinders are fitted to spray boom, air should be bled

from these lines before spraying.

3. Disconnect tilt cylinder rod eyes from wing section.

IMPORTANT:

WING SECTION MUST BE SUPPORTED BEFORE

REMOVAL OF HYDRAULIC CYLINDER ROD EYES.

4. Ensure cylinder is free for retraction and extension.

5. Start tractor engine and cycle fold cylinders by actuating double

acting outlet 10 times to bleed air from hydraulic system.

6. Stop tractor engine, check hydraulic oil level and fill as necessary.

7. Reattach tilt cylinder rods to boom sections.

4.5 Installing Center Frame Spray Tube Assembly

1. Attach brackets to center frame using M6x30mm cap screws and

lock nuts. If necessary, loosen lock nut swivel pin and turn pin so

bracket is flush against the frame.

NOTE:

To gain access to mounting holes on the nozzle track,

remove plastic nozzle retaining nuts closest to mount holes and

move tube as necessary to install cap screws from the bottom.

2. Attach spray tube assembly using M6x20mm cap screws with lock

nuts on top. The 4 nozzle tube is to be on the right -hand side.

Page 20

18 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

4.6 Adjusting the Center Section Cables

WARNING:

NEVER ATTEMPT TO ADJUST THE CENTER CABLES

WITHOUT HAVING THE BOOM FOLDED ALL THE WAY INTO THE

TRANSPORT POSITION.

The center section cables work together to keep the center frame

square to the stationary frame, while folding boom in for transport or

when spraying with one side raised and folded (HT and HZ only).

1. Fold boom into transport position.

2. Shut the tractor off.

3. Check that the tilt cylinders are COMPLETELY EXTENDED. Adjust

if necessary (HT and HZ only).

4. Loosen jam nuts (C)(Fig 9).

5. Check that the cables are routed over the center section nozzle

mount brackets.

A

B

C

C

B

A

Fig. 9

Page 21

19HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

4.7 Attaching Feed Hoses - Two Valve System

1. Remove nuts from end nozzles to gain access to center section

spray tubes.

2. Remove cap and plug from tube ends.

3. Lubricate adapter fitting radial seals, using vegetable based oils.

4. Attach solution hoses from boom wings to center section spray

tubes.

5. Route main feed hoses from each boom section to control valves.

IMPORTANT:

ENSURE ALL FEED HOSES ARE LONG ENOUGH TO

ALLOW FOR MOVEMENT AT HINGE WHEN BOOMS ARE

FOLDED.

6. Retain all hoses with tie straps.

IMPORTANT:

ALTERNATE FROM SIDE-TO-SIDE WHILE MAKING

ADJUSTMENTS. ADJUST ONE CABLE A SMALL AMOUNT

AND THEN THE OTHER, TO EQUALIZE CABLE TENSION AND

MAINTAIN A LEVEL CENTER FRAME. DO NOT

OVERTIGHTEN THE CABLE. ADJUST TENSION UNTIL

BELLEVILLE WASHERS JUST START TO COMPRESS, NOT

BEYOND.

6. Adjust jam nuts as above.

7. Properly adjusted cables will be very tight and only deflect a small

amount (fractions of an inch) when pulled on by hand.

Note: Cables will be loose when the booms are unfolded.

8. Tighten jam nuts (C)(Fig 9).

9. Unfold the boom to operating (spraying) position.

10. Fold the boom and check that the floating frame remains square to

the stationary frame.

Page 22

20 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

4.8 Attaching Feed Hoses - Three Valve System

1. Remove nuts from end nozzles to gain access to center section

spray tubes.

2. Remove cap and plugs from inner spray tube ends. Refit caps and

plugs to outer ends of center section spray tubes.

3. Remove existing hoses and fittings from inner wing section spray

tubes. Retain adapter fittings and clamps for use with the center

section spray tubes.

4. Cut 3/4” ID hose into two unequal pieces - 1 of 250mm (10”) and 1

of 100mm (4”) long.

IMPORTANT:

DO NOT USE PETROLEUM BASED LUBRICANTS.

THEY WILL DETERIORATE HOSES, CAUSING THEM TO

WEAKEN AND LEAK. LUBRICATE HOSE ENDS WITH LIQUID

DISH SOAP TO MAKE INSTALLATION EASIER.

TO AVOID REWORK, BE SURE OF FITTING LOCATIONS

PRIOR TO ATTACHING HOSES. PLACTIC FITTINGS USE

VERY AGGRESSIVE HOSE BARB WHICH MAKES HOSE

REMOVAL DIFFICULT.

5. Attach hoses to “T”piece using clamps.

6. Install adapter fittings in outer hose ends, using clamps.

7. Lubricate adapter fitting radial seals, using vegetable based oils.

8. Attach hose to center sections inner spray tube ends, with “T” inlet

directed to rear of sprayer.

9. Install plastic nuts on nozzle retaining bolts. Be sure “T” fitting will

not interfere with spray pattern from adjacent nozzles.

10. Install adapter fitting in 3/4” ID hose using clamps.

11. Lubricate radial seal with vegetable based oils and attach adapter

fitting to tee.

12. Route hoses from each boom section to control valve.

IMPORTANT:

ENSURE FEED HOSES HAVE SUFFICIENT SLACK

AROUND HINGE TO PREVENT HOSE BINDING WHEN BOOM IS

FOLDED.

13. Connect feed hoses to control valves.

14. Retain all hoses with tie straps.

Page 23

21HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

4.9 Hydraulic Hook- Up

The booms hydraulic system requires an oil capacity of approximately .8

GPM (3 litres/min.) and a minimum pressure of 1,950 PSI (130 bar).

WARNING:

•

BE SURE TO HOOK UP HYDRAULIC LINES PROPERLY!

• MAKE SURE THE HYDRAULIC LINES HAVE NOT BEEN DAMAGED DURING SHIPPING.

• ESCAPING HYDRAULIC FLUID UNDER PRESSURE CAN PENETRATE THE SKIN CAUSING SERIOUS INJURY. AVOID THIS

HAZARD BY RELIEVING PRESSURE BEFORE DISCONNECTING

HYDRAULIC LINES.

• ENSURE ALL CONNECTIONS ARE TIGHT BEFORE APPLYING

PRESSURE. SEARCH FOR LEAKS WITH A PIECE OF CARDBOARD NOT, YOUR HANDS!

• IMPROPER HOOK-UP CAN CAUSE DANGEROUS BOOM MOV

MENTS AND/OR DAMAGE TO THE SPRAYER HYDRAULICS.

• DO NOT ALLOW ANYONE NEAR A HYDRAULIC BOOM IN

OPERATION.

• ALWAYS SHUT TRACTOR OFF WHEN CONNECTING, SERVICING OR ADJUSTING BOOM.

IMPORTANT:

Due to the wide variations in tractor hydraulic

systems and capacities, care should be exercised when initially operating the sprayer hydraulic cylinders. It is advisable

to adjust the hydraulic flow control down to the minimum rate

before operating the system. Adjust/increase the flow control

after the system is bled of any air, if necessary.

Page 24

22 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

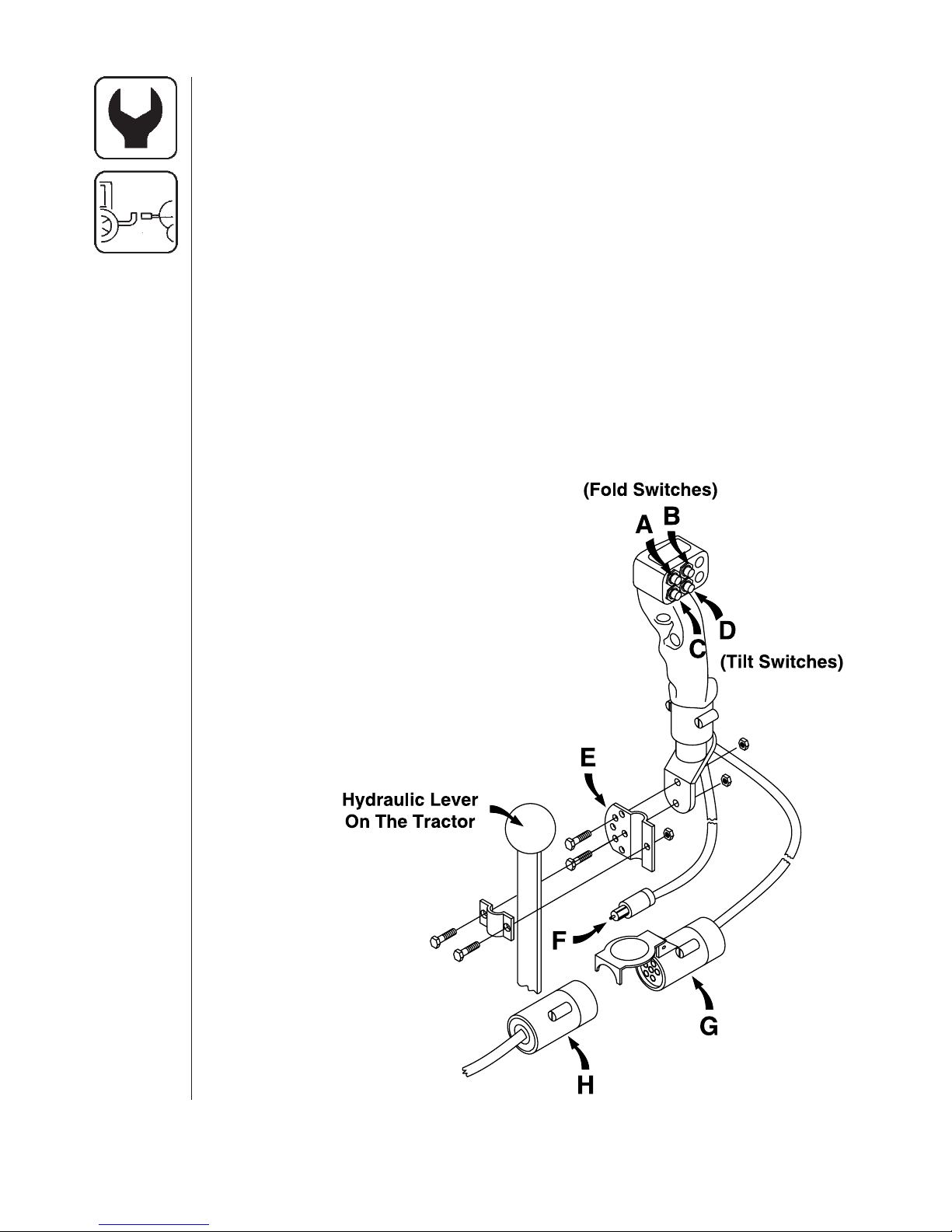

4.10 HZ Hydraulics Joystick Controls

Fig. 3

A) Installation Of Handle

1. Attach the control handle to the hydraulic lever that operates the

double acting outlet you intend to use (Fig. 10). The universal

mounting bracket (E)(Fig. 10) is very flexible and a number of

different mounting positions can be used.

2. Connect plug (F)(Fig. 10) to the tractor's 12V power system. Try to

hook-up the handle as close as possible to the battery or the starter

for a better power supply. HARDI recommends using electric

distribution

box #817925 to insure a good power supply to various

12V attachments.

Note: Check with your dealer or tractor operators manual for the best

location to hook up the 12V system.

Note polarity:

BROWN WIRE = POSITIVE (+)

BLUE WIRE = NEGATIVE (-)

3. Connect electric plug (H)(Fig. 10) from

sprayer hydraulics to plug (G) (Fig. 10)

on handle.

Fig. 10

Page 25

23HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

4.11 ‘DH’ Hydraulics (Optional)

Note: This kit can only be used on tractors with 'closed center' hydraulic

systems.

Switch A operates: Left hand fold cylinder

Switch B operates: Right hand fold cylinder

Switch C operates: Left hand tilt cylinder

Switch D operates: Right hand tilt cylinder

A) Installation Of The 'DH' Hydraulic

Switch Box

1. Remove the joystick control handle

complete with bayonet style 12V plug

and 7 pin female plug

(if previously fitted).

2. Route the cable, with the 7 pins, from the hydraulic mount

plate to the tractor.

3. Mount the 'DH' hydraulic switch box in a suitable

location in the tractor cab.

4. Connect the bayonet plug from the switch box to a

12V power supply. HARDI recommends using

electronic distribution box #817925 to ensure a good

power supply to various 12V attachments.

Note polarity: BROWN WIRE = POSITIVE (+)

BLUE WIRE = NEGATIVE (-)

5. Connect the female 7 pin plug from the switch box to the 7 pin male

plug from the sprayer.

4.12 Performing Final Inspection

1. Check hydraulic system for leaks.

2. Check hydraulic hoses for clearance and freedom of movement

throughout entire range of operation.

3. Lubricate all machine lubrication points. (Section 7.0)

4. Adjust machine for field operation.

5. Ensure all fasteners are tightened correctly.

Fig. 11

Page 26

24 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

5.0 OPERATING THE EAGLE 3PT BOOM

WARNING:

• USE EXTREME CAUTION THE FIRST SEVERAL TIMES YOU

OPERATE THE BOOM AS THE AIR IS BLED OUT.

• AIR MAY STILL BE TRAPPED IN THE HYDRAULICS SYSTEM.

THE BOOM CAN MAKE SUDDEN AND UNEXPECTED

MOVEMENTS!

• ALWAYS OPERATE BOOM ON LEVEL GROUND.

• BEFORE UNFOLDING THE BOOM, ENSURE THAT THE

SPRAYER IS HITCHED TO THE TRACTOR UNIT.

• ENSURE THAT THERE ARE NO OBSTRUCTIONS OR PERSONS

IN THE PATH OF TRAVEL BEFORE FOLDING OR UNFOLDING

THE BOOM.

• ENSURE THAT THE SAFETY CHAINS ARE FITTED BETWEEN

THE CENTER FRAME AND WING SECTIONS BEFORE

TRANSPORTING AND STORING THE EAGLE 3PT BOOM.

5.1 Folding & Unfolding the 3-point Boom

(HY and HT booms only)

1. Disconnect safety chains from wings.

2. Activate the tractors double acting hydraulic lever to unfold the

boom. Both wings will unfold simultaneously.

3. Set the desired spray height by raising or lowering the 3-point

hitch arms on the tractor.

4. After 3-point hitch has been raised, manually retract the rear

stands and lock in place. Swing front stand to stored position

under frame and lock in place with lock pin and locking ring.

5. To fold the boom, actuate the double acting hydraulic lever.

Page 27

25HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

5.2 Operating the Wing Tilt (If applicable)

1. The wing tilt cylinders are connected to the tractor hydraulics

independently. Determine which hydraulic lever actuates the side

to be tilted. Actuate the double acting outlet lever to tilt wing up or

down.

WARNING:

• NEVER ATTEMPT TO FOLD BOOM TO TRANSPORT POSITION

WHEN WINGS ARE TILTED UP. ALWAYS LET WINGS DOWN

TO HORIZONTAL POSITION PRIOR TO FOLDING.

• NEVER ATTEMPT TO WORK ON OR AROUND WING SECTION

WHEN TILTED UP.

• UNEXPECTED BOOM MOVEMENTS MAY OCCUR IF WINGS

ARE TILTED WHEN FOLDING.

• NEVER USE TILT FUNCTION WHEN BOOM IS FOLDED INTO

TRANSPORT POSITION.

5.3 Folding And Unfolding Boom (HZ Hydraulics)

A) Hydraulic Joystick Controls

1. Raise the boom to clear any obstructions

2. Depress switches (A) & (B) and move hydraulic handle forward

or rearward to activate oil flow. Switch positions of the hoses in the

double acting remote outlet if you do not like the direction required to

activate the boom.

3. "One side folding" will be achieved by following the above procedure

except that only one of the switches is depressed (Section 5.4).

B) ‘DH’ Hydraulics Control Box (Optional)

1. Raise the boom to clear any obstructions.

2. Engage the tractor’s double acting remote outlet lever and lock it in the

engaged position.

3. Activate switch (A)(Fig. 11) upwards and hold to unfold left hand boom

(Holding the switch in the down position will fold the boom). To unfold

right hand boom, activate switch (B)(Fig. 11).

4. "One side folding" will be achieved by following the above procedure

except that only one of the switches is activated.

Page 28

26 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

5.4 Folding One Side Only (HZ Hydraulics Only)

If only one side of the boom is to be used for spraying , first unfold the boom

completely and then turn switches off, then flip the switch for the side that

is to be folded and activate the double acting outlet to fold that side into

transport position.

Note: It is not advisable to go directly from transport position to

spray position with one side only. Both wings must first be

completely unfolded.

The following tables show what types of spray nozzles are suitable for

different applications. It is important to use the correct nozzle.

FLOOD NOZZLES set at 40"

spacing. Designed for high volume application.

4598

5.5 Nozzle Selection

Correct selection of nozzle and calibration of the sprayer are critical to

achieve accurate and cost effective use of farm crop protection products.

Your HARDI sprayer has been supplied with 110° flat spray Green Color

Tips™ that will apply approximately 20 U.S. GPA at 30 PSI and 5 MPH.

The 110° flat spray nozzle was chosen rather than the 80 degree nozzle

for two reasons: 1- It may be used at a lower minimum height which

reduces the risk of wind drift; 2- it's greater overlap permits better

uniformity of spray distribution, particularly if boom height varies on rough

ground. Normal boom height setting with 110° nozzles is 18" to 20" above

the crop or weeds, whichever is taller.

Should you wish a different application rate or different type of nozzle,

HARDI manufactures a nozzle for virtually every need.

IMPORTANT:

Always consult your chemical supplier for recommended chemical rate and water application rate. Always wear

protective gloves when handling nozzles.

Page 29

27HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

COLOR TIPS™ 110 degree flat

fan,one piece cap and nozzle;

color coded for flow rate selection.

For herbicides, insecticides, and

fertilizer applications. 50, 80, and

100 mesh screens are normally

used.

S4110

LowDrift COLOR TIPS™ 110

degree flat fan,one piece cap

and nozzle, 1553 solid stream

nozzle; color coded for flow rate

selection.

In-Line Filters will normally be

used.

SL4110

FLAT SPRAY NOZZLES in 65

degree, 80 degree, and 110 degree spray angles. For herbicides, insecticides, and fertilizer

applications. 50, 80, and 100

mesh screens are normally used.

4665-65 degree

2080-80 degree

4110-110 degree

Part # 330013-

O-ring

HOLLOW CONE NOZZLES for

high pressure and high volume

insecticide application in row

crops. 1553 nozzles are ALWAYS

used with swirl plates shown below EXCEPT when used as solid

stream nozzles. 50,80, or 100

mesh screens are normally used

with these nozzles.

1553

Must add swirl to

produce hollow

cone pattern

3-HOLE NOZZLE-SYNTAL/CERAMIC this nozzle disperses the

spray liquid in three solid streams,

thereby reducing the number of

plants at risk of scorching by the

application of liquid fertilizer.

371537

thru

371543

Page 30

28 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

HOLLOW CONE CERAMIC

NOZZLES for high pressure and

high volume fungicide and insecticide application.

1299

LARGE DROPLET HOLLOW

CONE NOZZLE for use where

drift must be kept to a minimum.

These nozzles must always be

fitted with 1553 nozzles and grey

swirl plates. 50,80 or 100 mesh

screens are normally used with

these nozzles.

371077

SWIRL PLATE used in conjunction with cone nozzle to create

desired spray pattern. These

swirls work with 1553 series cone

nozzles. Grey, blue, or black

swirls are used to create hollow

cone effect. White swirls are used

to create full cone effect.

Grey

Blue

Black

White

LARGE DROPLET FLAT SPRAY

TIP IN 150 DEGREE SPRAY

ANGLE. Always used in conjunc-

tion with 1553-14-16-18 or 20

cone nozzle. 50,80 or 100 mesh

screens are normally used with

these nozzles.

371551

SOLID STREAM NOZZLE for

high volume liquid fertilizer application. In this application, the

1553 nozzle is always used with

330013 o-ring and 50,80 or 100

mesh screens.

1553 less swirl

Page 31

29HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

5.6 Calibration

WARNING:

ALWAYS CALIBRATE YOUR SPRAYER WITH CLEAN

WATER ONLY! IN ADDITION, WEAR PROTECTIVE

CLOTHING WHEN CALIBRATING YOUR SPRAYER!

Why must you calibrate a sprayer?

A nozzle selection chart will tell you what application rate you should

expect. Variations due to nozzle wear, errors in pressure adjustment, and

tractor speedometer can result in a possible error in application rate.

How do you calibrate a sprayer?

Calibration kits are available from HARDI, #818103 for US gallons &

#818104 for metric calibration.

Following are some tips to remember when using the calibration kit

method:

• When determining the length of time required to drive the recommended

distance, drive in actual field conditions with a half-full tank.

• Repeat the test several times, each time avoiding the tracks from the

previous test. Take the average of the times recorded.

• Calibration of the sprayer should be completed at the beginning of the

season and repeated after every 2 to 3 full days of spraying, and every

time you change volume rate or use new nozzles.

• Before you calibrate, check the flow of each nozzle. If it puts out more

than 10% of its original volume, replace it.

Select your calibration method- Ounce method or Formula method.

Then follow the steps described on the following pages:

Page 32

30 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

Ounce Method

1. Determine how long it takes you to cover the test strip.

Use the following chart to determine the length of your test strip.

Row width for broadcast application is equal to your nozzle spacing.

For your drop nozzle or band application, use row spacing.

Row width or nozzle spacing (in.) Distance (ft.)

40 102

38 107

36 113

34 120

32 127

30 136

28 146

26 157

24 170

22 185

20 204

18 227

16 255

14 291

2. Measure the amount of time it takes you to travel the test strip when

throttle is set at spraying speed.

3. In a container (with oz. measurements), catch the spray from on

nozzle for that amount of time. For drop or band nozzles, catch the

spray from all nozzles for the row.

4. Read the ounces in the container. That is the actual U.S. GPA applied.

(ounces - GPA)

Page 33

31HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

Formula Method

1. Check your spraying speed. Measure a test strip of at least 200 feet

(300 feet is ideal). Travel the distance at the speed you plan on spraying

and record the time it takes to travel the distance. Read from the chart

or use the formula to find your exact travel speed.

Speed in MPH Travel Time (in seconds)

200 ft. 300 ft.

3.0 45 68

3.5 39 58

4.0 34 51

Formula: 4.5 30 45

distance (ft.) x 0.68

= MPH

5.0 27 41

seconds 6.0 23 34

7.0 19 29

7.5 18 27

8.0 17 26

9.0 15 23

2. Calculate the required nozzle output. Use either the nozzle wheel (if

nozzle spacing is 20 inches), or this formula:

Formula: Formula:

GPM =

GPA x MPH x W (in.)

GPM =

10 x 7 x 20

= .24 GPM

5940

5940

Note: W= • Nozzle spacing (in inches) for broadcast application.

• Row spacing (in inches) divided by number of nozzles

per row for drop nozzle application.

• Sprayed band width or swath width (in inches) for band

application divided by number of nozzles per band.

• Note that on the nozzle wheel, W = 20 inches.

3. Set correct pressure. Read the required pressure from the nozzle table

in the nozzle catalogue or nozzle wheel. With clean water in the tank

and line, turn on the sprayer and set the target pressure. Collect the

spray from one nozzle for one minute in a container. Adjust pressure

until you collect the precise GPM called for.

Page 34

32 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

Calibration for carriers other than water

Use the following water rate conversion chart to determine the right

conversion factor. When you've determined the new converted GPM or

GPA, you can follow the steps on either the pressure or ounce method of

calibration.

Weight of solution Specific Gravity Conversion Factors

7.00 lbs/gal .84 .92

8.00 lbs/gal .96 .98

8.34 lbs/gal-water 1.00 1.00

9.00 lbs/gal 1.08 1.04

10.00 lbs/gal 1.20 1.10

10.65 lbs/gal-28% N 1.28 1.13

11.00 lbs/gal 1.32 1.15

12.00 lbs/gal 1.44 1.20

14.00 lbs/gal 1.68 1.30

Example: 20 GPA of 28% N

Then GPA (solution) x conversion factor = GPA (water)

20 GPA (28% N) x 1.13 = 22.6 GPA (water)

Calibrate for 22.6 GPA of water

For conversion to Imperial gallons per acre, multiply U.S. GPA by .833

For conversion to liters per hectare, multiply U.S. GPA by 9.34

For conversion to liters per acre, multiply U.S. GPA by 3.78

Formula for tractor speed:

Distance (in feet) x .682

= MPH

Second

Page 35

33HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

6.0 ADJUSTMENTS

WARNING:

• HARDI CANNOT ASSUME RESPONSIBILITY OR BE HELD

LIABLE FOR ANY LOSS OR DAMAGE THAT OCCURS DUE TO

LACK OF ADJUSTMENTS OR MAINTENANCE.

• WE URGE YOU TO FOLLOW THE ADJUSTMENT AND

MAINTENANCE RECOMMENDATIONS FOR EVERYONE’S

SAFETY.

• MAKE IT A DAILY HABIT TO INSPECT YOUR BOOM FOR NEED

OF ADJUSTMENT OR MAINTENANCE.

• IMMEDIATELY REPLACE ANY PARTS ON THE BOOM THAT

ARE WORN OR BROKEN.

• ALWAYS CLEAN YOUR BOOM BEFORE ADJUSTING IT TO

AVOID UNNECESSARY CONTACT WITH CHEMICALS.

The boom wing sections on the Eagle 3 point boom have been preassembled, adjusted and tested in the factory. The boom however, will

require additional adjustments shortly after being taken into service (10

hours) and thereafter on a minimum annual basis to perform at its

maximum levels.

To further insure the booms proper performance, the Eagle 3 point boom

also has to be maintained on a regular basis.

PLEASE FOLLOW THE SUGGESTED MAINTENANCE INTERVALS.

Perform the adjustment procedures in the same sequence as they are

written in this manual.

6.1 Adjustment And Maintenance Intervals

IMPORTANT:

To maximize boom life and performance, retighten all

boom fasteners and inspect boom for proper adjustment after the first 10 hours of use. Thereafter adjust

the boom at a minimum of once a year and check all

fasteners at 50 hr. intervals. Lubrication of the boom

should be done daily to ensure maximum performance and life.

Page 36

34 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

6.2 Checking And Adjusting Sprocket Timing

1. With the boom unfolded (in the spraying position) while standing on

the rear side of the boom, check to ensure that the 7th pin connection

in the timing chain(on the 48’ and 66’ boom)(A)(Fig. 12) is aligned with

the center line between the sprocket cap screws (B)(Fig. 12).

2. To adjust timing, loosen the turnbuckles on the front and rear cables

until slack.

3. Line up the chain and sprocket as indicated in step 1.

4. Adjust front and rear cable tension (Section 6.10).

Right Wing Sprocket

Fig. 12

Page 37

35HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

6.4 Alignment Of Intermediate And Outer Boom Sections

1. Unfold the boom into

operating (spraying)

position.

2. Holding the M12x100

adjusting bolt, loosen

the lock nut (A)(Fig.14),

and turn nut (B)(Fig. 14)

so the cap of the bolt

head (C)(Fig. 14)

contacts the top stop

plate with the outer and

intermediate boom

sections aligned.

3. Check to ensure that the lock nut is tight.

Fig. 14

6.3 Alignment Of Wing Assemblies

1. With the boom unfolded (in the spraying position), check the alignment

of the intermediate section with the center frame.

2. With the fold cylinder pressurized, determine if the intermediate

section needs to be adjusted to the front or rear to come into alignment

with center frame.

Note: Because of adjustments made later, it is better to start with the

wing assemblies angled slightly to the rear.

3. Relieve pressure from cylinder by folding the boom in a few inches.

4. Disconnect cylinder rod eye (B)(Fig. 13) from the intermediate boom

section.

Note: Some cylinder rods

have a machined flat

which, if visible, can be

used for adjustments. If

using the machined flat for

adjustment, leave the rod

eye pinned to the boom

and loosen the jam nut.

5. Loosen jam nut (A)(Fig.

13) and adjust the rod eye

(B)(Fig. 13) IN to move the boom forward or OUT to move the

boom rearward. Then retighten the jam nut (A)(Fig. 13).

6. Reattach the cylinder rod to the boom and pressurize the cylinder to

check boom alignment.

Fig. 13

Page 38

36 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

6.5 Adjusting Front Fold Cable

The performance of the EAGLE 3 Point Boom, while spraying, depends

greatly on the front fold cable adjustment. A correctly adjusted cable will

also control the movement of the outer wing section.

WARNING:

THE REAR CABLE CAN SNAP AND INJURE YOU OR

SOMEONE ELSE IF TENSIONED WHEN THE BOOM IS

UNFOLDED. ALWAYS ADJUST THE

FRONT CABLE

FIRST WITH THE BOOM UNFOLDED AND REAR CABLE

LAST WITH THE BOOM FOLDED IN TRANSPORT POSITION.

1. Unfold boom into operating position.

2. Shut the tractor off.

3. Check the security of turnbuckle anchors to the hinge.

3. Slide a straight edge down the underside of the intermediate boom

section until it just contacts the front cable.

4. Suspend a 10lb (4.5kg) weight from the straight edge-to-cable contact

point and check deflection by measuring the distance from the

straightedge to the cable. Cable should deflect .50-.75 in. (13-20mm).

5. Loosen jam nuts (A)(Fig. 15) on the turnbuckle assembly and adjust

turnbuckle (B)(Fig. 15) for proper cable deflection.

6. Tighten jam nuts (A)(Fig. 15) and remove weight.

IMPORTANT:

Check boom alignment again. If front cable was tightened, the wing assembly will move forward; or if loosened, wing will

move rearward. Adjust fold cylinder (if necessary) as described in

Aligning Wing Assemblies, (Section 6.3).

Fig. 15

Page 39

37HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

6.6 Adjusting The Breakaway Clutch

WARNING:

NEVER PLACE FINGERS INTO THE OPEN BREAKAWAY

CLUTCH OR YOU MAY BE INJURED SHOULD THE

CLUTCH SNAP CLOSED!

DO NOT TIGHTEN THE BREAKAWAY CLUTCH MORE

THAN WHAT IS NECESSARY! OVER TIGHTENING CAN

CAUSE DAMAGE TO THE BOOM!

The tension on the breakaway for the outer wing can be adjusted by

loosening or tightening the adjustment nut on top of the sprocket between

the inner and outer wings (Fig. 16).

1. If the breakaway clutch releases too easily, tighten the nut.

2. If the breakaway clutch is too stiff, loosen the nut.

Note: Spring pressure from tensioned breakaway clutch only assists in

returning outer boom section to alignment.

3. Check that the lower nut (D)(Fig. 16) is fully tightened.

4. The breakaway wing section should pivot around the axle shaft

(E)(Fig. 16). Ensure that section (F)(Fig. 16) is free to move.

5. Loosen jam nut. (B)(Fig. 16).

6. Tighten nut (C)(Fig. 16) to stiffen clutch action. Clutch is properly

tensioned when breakaway boom section returns to alignment with

outer boom section after breaking away. Tighten jam nuts after

adjustment.

IMPORTANT:

Properly lubricate clutch assembly before adjusting

the tension. Breakaway clutch cap screws (A)(Fig. 16) must be

torqued to 40lb-ft (55 N-m) every week (40 hours) to prevent boom

damage. Lubricate every day (8 hours) to ensure maximum performance and life.

Fig. 16

Page 40

38 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

6.7 Adjusting Wings Level To Ground

With boom unfolded (in the spraying position), check that boom sections

are parallel to center frame and level to the ground. Adjust, if necessary,

as detailed below.

A) HY Booms

1. Loosen jam nut (A)(Fig.17).

2. Adjust nut (B)(Fig.17) in or out until wing is level to ground.

3. Secure jam nut (A)(Fig.17).

Same procedure applies to both sides.

Fig. 17

Fig. 18

C) HZ and HT Booms

1. Ensure cylinder is fully extended.

2. Loosen jam nut (A)(Fig.18).

3. Apply an adjustable wrench to

the machined surface at

(B)(Fig.18).

4. Turn the cylinder rod until boom

is level to the ground.

5. Secure jam nut (A)(Fig.18).

Same procedure applies to both

sides.

Page 41

39HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

6.9 Adjusting the Boom Transport Position

1. Lift the boom all the way to the top.

2. Fold the boom into the transport position. With the fold cylinder

pressurized, determine if the boom sections need to be adjusted

inwards or outwards.

Note: Ensure that the boom wings will not interfere with the tractors

wheels or structure.

3. Relieve the pressure from the fold cylinder by unfolding the

boom a few inches.

4. If the boom comes too far in towards the tractor cab,

loosen the nut (B)(Fig.20) and adjust collar

(A)(Fig.20) in towards the cylinder housing.

5.

If the boom goes too far out away from the

tractor cab, adjust the collar (A)(Fig.20)

away from the cylinder housing.

6. Secure the jam nut (B)

(Fig.20)

.

7. Pressurize cylinder to see if the boom

is properly adjusted. If not,

repeat the above procedure until it is correctly

adjusted.

6.8 Adjusting The Center Section

This adjustment will affect the suspension (trapeze function) and must

therefore be done properly to optimize the EAGLE 3 Point Boom performance.

IMPORTANT:

Lubricate pivot linkage and grease skid plates prior to

adjustment .

1. Ensure that the sprayer

is on level ground.

2. Tighten the four adjustment bolts (A)(Fig.19)

approx. 1/2 turn.

3. Grasp the wing by the

end and lift it approx. 20

in.(490mm). Release

the wing and it should

smoothly return to

approximately the

horizontal position.

4. If the trapeze will not let

the boom go back to horizontal position, the bolts must be loosened

again. The spray boom is properly adjusted when it returns to the

horizontal position under its own weight.

Fig. 20

Fig. 19

Page 42

40 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

6.10 Adjusting the Rear Cable

WARNING:

THE REAR CABLES CAN BREAK AND INJURE YOU OR

SOMEONE ELSE IF TENSIONED WHEN THE BOOM IS

UNFOLDED. ALWAYS ADJUST FRONT CABLE FIRST

WITH THE BOOM UNFOLDED INTO OPERATING

(SPRAYING) POSITION.

1. Raise the boom to its highest position. Fold the boom to transport

position with the tilt cylinders fully extended. Make sure the fold

cylinders are pressurized and that the boom is folded all the way in.

2. Shut the tractor off.

3. Ensure the boom transport stop arms are in contact with the outer

wing. Adjust if necessary.

4. Loosen the jam nuts on the turnbuckle. Adjust (tighten) the

turnbuckle so that the outer wing section contacts the boom

transport stop bracket.

Tighten the turnbuckle another four complete

turns and retighten the jam nuts

.

Page 43

41HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

7.0 MAINTENANCE

WARNING:

ALWAYS CLEAN YOUR BOOM AT THE END OF THE

WORK DAY OR BEFORE SERVICING IS DONE TO AVOID

UNNECESSARY CONTACT WITH CHEMICALS!

7.1 Lubrication

Lubrication of the boom daily will ensure maximum performance and life.

This lubrication includes the center frame, as well as the boom hinges and

breakaway clutches.

7.2 Greasing the Center Frame

Every 8 hours (daily) new grease should be applied to the wear surfaces

on the center frame (Fig. 21).

Every 50 hours the grease on the center frame should be completely

cleaned off with a degreasing solvent and new grease applied. Follow the

above steps when doing this.

Fig. 21

7.3 Greasing The Suspension/Pivot Linkage

Every 8 hours the places indicated in the following pictures should be

greased.

Page 44

42 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

Fig. 22

Fig. 23

7.4 Greasing The Boom

Grease the boom at all grease zerks in hinge, breakaway and chain

sprocket. Every 25 hours the chain and sprocket should be lubricated with

a chain lubricant.

7.5 Greasing The Breakaway Clutch

WARNING:

NEVER PLACE FINGERS INTO OPEN BREAKAWAY

CLUTCH OR YOU MAY BE INJURED SHOULD CLUTCH

SNAP CLOSED!

1. Unfold the boom into operating (spraying) position.

2. Standing in front of the outer wing, snap the breakaway open by quickly

pushing the boom away from you.

3. With the two clutches opened up, stick the nozzle of a grease gun into

the clutch and apply a generous amount of grease. This should be

done every 8 hours.

4. Apply oil to top of breakaway section hinge to lubricate bushing.

Page 45

43HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

7.6 Nozzle Filters

Each nozzle assembly is equipped with a 50 mesh filter screen as

standard on units equipped with 20 GPA green Color Tips™. Properly

maintained filters will eliminate the plugging of the screens and nozzles.

7.7 In-Line Filters (Optional)

If in-line filters are fitted, they should be cleaned every 8hrs. (daily).

Unscrew the bowl to remove sediment.

7.8 Nozzle Tubes And Fittings

Poor seals are usually caused by;

• Missing O-rings or gaskets

• Damaged or incorrectly seated O-rings

• Dry or deformed O-rings or gaskets

• Foreign materials

Therefore, in case of leaks; DO NOT overtighten any fittings (Fig. 24).

Disassemble, check the condition and position of the O-ring or gasket,

clean, lubricate and then reassemble. For radial seals (O-rings) (Fig.24)

only hand tighten the fittings. Do not use pliers or wrenches.

100

Nozzle

Size

Nozzle

Screen

Green (20)

& Larger

80

50*

Red (16)

White (18)

Lilac (08)

Brown (10)

Yellow (12)

Orange (14)

* Standard mesh

Inline Filters

(optional)

100

80

50*

Page 46

44 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

Fig. 24

HARDI recommends using a vegetable based oil to prolong the life of the

O-ring.

7.9 Maintenance of Triplets (when fitted)

Every 50 hours the triplets should be disassembled removed and cleaned.

This is done by pulling out the stainless clip on the side of the triplet

assembly. Clean the bottom part as well as the top part thoroughly. Coat

the O-ring with a light film of vegetable oil if the sprayer is to be stored for

a long period of time.

If the triplets are not cleaned regularly they will not rotate readily and

possible damage to them may occur.

Fig. 25

WARNING:

NEVER SERVICE YOUR CONTAMINATED NOZZLES

WITHOUT WEARING CHEMICAL RESISTANT GLOVES

AND SAFETY GOGGLES.

The O-rings need to be lubricated ALL THE WAY AROUND before fitting

on to the nozzle tube.

Page 47

45HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

8.0 PUMP & CONTROLS

There are two pump and

control kits available, the first

one featuring a model 361

PTO driven Diaphragm pump

with self-cleaning filter and 3section electric control with

HARDI-matic. The second

features a ACE 206

hydraulically driven

Centrifugal pump with 3section electric control.

The assembly, operation and

maintenance required for

these kits is covered in this

section.

8.1 P.T.O. Shaft Operator Safety

WARNING: ALWAYS STOP ENGINE BEFORE ATTACHING THE

TRANSMISSION SHAFT TO TRACTOR P.T.O. - MOST

TRACTOR P.T.O. SHAFTS CAN BE ROTATED BY HAND

TO FACILITATE SPLINE ALIGNMENT, WHEN ENGINE

IS STOPPED.

When attaching the shaft, make sure that the snap lock is FULLY

ENGAGED - push and pull shaft until it locks.

WARNING: ROTATING TRANSMISSION SHAFTS WITHOUT

PROTECTION GUARDS ARE FATAL.

Always keep protection guards and chains intact and make sure that it

covers all rotating parts, including CV-joints at each end of the shaft. Do

not use without protection guard.

Do not touch or stand on the transmission shaft when it is rotating - safety

distance: min 5' (1.5 meters).

Prevent protection guards from rotating by attaching the chains allowing

sufficient slack for turns.

Always STOP ENGINE and remove the ignition key before carrying out

maintenance or repairs to the transmission shaft or implement.

Fig. 26

Page 48

46 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

Fig. 28

min. 6" (150 mm)

Fig. 27

min. 3/4" (20 mm)

8.2 Installation of P.T.O. Shaft (361 pump only)

WARNING: THE P.T.O. SHAFT ANGLE WILL CHANGE WHEN

RAISING AND LOWERING THE 3 POINT LINKAGE ARMS.

TO PREVENT EXCESSIVE LOADING AND

BINDING ON THE P.T.O. SHAFT, IT MAY BE ADVISABLE

TO LEAVE THE P.T.O. SHAFT DISCONNECTED UNTIL

THE PTO LENGTH ADJUSTMENTS ARE COMPLETED.

Initial installation of the shaft is done as follows:

1. Attach the 3 point sprayer to tractor and set the sprayer in the

position with the shortest distance between the tractor and sprayer

pump P.T.O. shafts.

2. Stop the tractor engine and remove the ignition key.

3. If the P.T.O. shaft must be shortened, the shaft is pulled apart. Fit

the two shaft parts at tractor and sprayer pump and measure how

much it is necesary to shorten the shaft. Mark the protection guards.

Note: The shaft must always have a minimum overlap of 6" (150 mm)

(Fig. 28).

Page 49

47HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

min. 3/4" (20mm)

Fig. 29

Fig. 30

4. The two parts are shortened equally. Use a saw, and file the

profiles afterwards to remove burrs (Fig. 29).

5. Grease the profiles, and assemble male and female parts again.

6. Fit the shaft to tractor and sprayer pump.

Note: Female part towards tractor.

Fit the chains to prevent the protection guards from rotating with the

shaft (Fig. 30).

7. To ensure long life of the P.T.O. shaft, try to avoid working angles

greater than 15° (Fig. 30).

Page 50

48 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

8.3 Diaphragm Sprayer Plumbing Diagram

Review and study the following diagram(Fig.31). Following the flow

through the system will help you better understand the various

functions of the sprayer system.

Fig. 31

The following hoses will need to be connected to the spray tanks fitted

to the tractor. (Refer to Fig.31)

A. Suction hose to pump (1 1/2“ hose). Should be used with a

minimum of a 30 mesh filter or larger in this hose.

B. Self-cleaning filter to safety valve (1“ hose) the safety valve is

supplied in kit, and must be fitted to sprayer tank.

C. Agitation hose (1/2” hose) from adjustable agitation valve.

D. Constant pressure return hose (1”hose), from Electric Control Unit.

E. Return line from main on/off valve. (1” hose), from Electric Control

Unit.

F. Safety valve.

If the tanks to be used are polyethylene, HARDI can supply bulkhead

fittings with quick disconnect features for easier assembly &

disassembly of the Eagle 3-Point Boom to the tractor.

Page 51

49HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

EC operating unit

1. Adjustment screw for

consistant boom pressure

2. Main ON/OFF valve

3. Pressure control valve

4. Distribution valves

5. Pressure agitation valve

6. System pressure gauge

Fig. 32

8.4 Adjustment of the EC Controls

A. Operating switch for main ON/

OFF valve

B. Operating switch for distribution

valves

C. Pressure control switch

(to lower or raise)

1. Choose the correct nozzle (Section 5.5). Make sure that all the

nozzles are the same type and capacity.

2. Put the tractor in neutral and adjust the P.T.O. RPM's until the

number of revolutions of the pump corresponds to the intended

traveling speed. Remember the number of revolutions on the

P.T.O. must be kept between 300-600 rpm.

3. Open or close knob (5) (Fig.32) depending on whether pressure

agitation is required. (Remember pressure agitation takes 5% to

10% of pump output).

4. On-off switch (A) (Fig.33) is "ON" against green dot.

5.

All distribution valves switch (B) (Fig.33) are also "ON" against

green dot.

6. Hold pressure regulating switch (C -)

(Fig.33)

until handle (3)

(Fig.32) stops rotating, this will be the "minimum pressure" setting.

7. Hold pressure regulating switch (C+) (Fig.33) until desired pressure

is shown on the pressure gauge.

Fig. 33

EC Remote control box

Page 52

50 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

Note: Adjust the constant distribution boom pressure one section at a

time as follows:

(Start with the valve turned closed before

adjusting).

1. Shut-off the first boom distribution valve switch (B) (Fig.33).

2. Turn the adjusting screw (1) (Fig. 32) until the control unit pressure

gauge (7) (Fig. 32) again shows the same pressure as set in step 6

above. (Turn the screw clockwise for higher pressure,

counterclockwise for lower pressure).

3. Turn the first boom distribution valve switch (B) (Fig. 33) back on.

4. Repeat steps 7 through 9 for the remaining boom distribution

valves.

Note: Hereafter adjustment of the constant boom pressure will only be

needed if you change to nozzles with other capacities, but not

required if only changing pressure or application rate using the

same nozzles.

5. Operating the EC control unit while driving: In order to shut off the

entire boom activate on-off switch (A) (Fig.33). This returns all the

pump outputs to the tank through the return system. The diaphragm

anti-drip valves ensures instantaneous closing of all nozzles.

In order to shut off one or more sections of the boom, switch one or

more unneeded boom distribution valves (B) (Fig.33) to off position.

The constant pressure device ensures that the pressure does not

increase in the sections which are still operating.

In case of electrical failure it is still possible to manually overide all

functions of the operating unit. To operate manually, disconnect the

multiplug from the EC control box first and operate the handles by

hand. It is possible to change pressure, turn boom sections on or off,

or shut off the complete control unit manually.

IMPORTANT:

When the sprayer is stored, the EC control box and

the multiplug must be protected against moisture

and dirt. A plastic bag may be used to protect the

multiplug. Store the control box in a clean dry place.

8.5 Adjustment of Constant Pressure

Page 53

51HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

8.6 Agitation Adjustment (Agitation nozzles only)

Fig. 34

Agitation is necessary to keep the solution in your tank properly mixed.

Consult your chemical supplier for the recommended amount of agitation.

In general, maximum agitation is required but some products tend to foam

easily. To reduce foaming in some instances anti-foaming agents may be

added to the tank (Refer to chemical label). When running low liquid levels

in the tank, agitation may be reduced to facilitate pump priming and avoid

pressure fluctuations. Make sure that you have adjusted the agitation

properly before sprayer calibration.

Turning the Agitation Valve (A ) (Fig.34) clockwise will reduce the

agitation flow. Turning the valve counter clockwise will increase the

agitation flow.

Page 54

52 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

8.7 Self Cleaning Filter

1. From pump

2. To safety valve

3. Filter housing cover

4. To operating unit

5. Return line/

constant agitation

6. Filter housing cover nut

This filter automatically flushes out particles and chemical deposits,

reducing routine maintenance, nozzle plugging and operator exposure.

No adjustments are required but different mesh screens may be installed

for various types of products. A good practice is having the necessary new

O-rings on hand at the time of changing screens or when performing

routine maintenance. O-ring part numbers are #242020, #241953,

#242047.

Note: It is advisable to have the sprayer tank empty before carrying

out any maintenance on the self-cleaning filter.

To clean or replace filter, loosen nut (6) (Fig.35) to remove filter housing

cover (3) (Fig.35) lift filter screen out. Replace screen and filter housing

cover. Press down on cover (3) (Fig.35) and turn the cover nut (6) (Fig.35)

clockwise until snug.

Fig. 35

Page 55

53HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

On/off pressure

valve unit

A

8.8 Checking Ball Seat in EC Controls

If problems with on/off valve occurs (dripping nozzles when on/off valve

is closed), the ball and ball seat should be checked.

1. Remove the 2 bolts attaching the on/off-pressure valve unit to the

bracket.

2. Unscrew the union nut (A) (Fig. 36) and pull the on/off pressure valve

away from the distribution valves.

3. Check the ball for sharp edges and scratches and check the ball seat

for cracks and wear. Replace if necessary.

Fig. 36

8.9 Checking the Valve Cone in Distribution Valves

Periodically check the distribution valves for proper sealing.

1. Flush the sprayer with clean water and

open master on/off and all distribution

valves. (Shut sprayer off)

2. Remove clip (A) (Fig. 37) and remove hose

(B) (Fig. 37) for the constant pressure

device. When the housing is drained make

sure everything is clear from part (B) (Fig. 37).

3. Start the sprayer, there should not be any

flow of liquid through the constant pressure

passage. If there is any leakage, the valve

cone (E) (Fig. 37) must be changed. (Shut

sprayer off.)

4. Remove clip (C) (Fig. 37), and pull the EC

motor off the valve housing.

5. Remove (D) (Fig. 37) screw and replace

the valve cone (E) (Fig. 37). Reassemble in

opposite sequence.

Fig. 37

Page 56

54 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

8.10 Changing The Valves & Diaphragms in a 361/462

Pump

Note: It is recommended that if one or more diaphragms and/or valves

need replacing they all should be replaced. (#750342-Complete

361 rebuild kit, #750324-Complete 462 rebuild kit)

1. Remove valve cover (1) (Fig. 38). Before changing the valves

(2) (Fig. 38) note the orientation of the valves so that they are

replaced correctly.

IMPORTANT:

The two valves with vented flaps (2A and 2B)

(Fig. 38) must be placed in the valve openings as

shown.

2. It is recommended to use new O-rings (3) (Fig. 38) #330024 when

changing or checking the valves.

3. Remove the diaphragm bolt (4) (Fig. 38) after having dismantled the

valve cover as indicated above. The diaphragm (5) (Fig. 38) may now

be changed.

4. If fluids have reached the crank case, regrease the pump thoroughly.

Fig. 38

Model 361 Pump Shown 462 Similar

Page 57

55HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

8.11 Centrifugal Sprayer Plumbing Diagram

Review and study the following diagram(Fig.39). Following the flow

through the system will help you better understand the various

functions of the sprayer system.

The following hoses will need to be connected to the spray tanks fitted

to the tractor. (Refer to Fig.39)

A. Suction hose to pump (1 1/2“ hose). Should be used with a

minimum of a 30 mesh filter or larger in this hose.

B. Agitation hose (1/2” hose) from adjustable agitation valve.

C. Constant pressure return hose (1” hose), from Electric Control Unit.

If the tanks to be used are polyethylene, HARDI can supply bulkhead

fittings with quick disconnect features for easier assembly &

disassembly of the 3-point boom to the tractor.

Fig. 39

Page 58

56 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

8.12 Operation of the ESC Controls

ESC Operating Unit

1. Adjustment screw for constant boom pressure

2. Pressure control valve

3. Distribution valves

4. System pressure gauge

5. System pressure filter

ESC Control Box

A. Master operating switch for on-off valves

B. Operating switches for ditribution valves

C. Pressure regulating switch (-) lower, (+) raise

Fig. 40

Fig. 41

Page 59

57HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

1. Put the tractor in neutral and adjust the P.T.O. RPM's until the number

of revolutions of the pump corresponds to the intended traveling

speed. Remember the number of revolutions on the P.T.O. must be

kept between 300-600 rpm.

2. Open or close knob 5 depending on whether pressure agitation is

required. (Remember pressure agitation takes 5% to 10% of pump

output).

3. On-off switch (A) (Fig. 41) is "ON" against green dot.

4.

All distribution valves switch (B) (Fig. 41) are also "ON" against green

dot.

5. Hold pressure regulating switch (C -)

(Fig. 41)

until handle (3) (Fig. 40)

stops rotating, this will be the "minimum pressure" setting.

6. Hold pressure regulating switch (C+) (Fig. 41) until desired pressure

is shown on the pressure gauge.

Note: Adjust the constant distribution boom pressure one section at a

time as follows:

(Start with the valve turned closed before adjusting).

7. Shut-off the first boom distribution valve switch (B) (Fig. 41).

8. Turn the adjusting screw (1) (Fig. 41) until the control unit pressure

gauge (7) (Fig. 40) again shows the same pressure as set in step 6

above. (Turn the screw clockwise for higher pressure, counterclockwise for lower pressure).

9. Turn the first boom distribution valve switch (B) (Fig. 41) back on.

10. Repeat steps 7 through 9 for the two remaining boom distribution

valves.

Note: Hereafter adjustment of the constant boom pressure will only be

needed if you change to nozzles with other capacities, but not

required if only changing pressure or application rate using the

same nozzles.

11. Operating the control unit while driving: In order to shut off the entire

boom activate on-off switch (A) (Fig. 41). This returns all the pump

outputs to the tank through the return system. The diaphragm antidrip valves ensures instantaneous closing of all nozzles.

8.13 Adjustment of the ESC Controls

Page 60

58 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

Agitation is necessary to keep the solution

in your tank properly mixed.

Consult your chemical supplier for the

recommended amount of agitation.

In general, maximum agitation is required

but some products tend to foam easily. To

reduce foaming in some instances antifoaming agents may be added to the tank

(Refer to chemical label). When running

low liquid levels in the tank, agitation may

be reduced to facilitate pump priming and

avoid pressure fluctuations. Make sure

that you have adjusted the agitation

properly before sprayer calibration.

Turning the Agitation Valve (A ) (Fig.42)

clockwise will reduce the agitation flow.

Turning the valve counter clockwise will

increase the agitation flow.

In order to shut off one or more sections of the boom, switch one or more

unneeded boom distribution valves (B) (Fig. 41) to off position. The

constant pressure device ensures that the pressure does not increase in

the sections which are still operating.

In case of electrical failure it is still possible to manually overide all

functions of the operating unit. To operate manually, disconnect the

multiplug from the EC control box first and operate the handles by hand.

It is possible to change pressure, turn boom sections on or off, or shut off

the complete control unit manually.

IMPORTANT:

When the sprayer is stored, the ESC control box and

the multiplug must be protected against moisture and dirt. A plastic

bag may be used to protect the multiplug. Store the control box in a

clean dry place.

8.14 Agitation Adjustment (Agitation nozzles only)

Fig. 42

Page 61

59HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

8.15 Control Box for Electric Control Units

The control box for EC/ECS controls should be mounted at a convenient

place in the tractor cab. The control box has 4 screw holes in the back

cover, which need to be drilled out for mounting on a flat surface. There

should be a minimum of a 8 amp fuse protecting this circuit.

Power requirement is 12 volt DC.

Note polarity:

Brown positive (+)

Blue negative (-)

Use the optional HARDI

Electric 12 volt outlet box

(No. 817925) if more than

one power outlet is required.

12-volt junction box for 12-volt hook-up: EC/ECS controls,

HARDI PILOT, boom hydraulic controls, etc.

Fig. 43

Page 62

60 HARDI® EAGLE 3PT BOOM OPERATORS MANUAL

9.0 TRANSPORTATION AND STORAGE

9.1 Follow Safe Transport And Towing Procedures

WARNING:

KEEP AWAY FROM OVERHEAD POWER LINES TO