Page 1

COMMANDER

TWIN FORCE

Instruction book

670747-GB-2000/01

We congratulate you for choosing a HARDI plant protection product. The reliability and

efficiency of this product depend upon your care. The first step is to carefully read and

pay attention to this instruction book. It contains essential information for the efficient

use and long life of this quality product.

As the instruction book covers all COMMANDER plus models with HAY boom or HAZ

boom, please pay attention to the paragraphs dealing with precisely your model.

This book is to be read in conjunction with the Spray Technique book.

More information about the COMMANDER plus can be found on the products own web-

site at: http//www.commander-plus.com

Illustrations, technical information and data in this book are to the best of our belief correct at the time of printing. As

it is HARDI INTERNATIONAL A/S policy permanently to improve our products, we reserve the right to make

changes in design, features, accessories, specifications and maintenance instructions at any time and without

notice. HARDI INTERNATIONAL A/S is without any obligation in relation to implements purchased before or after

such changes.

HARDI INTERNATIONAL A/S cannot undertake any responsibility for possible omissions or inaccuracies in this

publication, although everything possible has been done to make it complete and correct.

As this instruction book covers more models and features or equipment, which are available in certain countries

only, please pay attention to paragraphs dealing with precisely your model.

Published and printed by HARDI INTERNATIONAL A/S

GB 01 06

1

Page 2

2

Page 3

TT

aa

bb

le ofle of

T

a

b

le of

TT

aa

bb

le ofle of

Declaration of Conformity ........................................................ 4

Operator safety ........................................................................ 5

COMMANDER plus .................................................................. 6

Sprayer use ............................................................................. 8

Unloading the sprayer from the truck ....................................... 8

Before putting the sprayer into operation ................................. 8

Connecting the sprayer ............................................................ 9

Transmission shaft ................................................................... 11

Track gauge ............................................................................. 13

Hydraulic systems .................................................................... 16

Control boxes and power supply ...............................................17

Brakes ......................................................................................18

Counter weight (TRACKER models only) ................................. 20

Transport ................................................................................. 21

Driving Technique .....................................................................23

Equipment - Standard and Additional ....................................... 25

Disconnecting the sprayer ....................................................... 29

Operating the boom ................................................................. 30

Operating the liquid system ...................................................... 32

MANIFOLD SYSTEM ............................................................... 32

Contents Contents

Contents

Contents Contents

Drawbars ..................................................................... 9

Fixed drawbar ...............................................................10

STEERING drawbar ..................................................... 10

SELF TRACK for COMMANDER 2200/2800 ................ 10

TRAIL CONTROL ......................................................... 10

Operator safety ............................................................ 11

Installation of transmission shaft ...................................11

Altering the track gauge ................................................13

Adjustment ranges - track width .................................... 14

Permitted rim positions ................................................. 15

Tractor Operated Hydraulics ......................................... 16

Direct Acting Hydraulic system ..................................... 16

Load Sensing ............................................................... 16

Emergency and parking brake (if fitted) ........................ 18

Hydraulic activated brakes (if fitted) .............................. 18

Air activated brakes (if fitted) ........................................ 18

Single-line brakes (if fitted) ........................................... 19

Dual-line brakes (if fitted) ..............................................19

Roadworthiness ........................................................... 21

Rear lights (if fitted) ...................................................... 21

Transport brackets, height setting ................................ 21

Transport lock .............................................................. 22

STEER TRACK and SELF TRACK ............................. 23

STEER TRACK ........................................................... 23

SELF TRACK .............................................................. 24

TRAIL CONTROL ........................................................ 24

Ladder ......................................................................... 25

Platform ....................................................................... 25

Tank level indicator ...................................................... 25

Large storage Locker (if fitted) ..................................... 25

Small storage Locker (if fitted) ..................................... 25

Front Locker (if fitted) .................................................. 25

Boom and Work lights (if fitted) ................................... 26

Crop protection Kit (if fitted) ........................................ 27

Mudguards (if fitted) .................................................... 28

The HAY boom .............................................................30

The HAZ boom ............................................................. 30

Air slot angling ............................................................. 30

Electrical fan speed adjustment (if fitted) ...................... 31

Boom suspension sensitivity ........................................ 31

Use of MANIFOLD valve system ................................. 32

Electrical operated MANIFOLD valves (if fitted) ............ 33

Quick reference ............................................................ 33

Filling of water .............................................................. 33

Filling of rinsing tank (if fitted) ....................................... 35

Filling of clean water tank ............................................. 36

Adjustment of EVC operating unit ................................ 36

Adjustment of pressure equalisation ............................. 36

Operating the control unit while spraying ...................... 37

Remote pressure gauge (if fitted) ................................. 37

Filters ....................................................................................... 37

Self-cleaning filter .........................................................37

Choice of correct restrictor ........................................... 37

Filling of chemicals ................................................................... 38

Filling of Liquid chemicals .............................................38

Filling of Powder chemicals .......................................... 39

Use of rinsing tank and rinsing nozzles (if fitted) ..................... 40

Technical Residue .................................................................... 41

Draining a residue ........................................................ 41

Using the drain valve ................................................................ 41

Using the suction quick coupler ................................................ 41

Operation of the drain valves .................................................... 41

Safety precautions ................................................................... 42

Personal protection .......................................................42

Air technique ............................................................................ 43

Air speed / Air volume ...................................................43

Blower adjustment ........................................................ 43

Angling of air and liquid ................................................ 43

Adjusting the air assistance .......................................... 43

Setting of air speed, rules of thumb .............................. 44

Angling of air and liquid, rules of thumb ........................ 44

Water sensitive paper ................................................... 45

Maintenance - rules of thumb ................................................... 49

Cleaning the sprayer ................................................................ 49

Cleaning the tank ......................................................... 49

Cleaning and maintenance of filters ..............................50

Lubrication ............................................................................... 51

Lubricating points ......................................................... 51

Service and Maintenance intervals ........................................... 56

10 hours service ........................................................... 56

50 hours service ........................................................... 56

100 hours service ......................................................... 56

250 hours service ......................................................... 56

500 hours service ......................................................... 56

1000 hours service or yearly, whichever comes first ..... 57

Occasional maintenance .............................................. 57

Off-season storage ................................................................... 76

Off-season storage program ......................................... 76

Preparing the sprayer for use after storage ...................76

Fault-finding ............................................................................. 77

Operational problems ............................................................... 77

TRACKER damping system ......................................... 77

Liquid system ............................................................... 78

EVC Operating unit ...................................................... 79

Hydraulic system (Tractor Operated Hydraulics) ........... 79

Hydraulic system (Direct Acting Hydraulic System) ....... 80

Hydraulic fan transmission ........................................... 81

Emergency operation of the sprayer ......................................... 82

The boom ..................................................................... 82

Steering drawbar (if fitted) ............................................ 82

Technical specifications ............................................................ 83

Overall dimensions ....................................................... 83

Weight ..........................................................................83

Pump capacity ............................................................. 85

Filters and nozzles ....................................................... 86

Temperature and pressure ranges.................................86

Brakes ..........................................................................86

Materials and recycling ................................................ 86

Disposal of the sprayer ................................................ 86

Conversion factors, SI to Imperial units ........................ 86

Electrical connections 86

Rear lights .................................................................... 86

Electrical connections for EVC operating unit ............... 87

Electrical chart (EVC) .................................................. 87

Installation instruction for boom and work light ............. 88

Electrical specifications for Boom and Work light ......... 89

Boom hydraulic charts .............................................................. 90

Subject index ............................................................................xx

3

Page 4

EC Declaration

Dec Dec

Dec

Dec Dec

Manufacturer, Importer,

HARDI INTERNATIONAL A/S

Helgeshøj Allé 38

DK 2630 Taastrup

DENMARK

declare that the following product;

_________________________________________________________________________________________

A. was manufactured in conformity with the provisions in the COUNCIL DIRECTIVE of 14 June 1989 on mutual

approximation of the laws of the Member States on the safety of machines (89/392/EEC as amended by directives

91/368/EEC and 93/368/EEC) with special reference to Annex 1 of the Directive on essential safety and health

requirements in relation to the construction and manufacture of machines.

larlar

lar

larlar

aa

tion oftion of

a

tion of

aa

tion oftion of

Conf Conf

Conf

Conf Conf

ormityormity

ormity

ormityormity

B. was manufactured in conformity with the current standards implementing harmonised standards in accordance

with Article 5 (2) and other relevant standards.

Taastrup, January 2000

_____________________________________________

Erik Holst

Managing Director

HARDI INTERNATIONAL A/S

Adhere extra shipping package labels in the Product Identification Certificate.

4 GB 02 01

Page 5

Safety notes

OperOper

Oper

OperOper

Note the following recommended precautions and safe

operating practices.

aa

tor saftor saf

a

tor saf

aa

tor saftor saf

Read and understand this instruction book

before using the equipment. It is equally

important that other operators of this equipment read and understand this book.

Local law may demand that the operator be

certified to use spray equipment. Adhere to

the law.

Pressure test with clean water prior to filling

with chemicals.

Wear protective clothing.

etyety

ety

etyety

Watch for this symbol .

It means WARNING, CAUTION,

NOTE. Your safety is involved so be

alert!

Keep children away from the equipment.

Do not attempt to enter the tank.

Do not go under any part of the sprayer unless

it is secured. The boom is secure when

placed in the transport brackets.

If any portion of this instruction book remainsunclear

after reading it, contact your HARDI dealer for further

explanation before using the equipment.

Rinse and wash equipment after use and

before servicing.

Depressurize equipment after use and before

servicing.

Never service or repair the equipment whilst it

is operating.

Disconnect electrical power before servicing.

Always replace all safety devices or shields

immediately after servicing.

If an arc welder is used on the equipment or

anything connected to the equipment, disconnect power leads before welding. Remove all

inflammable or explosive material from the

area.

Do not eat, drink or smoke whilst spraying or

working with contaminated equipment.

Wash and change clothes after spraying.

Wash tools if they have become contaminated.

In case of poisoning, immediately seek medical advice. Remember to identify chemicals

used.

5 GB 03 01

Page 6

Description

COMMANDER plusCOMMANDER plus

COMMANDER plus

COMMANDER plusCOMMANDER plus

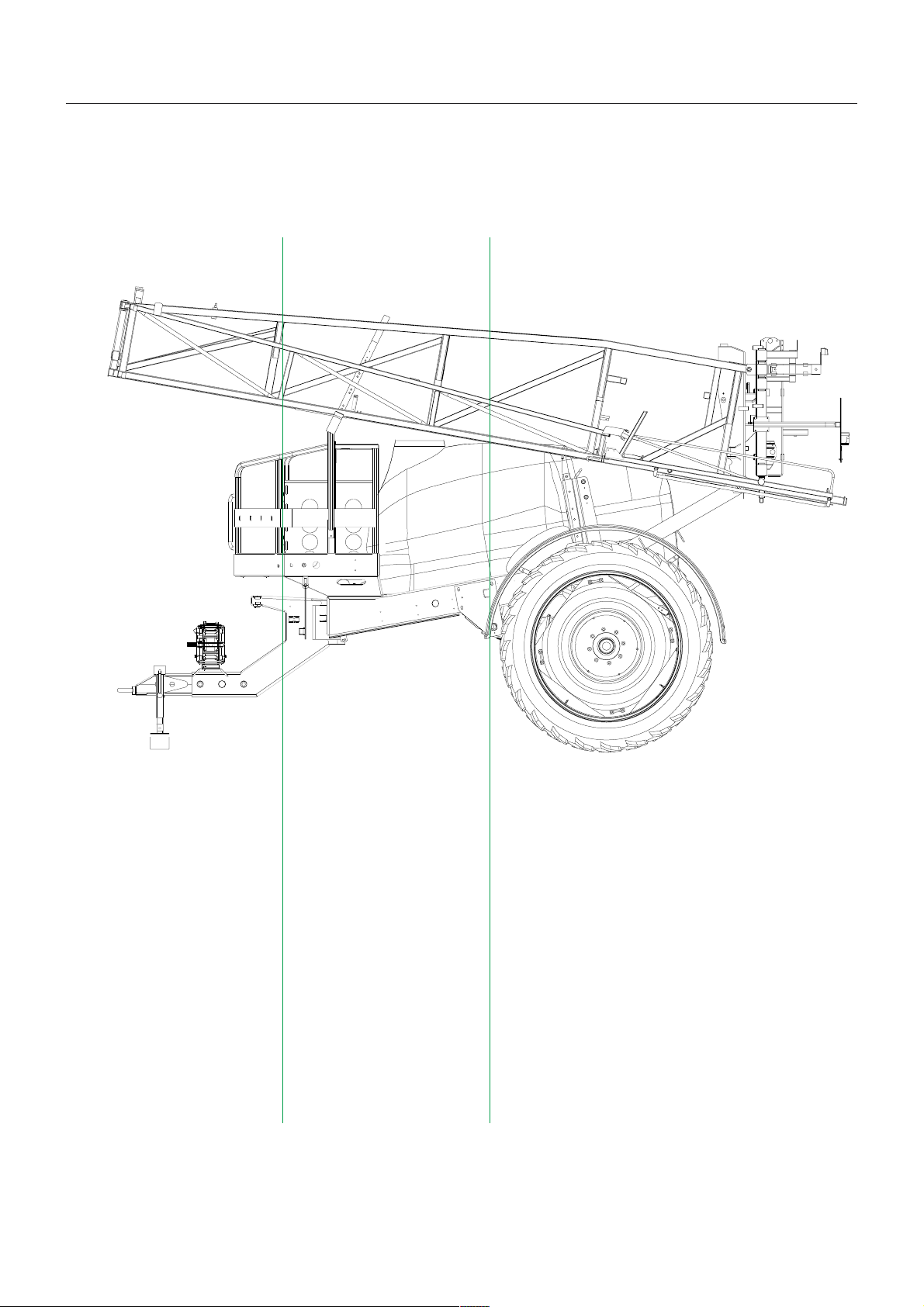

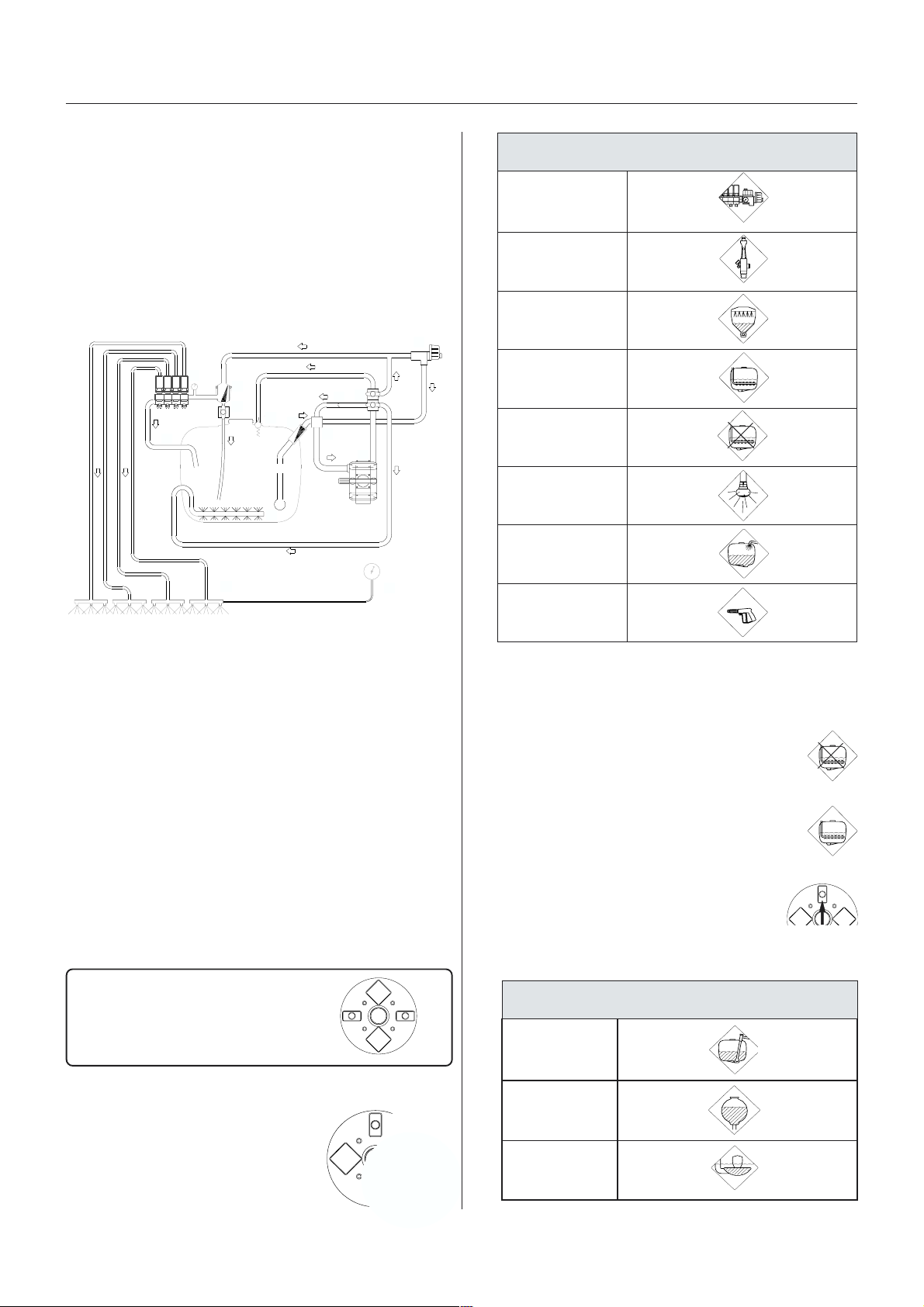

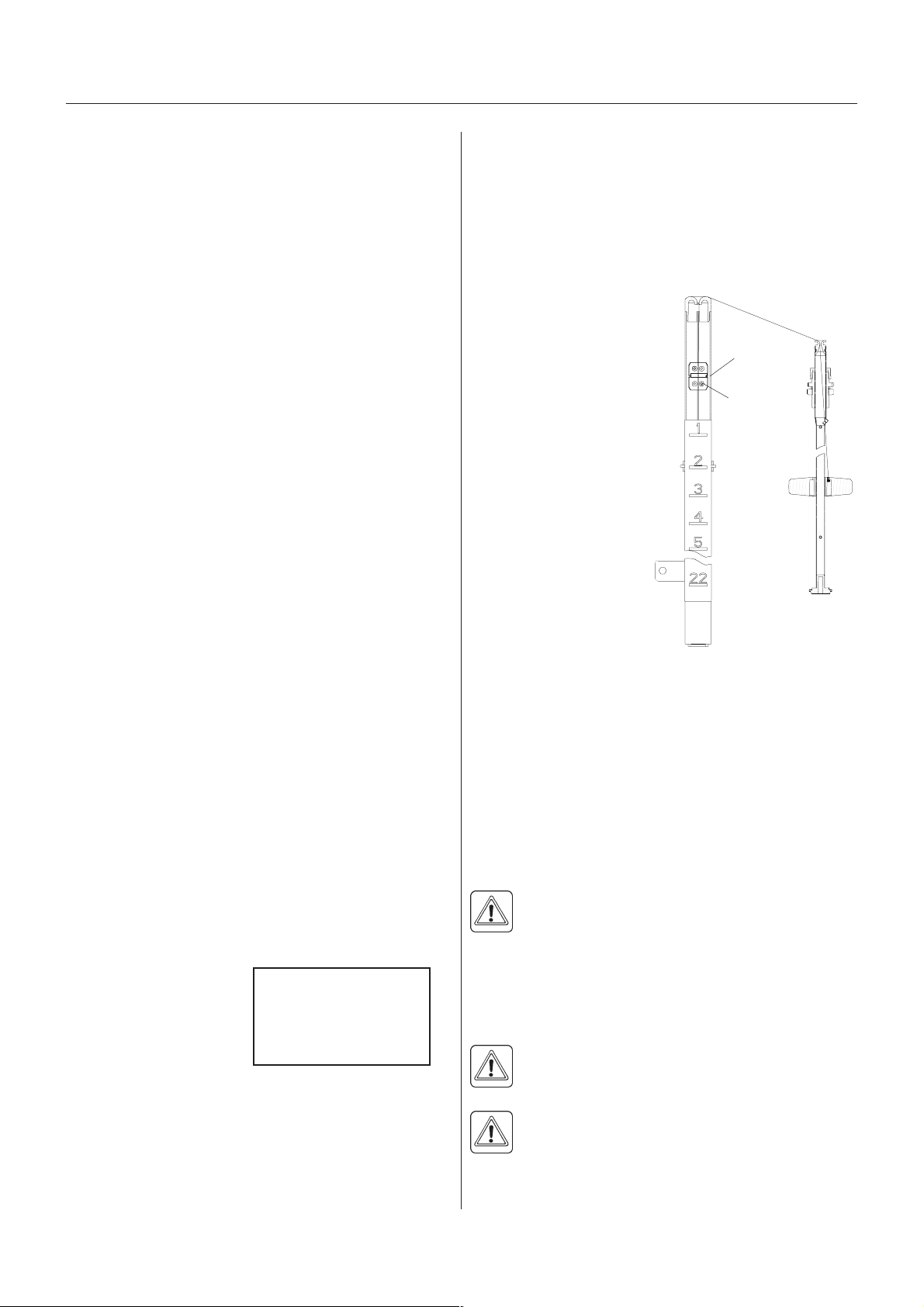

The COMMANDER plus is divided into three zones: a Clean zone, a Working zone and an Application zone, referring to the level of possible pesticide contamination.

CLEAN ZONE WORKING ZONE APPLICATION ZONE

T271-0010x

Locker for protective gear

Clean water tank

Tap for hand washing

Support leg

Pump

P.T.O. shaft

Please note that some of the features are optional equipment

Tank level indicator

MANIFOLD valves

Couplers for fast filling

Working platform with

ladder

Hydraulic and electric

components

Boom and Work lights

HARDI FILLER

Lockers for pesticide

containers and equipment

PARALIFT boom lift system

Boom

Nozzles

Mudguards

Suspension

Crop Protection Kit

6

GB 04 06

Page 7

Description

DescriptionDescription

Description

DescriptionDescription

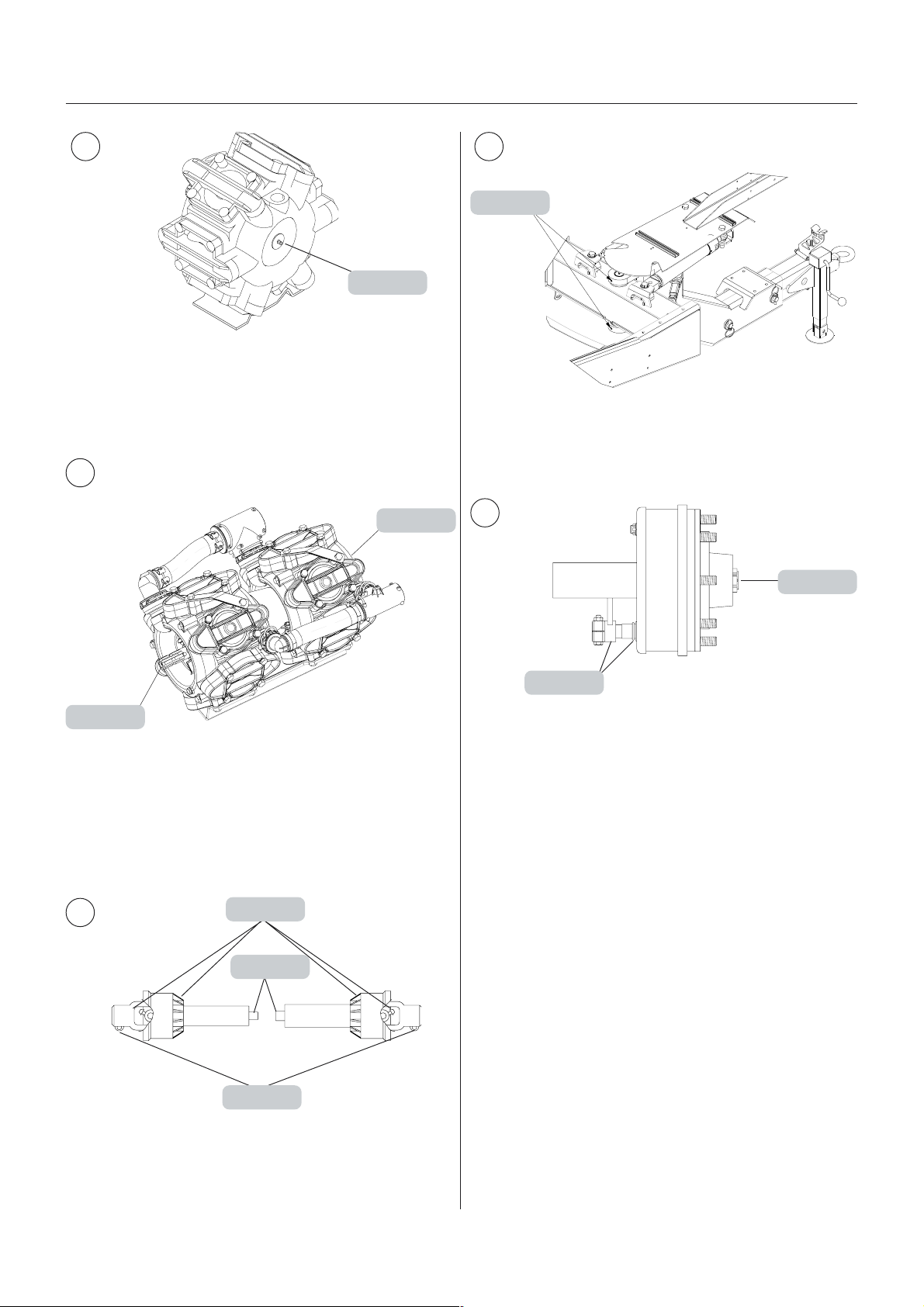

Frame

Strong and compact frame with several options of

drawbars and wheel sizes. The frame has a strong

chemical and weather resistant electrostatic lacquer

coat. Screws, nuts, etc. have been DELTA-MAGNI

treated to be resistant to corrosion.

Tank

UV-resistant Polyethylene in a suitable design with no

sharp corners for easy agitation, emptying and cleaning.

Nominal contents 2200, 2800, 3200 or 4200 l.

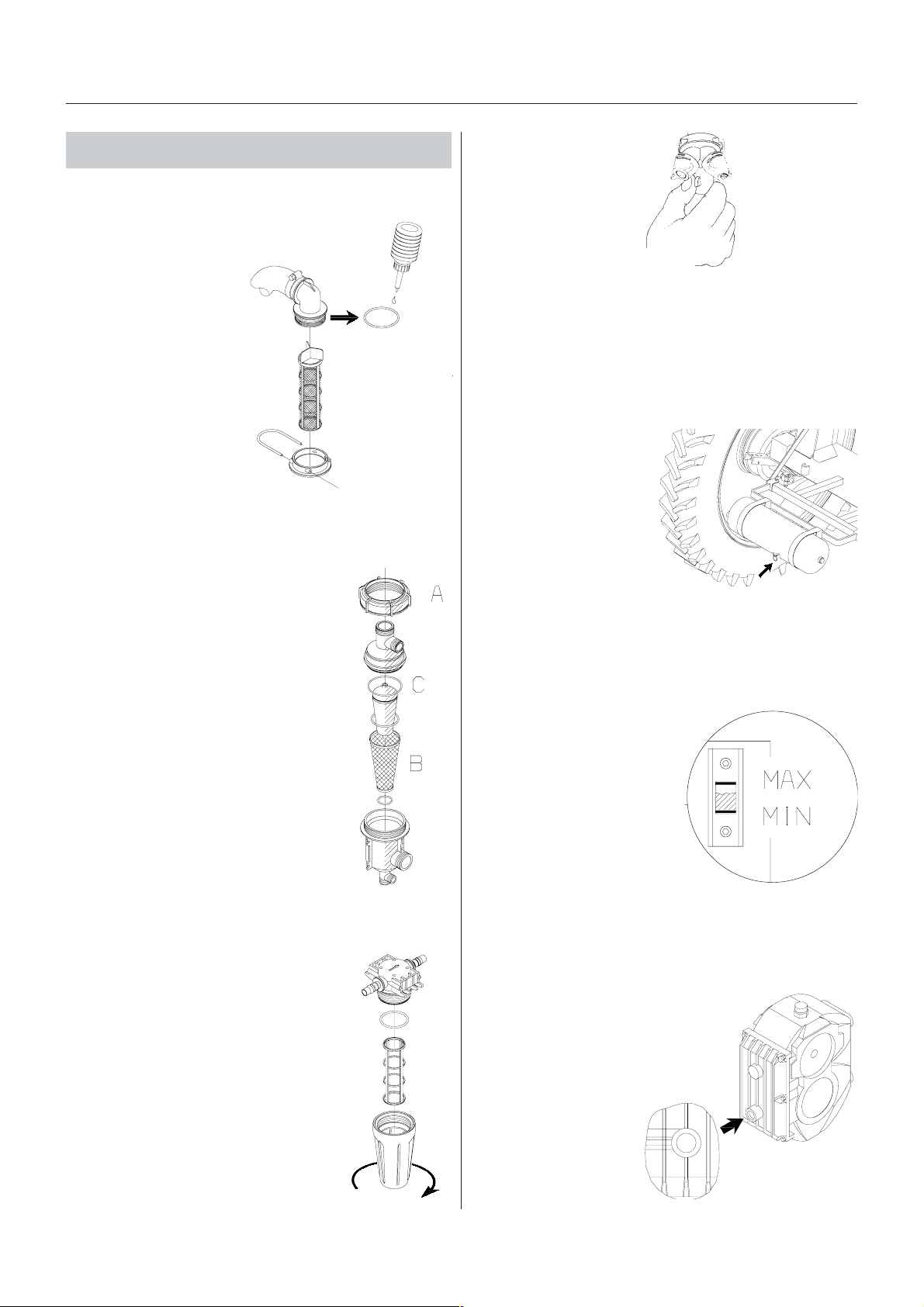

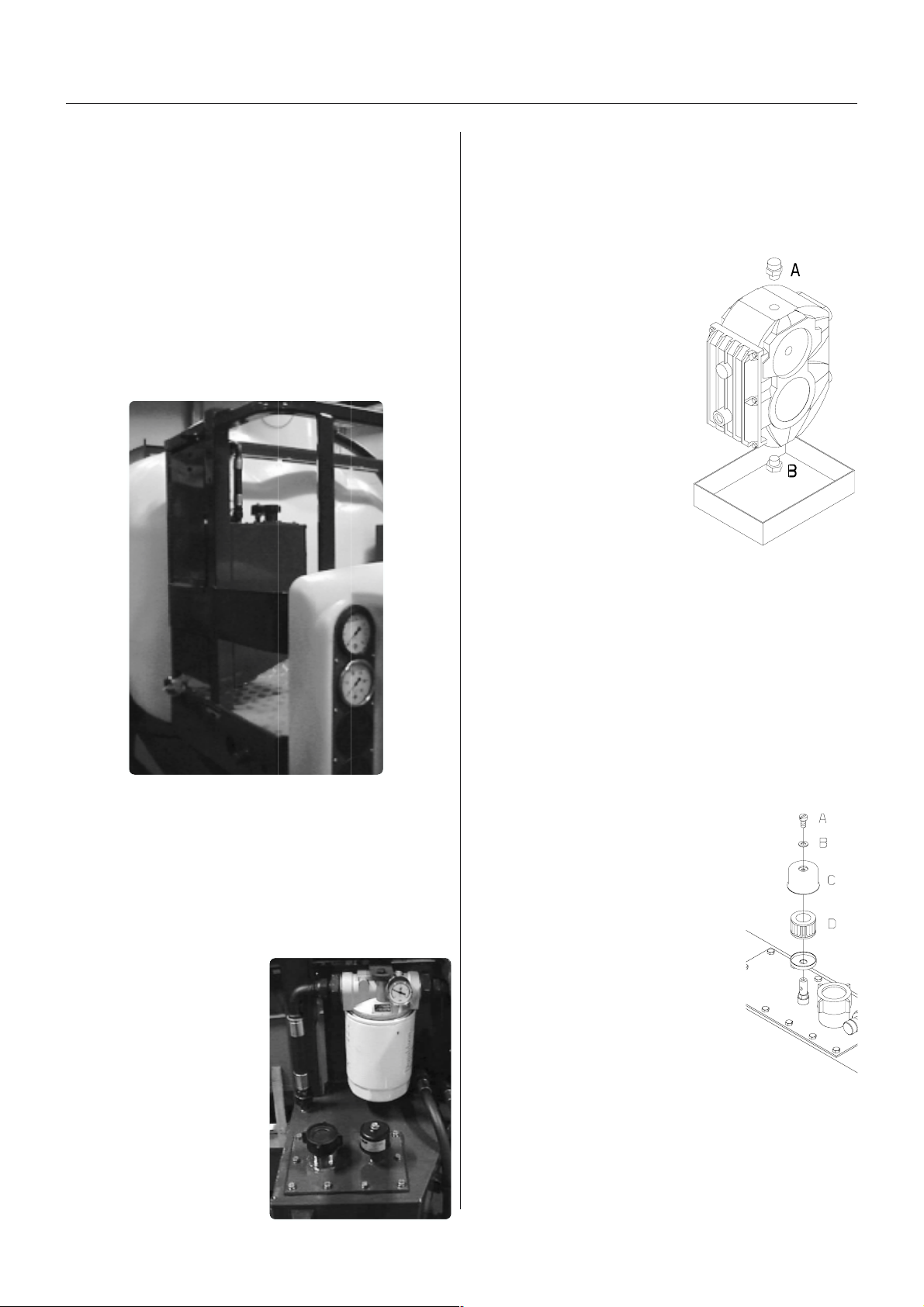

Pump

Diaphragm pump with 6 diaphragms, model 363 or 463,

depending on boom width, with easily accessible valves

and diaphragms. Standard = 540 r.p.m. (6 splines)

Optional = 1000 r.p.m. (21 splines).

MANIFOLD SYSTEM

All functions of the spray circuits are operated via the

centrally situated MANIFOLD valves with colour coded

plates and pictorial symbols for easy operation.

Operating unit

The system is based on EVC - Electrical Valve Control.

The on/off is linked to the section valves, which is

resulting in a very quick response to on/off.

and 28 m working width.

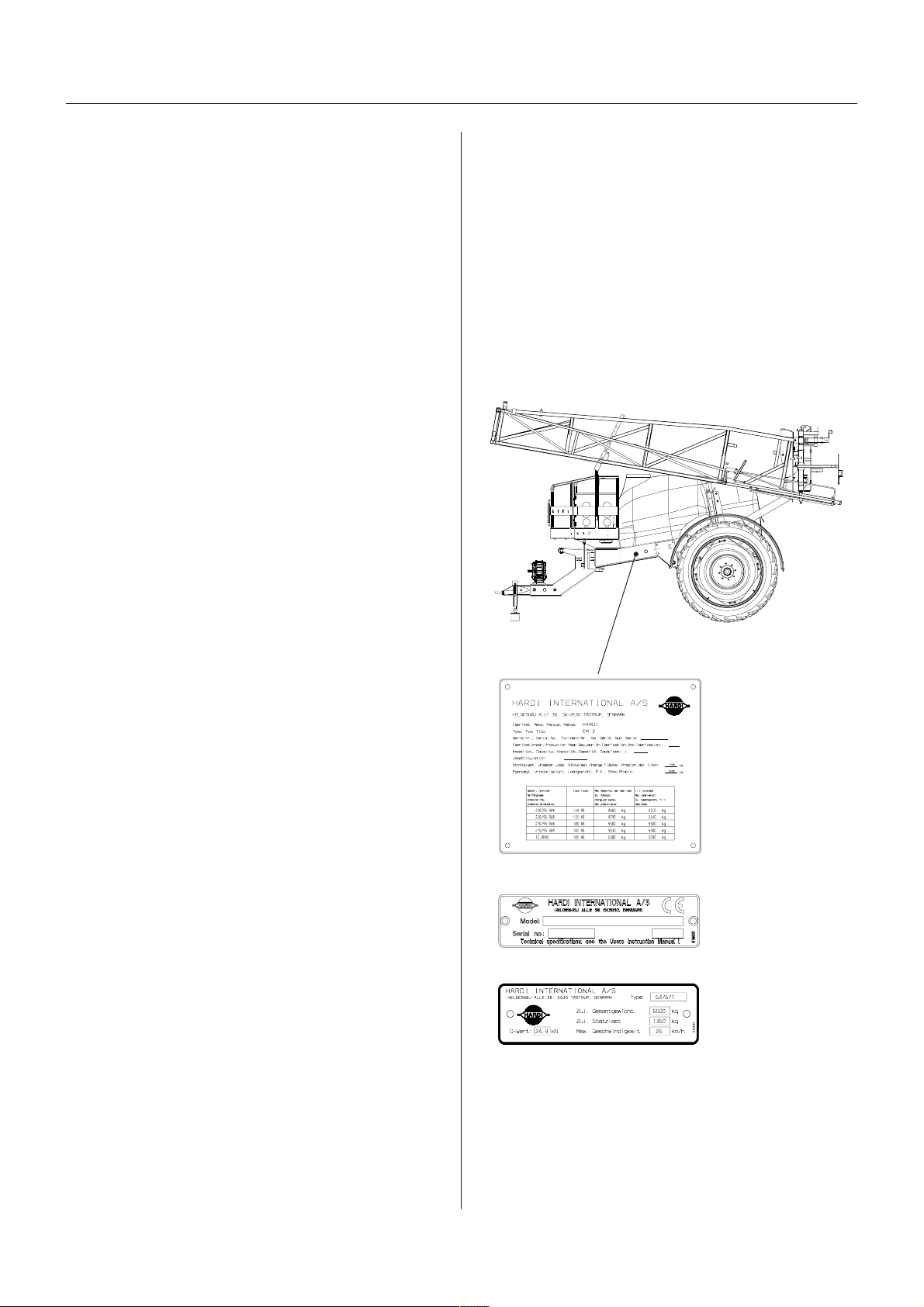

Identification plates

An identification plate fitted on the frame indicates

producer name, model, own weight, max. weight, max.

pressure of the hydraulic system, and max. pressure of

the spray liquid system. Frame, boom centre frame, and

inner/outer sections also have identification plates

indicating boom type and part number of spare parts. If

ordering spare parts, inform your dealer of these, so the

right model and version are described.

T271-0010x

The operating unit is constructed of modules and is

electrically controlled via a remote control box.

The built-in HARDI-MATIC ensures a constant volume

per hectare of the liquid (l/ha) at varying forward speed

within the same gear when the number of P.T.O. revolutions are between 300-600 r.p.m. (pump 540 r.p.m) or

650-1100 r.p.m. (pump 1000 r.p.m.).

Filters

With the self-cleaning filter the impurities that exist in the

spray liquid will bypass the filter and be recirculated back

to the tank via the return flow. Also suction filter and

nozzle filters are standard. In-line pressure filters can be

fitted as option.

Boom

All booms are suspended in a strong, stable parallelogram boom lift.

The HAY/HAZ booms are trapeze/pendulum suspended

and fully hydraulically operated, including boom slanting

control and air slot angling. HAZ models have Direct

Acting Hydraulics (D.A.H.) and individual boom tilt

function as well.

(Certain countries only)

T279-0005

T279-0002

T279-0006

The TWIN blowers are driven by a built-in hydrostatic

transmission powered via the tractor P.T.O. Blower

speed can be adjusted stepwise from the tractor cabin.

The HAY/HAZ booms are available in 18, 20, 21, 24, 27

GB 04 06

7

Page 8

Description

SprSpr

aa

yy

Spr

SprSpr

The HARDI COMMANDER sprayer is for the application

of crop protection chemicals and liquid fertilisers.

The equipment must only be used for this purpose. It is

not allowable to use the sprayer for other purposes.

If no local law demands that the operator must be

certified to use the spray equipment, it is strongly recommended to be trained in correct plant protection and in

safe handling of plant protection chemicals to avoid

unnecessary risk for persons and the environment when

doing the spray job.

er useer use

a

y

er use

aa

yy

er useer use

Unloading the sprUnloading the spr

Unloading the spr

Unloading the sprUnloading the spr

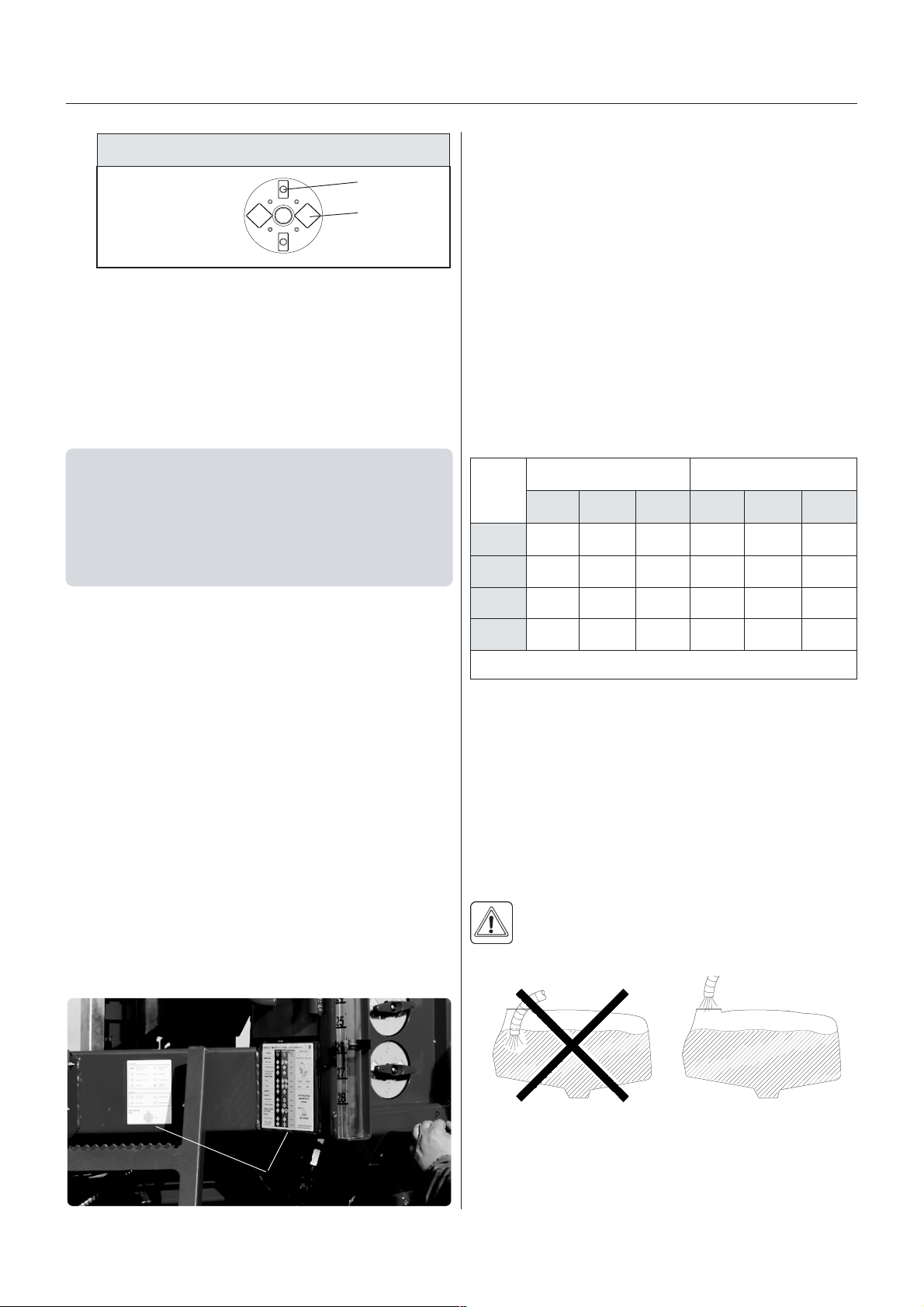

For the unloading of the sprayer a crane or a fork lift is

needed. When loading with a crane please observe the

lifting points as shown on the illustration, and make sure

that the straps or belts used for lifting are strong enough.

aa

a

aa

yy

er frer fr

y

er fr

yy

er frer fr

om the trom the tr

om the tr

om the trom the tr

ucuc

uc

ucuc

T021-0003

kk

k

kk

BefBef

oror

Bef

BefBef

operoper

oper

operoper

Although the sprayer has been applied with a strong and

protective surface treatment on steel parts, bolts etc. in

the factories, it is recommended to apply a film of

anticorrosion oil (e.g. CASTROL RUSTILLO or SHELL

ENSIS FLUID) on all metal parts in order to avoid

chemicals and fertilisers discolouring the enamel.

If this is done before the sprayer is put into operation for

the first time, it will always be easy to clean the sprayer

and keep the enamel shiny for many years.

This treatment should be carried out every time the

protection film is washed off.

8

e putting the spre putting the spr

or

e putting the spr

oror

e putting the spre putting the spr

aa

tiontion

a

tion

aa

tiontion

aa

yy

er intoer into

a

y

er into

aa

yy

er intoer into

GB 04 06

Page 9

Sprayer setup

Connecting the sprConnecting the spr

Connecting the spr

Connecting the sprConnecting the spr

DrDr

aa

wbarwbar

wbar

wbarwbar

ZPL/YPL

ss

s

ss

REDNAMMOC

DEXIF

RABWARD

Dr

a

DrDr

aa

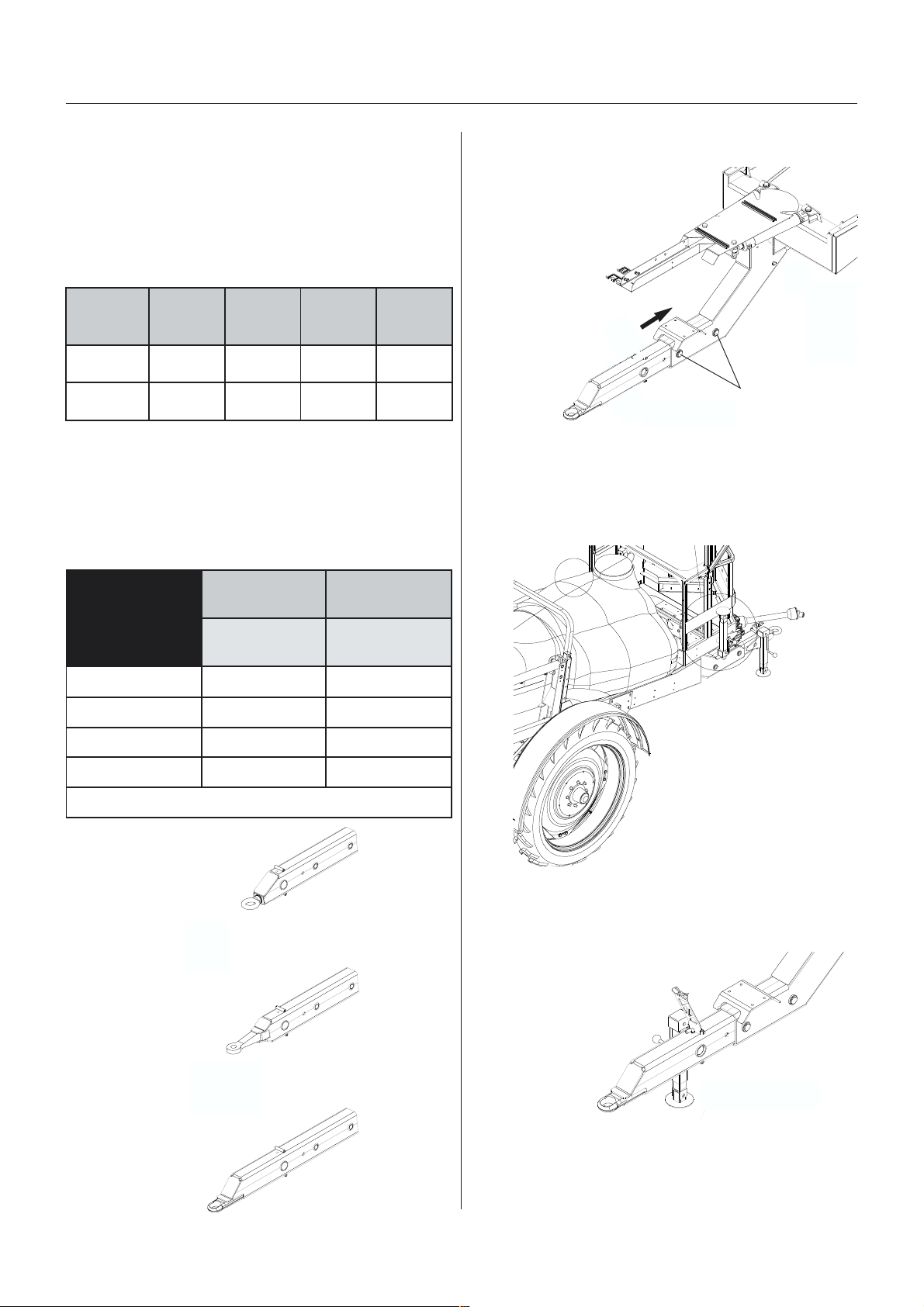

Mounted on the chassis in a centre pivot, the drawbar

can be either standard fixed or optionally steered.

Steering can be hydraulically operated or it can be

automatically controlled (TRAIL CONTROL).

Overview - Drawbar systems

aa

a

aa

yy

erer

y

er

yy

erer

GNIREETS

RABWARD

LIART

LORTNOC

FLES

KCART

0082/0022seYseYseYseY

0024/0023seYseYseYoN

035

Following drawbar extensions are available. The drawbar extensions are available - steering or fixed - for both

high and low tractor hitch points. Each drawbar is

available in a long or a short version.

Overview - Drawbar extensions

REDNAMMOC

rabwarD

snoisnetxe

0082/0022

WOLdnaHGIH

hctih

REDNAMMOC

0024/0023

WOLdnaHGIH

hctih

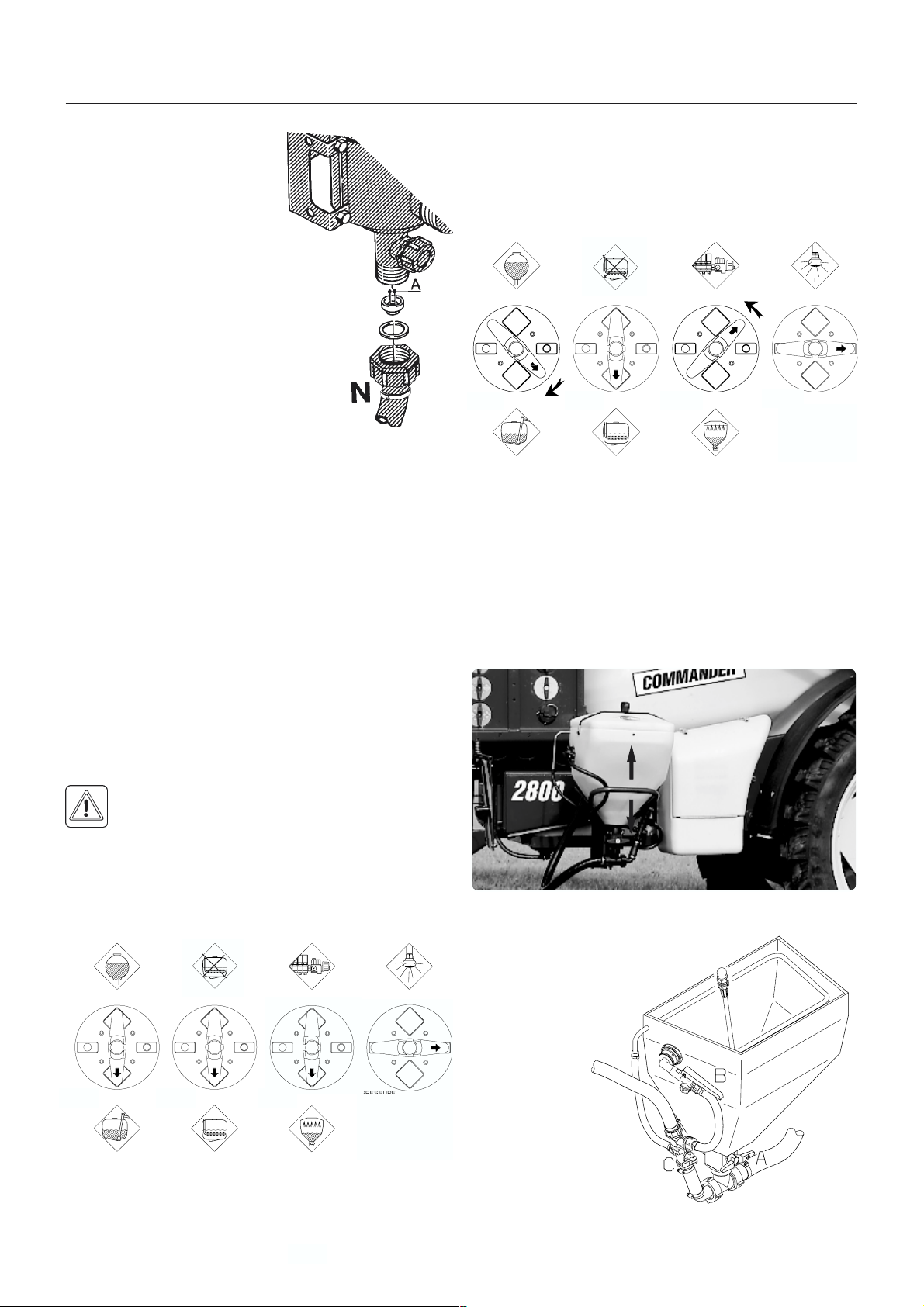

Mounting the drawbar extension

The extension piece is inserted into

the opening of the drawbar,

fastened by two main bolts

through the two holes A and

secured by two linch pins.

T251-0012x

A

Support leg

The support leg is stored in the bracket on the sprayers

right side when the sprayer is attached to the tractor.

33ØepytleviwSoNseY

63ØepytleviwSseYoN

04ØluamguZseYseY

)2965OSI(05ØhctiHseYseY

noisrevtrohsadnagnolanielbaliavaerasrabwardllA

Swivel type

Zugmaul

034

T142-0028x

To remove the support leg: Lift the leg, remove the linch

pin and pull out the support leg.

The support leg can then

be mounted to the drawbar

extension and secured by

linch pin.

T251-0012x

Hitch (ISO 5692)

T251-0014x

GB 05 02 01

9

Page 10

Sprayer setup

FF

ixix

ed dred dr

F

ix

ed dr

FF

ixix

ed dred dr

Make sure the drawbar points straight ahead from its

position on the trailer. If not, the two turn buckles A can

be adjusted till the drawbar is centred.

STEERING drSTEERING dr

STEERING dr

STEERING drSTEERING dr

Transport lock (if fitted)

The transport lock is a safeguard that will keep the

drawbar in a centred position in case of hydraulic

leakage during transport on public roads.

aa

wbarwbar

a

wbar

aa

wbarwbar

aa

wbarwbar

a

wbar

aa

wbarwbar

A

A

T251-0012x

T251-0016x

NOTE! If possible, lock the tractor hydraulic lever when

the lift arms are in the correct position to avoid the

sprayer weight resting on the stabiliser chains.

3. Tighten the lift arm stabiliser chains.

WARNING! Do not stand in the area around the

drawbar during manoeuvring.

The transport lock is fixed by linch pins.

If necessary, the transport lock can be adjusted by

turning the turnbuckle.

SELF TRASELF TRA

SELF TRA

SELF TRASELF TRA

SELF TRACK is connected as follows:

1. Attach the tractor lower links in the two mountings of

the SELF TRACK. Adjust the length of the drawbar if

necessary - to obtain the best tracking, choose the

setting where the distance X is equal to distance Y.

Secure with linch pins.

CK fCK f

or COMMANDER 2200/2800or COMMANDER 2200/2800

CK f

or COMMANDER 2200/2800

CK fCK f

or COMMANDER 2200/2800or COMMANDER 2200/2800

x

y

T251-0015x

TRAIL CONTROLTRAIL CONTROL

TRAIL CONTROL

TRAIL CONTROLTRAIL CONTROL

Please refer to separate instruction book.

Hose pacHose pac

Hose pac

Hose pacHose pac

To prevent hoses and wiring from being damaged by the

tractor wheels, all hoses, cables and wires are held by

the hose bracket A fitted to the drawbar.

kk

aa

gg

e suppore suppor

k

a

g

e suppor

kk

aa

gg

e suppore suppor

t t

t

t t

A

2. Attach safety chains to top link clevis. The chain will

prevent the transmission shaft from being damaged if

the lift arms are lowered too far. Adjust the chain

length so the chains are tight when the tractor P.T.O.

and pump shaft are in a horizontal line.

10

T251-0012x

Check that the length of the hoses and cables are

sufficient by tight turns.

GB 05 02 01

Page 11

Sprayer setup

TT

rr

ansmission shaftansmission shaft

T

r

ansmission shaft

TT

rr

ansmission shaftansmission shaft

OperOper

aa

Oper

OperOper

To avoid accidents and personal injuries, note the

following recommended precautions and safe operation

practices.

1. Always STOP ENGINE before attaching the transmis-

2. When attaching the shaft, make sure that the snap

3. Always keep protection guards and chains intact and

4. Do not touch or stand on the transmission shaft when

tor saftor saf

a

tor saf

aa

tor saftor saf

sion shaft to tractor P.T.O. - most tractor P.T.O. shafts

can be rotated by hand to facilitate spline alignment,

when engine is stopped.

lock is FULLY ENGAGED - push and pull shaft until it

locks.

WARNING! ROTATING TRANSMISSION

SHAFTS WITHOUT PROTECTION GUARDS

ARE FATAL.

make sure that it covers all rotating parts, including

CV-joints at each end of the shaft. Do not use without

protection guard.

it is rotating - safety distance: 1.5 meter.

etyety

ety

etyety

T259-0004

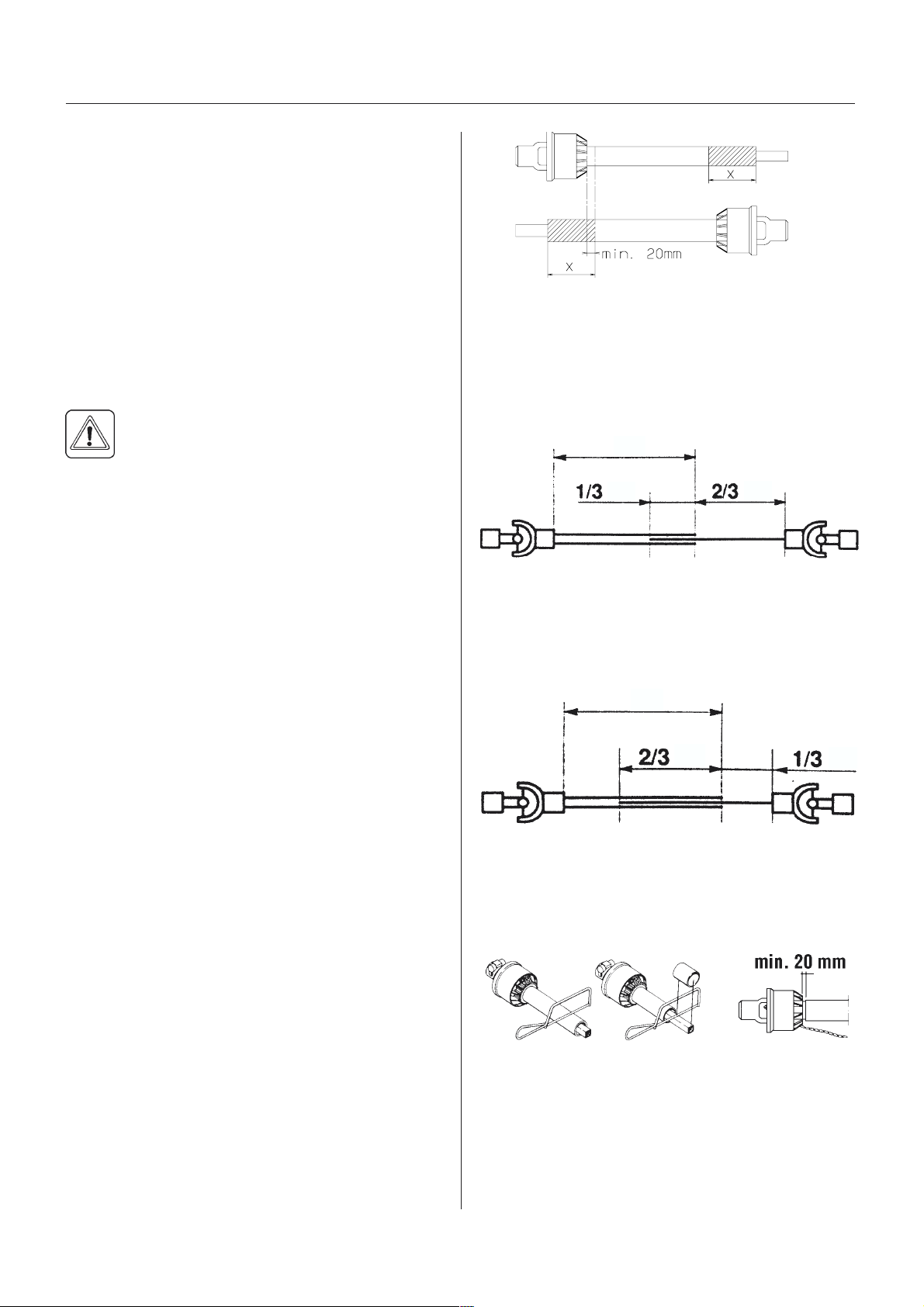

NOTE! The shaft must always have a minimum overlap.

The size of this overlap depends on the pump model:

Pump with 6 splines/540 r.p.m.

The shaft must always have an overlap of minimum 1/3

of the length.

T259-0011

5. Prevent protection guards from rotating by attaching

the chains allowing sufficient slack for turns.

6. Make sure that protection guards around tractor

P.T.O. and implement shaft are intact.

7. Always STOP ENGINE and remove the ignition key

before carrying out maintenance or repairs to the

transmission shaft or implement.

InstallaInstalla

Installa

InstallaInstalla

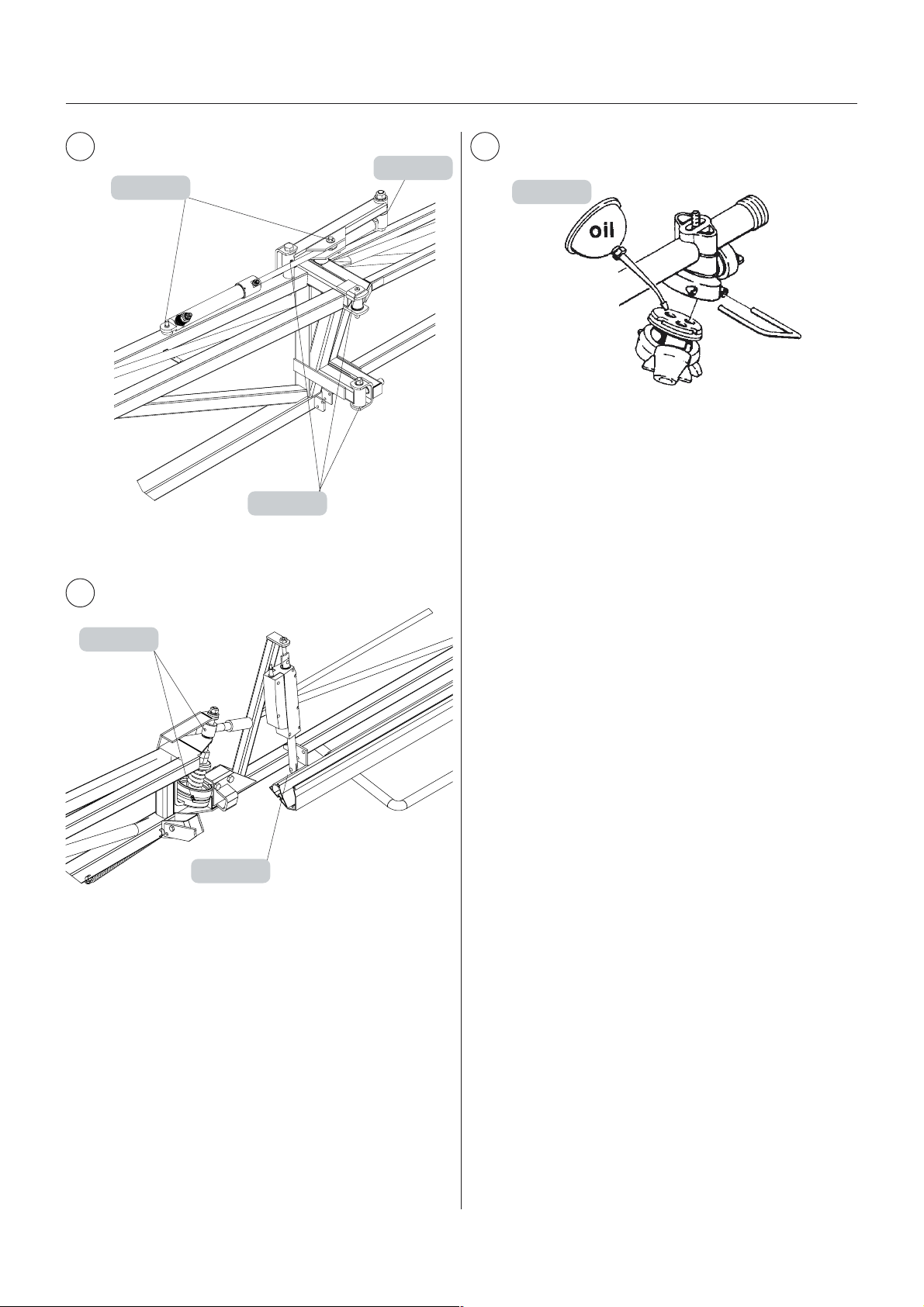

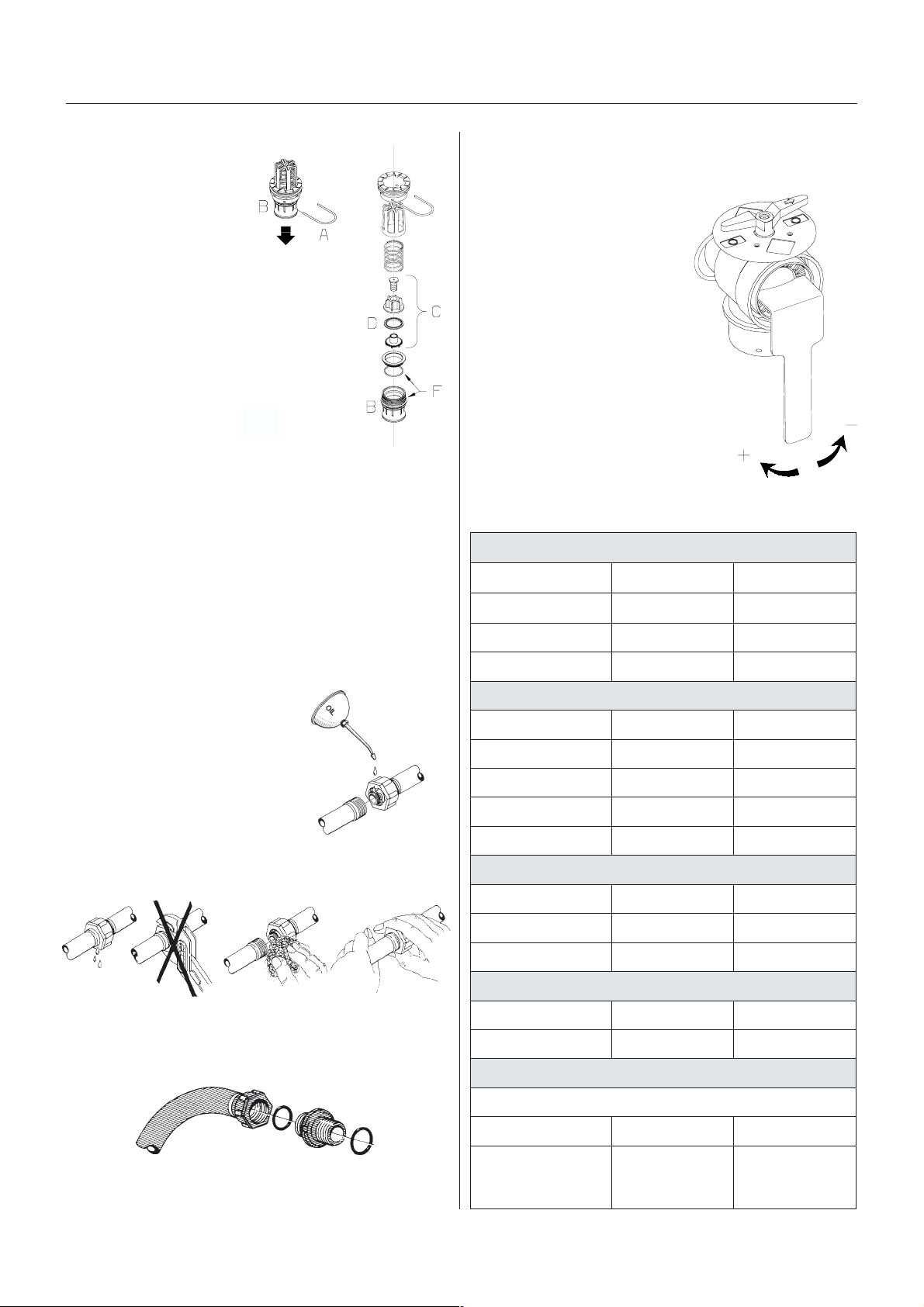

First installation of the transmission shaft is done in the

following way:

1. Attach sprayer to tractor and set sprayer height in the

2. Stop engine and remove ignition key.

3. If transmission shaft must be shortened, the shaft is

Fit the two shaft parts at tractor and sprayer pump

tion oftion of

tion of

tion oftion of

position with shortest distance between the tractor

and sprayer pump P.T.O. shafts.

pulled apart.

and measure how much it is necessary to shorten the

shaft.

tr tr

ansmission shaftansmission shaft

tr

ansmission shaft

tr tr

ansmission shaftansmission shaft

Pump with 21 splines/1000 r.p.m.

The shaft must always have an overlap of minimum 2/3

of the length.

T259-0011

4. The two parts are shortened equally. Use a saw, and

file the profiles afterwards to remove burrs.

T259-0005

5. Grease the tractor P.T.O. and pump shafts.

T259-0007

Mark the protection guards.

6. Fit the shaft to tractor P.T.O. and sprayer pump shaft.

NOTE: Female part marked with a tractor towards

tractor!

GB 05 03 01

11

Page 12

Sprayer setup

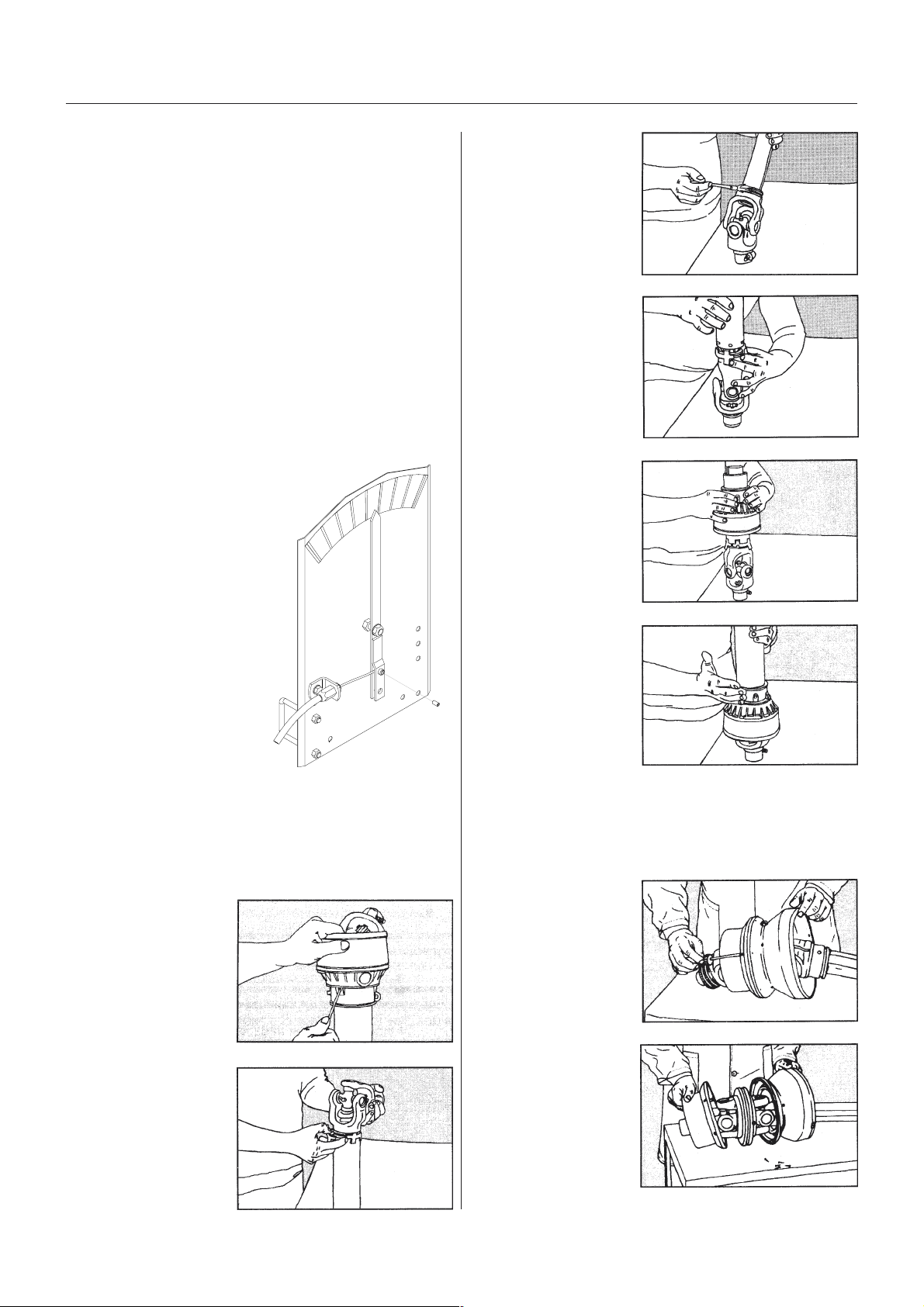

8. Twist the collar and slide the yoke onto the P.T.O.

shaft.

Make sure that the lock engages by pushing and

pulling the shaft forwards and backwards.

T259-0003

9. Fit the chains to prevent the protection guards from

rotating with the shaft.

T259-0008

NOTE!To ensure long life of the transmission shaft try to

avoid working- angles greater than 35°. The wide angle

shaft with Constant Velocity Joint works in angles up to

70°- 80° for short periods (during turning etc.).

T259-0002

12

GB 05 03 01

Page 13

Sprayer setup

TT

rr

acac

k gk g

augaug

T

r

ac

k g

TT

rr

acac

k gk g

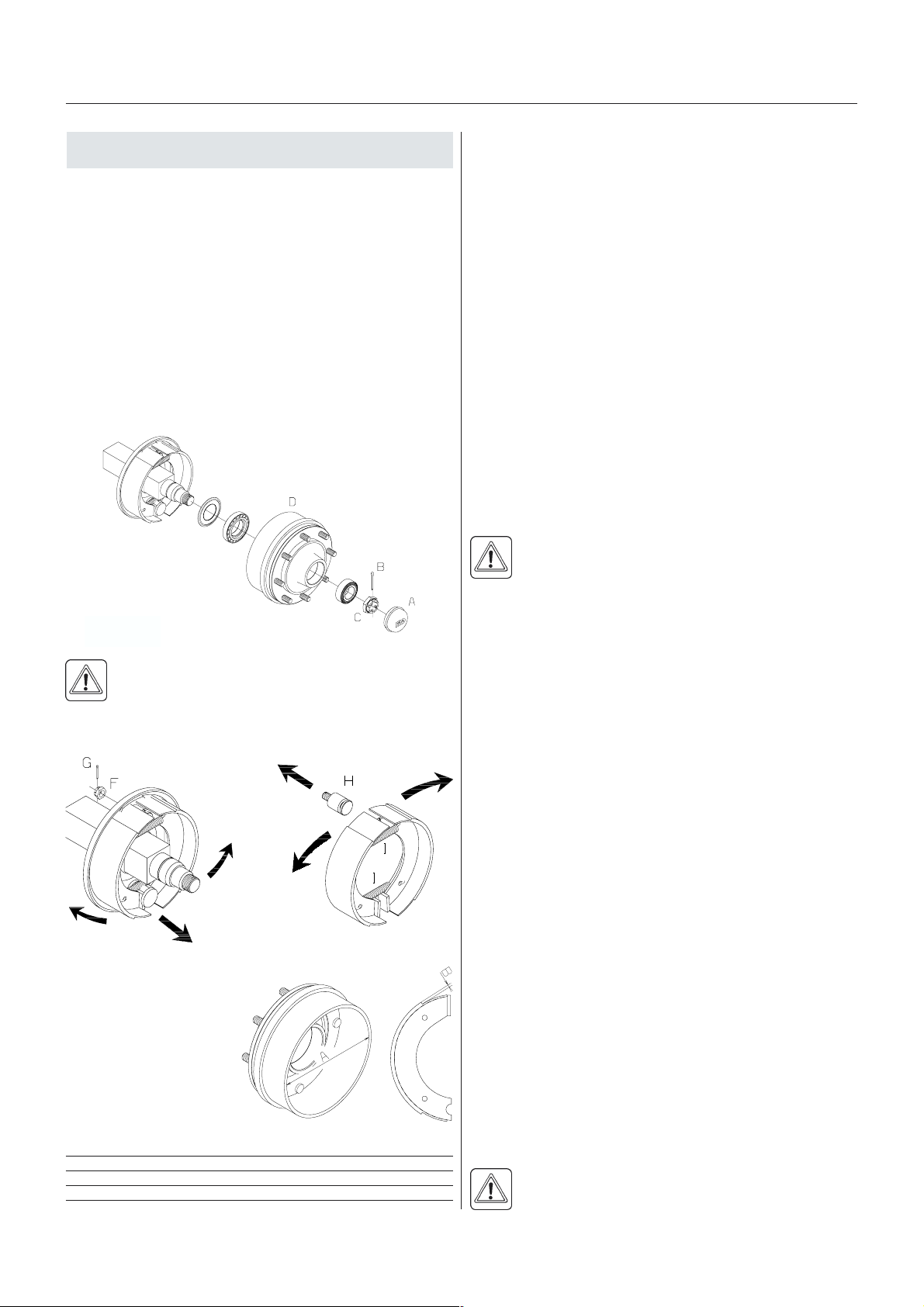

Altering the trAltering the tr

Altering the tr

Altering the trAltering the tr

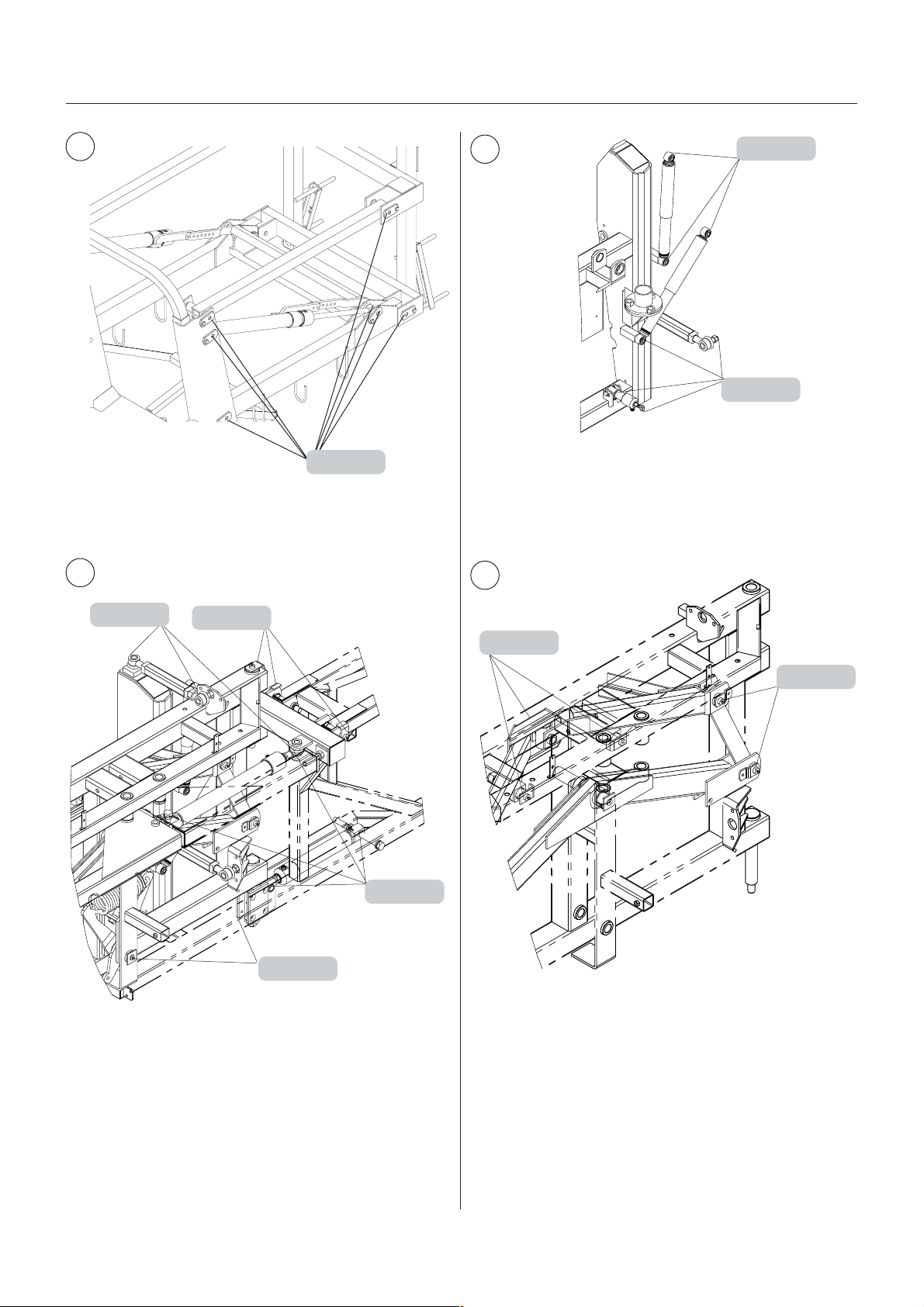

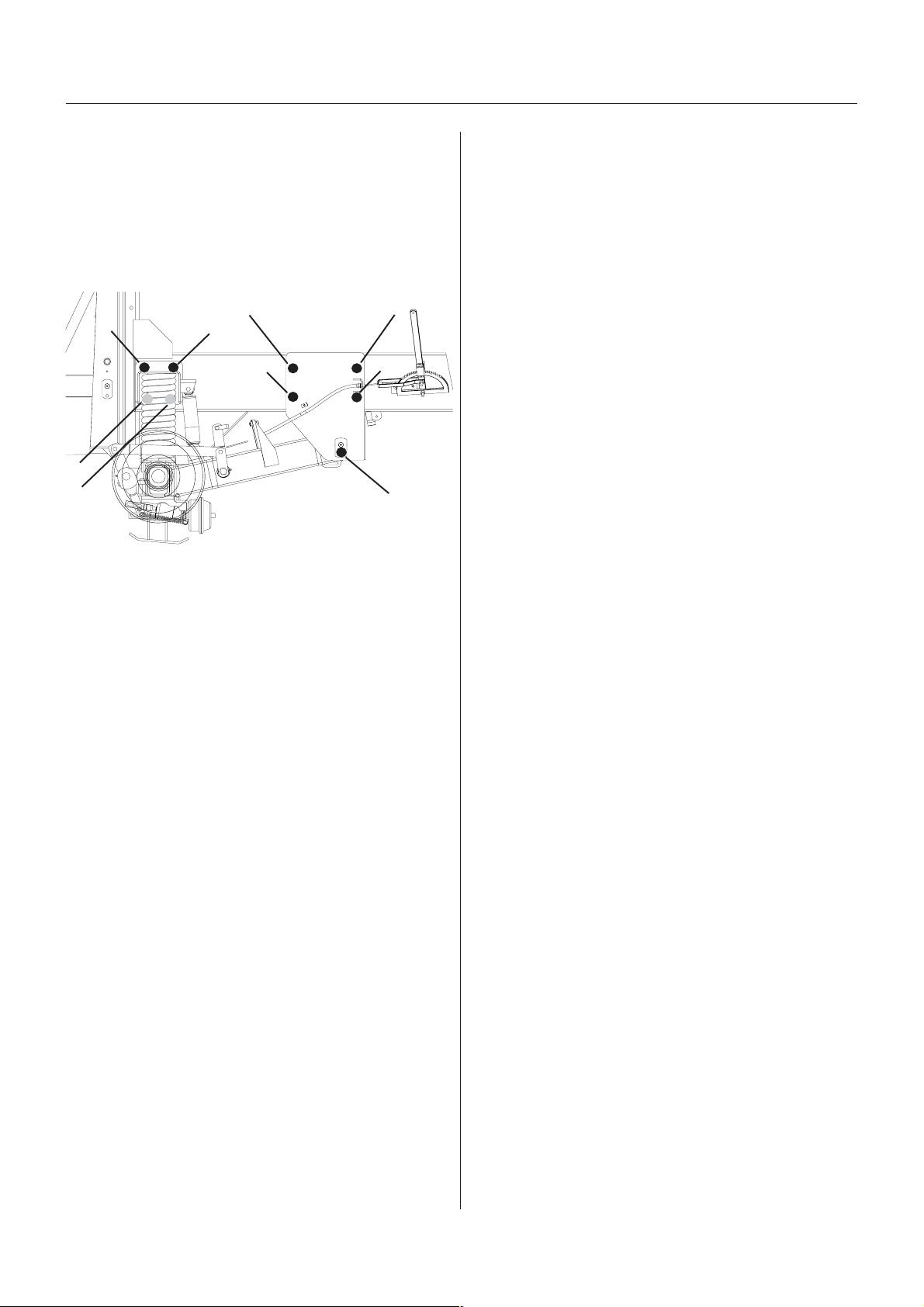

The track gauge of the COMMANDER can be altered

stepless as follows,

1. Measure the current track gauge (centre RH tyre to

centre LH tyre). Each side must be extended or

retracted half the desired alteration.

2. Attach the sprayer to tractor and engage tractor

parking brake.

3. Place stop wedges in front

of and behind RH wheel.

Jack up LH wheel, support

and secure sprayer body.

4. Loosen clamp bolts

for LH wheel axle.

5. Loosen the nut B on the brake operating arm.

Extend/retract this arm according to the adjustment of

the axle.

aug

augaug

ee

e

ee

acac

ac

acac

k gk g

k g

k gk g

augaug

aug

augaug

ee

e

ee

T251-0005

6. Extend or retract the axle.

A sack barrow and a

rod will facilitate the

operation.

T251-0006

7. If the rim position must be changed, do this first and

fine adjust by extending or retracting the axles.

Remember to tighten the wheel nuts to the specified

torque:

Rim plate to rim: 280 + 30 Nm (207 + 22 lbft)

Rim plate to hub: 490 Nm (288 lbft)

8. Tighten the clamp bolts to a torque of:

280 Nm (207 lb.ft) for 2200/2800

390 Nm (289 lbft) for 3200/4200.

COMMANDER

without suspension

B

9. Tighten nut B again.

IMPORTANT! Place the jack under the axle and lift the

wheel to remove load from the clamps before tightening

the clamp bolts to the specified torque.

10. Repeat the procedure on RH wheel.

11. Check the distance from centre tyre to centre of tank

frame is equal at RH and LH.

12. Retighten clamp bolts and wheel bolts to specified

torque after 8 hours of work.

T112-0005x

COMMANDER

with suspension

T112-0005x

B

GB 05 04 04

13

Page 14

Sprayer setup

Adjustment rAdjustment r

Adjustment r

Adjustment rAdjustment r

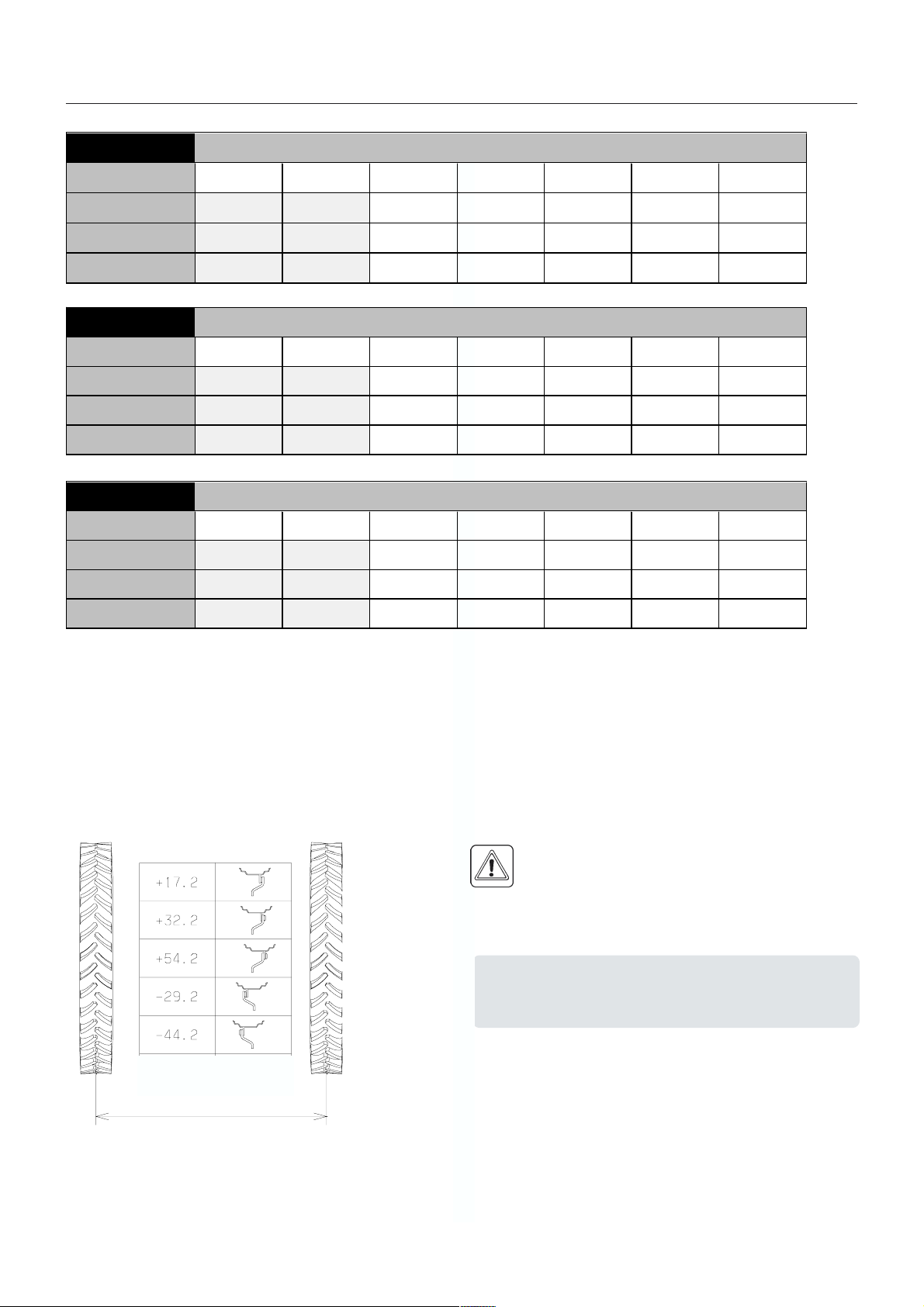

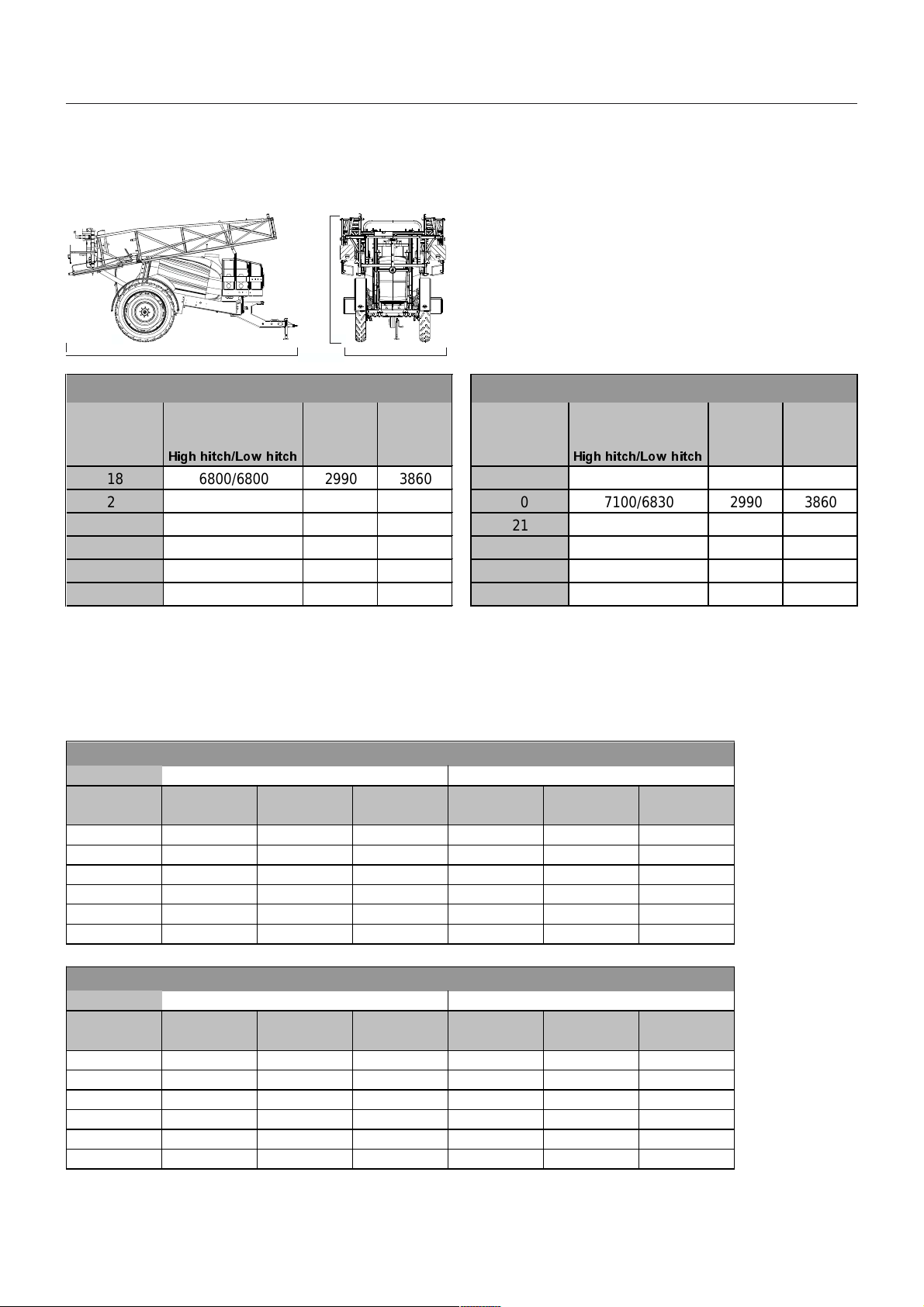

The maximum track width for all models is 2250 mm.

The minimum track width depends on the parameters in the charts beneath and whether the sprayer is equipped

with suspended axle or not. Please refer to the following charts (all figures are in mm).

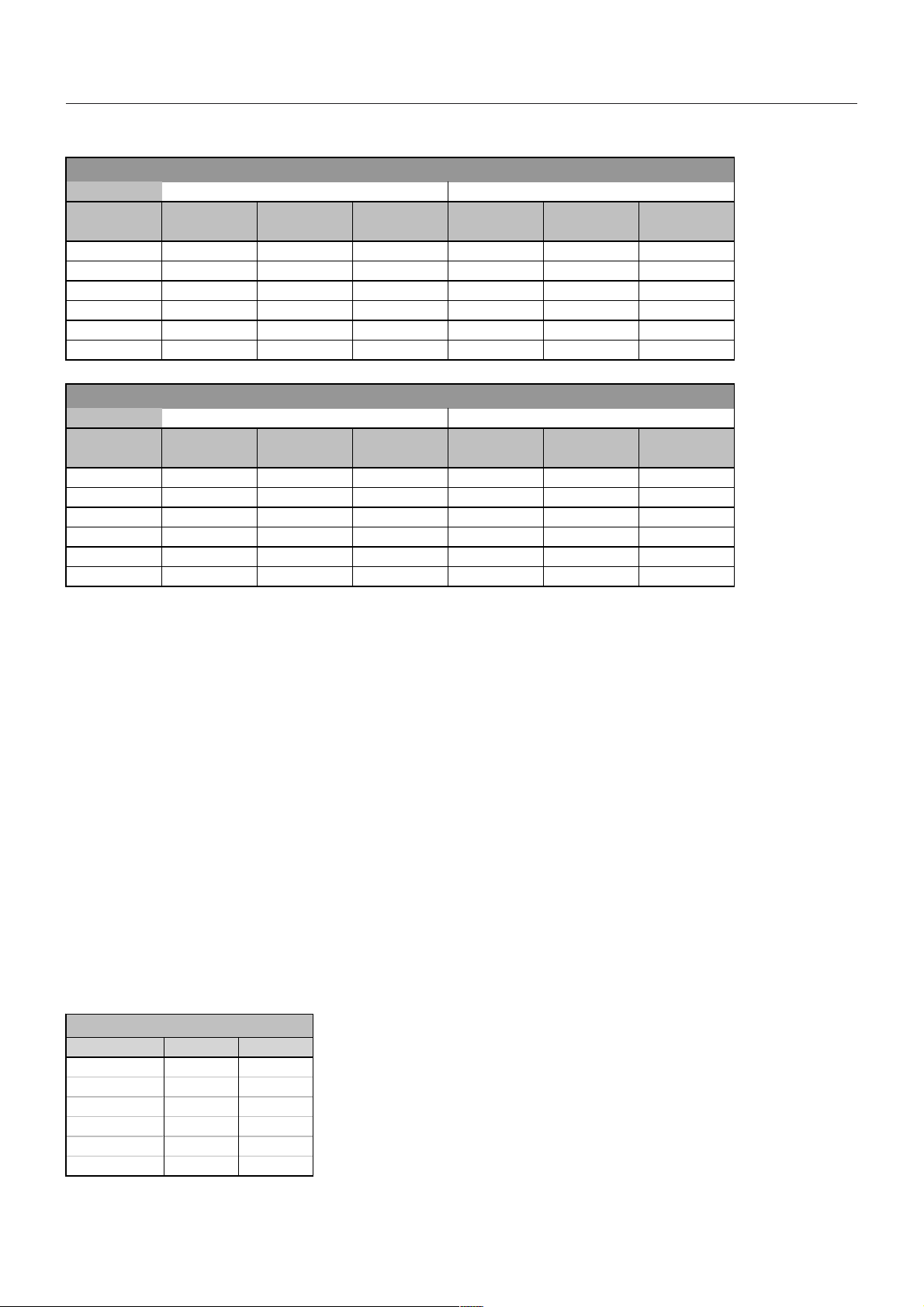

Min. track width - Sprayers without suspension

&0SOXV

Spra y e r wi th:

)ODQJHKXE

%UDNH KXE

0XGJXDUGV

&0SOXV

Spra yer with:

)ODQJHKXE

%UDNH KXE

angang

es - tres - tr

ang

es - tr

angang

es - tres - tr

[ [ [ [ [ [ [

[ [ [ [ [ [ [

acac

k widthk width

ac

k width

acac

k widthk width

7\UHVL]H

7\UHVL]H

0XGJXDUGV

&0SOXV

Spra yer wit h :

)ODQJHKXE

%UDNH KXE

0XGJXDUGV

[ [ [ [ [ [ [

&0SOXV

Spra y e r wi th:

)ODQJHKXE

%UDNH KXE

0XGJXDUGV

Min. track width - Sprayers with suspension

[ [ [ [ [ [ [

7\UHVL]H

7\UHVL]H

&0SOXV

Spra yer with:

)ODQJHKXE

%UDNH KXE

0XGJXDUGV

14

7\UHVL]H

[ [ [ [ [ [ [

GB 05 04 04

Page 15

Sprayer setup

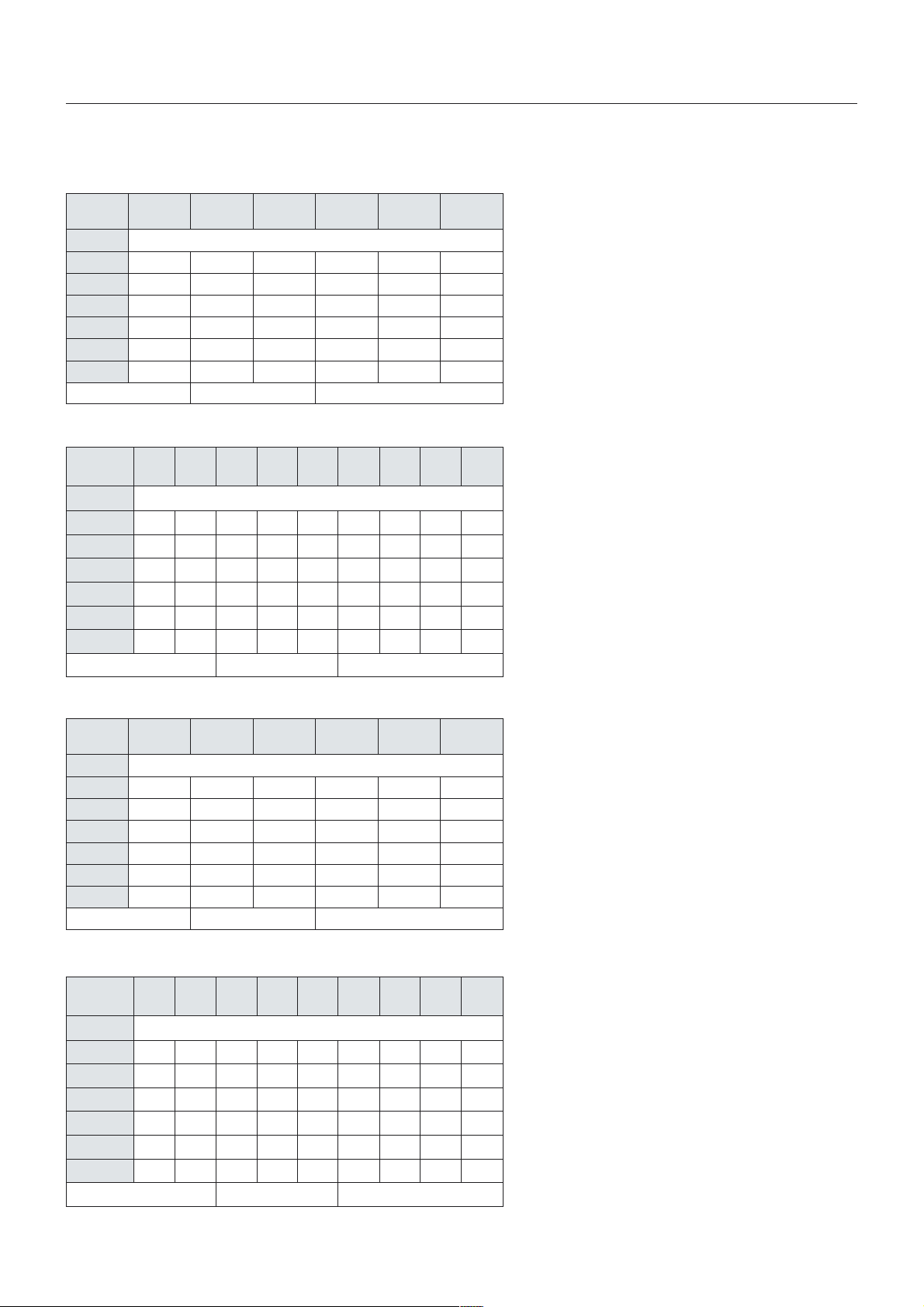

&0SOXV

Spra y e r wi th:

)ODQJHKXE

%UDNH KXE

0XGJXDUGV

&0SOXV

Sp rayer wit h :

)ODQJHKXE

%UDNH KXE

0XGJXDUGV

&0SOXV

Sp ray e r wi t h:

)ODQJH KXE

%UDNH KXE

7\UHVL]H

[ [ [ [ [ [ [

7\UHVL]H

[ [ [ [ [ [ [

7\UHVL]H

[ [ [ [ [ [ [

0XGJXDUGV

It is not permitted to fit dual wheels!

IMPORTANT! On TRACKER models a minimum track gauge of 1800 mm is strongly recommended to ensure

stability and to avoid the sprayer tipping over.

NOTE! The wider the track gauge, the better the stability of the sprayer and boom.

PP

ermitted rim positionsermitted rim positions

P

ermitted rim positions

PP

ermitted rim positionsermitted rim positions

WARNING! When altering track gauge by turning

rims and rim plates the maximum permitted

offset between centre wheel and hub flange must

be observed:

Max offset, hub flange and centre rim:

CM Min. rim offset Max. rim offset

2200/2800 -45 +55

3200/4200 -33 +33

T251-0003

T251-0004

IMPORTANT! Tyre sizes 18.4 x 38 and 20.8 x 38

are not permitted in any + position, only use the

- positions.

GB 05 04 04

15

Page 16

Sprayer setup

HyHy

drdr

Hy

HyHy

HyHy

Hy

HyHy

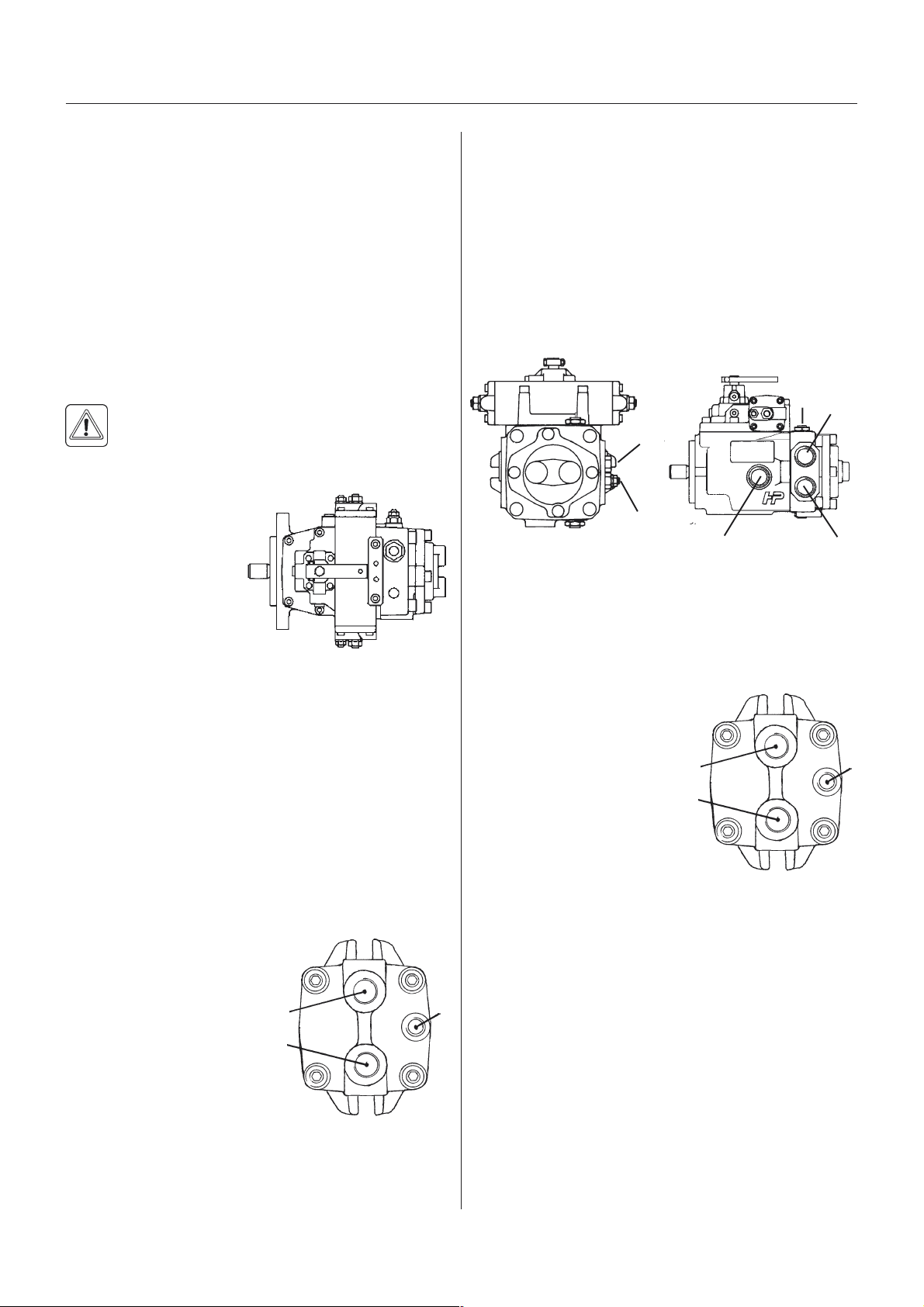

Tractor Operated Hydraulics

Connection requirements for COMMANDER-HAY are

one double acting and one single acting spool valve.

Single acting valve: Boom lift, up/down

Double acting valve: Boom folding and unfolding

Ensure the snap couplers are clean before connection!

aulic syaulic sy

dr

aulic sy

drdr

aulic syaulic sy

drdr

aulics COMMANDER-HAaulics COMMANDER-HA

dr

aulics COMMANDER-HA

drdr

aulics COMMANDER-HAaulics COMMANDER-HA

stemsstems

stems

stemsstems

YY

Y

YY

Flow regulator

If hydraulic slanting control is fitted another double acting

spool valve on the tractor is required.

NOTE! The hydraulic system requires a minimum oil

pressure of 130 bar, max. oil pressure of 210 bar and an

oil capacity of approx. 5 litres. After having operated the

boom and the system has been filled with oil, check

tractors hydraulic oil level and top up if necessary.

HyHy

drdr

aulics COMMANDER-HAZaulics COMMANDER-HAZ

Hy

dr

aulics COMMANDER-HAZ

HyHy

drdr

aulics COMMANDER-HAZaulics COMMANDER-HAZ

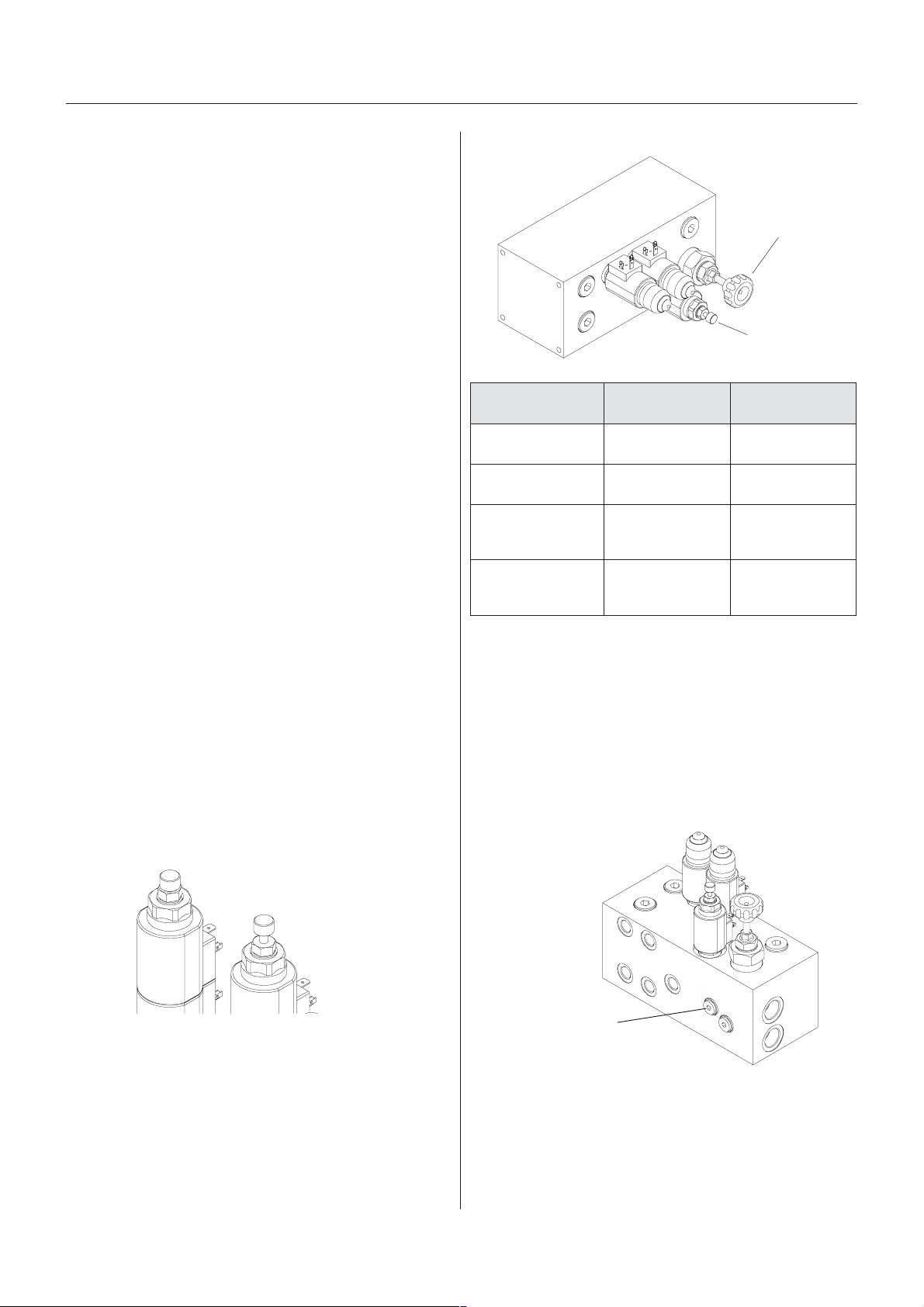

Direct Acting Hydraulic system

The D.A.H. system requires a double acting hydraulic

outlet. The hydraulic hoses are marked with arrows to

indicate direction of oil flow.

The D.A.H. system requires an oil flow between 10 and

90 l/min (19.8 Imp. gal/min.) and a min. pressure of 130

bar (1886 p.s.i.) The system has a built-in flow regulator

that maintains constant speed on hydraulic movements.

The hydraulic distribution block is situated underneath

the platform floor.

The valves on the block are operated by means of

manual override and each valve can be regulated to be

open or closed.

T112-0004x

metsys

dradnatS

.1 tuohtiW lanretxe

.2 htiW lanretxe

Load Sensing

Please consult your tractor dealer for correct setup and

correct connection.

Certain tractor models are able to use Load Sensing

without connecting an external sensing line (setting 1 in

scheme). But if optimal sensing control pressure cannot

be obtained, an external sensing line needs to be

mounted (setting 2 in scheme).

ciluardyh/rotcarT

)rotcartwolftnatsnoc(

ertnecdesolC

)srotcartDJniatrec(

gnisnesdaoL

enilgnisnes

gnisnesdaoL

enilgnisnes

nepOnepO

desolCdesolC

nepOnepO

desolCnepO

Cartridge valve

evlavegdirtraC rotalugerwolF

029

Valve closed

Valve open

T112-0004x

Before operating the hydraulics, the valves on the

sprayers hydraulic distribution block should be adjusted

according to the specific tractor model (please refer to

scheme later in this part).

If you have doubt about which type of hydraulic system

your tractor is equipped with, please ask your tractor

dealer.

16

Connect hose to

LS on the

distribution block

Requirements - Load Sensing hose:

1/4 Standard hose

Max. rated working pressure = 200 bar.

IMPORTANT! It is of essential importance that connectors on sensing line are kept totally clean. Failure to do

so will cause impurities entering the pump and thereby

cause damages to vital pump parts.

GB 05 06 06

LS

T112-0007x

Page 17

Sprayer setup

ContrContr

Contr

ContrContr

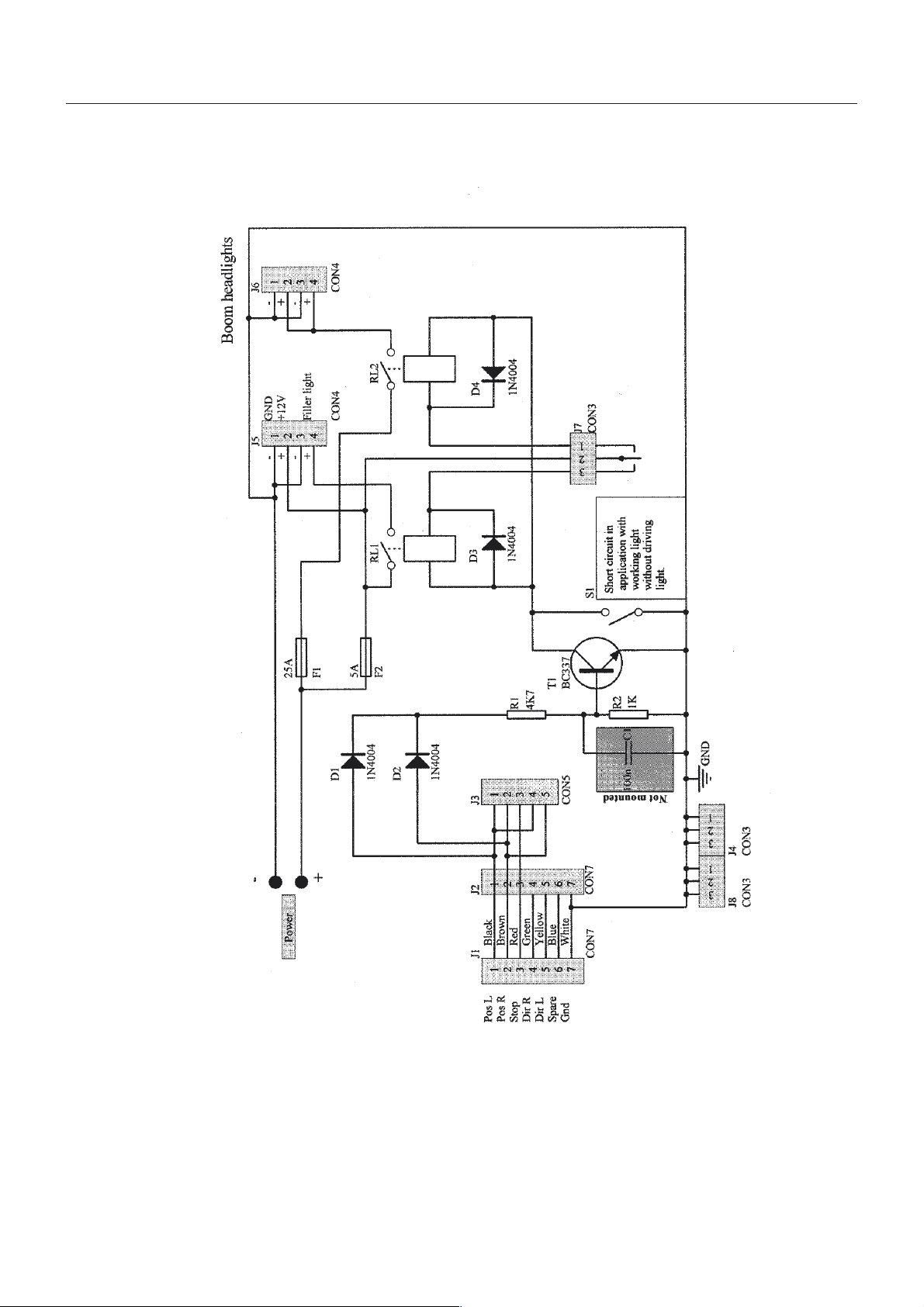

Power requirement is 12V DC.

Note Polarity!

For EVC: Brown pos. (+), Blue neg. (-).

For D.A.H.: White pos. (+), Black neg. (-).

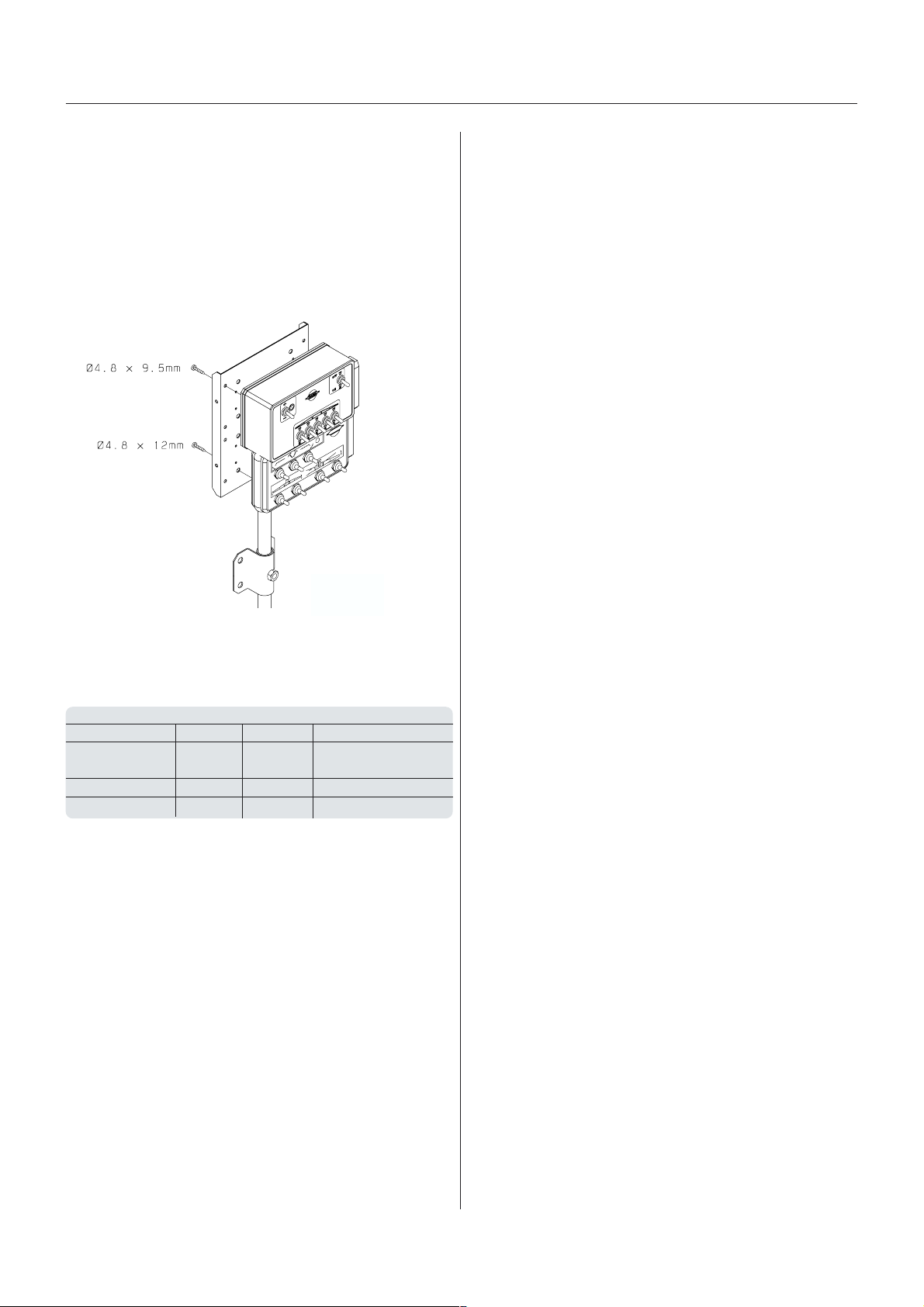

The control boxes for EVC-operating unit and D.A.H. are

fitted in the tractor cabin at a convenient place. Tapping

screws can be used for mounting.

ol bool bo

ol bo

ol bool bo

xx

es and powes and pow

x

es and pow

xx

es and powes and pow

er supplyer supply

er supply

er supplyer supply

T165-0013

The wires must have a cross sectional area of at least

4.0 mm to ensure sufficient power supply. For the EVCoperating unit the tractor circuit should have an 8 Amp

fuse and for the D.A.H. an 16 Amp fuse.

Control box for Polarity (wire colour) Required Fuse, Amp

Positive + Negative EVC operating

unit Brown Blue 8

D.A.H. Hydraulic White Black 16

MANIFOLD valve Brown Blue 8

Use the HARDI Electric distribution box (No. 817925) if

the tractor has a doubtful power supply.

GB 05 06 06

17

Page 18

Sprayer setup

BrBr

akak

Br

BrBr

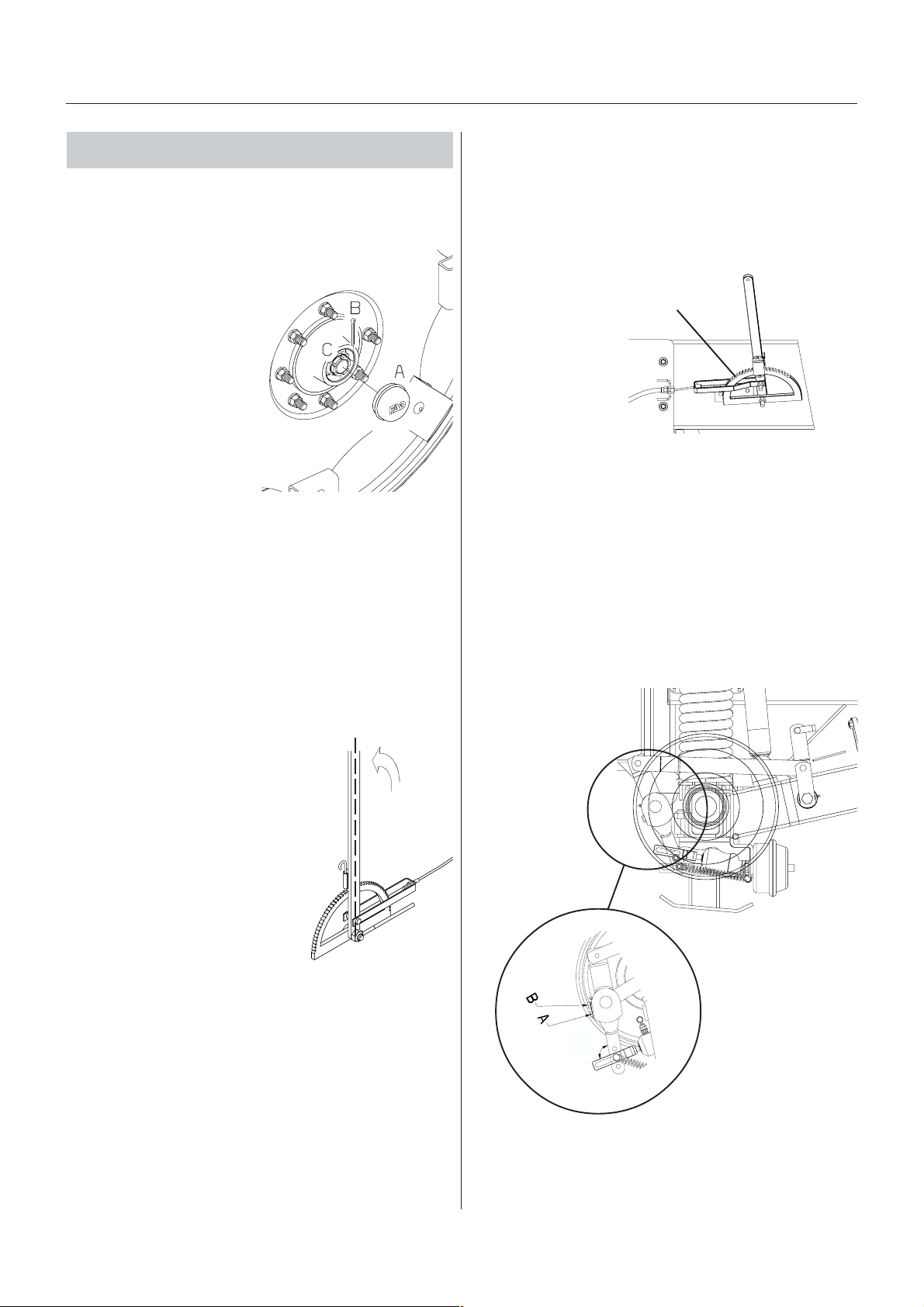

EmerEmer

Emer

EmerEmer

The parking brake lever has two function modes, which

are determined by the small pawl control clip (A).

To change between the

two modes, turn the clip.

Pos. 1: The pawl control

clip must point away from

the pawl.

Pos. 2: The pawl control

clip must rest against the

pawl.

To disengage the parking

brake:

1. Set pawl control clip in pos. 1.

2. Pull the lever a little forward to release the pawl from

To engage the parking brake:

1. Set pawl control clip in pos. 2.

2. Pull the lever firmly forwards until parking brake is fully

eses

ak

es

akak

eses

gg

encenc

y and pary and par

g

enc

y and par

gg

encenc

y and pary and par

the ratchet and then push the lever fully backwards.

engaged.

kk

ing bring br

k

ing br

kk

ing bring br

akak

e (ife (if

ak

e (if

akak

e (ife (if

A

Forward

f f

itted)itted)

f

itted)

f f

itted)itted)

B

12

Backward

T021-0001

Tractor Trailer

Oil

reservoir

Hydraulic pump

WARNING! Do not connect the brakes directly to

the tractor hydraulics without the brake valve. The

trailer brake power cannot be controlled, and

braking will therefore be hazardous.

IMPORTANT! Max. oil pressure is 150 bar (2175 p.s.i.)

in the brake line.

Relieve parking brake before driving.

Air activAir activ

Air activ

Air activAir activ

This system requires a tractor with

compressor and air brake system with

out-let(s) for trailer brakes.

aa

ted brted br

a

ted br

aa

ted brted br

akak

ak

akak

es (ifes (if

es (if

es (ifes (if

f f

itted)itted)

f

itted)

f f

itted)itted)

T021-0008

Emergency brake

1. Set pawl clip in pos. 2.

2. Attach the rope from the hole in top of the handbrake

lever (B) to e.g. the tractor top link attaching point. If

the sprayer is accidentally unhooked during transport

the rope will apply the parking brake before the rope

breaks.

IMPORTANT! To ensure safe engagement and to avoid

damages to the parking brake use rope with an ultimate

stress between 690 N (155 lb.) and 785 N (176 lb.).

HyHy

drdr

aulic activaulic activ

Hy

dr

aulic activ

HyHy

drdr

aulic activaulic activ

This requires a special trailer brake valve attached to the

tractor hydraulic and brake system. Connect the snap

coupler to the tractor brake outlet. When the tractor

brakes are applied, the trailer brakes will work proportionally to the tractor brakes, and ensure safe and

effective braking.

aa

ted brted br

a

ted br

aa

ted brted br

akak

ak

akak

es (ifes (if

es (if

es (ifes (if

f f

itted)itted)

f

itted)

f f

itted)itted)

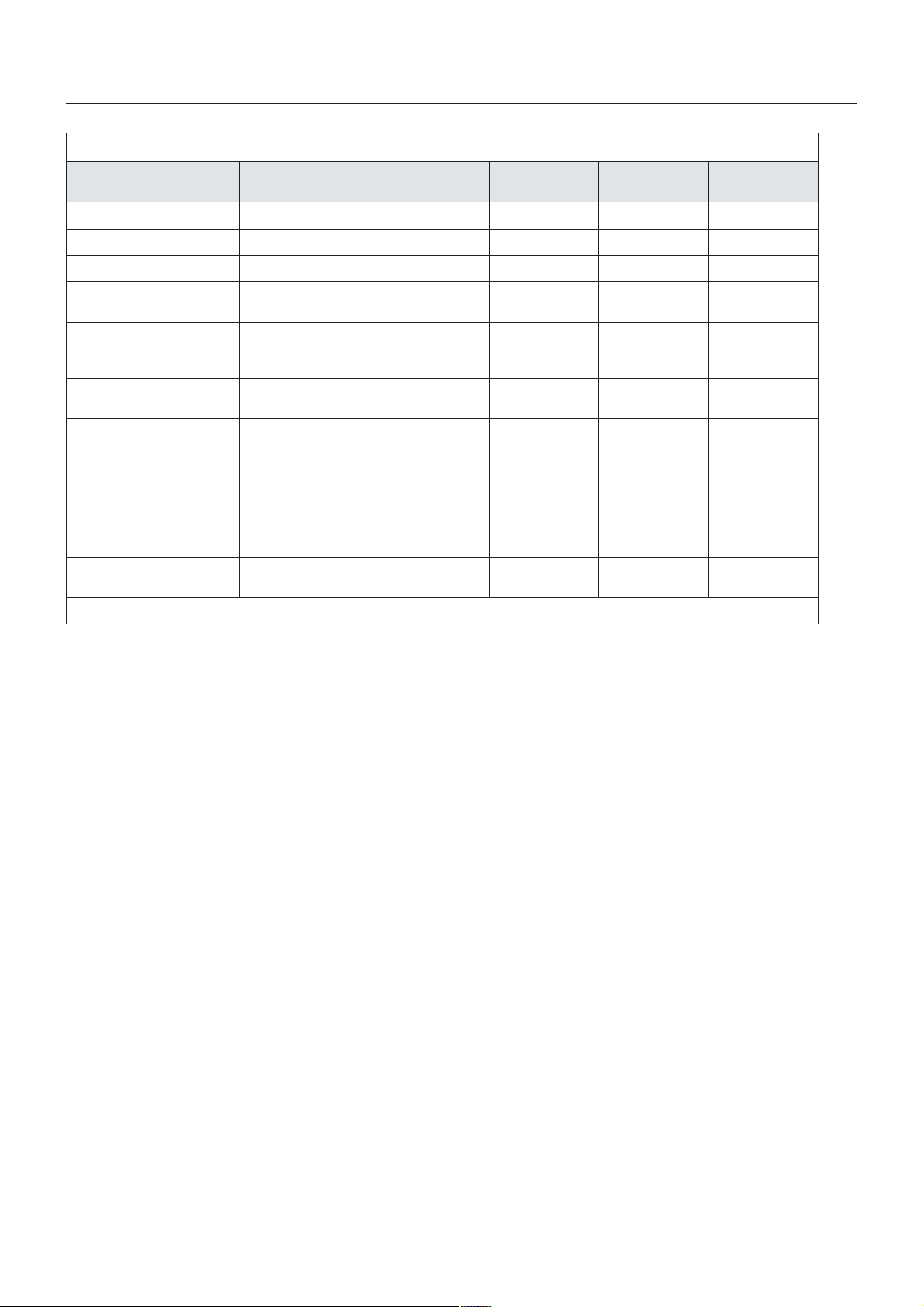

IMPORTANT! The load apportioning

valve must be set at the position

corresponding to the load on the

trailer, for obtaining optimal air pressure to the trailer brakes.

= Relieved = Half full tank

= Empty tank = Full tank

WARNING! Driving with wrong load apportioning

valve setting, will make the brakes under- or overapply, which can cause hazardous situations.

NOTE! If the air hose(s) are disconnected with air in the

brake air tank, control pressure

will be dumped and the brakes

will engage fully. If the sprayer

must be moved with air in the

tank and without the air hose(s)

connected to the tractor, the load

apportioning valve must be set

at relieved to disengage the

brakes. Remember to reset the

handle to brake position again

afterwards. When parking the

sprayer, always engage the parking brake, as the air

brakes will only be engaged as long as there is air in the

tank! Cover the couplings with the dust flaps when

hoses are disconnected.

T021-0009

Load valve

Position

setting

T021-0010

18

GB 05 05 02

Page 19

Sprayer setup

SingSing

le-line brle-line br

Sing

le-line br

SingSing

le-line brle-line br

Flip the snap coupler protection flap away and connect

the brake system snap coupler to the tractor outlet

(black) and let the compressor fill the sprayers air

reservoir.

Check brake circuit for leaks.

akak

ak

akak

es (ifes (if

es (if

es (ifes (if

f f

itted)itted)

f

itted)

f f

itted)itted)

Dual-line brDual-line br

Dual-line br

Dual-line brDual-line br

Flip the snap coupler protection flaps away and connect

the two snap couplers for supply and control to the

tractor outlets, and check brake circuits for leaks.

The couplers are colour coded and secured against

incorrect attachment:

Red = Supply line (RH)

Yellow= Control line (LH)

Relieve parking brake before driving

akak

ak

akak

es (ifes (if

es (if

es (ifes (if

f f

itted)itted)

f

itted)

f f

itted)itted)

GB 05 05 02

19

Page 20

Sprayer setup

Counter wCounter w

Counter w

Counter wCounter w

eight eight

eight

eight eight

(TRA(TRA

CKER models only)CKER models only)

(TRA

CKER models only)

(TRA(TRA

CKER models only)CKER models only)

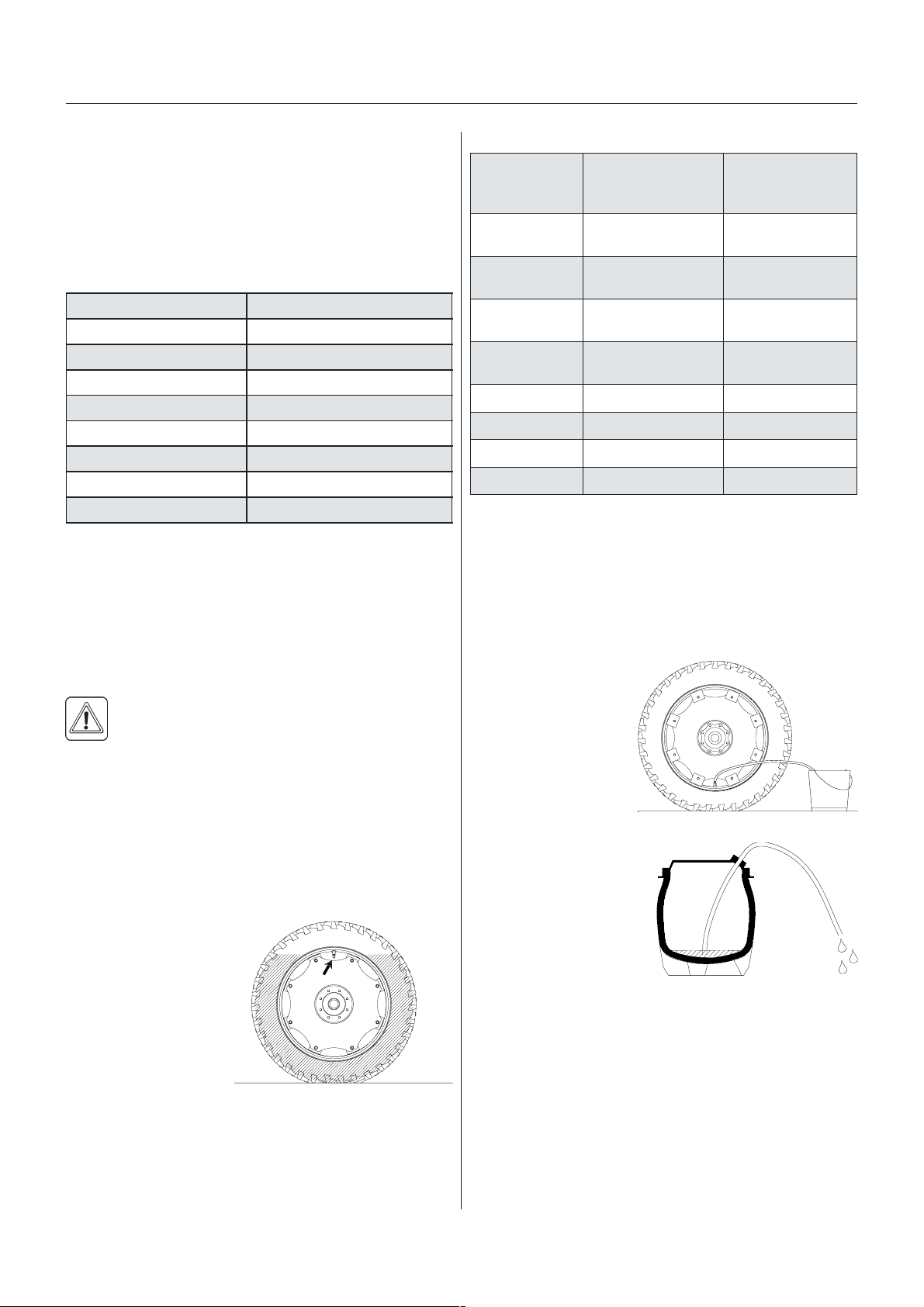

To improve stability on TRACKER models, extra weight

can be added by means of liquid-filled tyres.

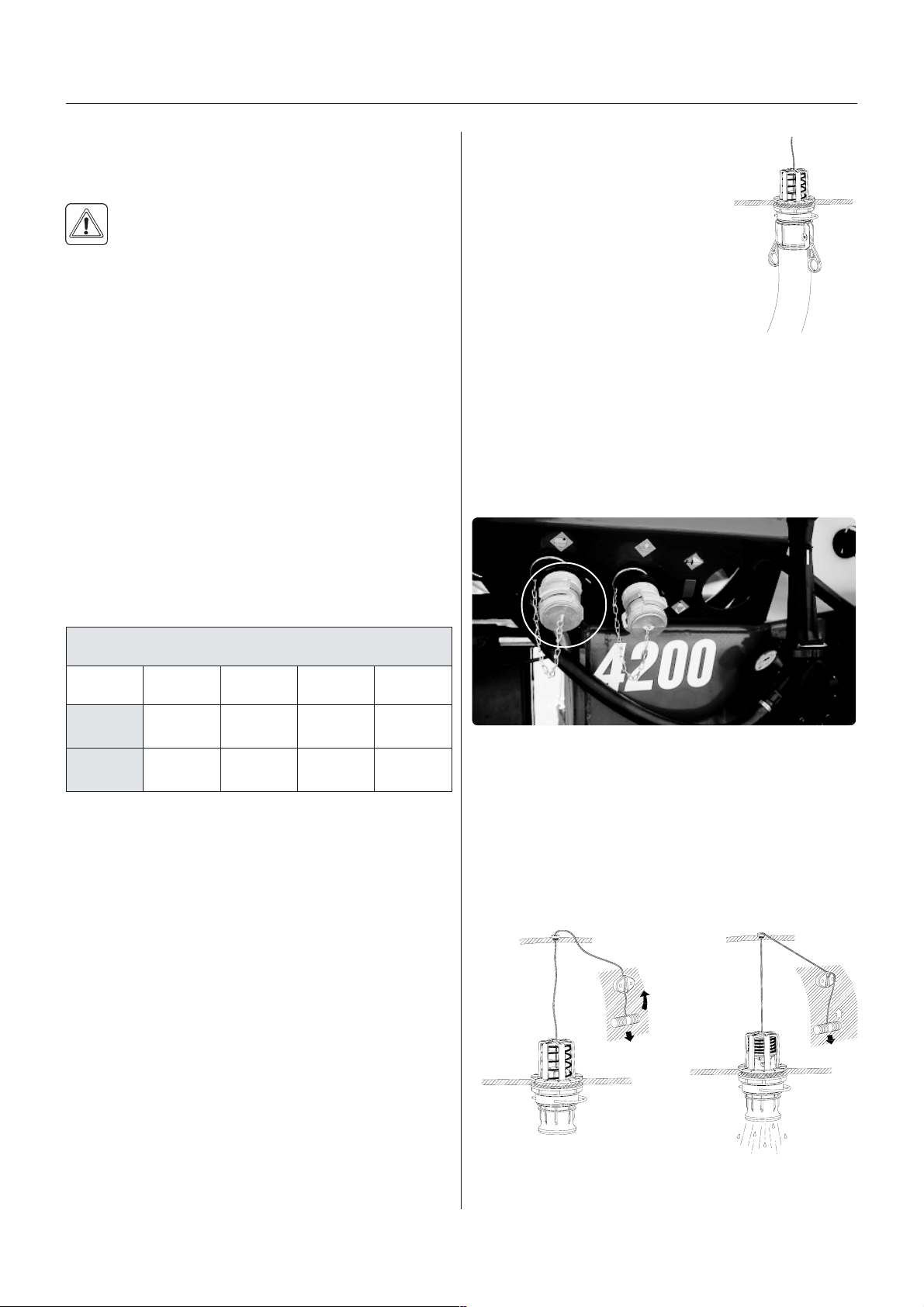

The standard tyre valve is an universal air-water valve.

The tyres can be filled with liquid to max. 75% of their

total volume. The table below indicates the 75% volume.

eziseryT erytrepdiuqilfosertil.xaM

"44x5.9101

"84x5.9 801

"44x2.11331

"84x2.11 441

"64x4.21871

"83x9.61 582

"83x4.81093

"83x8.02 664

1 litre = 0.264 US Gal. 1 litre = 0.22 Imp. Gal.

001

Use a mixture of water and CaCl2 to avoid frost damage

as described in table below:

Recommended tyre pressure:

eziseryT

59CR

44R59/032

)44x5.9(

84R59/032

)84x5.9(

44R59/072

)44x2.11(

84R59/072

)84x2.11(

64x4.21)25(6.3851/741

83x9.61 )32(6.1 251/141

83x4.81)32(6.1441/741

83x8.02 )81(2.1 151/451

dednemmoceR

nierusserpnoitalfni

).i.s.p(rab

)25(6.3541/431

)25(6.3 741/631

)25(6.3151/041

)25(6.3 351/241

muminiM

xednIdaoL

2A/8A

NOTE! When filling the tyres the valve should be positioned at 12 oclock and when adjusting the tyre pressure, the valve should be positioned at 6 oclock.

002

CaCl2 per litre water Protection to

200 g (7.1 oz) -15°C (30.6°F)

300 g (10.6 oz) -25°C (12.6°F)

435 g (15.4 oz) -35°C (-5.4°F)

WARNING! It is very important that the CaCl2 is

added to the water and agitated until it is fully

dissolved. Never pour water on to CaCl2! If you

get CaCl2 in the eyes, flush instantly with cold water for

at least 5 minutes and seek medical advice afterwards.

IMPORTANT! The tyres must be liquid filled to max. 75

% of total tyre volume. Fill only the qty. of liquid necessary to obtain sufficient stability of the sprayer. Do not fill

liquid and CaCl2 mixture in tyres without tubes!

To fill the tyres:

1. Jack up the wheel

and rotate wheel till

the valve is positioned at 12 oclock.

2. Remove the valve

body and fill liquid

until it reaches the

valve.

T021-0011

3. When surplus liquid

is drained through the

valve stem fit the valve body again.

4. Adjust tyre pressure and lower the wheel. (Please

refer to table for correct tyre pressure).

To empty the tyres:

1. Rotate wheel till the

valve is positioned at

6 oclock.

2. Remove the valve

body and let out the

liquid. Retain liquid in

an appropriate

container.

3. To empty the tyre

completely the tyre is

inflated and a thin drain

tube is lead to the

bottom of the tyre. The

air pressure will now

empty the remaining

liquid.

4. Remove the drain tube,

fit the valve and inflate

the tyre to specified

pressure. See the table Tyre pressure.

NOTE! Disposal of CaCl

has to take place according to

2

local legislation.

T021-0013

T021-0014

20

GB 05 10

Page 21

Sprayer setup

TT

rr

ansporanspor

T

r

anspor

TT

rr

ansporanspor

RR

oadwoadw

R

oadw

RR

oadwoadw

When driving on public roads and other areas where the

highway code applies, or areas where there are special

rules and regulations for marking and lights on implements, observe these and equip implements accordingly.

NOTE! Max. driving speed is 25 km/h for models without

brakes and 40 km/h for models equipped with brakes.

tt

t

tt

oror

thinessthiness

or

thiness

oror

thinessthiness

TT

rr

ansporanspor

T

r

anspor

TT

rr

ansporanspor

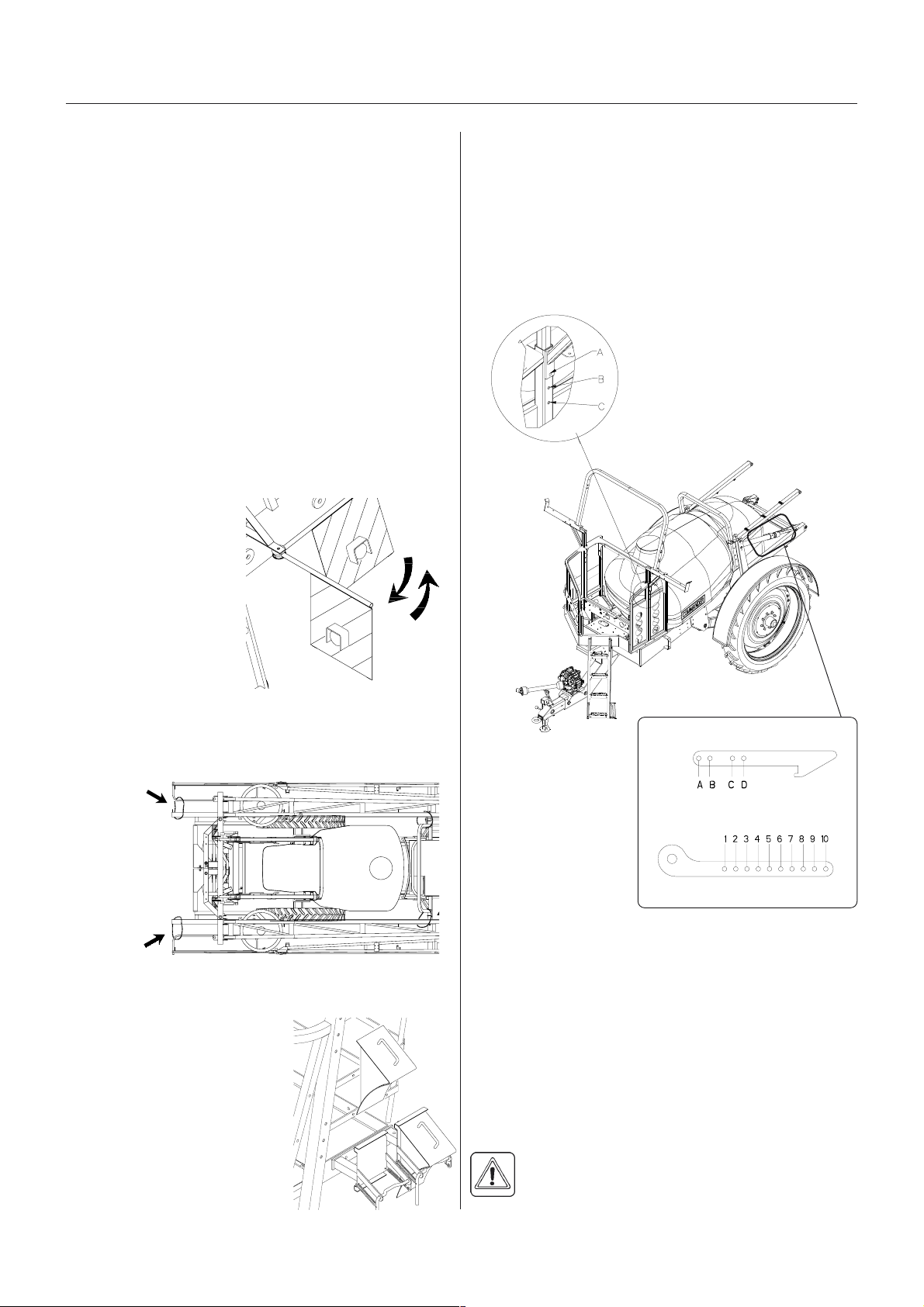

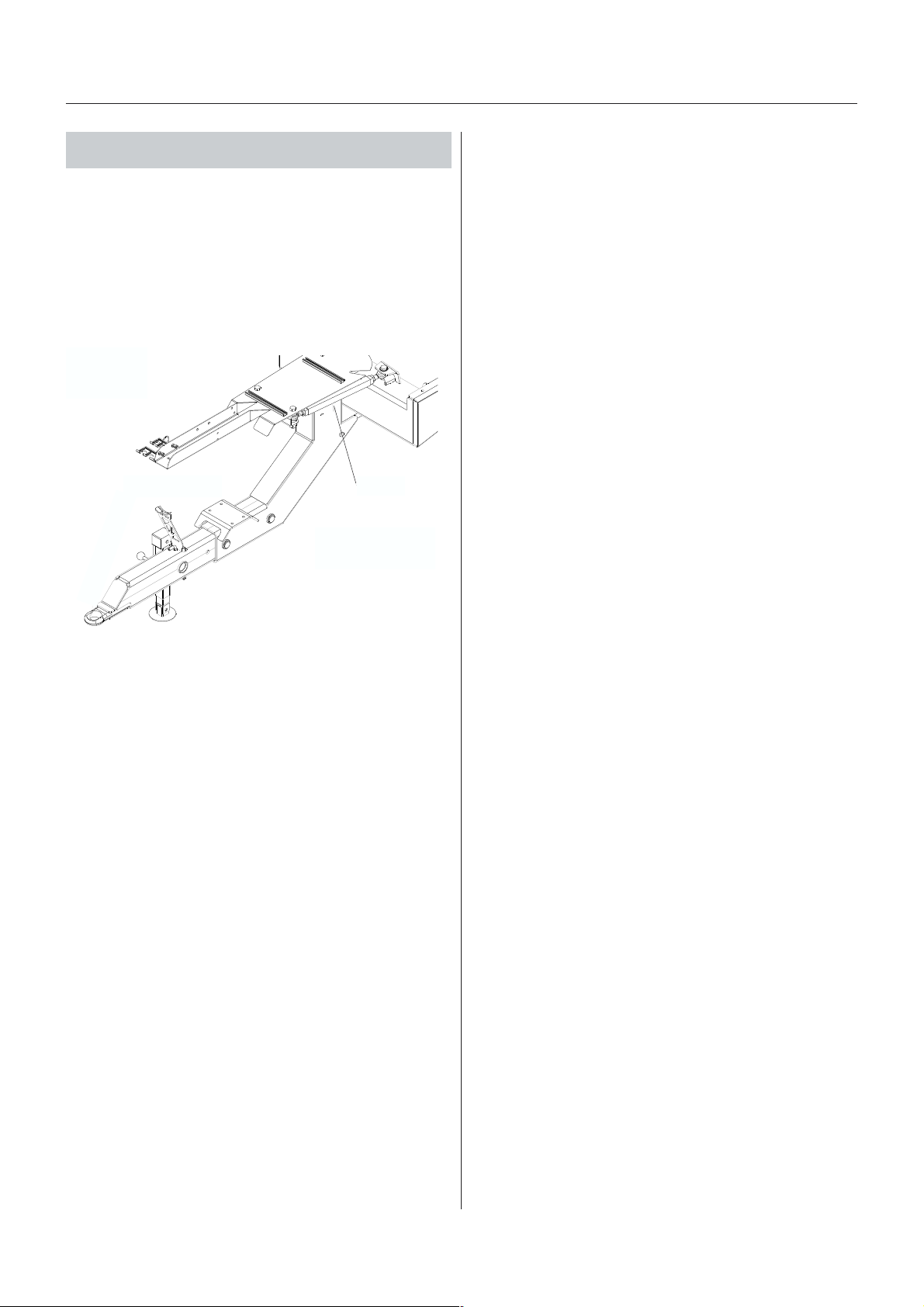

The transport brackets can be set in different positions.

Thereby it is possible to obtain different transport heights

and suitable clearance above various tractor cabins.

When changing the setting of the transport brackets it is

done as a combination of adjusting the transport brackets themselves (1) and adjusting the transport locks (2).

Always choose a transport height as low as possible.

t brt br

t br

t brt br

acac

ac

acac

kk

etsets

, height setting, height setting

k

ets

, height setting

kk

etsets

, height setting, height setting

RR

ear lights (ifear lights (if

R

ear lights (if

RR

ear lights (ifear lights (if

Connect plug for rear lights to the tractors 7-pin socket,

and check function of rear lights, stop lights and direction

indicators on both sides before driving.

The wiring is in accordance with ISO 1724. See section

on Technical specifications.

Before transport on

public roads the front

warning boards with

position lamps must be

folded out (fitted in

certain countries only).

Boom trBoom tr

Boom tr

Boom trBoom tr

Fit the safety chains as shown below before transport on

public road.

ansporanspor

anspor

ansporanspor

f f

itted)itted)

f

itted)

f f

itted)itted)

t saft saf

t saf

t saft saf

ety cety c

ety c

ety cety c

hain (ifhain (if

hain (if

hain (ifhain (if

f f

itted)itted)

f

itted)

f f

itted)itted)

T042-0003

(1)

T142-0026

1. Transport brackets

The transport bracket can be

set at three different positions

A, B or C.

Loosen the bolt to change

position and replace it according to new setting. The setting

must be identical on both

sides.

(2)

A

T030-0001

Stop wStop w

Stop w

Stop wStop w

Before driving, remove the

stop wedges and place them

in the storage brackets.

edgedg

edg

edgedg

es (ifes (if

es (if

es (ifes (if

f f

itted)itted)

f

itted)

f f

itted)itted)

T021-0004

2. Transport lock

To change position:

B

1. Lift and unfold inner sections till lock is disengaged.

2. Loosen and remove the two bolts, which keep the

parts A and B assembled.

3. Reassemble A and B according to desired hole

combination.

NOTE! Always use both bolts to assemble the lock. The

setting must be identical on both sides.

NOTE! The rear settings must correspond to the front

settings so the boom is resting on the front as well as

rear brackets.

WARNING! The max. transport height must

never exceed 4.0 m (13.1 ft.). Always measure

the actual total height and choose settings not

exceeding 4.0 m.

GB 05 08 05

T101-0031

21

Page 22

Sprayer setup

TT

rr

ansporanspor

T

r

anspor

TT

rr

ansporanspor

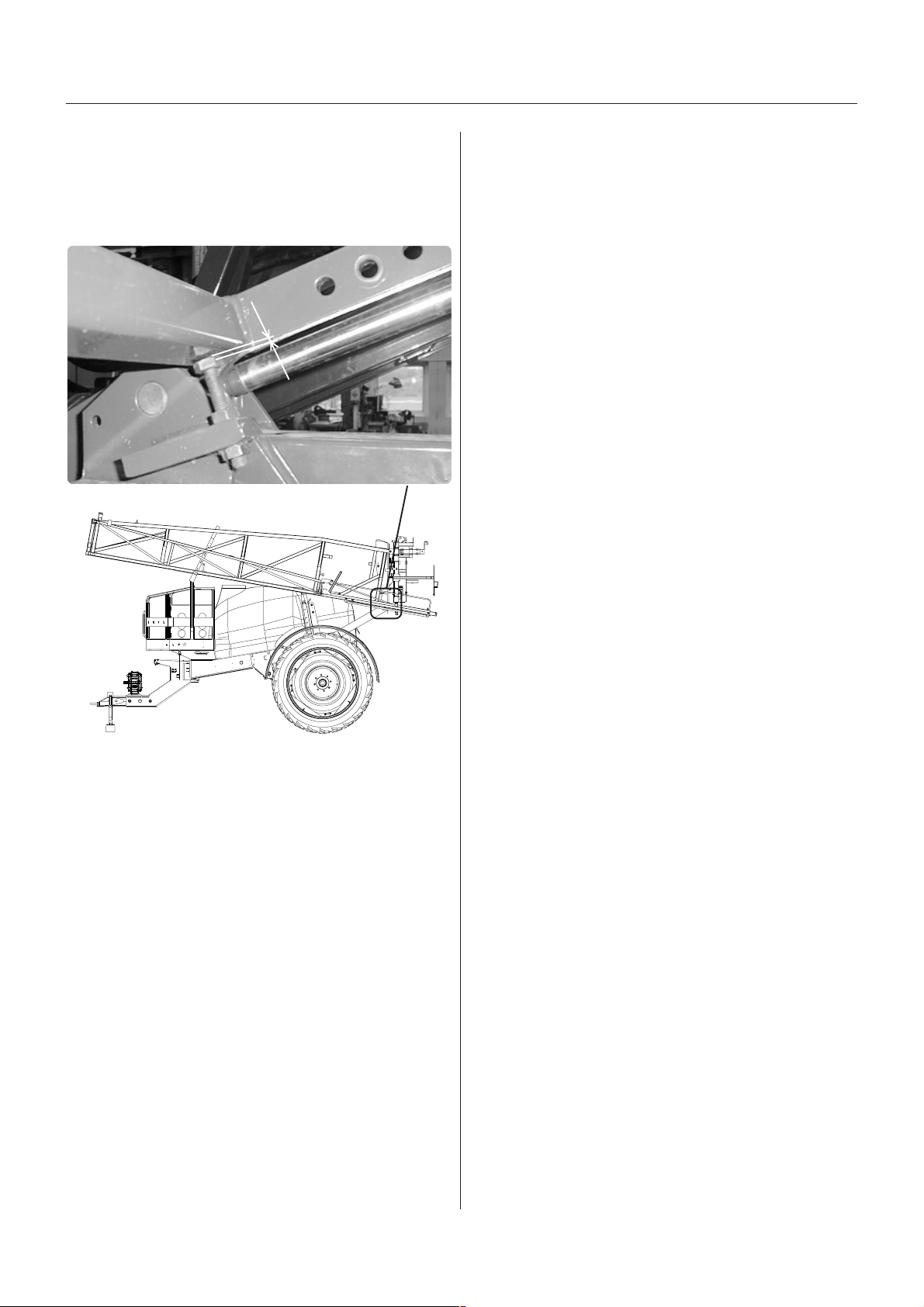

When the boom is unfolded: Inspect the gap between

the bolt A and the frame. Correct position = 1 mm gap.

If necessary, adjust the position of bolt A.

t loct loc

t loc

t loct loc

kk

k

kk

1 mm

A

T060-0128

T271-0010x

22

GB 05 08 05

Page 23

Sprayer setup

Driving TDriving T

Driving T

Driving TDriving T

STEER TRASTEER TRA

STEER TRA

STEER TRASTEER TRA

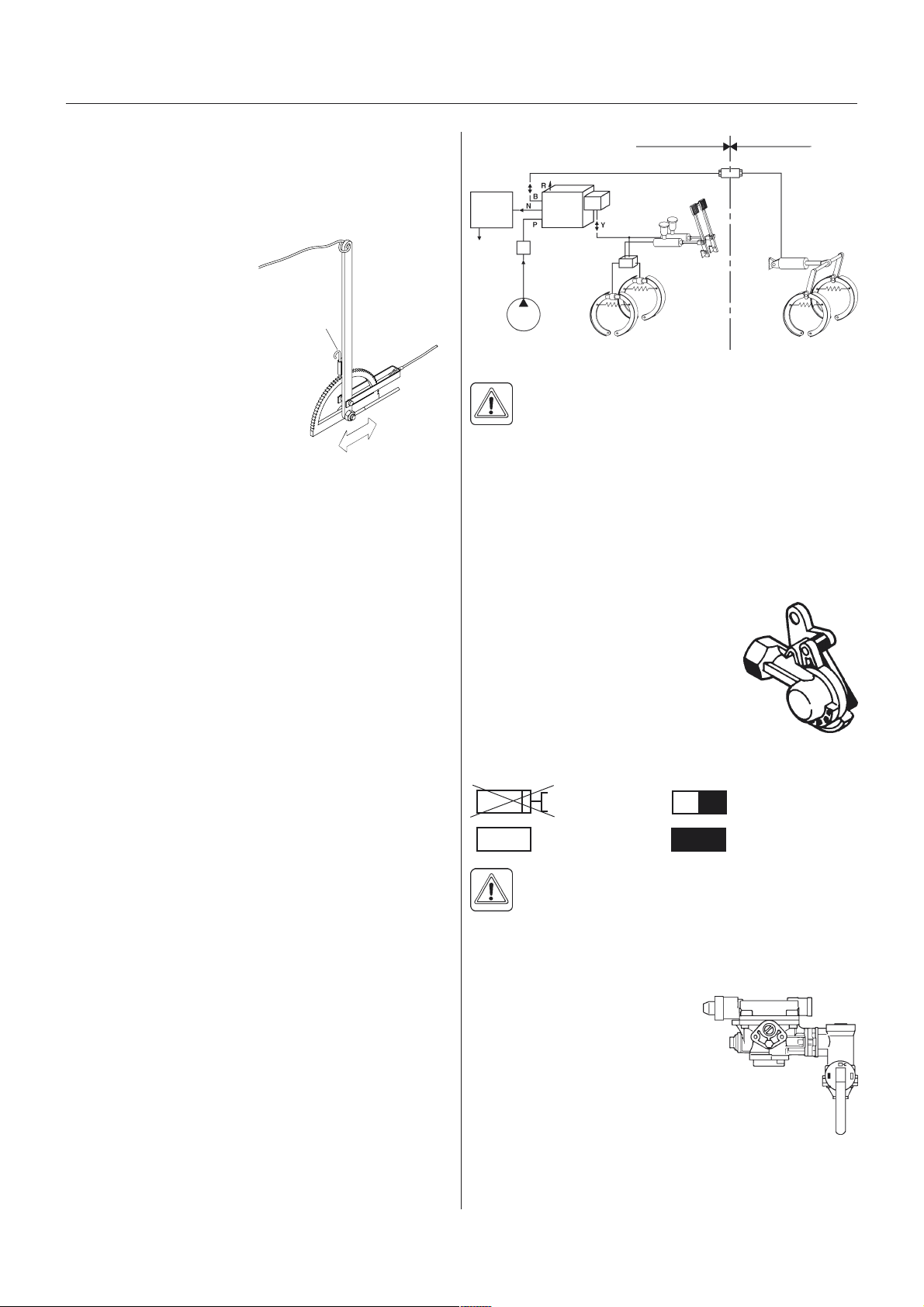

A trailer with articulating drawbar (TRACKER) behaves

differently than a normal trailer.

In tracking position the vehicle centre of gravity is

displaced further more compared to the vehicle centre

line of a normal trailer.

Compared to a conventional trailer a TRACKER has

decreased stability when turning, especially when turning

on hillsides.

To avoid overbalancing, pay attention to these guidelines:

1. Avoid sudden, tight turns

2. Slow down before entering a curve or turning, and

drive with a constant, low speed during the turn.

3. Never slow down too fast, never brake heavily and

never stop suddenly in a curve, or when turning on a

hillside, when the sprayer is articulated.

4. Be careful when turning on uneven ground

5. Set the track gauge as wide as possible

6. The proper function of the hydraulic damping is

essential to obtain good stability

7. Keep stabiliser chains on the tractors liftarms tight

8. For safety reasons, the following limitations are set for

TRACKERS (with unfolded booms):

ecec

hniquehnique

ec

hnique

ecec

hniquehnique

CK and SELF TRACK and SELF TRA

CK and SELF TRA

CK and SELF TRACK and SELF TRA

CKCK

CK

CKCK

NOTE! HARDI cannot

undertake any responsibility

for any damages caused by

the sprayer tipping over.

T029-0002

STEER TRASTEER TRA

STEER TRA

STEER TRASTEER TRA

(If the sprayer is equipped with HARDI NOVA, please

see separate instruction book).

The articulating drawbar on STEER TRACK is to be

operated manually via the D.A.H.

The switch on the D.A.H. control box is pushed sidewards to articulate the drawbar.

This is used when turning or as track correction when

driving on slopes.

CKCK

CK

CKCK

Speed by turning, max. 4 km/h (2.5 m.p.h.)

Ground inclination by turning, max. 8°

Track gauge, min. Please see the part

Track gauge

MAX. 4 KM/H

T029-0003

T029-0003

GB 06 02

T029-0004

23

Page 24

Sprayer setup

SELF TRASELF TRA

SELF TRA

SELF TRASELF TRA

The SELF TRACK is always in tracking mode.

The SELF TRACK drawbar will always articulate when

the tractor is turning and follow the tractor rear wheels.

The SELF TRACK drawbar is hydraulically damped to

obtain stable trailing.

to avoid the vehicle from tipping over.

TRAIL CONTROLTRAIL CONTROL

TRAIL CONTROL

TRAIL CONTROLTRAIL CONTROL

Please see separate instruction book.

CKCK

CK

CKCK

WARNING! Always drive the SELF TRACK very

carefully on public roads, and be aware of the

sprayers behaviour. Slow down before turning,

24

GB 06 02

Page 25

Equipment - StandarEquipment - Standar

Equipment - Standar

Equipment - StandarEquipment - Standar

LadderLadder

Ladder

LadderLadder

Sprayer setup

d and Additionald and Additional

d and Additional

d and Additionald and Additional

LarLar

gg

e store stor

Lar

g

e stor

LarLar

gg

e store stor

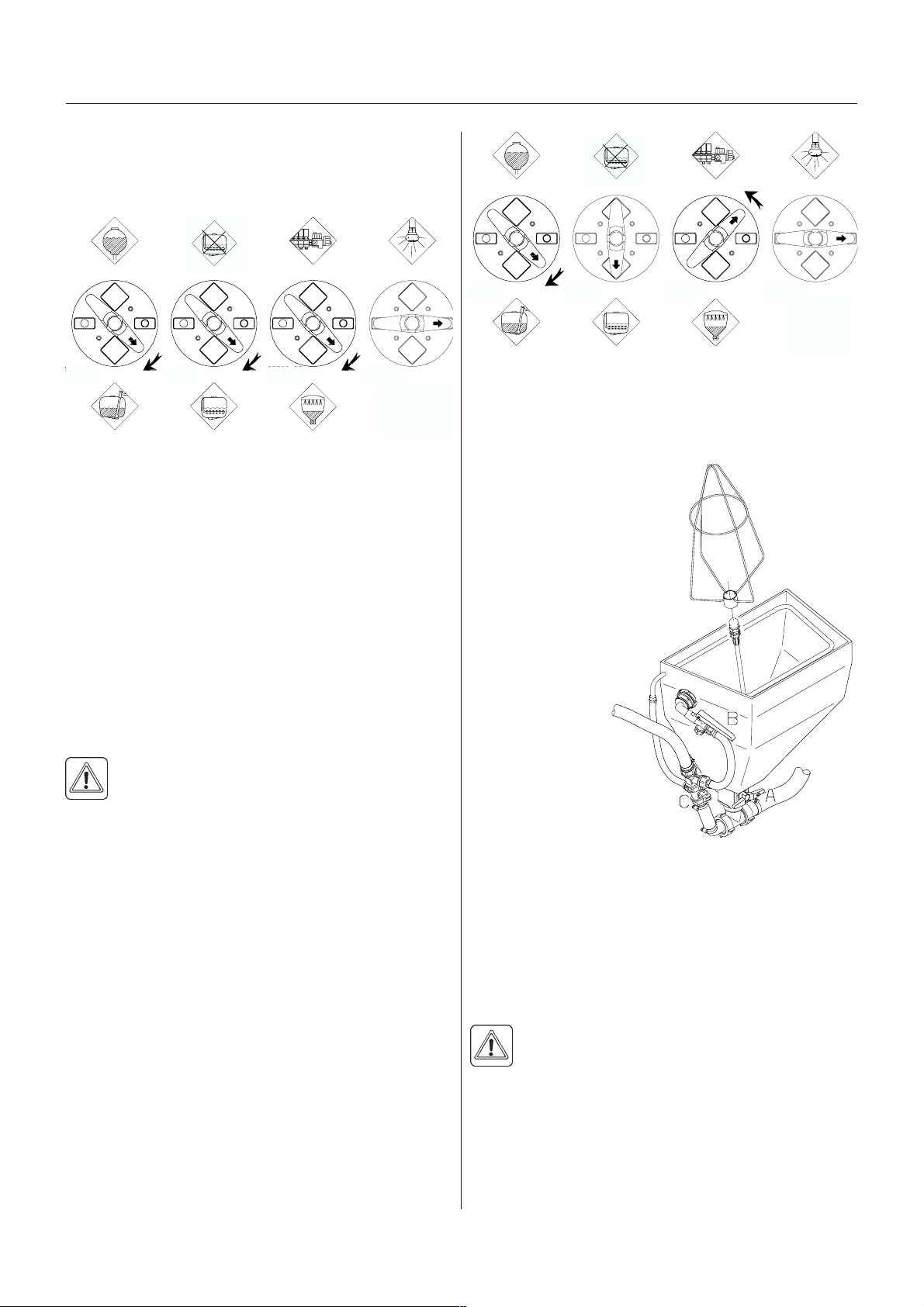

The locker A can be mounted on the sprayers right side

acting as a storage for sealed pesticide containers. The

locker is fitted to a mounting B, which is bolted to the

frame of the trailer.

A drain in the bottom makes it possible to clean and

drain the locker in case of leak by pesticide containers.

aa

gg

a

g

aa

gg

e Loce Loc

e Loc

e Loce Loc

kk

er (ifer (if

k

er (if

kk

er (ifer (if

f f

itted)itted)

f

itted)

f f

itted)itted)

A

C

T060-0121

Down: Pull the handle A to disengage the locking device

and drag down the ladder while supporting it by both

handles (B + C)

Up: The ladder will lock automatically when it is fully

retracted.

NOTE! Always retract the ladder before driving.

If necessary, grease the slide bars to make the ladder

slide smoother.

PlaPla

tftf

ormorm

Pla

tf

orm

PlaPla

tftf

ormorm

Access to the platform is possible via the ladder.

Hydraulic and electric components are situated underneath the platform floor. By lifting the platform floor,

these components are accessible. Also the clean water

tank is integrated in the platform.

B

B

T142-0025x

Small storSmall stor

Small stor

Small storSmall stor

The locker A can be mounted next to the HARDI

FILLER. It is for the purpose of storing pesticide containers in use, nozzles, calibration- and compound equipment. The locker is fitted to a mounting B, which is

bolted to the frame of the trailer.

B

aa

gg

a

g

aa

gg

e Loce Loc

e Loc

e Loce Loc

kk

er (ifer (if

k

er (if

kk

er (ifer (if

A

f f

itted)itted)

f

itted)

f f

itted)itted)

A

The platform gives

access to the clean

water tank lid, the

main tank lid, the top

mounted suction

filter and the selfcleaning filter, which

is situated behind the

wicket A on the

backside of the

MANIFOLD system.

TT

ank leank le

T

ank le

TT

ank leank le

indicaindica

indica

indicaindica

The actual tank level

in the main tank can

be observed on the

tank level indicator B. The scale is displayed in litres or

Imp. gal/US gal. (certain countries).

vv

v

vv

tortor

tor

tortor

elel

el

elel

A

B

T060-0114

T142-0024x

A drain in the bottom makes it possible to clean and

drain the locker in case of leak by pesticide containers.

FF

rr

ont Locont Loc

F

r

ont Loc

FF

rr

ont Locont Loc

The locker is mounted to the front of the platform. It is

for the purpose of storing non-contaminated protective

gear, soap for hand washing etc.

The locker is split in two compartments for the separation of clean clothes from gloves with risk of contamination.

GB 05 09 02

kk

er (ifer (if

k

er (if

kk

er (ifer (if

f f

itted)itted)

f

itted)

f f

itted)itted)

25

Page 26

Sprayer setup

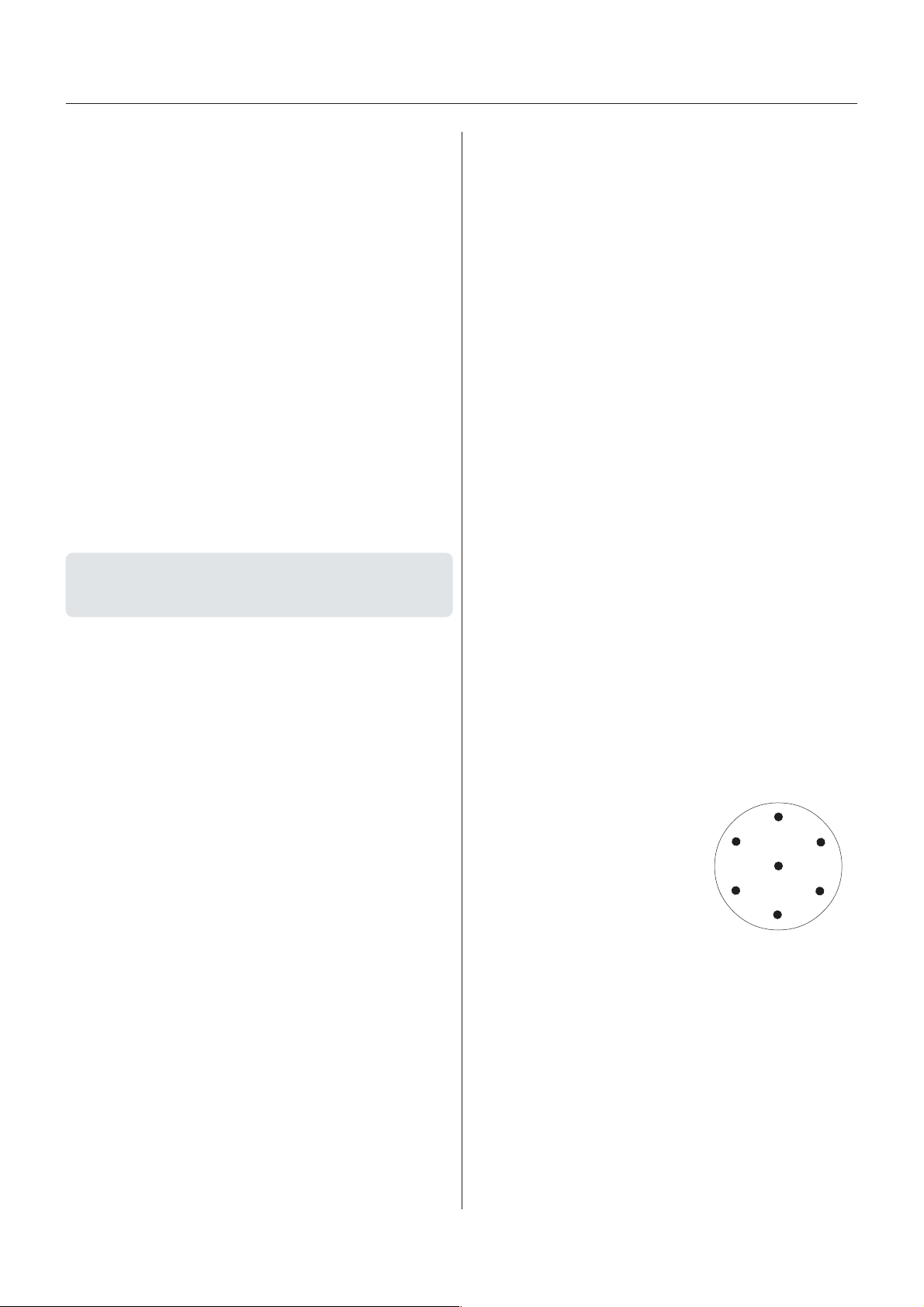

Boom light

(A)

Work light

(B)

Two compartments

The work light lamp B is also mounted to the railing of

the platform above the MANIFOLD valves. This lamp is

positioned to lighten the HARDI FILLER + the MANIFOLD system.

It is recommended to switch of the rear lights of the

tractor in order to save power consumption and to avoid

reflection.

Power supply is via the 7-pin socket. Please see the

Installation Instruction in the part Technical specifica-

tions.

T060-0110

A soap dispenser can be fitted in a device on the inside

of the locker door.

IMPORTANT! Although this locker is situated in the noncontaminated zone of the sprayer and is meant for

storing nontoxic items, it must never be used for storing

food, beverage or other things meant for consumption.

Boom and WBoom and W

Boom and W

Boom and WBoom and W

oror

k lights (ifk lights (if

or

k lights (if

oror

k lights (ifk lights (if

f f

itted)itted)

f

itted)

f f

itted)itted)

Selector switch

When mounting the selector switch A it is simply

clicked into the cutout in the frame below the MANIFOLD valves an is thereby fastened to the frame.

A

T060-0112

The switch has three positions:

1. Boom lights ON

T271-0009

The 2 boom light lamps A are mounted to the railing of

the platform (one at each side) and are positioned to

lighten both boom wings.

T060-0111

26

2. Lights OFF (neutral)

3. Work light ON

T040-0000

T040-0001

Connection box

The connection box is to be mounted underneath the

platform floor.

1. Lift the platform floor

2. Open the connection box and mount the flat part of

the box (A) by 4 screw to the 4 predrilled holes in the

platform floor.

GB 05 09 02

Page 27

Sprayer setup

Drag the split, twist

it 900 and drop the

split again to lock it

A

T060-0123

CrCr

op prop pr

Cr

CrCr

The kit consists of sheet, straw dividers and wheel brake

covers.

otection Kit (ifotection Kit (if

op pr

otection Kit (if

op prop pr

otection Kit (ifotection Kit (if

f f

itted)itted)

f

itted)

f f

itted)itted)

Each cutout in the shield is then fastened with a matching locking device, which are mounted along the lower

part of the sprayer.

T066-0074

Strawdividers

A strawdivider can be fitted on each trailer wheel.

Sheet

The PVC sheet is fitted underneath the trailer and

covers the undercarriage of the chassis

T060-0113

The sheet is lead through guiding rails fastened on both

sides of the trailer.

T060-0125

Wheel brake covers

A wheel brake cover A can be mounted in order to cover

the brake

A

T066-0073

GB 05 09 02

T060-0126

27

Page 28

Sprayer setup

MudguarMudguar

Mudguar

MudguarMudguar

Mudguards can be fitted on the trailer wheels by means

of a supporting frame which is bolted to a mounting on

the wheel axle.

ds (ifds (if

ds (if

ds (ifds (if

f f

itted)itted)

f

itted)

f f

itted)itted)

T060-0127

Mudguards are available for all wheel configurations.

T162-0109x

28

GB 05 09 02

Page 29

Sprayer setup

Disconnecting the sprDisconnecting the spr

Disconnecting the spr

Disconnecting the sprDisconnecting the spr

Always clean the sprayer - inside and outside - before

disconnecting and parking it.

Support leg

Before disconnecting from the tractor, make sure the

support leg is properly fitted and secured by linch pin.

T251-0012x

The support leg is stored in the bracket on the right side

of the trailer when the sprayer is attached to the tractor.

To remove the support leg: Lift the leg, remove the linch

pin and pull out the support leg.

a

aa

yy

erer

y

er

aa

yy

erer

Transmission shaft support

The transmission shaft rests on the bracket A when not

in use (Low hitch models).

A

T142-0029x

At High hitch models the transmission shaft is placed in

the hook underneath the drawbar when not in use

WARNING! To prevent the sprayer from tipping

over, do not disconnect the sprayer from the

tractor with the booms unfolded unless the boom

is supported!

Always engage the parking brake (if fitted).

If no parking brake is

fitted, or if local regulations requires so, place

stop wedges in front of

and behind the wheels.

Remember to disconnect all hoses and cables from the

tractor.

WARNING! If the sprayer is parked unattended

avoid unauthorised persons, children and animals from having access to the sprayer.

T021-0004

GB 11 02 03

29

Page 30

Operation

OperOper

Oper

OperOper

Therefore, take care that no persons or objects are hurt

or damaged in the process of testing.

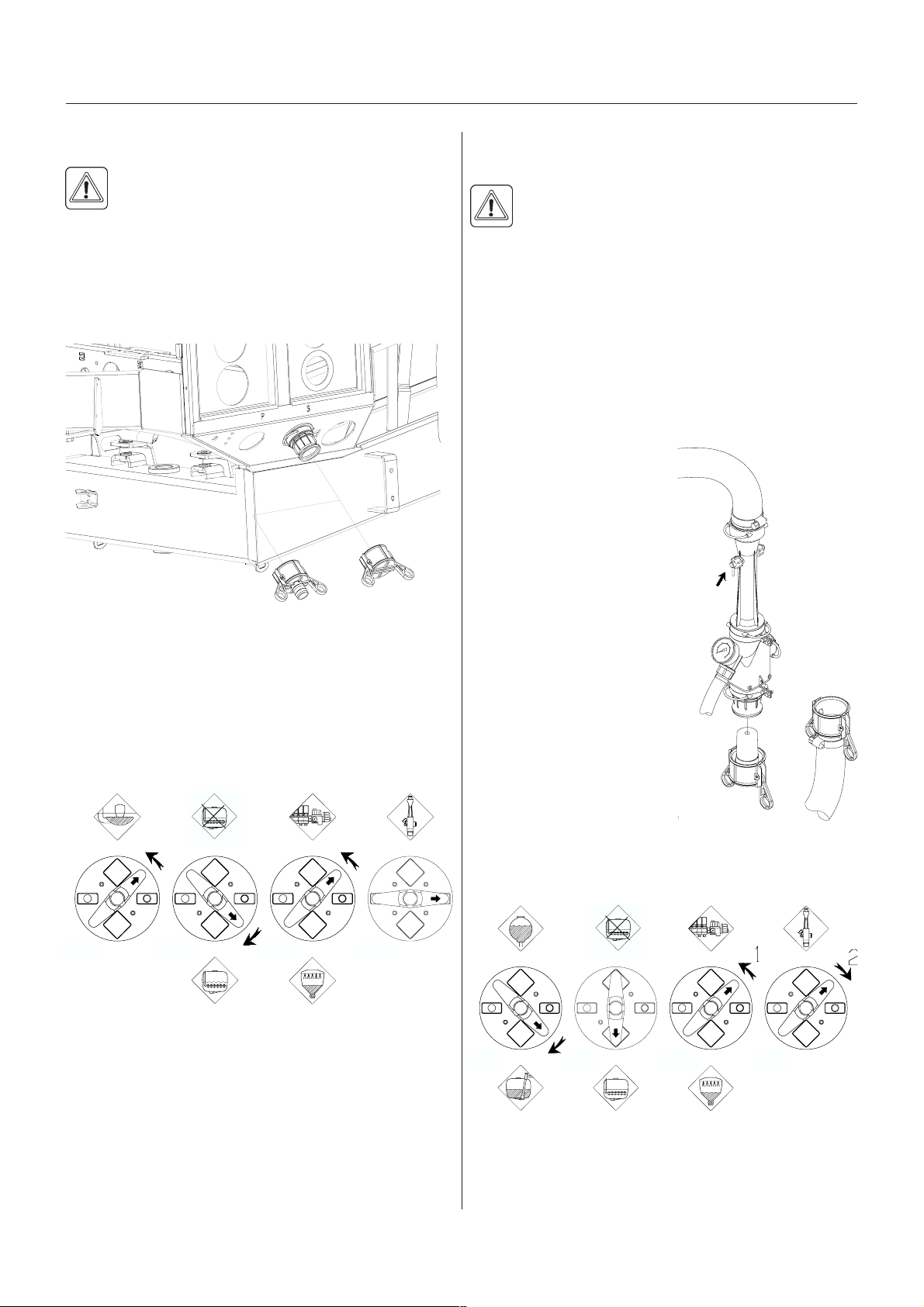

DANGER! When folding

and unfolding the boom,

be sure that no persons

or objects are in the

operating area of the

boom, and that the boom

cannot touch any electrical conductors!

TT

T

TT

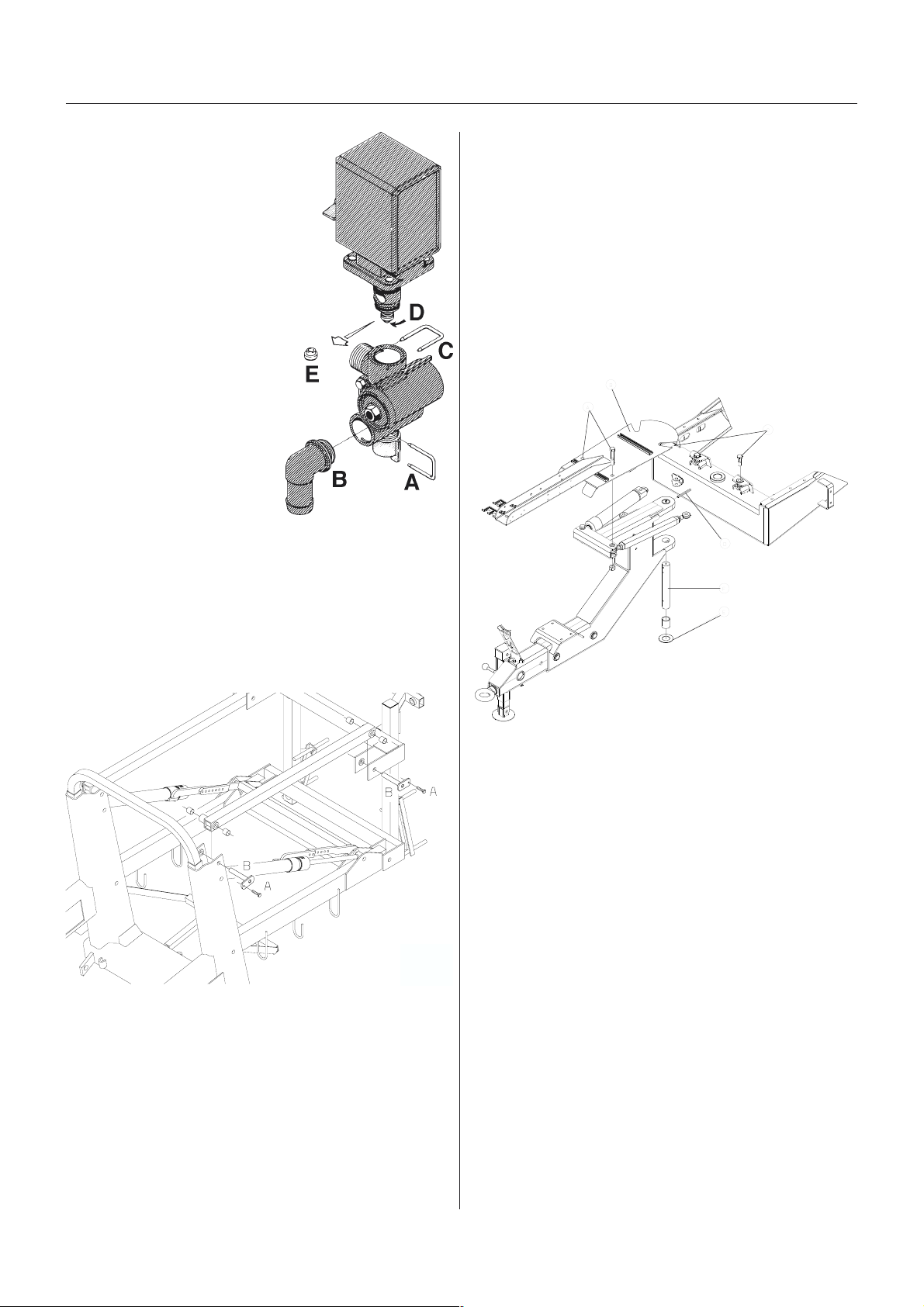

The boom unfolding/folding can be done according to

instructions below.

1.Lift up the boom lift until the boom is clear of the

2.Unfold the boom completely using the double acting

3.Lower the boom to correct working height above the

Folding is to be done in reverse order.

TT

T

TT

(If the sprayer is equipped with HARDI NOVA , please

see separate instruction book for operating instructions).

Functions of the control box:

aa

ting the boomting the boom

a

ting the boom

aa

ting the boomting the boom

WARNING: Be cautious with initial use of the

hydraulic system. If there is air in the system this

may cause violent movements of the boom.

T029-0010

he HAhe HA

he HA

he HAhe HA

he HAZ boomhe HAZ boom

he HAZ boom

he HAZ boomhe HAZ boom

Y boomY boom

Y boom

Y boomY boom

transport brackets using the single acting spool valve

spool valve

ground/crop 50 cm/20 in

The boom unfolding/folding can be done according to

instructions below:

Unfolding the boom

NOTE! Ensure that the transport safety chains are

removed and the boom is clear from the transport

brackets before unfolding.

1.Push switch 1 upwards to lift the boom clear of the

transport brackets.

2.Push switch 2 upwards to unfold the inner sections.

Rear transport hooks disengage automatically.

3.Push switches 6 and 7 downwards to lower individual

tilt rams.

4.Push switch 3 upwards to unfold outer sections.

5.Push switch 4 to correct slant angle.

6.Push switch 1 downwards to lower the boom to correct

height above crop or ground level.

7.In order to reduce wind drift and/or increase penetration of spray liquid in the crop, the slot angle can be

changed backwards and forwards with switch 5.

IMPORTANT! The two upper functions in the red rectangle with STOP signs must only be operated when the

sprayer is stationary! Failure to do so will damage the

boom.

Folding the boom

1.Check that the slanting function is midway 4.

2.Set slot angle at midway 5.

3.Raise boom 1 to upper position.

4.Fold outer sections 3

5.Lift individual boom tilt 6 and 7

6.Fold inner sections 2. Rear transport hooks

engage automatically.

7.Lower boom 1 until boom rests on transport

brackets.

1. Raising and lowering of boom

2. Unfolding/folding of inner sections

3. Unfolding/folding of outer sections

4. Slanting of boom

5. Angling of air slot/nozzle assembly

6. Boom tilt, RH

7. Boom tilt, LH

8. Fan speed adjustment

9. Drawbar mode (STEER TRACK only)

30

T030-0004

Hydraulic slanting control

The hydraulic slanting control 4 enables slanting of the

entire boom hydraulically. This is advantageous when

spraying across hillsides.

Reset position to neutral (midway) before folding the

boom.

Boom tilt function

The boom tilt function control 6 and 7 enables you to

adjust the boom height individually in right and left-hand

side.

Air slot angling

The air slot and nozzle assembly can be angled approx.

40º forwards and 30° backwards compared to vertical

position. Regarding adjustments - see section on

Air technique.

GB 07 02

Page 31

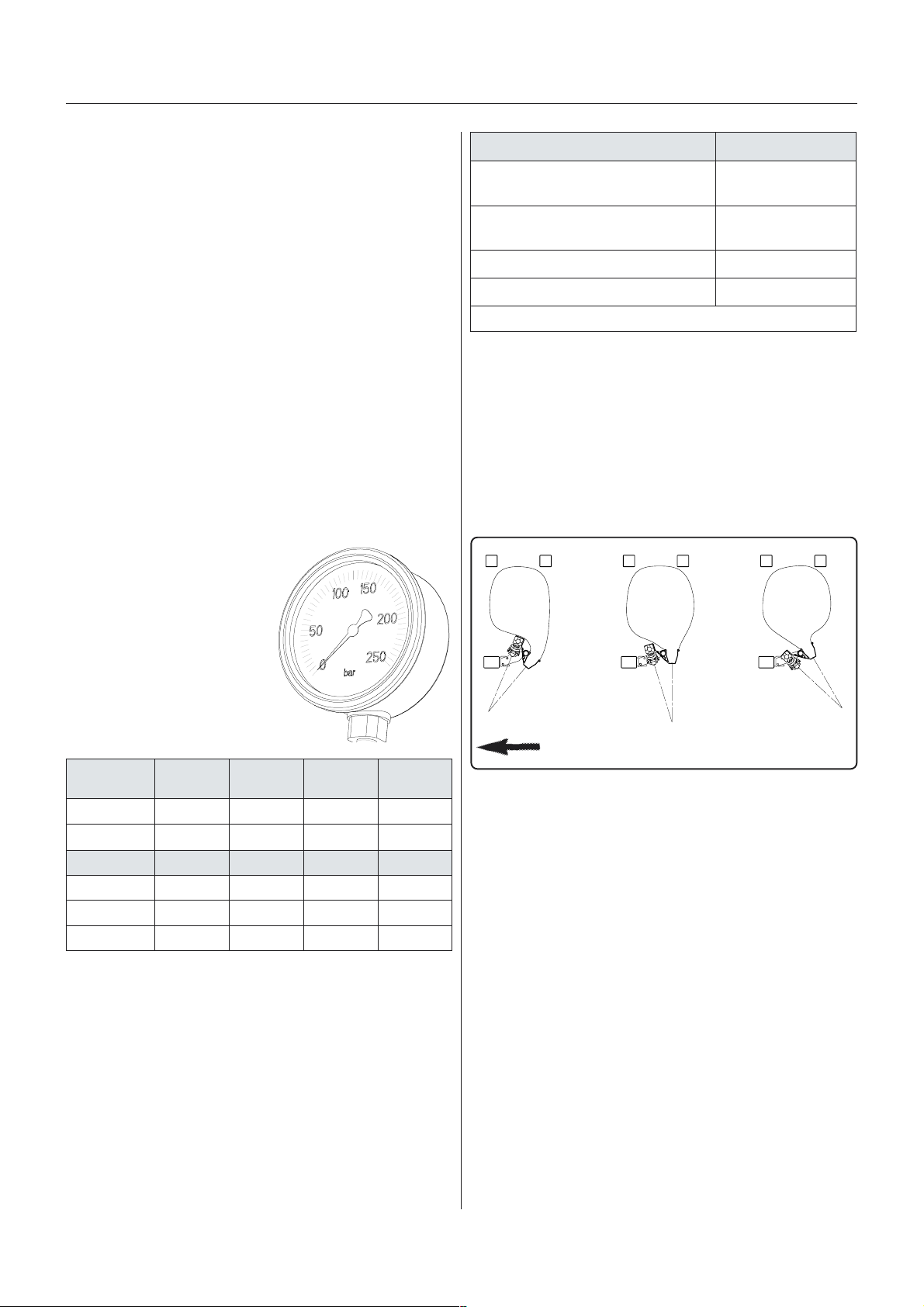

Electrical fan speed adjustment (if fitted)

Increasing of fan speed

Operation

Decreasing of fan speed

The max. Revolutions for the fan is 3100 r.p.m., which

will give full air speed of approx. 40 m/sec (90 mph).

The fan speed is indicated by the transmission working

pressure by means of a pressure gauge.

Conversion table between pressure and fan speed - see

section Air Technique

IMPORTANT! To avoid shock starting the fans always

set fan speed to 0 before engaging the P.T.O.

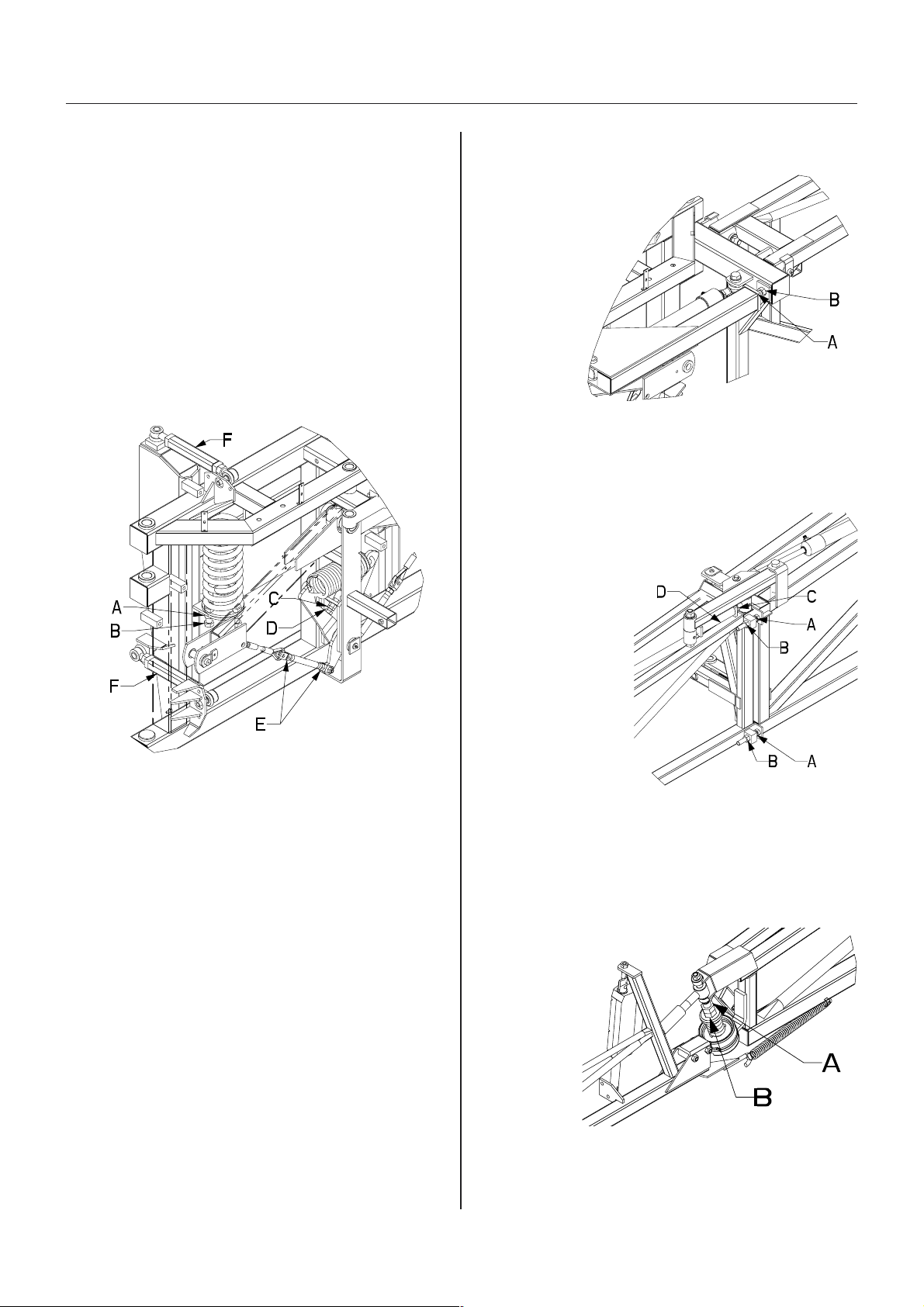

Boom supporBoom suppor

Boom suppor

Boom supporBoom suppor

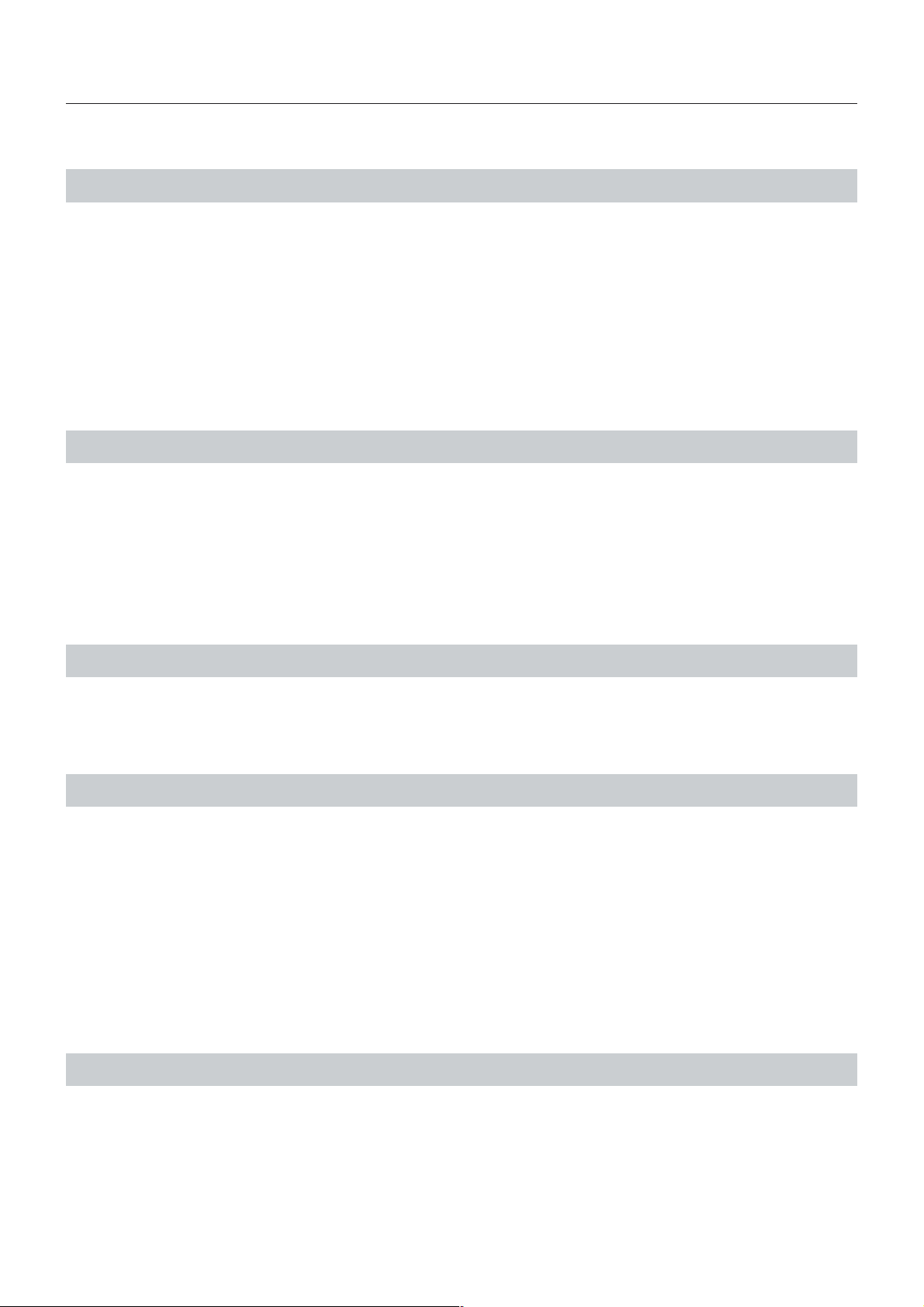

The boom is equipped with two support wheels. When

spraying with low boom heights on bare ground or plants

in the first growth stage it is recommended to fold down

the support wheels. In later growth stages the wheels

should remain folded up.

IMPORTANT! When driving on public roads the support

wheels should be folded up and secured in order to keep

the machine overall width according to the regulations!

t wheelst wheels

t wheels

t wheelst wheels

T030-0004

Boom suspension sensitivityBoom suspension sensitivity

Boom suspension sensitivity

Boom suspension sensitivityBoom suspension sensitivity

The boom suspension will normally suit most conditions

and do not require any adjustment. The suspension will

keep the boom parallel to the ground and compensate

for uneven ground.

However, special conditions or situations can require the

suspension to react less or more slowly.

When the RH and LH

guide rods are

parallel to each

other (factory

setting) the boom

suspension will

react immediately,

and the boom will

move independently of the

trailer or tractor.

If the boom

should follow the movements or inclinations of the trailer

the guide rods should be inclined towards each other at

the rear.

T030-0005

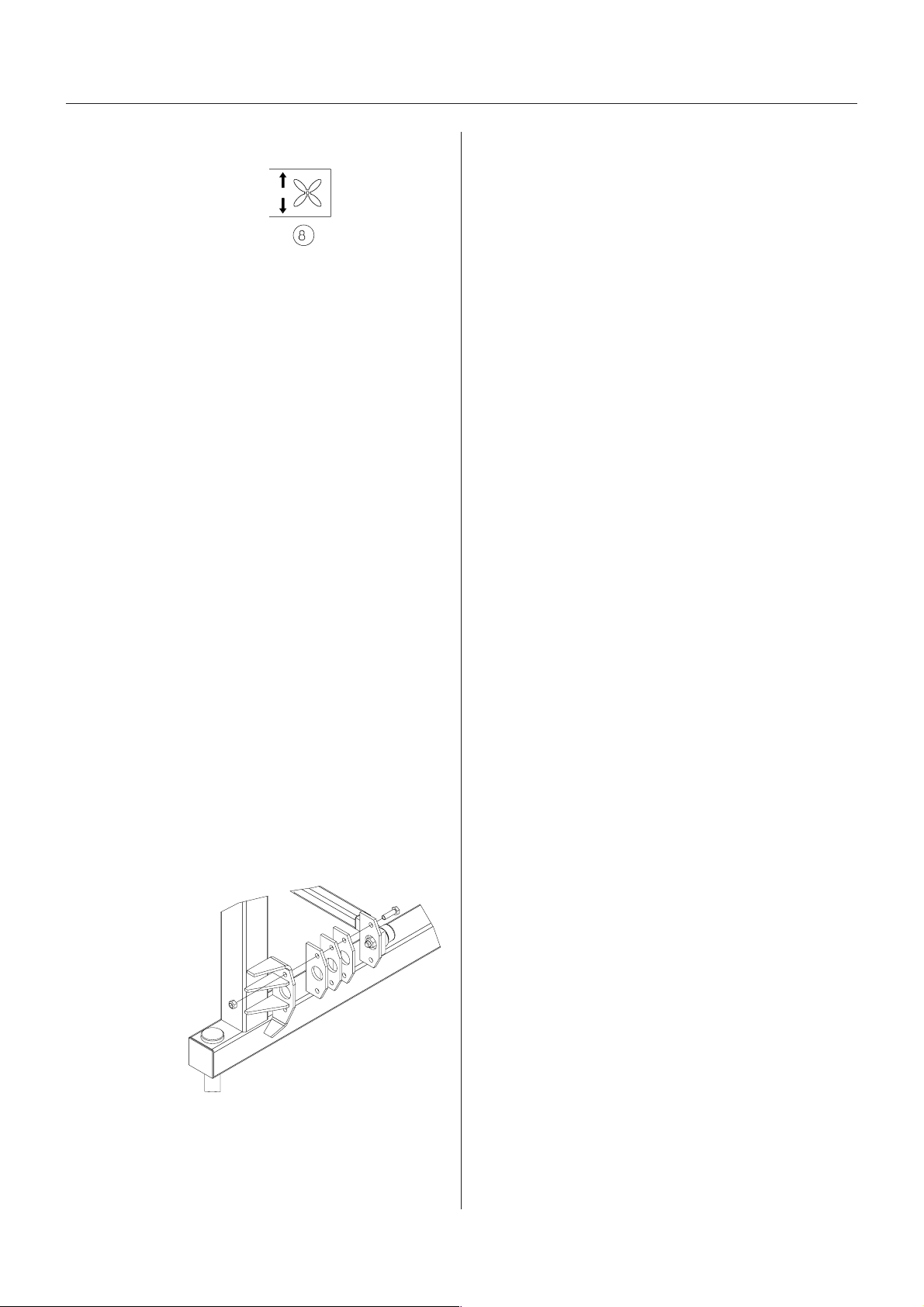

Add 1-4 pcs. of 10 mm spacers as shown at each rod

until the desired function i reached.

GB 07 02

31

Page 32

Operation

OperOper

Oper

OperOper

MANIFOLD SYMANIFOLD SY

MANIFOLD SY

MANIFOLD SYMANIFOLD SY

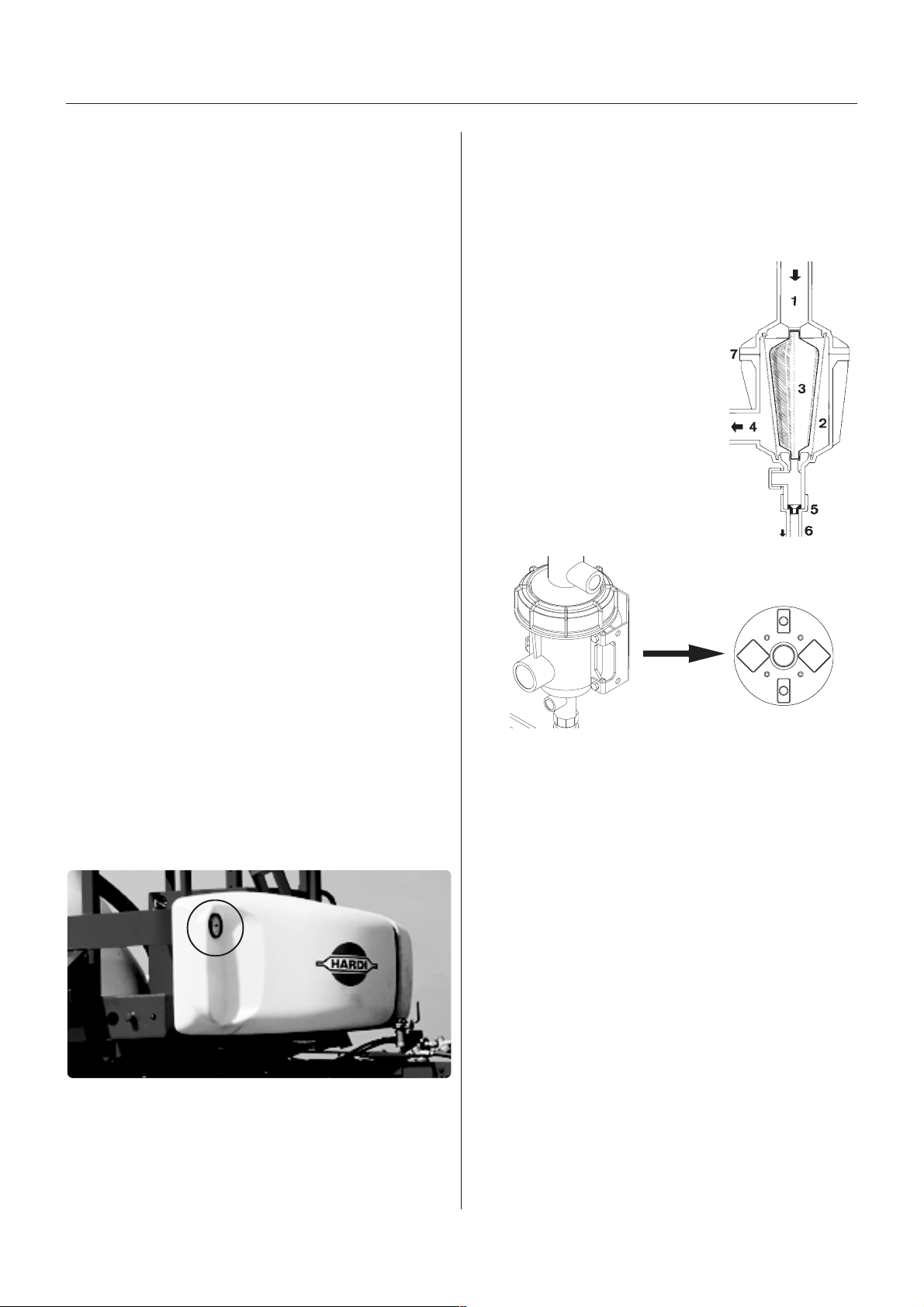

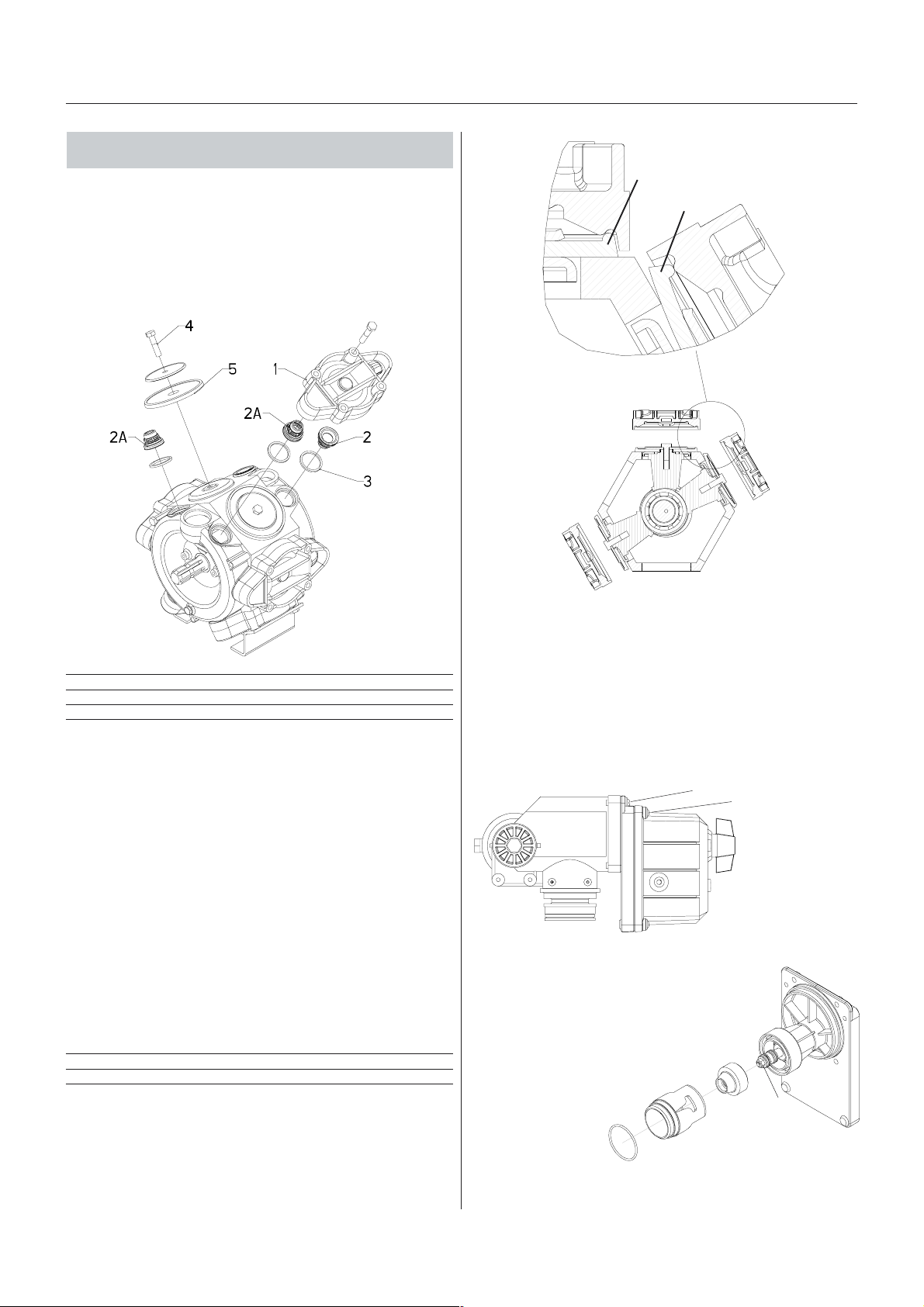

The MANIFOLD SYSTEM is located at the left side of

the sprayer and permits operation of the liquid system

from one position. The modular MANIFOLD system

facilitates the addition of up to two optional extras on the

pressure side and one extra on the suction side.

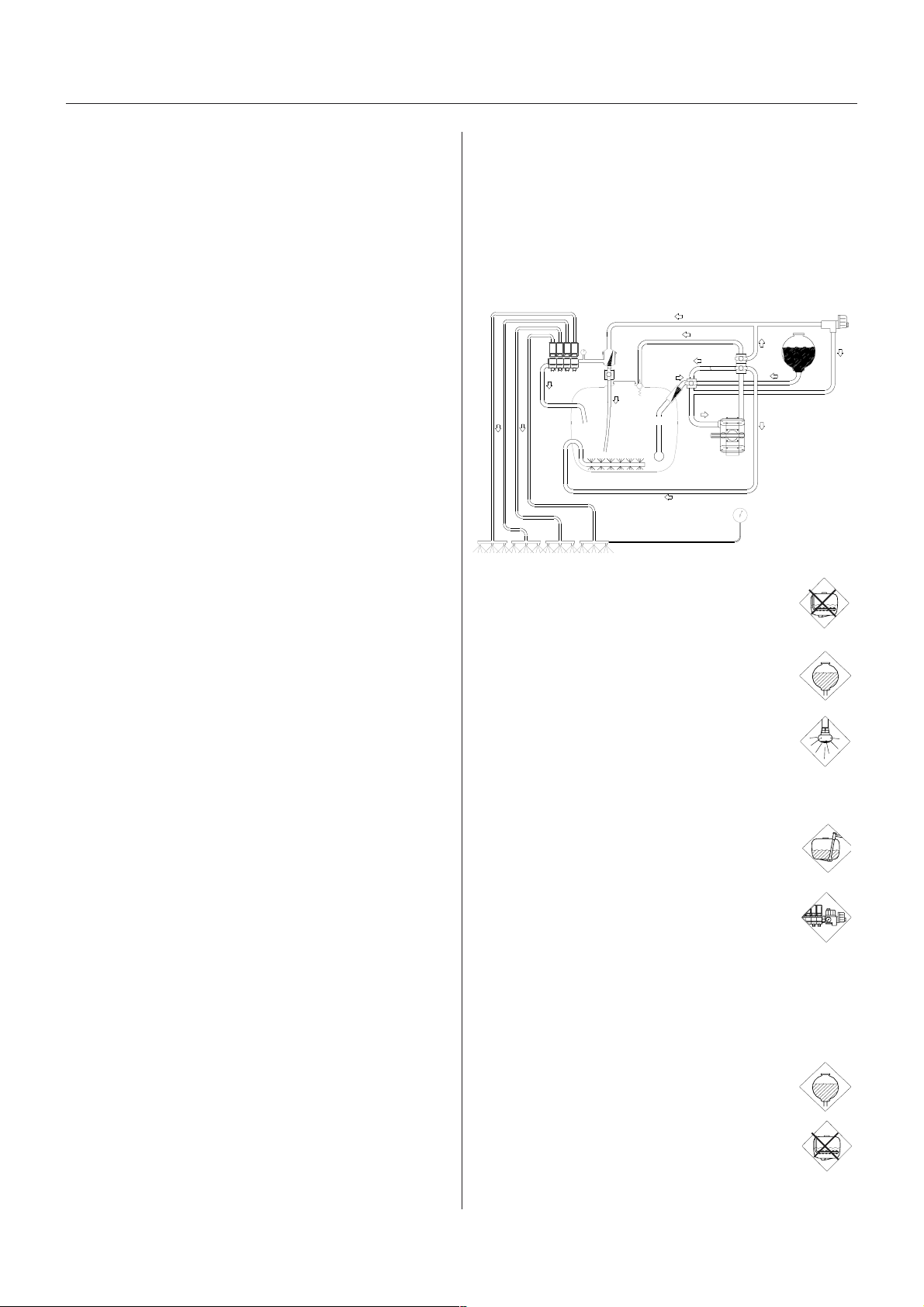

Function diagram - EVC (Standard)

aa

ting the liquid syting the liquid sy

a

ting the liquid sy

aa

ting the liquid syting the liquid sy

STEMSTEM

STEM

STEMSTEM

11

9

8

10

12

13

5

stemstem

stem

stemstem

1

7

4

6

2

3

14

T051-0007x

)erusserp(csidneerG-smargotciP

gninaelc-fleS

/retlif

tinugnitarepO

gnilliftsaF

ecived

RELLIFIDRAH

*

noitatigA

tuohtiW

noitatiga

gnihsulfknaT

elzzon

knatniamoT

nugyarpS

1. Suction filter

2. Suction manifold (black)

3. Pump

4. Pressure manifold (green)

5. Agitation

6. Without agitation (pressure equalisation)

7. HARDI MATIC

8. Return line (Self-cleaning filter)

9. Self-Cleaning Filter

10. Safety valve

11. Distribution valves

12. Return from Pressure Equalisation

13. Sprayer boom

14. Pressure gauge

Use ofUse of

Use of

Use ofUse of

The following pictograms and colours are used for

visualizing the functions of the MANIFOLD valves:

MANIFOLD v MANIFOLD v

MANIFOLD v

MANIFOLD v MANIFOLD v

Green disc = Pressure valve

Black disc = Suction valve

Yellow disc = Self-cleaning filter

alvalv

alv

alvalv

e sye sy

e sy

e sye sy

stemstem

stem

stemstem

026

*Agitation

Normally, Agitation should be on but please refer to the

following rules of thumb:

1. Choose Without Agitation if a high level of

effervescence occurs in order to reduce the

amount of foam.

2. Choose Agitation when using powder

chemicals in order to avoid sedimentation.

3. Close the valve if spraying with a high

volume and it is impossible to achieve

sufficient pressure.

)noitcus(csidkcalB-smargotciP

morfnoitcuS

knatniam

A function is activated/opened

by turning the handle

towards the desired

function

32

Function

open

Closed

knatgnisniR

gnilliF

ecived

025

GB 08 04

Page 33

Operation

QuicQuic

QuicQuic

Quic

k rk r

k rk r

k r

efef

efef

ef

erer

erer

er

enceence

enceence

ence

)retlifgninaelc-fles(csidwolleY

The disc has two

positions; open

or closed

The valves and functions may vary from machine to

machine depending on optional equipment fitted. Only

the functions to be used must be open - Always close

remaining valves.

TT

o opero oper

T

o oper

TT

o opero oper

Turn the handle on a green pressure valve towards the

function desired

Turn the handle on a black suction valve towards the

desired function

Open or close yellow disc (self-cleaning filter)

Close all remaining valves by setting the handle(s)

on O

aa

te the sprte the spr

a

te the spr

aa

te the sprte the spr

aa

ying functions:ying functions:

a

ying functions:

aa

ying functions:ying functions:

Closed

Open

027

FF

illing ofilling of

F

illing of

FF

illing ofilling of

Water can be filled into the main tank in five ways:

1. Filled through tank lid.

2. Filled by diaphragm pump through a suction side fitted

filling device (optional extra) using normal pump

capacity directly to the tank.

3. Filled by diaphragm pump through a pressure side

fitted injector/venturi type Fast Filling Device (optional

extra) providing up to 3 times normal pump capacity.

4. Combination of 2 and 3.

5. Quick coupler for external filling

The tank should normally be filled 1/3 with water, before

adding the chemicals - always read instruction on

chemical container!

NOTE! Max. permitted tank contents:

w w

aa

terter

w

a

ter

w w

aa

terter

retaw,emuloV*sresilitrefdiuqil,emuloV

ledoM

ertiL lag.pmI lagSU ertiL lag.pmI lagSU

l002200224848.08545128.3746.865

l008200826162.93745128.3746.865