Page 1

COMMANDER

TWIN FORCE

Original

Instruction book

67035300-100 - Version 1.00

GB - 05.2013

www.hardi-international.com

Page 2

We congratulate you for choosing a HARDI plant protection product. The reliability and

efficiency of this product depend upon your care. The first step is to carefully read and pay

attention to this instruction book. It contains essential information for the efficient use and

long life of this quality product.

This book covers updated COMMANDER models, also known as COMMANDER ‘11

series.

The original instruction book is approved and published in English. All other languages are translations of the

original. In the event of any conflicts, inaccuracies or deviations between the English original and other languages

the English version shall prevail.

Illustrations, technical information and data in this book are to the best of our belief correct at the time of printing.

As it is HARDI INTERNATIONAL A/S policy permanently to improve our products, we reserve the right to make

changes in design, features, accessories, specifications and maintenance instructions at any time and without

notice.

HARDI INTERNATIONAL A/S is without any obligation in relation to implements purchased before or after such

changes.

HARDI INTERNATIONAL A/S cannot undertake any responsibility for possible omissions or inaccuracies in this

publication, although everything possible has been done to make it complete and correct.

As this instruction book covers more models and features or equipment, which are available in certain countries

only, please pay attention to paragraphs dealing with precisely your model.

Published and printed by HARDI INTERNATIONAL A/S

Page 3

Table of Contents

1 - EC Declaration

EC Declaration of Conformity ................................................................................................................9

2 - Safety notes

Operator safety ...................................................................................................................................11

Symbols ..................................................................................................................................................................................................................... 11

Precautions ............................................................................................................................................................................................................. 11

Label explanation ............................................................................................................................................................................................... 12

3 - Description

General info .........................................................................................................................................15

View ............................................................................................................................................................................................................................. 15

View ............................................................................................................................................................................................................................. 16

Identification plates ........................................................................................................................................................................................... 16

Roadworthiness ................................................................................................................................................................................................... 16

Sprayer use .............................................................................................................................................................................................................. 17

Frame .......................................................................................................................................................................................................................... 17

Tanks and equipment ...................................................................................................................................................................................... 17

Liquid system ......................................................................................................................................18

Pump .......................................................................................................................................................................................................................... 18

Valves and symbols ............................................................................................................................................................................................ 18

DynamicFluid4 pressure regulation ........................................................................................................................................................ 19

Clean water tank .................................................................................................................................................................................................. 21

Rinsing tank ............................................................................................................................................................................................................ 21

Filters ........................................................................................................................................................................................................................... 21

EasyClean filter ...................................................................................................................................................................................................... 21

CycloneFilter .......................................................................................................................................................................................................... 22

TurboFiller ................................................................................................................................................................................................................ 23

Diagram - Basic liquid system ..................................................................................................................................................................... 24

Diagram - Liquid system with optional extras .................................................................................................................................. 25

Diagram - Intelligent liquid system with optional extras ........................................................................................................... 26

TWIN Air technique ..............................................................................................................................27

General info ............................................................................................................................................................................................................ 27

Boom ...................................................................................................................................................28

Boom and terminology ................................................................................................................................................................................... 28

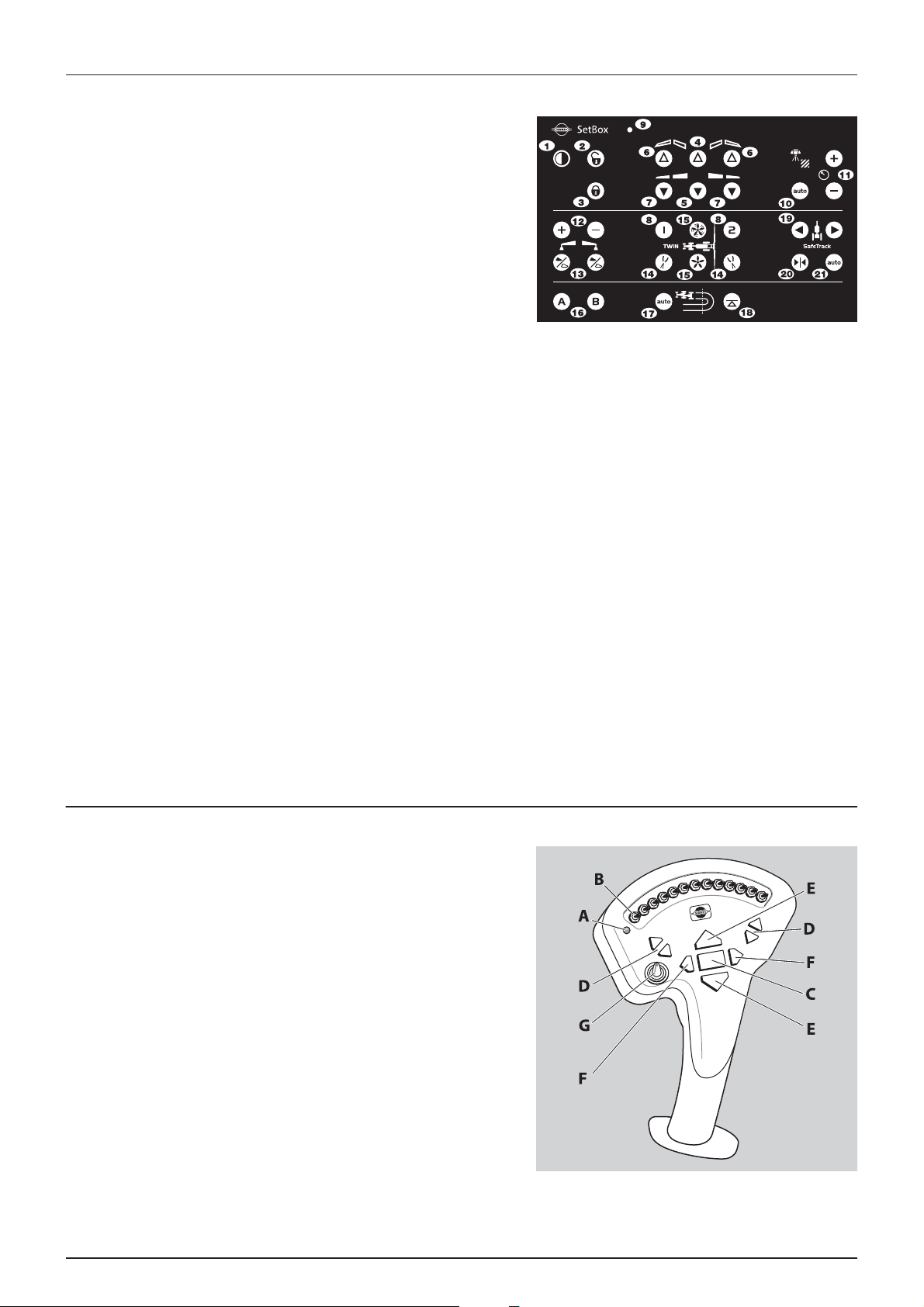

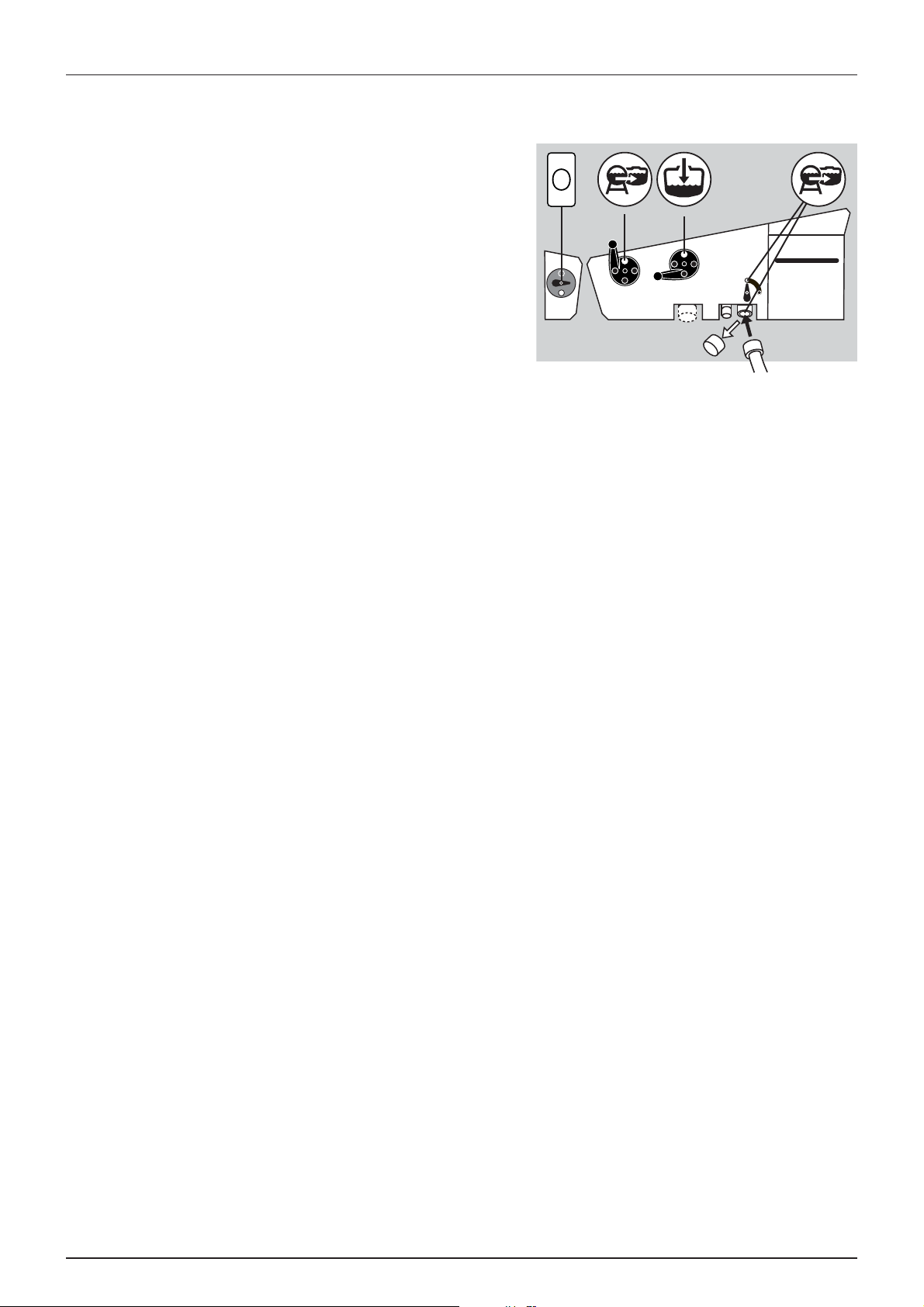

SetBox controls ..................................................................................................................................................................................................... 29

Grip controls ........................................................................................................................................................................................................... 29

Hydraulic systems ...............................................................................................................................30

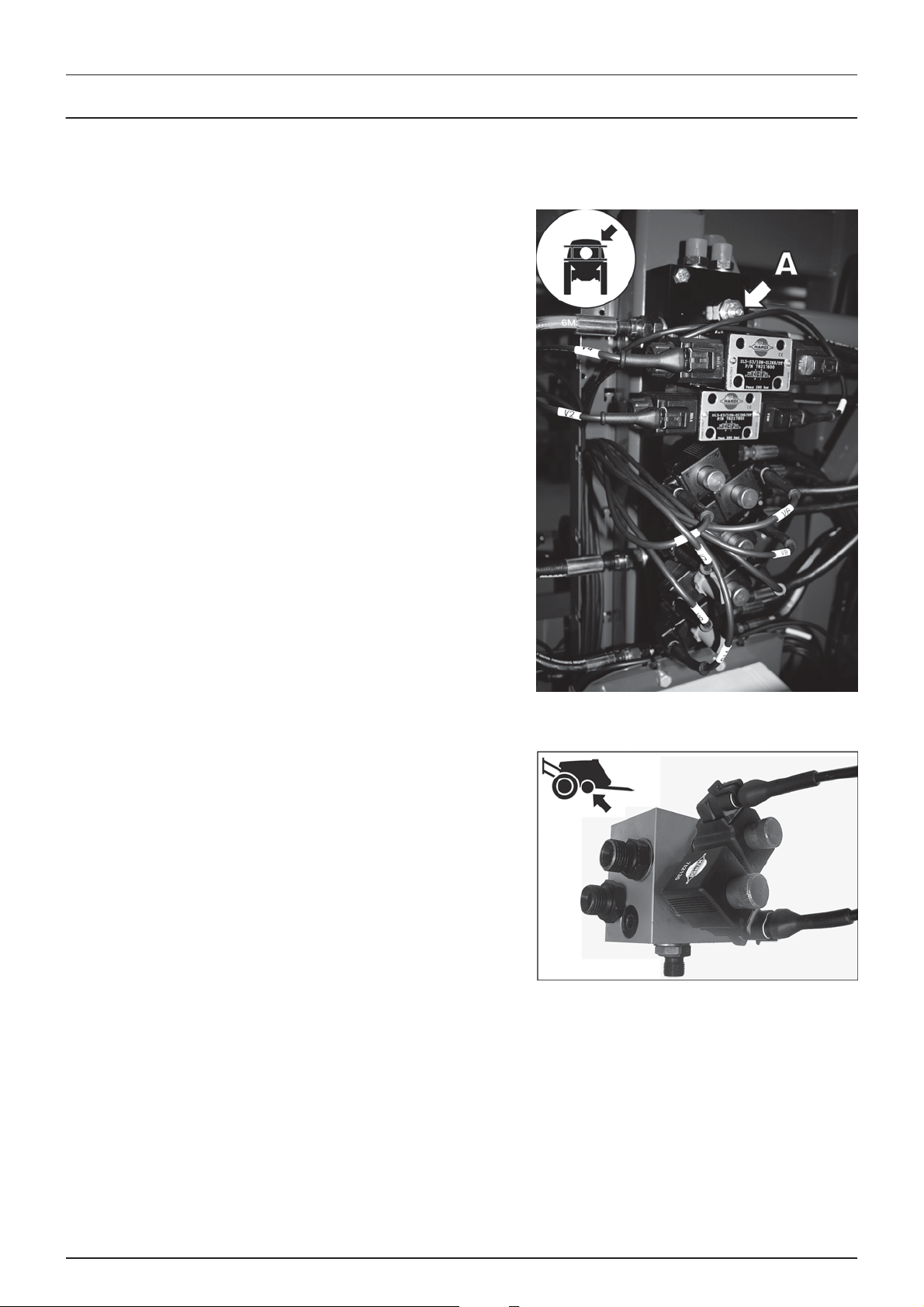

Hydraulic blocks ................................................................................................................................................................................................... 30

Equipment ...........................................................................................................................................32

SafeTrack ................................................................................................................................................................................................................... 32

Driving technique for SafeTrack ................................................................................................................................................................. 32

Platform ..................................................................................................................................................................................................................... 33

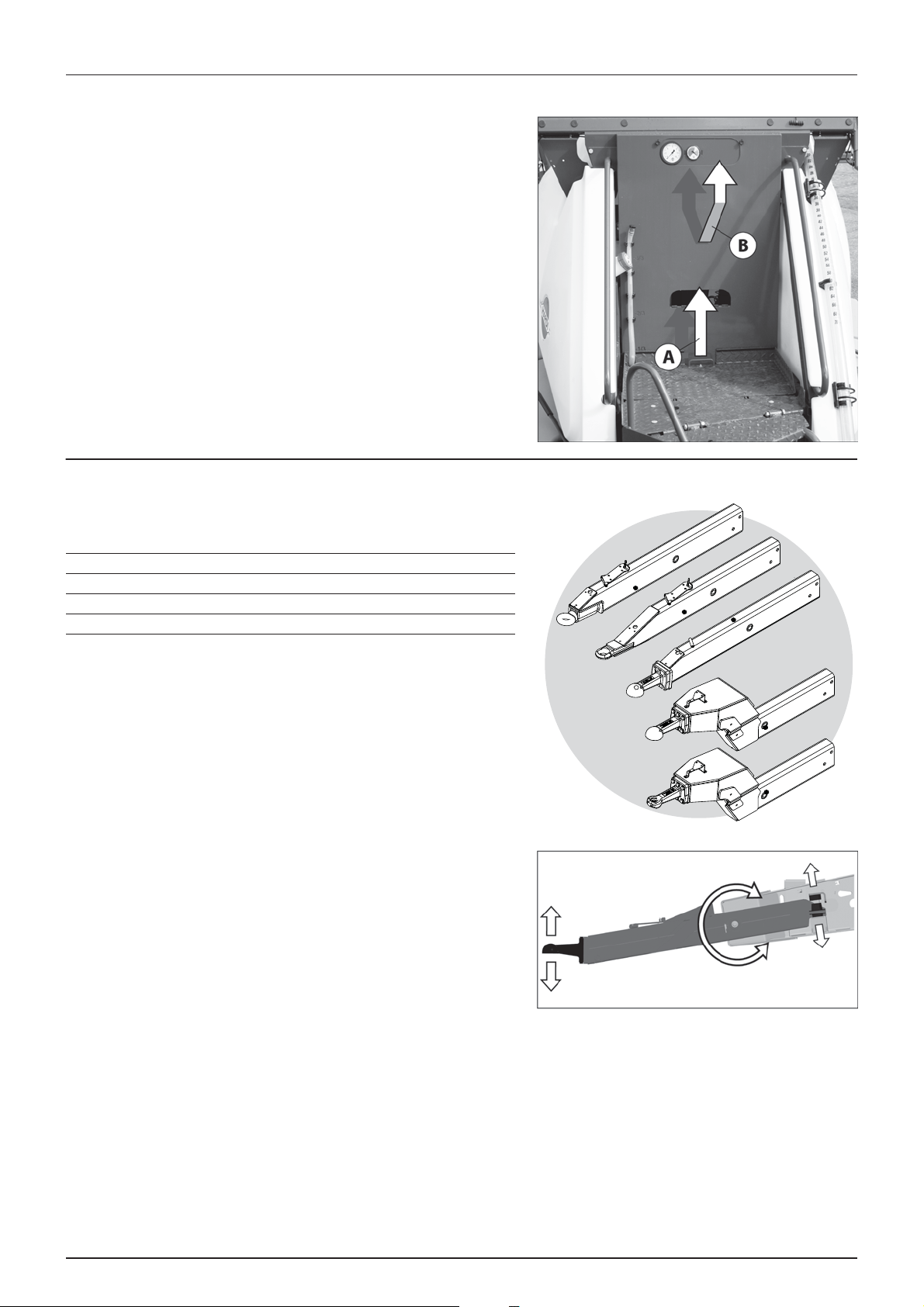

Drawbars .................................................................................................................................................................................................................. 33

Hydraulic support leg ....................................................................................................................................................................................... 34

Tank level indicator ............................................................................................................................................................................................ 35

External Cleaning Device (optional) ........................................................................................................................................................ 35

Nozzle pressure gauge .................................................................................................................................................................................... 35

SafetyLocker ........................................................................................................................................................................................................... 36

ChemLocker ........................................................................................................................................................................................................... 36

Night Spraying Light (optional) ................................................................................................................................................................. 37

4 - Sprayer setup

General info .........................................................................................................................................39

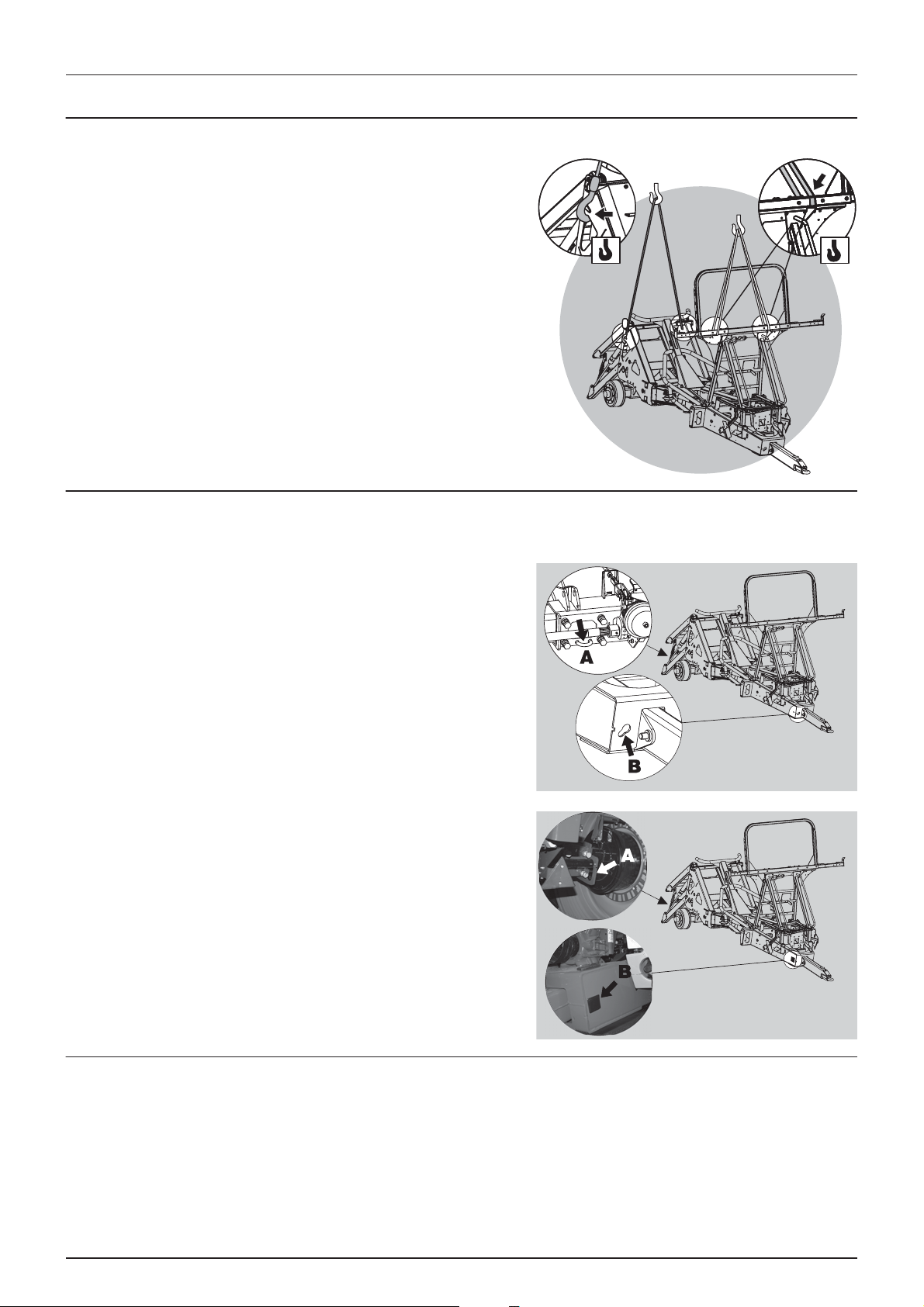

Unloading the sprayer from the truck ................................................................................................................................................... 39

Pulling the sprayer at the tie down hooks .......................................................................................................................................... 39

Before putting the sprayer into operation .......................................................................................................................................... 39

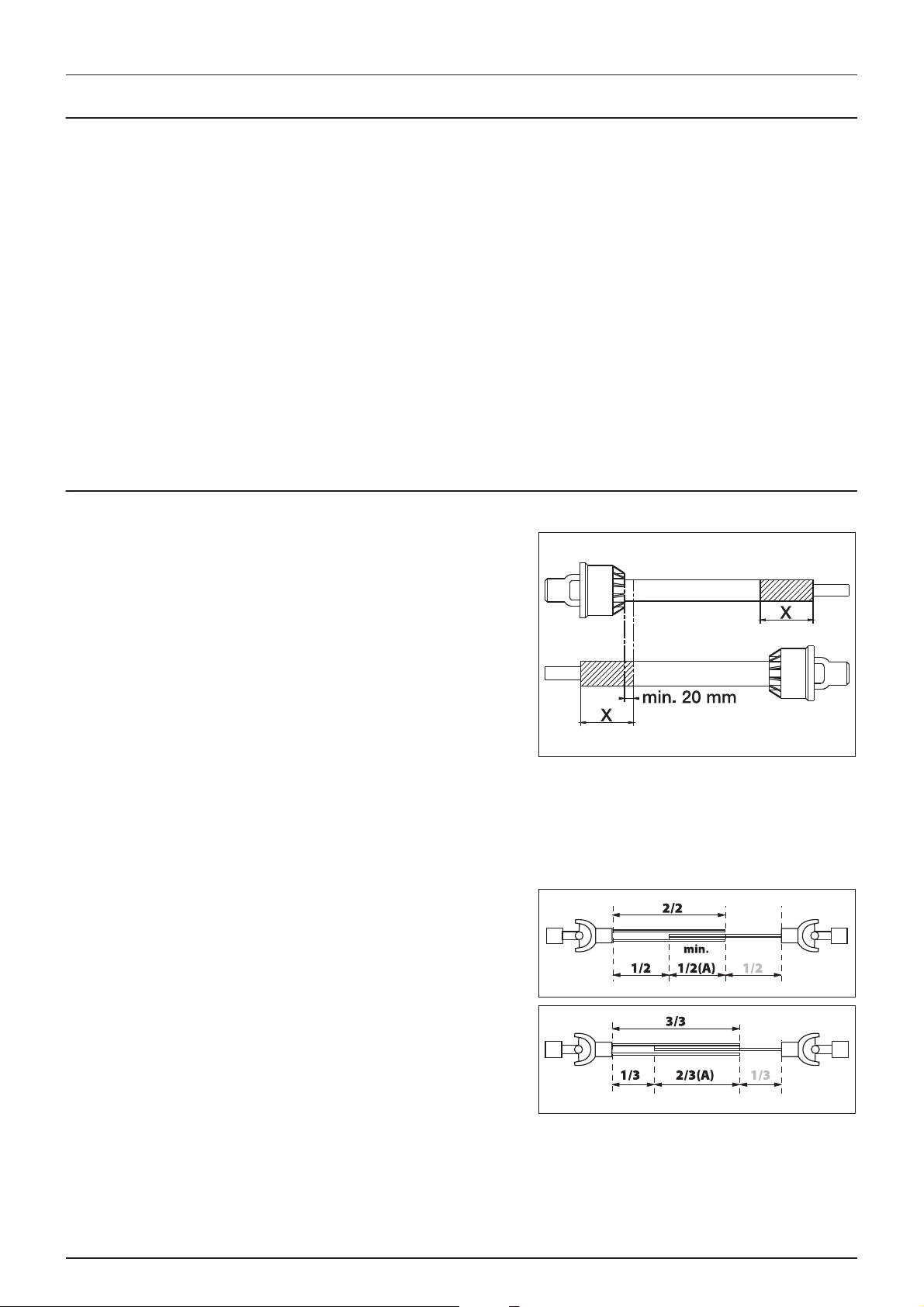

Hydraulic support leg (option for CM 3300/4500) ......................................................................................................................... 40

Jack up the sprayer ............................................................................................................................................................................................ 40

3

Page 4

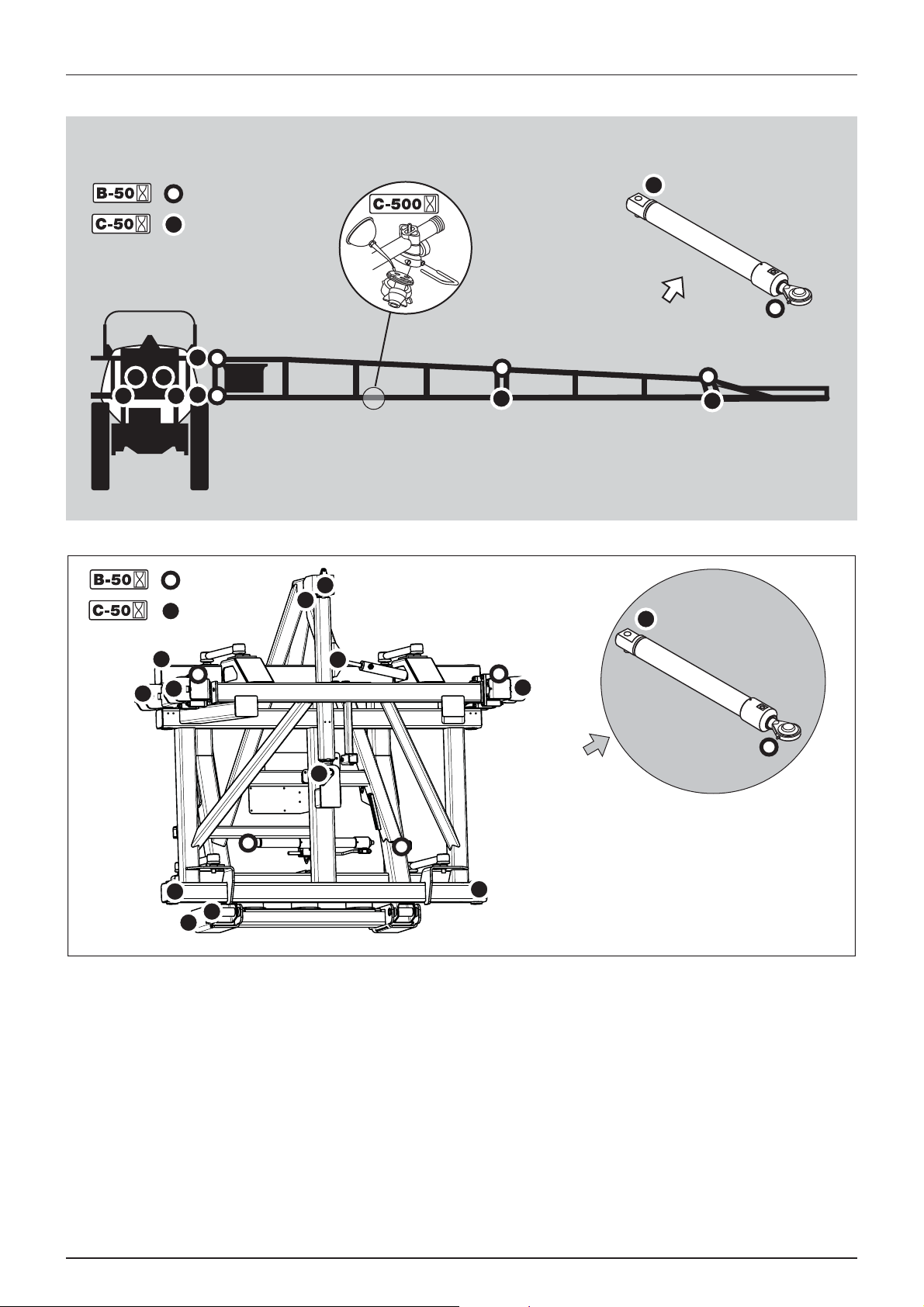

Transmission shaft ..............................................................................................................................41

Operator safety ..................................................................................................................................................................................................... 41

P.T.O. installation .................................................................................................................................................................................................. 41

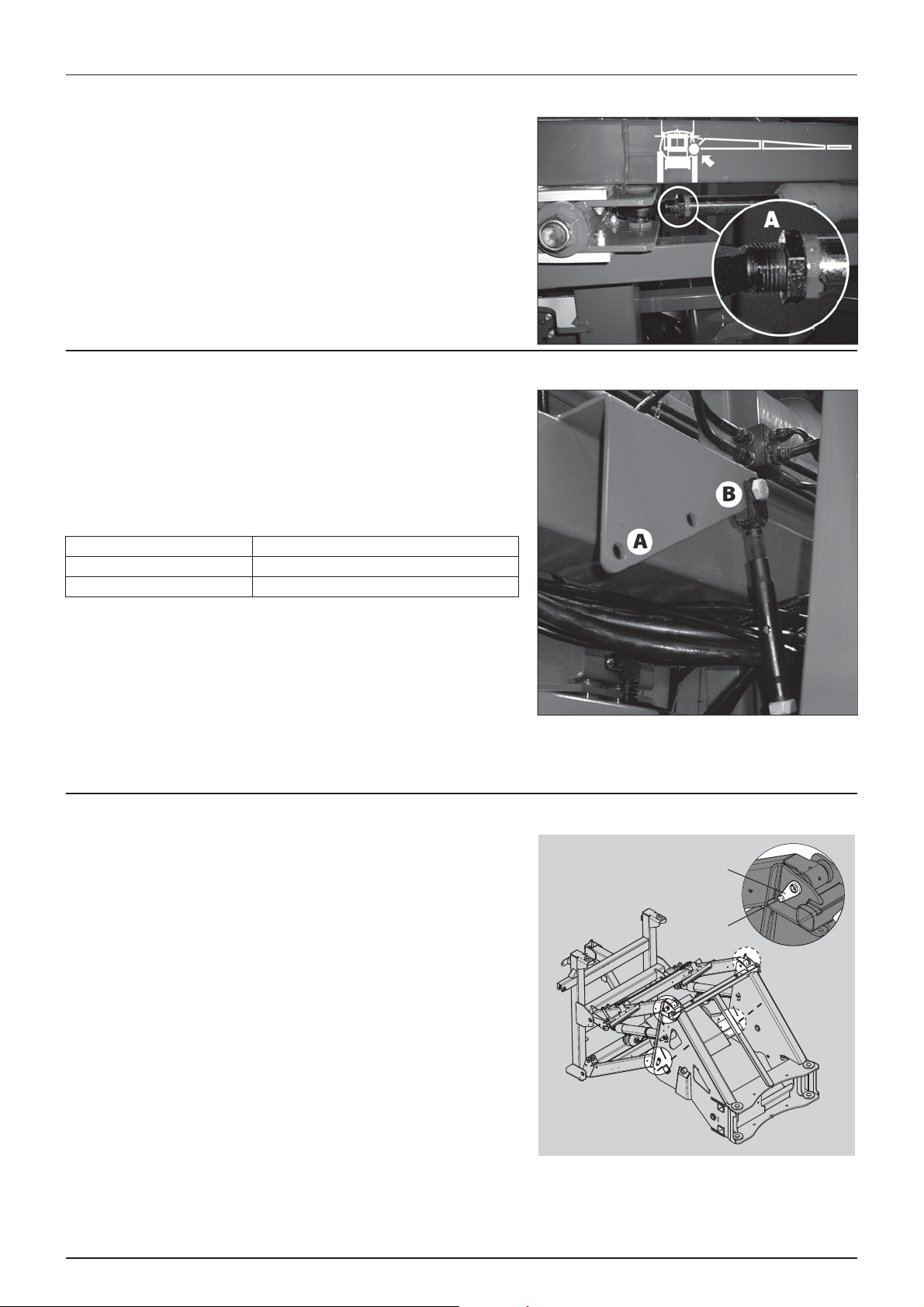

Mechanical connections ......................................................................................................................42

Hose package support ..................................................................................................................................................................................... 42

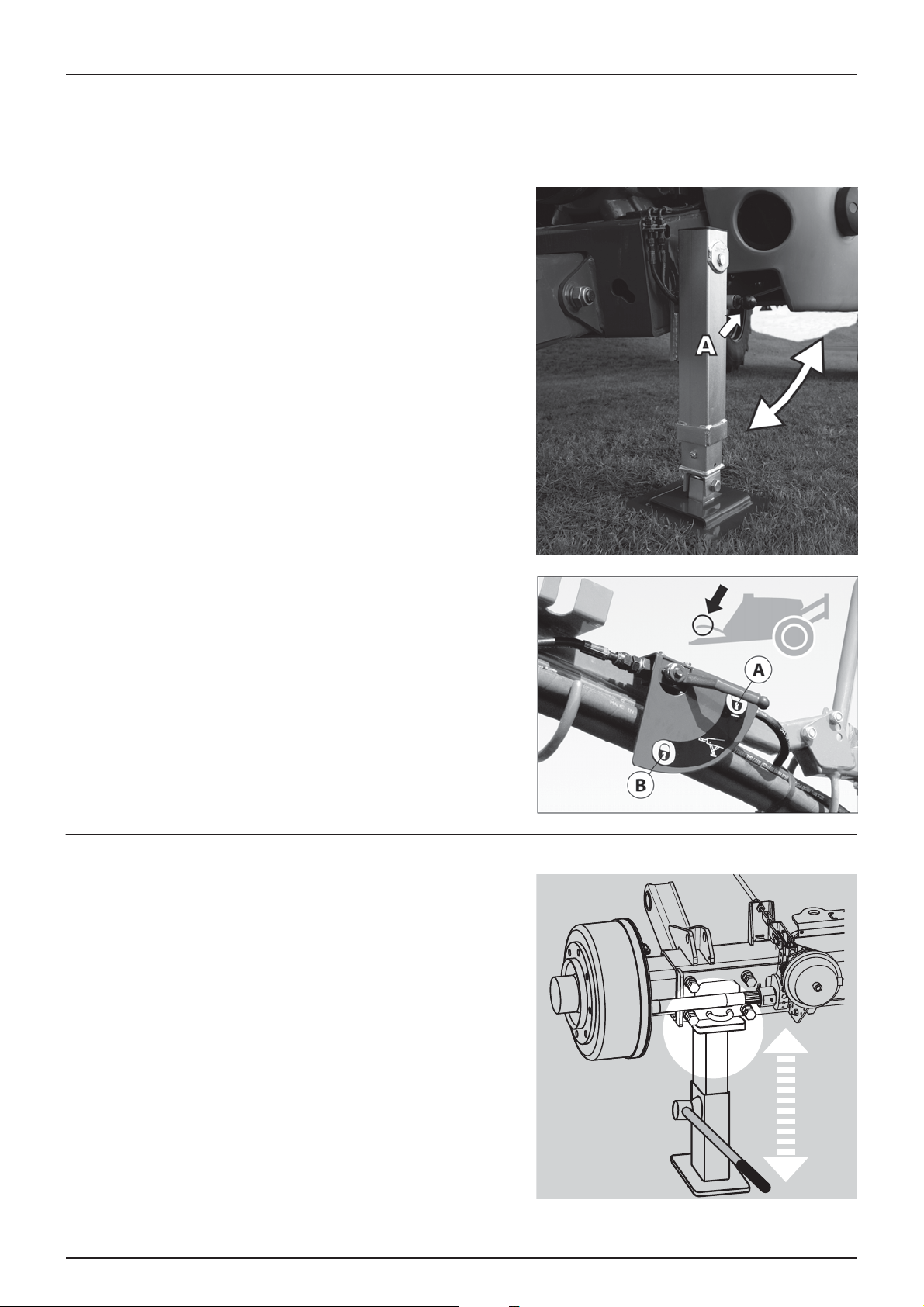

SafeTrack potentiometer connection .................................................................................................................................................... 42

Hydraulic systems ...............................................................................................................................43

General info ............................................................................................................................................................................................................ 43

Requirements - tractor (HAY model) ...................................................................................................................................................... 43

Requirements - tractor (HAZ model) ...................................................................................................................................................... 43

Open centre hydraulics (optional) ........................................................................................................................................................... 44

Electrical connections ..........................................................................................................................45

Installation of control unit brackets ......................................................................................................................................................... 45

Road safety kit ....................................................................................................................................................................................................... 45

Power supply ......................................................................................................................................................................................................... 46

Speed transducer for sprayer ...................................................................................................................................................................... 47

Liquid system ......................................................................................................................................48

CycloneFilter .......................................................................................................................................................................................................... 48

Boom ...................................................................................................................................................49

Damping adjustment ....................................................................................................................................................................................... 49

Boom folding speed adjustment .............................................................................................................................................................. 49

Boom folding speed adjustment - 32-36 m boom only ............................................................................................................. 49

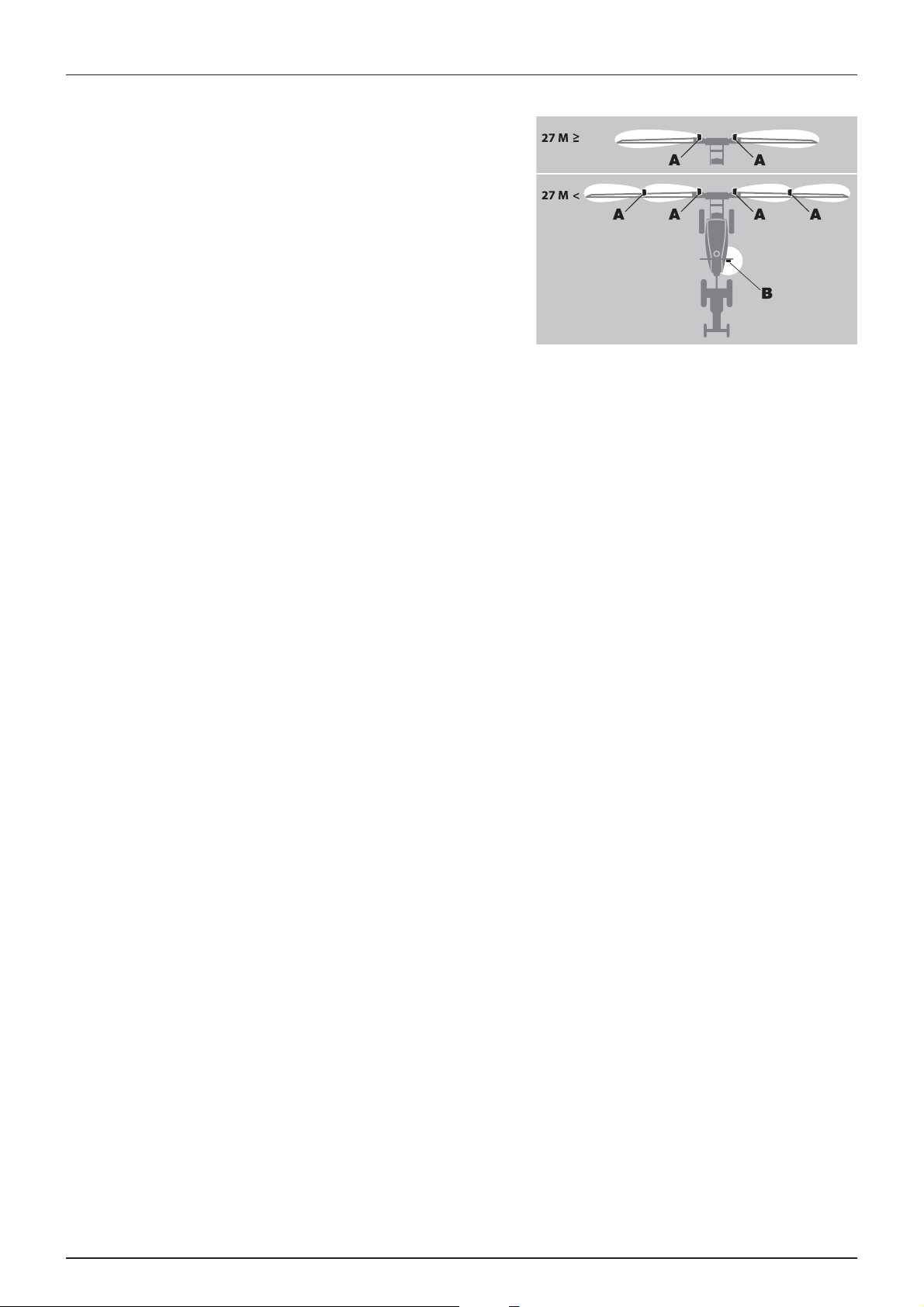

TWIN Air technique ..............................................................................................................................50

Adjusting the air assistance .......................................................................................................................................................................... 50

Setting of air speed, rules of thumb ........................................................................................................................................................ 50

Angling of air and liquid, rules of thumb ............................................................................................................................................. 51

Water sensitive paper ....................................................................................................................................................................................... 51

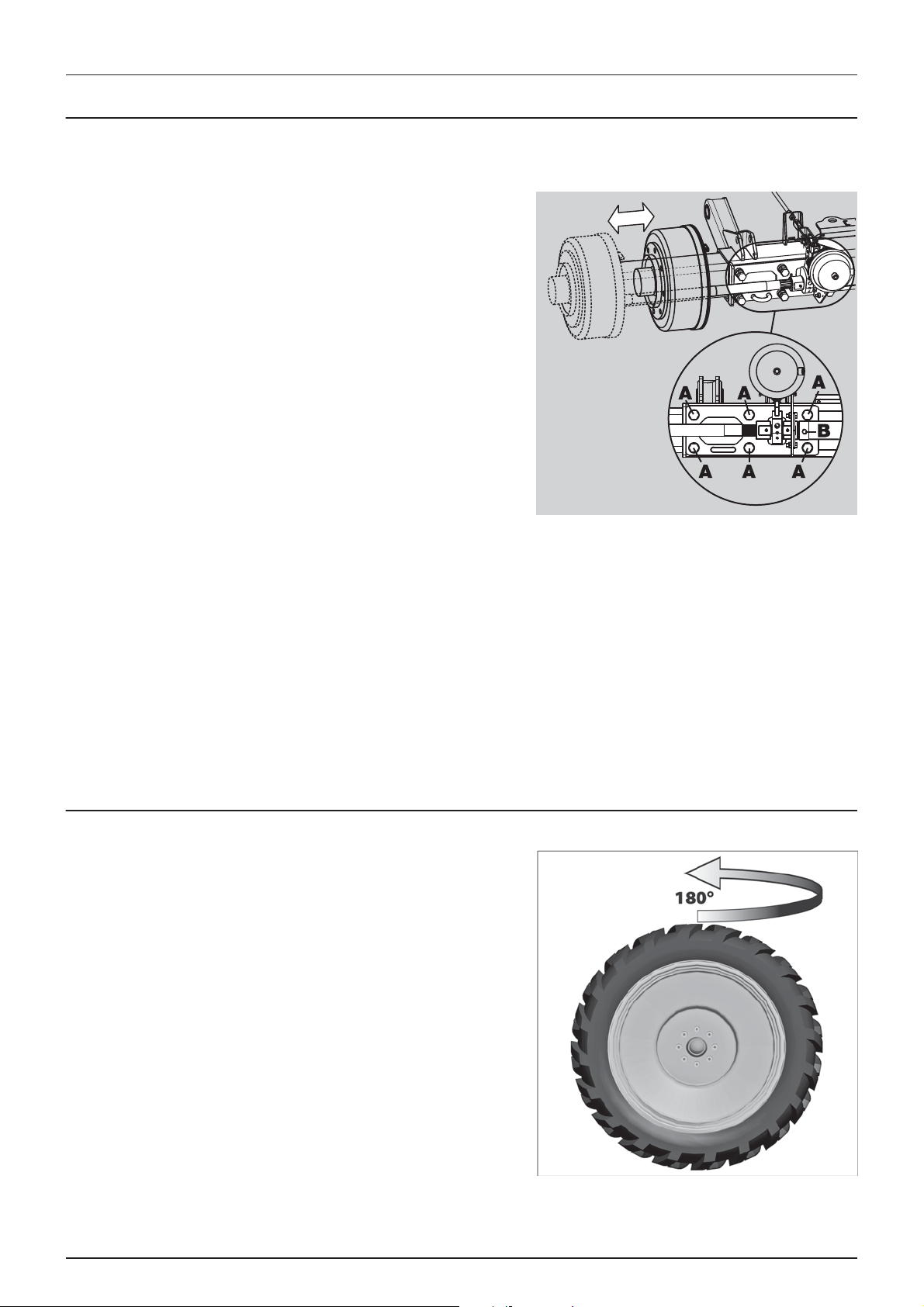

Track gauge, axles and wheels ............................................................................................................52

Altering the track width .................................................................................................................................................................................. 52

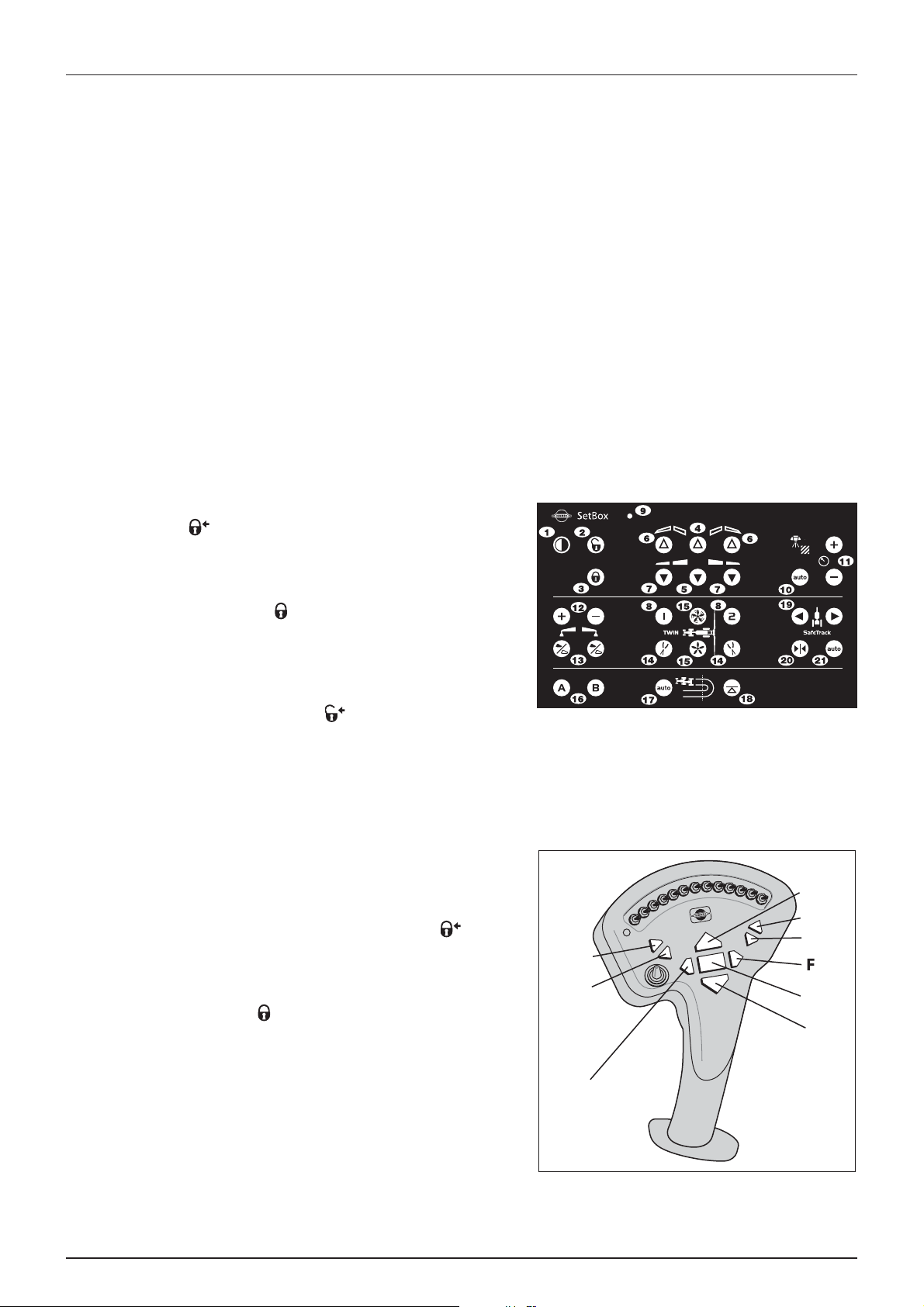

Turning rim ............................................................................................................................................................................................................. 52

Counter weight .................................................................................................................................................................................................... 53

Brakes ..................................................................................................................................................54

Emergency and parking brake .................................................................................................................................................................... 54

Hydraulic activated brakes ............................................................................................................................................................................ 54

Air activated brakes (optional) .................................................................................................................................................................... 55

Single-line brakes (optional) ......................................................................................................................................................................... 55

Dual-line brakes (optional) ............................................................................................................................................................................ 55

5 - Operation

General info .........................................................................................................................................57

Environmental info ............................................................................................................................................................................................ 57

Boom ...................................................................................................................................................58

Safety info ................................................................................................................................................................................................................ 58

Manoeuvring of the boom - HAY ............................................................................................................................................................. 58

Manoeuvring of the boom - HAZ ............................................................................................................................................................. 59

Hydraulic slanting control ............................................................................................................................................................................. 60

Z-models .................................................................................................................................................................................................................. 60

Boom tilt function ............................................................................................................................................................................................... 60

2/3 boom width ................................................................................................................................................................................................... 60

Half boom width ................................................................................................................................................................................................. 60

Hydraulic breakaway function .................................................................................................................................................................... 60

TWIN Air technique ..............................................................................................................................61

TWIN operation .................................................................................................................................................................................................... 61

Liquid system ......................................................................................................................................62

Filling/washing location requirements ................................................................................................................................................. 62

Filling of water ...................................................................................................................................................................................................... 62

Filling through tank lid .................................................................................................................................................................................... 63

Filling of rinsing tank ......................................................................................................................................................................................... 63

Filling of clean water tank .............................................................................................................................................................................. 63

4

Page 5

External Filling Device ...................................................................................................................................................................................... 64

Safety precautions - crop protection chemicals .............................................................................................................................. 65

Filling chemicals through tank lid ............................................................................................................................................................ 65

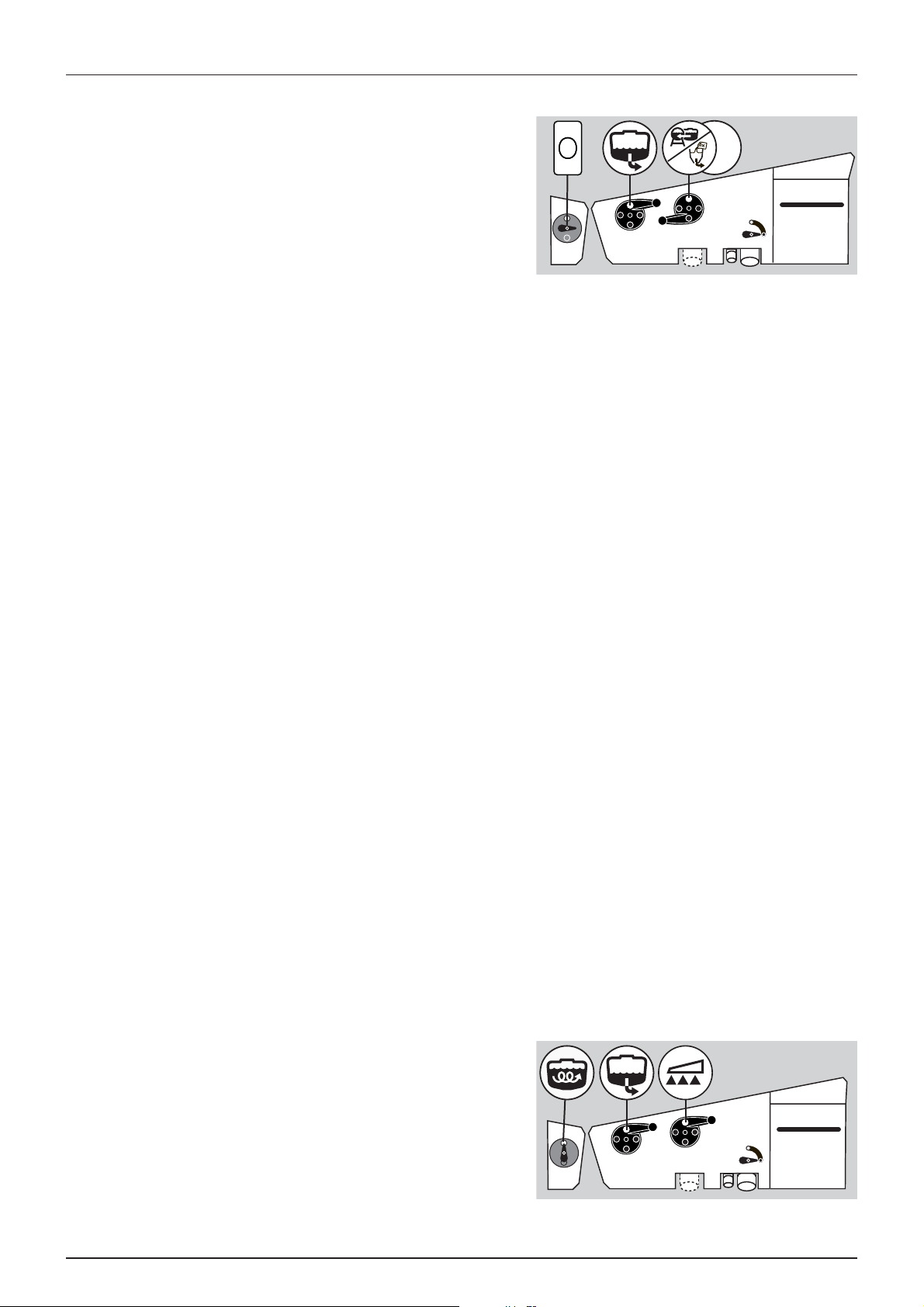

Filling liquid chemicals by HARDI TurboFiller ................................................................................................................................... 66

Filling powder chemicals by HARDI TurboFiller .............................................................................................................................. 67

TurboFiller rinsing ............................................................................................................................................................................................... 68

Operating the control units while spraying ....................................................................................................................................... 69

Before returning to refill the sprayer ....................................................................................................................................................... 70

Agitation before resuming a spray job .................................................................................................................................................. 70

Parking the sprayer ............................................................................................................................................................................................ 70

Quick reference - Operation ......................................................................................................................................................................... 71

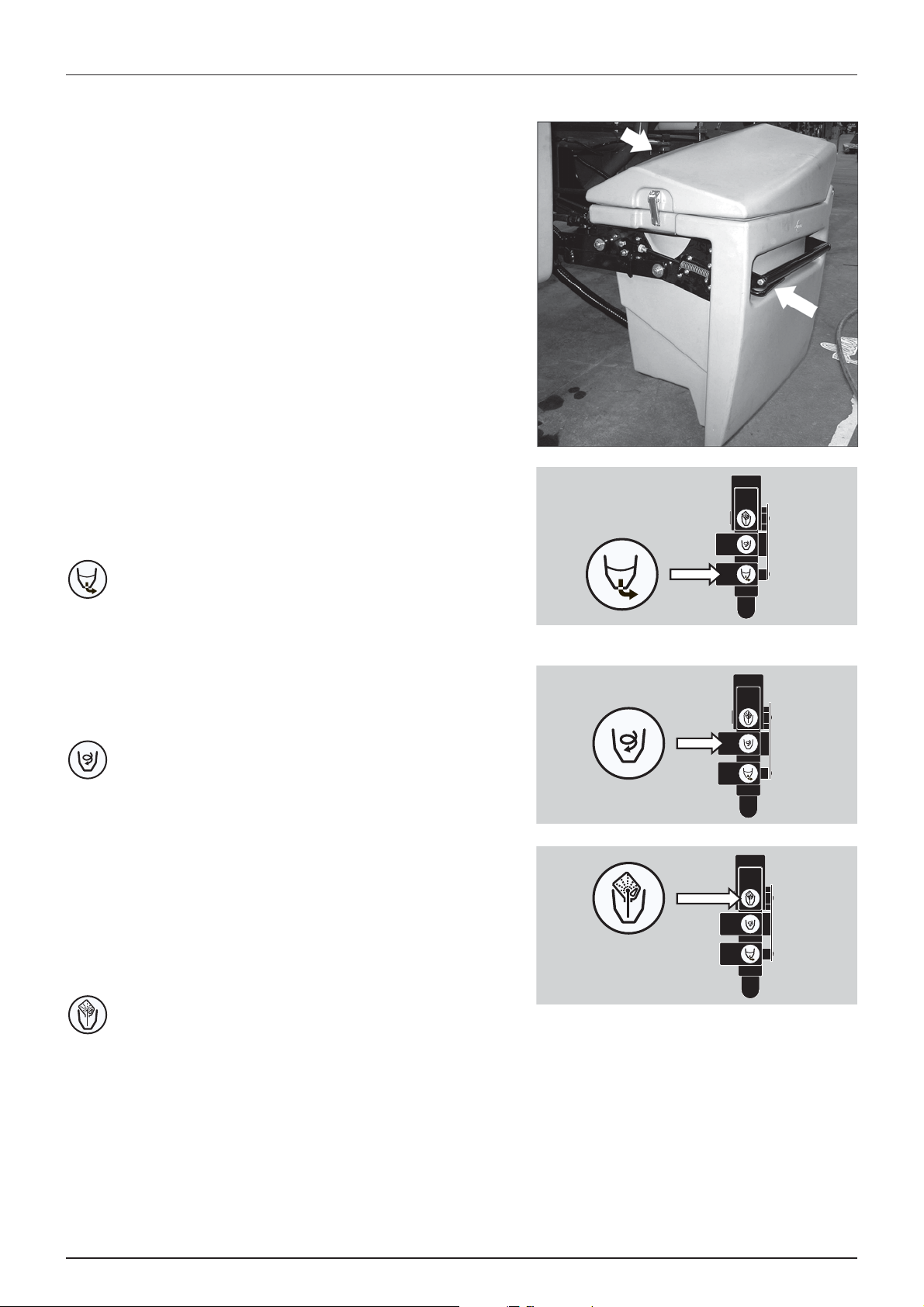

Cleaning ...............................................................................................................................................72

General info ............................................................................................................................................................................................................ 72

Quick reference - Cleaning ............................................................................................................................................................................ 73

Cleaning and maintenance of filters ....................................................................................................................................................... 74

Use of rinsing tank and rinsing nozzles ................................................................................................................................................. 74

A. Full internal rinsing ....................................................................................................................................................................................... 74

B. External cleaning ............................................................................................................................................................................................ 75

C. Rinsing spraying circuit without diluting main tank content ............................................................................................ 76

Full internal cleaning (Soak wash) ............................................................................................................................................................ 76

PrimeFlow - manual cleaning ..................................................................................................................................................................... 78

Use of detergents ............................................................................................................................................................................................... 78

Technical residue ................................................................................................................................................................................................ 78

Using the drain valve ........................................................................................................................................................................................ 78

Pressure draining (optional) ......................................................................................................................................................................... 79

6 - Maintenance

Lubrication ..........................................................................................................................................81

General info ............................................................................................................................................................................................................ 81

Recommended lubricants ............................................................................................................................................................................. 81

P.T.O. lubrication & oiling plan .................................................................................................................................................................... 81

Boom lubrication and oiling plan ............................................................................................................................................................. 82

Boom lubrication and oiling plan (32-36 m) ...................................................................................................................................... 83

Trailer/ParaLift lubrication & oiling plan ................................................................................................................................................ 84

Service and maintenance intervals .....................................................................................................85

10 hours service - Cyclone Filter ................................................................................................................................................................ 85

10 hours service - EasyClean filter ............................................................................................................................................................. 85

10 hours service - In-Line filter (not PrimeFlow) .............................................................................................................................. 86

10 hours service - Spraying circuit ............................................................................................................................................................ 86

10 hours service - Brakes (Standard for CM 5500 and 7000) .................................................................................................... 86

10 hours service - Brakes air tank (optional) ....................................................................................................................................... 86

10 hours service - Lubricate boom and centre ................................................................................................................................ 86

10 hours service - Hydraulic oil level ....................................................................................................................................................... 87

10 hours service - Gearbox oil level ......................................................................................................................................................... 87

50 hours service - Transmission shaft ..................................................................................................................................................... 87

50 hours service - Wheel nuts ..................................................................................................................................................................... 87

50 hours service - Air brakes (optional) ................................................................................................................................................. 87

50 hours service - Tyre pressure ................................................................................................................................................................. 87

50 hours service - Gearbox bolts ............................................................................................................................................................... 88

100 hours service - Check/tighten steering ....................................................................................................................................... 88

250 hours service - Readjustment of the boom .............................................................................................................................. 89

250 hours service - Wheel bearings ......................................................................................................................................................... 89

250 hours service - Hydraulic circuit ....................................................................................................................................................... 89

250 hours service - Hoses and tubes ...................................................................................................................................................... 89

250 hours service - Inspect parking brake (optional) ................................................................................................................... 90

250 hours service - Air brake filters (optional) ................................................................................................................................... 90

250 hours service - Brake adjustment (optional) ............................................................................................................................. 90

250 hours service - Hydraulic brakes (optional) ............................................................................................................................... 91

500 hours service - Hydraulic oil filter .................................................................................................................................................... 91

1000 hours service - Wheel bearings and brakes ............................................................................................................................ 91

5

Page 6

Occasional maintenance ......................................................................................................................93

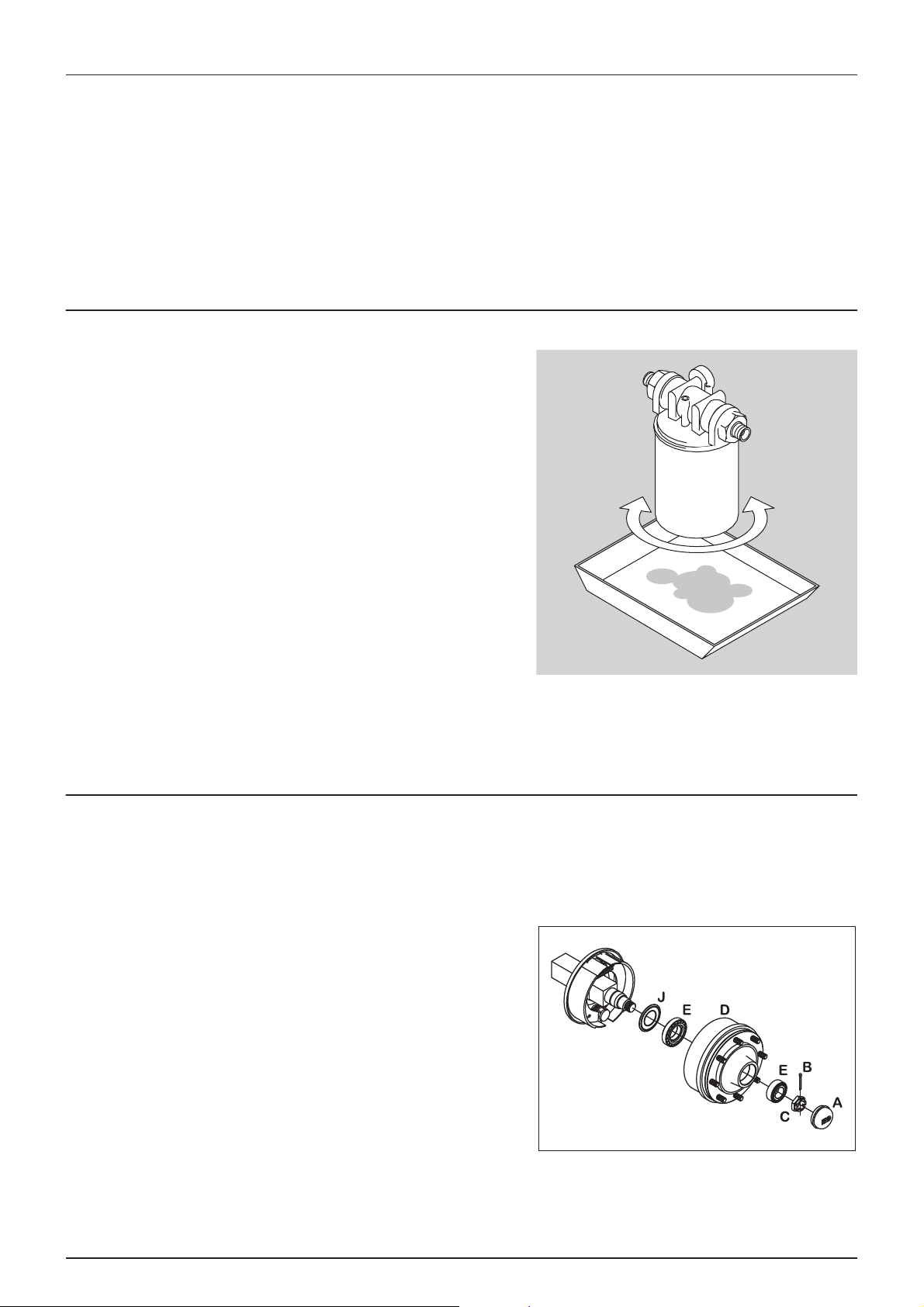

Pump valves and diaphragms renewal ................................................................................................................................................. 93

Level indicator wire renewal ........................................................................................................................................................................ 94

Level indicator adjustment ........................................................................................................................................................................... 94

Drain valve seal renewal ................................................................................................................................................................................. 94

Adjustment of 3-way valve ........................................................................................................................................................................... 95

Feed pipe snap-lock assembly ................................................................................................................................................................... 95

Feed pipe clamp assembly ........................................................................................................................................................................... 96

Opening the cable trays ................................................................................................................................................................................. 96

Readjustment boom - general info ......................................................................................................................................................... 97

Alignment of centre and inner wing sections .................................................................................................................................. 97

Alignment of inner and 1st outer wing sections ............................................................................................................................ 98

Alignment of inner and 1st outer wing sections (32-36 m) ..................................................................................................... 98

Breakaway section adjustment .................................................................................................................................................................. 98

Breakaway section adjustment (32-36m) ............................................................................................................................................ 99

Hydraulic slanting control adjustment .................................................................................................................................................. 99

Hydraulic slanting control adjustment (32-36m) ............................................................................................................................ 99

Wing tilt adjustment .......................................................................................................................................................................................100

Spring arrangement (32-36 m only) ......................................................................................................................................................100

Wear bushing renewal on boom lift .....................................................................................................................................................100

Change of bulbs ................................................................................................................................................................................................101

Wear bushing renewal on steering .......................................................................................................................................................101

Shield renewal on transmission shaft ...................................................................................................................................................101

Replacement of transmission shaft cross journals .......................................................................................................................101

Safety valve activation ...................................................................................................................................................................................101

Change of tyre ....................................................................................................................................................................................................102

Fan transmission priming ............................................................................................................................................................................102

Fan transmission pressure adjustment ...............................................................................................................................................103

Off-season storage ........................................................................................................................... 104

Off-season storage program ......................................................................................................................................................................104

7 - Fault finding

Operational problems ...................................................................................................................... 107

General info ..........................................................................................................................................................................................................107

Liquid system .......................................................................................................................................................................................................108

Hydraulic system - Z model ........................................................................................................................................................................109

Hydraulic system - Y model ........................................................................................................................................................................109

Hydraulic fan transmission ..........................................................................................................................................................................110

Controller fault codes .....................................................................................................................................................................................111

Mechanical problems ....................................................................................................................... 112

Emergency operation - Liquid system .................................................................................................................................................112

Emergency operation - EasyClean filter ..............................................................................................................................................112

8 - Technical specifications

Dimensions ....................................................................................................................................... 113

General info ..........................................................................................................................................................................................................113

Overall dimensions ..........................................................................................................................................................................................113

Weight .....................................................................................................................................................................................................................114

Wheel and axle dimensions .......................................................................................................................................................................115

Specifications ................................................................................................................................... 116

Pump model 463/5.5 ......................................................................................................................................................................................116

Pump model 463/6.5 ......................................................................................................................................................................................116

Pump model 463/10.0 ...................................................................................................................................................................................116

Pump model 463/12.0 ...................................................................................................................................................................................116

Technical residue ..............................................................................................................................................................................................116

Filters and nozzles ............................................................................................................................................................................................117

Power consumption .......................................................................................................................................................................................117

Brakes ........................................................................................................................................................................................................................117

Tyre pressure ........................................................................................................................................................................................................118

6

Page 7

Materials and recycling .................................................................................................................... 119

Disposal of the sprayer ..................................................................................................................................................................................119

Electrical connections ....................................................................................................................... 120

Rear lights ..............................................................................................................................................................................................................120

Charts ............................................................................................................................................... 121

Sprayer hydraulic ...............................................................................................................................................................................................121

Boom hydraulic - Y ...........................................................................................................................................................................................121

Boom hydraulic - Z ...........................................................................................................................................................................................122

Index

Index ................................................................................................................................................. 123

7

Page 8

8

Page 9

EC Declaration of Conformity

As manufacturer:

HARDI INTERNATIONAL A/S

Helgeshøj Allé 38

DK 2630 Taastrup

DENMARK

hereby declare that the following product(s):

1 - EC Declaration

COMMANDER TWIN FORCE (HAY/HAZ)

• Fulfils all the relevant provisions of Machinery Directive 2006/42/EC, 2009/127/EC and later amendments

• All the relevant provisions of Council Directive 2004/108/EC (EMC)

Taastrup, 01.04. 2013

Lars Bentsen

Vice president, Product development

HARDI INTERNATIONAL A/S

9

Page 10

1 - EC Declaration

10

Page 11

2 - Safety notes

Operator safety

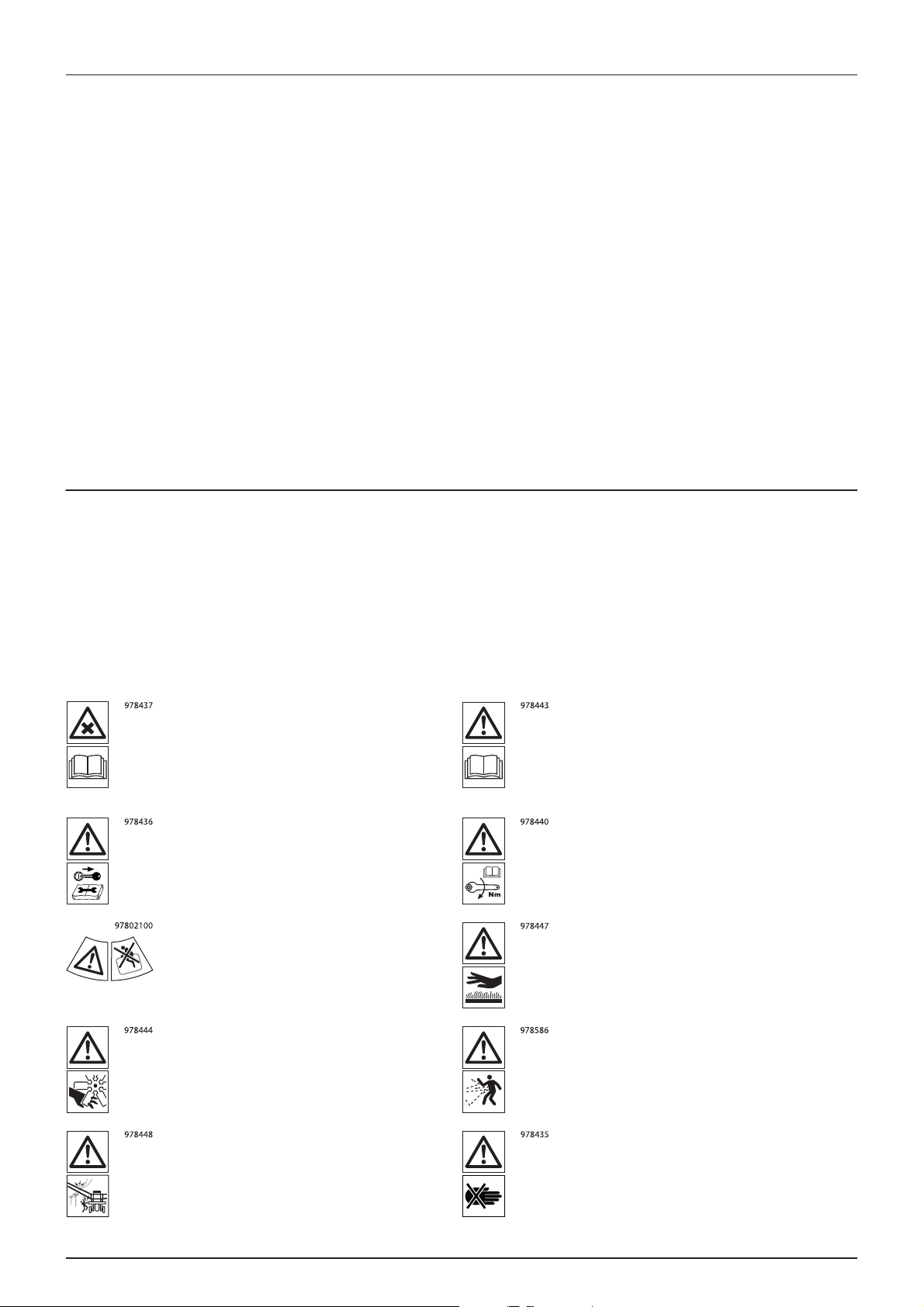

Symbols

These symbols are used thorough the book to designate where some sort of extra attention has to paid for the reader. The

four symbols have following meaning.

This symbol means DANGER. Be very alert as your safety is involved!

Ƚ

This symbol means WARNING. Be alert as your safety can be involved!

±

This symbol means ATTENTION. This guides to better, easier and more safe operation of your sprayer!

This symbol means NOTE.

÷

Precautions

Note the following recommended precautions and safe operating practices before using the sprayer.

General info

Read and understand this instruction book before using the equipment. It is equally important that other operators

€

of this equipment read and understand this book.

If any portion of this instruction book remains unclear after reading it, contact your HARDI dealer for further

explanation before using the equipment.

Local law may demand that the operator is certified to use spray equipment. Adhere to the law.

€

Tractor drivers seat is the intended working place during operation.

€

Wear protective clothing. Clothing may differ depending on chemical being sprayed. Adhere to the local law.

€

Wash and change clothes after spraying. Wash tools if they have become contaminated.

Do not eat, drink or smoke while spraying or working with contaminated equipment.

€

In case of poisoning, immediately seek medical advice. Remember to identify chemicals used.

Filling and spraying

No persons are allowed in the operations area of the sprayer. Be carefull not to hit people or surroundings when

€

manoeuvring the sprayer, especially when reversing.

Slow down when driving in uneven terrain as the machine might be in risk of turning over.

€

Keep children away from the equipment!

€

Do not attempt to enter the tank.

€

Do not go under any part of the sprayer unless it is secured. The boom is secure when placed in the transport

€

brackets.

11

Page 12

2 - Safety notes

Service

Pressure test with clean water prior to filling with chemicals. Never dismount the hoses if the machine is in operation.

€

DANGER! Do not exceed the P.T.O. max. recommended r.p.m.

Rinse and wash equipment after use and before servicing.

€

Never service or repair the equipment while it is operating. Always replace all safety devices or shields immediately

€

after servicing.

Disconnect electrical power before servicing and depressurize equipment after use and before servicing.

€

If an arc welder is used on the equipment or anything connected to the equipment, disconnect power leads before

€

welding. Remove all inflammable or explosive material from the area.

The External Cleaning Device should not be used if important parts of the equipment have been damaged, including

€

safety devices, high pressure hoses, etc.

Label explanation

The labels are designating potential dangerous places on the machine. Anybody working with or being in close range of

the sprayer must respect these labels!

The labels should always be clean and readable! Worn or damaged labels must be replaced with new ones. Contact your

local dealer for new labels.

Note that not all labels shown here will apply to your sprayer.

÷

Chemical handling!

Carefully read the informations about

chemical preparation before handling the

machine. Observe instructions and safety

rules when operating.

Service!

Shut off the engine and remove ignition key

before performing maintenance or repair.

Risk of death!

Do not attempt to enter tank.

Service!

Carefully read operators instruction book

before handling the machine. Observe

instructions and safety rules when operating.

Service!

Tighten to torque according to instruction

book.

Risk of burn!

Stay clear of hot surfaces.

12

Risk of injury!

Do not open or remove safety shields while

engine is running.

Risk of injury!

Keep sufficient distance away from electrical

power.

Risk of injury!

Flying objects, keep safe distance from

machine as long as the engine is running.

Risk of injury!

Keep hands away.

Page 13

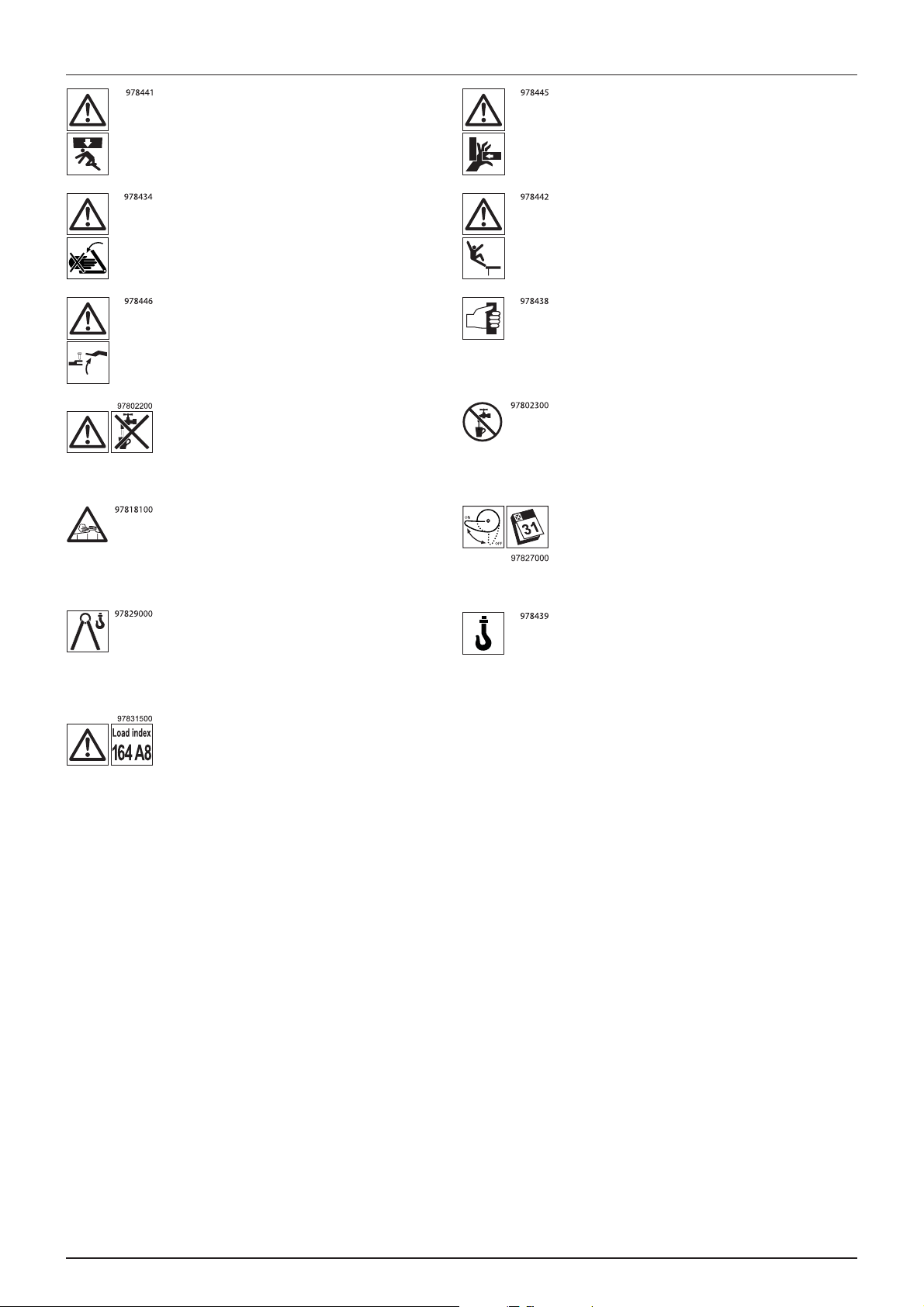

2 - Safety notes

Risk of squeeze!

Stay clear of raised unsecured loads.

Risk of squeeze!

Keep hands away, when parts is moving.

Risk of sprayer tipping over!

Be aware when disconnecting the sprayer.

Not for drinking!

This water must never be used for drinking

water.

Tank u n d e r pressure!

Beware when moving lid.

Risk of squeeze!

Never reach into the crushing danger area as

long as parts are moving.

Risk of falling off!

Do not ride on platform or ladder.

Grapping area!

Manual handling of boom etc.

Not for drinking!

This water must never be used for drinking

water.

EasyClean filter service!

Open and clean filter monthly.

Lifting point! Lifting point!

Load index!

Max. permitted load rating is 164 at 40 km/h.

13

Page 14

2 - Safety notes

14

Page 15

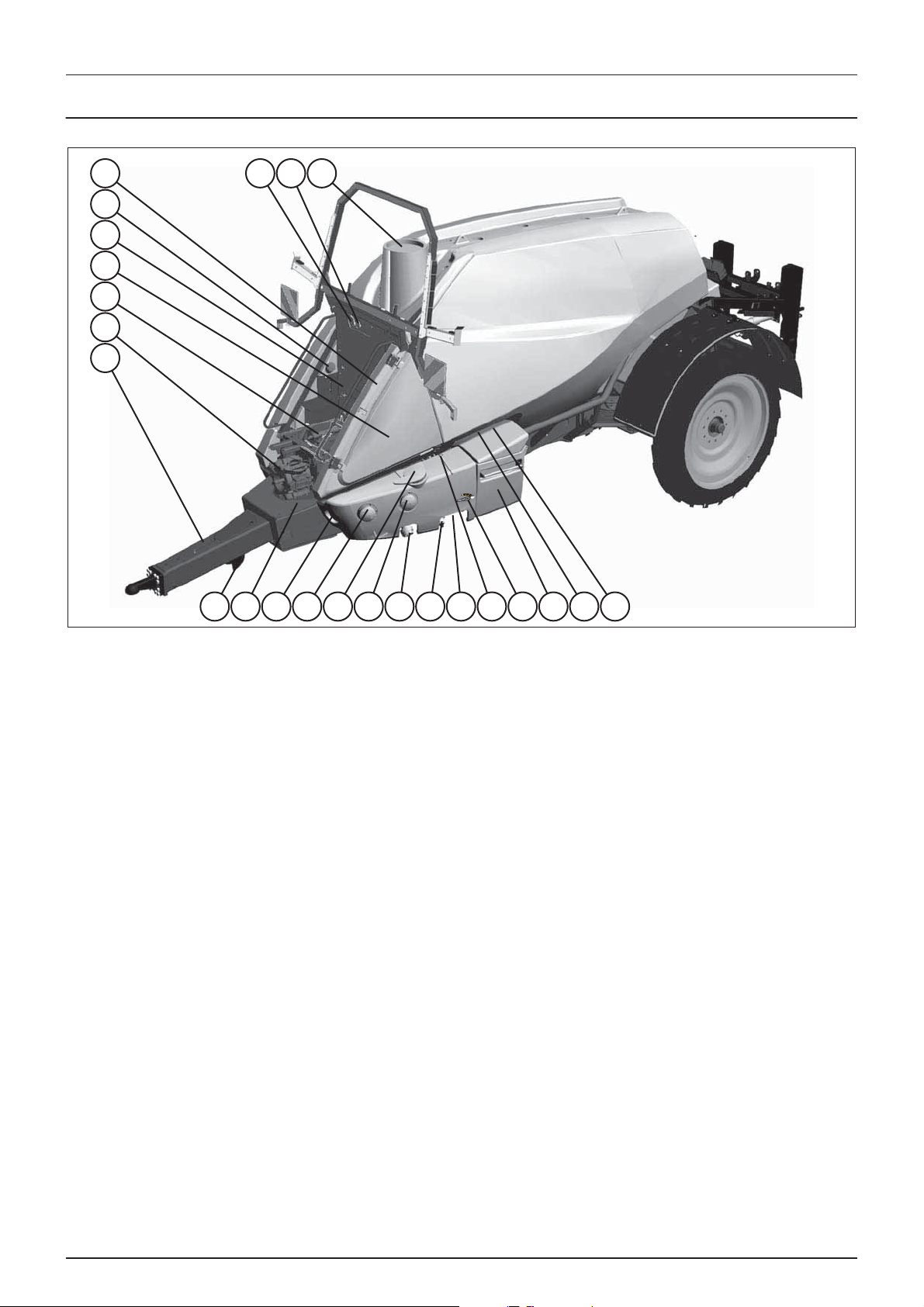

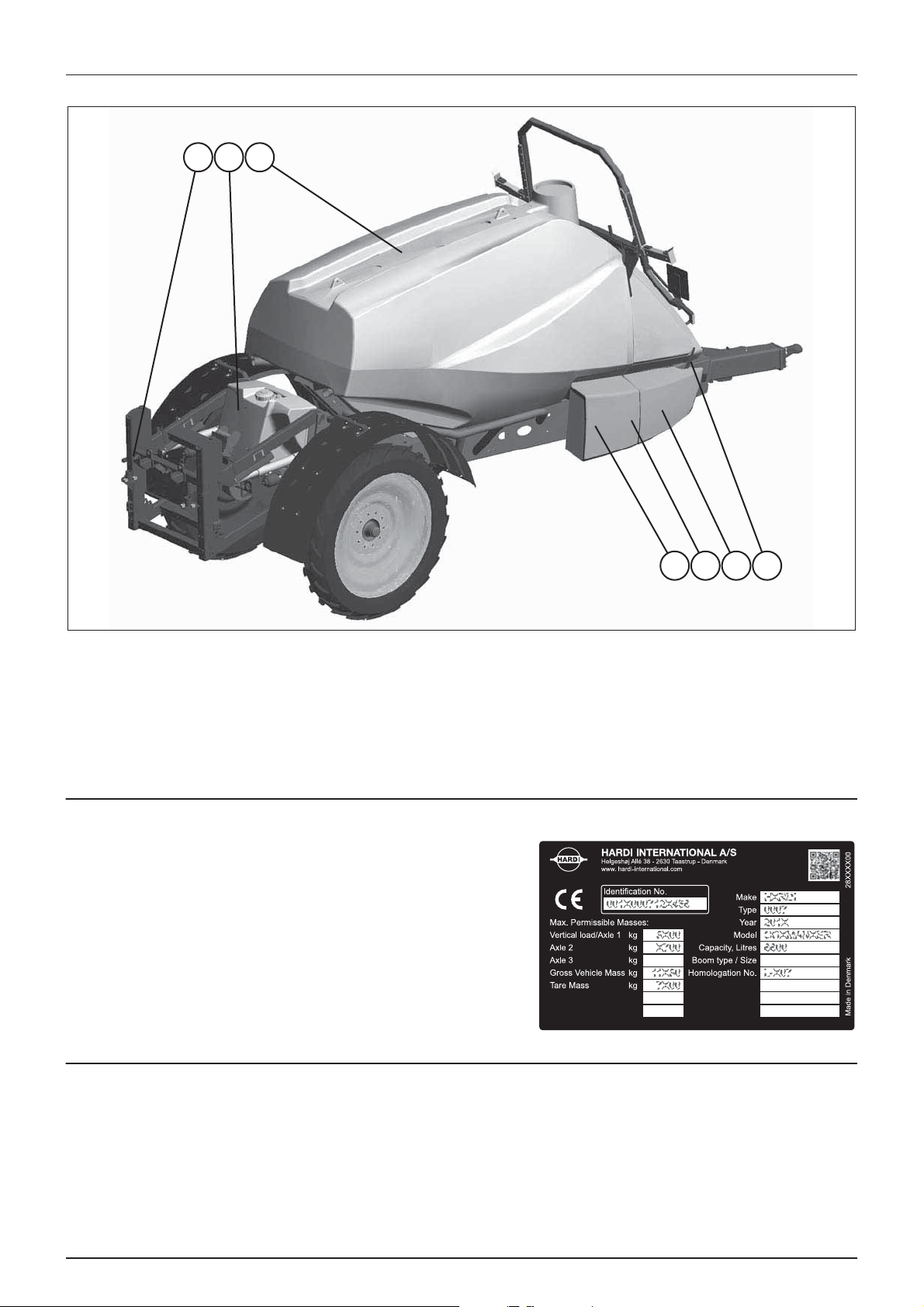

General info

11 10 13 14 15 16 17 18 19 20 21 22 23 24

12

9

8

7

6

4

5 3 2 1

View

3 - Description

1. Main tank lid

2. EasyClean clogging indicator

3. Spray pressure gauge

4. Clean water tank lid

5. Main tank level indicator

6. Rinsing tank level indicator

7. SafetyLocker

8. Platform

9. Pump

10. Ladder

11. Support leg

12. Drawbar hitch

13. Agitation/External Cleaning Device valve

14. Suction SmartValve

15. EasyClean filter

16. Pressure SmartValve

17. Pressure draining coupler

18. Rinsing tank coupler

19. External Filling coupler

20. Clean water tap

21. External Filling ON/OFF valve

22. TurboFiller

23. Lever for chemical container cleaning

24. TurboFiller Vortex nozzle valve

15

Page 16

3 - Description

25 26 27

28 29 30 31

View

25. Distribution valves (not illustrated)

26. Rinsing tank

27. Main tank

28. ChemLocker with FoamMarker tank

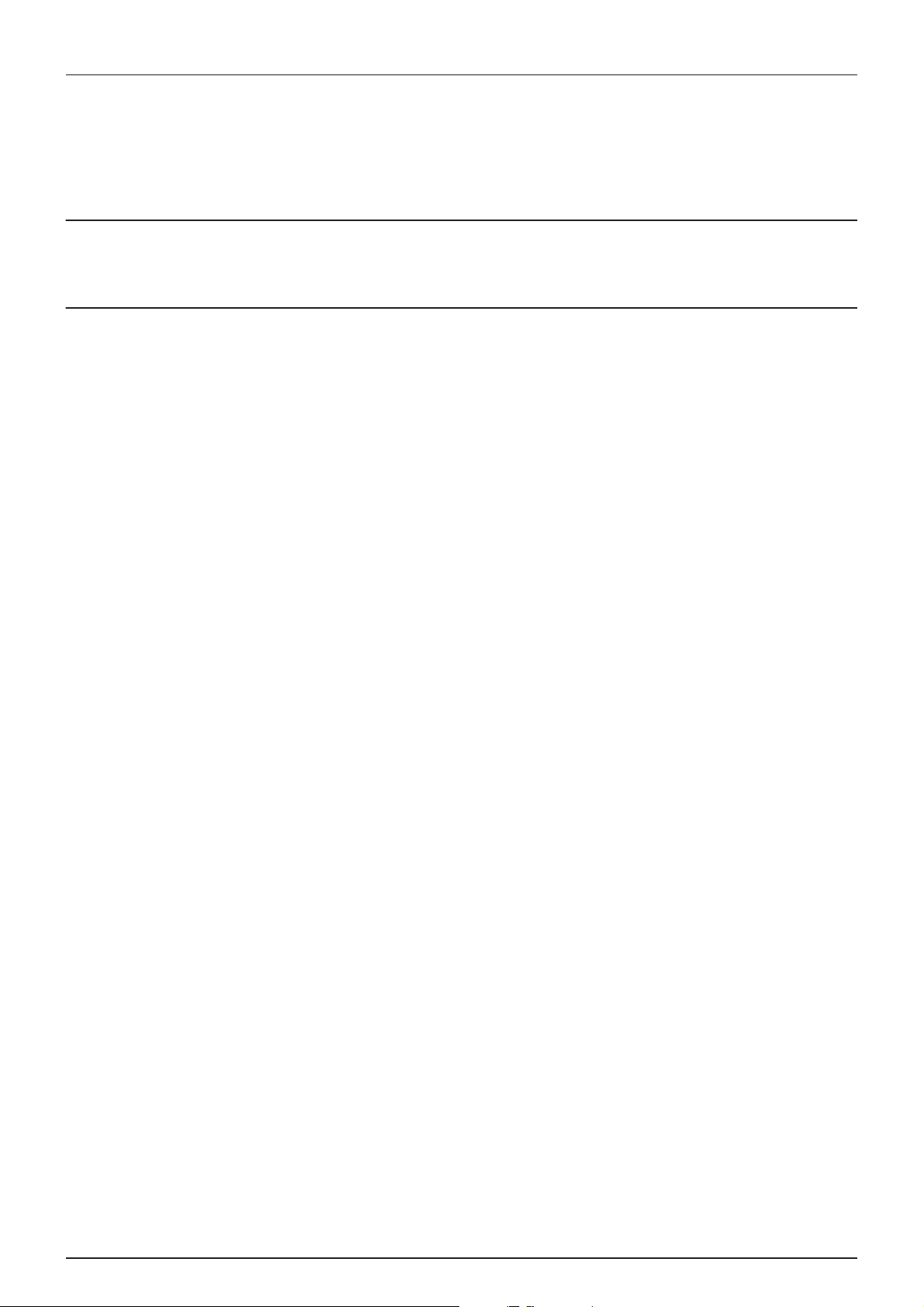

Identification plates

A CE identification plate fitted on the frame indicates producer name,

model, sprayer weights, etc.

The identification plate also has a QR-code which can be read by e.g.

smartphones to obtain more detailed data about the sprayer, which can

be useful for service staff.

Roadworthiness

When driving on public roads and other areas where the highway code applies, or areas with special rules and regulations

for marking and lights on implements, you should observe these and equip implements accordingly.

29. Spray lance for External Cleaning Device

30. CycloneFilter

31. Parking brake

AT TENTION! Max. driving speed for models without brakes and for models equipped with brakes is different. Be aware

that these speeds may differ due to local law. Contact local authorities for information of max. driving speeds!

16

Page 17

3 - Description

Sprayer use

The HARDI sprayer is for the application of crop protection chemicals and liquid fertilisers. The equipment must only be used

for this purpose. It is not allowed to use the sprayer for any other purposes. If no local law demands that the operator must

be certified to use spray equipment, it is strongly recommended to be trained in correct plant protection and in safe

handling of plant protection chemicals to avoid unnecessary risk for persons and the environment when doing your spray

job.

Frame

Very strong and compact frame which also has a strong chemical and weather resistant electrostatic lacquer coat. Screws,

nuts, etc. have been DELTA-MAGNI treated to be resistant to corrosion.

Tanks and equipment

The main tank made of impact-proof, UV-resistant and chemical resistant polyethylene, has a purposeful design with no

sharp corners for easy cleaning. The filling hole is placed so it can be accessed from the platform. This ensures an easy access

for the filling of sprays, cleaning of the tank, etc. The sprayer is also equipped with a rinsing tank and a clean water tank. A

large, easy to read tank contents indicator is placed beside the platform and is visible from the tractor cabin.

Nominal contents 3300, 4500, 5500 or 7000 litres.

17

Page 18

3 - Description

Liquid system

Pump

Diaphragm pump with 6 diaphragms, model 463. Standard = 540 r.p.m. (6 splines shaft). Optional = 1000 r.p.m. (21 splines

shaft). The design of the diaphragm pump is simple, with easily accessible diaphragms and valves which ensures liquid does

not contact the vital parts of the pump.

FlexCapacity pump

Some sprayers facilitates a dual pump setup with an extra hydraulically driven pump of same type as the main pump, placed

on sprayers right side.

The FlexCapacity pump is turned ON/OFF with a separate hydraulic lever in the tractor cabin.

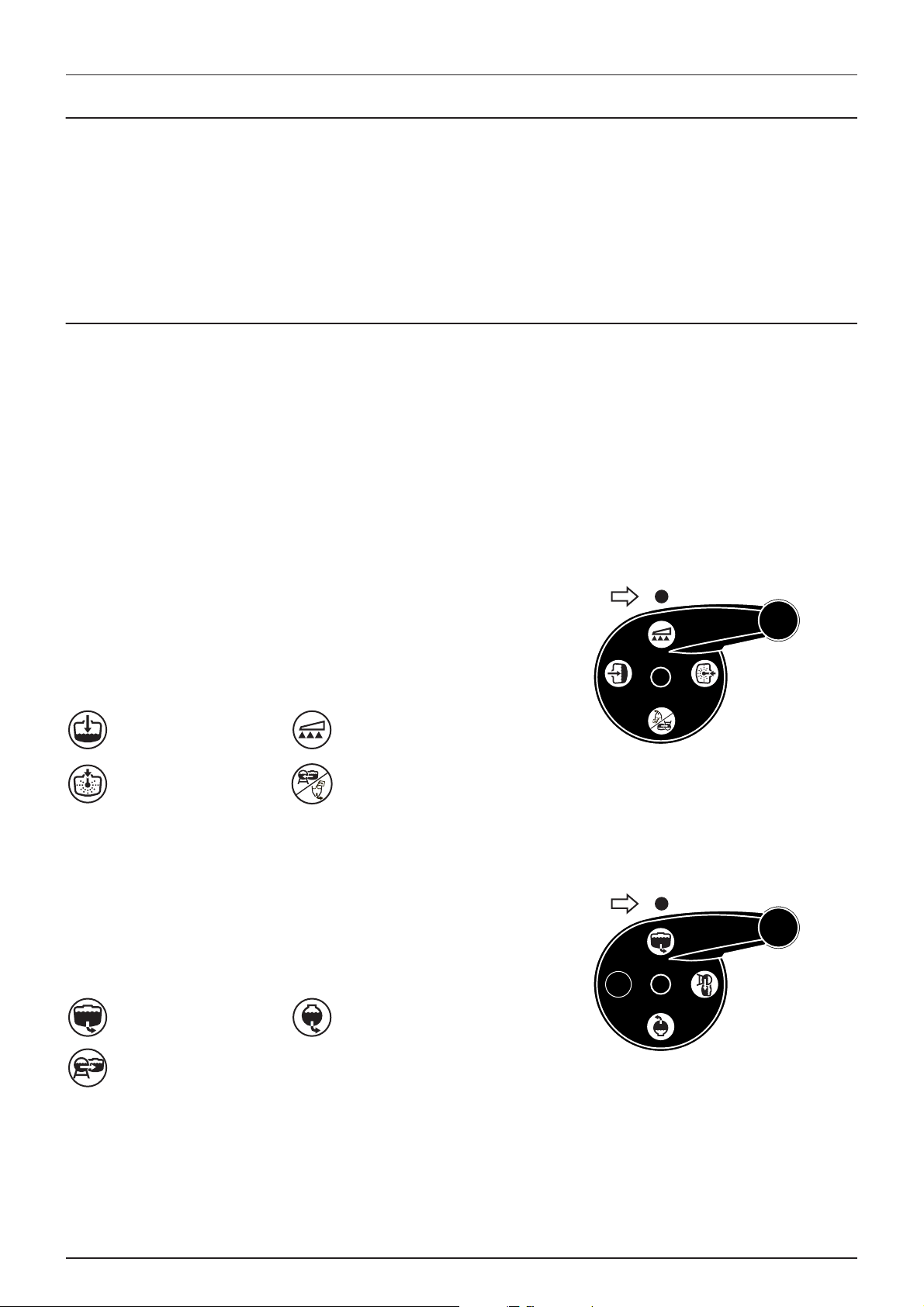

Valves and symbols

The possible functions of valves are distinguished by coloured identification on the function labels. The modular valve

system facilitates the addition of optional extras on both pressure side and suction side. A function is activated by turning

the handle towards the desired function.

ATTENTION! Only the functions used should be open - always close remaining valves.

ATTENTION! If a valve is too tight to operate - or to loose (= liquid leakage) - the valve needs to be serviced. Please see

“Pump valves and diaphragms renewal” on page 93 for further information.

Pressure SmartValve (Green symbols)

This valve is to select which function the pressurized liquid from the

pump will be routed to.

The active function is indicated by the indicator. The handle is turned so

the indicator points to the label for required function. If handle is turned

to a position without label (unused function) then the valve is closed.

Main tank Spraying

Internal tank cleaning

(Rinsing nozzles)

Suction SmartValve (Blue symbols)

This valve is to select suction from main tank or from the rinsing tank.

The handle is turned so the label for required function is directed to the

indicator. If handle is turned to vertical position (indicator not pointing

at a label) then the valve is closed.

Main tank Rinsing tank

Pressure draining (optional)

or TurboFiller

18

External filling (optional)

Page 19

3 - Description

DynamicFluid4 pressure regulation

Traditional fluid regulation starts when the nozzles are opened. With DynamicFluid4 the regulation is a continuous process

that continues even if the nozzles are closed. Two ceramic discs regulates the pressure and ensures quick reaction and zero

leakages. Sprayer speed, P.T.O. RPM and number of sections activated are parameters used, and the benefit is more precise

application rates from the second the sprayer begins spraying.

The DynamicFluid4 use feed forward technology based on 5 sensors that feeds the JobCom computer with data necessary

for optimal regulation. It auto-prime at start-up, starts and move the valve towards the final position immediately after the

operator makes changes. E.g. when section valves are opened or closed, the regulation valve is started at same time as the

section valve motors are started. This avoids overpressure situations e.g. after running empty and refill of main tank.

The 5 sensors are also back-up for each other and ensures the system can continue regulation even if one or more sensor

signal fails. Sensors used are:

• Sprayer speed sensor

• Flow sensor

• Pressure sensor

• Pump r.p.m. sensor

• Regulation valve opening angle sensor

The DynamicFluid4 pressure regulation features are:

• Very fast and accurate regulation when all sensors are ok, setup in menus are correct and pump, filters and valves are

in good conditions.

• Quick reacting valve when sections are turned ON/OFF and at speed changes.

• Optimized AutoSectionControl feature that predict boom sections to open and nozzle pressure.

• Optimized for different P.T.O. systems.

• Nozzle surveillance. No setup or tuning required for nozzle change.

• Warning in display if fail ures o ccur on boom plu mbing, such as seve re cloggi ng of l ine or nozzle f ilter s or large leak age s

on hoses and fittings.

• All functions work though with degraded performance (Limp home modes), if:

Faults occur in fluid system, e.g. pump defects, clogged filters, leaking valves.

Sensor failure appear on pressure sensor, flow sensor or RPM sensor.

There is wrong setup of sprayer data in menus.

• Emergency mode if angle sensor or speed sensor fails.

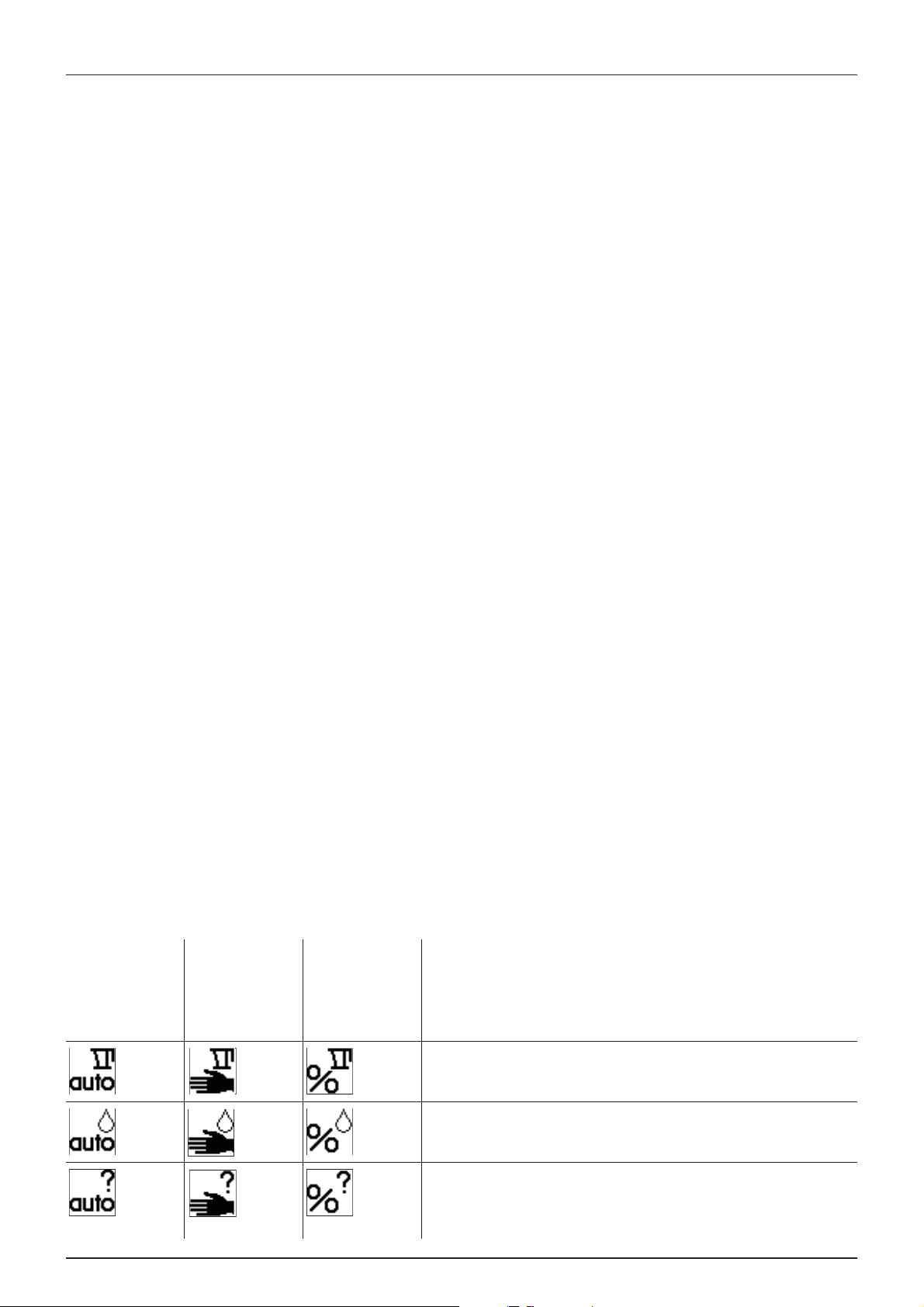

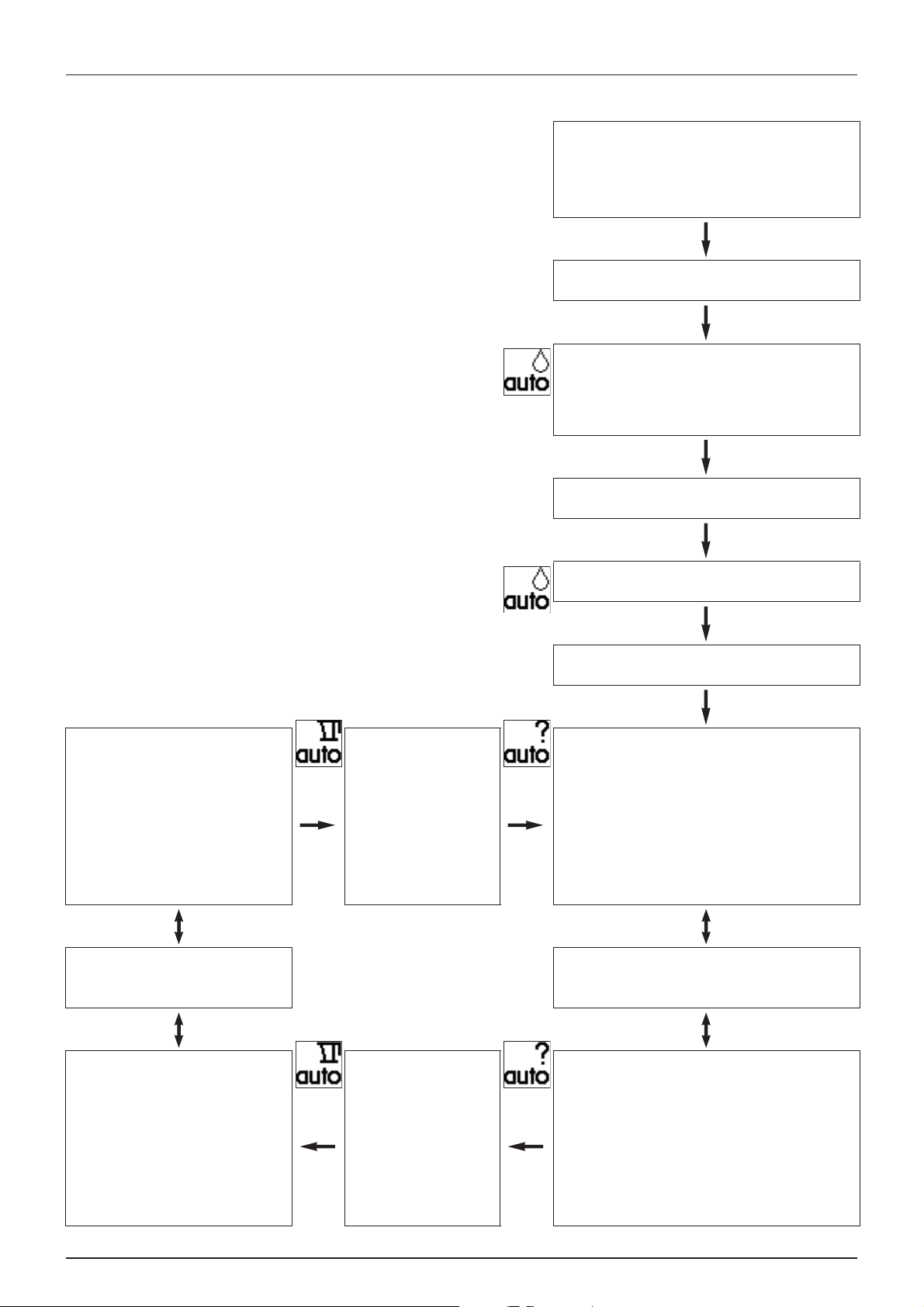

Screen icons

The sprayer driver selects one of three modes Auto, Manual or Increment steps. The sprayer computer detects one of three

regulation modes Drop, Question mark or calibration jug. This makes 9 modes in total.

Auto Manual Increment steps

When Automatic

Volume Rate button is

pressed on the SetBox.

When one of the

Manual pressure

control buttons is

pressed on the SetBox.

When the Volum e Rate

is changed in steps

with %-up or %-down

buttons on the

Ter mi nal .

Calibration jug

There is flow to section valves.

Nozzle size (L/min at 3 bar) has been calculated.

Drop

There is no flow to section valves.

The pump is not started or the pressure SmartValve is set to other function than spraying.

Question mark

There is flow to section valves but pressure and flow has not yet been stable, therefore

the nozzle size (L/min at 3 bar) has not been calculated.

The system uses the previously stored nozzle size.

19

Page 20

3 - Description

Regulation valve function diagram

ATTENTION! Auto mode icons shown, but could be Manual or

Increment steps icons, depending on driver selection.

Spray job begins

Start condition:

Controller is turned OFF. Pump is turned OFF.

Pressure SmartValve to Pressure draining/TurboFiller, suction

SmartValve to Main tank, have water in Main tank.

Driver action

Turn the controller ON.

Controller reaction

Controller detects no pressure or flow.

Starts in auto mode. Sets regulation valve to safe angle, to

avoid overpressure at pump start and to ensure that software

detects that pump is started (avoid hanging).

Driver action

Turn the pump ON.

Controller reaction

Headland (boom is closed)

Software use nozzle size and feed forward to

prepare for opening of boom.

Max. pressure limit is disabled, because last

saved nozzle size is reliable and therefore

software “dare” to close regulation valve

completely.

Driver action

Turn main OFF at headland. (go up)

Turn main ON to spray. (go down)

Headland (boom is closed)

for over 5 min

Boom is closed for a longer

period, that operator could

have changed to other nozzle

size. Last saved nozzle size

become unreliable.

Software enable max. pressure

limit.

Controller action

Controller detects no pressure or flow, Stay in safe position.

Driver action

Turn pressure SmartValve to Spraying.

Controller reaction

Headland (boom is closed)

Controller detects pressure at armature and bypass flow back

to tank. Software use last saved nozzle size and feed forward

to prepare for opening of boom.

Max. pressure limit is enabled, because last saved nozzle size

is unreliable and therefore software will not close regulation

valve completely. PrimeFlow booms are primed.

Driver action

Turn main OFF at headland. (go up)

Turn main ON to spray. (go down)

Controller reaction

Spraying (boom is open)

Boom is open and sprays.

Both flow measurement and pressure

measurement are good, and the actual

nozzle size is calculated.

The actual nozzle size is used to adjust to

correct liter/ha.

20

Flow and pressure are

good

Both flow measurement and

pressure measurement are

good.

Software disable max. pressure

limit.

Controller reaction

Spraying (boom is open)

Boom is open and sprays.

Software use last saved nozzle size and pressure sensor to

adjust to correct liter/ha.

Max. pressure limit is enabled to avoid overpressure in case

operator had changed to smaller nozzles.

Page 21

3 - Description

Clean water tank

The water in this tank is for hand washing, cleaning of clogged nozzles

etc. Only fill this tank with clean water from the well.

Capacity: approximately 20 litres.

WARNING! Although the clean water tank is only filled with clean

±

water, this water must NOT be used for drinking.

Rinsing tank

A rinsing tank is mounted to the rear of the sprayer. The tank are made of impact-proof and chemical resistant polyethylene.

Filling is done via the 1” threaded stud placed in the working area. The rinsing tank level indicator is placed at the platform.

Nominal content: approximately 450 litres.

Filters

A EasyClean suction filter is fitted in the working zone.

A Cyclone pressure filter is fitted to the sprayers right side just in front of the hose reel, hidden behind the right front cover.

It has a built-in self-cleaning function.

In-line pressure filters can be fitted at each boom section as an option (standard for certain booms).

Nozzle filters are fitted at each nozzle.

All filters should always be in use and their function checked regularly. Pay attention to the correct combination of filter and

mesh size (see “Spray Technique” book).

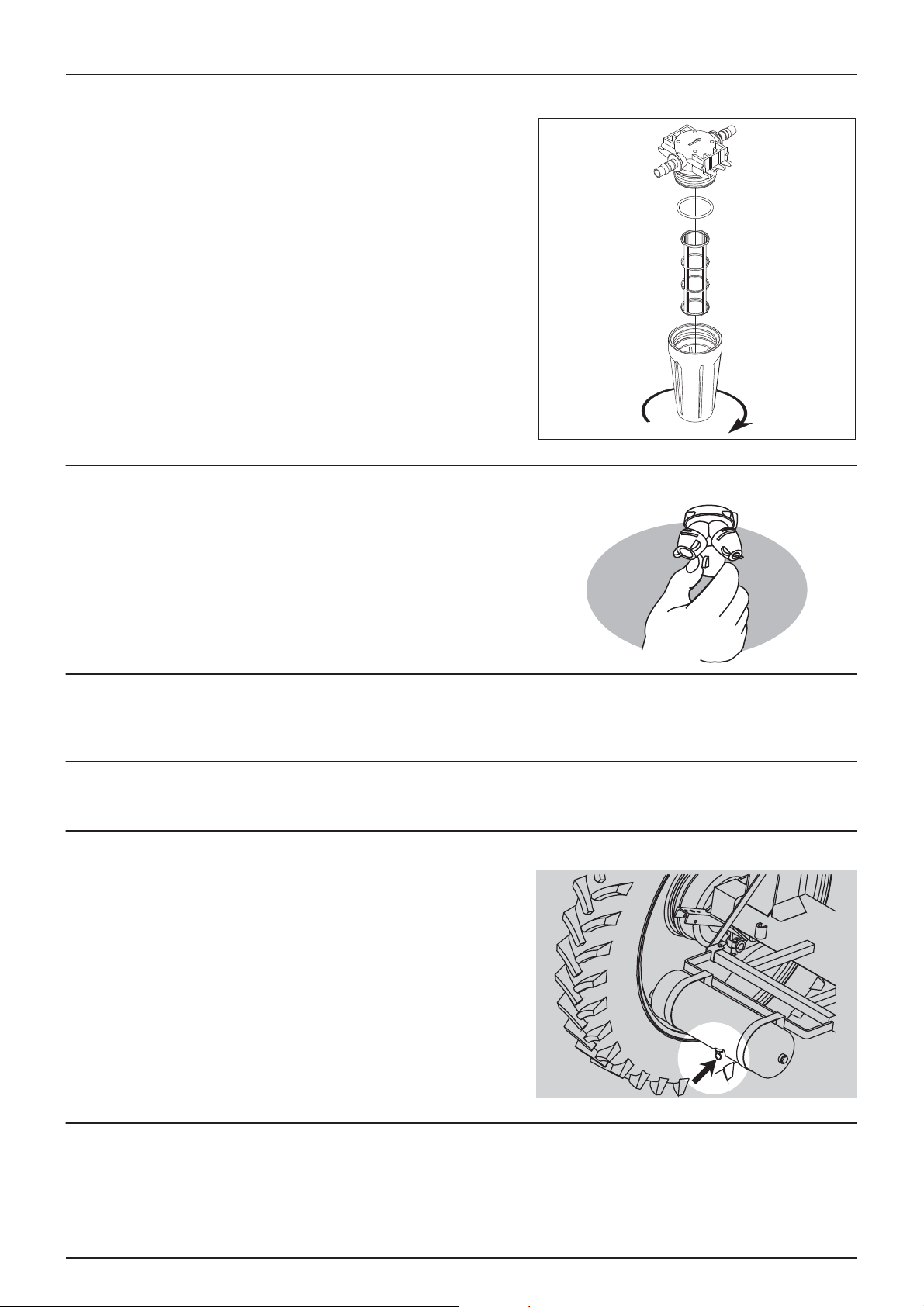

EasyClean filter

To ensure proper function of filter and its built-in valve the filter must be

opened at least 1 time per month. A label on the lid also designates this.

• To open filter then turn it counterclockwise and pull it up, like

shown on picture.

• Pull out the two locks (A) to remove filter element from the lid.

Beside the spray pressure gauge on the platform a EasyClean clogging

indicator is located:

Clogging indicator colour Filter status

Green indicator. No cleaning necessary.

Yellow indicator. It is possible to finish an ongoing spraying job and

Red indicator. Clean EasyClean filter immediately as filter is

then clean filter afterwards.

clogged.

21

Page 22

3 - Description

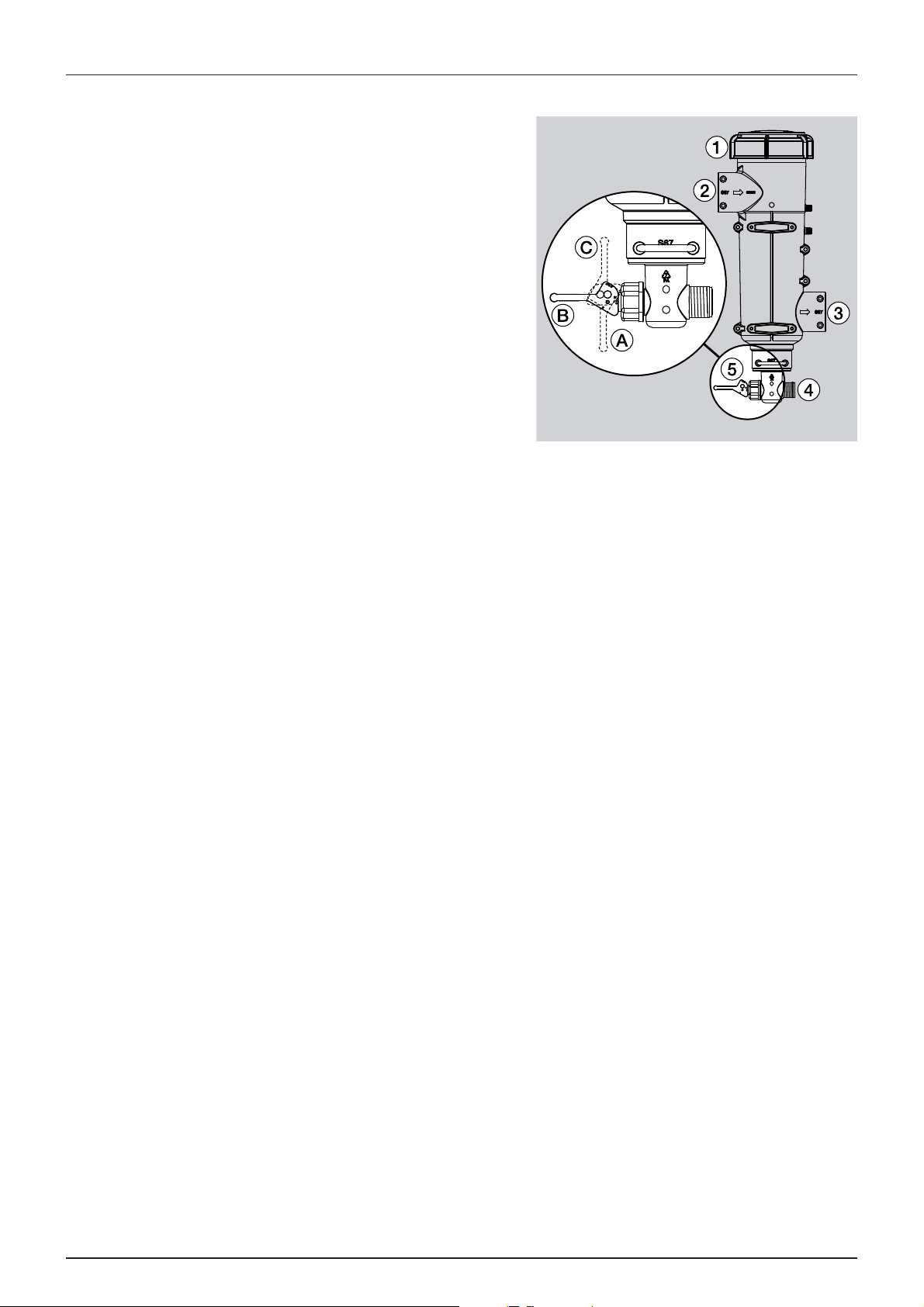

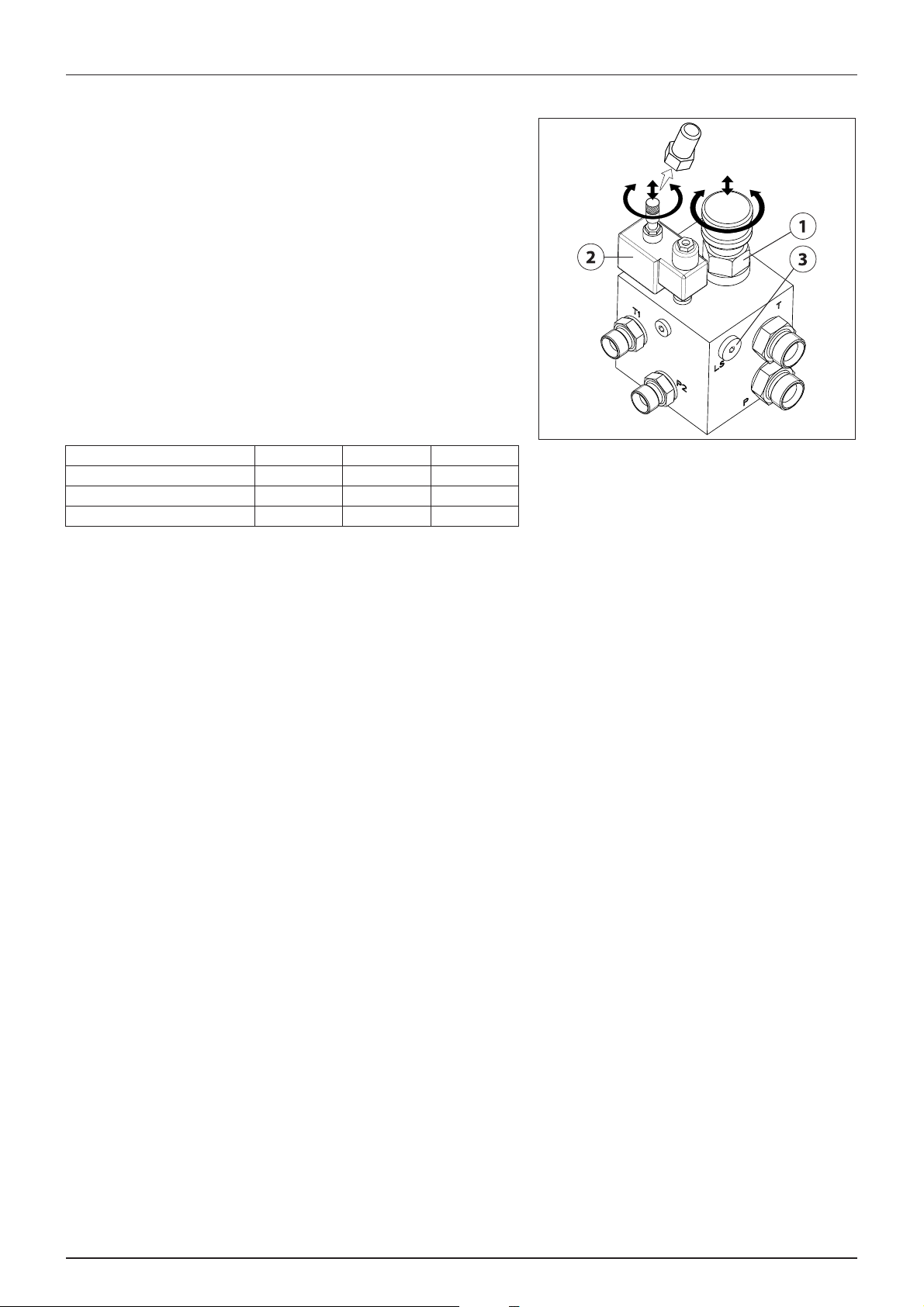

CycloneFilter

With the CycloneFilter any impurities in the spray liquid will by-pass the

filter and be re-circulated back to the tank via the return flow.

Function diagram

1. Filter lid

2. From pump

3. To b o o m

4. Return to tank

5. Return valve

Valve (5) has three positions marked with small dots on the lever:

A. This position marked with 1 dot: There is no return flow. Position is

used when rinsing the boom if there is spray liquid in the main

tank. Also used when high spraying volume is required.

B. This position marked with 2 dots: Normal spraying position. With

return flow to prevent filter is going to be clogged when spraying.

This position is used when rinsing the boom if the main tank is empty.

C. This position marked with 3 dots: Flushing position which is used if filter is clogged. Lift and hold the lever to use this

position which largely increases return flow and flushes the filter. The pressure SmartValve must be set to “Spraying”.

ATTENTION! Use of position C is no guarantee for a clean filter. Always regularly do a visual inspection and cleaning

of the filter. If necessary see “10 hours service - Cyclone Filter” on page 85.

DANGER! Never open the Cyclone filter unless the pressure SmartValve is turned to “Main tank”. Otherwise, spraying

€

liquid may hit you when opening the filter, and drain from the main tank!

22

Page 23

TurboFiller

Before use

• Push the handle (arrow) to unlock.

• Grab the handle to pull TurboFiller down until it clicks into locked

down-position.

After use

• Push the handle (arrow) to unlock.

• Grab the handle to push TurboFiller back in storing position until it

locks.

WARNING! Before releasing the lock (arrowed) always keep a

±

hand on the grip to avoid abrupt movement of the TurboFiller!

The TurboFiller valves and Chemical Container Rinsing lever are placed

on the backside (arrow).

TurboFiller suction valve

The valve is used simultaneously with the TurboFiller. The valve has 2

set tings: C ontin uously o pen or spr ing loaded normally closed. Op en the

valve when chemicals are to be filled into the TurboFiller and transferred

to main tank.

3 - Description

Suction from TurboFiller

TurboDeflector valve

This TurboDeflector valve activates the Vortex flushing of the TurboFiller.

Lift the lever to lock it in open position for continuous liquid rotation in

the hopper.

Start TurboDeflector

Chemical Container Rinsing lever

The upper lever is used for two purposes:

When the TurboFiller lid is open: For rinsing empty containers. Place the

container over the rotating flushing nozzle in the middle of the

TurboFiller to rinse the inside of the container.

When the TurboFiller lid is closed: Use the Chemical Container Rinsing

lever to rinse the hopper when the filling of chemicals is completed.

Chemical Container Rinsing

DANGER! Do not press the lever unless the multi-hole nozzle is covered by a container as spray liquid may otherwise

€

hit the operator.

23

Page 24

3 - Description

9

22

20

23

17

22

10

22

1

2

15

16

22

8

18 19

22

21

7

3

11

14

6

13

22

5 4

28

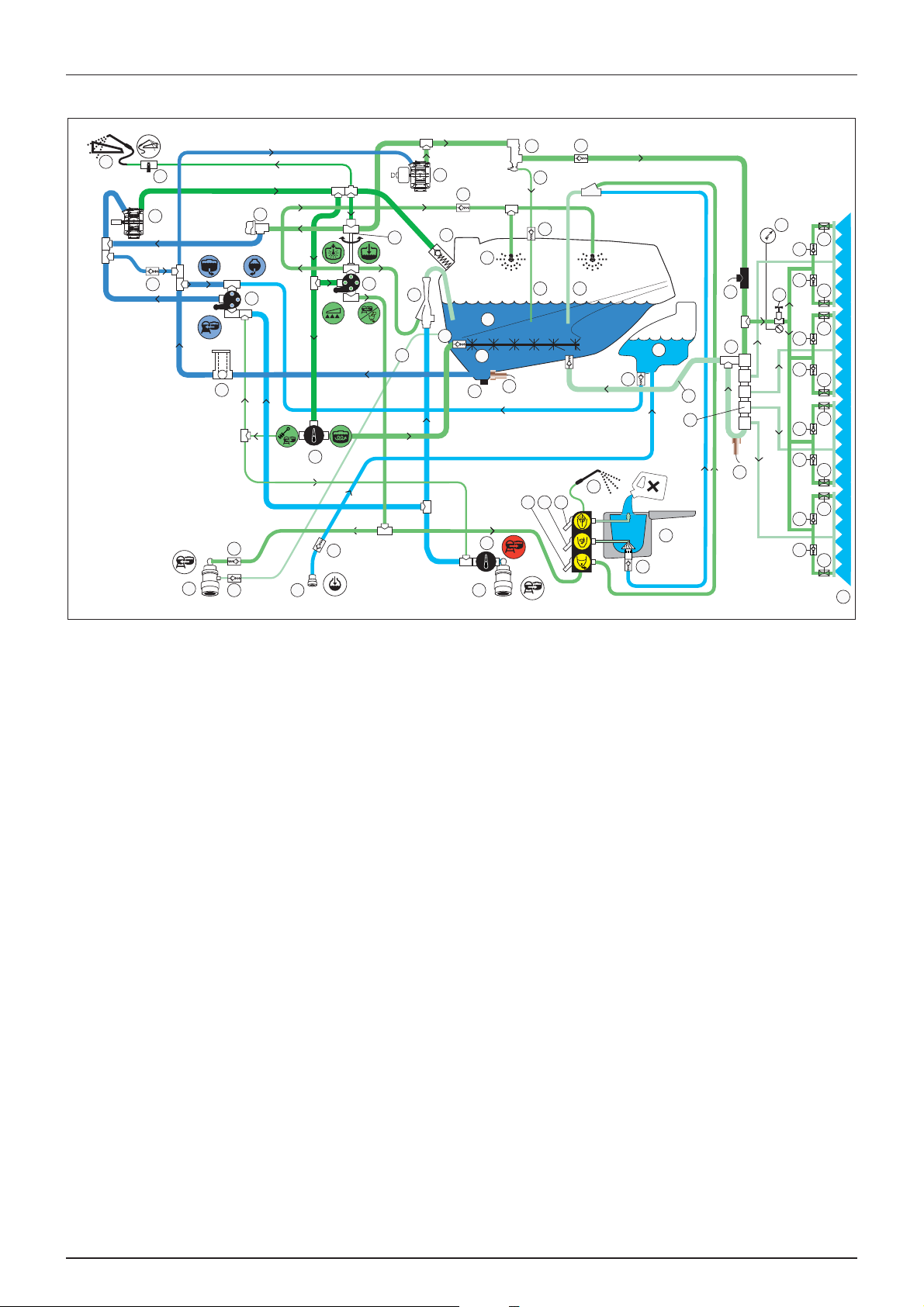

Diagram - Basic liquid system

12

22

37

25

26

22

29

27

1. Suction SmartValve

2. Pressure SmartValve

3. Agitation valve

4. Chemical container cleaning valve

5. TurboDeflector ON/OFF valve

6. TurboFiller suction ON/OFF valve

7. Pump

8. Main tank

9. EasyClean filter

10. RinseTank

11. Spray valve

12. CycloneFilter

13. TurboFiller

14. Lance for cleaning TurboFiller

15. Safety valve

16. Internal tank cleaning nozzles

24

17. Agitation tube

18. Return line for boost function

19. TurboFiller to tank tube

20. RinseTank coupler

21. DynamicFluid4 pressure regulation valve

22. One-way valve

23. Drain valve

24. Sprayer boom

25. Flowmeter

26. Bypass valve

27. Sensor for pressure gauge

28. Distribution valves

29. Return from distribution valves

Options

37. Boost valve

24

Page 25

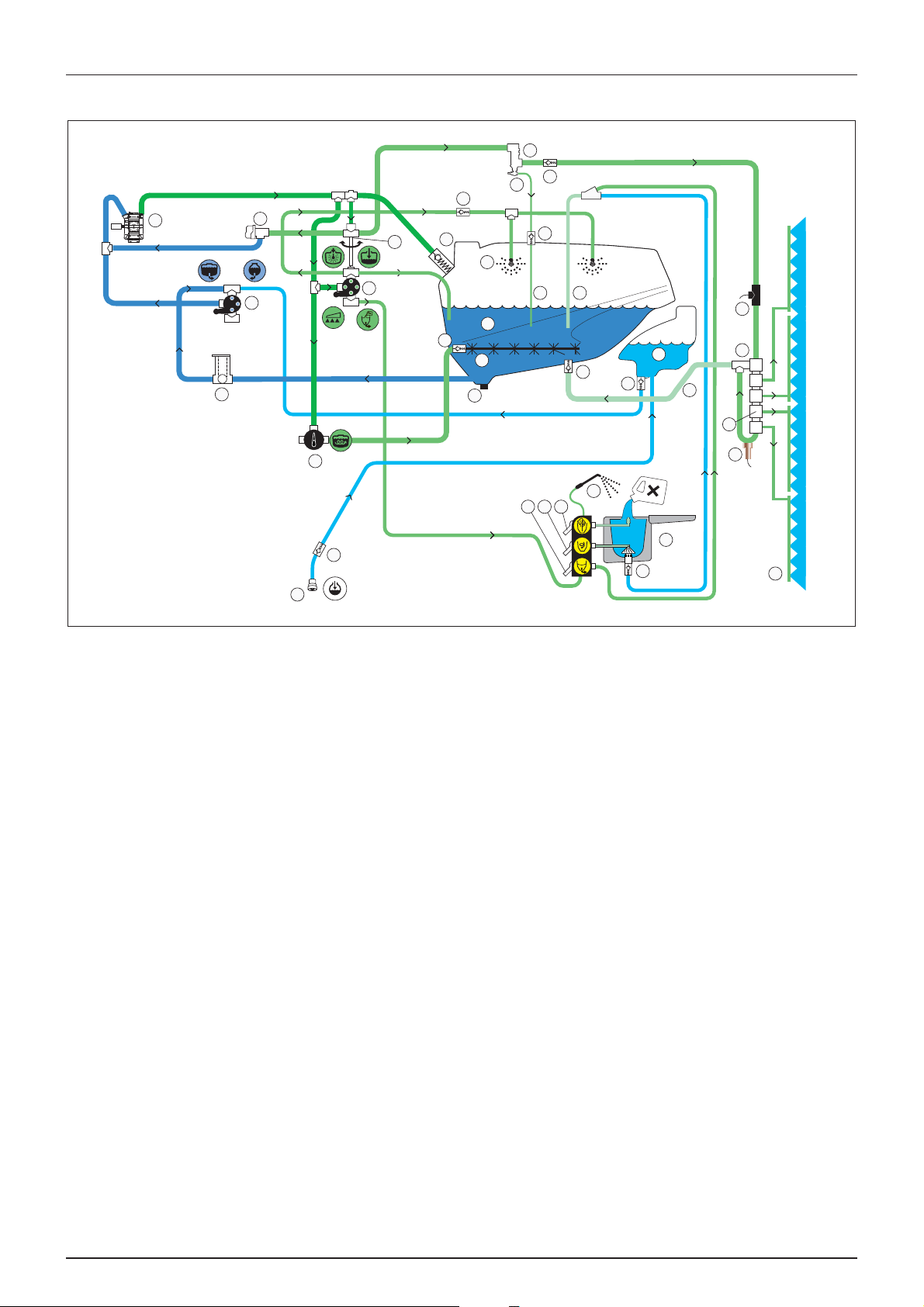

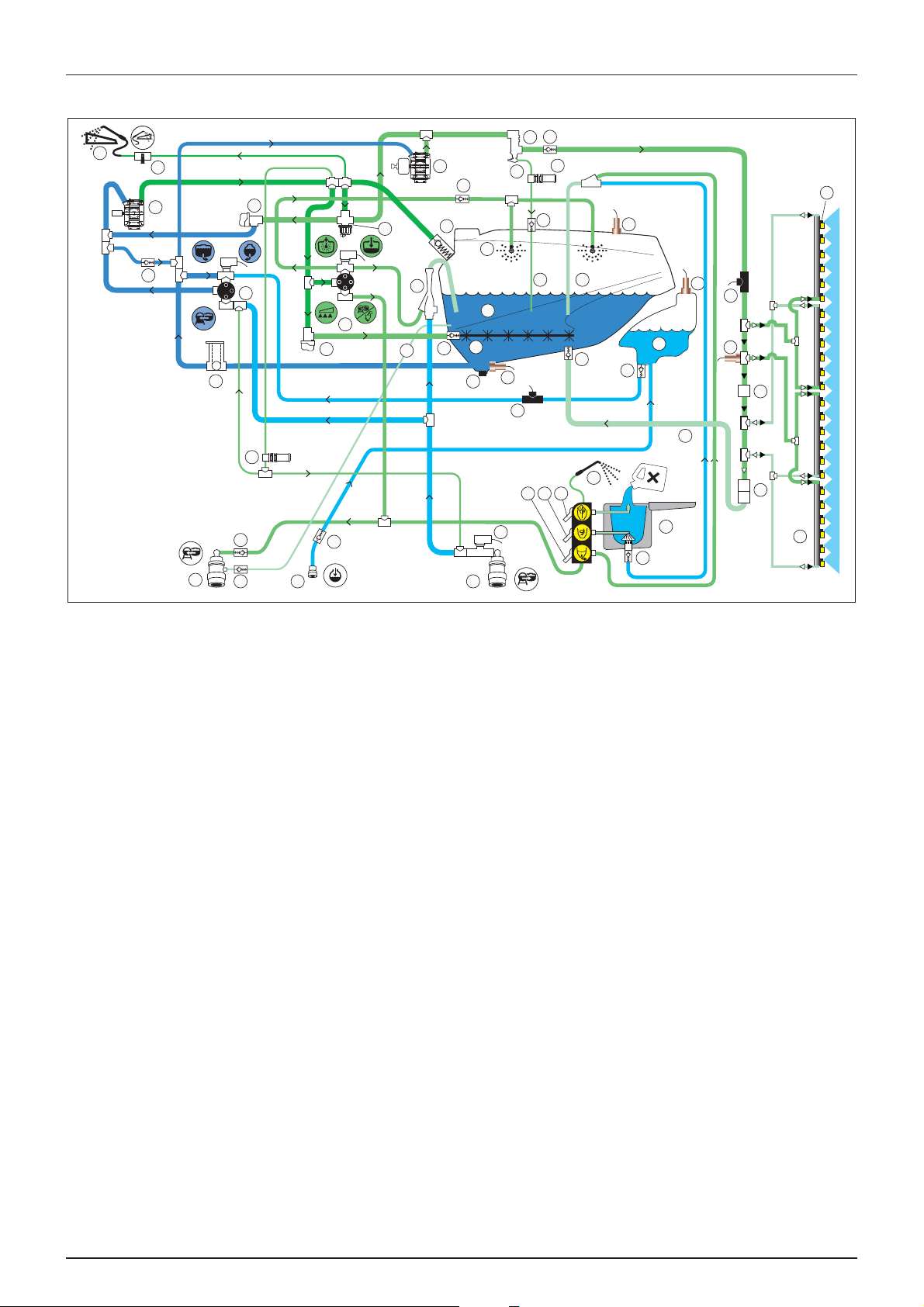

Diagram - Liquid system with optional extras

34

33

32

36

31

22

22

38

41

9

22

20

30

23

17

22

10

22

1

2

15

16

22

8

18 19

22

21

7

3

11

14

6

13

22

5 4

28

3 - Description

12

39

22

22

37

46

40

22

22

25

26

29

27

40

45

40

22

22

39

40

22

22

40

40

22

22

40

1. Suction SmartValve

2. Pressure SmartValve

3. Agitation/External cleaning valve

4. Chemical container cleaning valve

5. TurboDeflector ON/OFF valve

6. TurboFiller suction ON/OFF valve

7. Pump

8. Main tank

9. EasyClean filter

10. RinseTank

11. Spray valve

12. CycloneFilter

13. TurboFiller

14. Lance for cleaning TurboFiller

15. Safety valve

16. Internal tank cleaning nozzles

17. Agitation tube

18. Return line for boost function

19. TurboFiller to tank tube

20. RinseTank coupler

21. DynamicFluid4 pressure regulation valve

22. One-way valve

24

23. Drain valve

24. Sprayer boom

25. Flowmeter

26. Bypass valve

27. Sensor for pressure gauge

28. Distribution valves

29. Return from distribution valves

Options

30. Main tank gauge sensor

31. Pressure draining coupler

32. FastFiller coupler

33. External cleaning device

34. External cleaning ON/OFF valve

36. External fast filling ON/OFF valve

37. Boost valve

38. Ejector

39. FlexCapacity pump

40. Boom prime restrictor

41. Pressure relief line

45. Boom prime pressure control valve

46. Pressure gauge for BoomPrime

25

Page 26

3 - Description

42

43

Diagram - Intelligent liquid system with optional extras

33

34

7

21

11

39

22

15

22

12

40

37

36

22

16

45

22

1

9

22

31

22 20

1. Suction SmartValve

2. Pressure SmartValve

4. Chemical container cleaning valve

5. TurboDeflector ON/OFF valve

44

30

18 19

6

5 4

22

22

14

22

38

2

35

22

22

41

8

17

23

32

47

25

10

13

27

26

29

26

24

25. Flowmeter

26. Distribution valves

27. Sensor for pressure gauge

29. Return from distribution valves

6. TurboFiller suction ON/OFF valve

7. Pump

8. Main tank

9. EasyClean filter

10. RinseTank

11. Spray valve

12. CycloneFilter

13. TurboFiller

14. Lance for cleaning TurboFiller

15. Safety valve

16. Internal tank cleaning nozzles

17. Agitation tube

18. Return line for boost function

19. TurboFiller to tank tube

20. RinseTank coupler

21. DynamicFluid4 pressure regulation valve

22. One-way valve

23. Drain valve

Options

30. Main tank gauge sensor

31. Pressure draining coupler

32. FastFiller coupler

33. External cleaning device

34. External cleaning ON/OFF valve

35. AutoAgitation valve

36. PrimeFlow ON/OFF valve

37. Boost valve

38. Ejector

39. FlexCapacity pump

40. Boost line valve ON/OFF

41. Pressure relief line

42. Clean valve

43. RinseTank flowmeter

44. External fast filling ON/OFF valve

45. Main tank full sensor

47. RinseTank full sensor

24. Sprayer boom

26

Page 27

3 - Description

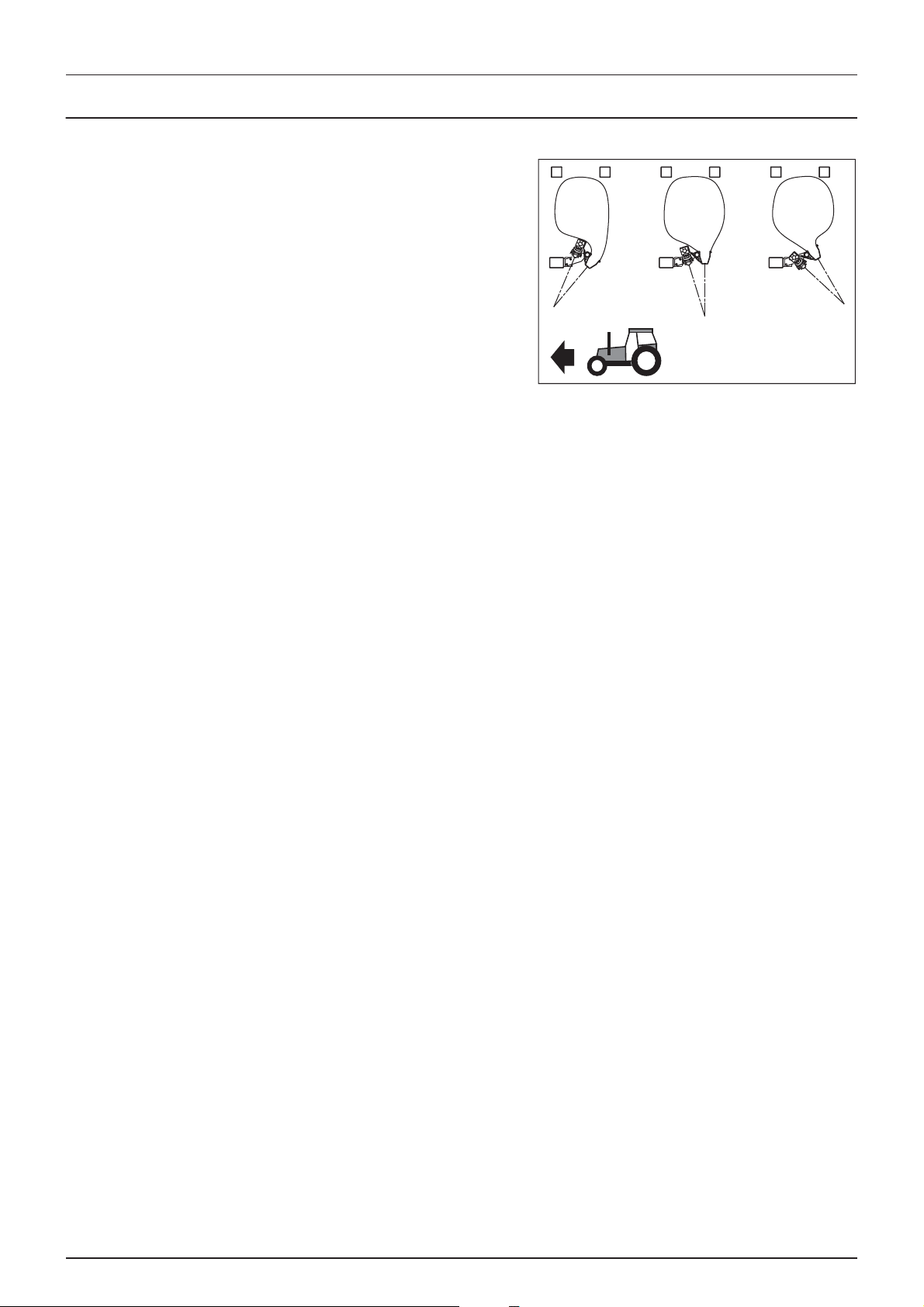

TWIN Air technique

General info

With TWIN air assistance energy is added to the spray droplets to

improve control with the spray liquid. The main purpose of the TWIN

angling system is to counteract for the negative influence which wind

direction and driving speed have on the quality of the spray job. Further

the “co-angling” af air and liquid can help “opening” dense crops for

better penetration.

This way TWIN makes it possible to:

• carry the spray droplets safely to the target and increase plant

deposit.

• minimize off-target deposit due to wind drift or loss on the ground.

• open the crop and obtain good penetration even with a low

volume rate.

• ensure a high coverage.

The TWIN FORCE air system can be set at any angle from 40° forward to 30° back (defined by the air stream). The fan speed

is infinitely variable and can produce from 0 to 35 m/s (78 mph) air speed at the air outlet. This equals from 0 to 2000 m3

air/m boom/hour (3.872 CFM/A boom/hour).

27

Page 28

3 - Description

Boom

Boom and terminology

The TWIN FORCE boom are found in two hydraulic versions which is suspended in a strong, stable parallelogram boom lift:

• HAY boom:

Working widths are 18, 20, 21, 24, 27, 28 and 30 metres.

The boom is pendulum suspended and equipped with 4 hydraulic rams. The raising/lowering and folding/unfolding

functions are operated via the tractor hydraulics.

• HAZ boom:

Working widths are 18, 20, 21, 24, 27, 28, 30, 32, 33 and 36 metres.

The boom is pendulum suspended and fully hydraulically operated, all functions are controlled via the Direct Acting

Hydraulic System (D.A.H.). The 32-36 metres booms is fully hydraulically operated, all functions are controlled via the

Direct Hydraulic System (D.H.).

Boom features

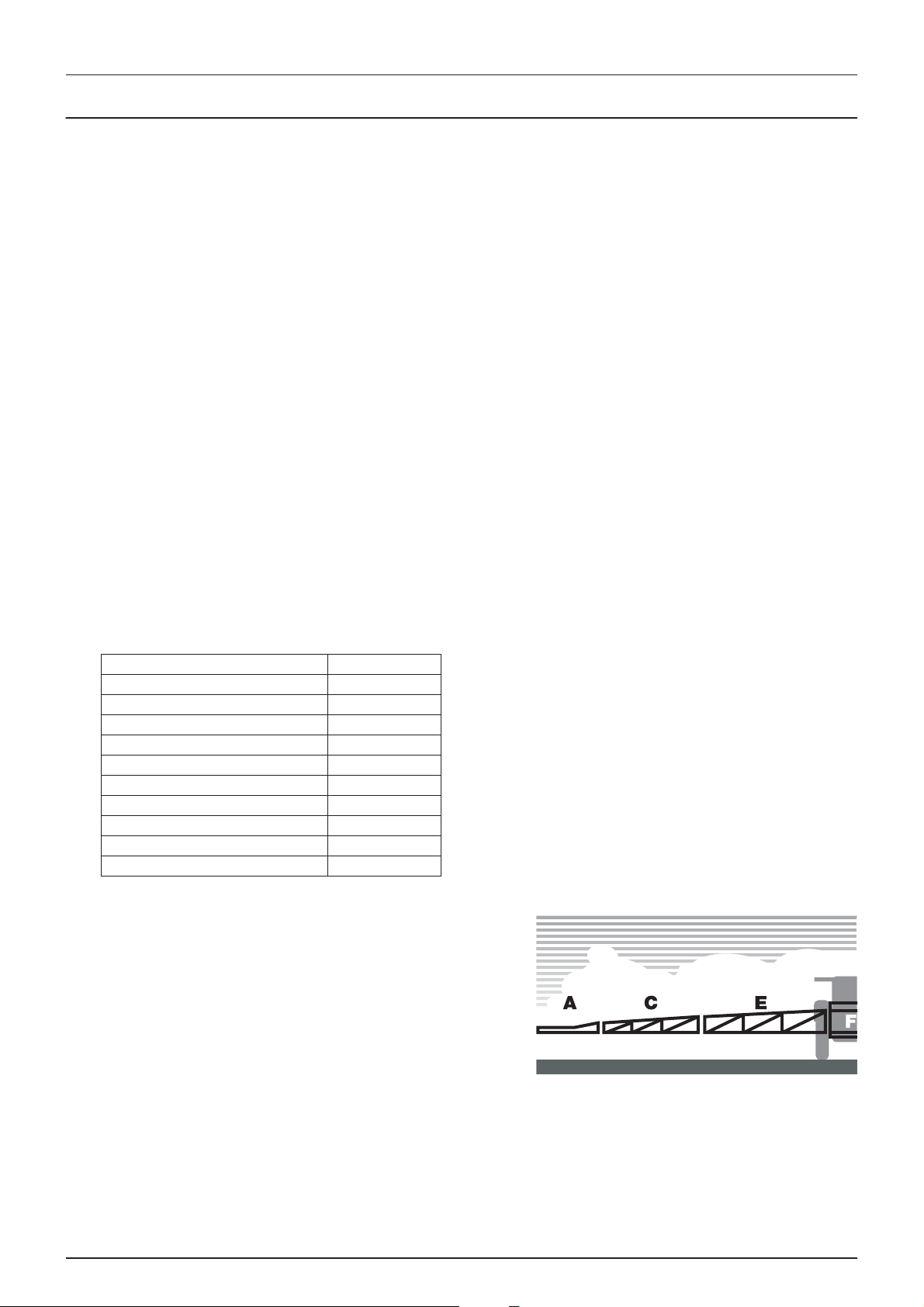

• All booms are 2-folded.

• TWIN blowers. These are driven by a built-in hydrostatic transmission powered via the tractor P.T.O. Blower speed can

be adjusted step wise from the tractor cabin.

• Outer sections incorporate spring-loaded breakaway.

• Hydraulic pendulum lock (HAZ only).

• Individual boom tilt control (HAZ only).

• Individual folding of outer sections. This enables alternative boom widths.

The boom can be used in half folded position. Half folded lengths are the following:

Full working width 1/2 folded

18 metres 12 metres

20 metres 12 metres

21 metres 12 metres

24 metres 12 metres

27 metres 14 metres

28 metres 14 metres

30 metres 15 metres

32 metres 17 metres

33 metres 17 metres

36 metres 18 metres

For 2-folded booms the terminology are as follows: