Page 1

COMMANDER

Operator’s Manual

67020003 (6/02)

Page 2

Page 3

HARDI

COMMANDER

Operator’s Manual

67020003 (6/02)

HARDI® reserves the right to make changes in design,

material, or specification without notice thereof.

®

and other product names are registered trademarks

HARDI

of HARDI

®

Inc. in the U.S. and in other countries.

Page 4

Table of Contents

Introduction ................................................................4

COMMANDER Plus ..............................................5

Description ................................................................. 6

Frame.................................................................... 6

Tank ...................................................................... 6

Pump..................................................................... 6

MANIFOLD system ...............................................6

Operating unit .......................................................6

Filters ....................................................................6

Paralift™ ...............................................................6

Booms ...................................................................6

Boom hydraulics ...................................................6

Identification plates ............................................... 6

Sprayer use ................................................................ 7

Unloading the sprayer from the truck ..................... 7

Before putting the sprayer into operation .............. 7

Safety Instructions .................................................... 8

Operating The Sprayer Safely ..............................8

Handling Chemical Products Safely .....................9

Local Poison Information Center ..........................9

Connecting the sprayer........................................... 10

Drawbars ............................................................ 10

Mounting the drawbar hitch ................................10

Drawbar hitch height adjustment ........................ 10

Support jack ........................................................10

Fixed drawbar adjustment .................................. 11

Steering drawbar (optional) ................................ 11

Hose package support........................................ 11

P.T.O. Shaft............................................................... 12

P. T.O. Shaft Operator Safety ..............................12

Installation of P.T.O. Shaft ..................................12

Wheel tread adjustments ........................................ 13

Altering the wheel track width.............................13

Axle Systems & Tire Assemblies ...........................14

Hydraulic system .....................................................15

Hydraulics - standard joystick handle .................15

Direct Acting Hydraulic system (D.H.) ................16

Control boxes and power supply ........................16

Transport .................................................................. 17

Roadworthiness ..................................................17

Rear lights........................................................... 17

Transport brackets, height setting ......................17

Transport lock .....................................................17

Transport lock arm stop ...................................... 18

Adjusting boom transport position ......................18

Driving Technique ................................................... 19

Steering Drawbar (optional)................................ 19

Disconnecting the sprayer...................................... 20

Support leg ......................................................... 20

P. T.O. shaft support ............................................ 20

Operating the boom ................................................. 21

Unfolding and folding the HZ EAGLE™ boom ...21

Unfolding and folding the HZ FORCE™ boom .. 22

Tilting the HZ FORCE™ boom ...........................23

ECP Plumbing Diagram ........................................... 24

Operating the liquid system ................................... 25

MANIFOLD SYSTEM ......................................... 25

Use of MANIFOLD valve system ........................25

Electrical operated MANIFOLD valves (opt.) ..... 26

Filling the tanks on the COMMANDER Plus ......... 26

Filling main tank through tank lid ........................ 26

Filling flush tank (optional) through lid................26

Filling with external Quick Fill (optional) ............. 27

Filling of clean water tank ...................................27

Adjustment of ECP operating unit .........................28

Adjustment of constant pressure ........................ 28

Operating the control unit while spraying ...........28

Remote 4” pressure gauge ..................................... 29

Self cleaning filters .................................................. 29

Choice of correct restrictor for S.C.F. ................. 29

Adjustment of Air Pressure in Pressure Damper

(1302 Pump Only) .................................................... 29

Filling of chemicals ................................................. 30

Filling through tank lid......................................... 30

Filling with HARDI

Operating with Liquid-based chemicals.............. 30

Operating with Powder-base chemicals .............31

Use of flush tank and rinse nozzles (optional) .....32

Technical Residue ................................................... 32

Draining tanks .......................................................... 32

Main tank drain valve.......................................... 32

Flush tank (optional) ...........................................32

Foam marker tank (optional) .............................. 32

Nozzle Selection ...................................................... 33

Calibration ................................................................ 35

Maintenance - rules of thumb .................................36

Cleaning the sprayer ..........................................36

Cleaning the tank ................................................37

Cleaning and maintenance of filters ...................37

Lubrication ............................................................... 38

About lubricants .................................................. 38

Recommended lubricants ................................... 38

Lubrication schedule........................................... 39

Service and Maintenance intervals ........................ 42

10 hours service ................................................. 42

50 hours service ................................................. 42

100 hours service ............................................... 42

250 hours service ............................................... 42

1000 hours service or yearly .............................. 42

Occasional maintenance .................................... 43

Off-season storage ..................................................50

Preparation after off season storage ..................50

Equipment and Accessories .................................. 51

Troubleshooting ...................................................... 55

Emergency operation of the sprayer .....................60

Technical specifications ......................................... 61

Overall measurements ....................................... 61

Weight .................................................................61

Filters and nozzles ..............................................62

Temperature and pressure ranges ..................... 62

Electrical connections - Rear lights ....................62

Electrical connections for ECP operating unit ....62

Installation instruction for boom and work light ..63

EAGLE™ and FORCE™ boom hydraulics ............ 64

Warranty Policy and Conditions ............................ 65

®

CHEMICAL FILLER ............ 30

2 HARDI® COMMANDER OPERATOR’S MANUAL

Page 5

Dear Owner,

Thank you for purchasing a HARDI

®

HARDI

sprayer owners.

®

product and welcome to the ever- increasing family of

Our sprayers and accessories are rapidly becoming a familiar sight on North American farms.

We believe that this results from growers becoming increasingly conscious of crop protection

input costs and the vital need for cost effective spray application equipment.

Please take the time to thoroughly read the Operator’s Manual before using your equipment.

You will find many helpful hints as well as important safety and operation information.

Some of the features on your HARDI

®

COMMANDER Plus sprayer were suggested by growers. There is no substitute for “on farm” experience and we invite your comments and suggestions.

Please address your correspondence to the Service Manager at one of these branches:

HARDI® MIDWEST

1500 West 76th St.

Davenport, Iowa 52806

Phone: (563) 386-1730

Fax: (563) 386-1710

HARDI® WEST COAST

5646 W. Barstow, Suite 101

Fresno, California 93722

Phone: (559) 271-3106

Fax: (559) 271-3107

HARDI® GREAT LAKES

290 Sovereign Rd.

London, Ontario N6M 1B3

Phone: (519) 659-2771

Fax: (519) 659-2821

Sincerely,

Tom L. Kinzenbaw

President

3HARDI® COMMANDER OPERATOR’S MANUAL

Page 6

Introduction

We congratulate you for choosing a HARDI® plant protection product. The reliability and efficiency of this product

depends upon your care. The first step is to carefully read and pay attention to this instruction book. It contains

essential information for the efficient use and long life of this quality product.

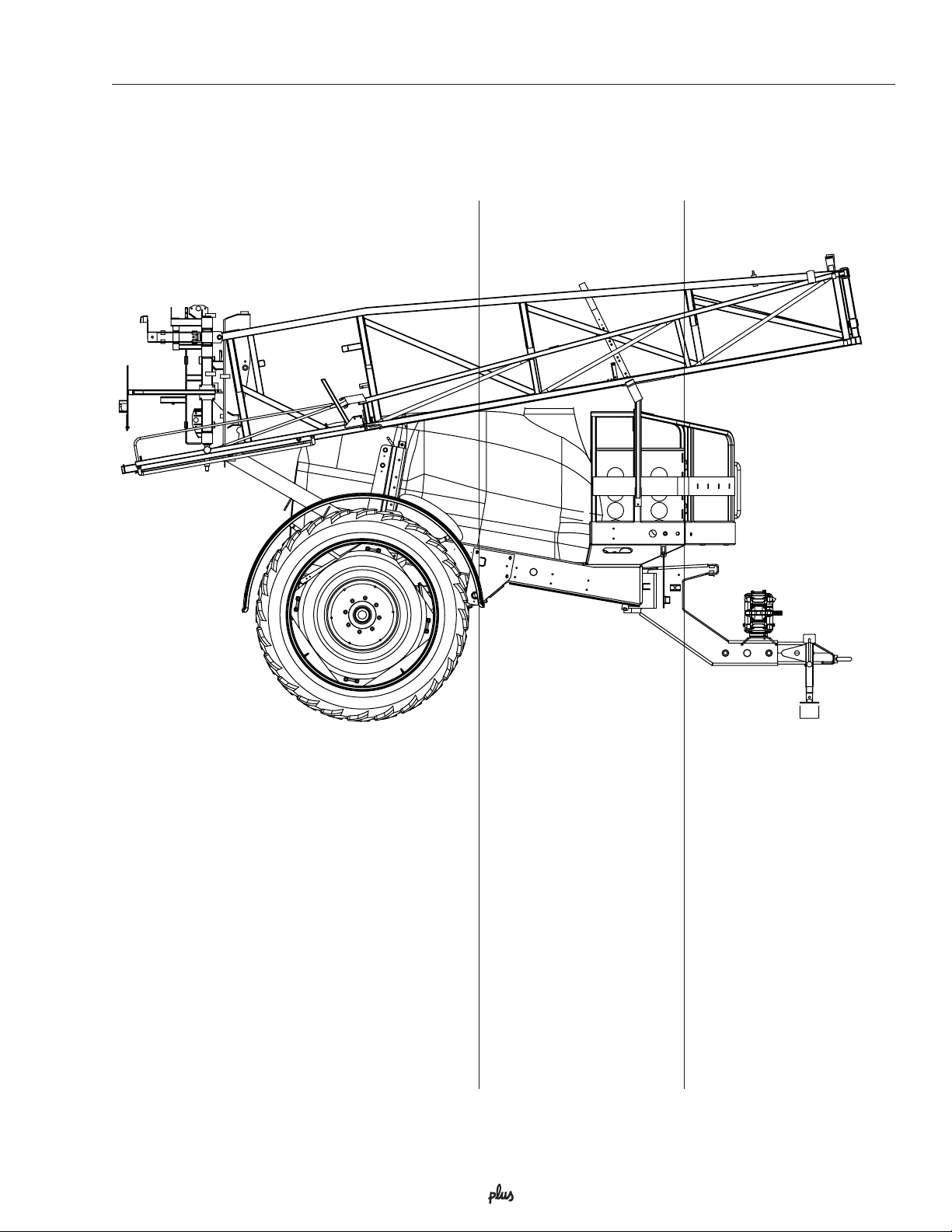

The COMMANDER Plus 750 and 1200 trailer sprayers consist of a powder coated frame with a tank, diaphragm

pump, ECP control (Electric Control Plus), HARDI

System, and 45’, 50’, 60’ or 66’ EAGLE™ series spray boom. The 1200 trailer sprayers additionally offer 80’, 88’,

90’, or 100’ EAGLE™ series spray boom and 80’, 88’, 90’, 100’, or 120’ FORCE™ series spray boom.

®

Manifold system, Self-Cleaning Filter, Paralift™ Boom Lift

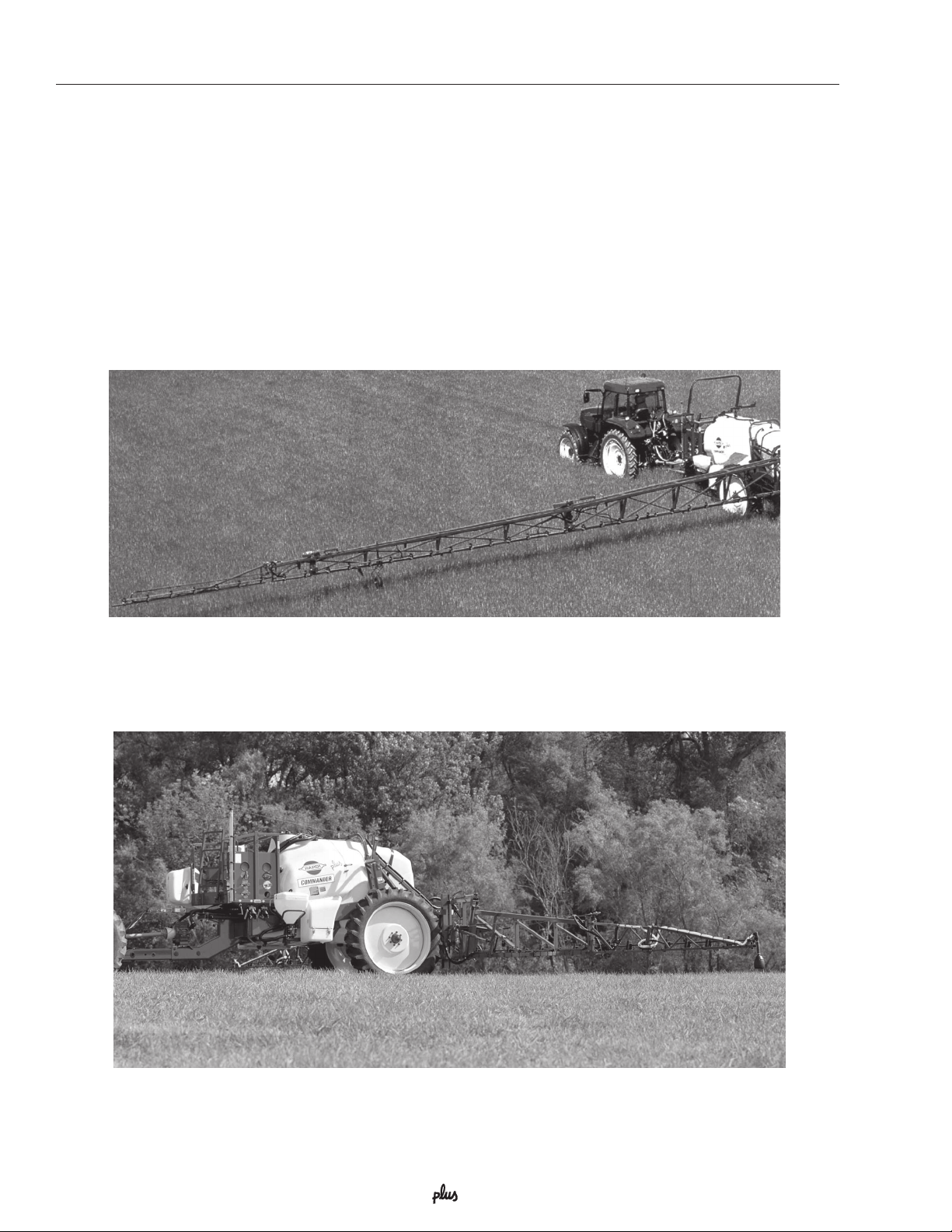

Commander plus 1200 gallon with 120’ Force™ boom

Commander plus 750 gallon with 60’ Eagle™ boom

4 HARDI® COMMANDER OPERATOR’S MANUAL

Page 7

Introduction

COMMANDER Plus

The COMMANDER Plus is divided into three zones: a Clean zone, a Working zone and an Application zone,

referring to the level of possible pesticide contamination.

CLEAN ZONEWORKING ZONEAPPLICATION ZONE

PARALIFT™ boom lift system

Boom

Nozzles

Suspension

*

Please note that some of the features are optional equipment

*

Tank level indicator

MANIFOLD valves

Couplers for Quick Fill

Working platform with

ladder

Hydraulic and electric

components

Boom and Work lights

*

HARDI

*

Lockers for pesticide

*

containers and equipment

®

FILLER

Locker for protective gear

Clean water tank

Tap for hand washing

Support leg

Pump

P. T.O. shaft

5HARDI® COMMANDER OPERATOR’S MANUAL

Page 8

Description

Description

Frame

Strong and compact frame with optional drawbars and

wheel sizes. The frame has a strong chemical and

weather resistant powder coat. Screws, nuts, etc. have

been electrochemically treated to be resistant to

corrosion.

Tank

The tanks, made of impact proof and chemical resistant

polyethylene, have a purposeful design with rounded

contours which allows for efficient cleaning and draining. The tanks are designed with a large deep sump, so

that they can be completely emptied even when the

sprayer is used on slopes up to 15% inclination. A

remote operated valve drain is fitted for efficient draining.

Pump

The HARDI® diaphragm pumps have low maintenance

requirements and guaranteed pump life. The bearings

and crankshaft are grease lubricated and are therefore

protected from spray solution if any diaphragm fails in

service. A drain hole is in the base of the crank case to

facilitate the draining of any foreign matter. The diaphragm pumps are self priming and can be run dry

without damage.

MANIFOLD SYSTEM

All functions of the spray circuits are operated via the

centrally situated MANIFOLD valves with color coded

plates and pictorial symbols for easy operation.

Operating unit

The ECP - Electrical Control Plus is divided into two

sections. The pressure regulation valve is located at

the front of the sprayer. The boom section control

valves with pressure equalization are mounted at the

rear of the sprayer. The on/off switch is linked to the

boom section valves, which results in a very quick

response to on/off operation. The built-in HARDIMATIC mechanical rate controller ensures a constant

volume per acre of the liquid (gpa) at varying forward

speed within the same gear when the number of P.T.O.

revolutions are between 300-600 r.p.m. (540 r.p.m

pump) or 650-1100 r.p.m. (1000 r.p.m. pump).

Paralift™

The Paralift™ boom lift system consists of parallel lift

arms that hydraulically lift and lower the boom assembly, ensuring that the boom remains parallel to the

ground. A locking cylinder and arms are fitted to ensure

that the paralift cylinders are relieved of any hydraulic

pressure when the boom is in the transport position.

Booms

The EAGLE™ SPB boom is available in 45’, 50’, 60’,

and 66’ working width.

The EAGLE™ SPC boom is available in 80’, 88’, 90’

and 100’ working width.

The FORCE™ FTZ boom is available in 80’, 88’, 90’,

100’ and 120’ working widths.

Outer sections incorporate spring loaded breakaways.

Boom hydraulics

The SPB, SPC and FTZ booms are equipped with

I.A.H. (Indirect Acting Hydraulics). Optional D.H. (Direct

Acting Hydraulics) is available.

The boom is operated via the tractor hydraulics. It

features hydraulic lift cylinders for boom height adjustment, boom wing fold and tilt cylinders that give the

ability to obtain individual boom wing tilt as well as

individual boom wing fold.

The hydraulics are controlled via a joystick or via a

hydraulic control box.

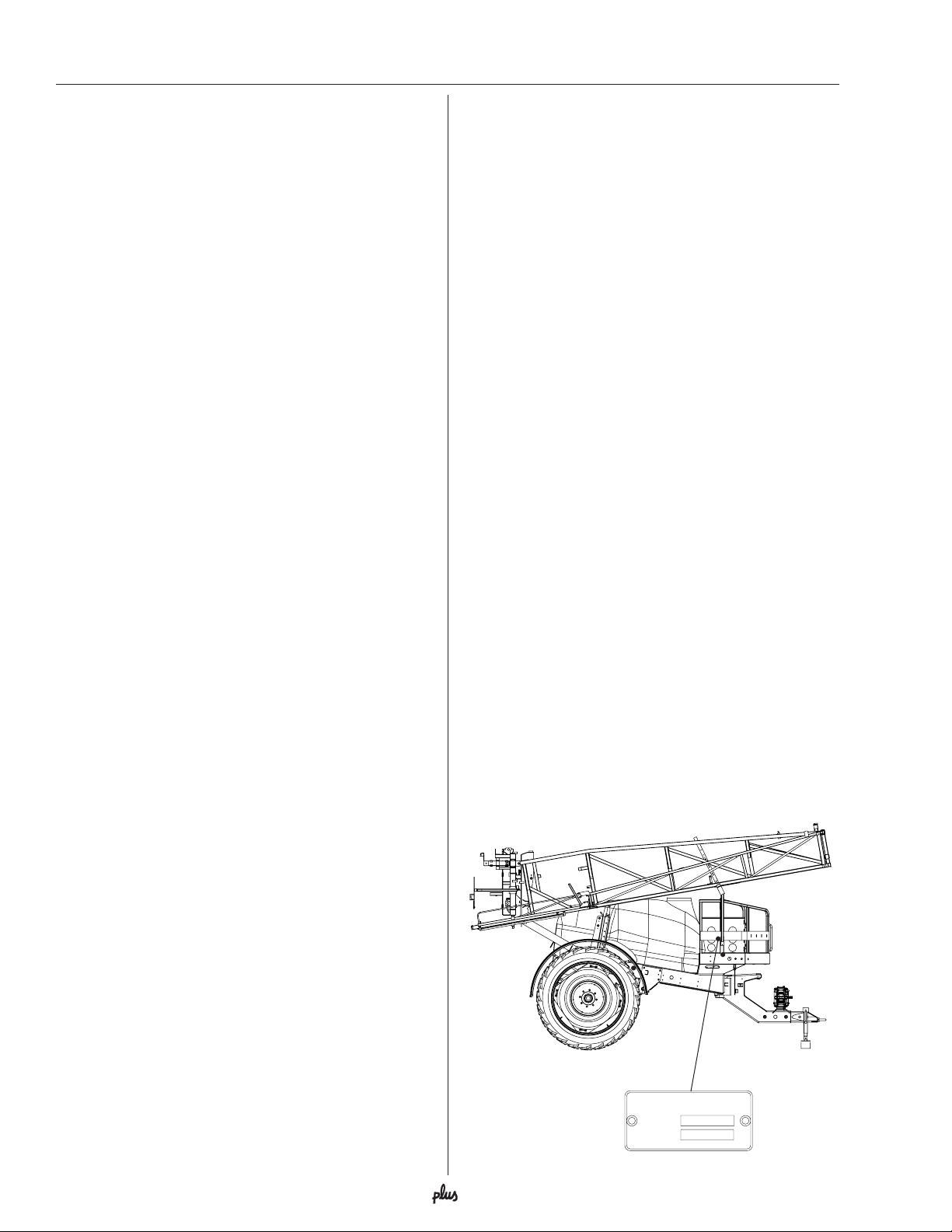

Identification plates

An identification plate fitted on the frame indicates

model and serial number. Frame, boom center frame,

and inner/outer sections also have identification plates

indicating boom type and part number of spare parts. If

ordering spare parts, inform your dealer of these, so

the right model and version are described.

Filters

With the self-cleaning filter, the impurities that exist in

the spray liquid will bypass the filter and be recirculated

back to the tank via the return flow. Suction filter and inline pressure filters are standard with all booms.

6 HARDI® COMMANDER OPERATOR’S MANUAL

HARDI

INC

Model

Serial No.

DAVENPORT

IOWA

C+1200

12-0002

Page 9

Description

Sprayer use

The HARDI® COMMANDER Plus sprayer is for the

application of crop protection chemicals and liquid

fertilizers.

If no local law demands that the operator must be

certified to use the spray equipment, it is strongly

recommended to be trained in correct plant protection

and in safe handling of plant protection chemicals to

avoid unnecessary risk for persons and the environment when doing the spray job.

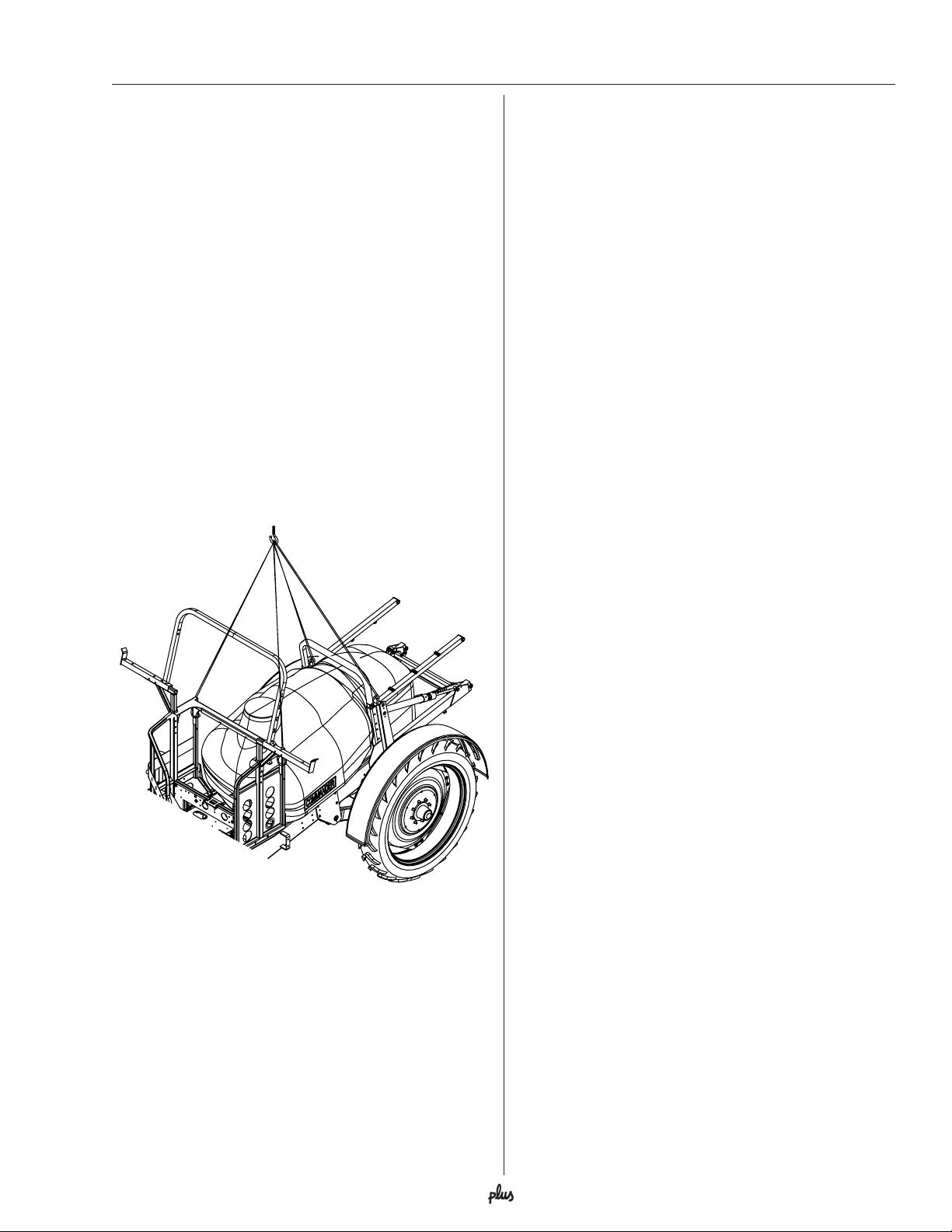

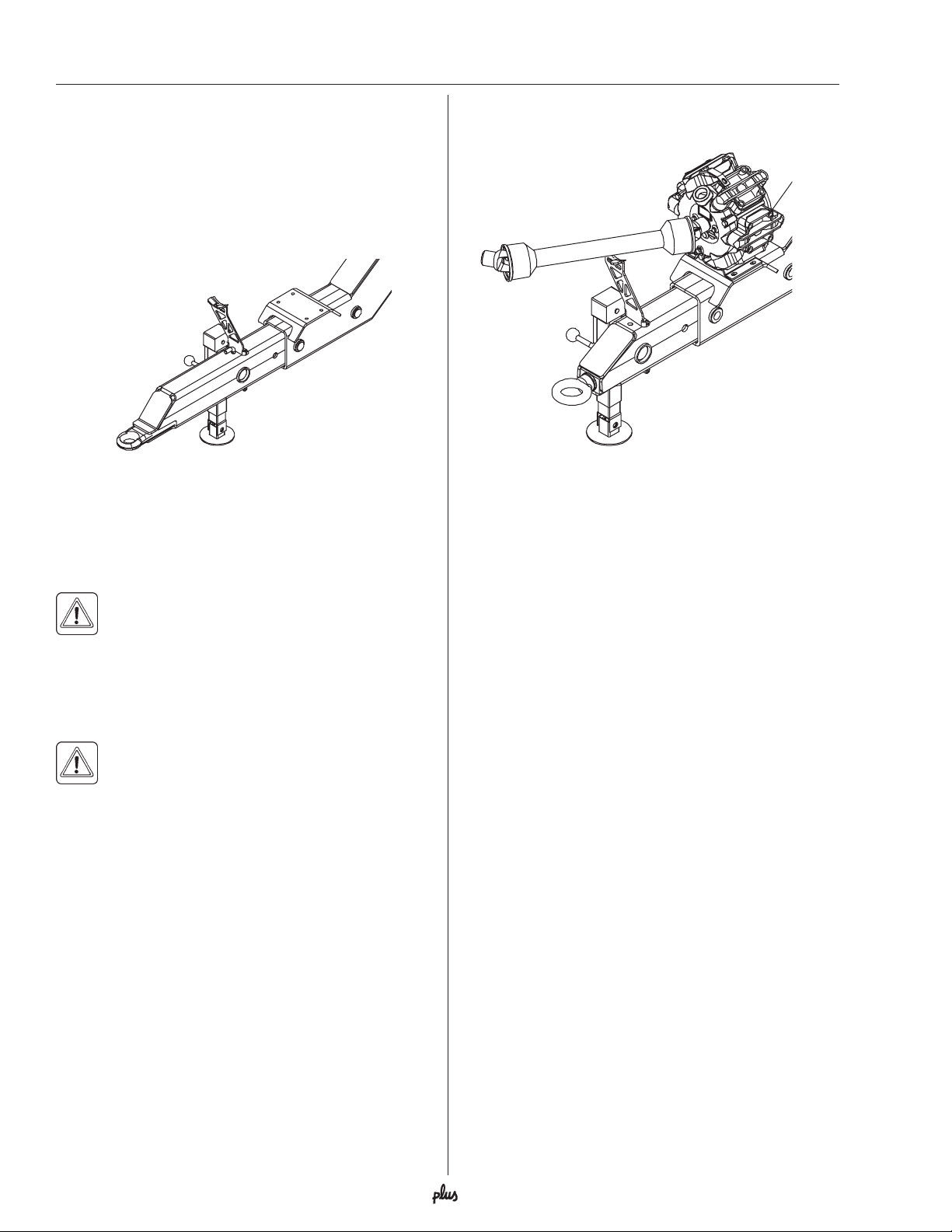

Unloading the sprayer from the truck

When unloading the sprayer, a crane or a fork lift is

needed. When loading with a crane, please observe

the lifting points as shown on the illustration and make

sure that the straps or belts used for lifting are suitable

for the application.

Before putting the sprayer into

operation

Although the sprayer has been applied with a strong

and protective surface treatment on steel parts, bolts

etc. in the factories, it is recommended to apply a film

of anticorrosion oil (e.g. CASTROL RUSTILLO or

SHELL ENSIS FLUID) on all metal parts in order to

avoid chemicals and fertilizers discoloring the enamel.

Avoid oil on rubber parts, hoses and tires.

If this is done before the sprayer is put into operation

for the first time, it will always be easy to clean the

sprayer and keep the enamel shiny for many years.

This treatment should be carried out every time the

protection film is washed off.

7HARDI® COMMANDER OPERATOR’S MANUAL

Page 10

Safety instructions

SAFETY INFORMATION

WARNING

ALWAYS READ OPERATOR’S MANUAL BEFORE

USING EQUIPMENT

DO NOT REMOVE ANY SAFETY DEVICES OR

SHIELDS. NEVER SERVICE, CLEAN OR REPAIR A

MACHINE WHILE IT IS OPERATING

WARNING

• Keep your sprayer in proper working condition.

Unauthorized modifications or use may impair the

function and/or safety and affect the machine’s life.

• If you do not understand any part of this manual and

need assistance, please contact your authorized

HARDI® dealer.

Operating The Sprayer Safely

1. Read the complete manual carefully and become

familiar with the operation of the equipment before

initial operation in each spraying season. Failure to

do so may result in possible over or under application of spray solution which may drastically affect

crop production and lead to personal injury.

2. Before starting the engine on the tractor unit, be

sure all operating controls are in the off or neutral

position, including (but not limited to) the P.T.O.

shaft and/or spray controls. Be sure the tractor

power train is disengaged.

3. Operate spray and boom functions only when

seated in the operator’s seat.

4. One of the most frequent causes of personal injury

ALWAYS WATCH FOR THIS SYMBOL TO POINT

OUT IMPORTANT SAFETY PRECAUTIONS

IT MEANS ATTENTION! BECOME ALERT!

YOUR SAFETY IS INVOLVED!

RECOGNIZE SAFETY INFORMATION

This is the Safety-alert symbol.

When you see this symbol on your

machine or in this manual, be alert

to the potential for personal injury.

Follow recommended precautions

and safe operating practices.

or death results from persons falling off or being run

over. Do not permit others to ride on or in. Only one

person should be working the machine when in

operation.

5. Before leaving the tractor seat, stop the engine, put

all controls in neutral, and put the transmission

control lever in the park position or neutral with the

brakes locked. Read the tractor operation manual

for added safety precautions.

6. P.T.O. driven equipment can cause serious injury.

Before working on or near the P.T.O. shaft, servicing or cleaning the equipment, put P.T.O. lever in

the DISENGAGE position and stop the engine.

7. Do not fold or unfold boom near overhead wires.

Serious injury or death could result if contact is

made with electric wires.

Follow Safety Instructions

• Carefully read all the safety messages in this manual

and the safety labels fitted to the machine. Keep

safety labels in good condition. Replace missing or

damaged safety labels. Be sure that new equipment

components include any current safety labels. Replacement safety labels are available from your

authorized HARDI® dealer.

• Learn how to operate the sprayer and how to use the

controls properly. Do not let anyone operate the

machine without proper instructions.

8 HARDI® COMMANDER OPERATOR’S MANUAL

8. Keep hands, feet & clothing away from moving

parts.

9. Wear relatively tight and belted clothing to prevent

from being caught on some part of the machine.

10. Slow down when turning, especially with boom

unfolded.

11. Always keep children away from your sprayer and/

or tractor unit.

Page 11

Safety instructions

12. Before transporting the sprayer, ensure that the

boom is fully folded and fully locked into transport

position. Ensure all locking devices are fully engaged, whether hydraulic or mechanical.

13. Slow moving tractors and spray equipment can

create a hazard when on public roads. Avoid

personal injury or death resulting from any accidents by using flashing lights. Local regulations

may require installation of flashing warning lights.

14. Avoid injuries from high pressure fluids penetrating

the skin by relieving system pressure before disconnecting hydraulics or other lines. Ensure all

fittings are tight before applying pressure to the

system.

15. Understand service procedures before undertaking

any maintenance. Never lubricate, service, or

adjust the machine while it’s moving. Securely

support any components before working on them.

16. Keep all parts in good condition and properly

installed. Fix damaged parts immediately. Replace

worn or broken parts. Remove excessive buildup of

grease, oil or debris.

5. Decontaminate equipment used in mixing, transferring and applying chemicals after use. Follow the

instructions on the chemical label for the correct

procedure required. Wash spray residue from

outside of the sprayer to prevent corrosion.

6. Extreme care should be taken in measuring spray

products. Powders should be used in suitable sized

packages or weighed accurately. Liquids should be

poured into a suitable graduated container. Keep

chemical containers low when pouring. Wear a

filtered respirator and let the wind blow away from

you to avoid dust and/or splashes contacting the

skin or hair.

7. Store chemicals in a separate, plainly marked

locked building. Keep the chemical in its original

container with the label intact.

8. Dispose all empty containers after rinsing in accordance with local regulations & by-laws. Dispose of

all unused chemicals and left over fertilizer in an

approved manner.

9. Keep a first aid kit and fire extinguisher available at

all times when handling chemicals.

Handling Chemical Products Safely

1. Direct exposure to hazardous chemicals can cause

serious injury. These chemicals can include lubricants, coolants, paints, adhesives and agricultural

chemicals. Material Safety Data Sheets (M.S.D.S.)

are available for all hazardous chemicals which

inform the user of specific details including: physical and health hazards, safety procedures, and

emergency response techniques.

2. Protective clothing such as rubber gloves, goggles,

coveralls and respirator must be worn while handling chemicals. All protective clothing should be

kept in excellent condition and cleaned regularly or

discarded.

3. If chemicals come in contact with any exposed skin

areas, wash immediately with clean water and

detergent. Never place nozzle tips or any other

components that have been exposed to chemicals

to lips to blow out obstructions. Use a soft brush to

clean spray nozzles.

4. Dedicate an area to fill, flush, calibrate and decontaminate sprayer where chemicals will not drift or

run off to contaminate people, animals, vegetation,

water supply, etc. Locate this area where there is

no chance of children coming in contact with this

residue.

Local Poison Information Center

If you live anywhere in the United States, the following

toll free number will connect you to your Local Poison

Information Center.

PHONE NO. 1 - 8 0 0 - 2 2 2 - 1 2 2 2

If you live outside the United States, find the number

for the poison control center in your phone book and

write it in the space below:

PHONE NO. _______-_______-__________

Keep a list, in the space provided below, of all the

chemicals that you have in use.

1._________________________________________

2._________________________________________

3._________________________________________

4._________________________________________

5._________________________________________

6._________________________________________

7._________________________________________

8._________________________________________

9._________________________________________

10._________________________________________

9HARDI® COMMANDER OPERATOR’S MANUAL

Page 12

Sprayer setup

Connecting the sprayer

Drawbars

Mounted on the frame in a center pivot, the drawbar

can be either standard fixed or optionally steered. The

steering drawbar is hydraulically operated.

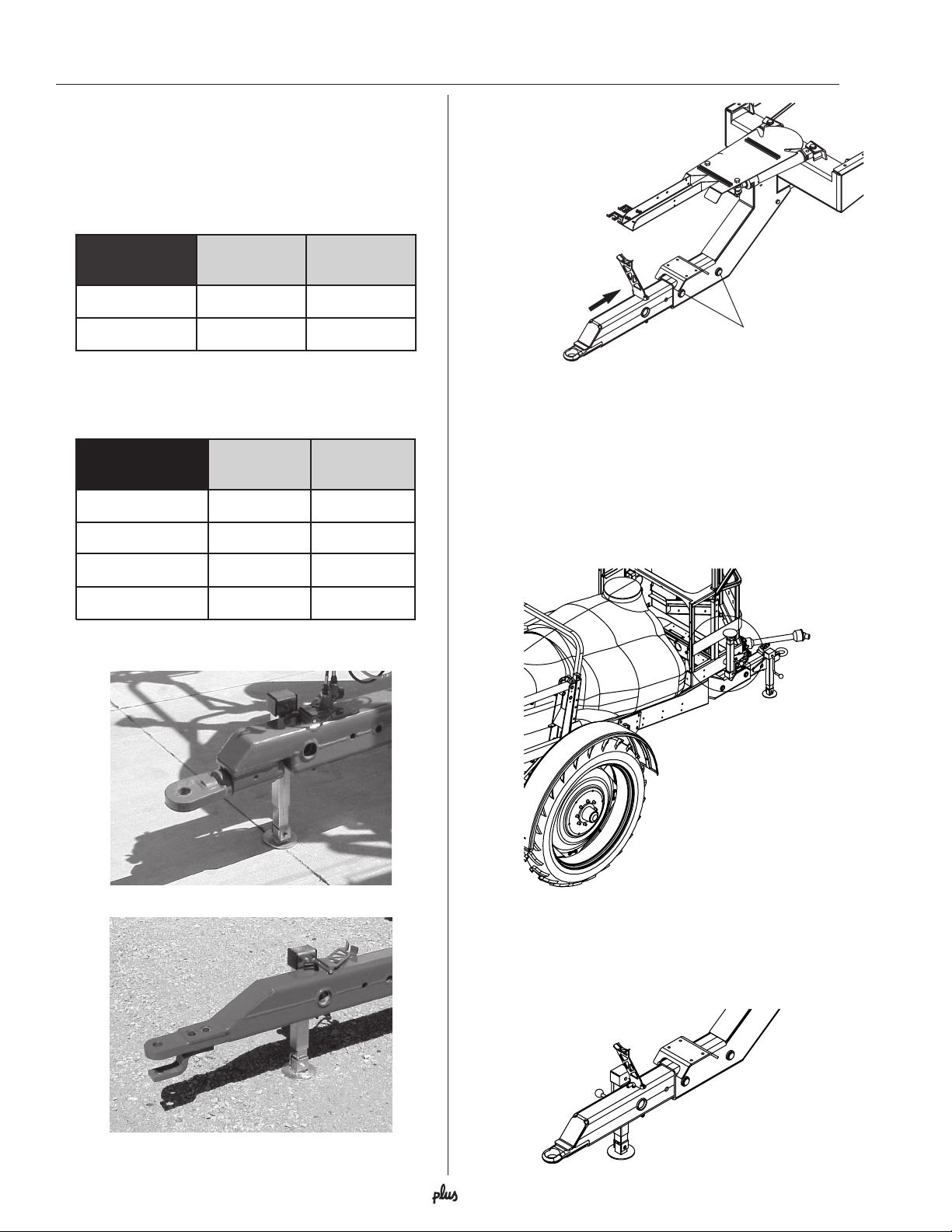

Overview - Drawbar systems

COMMANDER

750

1200

The following hitch types are available:

Overview - Hitch types

Hitch

type

Swivel type Ø36

Clevis type Ø33

Swivel type Ø42

FIXED

DRAWBAR

YES

YES

Commander

750

Yes

Yes

No

STEERING

DRAWBAR

YES

YES

Commander

1200

No

No

Yes

Mounting the drawbar hitch

The drawbar hitch is inserted into

the opening of the drawbar,

fastened by two pins through

the two holes A and secured

by two roll pins.

A

Drawbar hitch height adjustment

The drawbar hitch may be inverted for height adjustment. Remove the two pins (A) and the P.T.O. support

bracket. Invert the drawbar hitch and replace the two

pins (A) and P.T.O. support bracket.

Support jack

The support jack is stored upside-down in the bracket

on the sprayer’s right side when the sprayer is attached

to the tractor.

Clevis type Ø42

Swivel type

Clevis type

No

Yes

To remove the support jack from the drawbar hitch: Lift

the leg, remove the linch pin and pull out the support

jack. The support jack can then be mounted to the

storage bracket and secured by the linch pin.

10 HARDI® COMMANDER OPERATOR’S MANUAL

Page 13

Sprayer setup

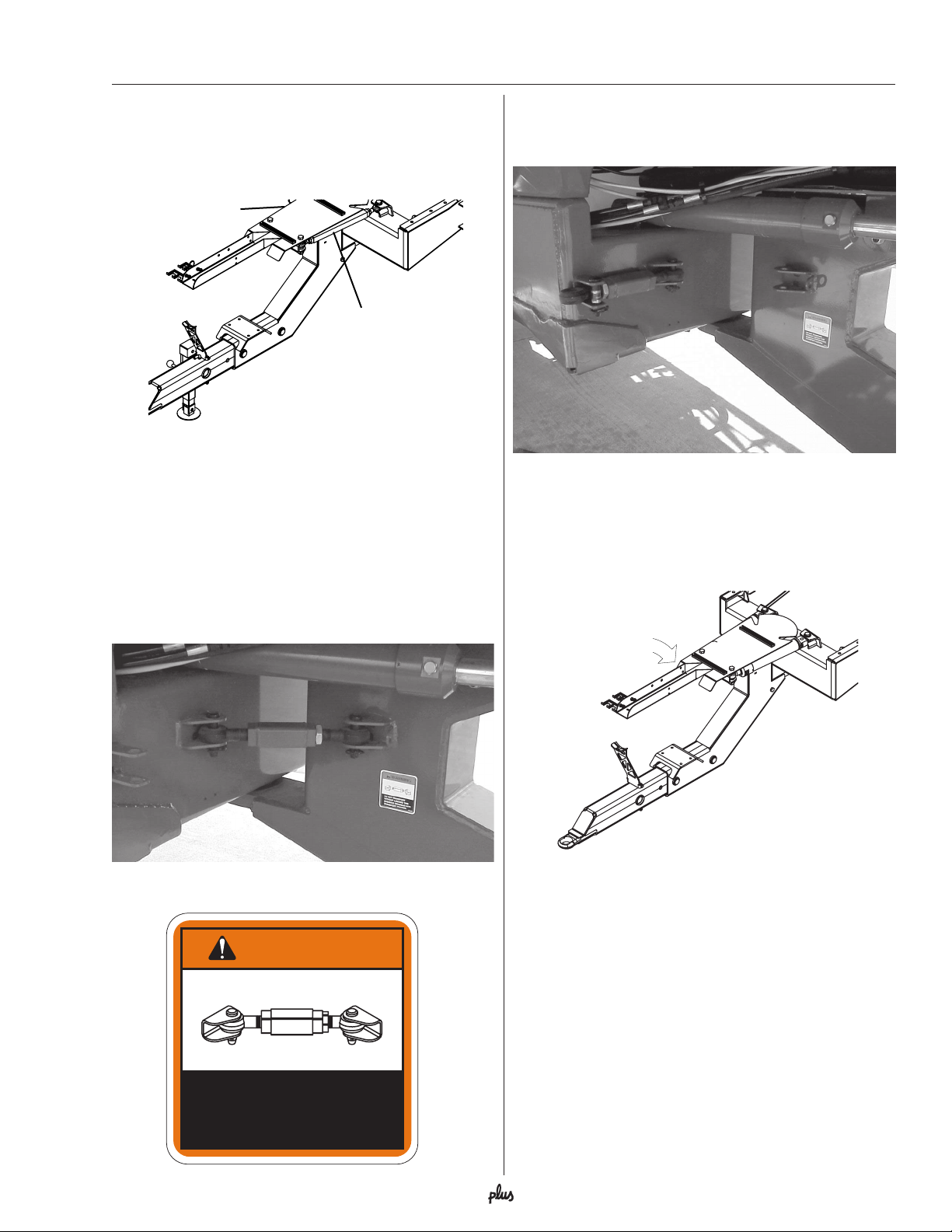

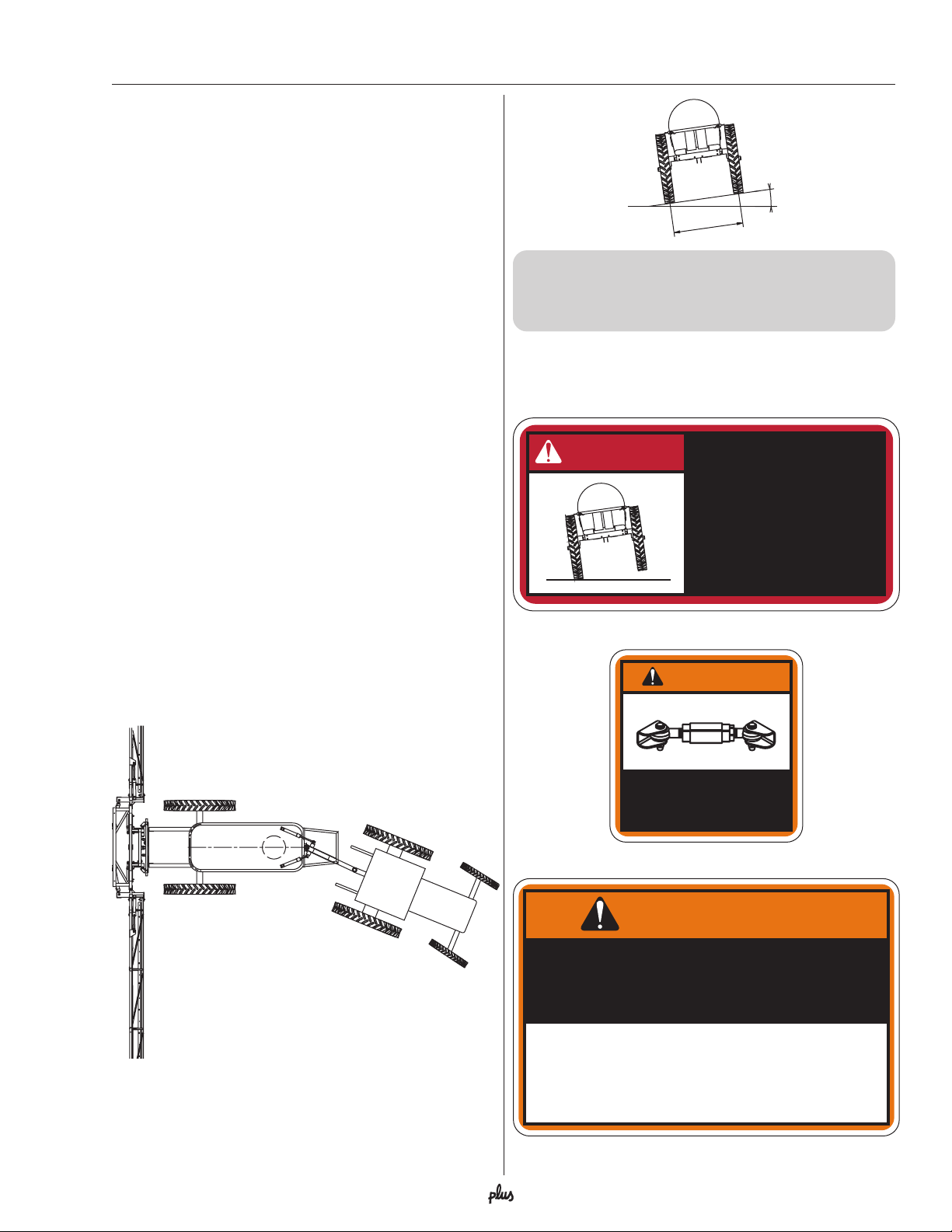

Fixed drawbar adjustment

Make sure the drawbar points straight ahead from its

position on the trailer. If not, the two turnbuckles A can

be adjusted until the drawbar is centered.

A

A

STEERING drawbar (optional)

Transport lock (if fitted)

The transport lock is a safeguard that will keep the

drawbar in a centered position in case of hydraulic

leakage during transport on public roads.

The transport lock is held in place by pins and snap

rings. If necessary, the transport lock can be adjusted

by turning the turnbuckle.

When the hydraulic steering is needed again, remove

the front pin and snap ring, swing the transport lock out

to the field position and secure with pin and snap ring.

Transport lock - Field position

Hose package support

To prevent hoses and wiring from being damaged by

the tractor wheels, all hoses, cables and wires are held

by the hose bracket A fitted to the drawbar.

A

Transport lock - Road position

WARNING

DO NOT TRANSPORT

WITHOUT LOCKING THIS

STEERING DRAWBAR INTO

TRANSPORT POSTION.

Check that the length of the hoses and cables is

sufficient in tight turns, especially when the optional

steering drawbar is fitted.

97604303

11HARDI® COMMANDER OPERATOR’S MANUAL

Page 14

Sprayer setup

P. T.O. Shaft Operator Safety

WARNING:

ATTACHING THE TRANSMISSION SHAFT

TO TRACTOR P.T.O. MOST TRACTOR P.T.O.

SHAFTS CAN BE ROTATED BY HAND TO FACILI

SPLINE ALIGNMENT WHEN ENGINE IS STOPPED.

When attaching the shaft, make sure that the snap lock

is FULLY ENGAGED - push and pull shaft until it locks.

WARNING:

SHAFTS WITHOUT PROTECTION GUARDS

ARE FATAL.

Always keep protection guards and chains intact and

make sure that the guards cover all rotating parts,

including CV-joints at each end of the shaft.

Do not use without protection guard.

Do not touch or stand on the transmission shaft when it

is rotating - safety distance: min 5’ (1.5 meters).

Prevent protection guards from rotating by attaching

the chains, allowing sufficient slack for turns.

Make sure that protection guards around the tractor

P. T.O. and implement shaft are intact. Always STOP

ENGINE and remove the ignition key before carrying

out maintenance or repairs to the transmission shaft or

implement.

ALWAYS STOP ENGINE BEFORE

TATE

ROTATING TRANSMISSION

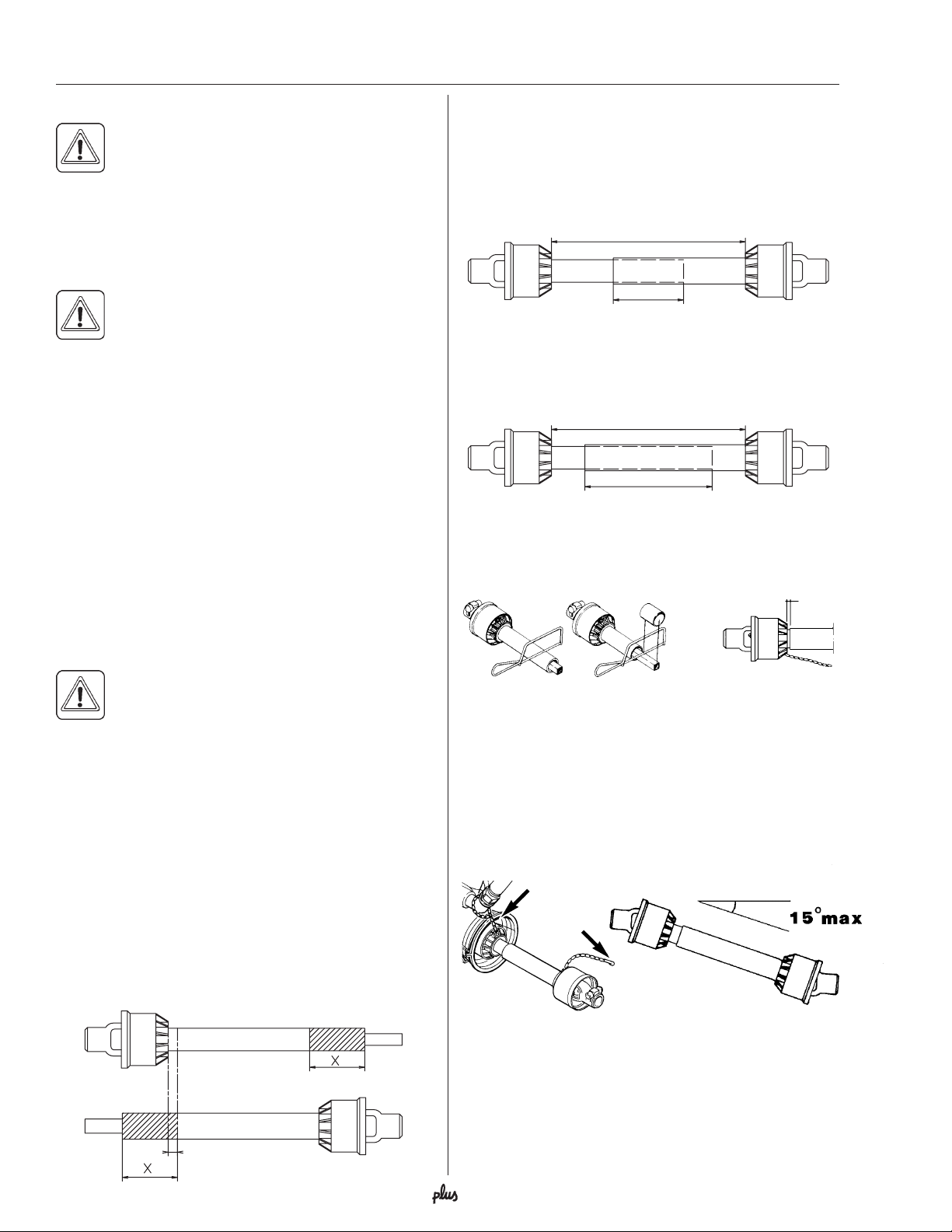

Note: The minimum allowable overlap for the shaft

depends on the pump model.

Pump with 6 splines (540 r.p.m.)

The shaft must always have a minimum overlap of 1/3

the length.

Length

Min. 1/3 of Length

Pump with 21 splines (1000 r.p.m.)

The shaft must always have a minimum overlap of 2/3

the length.

Length

Min. 2/3 of Length

4. The two parts are shortened equally. Use a saw, and

file the profiles afterwards to remove burrs.

Min. 13/16” (20mm)

INSTALLATION OF P.T.O. SHAFT

WARNING:

CHANGE WHEN RAISING AND LOWERING

THE CLEVIS. TO PREVENT EXCESSIVE

LOADING AND BINDING ON THE P.T.O. SHAFT, IT

MAY BE ADVISABLE TO LEAVE THE P.T.O. SHAFT

DISCONNECTED UNTIL THE CLEVIS ADJUSTMENT

IS COMPLETED. THEN THE P.T.O. SHAFT ADJUSTMENTS CAN BE MADE.

Initial installation of the shaft is done as follows:

1. Attach sprayer to tractor and set sprayer in the

position with shortest distance between the tractor

and sprayer pump P.T.O. shafts.

2. Stop engine and remove ignition key.

3. If P.T.O. shaft must be shortened, the shaft is pulled

apart. Fit the two shaft parts at tractor and sprayer

pump and measure how much it is necessary to

shorten the shaft. Mark the protection guards.

THE P.T.O. SHAFT ANGLE WILL

5. Grease the profiles, and assemble male and female

parts again.

6. Fit the shaft to tractor and sprayer pump.

Note: Female part towards tractor. Fit chains to prevent

the protection guards from rotating with the shaft.

7. To ensure long life of the P.T.O. shaft, try to avoid

working angles greater than 15°.

Min 13/16" (20mm)

12 HARDI® COMMANDER OPERATOR’S MANUAL

Page 15

Sprayer setup

Wheel tread adjustments

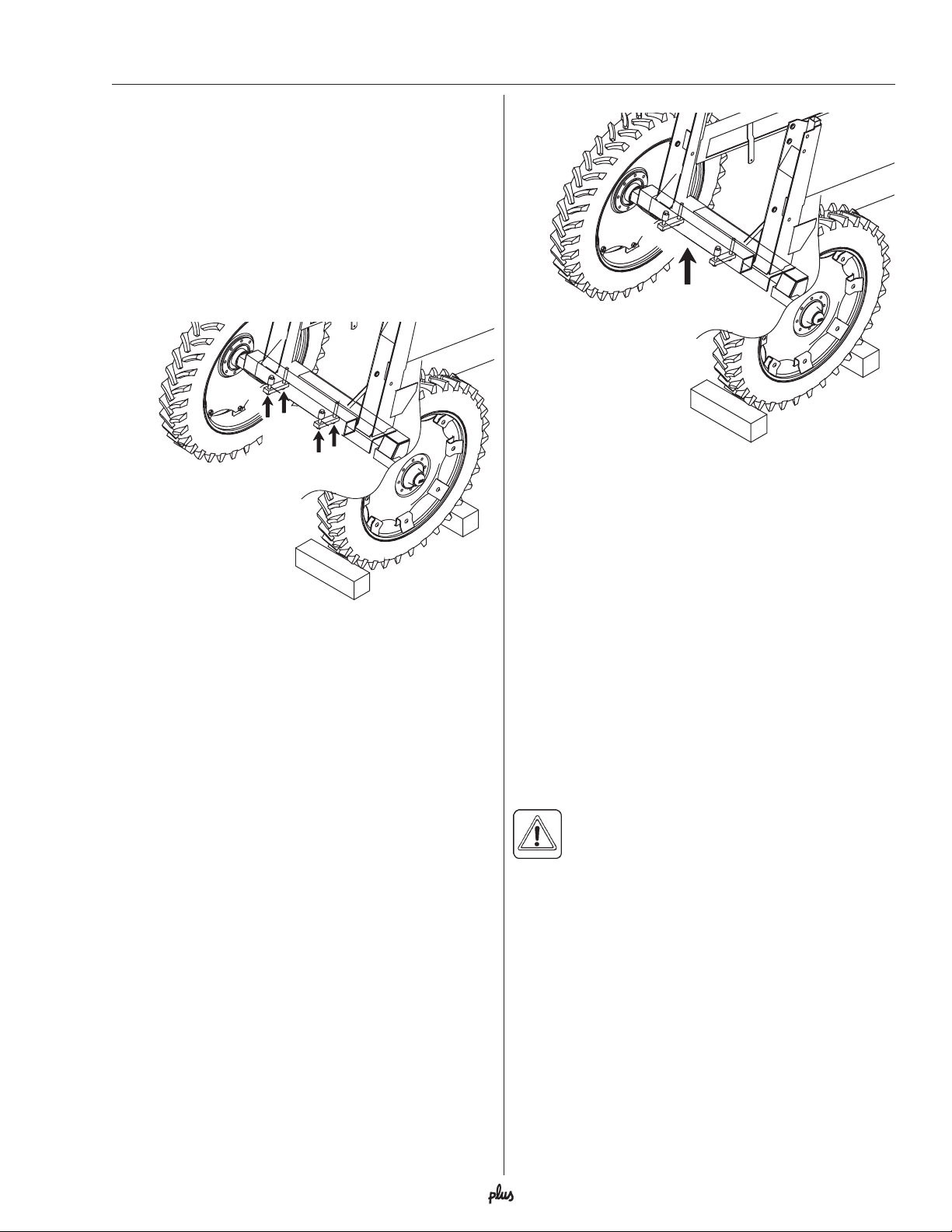

Altering the wheel track width

The track width of the COMMANDER Plus can be

adjusted as follows:

1. Measure the current track (center RH tire to center

LH tire). Each side must be extended or retracted

half the desired adjustment.

2. Attach the sprayer to tractor and engage tractor

parking brake.

A

A

3. Place wheel stops in front of and behind the RH

wheel. Jack up the LH wheel, support and secure

the sprayer frame.

4. Loosen the axle clamp bolts A for the LH wheel axle.

5. Extend or retract the axle as needed.

IMPORTANT! Place the jack under the axle and lift the

wheel to remove any load from the axle clamps before

tightening the axle clamp bolts to the specified torque.

6. Tighten the clamp bolts to a torque of:

207 Ft/lb (280 Nm) for CM+ 750

289 Ft/lb (390 Nm) for CM+ 1200

7. Repeat the procedure for the RH wheel.

8. Make sure the distance from the center of the tire to

the center of the tank frame is equal on RH and LH

sides.

9. Retighten the axle clamp bolts and wheel bolts to

specified torque after 10 hours of operation.

IMPORTANT! With Drawbar Steering

models, a minimum track width of

72” is required to ensure stability

and to prevent the sprayer from

tipping over.

Note: The wider the track width, the better is the

stability of the sprayer and boom.

13HARDI® COMMANDER OPERATOR’S MANUAL

Page 16

Sprayer setup

Axle Systems & Tire Assemblies

COMMANDER PLUS 750

• 60”- 88” adjustable axle inserts with 2 x 12.4 x 42” tire assemblies

• 120” fixed axle with 2 x 12.4 x 42” tire assemblies

COMMANDER PLUS 1200

• 60”- 90” or 72”- 90” adjustable axle inserts with 2 x 320/90R46” tire assemblies

(Note: 60”- 90” axle system ONLY available with EAGLE™ booms)

• 120” fixed axle with 2 x 320/90R46” tire assemblies

• 60”/120” Dual Wheel axle with 4 x 320/90R46” tire assemblies for 30” rows

• 88”/132” Dual Wheel axle with 4 x 270/95R48” tire assemblies for 22” rows

• 72”- 90” coil spring suspended adjustable axle inserts with 2 x 320/90R46” tire assemblies

• 76”- 90” or (80”- 90”) coil spring suspended adjustable axle inserts with 2 x 380/90R46” or

(2 x 18.4R46”) tire assemblies

• 120” coil spring suspended fixed axle system with 2 x 320/90R46” or 2 x 380/90R46” or

2 x 18.4R46” tire assemblies

• 88”/132” coil spring suspended Dual Wheel axle with 4 x 270/95R48” tire assemblies for 22”

rows

IMPORTANT! With Drawbar Steering models, a minimum track width of 72” is

required to ensure stability and to prevent the sprayer from tipping over.

Note: The wider the track width, the better is the stability of the sprayer and boom.

14 HARDI® COMMANDER OPERATOR’S MANUAL

Page 17

Sprayer setup

Hydraulic system

Connection requirements for HZ booms are:

• One single acting outlet for the lift function of the

spray boom

• One double acting outlet for the folding function

• 12 Volt electric supply

Note: The hydraulic system requires an oil capacity of

approximately 0.8 GPM (3 liters) and a minimum

pressure of 1,950 PSI (130 bar).

BE SURE TO HOOK UP HYDRAULIC LINES

PROPERLY!

ENSURE HYDRAULIC LINES HAVE NOT BEEN

DAMAGED DURING SHIPPING.

ESCAPING HYDRAULIC FLUID UNDER PRESSURE

CAN PENETRATE THE SKIN CAUSING SERIOUS

INJURY. AVOID THIS HAZARD BY RELIEVING

PRESSURE BEFORE DISCONNECTING HYDRAULIC LINES.

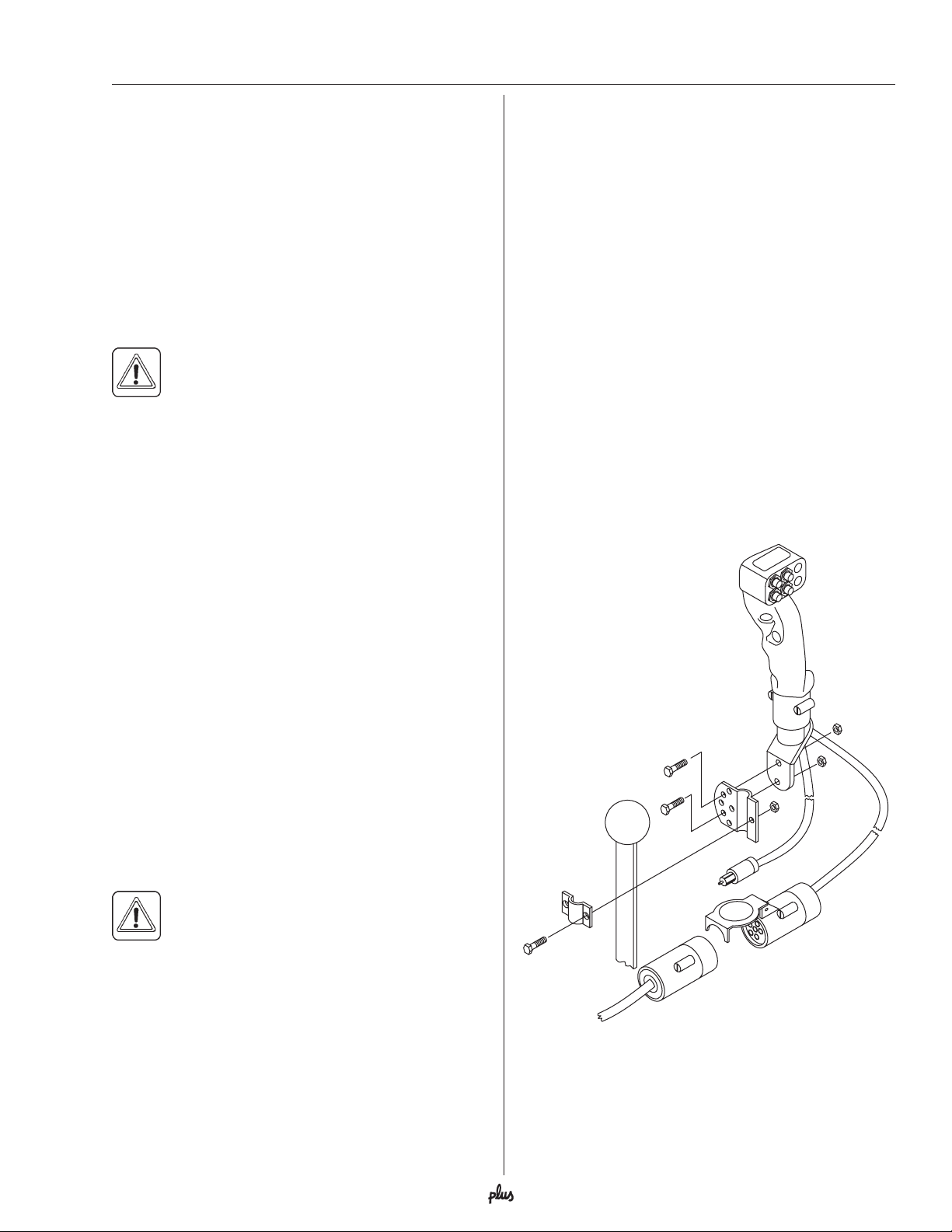

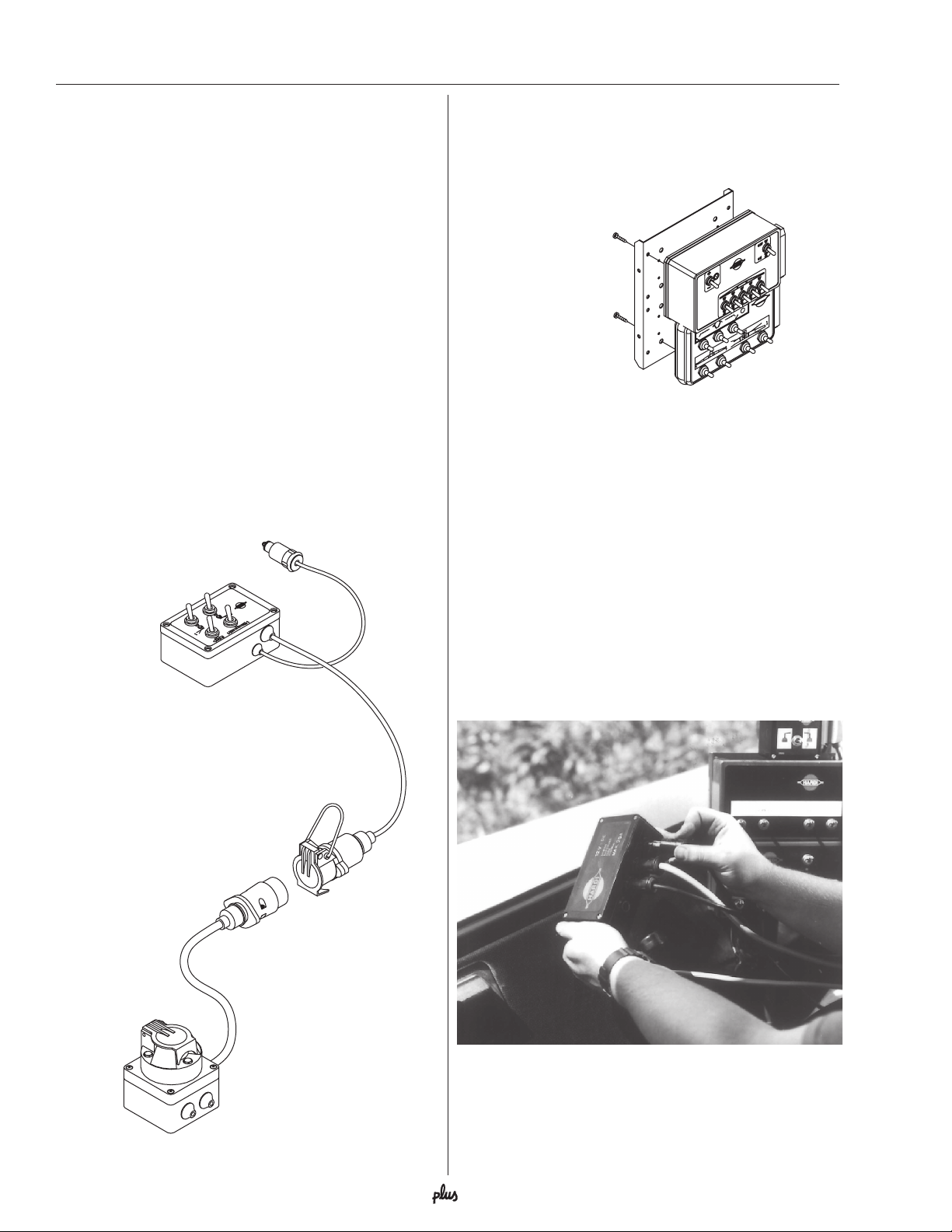

Hydraulics - standard joystick handle

Installation of handle

1. Attach the control handle/joystick A to the hydraulic

lever that operates the double acting outlet to be

used. The universal mounting bracket B is very

flexible and a number of different mounting positions

can be used.

2. Connect the plug C to the tractor’s 12V power

system. Try to hook-up the handle as close as

possible to the battery power supply. HARDI

mends using an electric distribution box (ref. no.

817925) to ensure a good power supply to various

12V attachments.

Note: Check with your dealer or tractor operator’s

manual for the best location to hook up the 12V system.

Note polarity: BROWN wire = Positive (+)

BLUE wire = Negative (-)

3. Connect electric plug D from sprayer’s hydraulics to

plug E on handle.

®

recom-

ENSURE ALL CONNECTIONS ARE TIGHT BEFORE

APPLYING PRESSURE, SEARCH FOR LEAKS WITH

A PIECE OF CARDBOARD NOT YOUR HANDS!

IMPROPER HOOK-UP CAN CAUSE DANGEROUS

BOOM MOVEMENTS AND/OR DAMAGE TO THE

SPRAYER HYDRAULICS.

DO NOT ALLOW ANYONE NEAR A HYDRAULIC

BOOM IN OPERATION.

ALWAYS SHUT TRACTOR OFF WHEN CONNECTING, SERVICING OR ADJUSTING BOOM.

Make sure that the hydraulic couplers are clean before

connecting to the tractor’s remote outlets.

IMPORTANT! Due to the variation in tractor

hydraulic systems and capacities, care should

be exercised when initially operating the

sprayer hydraulic cylinders. It is advisable to adjust the

hydraulic flow control down to the minimum rate before

operating the system. Adjust/increase the flow control

after the system is bled of any air, if necessary.

A

B

Hydraulic lever

C

E

D

15HARDI® COMMANDER OPERATOR’S MANUAL

Page 18

Sprayer setup

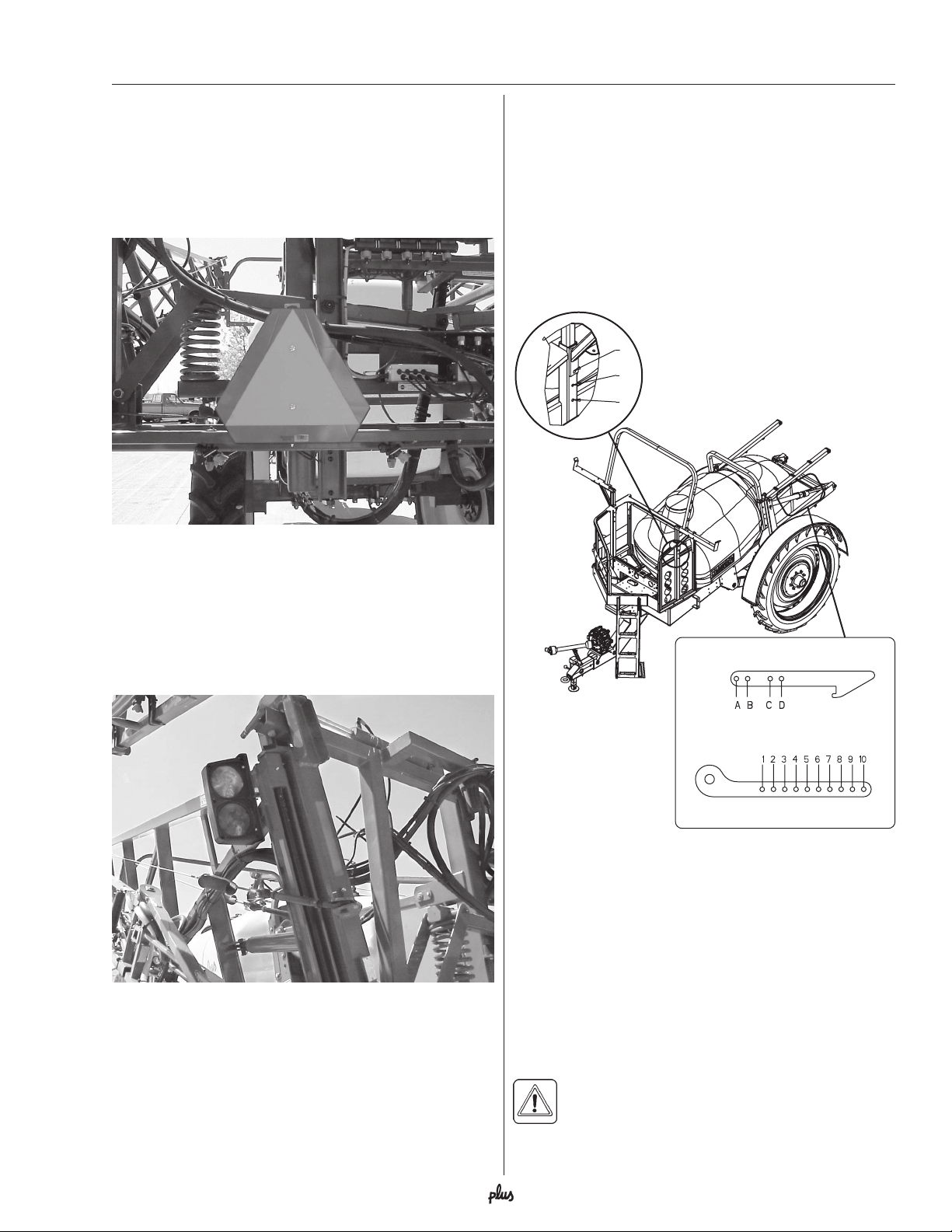

Direct Acting Hydraulic system (D.H.)

(optional)

Installation of control box

1. Connect the plug A to the tractor’s 12V power

system. Try to hook up the handle as close as

possible to the battery power supply. HARDI

recommends using an electric distribution box (ref.

no. 817925) to ensure a good power supply to

various 12V attachments.

Note: Check with your dealer or tractor operator’s

manual for the best location to hook up the 12V system.

Note polarity: BROWN wire = Positive (+)

BLUE wire = Negative (-)

2. Route the cable with the 7 pins, from the sprayer’s

hydraulic mount plate to the tractor.

3. Mount the hydraulic control box B in a suitable

location in the tractor cabin.

4. Connect the female 7 pin plug C from the switch box

to the 7 pin male plug D from the sprayer.

A

B

®

Control boxes and power supply

The control boxes for the ECP operating unit are fitted

in the tractor cabin in a convenient place. Self-tapping

screws can be used for mounting.

Ø4.8 x 9.5mm

Ø4.8 x 12mm

Power requirement is 12V DC.

Note polarity: BROWN wire = Positive (+)

BLUE wire = Negative (-)

The wires must have a cross sectional area of at least

12wg (4 mm

the ECP operating unit the tractor circuit should have

an 8 Amp fuse (5 Amp fuse for hydraulic system).

The 12V power sockets on the control boxes can be

plugged directly into either a HARDI

tion box (#817925) or a single female bayonet style

plug (#260827). Both of these are available from your

HARDI® Dealer.

2

) to ensure sufficient power supply. For

®

4 outlet connec-

C

D

12-volt junction box (#817925) for 12-volt hook-up.

16 HARDI® COMMANDER OPERATOR’S MANUAL

Page 19

Sprayer setup

Transport

Roadworthiness

Slow moving tractors and spray equipment can create

a hazard when on public roads. Make sure the S.M.V.

sign is in place and clearly visible from the rear of the

sprayer.

NOTE! Max. driving speed is 15 mph (25 km/h).

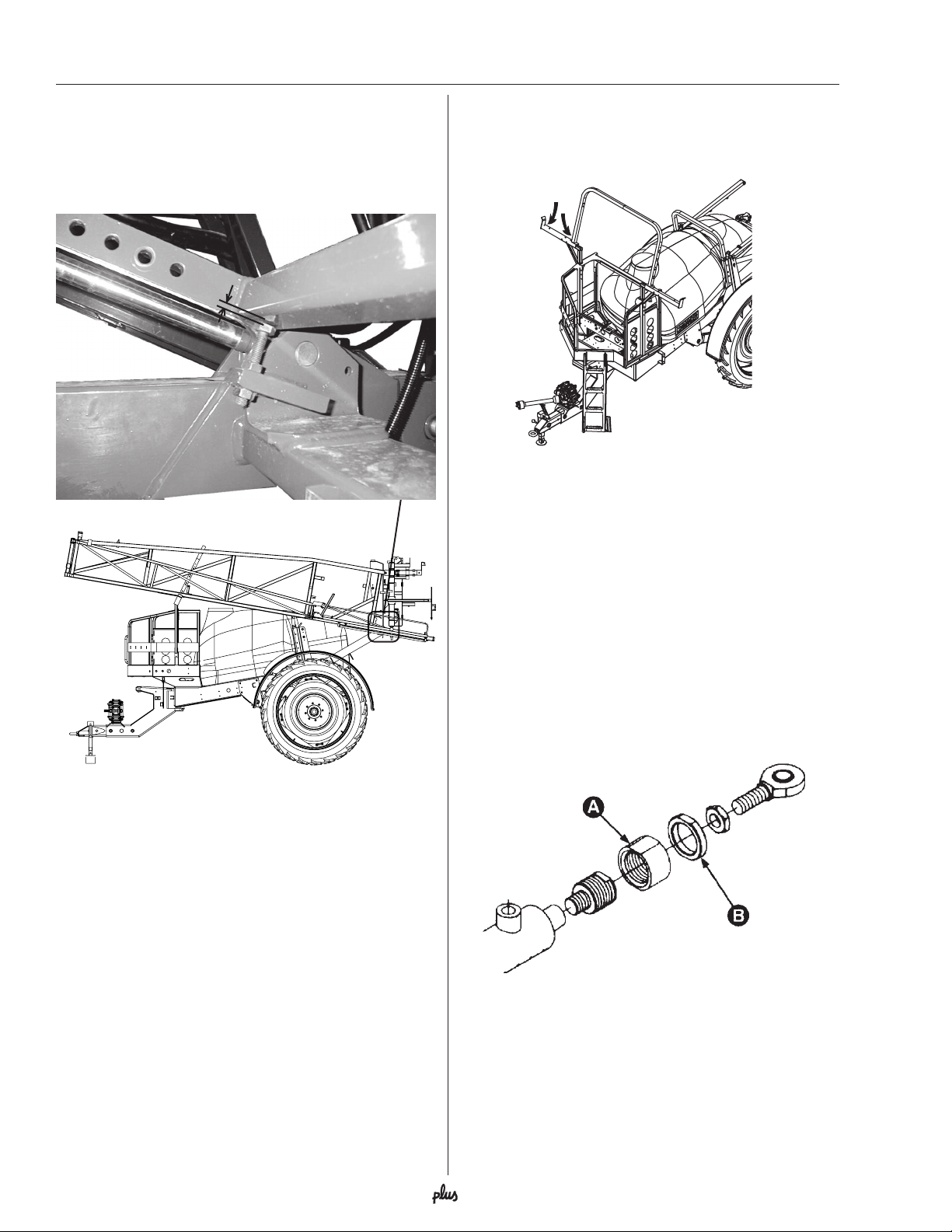

Transport brackets, height setting

The transport brackets can be set in different positions

to obtain different transport heights and suitable clearance above various tractor cabins.

When changing the setting of the transport brackets it

is done as a combination of adjusting the transport

brackets themselves (1) and adjusting the transport

locks (2). Always choose a transport height as low as

possible.

1. Transport brackets

(1)

The transport bracket can be set at

three different positions A, B or C.

A

Loosen the bolt to change position

B

and replace it according to new

setting. The setting must be identical

C

on both sides.

Rear lights

Local regulations may require the use of flashing

warning lights. Connect plug for rear lights to the

tractor’s 7-pin socket, and check function of rear lights,

stop lights and direction indicators on both sides before

driving.

(2)

A

2. Transport lock

To change position:

1. Lift and unfold inner sections till lock is disengaged.

2. Loosen and remove the two bolts, which keep the

parts A and B assembled.

3. Reassemble A and B according to desired hole

combination.

Note: Always use both bolts to assemble the lock. The

setting must be identical on both sides.

Note: The rear settings must correspond to the front

settings so the boom is resting on the front as well as

rear locks.

B

WARNING! The max. transport height must

never exceed 13.1 ft. (4.0 m). Always measure

the actual total height and choose settings not

exceeding 13.1 ft (4.0m).

17HARDI® COMMANDER OPERATOR’S MANUAL

Page 20

Sprayer setup

Transport lock arm stop

When the boom is unfolded: Inspect the gap between

the bolt A and the frame. Correct position = 1/16” gap

(2 mm).

If necessary, adjust the position of bolt A.

1/16” (2 mm)

A

Adjusting boom transport position

If the boom wings do not rest accurately in the transport brackets, the wings can be adjusted as described

below:

1. Lift the boom all the way to the top.

2. Fold the boom into transport position. With the fold

cylinder pressurized, determine if the boom wings

need to be adjusted inwards or outwards.

3. Relieve the pressure from the fold cylinder by unfolding the boom a few inches.

If the boom rests too far in on the transport brackets,

loosen the nut B and adjust collar A in towards the

cylinder housing.

If the boom rests too far out on the transport brackets,

the collar A has to go out from the cylinder housing.

4. Secure jam nut B.

5. Pressurize the cylinder to see if the boom is properly

adjusted. If not, repeat the above procedure until it is

correctly adjusted.

18 HARDI® COMMANDER OPERATOR’S MANUAL

Page 21

Sprayer setup

Driving Technique

Steering drawbar (optional)

A trailer with an articulating drawbar behaves differently

than a normal trailer.

In tracking position the vehicle’s center of gravity is

displaced further from the vehicle’s center line than that

of a normal trailer.

Compared to a conventional trailer, a trailer equipped

with a steering drawbar has decreased stability when

turning, especially when turning on hillsides.

To avoid instability or overbalancing, pay attention to

these guidelines:

1. Avoid sudden, tight turns

2. Slow down before entering a curve or turning, and

drive with a constant, low speed during the turn.

3. Never slow down too fast, never brake heavily and

never stop suddenly in a curve, or when turning on a

hillside, when the sprayer is articulated.

4. Be careful when turning on uneven ground

5. Set the wheel width as wide as possible

6. The proper function of the hydraulic damping is

essential to obtain good stability

7. Keep stabilizer chains on the tractor’s liftarms tight

8. For safety reasons, the following limitations are set

for sprayers equipped with steering drawbar (with

unfolded booms):

MAX. 8º

MIN. 72"

Speed while turning, max. 2.5 m.p.h. (4 km/h)

Ground inclination while turning, max. 8°

Wheel width, min. 72” with steering drawbar

Make sure the following safety decals are in place and

that you understand and follow each one:

DANGER

USING THE STEERING

DRAWBAR WILL

DECREASE SPRAYER

STABILITY. USE

EXTREME CAUTION!

97604203

Decal #97604203

WARNING

DO NOT TRANSPORT

WITHOUT LOCKING THIS

STEERING DRAWBAR INTO

TRANSPORT POSTION.

97604303

Decal #97604303

WARNING

DO NOT USE STEERING DRAWBAR

WITH SPRAYER/AXLE CONFIGURATION

OTHER THAN THOSE LISTED BELOW:

CM Plus 750 .............SPB EAGLE™ BOOM ............72" OR WIDER AXLE

CM Plus 875/1200 ....SPB/SPC EAGLE™ BOOM ...72" OR WIDER AND DUALS

CM Plus 875/1200 ....FORCE™ BOOM ...................120" AND DUALS

CM Plus 750 .............TWIN FORCE ........................72" OR WIDER AXLE

CM Plus 875 .............TWIN FORCE UP TO 66' .......72" OR WIDER AXLE

CM Plus 875 .............TWIN FORCE 80'-90' ............120" AND DUALS

CM Plus 1200 ...........TWIN FORCE 60'-90' ............120" AND DUALS

Decal #97604403

97604403

19HARDI® COMMANDER OPERATOR’S MANUAL

Page 22

Sprayer setup

Disconnecting the sprayer

Always clean the sprayer - inside and outside - before

disconnecting and parking it.

Support leg

Before disconnecting the sprayer from the tractor,

make sure the support leg is properly fitted with the

linch pin secured.

The support leg is stored in the storage bracket on the

right side of the trailer when the sprayer is attached to

the tractor. To remove the support leg: Lift the leg,

remove the pin and pull out the support leg.

P. T.O. shaft support

The P.T.O. shaft rests on the bracket A when not in use.

A

WARNING! To prevent the sprayer from tipping

over, do not disconnect the sprayer from the

tractor with the booms unfolded unless the

boom is supported!

Remember to disconnect all hoses and cables from the

tractor.

WARNING! If the sprayer is parked unattended

avoid unauthorized persons, children and

animals from having access to the sprayer.

20 HARDI® COMMANDER OPERATOR’S MANUAL

Page 23

Operation

Operating the boom

BEFORE UNFOLDING THE BOOM, IT IS

IMPORTANT TO HAVE THE SPRAYER

HOOKED TO THE TRACTOR TO PREVENT

OVERBALANCING THE SPRAYER. ONLY THEN

LIFT THE BOOM OFF THE TRANSPORT BRACKETS WHICH HOLD IT IN THE TRANSPORT POSITION.

• ENSURE THAT BOOMS ARE BACK IN THE

TRANSPORT POSITION BEFORE UNHOOKING

THE SPRAYER FROM THE TRACTOR.

• THE HYDRAULIC SYSTEM SHOULD BE CHECKED

VERY CAUTIOUSLY THE FIRST TIME OF OPERATION; THERE MAY BE AIR IN THE SYSTEM AND

THIS COULD CAUSE VIOLENT MOVEMENTS OF

THE BOOM. ENSURE THAT NO PERSONS OR

OBJECTS ARE IN THE WAY WHILE CHECKING

THE SYSTEM.

• FOR INFORMATION ON BOOM ADJUSTMENT,

SEE THE APPROPRIATE EAGLE™ OR FORCE™

BOOM OPERATOR’S MANUAL.

Unfolding and folding the HZ EAGLE™ boom

WARNING! Always put the boom wings in the

horizontal position prior to folding. Never at-

tempt to fold the boom to transport position

when the boom wings are tilted - unexpected boom

movements may occur, if the wings are tilted when

folding.

A. Hydraulic joystick controls

Switch A operates: Left hand fold cylinder

Switch B operates: Right hand fold cylinder

Switch C operates: Left hand tilt cylinder

Switch D operates: Right hand tilt cylinder

A

C

B

D

1. Raise the boom to release it from the transport

brackets.

2. Depress switches A and B and move the joystick

forward or rearward to activate oil flow. Switch

positions of the hoses in the double acting remote

outlet if you do not like the direction required to

activate the boom.

3. ‘One side folding’ is achieved by following the above

procedure - except that only one of the switches is

depressed (See

‘Folding one side only’

below).

B. D.H. Hydraulic control box (optional)

Switch A operates: Left hand fold cylinder

Switch B operates: Right hand fold cylinder

Switch C operates: Left hand tilt cylinder

Switch D operates: Right hand tilt cylinder

C

A

D

B

1. Raise the boom to release it from the transport

brackets.

2. Engage the tractor’s double acting remote outlet

lever and lock it in the engaged position.

3. Activate switch A upwards and hold it to unfold left

hand boom wing. (Holding the switch in the ‘down’

position will fold the boom wing). To unfold right hand

boom, activate switch B.

4. ‘One side folding’ is achieved by following the above

procedure - except that only one of the switches is

activated. (See section

Folding one side only

If only one side of the boom is to be unfolded, first

unfold the boom completely and then turn switches off.

Then flip the switch for the side that is to be folded and

activate the double acting outlet to fold that side into

transport position.

Note: It is not advisable to go directly from transport

position to spraying position with one side only. Therefore, first unfold both boom wings completely.

‘Folding one side only’

).

21HARDI® COMMANDER OPERATOR’S MANUAL

Page 24

Operation

Unfolding and folding the HZ FORCE™ boom

WARNING! Always operate the boom on level

ground.

A. Hydraulic joystick controls

Switch A operates: Inner wing fold cylinders

Switch B operates: Outer wing fold cylinder

Switch C operates: Left hand tilt cylinder

Switch D operates: Right hand tilt cylinder

A

C

B

D

3. Tilt wings up approx. 15° (See Tilting the HZ Force™

boom - p. 23).

4. Depress switch A to fold in the inner wing sections

allowing the bottom profile of the wing to come in

contact with the vertical part of the front transport

bracket.

5. Lower boom down, activating the Paralift™ lift

cylinders. Make sure that the transport hooks are

engaged on the cylinders. Then lower the tilt cylinders (switch C and D) until the wings are resting on

the front transport supports.

6. Relieve all oil out of the system by activating the

tractor levers without any switches pushed.

B. D.H. Hydraulic control box (optional)

Switch A operates: Left hand fold cylinder

Switch B operates: Right hand fold cylinder

Switch C operates: Left hand tilt cylinder

Switch D operates: Right hand tilt cylinder

C

A

D

TO UNFOLD BOOM

1. Raise the boom to release it from the transport

brackets.

2. Depress switches A and move the joystick forward or

rearward to unfold the inner wing sections of the

boom. Switch positions of the hoses in the double

acting remote outlet if you do not like the direction

required to activate the boom.

Note: When unfolding the inner wings, the transport

hooks on the two Paralift™ cylinders will disengage.

3. With the boom still at the highest point, depress

switch B to unfold the outer wing sections (unless

spraying half folded). Lower boom to desired spray

height.

TO FOLD BOOM

1. Raise the boom 75% of the highest point.

2. Depress switch B and move joystick in opposite

direction as unfold to fold in the outer wing sections.

B

TO UNFOLD BOOM

1. Raise the boom to the highest point to release it from

the transport supports and hooks.

2. Engage the tractor’s double acting remote outlet

lever and lock it in the engaged position.

3. Activate switch A upwards and hold it to unfold the

inner wing sections.

Note: When unfolding the inner wings, the transport

hooks on the two Parilift™ cylinders will disengage.

4. Activate switch B upwards and hold to unfold the

outer wing sections (unless spraying half folded).

Lower boom to desired spray height.

TO FOLD BOOM

1. Raise the boom 75% of the highest point.

2. With the double acting remote outlet lever engaged,

activate switch B downwards and hold to fold in the

outer wing sections.

Note: Be sure that the boom is raised when folding or

damage can occur when the transport hooks are

engaged.

Note: Be sure that the boom is raised when folding or

damage can occur when the transport hooks are

engaged.

22 HARDI® COMMANDER OPERATOR’S MANUAL

3. Tilt wings up approx. 15° (See Tilting the HZ Force™

boom - p. 23).

Page 25

Operation

4. Depress switch A to fold in the inner wing sections

allowing the bottom profile of the wing to come in

contact with the vertical part of the front transport

bracket.

5. Lower boom down, activating the Paralift™ lift

cylinders. Make sure that the transport hooks are

engaged on the cylinders. Then lower the tilt cylinders (switch C and D) until the wings are resting on

the front transport supports.

6. Relieve all oil out of the system by activating the

tractor levers without any switches pushed.

Tilting the HZ FORCE™ boom

WARNING! Never attempt to work on or around

boom when tilted up.

A

B

B. D.H. Hydraulic control box (optional)

1. Engage the tractor’s double acting remote outlet

lever and lock it in the engaged position.

2. Activate switch C upwards and hold to tilt left-hand

boom up (Holding the switch in the down position will

tilt the boom down). To tilt the right-hand boom,

activate switch D.

C

A

D

B

C

D

A. Hydraulic joystick controls

1. Activate switch C and move hydraulic handle forward

or rearward to tilt left-hand boom up. To tilt the righthand boom, activate switch D. Switch positions of

the hoses in the double acting outlet if you do not

like the direction required to activate the boom.

23HARDI® COMMANDER OPERATOR’S MANUAL

Page 26

OperationOperation

The HARDI® COMMANDER Plus trailer sprayer uses a diaphragm pump with ECP control.

Take time to review and study the plumbing diagram for your sprayer. By following the flow

through the diagram, you will better understand the various functions of your sprayer system.

ECP PLUMBING DIAGRAM

7

3

10

4

12

14

9

11

16

1

2

8

15

6

17

5

19

17

18

13

1. Suction filter

2. Suction manifold

3. Pump

4. Pressure manifold

5. Sparge tube agitation

6. Safety valve

7. HARDI-MATIC

8. Self-cleaning filter valve return

9. Self-cleaning filter

10. Check valve

11. Boom section valves

12. Pressure agitation return

with restrictor

13. Boom

14. Boom pressure gauge

15. Flush tank

®

16. HARDI

chemical inductor

17. Tank rinse nozzles

18. Pressure equalization return

19. Feed hose pressure return

24 HARDI® COMMANDER OPERATOR’S MANUAL

Page 27

Operation

Operating the liquid system

MANIFOLD SYSTEM

The “Manifold System” is located at the left side of the

sprayer, permitting operation of most of the (fitted)

accessories from one position. The modular design of

the Manifold system allows the easy addition of many

accessories to the plumbing system of the sprayer. The

system can be expanded to a maximum of 4 valves on

the pressure side. The suction side can be expanded to

a maximum of 2 valves. The system is also fitted with

an agitation valve, enabling the tank agitation to be

turned on or off. It also features a self-cleaning filter

return hose on/off valve, which allows the return to be

turned on or off.

Use of MANIFOLD valve system

The Manifold valve faces are colored discs for easy

identification:

Green disc = Pressure valve

Black disc = Suction valve

Yellow disc = Self-cleaning filter

Closed

A function is activated/opened

by turning the handle

towards the desired

function

Function

open

Decals - Black disc (suction)

Suction from

main tank

Flush tank

(optional)

)retlifgninaelc-fles(csidwolleY

The disc has two

positions; open

Closed

Open

or closed

The valves and functions may vary from machine to

machine depending on optional equipment fitted. Only

the functions to be used must be open - Always close

all remaining manifold valves.

*Agitation

Normally, Agitation should be on, but please refer to

the following rules of thumb:

1. Choose “Without Agitation” if a high level of

foaming occurs, in order to reduce the

amount of foam.

Symbols (shown below) are fitted to the faces of the 3way valves indicating the direction of flow of the liquid.

Decals - Green disc (pressure)

Self-cleaning

filter /

Operating unit

HARDI FILLER

(optional)

Agitation *

Without

agitation

Tank rinsing

nozzle

To main tank

Spray gun

(optional)

®

2. Choose “Agitation” when using powder

chemicals in order to avoid sedimentation.

3. Close the agitation valve if spraying with

a high volume and it is impossible to

achieve sufficient operating pressure.

25HARDI® COMMANDER OPERATOR’S MANUAL

Page 28

Operation

To operate the spraying functions:

• Turn the handle on a green pressure valve towards

the desired function

• Turn the handle on a black suction valve towards the

desired function

• Open or close yellow disc (self-cleaning filter)

• Close all remaining valves by setting the handle(s)

on “O”

Note: If a MANIFOLD valve is too tight to operate - or

if it is too loose (= liquid leakage), the 3-way-valve

needs to be serviced. Please see the part

of 3-way-valve (suction)” (p. 50)

Correct setting is when the valve can be operated

smoothly by one hand

for further information.

Electrical operated MANIFOLD valves

(optional)

One or more MANIFOLD valve(s) can be electrically

operated via a control box in the tractor cab. In case of

a power failure, these can only be operated manually

when the power to the valve motor is disconnected.

Quick reference decals are located on the frame near

the MANIFOLD SYSTEM for easy “in field” operation of

the valves.

“Adjustment

1. Filling main tank through tank lid

Remove the tank lid and fill water through strainer

basket to prevent rust or other foreign particles from

entering the tank.

It is recommended to use a water supply as clean as

possible for spraying purposes.

WARNING!

ETC. ENTER THE TANK. KEEP IT OUTSIDE

THE TANK, POINTING TOWARDS THE

FILLING HOLE.

IF THE HOSE IS LEAD TO THE BOTTOM OF THE

TANK, AND THE WATER PUMP AT THE WATER

SUPPLY PLANT STOPS, CHEMICALS CAN BE

SIPHONED BACK AND CONTAMINATE THE WATER

SUPPLY LINES.

DO NOT LET THE FILLING HOSE

2. Filling flush tank (optional) through lid

The flush tank is situated at the front under the platform

and main tank. Access to the flush tank lid is at the rear

of the platform. Fill only with clean water.

Filling the tanks on the COMMANDER Plus

The main tank and flush tank can be filled in two ways:

1. Filled through tank lid.

2. Filled with external Quick Fill (optional), which

enables the connection to a nurse tank.

Flush tank capacity (optional)

The main tank should normally be filled 1/3 with water,

before adding the chemicals - always read instruction

on chemical container!

IMPORTANT! If the sprayer is stored with liquid in the

main tank, all MANIFOLD valves must be closed.

26 HARDI® COMMANDER OPERATOR’S MANUAL

Model LiterUS Gal.

750

1200

70

110

280

420

Page 29

Operation

3. Filling with external Quick Fill (optional)

Main tank Quick Fill coupler

A water level indicator for the flush tank (clear hose

with floating ball) is situated beneath the platform.

4. Filling of clean water tank

The clean water tank is integrated in the platform and

has a capacity of 8 gallons (30 liters). Access to the

tank lid is possible from the platform. Fill this tank with

clean water only.

Flush tank Quick Fill coupler

The Quick Fill is operated as follows:

1. Remove the plug from the quick fill coupler for the

tank you wish to fill (main tank or flush tank).

2. Fit the external water supply hose to the quick

coupler on the trailer.

3. Fill tank to desired level.

WARNING: Do not leave the sprayer while filling

the tank, and keep an eye on the tank level sight

gauge in order NOT to overfill the tank!

4. Remove external water supply hose from the quick

coupler.

5. Replace the plug on the quick coupler.

Note: Observe local legislation regarding use of Quick

Filling Device. In some areas it is prohibited to fill from

open water reservoirs (lakes, rivers, etc.). It is recommended only to fill from closed reservoirs (mobile water

tank, etc.) to avoid contamination.

WARNING!

CARRIED ON THE SPRAYER, IT CAN BE

CONTAMINATED BY SPRAY DRIFT WHICH

WILL BE TRANSFERRED TO WATER SUPPLY

WHEN FILLING.

IF SUCTION HOSE/FILTER IS

The water from this tank is for hand washing, cleaning

of clogged nozzles etc. The tap is located within reach

from the MANIFOLD valves and is opened/closed by a

tap handle.

WARNING! Although the clean water tank is

only filled with clean water, it must never be

used for drinking.

27HARDI® COMMANDER OPERATOR’S MANUAL

Page 30

Operation

Adjustment of ECP operating controls

Distribution

Valves

Constant Pressure

Adjusting Screws

C

System Pressure

Gauge

Pressure

A

BBBBB

Control

Val ve

Adjustment of constant pressure

Note: Adjust the constant distribution boom pressure

one section at a time as follows: (Start with the

valve turned closed before adjusting).

1. Shut-off the first boom distribution valve switch B.

2. Turn the adjusting screw(s) until the control pressure gauge again shows the same pressure as in

step 6 (to left) (Turn the screw clockwise for higher

pressure, counterclockwise for lower pressure).

3. Turn the first boom distribution valve switch B back

on.

4. Repeat steps 1-3 for the remaining boom distribution

valves.

Note: Hereafter adjustment of the constant boom

pressure will only be needed if you change to nozzles

with other capacities, but not required if only changing

pressure or application rate using the same nozzles.

Operating the control unit while spraying

In order to shut off the entire boom, flip on-off switch A

to the off (red) symbol (up position). This returns all the

pump outputs to the main tank through the return

system. The diaphragm anti-drip valves ensure instantaneous closing of all nozzles.

A. Operating switch for main on/off

B. Operating switch for distribution valves

C. Pressure control switch (to lower or raise)

Before spraying, adjust the ECP operating unit

using clean water (without chemicals).

1. Choose the correct nozzle (pp. 33-34). Make sure

that all nozzles are the same type and capacity.

2. Put the tractor in neutral and adjust the P.T.O. r.p.m.

until the number of revolutions of the pump corresponds to the intended traveling speed. Remember

the number of revolutions on the P.T.O. must be kept

between 300-600 r.p.m. (540 r.p.m. pump) or 6501100 (1000 r.p.m. pump) to ensure correct operation

of the HARDI-MATIC system.

3. On-off switch A is “ON” against green symbol (down

position).

4. All distribution valve switches B are also “ON”

against green symbol (down position).

5. Hold pressure regulating switch C down (-) until

handle stops rotating. This will be the “minimum

pressure” setting.

6. Hold pressure regulating switch C up (+) until desired pressure is shown on the boom pressure

gauge.

In order to shut off one or more sections of the boom,

switch the relevant distribution valve B to off position.

The constant pressure system ensures that the pressure does not increase in the sections which are still

open.

In case of electrical failure, it is still possible to manually override all functions of the operating unit. To

operate manually, disconnect the multiplug from the

ECP control box first and operate the handles by hand.

It is possible to change pressure and turn boom sections on or off.

Note: Since the on-off switch normally operates by

shutting off all the boom distribution valves, you will

need to manually shut off all the distribution valves to

shut off the complete control unit manually.

IMPORTANT! When the sprayer is stored,

the ECP control box and the multiplug must

be protected against moisture and dirt. A

plastic bag may be used to protect the multi plug.

Store the control box in a clean dry place.

28 HARDI® COMMANDER OPERATOR’S MANUAL

Page 31

Operation

Remote 4” pressure gauge

The remote pressure gauge is integrated into the front

locker. This gauge measures the working pressure in

the boom tubes as close to the nozzles as possible.

This pressure reading will always be slightly lower than

the reading at the operating unit pressure gauge.

The outputs stated in the nozzle charts are always

based on the pressures measured at the nozzle.

Note:

Always adjust pressure when calibrating and spray-

ing according to readings at the Remote pressure gauge.

Self cleaning filters

This filter automatically flushes out particles and

chemical deposits, reducing routine maintenance,

nozzle plugging and operator exposure. No adjustments are required, but different mesh screens may be

installed for various types of products. The mesh size

of the filter in use should always be smaller than the

flow average of the nozzles used.

Operating diagram

1. From pump

2. Double filter screen

3. Guide cone

4. To operating unit

5. Replaceable restrictor

6. Return to tank

7. Screw-joint

The self-cleaning filter is operated via

the yellow MANIFOLD valve.

IMPORTANT! The yellow MANIFOLD valve should

normally be open, but must be closed in the following

cases:

1. If rinsing with water from the flush tank and a quantity of spray liquid still remains in the main tank

(otherwise the spray liquid will be diluted).

2. If opening the self-cleaning filter and a quantity of

spray liquid still remains in the main tank (otherwise

there is a risk that spray liquid will flow out).

Choice of correct restrictor for S.C.F.

It is important to have a large flow through the self

cleaning filter. This is achieved by choosing the

restrictor size in relation to the liquid consumption of

the spray boom.

The hose (A) is unscrewed

from the self-cleaning filter.

Be careful not to lose the

seal ball or spring when

the restrictor is put in the

hose and the hose is

refitted. If the required

working pressure can not

be obtained, the restrictor

is too large. 4 restrictors

are supplied. Use the

green one (largest orifice)

first. Then choose the next

smaller restrictor, starting

with black, then white and finally a red one.

Adjustment of Air Pressure in Pressure

Damper (1302 Pump Only)

The air pressure in the damper on

the 1302 pump is factory preset at

30 psi (2 bar). This is suitable for

nozzle spray pressures between

45 psi (3 bar) and 225 psi (15

bar). If different nozzle pressures

are required, set pressure damper

at pressures indicated.

PSI (BAR)

20-45 (1-3)

45-225 (3-15)

PSI (BAR)

0-15 (0-1)

15-45 (1-3)

Open

Closed

29HARDI® COMMANDER OPERATOR’S MANUAL

Page 32

Operation

Filling of chemicals

Chemicals can be filled into the tank two different ways:

1. Through the tank lid.

2. By using the HARDI® CHEMICAL FILLER device.

WARNING! Be careful not to slip or splash

chemicals when carrying chemicals up to

the tank lid!

WARNING! Always use the personal protection stated on the chemical container and as

a minimum, always use gloves, face protec-

tion shield and coveralls.

1. Filling through tank lid

The chemicals are filled through the tank lid - Note

instructions on the chemical container!

1. Make sure the ECP is switched off.

2. Set the MANIFOLD valves to correct position. Black

valve “Suction from main tank”, green valve towards

“Agitation.”

Black Green Green Green

3. Engage the pump and set P.T.O. revolutions to 540

r.p.m. or 1000 r.p.m. (depending on pump model).

4. Add the chemicals through the main tank hole.

5. When the spray liquid is well mixed, turn handle on

the Pressure Manifold towards “Spraying” position.

Keep P.T.O. engaged so the spray liquid is continuously agitated until it has been sprayed on the crop.

2. Filling with HARDI® CHEMICAL FILLER

To get access to the HARDI® CHEMICAL FILLER,

grab the handle, disengage the lock with your foot, and

drag the HARDI

down. After use, push it all the way up again.

®

CHEMICAL FILLER all the way

Operating with Liquid-based chemicals

1. Fill the main tank at least 1/3 with

water (unless something else

is stated on the chemical

container label). See

“Filling the tanks on the

COMMANDER Plus”

(pp.26-27).

2. Turn the handle

at the Suction

Manifold towards “Main

tank” . Turn green valve

towards “HARDI

CHEMICAL FILLER” and

other green valve towards

agitation. Close remaining valves.

3. Check that bottom valve A at the FILLER is closed.

®

C

B

A

Black Green Green Green

4. Engage the pump and set P.T.O. speed at 540 r/min

Black Green Green Green

30 HARDI® COMMANDER OPERATOR’S MANUAL

or 1000 r/min (depending on pump model).

5. Open HARDI® CHEMICAL FILLER lid.

6. Measure the correct quantity of chemical and fill it

into the hopper.

Page 33

Operation

Note: The measuring scale in the hopper can only be

used if the sprayer is parked on level ground! It is

recommended to use a measuring jug for best accuracy.

7. Open the bottom valve A. The chemical is then

transferred to the main tank.

8. If the chemical container is empty, it can be rinsed by

using the Bag & Bottle Rinse (optional). Place the

container over the multi-hole nozzle and press the

lever B.

WARNING! Do not press lever B unless the

multi-hole nozzle is covered by a container to

avoid spray liquid hitting the operator.

IMPORTANT! The Bag & Bottle Rinse uses spray liquid

from the main tank to rinse containers of concentrated

chemicals. Always rinse the chemical containers with

clean water several times until they are clean before

disposal.

9.

Engage the hopper rinsing device by opening valve C.

10. Close valve C again when the hopper is rinsed.

IMPORTANT! The hopper rinsing device uses spray

liquid from the main tank for rinsing the hopper of

concentrated chemical. The HARDI

®

CHEMICAL

FILLER must always be cleaned together with the rest

of the sprayer when the spray job is done.

11. Close valve A and the HARDI

®

CHEMICAL FILLER

lid again.

12. When the spray liquid is well mixed, turn handle on

the Pressure Manifold towards “Spraying” position.

Keep P.T.O. engaged so the spray liquid is continuously agitated until it has been sprayed on the crop.

3. Engage the pump and set

P. T.O. speed at 540 r.p.m. or

1000 r.p.m. (depending on

pump model).

4. Open the bottom valve A on

®

the HARDI

CHEMICAL

FILLER and open the lid.

Engage the hopper rinsing

5.

device by opening valve C.

6. Measure the correct

quantity of chemical

and sprinkle it into

the hopper as fast

as the rinsing

device can flush

B

it down.

7. If the chemical

container is empty it

can be rinsed by using

the Bag & Bottle Rinse

C

A

(optional). Fit the bag

bracket and place the

powder bag over the multi-hole nozzle and press the

lever B.

WARNING! Do not press lever B unless the

multi-hole nozzle is covered by a container to

avoid spray liquid hitting the operator.

IMPORTANT! The Bag & Bottle Rinse uses spray liquid

from the main tank to rinse containers of concentrated

chemicals. Always rinse the chemical containers with

clean water several times until they are clean before

disposal.

9. Close valve C again when the hopper is rinsed.

Operating with Powder-based chemicals

Black Green Green Green

1. Fill the main tank at least half full with water, unless

something else is stated on the chemical container

label. See section

Filling of Water

2. Turn the handle at the suction Manifold towards

“Main tank” and green valve towards “Agitation”.

Turn the handle at the Pressure Manifold towards

“HARDI

®

CHEMICAL FILLER”. Close remaining

valves.

.

IMPORTANT! The hopper rinsing device uses spray

liquid from the main tank for rinsing the hopper of

®

concentrated chemical. The HARDI

CHEMICAL

FILLER must always be cleaned together with the rest

of the sprayer when the spray job is done.

10. Close valve A and the FILLER lid again.

11. When the spray liquid is well mixed, turn handle on

the Pressure Manifold towards “Spraying” position.

Keep P.T.O. engaged so the spray liquid is continuously agitated until it has been sprayed on the crop.

31HARDI® COMMANDER OPERATOR’S MANUAL

Page 34

Operation

Use of flush tank and rinse nozzles

(optional)

The incorporated flush tank can be used for two different purposes.

A. In-field diluting of remaining spray liquid residue in

the spraying circuit for spraying the liquid in the field,

before cleaning the sprayer.

1. Empty the sprayer as much as possible.

Turn the green pressure valve towards “No

Agitation” and spray until air comes out of

all nozzles.

2. Remove the tank filter basket.

3. Turn black suction valve towards “Flush

tank”.

4. Turn green pressure valves towards “Rinsing nozzle” (optional).

5. Engage and set the pump at approx. 300

r.p.m.

6. When rinsing water corresponding to approx. 10

times the spray liquid residue (see paragraph

“Technical Residue”) is used, turn black

suction valve towards “Suction from main

tank” and operate all valves, so all hoses

and components are rinsed.

7. Turn green pressure valve back to “Operating unit” and spray liquid in the field you

have just sprayed.

8. Repeat point 3-7 until the flush tank is empty.

5. Disengage pump again.

6. Open Self-cleaning filter again.

WARNING! The rinsing nozzles cannot always

guarantee a 100% cleaning of the tank. Always

clean manually with a brush afterwards, especially if crops sensitive to the chemical just sprayed are

going to be sprayed afterwards!

Technical Residue

Inevitably a quantity of spray liquid will remain in the

system. It cannot be sprayed properly on the crop, as the

pump takes in air when the tank is about to be empty.

This Technical Residue is defined as the remaining

liquid qty. in the system as the first clear pressure drop

on the pressure gauge is read.

The dilutable residue must be diluted with 10 times the

amount of clean water and sprayed to the crop just

sprayed before cleaning the sprayer - See “Cleaning

the sprayer” (pp. 36-37).

Draining tanks

Operation of the main tank drain valve

WARNING! Before using the top drain, verify that

disposal of waste is done according to chemical

label instructions and local regulations.

Pull the red handle at left hand side of the tank to open

the drain valve. The valve is spring loaded to close it,

but can be kept open by pulling the string out and

upwards in the V-shaped slot. To release and close the

drain valve again, pull the string downwards and the

valve will close automatically. If draining residues (e.g.

liquid fertilizer) into a reservoir, a snap-coupler with

hose can rapidly be connected to the drain valve and

the liquid safely drained.

B. Rinsing the pump, operating unit, spray lines, etc. in